Oil squeezing device for juglans sigllata dode oil squeezing

An oil pressing device, walnut oil technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems affecting production efficiency, no-load of the press, and smooth bore of the press, and achieve the effect of continuous production and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

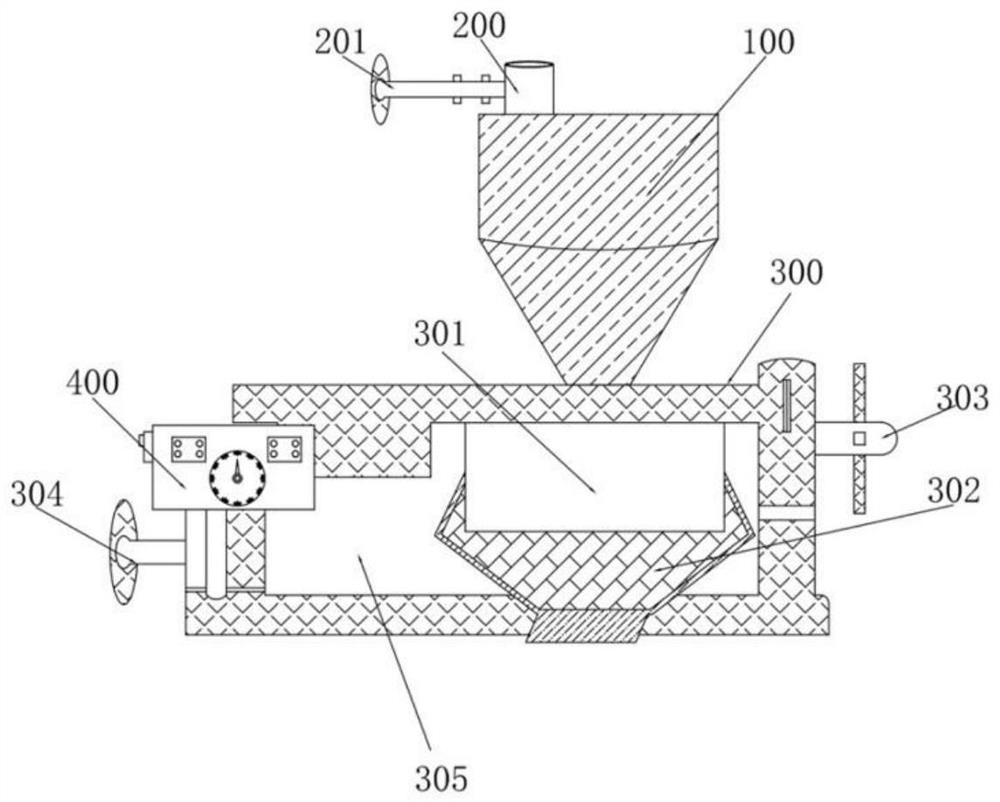

[0035] A kind of oil pressing device for iron walnut oil pressing, such as figure 1As shown, it includes a press machine main body 100 and a controller 400 . The inside of the press main body 100 is provided with a squeeze bin 103 , the top of one side is connected to the feeding pipe 200 , and the bottom of the other side is connected to the material collection bin 301 of the recovery device 300 through the discharge port 202 . The bottom of the material collection bin 301 is provided with a sloping plate 302 which is inclined downward and connected to the waste collection device, and an oil outlet pipe 304 is provided on the side wall.

