Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Eliminate sliding friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

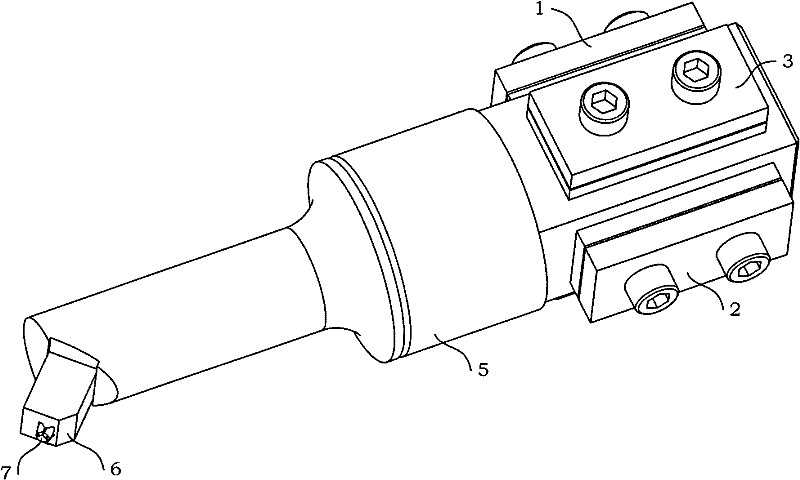

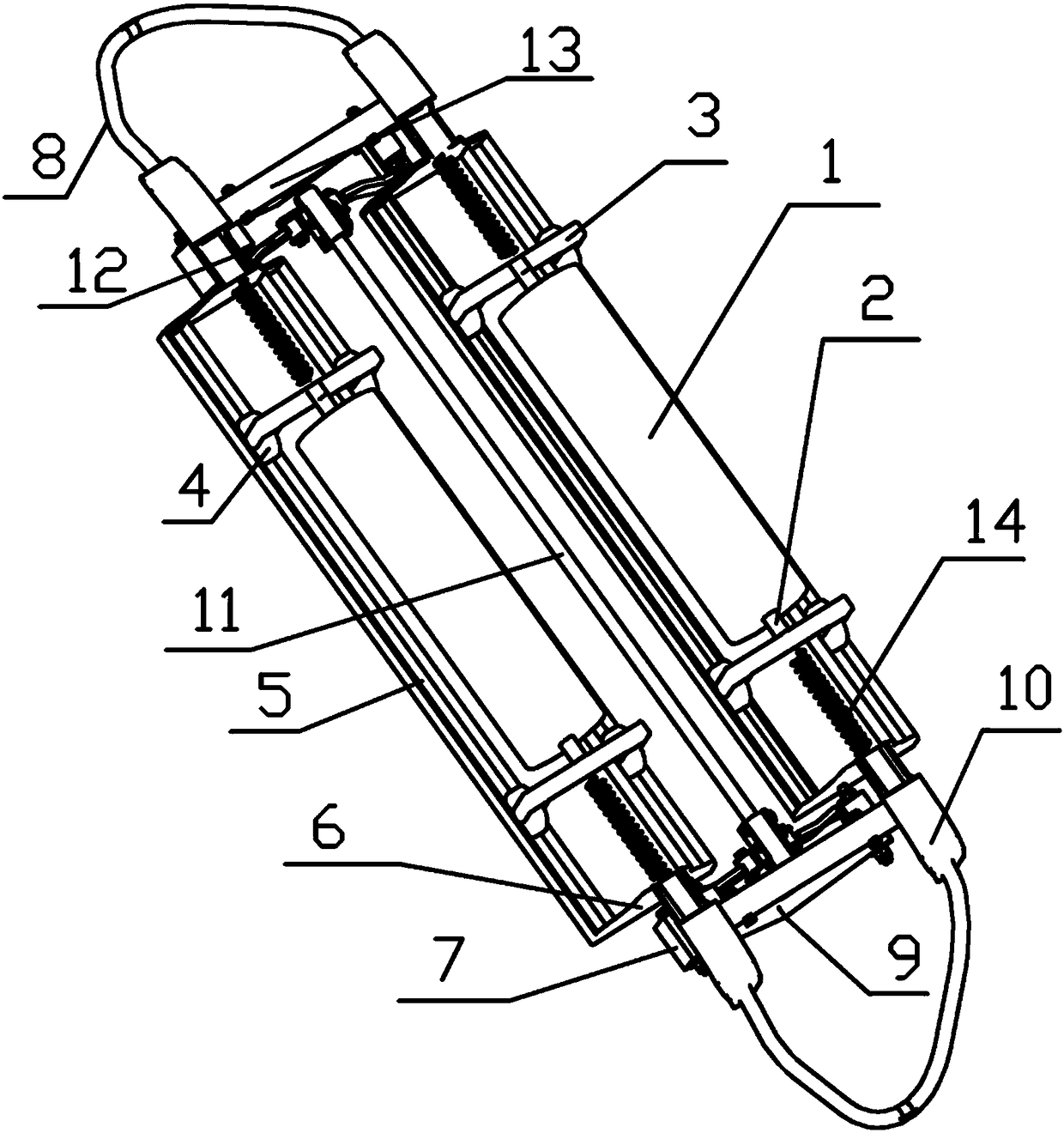

Ultrasonic elliptical vibration extrusion device and vibration extrusion processing method for carrying out surface finishing of part by using same

InactiveCN101942547BReduce volumeSolve the lack of cooling capacityMechanical vibrations separationTransformerSurface roughness

The invention discloses an ultrasonic elliptical vibration extrusion device and a vibration extrusion processing method for carrying out surface finishing of a part by using the same. The ultrasonic elliptical vibration extrusion device comprises an amplitude transformer, four excitation sources with the same structure and an extrusion tool, wherein the extrusion tool is arranged on the output section of the amplitude transformer; and the four excitation sources are respectively arranged in the four grooves of the excitation section of the amplitude transformer. In the vibration extrusion processing process, an extrusion head makes the ultrasonic vibration in an elliptic orbit relative to the processed surface of the part under the driving of the excitation sources through adjusting an extrusion contact angle between the part and the diamond extrusion head and the processing parameters of ultrasonic elliptical vibration extrusion device. On one hand, the device reduces an extrusion force by utilizing the pulse impact action of the ultrasonic vibration, and thereby, the extrusion process can be applied to thin-wall parts and long and thin parts; on the other hand, the front direct impact is avoided and the sliding friction of the extrusion head and the processed surface of the part is reduced even eliminated by utilizing the separation characteristic and the movement locus characteristic of the elliptical vibration, and thereby, the surface roughness of the processed surface of the part is reduced, and the service life of the extrusion head is prolonged.

Owner:BEIHANG UNIV

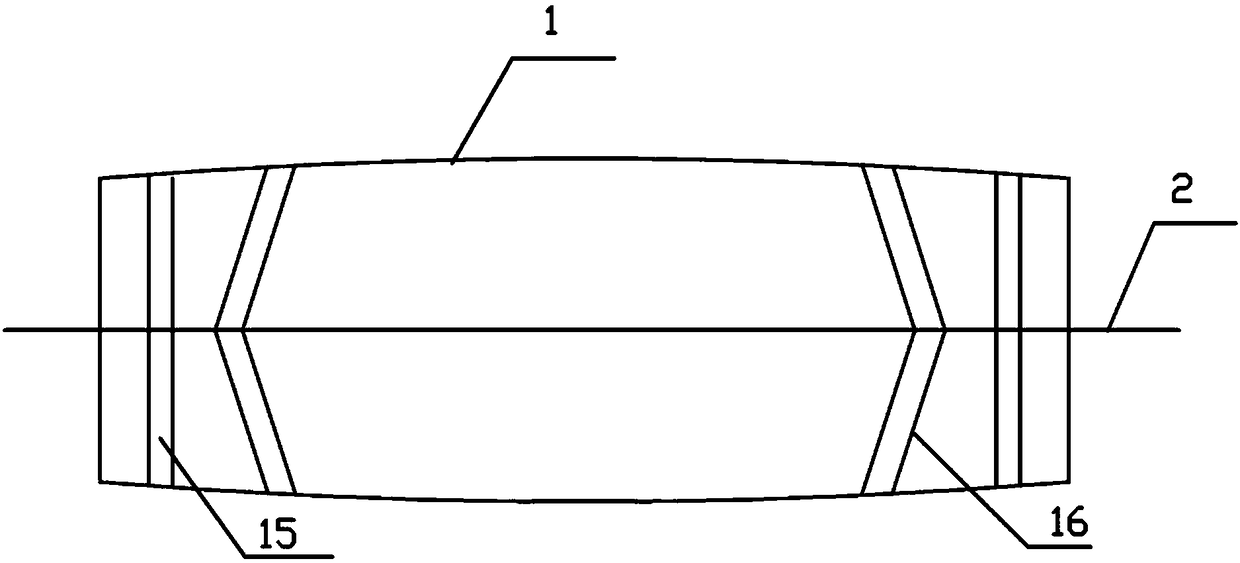

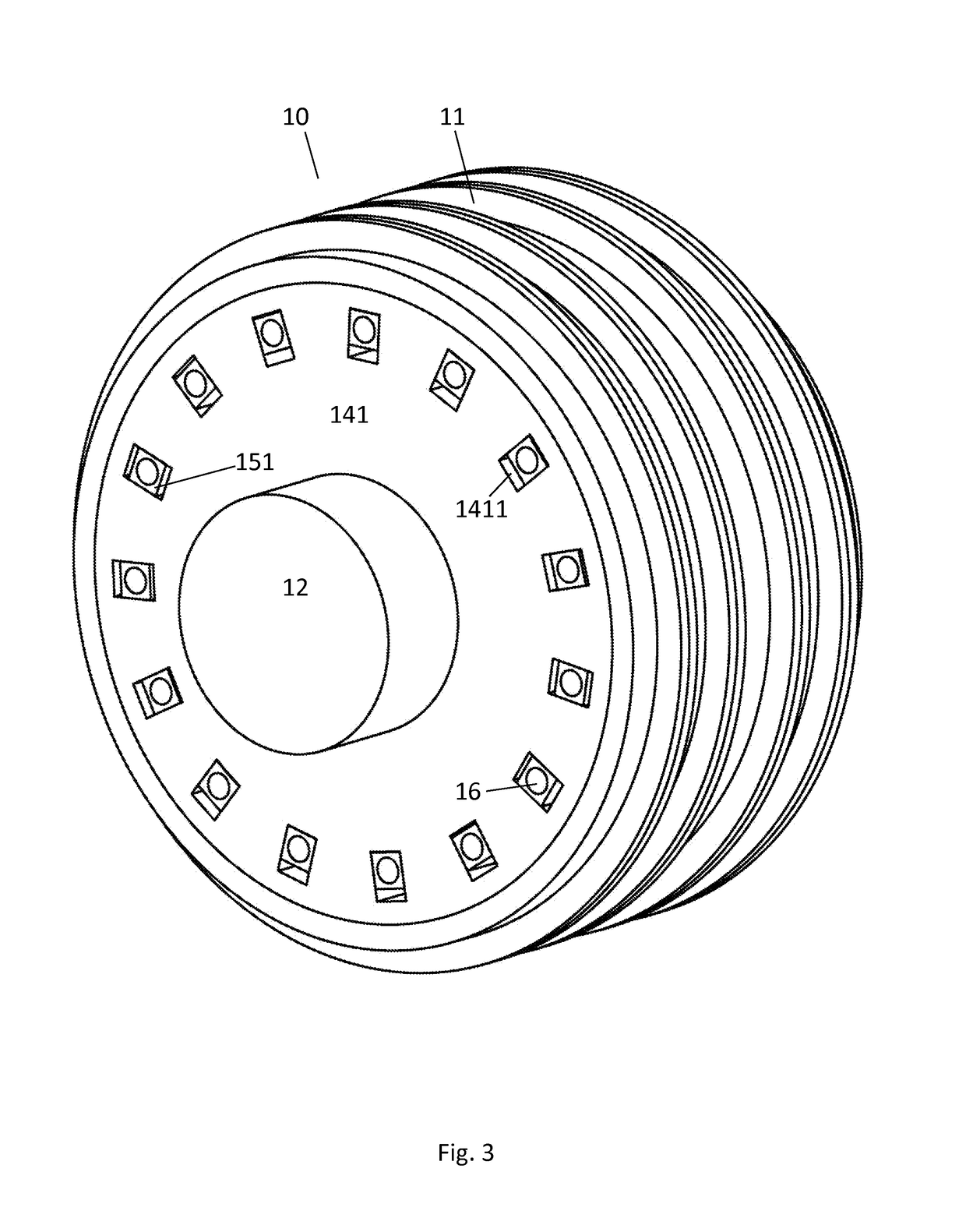

Sliding friction- free gear

ActiveUS20170023110A1Strict requirementsLarge transmission ratioFriction gearingsGear wheelEngineering

A sliding friction-free gear has cams of specific profiles, rollers separating cooperating cams that roll over the cams of the gears, thus eliminating the sliding friction between the gears. The rollers are mounted rotatably e.g. in sliders or eccentrics, wherein the sliders, resp. eccentrics, are mounted slidingly, resp. rotatably, in a yoke attached rigidly to a shaft. The rollers are free to execute oscillating motion relative the yoke while rolling over the cam profiles of the cams of the gears. The cooperating members of the gear contact along a line like in conventional evolvent gears, and unlike in the Wildhaber-Novikov's gear (where the momentary contact between teeth of cooperating toothed wheels is pointwise); therefore the gear according to the present invention offers much larger transmission capacity and is much less prone to seizure than known gears.

