Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Avoid premature curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimicrobial radiation curable coating

InactiveUS7098256B2The environment is moreOptimal for incorporationBiocideAntifouling/underwater paintsCross-linkCarbamate

Owner:MICROBAN PROD CO INC

Antimicrobial radiation curable coating

InactiveUS20050080158A1Activity depletedInferior antimicrobial efficacyBiocideAntifouling/underwater paintsCross-linkOligomer

The invention is a radiation curable coating containing an antimicrobial agent, where upon irradiation with UV light, the radiation curable coating rapidly cures to a polymeric coating. The polymeric coating has durable antimicrobial properties, being especially effective at preventing the growth of Staphylococcus aureaus and Kleibsella pneunoniae on wood flooring and furniture. The major components in the radiation curable coating are a urethane acrylic oligomer, a radiation cure package, an antimicrobial agent, a cross-linking agent, and optionally, an additive package. The radiation curable urethane oligomer is a relatively short chain backbone urethane polymer that is end capped with a radiation curable moiety, where the moiety is an acrylic. The cross-linking agent is one or more monomers used to lower the viscosity and promote cross-linking, and include acrylate esters of mono-, di-, tri-, or tetrafunctional alcohols. The radiation cure package contains at least one photoinitiator.

Owner:MICROBAN PROD CO INC

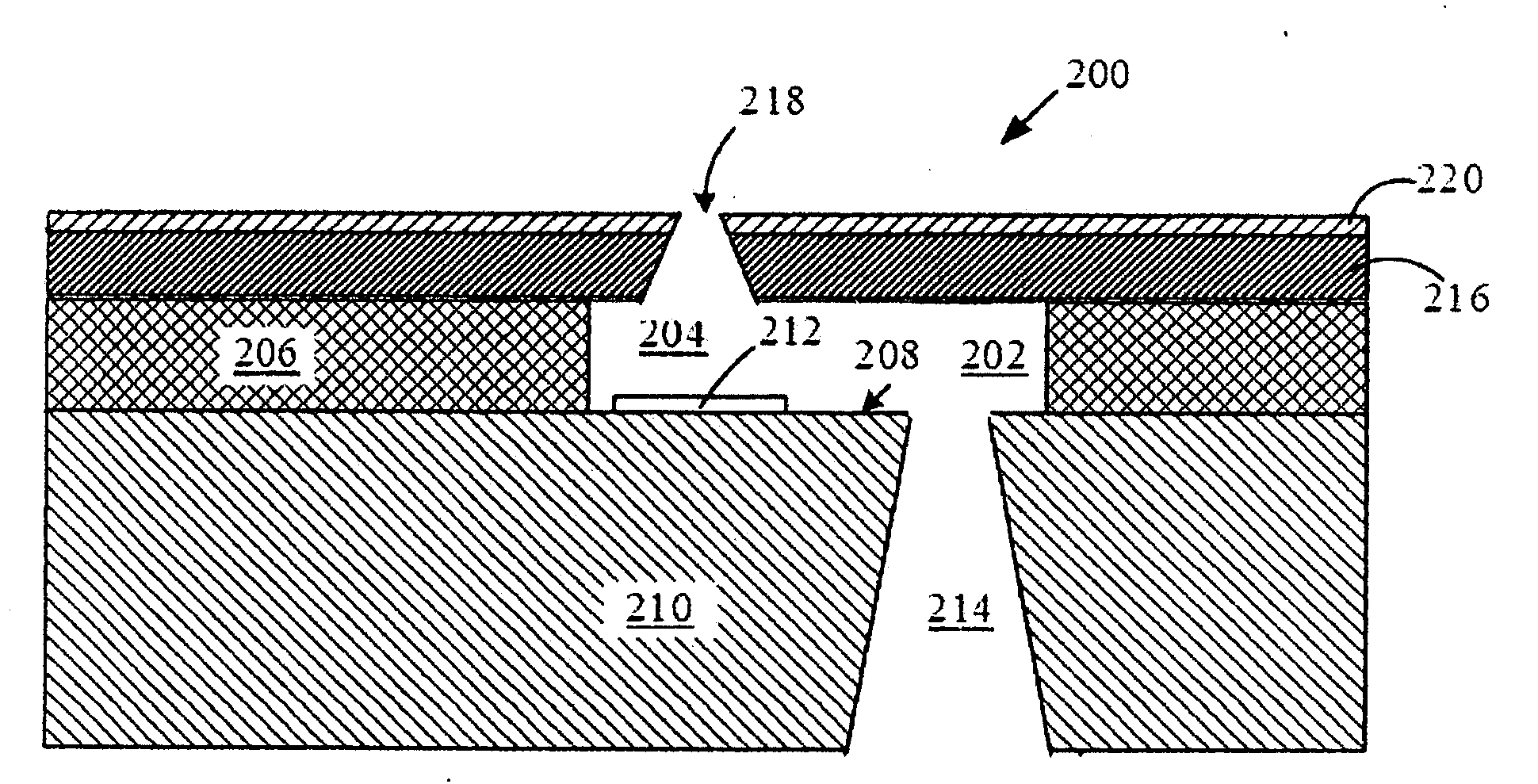

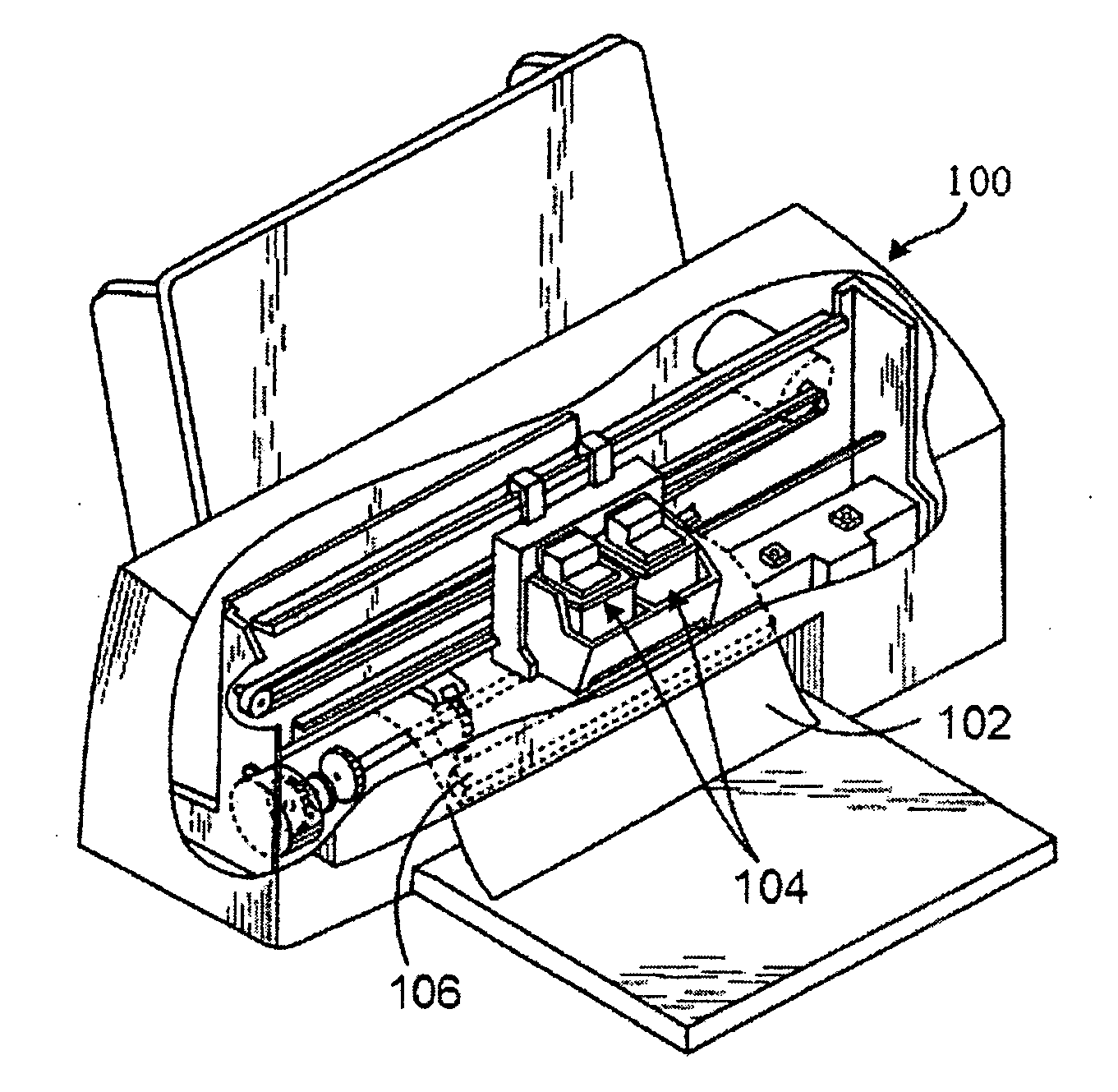

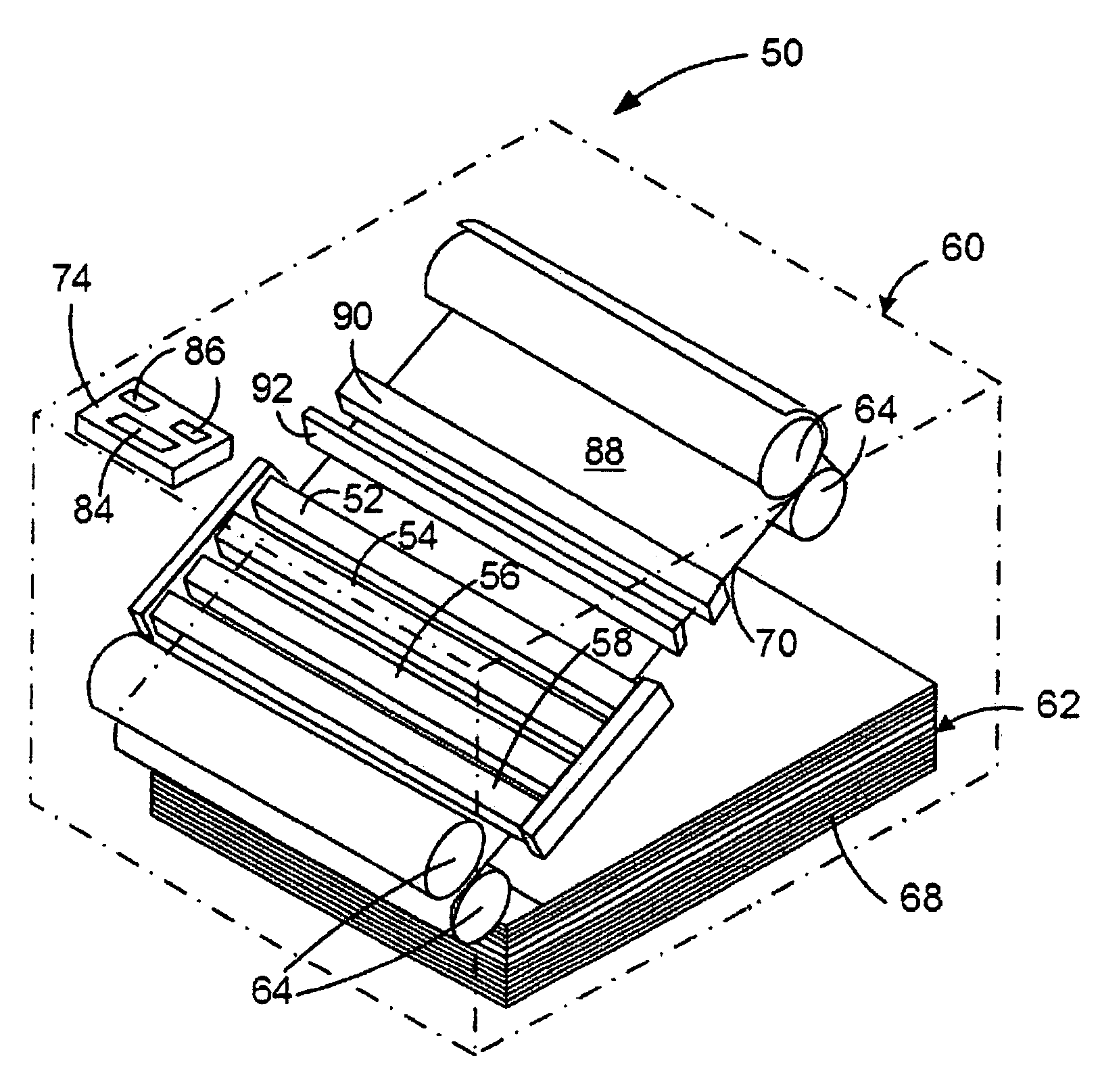

Uv-curable coatings and methods for applying uv-curable coatings using thermal micro-fluid ejection heads

ActiveUS20100152316A1Improving droplet ejection directionality dropletImproving droplet droplet placementLiquid surface applicatorsOrganic chemistryWater basedCarrier fluid

An aqueous-based UV-curable fluid composition for use in a micro-fluid ejection device. The fluid composition includes a mixture of poly-functional compounds, a colorant compound, a photo-initiator and less than about 50 weight percent water based on a total weight of the fluid composition, wherein the fluid composition is substantially devoid of volatile organic carrier fluids.

Owner:FUNAI ELECTRIC CO LTD

Uv-curable coatings and methods for applying uv-curable coatings using thermal micro-fluid ejection heads

InactiveUS20100151142A1Improving droplet ejection directionality and droplet placementHigh viscosityDuplicating/marking methodsPhotomechanical apparatusPhotoinitiatorFluid composition

An aqueous-based UV-curable fluid composition for use in a micro-fluid ejection device. The fluid composition includes a mixture of poly-functional compounds, a colorant compound, a photo-initiator and less than about 50 weight percent water based on a total weight of the fluid composition, wherein the fluid composition is substantially devoid of volatile organic carrier fluids.

