Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Eliminate retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

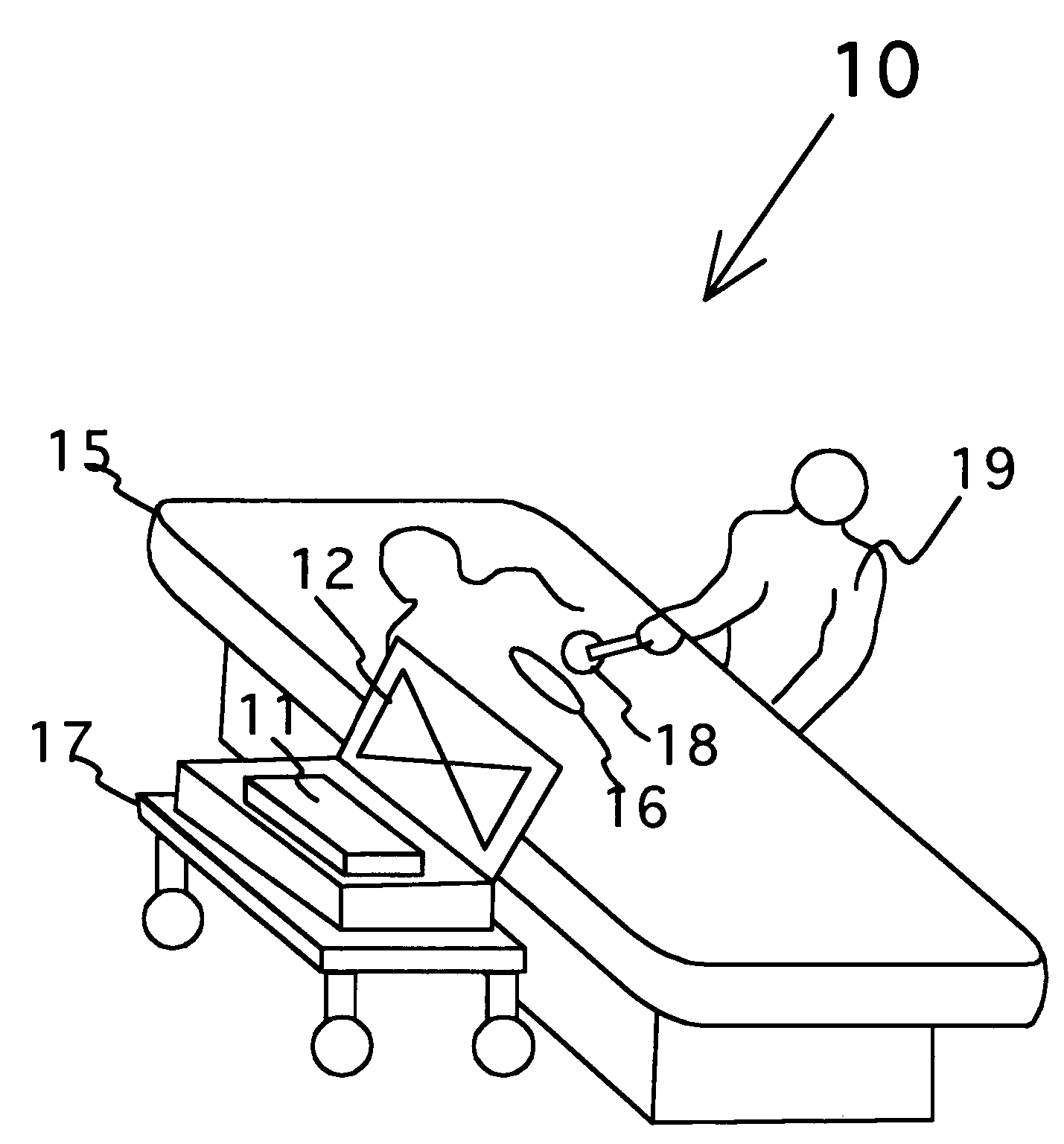

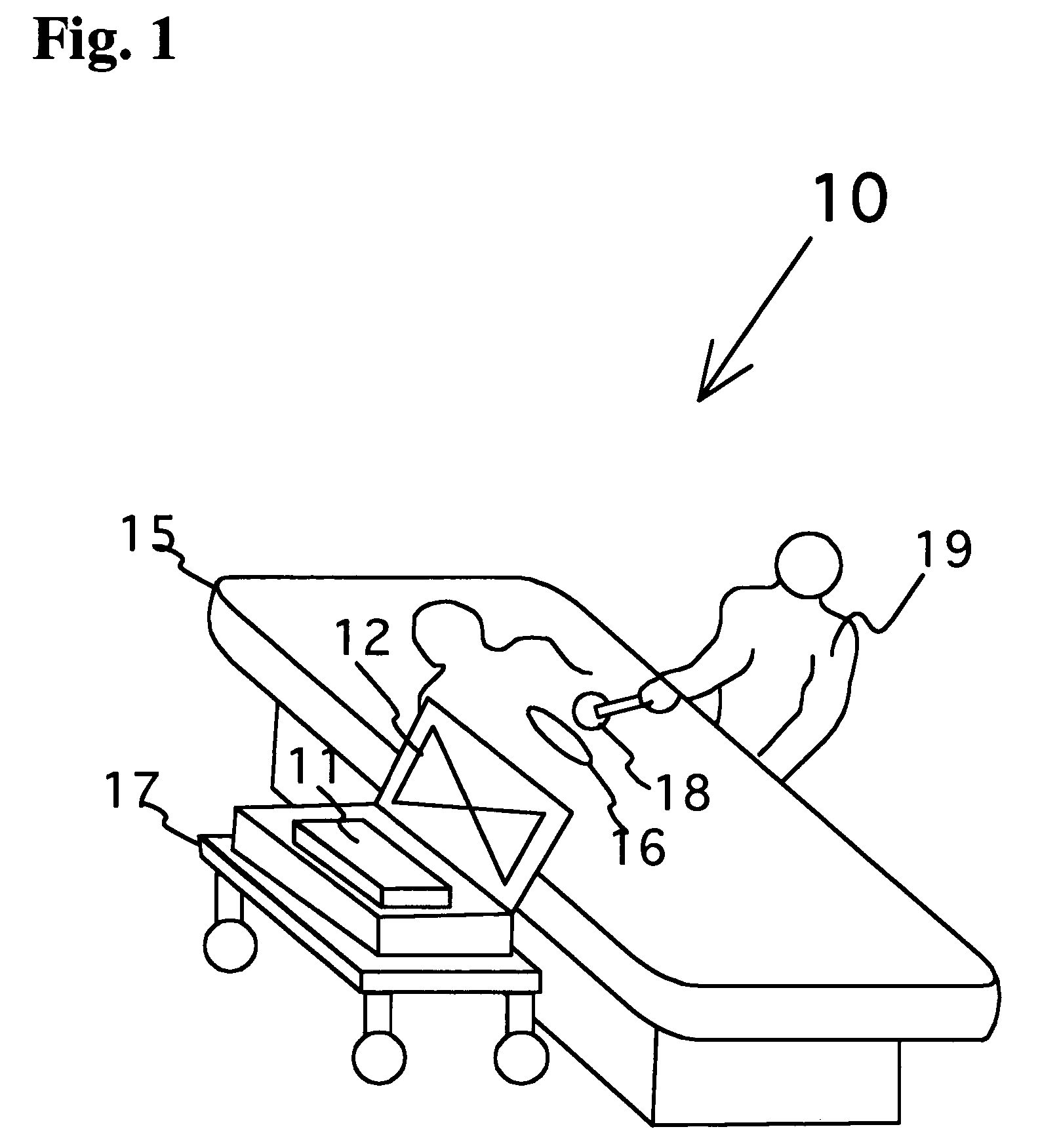

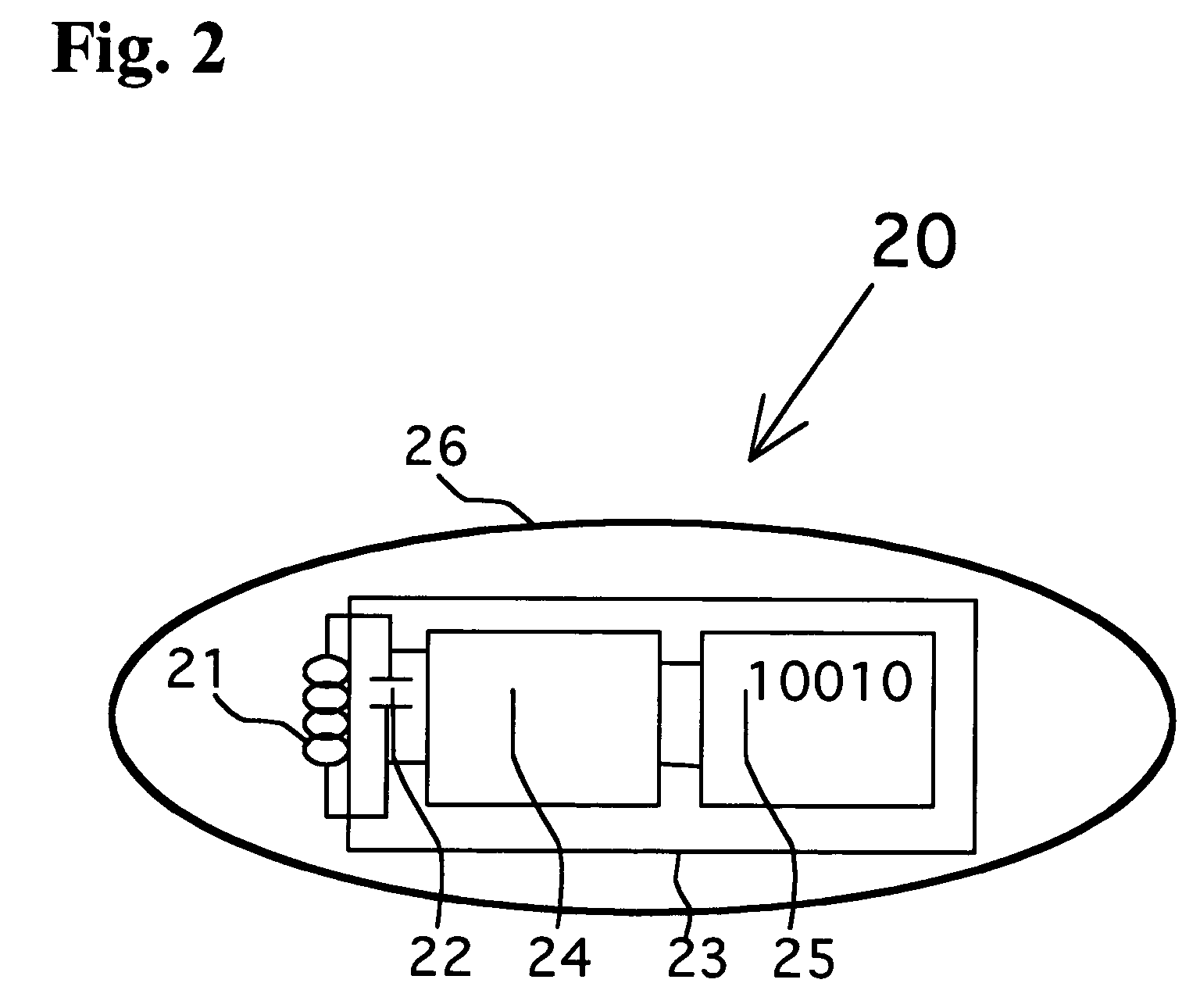

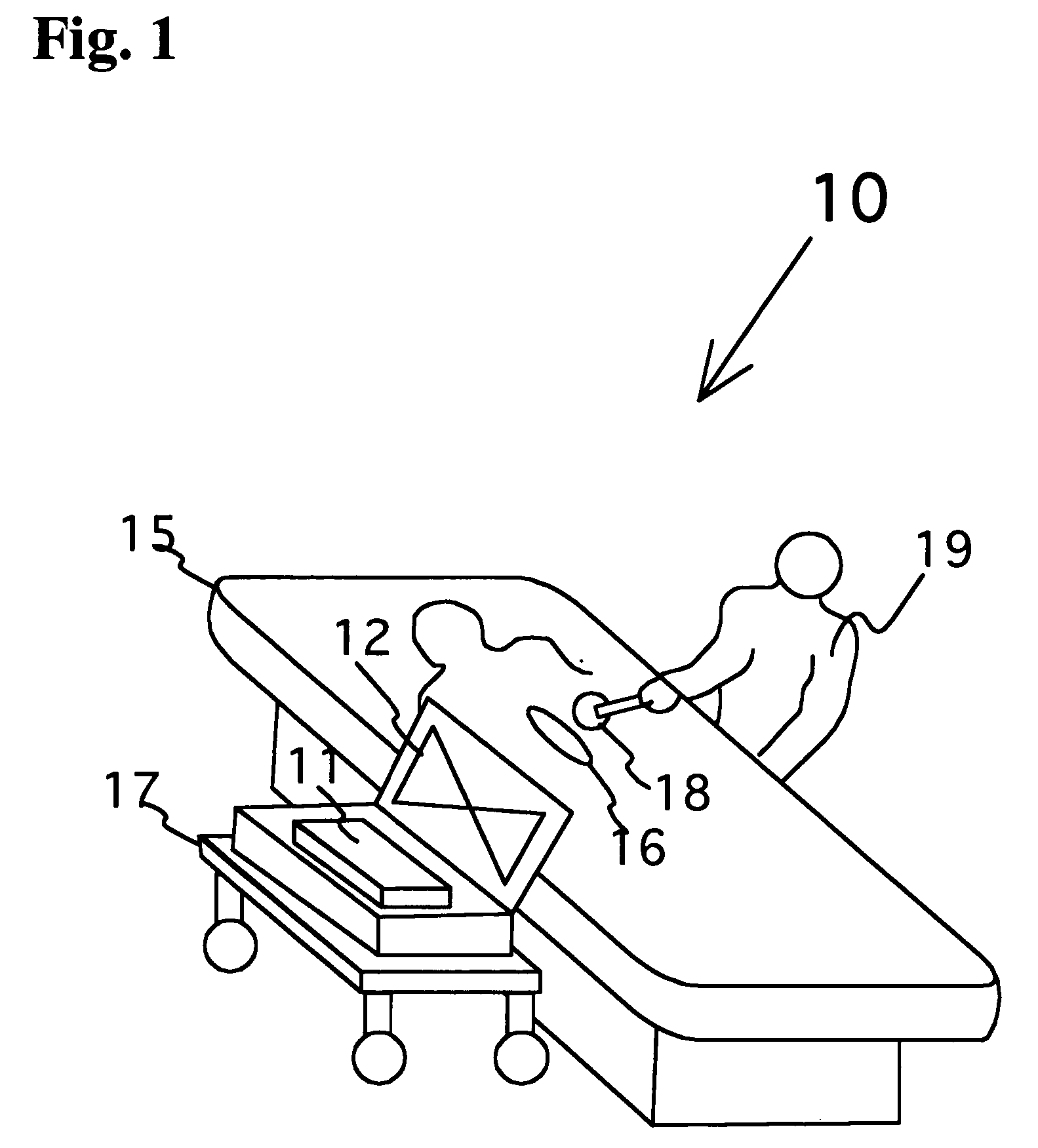

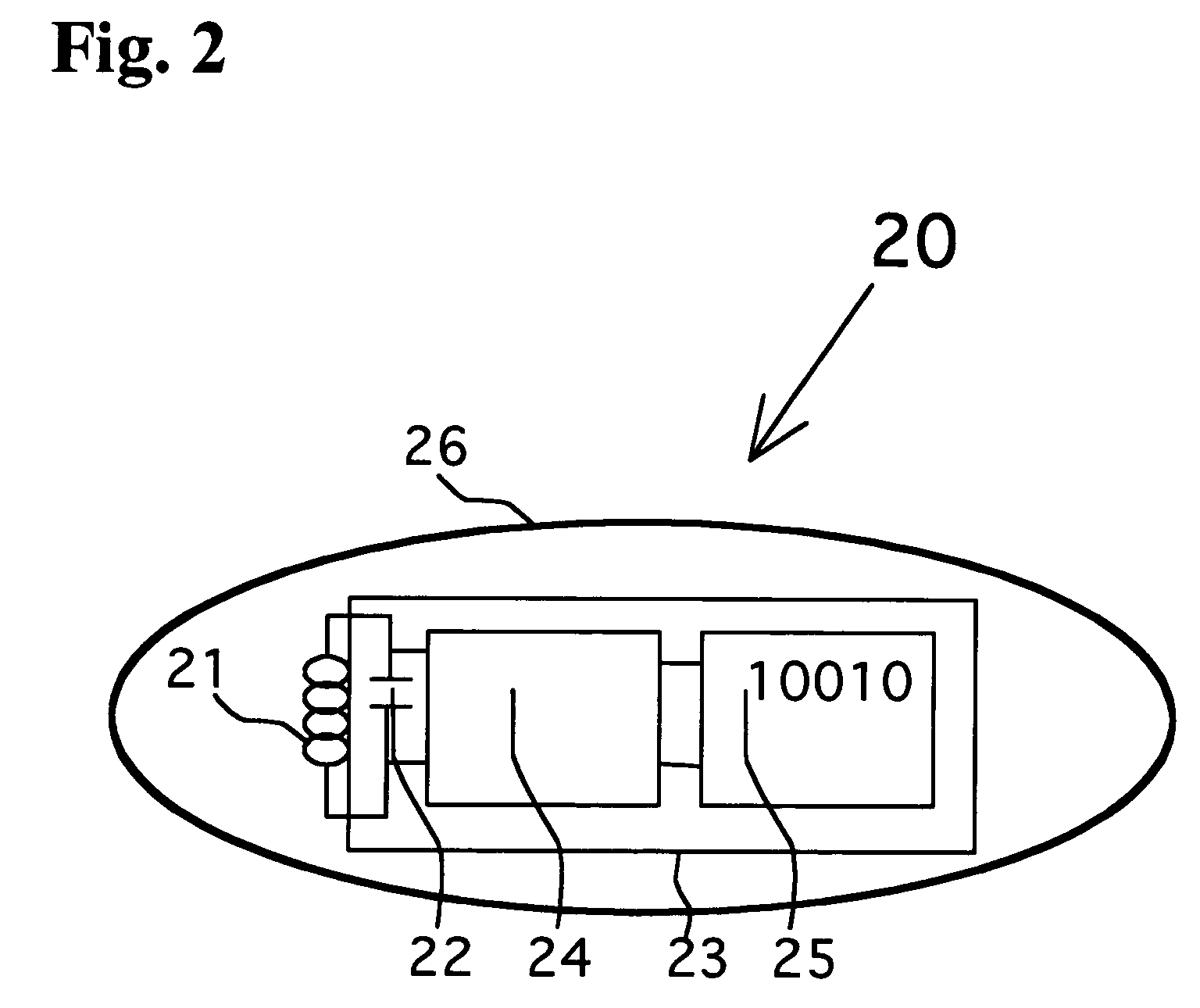

Surgical implement detector utilizing a radio-frequency identification marker

InactiveUS7307530B2Control moreSevere possibilitySurgeryElectric/electromagnetic visible signallingModulation functionEngineering

A radio-frequency surgical implement detection system detects surgical implements in a surgical wound during and at the completion of a surgical procedure. Surgical implements, including surgical sponges or laparotomy pads, gauze pads and metallic surgical instruments, are individually attached to a non battery-powered, encapsulated radio-frequency marker. The marker comprises an integrated chip having a burnt-in memory code, which is broadcast through an antenna using a modulated carrier frequency. The code is received by an interrogating antenna of a detector. The interrogating antenna provides a power pulse, which is received by the antenna of the radio-frequency marker. The power pulse charges a capacitor, which proves power for the read function, carrier frequency modulation function and broadcast function of the integrated chip, permitting each marker-containing implement to be specifically identified.

