Cell plate auxiliary transmission device with sintering furnace mesh belt

A technology of transmission device and sintering furnace, which is applied in the direction of transportation, packaging, furnace, circuit, etc., can solve the problems affecting the continuous transmission of cells, the inability to realize seamless connection, and the retention and accumulation of cells, so as to eliminate retention and accumulation, improve Production efficiency and product yield, the effect of eliminating stagnation and aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

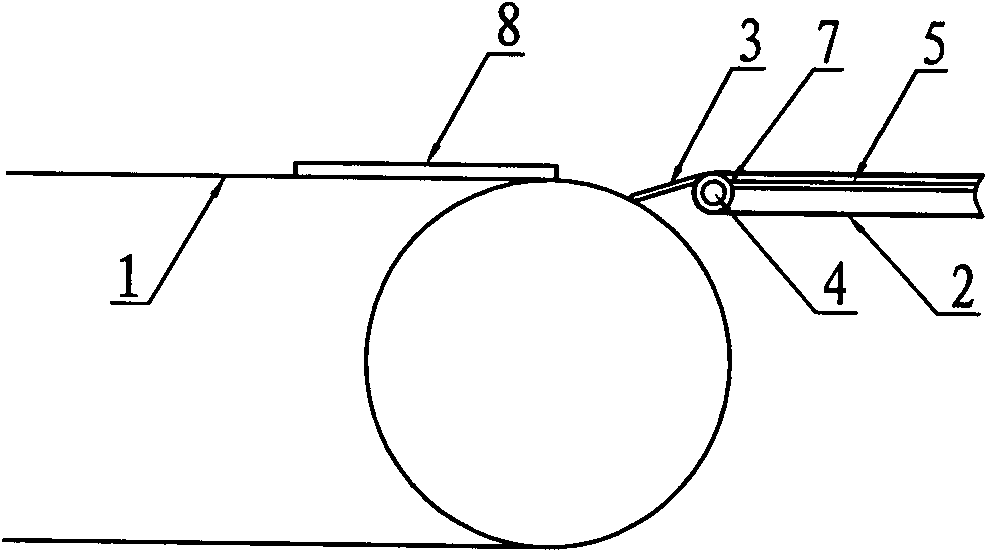

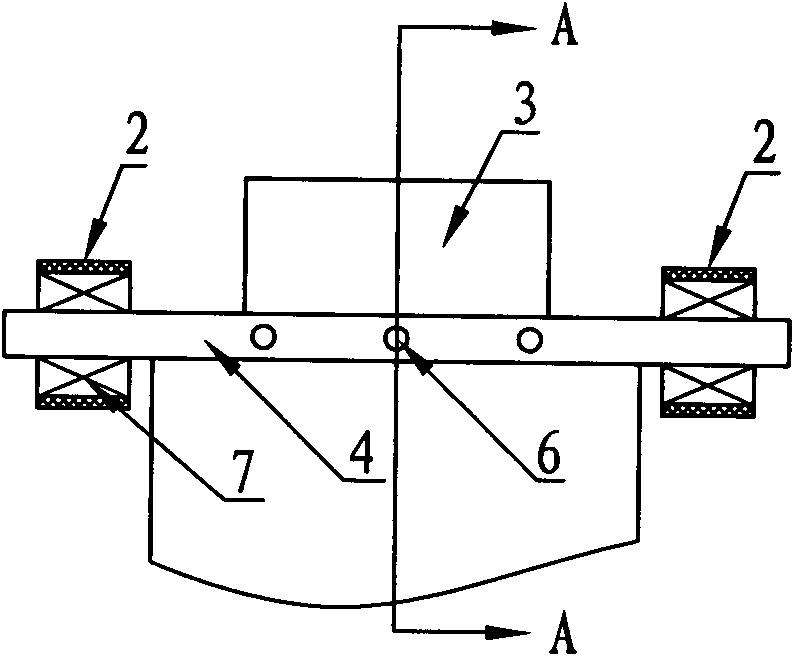

[0016] Said a kind of sintering furnace mesh belt cell auxiliary transmission device, such as Figure 1 ~ Figure 4 As shown, it includes a sintering furnace mesh belt 1, a synchronous transmission belt 2, a guide plate 3, a rotating shaft 4, a fixed supporting plate 5, a fastening screw 6 and a roller 7, and two rollers 7 are installed at both ends of the rotating shaft 4, two The synchronous transmission belt 2 is set on the rollers 7 respectively, the guide plate 3 is located in the middle of the synchronous transmission belt 2, and its width is 1 / 3~1 of the width of the battery sheet 8, and the leading end of the guide plate 3 is connected with the end of the mesh belt 1 of the sintering furnace. The upper end surface of the lead-in end of the guide plate 3 is close to the lower end surface of the battery sheet 8, the upper end surface of the lead-out end of the guide plate 3 is close to the upper end surface of the synchronous transmission belt 2, the guide plate 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com