Owner:LEXMARK INT INC

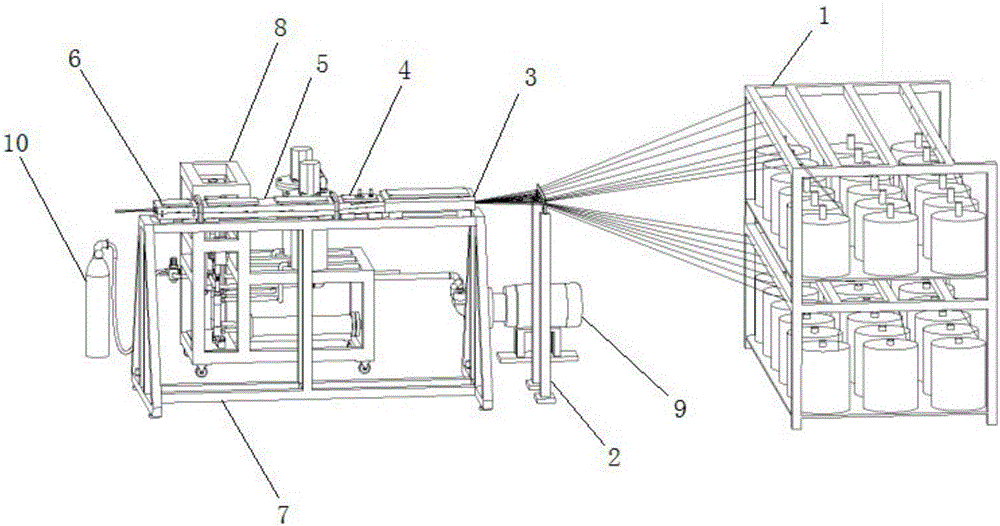

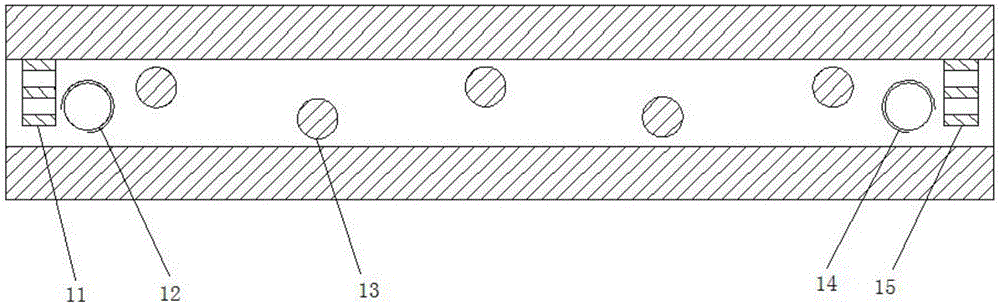

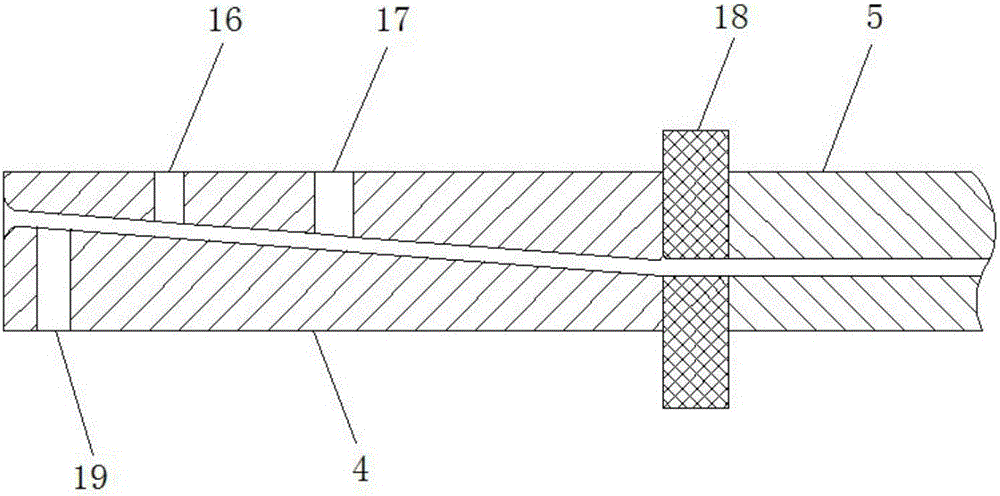

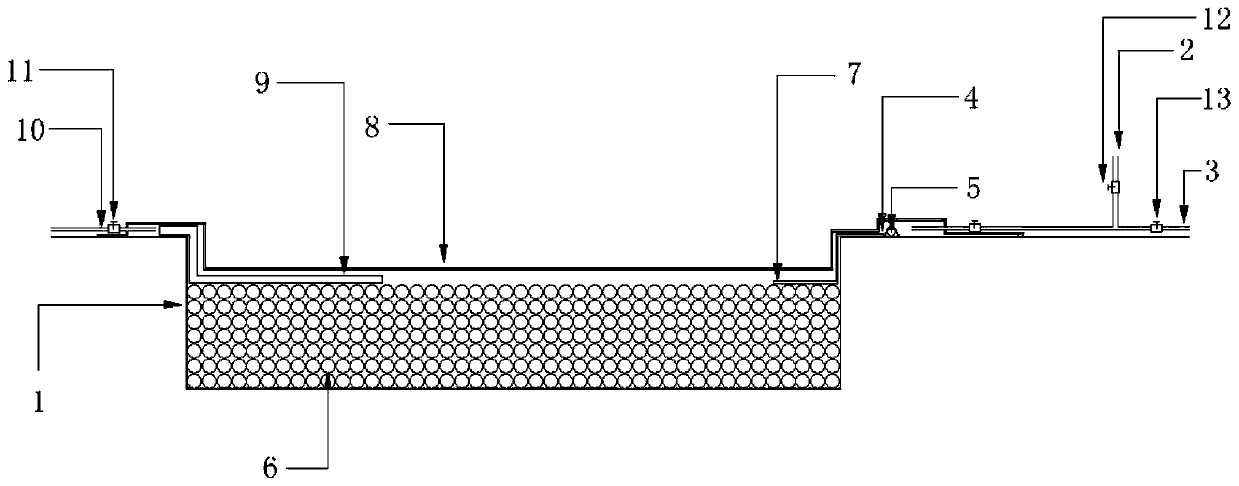

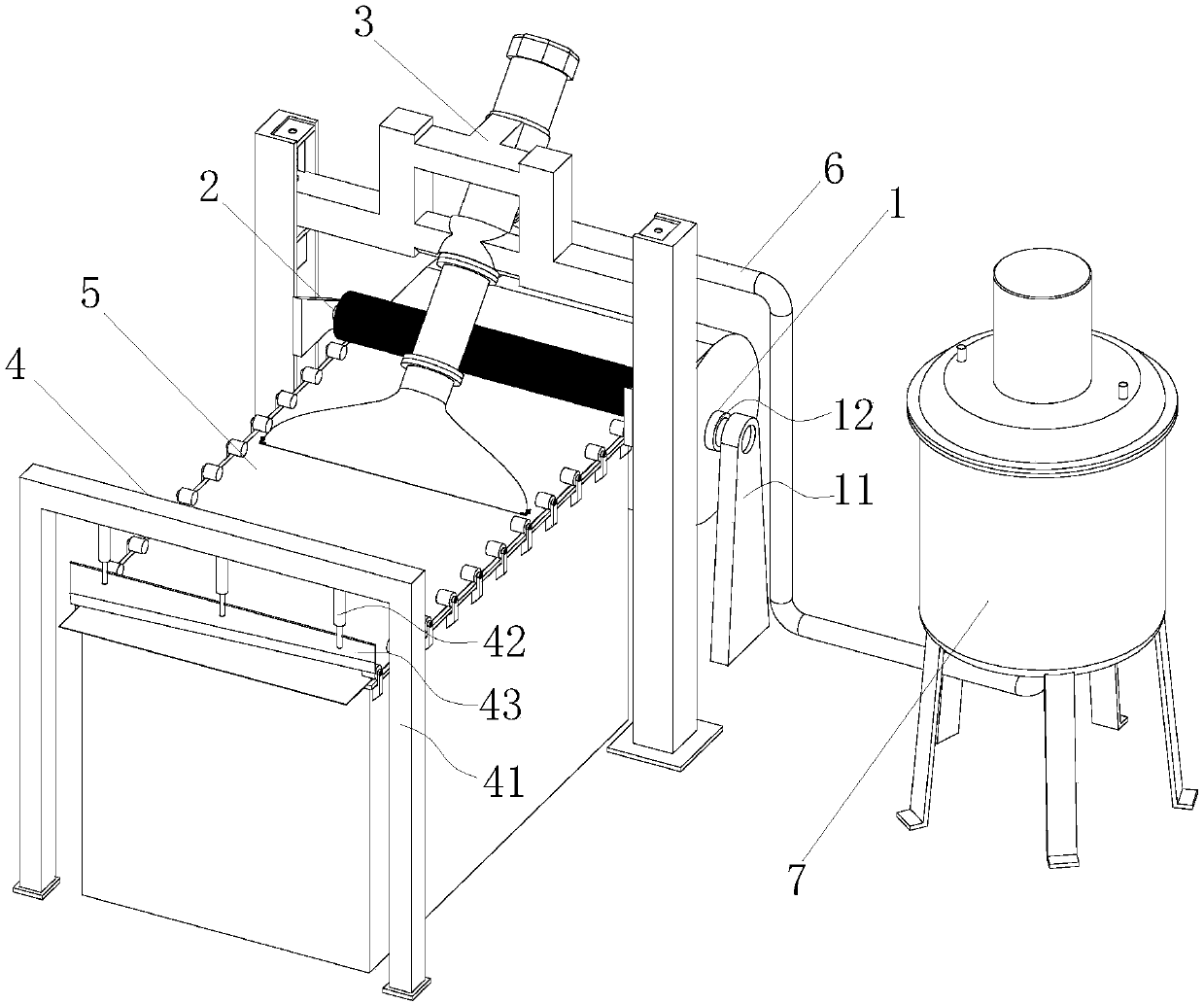

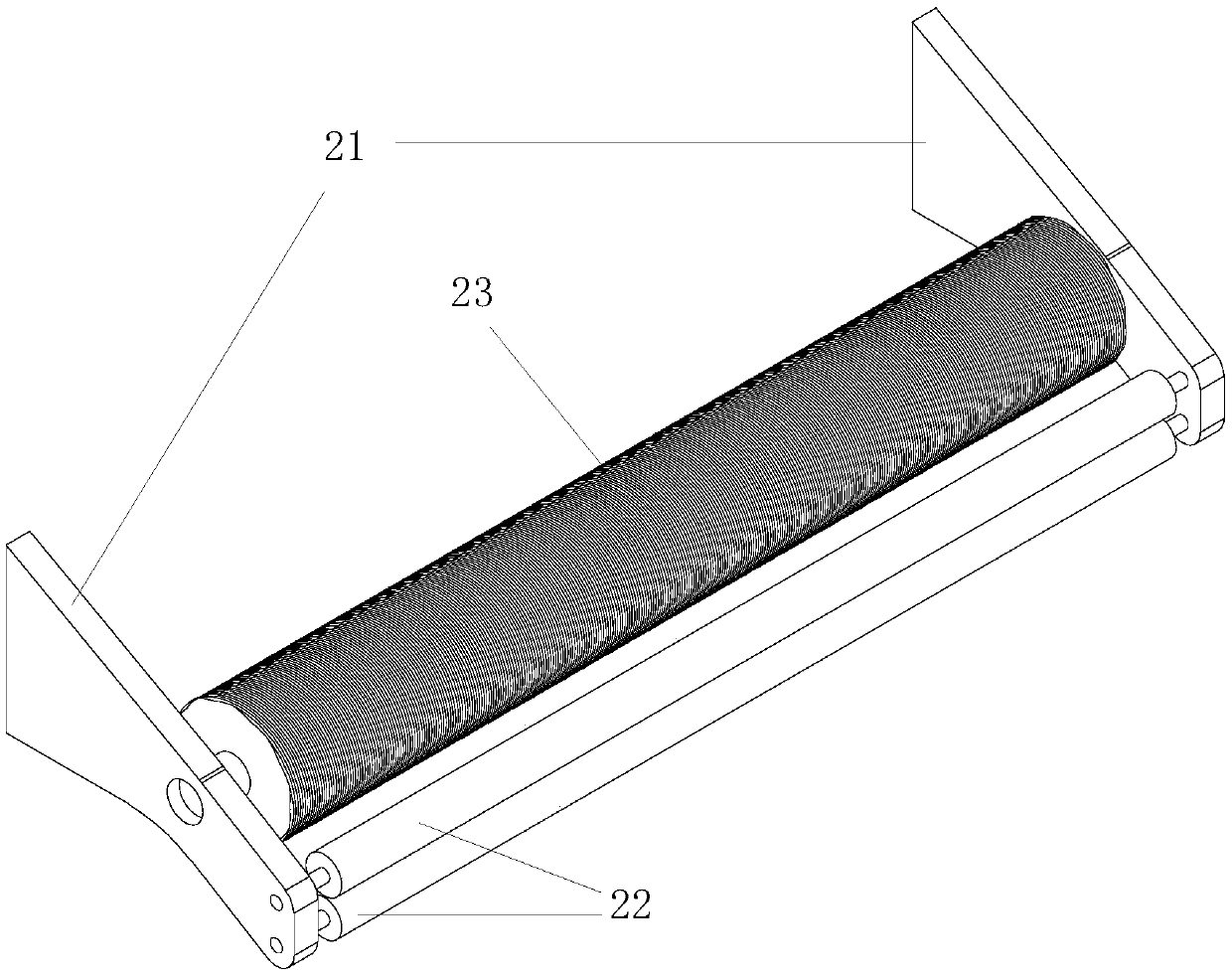

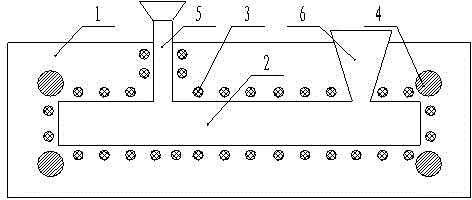

Reaction injection pultrusion equipment and reaction injection pultrusion method

ActiveCN106515047AOvercome the defects of larger pollutionImprove performancePolyresinMaterials science

The invention provides reaction injection pultrusion equipment and a reaction injection pultrusion method for solving the problems of weak fiber dipping effect and volatilization of poisonous gas in a traditional composite material pultrusion technology. The reaction injection pultrusion equipment comprises a forming unit for forming resins and fibers; the forming unit includes the following at least four machining sections connected in sequence: a preheating section for preheating the fibers, a dipping section for dipping the resins and the preheated fibers, a heating section for curing the resins, and a cooling section for cooling a cured composite material for formation; and the machining sections form a closed machining channel with two ports. The pultrusion method and the corresponding reaction injection pultrusion equipment can realize online resin mixing and fiber dipping, have such advantages as good dipping effect and no volatilization of poisonous gas, and prepare high-fiber content continuous fiber reinforced nylon composite materials.

Owner:BEIJING UNIV OF CHEM TECH

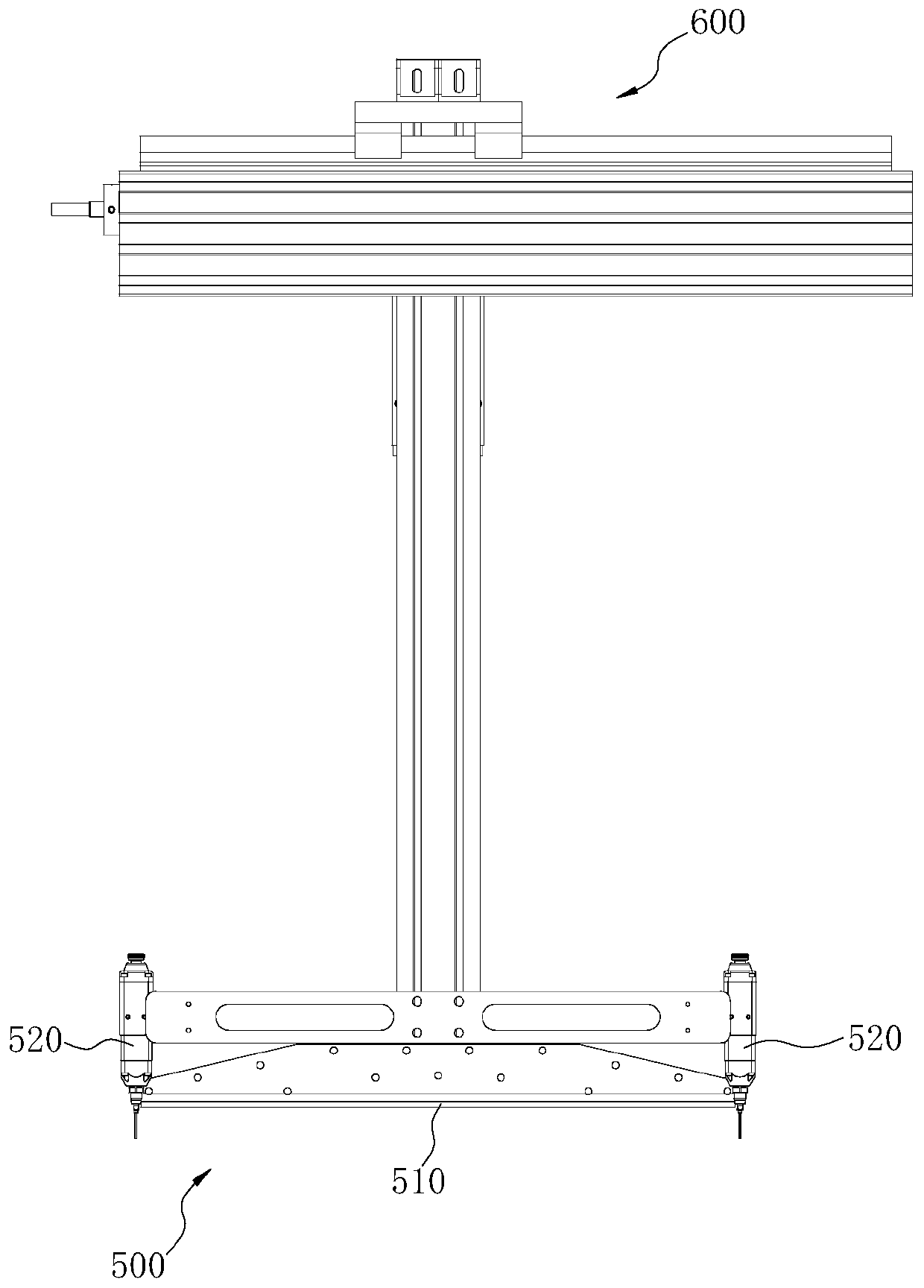

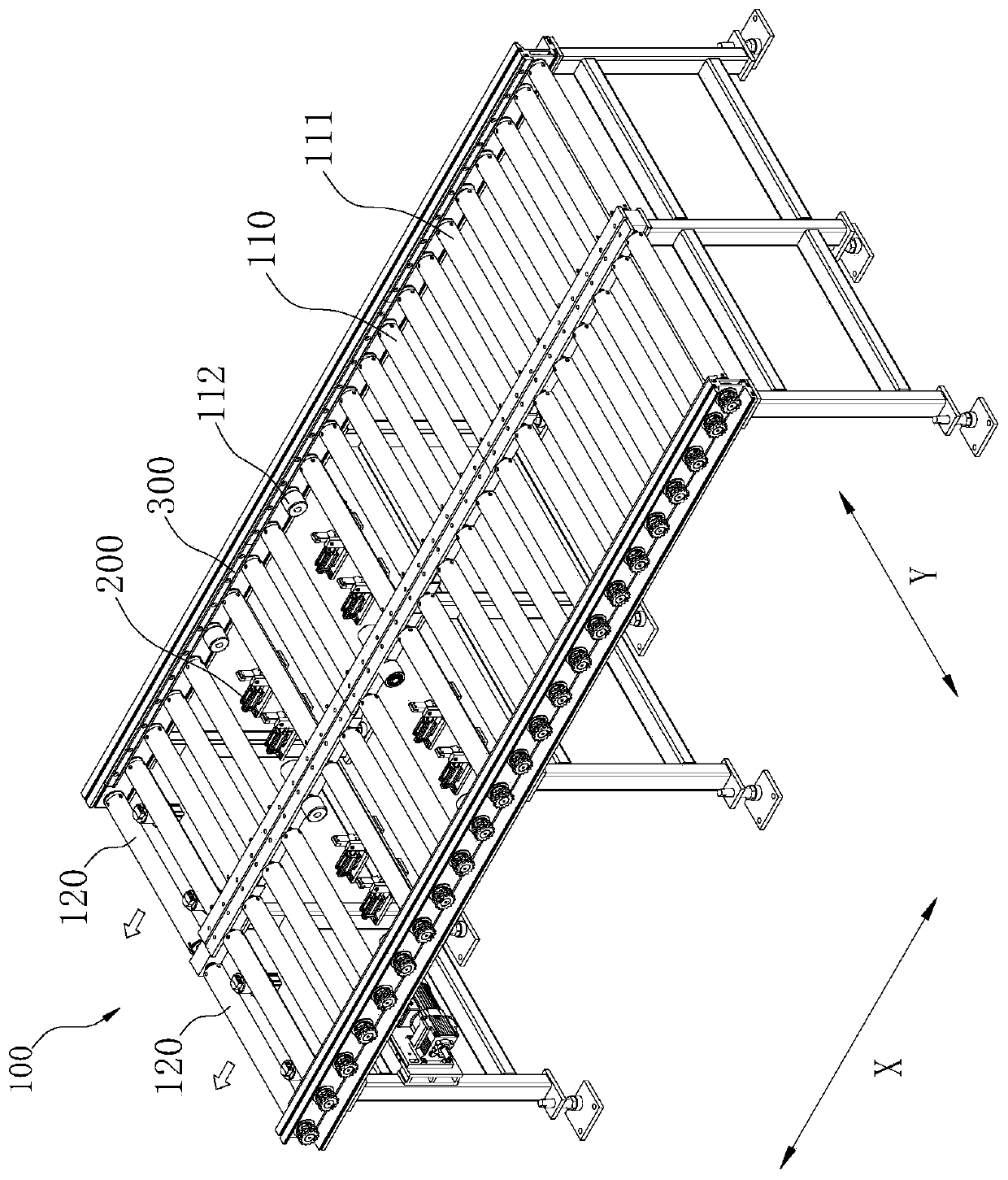

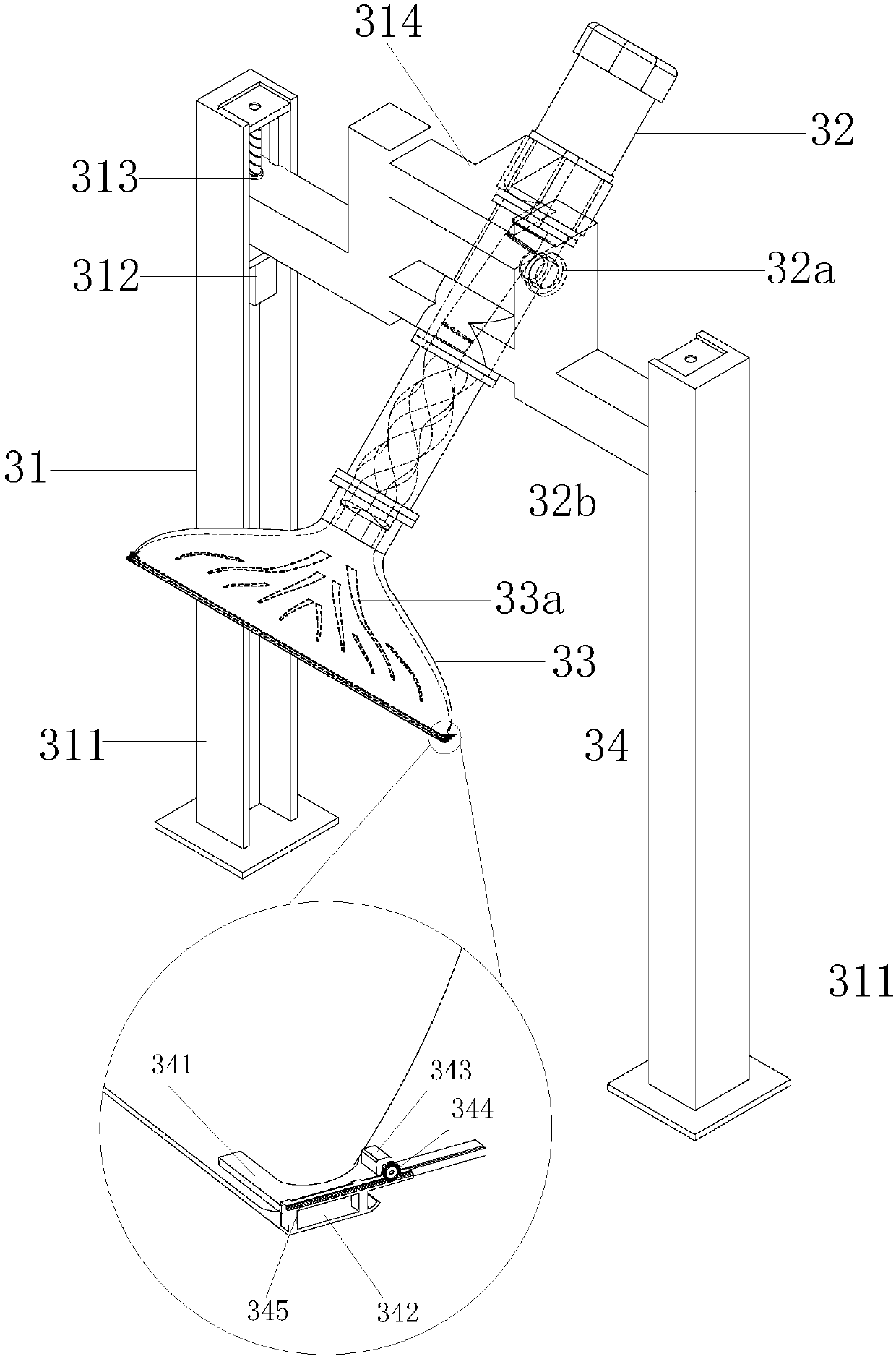

Device for on-track 4D printing of thermosetting shape memory polymers

ActiveCN109483869AOvercoming Unprintable ProblemsAvoid demandManufacturing driving means3D object support structures4d printingInjection pump