Owner:FABIAN CARL E

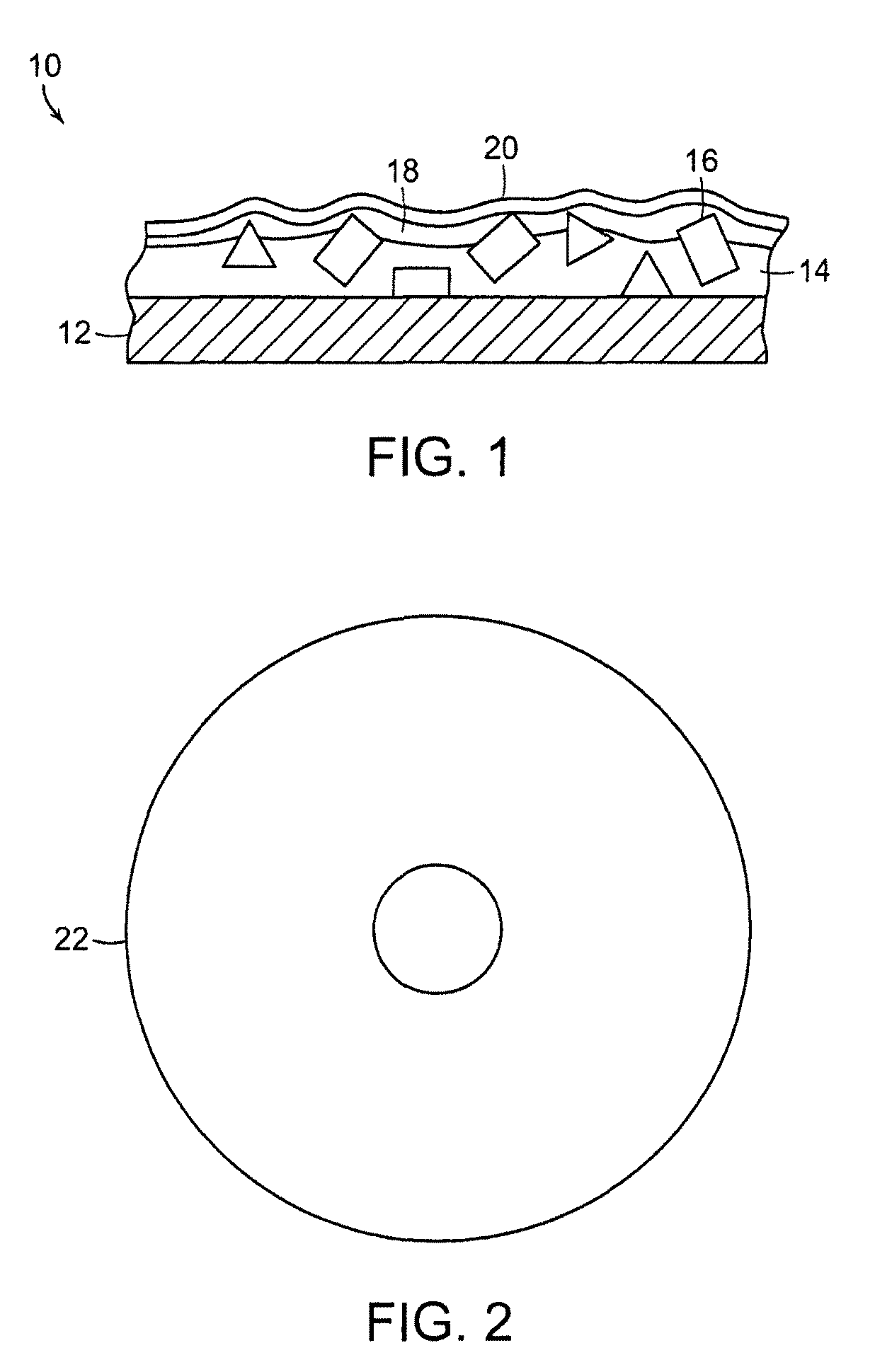

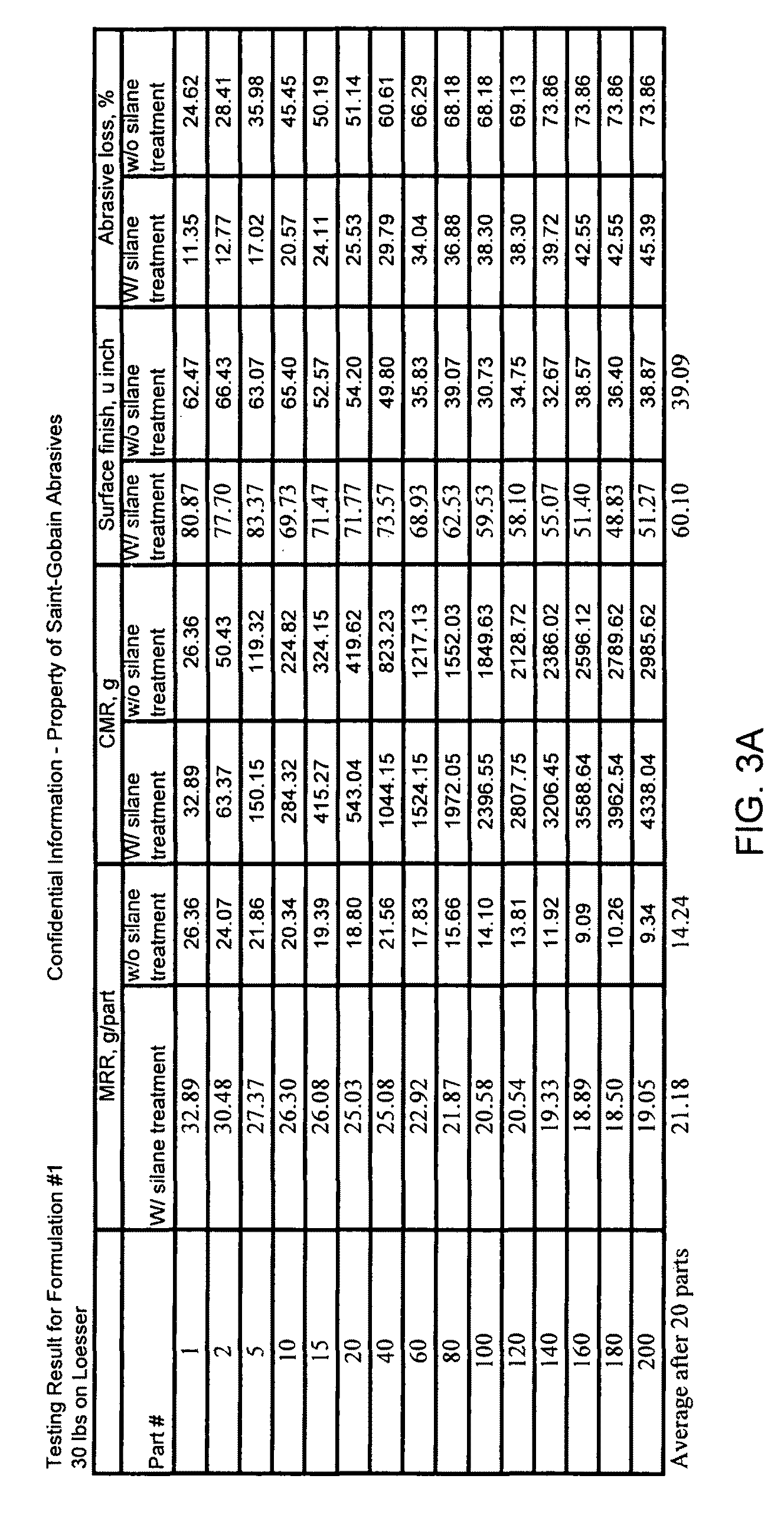

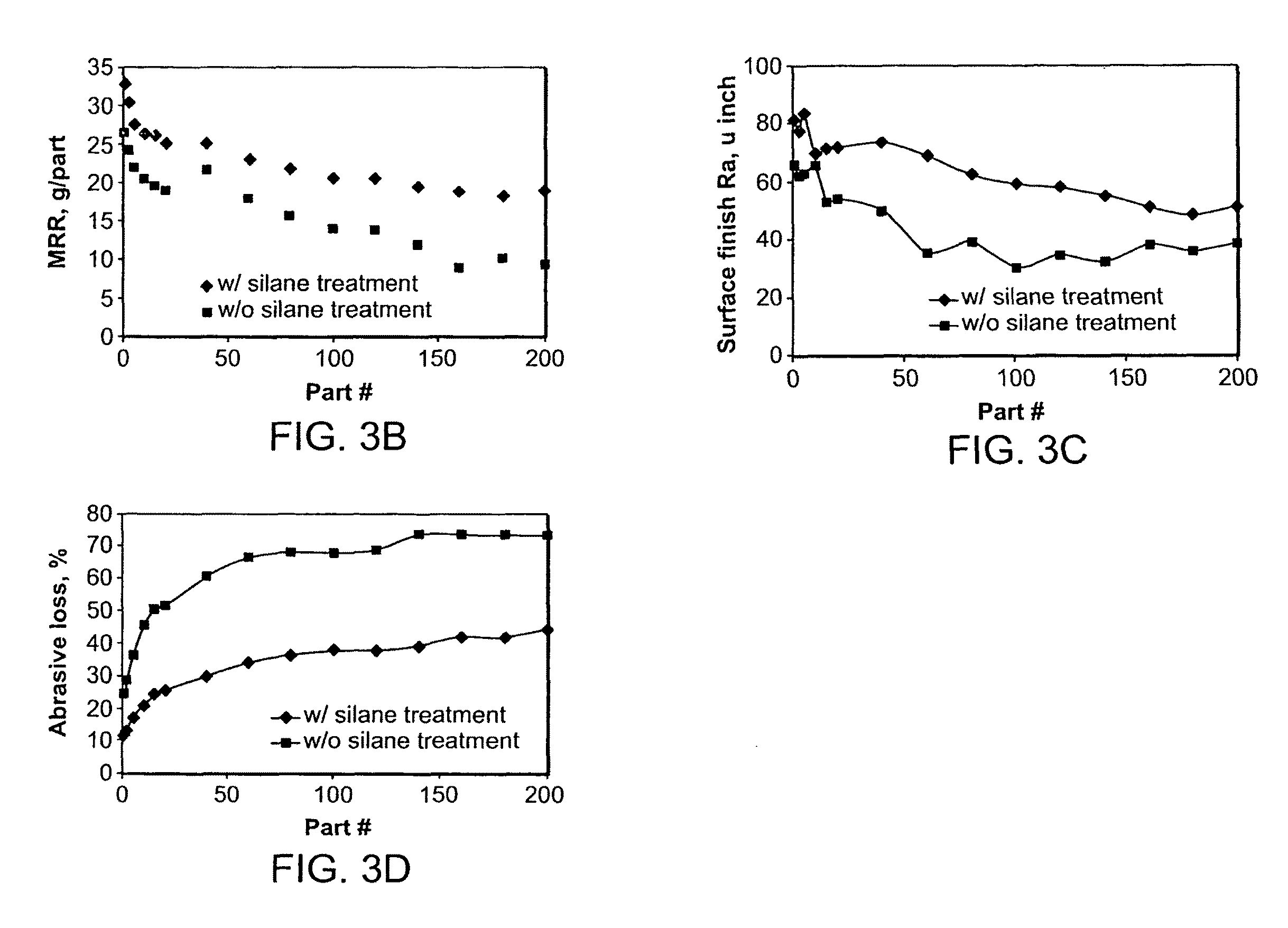

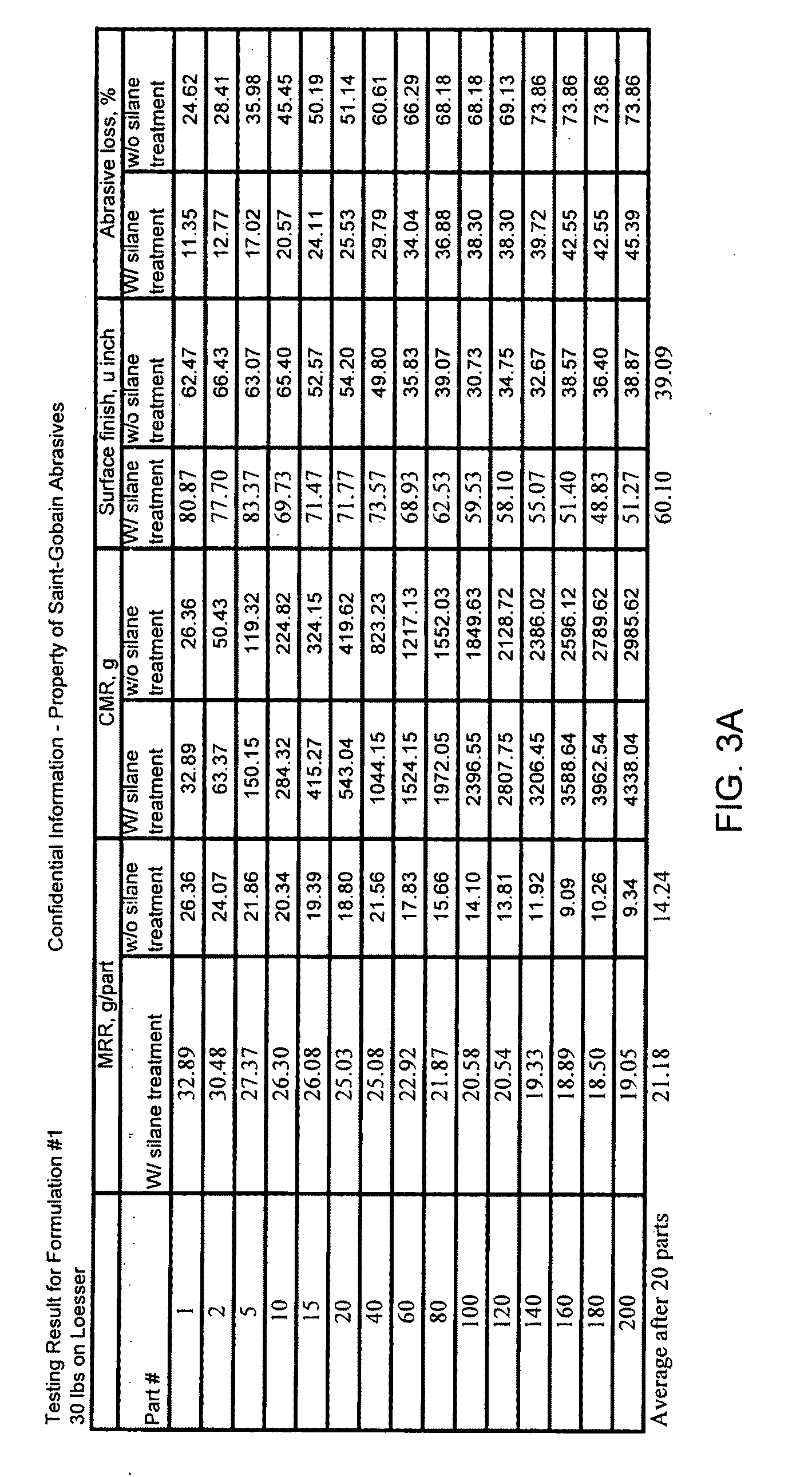

Hydrophilic and hydrophobic silane surface modification of abrasive grains

ActiveUS8021449B2Effective penetrationReduce penetrationPigmenting treatmentOther chemical processesSilanesSurface modification

Owner:SAINT GOBAIN ABRASIVES INC +1

Surgical implement detector utilizing a radio-frequency identification marker

InactiveUS20060187059A1High bandwidthControl moreSurgeryElectric/electromagnetic visible signallingEngineeringFrequency modulation

A radio-frequency surgical implement detection system detects surgical implements in a surgical wound during and at the completion of a surgical procedure. Surgical implements, including surgical sponges or laparotomy pads, gauze pads and metallic surgical instruments, are individually attached to a non battery-powered, encapsulated radio-frequency marker. The marker comprises an integrated chip having a burnt-in memory code, which is broadcast through an antenna using a modulated carrier frequency. The code is received by an interrogating antenna of a detector. The interrogating antenna provides a power pulse, which is received by the antenna of the radio-frequency marker. The power pulse charges a capacitor, which proves power for the read function, carrier frequency modulation function and broadcast function of the integrated chip, permitting each marker-containing implement to be specifically identified.

Owner:FABIAN CARL E

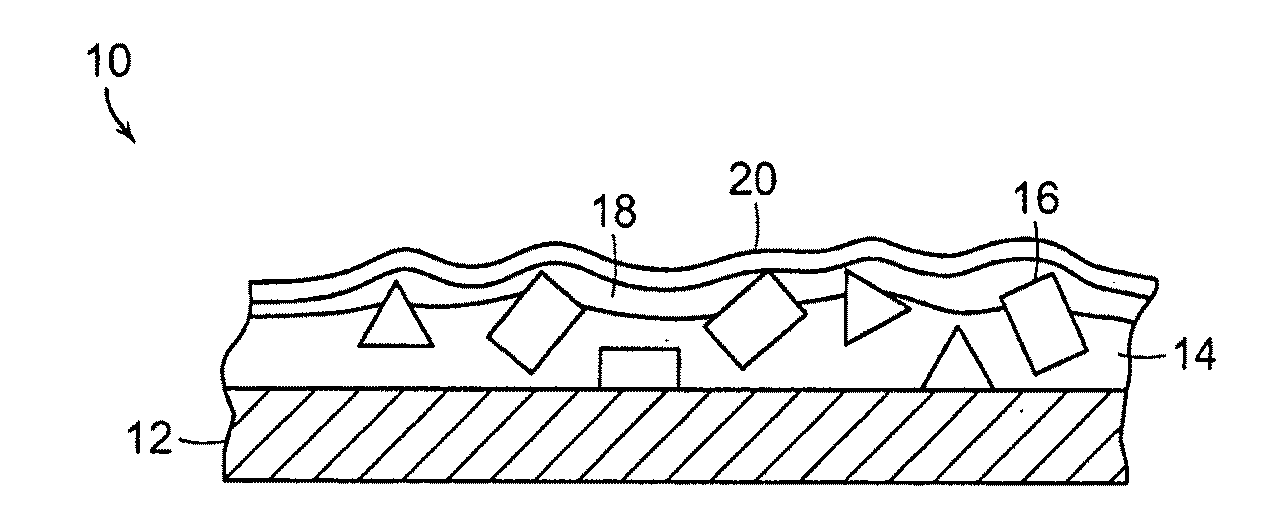

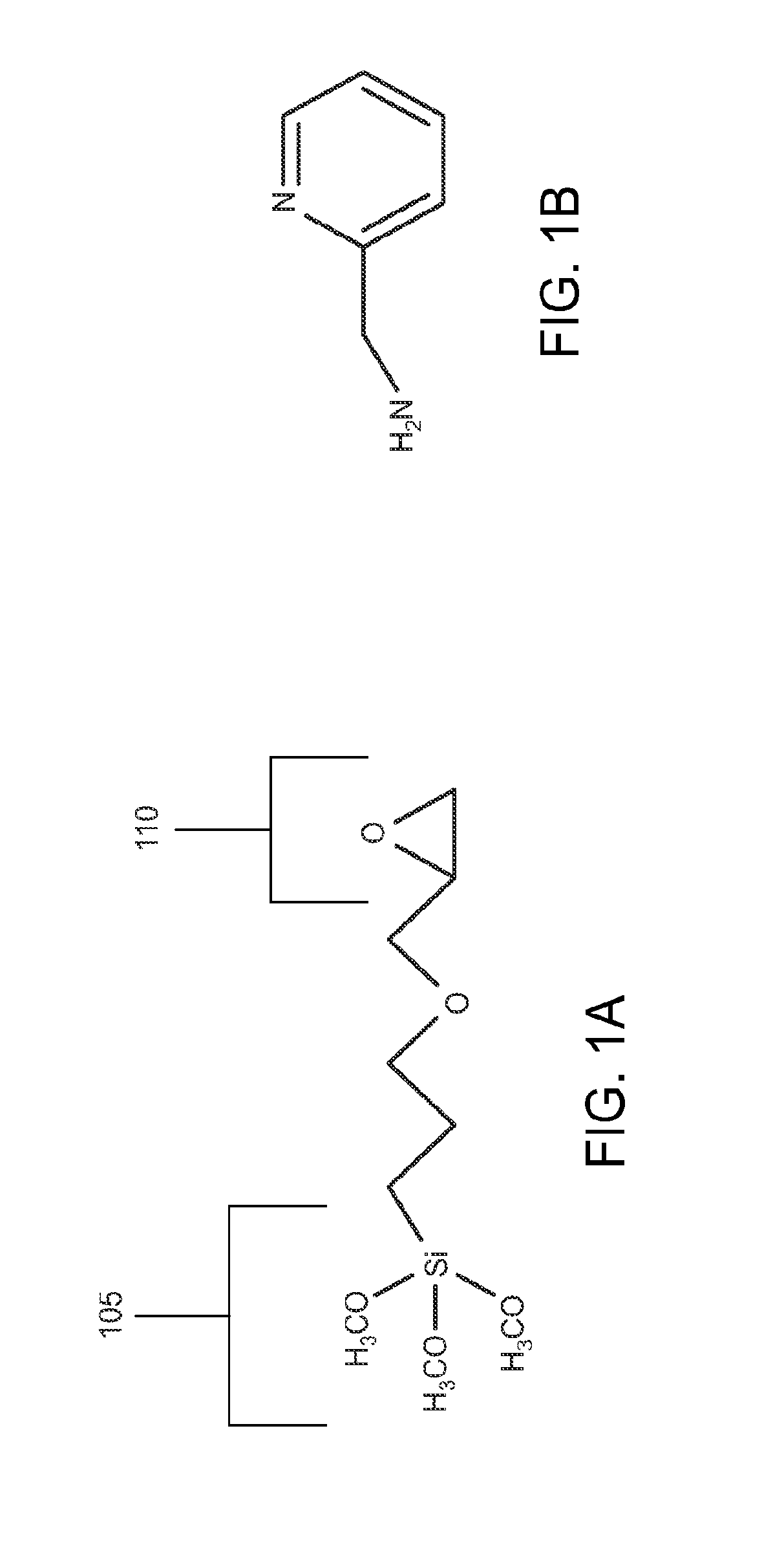

Hydrophilic and hydrophobic silane surface modification of abrasive grains

ActiveUS20090260297A1Effective penetrationReduce penetrationPigmenting treatmentOther chemical processesMaterials scienceSurface modification

A surface-modified abrasive grain includes an abrasive grain as a substrate, and a film on the abrasive grain that includes a relatively hydrophilic silane component and a relatively hydrophobic silane component. The film can be a single film layer or multiple film layers, wherein a film layer most proximal to the abrasive grain has a predominately hydrophilic silane component, and a film layer more distal to the abrasive grain includes predominately a relatively hydrophobic silane component. Coated abrasive products and bonded abrasive products include the surface-modified abrasive grains.

