Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to ""Efficient operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

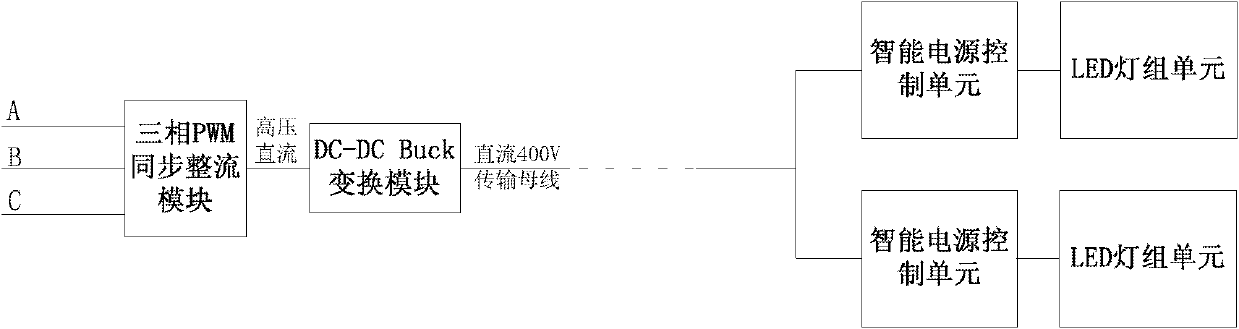

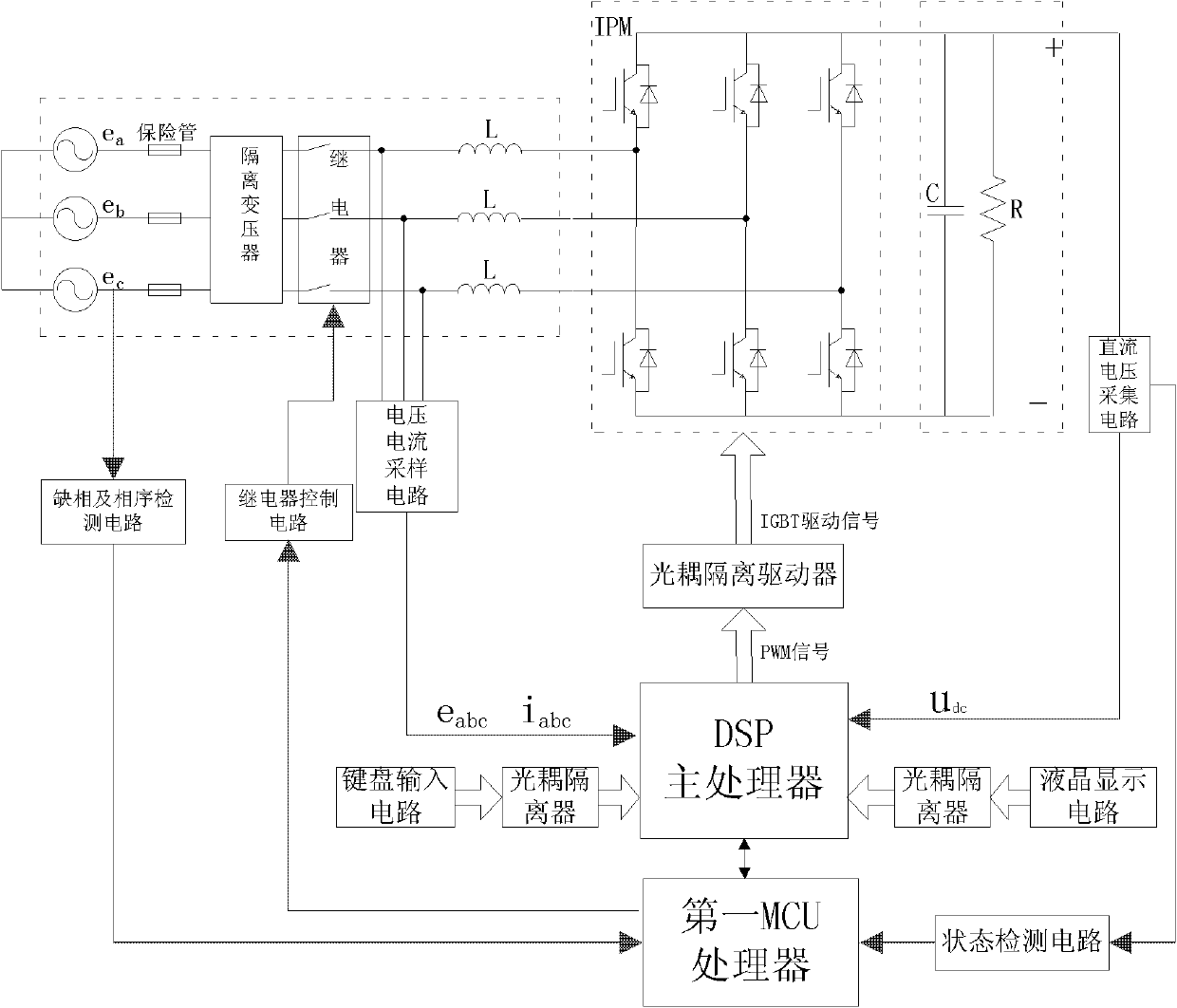

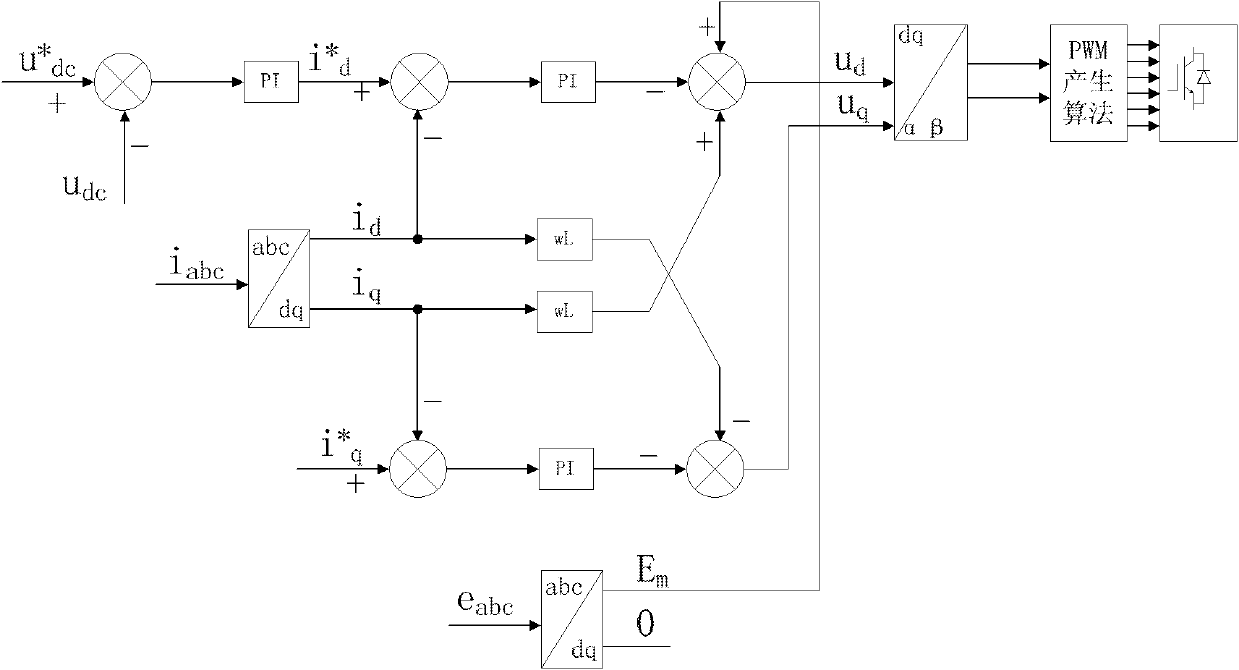

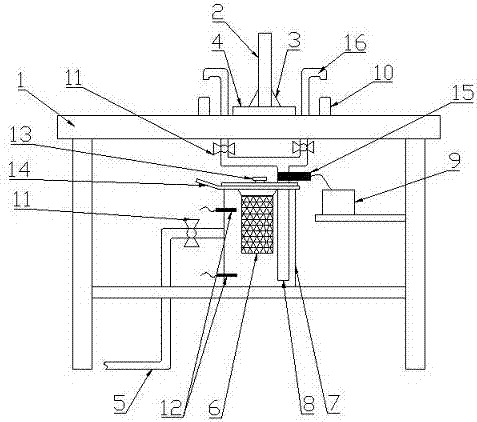

LED (Light Emitting Diode) illumination intelligent control system

InactiveCN102438378AImprove working environment temperatureReduce heat radiationAc-dc conversionElectric light circuit arrangementPower factorHigh-voltage direct current

The invention relates to an LED (Light Emitting Diode) illumination intelligent control system which comprises a synchronous rectification unit used for providing direct-current power for at least two intelligent power control units, wherein the output end of each intelligent power control unit is connected with a corresponding LED light group unit via an electric wire; and the synchronous rectification unit is connected with each intelligent power control unit by a high-voltage direct-current bus. In the intelligent control system, stable constant-voltage direct current is provided for an LED illumination system by the synchronous rectification unit, so that the whole illumination system can operate under high power factor with less harmonic wave. the corresponding LED light group units are dynamically and precisely dimmed by the intelligent power control units, and the LED operation situation is detected in real time and communication with an external control center is carried out. The intelligent control system has the characteristic of reasonable structure, and is convenient to control, the working environment temperature of an LED light group can be improved, and the reliability and the service life of an LED illumination light can be improved.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

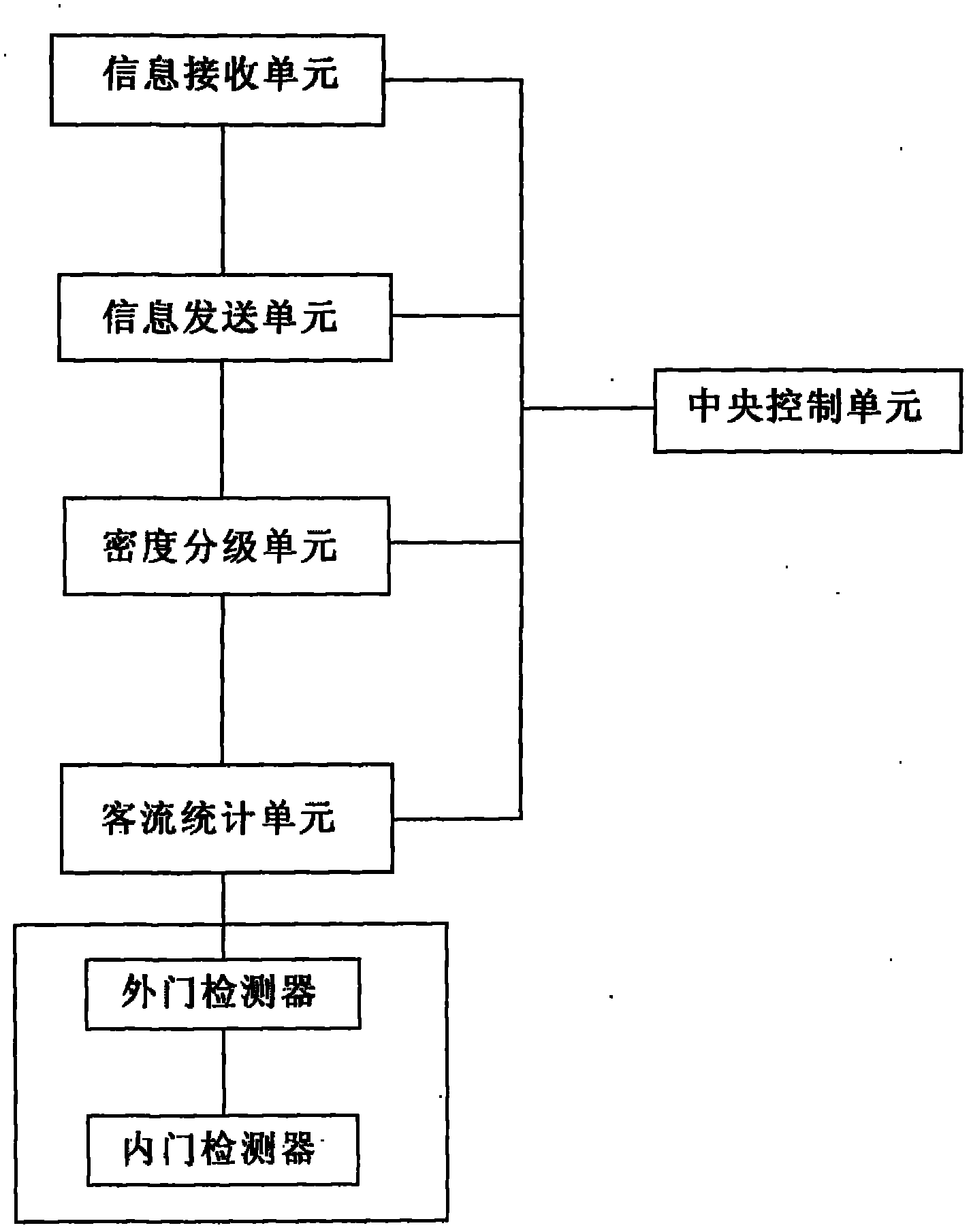

Subway passenger conducting management control system and method thereof

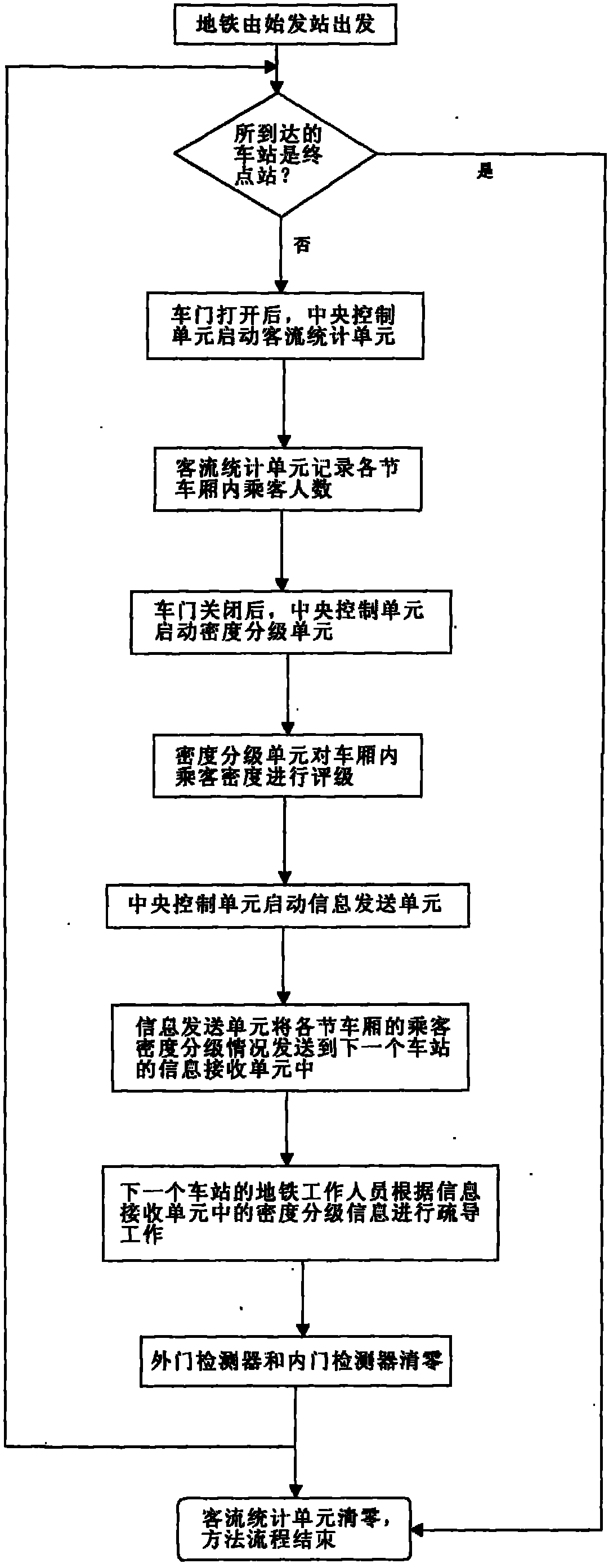

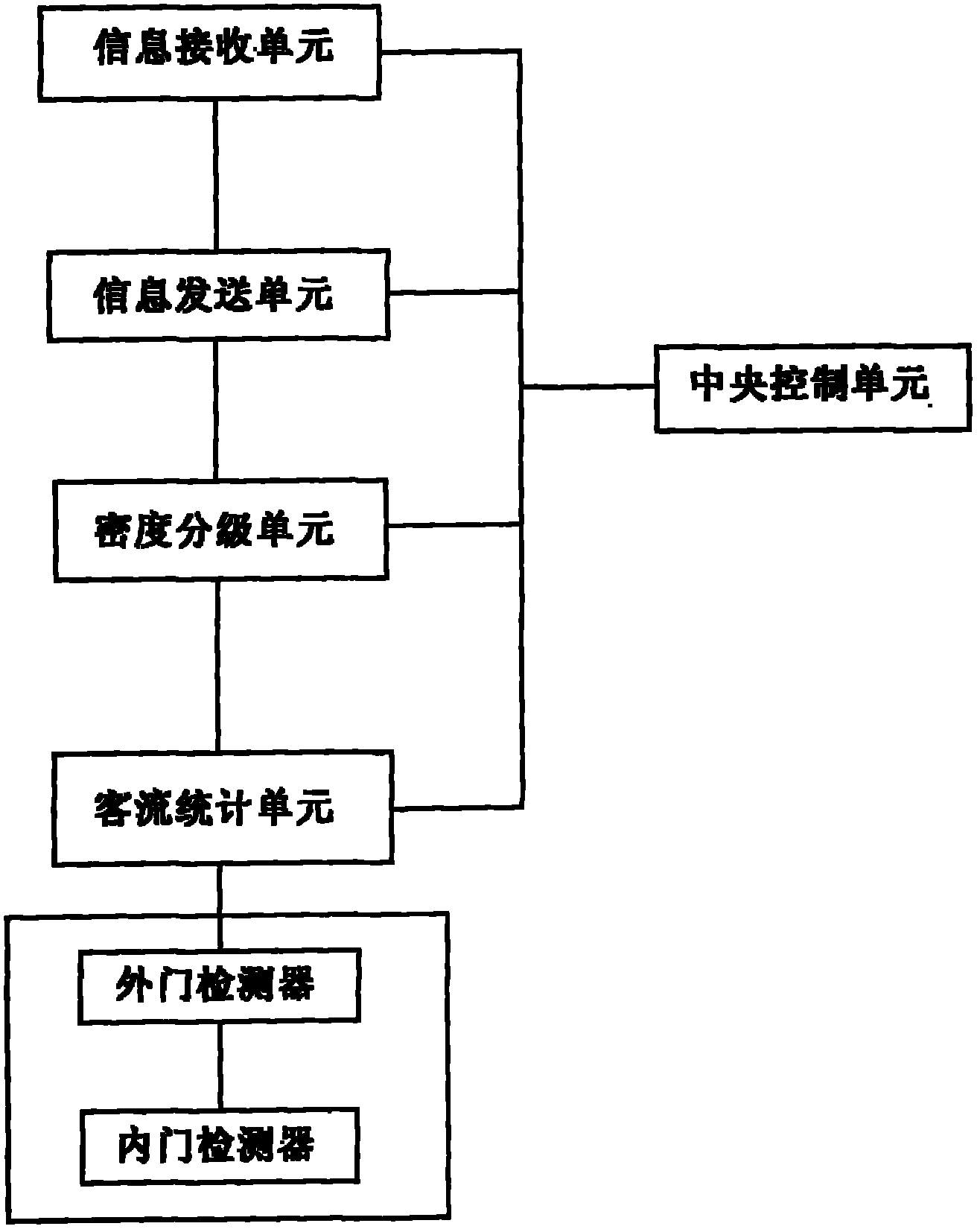

InactiveCN101944289AAvoid mistakesEfficient operationDetection of traffic movementControl systemBody compartment

The invention discloses a subway passenger conducting management control system and a method thereof. The subway passenger diversion management control system comprises a passenger flow statistical unit, a density grading unit, an information transmitting unit, an information receiving unit and a central control unit, wherein the passenger flow statistical unit comprises an external door detector and an internal door detector; when a subway train departs, the central control unit starts the passenger flow statistical unit; and every time the subway train arrives at one station, the external door detector detects the number of passengers who walk into the door, the internal door detector detects the number of passengers who walk out of the door, the density grading unit grades the density of the current number of passengers in each carriage and sets the density factor, the information transmitting unit transmits the density factor of each carriage to the information receiving unit of the next station, and a subway working personnel reminds the passengers to go to the carriages with fewer passengers to wait for the train according to the density factor of each carriage received by the information receiving unit. Thus, the invention scientifically and effectively diverts the passengers, helps the subway stations to conveniently and quickly conduct the passengers, and facilitates traveling of people.