The invention discloses a device for on-track 4D printing of thermosetting shape memory polymers, and relates to the technical field of printing. The problem that an existing 4D printing device cannotwork on track is solved. The device for on-track 4D printing of the thermosetting shape memory polymers comprises a printing platform, a printing spray-head, a driving device, a feeding device, a curing device and a three-axis motion device, wherein the printing spray-head is adapted to spray thermosetting materials; the driving device is connected with the printing spray-head and drives the printing spray-head to spray the thermosetting materials, and the driving device is a piezoelectric vibration device; the feeding device comprises an injection pump and is connected with the printing spray-head through a feeding pipe; the curing device is fixedly connected with the printing spray-head, and the curing device heats the thermosetting materials sprayed on the printing platform by the printing spray-head in real time; and the three-axis motion device drives the printing spray-head, the curing device and the printing platform to move in the three-dimensional direction. The device for on-track 4D printing of the thermosetting shape memory polymers solves the problem that printing cannot be performed in weightlessness environment, improves the flexibility of a space station, and effectively reduces the dependence of the space station on ground supply.

Owner:HARBIN INST OF TECH

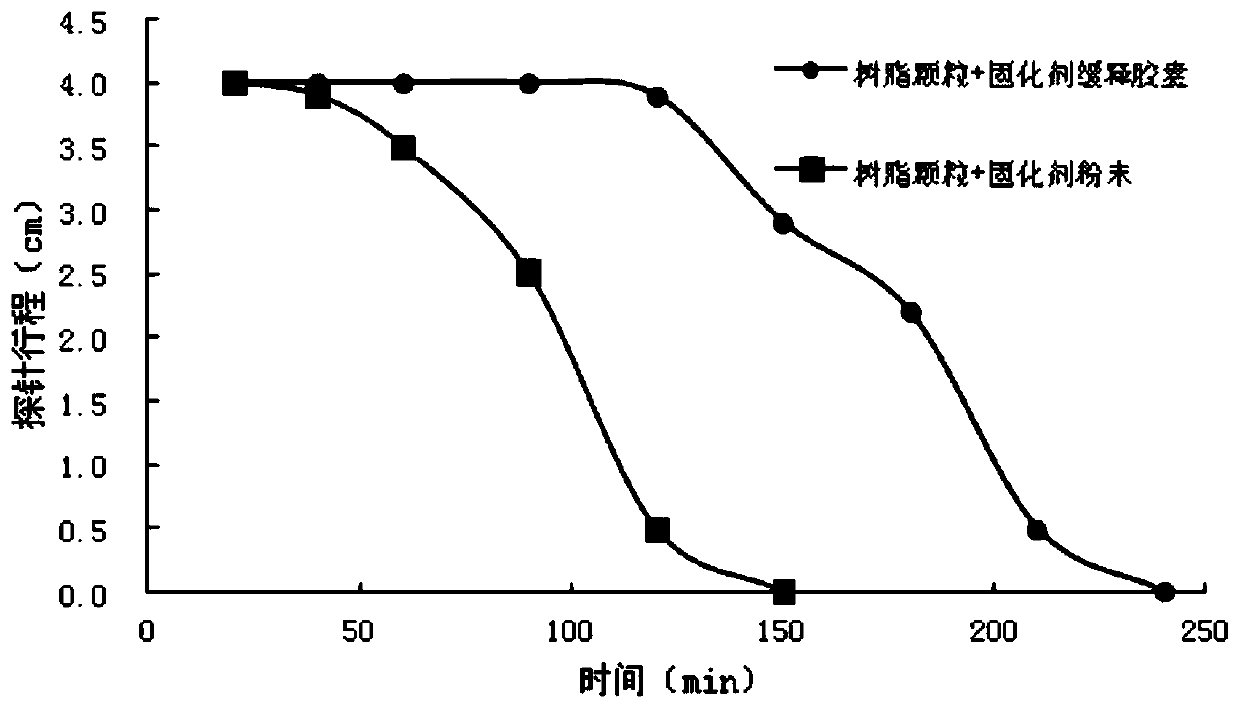

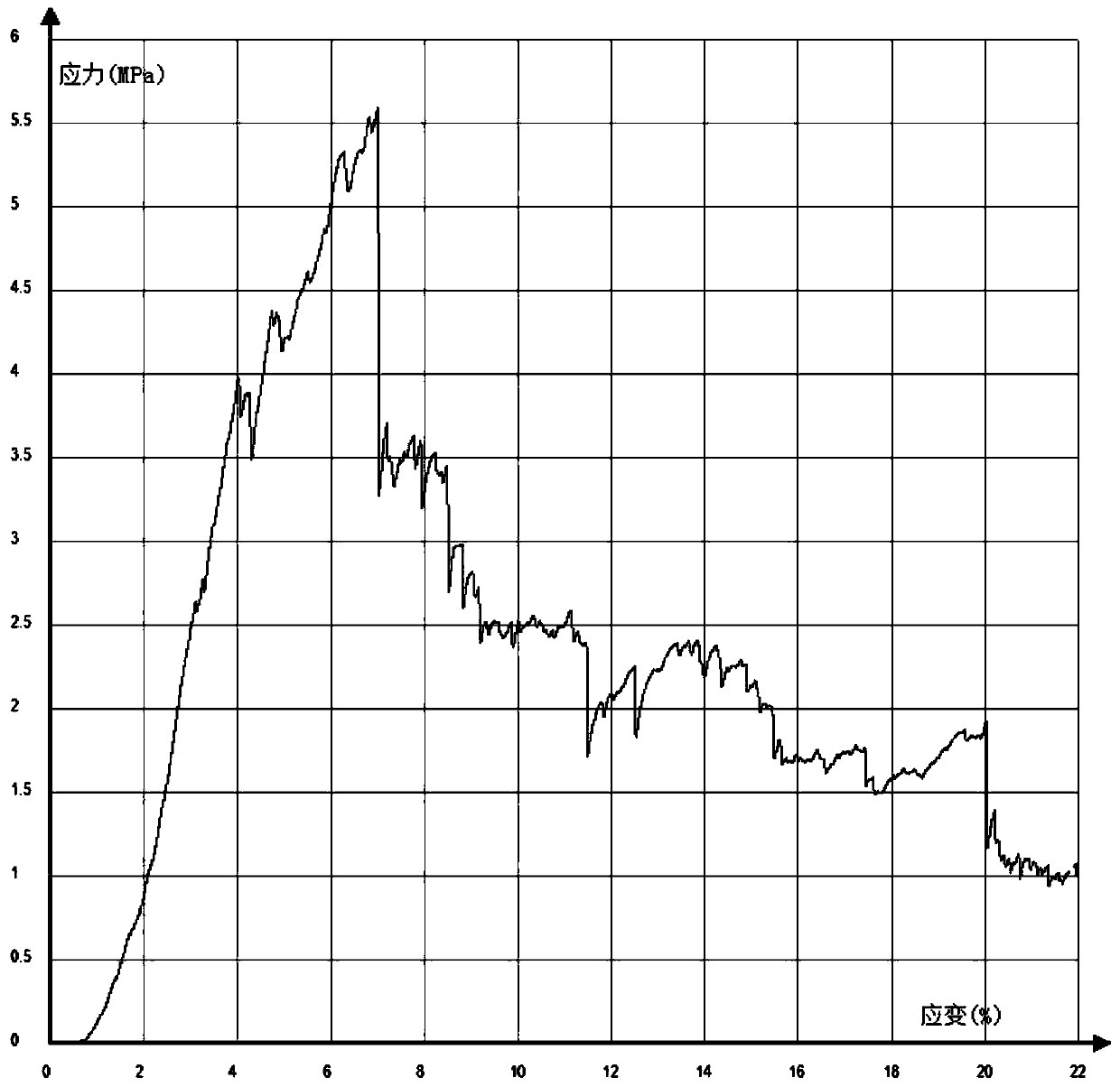

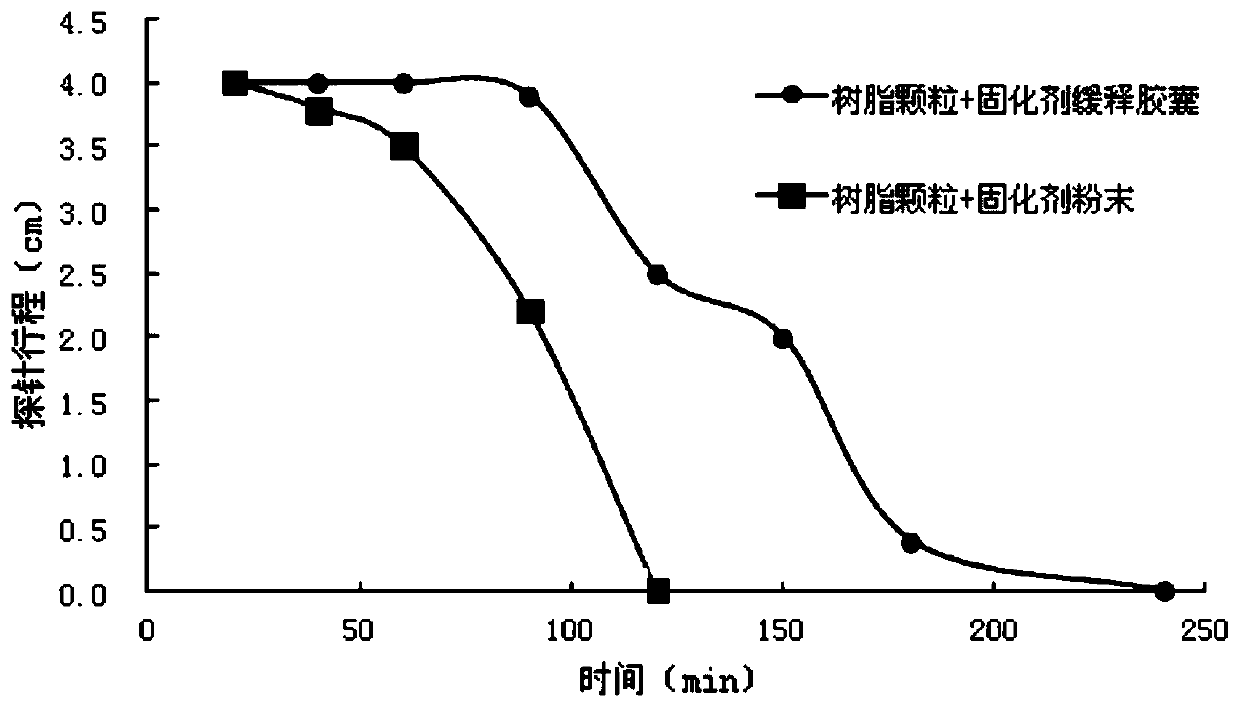

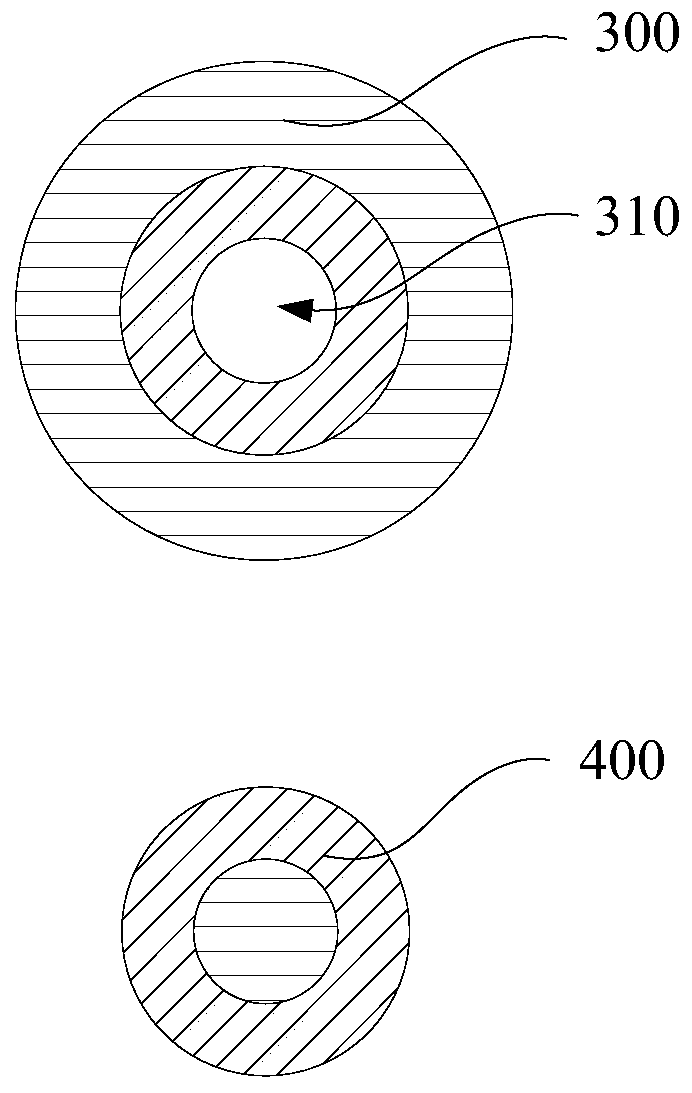

Curing agent sustained release capsule for gas injection channeling prevention, channeling prevention agent and preparation method of curing agent sustained release capsule

ActiveCN109880605AGood sealingExtend curing timeDrilling compositionMedicineSustained Release Capsule

The invention discloses a curing agent sustained release capsule for gas injection channeling prevention, a channeling prevention agent and a preparation method of the curing agent sustained release capsule. The curing agent sustained release capsule is prepared from the following components in parts by weight, 20-40 parts of a resin curing agent, 5-35 parts of a density regulator and 45-75 partsof a coating agent, the resin curing agent is sealed in the coating agent, and the density of the curing agent sustained release capsule is 0.66-0.8 g / cm<3>. The preparation method of the curing agentsustained release capsule comprises the following steps that all the components are evenly mixed at the high temperature according to a certain proportion, cooling is conducted to the room temperature, crushing and granulation are conducted, and thus the curing agent sustained release capsule can be obtained. The density of the curing agent sustained release capsule prepared through the preparation method is between the density of water and the density of injected nitrogen, and is closer to the density of the nitrogen, thus the curing agent sustained release capsule can flow along with a gasinjection channel after being mixed with a resin material, the curing agent sustained release capsule has excellent wellbore injectivity and meanwhile has the sustained release action, a curing reaction is generated only when the curing agent sustained release capsule enters the deep part of an oil reservoir, and the excellent plugging property is achieved.

