Valve actuator

A technology of valve actuator and magnetic parts, applied in valve details, valve device, valve operation/release device, etc., which can solve the problems of large influence of feedback accuracy, potentiometer affected by temperature, obvious contact friction and heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

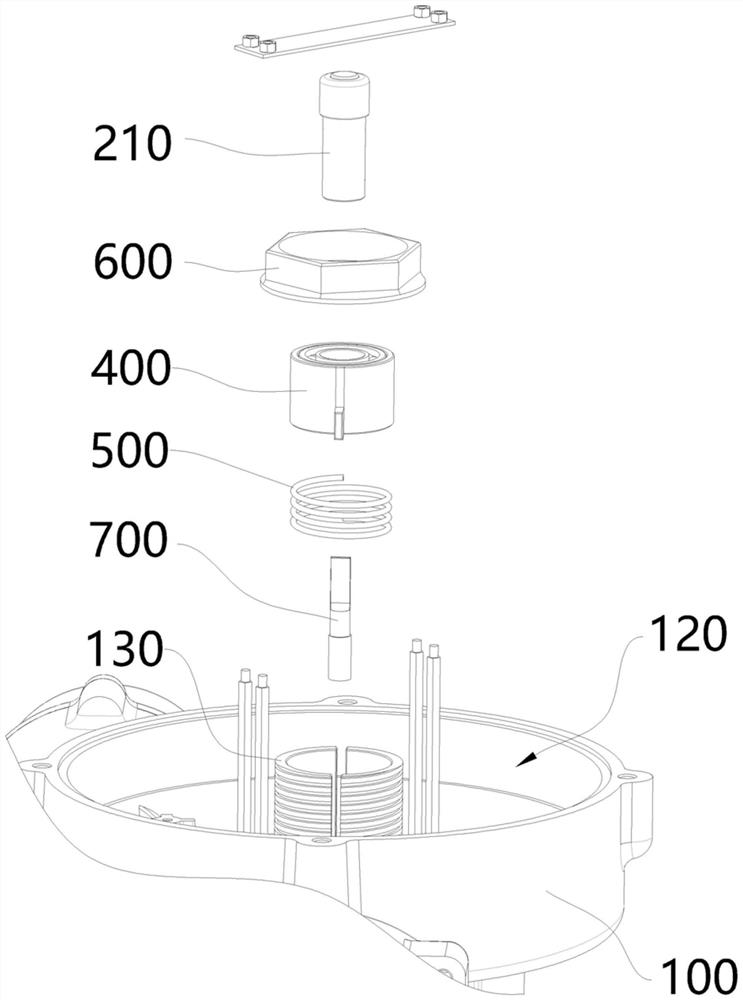

[0025] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0026] Such as figure 1 and 2 As shown, the present invention provides a valve actuator, including a housing 100, a magnetic member 200 and a Hall element 300, the housing 100 has an output shaft 110 for output torque, and the magnetic member 200 is coaxial with the output shaft 110 set, and the magnetic part 200 is connected to the tail end of the output shaft 110, the Hall element 300 is fixedly arranged on the housing 100, and the Hall element 300 is opposite to the magnetic part 200, when the magnetic part 200 rotates with the output shaft 110 The change of the magnetic field of the magnetic member 400 is sensed by the Hall element 300 , so as to recognize the rotation ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com