Coating composition and antireflection film

An anti-reflection film and composition technology, applied in anti-reflection coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as poor mechanical strength of porous bodies, achieve excellent weather resistance, simple anti-reflection characteristics, Excellent antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

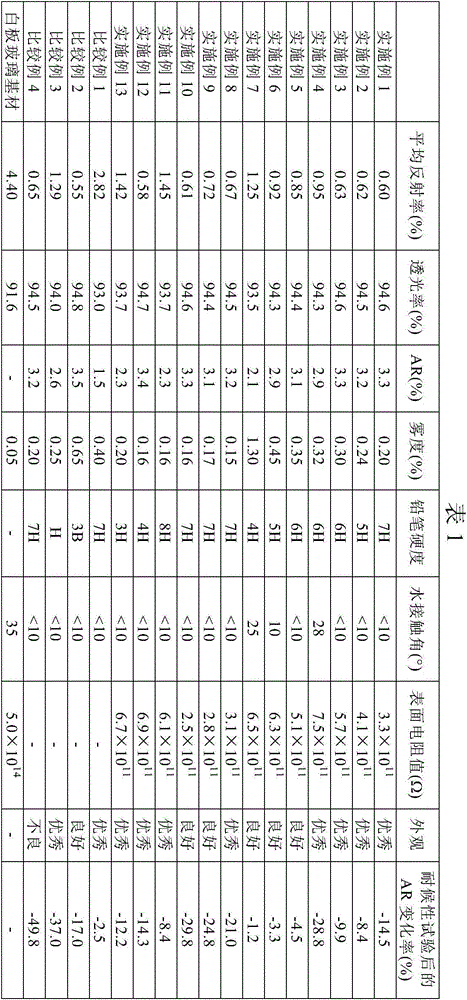

Examples

Embodiment

[0173] The present invention will be specifically described by the following examples, synthesis examples, and comparative examples, but these examples do not limit the scope of the present invention. In Examples, Synthesis Examples, and Comparative Examples, various physical properties were measured by the following methods.

[0174] (1) Determination of average particle size, average aspect ratio and average aspect ratio

[0175]For spherical metal oxides, the magnification is 50,000 to 100,000 times, adjusted so that 100 to 200 spherical metal oxide particles are photographed, and then a transmission microscope photograph is taken. Then, the particle diameter (the average value of the major axis and the minor axis) of each photographed spherical metal oxide particle was measured, and the average value was obtained as the average particle diameter.

[0176] For chain-shaped metal oxides, magnify to 50,000 to 100,000 times, adjust so that 100 to 200 chain-shaped metal oxide ...

Synthetic example 1

[0196] ·Synthesis of aqueous dispersion of polymer emulsion particles (B-1)

[0197] In a reactor equipped with a reflux condenser, a dropping tank, a thermometer, and a stirring device, 1600 g of ion-exchanged water and 7 g of dodecylbenzenesulfonic acid were charged, and heated to 80° C. while stirring to obtain a mixed solution (1) . To the obtained mixed solution (1), a mixture of 185 g of dimethyldimethoxysilane and 117 g of phenyltrimethoxysilane was added dropwise over about 2 hours while keeping the temperature in the reaction vessel at 80°C. solution (2) to obtain a mixed solution (3). Then, the mixed solution (3) was stirred for about 1 hour with the temperature in the reaction vessel at 80°C. Then, 150 g of butyl acrylate, 30 g of tetraethoxysilane, phenyltrimethoxy A mixture (4) of 145 g of methoxysilane and 1.3 g of 3-methacryloxypropyltrimethoxysilane, 165 g of diethylacrylamide, 3 g of acrylic acid, and a reactive emulsifier (trade name "Adecariasup SR-1025 ...

Embodiment 1

[0200] In 80 g of 20% ethanol aqueous solution, 1.8 g of the aqueous dispersion of the polymer emulsion particles (B-1) synthesized in Synthesis Example 1 as the polymer emulsion particles (B), 1.8 g of the aqueous dispersion of the polymer emulsion particles (B-1) as the spherical metal oxide (a1 ) as a raw material of 2.5 g of water-dispersed colloidal silica (trade name "Snow-Tex OXS", manufactured by Nissan Chemical Industries, Ltd., solid content 10% by mass) with an average particle diameter of 5 nm, as a chain metal oxide (a2) Beaded silica made of primary silica particles with an average diameter of about 12 nm, an average long diameter of about 70 nm, and an aspect ratio (long diameter / short diameter) of most particles in the range of 3 to 25 12.0 g of an aqueous dispersion (trade name "Snow-Tex OUP", manufactured by Nissan Chemical Industries, Ltd., solid content 15% by mass), and tetraethoxysilane (manufactured by Shin-Etsu Chemical Industries, Ltd.) as a hydrolyzabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com