Owner:OLEDZKI WIESLAW JULIAN

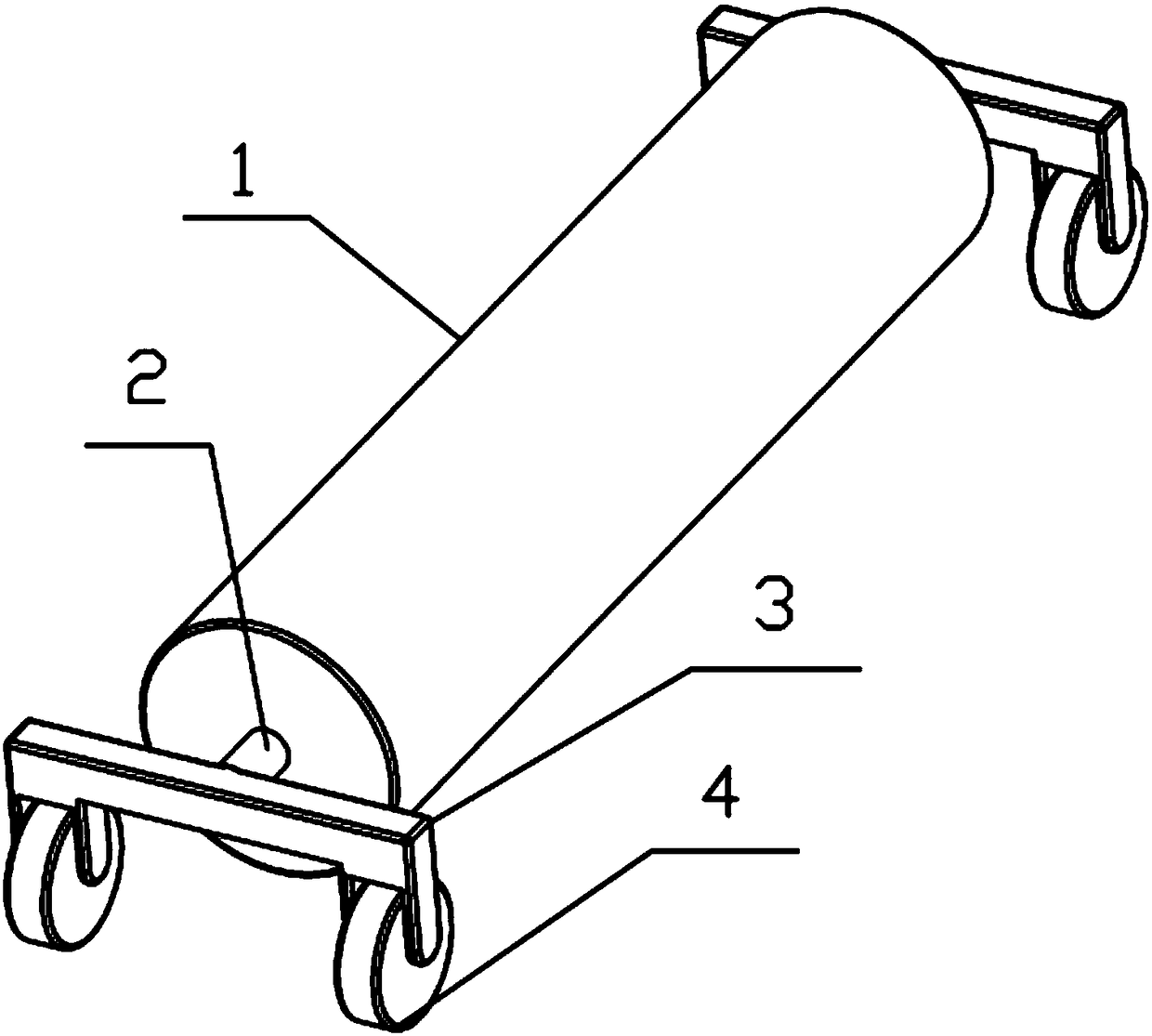

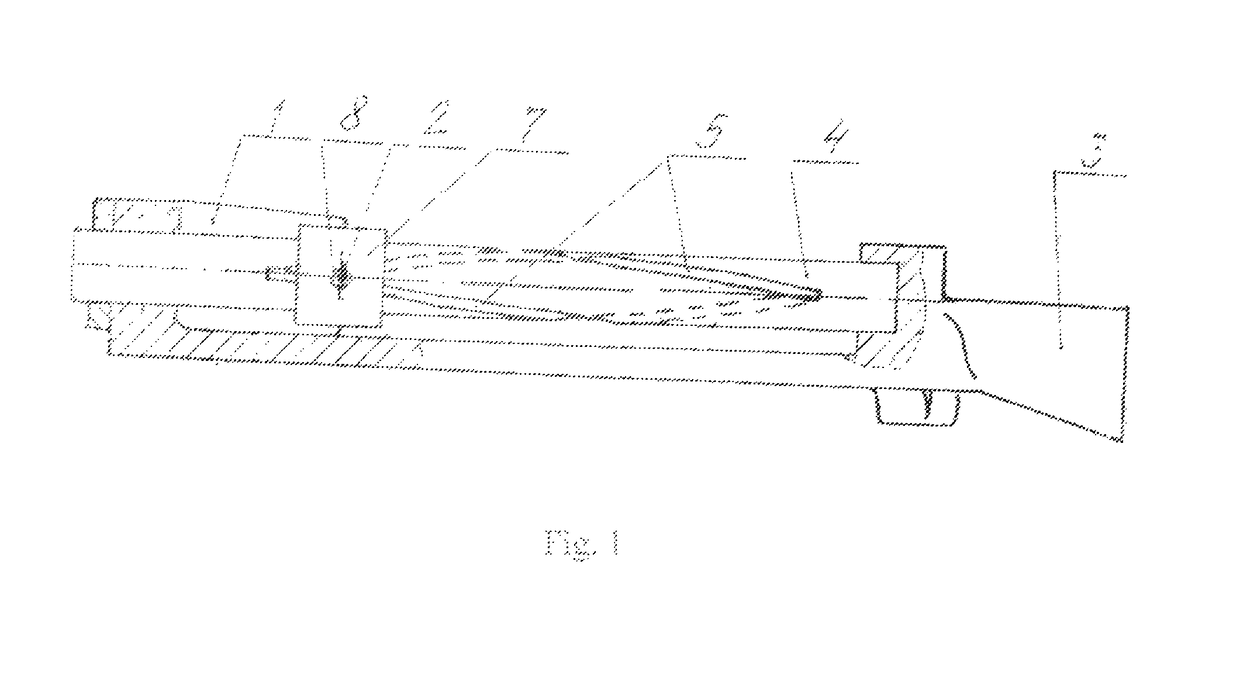

Improved winding-machine for rolled or drawn wire/rod

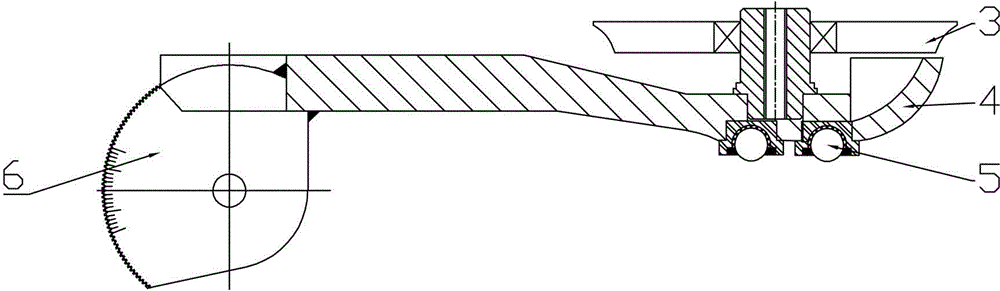

Winding-machine for rolled or drawn wire / rod (F) with device to form a wire / rod coil (R) in a winding-machine with one or more winding reels (1) placed downstream of a wire / rod working installation, provided with wire / rod-drawing means (2-3) and5 thereafter: an oscillating wire / rod-guide (4) with wire / rod-guide handling means (6) to lead the end of the wire / rod-guide reel side to follow the winding so that the wire / rod from the said advancing means (2-3) is wound up in the reel (1) with first translation means (65) to move the reel side end (1) of the exit opening said wire / rod-guide (4) parallel to the reel / mandrel axis (1) and second translation means (8-6) to move said exit opening of said wire / rod-guide (4) in withdrawal / approach perpendicularly to the axis of said reel / mandrel (1) in order to follow the increase of diameter of the coil (R) during winding-up with improved wire / rod containment system at said exit opening (7).

Owner:SIMAC

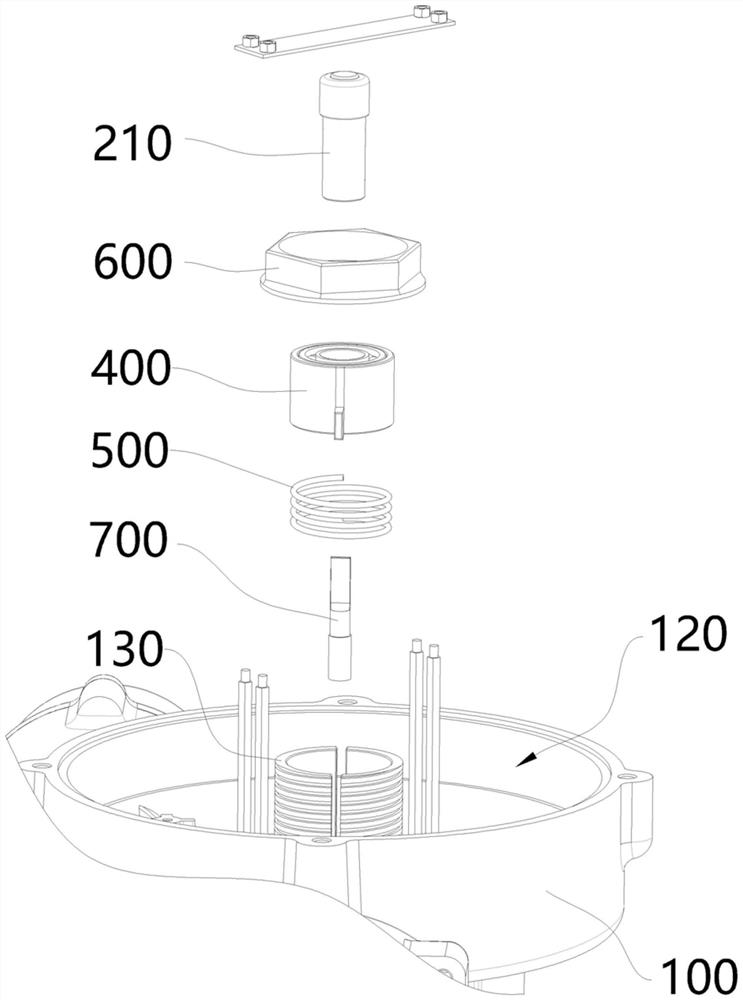

Rope-rod hybrid driving super-redundant robot

ActiveCN109176474AEliminate sliding frictionLarge working spaceProgramme-controlled manipulatorEngineeringHeavy load

The invention discloses a rope-rod hybrid driving super-redundant robot. The rope-rod hybrid driving super-redundant robot comprises a base, a plurality of motors arranged on the base, a plurality ofrod system branched chains, a plurality of rope branched chains and a plurality of movable platforms; the plurality of movable platforms are sequentially connected in series to form an integrated structure through the rod system branched chains and are connected to the base; the plurality of movable platforms are sequentially connected with a wire winding wheel disc of the motors on the base through the rope branch chains. Compared with a traditional rigid branched-chain hyper-redundant robot, has a larger working space, and is higher in flexibility and smaller in quality, low in manufacturingcost, easy to install and the like, the sliding friction between the rope and the platform is eliminated, the rope-rod hybrid driving super-redundant robot can be used for a large-range attitude adjustment, position tracking, motion simulation and the like in a high-speed / heavy-load occasion.

Owner:SHANTOU UNIV

Vacuum guide roller

The invention relates to the field of paper manufacturing machinery, specifically to a vacuum guide roller. The vacuum guide roller is mainly composed of components such as a shell, a core shaft, sealing devices, bearing devices and so on, wherein the shell is sleeved outside the core shaft; through holes for interior and exterior of the roller shell communicate with each other are processed on the shell; two ends of the shell are equipped with the bearing devices; inside paths of the bearing devices are fixed on the core shaft; a hollow structure is arranged in an axial direction of the shaft, and elongated open holes are processed in part of the axial direction in the shell; and the sealing devices are mounted on the elongated open holes to contact an inner wall of the roller shell. According to the invention, the hollow core shaft sucks, dewaters and cleans carpets, at the same time, the roller shell can be supported by the bearing devices to rotate, relative movement between the roller shell and carpets of paper machines are reduced greatly, and sliding friction in a vacuum box can be removed so as to greatly power consumption and carpet consumption generated by friction of carpets; compared with the existing vacuum roller, the roller can not be equipped with a transmission device so as to simplify device configuration.