Owner:SAINT GOBAIN ABRASIVES INC +1

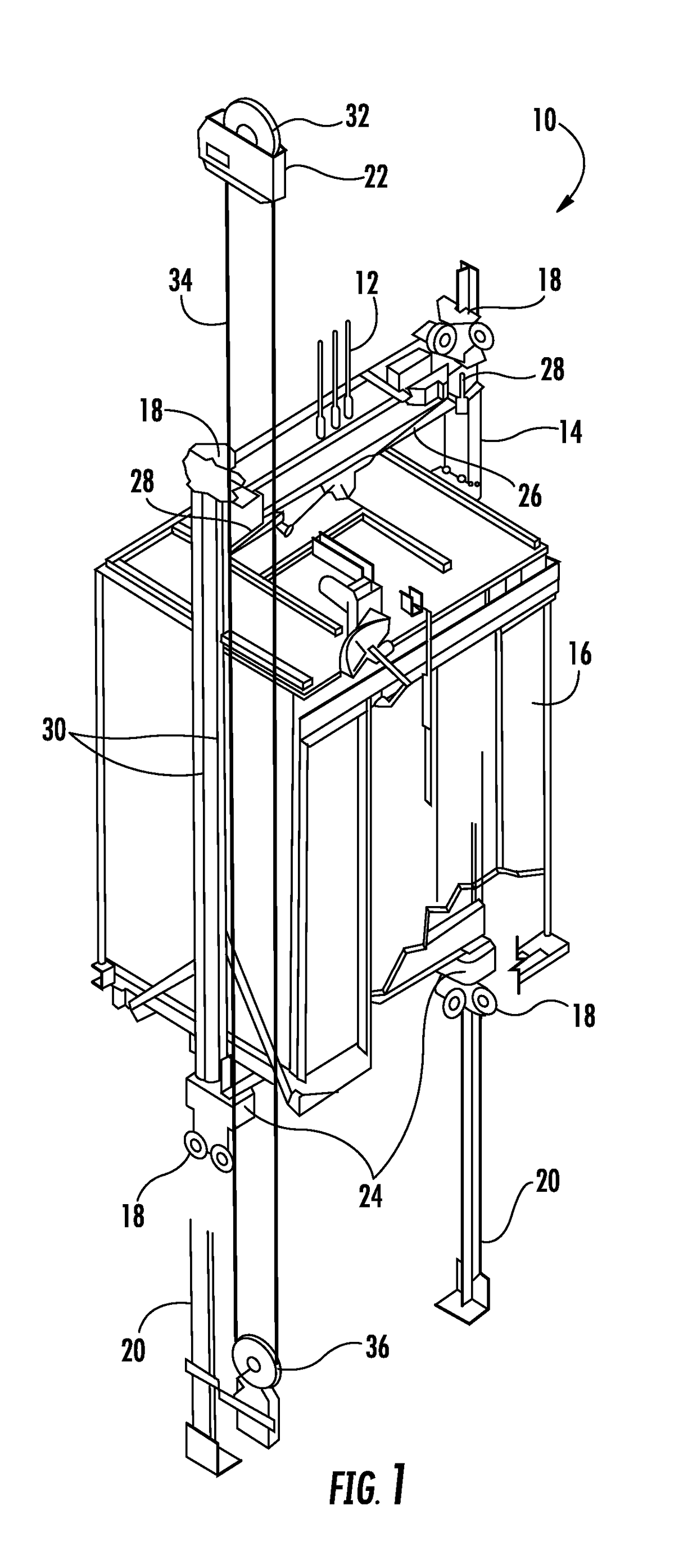

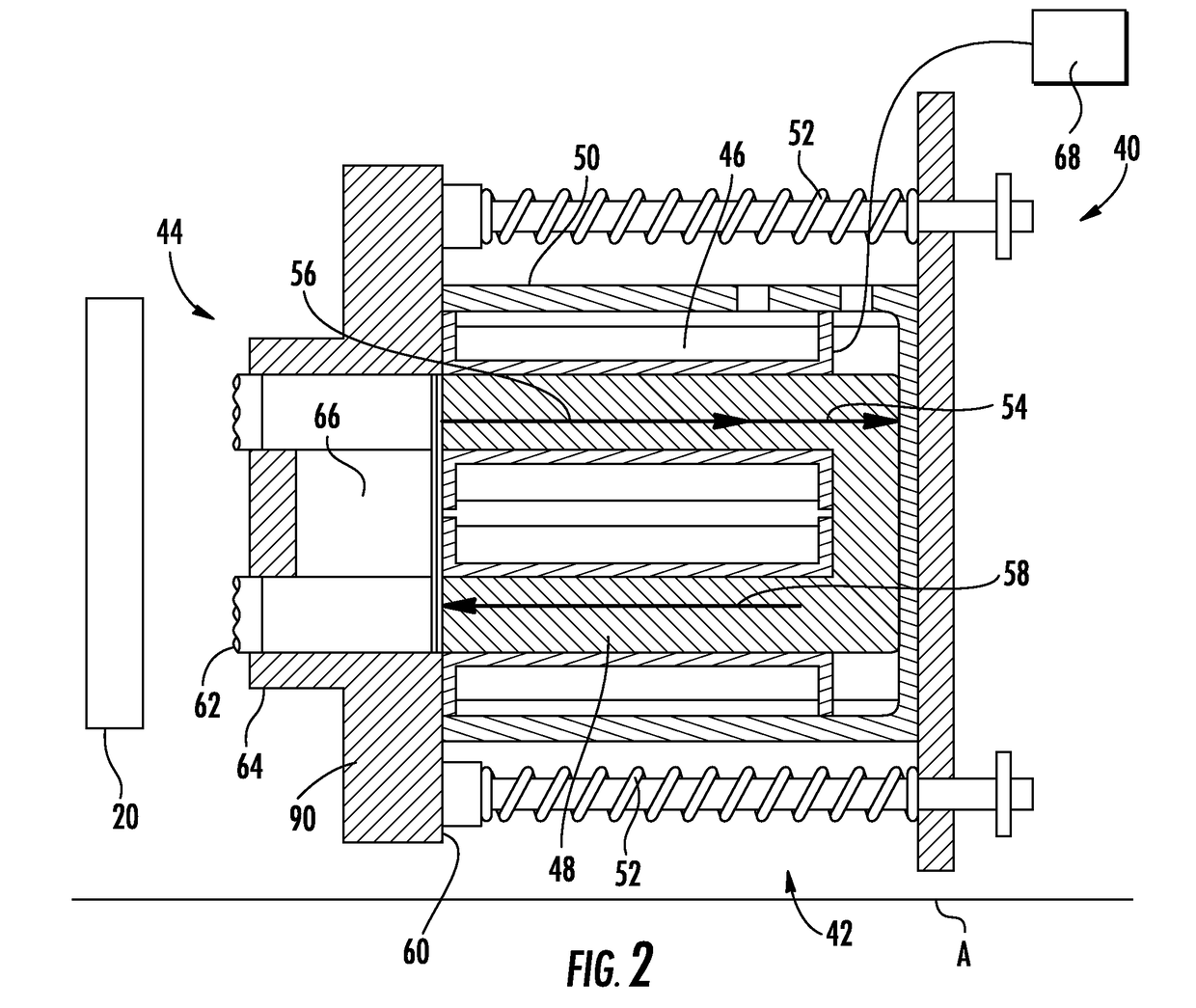

Electronic safety actuator

PendingUS20180327224A1Eliminate retentionImprove gripElevatorsBuilding liftsActuatorElectronic security

The present disclosure relates generally to a selectively operable magnetic braking system having a safety brake adapted to arrest movement when moved from a non-braking state into a braking state, a magnetic brake configured to move between an engaging position and a non-engaging position, the magnetic brake, when in the engaging position, moving the safety brake from the non-braking state into the braking state, and an electromagnetic component configured to hold the magnetic brake with a hold power in the non-engaging position.

Owner:OTIS ELEVATOR CO

Chromatographic materials for the separation of unsaturated molecules

ActiveUS20140319057A1Superior retention , peak capacity and peak shapeImprove peak capacity and tailingIon-exchange process apparatusSilicon organic compoundsChemistryStationary phase

The present disclosure relates to a method of separating a compound of interest, particularly unsaturated compound(s) of interest, from a mixture. The compound is separated using a column having a chromatographic stationary phase material for various different modes of chromatography containing a first substituent and a second substituent. The first substituent minimizes compound retention variation over time under chromatographic conditions. The second substituent chromatographically and selectively retains the compound by incorporating one or more aromatic, polyaromatic, heterocyclic aromatic, or polyheterocyclic aromatic hydrocarbon groups, each group being optionally substituted with an aliphatic group.

