Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Eliminate the risk of leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

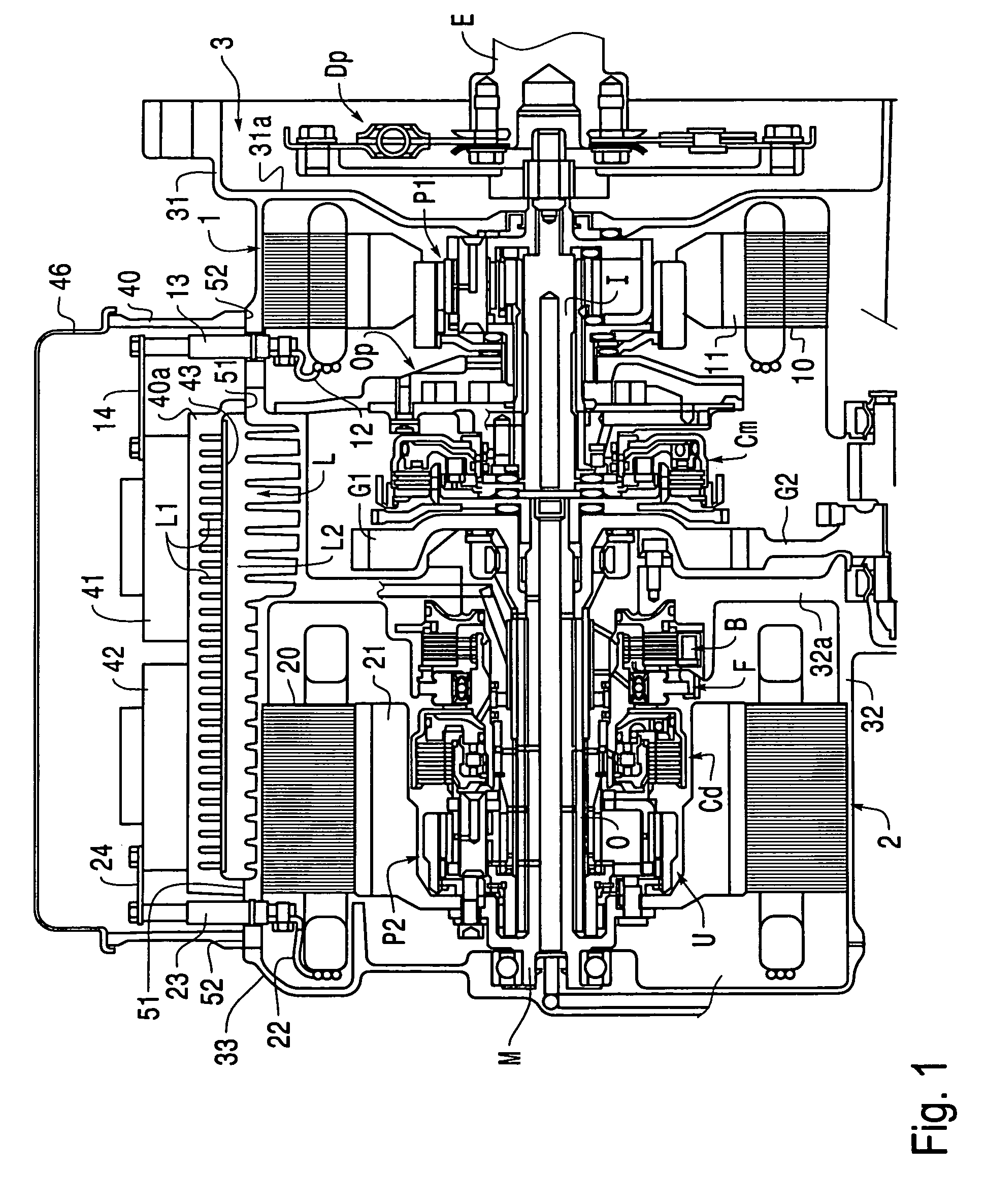

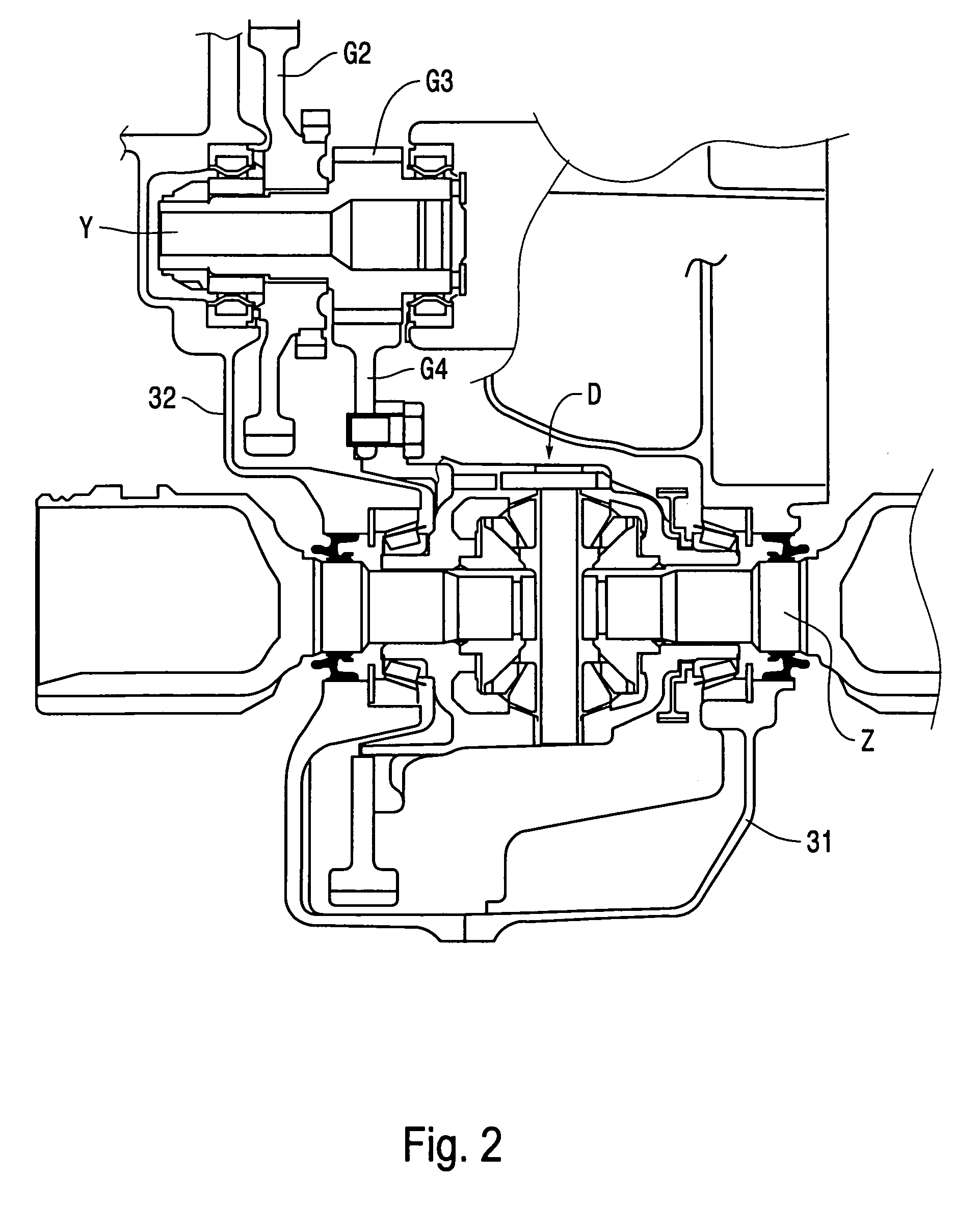

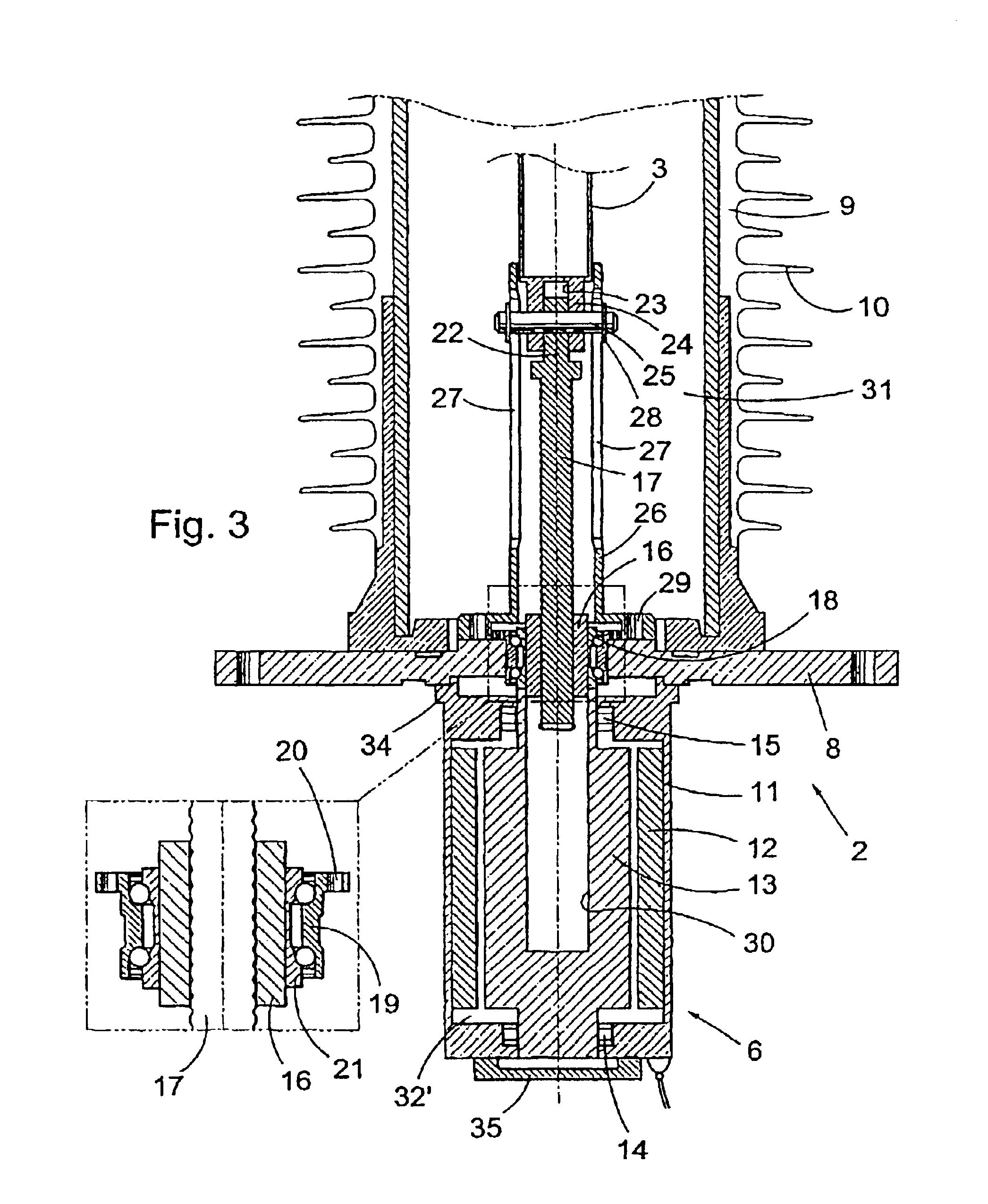

Drive system including electric power devices

InactiveUS7211912B2Improve sealingReliable preventionHybrid vehiclesPlural diverse prime-mover propulsion mountingEngineeringElectric power

A drive system includes a plurality of electric power devices, a drive case having a plurality of case segments which are connected to each other, each of the electric power devices being contained in one of the case segments, and a plurality of inverters, one for each of the electric power devices. The inverters are collectively attached to one of the case segments, and a flow path of a coolant for cooling the inverters is positioned between the case segment to which the inverters are attached and the inverters. Accordingly, a cooling unit which performs heat insulation and cooling between the drive system and the inverters is positioned only on the outer surface of one of the case segments and does not extend across the connection interfaces between the case segments. Therefore, the risk of leakage of the coolant into the drive case can be substantially eliminated.

Owner:AISIN AW CO LTD

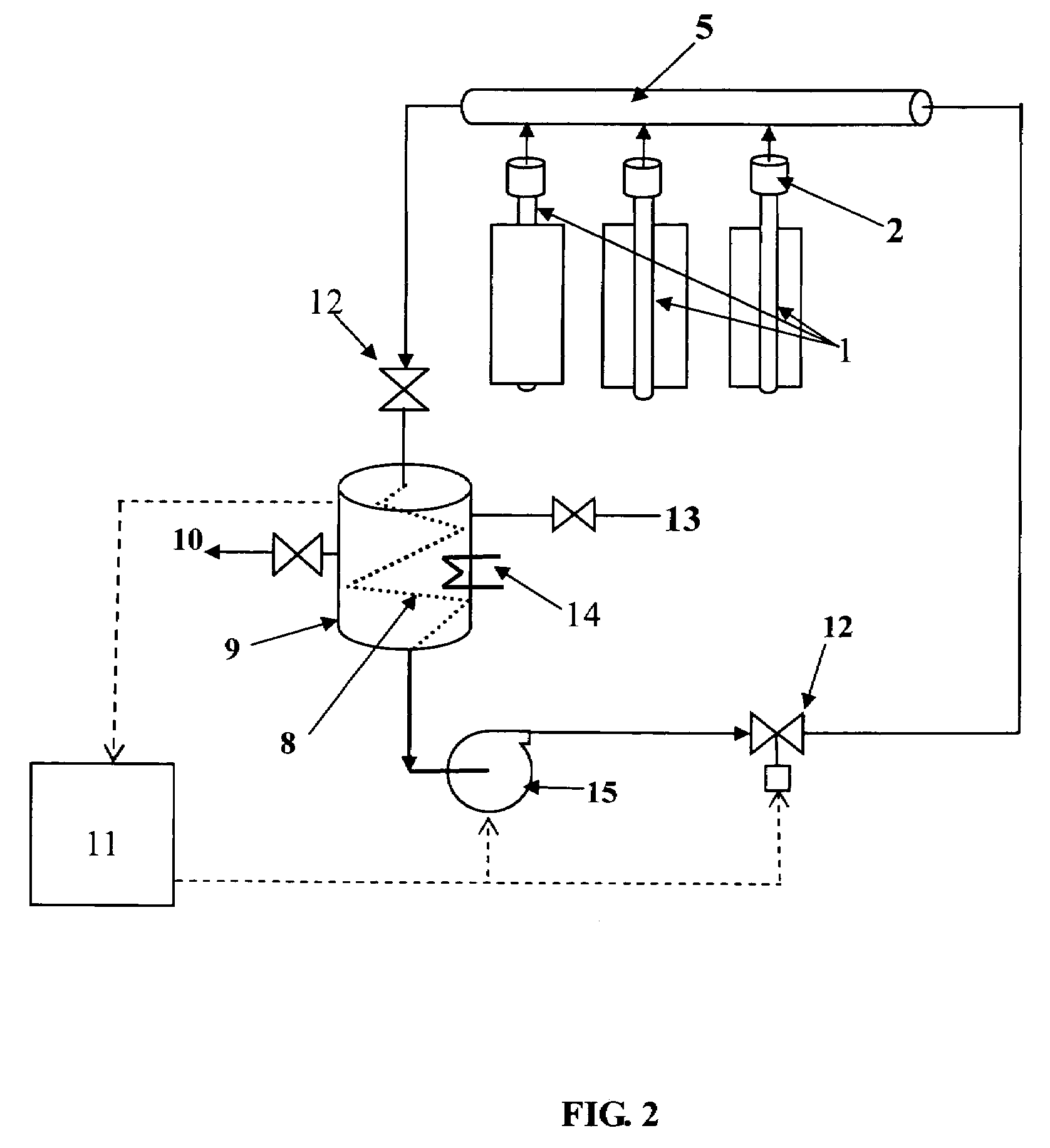

Solar-architectural material and building integrative solar energy utilization

InactiveUS20080209907A1Upgrade cost efficiencyExclude leakage riskSolar heating energySolar heat devicesBuilding materialThermal energy

The present invention provides a kind of solar-architectural materials which receive solar radiation and transfer it into heat energy and at the same time works as building finishing and decoration material, and thereof a system of building integrative solar heat utilization in which comprise a kind of heat-energy-conflux-device via metal matching surface impinging on each other without leakage possibility of liquid as heat transfer medium in the system.