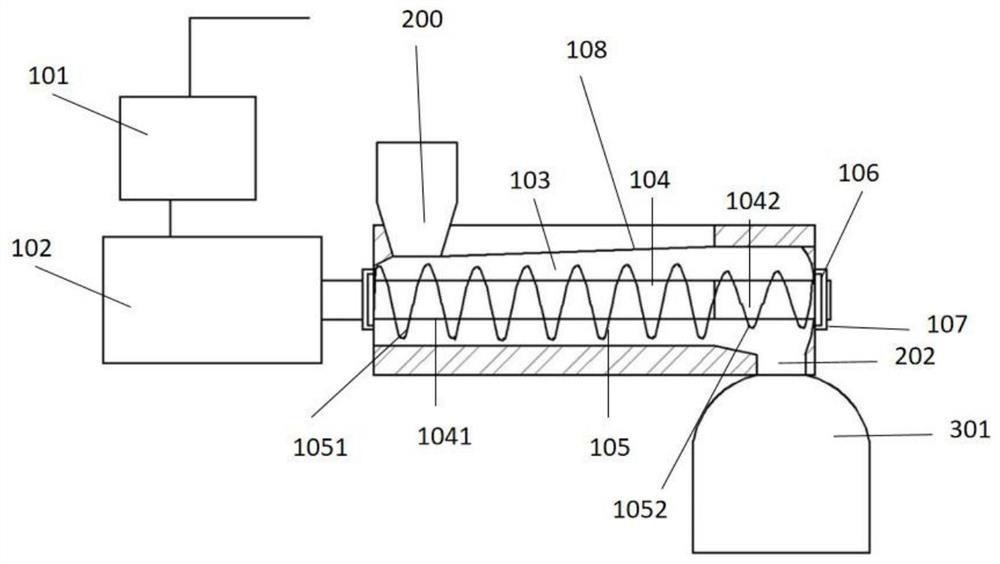

[0036] Such as figure 2 As shown, a screw 104 is horizontally arranged in the squeeze chamber 103, and a raised thread 105 is arranged on the screw 104 along the outer surface of the screw. One end of the screw 104 is rotatably connected to the squeeze bin 103 , and the other end is rotatably connected to the squeeze bin 103 and extends t...

Embodiment 2

[0043] Based on the iron walnut oil pressing described in embodiment 1, the oil extraction device, such as figure 2 As shown, the screw 104 is rotatably connected with the bin wall of the pressing bin 103 through a bearing 106 . The outer wall of the press chamber 103 is provided with an oil seal device 107 at the bearing 106 . This setting can prevent the grease in the pressing bin 103 from overflowing.

Embodiment 3

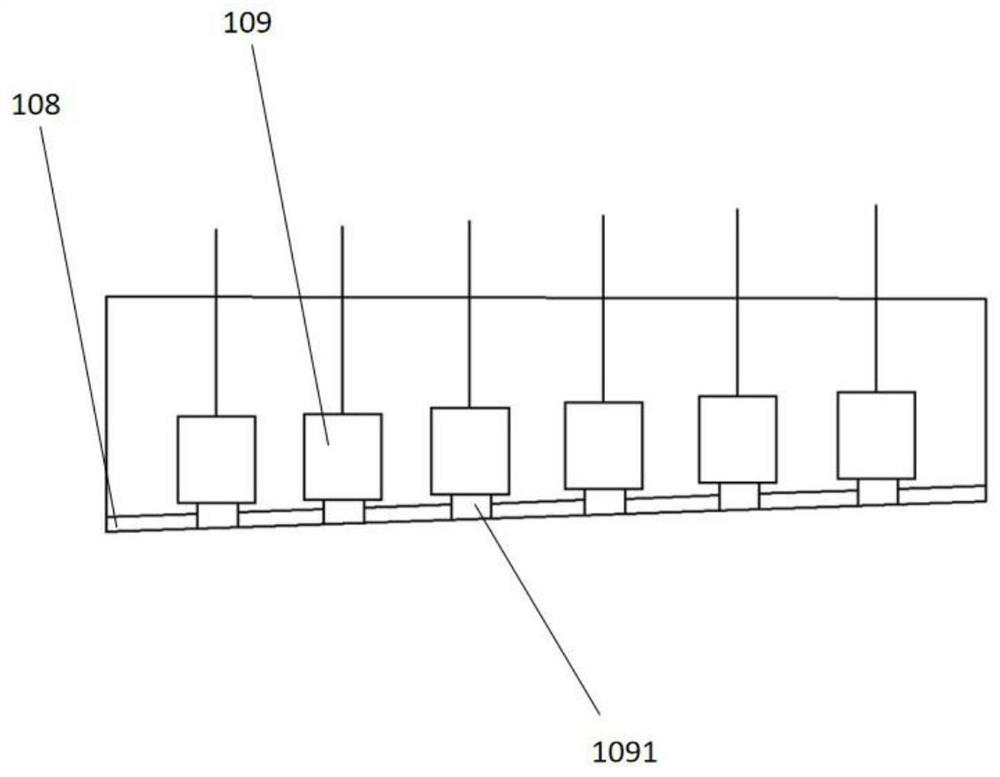

[0045] Based on the iron walnut oil pressing described in embodiment 1, the oil extraction device, such as Figures 1 to 3 As shown, the feeding pipe 200 is provided with an electronically controlled forced feeder 201 , the driving device 102 is a three-phase asynchronous motor, and the power supply end of the driving device 102 is electrically connected to an external power supply through a reactive power monitoring device 101 . The top of the press bin 103 is provided with an anti-pressure plate 108 from the feed pipe 200 to the discharge port 202 . The end of the anti-pressure plate 108 facing away from the squeeze chamber 103 is provided with n pressure detectors 109 arranged along the axis of the screw 104, where n is a natural number ≥ 2. The bottom surface of the detection end of the pressure detector 109 is flush with the bottom surface of the pressure-resistant plate 108 . The signal output terminals of the reactive power monitoring device 101 and n pressure detector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com