Owner:WATERS TECH CORP

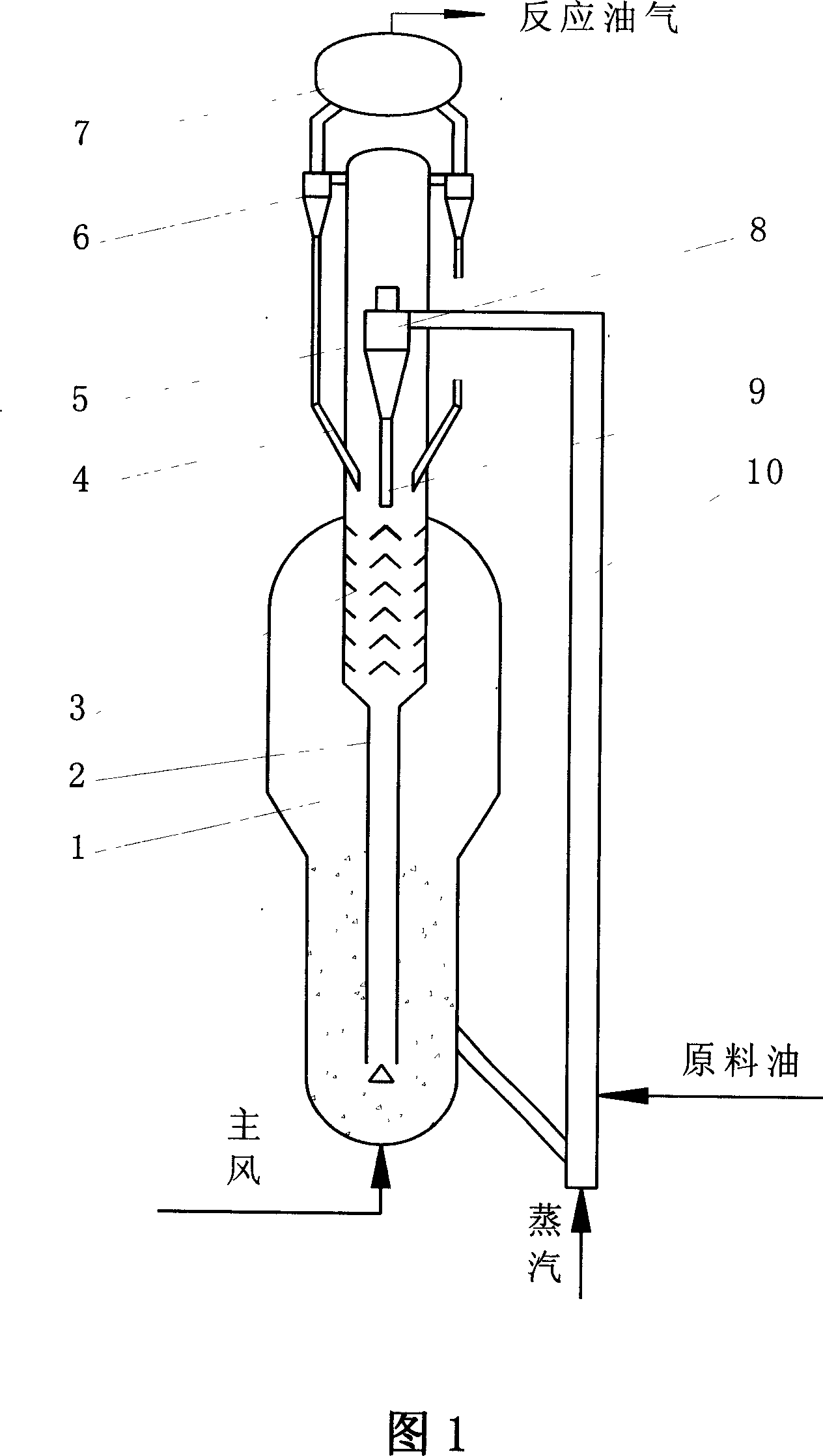

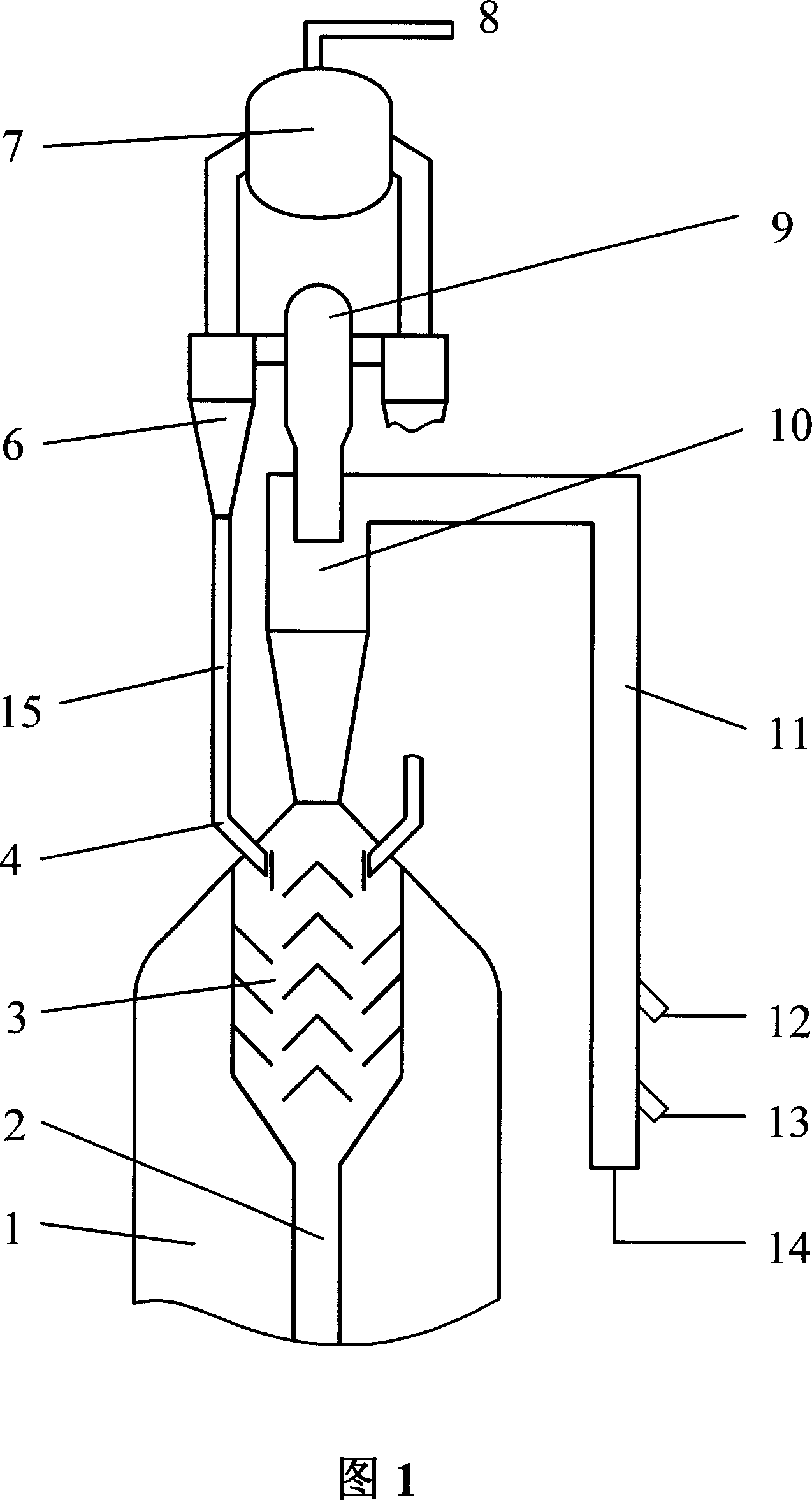

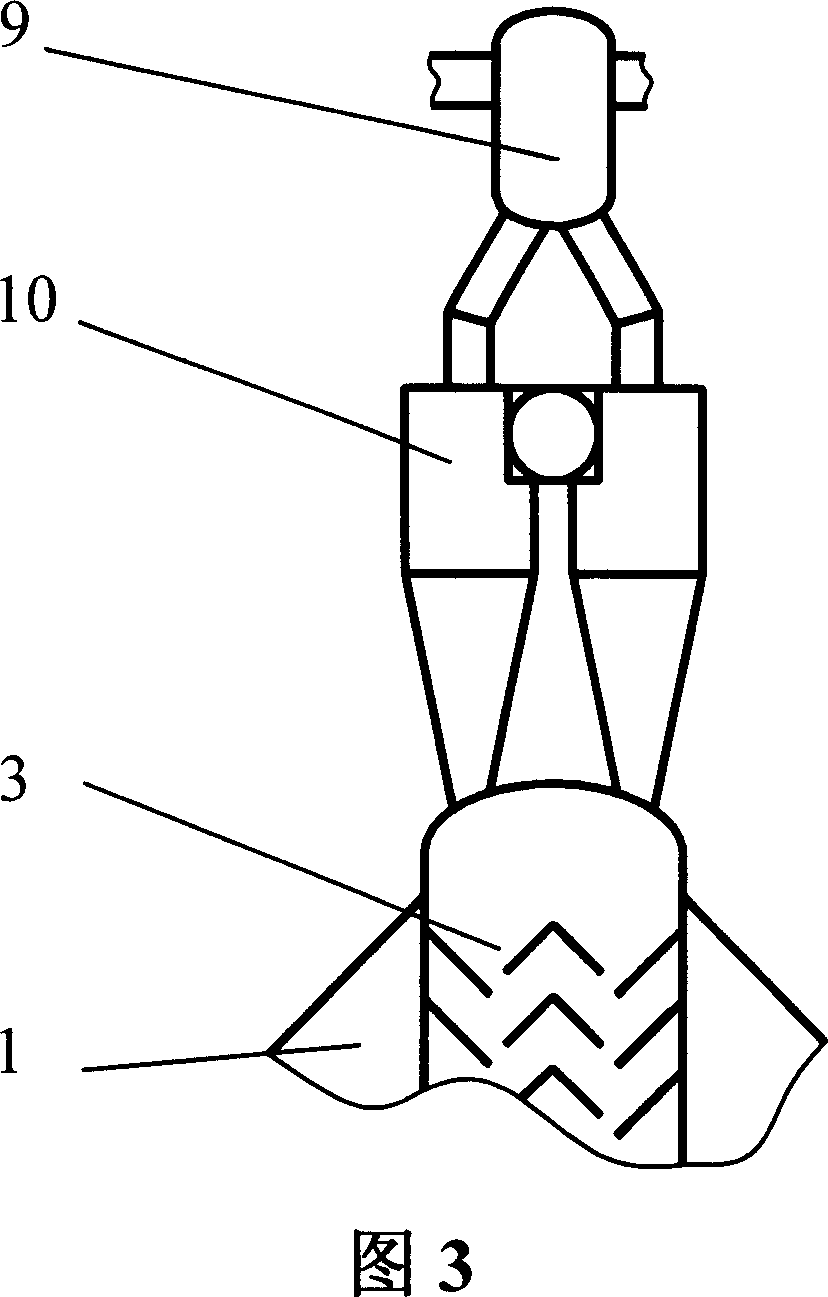

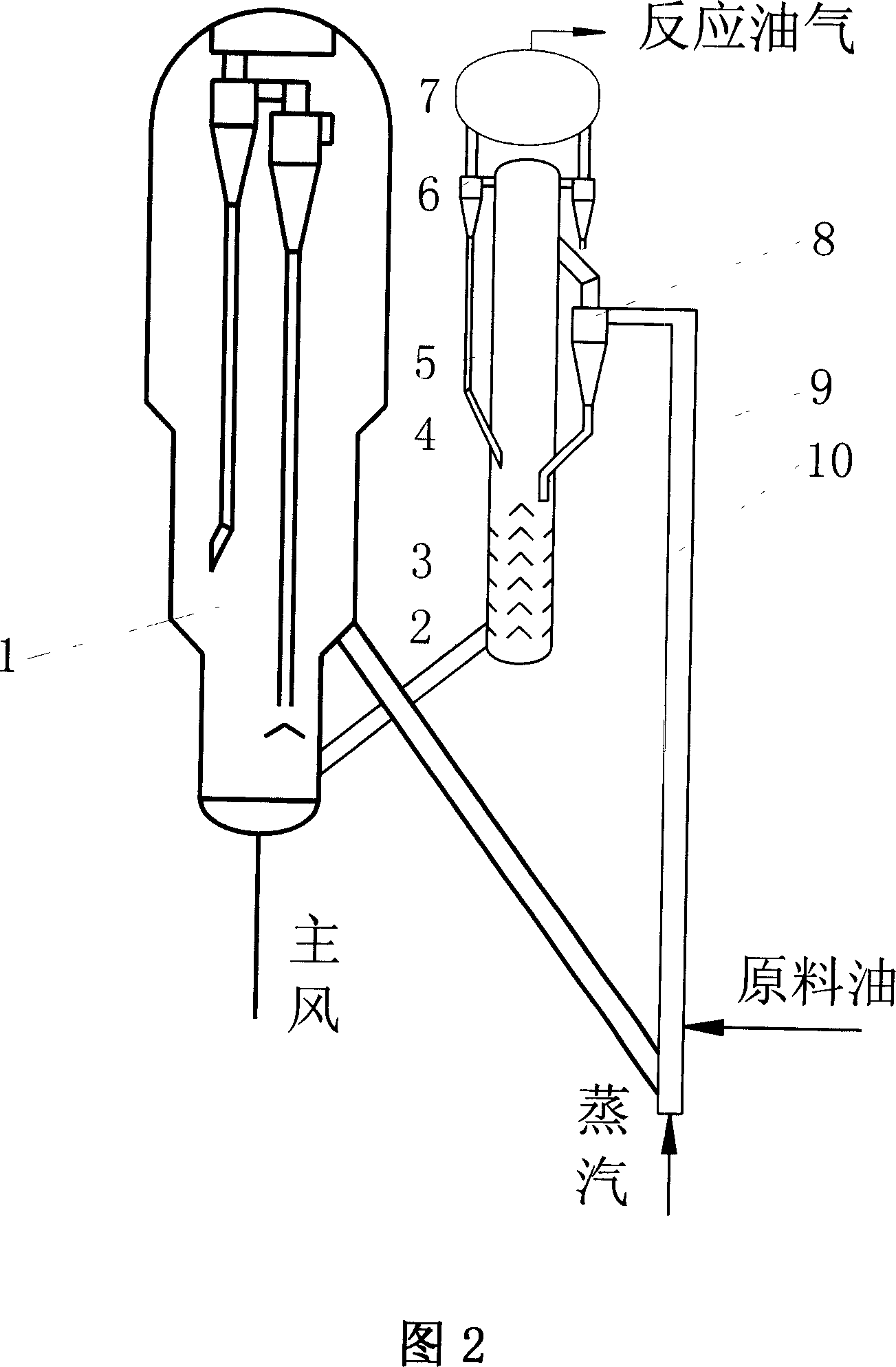

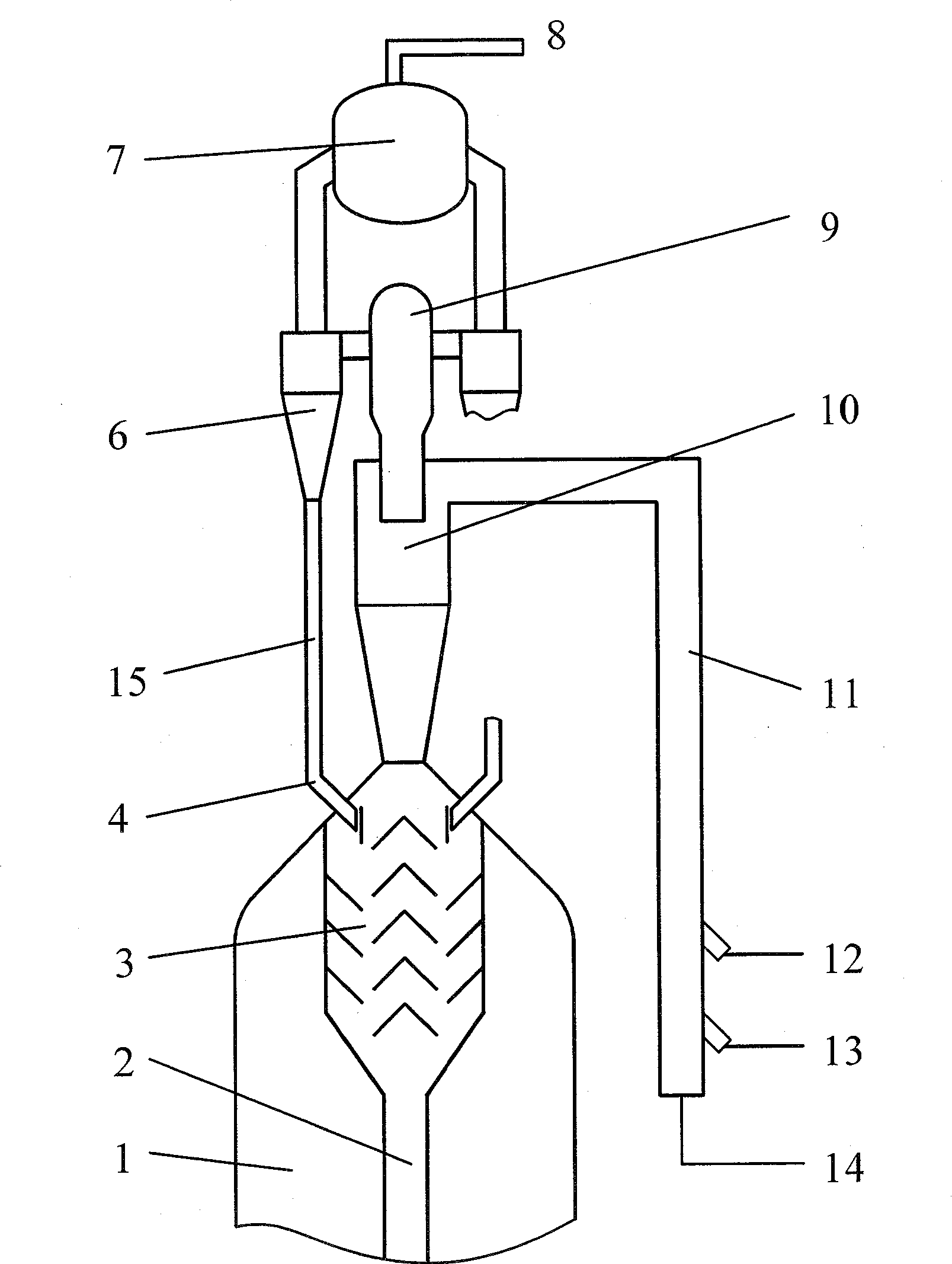

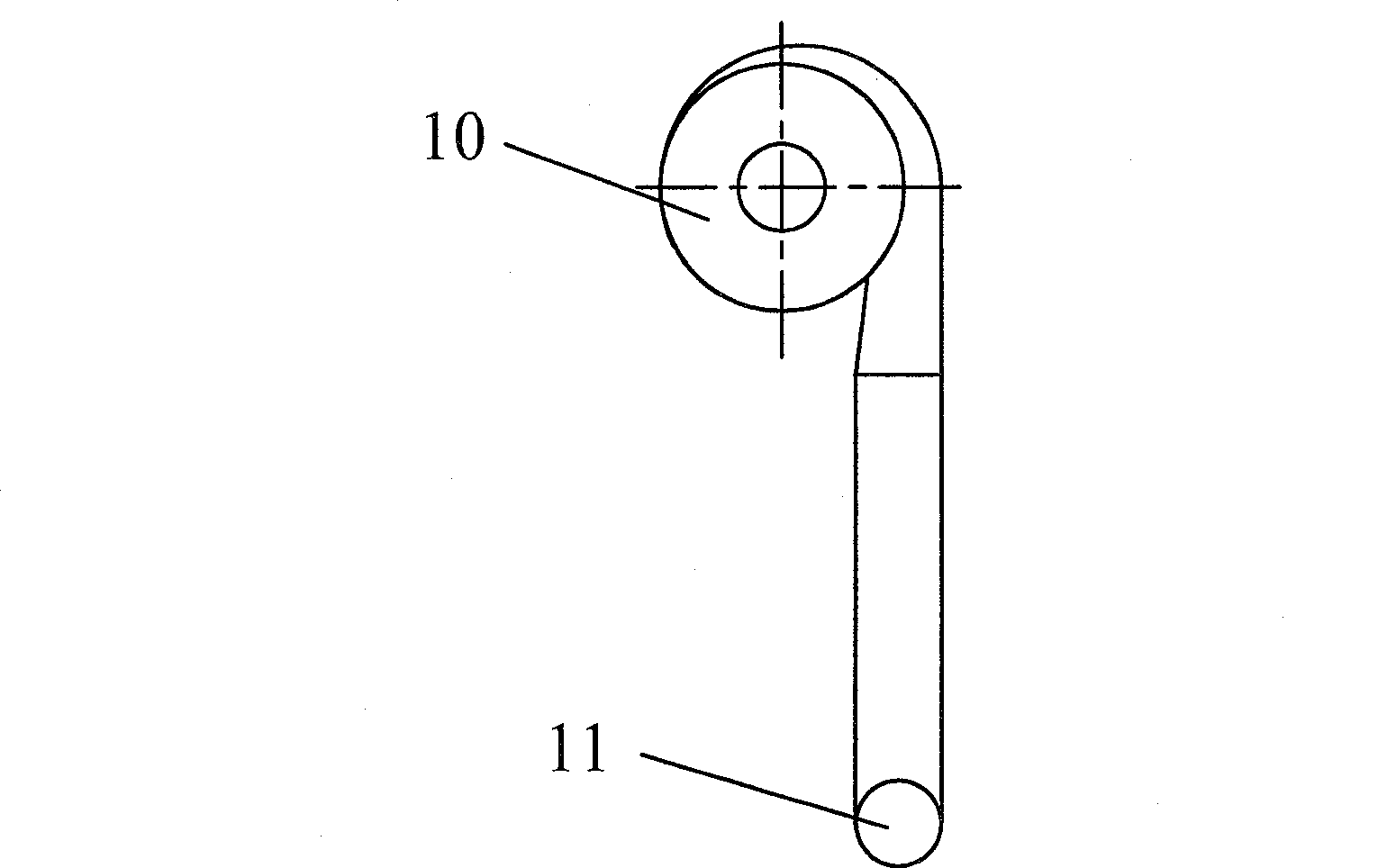

Catalytic cracker with internal tubular settler

The present invention is fluid catalytic cracker with fast separation of oil gas from catalyst. The fluid catalytic cracker has a riser with outlet connected to thick coiled pipe inside the tube settler, a stripping device below the tube settler, a catalyst regenerator connected through pipe tot lower end of the stripping device, and a top coiled pipe outside the tube settler. The fluid catalytic cracker can realize the efficient and fast gas-solid separation in the separation efficiency as high as 99.99 %, reduce average oil gas residence time to less than 2-3 sec and decrease scaling, and has compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

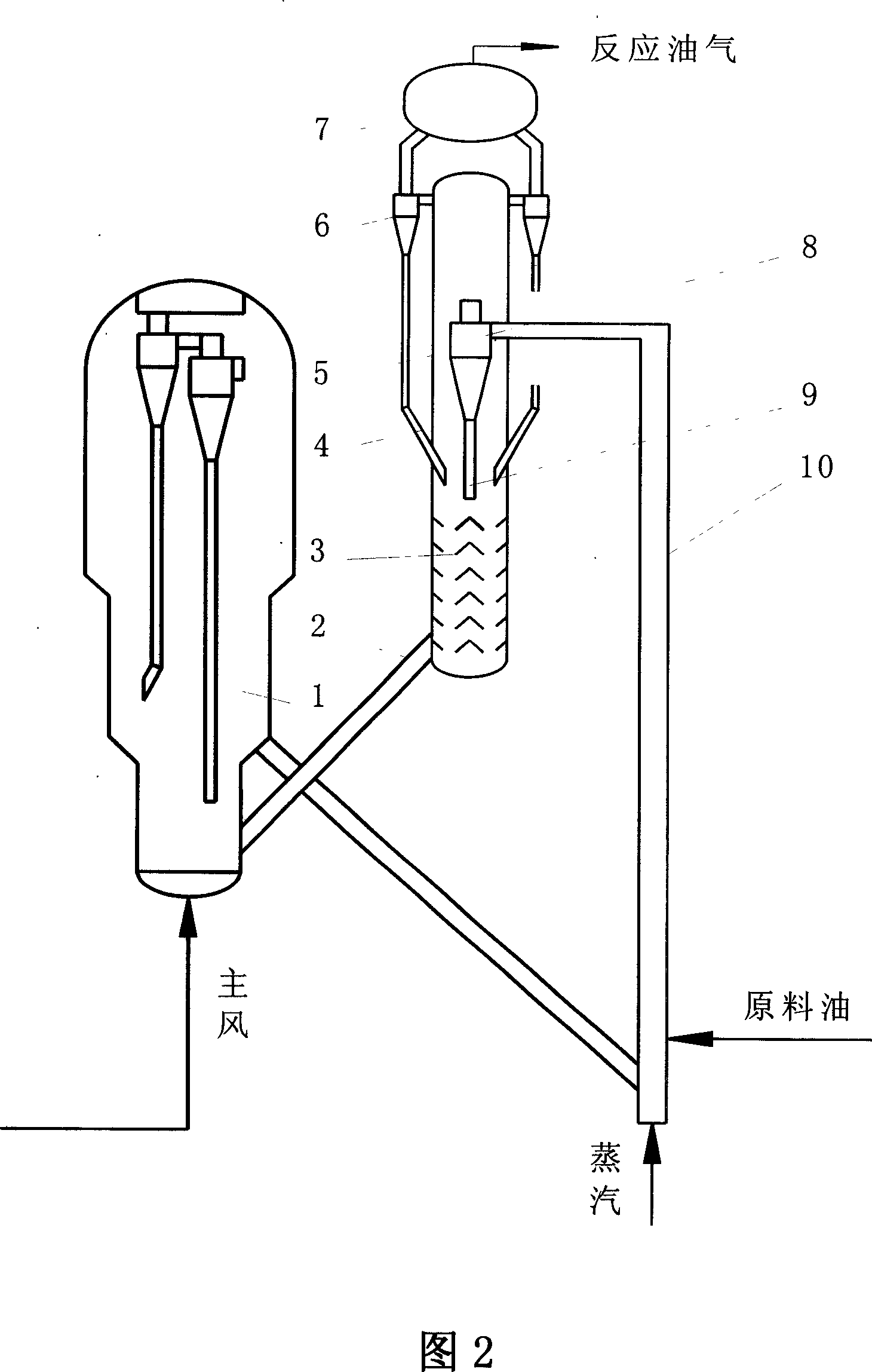

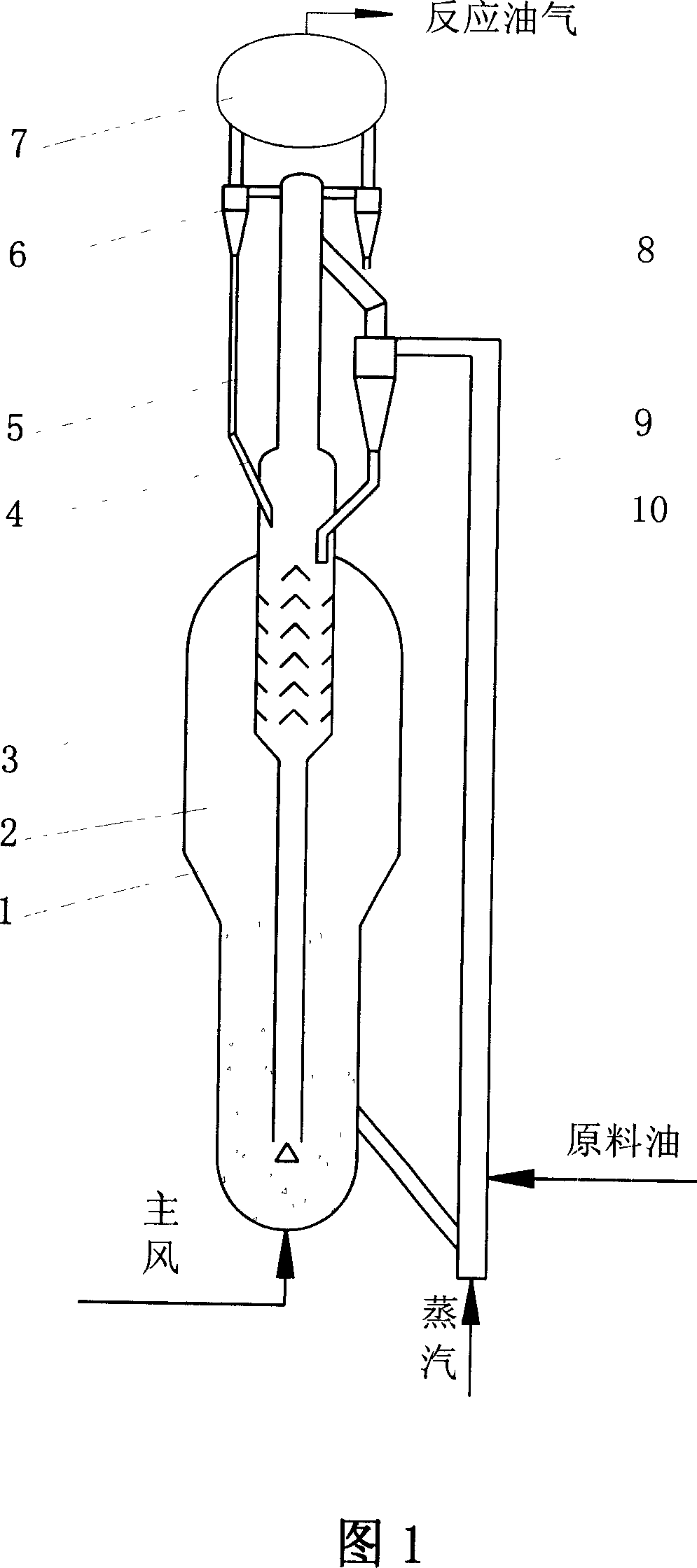

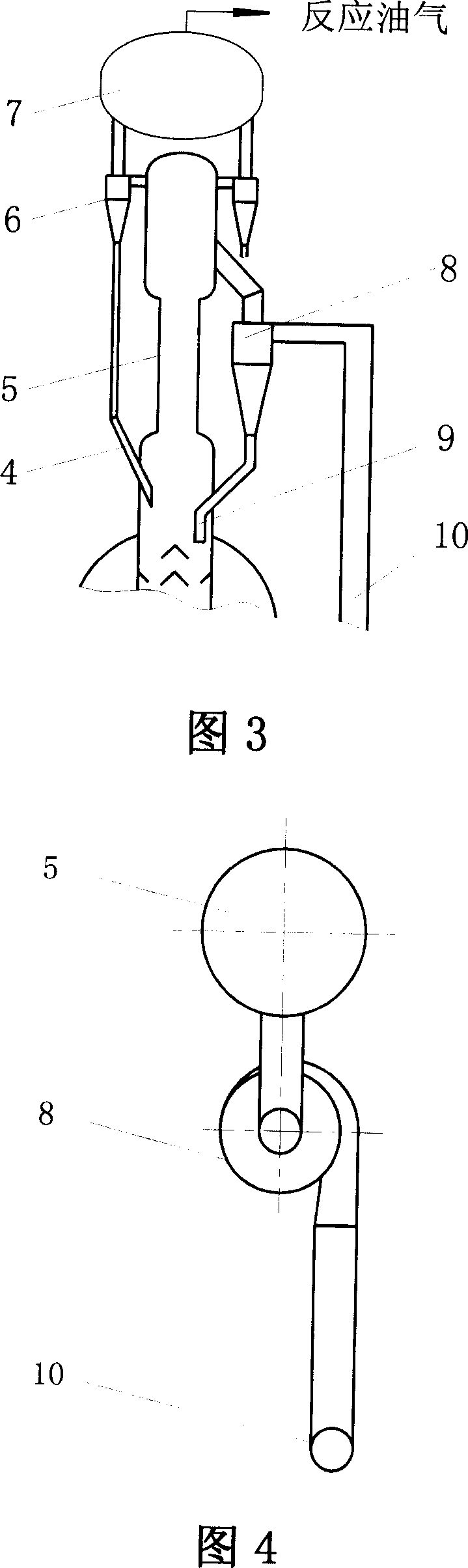

Catalytic cracker without settler

InactiveCN1974728AGood effectEasy to separateCatalytic crackingChemical/physical processesResidence timeHydrocarbon

The present invention relates to fast oil gas and catalyst separation in hydrocarbon material fluid catalytic cracking, and is especially one catalytic cracker without settler. The catalytic cracker without settler features the stripping unit with lower end connected via a vertical pipe to one regenerator, the first cyclone separator connected to the upper end of the stripping unit, the riser tube with outlet connected to the first cyclone separator via pipeline, and the second cyclone separator connected serially to the upper end of the first cyclone separator and with material feeding structure communicated to the stripping unit. The catalytic cracker can realize the efficient fast gas-solid separation in the separating efficiency up to 99.99 % and average oil gas residence time shortened to 2-3 sec, and has less scaling, compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