Owner:郭秀梅

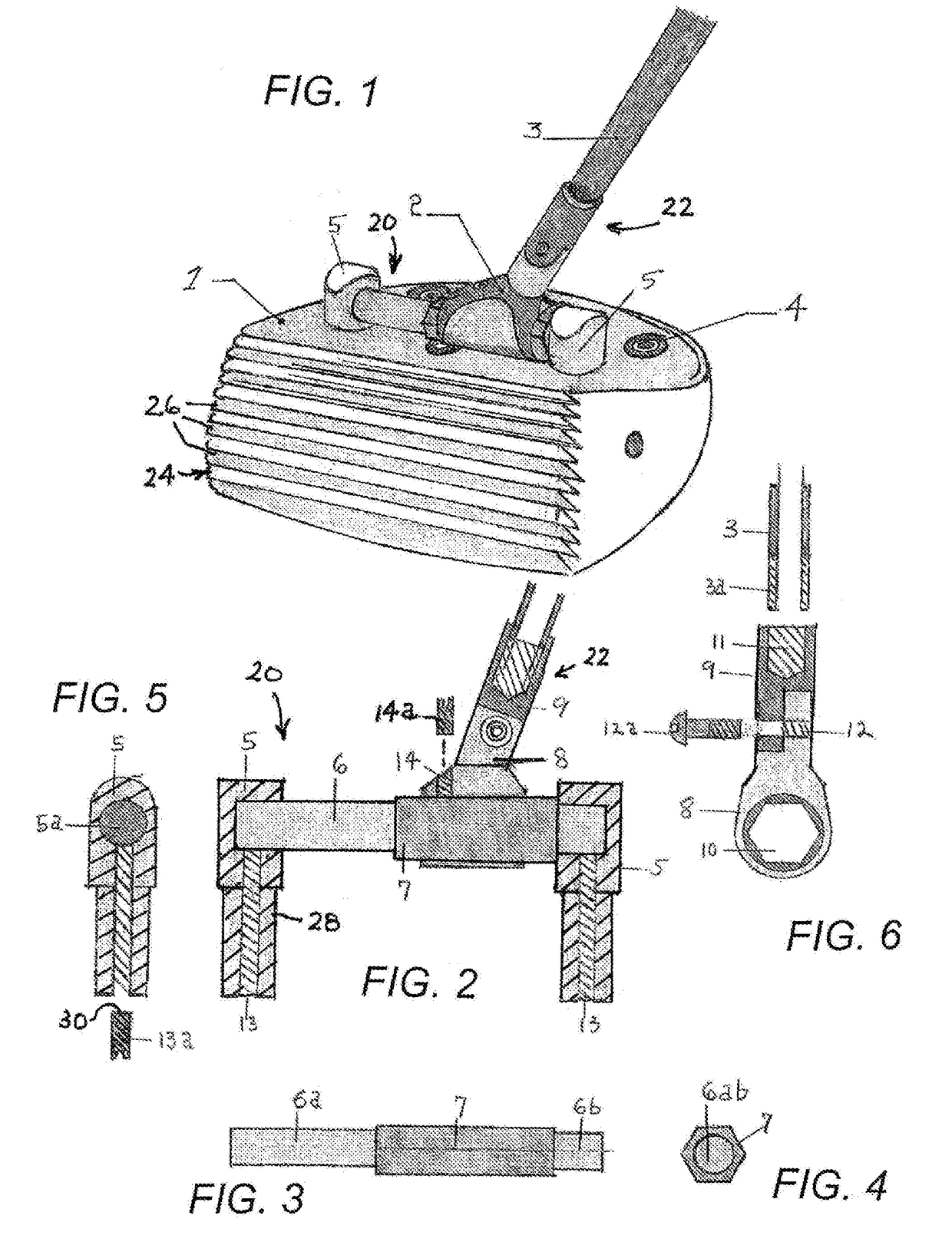

Adjustable golf putter head having teeth

In a golf club head assembly a body member has a top-forward angled front face, the face comprising a plurality of generally forward-facing teeth. The golf club head assembly further comprises a loft angle adjustment mechanism attached to the body member for adjusting a loft angle of the face. The mechanism includes a hosel element releasably attached to a bar rotatably mounted to an upper side of the body member parallel to the face. The bar is rotatably journaled or mounted in a pair of bar supports attached to the body member. Set screws reside in threaded holes in the bar supports, the set screws operable to releasably lock the bar in a selected orientation relative to the body member, where the selected orientation of the bar corresponds to and determines the loft angle of the front face. The forward angle of the front face, the angles of the teeth, and loft angle of the face are jointly chosen to impart a pure rolling motion onto a struck golf ball.

Owner:BRANDT RICHARD A +1

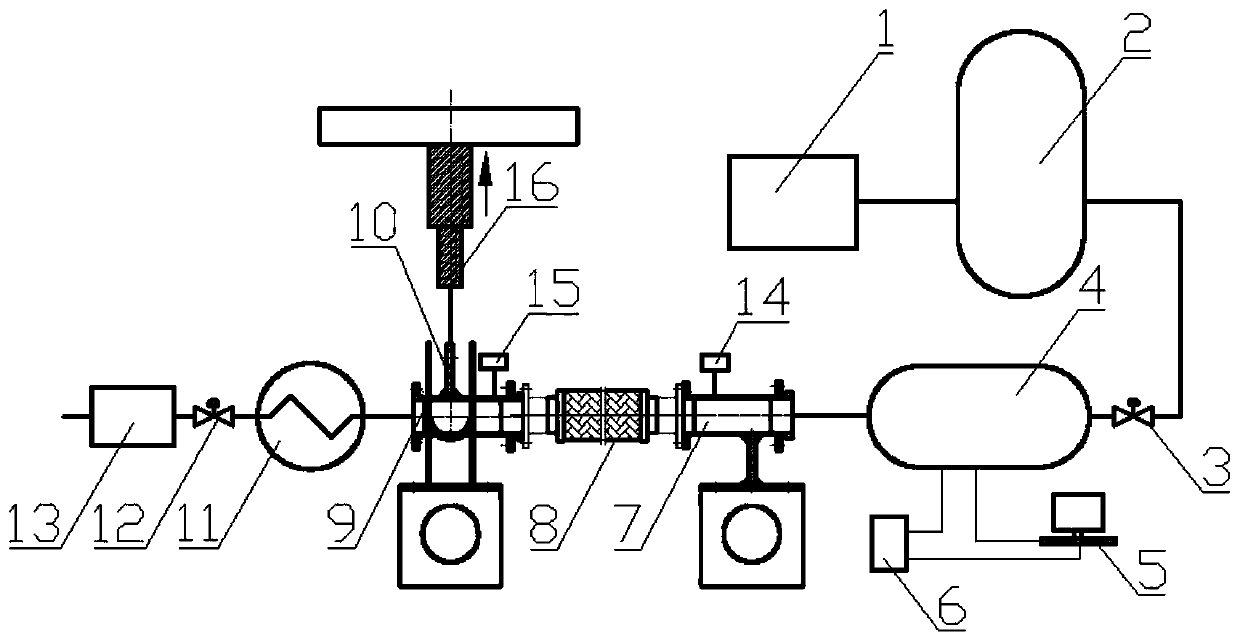

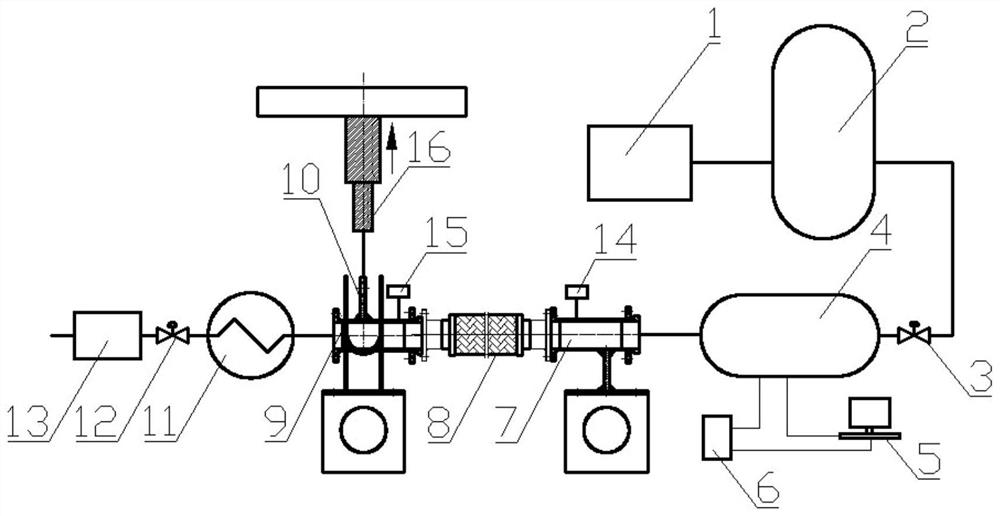

High-temperature internal pressure shear deformation lateral stiffness test system of pipeline system

ActiveCN110455519AEliminate sliding frictionReduce adverse effectsMachine part testingGas-turbine engine testingInternal pressureLateral shear

The invention discloses a high-temperature internal pressure shear deformation lateral stiffness test system of a pipeline system. Technical difficultiesinequivalent simulation of lateral shear deformation under the working conditions of high temperature and internal pressure of a pipeline structure are overcome, and the influence of tool friction on lateral stiffness by axial elongation ofpipelines is eliminated to a certain extent. The test system can synchronously simulatethe conditions oftemperature, internal pressure and lateral shear deformation and examine structural strength, rigidityand sealing performance, thereby being capable of providing a design basis for various engine related pipeline structures.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