Owner:SUN YAT SEN UNIV

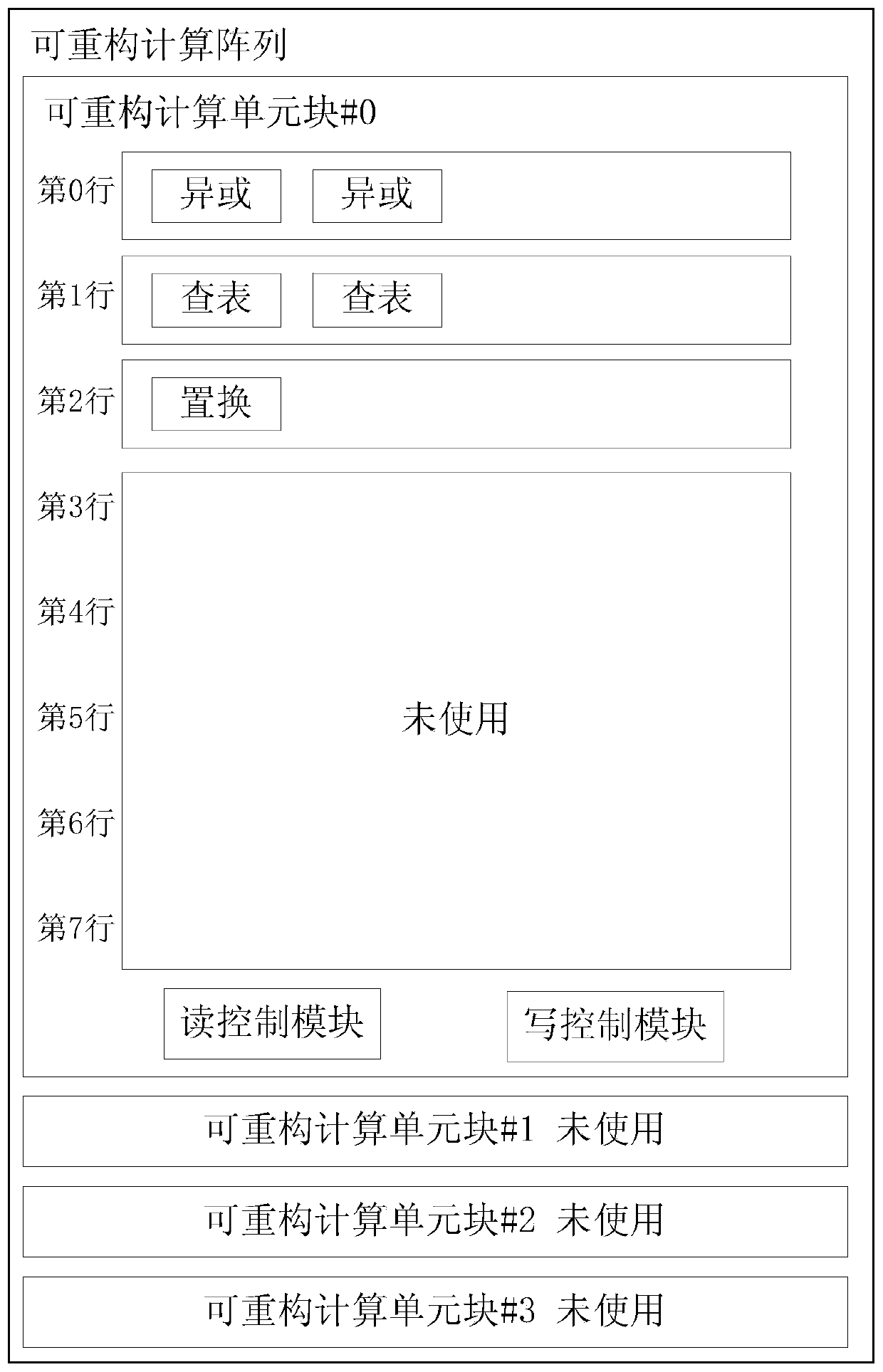

PRESENT encryption algorithm implementation method and system based on coarse-grained reconfigurable computing unit

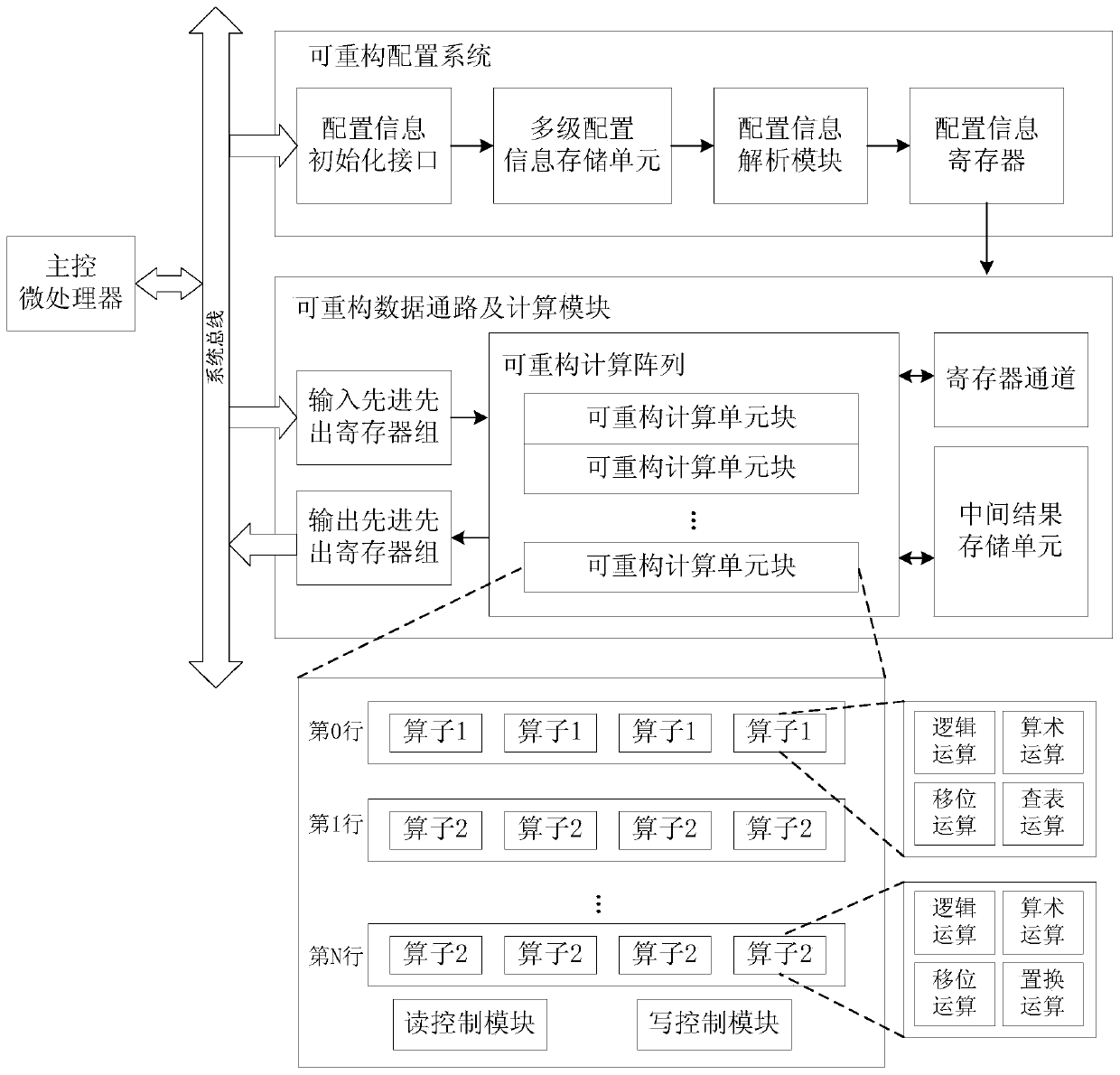

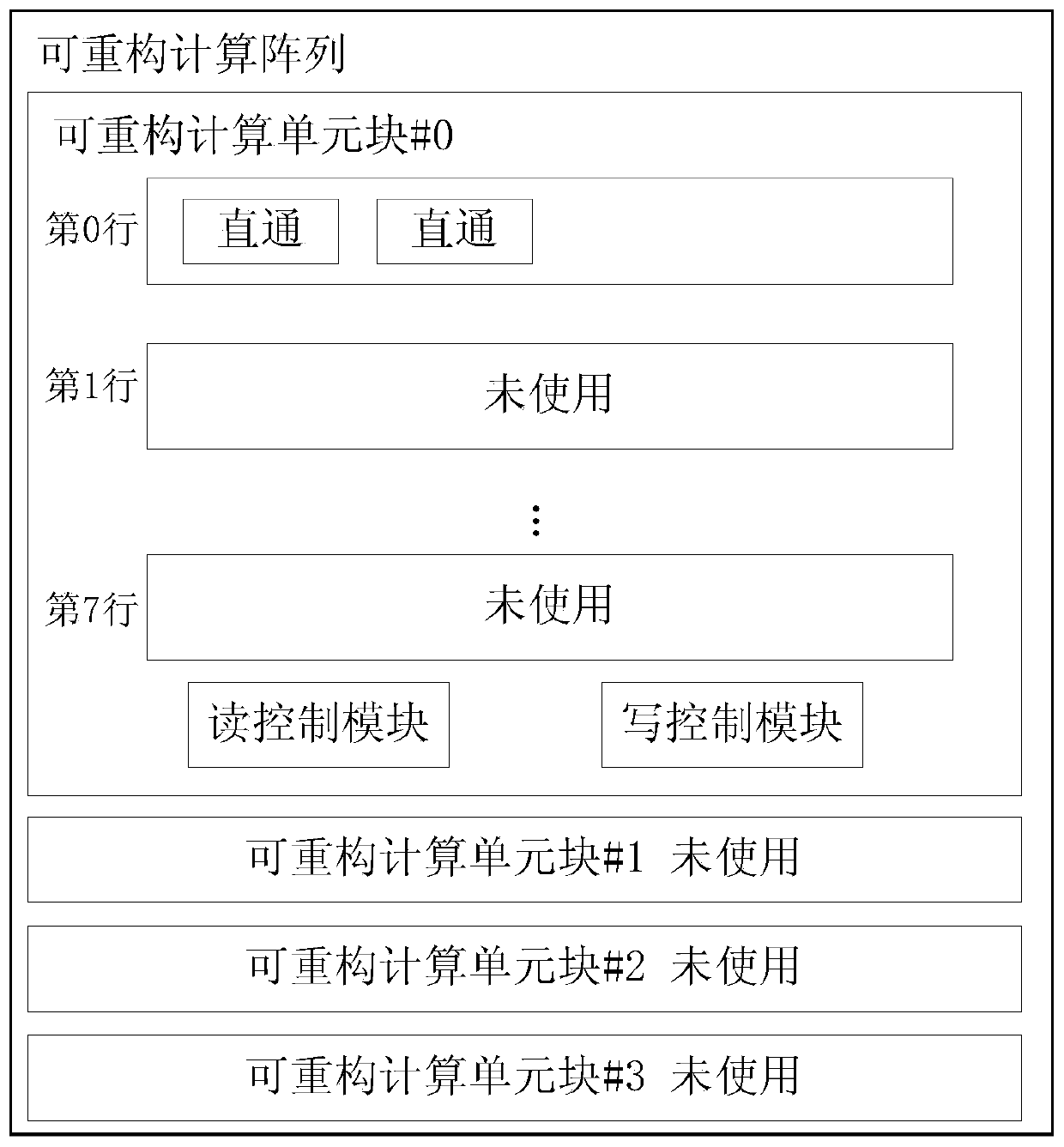

PendingCN110321162AEfficient operationEasy to operateRegister arrangementsInternal/peripheral component protectionReconfigurable computingConfiguration system

The invention provides a PRESENT encryption algorithm system based on a coarse-grained reconfigurable computing unit. The PRESENT encryption algorithm system comprises a reconfigurable configuration system, a reconfigurable data path, a computing module, a main control microprocessor and a system bus, the reconfigurable configuration system comprises a configuration information initialization interface. The reconfigurable data path and calculation module comprises a reconfigurable calculation array, a register channel, an intermediate result storage unit, an input first-in first-out register set and an output first-in first-out register set. Wherein the reconfigurable computing array comprises a reconfigurable computing unit block, and the reconfigurable computing unit block comprises multiple rows of operators, a read control module and a write control module; according to the invention, efficient operation of the PRESENT encryption algorithm can be realized.

Owner:无锡沐创集成电路设计有限公司 +1

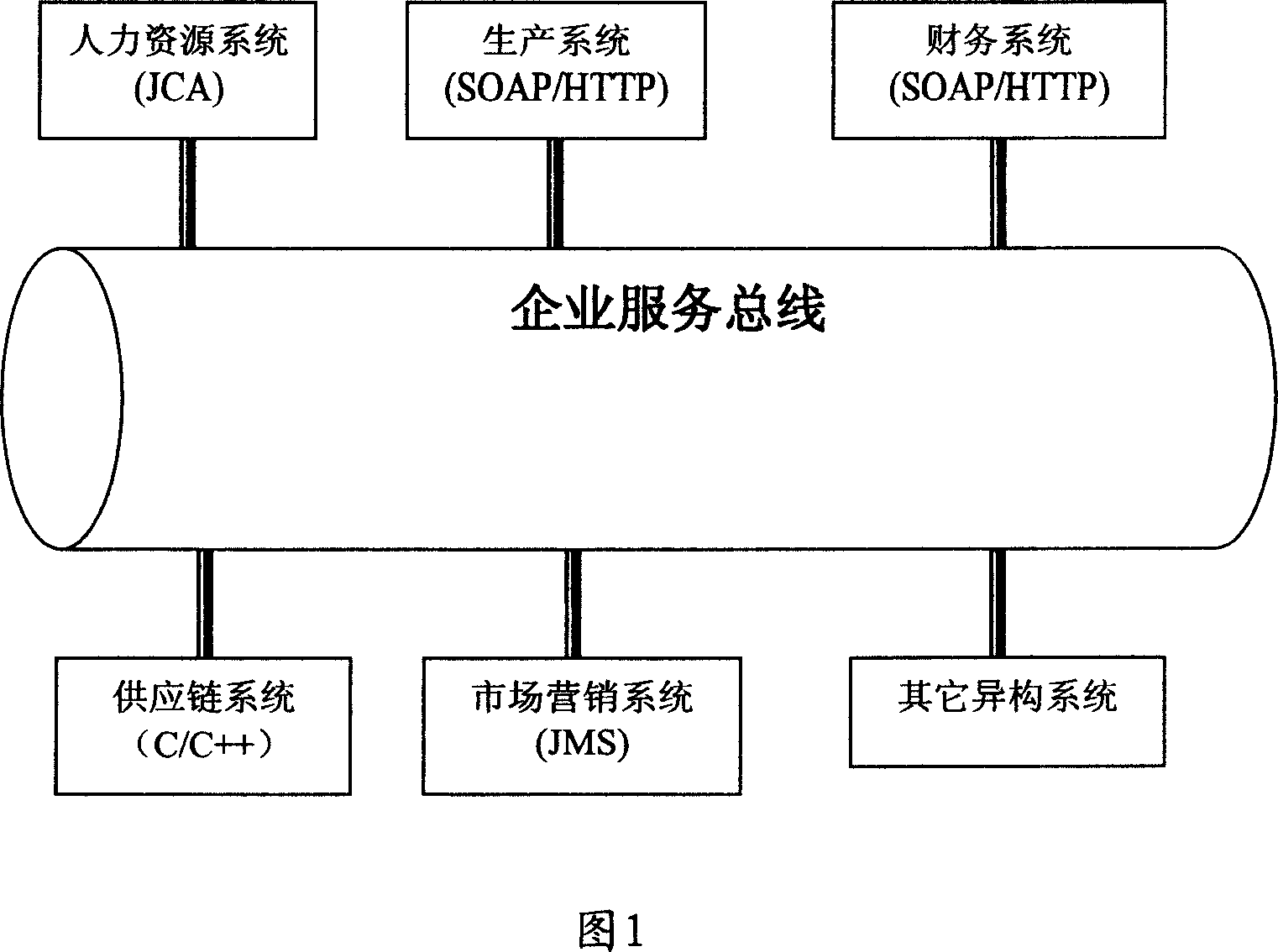

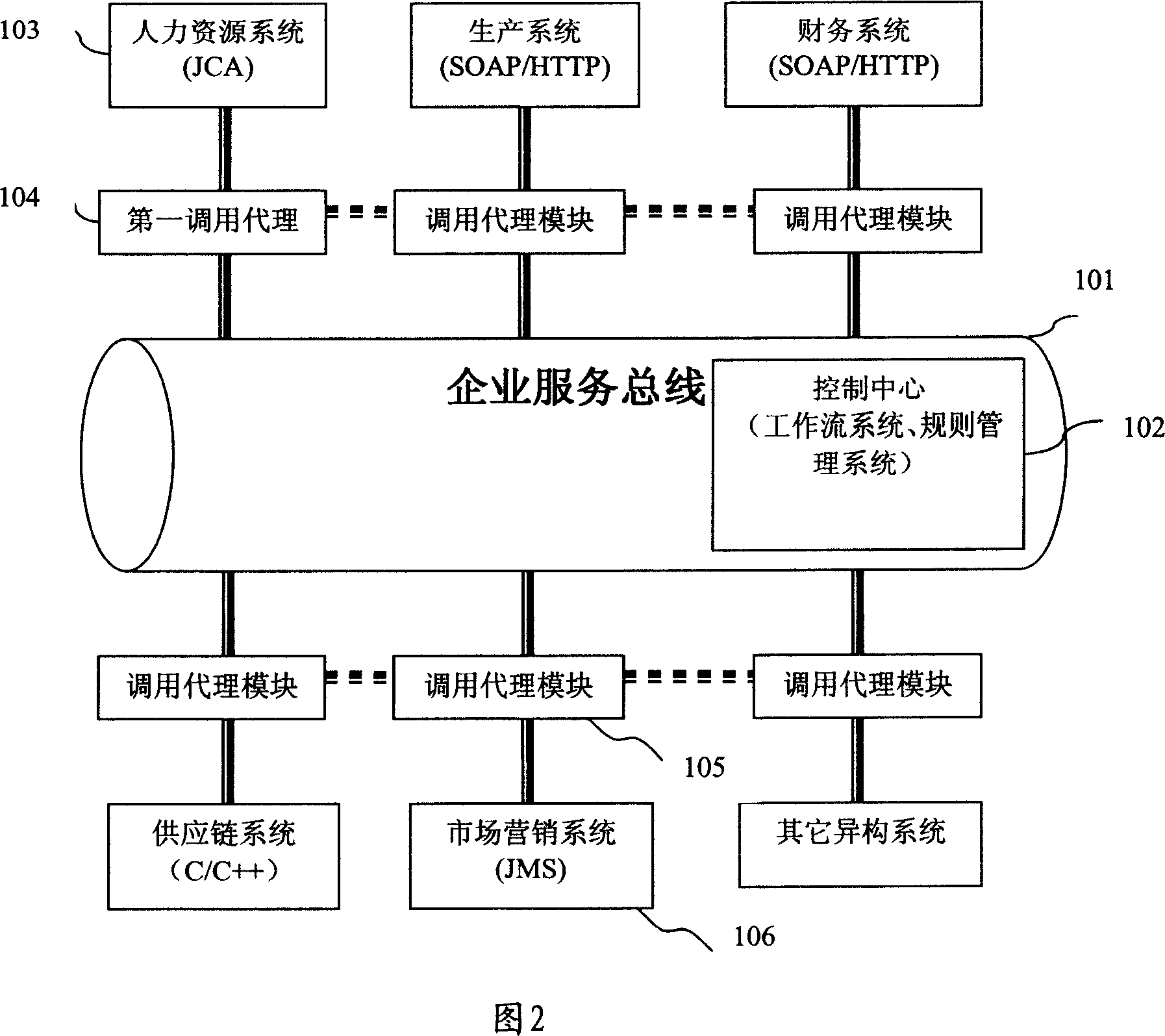

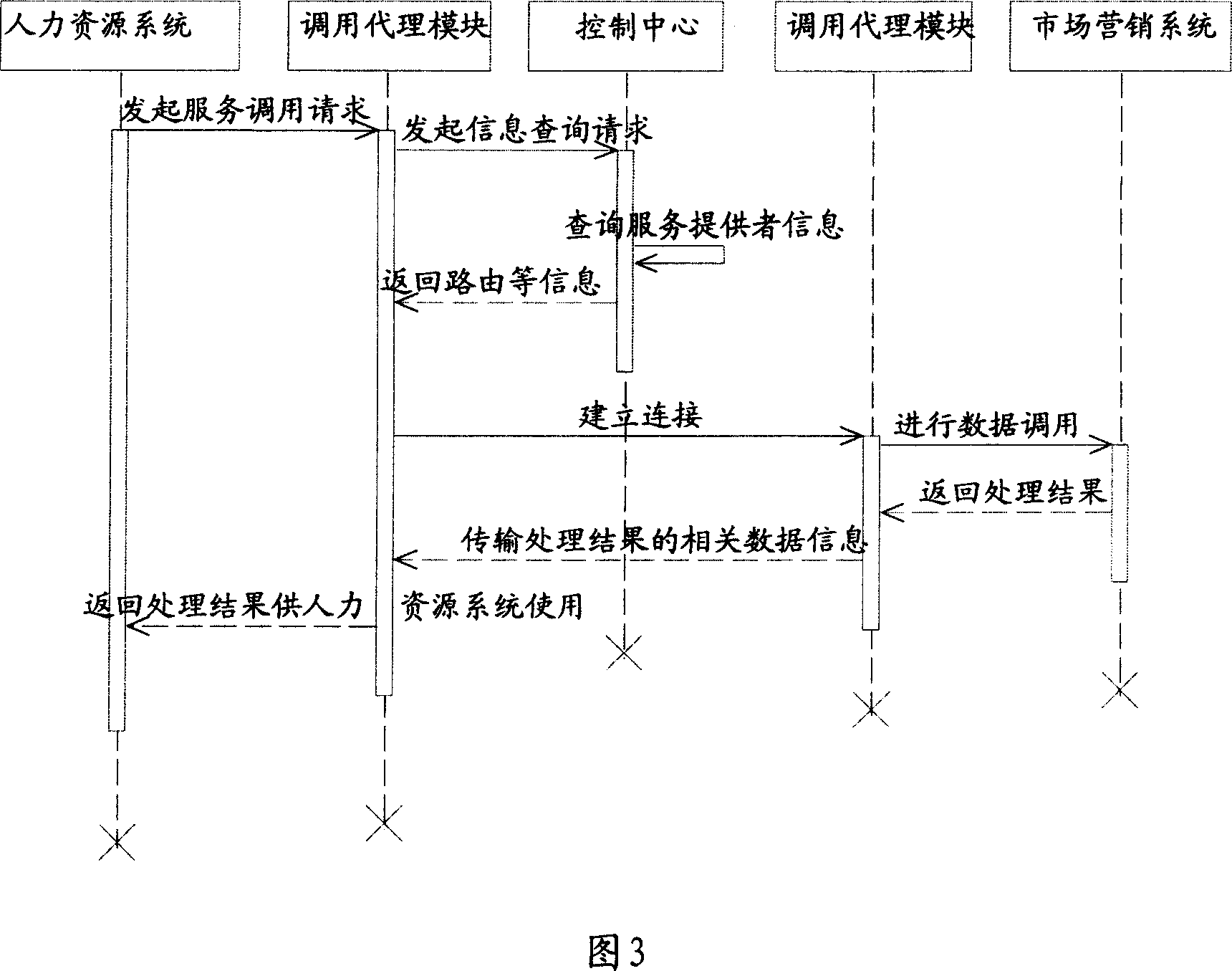

System and method for lowering load of enterprise service bus

This invention discloses a service call system based on enterprise service bus including the following modules: a control module, a first call proxy module, a second call proxy module and a service process module, in which, the first one is used in receiving a service call request sent to a second service process module from a first service process module connected with it and asks for the control information of the second service process module to the control module via an enterprise service bus and sends the call request to the second module based on said control information to return the call result to the first module, the second call proxy module is used in receiving the service call request sent to the second service process module by the first proxy module and transfers said request to second process module to transmit the result from the second process module to the first proxy module, the control module is used in returning the control information of the second service process module to the first proxy module via the service bus.