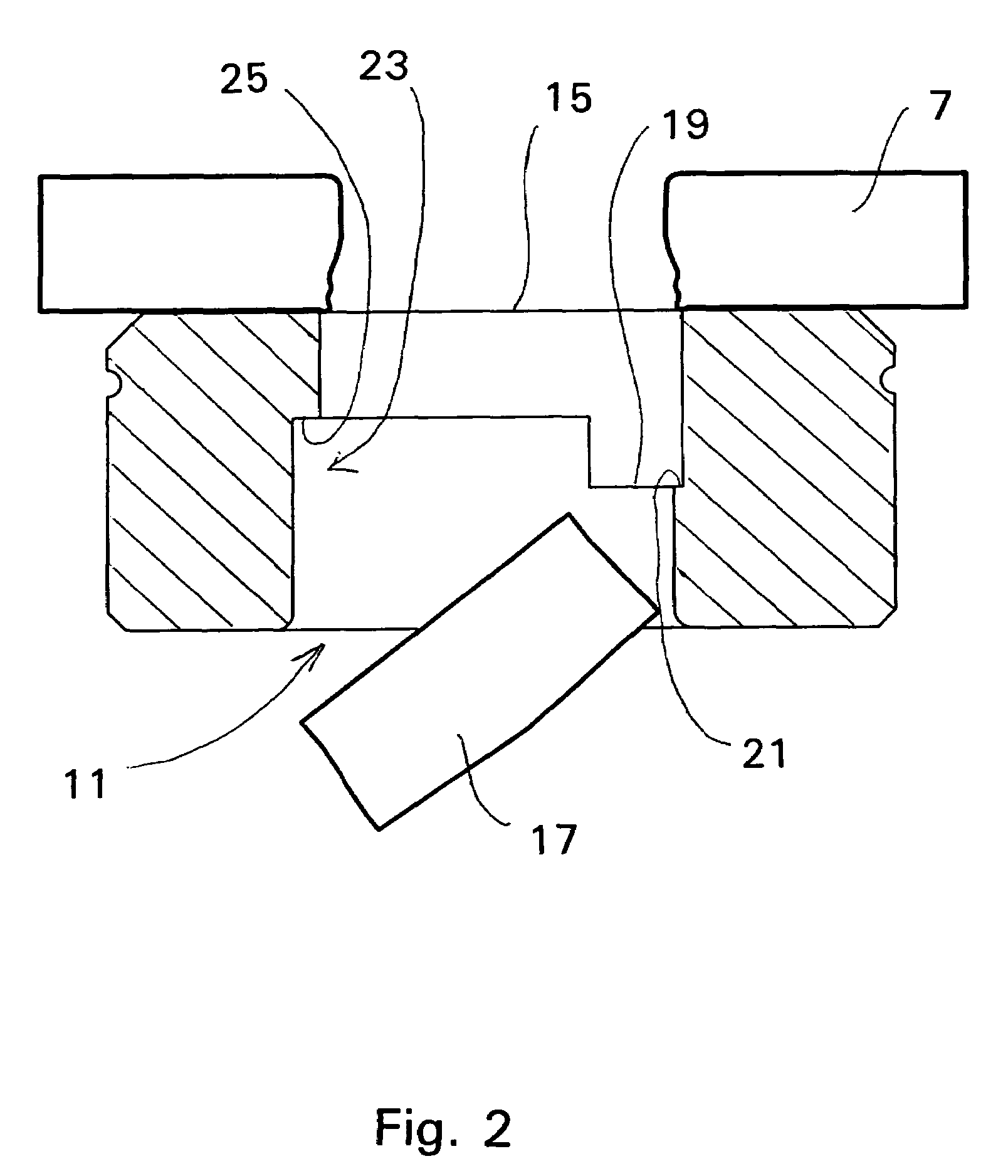

Slug pulling preventing tooling die

ActiveUS7210384B2Eliminate the problemEasy to eliminatePerforating toolsMetal working apparatusMetal machiningMetal sheet

A punch and die tooling apparatus commonly used by metal fabricators for creating holes, passages and cavities in metal plate, the die having a unique internal bore which relieves the problem of slug pulling to ensure that a slug punched out of a metal sheet is not retained on the punch face to interfere with further operation of the apparatus. The die is provided with a substantially horizontal ridge and a corresponding horizontal land and relief space formed within the bore to facilitate tipping of the slug relative to the punch and thereby break any attachment between the slug and the punch face which causes slug pulling.

Owner:DEGELMAN IND LP

Catalytic cracker with external tubular settler

The present invention is fluid catalytic cracker with fast separation of oil gas from catalyst. The fluid catalytic cracker has a riser with outlet connected to thick coiled pipe inside the tube settler, a stripping device below the tube settler, a catalyst regenerator connected through pipe tot lower end of the stripping device, and a top coiled pipe outside the tube settler. The fluid catalytic cracker can realize the efficient and fast gas-solid separation in the separation efficiency as high as 99.99 %, reduce average oil gas residence time to less than 2-3 sec and decrease scaling, and has compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

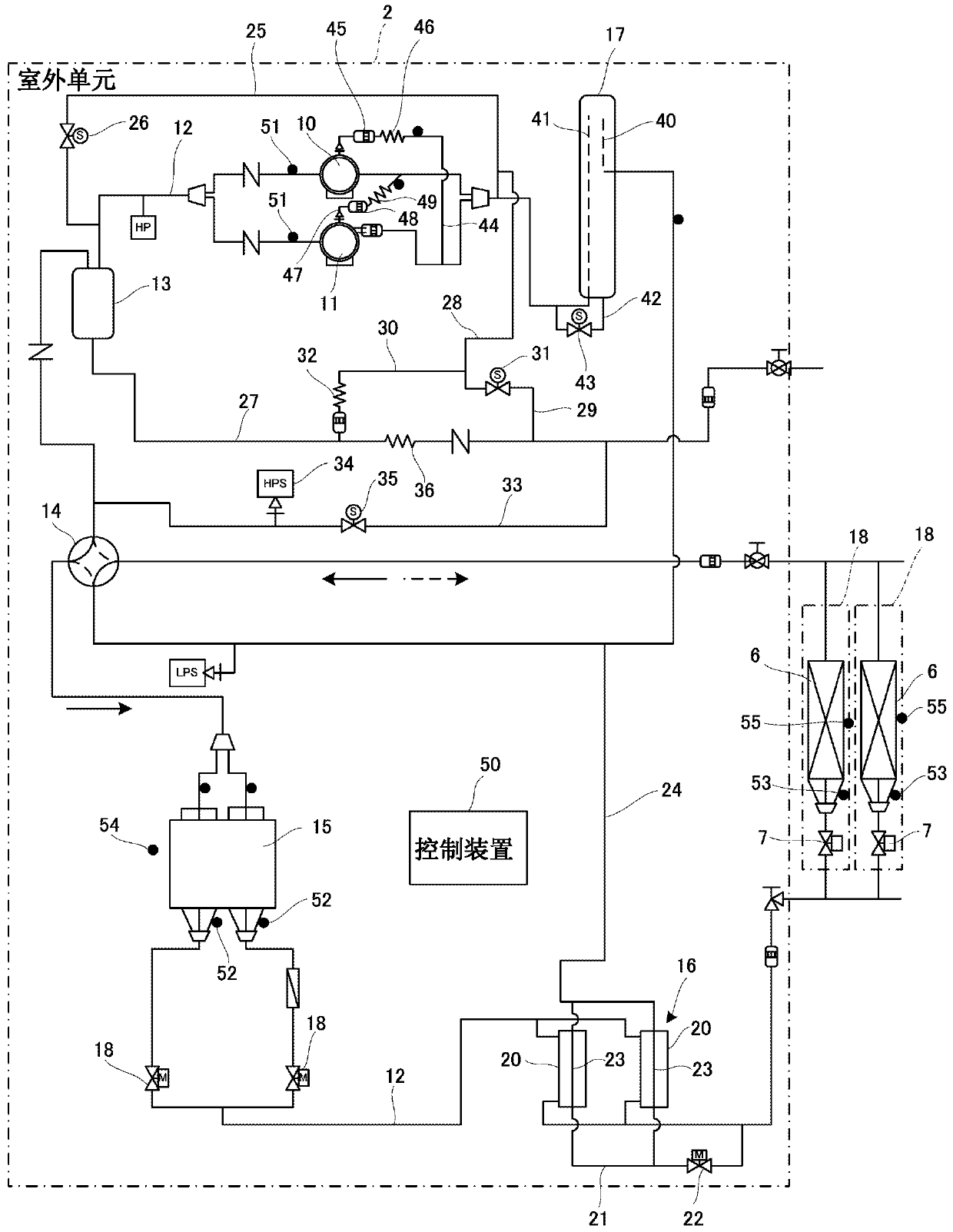

Outdoor unit for air-conditioning apparatus, and air-conditioning apparatus

ActiveCN103574855AGuaranteed heating effectEliminate retentionMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

An outdoor unit for an air-conditioning apparatus includes an outdoor heat exchanger; a compressor; a refrigerant pipe configured to couple the outdoor heat exchanger and the compressor with an indoor unit including an indoor heat exchanger; and a control unit that determines whether the heating capacity of the indoor unit performing a heating operation is decreased by the refrigerant stagnated in the indoor heat exchanger.

Owner:FUJITSU GENERAL LTD

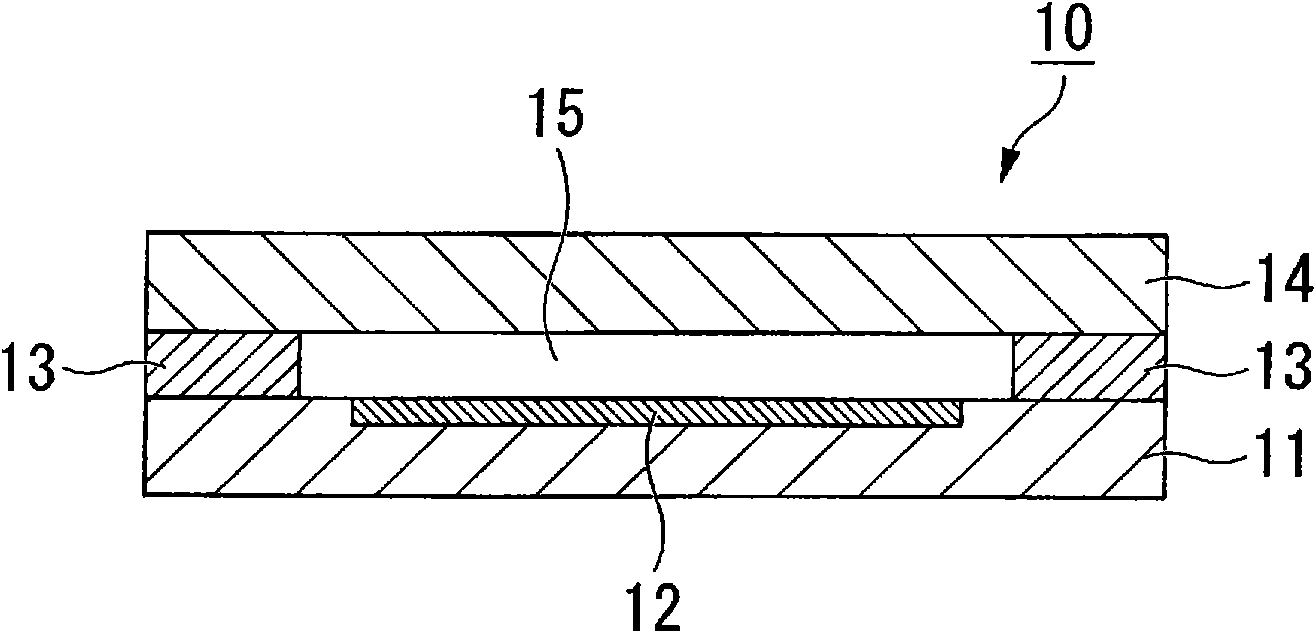

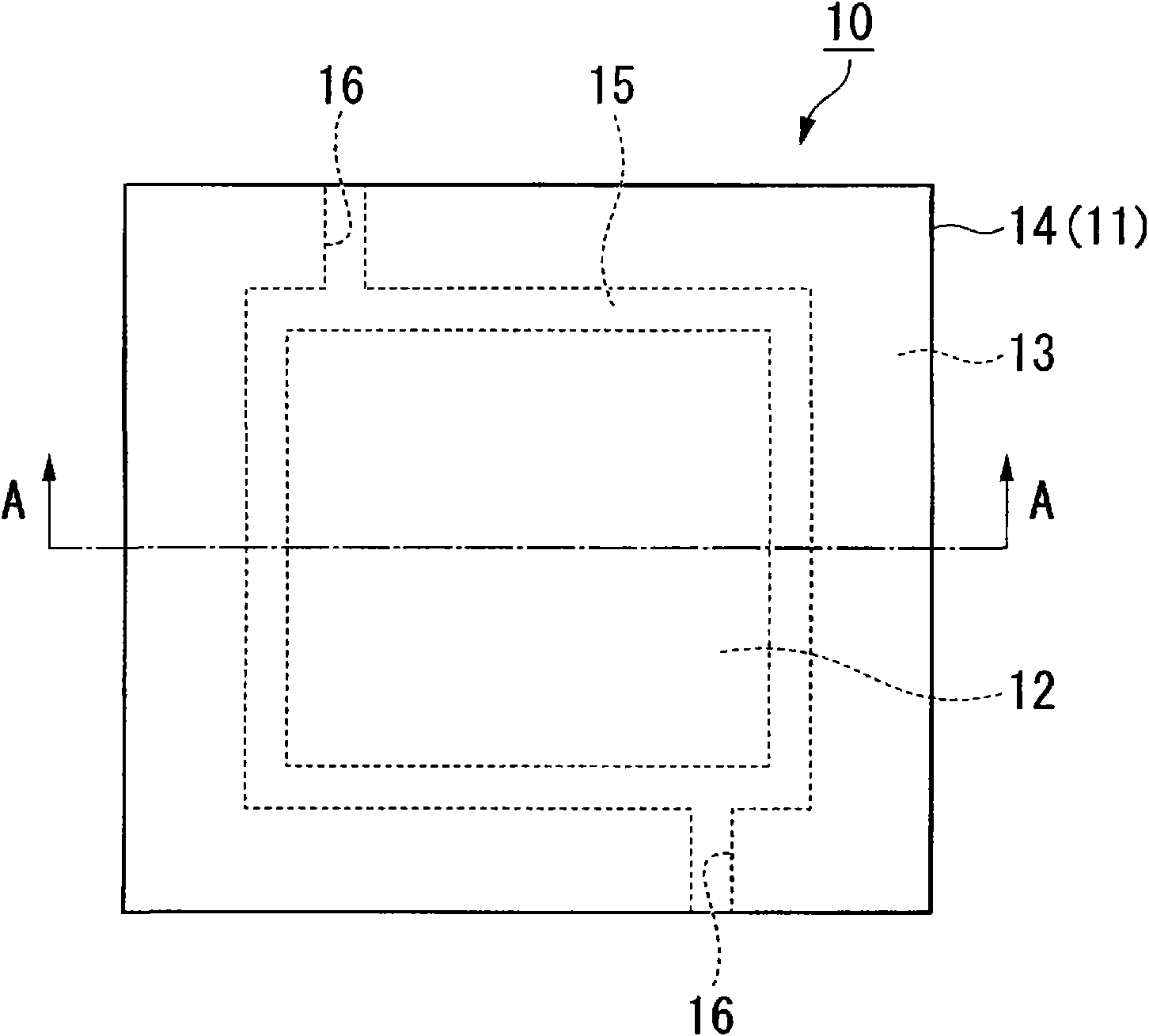

Semiconductor package and its manufacturing method

InactiveCN101689534ASimple structureEliminate retentionTelevision system detailsSemiconductor/solid-state device detailsSemiconductor packageEngineering

A semiconductor package is provided with a workpiece that is provided with a device at least on one side, a wall part provided in a manner spaced apart along the outer periphery of the device, and a cover member that is arranged in such a manner as to form a first space at the upper part of the device and supported by the workpiece through the wall part. The first space is provided with at least one or more second spaces communicating with an external space.

Owner:FUJIKURA LTD

Chromatographic materials

ActiveUS20150133294A1Reduced secondary interactionHigh surfaceIon-exchange process apparatusSilicon organic compoundsStationary phaseHydrogen

In one aspect, the present invention provides a chromatographic stationary phase material for various different modes of chromatography represented by Formula 1: [X](W)a(Q)b(T)c (Formula 1). X can be a high purity chromatographic core composition having a surface comprising a silica core material, metal oxide core material, an inorganic-organic hybrid material or a group of block copolymers thereof. W can be absent and / or can include hydrogen and / or can include a hydroxyl on the surface of X. Q can be a functional group that minimizes retention variation over time (drift) under chromatographic conditions utilizing low water concentrations. T can include one or more hydrophilic, polar, ionizable, and / or charged functional groups that chromatographically interact with the analyte. Additionally, b and c can be positive numbers, with the ratio 0.05≦(b / c)≦100, and a≧0.

Owner:WATERS TECH CORP

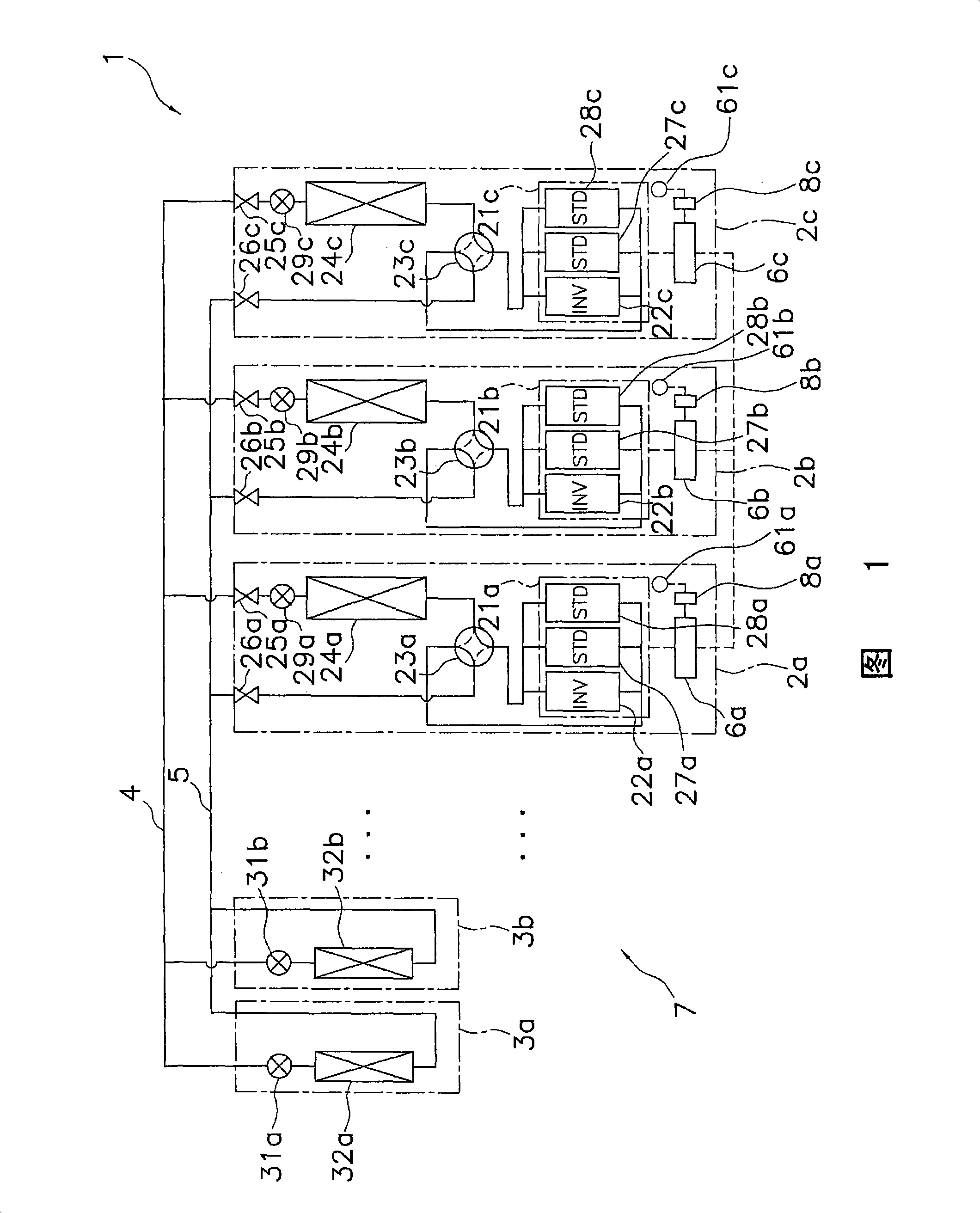

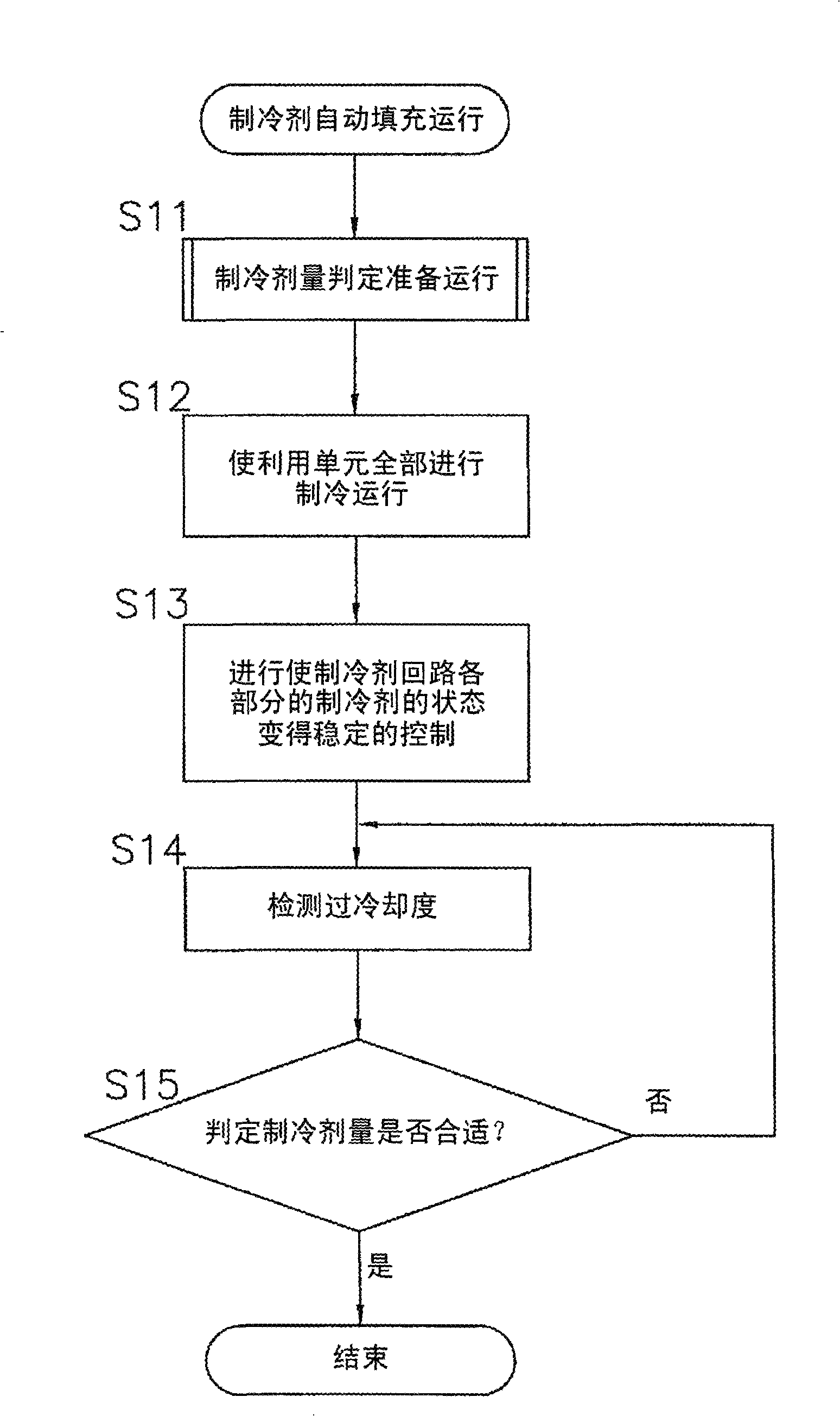

Air conditioner

ActiveCN101331366AEliminate retentionReduce forecast errorCompression machines with non-reversible cycleCompression machines with reversible cycleEngineeringRefrigerant