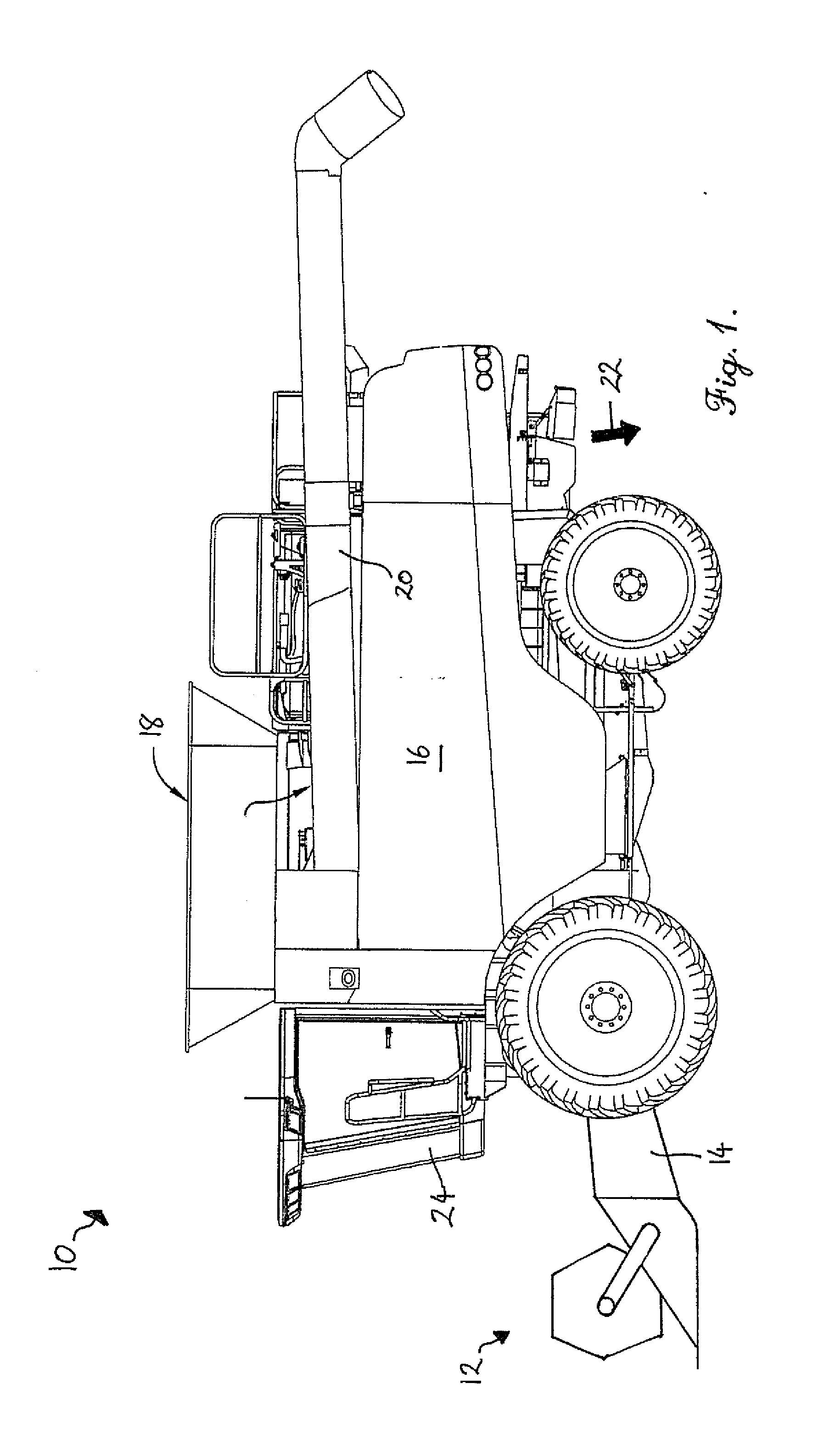

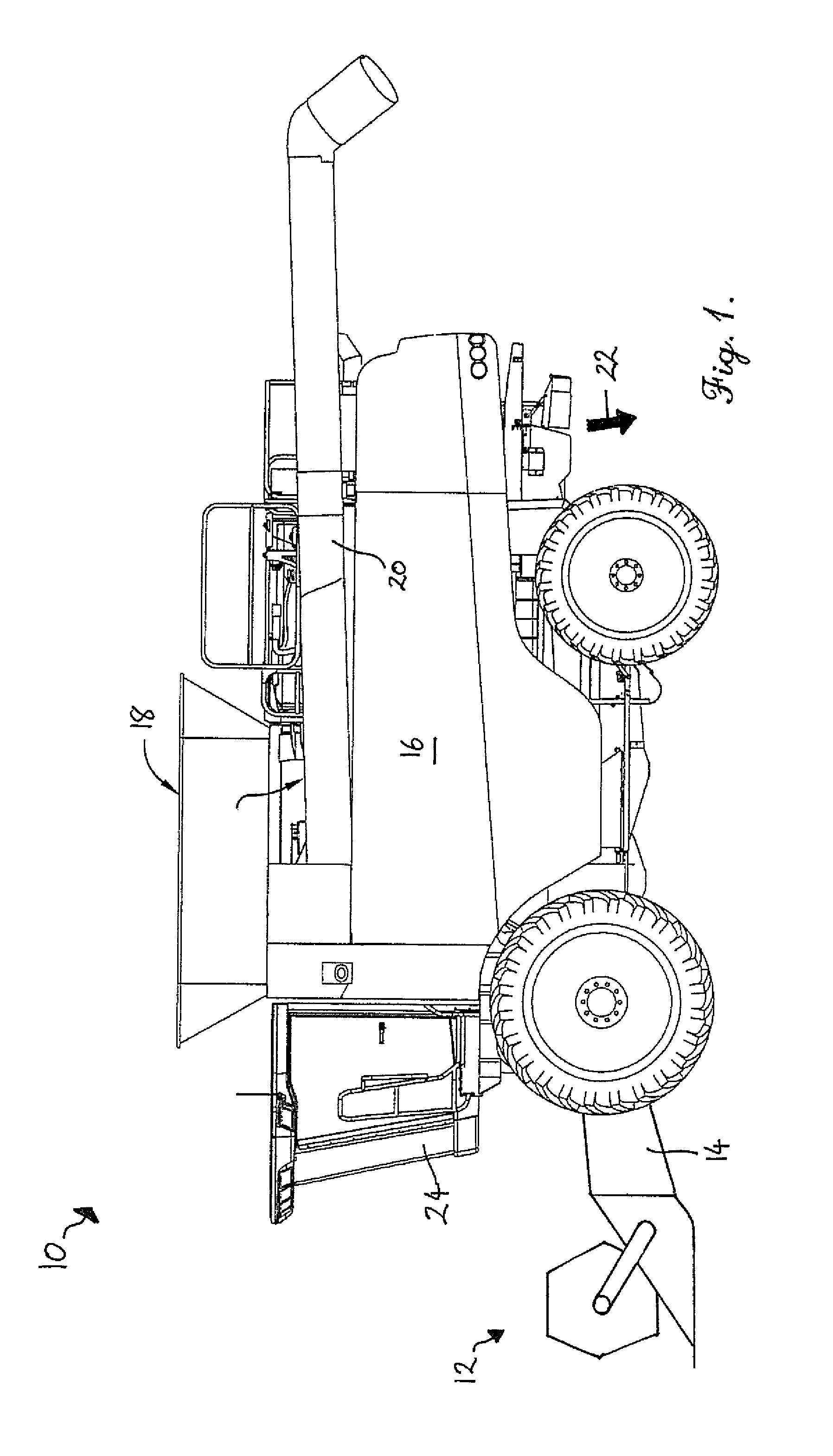

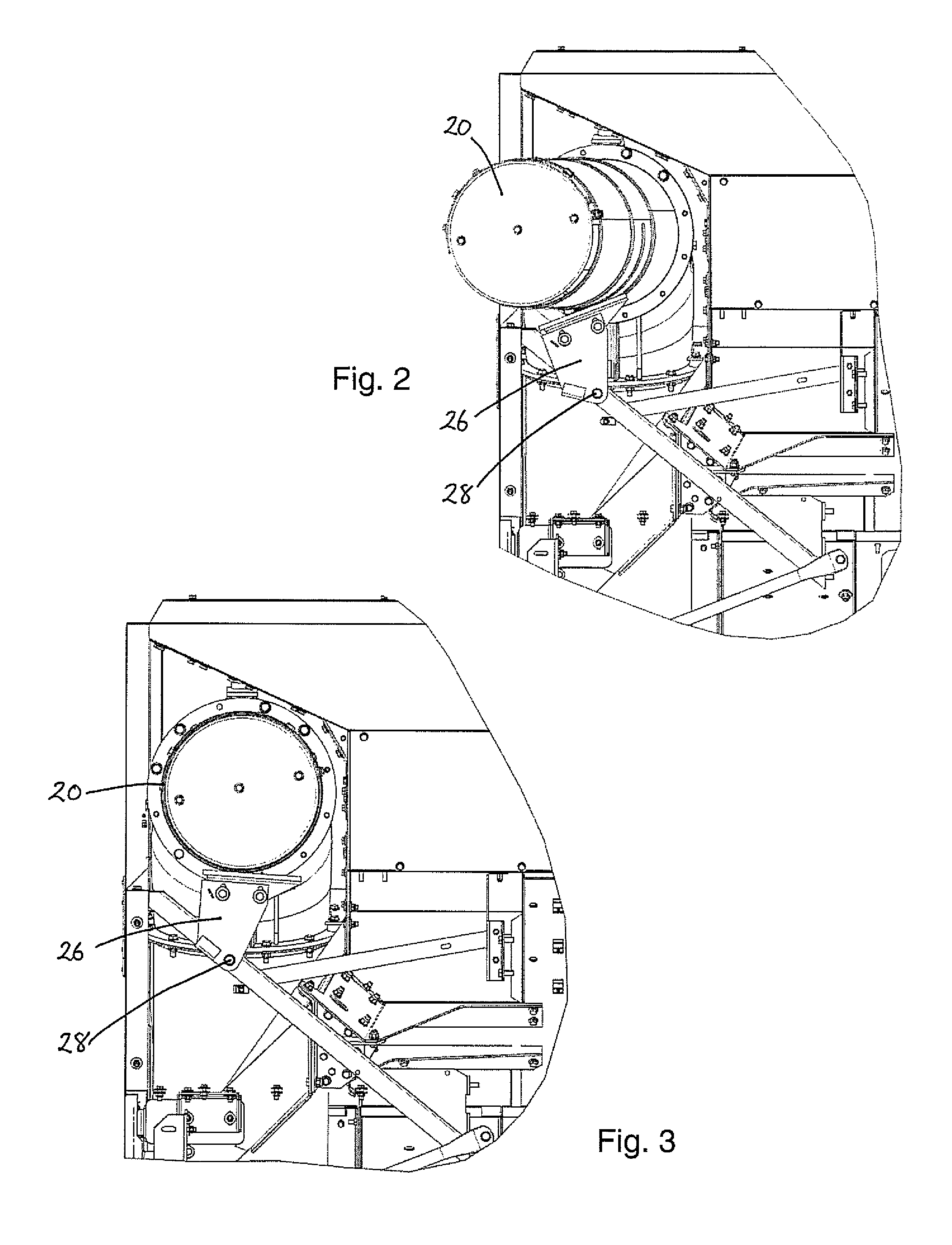

Combine Harvester Unloading System

A combine harvester unloading system is provided in which an unloading auger (20) is swingable between a stowed position and an unloading position around an upright pivot axis disposed at one end of the auger. A pivotally mounted auger support cradle (26) is moveable between a reception position to engage the underside of the auger when transitioning into the stowed position and a supporting position under the auger when in the stowed position.

Owner:LAVERDA

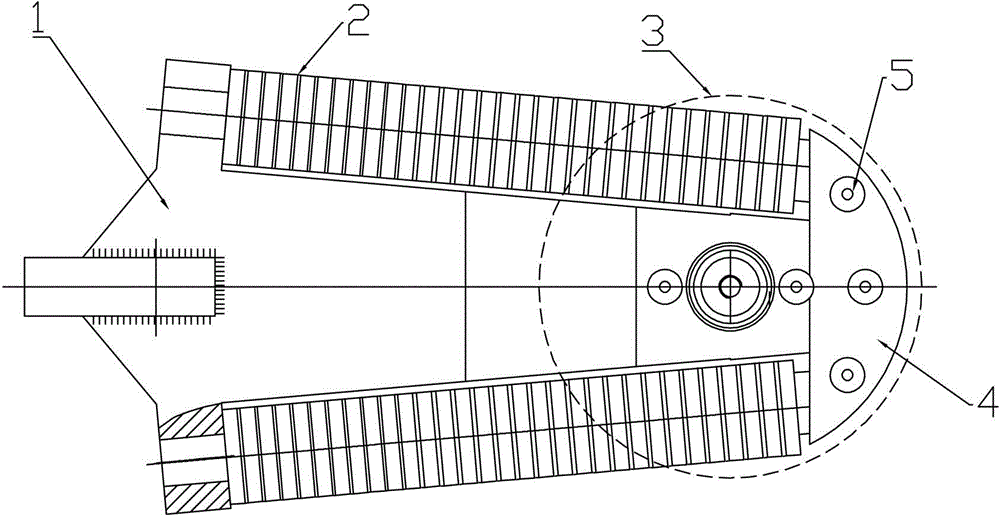

Pantograph head

InactiveCN108275003AReduce arcing phenomenonImprove flow relationshipRailway vehiclesPower current collectorsEngineeringSlide plate

The invention discloses a pantograph head. The pantograph head comprises a supporting structure, a roller structure, a connecting structure and a transverse alignment spring, wherein the roller structure can be in contact with a contact line to achieve the breakover with the contact line and can roll around the axial direction of the contact line; the connecting structure is connected with the roller structure and the supporting structure and enable the roller structure to move on the supporting structure around the radial direction of the contact line; and the transverse alignment spring is arranged on the supporting structure and can apply elastic force to the roller structure, so that the roller structure moves on the radial direction of the contact line and is aligned with the contactline again. According to the pantograph head, the sliding friction of a sliding plate and contact line of the pantograph head is avoided both laterally and longitudinally, the current receiving effectamong bow nets is significantly improved, the maintenance and the repair are simultaneously convenient, the maintenance cost is reduced, and the alignment between the contact line and the pantographhead can be better achieved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Full-automatic sidewall turn-up system of all-steel tire two-drum forming machine

ActiveCN104960218AMeet the needs of angle changesStretch smoothlyTyresUltimate tensile strengthCircular surface

The invention relates to a full-automatic sidewall turn-up system of an all-steel tire two-drum forming machine. Two sides of the all-steel tire two-drum forming machine are provided with a conical turn-up wheel, each conical turn-up wheel is connected with the all-steel tire two-drum forming machine by virtue of a sidewall turn-up arm apparatus; the specific structure of the sidewall turn-up arm apparatus is as follows: the conical turn-up wheel is arranged on the inner side surface of the front end of a main support by virtue of a central bearing, the front end of the main support is provided with a curved surface supporting plate, the curved surface supporting plate is coaxial with the conical turn-up wheel, and the radius of the curved surface supporting plate is 3 to 8 mm less than the radius of the conical turn-up wheel; the curved surface supporting plate is provided with a plurality of micro universal balls, the micro universal balls are protruded out of the outer circular surface of the curved surface supporting plate, and the micro universal balls are fit to a sidewall part. By adopting the system, the automatic turn-up of a sidewall can be realized, the sidewall is enabled to be uniformly stretched, and characteristics for lowering the labor intensity, improving the labor efficiency and eliminating the pollution to a mold can be realized.