Owner:XIAO WENZHAO +3

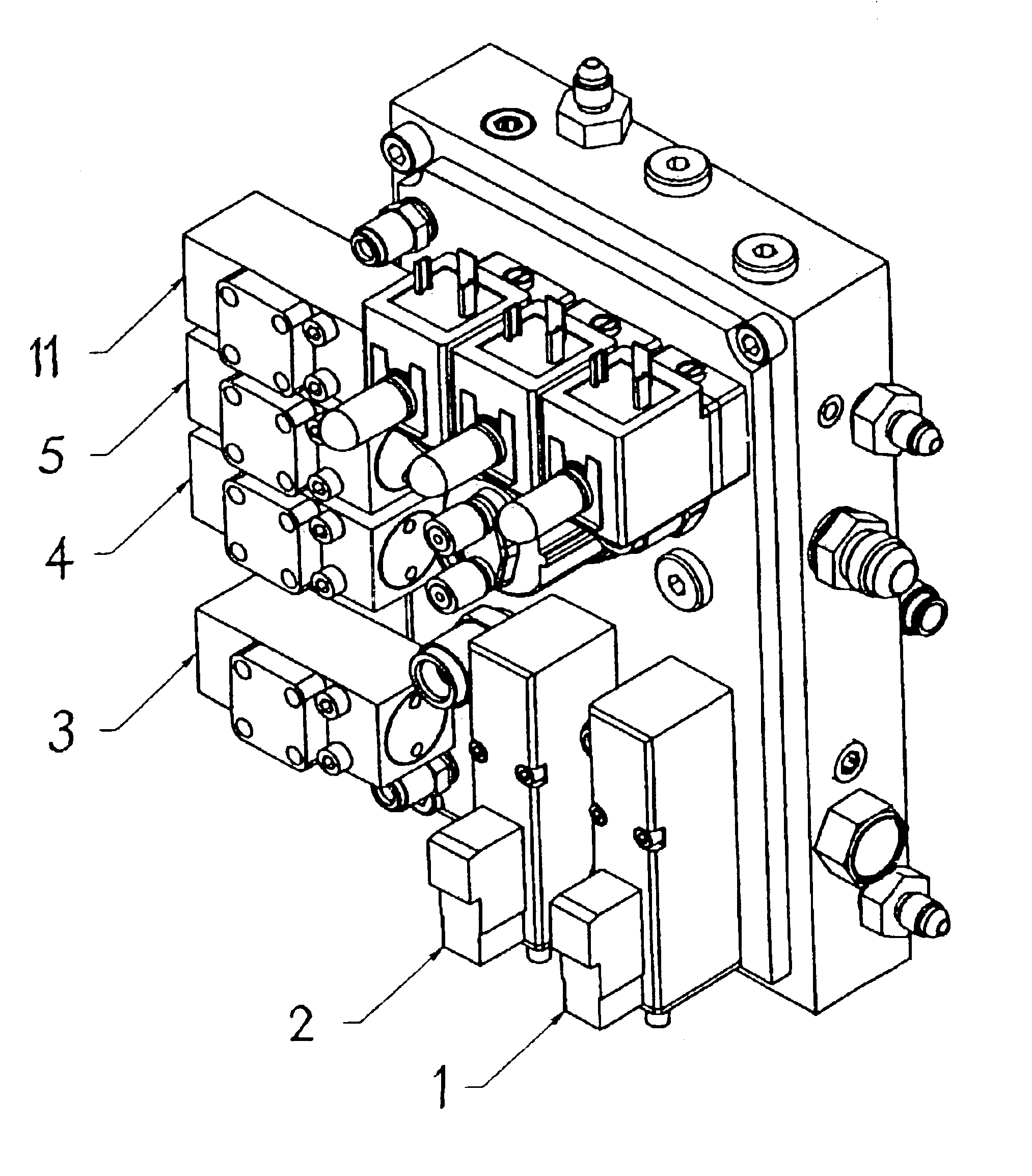

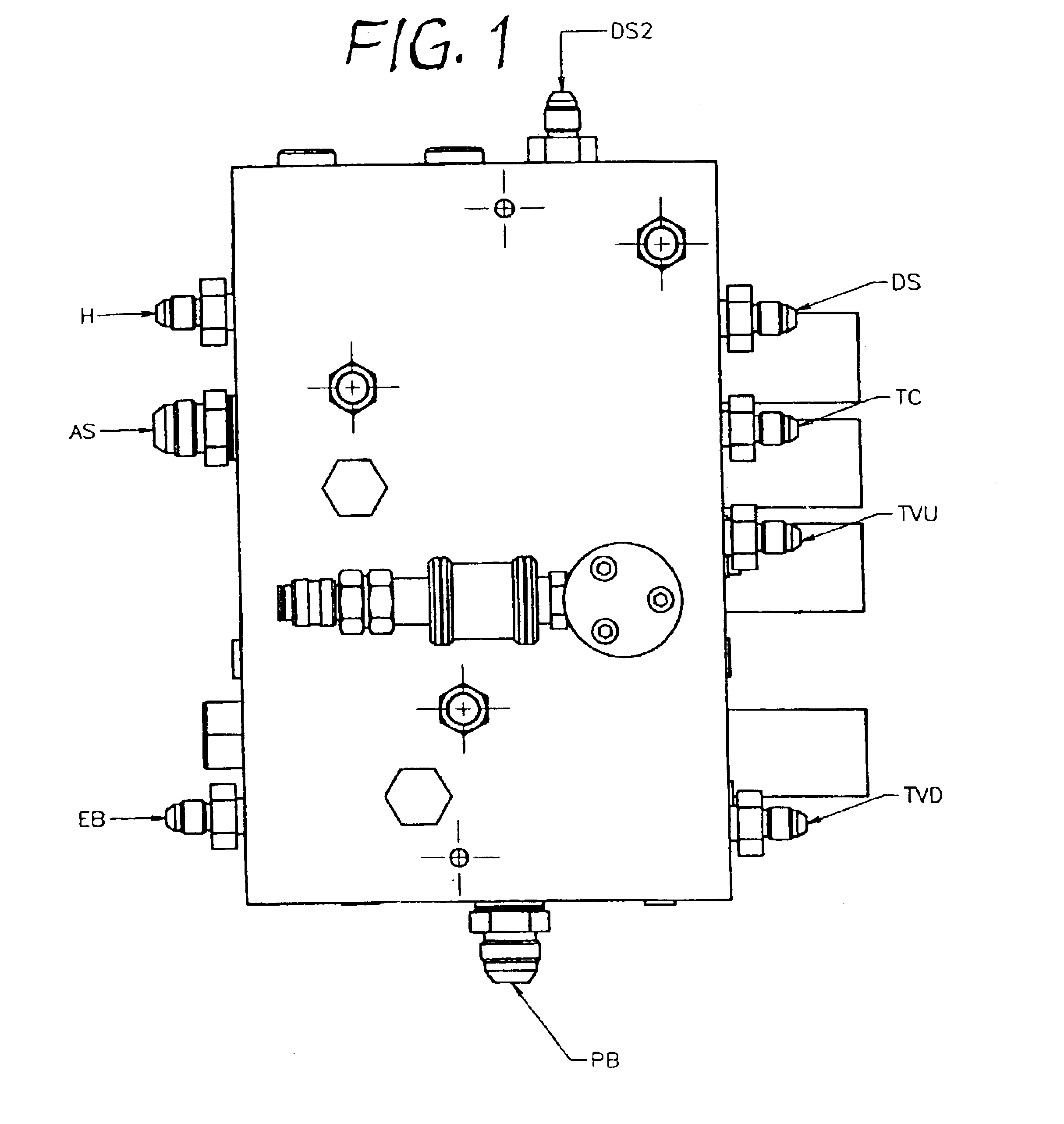

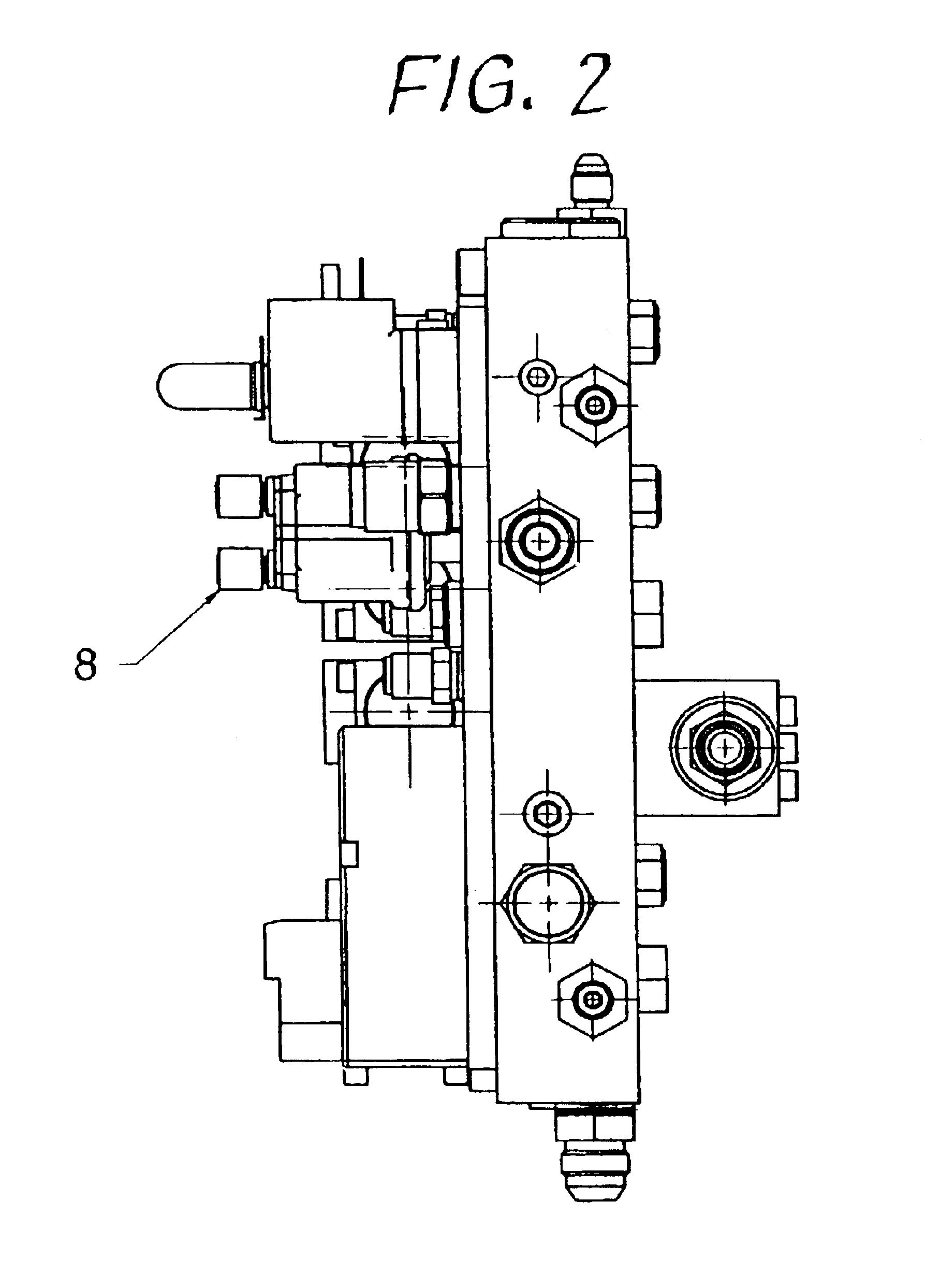

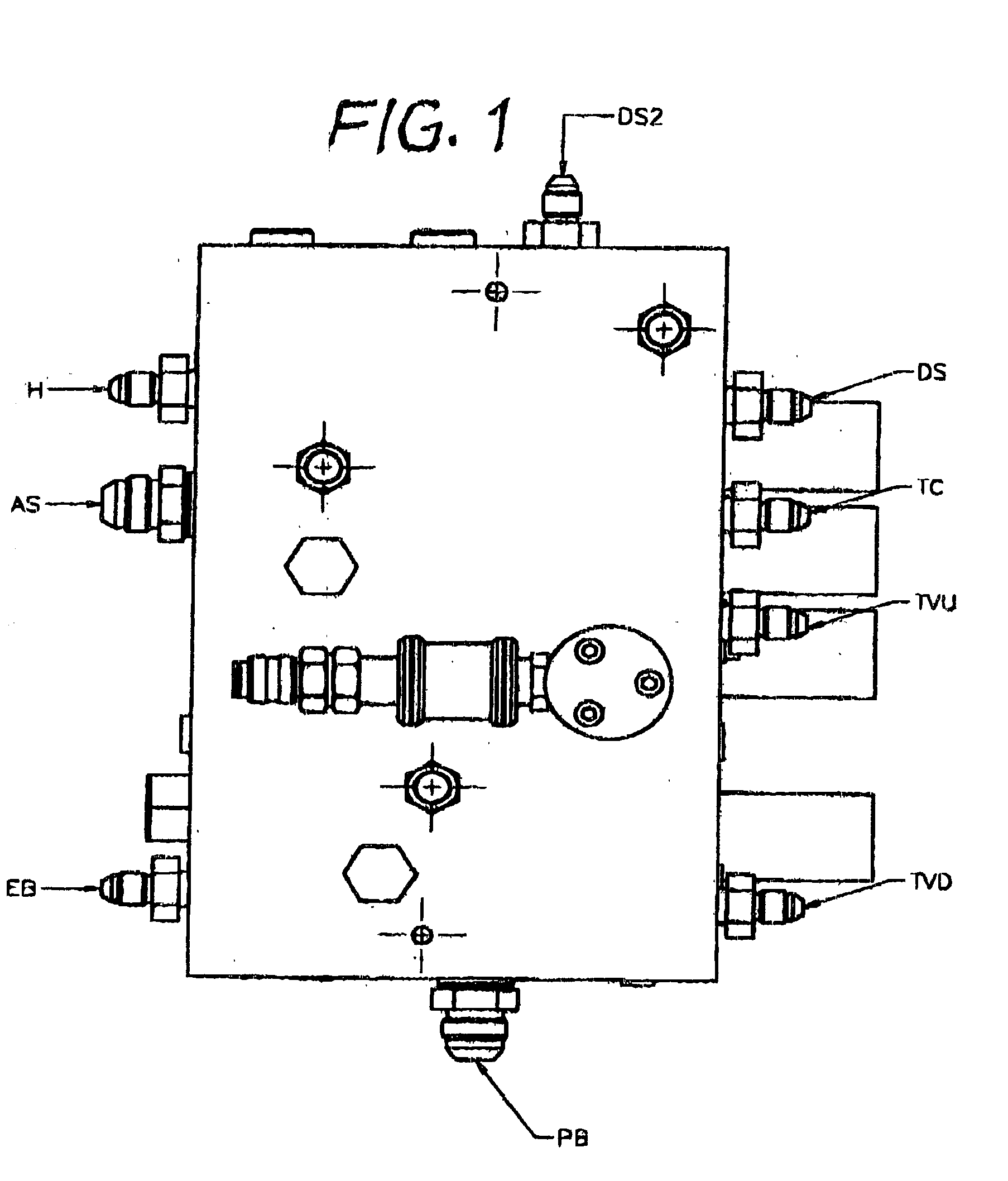

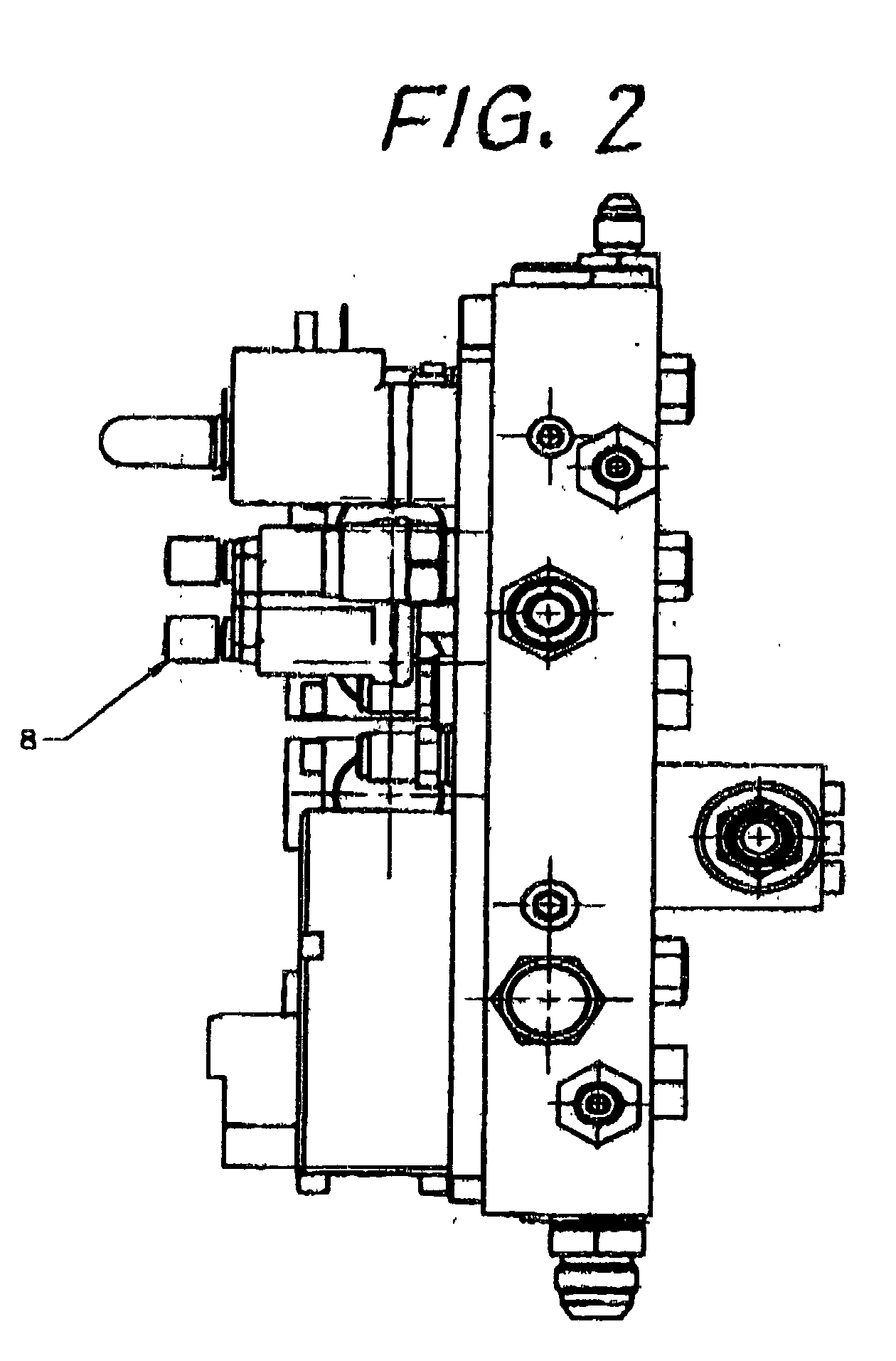

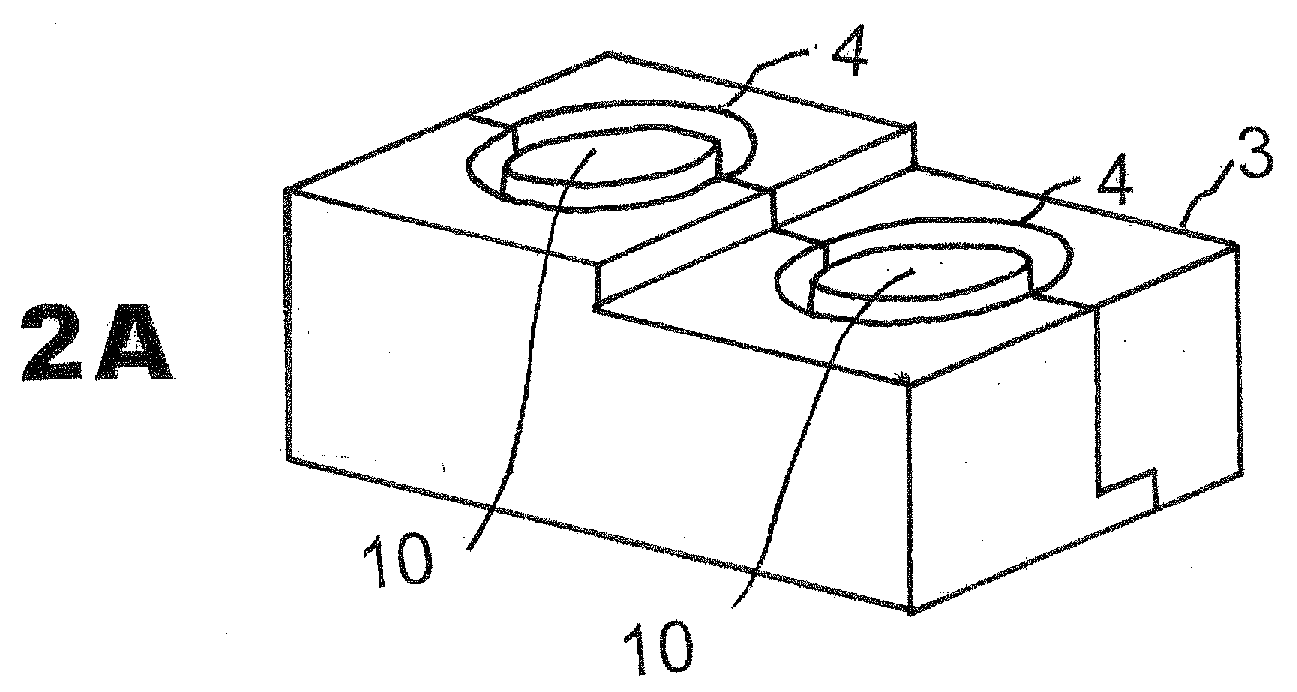

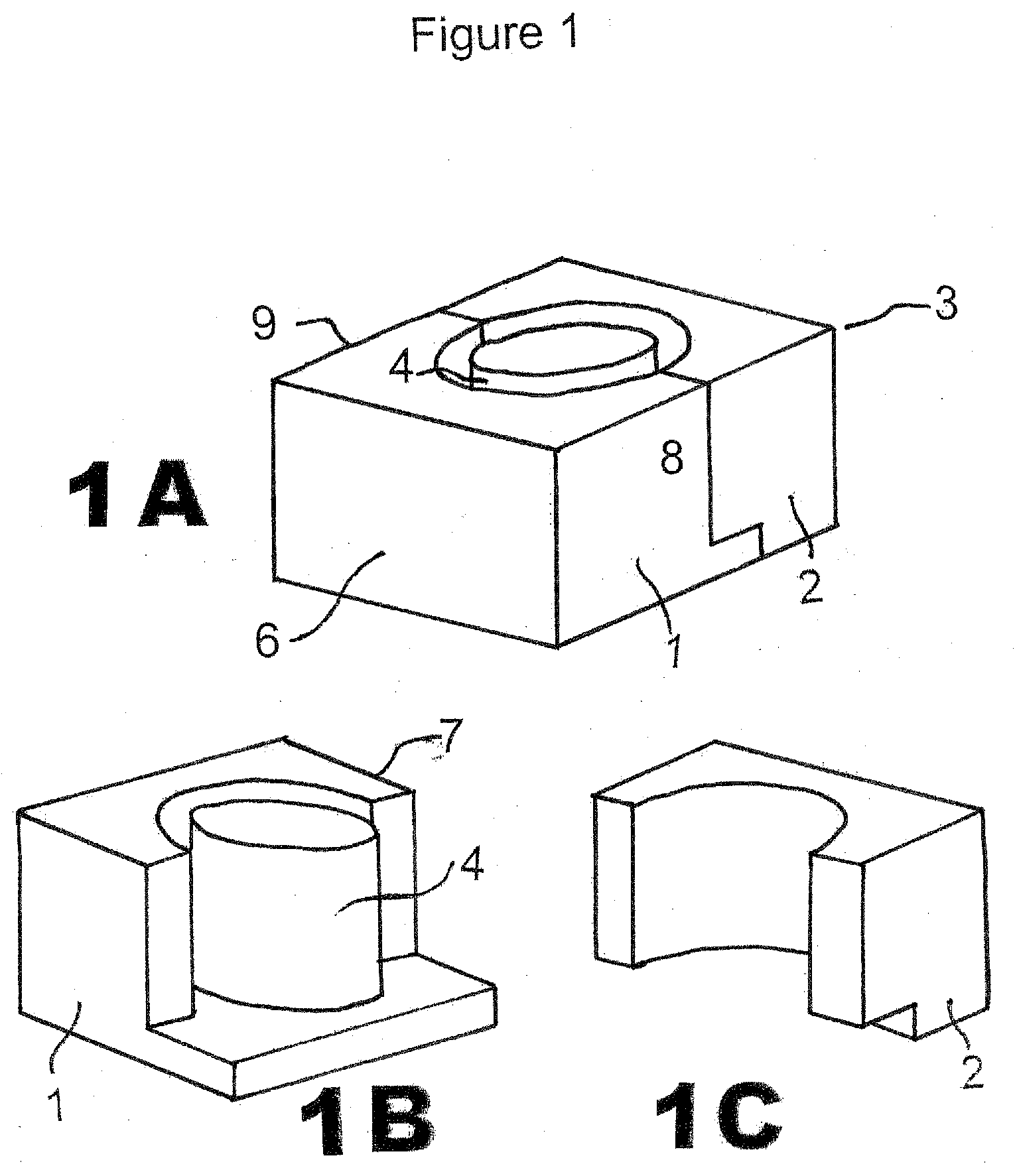

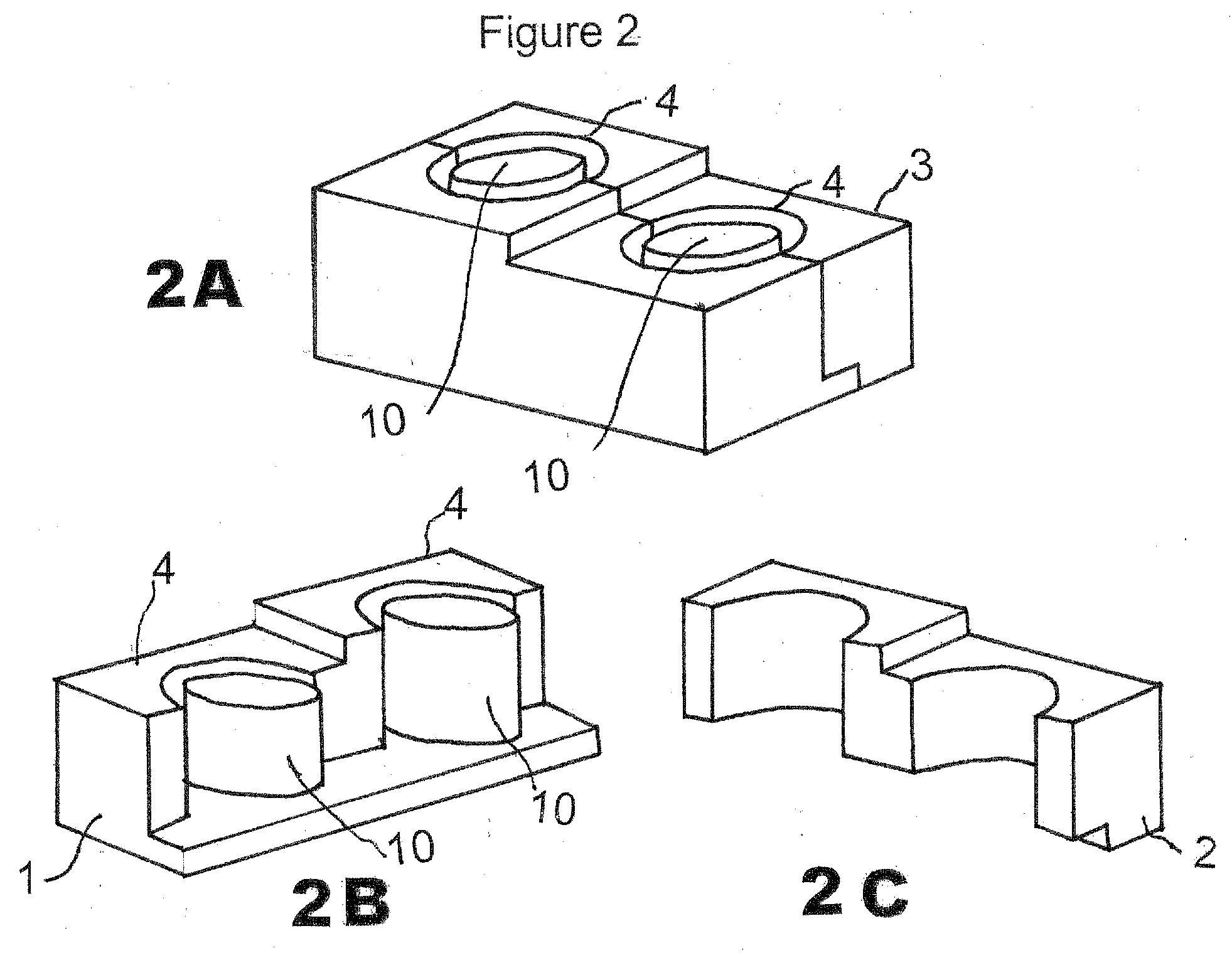

Integrated pneumatic manifold

InactiveUS6834669B2Eliminate the risk of leakageReduce in quantityFlow mixersTank vehiclesEngineeringMechanical engineering

An integrated pneumatic manifold for installations that require electrical and other components to be separated from a harmful or dangerous environment, in which pneumatic (and / or hydraulic) devices operate, the manifold comprising a block that has drilled into it a large number of passages that are directed in various directions and located at various levels, some passages crossing partially and some wholly with others and cavities machined in various positions. The block has mounting points for components on its surfaces and passive and active pneumatic components are integrated into the cavities and passages of the block. The block serves as a separation between the safe and harmful environments and as a substitution for many passive and active pneumatic components that would normally be individually connected.

Owner:SEYFARTH OTTO HERMAN

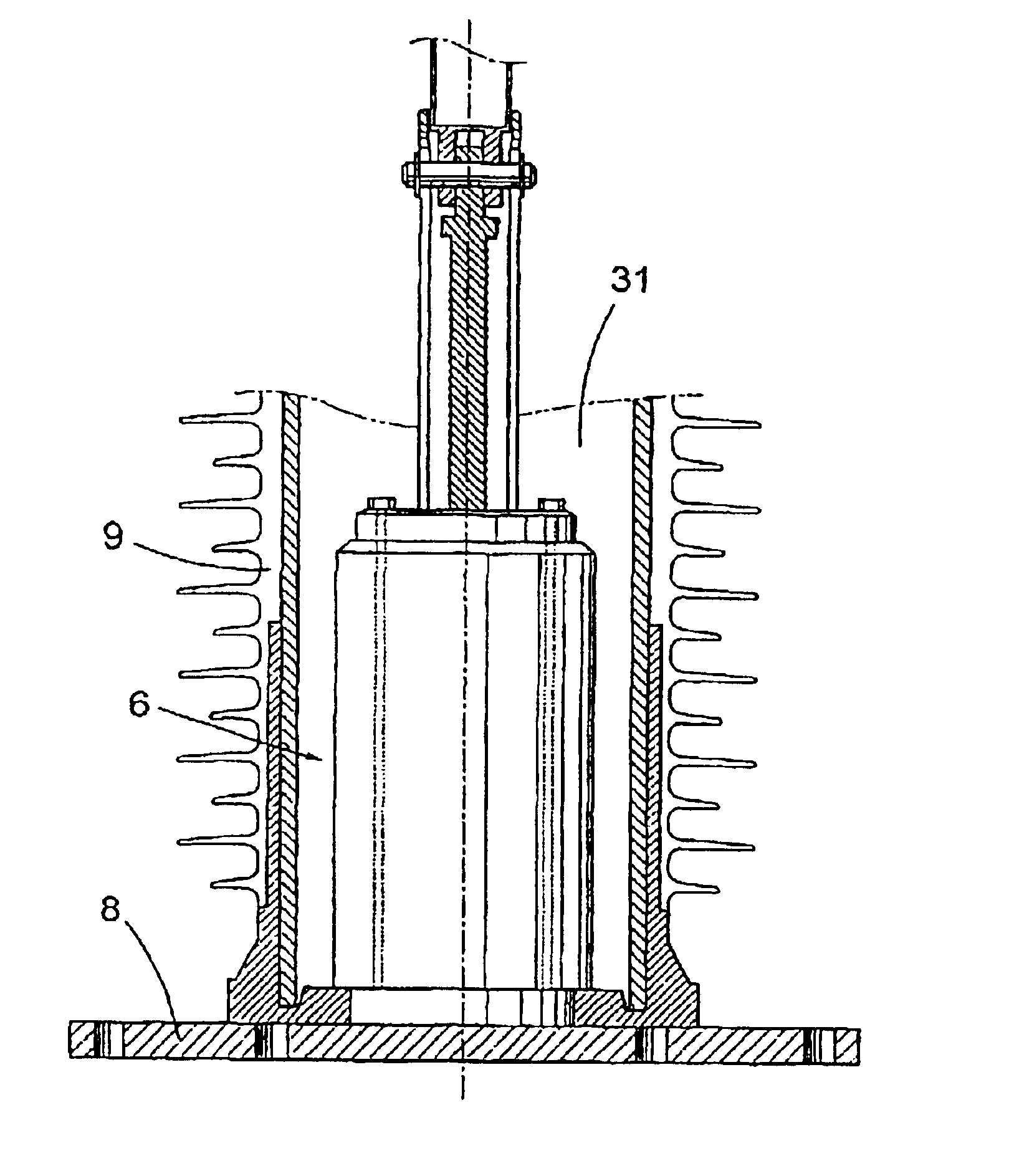

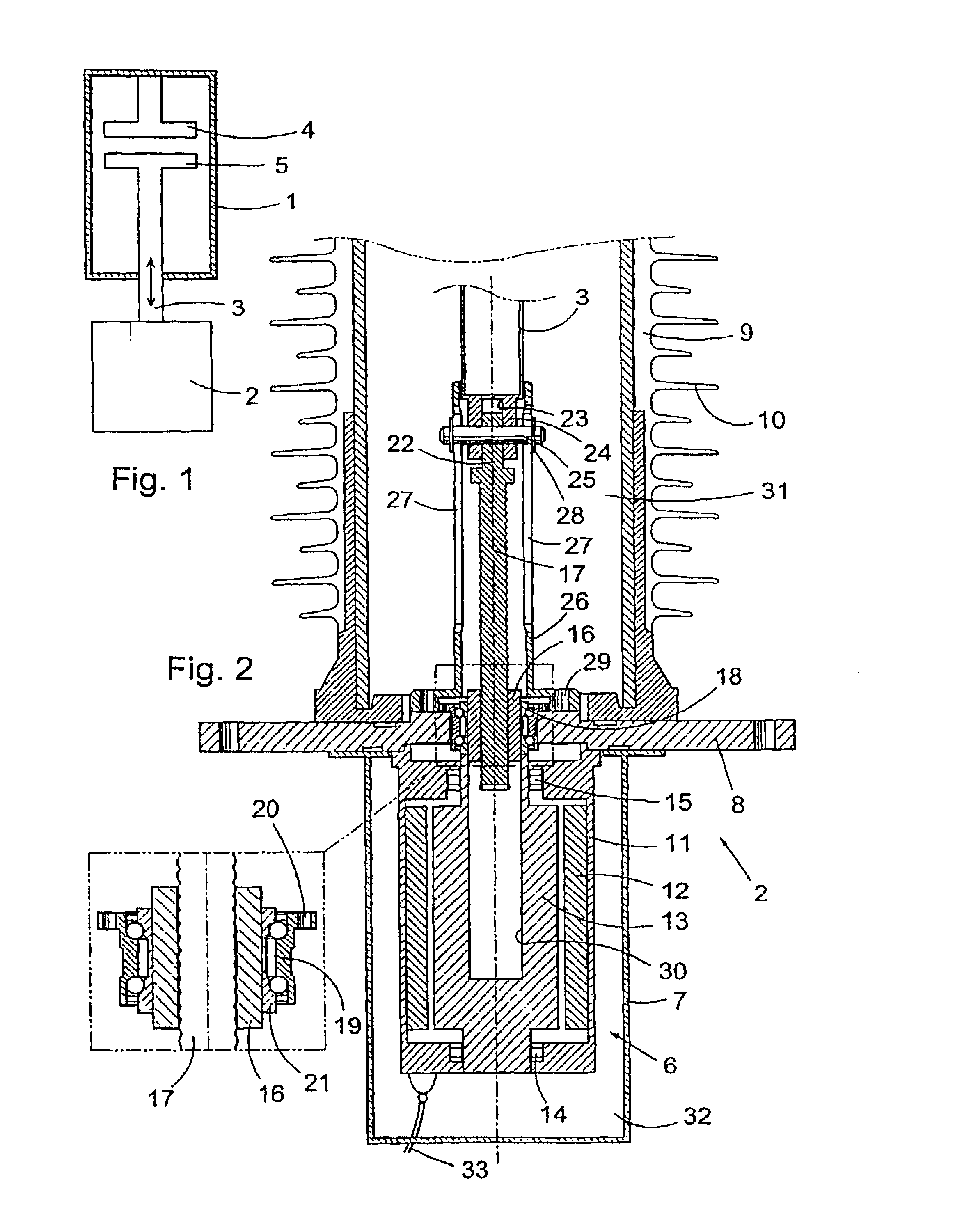

Circuit breaker

InactiveUS6927355B2Risk of leakagePower loss can be reduced and eliminatedContact mechanismsHigh-tension/heavy-dress switchesEngineeringHigh pressure

The invention relates to a circuit breaker, preferably for high or medium voltage. The movable conact of each breaker pole is connected, via mechanical means for transmitting movement, to a movable part of an electric motor (6). The movable contact and the means for transmitting movement are arranged in a gas-tight apparatus chamber (31) surrounded by a gas-tight apparatus housing (9) of insulating material such as porcelain. In accordance with the invention the motor (6) is arranged entirely in the apparatus chamber (31). The invention also relates to an electric plant provided with the breaker claimed, uses of the breaker claimed and a method of breaking electric current in which the breaker claimed is used.

