Optical element

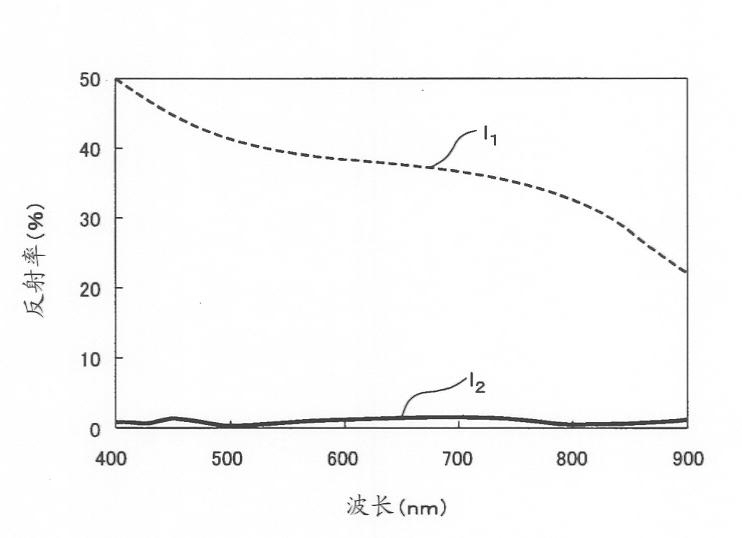

An optical element, visible light technology, applied in optical elements, optics, instruments, etc., can solve problems such as low-reflection structures, and achieve high anti-reflection properties, excellent anti-reflection properties, and high productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

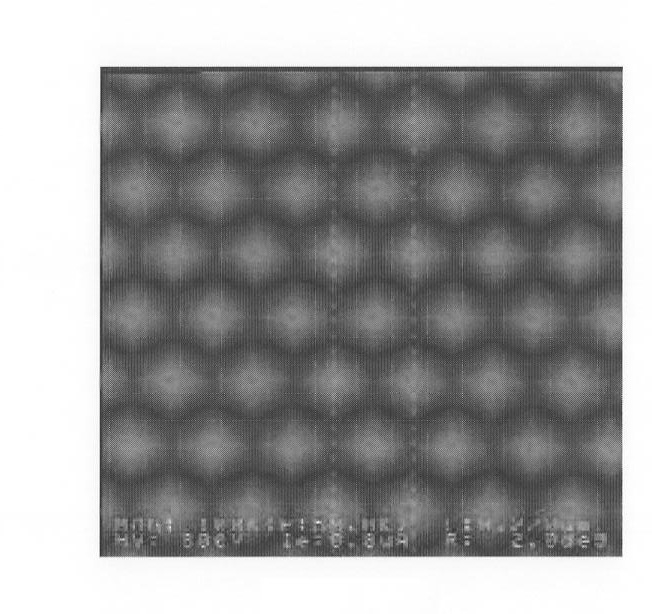

[0072] (1-1) Structure of optical element

[0073] Figure 8A is a schematic plan view showing a structural example of the optical element according to the first embodiment of the present invention. Figure 8B yes Figure 8A An enlarged plan view of a portion of the optical components shown. Figure 8C is along Figure 8B Sectional views taken of tracks T1, T3, . . . are shown. Figure 8D is along Figure 8B Sectional views of the tracks T2, T4, . . . shown.

[0074] The optical element 1 is applicable to various optical devices such as displays, optoelectronic devices, optical communication devices (optical fibers), solar cells, and lighting devices. For example, the optical element 1 can be used for an antireflection substrate and a light guide plate suitable for preventing reflection of light having a wavelength range of visible light. Furthermore, the optical element 1 can be used for an optical filter having transmittance according to an incident angle of incident ...

no. 2 approach

[0136] (2-1) Structure of optical element

[0137] Figure 15A is a schematic plan view showing a structural example of an optical element according to a second embodiment of the present invention. Figure 15B yes Figure 15A An enlarged plan view of a portion of the optical components shown. Figure 15C is along Figure 15B Sectional views taken of tracks T1, T3, . . . are shown. Figure 15D is along Figure 15B Sectional views of the tracks T2, T4, . . . shown.

[0138] In the optical element 1 according to the second embodiment, the track T has an arc shape, and the main structures 3 are arranged in the arc shape. Such as Figure 15B As shown, in the tracks (T1~T3) of three adjacent rows, the main structures 3 are arranged to form a quasi-hexagonal lattice pattern having the centers of the main structures 3 positioned at points a1~a7. The term "quasi-hexagonal lattice pattern" refers to a hexagonal lattice pattern in which the arc shape along a track T is distorted ...

no. 3 approach

[0153] Figure 18A is a schematic plan view showing a structural example of an optical element according to a third embodiment of the present invention. Figure 18B yes Figure 18A An enlarged plan view of a portion of the optical components shown. Figure 18C is along Figure 18B Sectional views taken of tracks T1, T3, . . . are shown. Figure 18D is along Figure 18B Sectional views of the tracks T2, T4, . . . shown.

[0154] The optical element 1 according to the third embodiment differs from the first embodiment in that in the tracks of three adjacent rows the primary structures 3 form a tetragonal lattice pattern or a quasi-tetragonal lattice pattern. The term "quasi-tetragonal lattice pattern" refers to a tetragonal lattice pattern that is stretched and distorted in the direction of track extension (X direction) different from a regular tetragonal lattice pattern. When the main structures 3 are periodically arranged in a tetragonal lattice pattern or a quasi-tetrag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com