Owner:SHENYANG HEPING ZIWUXIAN TIRE MFG CO LTD

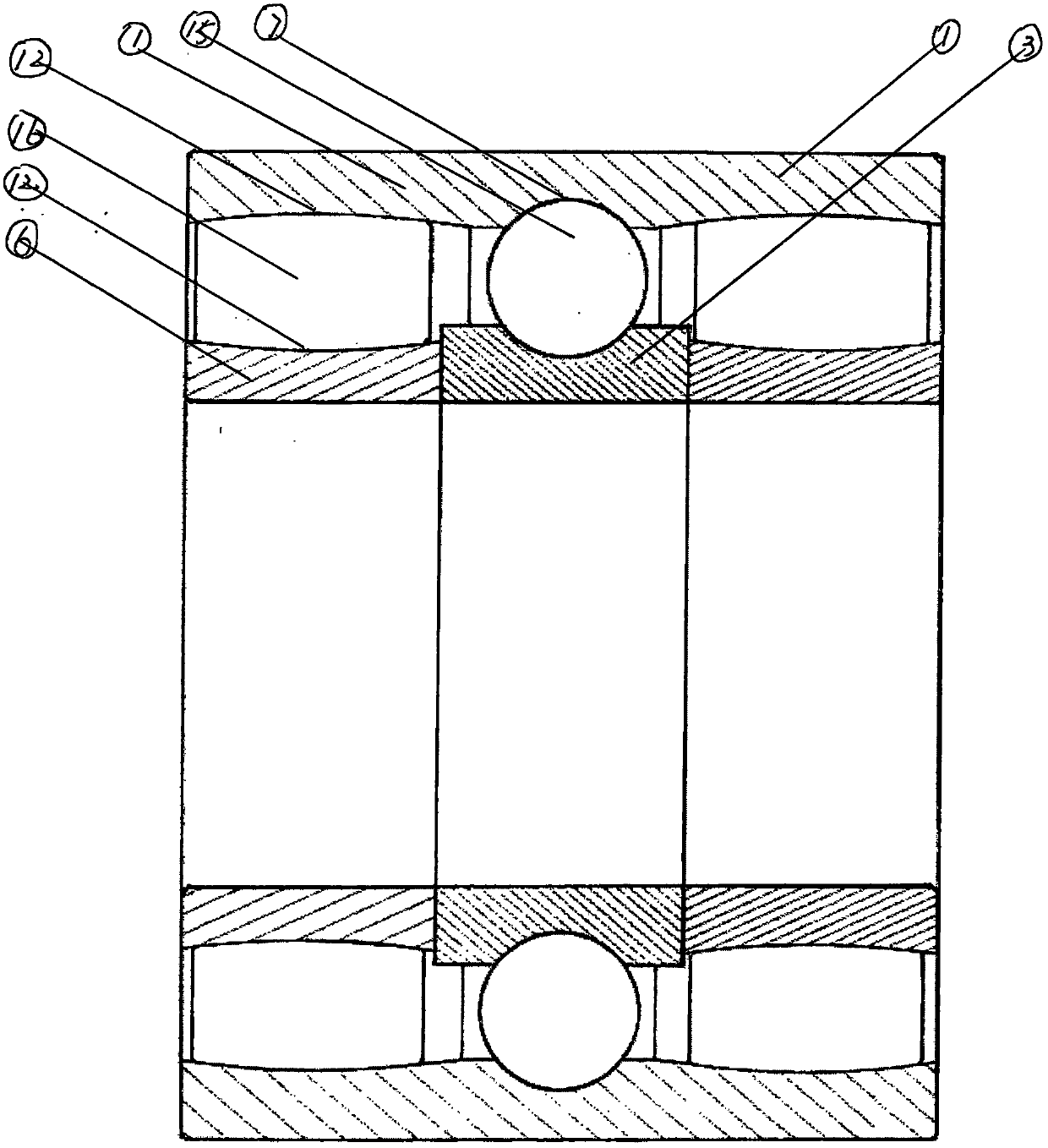

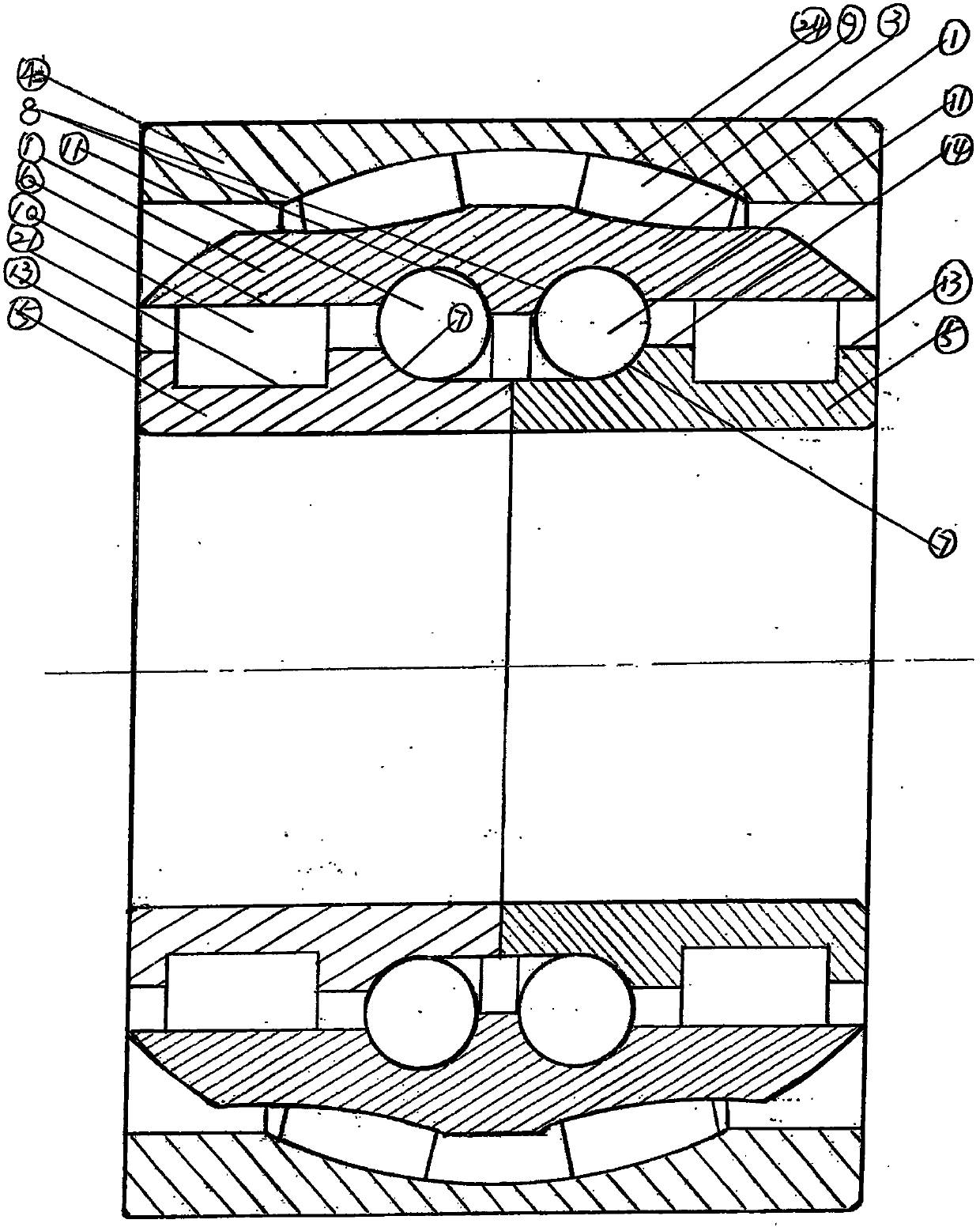

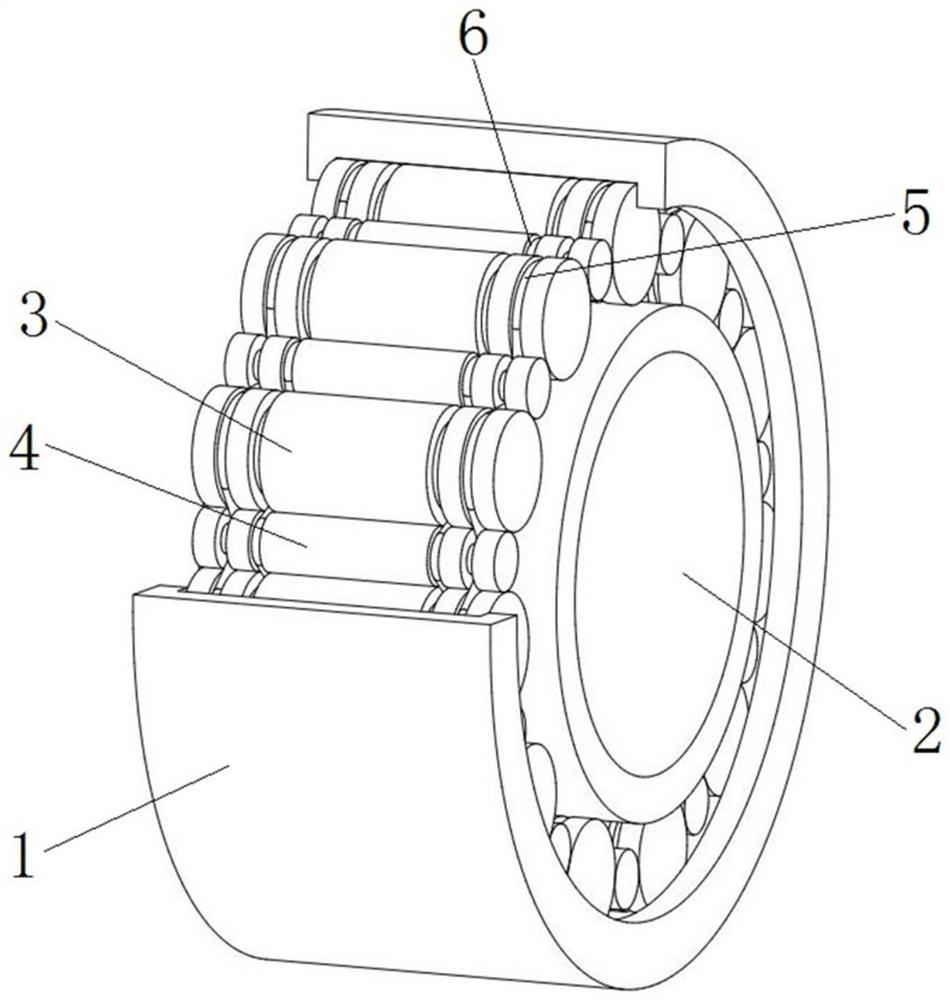

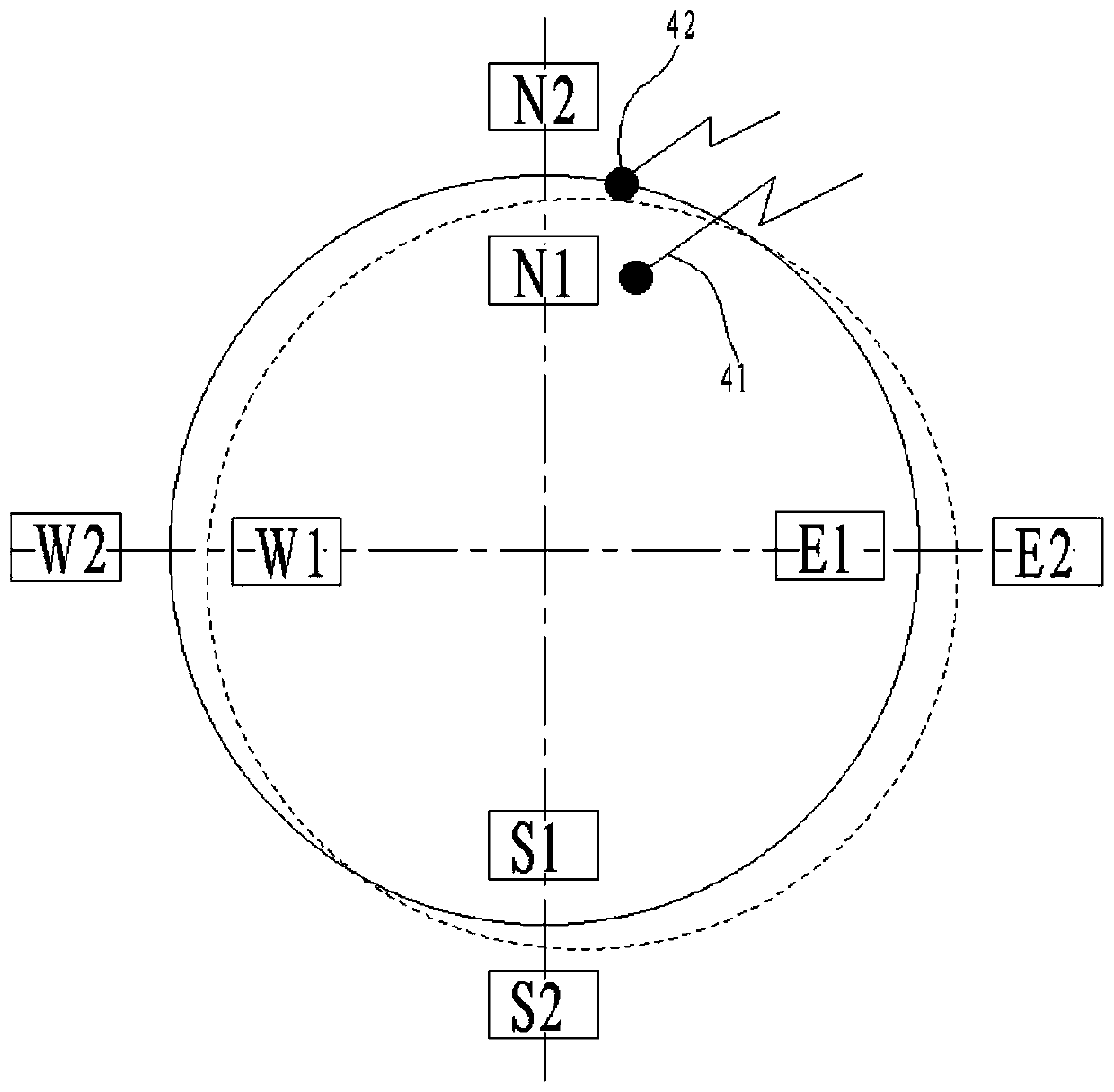

Novel high-speed heavy-duty high-speed rail bearing

PendingCN110966307AFit closelyReduce coefficient of frictionBearing componentsRolling resistance optimizationBall bearingClassical mechanics

The invention relates to a bearing, in particular to a high-speed heavy-duty high-speed rail bearing with a middle ball. The novel high-speed heavy-duty high-speed rail bearing is composed of an outerring with the middle ball, a deep groove ball bearing inner ring, two double-half inner rings and three rows of rolling bodies, wherein a deep groove ball bearing rolling body track is arranged in the middle of the inner circumference of the outer ring, circular roller tracks are respectively arranged on both ends of the deep groove ball bearing rolling body track at an interval, and circular rollers are respectively arranged in the tracks. A deep groove ball bearing structure is arranged in the middle of the inner circumference of the outer ring and between double sections of circular rollers or cylindrical rollers, the advantages of pure rolling friction of two-point contact of ball rolling bodies, high rotating speed and capability of bearing two-way combined load are fully used so asto design a mechanical structure of the middle ball, the scheme that the axial force of a roller contact angle bearing is increased by a double-section tapered roller bearing is replaced, roller deflection and frictional heating which are caused by stress concentration of the small end of a tapered roller can be effectively reduced, and the rotating speed and the rotary accuracy of the bearing areincreased. Because SKF bearing materials verify that the load carried by the rollers is uniformly distributed on the rollers and a raceway contact surface by virtue of the special circular cambered surfaces of the circular rollers, the middle ball is arranged between the double-row circular rollers, so that the radial bearing capacity of the bearing can be greatly increased, and low friction, lowtemperature rise and long service life are realized.

Owner:孟萍

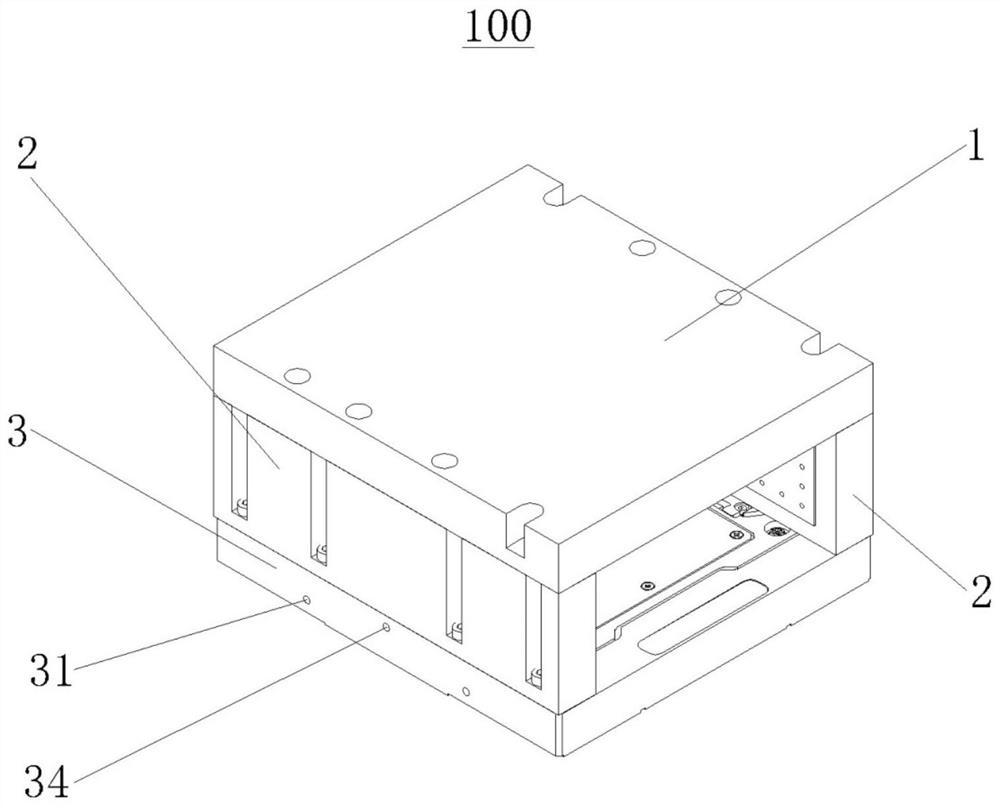

Wall corner surface car anti-scratch device for underground garage

PendingCN110630073AEliminate sliding frictionProtection securityCovering/liningsParkingsEngineeringFriction force

The invention discloses a wall corner surface car anti-scratch device for an underground garage. The wall corner surface car anti-scratch device comprises two supporting assemblies and a rotating assembly, the rotating assembly comprises a rotating shaft and a plurality of elastic contact pieces, and the contact pieces are arrayed along the axis of the rotating shaft and are all connected to the rotating shaft in a sleeving mode; and the supporting assemblies are fixed to a wall, the two supporting assemblies are located at the upper end and the lower end of the rotating shaft correspondingly,and the rotating shaft is rotationally connected with the supporting assemblies. The wall corner surface car anti-scratch device rotates with a car contact part to reduce and even eliminate sliding friction force between the wall surface and the surface of a car so as to ensure the surface quality of the car and prevent scratching; and meanwhile, by additionally setting the elastic deformation function on the horizontal surface, a buffer space close to the wall is provided for the car through the elastic deformation function, the situation that the car collides with the wall and consequently,the shape of the car is pressed and deforms is avoided, the surface quality of the car and the safety of a driver and passengers are further ensured, and the sudden collision situation is avoided.