Owner:HUAWEI TECH CO LTD

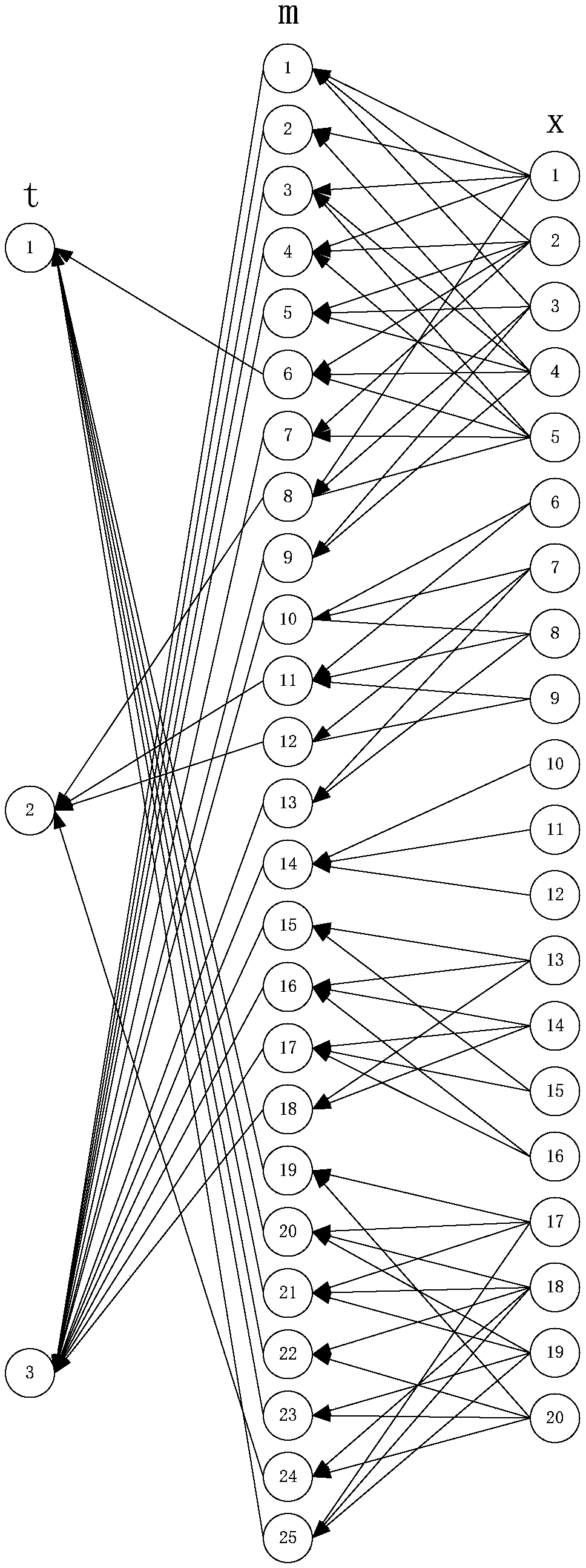

A Bayesian network-based dynamic approximate weight wind turbine generator operation state comprehensive evaluation method

ActiveCN109685371AEffective evaluationReal-time effective running statusResourcesSystems intergating technologiesElectricityRelationship - Father

According to the Bayesian network-based dynamic approximate weight wind turbine generator running state comprehensive evaluation method, The method comprises steps of utilizing scada data to determinea wind turbine generator state evaluation parameter vector, and classifying wind turbine generator fault modes; And constructing a three-layer Bayesian network to describe the operation parameter vector of the wind turbine generator and the fault causal relationship, determining the prior distribution of the Bayesian network parameter vector, and determining the hyper-parameter of the product Dirichlet distribution through the experience knowledge of the wind turbine generator. And determining the posterior probability distribution of the Bayesian network parameters. And calculating conditional probability distribution of each node in the Bayesian network under different states of father nodes of the node. And comprehensively evaluating the operation state of the wind turbine generator according to the dynamic approximate weight of the comprehensive evaluation of the operation state of the wind turbine generator. According to the method, the operation state of the wind turbine generator is evaluated rapidly and effectively, the abnormity and degradation trend of equipment are found in advance, predictive maintenance is achieved, faults are effectively avoided, economic losses arereduced, and the economy and safety of the wind power plant are improved.

Owner:华能陕西定边电力有限公司

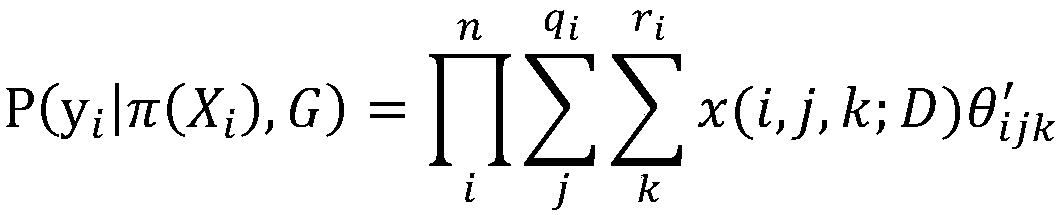

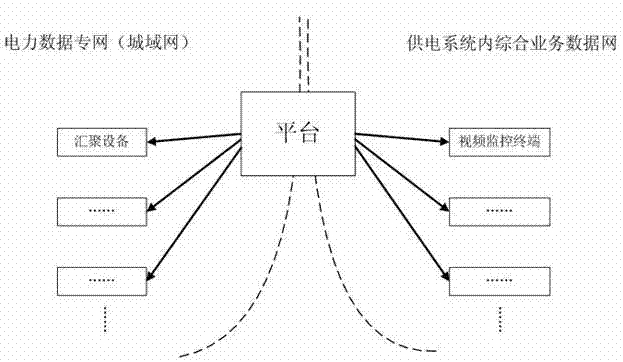

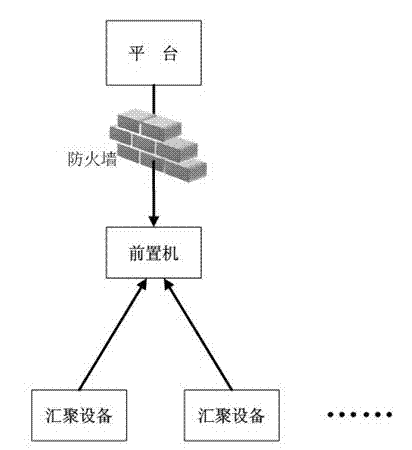

Power distribution surveillance video data transmission system based on metropolitan area network distributed architecture and control method

InactiveCN103096033ANo long-term occupationControl inputClosed circuit television systemsTransmissionNetwork conditionsData shipping

The invention discloses a power distribution surveillance video data transmission system based on a metropolitan area network distributed architecture. The power distribution surveillance video data transmission system comprises a photographic device in a power distribution room in a community, a converging device used for converging multiple paths of power distribution video surveillance signals, and a power distribution video surveillance platform. The photographic device sends the multiple paths of power distribution video surveillance signals to the converging device for backup. The converging device is connected and communicated with the power distribution video surveillance platform through an electric power gateway with a firewall function and a metropolitan area network special for electric power. The power distribution video surveillance platform actively issues a flow guiding demand instruction to the converging device in the community, and the converging device in the community responds and then uploads power distribution video surveillance signal data which is collected through the photographic device in the power distribution room according to the instruction. The invention also discloses a power distribution surveillance video data transmission control method based on the metropolitan area network distributed architecture at the same time. According to the power distribution surveillance video data transmission system and the power distribution surveillance video data transmission control method based on the metropolitan area network distributed architecture, necessary hardware investment cost is reduced, existing network conditions and resources are fully utilized, network loads and long-time bandwidth occupation are reduced, and ordered management of a city-level power distribution equipment surveillance system is realized.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

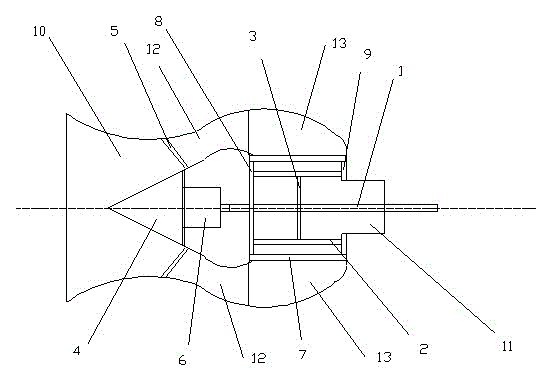

Hybrid lift type impeller

InactiveCN102943732AOvercome the shortcomings of weak work abilityImprove working abilityHydro energy generationWind motor combinationsImpellerWater flow

The invention discloses a hybrid lift type impeller. The hybrid lift type impeller comprises a rotating shaft, two or more than two lift type vanes, an electric generator and a casing, the lift type vanes are arranged on the rotating shaft, the electric generator is connected with the rotating shaft, the casing is provided with a fluid inlet and a fluid outlet, a tapered flow guide cover is disposed in the middle in the casing, the electric generator is mounted in the tapered flow guide cover, the lift type vanes are located in the fluid outlet, an annular channel is formed between the tapered flow guide cover and the casing, a flow gathering chamber is formed between the lift type vanes and the casing, the annular channel is communicated with the flow gathering chamber, grids are annularly distributed at an outlet of the flow gathering chamber, and the grids are parallel to the lift type vanes. By means of the hybrid lift type impeller, water flow changes from transverse flowing to longitudinal flowing under the combined action of an inlet flow channel, the flow guide cover, the annular flow channel, the flow gathering chamber and the grids sequentially, the water flow flows into a vane working area along the normal direction of the vane rotating circle, so that the lift type vanes can obtain an optimal fluid dynamic field, and the working capacity of the vanes is improved.

Owner:HOHAI UNIV

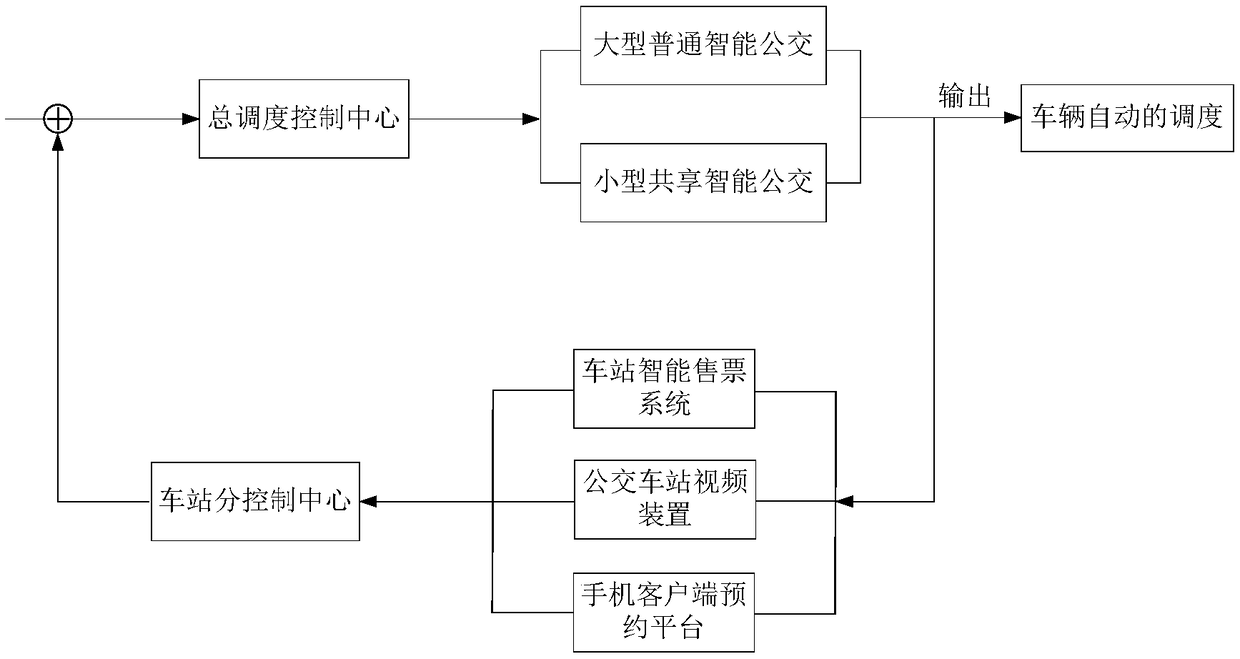

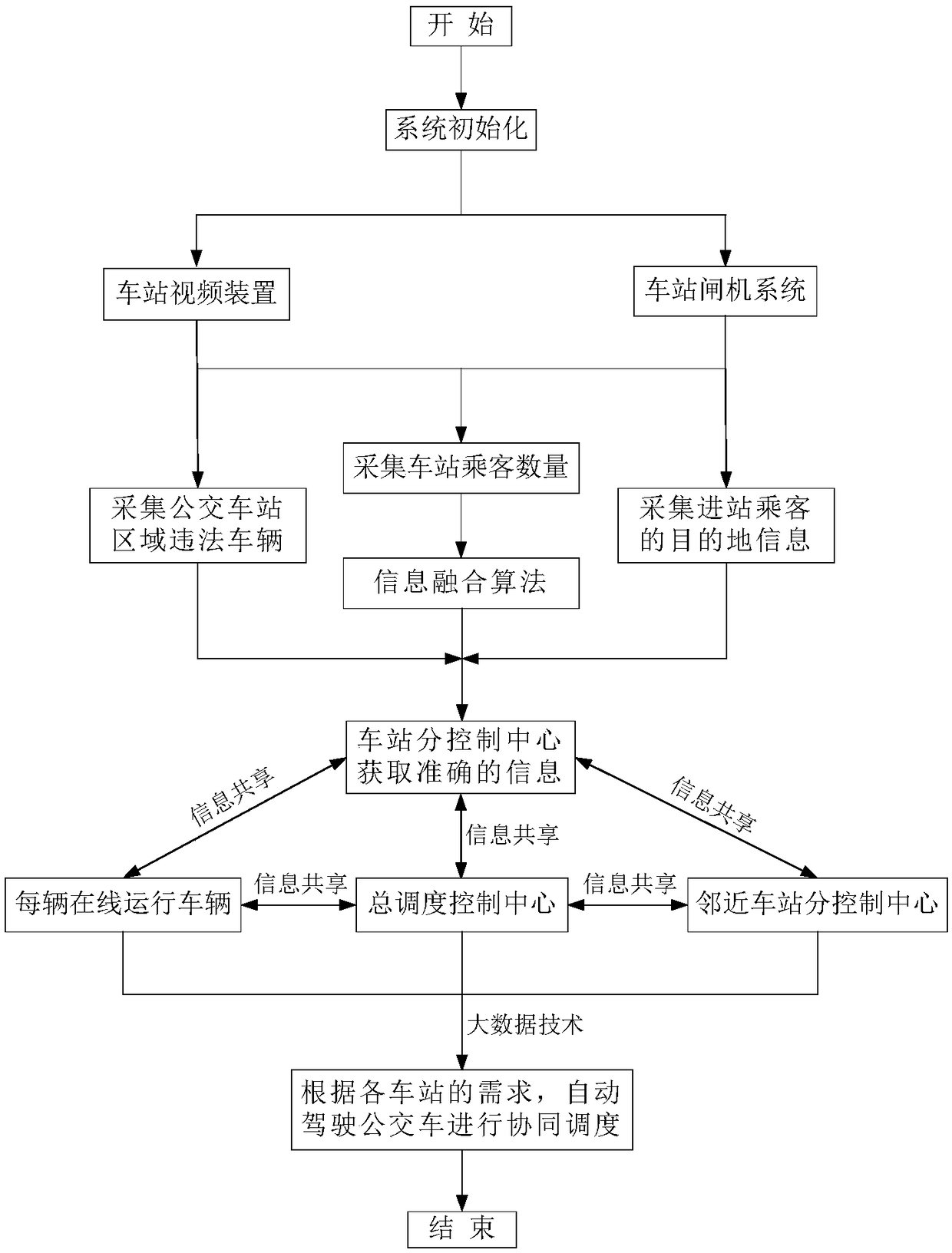

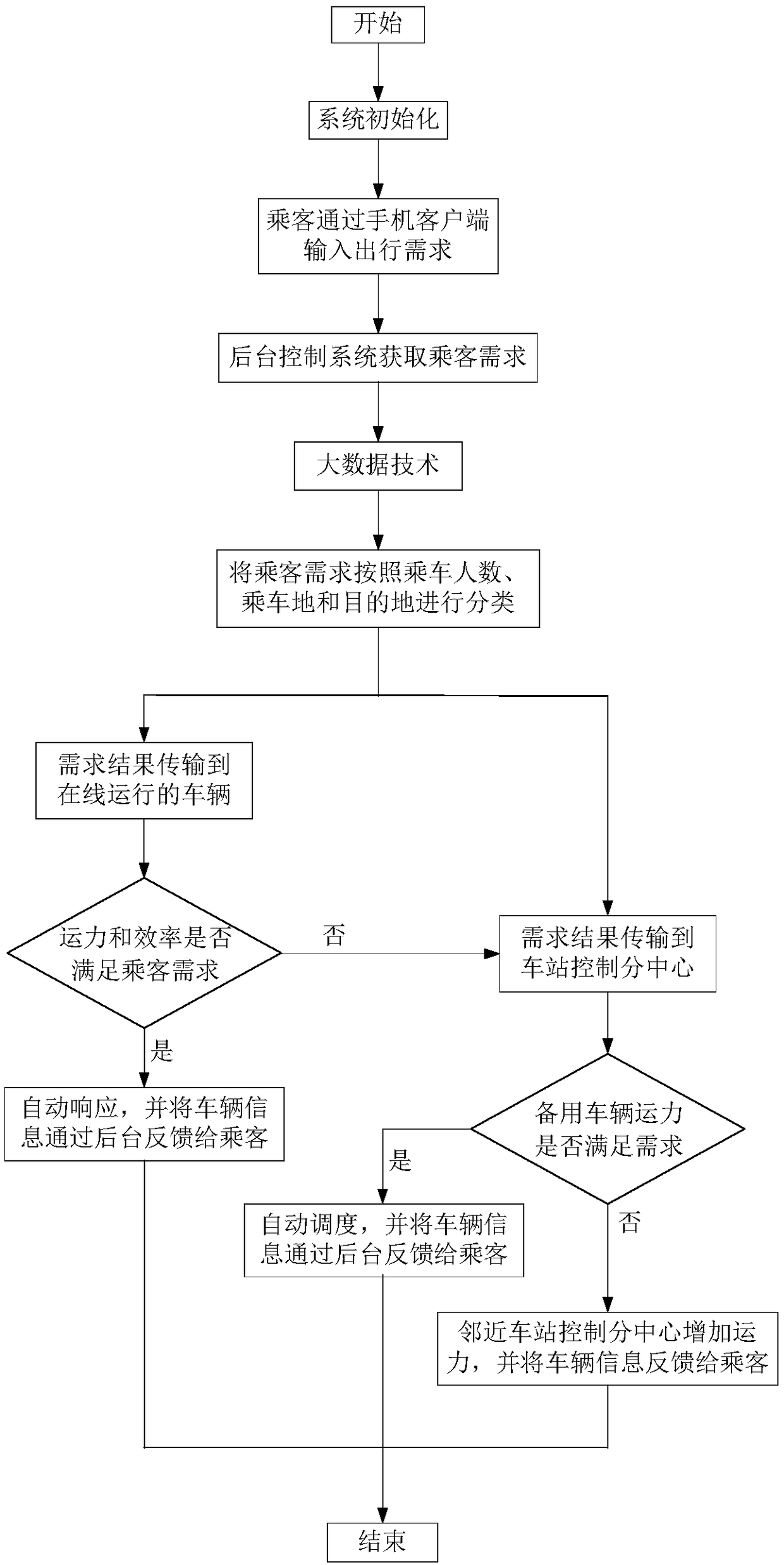

Vehicle-road coordination control system for intelligent bus, and application method of vehicle-road coordination control system

InactiveCN109410618AGuaranteed arrival timeEfficient operationDetection of traffic movementEngineeringTime information

The invention provides a vehicle-road coordination control system for the intelligent bus, and an application method of the vehicle-road coordination control system. The system comprises vehicle station control branch centers, a general dispatching control center, passenger cellphone clients, and online intelligent operation vehicles. The vehicle station control branch centers are respectively disposed in all buses, and control the online intelligent operation vehicles, achieve the sharing of the real-time information with the general dispatching control center and the online intelligent operation vehicles, and complete the dispatching of the online intelligent operation vehicles. Each bus stop is disposed in an expressway service area, and the online intelligent operation vehicles just run on an automatic drive exclusive lane of an expressway. The control system in the invention is a completely intelligent operation system, can achieve the information intercommunication with passengers, is convenient in operation, and meets the intelligent travel demands of the passengers. The online intelligent operation vehicles of a clean energy type are all of an automatic drive type, therebyreducing the labor force, and achieving the efficient and green travel for the passengers.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

