Lixiviation type film separating system for sewage and waste water high treatment

A membrane separation system, membrane separation aerobic technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of incomplete removal and natural environment damage , pollution of rivers or soil, etc., to achieve the effect of good operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

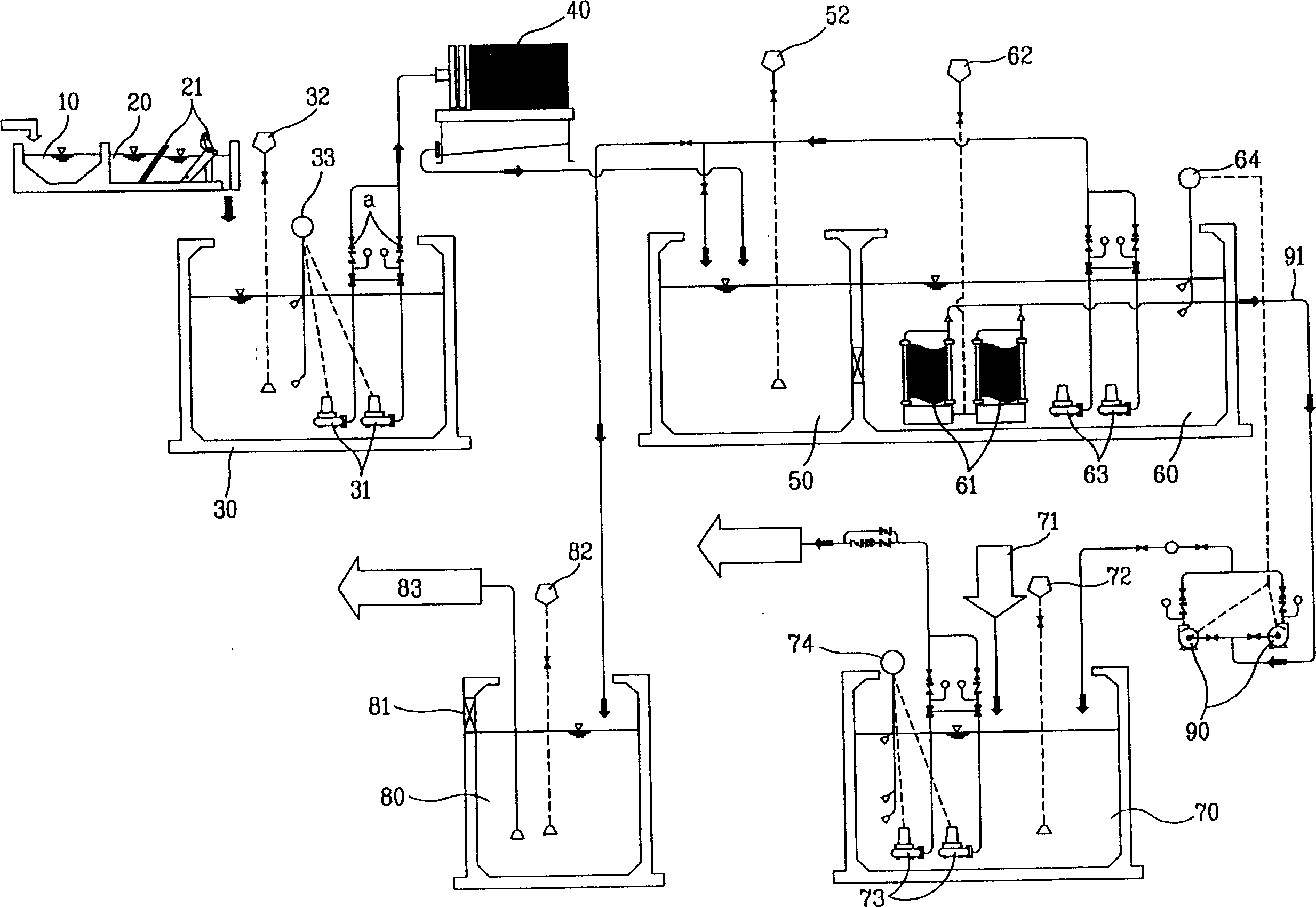

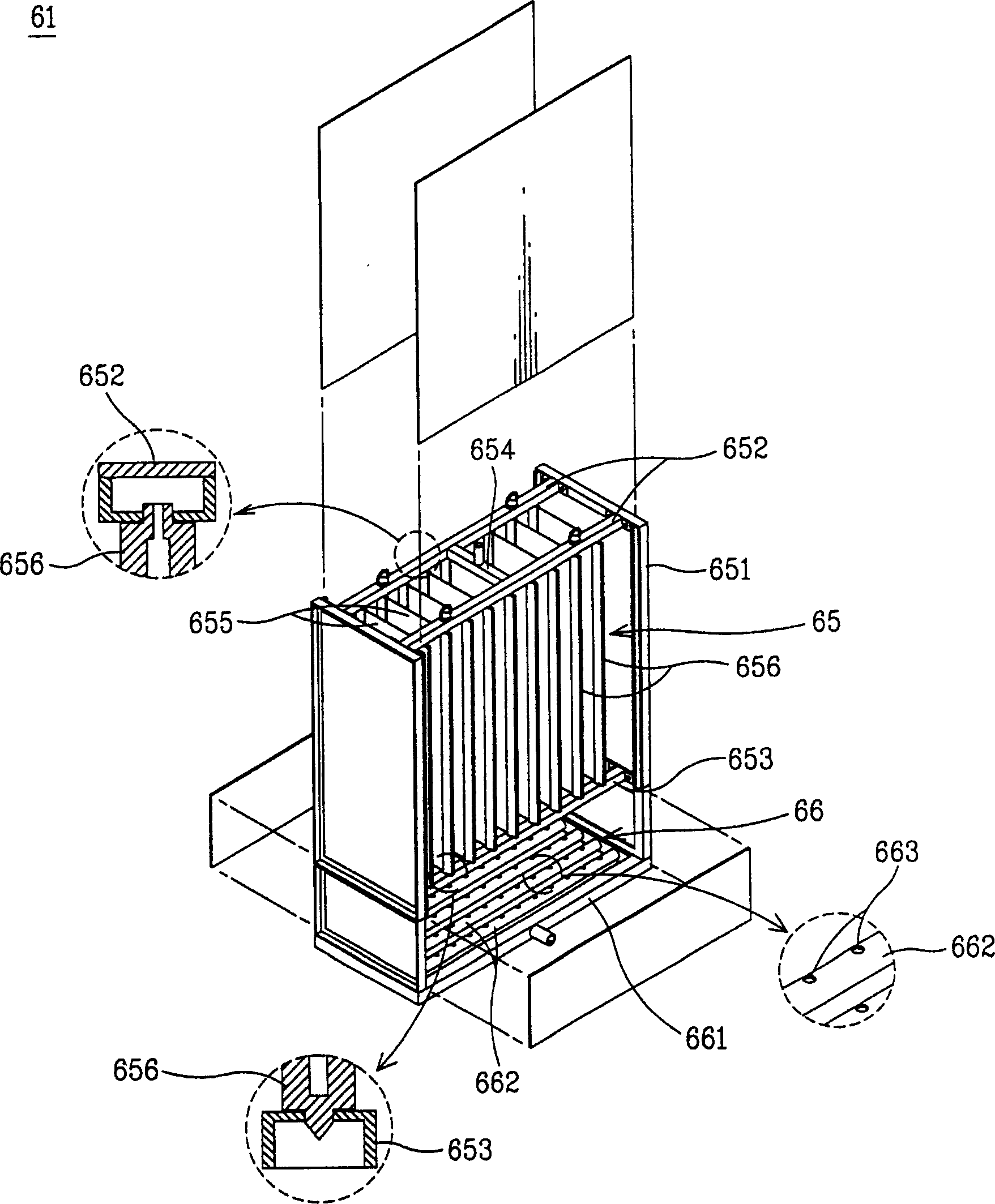

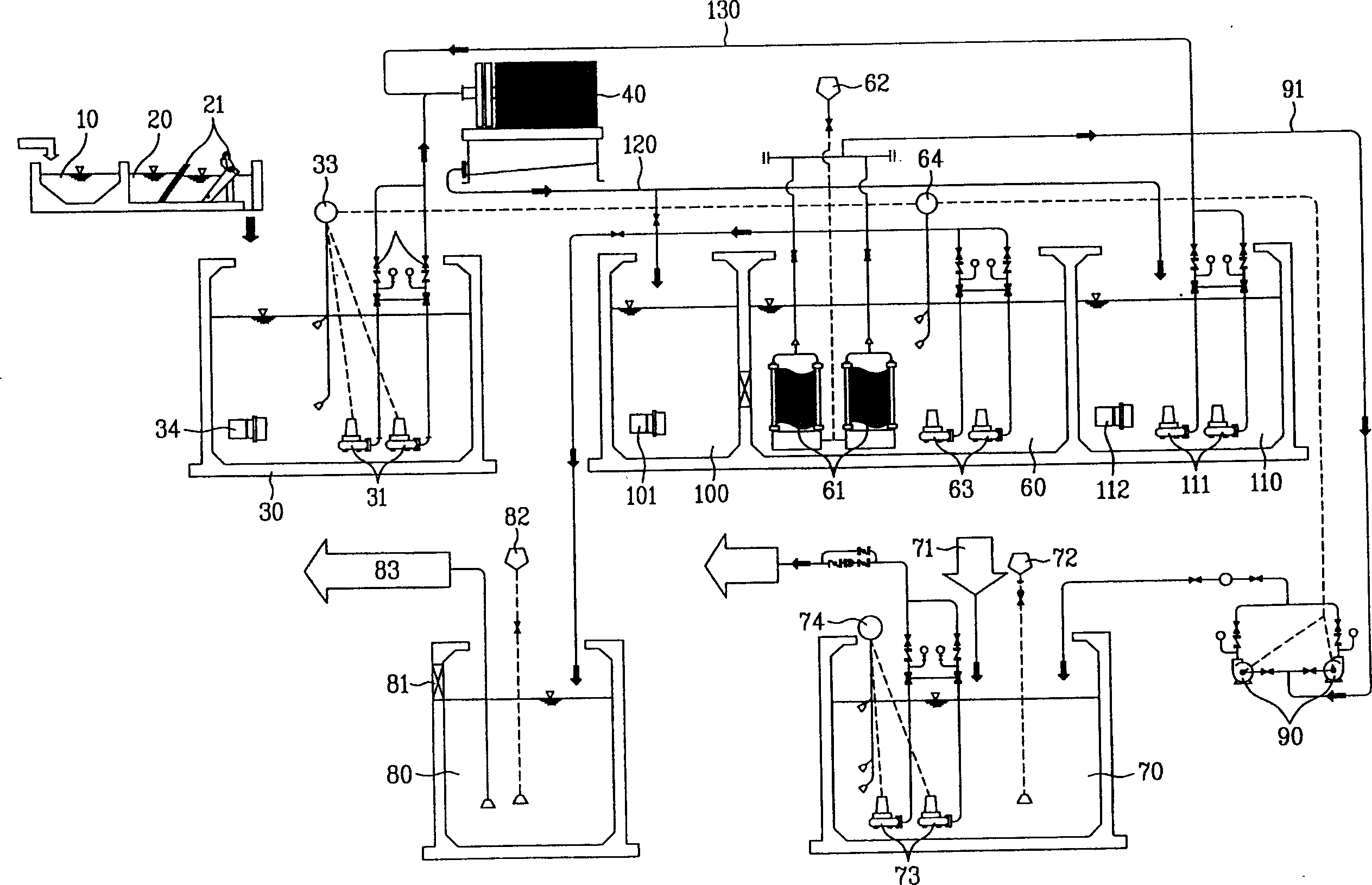

[0070] Below, refer to the attached Figure 3 to Figure 9d , specifically explaining the feasible embodiments of the present invention.

[0071] The descriptions of the leaching membrane separation system and the traditional repeated parts are omitted or only briefly described, and the same components are marked with the same symbols.

[0072] The present invention is provided with a grit chamber 10, which makes the sand or pebbles contained in the sewage settle while blocking the inflow of sewage and the rapid flow of waste water; on the outside of the grit chamber 10, a filter screen groove 20 is arranged. , it has a plurality of filter screens 21, which can filter out the coarse impurities contained in the sewage.

[0073] On the outside of the filter screen tank 20, a flow adjustment tank 30 is provided, which allows the sewage that has filtered out the coarse impurities to flow in and flow out at a certain flow rate; A sewage water pump 31 with suction force, a water le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com