Owner:雍敔浩

Combine harvester unloading system

A combine harvester unloading system is provided in which an unloading auger (20) is swingable between a stowed position and an unloading position around an upright pivot axis disposed at one end of the auger. A pivotally mounted auger support cradle (26) is moveable between a reception position to engage the underside of the auger when transitioning into the stowed position and a supporting position under the auger when in the stowed position.

Owner:LAVERDA

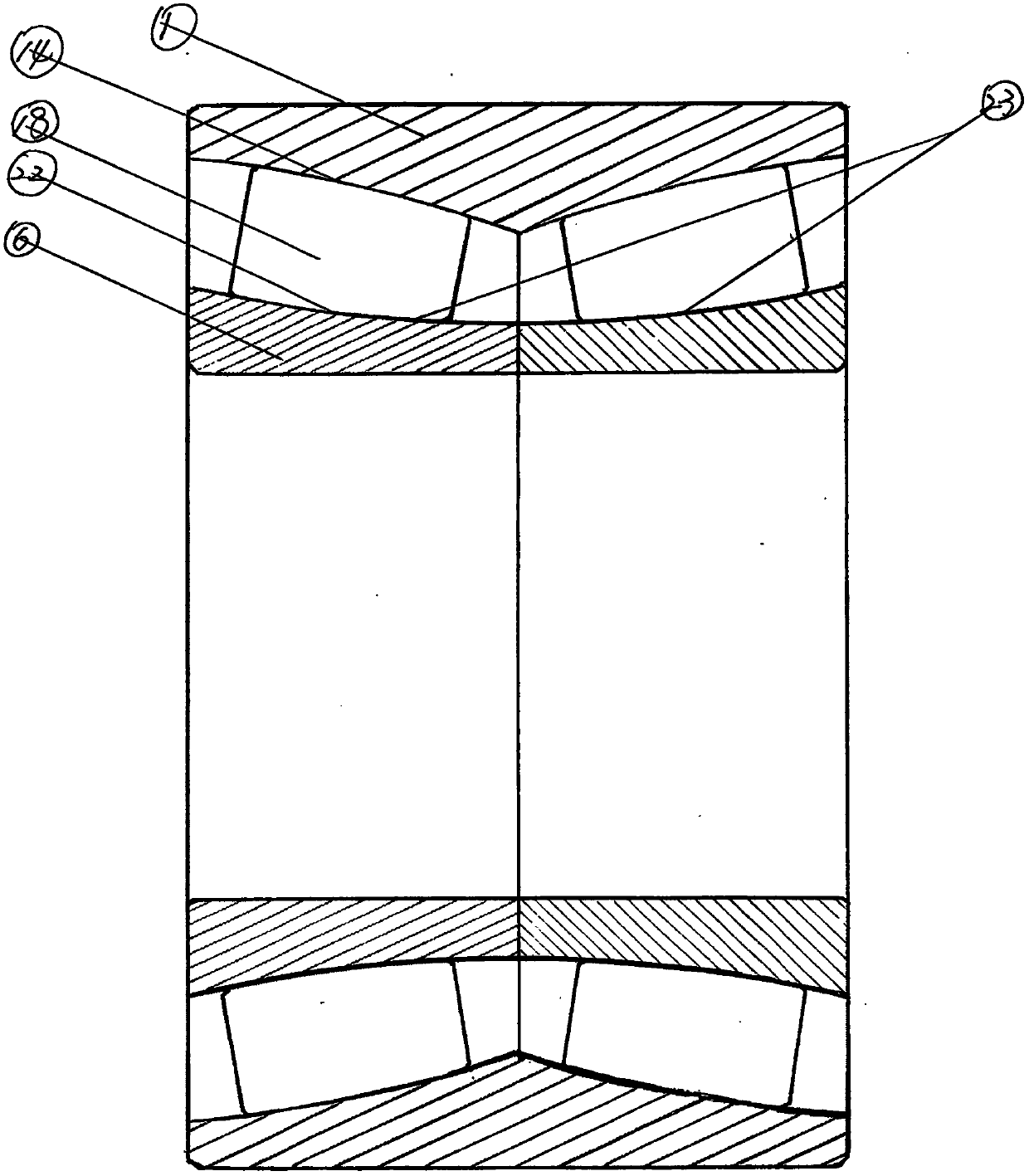

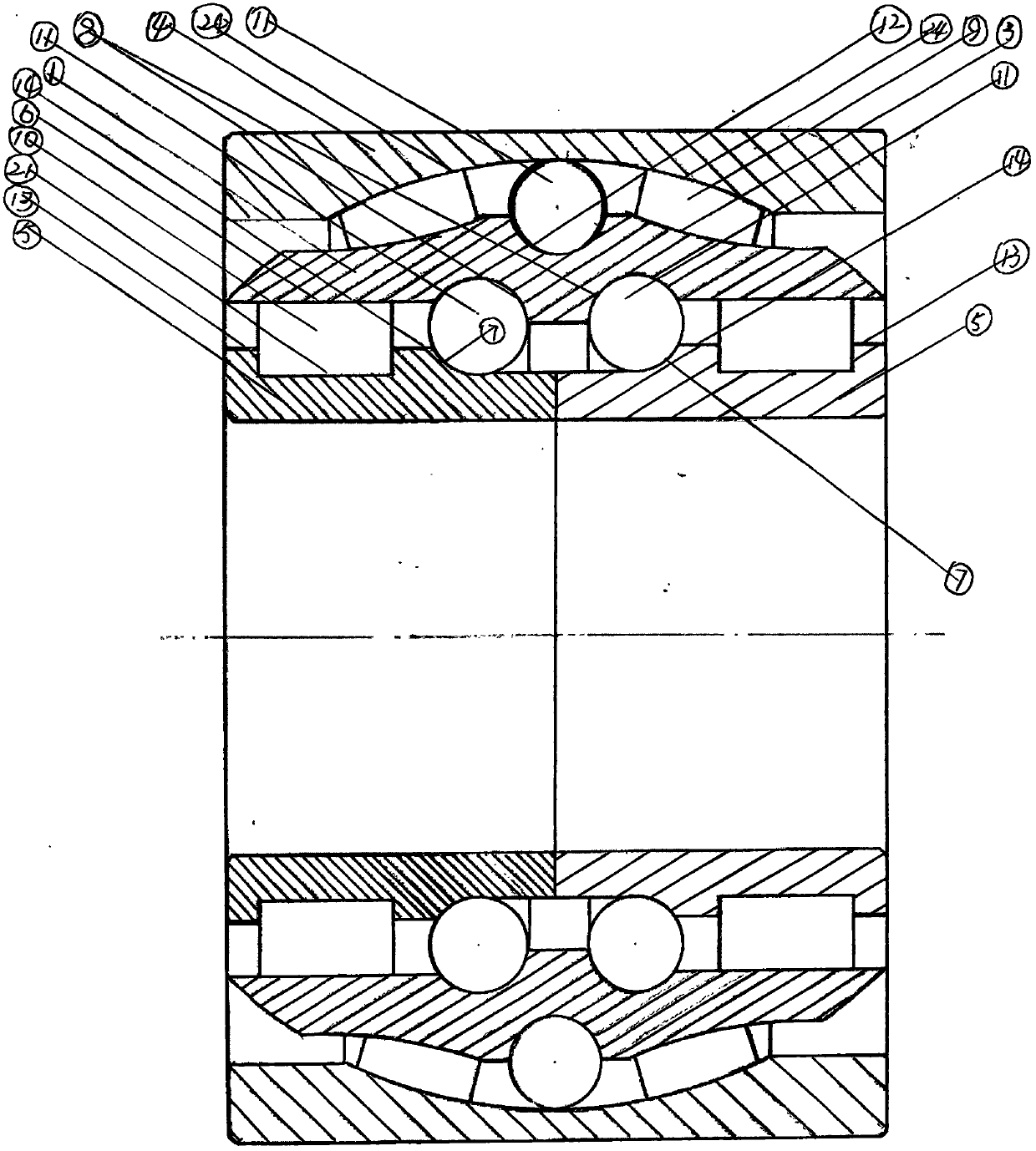

Novel high-speed railway power bearing

PendingCN110966301AFit closelyReduce coefficient of frictionBall and roller bearingsBearing componentsBall (bearing)Structural engineering

The invention relates to bearings, in particular to a high-speed railway power bearing provided with a middle ball reducing middle ring. The novel high-speed railway power bearing is composed of the reducing middle ring provided with a middle ball, an outer ferrule provided with a ball bladder inner track, two double-half inner ferrules, an inner-layer rolling body and an outer-layer rolling body.According to the bearing, the mechanical structure of a double-row angular contact ball bearing or a deep groove ball bearing is arranged in the middle of the inner circumference (or the inner circumference and the outer circumference) of the reducing middle ring and arranged between two sections of circular ring rollers or two sections of cylindrical rollers, the advantage of two-point contact pure rolling friction of a ball rolling body is fully utilized to bear bidirectional combined loads, the mechanical structure of the middle ball is created, the radial bearing capacity of the bearing can be greatly improved, the rotating speed and the rotating precision of the bearing are effectively improved, and the bearing is high in speed, low in friction, slow in temperature rise and long in service life.

Owner:孟萍

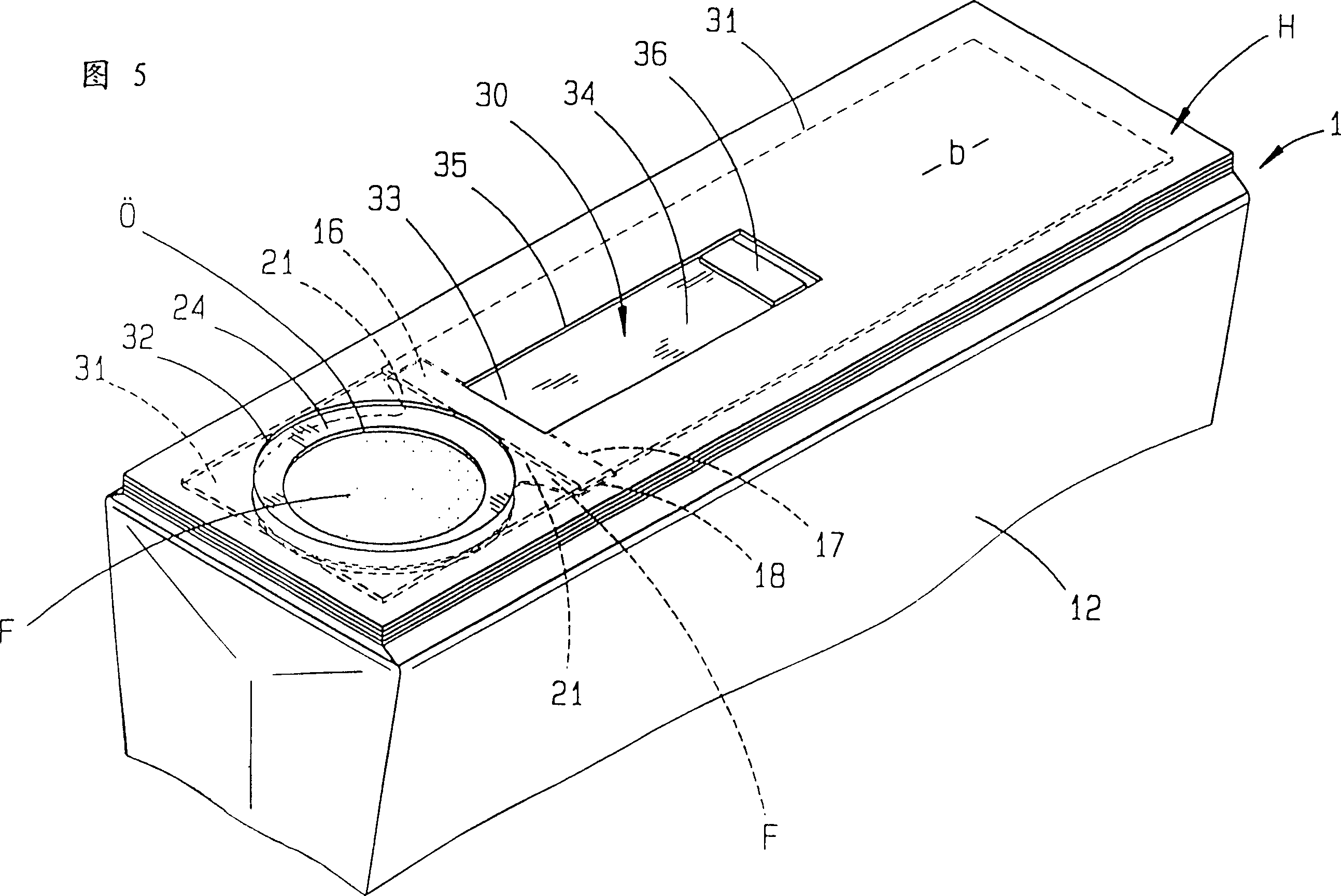

Dust filter bag for vacuuon cleaner

InactiveCN1121188CImprove restoring forceWon't get in the way of cloggingSuction filtersCardboardStructural engineering

PCT No. PCT / EP95 / 01528 Sec. 371 Date Jan. 21, 1997 Sec. 102(e) Date Jan. 21, 1997 PCT Filed Apr. 22, 1995 PCT Pub. No. WO95 / 29621 PCT Pub. Date Nov. 9, 1995A dust filter bag (1) for a vacuum cleaner (3), with a retaining plate (H). The bag is constructed of a solid paper material, such as cardboard for example, to which a dust bag (12) is joined, for example adhesively, with a closure flap (13) turned towards the inside (15) of the dust bag (12), hinged on the retaining plate (H), which closure flap (13) is openable against a spring action and, in closed condition, keeps closed an opening (O) in the retaining plate (H). To make the dust filter bag simpler in construction and more advantageous as regards use, a band-like spring element (F) is attached to the closure flap (13) in such a way that, in the closed condition (FIG. 4), there is formed a clearance (Y) between a band end (E-E) and a hinge axis (14), lying outside of the band, of the closure flap (13), where the hinge axis (14) is provided turned towards the inside (15) of the dust bag (1).