Owner:CHINA PETROLEUM & CHEM CORP

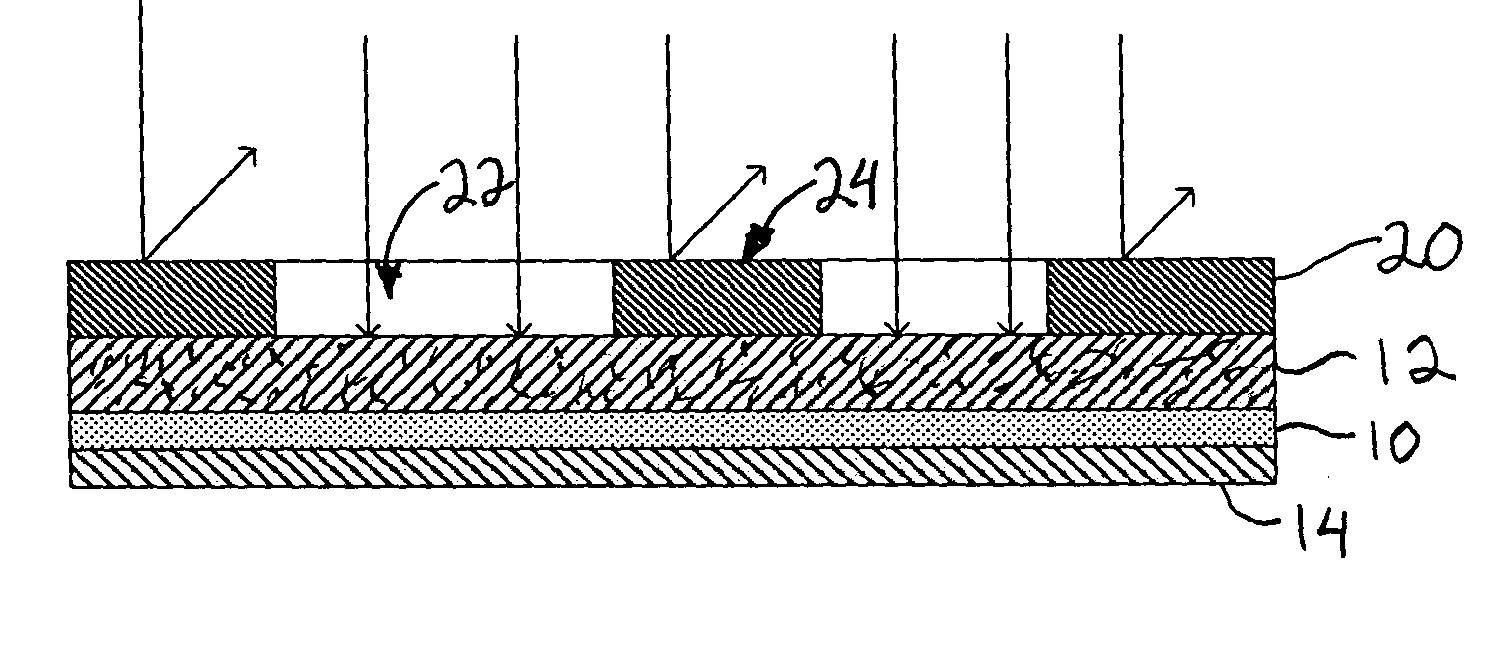

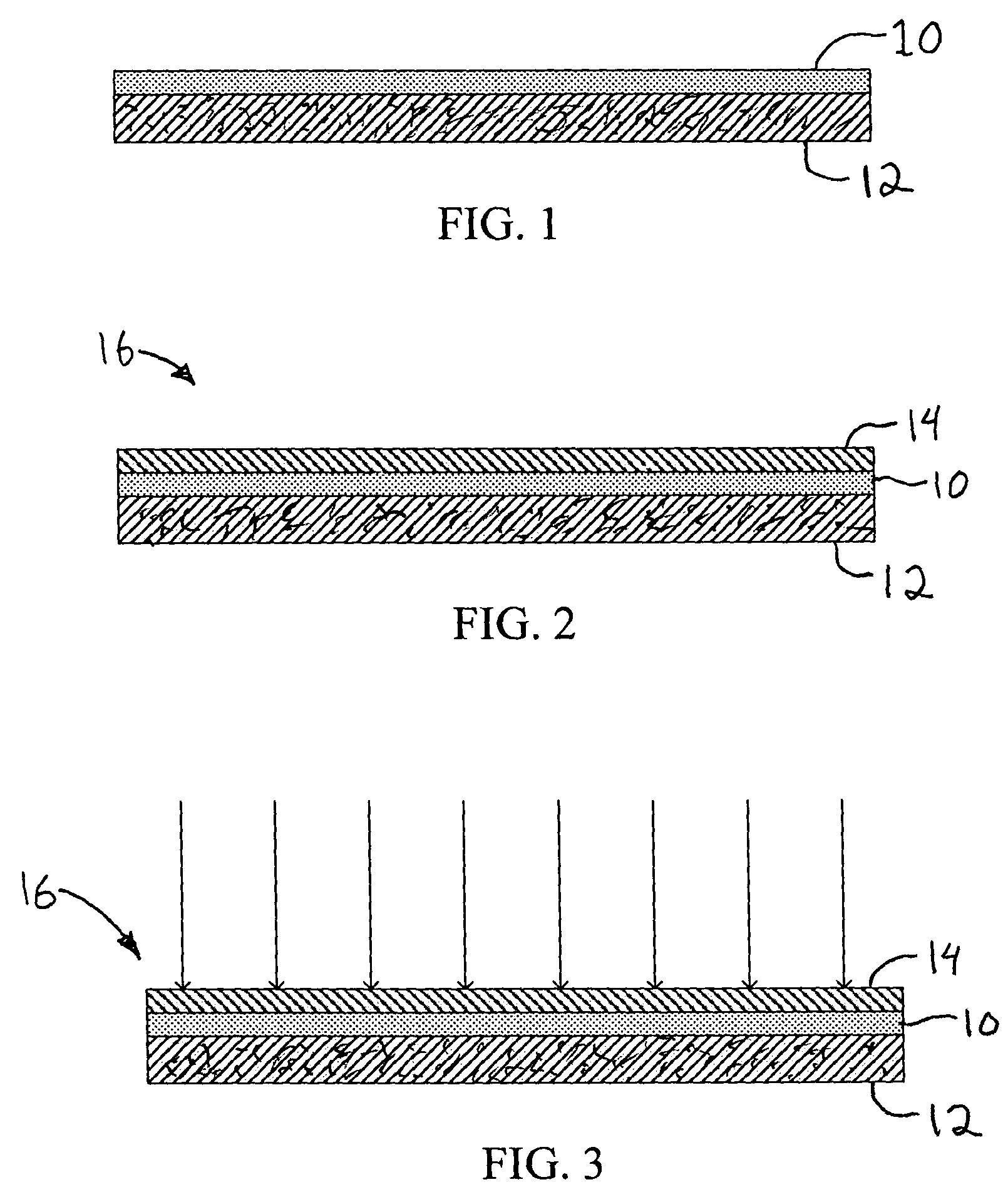

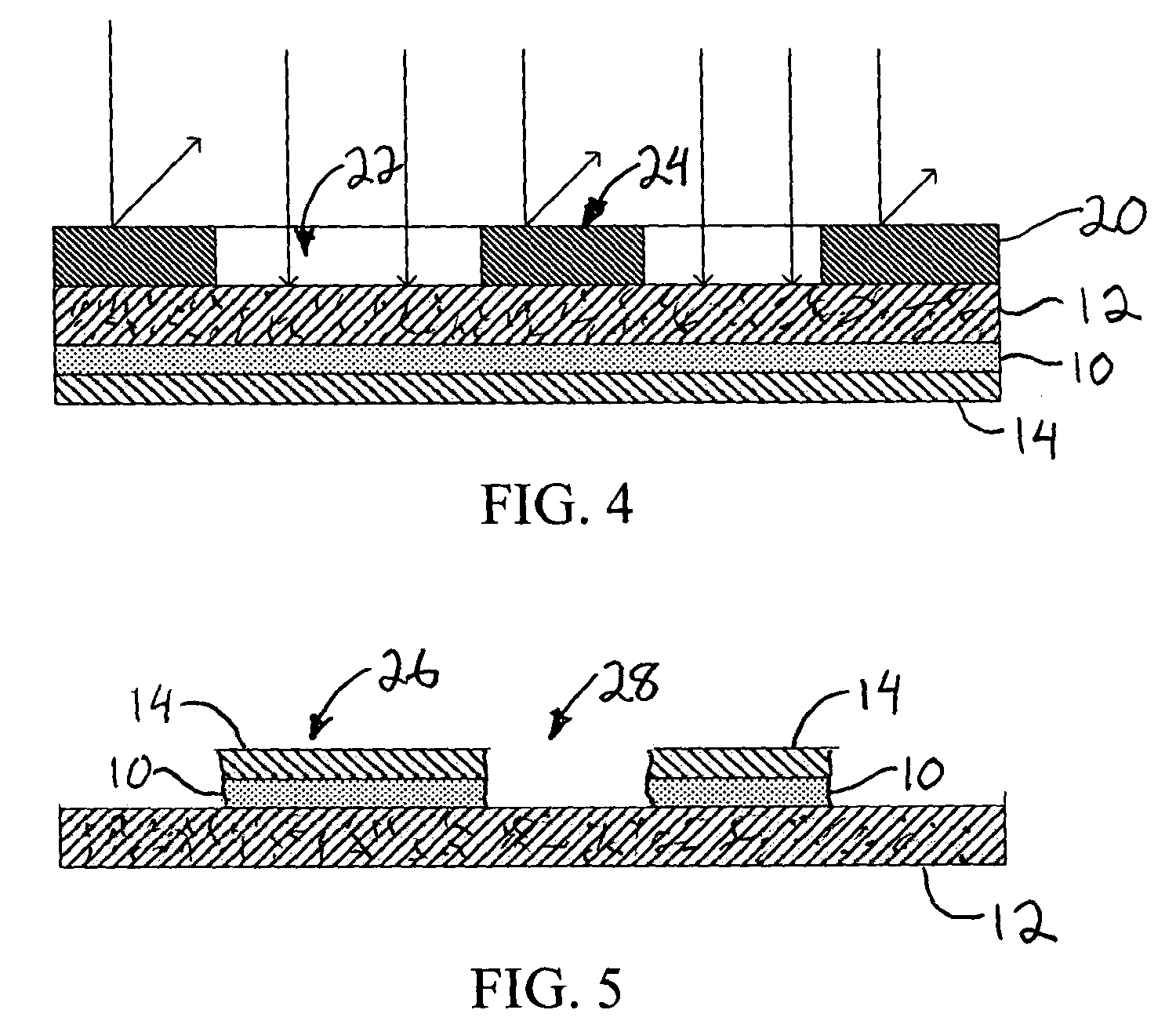

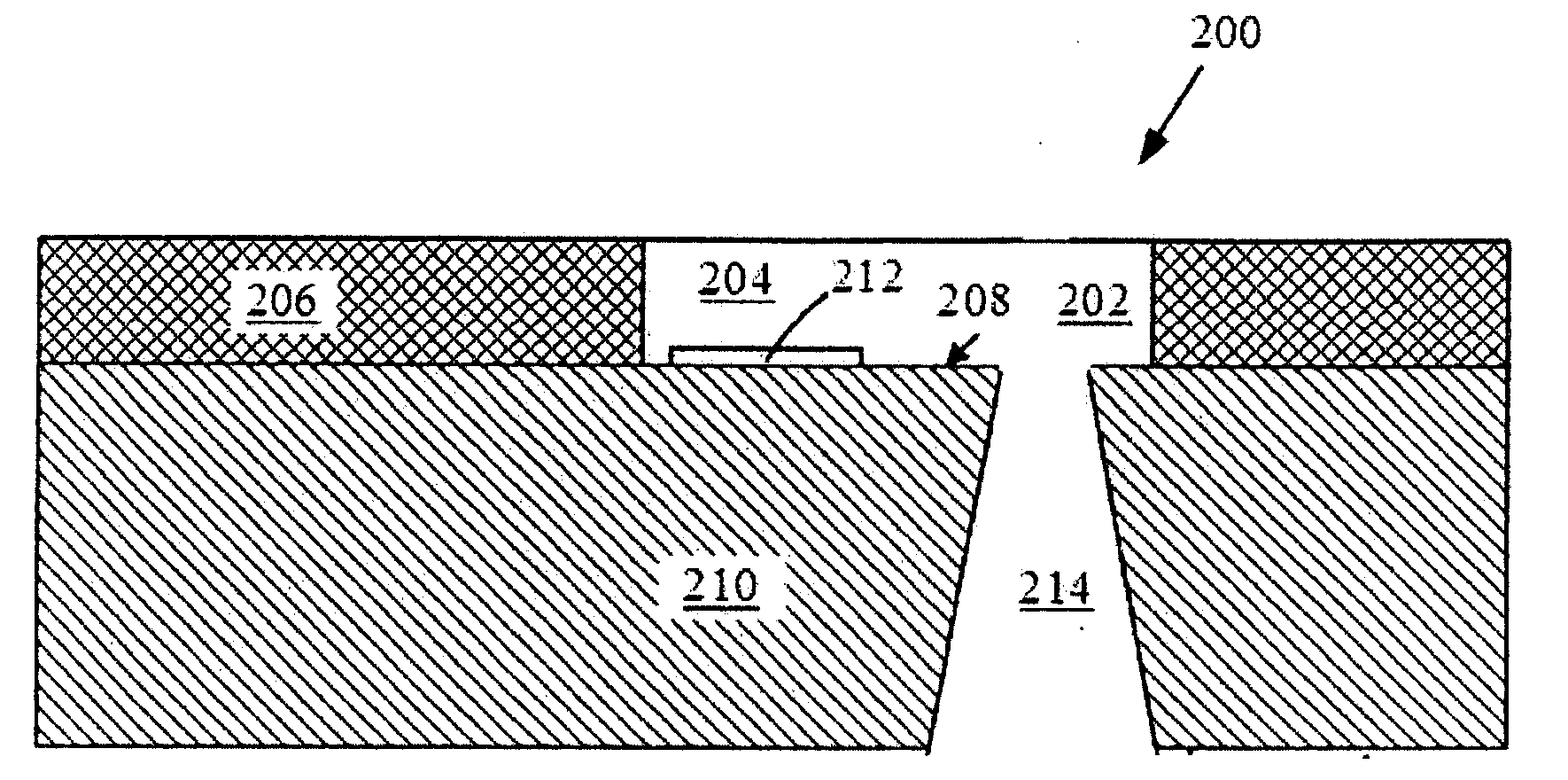

Methods for coating surfaces with metal and products made thereby

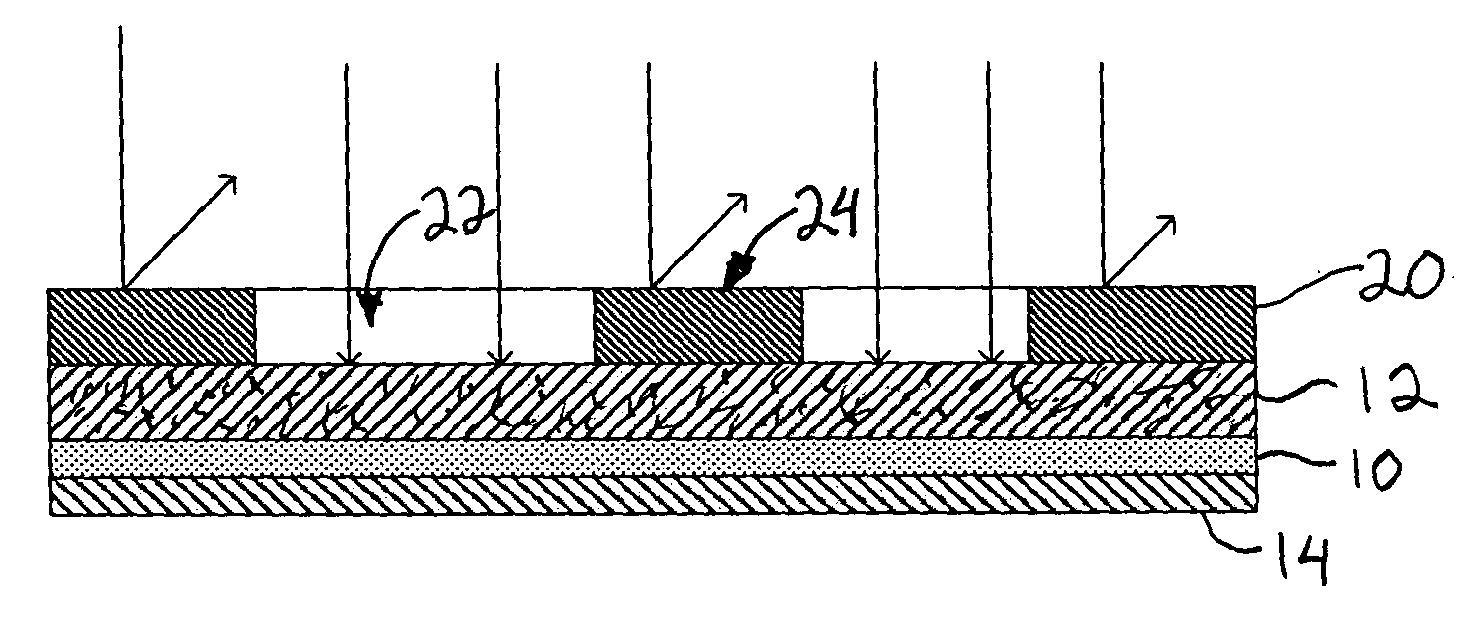

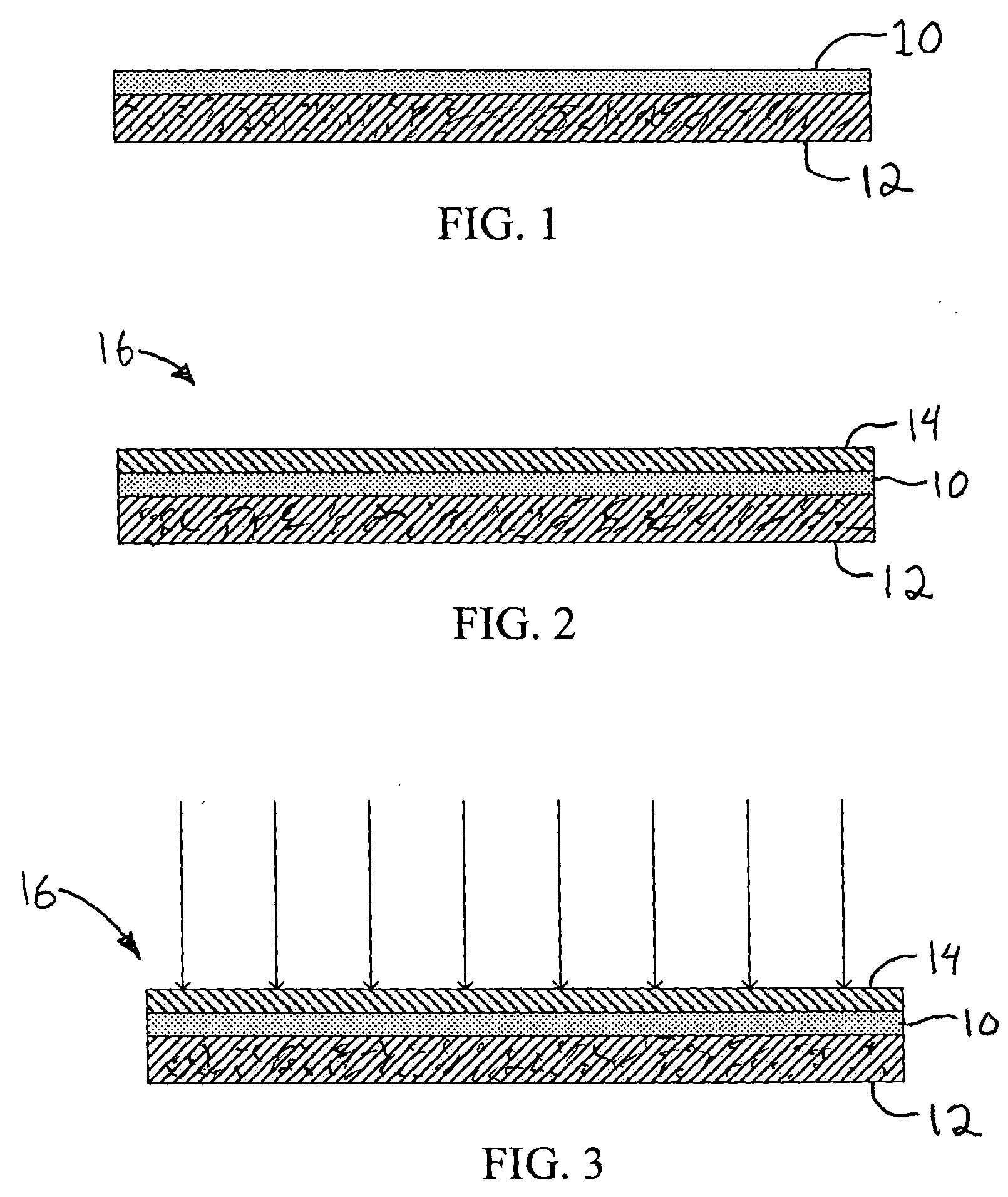

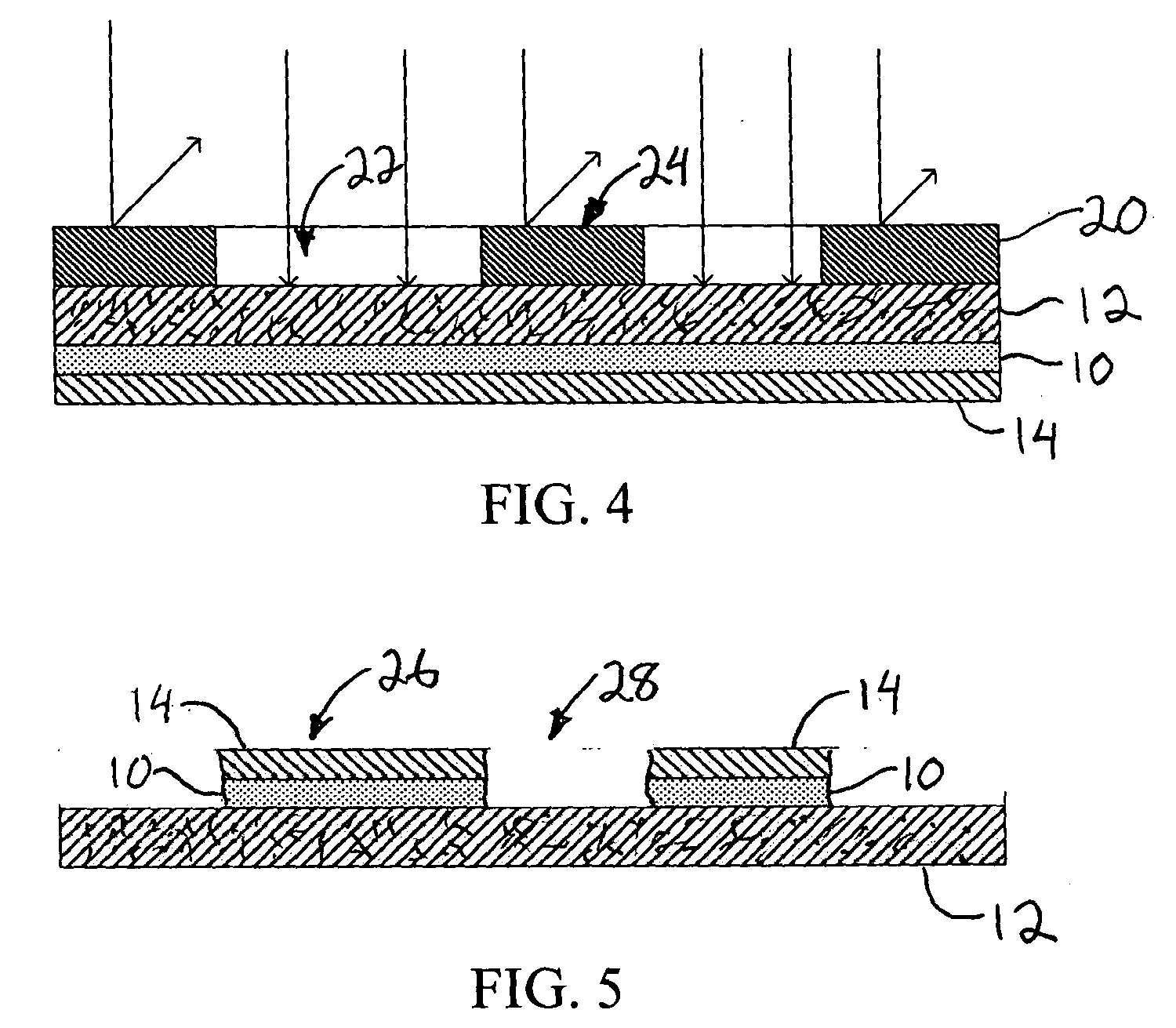

InactiveUS20050196595A1Avoid premature curingFully curedPhototackifying patterningDecorative surface effectsMetal coatingEmulsion

According to the process for coating metal substrates, a light-sensitive (or photo-sensitive) bonding material, such as an emulsion or a photopolymer film, is used to adhere metal directly to a substrate to provide various forms of metal coatings on the substrate. The light-sensitive bonding material is generally applied directly between the substrate and the metal layer. The light-sensitive bonding material is applied under conditions (e.g., lighting and temperature) that prevent premature curing of the light-sensitive bonding material. The light-sensitive bonding material applied between the substrate and metal is then dried and exposed to light to cure the light-sensitive bonding material in selected areas, causing the metal to adhere to the substrate in the selected areas.

Owner:RATTE MICHELE +1

UV-curable coatings and methods for applying UV-curable coatings using thermal micro-fluid ejection heads

ActiveUS7977398B2Avoid premature curingHigh viscosityLiquid surface applicatorsOrganic chemistryWater basedCarrier fluid

An aqueous-based UV-curable fluid composition for use in a micro-fluid ejection device. The fluid composition includes a mixture of poly-functional compounds, a colorant compound, a photo-initiator and less than about 50 weight percent water based on a total weight of the fluid composition, wherein the fluid composition is substantially devoid of volatile organic carrier fluids.

Owner:FUNAI ELECTRIC CO LTD

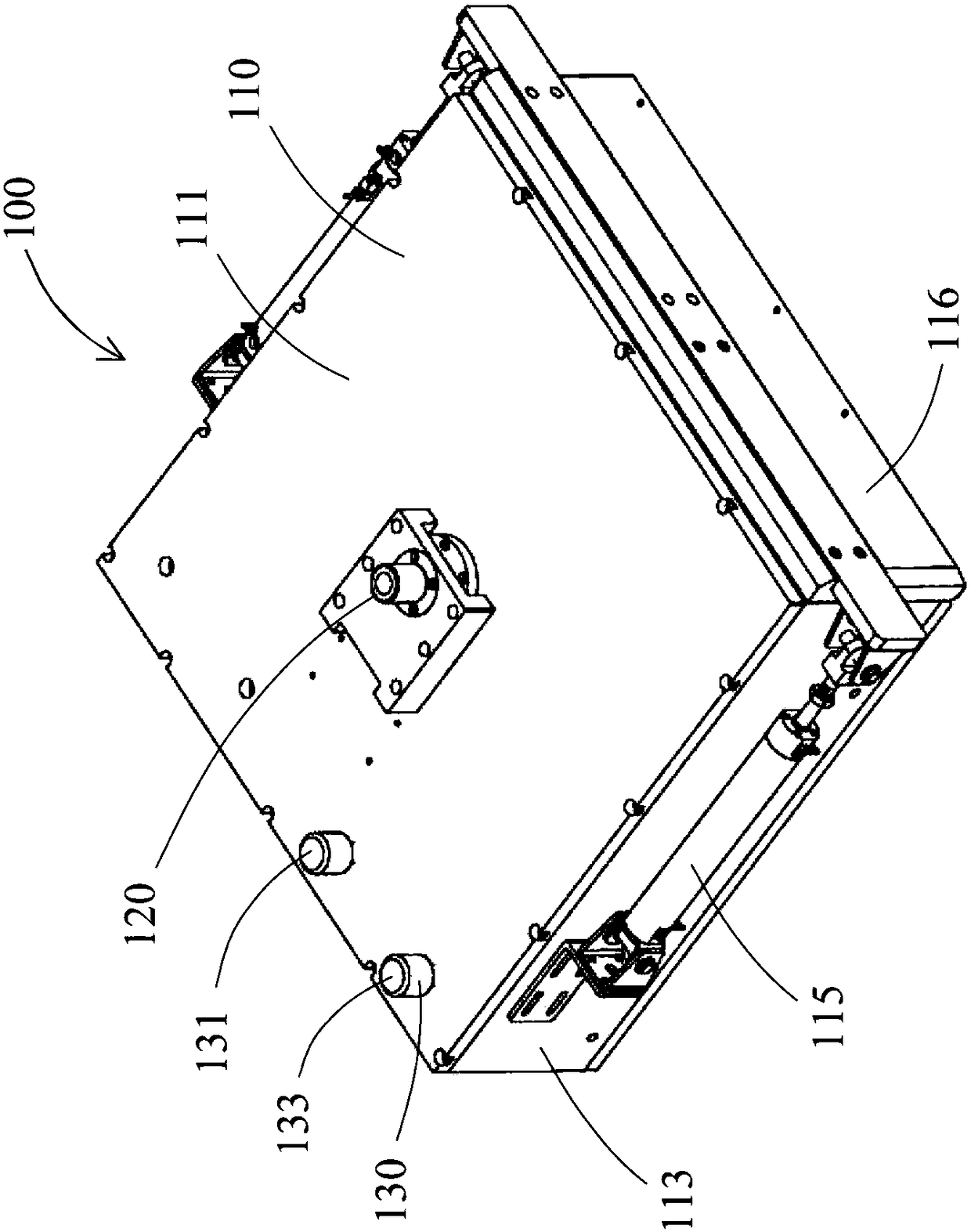

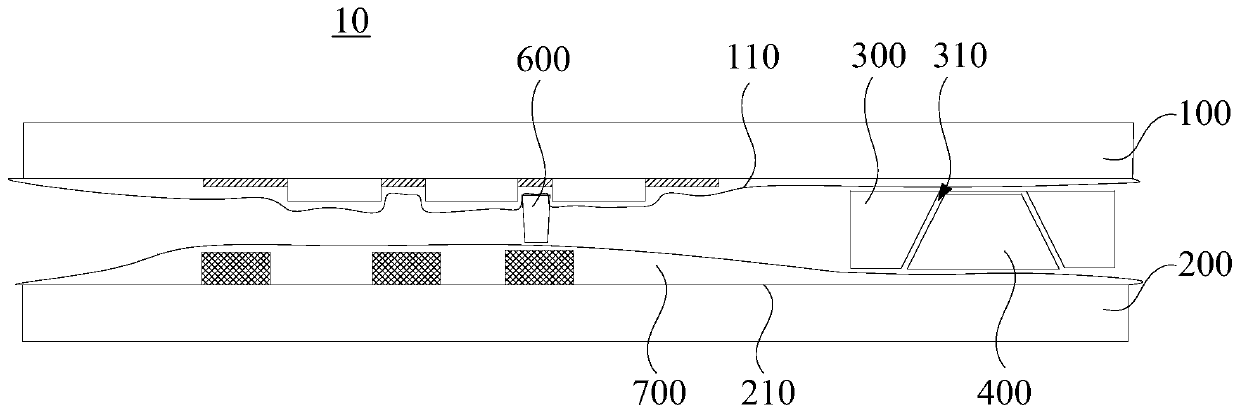

Vacuum film pasting apparatus and method

ActiveCN108321097AReduce bubble defectsImprove yieldSemiconductor/solid-state device manufacturingSemiconductor devicesAdhesiveEngineering

The invention provides a vacuum film pasting apparatus. The vacuum film pasting apparatus comprises a vacuum cavity module, a film pressing module, a bearing module and a heating platform, wherein thefilm pressing module comprises a film pressing plate; and the bearing module comprises a bearing plate and a spring device. When the vacuum film pasting apparatus acts, the film pressing plate presses a film downwards to drive the bearing plate to move to the heating platform so as to heat the film sheet to enable jointing adhesive to be cured and laminated; after heating is completed, the film pressing plate moves upwards, and the