Prediction error in quantity of refrigerant due to difference in solubility of refrigerant into oil is minimized by eliminating refrigerant liquefied into refrigerating machine oil in a compression machine mechanism. The air conditioner (1) comprises a refrigerant circuit (7), means (8a-8c) for judging refrigerant, and operation controllers (6a-6c). The refrigerant circuit includes heat source units (2a-2c), refrigerant communication pipings (4, 5), expansion mechanisms (31a, 31b, ...), and utilization units (29a-29c, 3a, 3b, ...). The refrigerant communication piping is connected with the heat source units and the utilization units. The heat source unit has compression mechanisms (21a-21c) and heat source side heat exchangers (24a-24c). The means for judging liquefied refrigerant can judge the situation of liquefied refrigerant in the compression mechanism. When liquefied refrigerant is detected in the compression mechanism before operation for judging the quantity of refrigerant in the circuit is performed, the operation controller performs an operation for eliminating the liquefied refrigerant.

Owner:DAIKIN IND LTD

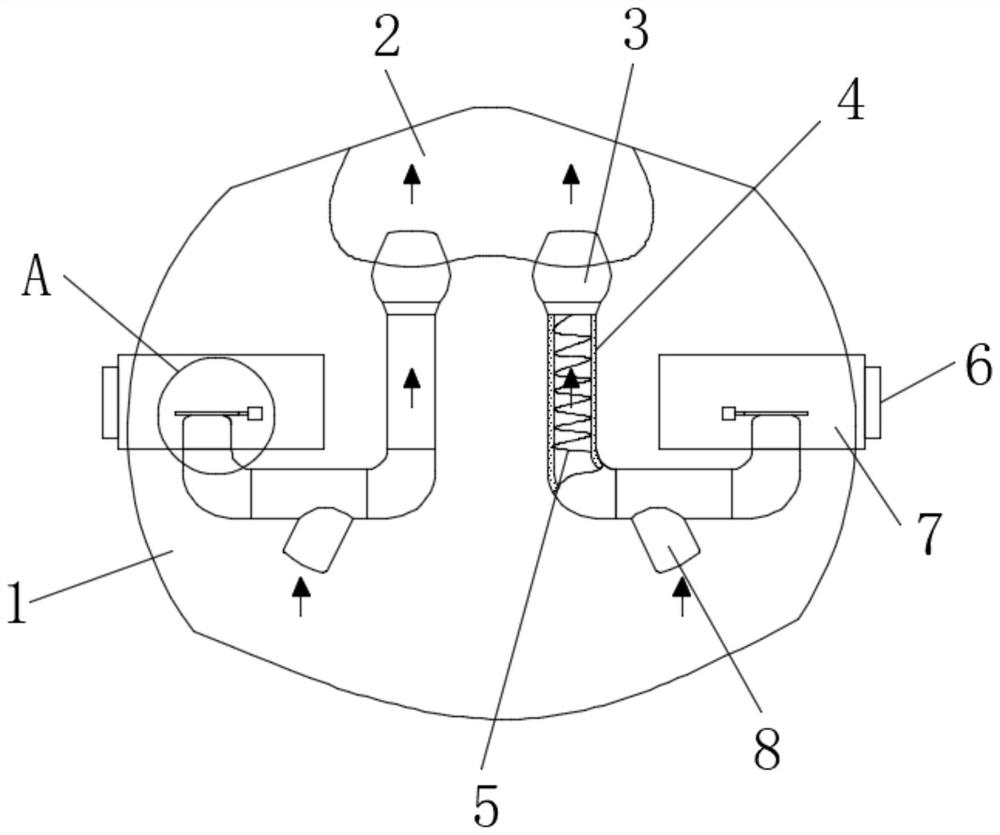

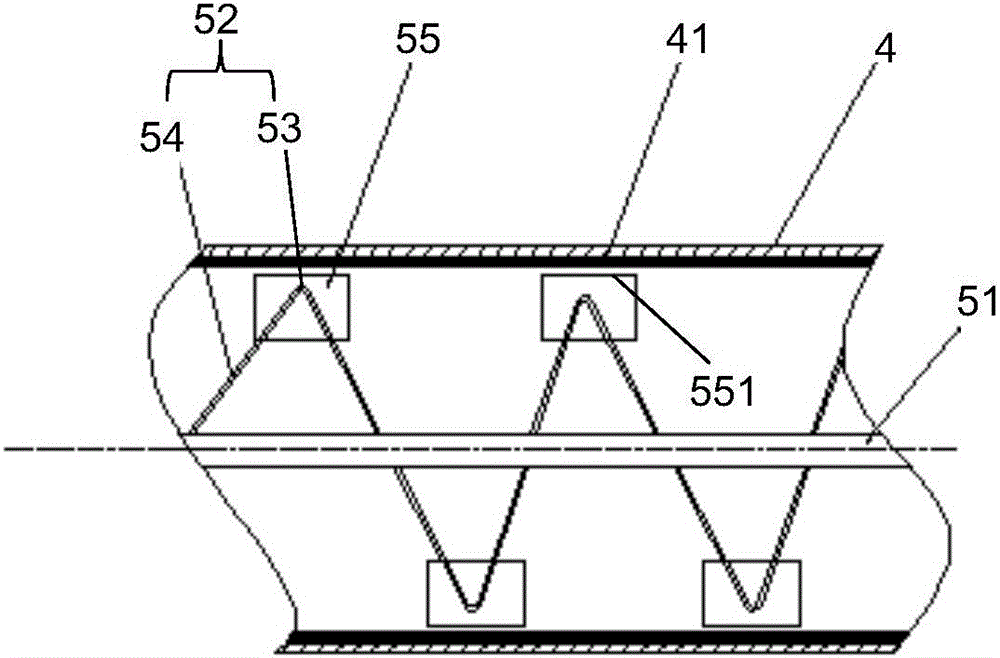

Method for separately treating exhaled air and inhaled air and breathing branch channels

PendingCN112704825AEliminate retentionEnsure safetyBreathing masksFire rescueBreath outBreathing system

The invention discloses a method for separately treating exhaled air and inhaled air and breathing branch channels. The invention belongs to the technical field of masks, and discloses a method for separately treating exhaled air and inhaled air. The method comprises the following steps that respiration is divided into the exhaling channel and the inhaling channel by using power and energy of the human respiratory system; when the human respiratory system exhales, exhaled air is exhausted through the exhaling channel; and when the human respiratory system inhales, air is inhaled through the inhaling channel. According to the method for separately treating exhaled air and inhaled air and the breathing branch channels, exhaled carbon dioxide is prevented from being retained in the space between a mask body and the human face, due to rapid exhausting of exhaled air, the air pressure between the human face and the mask body is low, air outside the mask body can rapidly enter the mask body after being filtered during inspiration, enough air amount is guaranteed during inspiration, and an effective guarantee is provided for the safety and the health of the human body.

Owner:SHANGHAI RUIZHENG ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Catalytic cracker without settler

InactiveCN100487082CEasy to separateQuick leadCatalytic crackingChemical/physical processesResidence timeHydrocarbon

The present invention relates to fast oil gas and catalyst separation in hydrocarbon material fluid catalytic cracking, and is especially one catalytic cracker without settler. The catalytic cracker without settler features the stripping unit with lower end connected via a vertical pipe to one regenerator, the first cyclone separator connected to the upper end of the stripping unit, the riser tube with outlet connected to the first cyclone separator via pipeline, and the second cyclone separator connected serially to the upper end of the first cyclone separator and with material feeding structure communicated to the stripping unit. The catalytic cracker can realize the efficient fast gas-solid separation in the separating efficiency up to 99.99 % and average oil gas residence time shortened to 2-3 sec, and has less scaling, compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

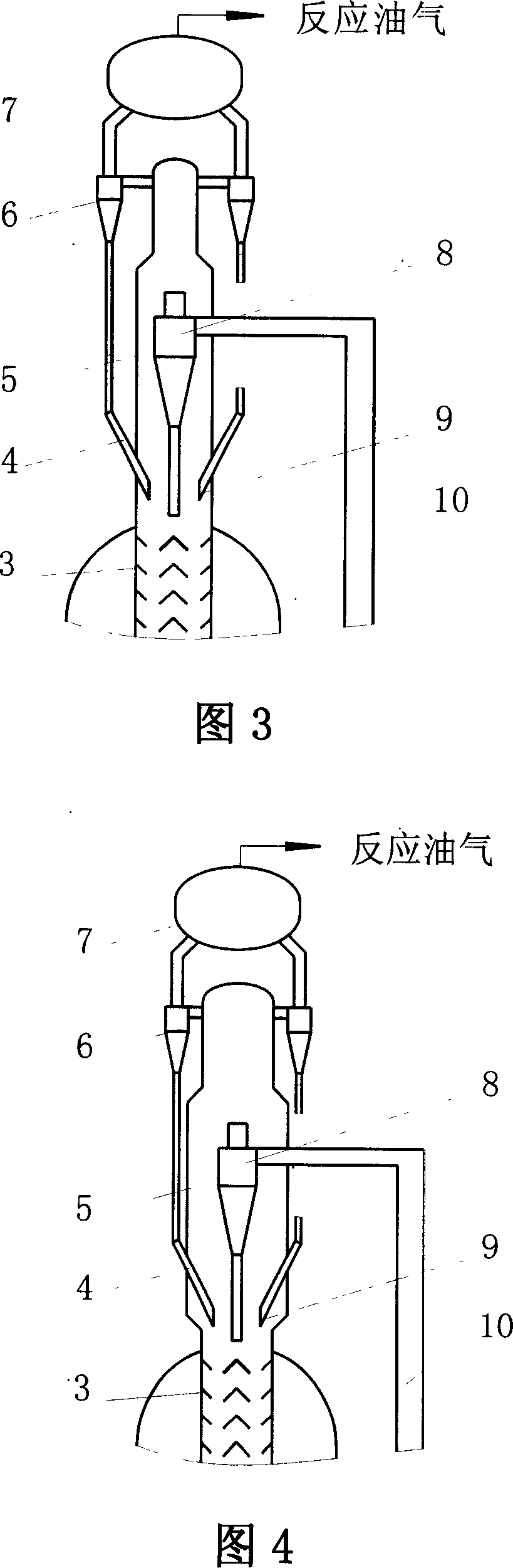

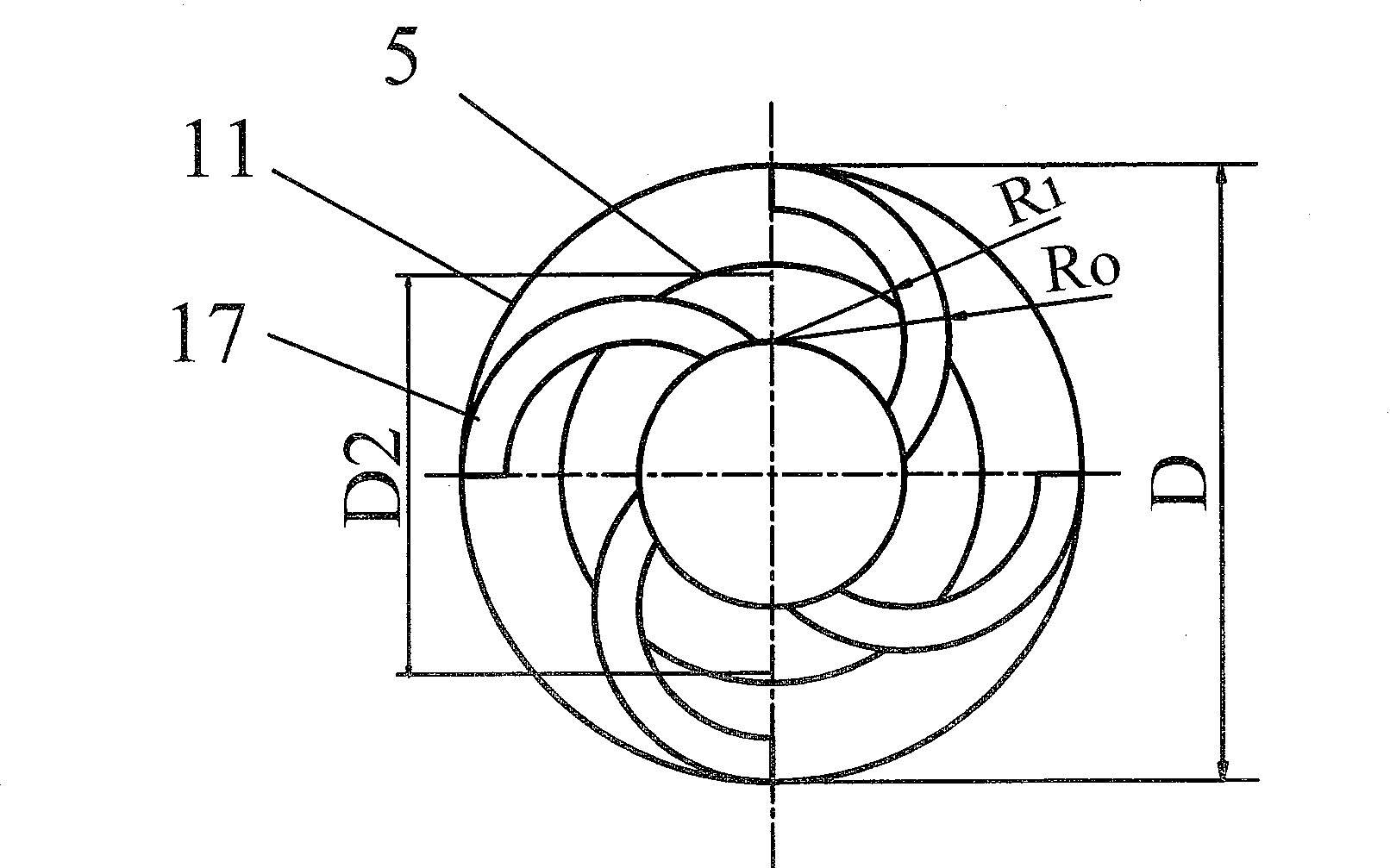

Catalytic cracker without settler

ActiveCN100487081CQuick leadEfficient extractionCatalytic crackingChemical/physical processesResidence timeHydrocarbon

The present invention relates to fast oil gas and catalyst separation in hydrocarbon material fluid catalytic cracking, and is especially one catalytic cracker without settler. The catalytic cracker without settler features the fast eddy flow separator in the outlet of the riser tube, the cyclone separator connected serially to the upper end of the fast eddy flow separator and the V-shaped leg structure below the fast eddy flow separator. The catalytic cracker can realize the efficient fast gas-solid separation in the separating efficiency up to 99.99 % and average oil gas residence time shortened to 2-3 sec, and has less scaling, compact structure and low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Application of double-layer aseptic vacuum technique in external package of large volume injection

InactiveCN101804869AReduce medical errorsKeep healthyPharmaceutical containersBagsHygieneEngineering

The invention relates to application of a double-layer aseptic vacuum technique in the external package of large volume injection. The invention adopts a technical scheme comprising the following steps of: 1, filling medicinal liquid; 2, packaging the large volume injection into the external protective package and sealing; 3, vacuumizing a space between the internal package and the external package; 4, placing the package in a sterilizing device to sterilize; 5, drying; and 6, checking micro-leakage and removing the large volume injection which forms obvious water mist or droplet between the internal package and the external package. The external protective package can be PVC and non-PVC materials. Through the application, the large volume injection which forms micro-package in the internal package can be removed conveniently and effectively. At the same time, the application ensures that the internal package is under an aseptic condition and is not polluted from the sterilizing process to the use in medicinal places; and when used in the medicinal places with strict hygiene level requirement (such as a surgical operating room, an intensive care unit and the like), the internal package does not pollute the environments and does not carry bacteria into the medicinal places.