Owner:ABB (SCHWEIZ) AG

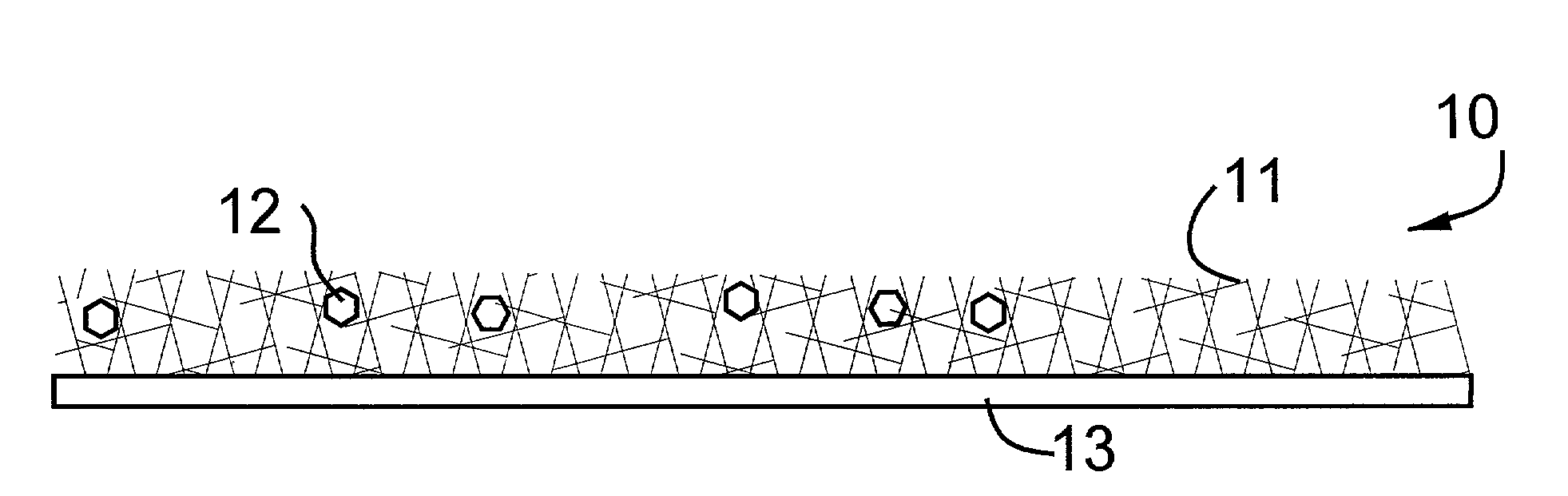

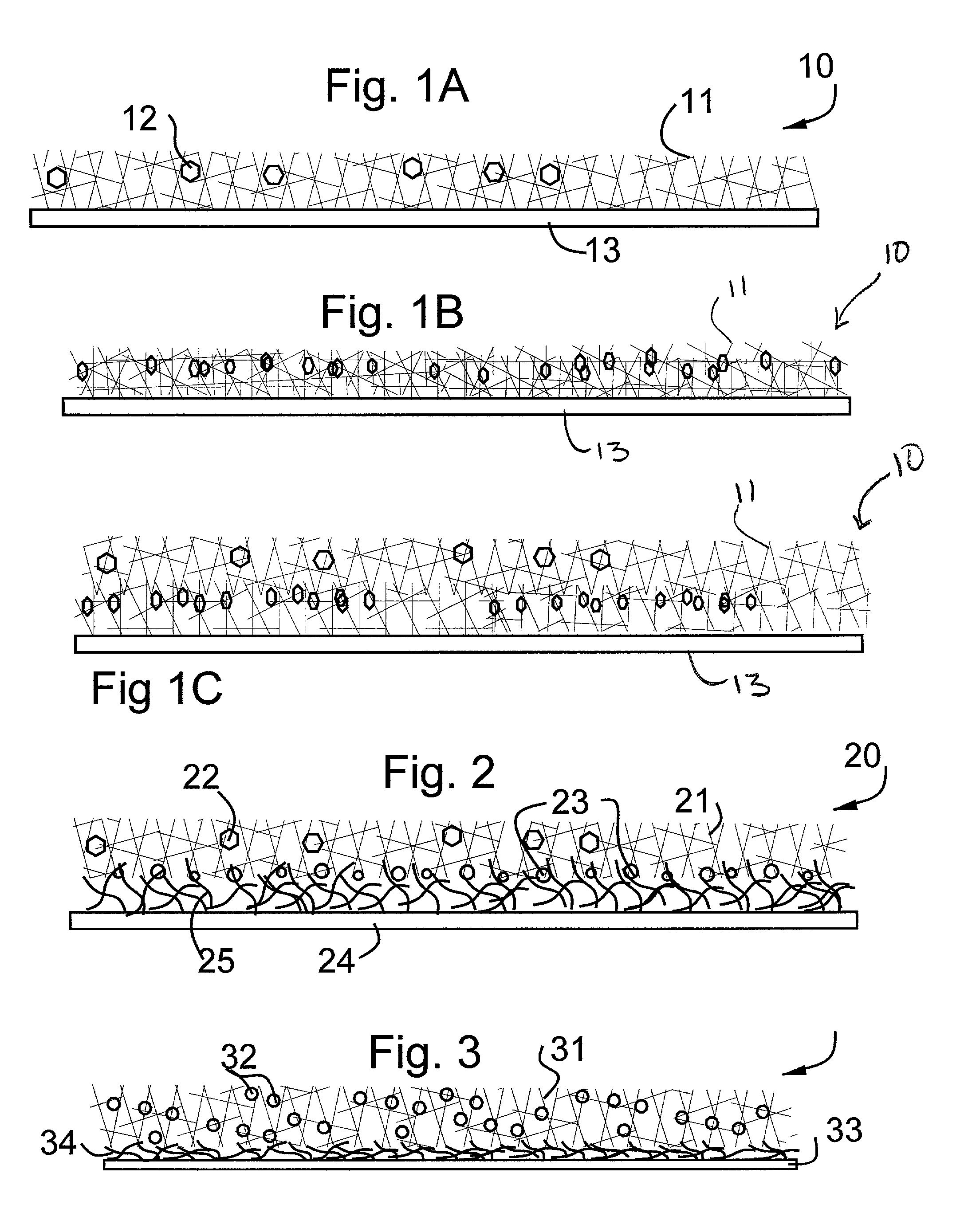

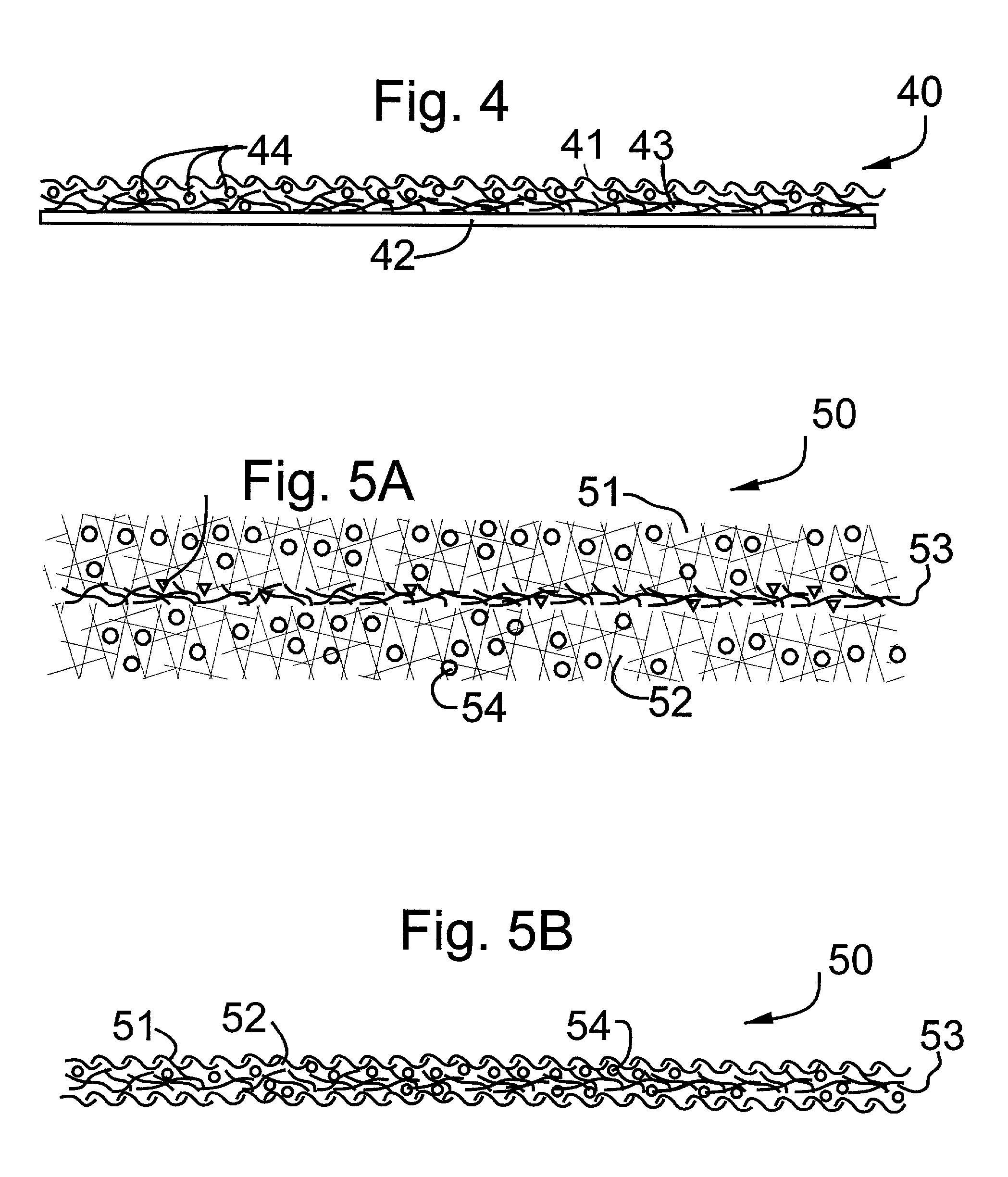

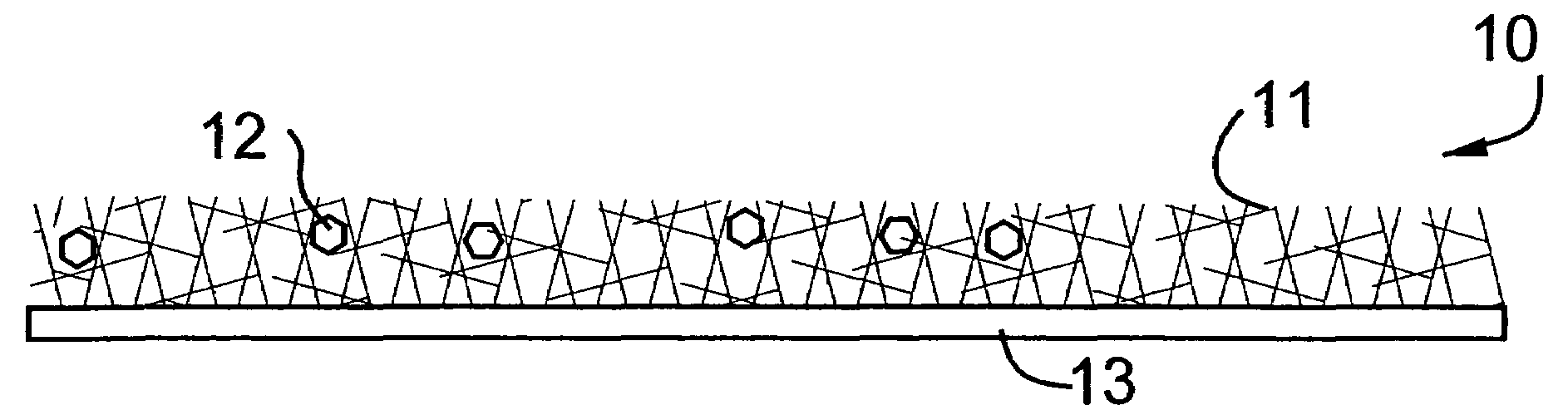

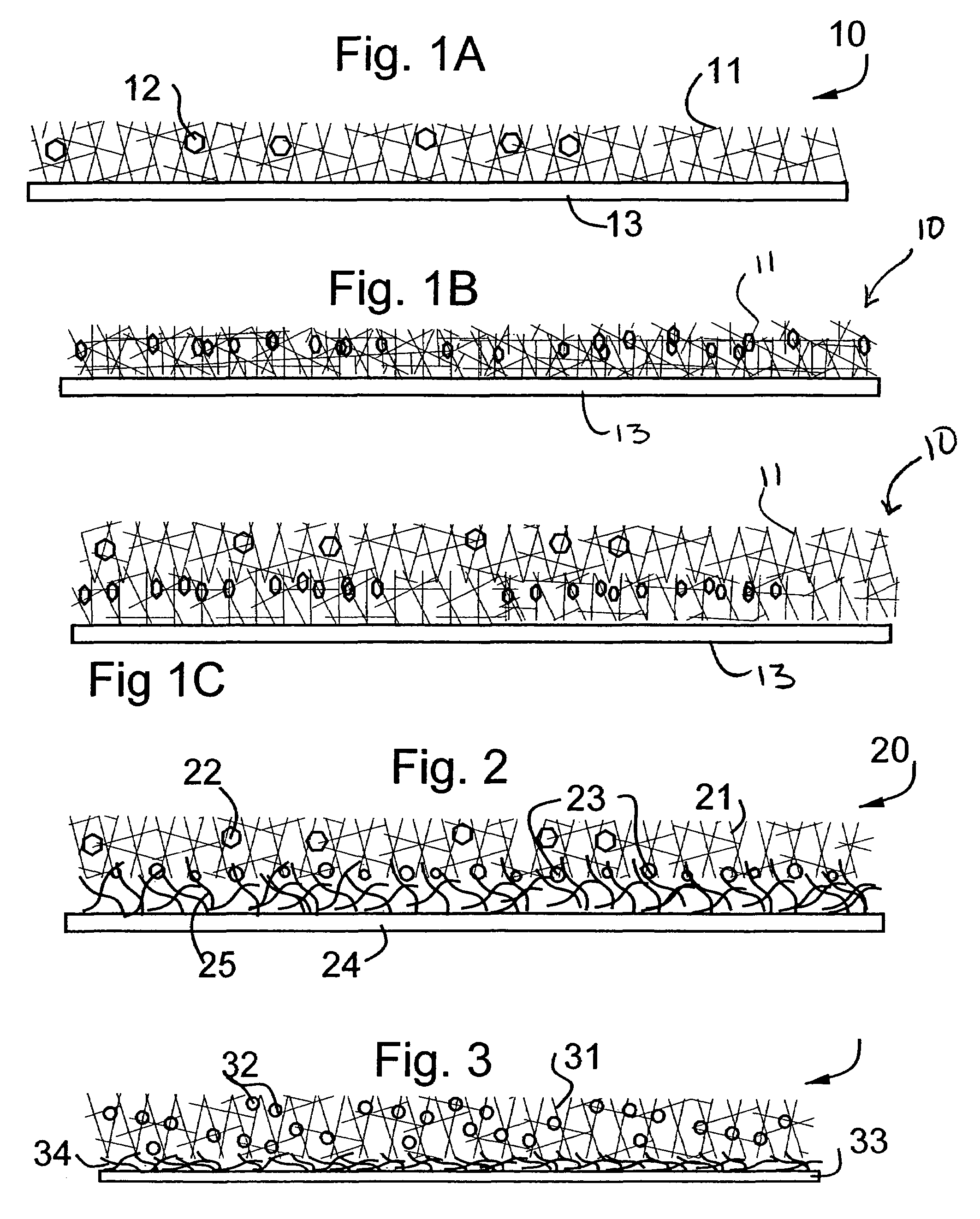

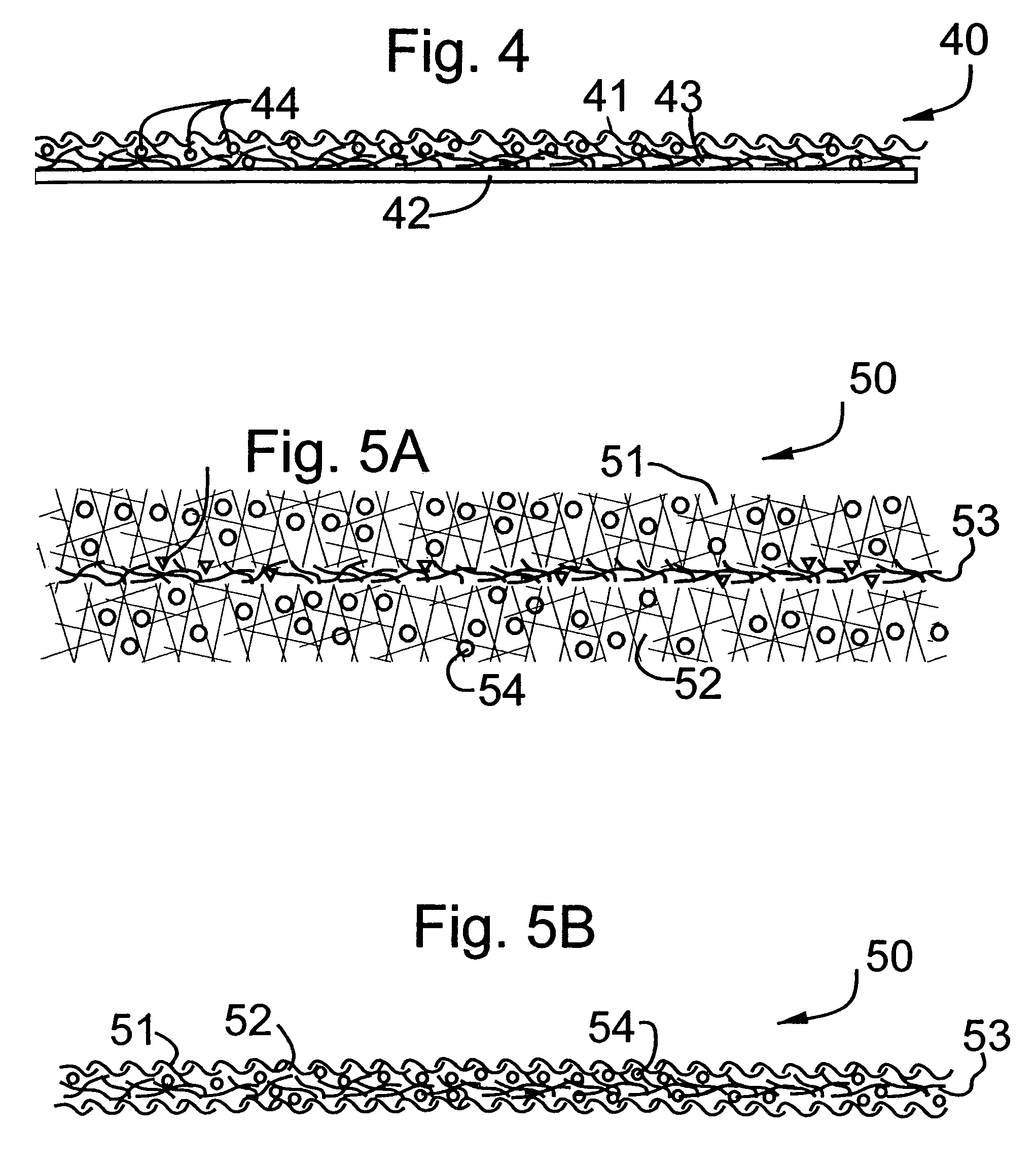

Absorbent pad for entrapping small and coarse particles, retaining liquids and eliminating odors

InactiveUS7726260B1Excellent liquid absorption rateExcellent planar diffusionKitchenware cleanersPaper/cardboard layered productsEngineeringAbsorbent material

A layered pad comprising a bottom impervious layer, a top layer of a fibrous high loft non woven capable of entrapping fine or coarse particles and preventing their scatter, optionally combined with a middle layer of fibers and super absorbent agent, wherein liquids pass through the top layer, become absorbed by the middle layer, and evaporate. As particles from an animal litter box or cage, shoes, metal cutting, wood shavings, and copy machines are generated, they immediately encounter the high loft non-woven top layer, which immediately immobilizes and then entraps them, preventing them from scattering. The filament count of the non-woven can be varied to design the pads to be more effective in trapping smaller or larger particles. In addition, a film of oily substance can be applied to the fibers to make them more sensitive to absorbing and entrapping extremely small particles. If absorbency is required under the high loft fibrous non-woven, a layer of absorbent material is added between the two layers. The layered pad is optionally treated with super absorbent polymer, deodorants, antibacterial agents, anti-fungal agents, and other substances depending on the use of pad.

Owner:YANANTON PAT

Absorbent pad for entrapping small and large particles, retaining liquids and eliminating odors

InactiveUS7654227B1Eliminate odorEnhance particle entrapmentAnimal housingOther apparatusFiberInter layer

A layered pad comprising a bottom impervious layer, a top layer of a fibrous high loft non woven capable of entrapping small or large particles and preventing their scatter, optionally combined with a middle layer of fibers and super absorbent agent, wherein liquids pass through the top layer, become absorbed by the middle layer, and evaporate; and a method for manufacturing a non-woven pad layer having an at least partially open-ended configuration. The method of manufacturing the open-ended non-woven layer includes cutting at least one surface of the non-woven layer and then abrading the cut surface with an abrading tool.

Owner:YANANTON PAT

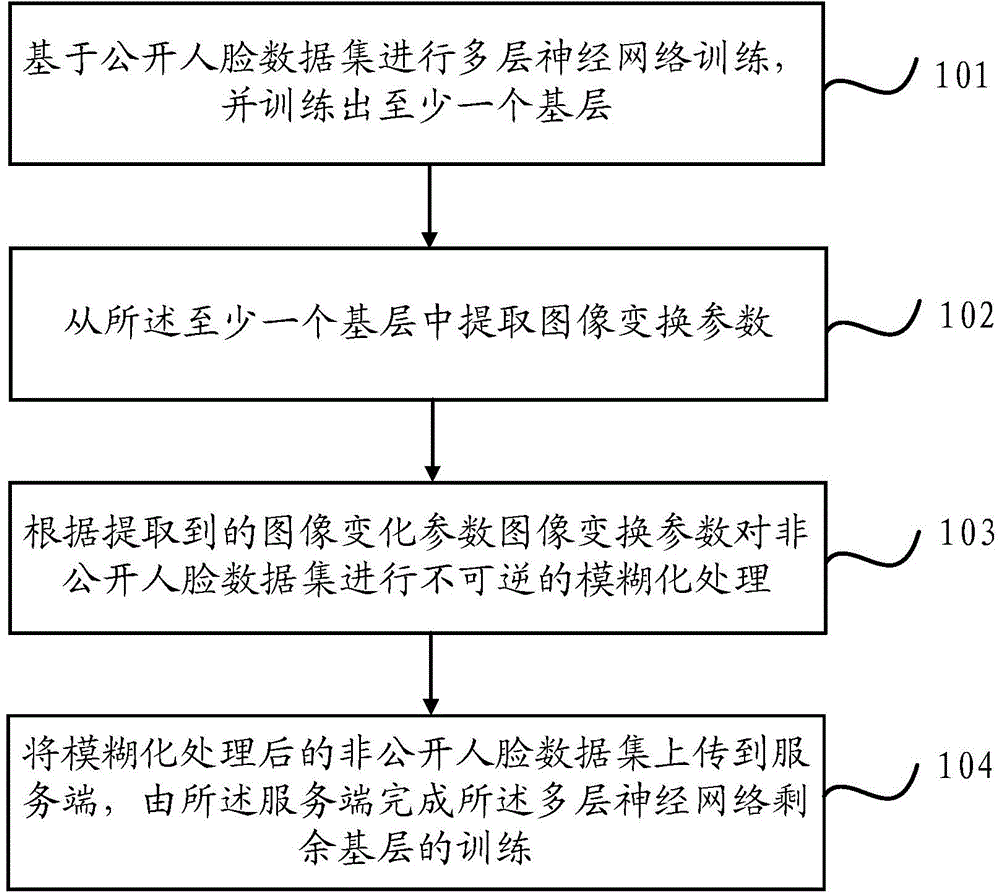

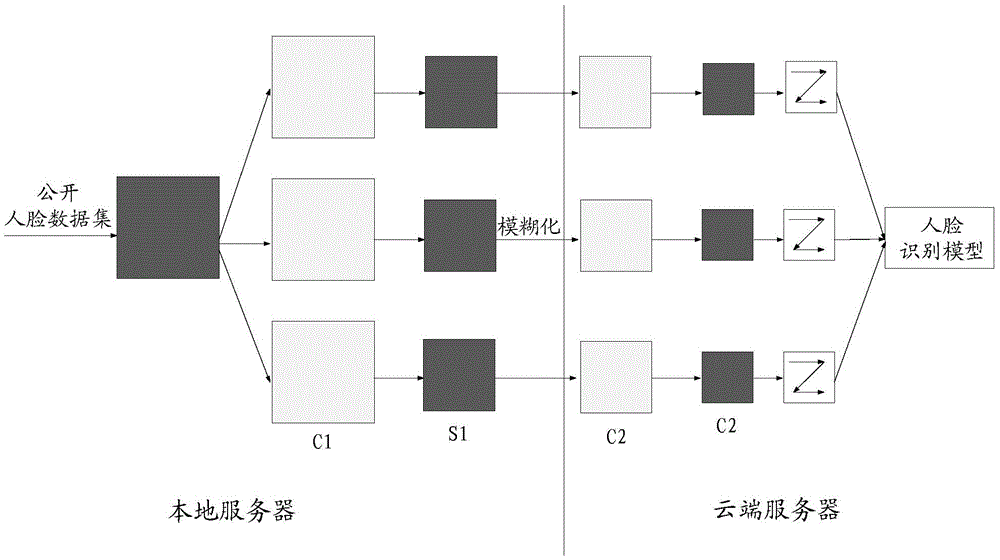

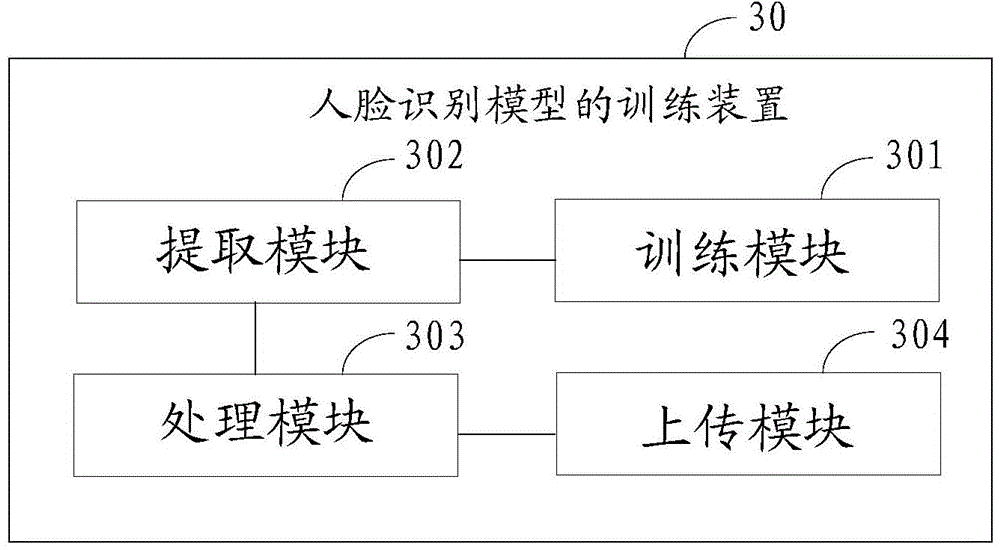

Human face recognition model training method and device

ActiveCN105868678AEliminate the risk of leakageCharacter and pattern recognitionPattern recognitionData set

The application provides a human face recognition model training method and device. The method comprises: multi-layer neural network training is conducted on the basis of a public human face dataset, and at least one base layer is obtained through training; an image transformation parameter is extracted from the at least one base layer; irreversible fuzzy processing is carried out on a non-public human face dataset according to the extracted image transformation parameter; the non-public human face dataset subjected to the fuzzy processing is uploaded to a server end, and the server end completes training of remaining base layers of the multi-layer neural network. The method can eliminate the risk of leakage during non-public human face data uploading.

