Laboratory intelligent air-exhaust sterilization structure and use method

A sterilizing structure and laboratory technology, applied in application, household heating, heating methods, etc., can solve the problems of metal tool damage to the bag body, germs and viruses leaking, and pleats on the bag mouth, so as to avoid a global catastrophe Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

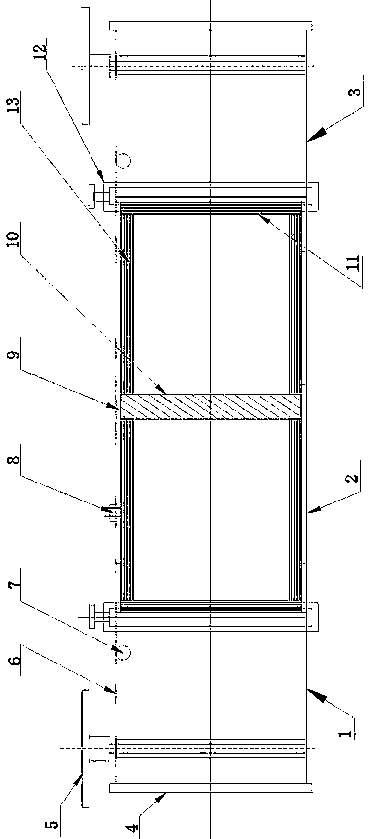

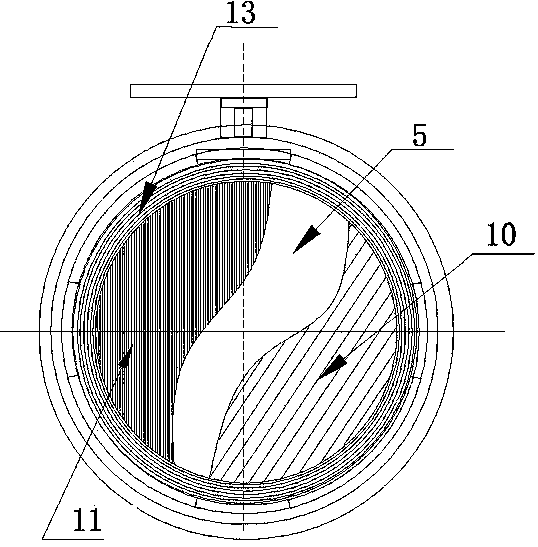

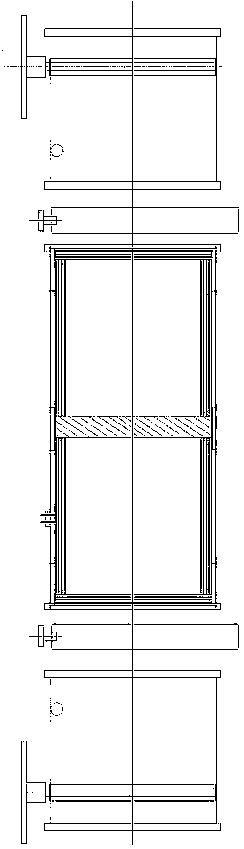

[0035] The P3 / P4 laboratory intelligent exhaust sterilization structure of the present invention includes an air inlet conveying cylinder 1, a sterilizing filter cartridge 2 and an air outlet conveying cylinder 3, an air inlet conveying cylinder 1, a sterilizing filter cartridge 2 and an air outlet conveying cylinder 3. Seal and connect through the fast-installation clamp 12 of the connecting piece of the sealing flange in turn. There are flange connection ports 4 at both ends of the air inlet conveying cylinder 1 and the air outlet conveying cylinder 3, the air inlet conveying cylinder 1 and the air outlet conveying cylinder 3 are provided with sealing valves 5, the air inlet conveying cylinder 1 and the air outlet conveying cylinder 3 A detection sensor 7 is provided inside, and the detection sensor 7 is equipped with a pressure sensor, a temperature sensor, and a wind speed sensor, and the detection sensor 7 is connected with the controller. The two ends of the sterilizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com