Coating composition for antireflection, antireflection film and method for preparing the same

An anti-reflection film, composition technology, applied in anti-reflection coatings, nanotechnology for materials and surface science, coatings, etc., can solve problems such as difficulty in obtaining wear resistance, poor wear resistance, and resolution degradation , to achieve the effect of reducing production cost, improving processing efficiency, excellent wear resistance and low refraction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] Preparation The method for preparing an anti-reflection film according to the present invention comprises the following steps:

[0096] a) preparing the above-mentioned coating composition for antireflection;

[0097] b) applying the coating composition to a substrate to form a coating;

[0098] c) drying the coating to phase separate the low and high refractive materials; and

[0099] d) Curing the dried coating.

[0100] In step b), the substrate may be glass, plastic sheet or film, and its thickness is not limited. Examples of plastic films may include cellulose triacetate films, norbornene cycloolefin polymer films, polyester films, polymethacrylate films, and polycarbonate films, but are not limited thereto.

[0101] In step b), the method of coating the coating composition can be such as rod coating, two-roll or three-roll reverse coating, gravure coating, die coating (die coating), micro gravure coating Various methods of coating method and continuous coating...

Embodiment approach

[0112] Hereinafter, preferred examples are provided for better understanding of the present invention. However, these examples are for illustrative purposes only, and the present invention is not intended to be limited by these examples.

Embodiment 1

[0132] 30 parts by weight of low refraction-thermosetting material A and 70 parts by weight of high refraction-UV curable material E were uniformly mixed to prepare a coating composition for antireflection.

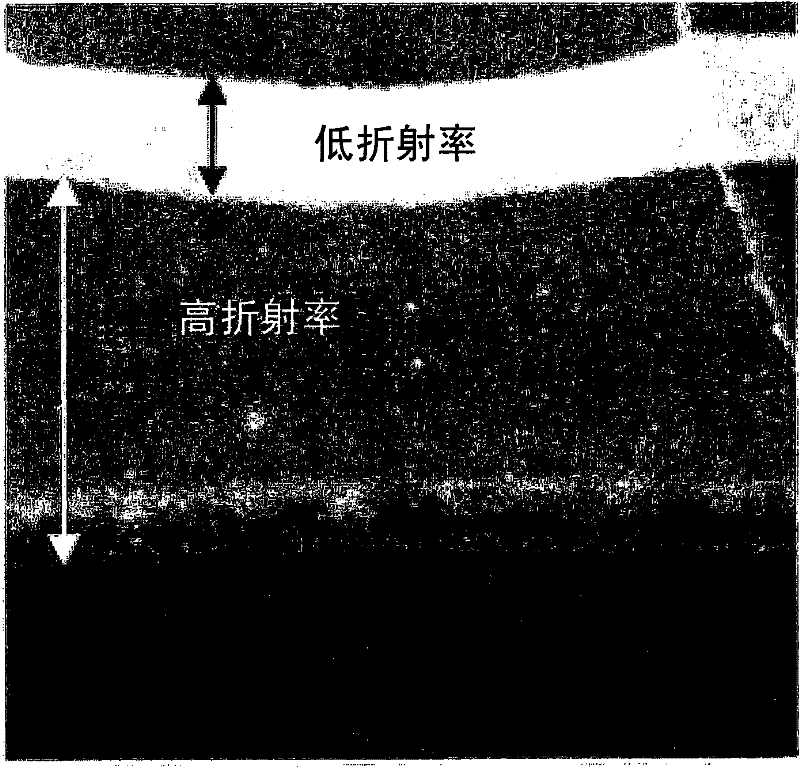

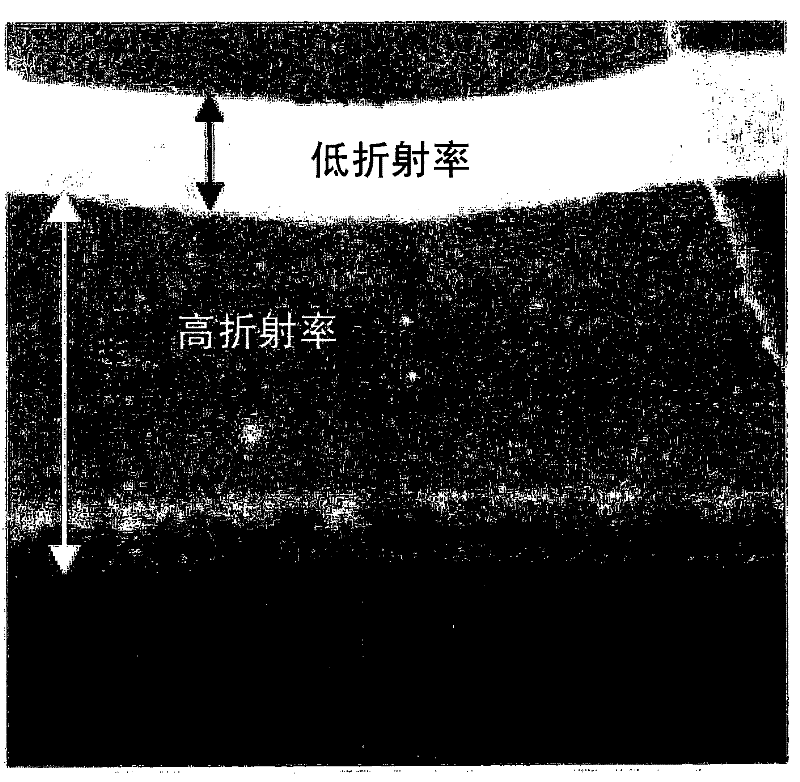

[0133] The prepared composition was coated on a cellulose triacetate film having a thickness of 80 μm using a wire bar (No. 5). The film was dried in an oven at 60°C for 2 minutes and irradiated by 1J / cm 2 Dosage of UV to cure, followed by heat curing in a 120 ℃ oven for 1 day. The final coating thickness was 1 μm, and the cross-section was observed under a transmission electron microscope, which is shown in figure 1 middle.

[0134] refer to figure 1 , it was found that a high-refractive material layer and a low-refractive material layer were respectively formed in a layer structure on the substrate. When a layered structure is formed of materials having different refractive indices, more effective reflectance can be obtained compared to a single-layered structure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com