Owner:ADVANCED NEW TECH CO LTD

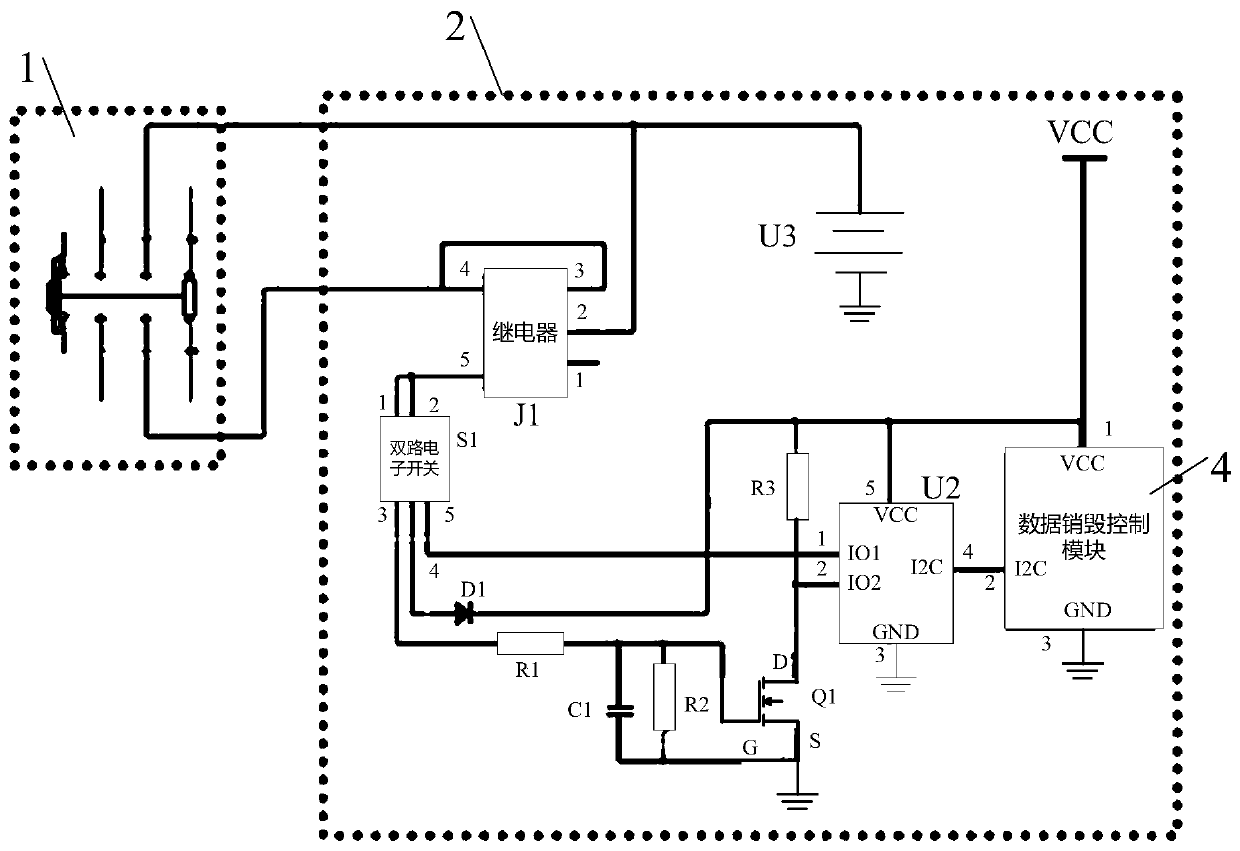

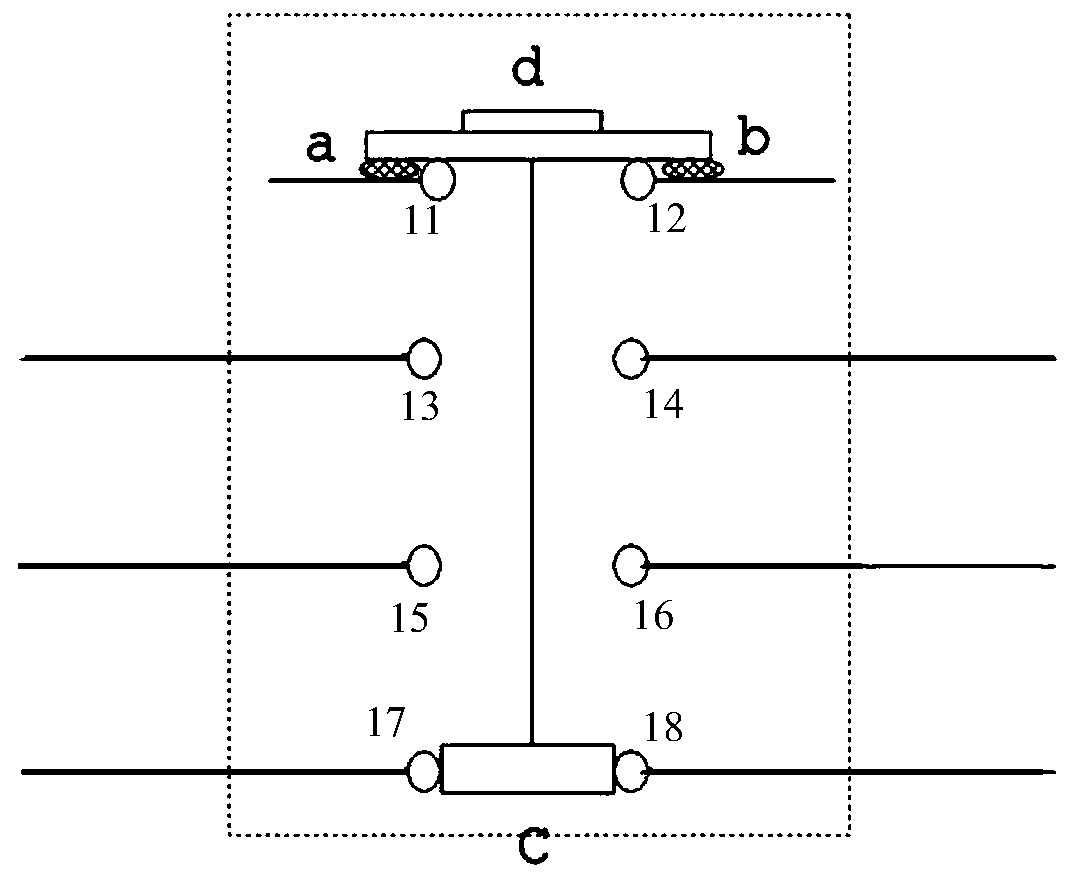

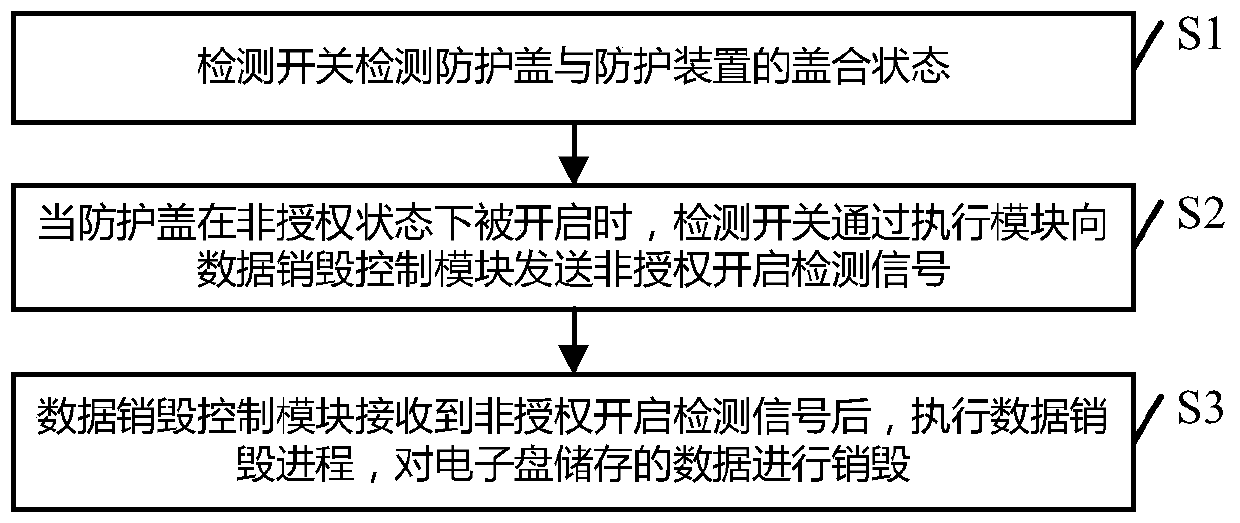

Electronic disk system with data self-destruction protection and method

ActiveCN110020560AEliminate the risk of leakageEnsure safetyInternal/peripheral component protectionDigital data authenticationData informationData file

The invention provides an electronic disk system with data self-destruction protection and a method. The electronic disk system comprises a protection device, wherein an electronic disk used for storing data files and a data destruction control module connected with the electronic disk and used for a user to destruct data information in the electronic disk are installed in the protection device, and the protective device is provided with a protective cover; a detection switch, wherein the detection swtich detects the covering state of the protective cover and the protective device, and when the protective cover is opened in an unauthorized state, the detection switch sends an unauthorized opening detection signal to the data destruction control module through the execution module, and thedata destruction control module executes a data destruction process after receiving the unauthorized opening detection signal and destructs data stored in the electronic disk. The risk of data leakageafter the hard disk or the computer is illegally stolen and dismantled is radically eradicated. The arrangement of active destruction and self-destruction of the electronic disk has irreplaceability,so that the information security is ensured to the maximum extent.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

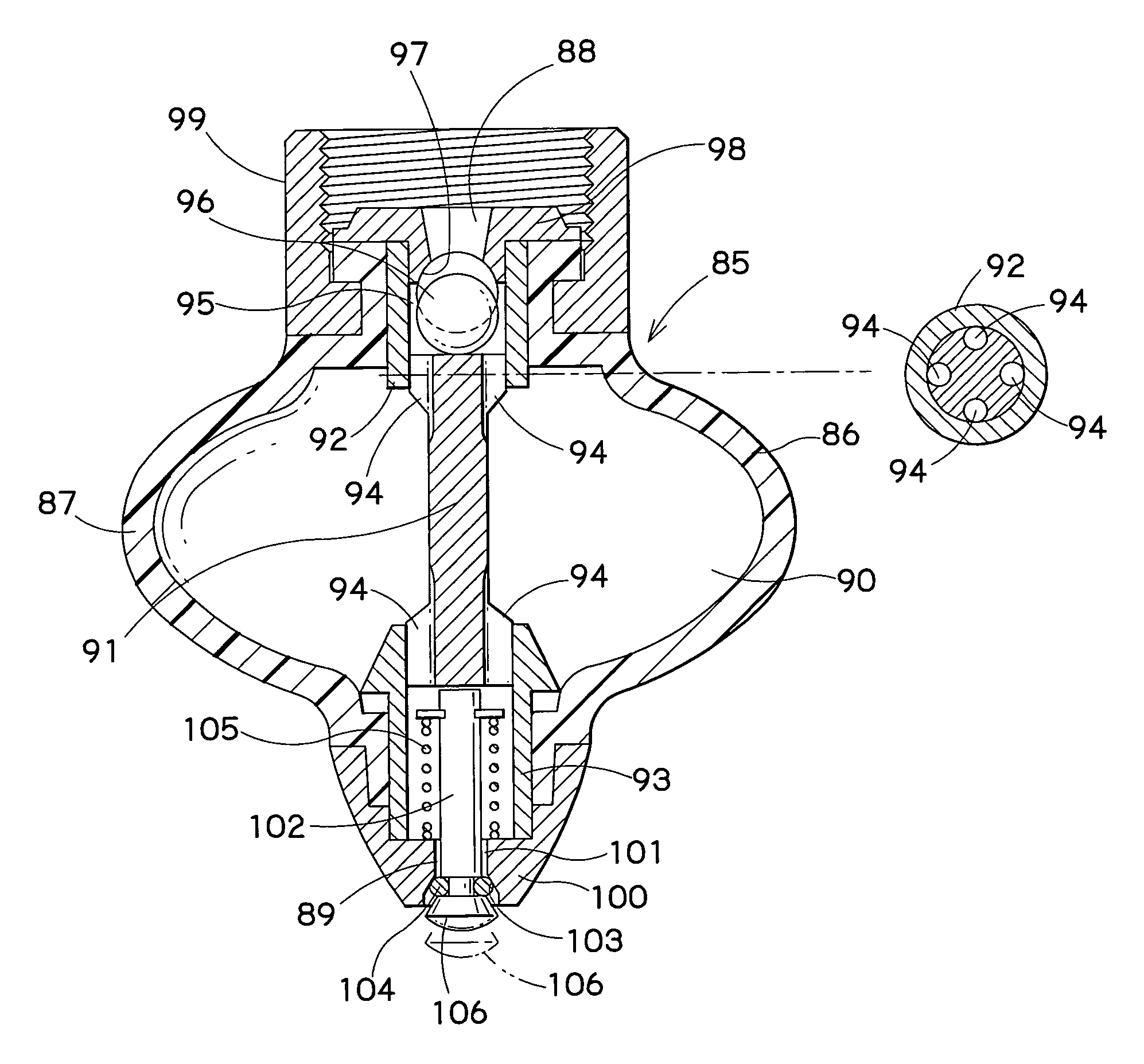

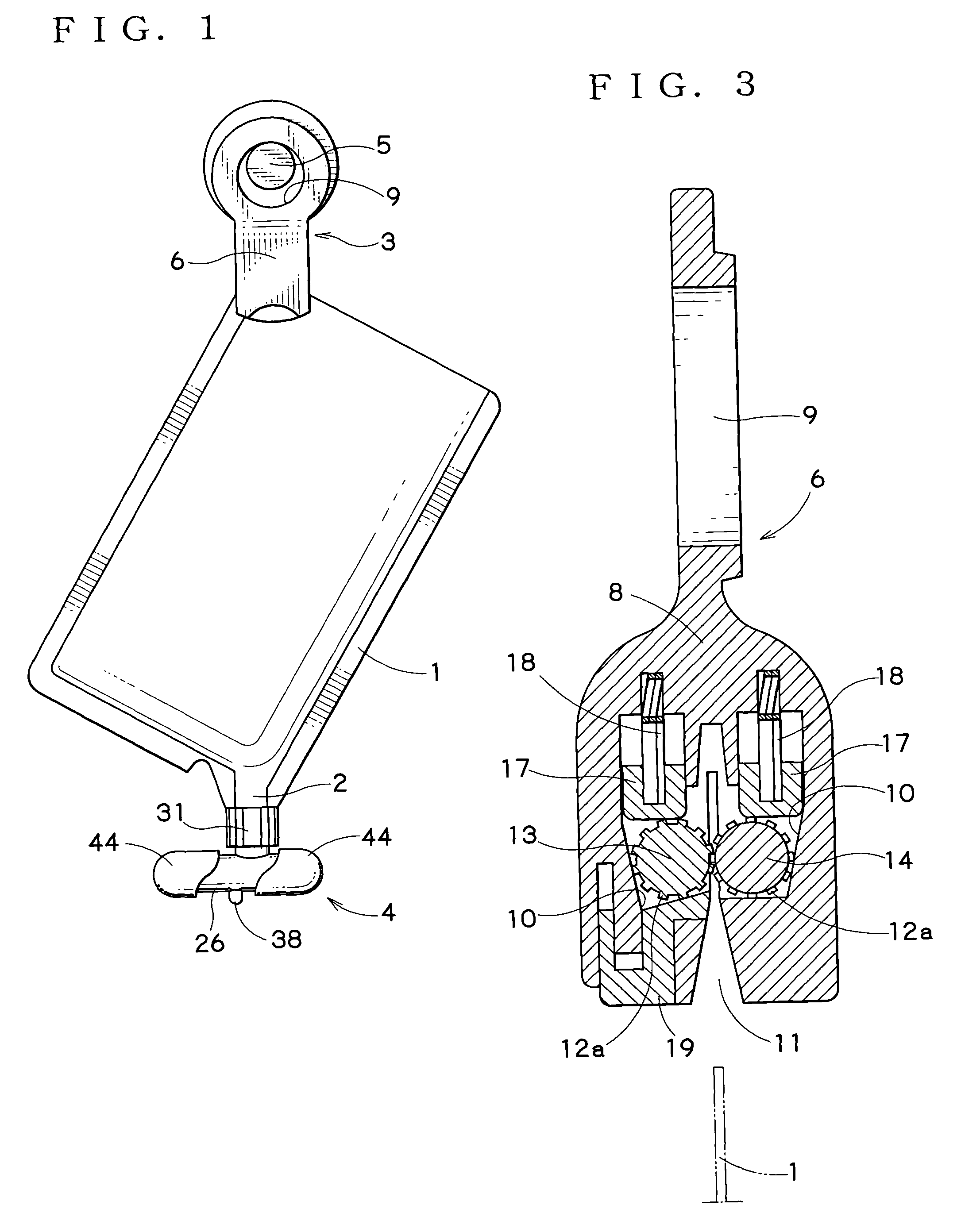

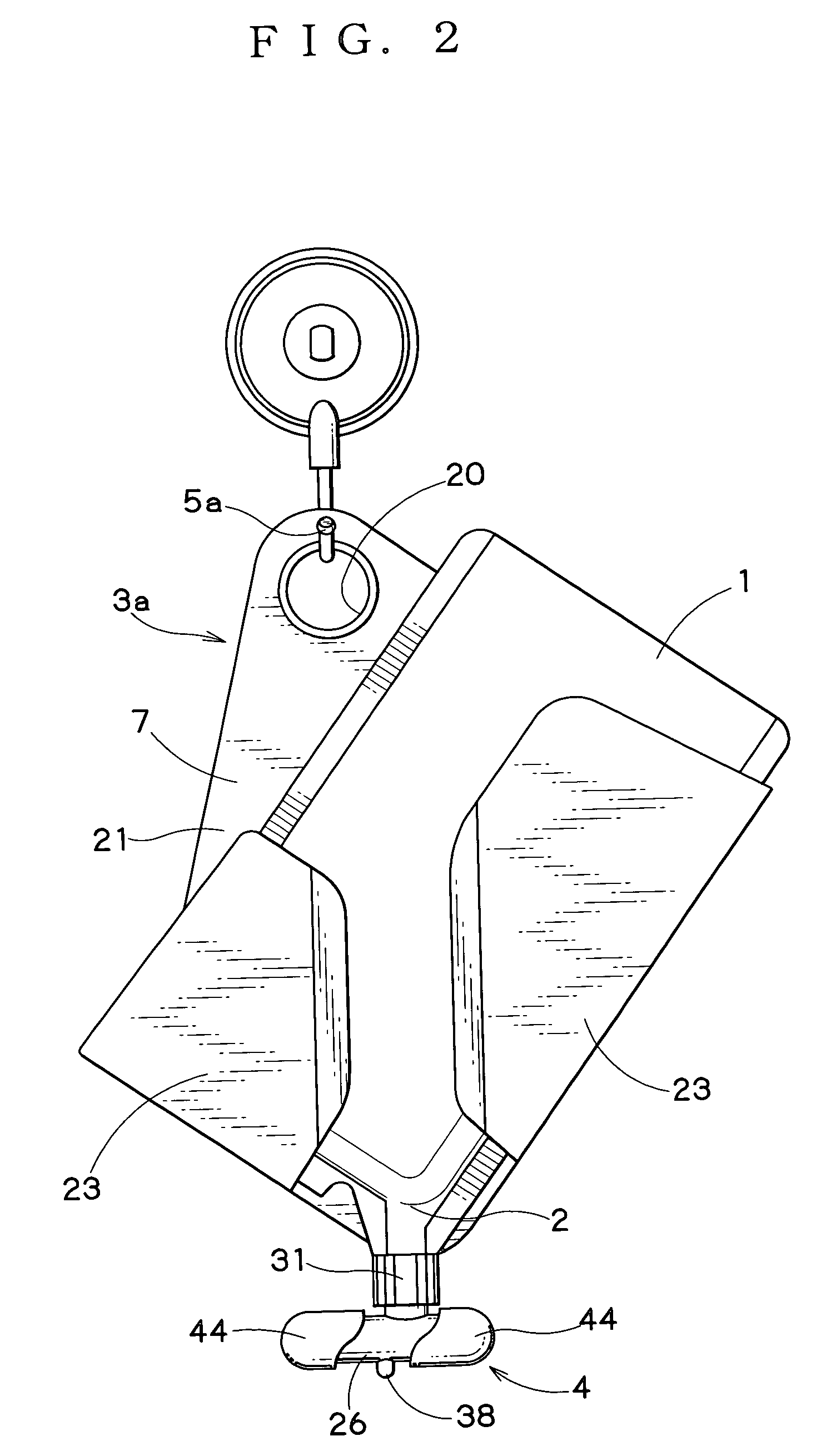

Apparatus for extracting the contents from a refill pouch

An apparatus for extracting the contents from a refill pouch comprises a holding member for holding the pouch with its extraction port facing downward, and a pump attached to the extraction port of the pouch. The pump has a pump body defining a housing space having an inlet opening and an outlet opening, an inlet-side valve which communicates with the extraction port to open and close the inlet opening so that the contents can be introduced into the housing space from the pouch, and an outlet-side valve to open and close the outlet opening so that the contents in the housing space can be discharged through a nozzle that communicates with the outlet-side valve. The pump wall portion is constituted by a resiliently compressible, restorable and flexible material so that the contents in the housing space can be extracted through the nozzle by manually squeezing the pump wall portion thereby pressurizing the housing space.