spring device can release the spring potential energy pre-stored in lamination, and drives the bearing plate to move upwards to recover to the initial position. The invention also provides a vacuum film pasting method; and by virtue of the vacuum film pasting apparatus and method, lamination shortcoming caused by air bubbles between the film sheet and the to-be-pasted film part can be reduced, and the combination force between the film sheet and the to-be-pasted film part can be improved.

Owner:MAVEN OPTRONICS CO LTD

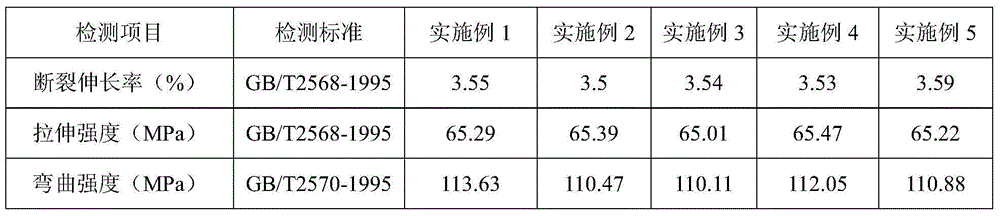

Unsaturated polyester resin used for bulk molding compound and preparation method thereof

The invention discloses unsaturated polyester resin used for a bulk molding compound and a preparation method thereof. The resin is mainly prepared from the following raw materials by weight: 2000 to 2500 parts of phthalic anhydride, 7500 to 8500 parts of maleic anhydride, 3500 to 4000 parts of diethylene glycol, 4500 to 5000 parts of 1,2-propylene glycol, 3 to 5 parts of an antioxidant, 8 to 12 parts of a polymerization inhibitor, 3 to 7 parts of methylhydroquinone, 8500 to 9000 parts of styrene and 1 to 2 parts of p-benzoquinone. Compared with the prior art, the unsaturated polyester resin for the bulk molding compound provided by the invention has the following advantages: cost is significantly reduced, and excellent mechanical property is maintained.

Owner:宜兴市兴合树脂有限公司

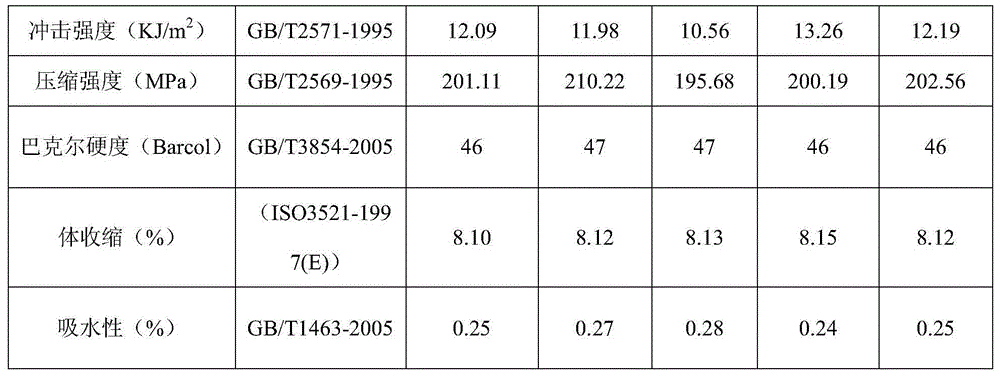

Production method for capacitive touch screen

InactiveCN108776562AAvoid premature curingImprove adhesion strengthInput/output processes for data processingIntegrated circuit manufacturingProtective glasses

The invention discloses a production method for a capacitive touch screen. The method includes the following steps: step 100. preparing a transparent electric level layer, and etching a capacitive sensing circuit on a transparent circuit board by using an integrated circuit manufacturing process; step 200. installing the transparent electric level layer, and pressing the transparent electric levellayer and a glass substrate into one body; and step 300. producing a touch screen to form into a shape, and adhering protective glass to the transparent electric level layer after the transparent electric layer is integrated. Through adoption of the scheme, optical cement is prevented from prematurely curing by controlling the time of constant temperature and cooling, thereby improving the adhesion strength, and the curing efficiency can be improved, and the curing time is shortened through the combination of air cooling and ultraviolet light; and the flatness during adhesion can be improved,uneven thickness of the optical cement is prevented, thereby improving the production quality, and further the cooling efficiency is improved by employing a mode of cooling roller extrusion.