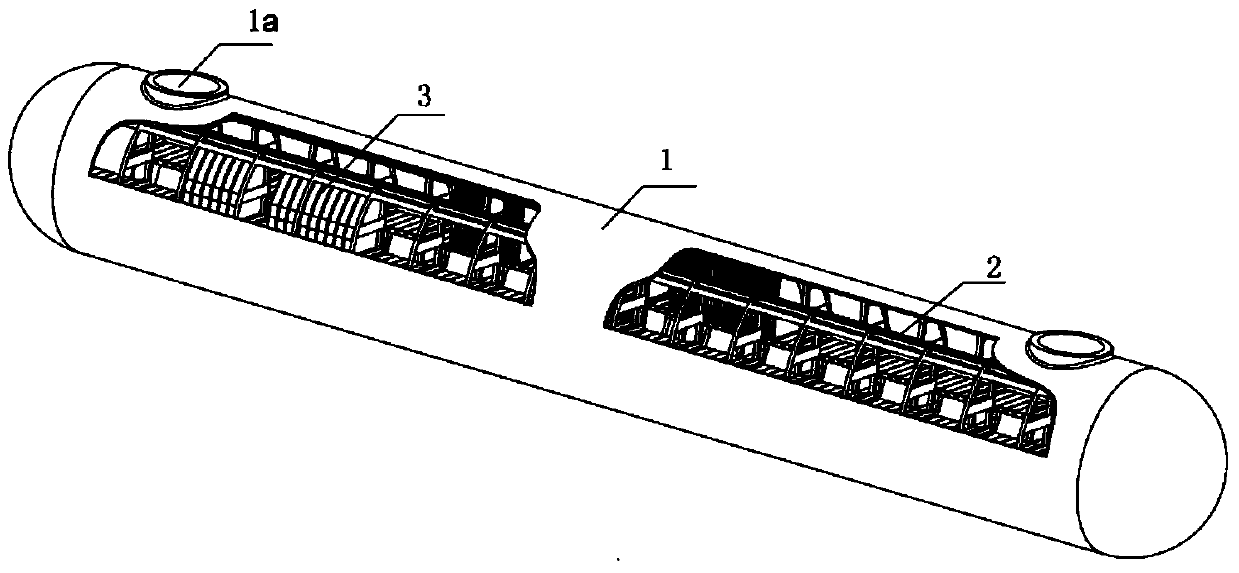

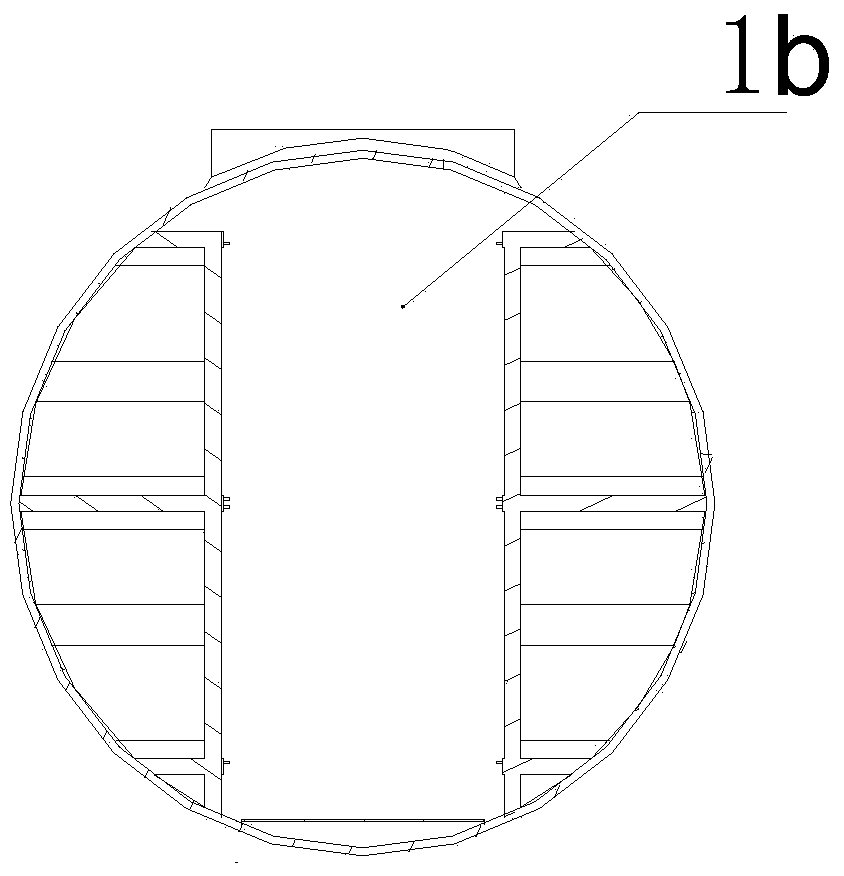

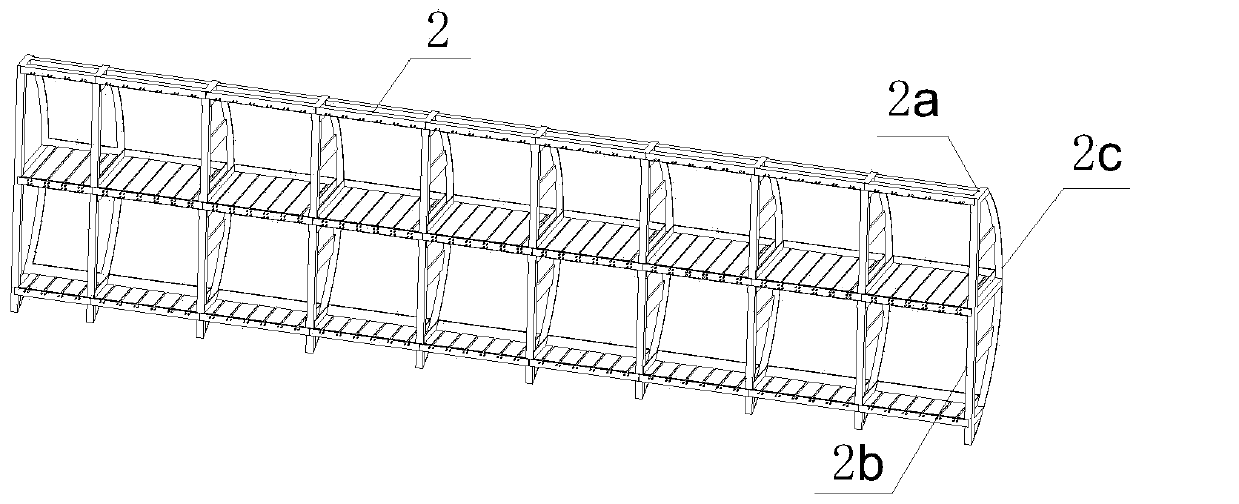

Lithium battery pack of large underwater vehicle

ActiveCN103700794AHigh specific energyIncrease powerAssembling battery machinesFinal product manufactureLocking mechanismElectrical battery

The invention discloses a lithium battery pack of a large underwater vehicle. The lithium battery pack is characterized by comprising a battery cabin, battery modules, a bus bar, two battery racks, a fastening pressure plate, a battery management system and locking mechanisms, wherein the battery cabin is cylindrical, the head and the tail of the cabin are semispherical, an inlet and an outlet are formed in the upper part of the cabin, the two battery racks are symmetrically arranged on the two sides of the cabin, and a maintenance channel is formed in the middle of the cabin; the cross section of each battery rack is bow-shaped and comprises two straight edges and an arc, and the radius of the arc is the same as that of the inner wall of the battery cabin; the battery rack is divided into an upper layer and a lower layer; each layer is provided with a plurality of compartments, the locking mechanisms are arranged in the compartments, and the battery modules are symmetrically mounted in the compartments. The lithium battery pack provided by the invention is high in volumetric specific energy, good in safety performance, strong in environmental adaptability and convenient to maintain.

Owner:BEIJING SHENZHOU YUANWANG TECH

Electronic public transport stop board realizing relay type communication by using ISM frequency band

InactiveCN101393685ASave energyReduce RF PollutionNear-field transmissionRoad vehicles traffic controlMicrocontrollerTime information

The invention relates to an electronic bus station board which can realize relay type communication through an ISM public frequency band. The normal station name, line numbers and orderly arranged line drawing marked with the name of each station are arranged on the front side of the board, and a light emitting diode (LED) is embedded below each station name; a circuit board is installed on the back side of the board, and a board-to-board relay type ISM wireless communication module, a board-to-arriving bus ISM wireless communication module, a bus arriving detector and an LED bus stopping position display which are arranged on the circuit board are connected with a microcontroller; and a solar panel and an accumulator module are connected with both the microcontroller and each element circuit on the circuit board. The electronic bus station board has the advantages that the fabrication cost is low, the pollution of the electromagnetic wave is small, and the feed of commercial power is not needed; not only the real-time information on the position of the coming bus is visually provided for the passengers waiting for the bus, but also the real-time efficient dispatching can be possible for the bus line management department.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

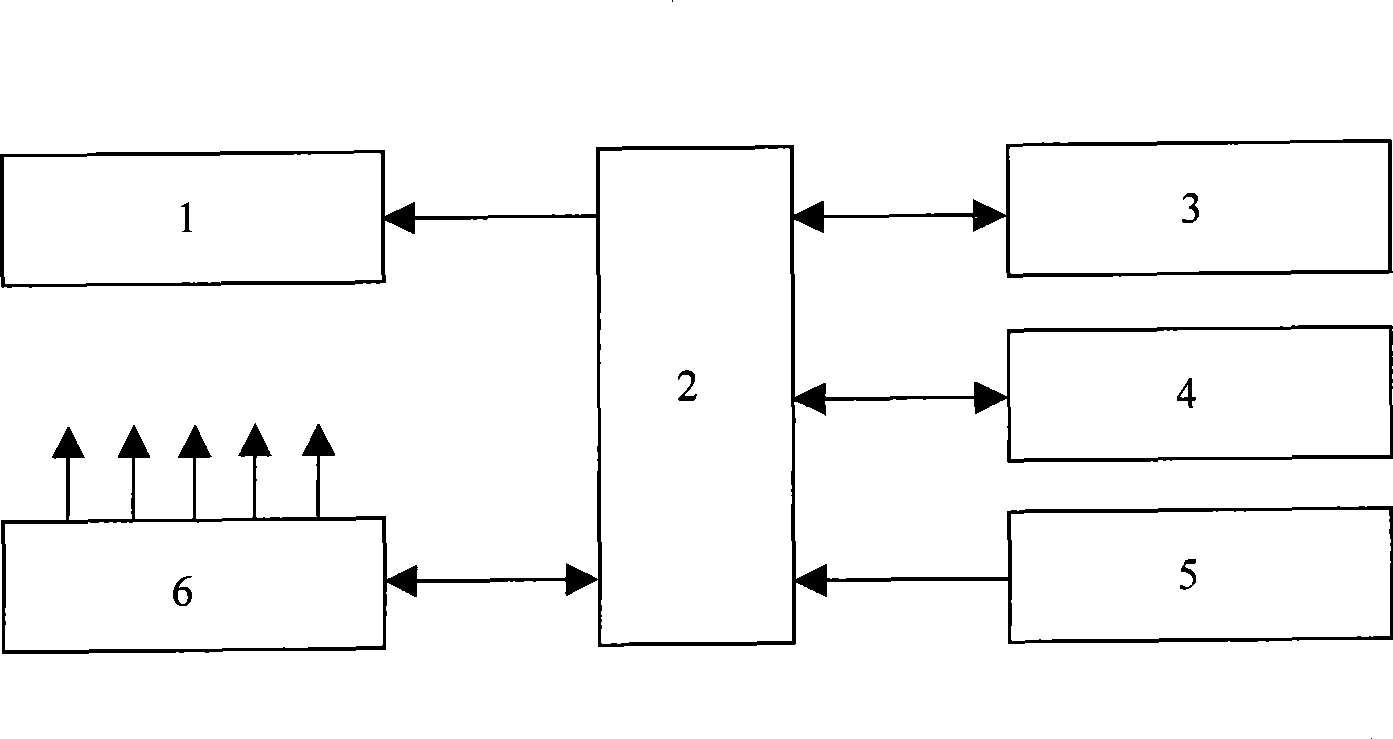

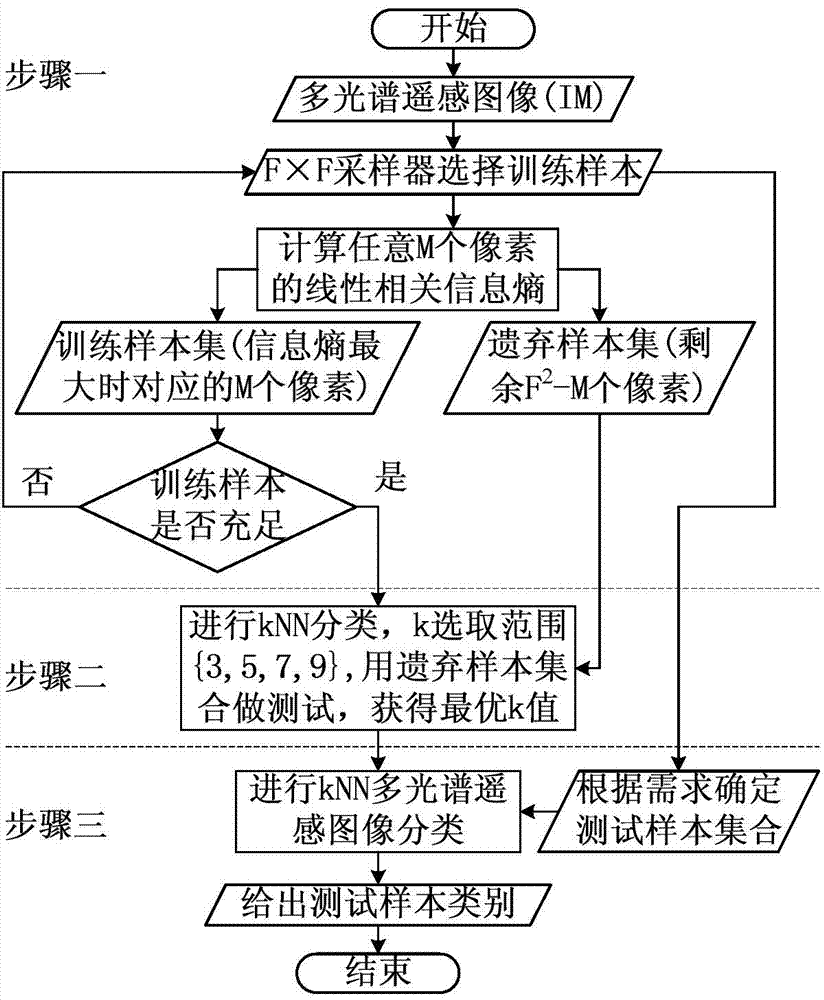

Multi-spectrum data supervised classification method based on relevant linear information entropy

ActiveCN104504399AEfficient operationThe classification result is accurateCharacter and pattern recognitionLinear correlationMultispectral data

The invention discloses a multi-spectrum data supervised classification method based on relevant linear information entropy and relates to a remote sensing image supervised classification method based on relevant linear information entropy and a kNN classifier. The supervised classification method comprises the following steps of: firstly, automatically filtrating training sample sets required for supervised classification after manually sampling; secondly, automatically optimizing the parameters for determining the kNN classifier algorithm; thirdly, classifying multi-spectral remote-sensing images by using the kNN classifier algorithm. The supervised classification method is characterized in that the classification precision of the kNN classifier algorithm can be effectively improved and the classification time is reduced by efficiently and automatically filtrating training samples input by multiple variables and automatically optimizing the classifier parameters, so that the supervised classification method is more appropriate for the high-precision classification task of the multi-spectral remote-sensing images with large data volume.

Owner:HARBIN INST OF TECH

Load flow analysis method of direct current transmission feed end islanding system

ActiveCN103904674ABoost or reduce DC powerAccurately reflect the actual situationElectric power transfer ac networkPower compensationIslanding

The invention discloses a load flow analysis method of a direct current transmission feed end islanding system. The method includes the following steps that (1) an alternating current system and a direct current system are divided; (2) the load flow of the islanding alternating current system is solved; (3) out-of-limit judgment is conducted on the reactive power exchange capacity of the alternating current system and the direct current system, if reactive power exchange exceeds a normal operation set value, the amplitude of a commutation busbar voltage is adjusted, the step (2) is executed again to continue, and otherwise the step (4) is executed; (4) the number of reactive power compensation groups is determined; (5) the reactive power consumption of a direct current convertor station is determined; (6) converter firing angle amplitude limiting inspection is carried out, if the amplitude is within a normal operation range limiting value, the step (7) is executed, otherwise the number of the reactive power compensation groups is added, and the step (5) is executed again; (7) a commutation tap is determined; (8) load flow convergence is judged; (9) the direct current frequency limiting value function is set. By means of the load flow analysis method of the direct current transmission feed end islanding system, the practical situation of the direct current transmission islanding system can be reflected more accurately, and planning and operating of the direct current transmission islanding system can be guided more efficiently.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

Dining table having self-help food ordering and drinking water functions

InactiveCN106942904AReduce in quantityEfficient operationData processing applicationsBeverage vesselsEngineeringLiquid level sensor

The invention belongs to the field of manufacturing of dining tables, and in particular discloses a dining table having self-help food ordering and drinking water functions. The dining table comprises a dining table body, a food ordering device and a drinking water device. The food ordering device comprises a food ordering display screen, support frames and a revolving base; the food ordering display screen is vertically arranged and is fixed to the support frame; the revolving base is arranged in the center of the dining table body and the support fame is fixedly arranged on the revolving base; the drinking water device comprises a running water pipeline, a tea strainer, a tea water container, a tea water conveying pipeline, a controller and a teacup area; the running water pipeline is connected to the tea water container and is provided with electromagnetic valves; the tea strainer and liquid level sensors are arranged in the tea water container, and an enclosure cover is arranged at the top of the tea water container; a pad provided with a handle is welded on the outer edge of a port of the tea strainer; the tea water container is connected to one end of the tea water conveying pipeline, a water pump is arranged in the middle of the tea water conveying pipeline and a plurality of pipelines provided with electromagnetic valves are arranged at the other end of the tea water conveying pipeline; the controller is connected to the liquid level sensors, the electromagnetic valves, the water pump and the food ordering display screen; and the teacup area is arranged below the tea water conveying pipeline on the dining table. The dining table is simple and easy to operate and high in degree of being intelligent and automatic.

Owner:黄科钧

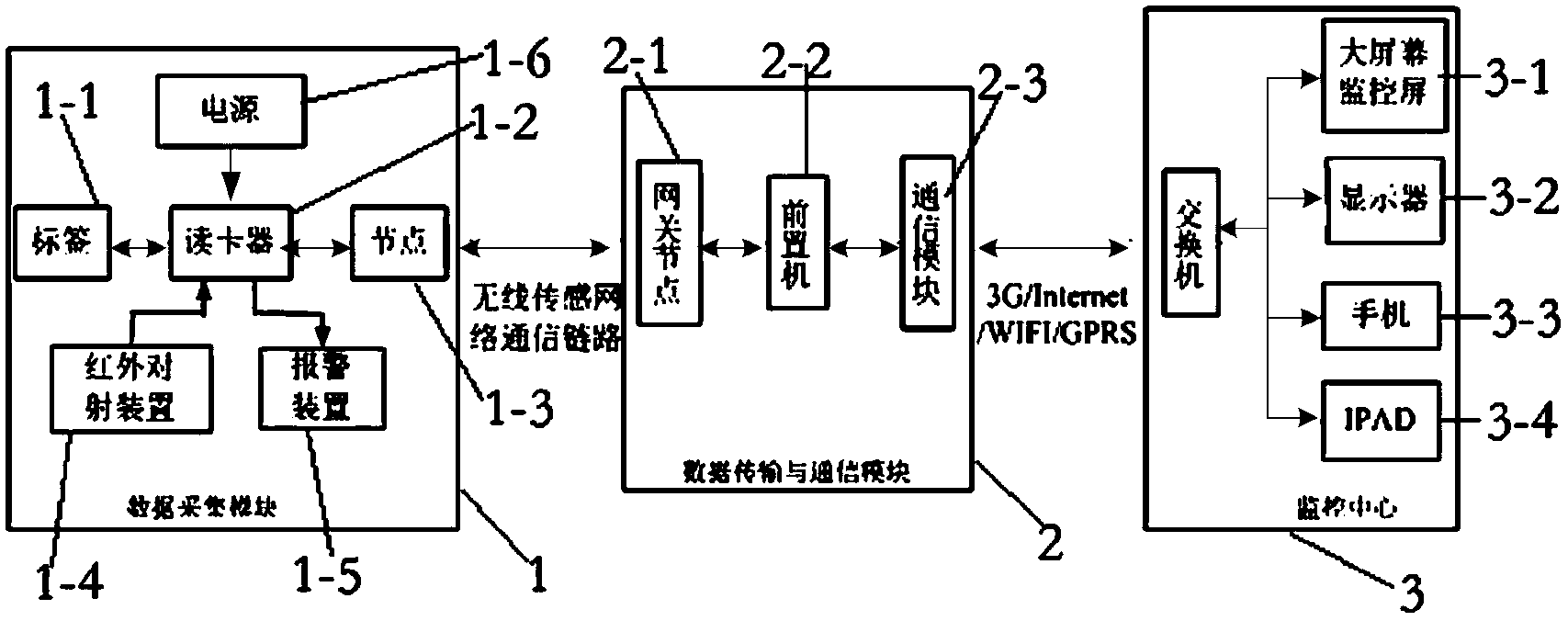

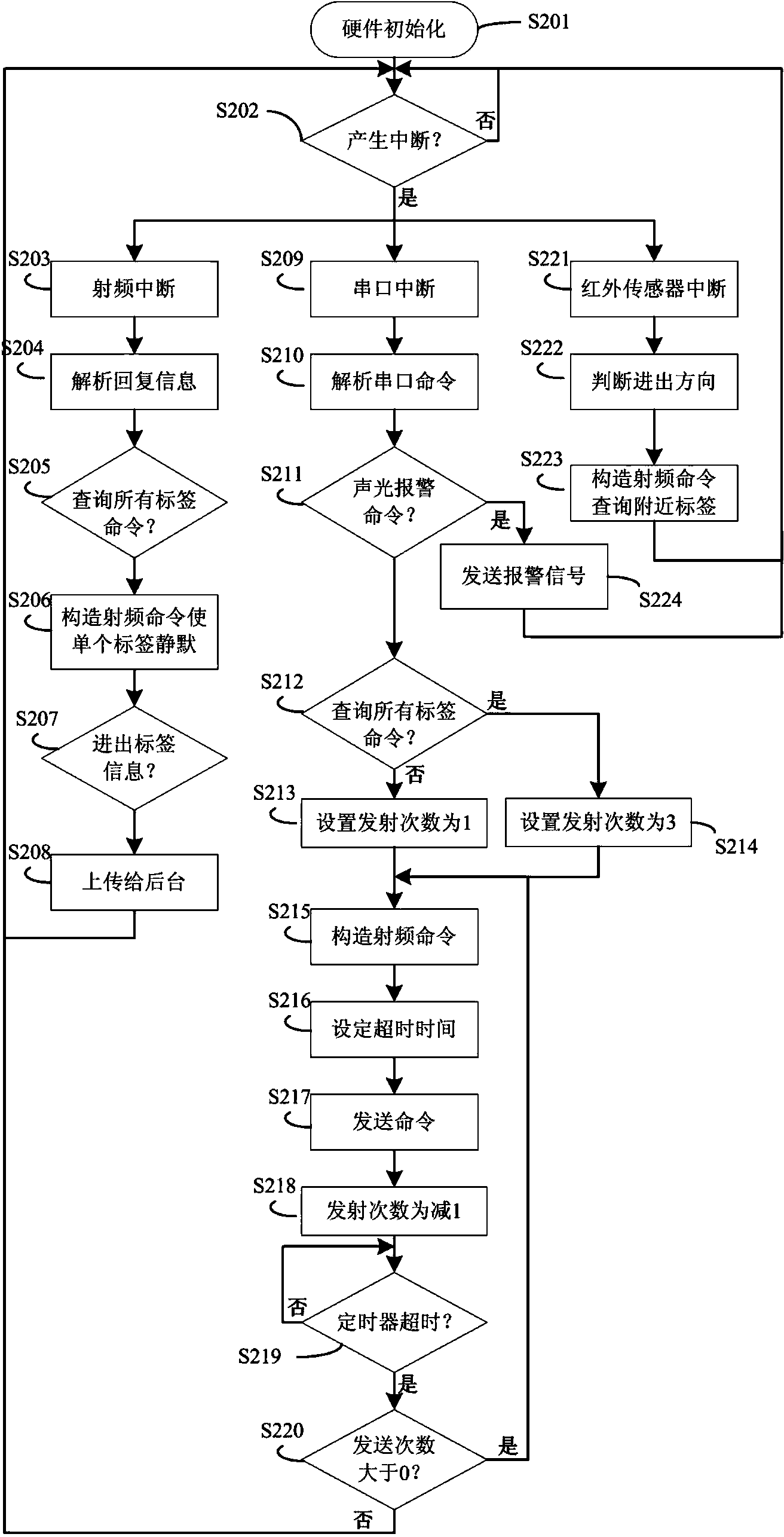

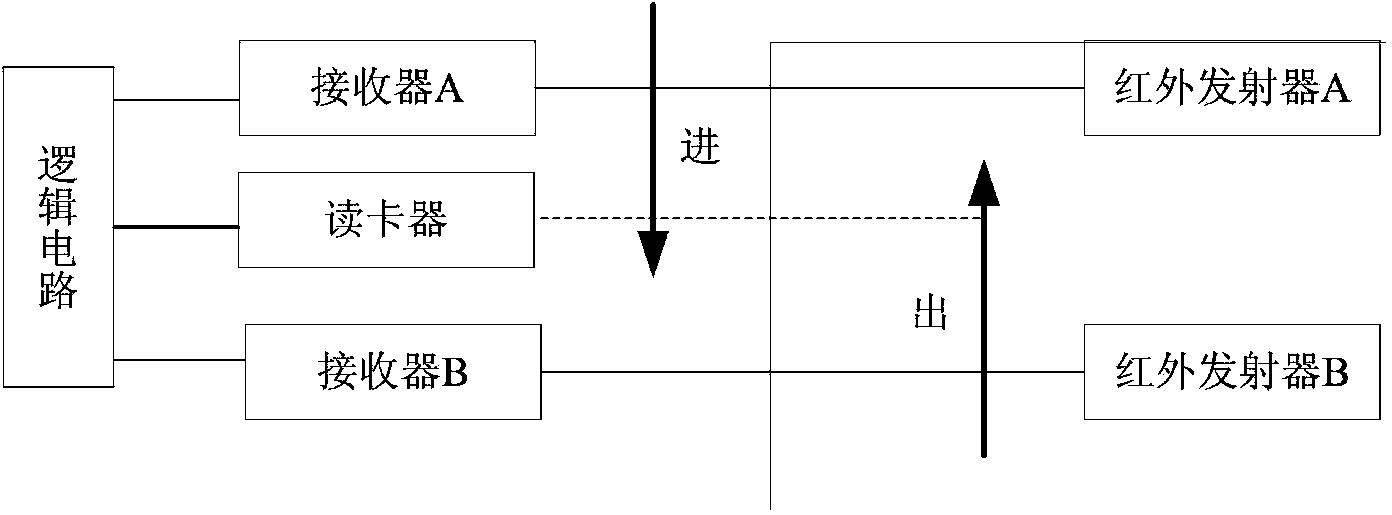

Material condition monitoring system and method based on radio frequency identification (RFID) technology