Owner:VORWERK & CO INTERHOLDING GMBH

High-speed indexing separator

The invention discloses a high-speed indexing separator. The high-speed indexing separator comprises a power input cam, a power output rotating tower and a power output shaft, wherein the power input cam is in transmission connection with the power output rotating tower; the power output rotating tower is in transmission connection with the power output shaft; a plurality of roller pairs are distributed around the power output rotating tower in the radial direction, and each roller pair comprises a forward rotating roller and a backward rotating roller which are structured the same; supporting ribs with driving curve outlines are arranged on the power input cam; the roller pairs are positioned in clearances which are formed through the circularly-distributed supporting ribs; the forward rotating rollers and the backward rotating rollers of one roller pair are correspondingly in contact fitting with the surfaces of the supporting ribs at two sides of the clearances; and the forward rotating rollers and the backwards rotating rollers of adjacent roller pairs fit two surfaces of the supporting ribs at the same position. The high-speed indexing separator is long in service life; the rotating speed of the high-speed indexing separator in actual work is doubled that of a traditional separator, so that the efficiency of the separator as well as a production line of the separator can be extremely improved.

Owner:宁波天相机械制造有限公司

A pantograph bow head

ActiveCN108177529BImprove flow relationshipEliminate uneven defectsRailway vehiclesPower current collectorsClassical mechanicsEngineering

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

Precise movement air floatation supporting device

PendingCN113833763AReach equilibriumMovement is easily controlledGas cushion bearingsBraced frameMechanical engineering

The invention relates to the technical field of precise movement, and discloses a precise movement air floatation supporting device which comprises a base, a guide rail and a supporting frame, wherein the guide rail is horizontally arranged on the base and fixedly connected with the base, the supporting frame is arranged on the guide rail in a sleeving mode and can slide along the guide rail, and the supporting frame comprises a bottom air floatation plate, a top air floatation plate and lateral air floatation plates; the number of the lateral air floating plates is two, the two lateral air floating plates are symmetrically arranged, lateral air paths are arranged in the lateral air floating plates, lateral air inlet holes and lateral exhaust holes which are communicated with the lateral air paths are formed in the surfaces of the lateral air floating plates, and a bottom surface air path is arranged in the bottom air floating plate. And the surface of the bottom air floating plate is provided with a bottom surface air inlet hole and a bottom surface air outlet hole which are communicated with the bottom surface air path. Compared with the prior art, the precise movement air floatation supporting device is simple and reliable in structural design, the air inlet and outlet holes and the air path design can effectively reduce the space occupation amount of an air source, the supporting frame has good movement posture and movement precision, and the use experience of operators is good.

Owner:HARBIN INST OF TECH

Cylindrical roller bearing and assembling method thereof

PendingCN114876951AEliminate sliding frictionReduce sliding frictionRoller bearingsBearing componentsRoller bearingMechanical engineering

The invention belongs to the field of bearings, and particularly relates to a cylindrical roller bearing and an assembling method of the cylindrical roller bearing, rollers are arranged between an inner ring and an outer ring of the cylindrical roller bearing, a cylindrical isolation rod with the diameter smaller than that of the rollers is arranged between every two adjacent rollers so as to separate the two adjacent rollers, the cylindrical roller bearing further comprises a hooping ring set, and the hooping ring set is arranged between the inner ring and the outer ring of the cylindrical roller bearing. The hooping ring set comprises a first hooping ring and a second hooping ring, roller hooping ring matching ring grooves are formed in the rollers, the first hooping ring sequentially bypasses the rollers and the isolation rods alternately inside and outside, the second hooping ring and the first hooping ring are arranged in the axial direction of the rollers in a spaced mode, and the second hooping ring sequentially bypasses the rollers and the isolation rods inside and outside in the direction opposite to the first hooping ring. The first hooping ring and the second hooping ring are arranged in the hooping ring set so that the rollers and the isolation rods can be clamped between the first hooping ring and the second hooping ring, the cross section size of the roller hooping ring matched ring groove in the axial direction of the rollers is equal to or larger than that of the hooping ring set, the hooping rings hoop the rollers on the inner ring, and sliding friction is effectively reduced or even avoided.

Owner:HENAN UNIV OF SCI & TECH

Centring platform of large machine coupling

ActiveCN110480330AEliminate sliding frictionImprove versatilityWork holdersMetal working apparatusMotor shaftFastener

The invention discloses a centring platform of a large machine coupling. The centring platform is used for centring a machine shaft and a motor shaft. The centring platform of the machine coupling comprises V opening blocks, a middle column, first dial indicators and a second dial indicator. The total number of the V opening blocks is two. Each V opening block comprises a V-shaped portion and an end plate. Each end plate is arranged on the end face of one side of the corresponding V-shaped portion. Butt clamp holes used for combining mounting of the two V opening blocks are formed in the two sides of the V-shaped portions. The end face of one side of the middle column and the end faces of the sides, deviating from the V-shaped portions, of the end plates are connected through fasteners. The axis of the middle column coincides with the butt clamp center line of the V-shaped faces of the two V-shaped portions. The first dial indicators and the second dial indicator are connected to the middle column. The V opening blocks, the middle column, the first dial indicators and the second dial indicator are arranged on the machine shaft, the first dial indicators rotate along with the middlecolumn to measure the end face beating degree of the motor shaft, and the second dial indicator rotates along with the middle column to measure the radial beating degree of the motor shaft.

Owner:泰安泰山科技有限公司

Valve actuator

ActiveCN113389939AEffect of Small Feedback AccuracyEliminate sliding frictionOperating means/releasing devices for valvesValve actuatorHall element

The invention discloses a valve actuator, and belongs to the related technical field of valve actuators. The valve actuator mainly comprises a shell, wherein an output shaft used for outputting torque is arranged in the shell, the valve actuator further comprises a magnetic part and a Hall element, the magnetic part and the output shaft are coaxially arranged, the magnetic part is connected with the output shaft, the Hall element is fixed to the shell, the Hall element and the magnetic part are oppositely arranged, and the Hall element is used for sensing change of a magnetic field of the magnetic part when the magnetic part rotates along with the output shaft, so that position feedback of the output shaft is achieved. According to the valve actuator, effects of rapid operation or high-frequency operation of the valve actuator on the feedback precision of the valve actuator can be avoided.

Owner:江苏海博流体控制有限公司

Sliding friction-free gear

A sliding friction-free gear has cams of specific profiles, rollers separating cooperating cams that roll over the cams of the gears, thus eliminating the sliding friction between the gears. The rollers are mounted rotatably e.g. in sliders or eccentrics, wherein the sliders, resp. eccentrics, are mounted slidingly, resp. rotatably, in a yoke attached rigidly to a shaft. The rollers are free to execute oscillating motion relative the yoke while rolling over the cam profiles of the cams of the gears. The cooperating members of the gear contact along a line like in conventional evolvent gears, and unlike in the Wildhaber-Novikov's gear (where the momentary contact between teeth of cooperating toothed wheels is pointwise); therefore the gear according to the present invention offers much larger transmission capacity and is much less prone to seizure than known gears.

Owner:OLEDZKI WIESLAW JULIAN

Conveyor device with powered endless pulling means for products from the tobacco processing industry

InactiveCN103082409AReduce saggingAngle orientation can be adjustedConveyorsCigarette manufactureEngineeringTraction unit

The present invention relates to a conveyor device with a powered endless pulling means for products from the tobacco processing industry. The conveyor device has a deflection device, an endless traction unit rotating on an outer face on the deflection device; and an entrainment unit extending outwards on the endless traction unit. The deflection device is formed by at least one guide piece supported by rotating means and is pressed against the endless traction unit via a guide face outside the radial direction. The guide surface is interrupted by regularly arranged recesses (12) into which an entrainment unit (15) is accommodated. An adjusting device is provided for adjusting the orientation of the guide unit (3) with respect to the endless traction unit (2) during operation of the conveyor (1).

Owner:HAUNI MASCHINENBAU AG

Crossbow

The invention relates to the field of sports weapons. The crossbow comprises a bow with a bow string, a shoulder stock and a tubular stock which connects said bow and shoulder stock and has two diametrically arranged longitudinal helical grooves, the helical grooves in the stock are of through design, and the bow string is passed through the helical grooves, wherein the helical grooves have a length of not less than the value of the bow string tensioning motion. Furthermore, an arrow to be launched is arranged inside the stock and is brought into engagement with the bow string such that an axial force and a rotational moment can be transmitted to one of the structural elements: by means of an annular slide with two radial openings which are open therein, are diametrically arranged and through which the bow string is passed, inside a tube inserted into said openings, or without a slide, only with the aid of a tube which is slipped onto the bow string, for which supports are formed on the bow string, or directly from the bow string, without a slide and without a tube. A simplification of the design, a reduction in the weight and necessary power of the crossbow, and an increase in the stabilization of an arrow during flight are achieved.

Owner:RASSULOV ALEKSEI MOSSUDOVICH

Crossbow

The invention relates to the field of sports weapons. The crossbow comprises a bow with a bow string, a shoulder stock and a tubular stock which connects said bow and shoulder stock and has two diametrically arranged longitudinal helical grooves, the helical grooves in the stock are of through design, and the bow string is passed through the helical grooves, wherein the helical grooves have a length of not less than the value of the bow string tensioning motion. Furthermore, an arrow to be launched is arranged inside the stock and is brought into engagement with the bow string such that an axial force and a rotational moment can be transmitted to one of the structural elements: by means of an annular slide with two radial openings which are open therein, are diametrically arranged and through which the bow string is passed, inside a tube inserted into said openings, or without a slide, only with the aid of a tube which is slipped onto the bow string, for which supports are formed on the bow string, or directly from the bow string, without a slide and without a tube. A simplification of the design, a reduction in the weight and necessary power of the crossbow, and an increase in the stabilization of an arrow during flight are achieved.

Owner:RASSULOV ALEKSEI MOSSUDOVICH

Production device for preventing scratch of pull ring material, and detection method thereof

ActiveCN109309812AAvoid scratch damageAvoidance of reduced diameterTelevision system detailsCharacter and pattern recognitionProduction lineImaging processing

The invention discloses a production device for preventing the scratch of a pull ring material, and a detection method thereof. The production device comprises: a bracket A, a rolling shaft and an unrolling shaft are respectively installed on left and right sides of the bracket A, and a driving device C is connected to one end of the rolling shaft; a plurality of rollers are installed on the bracket A, and two sliding devices are installed on the bracket A; an upper shooting device is installed on the sliding device located above the strip-shaped pull ring material, a lower shooting device isinstalled on the sliding device located below the strip-shaped pull ring material, and camera devices are installed in both of the upper shooting device and the lower shooting device; a positioning sensor is further installed between each camera device and the unrolling shaft, and the camera devices are connected with an image processing system through signal lines; and the production device disclosed by the invention can improve the problems that the surface of the pull ring material is easy to generate friction with the rollers to be scratched in the existing automatic production line of thepull ring material, and that synchronous tracking detection cannot be performed on the defects on the surface of the pull ring material, resulting in increased defective products.