Owner:JIANGSU DIJIA ELECTRONICS CO LTD

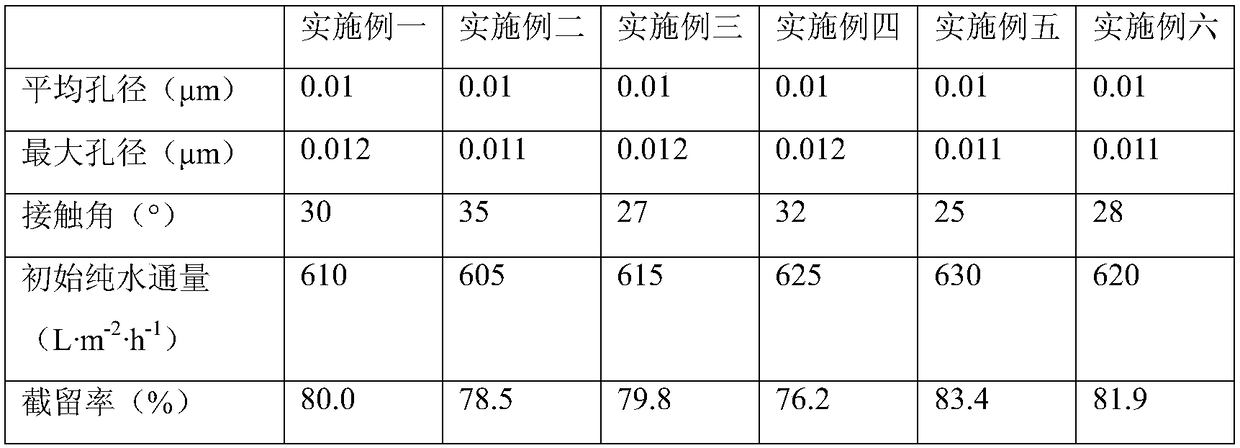

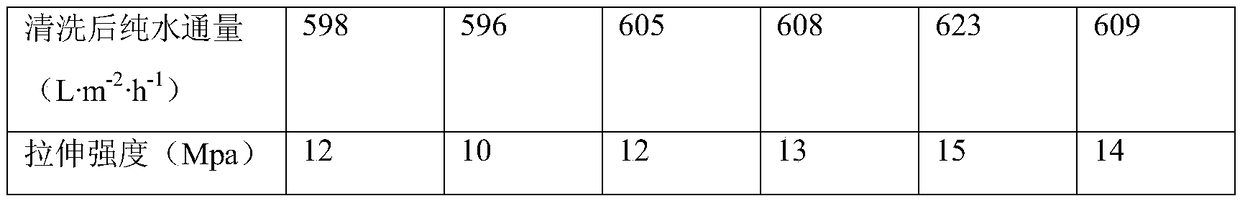

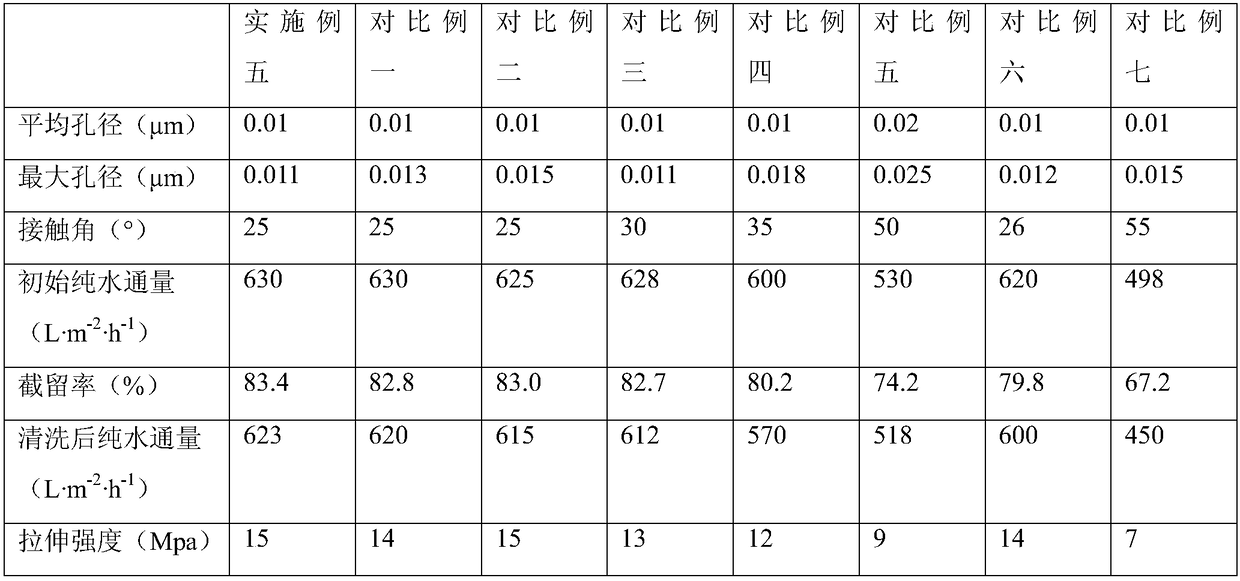

PVDF composite graphene filter element membrane and production process thereof

ActiveCN108499374AImprove hydrophilicityGood distribution of poresSemi-permeable membranesMembranesPorosityFiltration

The invention discloses a PVDF composite graphene filter element membrane and a production process thereof. The objective of the invention is to overcome the problem that the porosity and permeabilityof conventional PVDF membranes are reduced to varying degrees since nanoparticles have poor dispersibility in polyvinylidene fluoride and are prone to agglomeration. According to a technical scheme in the invention, the PVDF composite graphene filter element membrane comprises, by mass, 30 to 45 parts of a PVDF homopolymer, 60 to 75 parts of DMAC, 1 to 2 parts of PVP and 0.5 to 2.5 parts of modified graphene. The above components are added into a reaction vessel for preparation of a spun membrane and spinning molding is carried out; so the dispersibility, hydrophilicity and mechanical strength of the raw materials of a filter element are improved, and the filter element is allowed to have stable filtration precision.

Owner:宁波杜康陶瓷有限公司

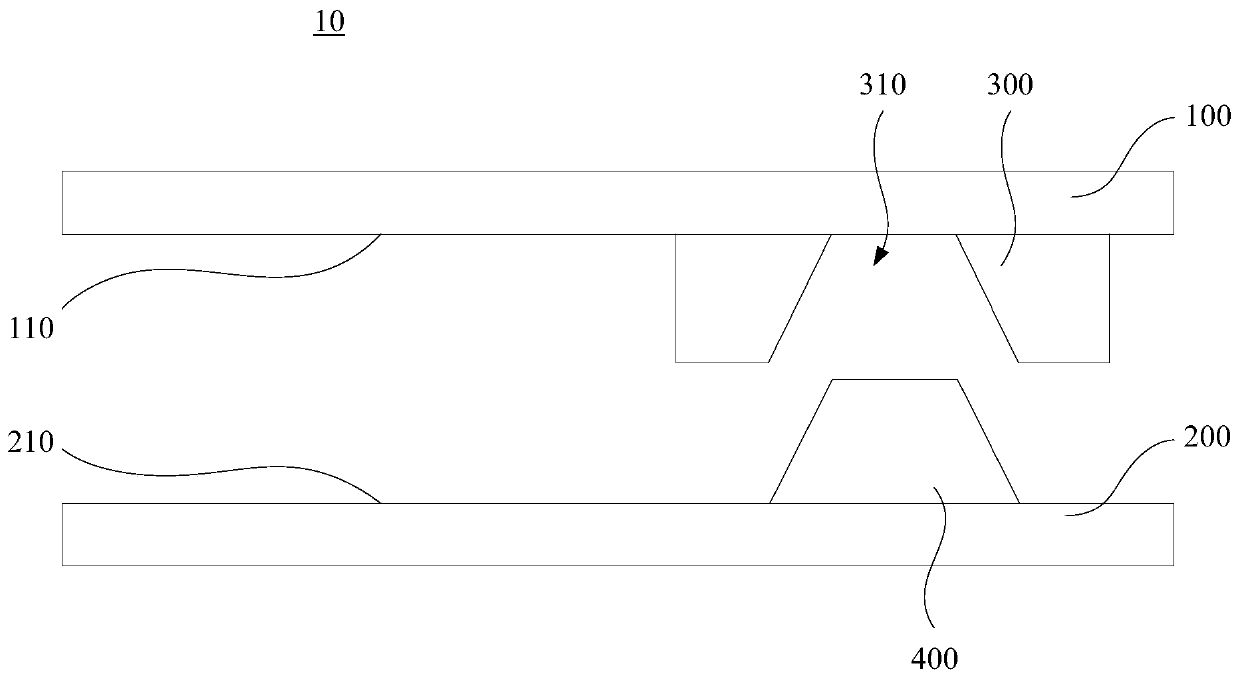

Liquid crystal display panel and substrate attaching method

The invention relates to a liquid crystal display panel and a substrate attaching method. The liquid crystal display panel comprises a CF substrate and a TFT substrate. The CF substrate is provided with a first arranged plate face; the TFT substrate is provided with a second arranged plate face, and the second arranged plate face and the first arranged plate face are opposite; and one of the firstarranged plate face and the second arranged plate face is provided with one or more protruding blocks, the protruding blocks are provided with clamping grooves, the other one of the first arranged plate face and the second arranged plate face is provided with one or more clamping blocks, and each clamping block is inserted into the corresponding clamping groove in a matched mode. According to theliquid crystal display panel and the substrate attaching method, the attaching precision of the CF substrate and the TFT substrate in the carrying process from attaching equipment and UV curing equipment is ensured, a dot curing device is omitted, in addition, the procedure is saved, thus the manufacturing cost of the liquid crystal display panel is lowered, the production efficiency is improved,and the product yield is increased.

Owner:TRULY HUIZHOU SMART DISPLAY

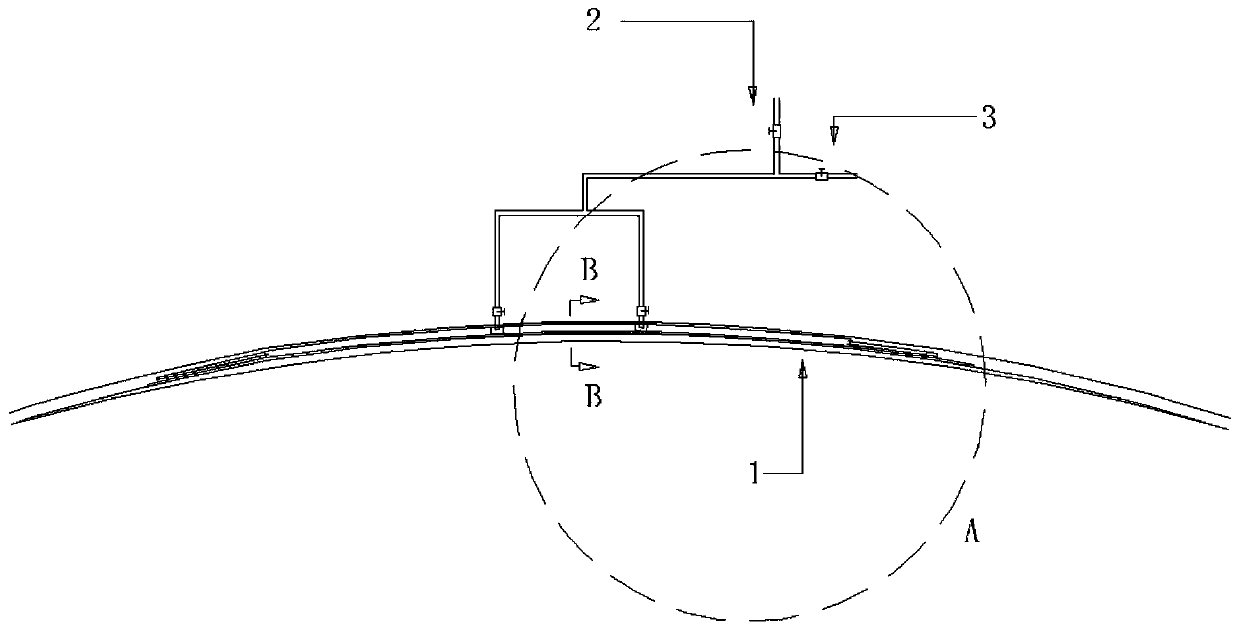

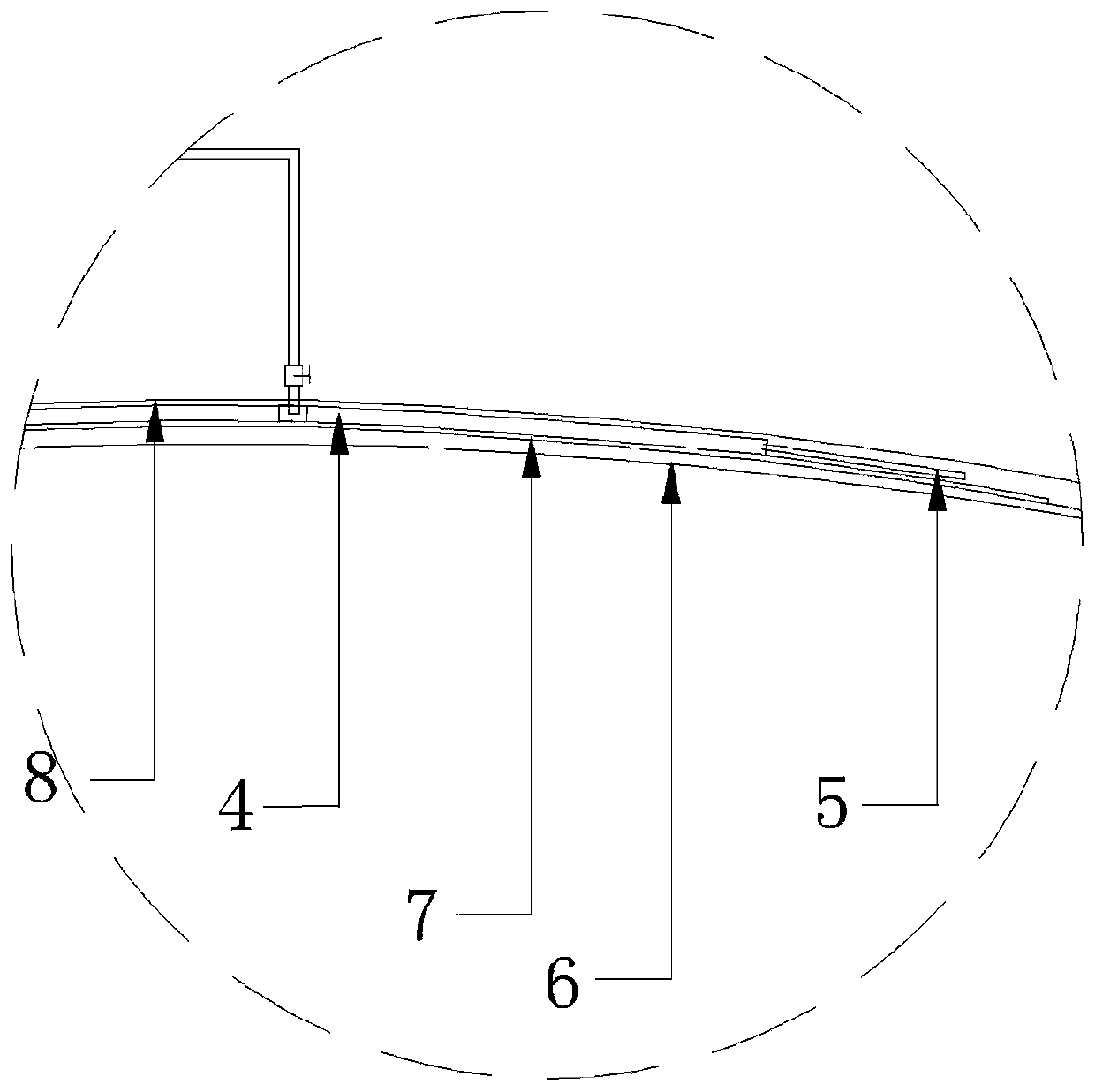

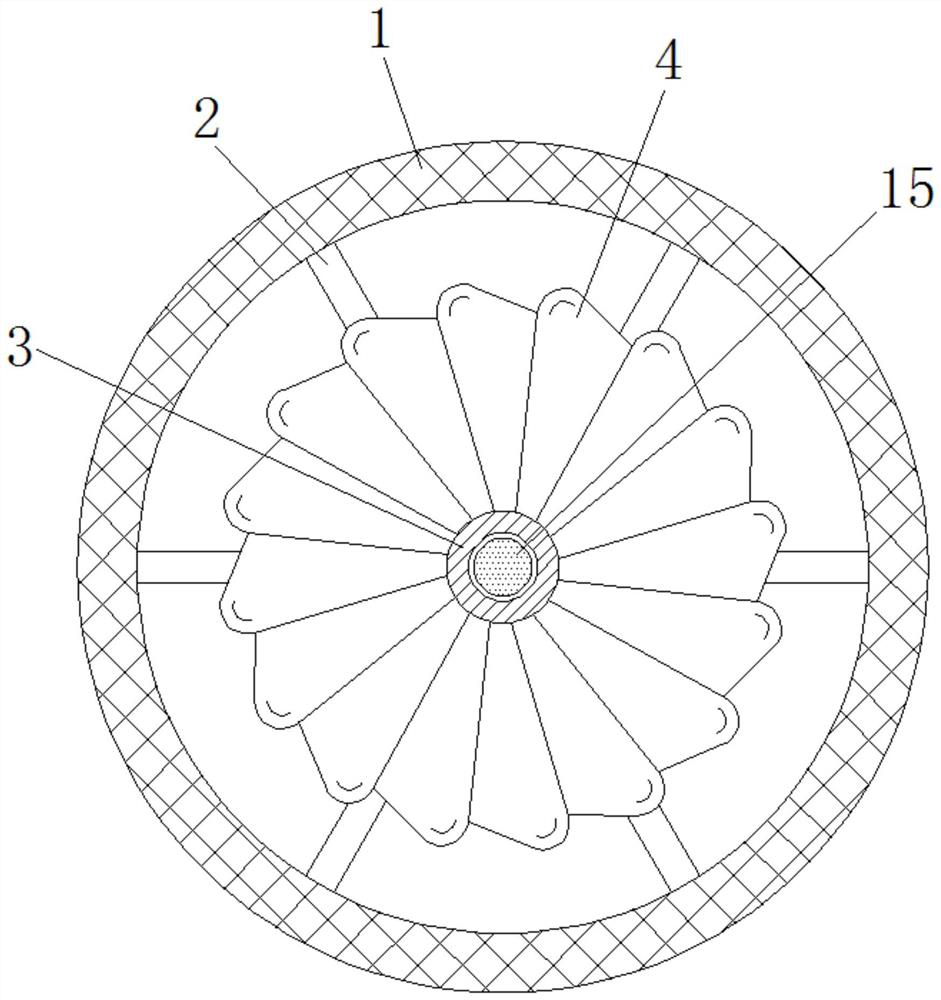

Polyurethane resin pouring structure of wind turbine blade, and forming method

ActiveCN110884167AControl propulsion speedMeet infusion molding requirementsFinal product manufactureDomestic articlesTurbine bladeLap joint

The invention discloses a polyurethane resin pouring structure of a wind turbine blade, and a forming method. The pouring structure comprises a bottom-layer diversion medium, a reinforcement material,an upper-surface diversion medium, a glue pouring pipeline, an Ohm pipe used for glue pouring and a spiral pipe, wherein the bottom-layer diversion medium is disposed on the bottommost layer of a die; the reinforcement material is paved on the bottom-layer diversion medium; the upper-surface diversion medium is disposed on the upper surface of the reinforcement material at a chordwise glue filling side and is in partial lap joint with the upper surface of the reinforcement material; the Ohm pipe is disposed on an edge of the upper-surface diversion medium along an extending direction; a sleeving tubular diameter of two ends of the Ohm pipe is smaller than the diameter of the spiral pipe of the Ohm pipe; and a glue pouring hole of the glue pouring pipeline is located at the middle of the extending direction of the die and is docked with the Ohm pipe. The pouring structure disclosed by the invention has the beneficial effects that an overall pouring speed is increased; prolonging of pouring time caused by irrational flow channel design at a few of positions is avoided, so production efficiency is increased; easy occurrence of pouring failure during manufacture of polyurethane composite material products can be improved; and risks in shaping are reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Uv-curable coatings and methods for applying uv-curable coatings using thermal micro-fluid ejection heads

InactiveUS20100149296A1Improving droplet ejection directionality dropletImproving droplet droplet placementOther printing apparatusWater basedCarrier fluid

An aqueous-based UV-curable fluid composition for use in a micro-fluid ejection device. The fluid composition includes a mixture of poly-functional compounds, a colorant compound, a photo-initiator and less than about 50 weight percent water based on a total weight of the fluid composition, wherein the fluid composition is substantially devoid of volatile organic carrier fluids.