InactiveCN104345721AEfficient operationRealize automatic collectionEnergy industryTotal factory controlData transmissionCondition monitoring

The invention discloses a material condition monitoring system and a method based on radio frequency identification (RFID) technology. The system comprises a data collecting module, a data transmission and communication module and a monitoring center which are connected in sequence. The method disclosed by the invention comprises the steps of pasting an RFID electronic tag that records the corresponding material information on a piece of material equipment; automatically completing operations of putting in storage, identifying, positioning, tracking, checking, monitoring, scraping and the like through a card reader mounted at a fixed position and a hand-held mobile card reader. A user can log in the system on any personal computer (PC) in an enterprise network to perform the operations of remote plan declaration, remote inquiry and the like. The system and the method disclosed by the invention take full advantages of the RFID technology, the automatic collection and inquiry of the material information can be realized, the running temperature of the material equipment is monitored, the functions that a behavior of illegally taking out materials is monitored, the materials can be positioned to rooms and the like are realized, so that the safe, reasonable, economical and efficient operations of the materials of power enterprises are ensured.

Owner:HUANGHE S & T COLLEGE

Distribution network device detection informatization management method

PendingCN109302330ARealize whole-life quality managementSolve positioningPosition fixationData switching networksInformatizationLogistics management

The invention relates to a distribution network device detection informatization management method. The method comprises a PC and comprises the following steps in sequence: obtaining location information, obtaining device information and detection station state information, obtaining detection information, and formulating a detection scheme and a logistics scheme. The distribution network device detection informatization management method provided by the invention has the advantages that the step 1 realizes the distribution position informatization of a detected product on a spatial scale to solve the problems that the detected product is inconvenient to be positioned and searched within a detection period, and that assorted devices are easily confused after the detection, the warehouse-out and warehouse-in of the detected devices and the fast assembly of the assorted devices are facilitated, and a dynamic logistics scheme is formed, and the step 2 realizes the detection progress informatization of the detected product on a time scale to accurately master the detection progress of the detected product and the working conditions of each test area in real time, thereby optimizing thedetection scheme, reducing the human intervention, optimizing the logistics resources and the detection resources and greatly improving the detection efficiency.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +3

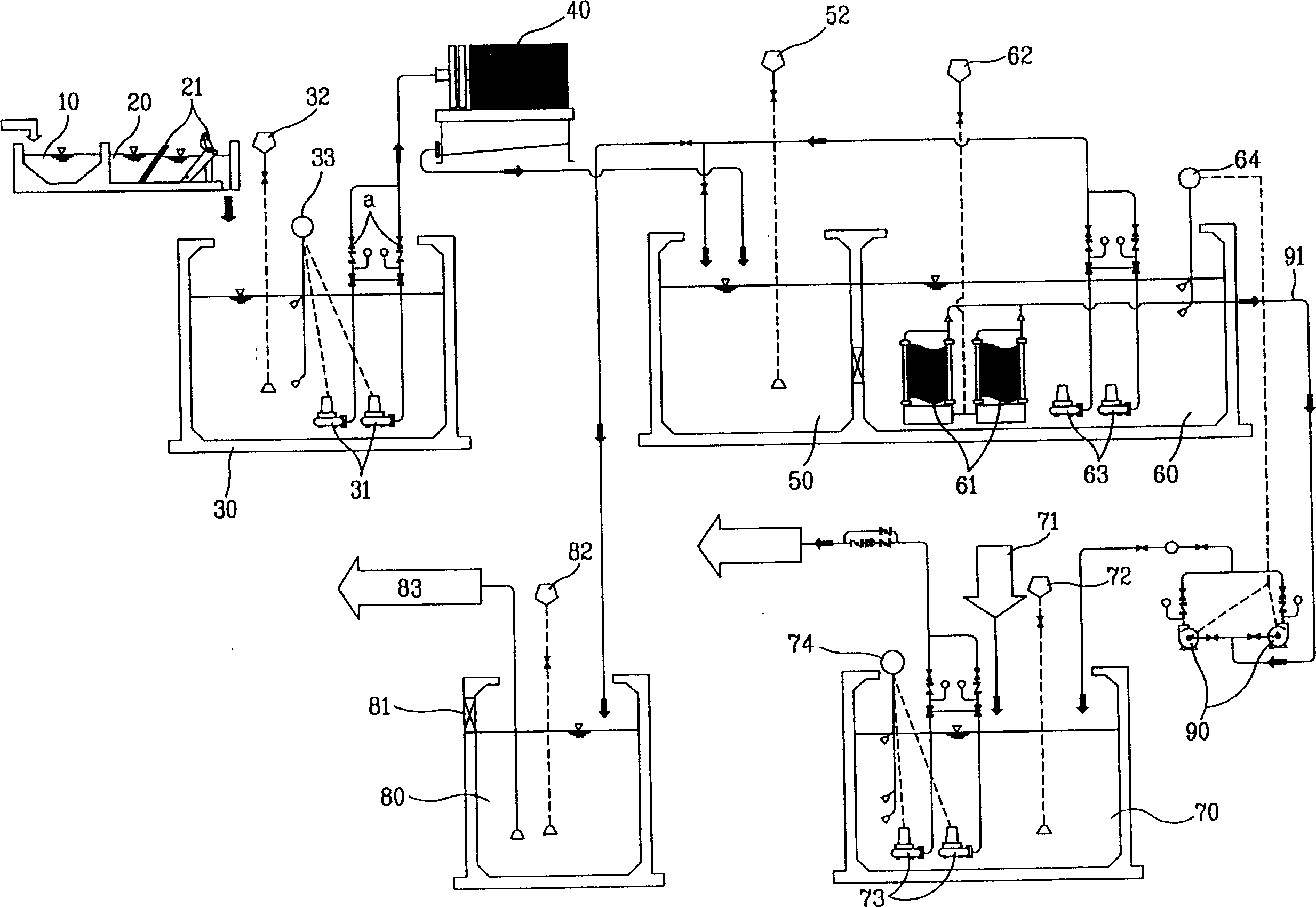

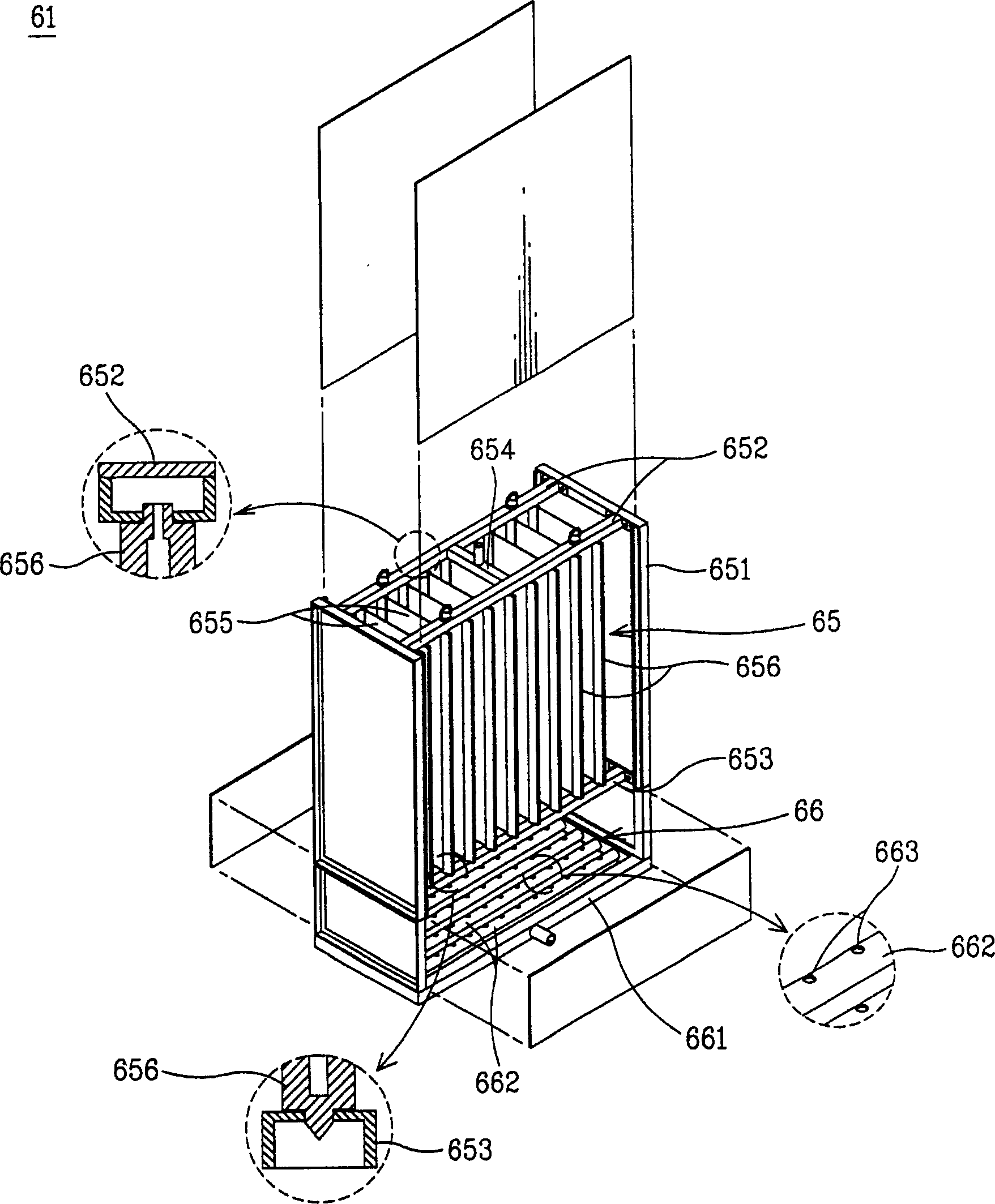

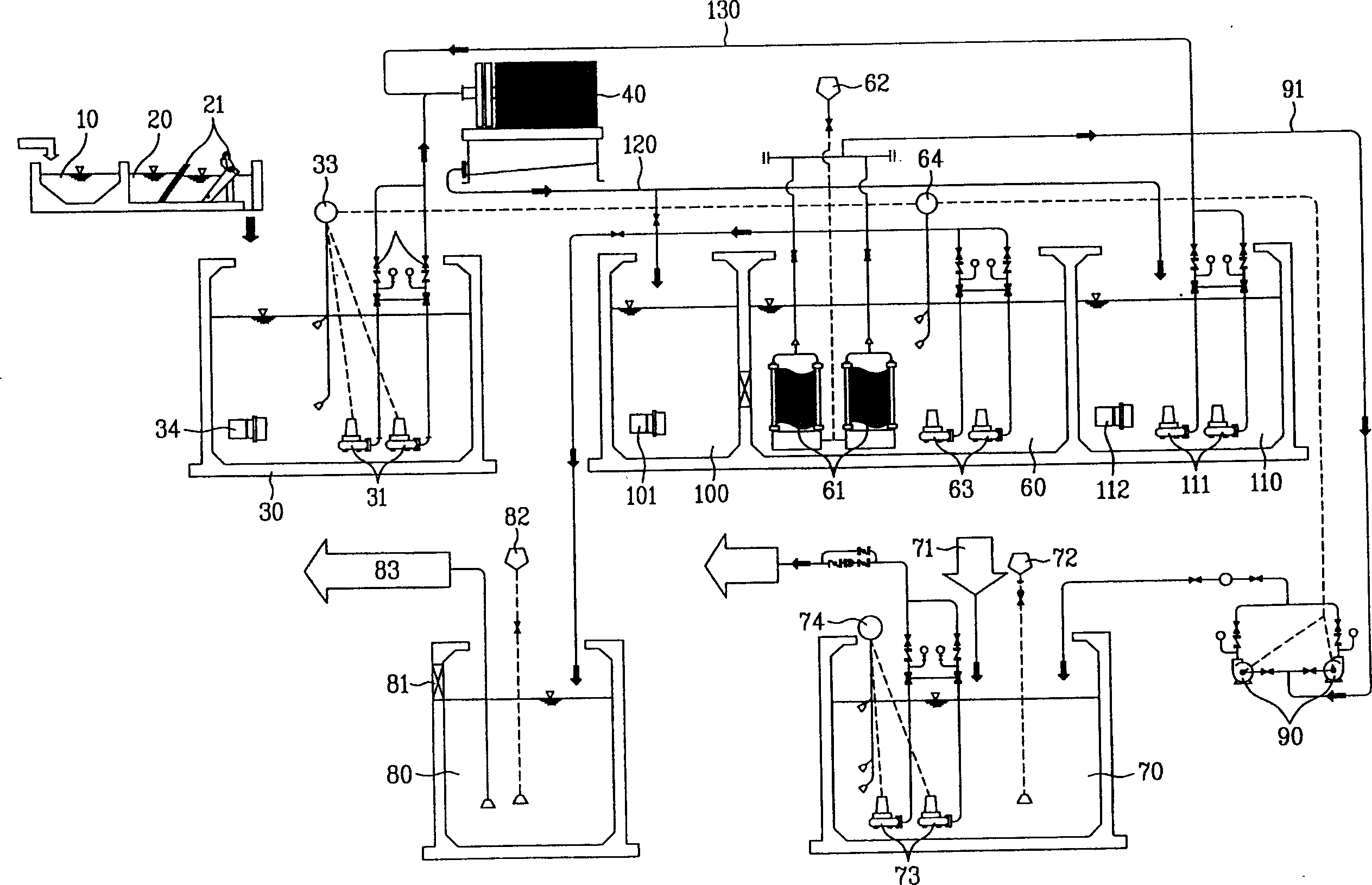

Lixiviation type film separating system for sewage and waste water high treatment

ActiveCN1548391AImprove efficiencyEfficient operationSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentNitrogen gasPhosphate

The leaching membrane separating system has settling basin, fine filtering net tank, etc. and includes also anaerobic tank outside the fine filtering net tank for eliminating pollutant and leaching phosphate; aerobic separating membrane tank with separating membrane unit outside the anaerobic tank for eliminating pollutant, phosphate and suspended matter; oxygen-free tank outside the aerobic separating membrane tank for separating nitrogen and oxygen via denitrification reaction and returning the mixed liquid to the fine filtering net tank by means of the returning pump and returning pipe; and distributing pipe connected to the fine filtering net tank for distributing sewage to the anaerobic tank and the oxygen-free tank. The system can prevent impurity from being concentrated and eliminate various suspended matter, organic matter, nitrogen and phosphate and has high sewage and waste water treating efficiency.

Owner:大韩通运株式会社

Ice making air source heat pump

PendingCN109724290AEfficient operationLow investment costIce productionFood processingCooling towerNew energy

An ice making evaporator is added on an air source heat pump, multiple loops can be formed, multiple modes and multiple working conditions of air source heating, ice making heating, heat storage, icemaking cold storage, and direct refrigeration are operated, a cooling tower does not need to be matched, ice making heating can be achieved, a water source facility is not needed, ice treatment measures are not needed, one device is adopted to achieve the aims of efficient clean heat supply, peak clipping valley filling energy-saving cold supply and efficient heat supply under the ultra low temperature environment, the distribution low cost direct cold heat energy storage mode is achieved, the energy-saving and environment-friendly aims of the cold and heat supply can be achieved in an economic manner, and the effective buffering and stable foundation is provided for new energy power generation efficient running.

Owner:罗良宜

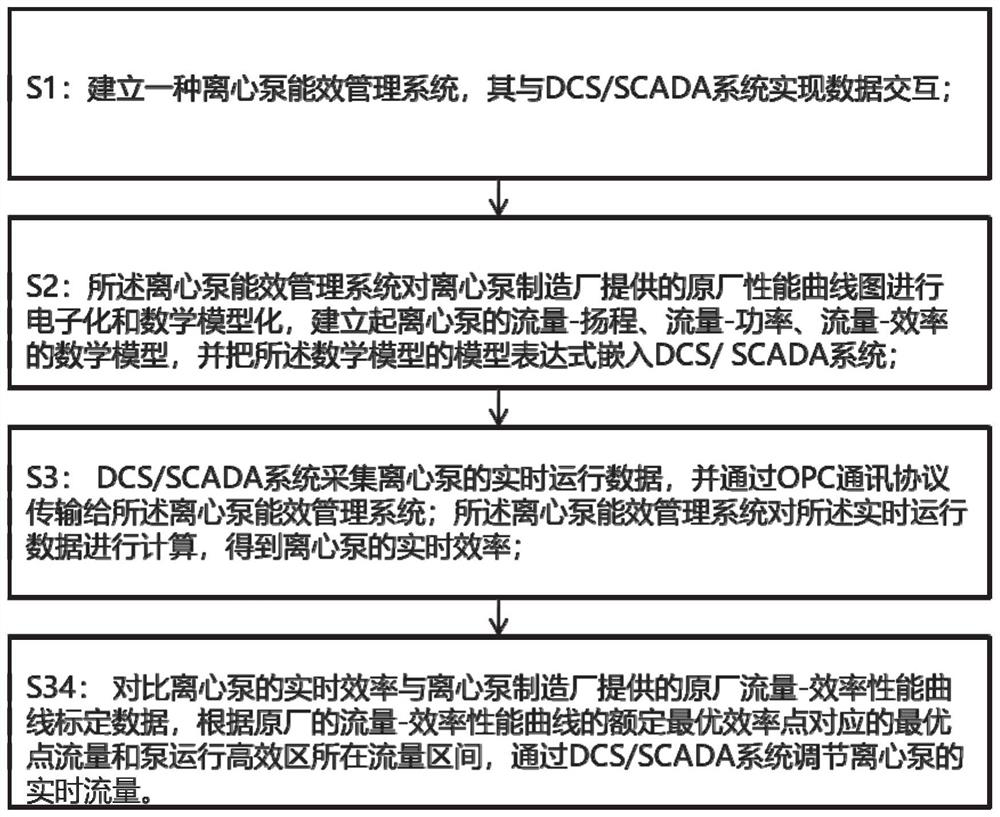

Efficient centrifugal pump energy efficiency management method and system

ActiveCN112483427AEfficient operationEnergy efficientDesign optimisation/simulationPump controlCentrifugal pumpSCADA

The invention provides an efficient centrifugal pump energy efficiency management method. The comprises the following steps that S1, a centrifugal pump energy efficiency management system is established, and data interaction is achieved between the centrifugal pump energy efficiency management system and a DCS / SCADA system; S2, the centrifugal pump energy efficiency management system carries out electronization and mathematical modeling on an original factory performance curve graph, a mathematical model of the flow-lift, the flow-power and the flow-efficiency of a centrifugal pump is established, and a model expression of the mathematical model is embedded into a DCS / SCADA system; S3, the DCS / SCADA system collects real-time operation data of the centrifugal pump and transmits the real-time operation data to the centrifugal pump energy efficiency management system through an OPC communication protocol, and the centrifugal pump energy efficiency management system calculates the real-time operation data to obtain the real-time efficiency of the centrifugal pump; and S4, the real-time efficiency of the centrifugal pump is compared with original factory flow-efficiency performance curve calibration data, and the real-time flow of the centrifugal pump is adjusted through the DCS / SCADA system.

