Catalytic cracker without settler

A catalytic cracking unit, non-settling technology, applied in the petrochemical field, can solve the problems of large oil and gas retention space, easy to cause coking, unspecified and other problems, and achieve the effect of shortening the residence time, eliminating the retention of coke and coke, and avoiding temperature drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

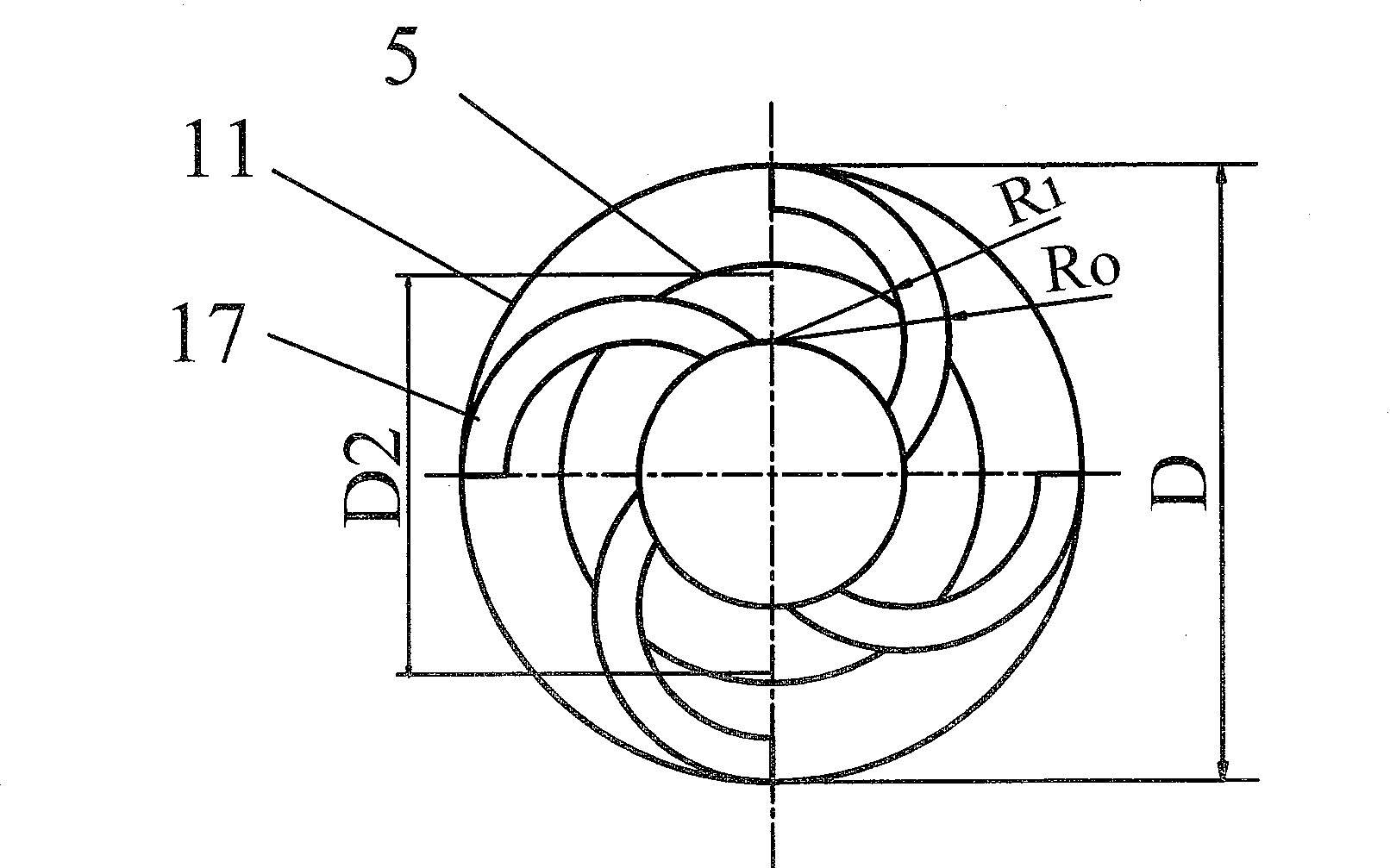

[0058] When using a fluidized catalytic cracking unit without a settler of the present invention, the raw oil 14 and the back-refined oil 15 enter the riser 2, and are mixed with the regenerated catalyst from the regenerator that is input through the regeneration inclined pipe 1, and are heated in the lifting steam or lifting dry Under the lifting action of gas 15, the mixture flows upwards, and the catalytic cracking reaction occurs at the same time. The reaction oil gas and catalyst enter the swirl-type quick separator 6 at the outlet of the riser, and are ejected tangentially downward through the spiral arm 17 of the swirl-type quick separator 6. The rotary motion of the gas-solid mixture is formed in the annular space between the partitioning cylinders 5, and most of the catalyst in the mixture is separated under the action of the centrifugal force field and falls to the stripping section 13 along the inner wall of the outer cylinder 11. In the stripping section 13, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com