Owner:山东龙口三元铝材有限公司 +1

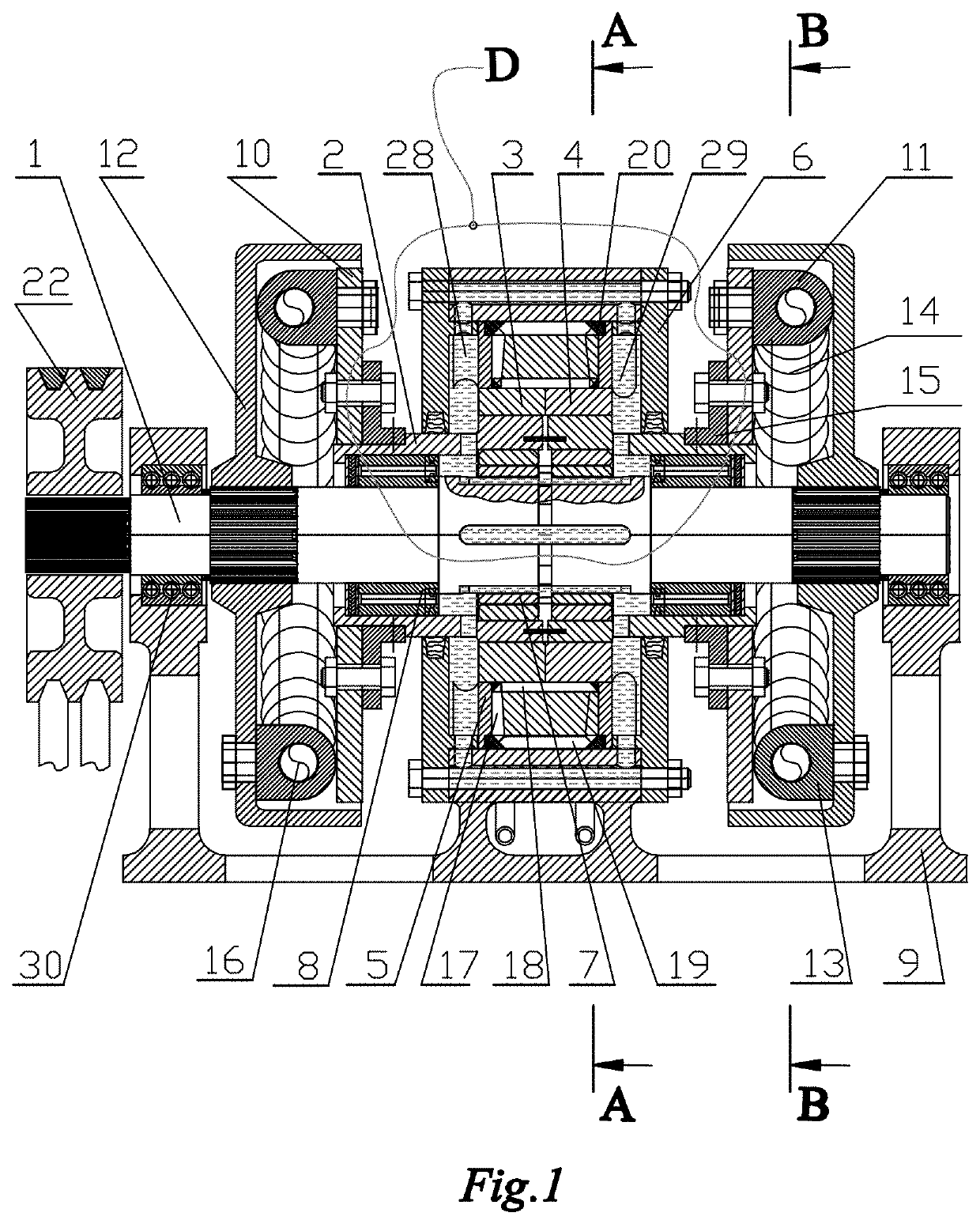

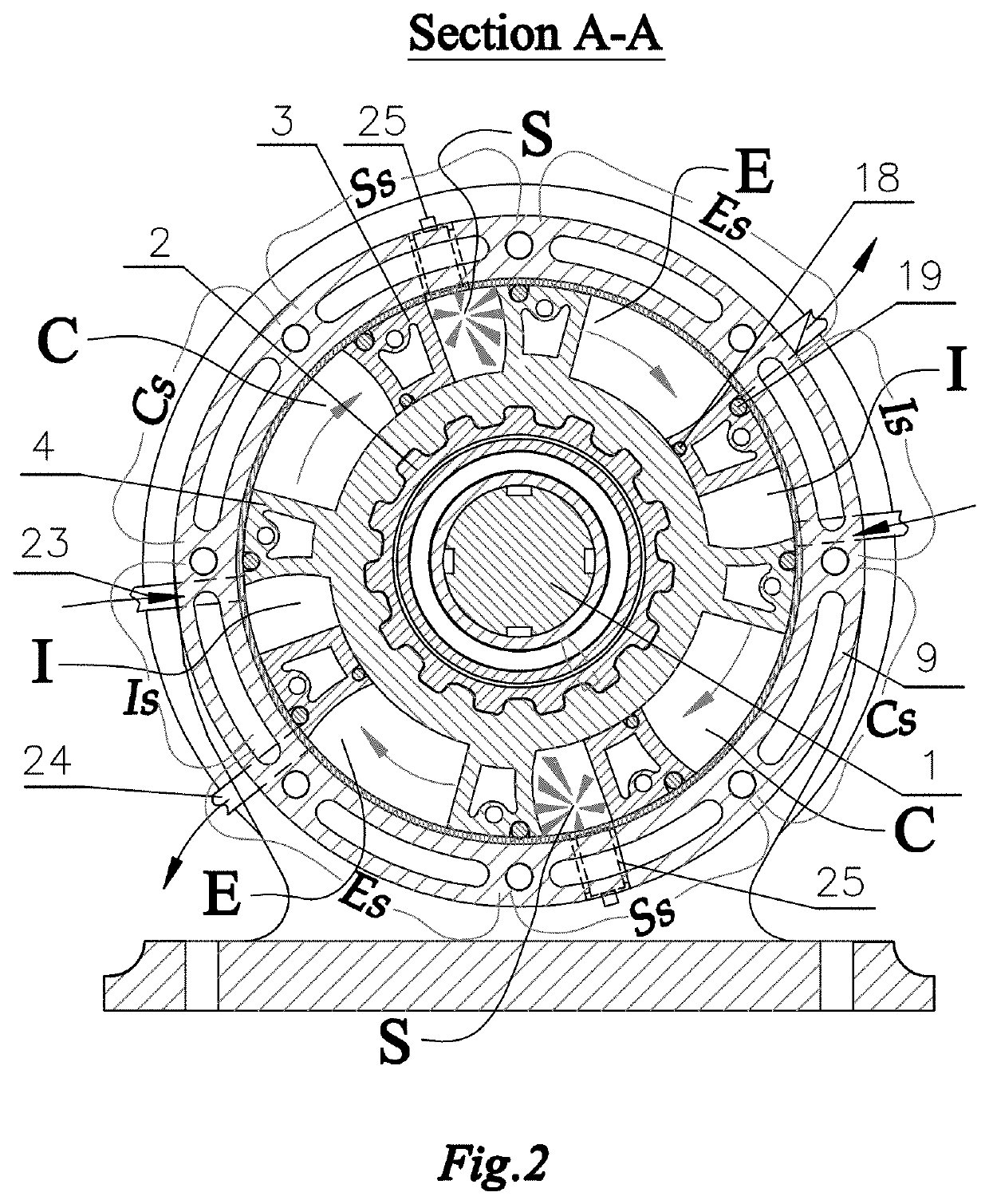

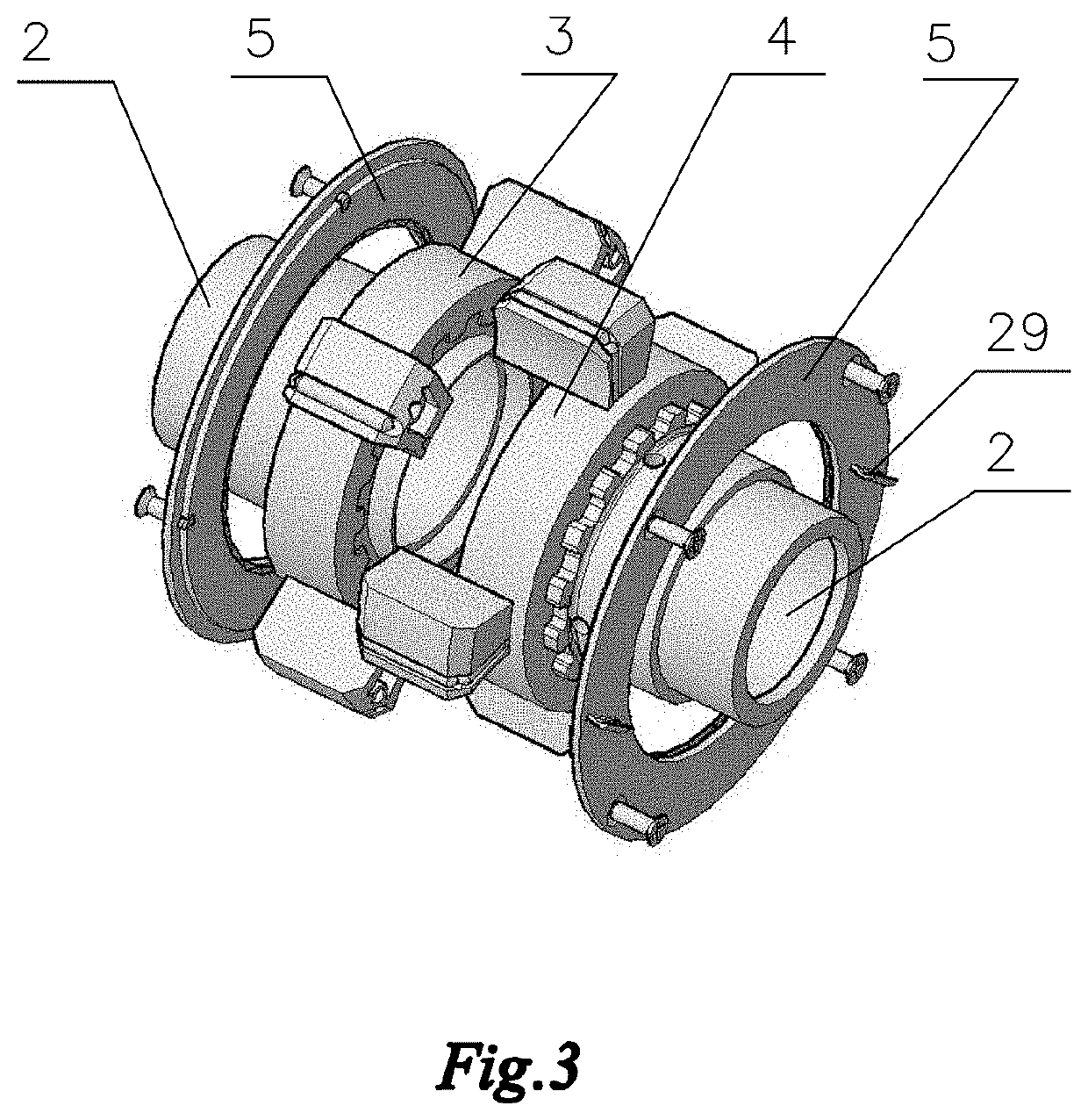

Rotary vane internal combustion engine

ActiveUS20220018282A1Eliminate needPrevent reversalInternal combustion piston enginesEngine of arcuate-engagement typeCombustion chamberInternal combustion engine

Rotary vane internal combustion engine comprises of two side-by-side rotors, placed in a cylindrical housing, wherein each rotor has at least two radial vanes rigidly attached to the rotor that form chambers for intake, compression, combustion, and exhaust. Each rotor alternately engages with a shaft by overrunning one-way clutches and is held from turning back, through the damper, mounted on a corresponding flywheel and forming a part of the flywheel assembly, which is rigidly attached on the shaft. The assembled rotors from the outside are rigidly closed by flanges on each of which is mounted at least one blade. The blades are positioned into formed cavities between the rotors and caps of the housing, thereby forming two cooling cavities through which coolant circulates around rotors through openings in the housing and through longitudinal grooves in the shaft. On the vanes are mounted cylindrical and conical seals, which remove the need for lubrication.

Owner:STANETSKY ANATOLI

A low-flow pulsation two-way gear pump

ActiveCN104329250BRelieve pressureReduce noiseRotary piston pumpsRotary piston liquid enginesGear driveGear pump

The invention discloses a low flow pulsating bidirectional gear pump. The pump comprises a pump shell, a driving shaft and a driven shaft, which are arranged in the pump shell, internal gears driven by the driving shaft, external gears, which are fixedly connected to the driven shaft, and a crescent block arranged between the external gears and the internal gears. Three external gears are arranged in the same axis. Three internal gears are arranged in the same axis and engage with the corresponding external gears. The outmost internal gear is fixed with the driving shaft, and two neighbored internal gears cooperate in transmission. Three groups of gears are adopted, wherein in each group the gears are internally engaged, thus the flow pulsation and pressure pulsation during the operation process of gear pump are largely reduced, and the noise and impact are reduced. Passing holes are arranged in the internal gears, so that the fluid can directly enter the gear pump in the radial direction. The structure of the internally engaged gear pump is simplified, and the pump becomes more compact. The three internal gears are inserted and engaged in sequence, thus the slide friction between the outer rings of the three internal gears and the pump shell is eliminated, the rigidity and stability of the system is guaranteed, the pump noise is reduced, and the service life is prolonged.

Owner:ZHEJIANG UNIV +1

A lateral stiffness test system for high temperature internal pressure shear deformation of pipeline system

ActiveCN110455519BEliminate sliding frictionReduce adverse effectsMachine part testingGas-turbine engine testingLateral stiffnessLateral shear

The invention discloses a lateral stiffness test system for high-temperature internal pressure shear deformation of a pipeline system, which solves the technical difficulties of equivalent simulation of lateral shear deformation under high temperature and internal pressure working conditions of the pipeline structure, and to a certain extent The influence of the tooling friction on the lateral stiffness due to the axial elongation of the pipeline is excluded. The test system can simultaneously simulate "temperature + internal pressure + lateral shear deformation" and assess structural strength, stiffness, and sealing performance, which can provide design basis for various engine-related pipeline structures.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Improved winding-machine for rolled or drawn wire/rod

InactiveCN100450658CEliminate sliding frictionReduced risk of cloggingWire rodStructural engineering

Winding-machine for rolled or drawn wire / rod (F) with device to form a wire / rod coil (R) in a winding-machine with one or more winding reels (1) placed downstream of a wire / rod working installation, provided with wire / rod-drawing means (2-3) and thereafter: an oscillating wire / rod-guide (4) with wire / rod-guide handling means (6) to lead the end of the wire / rod-guide reel side to follow the winding so that the wire / rod from the said advancing means (2-3) is wound up in the reel (1) with first translation means (65) to move the reel side end (1) of the exit opening said wire / rod-guide (4) parallel to the reel / mandrel axis (1) and second translation means (8-6) to move said exit opening of said wire / rod-guide (4) in withdrawal / approach perpendicularly to the axis of said reel / mandrel (1) in order to follow the increase of diameter of the coil (R) during winding-up with improved wire / rod containment system at said exit opening (7). Said wire / rod containment system consists of at least one opposite pair of containment rolls (71) provided at the exit opening (7) of said wire / rod-guide (4).

Owner:SIMAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com