Circular polarizer and preparation method thereof

A circular polarizer and polarizing layer technology, applied in optics, optical elements, polarizing elements, etc., can solve the problems of complicated polarizer process, increased weight of organic electroluminescence display, poor flexural performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

[0041] In this embodiment, "%" refers to mass percentage unless otherwise specified.

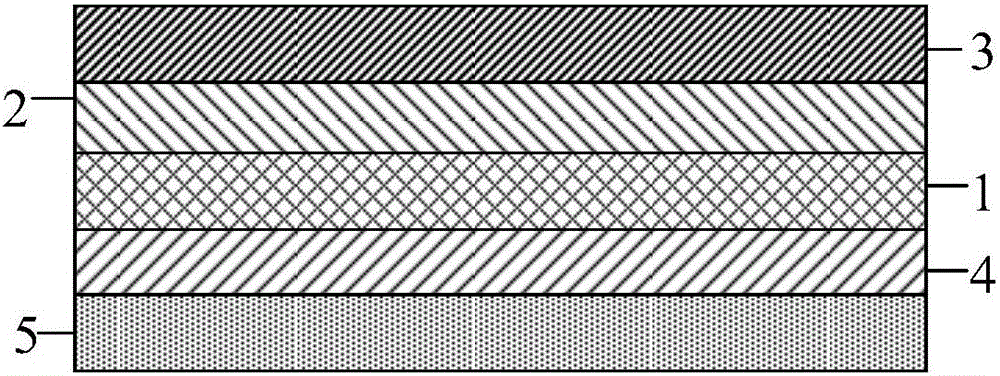

[0042] Such as figure 1 As shown, the circular polarizer of this embodiment includes: a substrate 1 , a first alignment layer 2 , a polarizing layer 3 , a second alignment layer 4 and a retardation layer 5 .

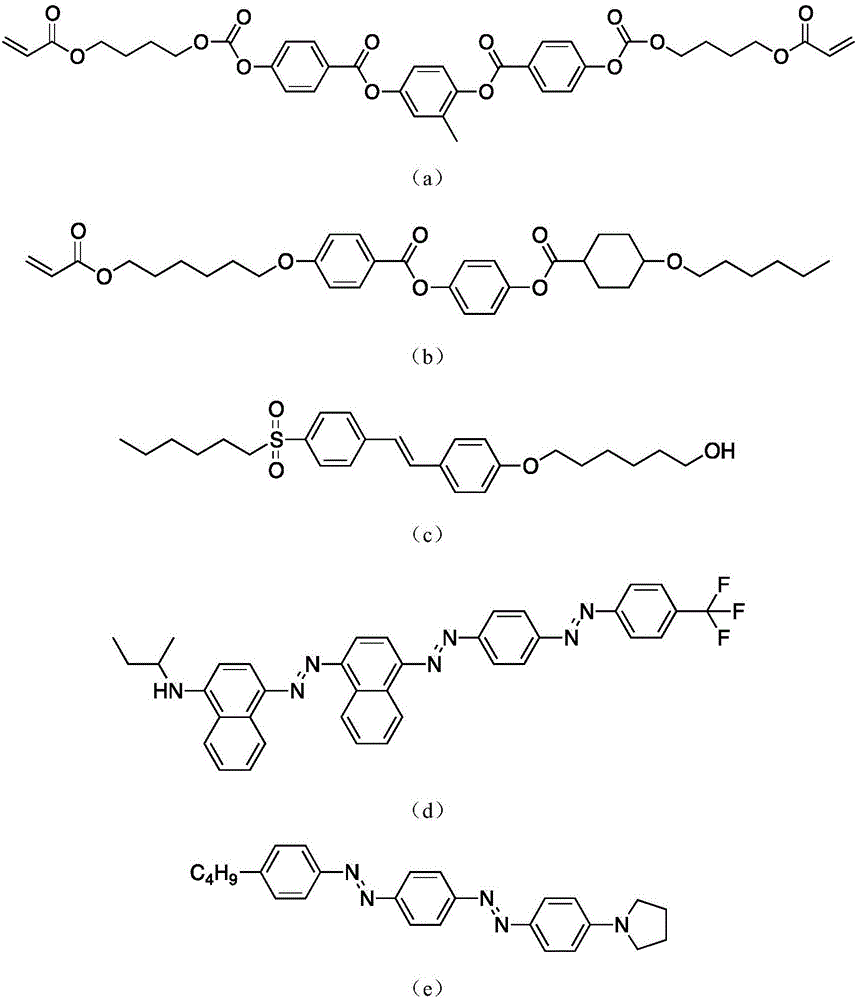

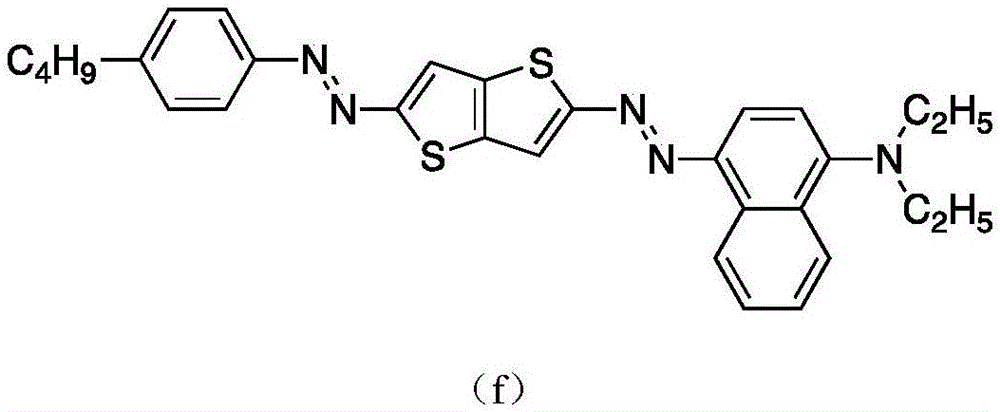

[0043] In this embodiment, the polymerizable liquid crystal monomers in the polymerizable liquid crystals in the polarizing layer include double polymerizable group monomers and single polymerizable group monomers; Isotropic, nematic, and crystalline phases, monopolymerizable group monomers exhibit isotropy, nematic phase, smectic phase, and crystalline phase in sequence from low to high temperature, when the temperature is slightly lower than the monopolymerizable group monomer When the transition point from the bulk nematic phase to the smectic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com