Owner:SANKI CO LTD

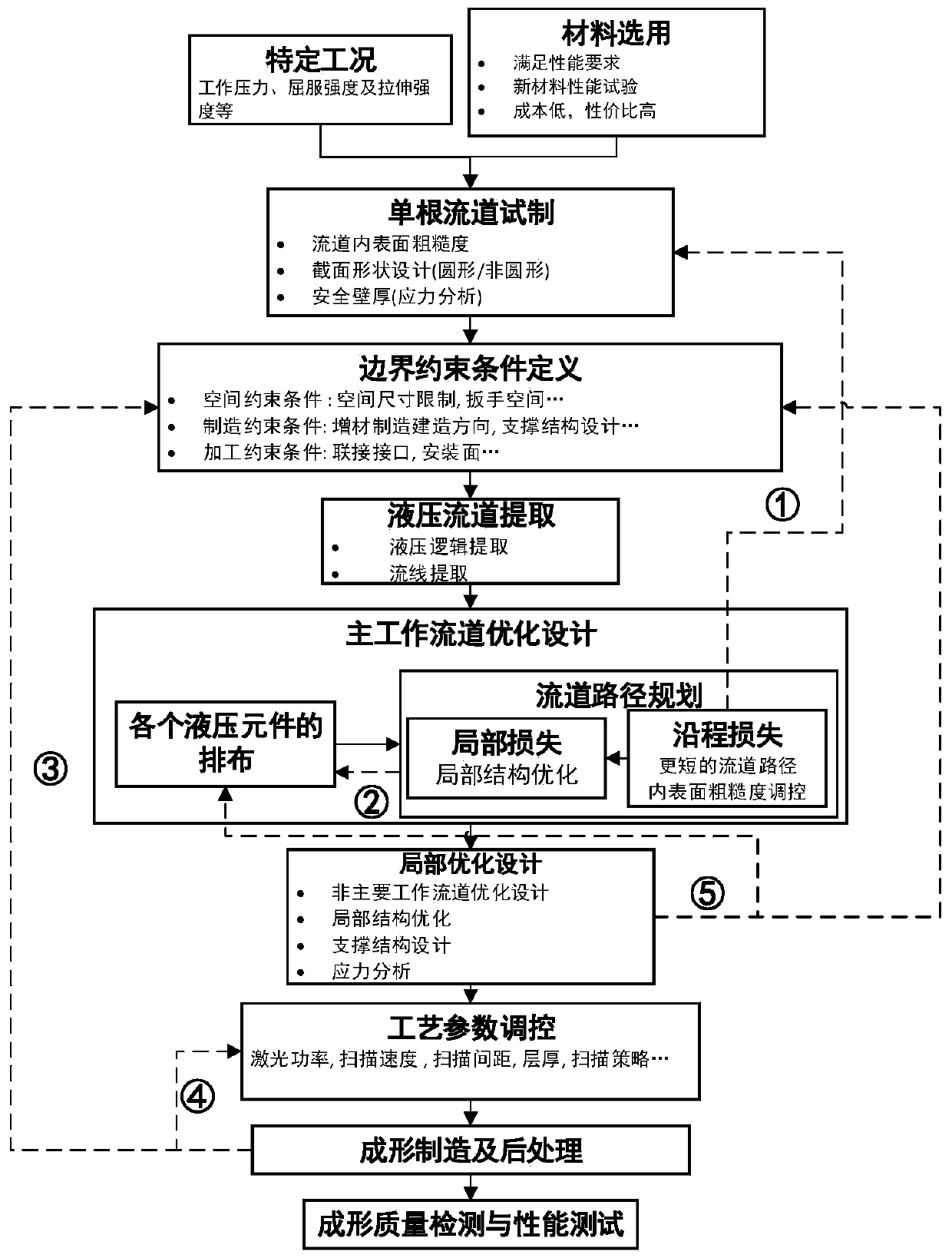

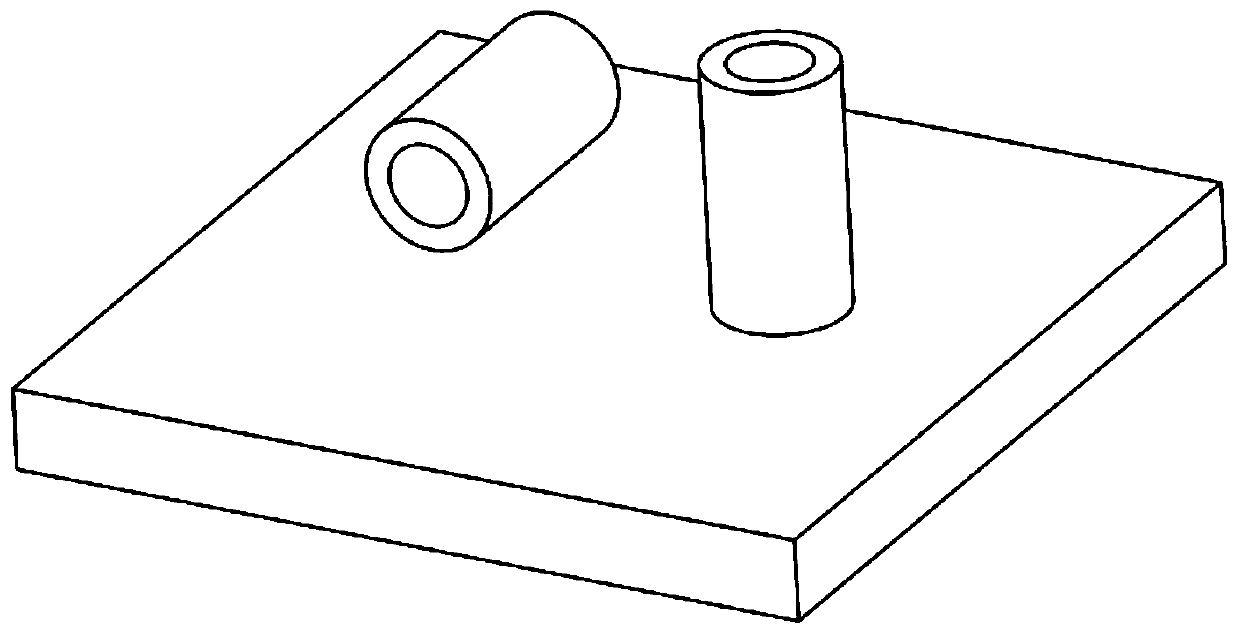

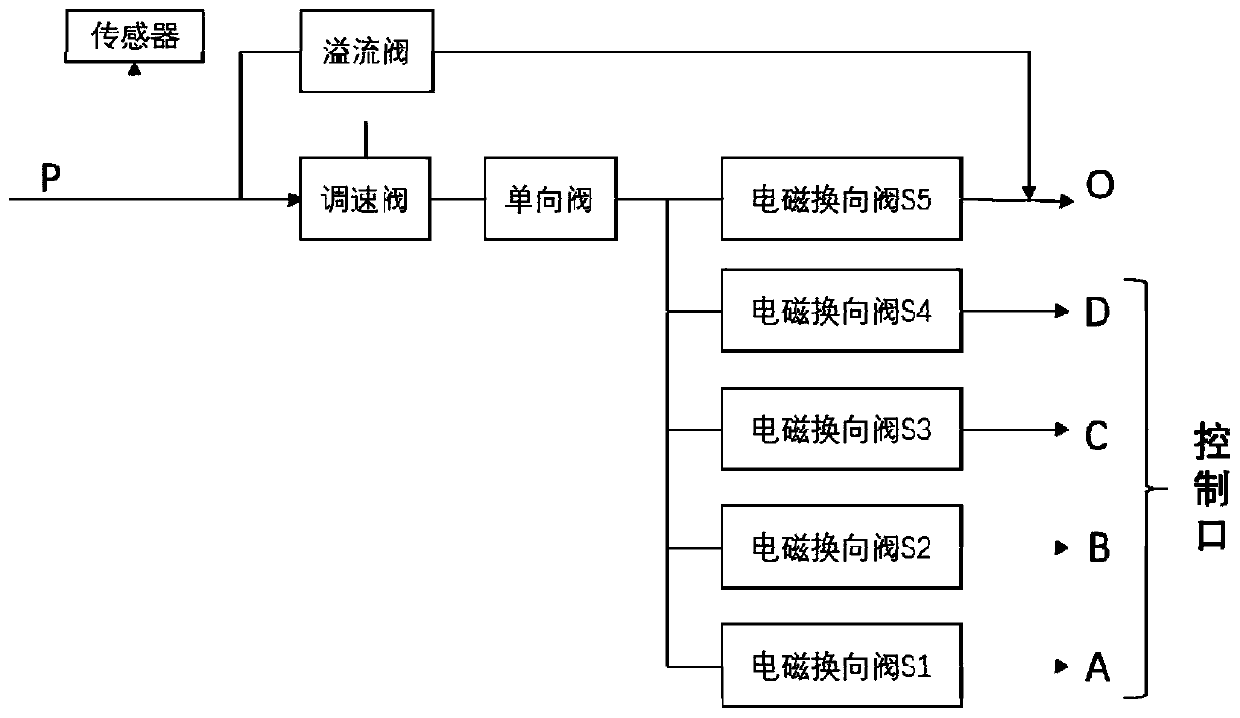

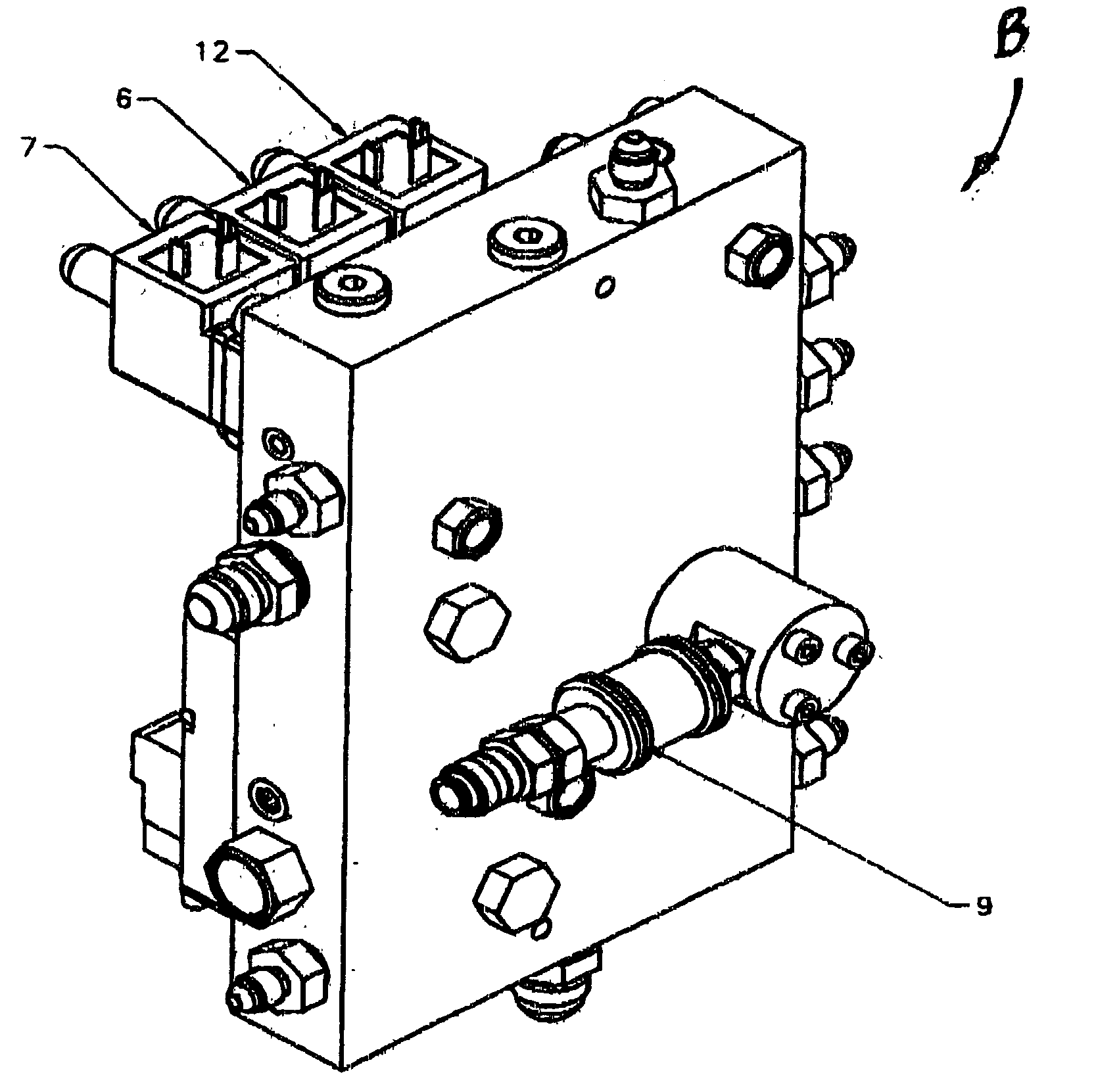

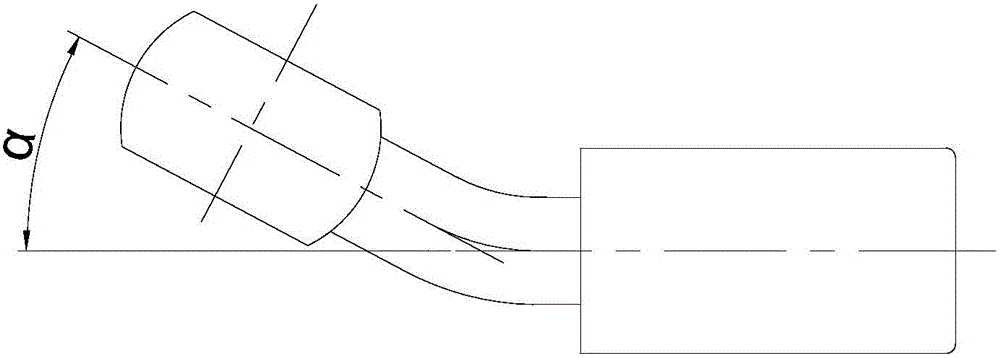

Hydraulic valve block lightweight design method based on selective laser melting

InactiveCN110625115AShort processAvoid time costAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a hydraulic valve block lightweight design method based on selective laser melting. The method comprises the following steps that (1) material selection is carried out; (2) a single flow channel of a hydraulic valve block is subjected to trial-manufacturing, and therefore the wall thickness and section shape of the flow channel are determined; (3) boundary constraint conditioners are set; (4) the hydraulic logic of the hydraulic valve block is extracted; (5) modeling and optimization design of a main work flow channel are carried out; (6) local structure modeling and optimization design are carried out; (7) selective laser melting forming process parameters are regulated and controlled; (8) a hydraulic valve block model is subjected modeling, form manufacturing andaftertreatment operation; and (9) forming quality inspection and performance testing of the formed valve block are carried out. According to the hydraulic valve block lightweight design method based on selective laser melting, the technological process of hydraulic valve block manufacturing and detecting is redesigned through selective laser melting, the weight of the hydraulic valve block is reduced greatly through the additive manufacturing technology, the flowing performance of fluid is improved, the power-to-weight ratio is increased, and the hydraulic valve block lightweight design methodhas god application prospects on the aspects of aerospace and war industry.

Owner:ZHEJIANG UNIV

Integrated pneumatic manifold

InactiveUS20030127144A1Lower Level RequirementsEasy to controlTank vehiclesFlow mixersEngineeringMechanical engineering

An integrated pneumatic manifold for installations that require electrical and other components to be separated from a harmful or dangerous environment, in which pneumatic (and / or hydraulic) devices operate, the manifold comprising a block that has drilled into it a large number of passages that are directed in various directions and located at various levels, some passages crossing partially and some wholly with others and cavities machined in various positions. The block has mounting points for components on its surfaces and passive and active pneumatic components are integrated into the cavities and passages of the block. The block serves as a separation between the safe and harmful environments and as a substitution for many passive and active pneumatic components that would normally be individually connected.

Owner:SEYFARTH OTTO HERMAN

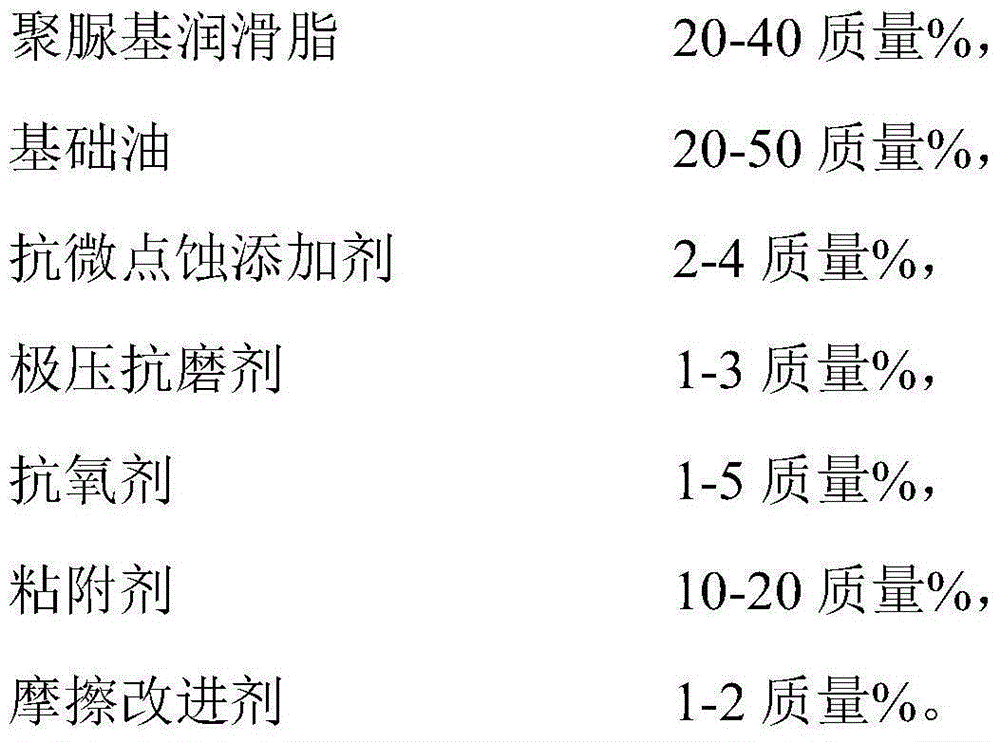

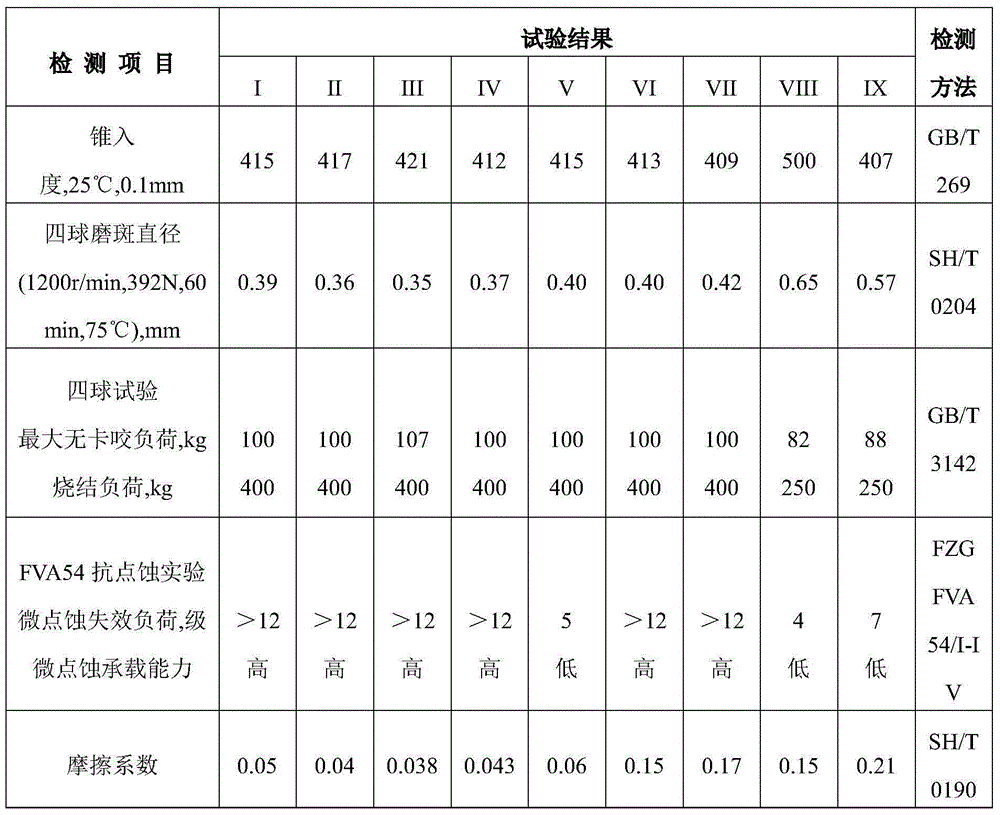

Gearbox lubricating agent composition and preparation method thereof

ActiveCN105038914AImprove the lubrication effectExtend working lifeLubricant compositionMicro pittingLow speed

The invention discloses a gearbox lubricating agent composition and a preparation method thereof. The gearbox lubricating agent composition comprises the following components in 100% of the total mass: 20-40% of polyurea-based lubricating grease, 20-50% of base oil, 2-4% of micro-pitting resistant additive, 1-3% of anti-wear reagent at extreme pressure, 1-5% of antioxidant, 10-20% of adhesive and 1-2% of friction modifier. The gearbox lubricating agent disclosed by the invention has excellent lubricating performance and can be used for reducing the temperature of a gearbox and avoiding the damage to a certain degree to a gear due to overhigh temperature; the gearbox lubricating agent composition has excellent low-speed and heavy-duty shear stability; according to the gearbox lubricating agent composition, the replacement period of a gearbox lubricating agent is prolonged, and the production cost is reduced; the pitting on the gear surface of the gear inside the gearbox can be effectively restricted; the gearbox lubricating agent disclosed by the invention has no any corrosion to a sealing member of the gearbox; furthermore, the risk of the lubricating agent leakage in the gearbox is eliminated.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Phase transition heat storage film, and prepration method thereof

InactiveCN109897610AStable high temperature aging performanceStabilize its own performance parametersHeat-exchange elementsPhase-change materialPressure sensitive

The invention discloses a phase transition heat storage film. The phase transition heat storage film comprises a lower rubber film, a heat storage functional layer, and an upper rubber film which arelaminated successively; the lower surface of the upper rubber film, and the lower surface of the lower rubber film are coated with pressure sensitive adhesive layers; the heat storage functional layercomprises matrix resin, and phase transition microcapsules distributed in the matrix resin; the matrix resin is a thermoplastic resin or a thermosetting resin. The invention also discloses a preparation method of the phase transition heat storage film. According to the phase transition heat storage film, defects in the prior art that in phase transition circulation of conventional phase transition heat storage film, phase transition material precipitate and leakage are caused; and phase transition heat storage sheet material terminal application stability is improved.

Owner:SUZHOU TIANMAI THERMAL TECH

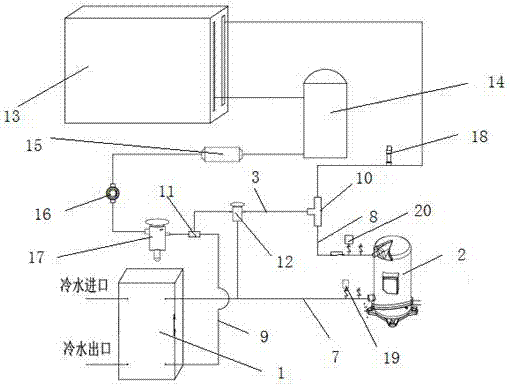

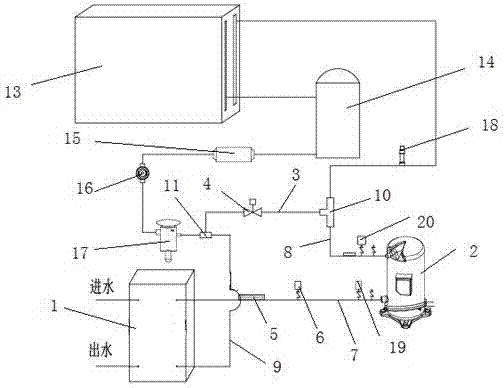

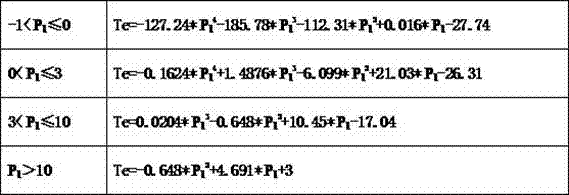

Cold water air conditioner system

InactiveCN107131598AEffect of heat transfer efficiencyThe heat transfer efficiency will not affect theSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringPressure balance

The invention discloses a cold water air conditioner system comprising a plate-type evaporator, a compressor and a condenser. The plate-type evaporator, the compressor and the condenser are connected through a pipeline. A temperature sensor and a pressure sensor are mounted on an air suction pipeline of the compressor. A bypass pipeline is connected on an outlet pipeline of the compressor. The other end of the bypass pipeline communicates with an inlet pipeline of the plate-type evaporator. An electromagnetic valve is mounted on the bypass pipeline. When the actual superheat degree is smaller than the standard superheat degree and the air suction pressure is smaller than the standard air suction pressure, the electromagnetic valve is opened. When the actual superheat degree is larger than or equal to the standard superheat degree or the air suction pressure is larger than or equal to the standard air suction pressure, the electromagnetic valve is opened. A pressure balancing valve is not adopted to preventing ice blockage any more but a common electromagnetic valve is adopted to achieve the ice blockage preventing effect, so that the ice blockage preventing cost is reduced greatly. Compared with the pressure balancing valve, the electromagnetic valve is higher in precision, smaller in weight and more precise in controlling, it is guaranteed that the interior of the evaporator is free from icing, and the ice blockage phenomenon of the plate-type evaporator is removed thoroughly.

Owner:YIMIKANG TECH GRP CO LTD

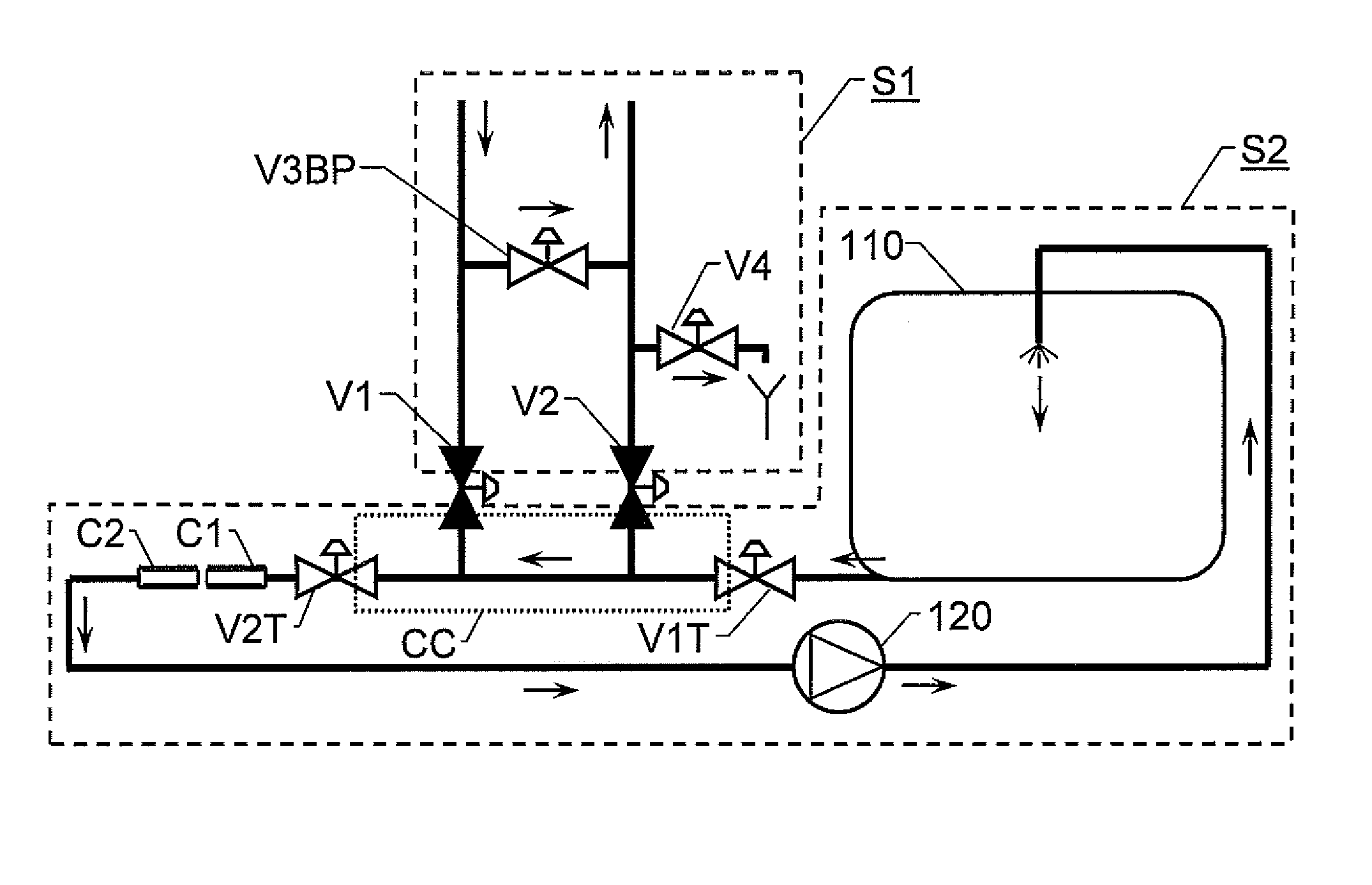

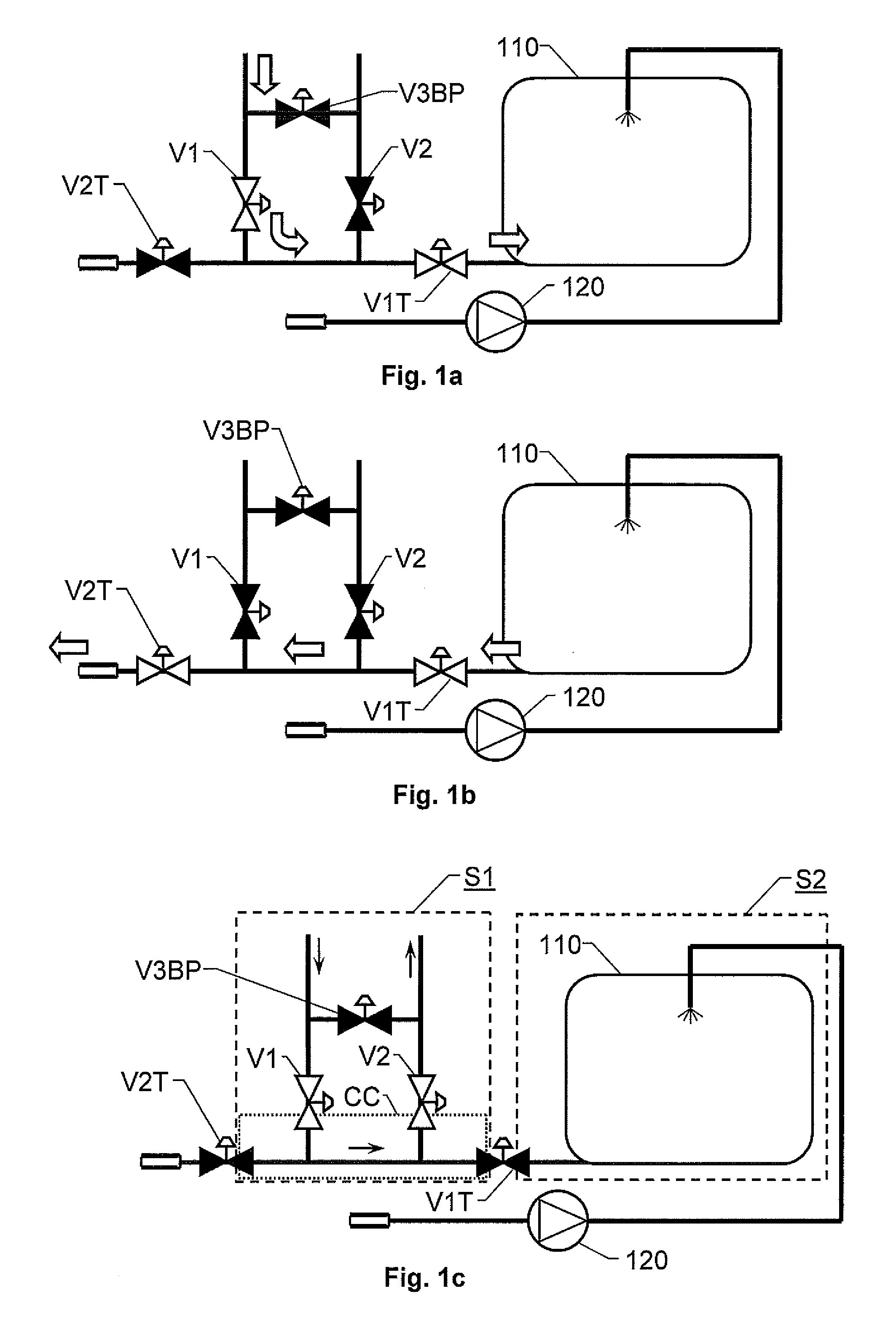

Independent cleaning of interfaces between separable fluid systems

ActiveUS9072272B2Efficient and reliable and flexibleEasy to cleanHollow article cleaningCleaning using liquidsEngineeringMechanical engineering

A milking installation includes first and second fluid systems (S1; S2) and a coupling arrangement for connecting and disconnecting the first fluid system (S1) to and from the second fluid system (S2). In a connected state, the first and second fluid systems (S1, S2) are in fluid communication with one another, and in a disconnected state the first and second fluid systems (S1, S2) are not in fluid communication with one another. The coupling arrangement includes a common cavity (CC) configured to be alternately included in the first fluid system (S1) or in the second fluid system (S2) for through passage of fluid while the first and second fluid systems (S1, S2) are disconnected from one another. The first fluid system (S1) also has a by-pass arrangement configured to allow fluid in the first fluid system (S1) to circulate independently from the passage of fluid through the common cavity (CC) when the common cavity (CC) is included in the second fluid system (S2).

Owner:DELAVAL HLDG AB

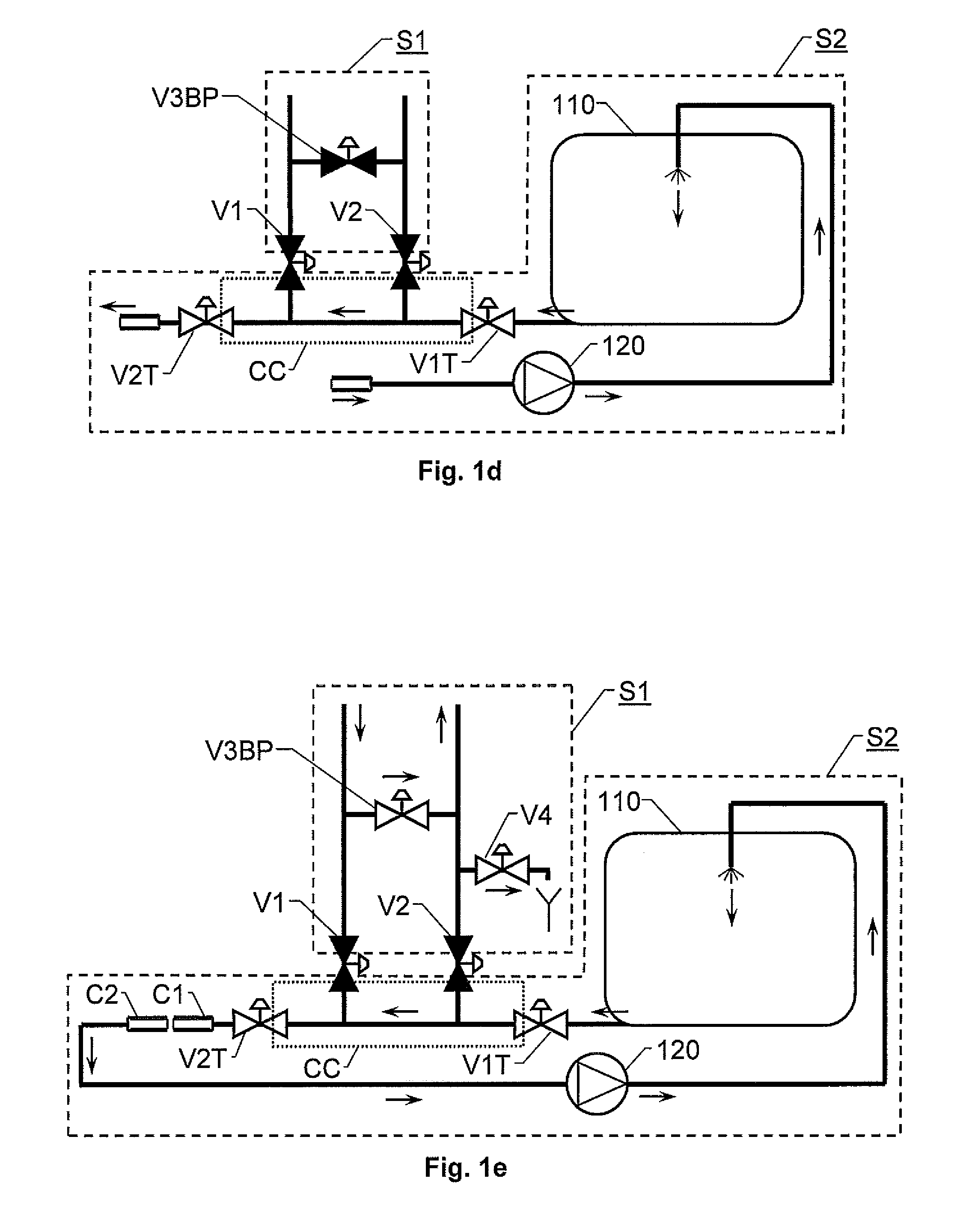

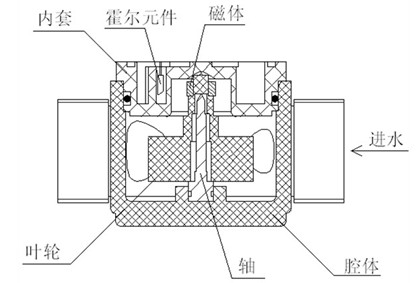

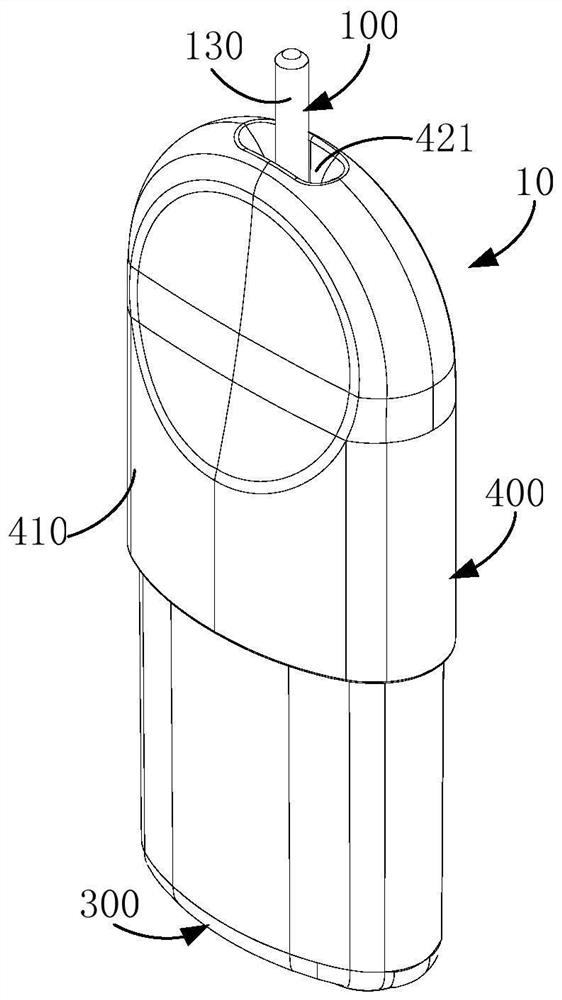

Nutrition pump, infusion device, control valve and liquid control method

PendingCN109846716AEliminate the problem of leakageEliminate the risk of leakageMedical devicesPressure infusionMotor driveInfusion set

The invention relates to a nutrition pump, an infusion device, a control valve and a liquid control method. The nutrition pump comprises a pump body and an infusion device, the infusion device comprises a control valve, and a pump wheel is arranged on the pump body; and the control valve comprises a valve body and a valve core which is in cooperative connection with the valve body, the valve bodycomprises a first input pipe and a second input pipe which are used for being connected to a liquid to be transfused, a cylindrical structure and an output pipe which is used for outputting the liquidto be transfused, one end of a switching shaft is connected to a motor, and the other end is connected to the valve core, so that the motor drives the valve core to rotate through the switching shaft. The nutrition pump can realize the free switching of two liquids, eliminates the liquid tainting risk in the nutrition pump feeding process, and has low cost and high precision.