Owner:LEXMARK INT INC

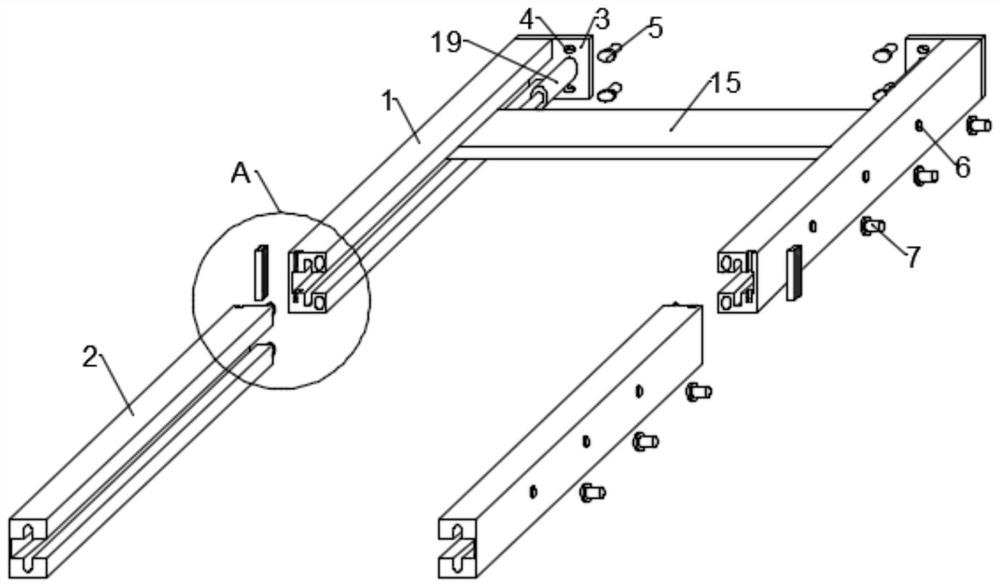

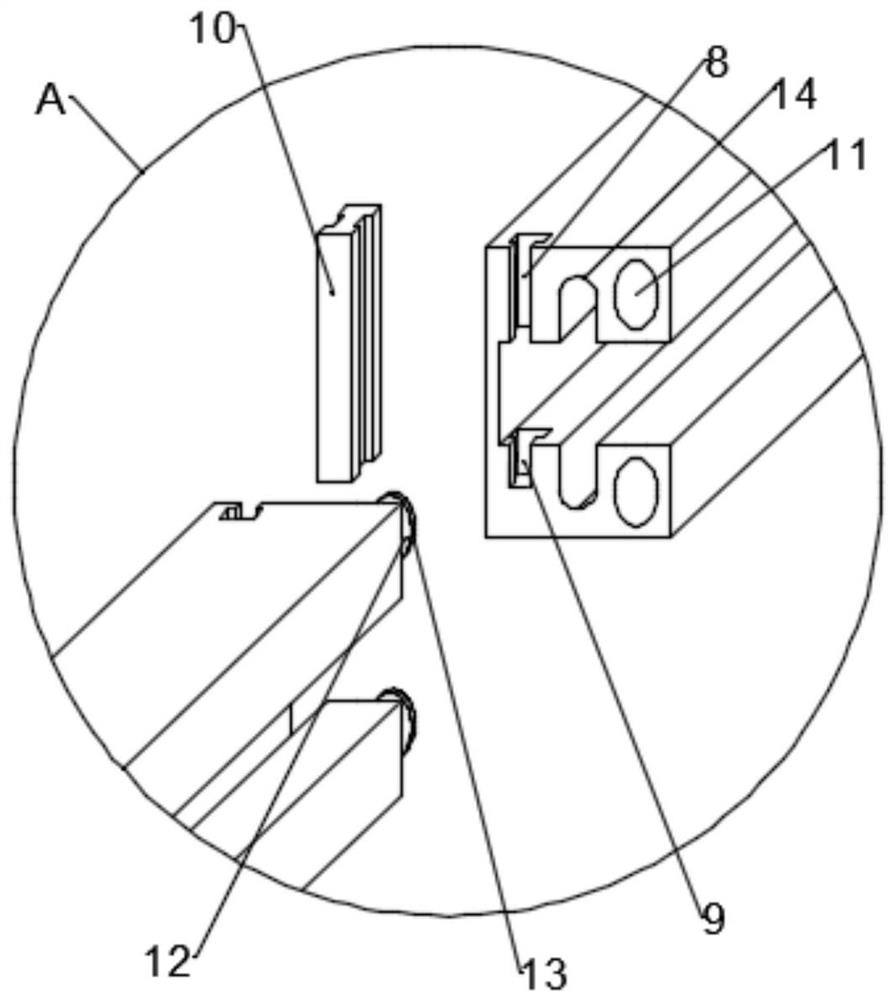

Automatic homogenization equipment for building construction

InactiveCN111618997AHigh degree of automationReduce workloadMixing operation control apparatusBuilding constructionsArchitectural engineeringCement mortar

The invention belongs to the technical field of building construction equipment, and provides an automatic homogenization equipment for building construction. The automatic homogenization equipment includes two left-right symmetrical fixing mechanisms, and mounting plates are movably installed in the two fixing mechanisms through slide-moving mechanisms. Each fixing mechanism includes a first fixing plate and a second fixing plate, the first fixing plates and the second fixing plates are connected by connecting assemblies and positioning assemblies, automatic mortar discharging mechanisms areinstalled on the lower surfaces of the mounting plates, stirring assemblies are installed on the upper surfaces of the mounting plates, the stirring assemblies are connected with the automatic mortardischarging mechanisms, and automatic leveling mechanisms are installed on the rear sides of the automatic mortar discharging mechanisms. The automatic homogenization equipment is high in degree of automation, the work burden of construction personnel can be reduced, mortar can be automatically spread on a concrete floor before ceramic tiles are laid, the construction efficiency is improved, cement mortar can be prepared while use, and the cement mortar is prevented from solidifying in advance.

Owner:李汉荣

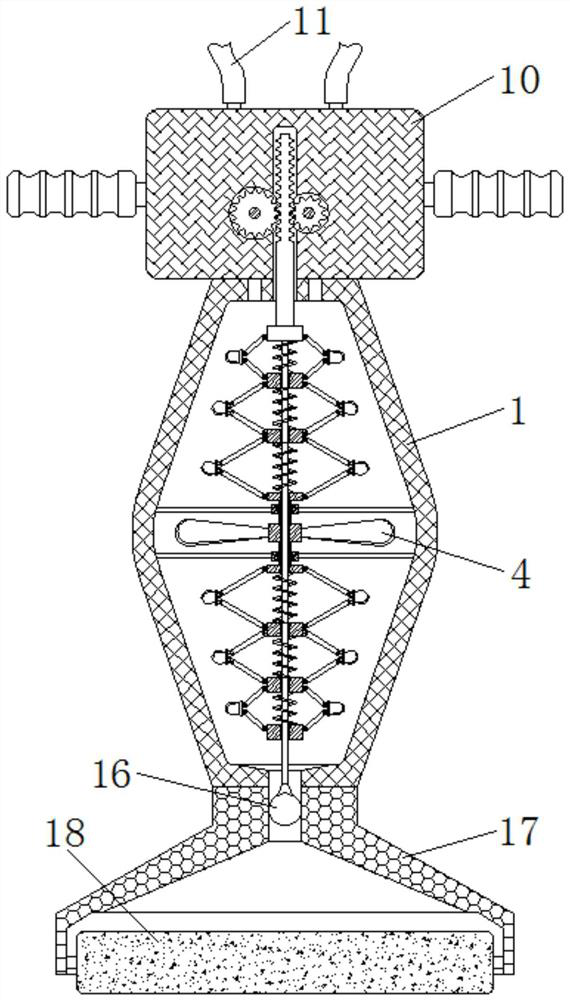

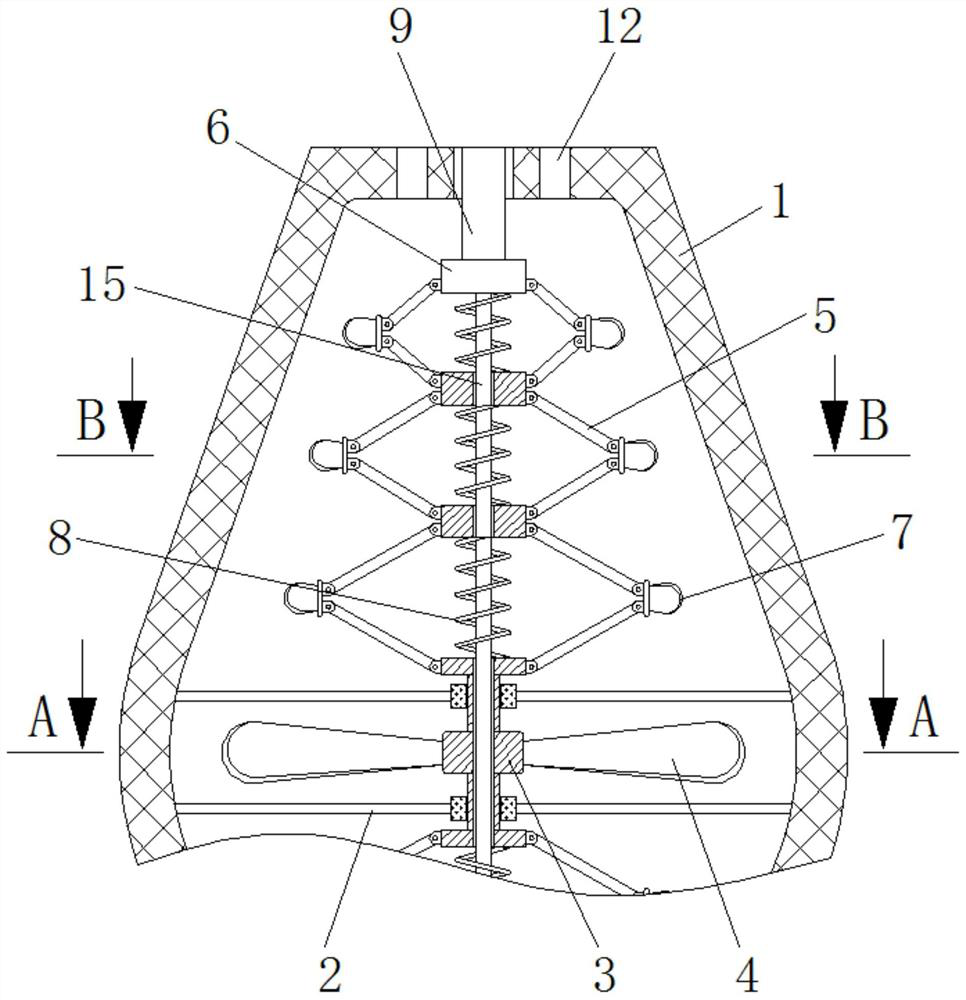

Floor waterproof paint mixing and coating integrated device for building construction

InactiveCN112796494AAvoid premature curingEnhance stirringRotary stirring mixersTransportation and packagingAdhesiveArchitectural engineering

The invention provides a floor waterproof paint mixing and coating integrated device for building construction, and relates to the technical field of waterproof paint coating. The floor waterproof paint mixing and coating integrated device for building construction comprises a tank body, a mounting frame is fixedly mounted in the tank body, a rotating cylinder is rotationally connected to the center of the mounting frame, stirring blades are fixedly connected to the periphery of the rotating cylinder, and the upper end and the lower end of the rotating cylinder are in transmission connection with connecting blocks through transmission rods. According to the floor waterproof paint mixing and coating integrated device for building construction, the waterproof paint and an adhesive can continuously flow into the tank body according to a certain proportion to be stirred, the purpose that the waterproof paint and the adhesive are taken and used at any time is achieved, advanced curing of a disposable stirring paint is avoided, then the stirring and coating effects are improved, sufficient stirring of the paint is guaranteed, and the discharging speed can be controlled by adjusting the rotating speed of the rotating cylinder, so that the casting phenomenon and the paint waste are avoided.

Owner:谭正财

Methods for coating surfaces with metal and products made thereby

InactiveUS7094307B2Avoid premature curingFully curedPhototackifying patterningDecorative surface effectsMetal coatingEmulsion

Owner:RATTE MICHELE +1

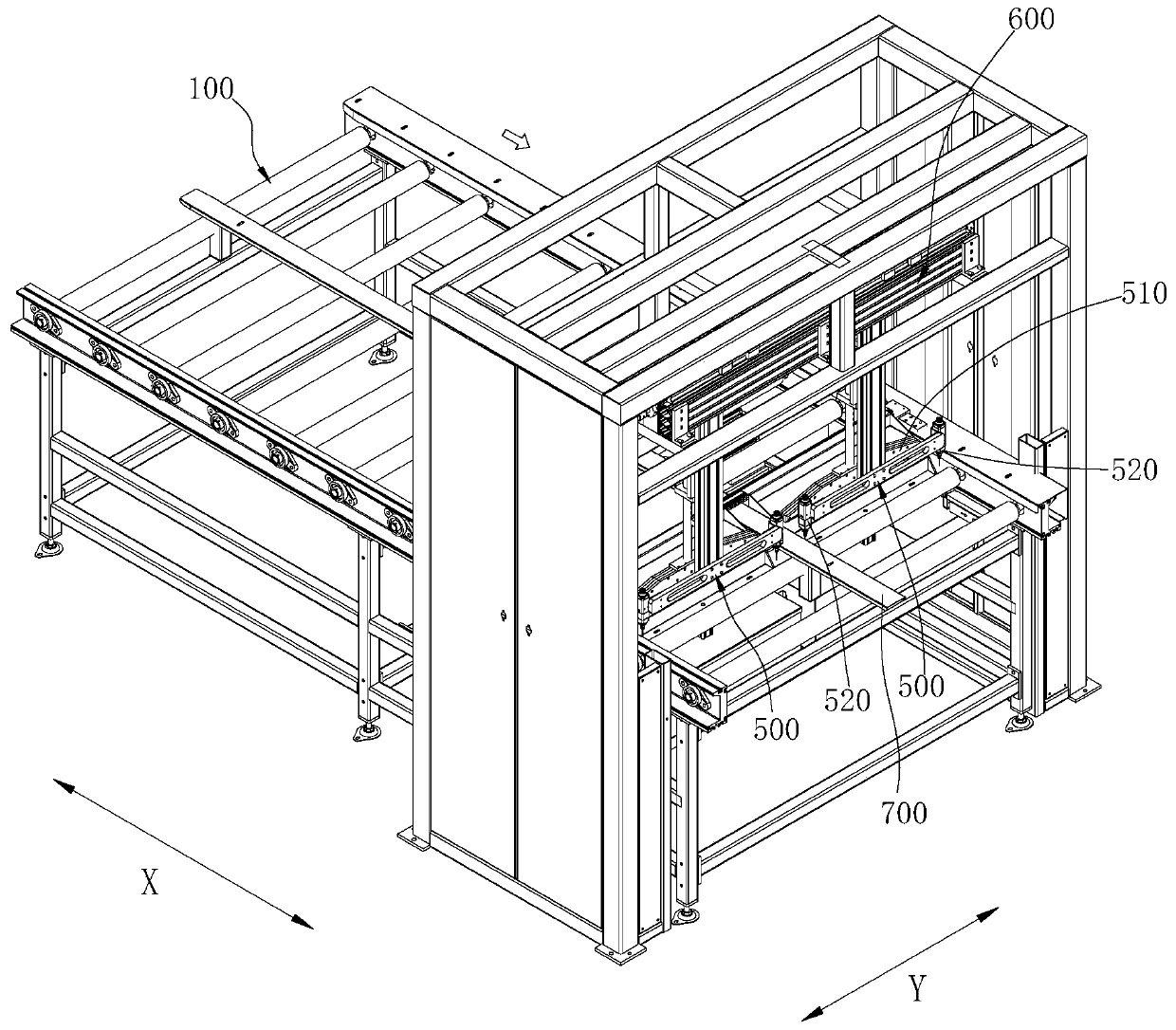

Gluing device

PendingCN111375526AAvoid misalignmentLow viscosityLiquid surface applicatorsCoatingsAdhesive glueComposite material

The invention discloses gluing device. The gluing device comprises a conveying track and a glue application module, wherein the conveying track is used for conveying products, the glue application module is arranged above the conveying track and comprises a low-viscosity glue spray system and a high-viscosity glue spray system, the low-viscosity glue spray system comprises low-viscosity glue and afirst glue gun, and the high-viscosity glue spray system comprises high-viscosity glue and two second glue guns. According to the gluing device, the low-viscosity glue and the high-viscosity glue areadopted to replace traditional PUR hot melt glue, the low-viscosity glue has relatively low viscosity, is less affected by temperature and can be prevented from curing in advance under the conditionof relatively low temperature, and product bonding quality is ensured; and the second glue guns are arranged on two sides of the first glue gun and apply the high-viscosity glue to edge positions of two sides of the product, so that dislocation and offset of composite actions due to insufficient viscosity after application of the low-viscosity glue are avoided. The gluing device is used in the technical field of glue joint.

Owner:国机智能科技有限公司 +1

Uv-curable coatings and methods for applying uv-curable coatings using thermal micro-fluid ejection heads

ActiveUS20100149259A1Avoid premature curingHigh viscosityOther printing apparatusWater basedCarrier fluid

An aqueous-based UV-curable fluid composition for use in a micro-fluid ejection device. The fluid composition includes a mixture of poly-functional compounds, a colorant compound, a photo-initiator and less than about 50 weight percent water based on a total weight of the fluid composition, wherein the fluid composition is substantially devoid of volatile organic carrier fluids.