Owner:SICHUAN TAIPINGYANG PHARMA

Split-type material storage die head in two-layer two-spiral channel

InactiveCN102962987AEliminates melt retention problemsAvoid heat loss and inhomogeneityHollow articlesMelt temperatureOuter core

The invention discloses a split-type material storage die head in a two-layer two-spiral channel. In the split-type material storage die head, melt mixing is even, double-layer melt temperature is uniform, temperature loss is small and the die head is contained by two-layer melt, and seam is removed. The split-type material storage die head comprises a die head outer barrel, an upper end cover, a lower end cover, an inner core, an outer core, a centre rod, a flow guide sleeve, a die and a pushing mechanism. The die head is characterized in that a split-flow core sleeve fixedly connected with the upper end cover is mounted on the outer core; a split-flow hole corresponding to a feed hole of the die head outer barrel is formed in the split-flow core sleeve; two outer spiral channels are arranged on the outer core; two inner spiral channels are arranged on the inner core; the starting points of the two outer spiral channels and the starting points of the two inner spiral channels are symmetrically arranged for 180 degrees respectively; two guide channels corresponding to a split-flow cone of the split-flow hole and used for connecting two sides of the split-flow cone with two outer spiral channels on the outer core are arranged on the outer core; and flow guide through holes communicated with the two inner spiral channels on the inner core are respectively formed in the tail ends of the two guide channels.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY +1

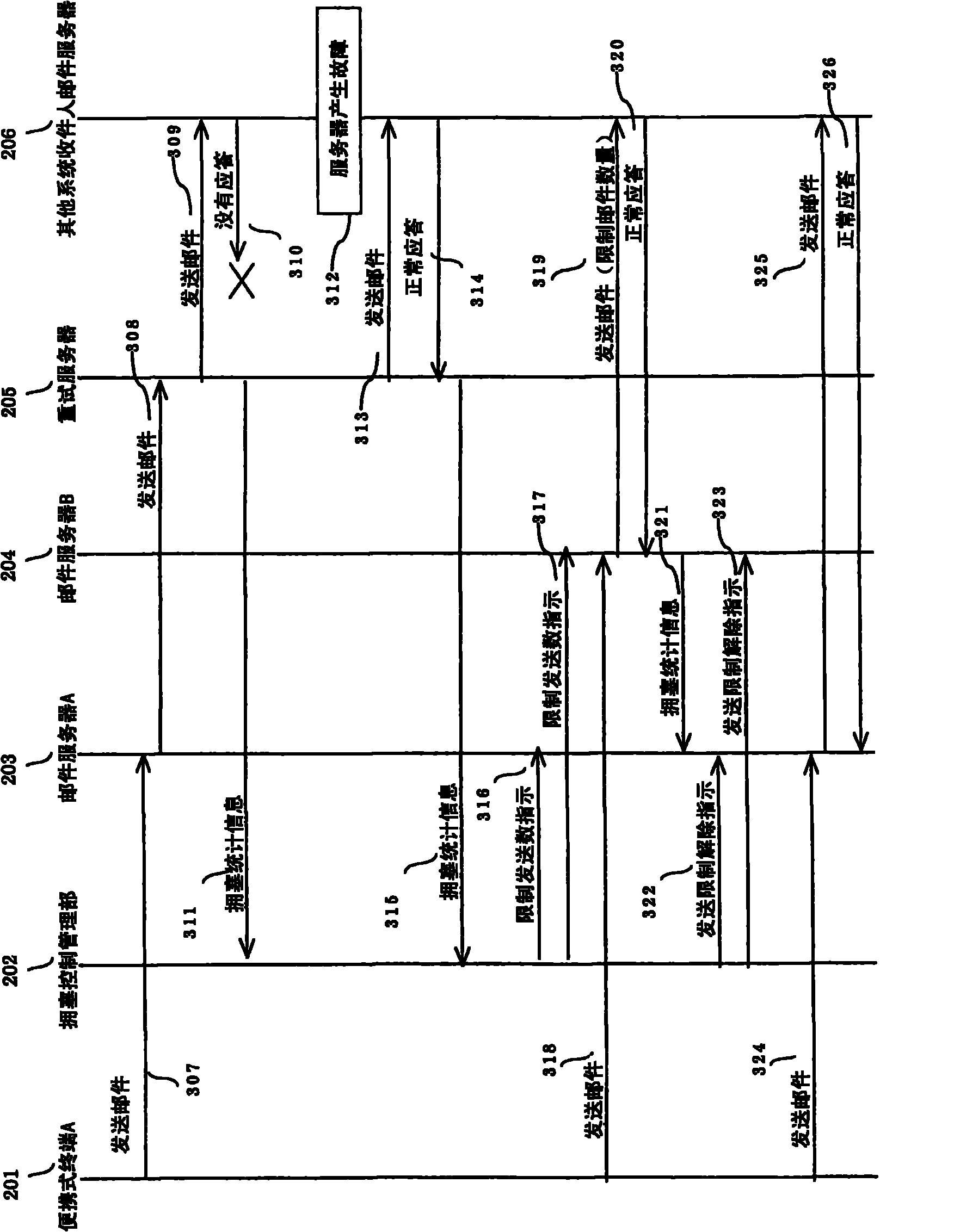

Mail server system and congestion control method

InactiveCN101924694AEfficient use ofProcessing effectsData switching networksDistributed computingNetwork congestion

The invention relates to a mail server system and a congestion control method, whereby in some cases the mail server resource could not be effectively utilized in the overall system. A mail server system includes a congestion control management section managing a congestion control over the mail server system, a congestion statistical information collection section collecting the congestion statistical information of each mail server, and a resend queue having enough capacity, wherein a retry server for performing a retry process is provided. The congestion control management section detects the mail server where a fault occurs from the collected congestion statistical information and gives an instruction of regulating the sending of a mail directed to the faulty mail server to each mail server. The mail server instructed the regulating the sending of the mail directed to the faulty mail server transfers all the mails directed to that destination to the retry server, and transfers the received mail directed to the faulty mail server to the retry server until there is a regulation dissolution instruction from the congestion control management section.

Owner:HITACHI LTD

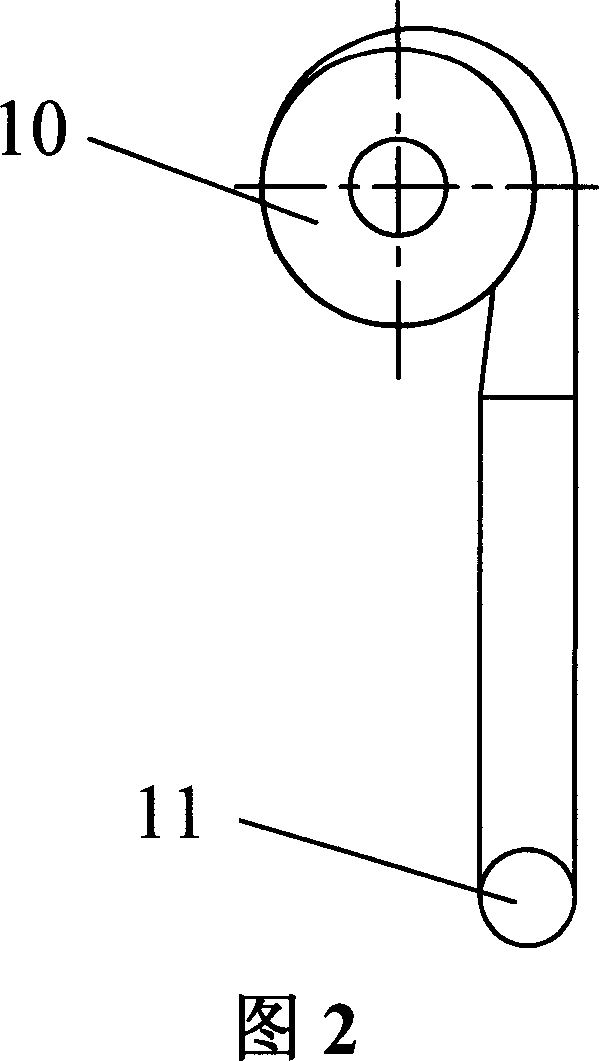

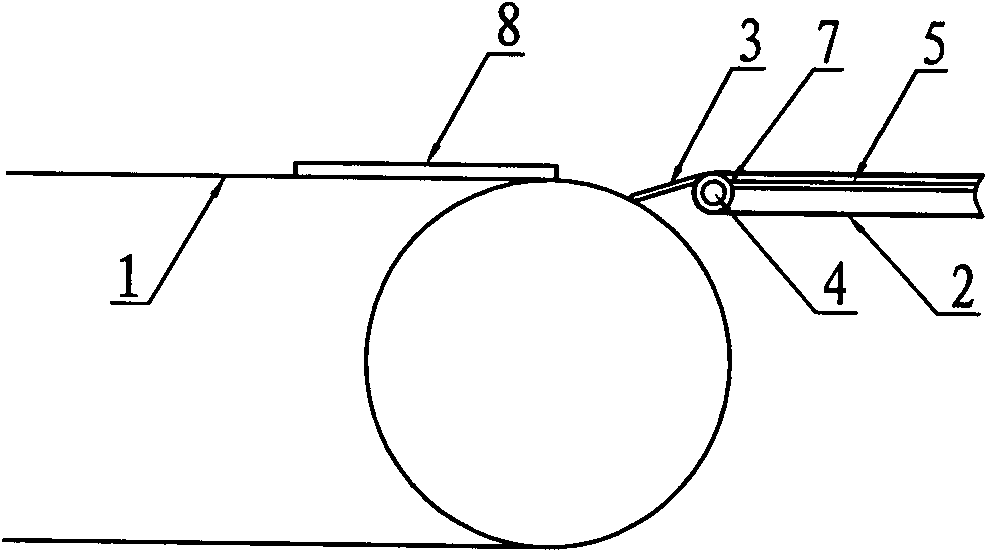

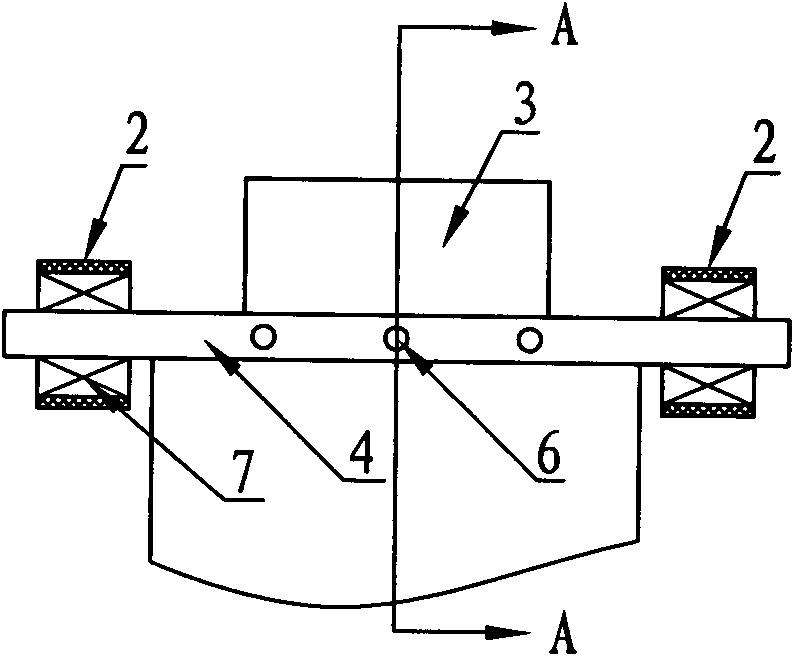

Cell plate auxiliary transmission device with sintering furnace mesh belt

InactiveCN102176492AStable deliverySmooth transmissionFinal product manufactureCharge manipulationEngineeringConveyor belt

The invention provides a cell plate auxiliary transmission device with a sintering furnace mesh belt. The cell plate auxiliary transmission device comprises a sintering furnace mesh belt, synchronous driving belts, a guide plate, a revolving shaft, a fixed supporting plate, a fastening screw and roller wheels, wherein two roller wheels are arranged at the two ends of the revolving shaft; two synchronous driving belt are respectively sleeved on the roller wheels; the guide plate is arranged between the synchronous driving belts, and the width of the guide plate is equivalent to that of a cell plate; the import end of the guide plate is jointed with the tail end of the sintering furnace mesh belt; the upper end surface of the import end of the guide plate is close to the lower end surface of the cell plate, and the upper end surface of the export end of the guide plate is close to the upper end surfaces of the synchronous driving belts; the guide plate is fixed on the revolving shaft, the fixed supporting plate is arranged below the synchronous driving belts, and the revolving shaft is fixed on the fixed supporting plate. By using the cell plate auxiliary transmission device, the blocking and gathering phenomena of cell plates can be fundamentally eliminated, thereby ensuring the smooth transmission of cell plates and improving production efficiency and product quality.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

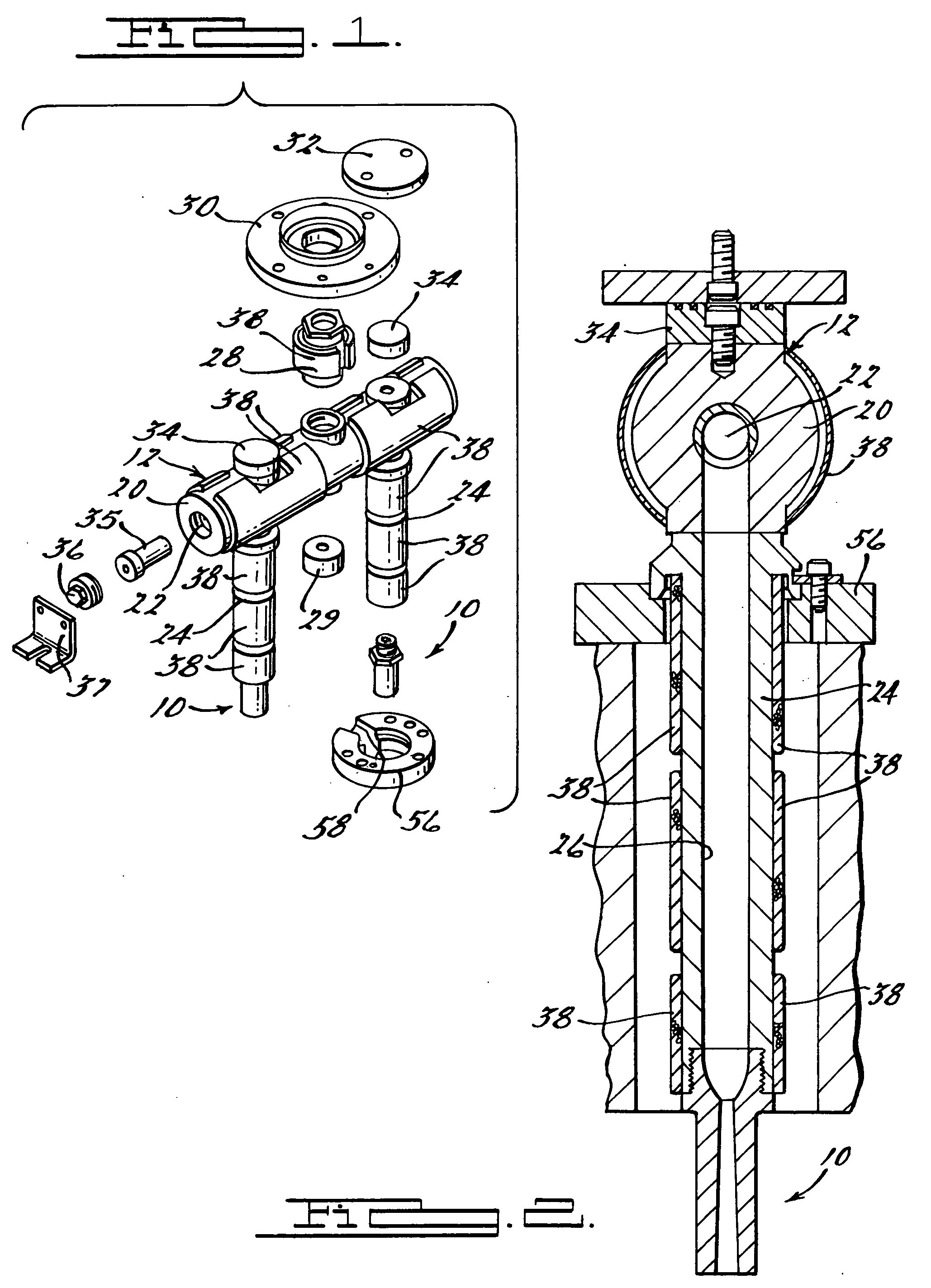

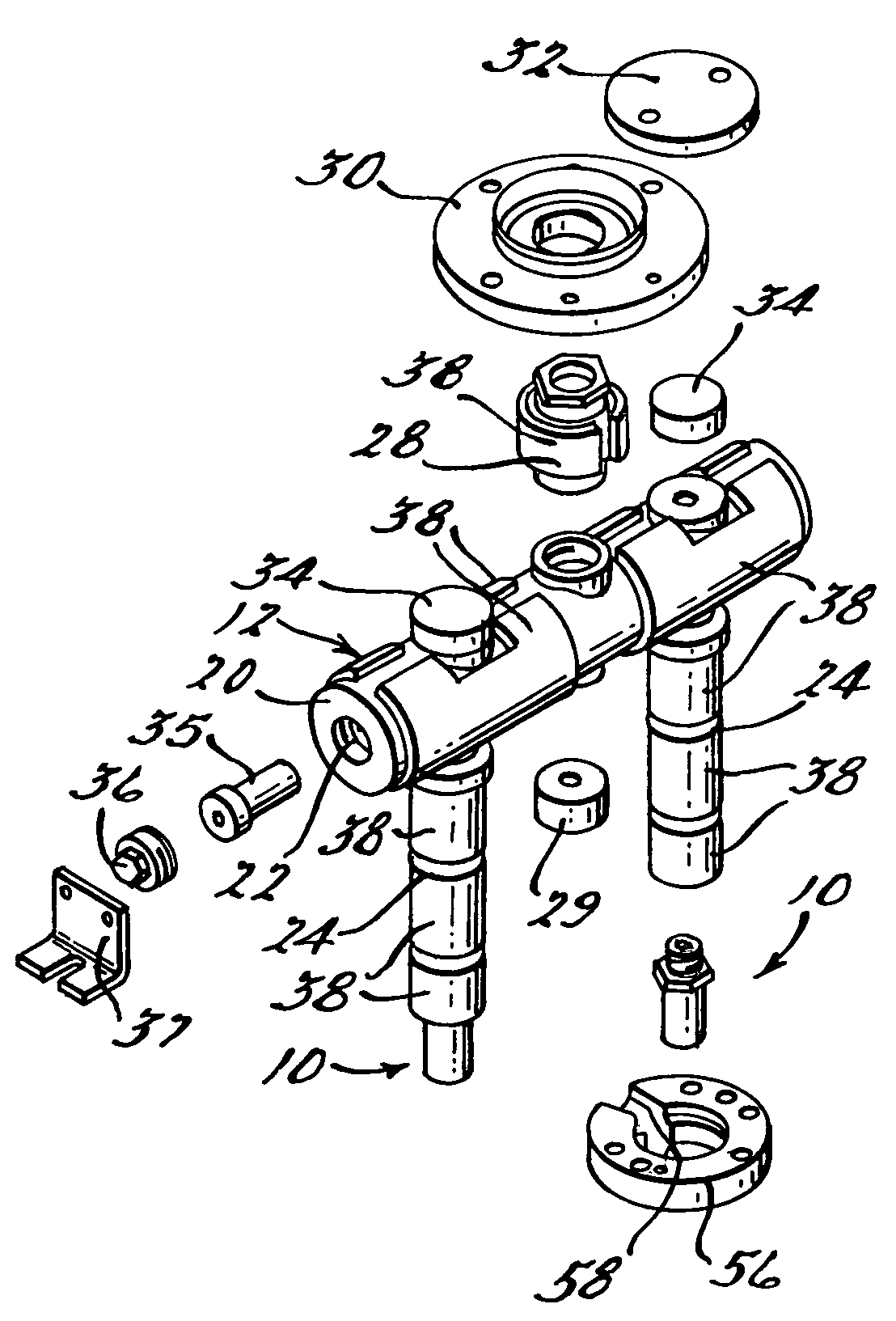

Drop tip

InactiveUS20060093703A1Reduces and eliminates mixingEliminate scrappingFood shapingBiomedical engineeringMaterial supply

A drop tip is provided for conveying injection molding material from a molding material supply into a mold. The drop tip has a body including an internal bore and a drop passage extending from the internal bore. The internal bore has an arcuate lower end terminating in a gate to prevent retention of molten material therein.

Owner:PLASTIC ENG & TECHN SERVICES

Injection molding drop tip

InactiveUS7458804B2Reduces and eliminates mixingEliminate scrappingFood shapingShell moldingInjection molding machine

A drop tip is provided for conveying injection molding material from a molding material supply into a mold. The drop tip has a body including an internal bore and a drop passage extending from the internal bore. The internal bore has an arcuate lower end terminating in a gate to prevent retention of molten material therein.

Owner:PLASTIC ENG & TECHN SERVICES

External traditional Chinese medicine for treating ascites due to cirrhosis

InactiveCN104645212APromote reabsorptionEasy to primeDigestive systemUnknown materialsCoptisPharmacology

The invention relates to an external traditional Chinese medicine for treating ascites due to cirrhosis. The external traditional Chinese medicine belongs to a traditional Chinese medicine composition. The external traditional Chinese medicine for treating ascites due to cirrhosis has substantial curative effects. The external traditional Chinese medicine for treating ascites due to cirrhosis comprises 100-140g of Chinese Shizhu panax as a monarch drug, 70-90g of Chinese prickly ash, 20-30g of turtle shell, 10-15g of rhizoma sparganii, 30-40g of curcuma rhizome, 40-60g of peach seed, 20-30g of safflower, 10-15g of ferula asafetida, 40-60g of pokeberry root, 15-20g of coptis root, 5-10g of flying squirrel feces, 25-35g of red peony root and 10-20g of betel nut.