Owner:ZHEJIANG MDKINGDOM TECH CO LTD

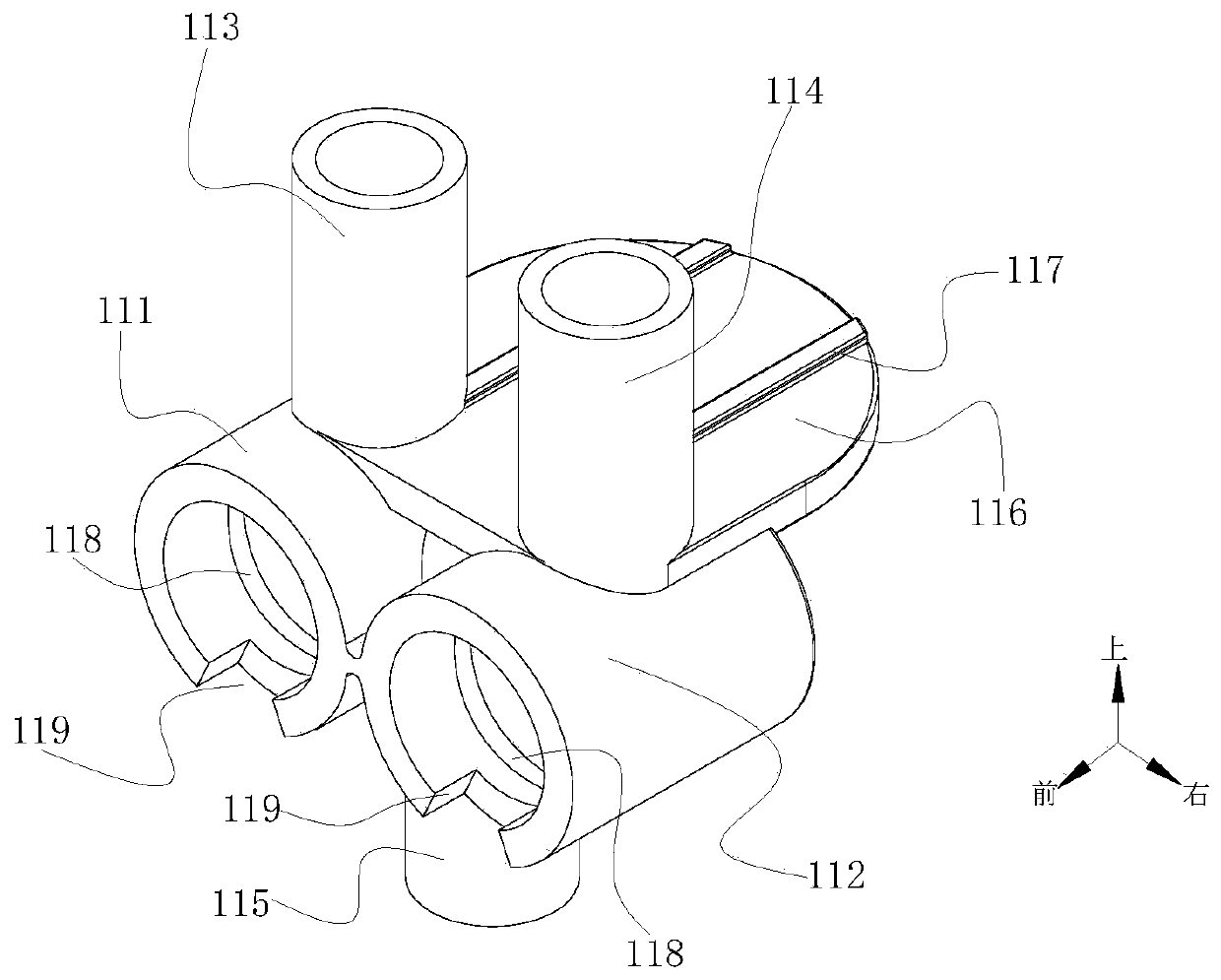

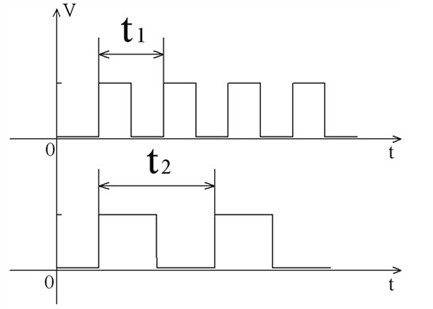

Monostable protective circuit and automatic control circuit for water heater

ActiveCN102591242APrevention of dry burningEnsure safetyProgramme controlComputer controlMicrocontrollerAutomatic control

The invention relates to a fuel gas water heater controller, in particular to a monostable protective circuit for the fuel gas water heater controller. The monostable protective circuit comprises a comparer N6B and a first triode V33, wherein the negative input end of the comparer N6B is connected with a power supply and the collector of the first triode V33 respectively; the emitter of the first triode V33 is grounded; the positive input end of the comparer N6B is connected with the power supply through a fourth resistor R49 and grounded through a fifth resistor R50; and the resistance values of the fourth resistor R49 and the fifth resistor R50 are the same. The negative input end of the comparer N6B is at a high level or low level by controlling the collector and the emitter of the first triode V33 to be switched on or off. The monostable protective circuit is relatively independent in the whole control circuit, so that the dry combustion of a water heater without a water flow signal is avoided when a singlechip or an application specific integrated circuit (ASIC) device fails.

Owner:成都前锋电子有限责任公司

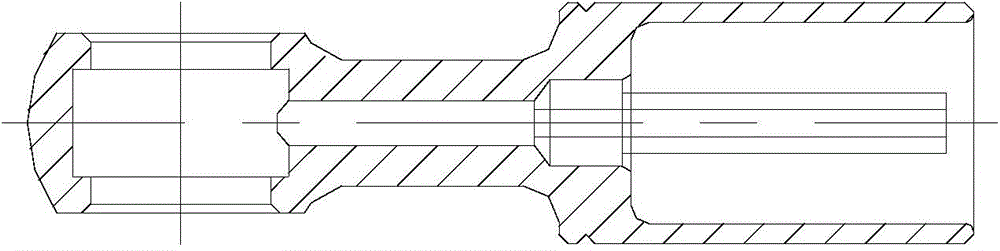

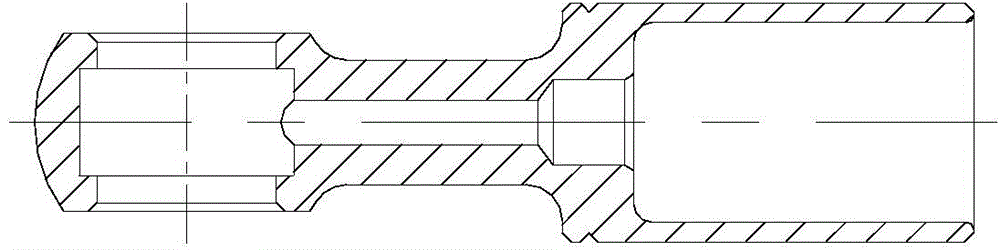

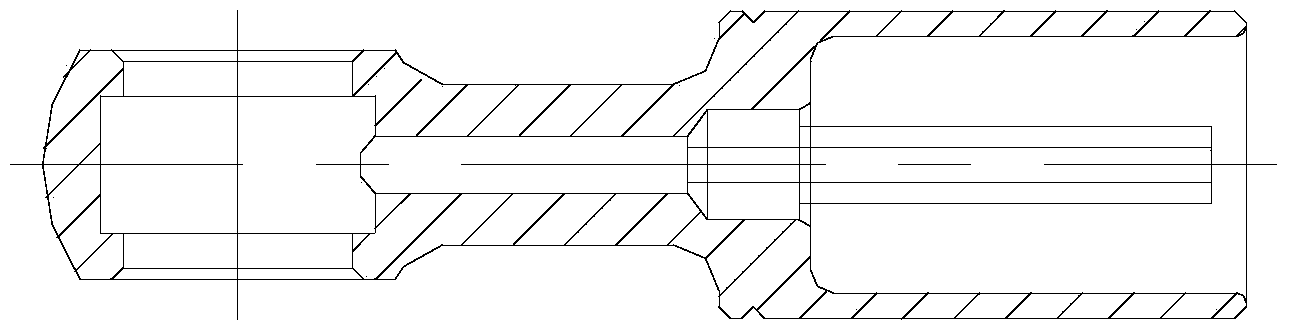

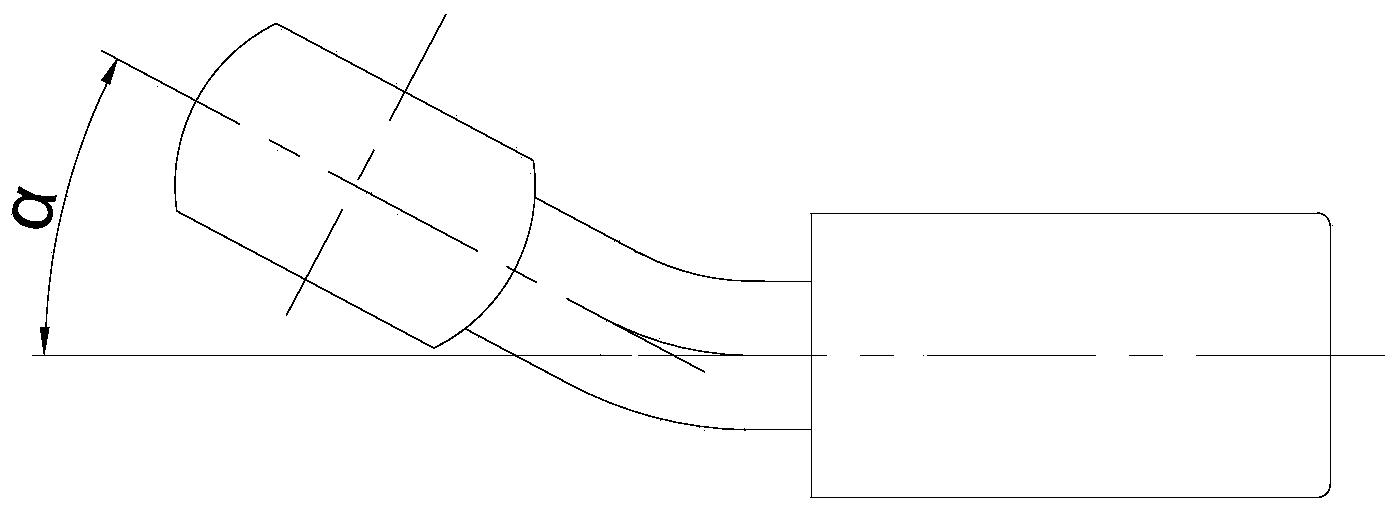

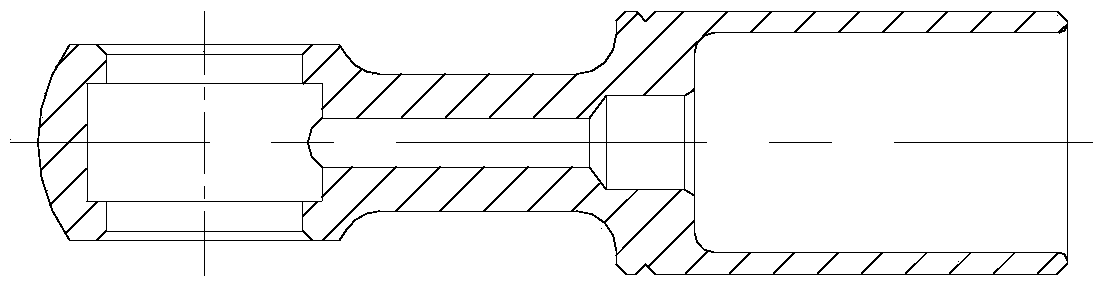

Integrated spherical hydraulic hose metal joint structure and production process thereof

ActiveCN104373721AEnsure safetyHigh dimensional accuracyBranching pipesEngine componentsHigh volume manufacturingEngineering

The invention provides an integrated spherical hydraulic hose metal joint structure and a production process thereof. The integrated spherical hydraulic hose metal joint structure is characterized in that a metal connector body (1), a spherical connector (3), a tee structure through hole (4), a hollow liner core pipe (5), a liner core connection pipe (6) and a connection rod (8) are integrated. The integrated spherical hydraulic hose metal joint structure can be produced in a mass mode through the production process and a cold header, the integrated spherical hydraulic hose metal joint structure and the production process thereof can save more than 60% of raw materials and a large amount of electric energy compared with a traditional method, and the material finished product ratio through the manufacturing method can reach 99%.

Owner:JIANGSU TIANYI PIPELINE COLD HEADING MFG

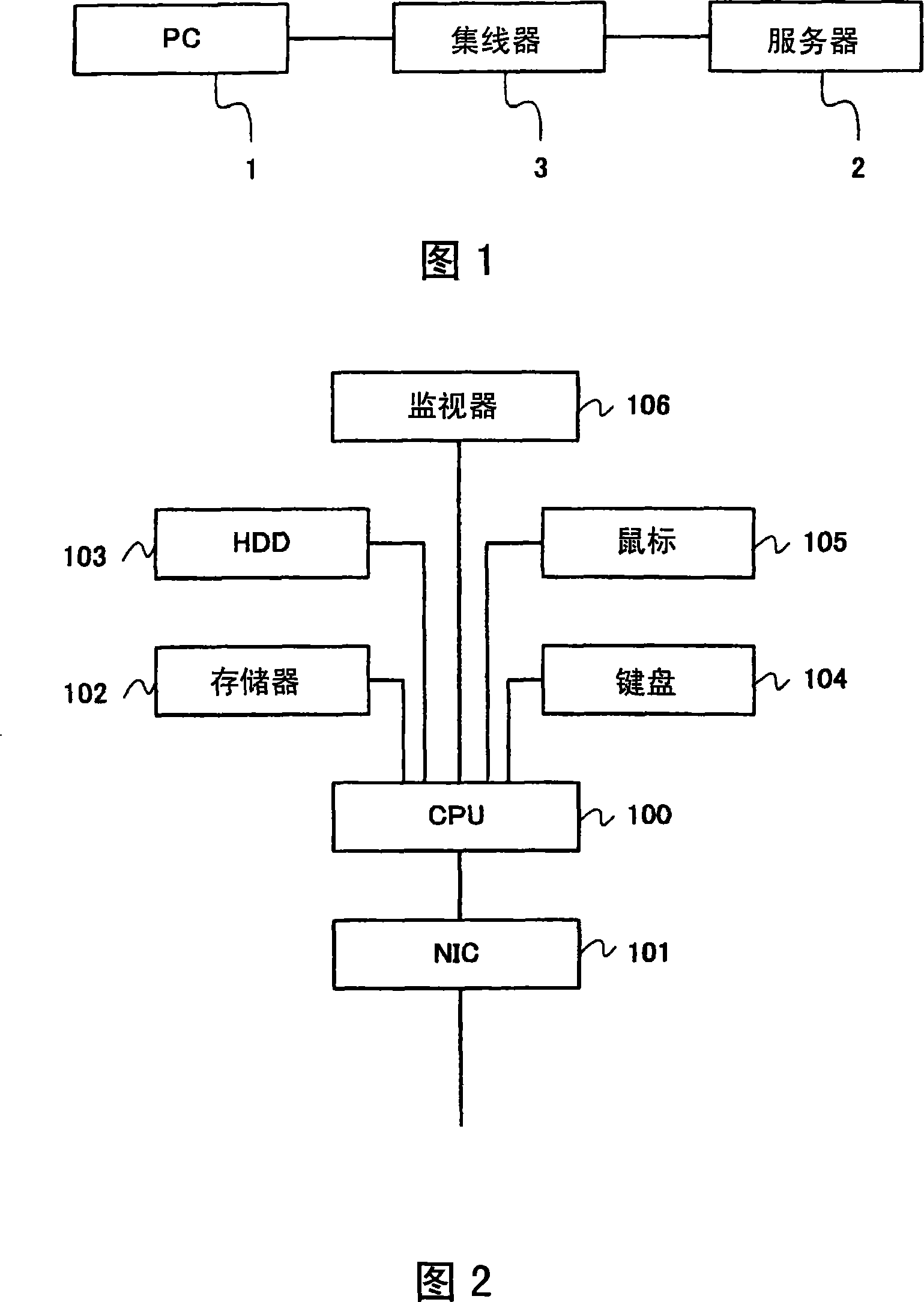

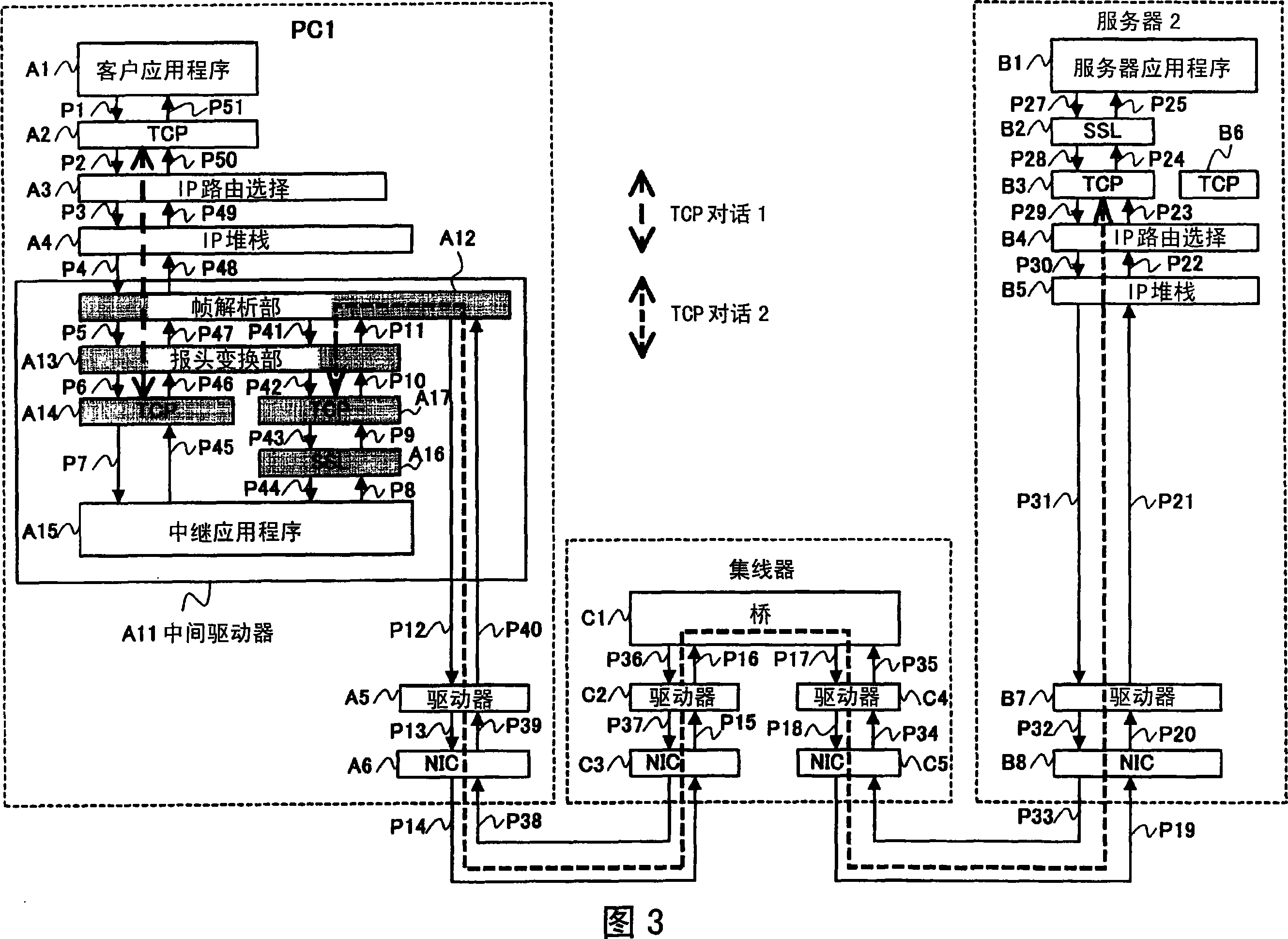

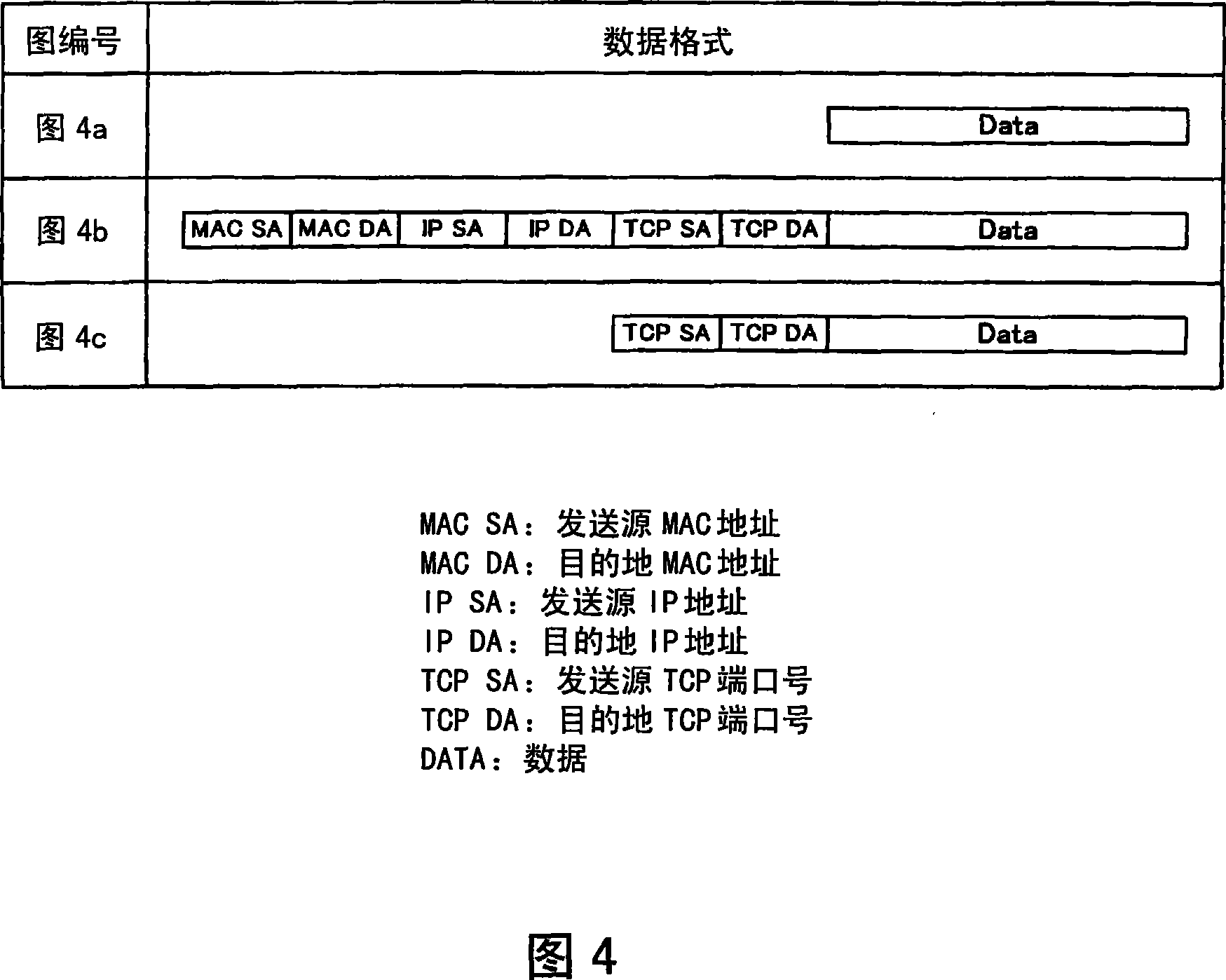

Communication system, communication apparatus, communication method, and program

InactiveCN101112041ASave the hassle of setting up encryption keysEliminate dangerData switching networksSecuring communicationCommunications systemEncryption

If it is determined by a frame analyzing means in an intermediate driver (A11) of PC 1 that data, which is to be transmitted from a client application (A1) to a server application (B1), needs to be encrypted, then the data is relayed by use of a total of two TCP cessions consisting of a TCP cession 1 between TCP (A14) and TCP (A2) and a TCP cession 2 between TCP (A17) and TCP (B3). In this way, relaying the TCP cessions can achieve a coincidence of TCP / IP protocol hierarchy between SSL (A16) in the intermediate driver (A11) and the SSL (B2) in the server (2). This allows automatic exchanges of the certificate information, encryption algorithm and so on required for the starting of an SSL cession therebetween. As a result, secret data to be transmitted from the PC can be encrypted without changing the setting of the server or installing any software.