Owner:ZHEJIANG SUPCON TECH

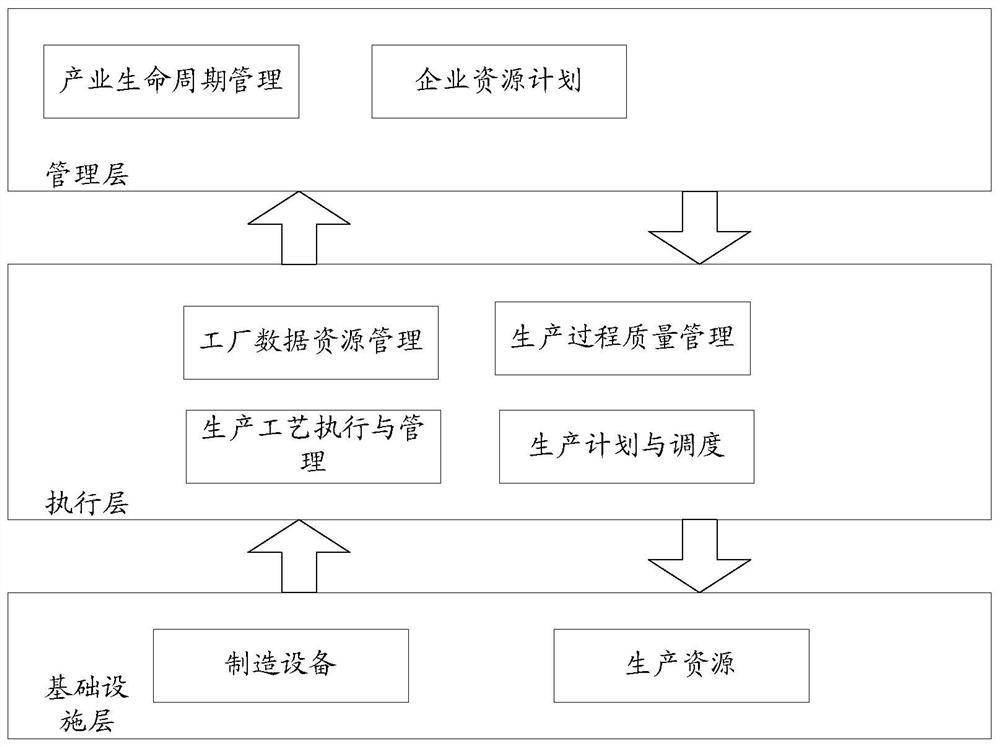

Dairy product digital factory system

PendingCN112270612AGo digitalEfficient overall managementResourcesManufacturing computing systemsBusiness enterpriseQuality management

The invention provides a dairy product digital factory system, which comprises an infrastructure layer, an execution layer and a management layer, and the infrastructure layer comprises facility equipment and production resources; the execution layer acquires a production order allocated to the current factory, generates a production instruction, issues the production instruction to the infrastructure layer, generates a digital process specification to guide field operation personnel, acquires execution feedback of the infrastructure layer, generates a quality management specification to guidethe field operation personnel to execute quality management, and collects a quality management result fed back by the infrastructure layer; and the management layer manages the life cycle of the product according to the process operation plan, the execution feedback of the infrastructure layer and the quality management result. By constructing the infrastructure layer, the execution layer and themanagement layer and reasonably arranging the functional modules of all the functional layers, digitization, lean and transparency of the factory manufacturing process can be achieved, enterprises are helped to achieve the functions of efficient overall management, efficient equipment operation and maintenance and the like, and the management decision level is improved.

Owner:CHINA NAT INST OF STANDARDIZATION

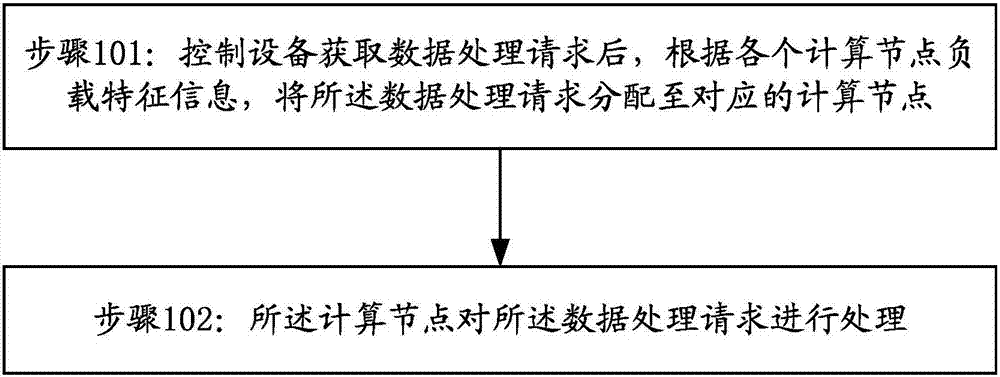

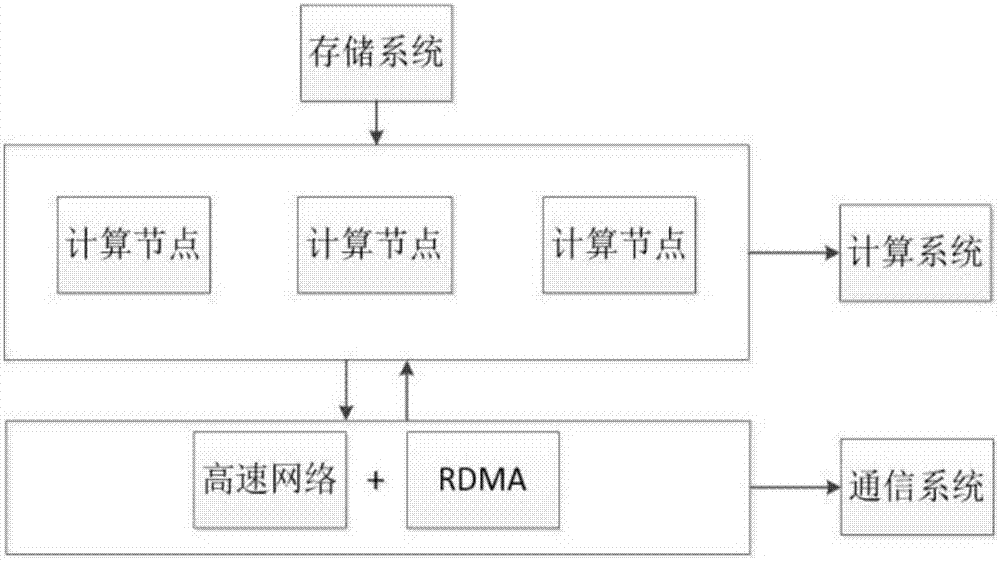

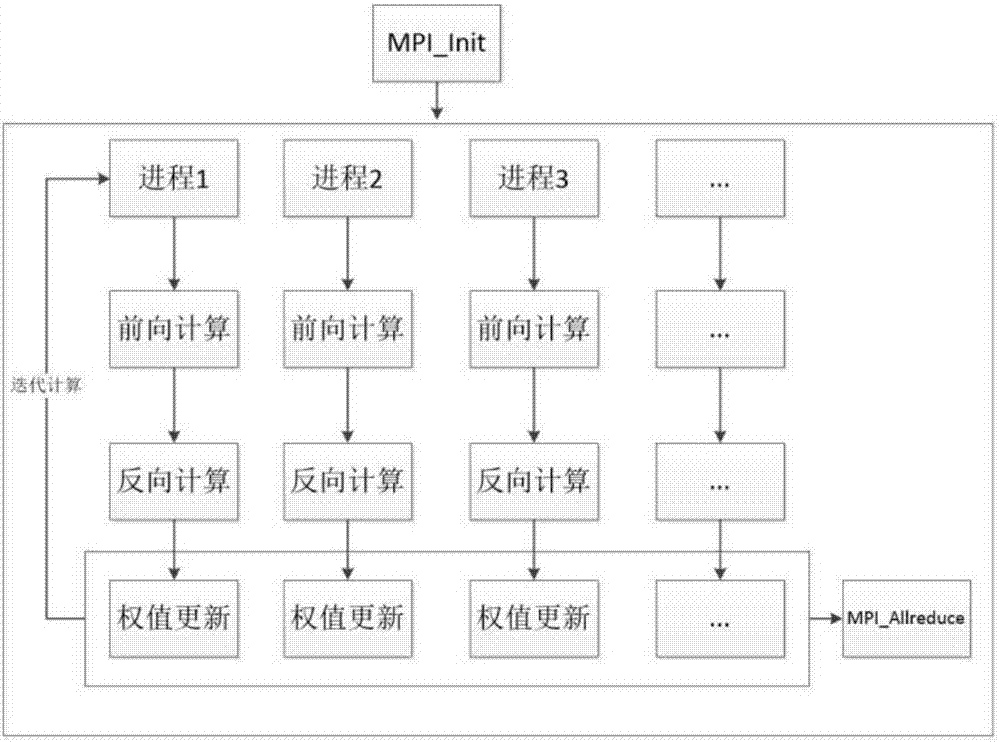

Data processing method and apparatus

InactiveCN107341057AImprove equipment utilizationEfficient operationResource allocationControl equipmentReal-time computing

The invention provides a data processing method and apparatus. The method comprises the following steps that a control device obtains a data processing request and then allocates the data processing request to corresponding computing nodes according to load feature information of the computing nodes; and the computing nodes process the data processing request. According to the technical scheme, the data processing request is allocated according to the load feature information of the computing nodes, so that load balance among the computing nodes is realized; the utilization rate of system equipment is high; different computing nodes do not wait for one another; and the computing nodes in a system do not have idle states, so that the whole system can run efficiently.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

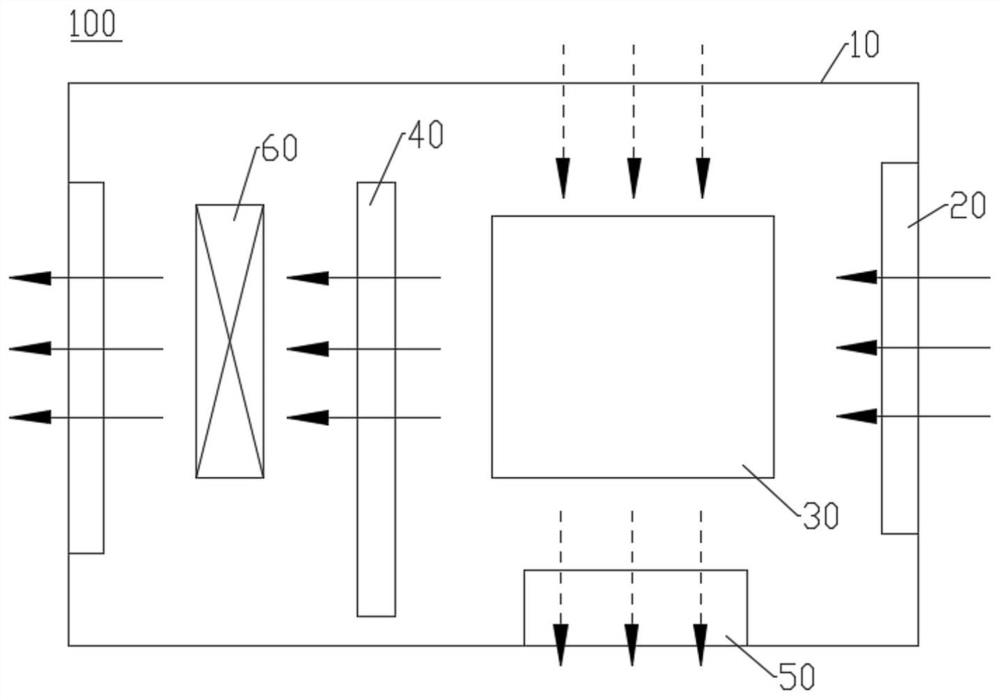

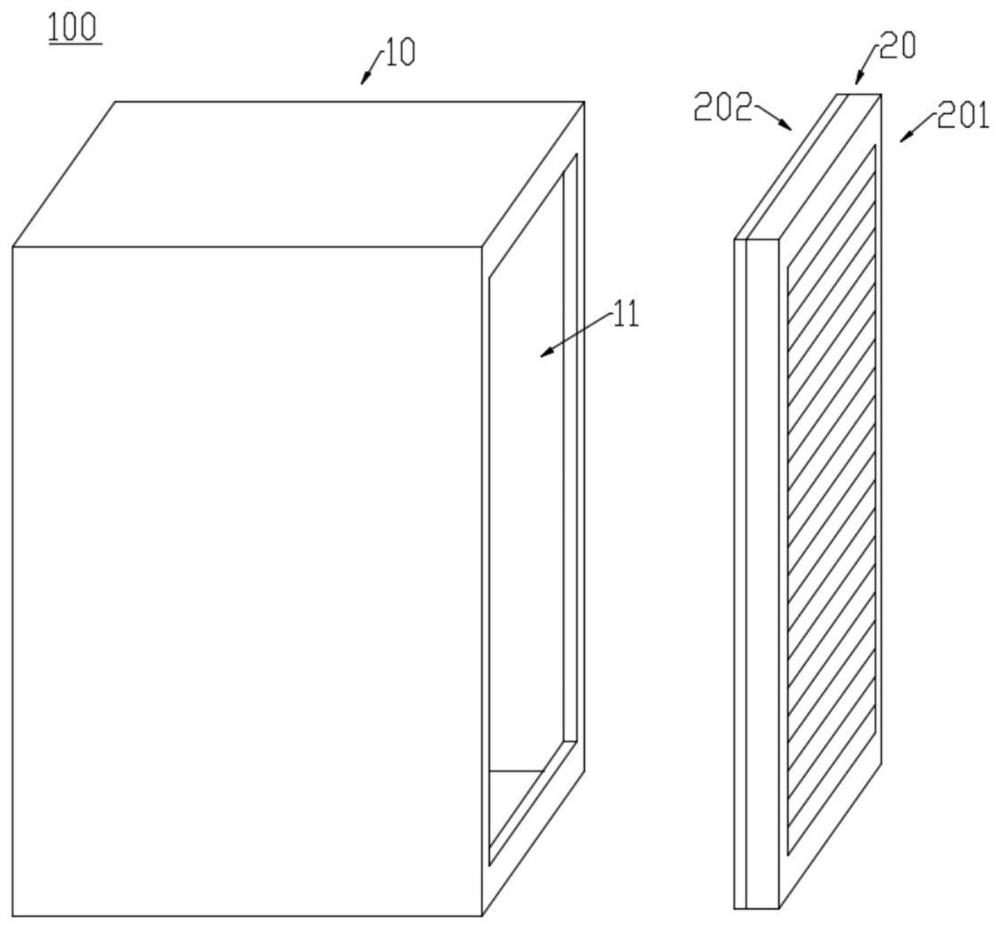

Ventilation device, control method thereof and electronic equipment

PendingCN112672623AAvoid enteringDissipate heat in timeCooling/ventilation/heating modificationsLouverPhysics

The embodiment of the invention provides a ventilation device and electronic equipment comprising the ventilation device. The ventilation device comprises a louver and heating pieces, the louver comprises a fixing frame and a plurality of louver blades, the louver blades are installed on the fixing frame at intervals in a first direction, an air duct is formed between every two adjacent louver blades, each air duct comprises an air inlet and an air outlet, the air inlets and the air outlets are arranged in a staggered mode in a direction perpendicular to the first direction, and the heating pieces are arranged on the surfaces of or in the louver blades. The invention aims to obtain the ventilation device capable of effectively melting ice and snow and the electronic equipment.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

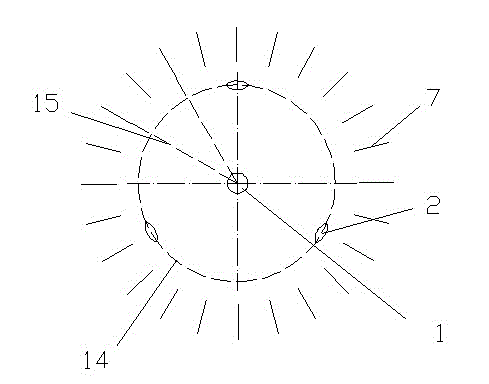

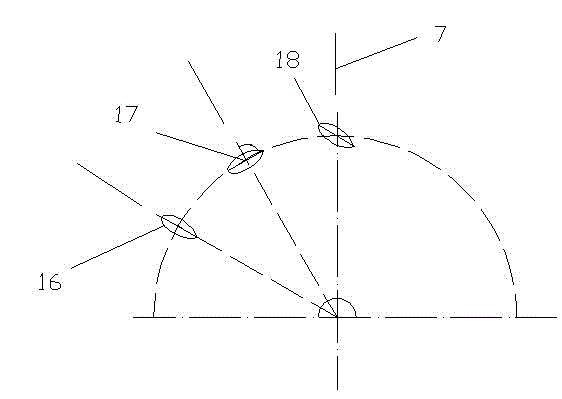

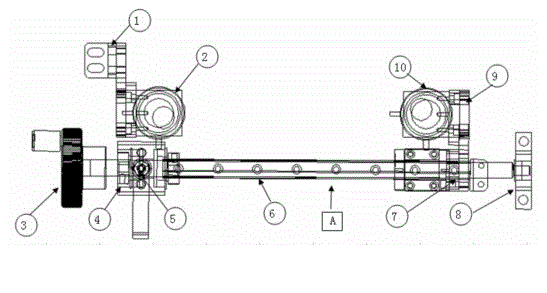

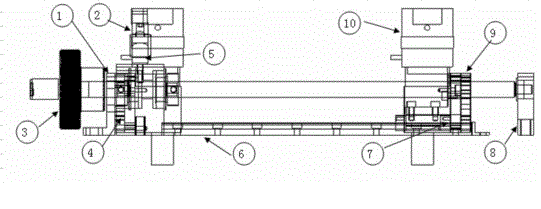

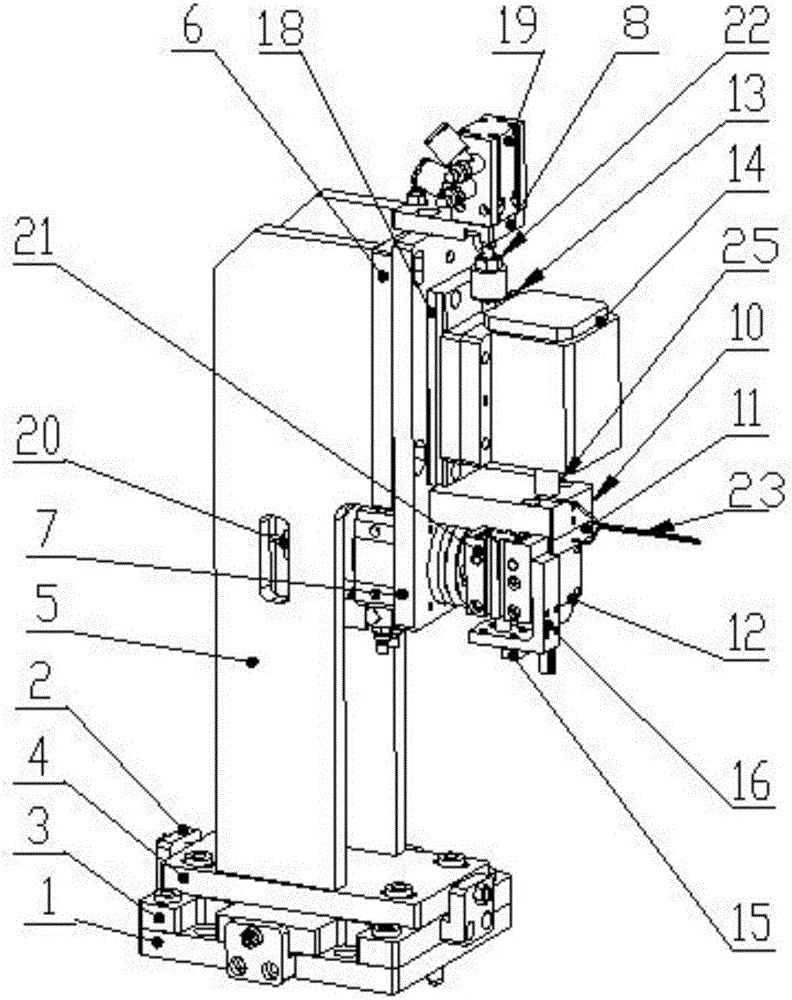

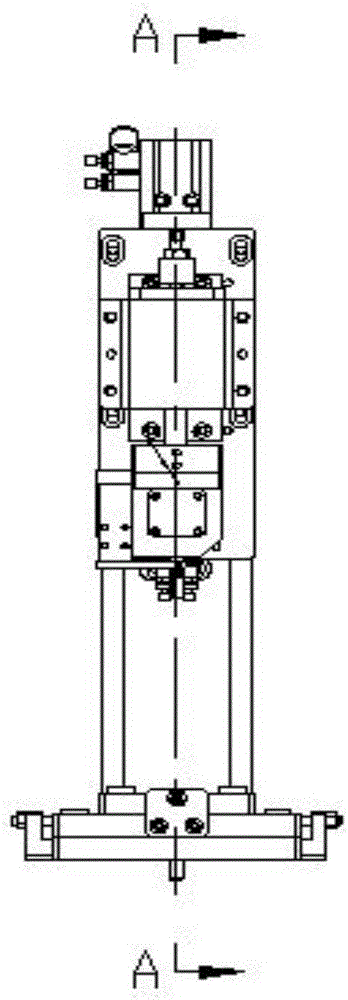

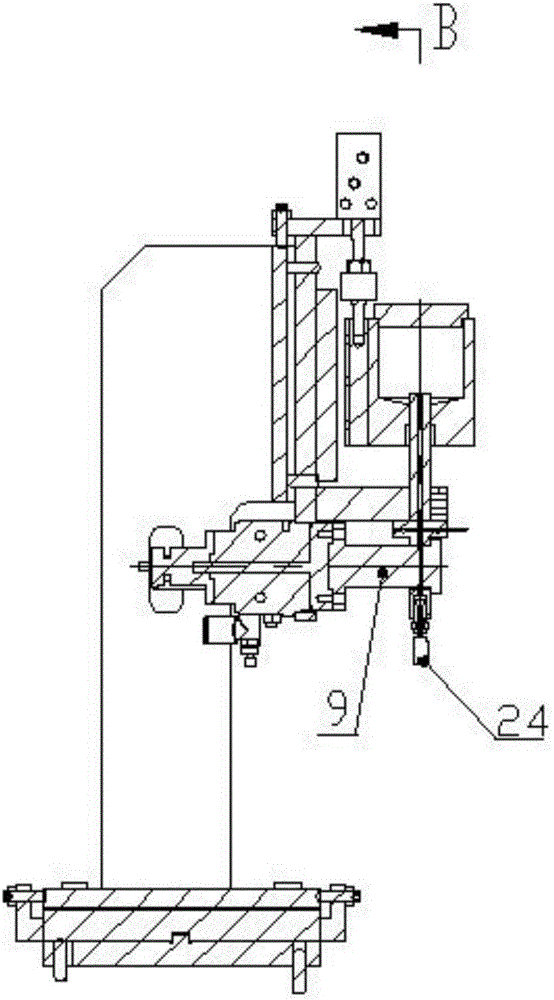

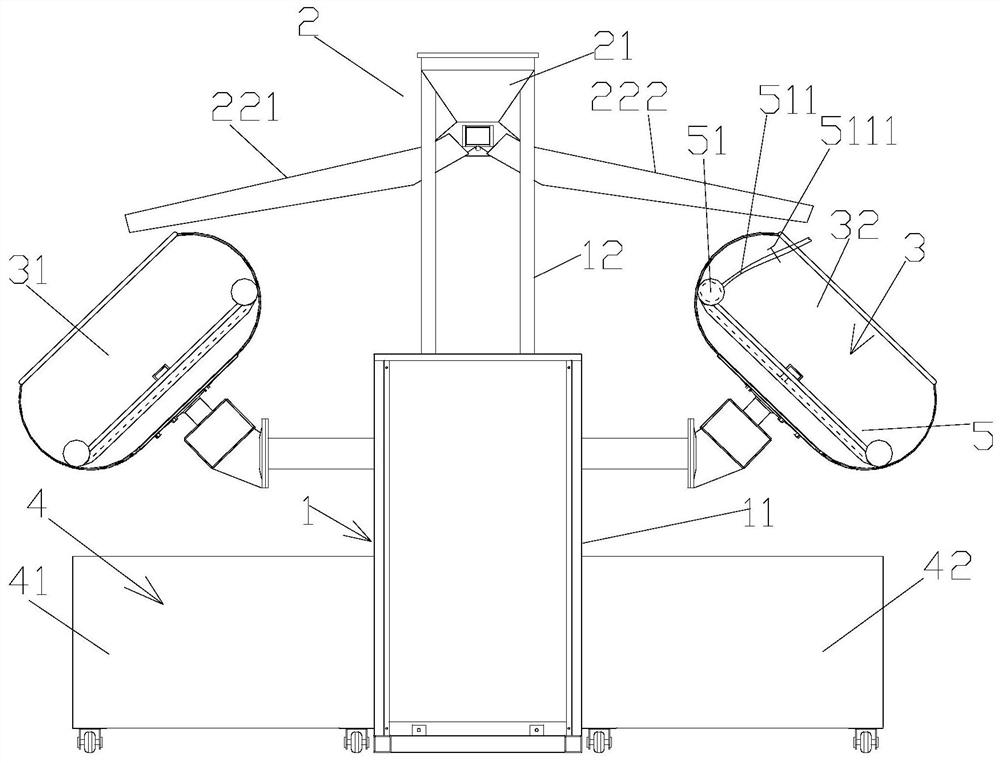

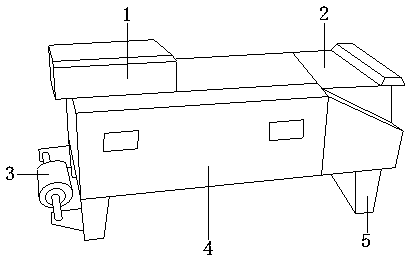

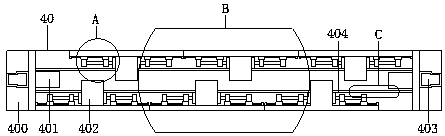

Mechanism for detecting camera of fully-automatic backlight assembly machine

InactiveCN104661017ATakes up spaceEfficient operationTelevision systemsFully automaticComputer science