Owner:刘铮

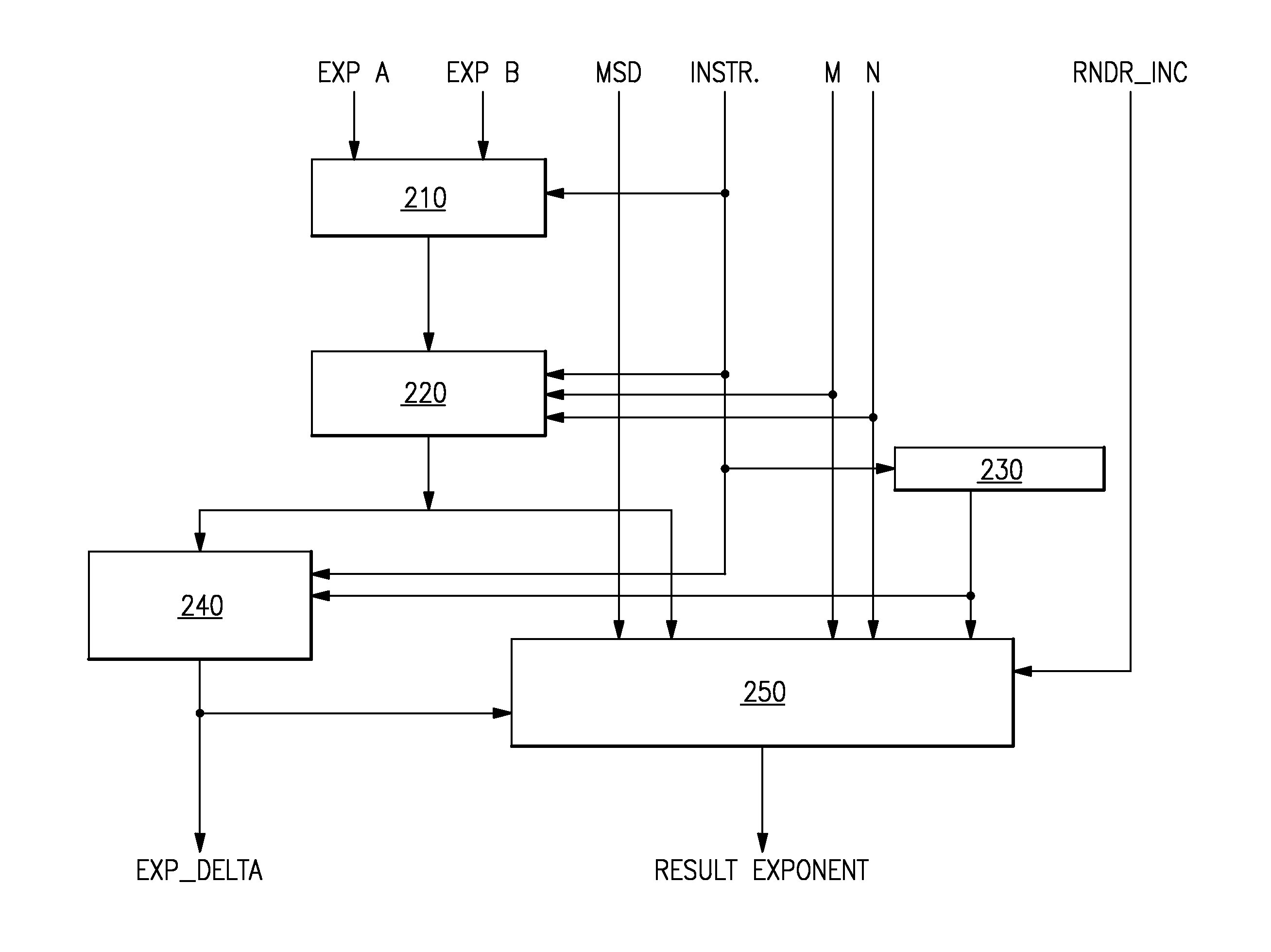

Decimal Floating Point Mechanism and Process of Multiplication without Resultant Leading Zero Detection

InactiveUS20110320512A1Simplifies and reduces number of cycleNot easy to make mistakesComputations using contact-making devicesComputation using non-contact making devicesFloating pointLeading zero

A decimal multiplication mechanism for fixed and floating point computation in a computer having a coefficient mechanism without resulting leading zero detection (LZD) and process which assumes that the final product will be M+N digits in length and performs all calculations based on this assumption. Least significant digits that would be truncated are no longer stored, but retained as sticky information which is used to finalize the result product. Once the computation of the product is complete, a final check based on the examination of key bits observed during partial product accumulation is used to determine if the final product is truly M+N digits in length, or M+N−1 digits. If the latter is true, then corrective final product shifting is employed to obtain the proper result. This eliminates the need for dedicated leading zero detection hardware used to determine the number of significant digits in the final product. The corrective final product shifting also incorporates adjustments to the coefficient of the product when the product's exponent is at its extremes and the final product must be brought to be within the precision and range of a given format.

Owner:IBM CORP

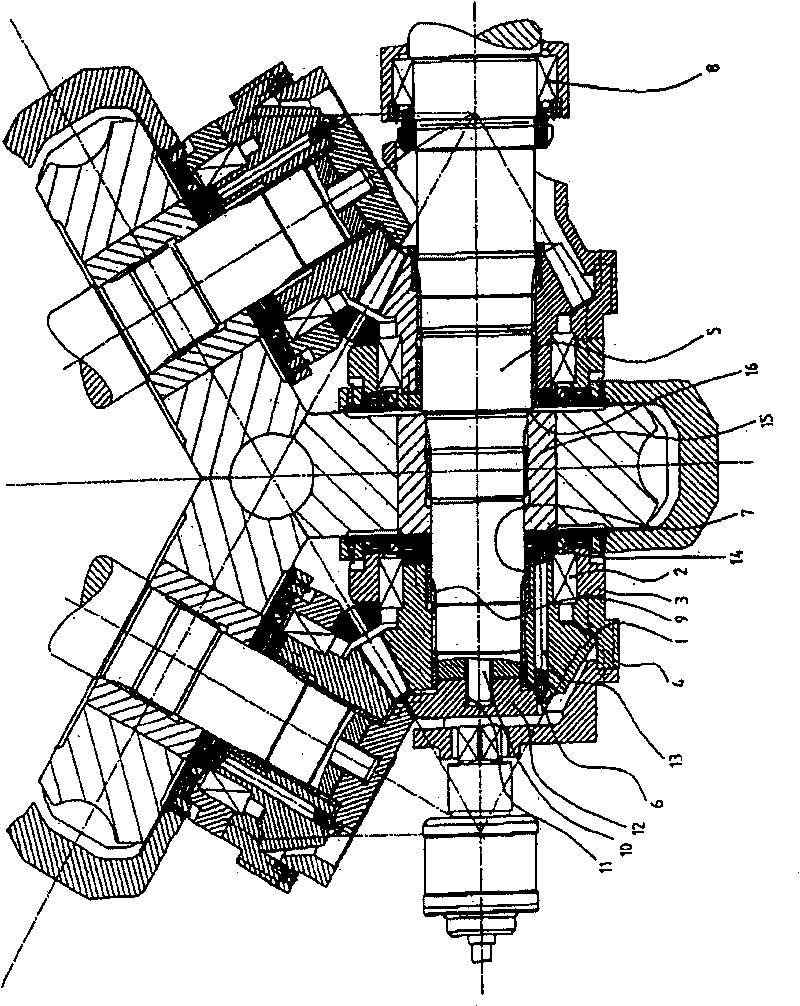

Mill stand for rolling rod-like or tubular rolling stock

The invention discloses a mill housing for bar or tubular rolled piece, comprising at least one axis supporting the roller, said roller is installed on said axis movably in axial direction, the two sides of roller is equipped with a location device in axial direction, and a bushing is installed on said axis. The location device is formed by at least one movable location element extending through bushing from side far away from roller to side facing roller in axial direction; the place far away from roller in bushing is bounded by a backstop element installed on side far away from roller; and said backstop element is adjustable in axial direction and fixed connected with axis. s

Owner:KOCKS TECH GMBH & CO

Preparation device of deck covering for ship

PendingCN106823904AAvoid stickingInhibition retentionRotary stirring mixersTransportation and packagingRaw materialAerospace engineering

The invention discloses a preparation device of a deck covering for a ship. The preparation device comprises a circular tube-shaped pushing cavity, wherein two ends of the pushing cavity are respectively provided with a feed inlet and a discharge outlet, a screw propulsion rod is coaxially arranged in the pushing cavity, a screw surface of the screw propulsion rod is provided with multiple scraper blades extending outwards, the mounting position of each scraper blade is adjustable, the scraper blades are arranged along the axial direction of the screw propulsion rod, the outer edge of each scraper blade and the inner wall of the pushing cavity form clearance fit, and the inner wall surface of the pushing cavity and the surface of the screw propulsion rod are provided with smoothing layers; by rotating the screw propulsion rod, various raw materials including a viscous material can be pushed to the discharge outlet from the feed inlet in sequence, and a viscous mixture adhered to the inner wall of the pushing cavity and formed by mixing various raw materials can be scraped off by the scraper blades, and is also pushed to the discharge outlet, so that the raw materials are prevented from remaining in a production device, and accurate metering is realized.

Owner:SHANGHAI YIBOW SHIPPING CO LTD

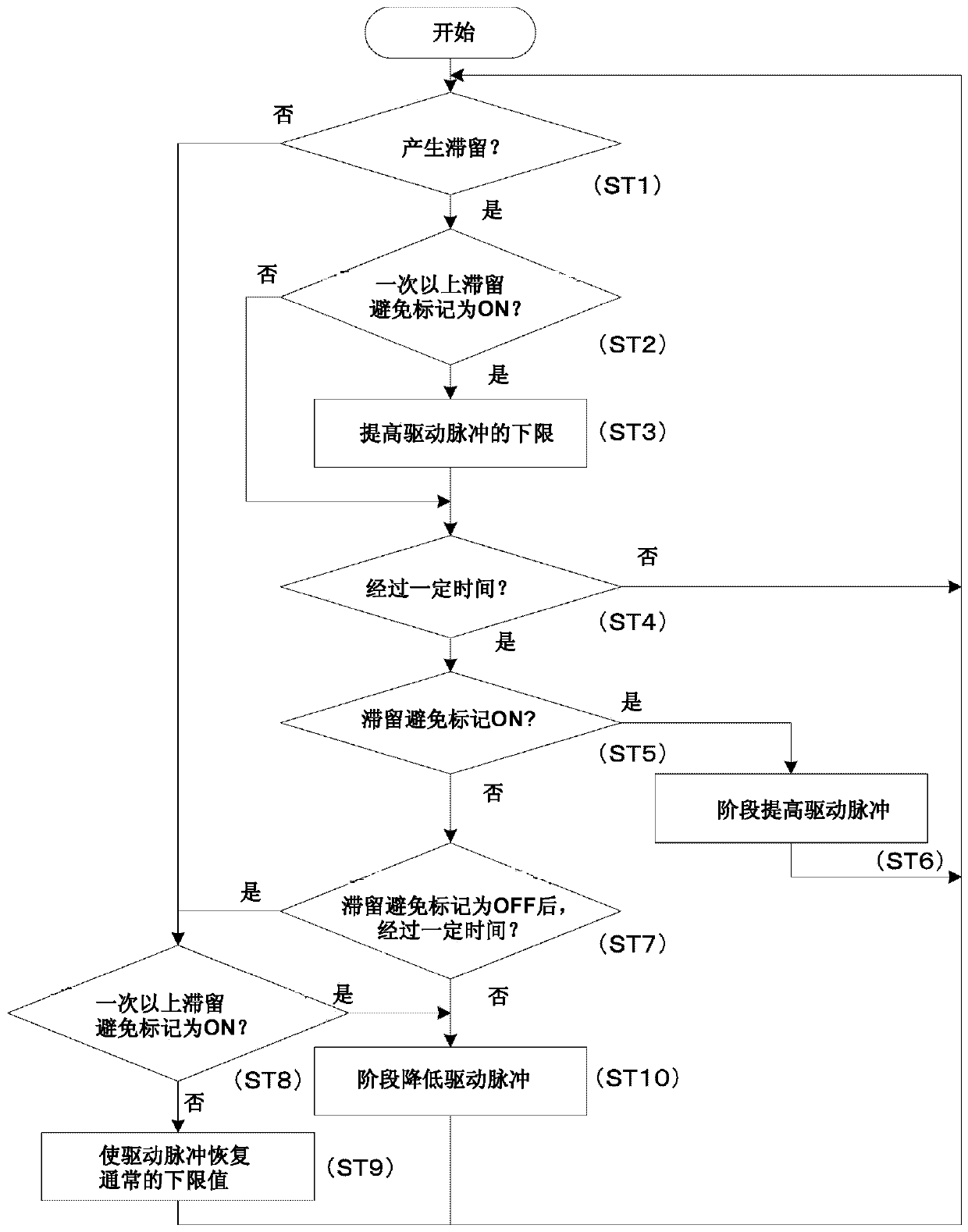

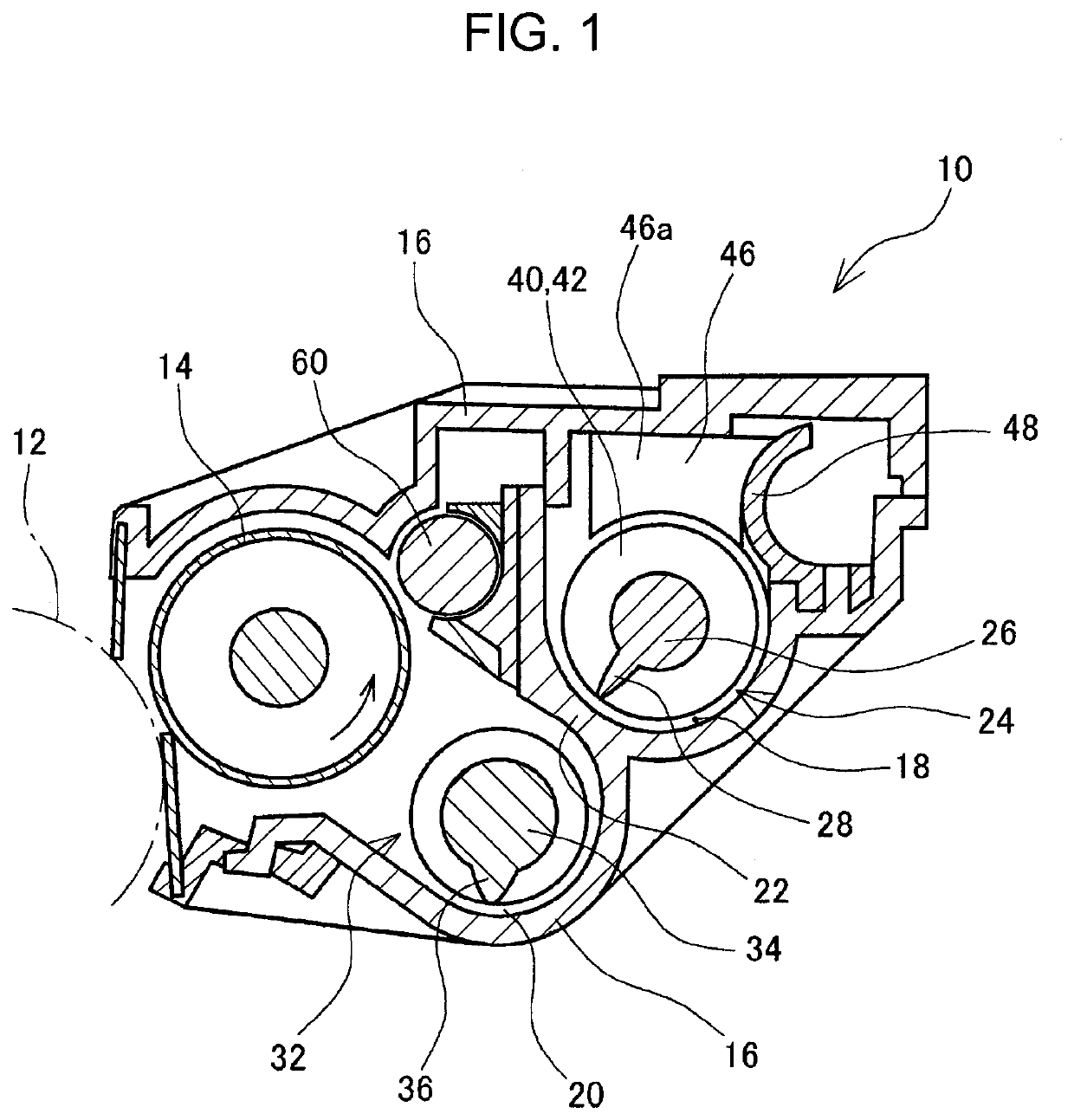

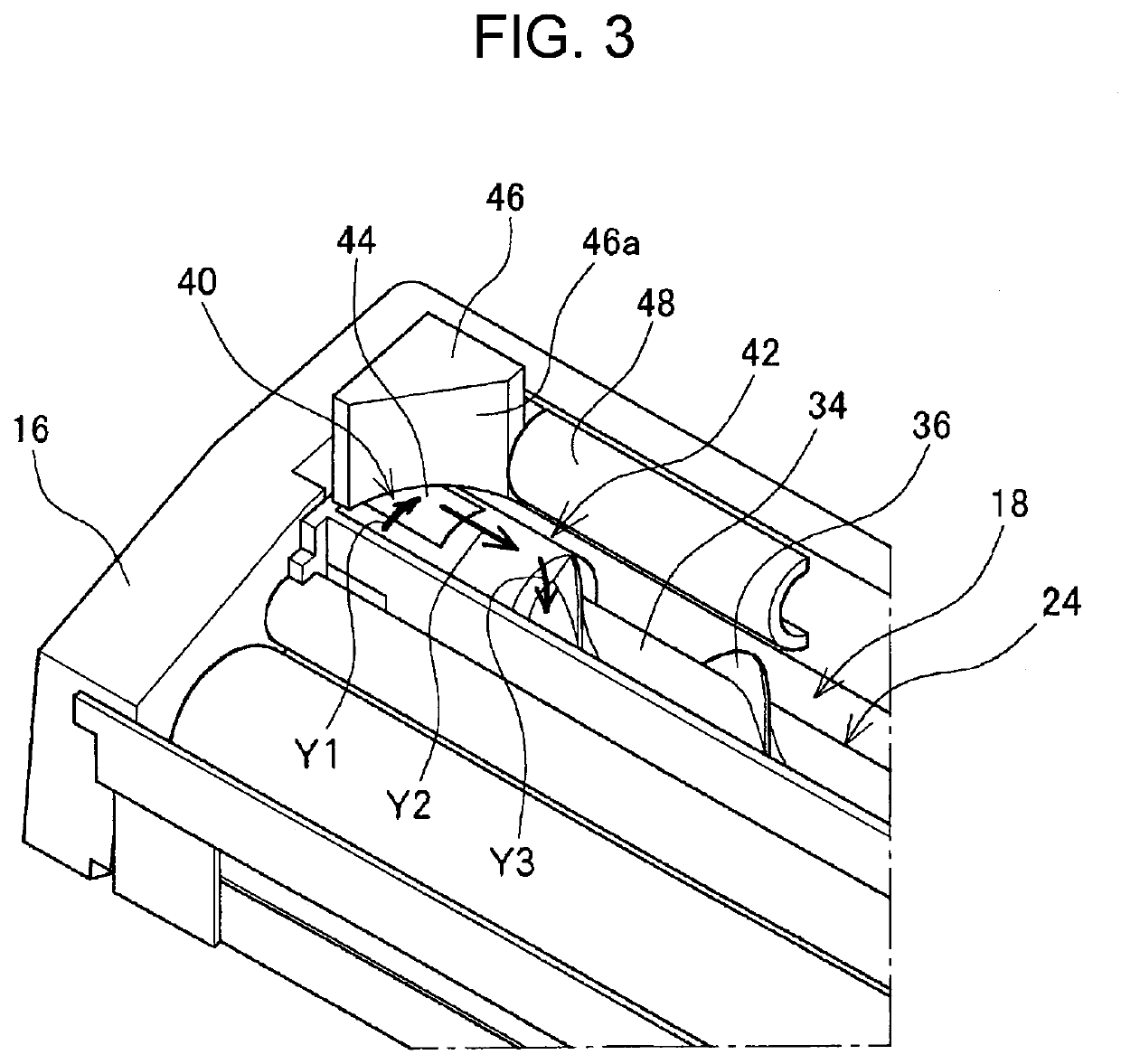

air conditioner

ActiveCN105605673BGuaranteed trafficEliminate retentionMechanical apparatusFluid circulation arrangementEngineeringAir conditioning

The present invention provides an air conditioner capable of eliminating stagnation of refrigerant in an indoor heat exchanger without providing a liquid receiver. In an air-conditioning device including an indoor heat exchanger (6) and an outdoor heat exchanger (15), a control device (50) is provided. In the case of the outdoor heat exchanger (15), the lower limit of the opening degree of the outdoor electronic control valve (18) is controlled to be increased.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Air conditioner

ActiveCN101331366BEliminate retentionReduce forecast errorCompression machines with non-reversible cycleCompression machines with reversible cycleEngineeringRefrigerant

Prediction error in quantity of refrigerant due to difference in solubility of refrigerant into oil is minimized by eliminating refrigerant liquefied into refrigerating machine oil in a compression machine mechanism. The air conditioner (1) comprises a refrigerant circuit (7), means (8a-8c) for judging refrigerant, and operation controllers (6a-6c). The refrigerant circuit includes heat source units (2a-2c), refrigerant communication pipings (4, 5), expansion mechanisms (31a, 31b, ...), and utilization units (29a-29c, 3a, 3b, ...). The refrigerant communication piping is connected with the heat source units and the utilization units. The heat source unit has compression mechanisms (21a-21c) and heat source side heat exchangers (24a-24c). The means for judging liquefied refrigerant can judge the situation of liquefied refrigerant in the compression mechanism. When liquefied refrigerant is detected in the compression mechanism before operation for judging the quantity of refrigerant in the circuit is performed, the operation controller performs an operation for eliminating the liquefied refrigerant.

Owner:DAIKIN IND LTD

Developing device

ActiveUS20200096908A1Eliminate retentionElectrographic process apparatusMagnetic tension forceComputer science

A developing device includes a first developer transport path, called as first path hereinafter; a first transport screw that transports a developer in the first path; a first conveyance roller that is thicker than a shaft of the first transport screw, attracts by magnetic force the developer at a downstream end portion of a second developer transport path arranged next to the first path, and conveys the developer to an upper portion located upstream of the first path; a first scraping wall that scrapes and sends the attracted developer; and a first guide columnar body that is adjacent to the first conveyance roller, has a peripheral surface continuous to the first conveyance roller, receives, using the peripheral surface, and guides the sent developer to an upstream end portion of the first path, and has a length that the guided developer is not attracted by the magnetic force.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com