Owner:NEC CORP

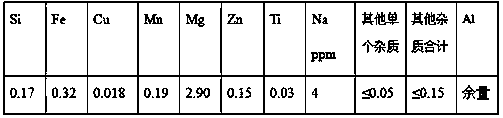

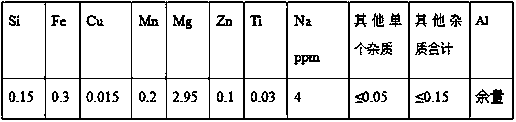

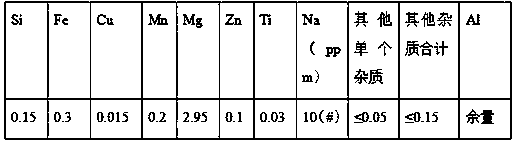

Preparation method of aluminum alloy for aerosol bottle cap

ActiveCN108642344AOvercoming technical deficienciesSolve problems such as slag inclusionSlagImpurity

The invention provides a preparation method of an aluminum alloy for an aerosol bottle cap. The method comprises the steps of S1, preparing a cast ingot through alloy components based on the mixing ratio; S2, milling the cast ingot; S3, uniformly thermally processing the cast ingot; S4, performing hot rolling on the cast iron to obtain a blank; S5, performing cold rolling to the blank which is subjected to hot rolling until the intermediate annealing thickness is reached; S6, washing the surface with weak alkali; S7, completely recrystallizing and annealing the middle; S8, performing pass rolling on a finished product; S9, stably chemically processing the finished product; and S10, stretching and bending and correcting back roll. According to the method, the Na content is effectively decreased based on the component mixing ratio and the technical method; the range of Na element which easily causes Na embrittlement in a high-magnesium alloy is avoided, and thus the problem of Na embrittlement is solved; and meanwhile, the component fluctuation is well controlled, and the problem that the magnesium element easily results to slag inclusion is solved; and meanwhile, the problem of liquid leaking caused by impurities adhering to the surface can be solved by a special weak alkali washing technology in the middle process; and the produced aluminum alloy for the aerosol bottle cap is high in stability in batch.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

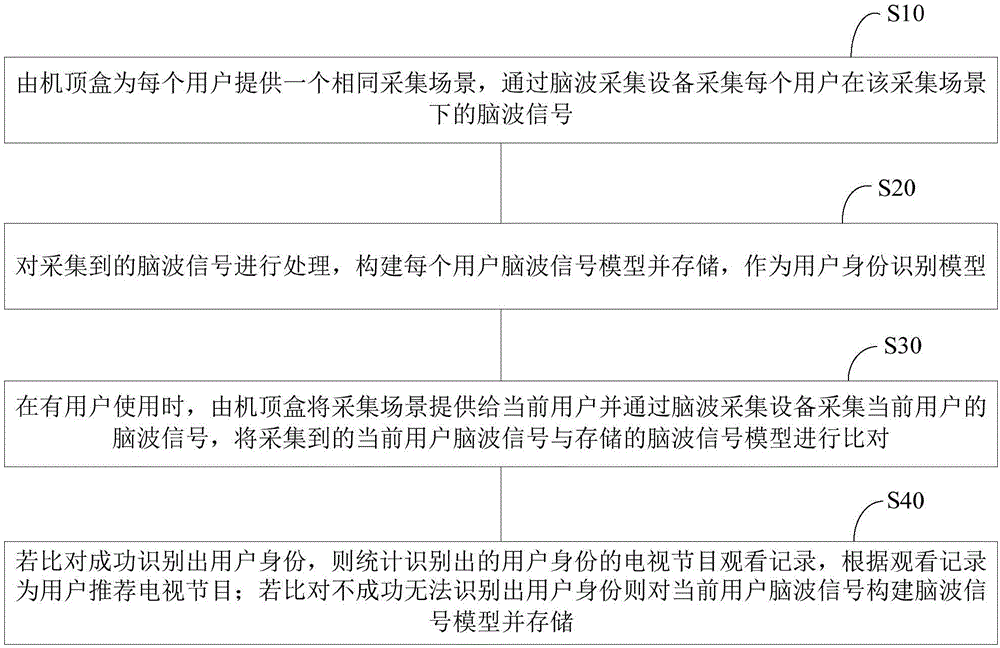

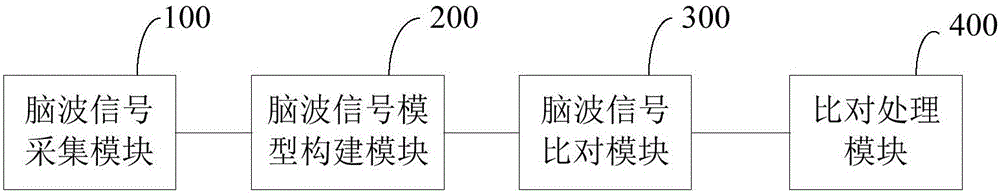

Identity-based program recommendation method and system

InactiveCN106385604AImprove experienceThere is no problem of leakageSelective content distributionIdentity recognitionPassword

The invention relates to an identity-based program recommendation method and system. The brain wave signals of a user are acquired so as to construct a user brain wave signal model. The identity of the user is recognized through the brain wave signal model, user identity recognition is performed through the brain wave technology, and the user only requires to carry brain wave acquisition equipment to acquire the brain waves without inputting the user ID or passwords so that operation is easy and convenient, the problem of disclosure of the user ID and passwords does not exist, the risk of personal information disclosure of the user can be eliminated and great convenience and great experience can be brought to the user.

Owner:SHENZHEN JIUZHOU ELECTRIC

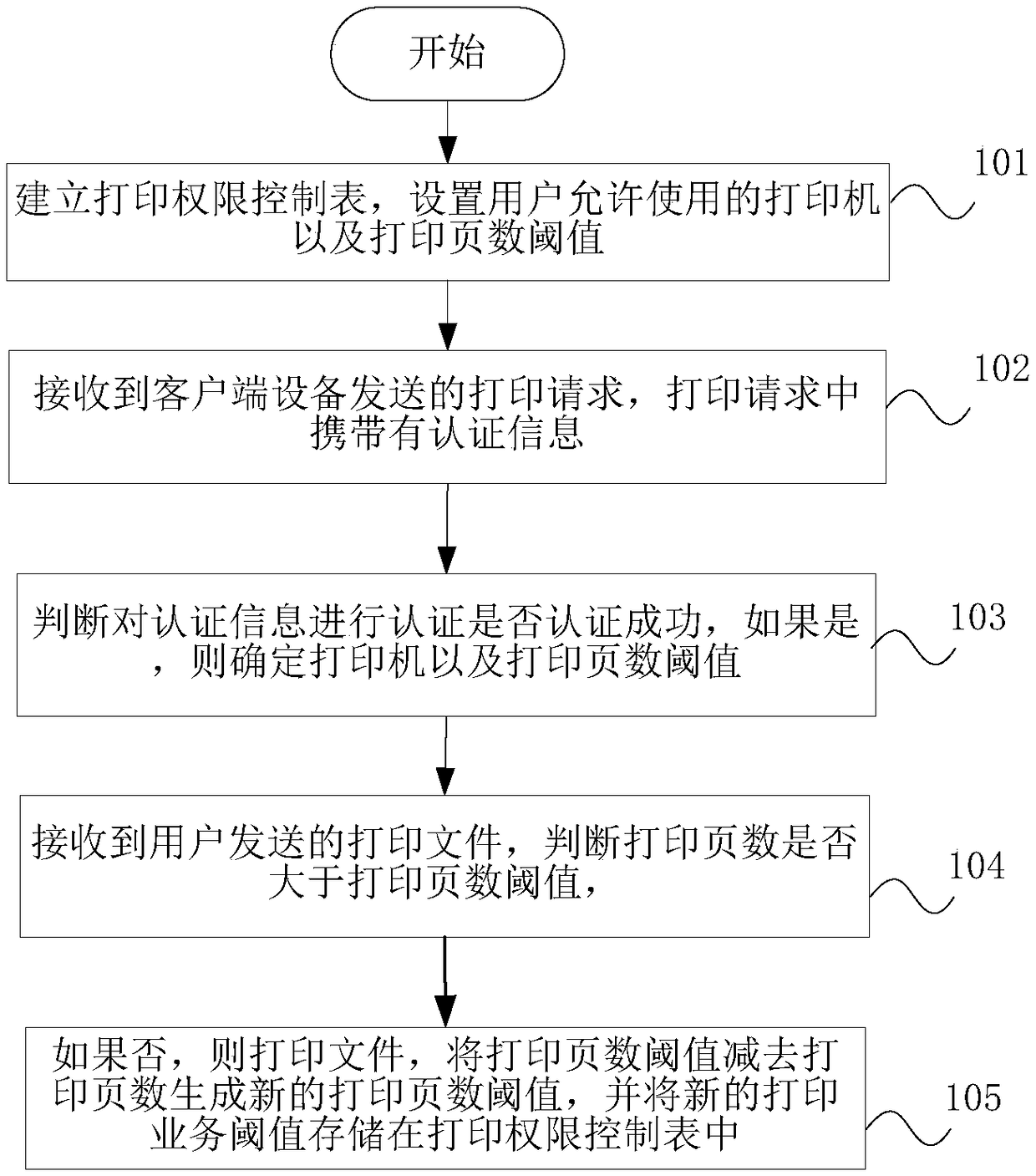

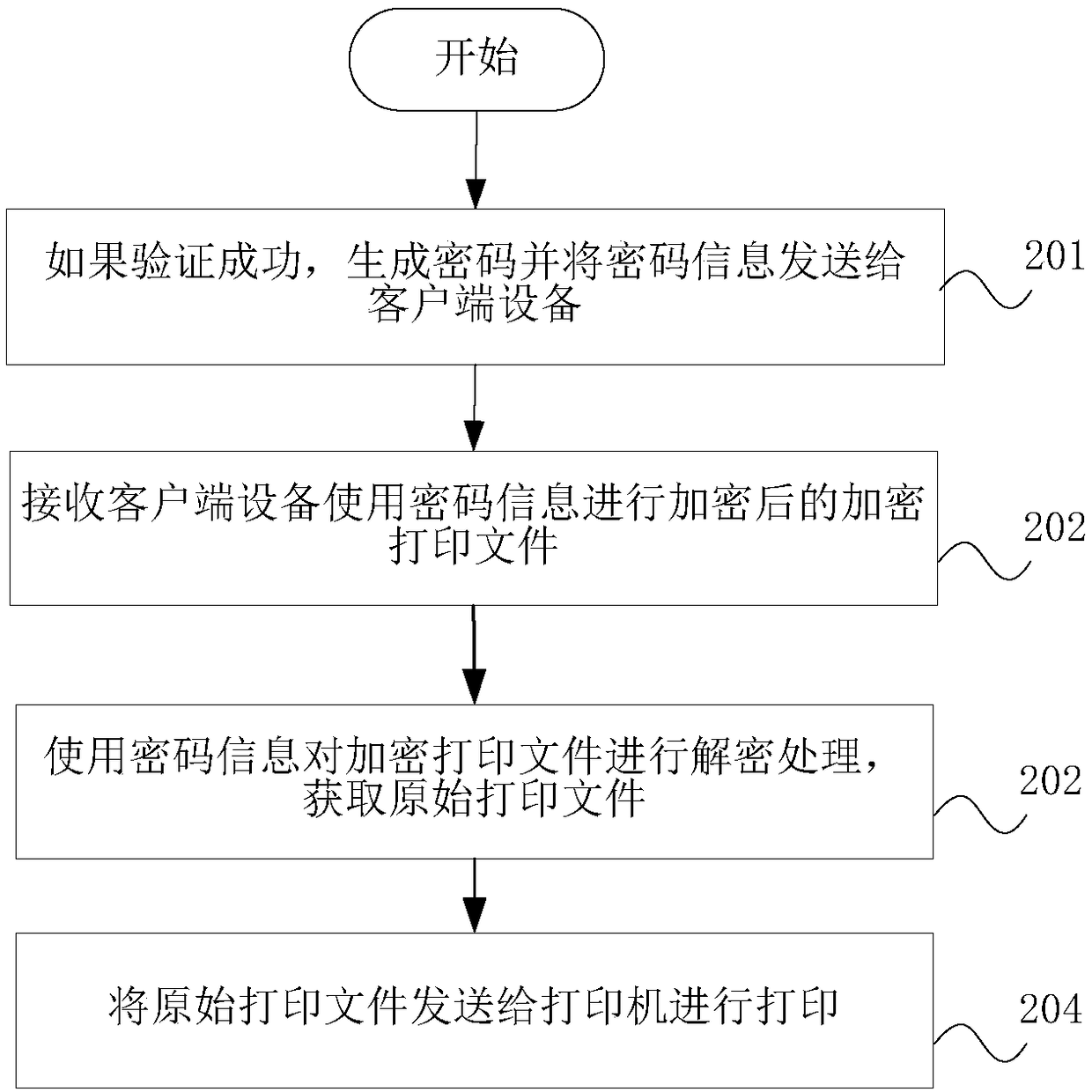

A user right management method for network printing

InactiveCN109426462AEliminate the Risk of LeakageAvoid safety hazardsDigital output to print unitsControl tablePrint-through

The invention discloses a user right management method for network printing, which relates to the printing field. The method comprises the following steps of establishing a printing right control table, setting a printer allowed to be used by a user and a printing page number threshold value; judging whether the authentication information is authenticate successfully; if yes, judging whether the number of printed pages is larger than the threshold value of the number of printed pages; if no, controlling the printer to print the document, and subtracting the threshold value of the number of printed pages from the threshold value of the number of printed pages to generate a new threshold value of the number of printed pages, and storing the new threshold value of the printing service in theprinting right control table. According to the method of the invention, a printing quantity threshold can be set for printing and a printing security control mechanism can be provided, the method of the invention realizes the identification confirmation of the user before the encrypted document is printed, eliminates the defect of the confidential leakage risk after the document is printed, avoidsthe security hidden trouble caused by the transmission of the document to be printed through the plaintext mode, and can centrally manage and verify the network printing, so that the network printingfunction is more convenient and reliable.

Owner:BEIJING LANXUM COMP TECH

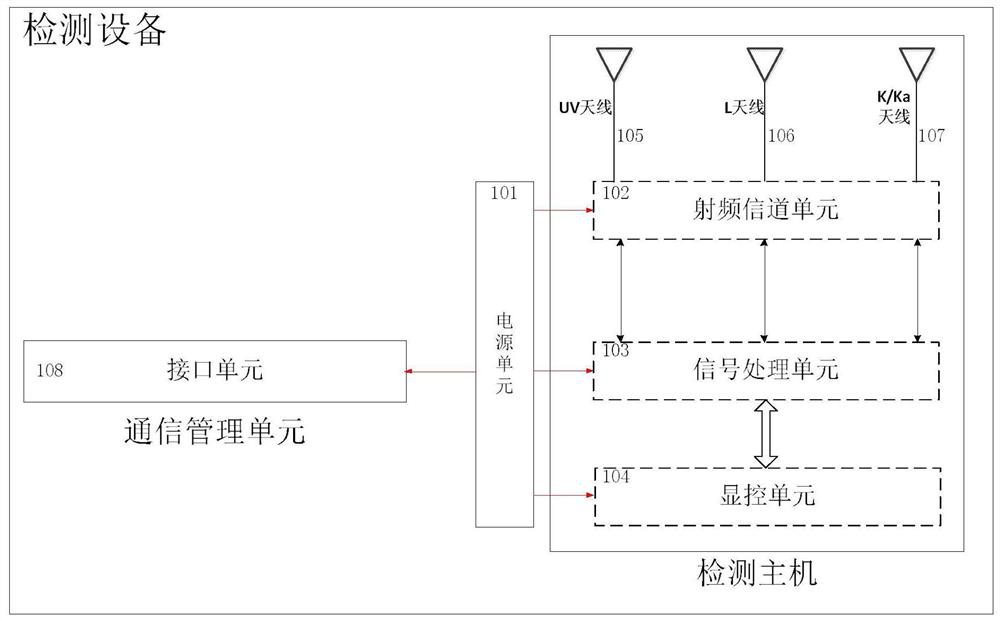

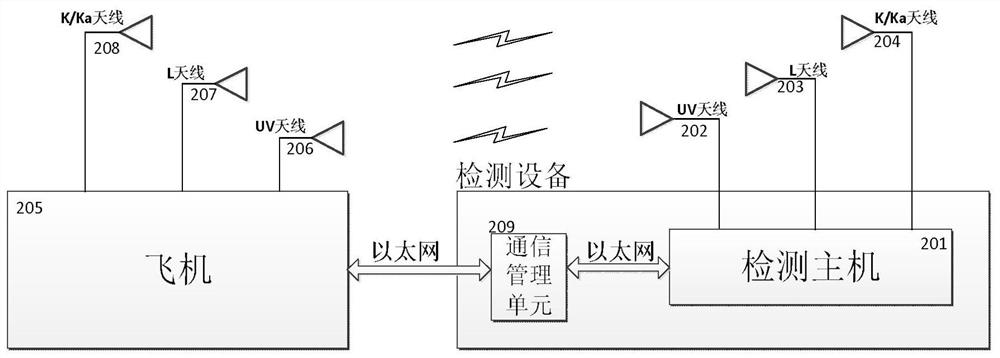

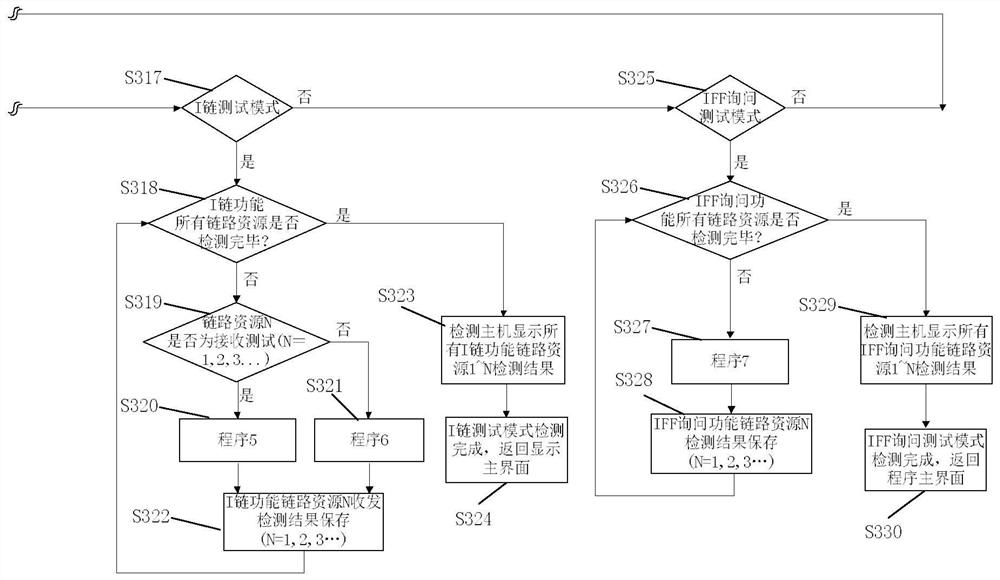

CNI external field wireless automatic detection equipment

ActiveCN111614406AEliminate the effects ofNo loss of appearanceTransmission monitoringHigh level techniquesRadio frequency signalError correction coding

The invention discloses CNI external field wireless automatic detection equipment, and aims to provide an external field detection CNI device and method which are simple and convenient to operate andhigh in detection efficiency. According to the technical scheme, a radio frequency channel unit sends a received signal to a radio frequency channel unit for processing and then sends the processed signal to a signal processing unit; AD conversion is carried out on the radio frequency modulated signal to obtain a baseband signal; or the baseband signal is converted into a radio frequency signal through digital-to-analog DA conversion; modulation / demodulation, dispreading / de-hopping, error correction coding and decoding, beam envelope processing and time measurement of various modes are realized; one or more specific tasks or services is distributed to form a reconfigurable FPGA program storage space processing platform capable of configuring standard signals; detection of different functions is achieved through loading software, control over the working parameters and the working state of the detection host and control over the working parameters and the working state of the detected aircraft CNI system are completed, and a display control unit displays a user operation interface and conducts data monitoring.

Owner:10TH RES INST OF CETC

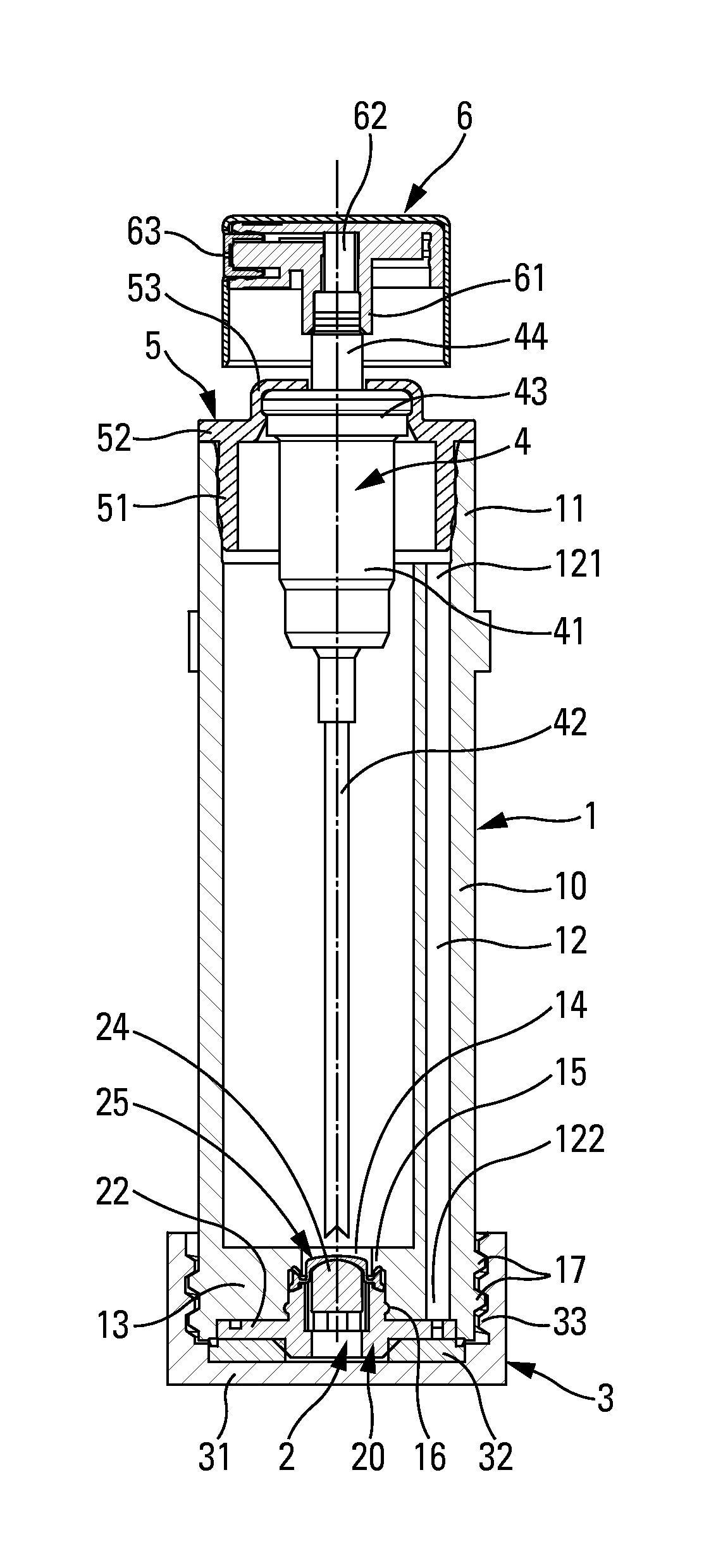

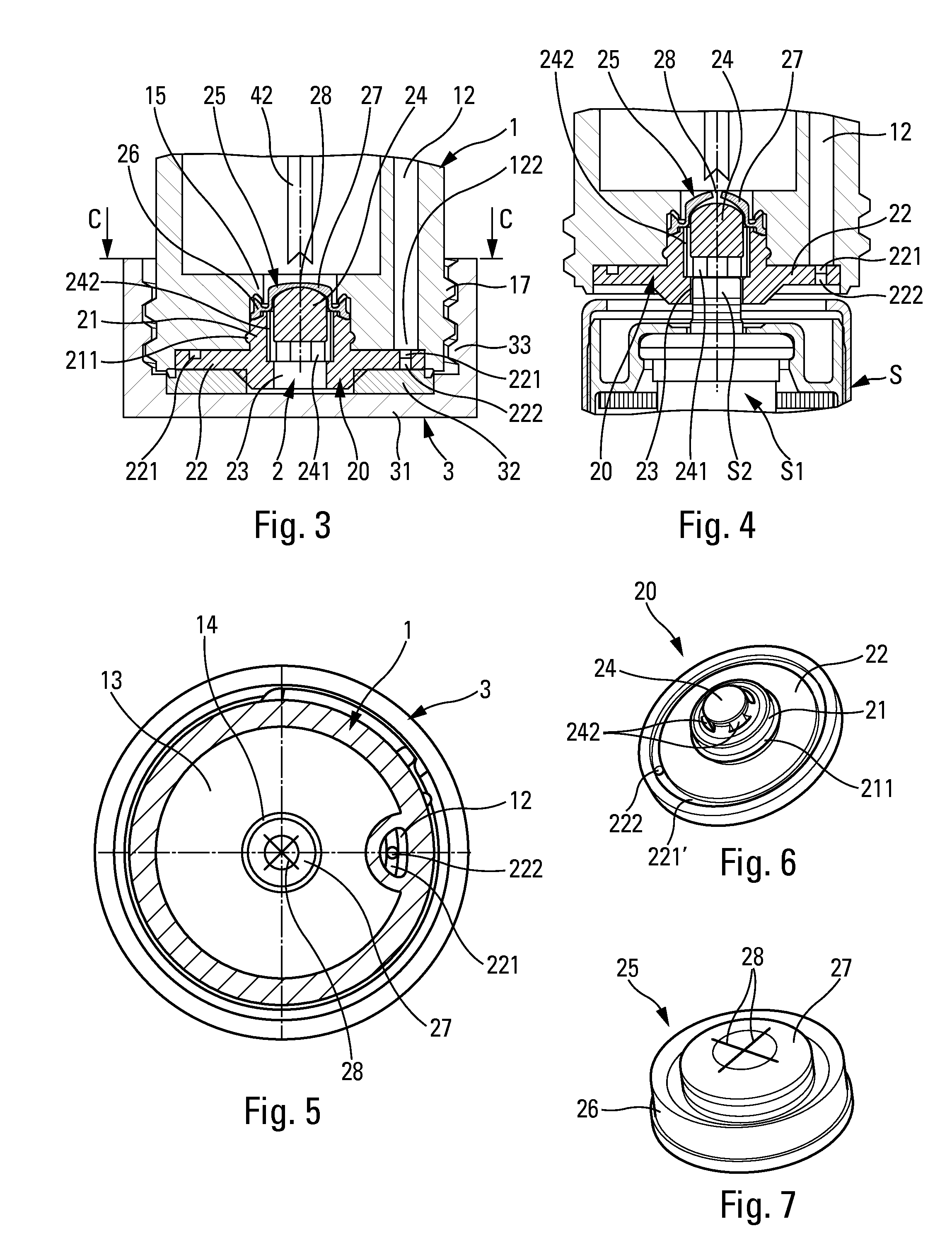

Fluid dispenser

ActiveUS20140197208A1Easy and less-costly to incorporateEliminate the risk of leakageLarge containersSingle-unit apparatusEngineeringVALVE PORT

Owner:APTAR FRANCE SAS

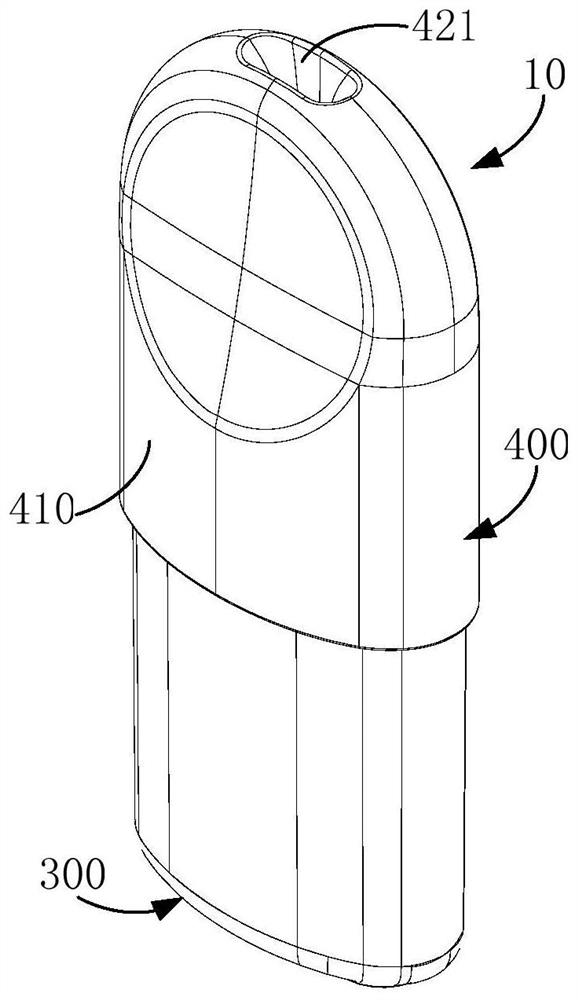

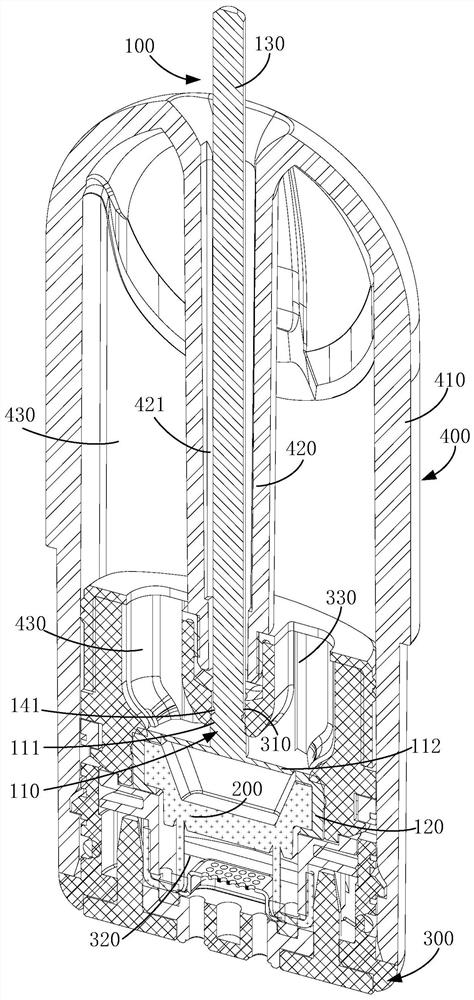

Sealing element, atomizer and electronic atomization device

PendingCN112353008AEliminate the risk of leakageImprove stability and reliabilityTobaccoPhysicsFluid Leak

The invention relates to a sealing element, an atomizer and an electronic atomization device. The atomizer comprises a sealing piece and a fixedly-arranged atomizing core. The atomizer is provided with a liquid storage cavity, a mounting hole and an air suction channel. The sealing piece comprises a pulling part, a first sealing part and a second sealing part, the second sealing part is arranged on the atomizing core, and the pulling part and the first sealing part can move relative to the mounting hole, so that the sealing piece has a sealing state and a using state. In the sealing state, thepulling part, the first sealing part and the second sealing part are connected with one another, and the first sealing part and the second sealing part isolate and seal the air suction channel and the atomization core from the liquid storage cavity. The pulling part is arranged in the air suction channel, and one end of the pulling part protrudes out of the air suction channel. And / or in the using state, the pulling part is separated from the first sealing part and pulled out of the air suction channel, and the air suction channel is opened; and the first sealing part is separated from the second sealing part to communicate the liquid storage cavity with the atomizing core. Therefore, the hidden danger of liquid leakage of the atomizer can be eliminated.