The invention discloses a mechanism for detecting a camera of a fully-automatic backlight assembly machine. The working principle of the mechanism is as follows: a positioning camera end is used for detecting fixed MAX points, and the camera is finely tuned for ensuring focal distance; a movable camera end is used for moving, finely tuning and detecting MAX points on the other side for ensuring the focal distance, so as to determine positions of MAK points of backlight or glass. The mechanism comprises a fixing part (1) used for fixing the camera (2), a movable camera side, a hand wheel (3), a processing part (4), a mounting handle (5), a linear guide rail (6), a movable block (7), a fixed side (8) and a camera mounting plate (9), wherein the hand wheel (3) is connected with the processing part (4); two bearings are mounted in the inner cavity of the processing part (4); the linear guide rail (6) is mounted under the processing part; the upper part of the linear guide rail (6) is connected with the movable block (7); the camera mounting plate (9) is mounted on the side surface and is used for aligning when mounting the camera; the fixed side (8) is mounted at the tail end; a bearing is arranged in the linear guide rail; the hand wheel is manually rotated to move the position of the camera.

Owner:DALIAN YISHENGDA INTELLIGENT TECH

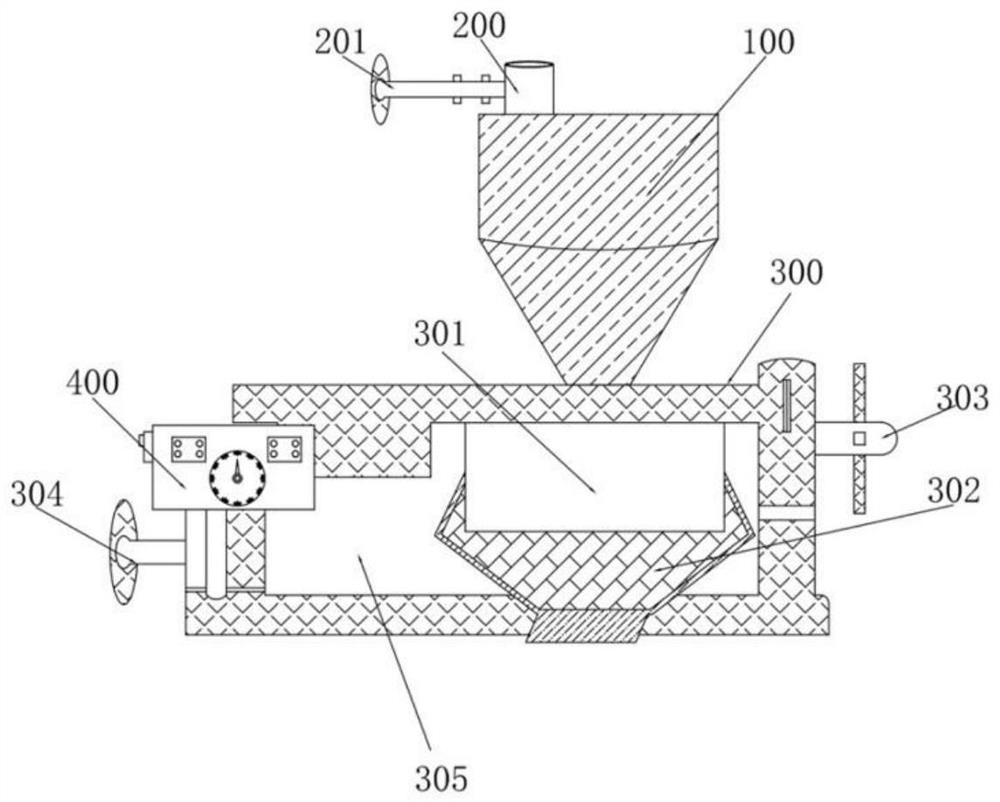

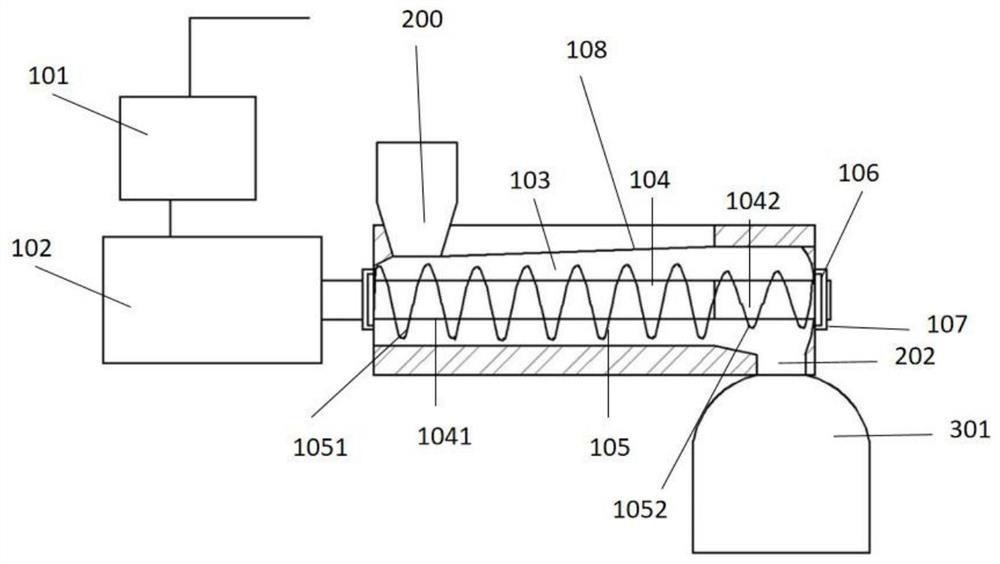

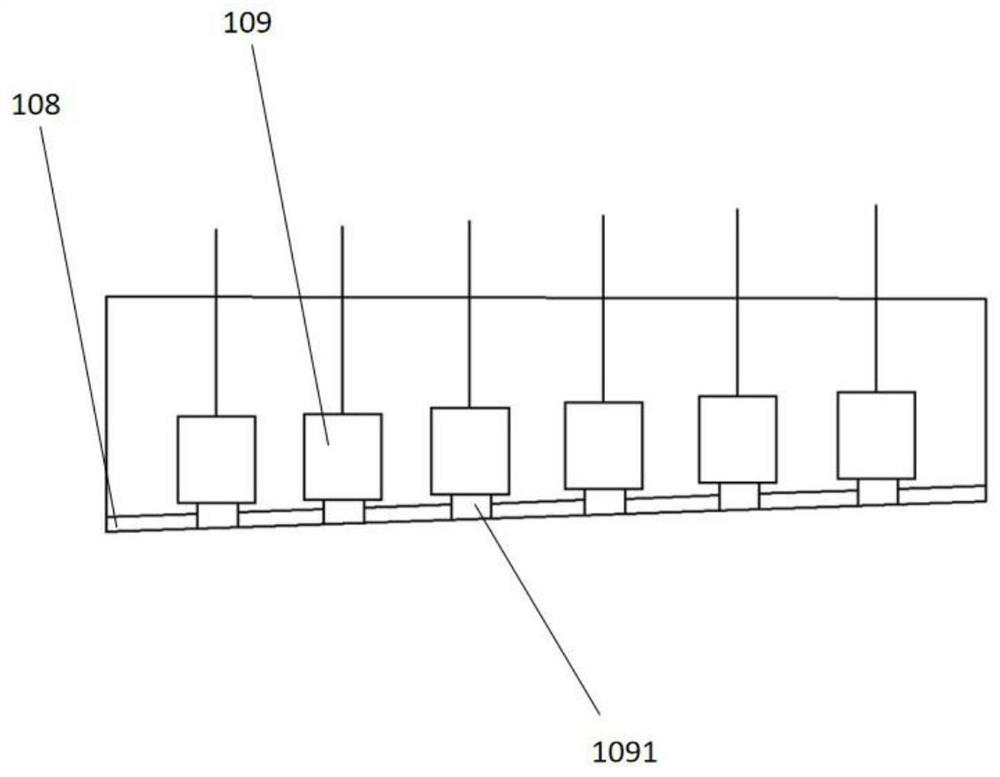

Oil squeezing device for juglans sigllata dode oil squeezing

ActiveCN113650339AImprove qualityAchieve continuous long-term oil extractionFatty substance recoveryPressesWalnut NutThermodynamics

The invention relates to the technical field of walnut oil squeezing, and discloses an oil squeezing device for juglans sigllata dode oil squeezing. The oil squeezing device comprises a squeezer body and a controller, a squeezing bin is arranged in the squeezer body, the top of one side of the squeezing bin communicates with a feeding pipe, and the bottom of the other side of the squeezing bin communicates with a material collecting bin of a recycling device through a discharging opening; a screw is horizontally arranged in the squeezing bin, and protruding threads are arranged on the screw along the outer surface of the screw in a surrounding mode; one end of the screw is rotatably connected with the squeezing bin, and the other end of the screw is rotatably connected with the squeezing bin, extends out of the squeezing bin and is in driving connection with the driving output end of a driving device; the part, located in the squeezing bin, of the screw is coaxially provided with a squeezing screw close to the feeding pipe and an auxiliary screw close to the discharging opening; and the squeezing screw is provided with squeezing threads, and the auxiliary screw is provided with auxiliary threads. Continuous long-time oil squeezing of the juglans sigllata dode can be achieved, and the time interval of shutdown maintenance of an oil press is similar to that of an existing screw type oil press.

Owner:丽江永胜边屯食尚养生园有限公司

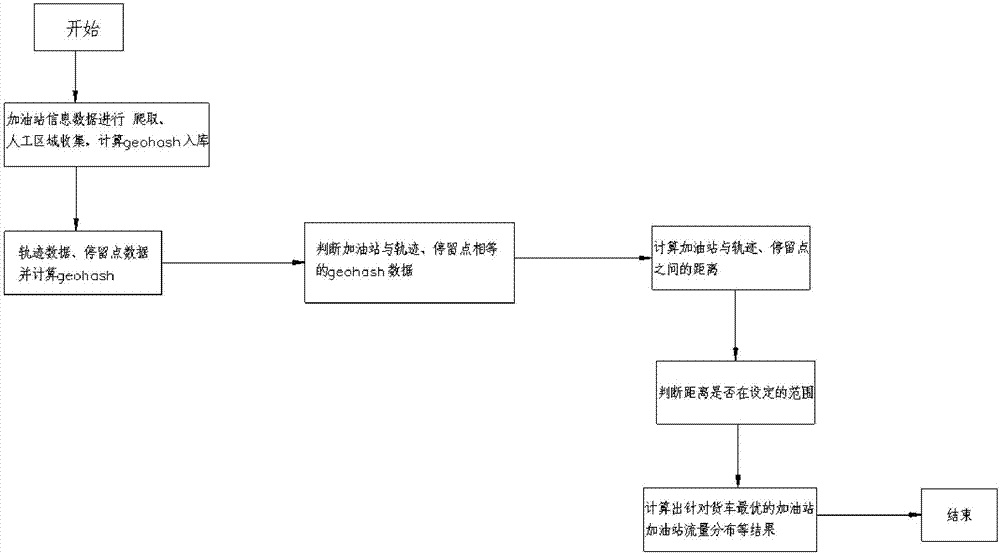

Freight vehicle targeted intelligent marketing algorithm for petrol stations

The invention discloses a freight vehicle targeted intelligent marketing algorithm for petrol stations. The algorithm includes steps: A, domestic published petrol station information data are subjected to fetching and artificial area collection through a data platform and continuously accumulating to the platform to serve as petrol station base data; B, hundreds of thousands of vehicles with G7 generate corresponding trail data and stay point data, the data are stored in a big data platform through an acquisition program, and the trail data and the stay point data are subjected to geohash value calculation; C, a distance value is set to define whether vehicles stay at or pass through petrol station ranges, and matching with petrol station geohash values is performed through vehicle trail geohash and stay point geohash. According to the algorithm, the nearest petrol stations optimum in petrol price are intelligently recommended for refueling freight vehicles according to positions of the freight vehicles, the petrol stations can be assisted in efficient operation, the flow rate of the petrol stations is increased, and profits of the petrol stations are maximized.

Owner:JIQI CHENGDU TECH CO LTD

Solar air source heat pump unit

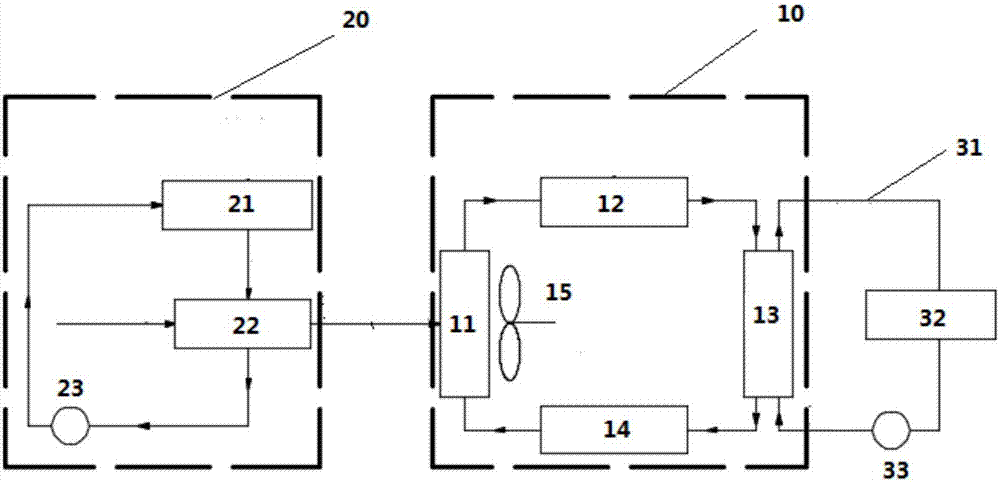

PendingCN107883608ATake advantage ofSolve runnabilitySolar heating energyHeat pumpsEngineeringWater circulation

The invention provides a solar air source heat pump unit. The solar air source heat pump unit comprises an air source heat pump system and a solar heat collecting system, wherein the air source heat pump system is connected with a water circulation system of a heat user, exchanges heat with the water circulation system and includes an evaporator; the solar heat collecting system comprises a solarcollector and a heat exchanger which are connected to each other in an end-to-end mode; the solar collector can heat an internal heat conduction medium through solar energy and conveys the heated internal heat conduction medium into the heat exchanger; the heat exchanger can convey the heat-exchanged heat conduction medium back to the solar collector; and the heat exchanger and the evaporator arearranged in parallel, the heat exchanger can pre-heat outdoor air and then conveys the outdoor air to the evaporator, and the pre-heated outdoor air can exchange heat with a refrigerant in the evaporator and then is exhausted. The solar air source heat pump unit has the beneficial effect that the effects that the heat pump unit runs normally under the condition of low outdoor environment in winter, and meanwhile, and frosting of an air source heat pump system is relived are achieved.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

Spherical material supplying mechanism

ActiveCN106743385AReduce in quantityStable workabilityConveyorsConveyor partsEngineeringMaterial supply

Owner:DALIAN YUN MING AUTOMATION TECH

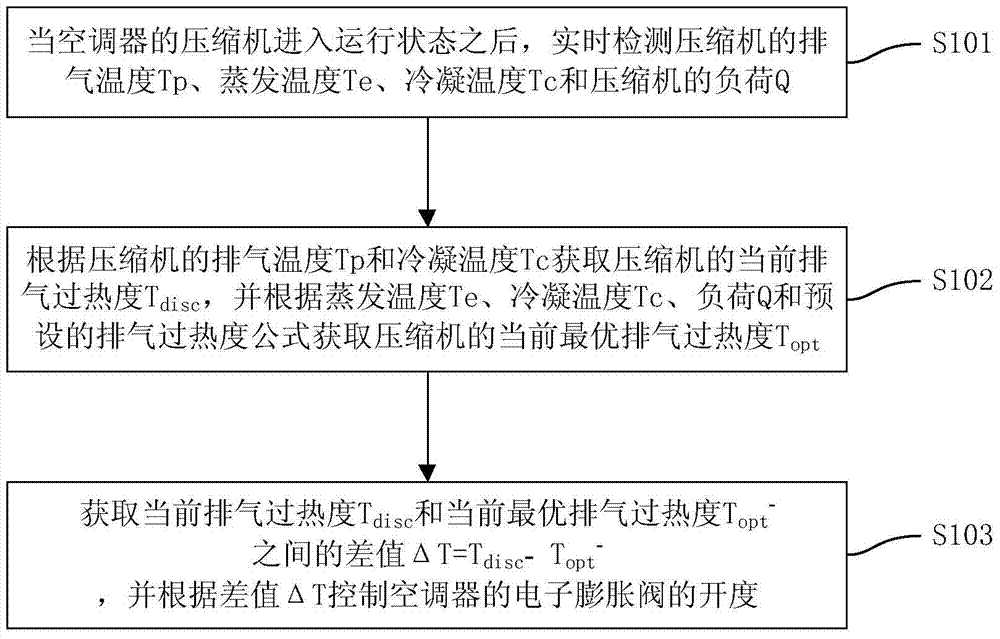

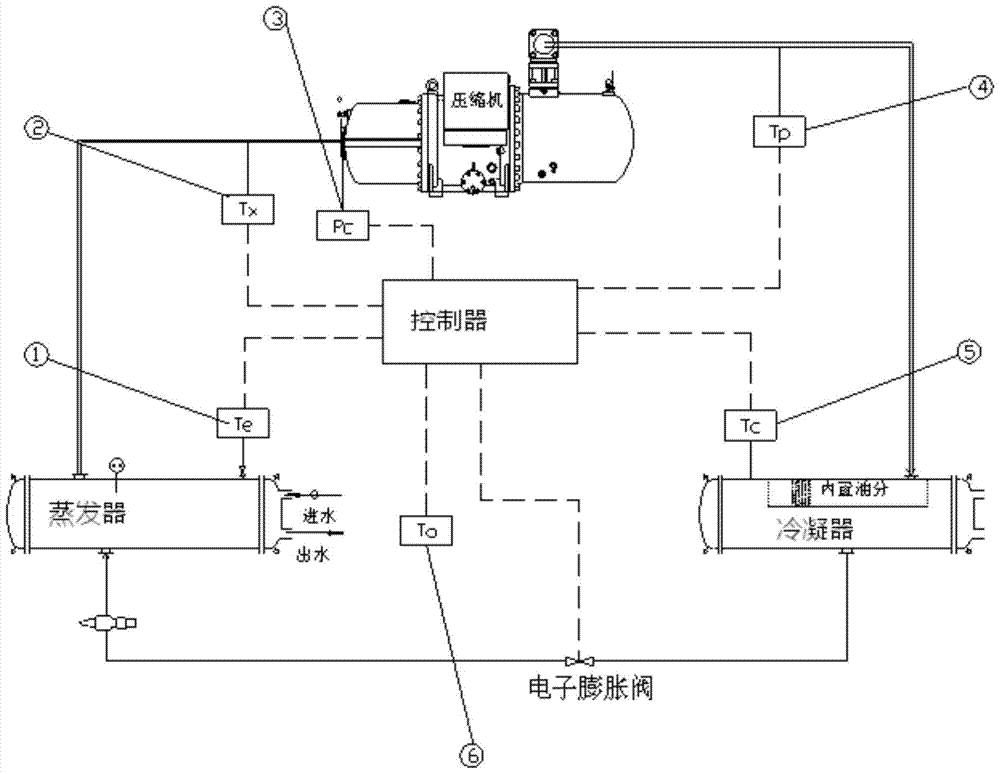

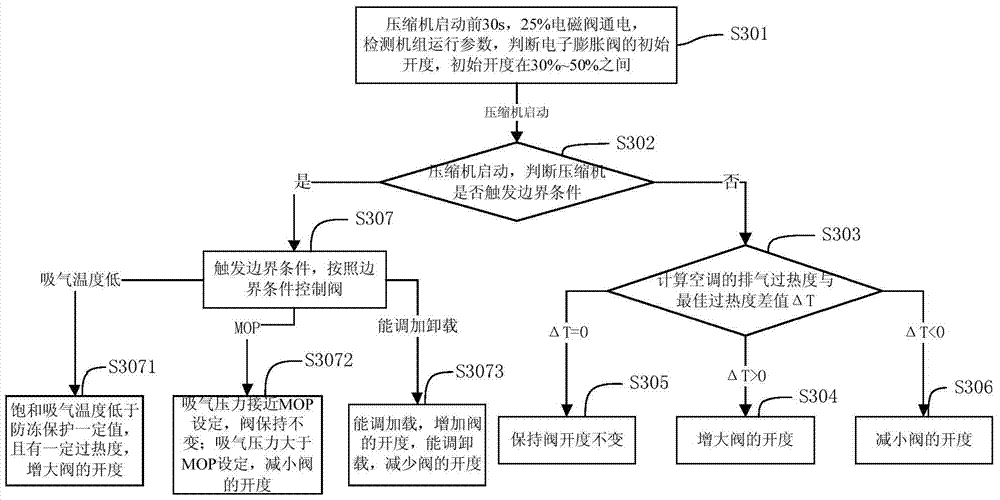

Air conditioner, its control method, and control device

ActiveCN104990294BGuaranteed uptimeStable operationMechanical apparatusCompression machines with non-reversible cycleEngineeringLoad following power plant

The invention discloses an air conditioner, and a control method and a control device thereof. The method comprises: after a compressor of the air conditioner enters an operating state, detecting discharge temperature Tp of the compressor, evaporation temperature Te, condensing temperature Tc, and load Q of the compressor in real time; according to the discharge temperature Tp and the condensing temperature Tc of the compressor, obtaining current discharge superheat Tdisc of the compressor, and according to the evaporation temperature Te, the condensing temperature Tc, the load Q, and a preset discharge superheat formula, obtaining current optimal discharge superheat Topt of the compressor; and obtaining the difference [delta]T=Tdisc-Topt between the current discharge superheat Tdisc and the current optimal discharge superheat Topt, and according to the difference [delta]T to control opening of the electronic expansion valve of the air conditioner. The method prevents a dry pipe of a flooded evaporator, and improves heat exchange effect of the evaporator. On the premise of ensuring reliable operation of a unit, the method makes the unit in a most efficient operating state.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP

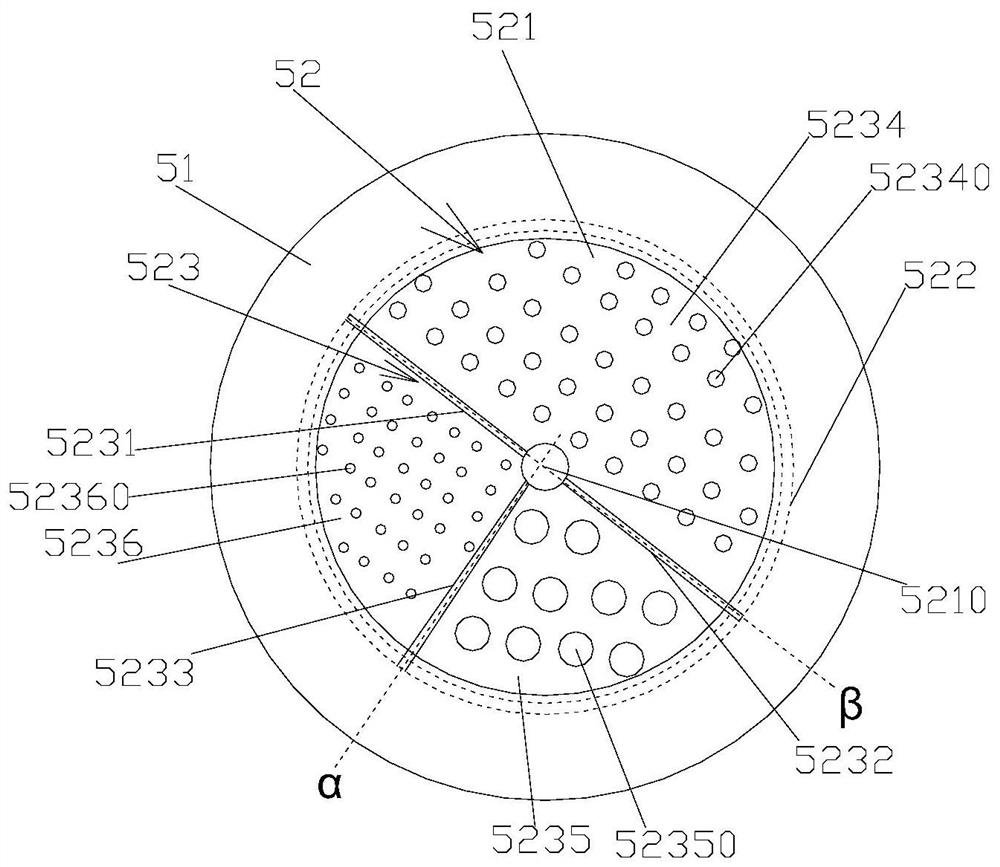

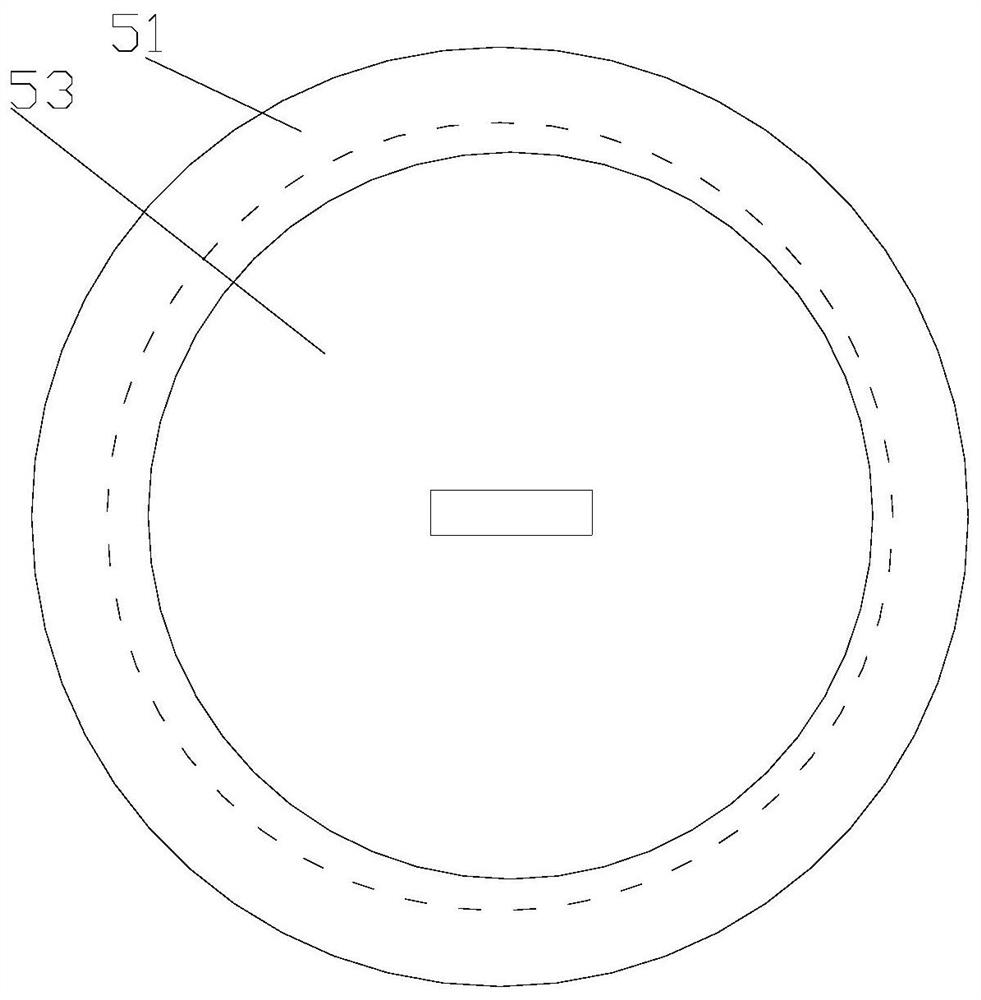

Six-ingredient rehmannia pill type production equipment and process

InactiveCN112620080AEfficient operationReasonable process stepsSievingScreeningManufacturing engineeringMechanical engineering

The invention relates to the field of traditional Chinese medicines, in particular to six-ingredient rehmannia pill type production equipment and process. The equipment comprises a rack, a discharging assembly, a polishing pot assembly and a receiving assembly, the discharging assembly is arranged on the upper portion of the rack, the polishing pot assembly is located on the lower portion of the discharging assembly, an outlet of the discharging assembly corresponds to an inlet of the polishing pot assembly, and the receiving assembly is arranged at the bottom of the polishing pot assembly; and a material suction assembly is arranged in the polishing pot assembly. The equipment is efficient in running cooperation and reasonable in process step, the rack plays a supporting role, the discharging assembly can place materials in the polishing pot assembly from the two sides at the same time, meanwhile, the polishing pot assembly operates on the two sides, the operation efficiency is improved, pills can be directly placed in the receiving assembly, and the pill storage and placement steps are simplified. The material suction assembly is used for picking up pills in the polishing pot assembly on one hand and completing size screening of the pills in the polishing pot assembly on the other hand.

Owner:河南庚贤堂制药有限公司

High-efficiency and high-quality folding and film pasting integrated carton three-dimensional packing machine

InactiveCN110723360AEfficient operationImprove processing efficiencyBox making operationsPaper-makingElectric machineryStructural engineering

The invention discloses a high-efficiency and high-quality folding and film pasting integrated carton three-dimensional packing machine. The machine comprises a drawer, a shelf, an outer motor, a packer and a bracket; the drawer is mounted and connected with the packer; the shelf is welded with the packer; the outer motor is mounted on the packer and the bracket; the bracket is locked with the shelf and the packer; an internal device is mounted in the packer, and consists of a mounting frame, a feed port, an internal packer, an inner motor and a conveying rail; the mounting frame is provided with the feed port; the inner motor is mounted on the mounting frame; and the mounting frame is mounted and connected with the internal packer. Papers in cartons are fed in and out from the feed port,are conveyed on the conveying rail, and are folded and pasted with films through the internal packer to realize once three-dimensional packing; no manual assistance is needed in molding and film pasting; and through transmission of an auxiliary shaft, the material friction and slippage phenomenon during conveying is reduced, the efficient operation is realized, the machining efficiency is high, and the quality is good.

Owner:吴志宁

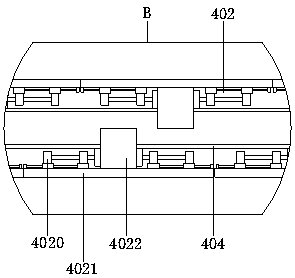

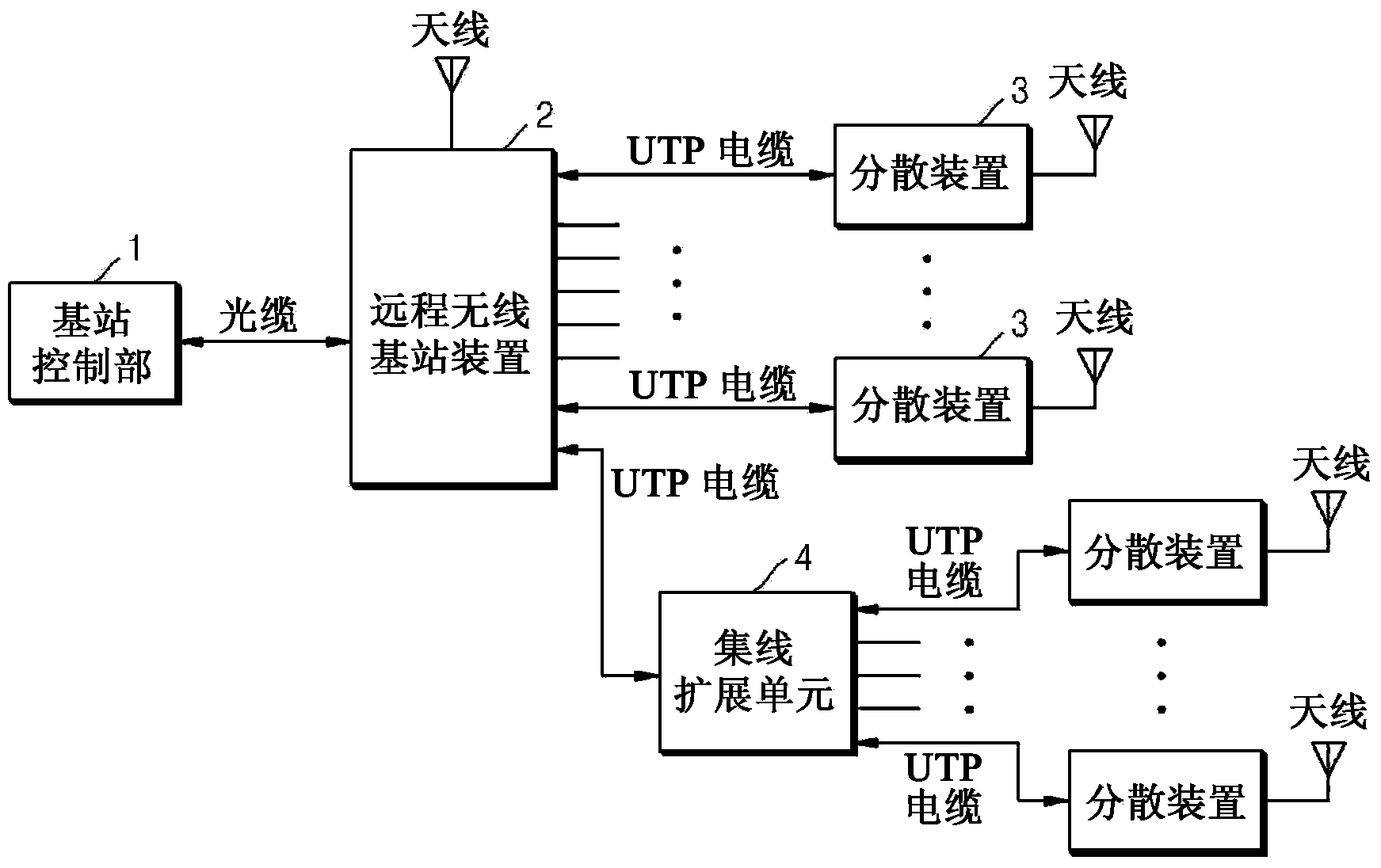

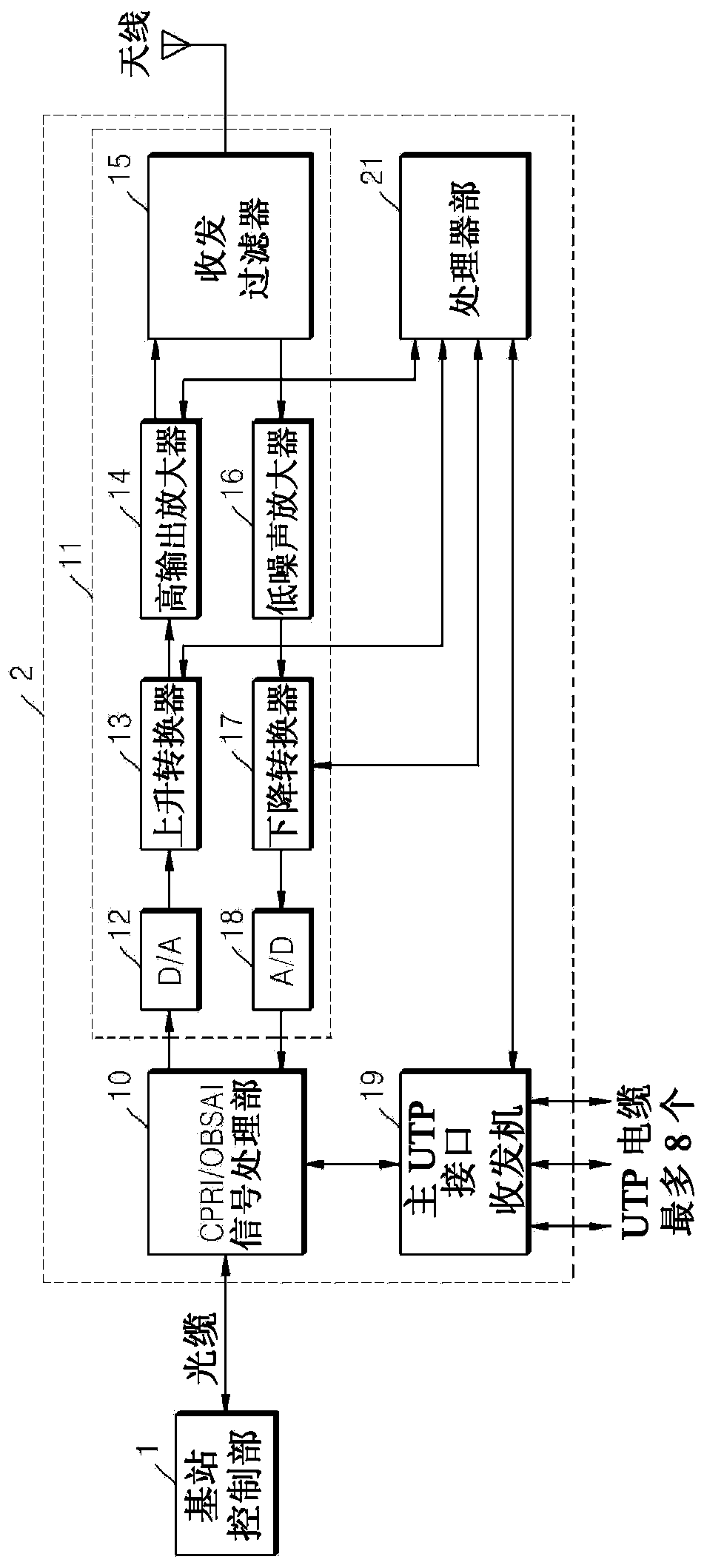

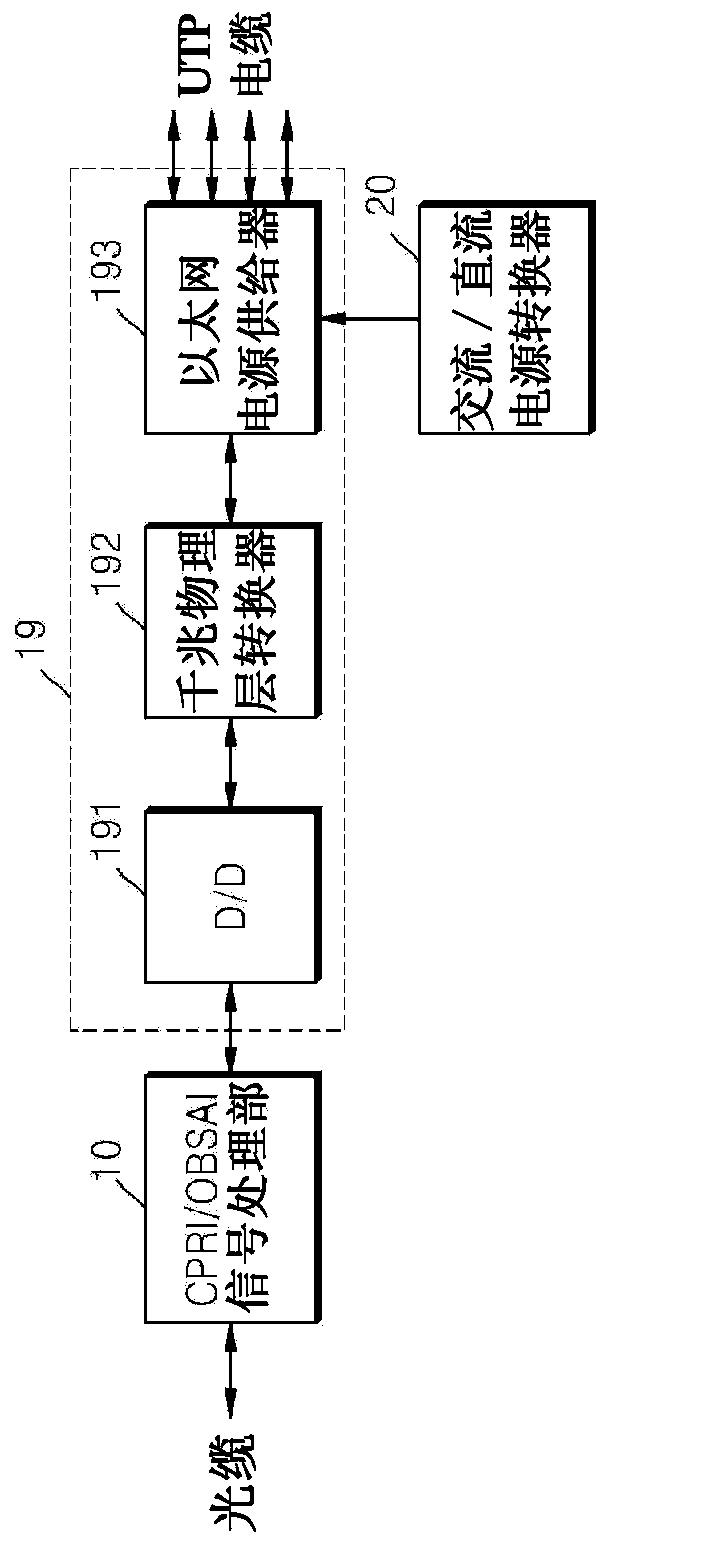

Remote wireless base station device having in-house expandability and in-building relay system

InactiveCN104380619ASolve the shadow area of mobile communication propagationQuality improvementRadio relay systemsTransceiverAnalog signal

A remote wireless base station device having in-house expandability and an in-building relay system is disclosed. The remote wireless base station device according to one embodiment of the present invention includes: a CPRI / OBSAI signal processing unit that is connected to a base station control unit by means of a first cable and that transmits information to and receives information from the base station control unit using a first digital communication scheme; and a master UTP interface transceiver that converts a first digital communication type signal received from the CPRI / OBSAI signal processing unit into a second digital communication type signal without an analog signal conversion process, and converts the second digital communication type signal, received from a plurality of distribution devices that are connected to each other by means of a second cable and installed at the shaded regions of buildings, into the first digital communication type signal without an analog signal conversion process.

Owner:UNITRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com