Owner:SHENZHEN SMOORE TECH LTD

Totally chip-free spherical integrated hydraulic hose metal joint structure and production process thereof

ActiveCN104235542AEnsure safetyHigh speed mass productionEngine componentsHose connectionsHigh volume manufacturingBall type

The invention discloses a totally chip-free spherical integrated hydraulic hose metal joint structure and a production process thereof. The structure is characterized in that a metal joint main body (1), a ball joint (3), a tee joint structure through hole (4), a hollow lining core tube (5), a lining core connecting tube (6) and a connecting rod (8) are of an integrated structure. The totally chip-free spherical integrated hydraulic hose metal joint structure can be massively produced at a high speed through a cold header according to the production process. The totally chip-free spherical integrated hydraulic hose metal joint structure and the production process thereof have the advantages of saving more than 60 percent of raw materials and saving a large amount of electric energy compared with the traditional method. According to the manufacturing method, a material-to-finished product ratio can reach 99 percent.

Owner:JIANGSU TIANYI PIPELINE COLD HEADING MFG

Laboratory intelligent air-exhaust sterilization structure and use method

PendingCN111219809AEliminate the risk of leakageAvoid condensation failureMechanical apparatusLighting and heating apparatusProcess engineeringEnvironmental engineering

The invention provides a laboratory intelligent air-exhaust sterilization structure and use method. The laboratory intelligent air-exhaust sterilization structure comprises an air inlet conveying tube, a sterilization filter tube and an air outlet conveying tube, wherein the air inlet conveying tube and the air outlet conveying tube are installed at the two ends of the sterilization filter tube and are provided with seal valves, the sterilization filter tube is internally provided with heaters and is internally and longitudinally provided with a high-efficiency filter, and the heaters and thehigh-efficiency filter are connected with a controller. The laboratory air-exhaust structure provided by the invention is easy to machine, reliable in sterilization and inactivation and easy to use and operate, live bacteria leakage will not appear, after the sterilization and inactivation, a filter element is convenient and safe to replace, filter bacteria filtration and mesh heater sterilizationare simultaneously performed while air supply is performed, and double-stage protection measures of the filter bacteria filtration and high-temperature sterilization are adopted.

Owner:大连富森智能科技有限公司

Methods for molding interbody devices in situ

InactiveUS20090001622A1Low costReduce riskBone implantSpinal implantsBiocompatibility TestingUltimate tensile strength

A method is provided for producing and inserting a cervical interbody mold device (CIMD). The CIMD produces an interbody device that is formed in situ and that possesses suitable strength and biocompatibility so as to provide sufficient vertebral support while providing optimal ease of use and insertion for the surgeon.

Owner:NADER REMI +1

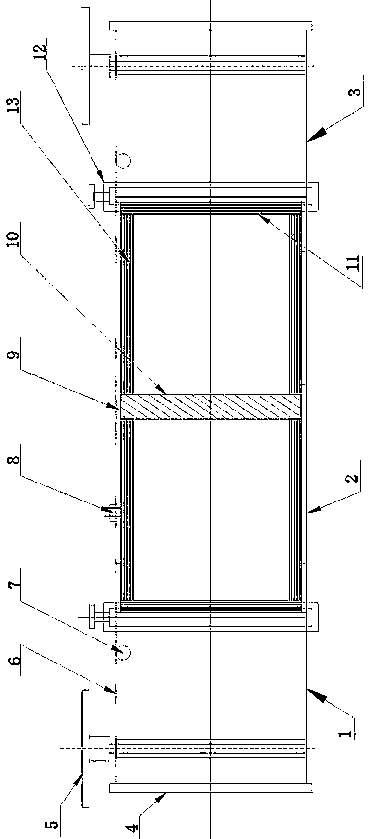

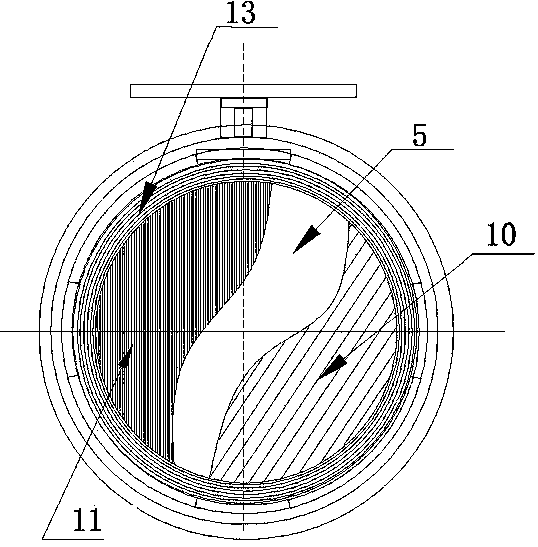

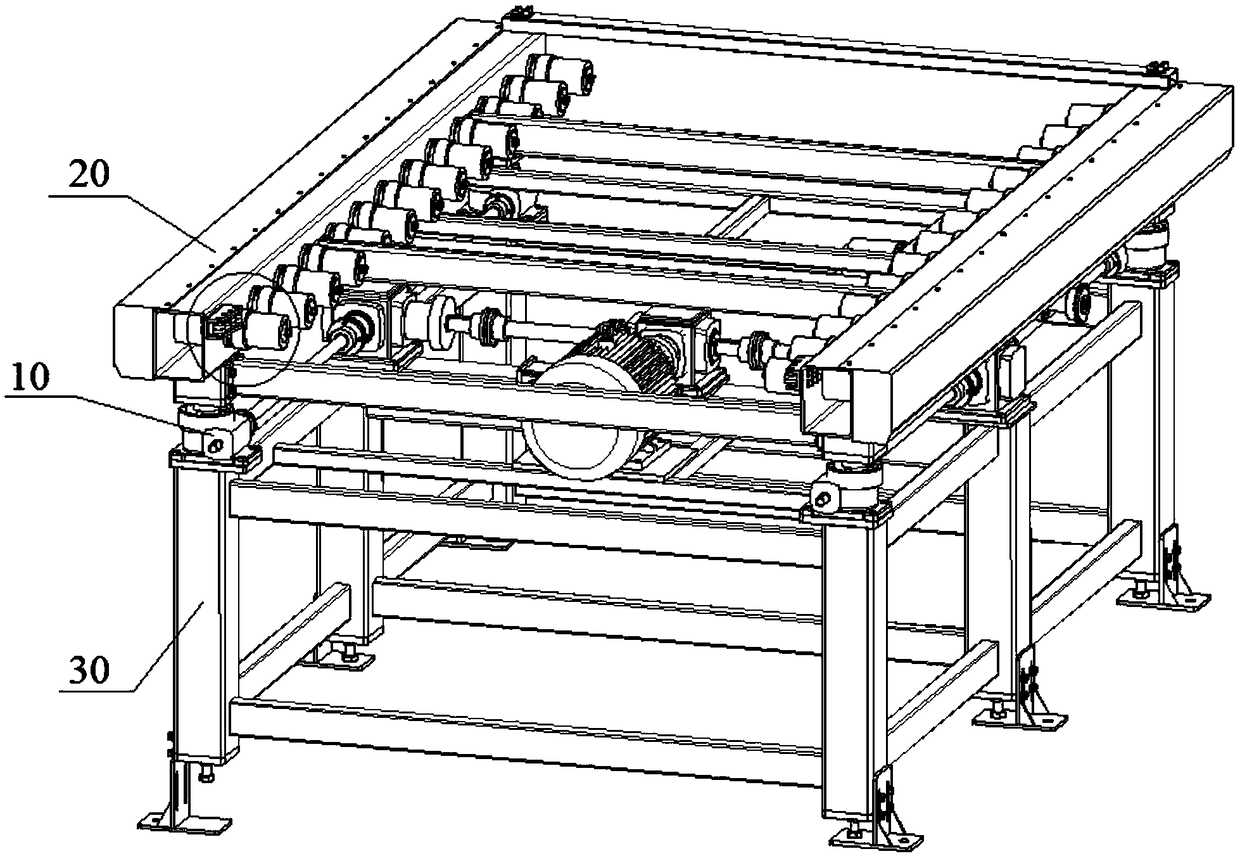

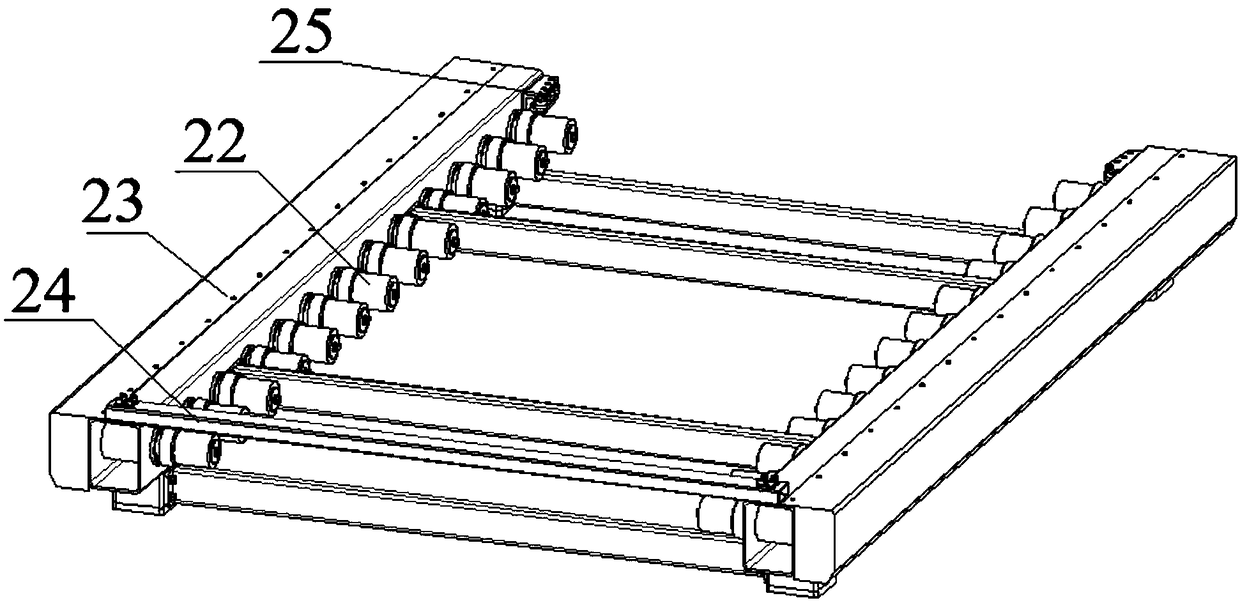

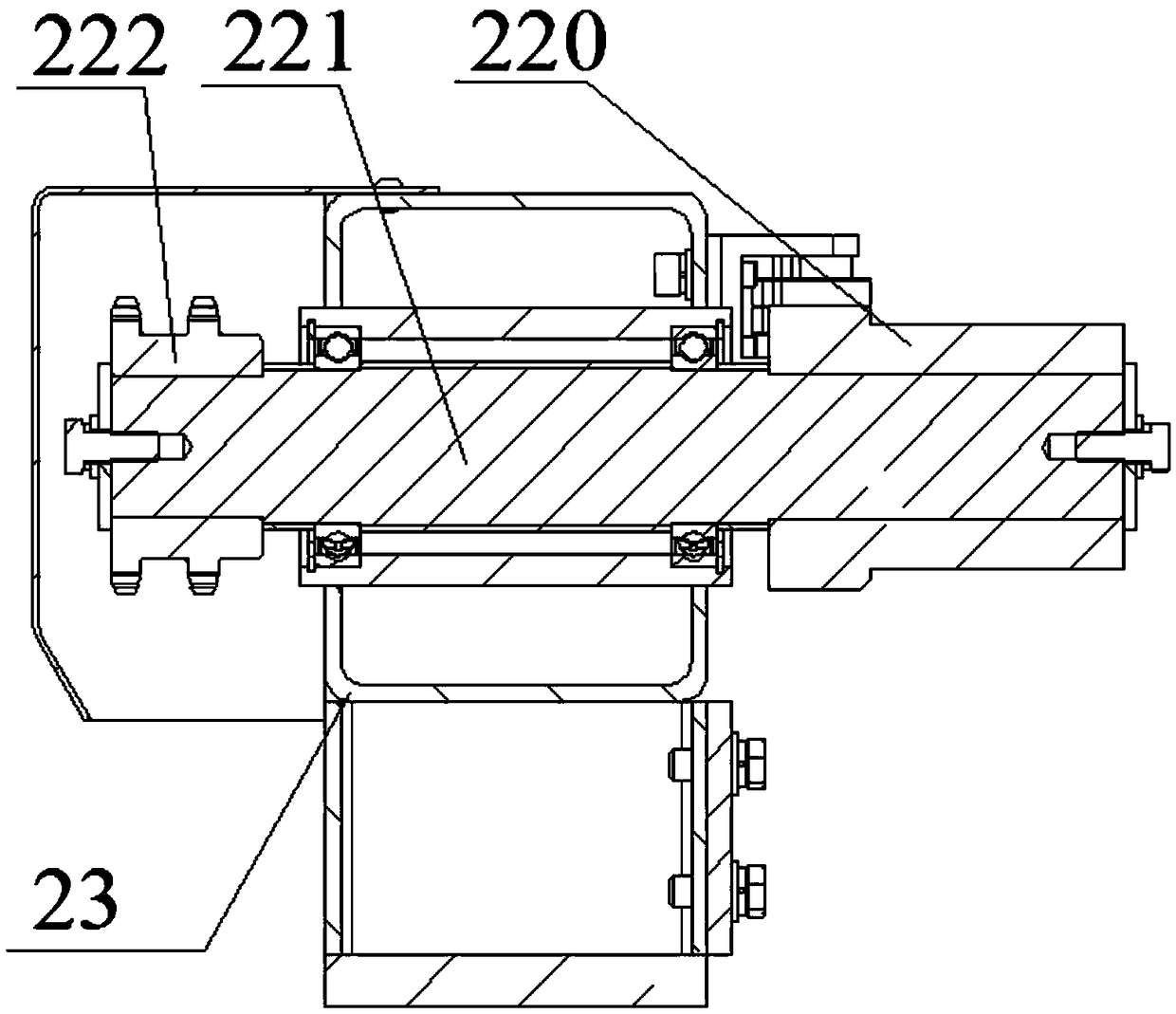

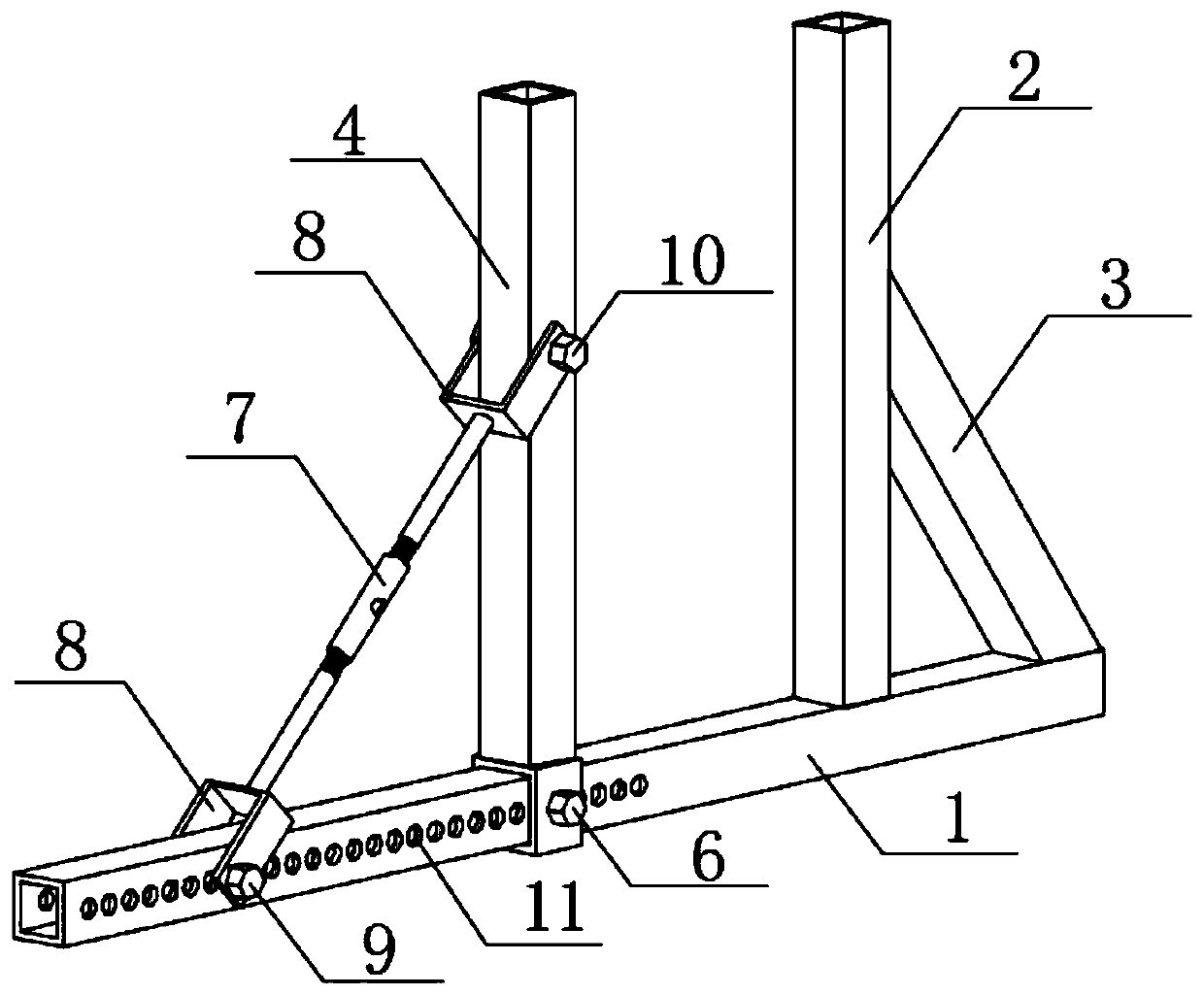

Lifting facility

PendingCN109305506AEliminate the risk of leakageHigh rotation accuracySupporting framesRoller-waysMicrowaveFixed frame

The invention provides a lifting facility. The lifting facility comprises a lifting device, a roller bed device and a fixing frame. The roller bed device is arranged on the upper portion of the lifting device which is arranged on the fixing frame. The lifting device is used for lifting the roller bed device. Two rows of roller shafts are separately mounted on the two sides of the upper portion ofa roller bed frame through bearings. Wheel bodies are mounted on the opposite sides of the two rows of roller shafts, and roller chain wheels are mounted on the outer sides of the roller shafts. Eachroller chain wheel is formed by two circles of teeth arranged side by side. Every two adjacent roller chain wheels are connected through a chain. A driving motor drives a rotary shaft to rotate through a transmission device. Two chain wheels are separately arranged at the two ends of the rotary shaft. The two chain wheels are in linkage with the corresponding roller chain wheels in the two rows through the chains, then the driving motor drives rollers on the two sides to synchronously rotate, and a roller bed synchronously rolls at high precision and is synchronously lifted at high precision,so that tight butt joint of a workbox and a microwave device is completed, and microwave leakage is avoided.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

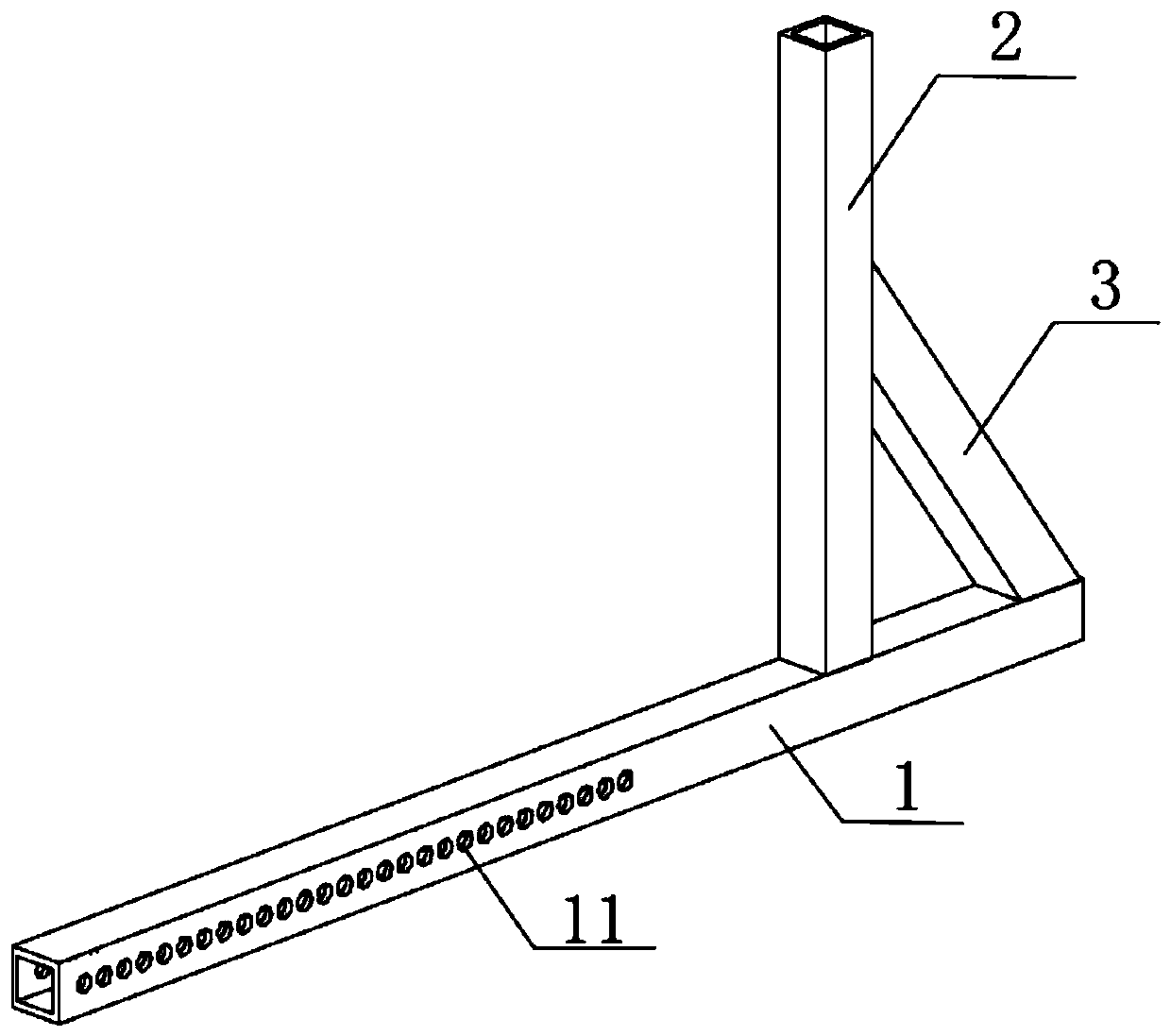

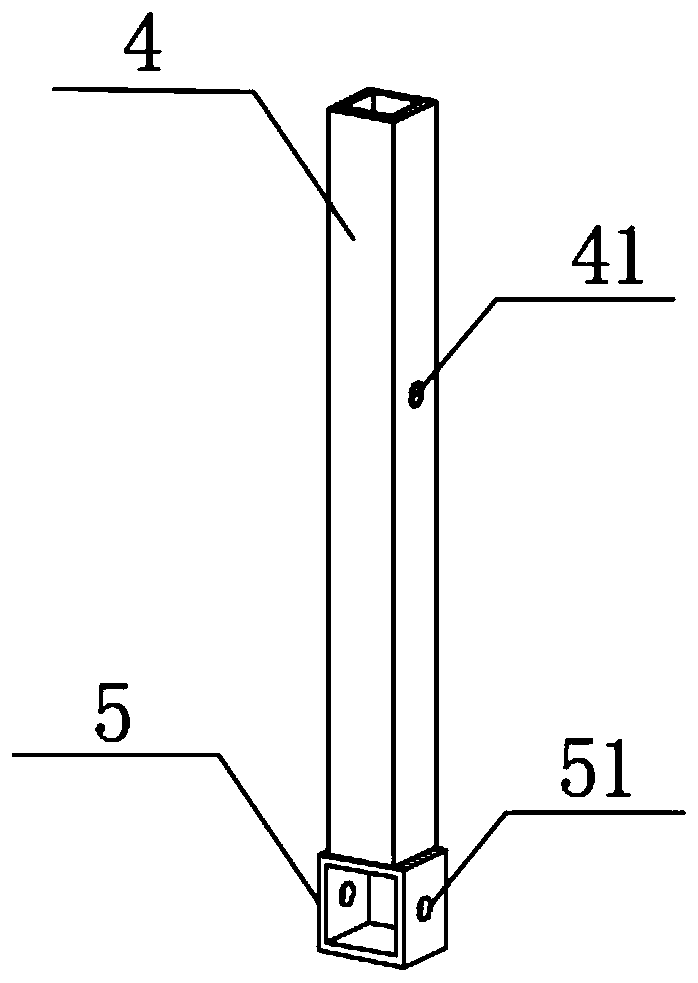

Structural beam formwork reinforcing device and method without split bolts

PendingCN111236639AStable and reliable supportGuarantee the construction qualityForms/shuttering/falseworksEngineeringStructural engineering

The invention discloses a structural beam formwork reinforcing device and method without split bolts, and relates to the technical field of building construction. The device comprises a cross rod, a fixed vertical rod structure, an adjustable vertical rod structure and a fastening device. The fixed vertical rod structure and the adjustable vertical rod structure are arranged on the cross rod and arranged at the two ends of the cross rod correspondingly. A locking structure is arranged between the adjustable vertical rod structure and the cross rod. The fastening device is arranged on the otherside, relative to the fixed vertical rod structure, of the adjustable vertical rod structure, one end of the fastening device is movably connected with the cross rod, and the other end of the fastening device is movably connected with the adjustable vertical rod structure and used for supporting the adjustable vertical rod structure. By means of the technical scheme, the reinforcing effect of a structural beam formwork can be guaranteed, through-wall bolt holes can be effectively prevented from being left in a structural beam, and the construction quality of the structural beam is guaranteed;and multi-time circulation turnover use can be achieved, the construction cost is reduced, the characteristic of environmental friendliness is achieved, and the device and method have good application prospects and practical value in practice and are suitable for being used and popularized.

Owner:CHINA MCC5 GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com