Owner:SLINGSHOT PRINTING LLC

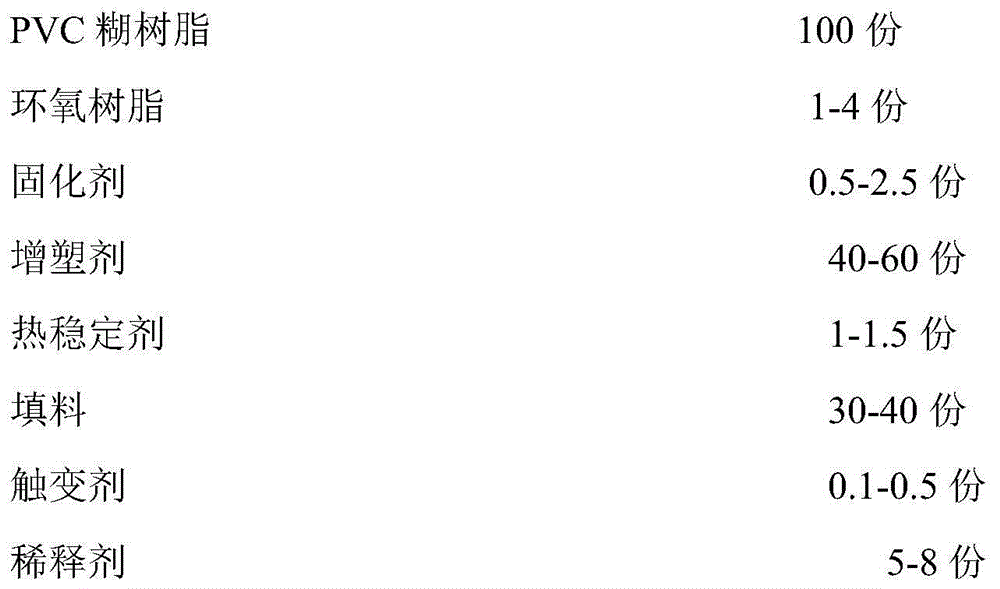

Polyvinyl chloride plastisol and preparation method and application thereof

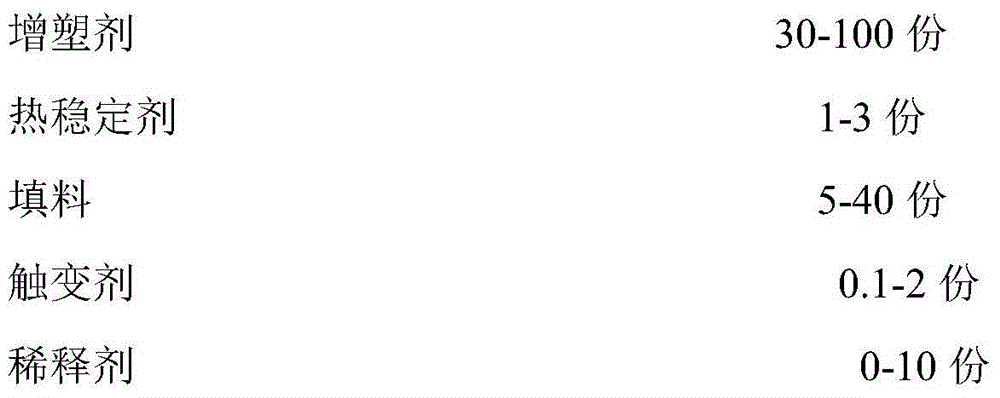

The invention discloses a polyvinyl chloride plastisol and a preparation method and application thereof. The polyvinyl chloride plastisol is prepared from, by weight, 100 parts of PVC paste resin, 1-5 parts of epoxy resin, 0.1-3 parts of a curing agent, 30-100 parts of a plasticizer, 1-3 parts of a heat stabilizer, 5-40 parts of filler, 0.1-2 parts of a thixotropic agent and 0-10 parts of a diluent. The breaking strength of the obtained product can reach 4-6 MPa, and the elongation of the obtained product can reach 200-300%. The polyvinyl chloride plastisol can be used for preparing polyvinyl chloride films. According to the polyvinyl chloride plastisol and the preparation method and application thereof, the strength of a plastisol cured product is effectively improved without influencing the elongation of the plastisol cured product; by using the thermal decomposition curing agent, it is avoided that the epoxy resin is cured ahead of time.

Owner:SHANGHAI CHLOR ALKALI CHEM

Uv-curable coatings and methods for applying uv-curable coatings using thermal micro-fluid ejection heads

InactiveUS20100151143A1Improve directionalityHigh viscosityPretreated surfacesInksChemistryPhotoinitiator

An aqueous-based UV-curable fluid composition for use in a micro-fluid ejection device. The fluid composition includes a mixture of poly-functional compounds, a colorant compound, a photo-initiator and less than about 50 weight percent water based on a total weight of the fluid composition, wherein the fluid composition is substantially devoid of volatile organic carrier fluids.

Owner:LEXMARK INT INC

UV-curable coatings and methods for applying UV-curable coatings using thermal micro-fluid ejection heads

ActiveUS8235518B2Avoid premature curingHigh viscosityOther printing apparatusWater basedCarrier fluid

Owner:SLINGSHOT PRINTING LLC

Copper-based resin prepreg production equipment for mobile communication circuit boards

PendingCN109551247ASolve problems such as low production yieldLower initial temperatureOther manufacturing equipments/toolsEngineeringCopper foil

The invention relates to the technical field of copper-clad plate production for mobile communication circuit boards, in particular to copper-based resin prepreg production equipment for the mobile communication circuit boards. The equipment comprises a copper foil winding drum, a grinding device, a coating device and a cutting device, a drying device and a glue supply device, wherein the copper foil winding drum, the grinding device, the coating device and the cutting device are sequentially arranged from front to back, the drying device is installed below between the coating device and the cutting device, and the glue supply device is connected with the coating device through a conveying pipe. A copper-based resin prepreg produced by using the equipment and reinforcing materials are laminated at high temperature to manufacture a copper-clad plate, so that the problem that in the prior art, the yield of copper-clad plate production is reduced due to the fact that defects such as inclusion of bubbles, uneven composition of the prepreg are prone to occurring in the processes of gum dipping and curing of the reinforcing materials is solved.

Owner:XIAN HUAYUN TIANCHENG COMM TECH

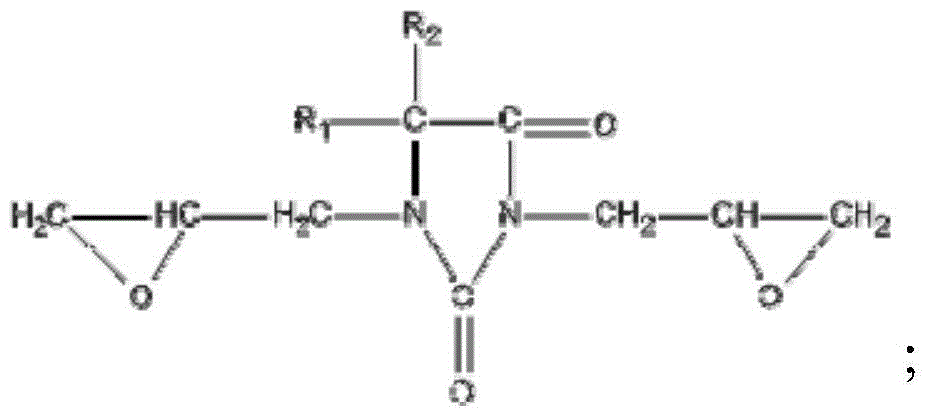

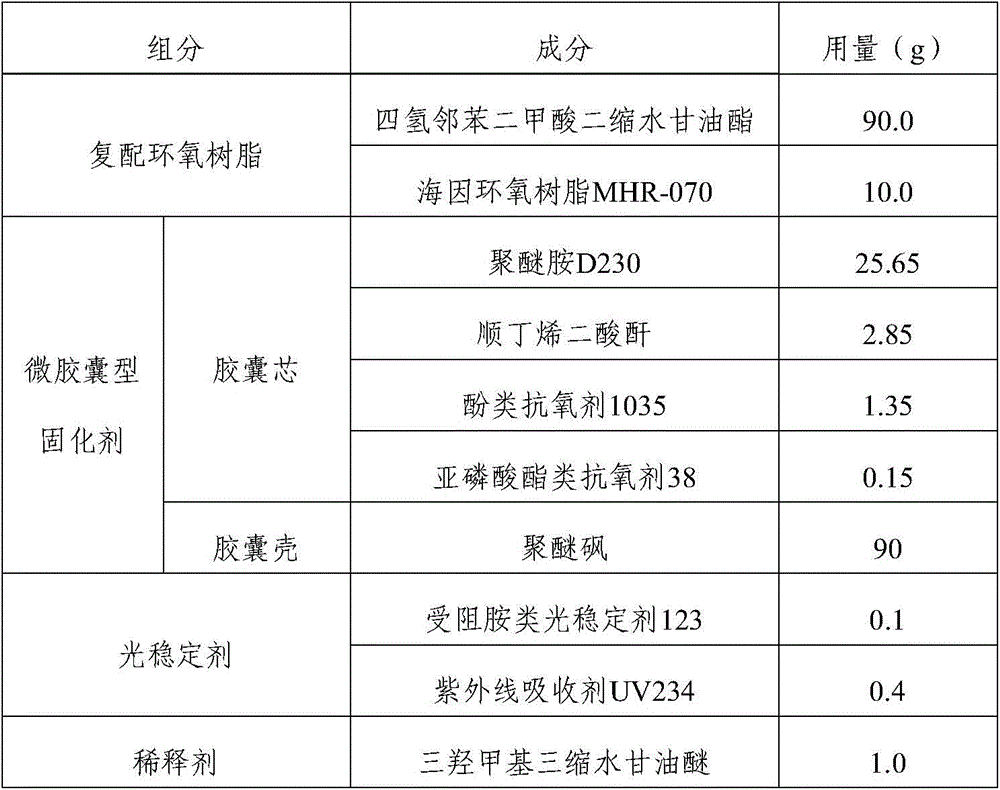

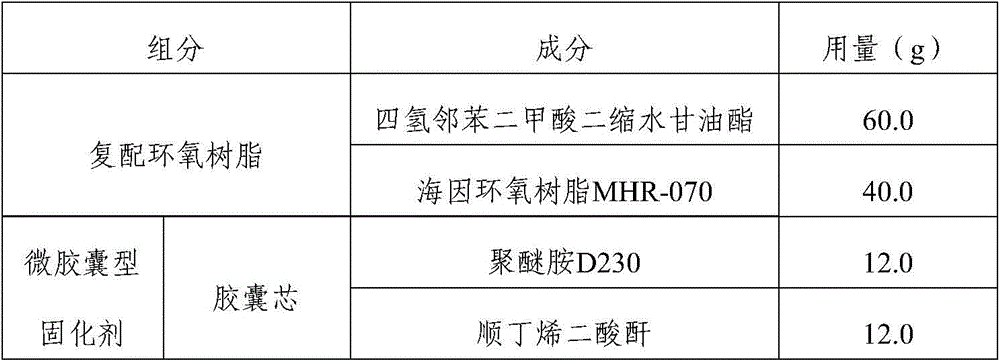

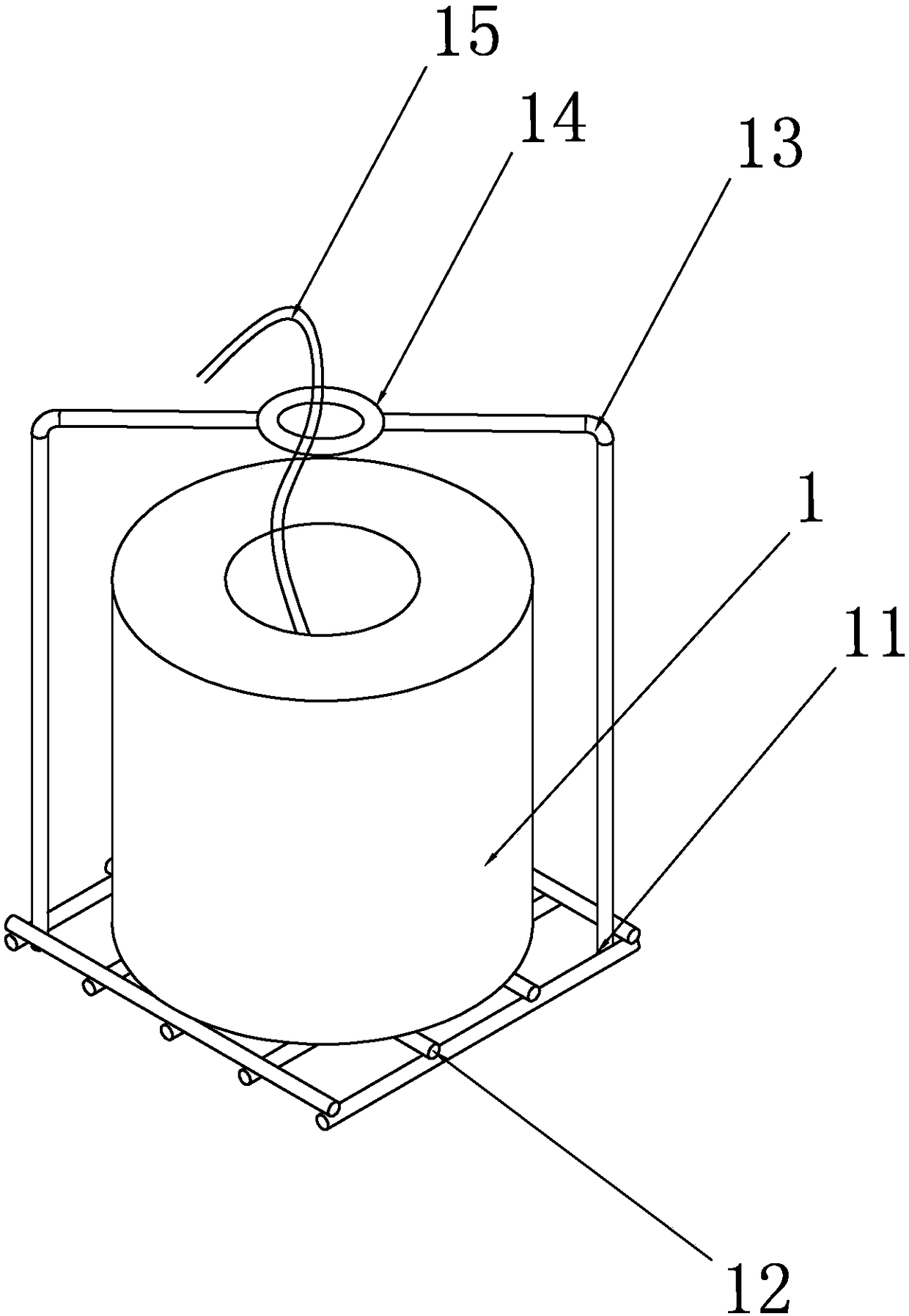

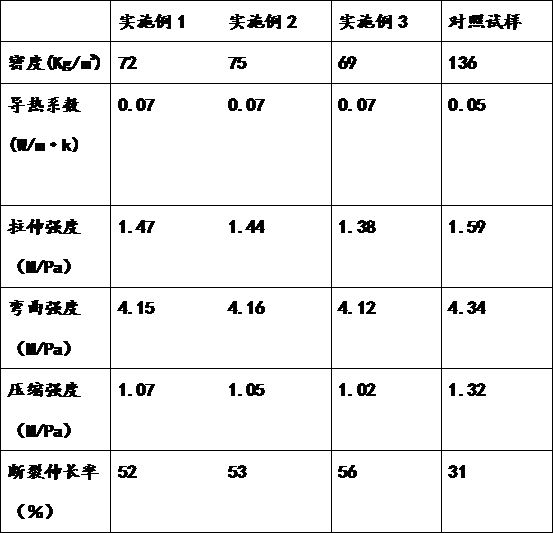

One-part anti-aging epoxy resin composition for rtm molding

The invention relates to a one-component RTM (Resin Transfer Molding) anti-aging epoxy resin composition which comprises the following components in parts by weight: 100 parts of compound epoxy resin, 90-150 parts of a microcapsule-type curing agent, 0.5-5 parts of a compound light stabilizer and 1-10 parts of a diluent, wherein the microcapsule-type curing agent is composed of a capsule core and a capsule shell at the mass ratio of 1: (2-3), and the capsule core contains 80-95 percent by mass of a compound curing agent and 5-20 percent by mass of a compound antioxidant. The invention further protects molding epoxy resin prepared by taking the composition as a raw material.

Owner:CHINA NAT BLUESTAR (GRP) CO LTD +1

Glass yarn glue-dipping method

InactiveCN108483944AAvoid premature curingReduce the burden onEnergy consumptionPulp and paper industry

The invention discloses a glass yarn glue-dipping method. The method comprises placing a roll of glass yarn in a vacuum box connected to a vacuum pump and a pressure relief valve, opening the vacuum pump to form a vacuum environment in the vacuum box, feeding a mixed liquid of an epoxy resin and a curing agent into a vacuum box until the level of the mixed liquid exceeds the highest level of the glass yarn by a certain distance, carrying out degassing on the mixed liquid in the vacuum box until the mixed liquid does not have a large amount of air bubbles, opening the pressure relief valve so that the external gas enters the vacuum box and penetrates into the glass yarn by the imbalance of the internal and external air pressure, and soaking the glass yarn in the mixed liquid for a period oftime to obtain finished glass yarn. The glass yarn is infiltrated in vacuum and the glass yarn roll maintains the state at the factory without re-winding and unwinding so that the yarn output is moresmooth, the preparation time is short, the mixed liquid curing in advance is prevented, the possibility of hydrolysis is reduced, the corresponding equipment is low in cost, the floor space is reduced and the energy consumption is reduced.

Owner:ZHUHAI LANRUIMENG ELECTRIC

High-strength organic silicon foamed plastic and preparation method thereof

The invention discloses high-strength organic silicon foamed plastic and a preparation method thereof, and belongs to the technical field of foamed plastic, and the high-strength organic silicon foamed plastic is prepared from the following components in parts by weight: 100-120 parts of hydroxyl-terminated polymethyl silicone resin, 10-20 parts of vinyl-terminated silicone oil, 4-10 parts of foaming agent, 2-16 parts of pentaerythritol, 6-14 parts of cross-linking agent, 20-30 parts of filler. 1-10 parts by weight of a catalyst and 1-10 parts by weight of epoxy resin. According to the invention, the prepared high-strength organic silicon foamed plastic has the effects of low preparation cost, low density and high tear strength.

Owner:漳州普瑞邦节能科技有限公司

Rigid polyurethane foam plastic with constant temperature function and preparation method thereof

InactiveCN112592453AWith constant temperature functionImprove heat resistancePolymer sciencePtru catalyst

The invention discloses rigid polyurethane foam plastic with a constant temperature function. The rigid polyurethane foam plastic is prepared from the following components in parts by weight: 70-90 parts of polyisocyanate, 50-80 parts by weight of a polyol, 4-10 parts by weight of a foaming agent, 0.5-1 part by weight of a catalyst, 1-5 parts by weight of an opening agent, 1-2 parts by weight of afoam stabilizer, 1-2 parts by weight of a cross-linking agent, 1-3 parts by weight of an outer foaming agent, 5-10 parts by weight of a phase change heat storage material, and 3-7 parts by weight ofexpanded graphite. According to the rigid polyurethane foam plastic and the preparation method thereof, the flame retardant property of the rigid polyurethane foam plastic can be remarkably improved,the rigid polyurethane foam plastic still has good mechanical properties at low density, meanwhile, the rigid polyurethane foam plastic has heat preservation and temperature adjustment functions, andthe usability of the rigid polyurethane foam plastic in the field of building materials is greatly improved.

Owner:漳州普瑞邦节能科技有限公司

Injection mold with high forming quality

The invention discloses an injection mold with high forming quality. The injection mold comprises mold bases and a cavity, the cavity is in the mold base, a plurality of electric-heating rods and cooling pipes are arranged in the mold base, the electric-heating rods are uniformly arranged in a mode of surrounding the cavity, the cooling pipes surround the four corners of the cavity, the mold base is further provided with a sprue gate, the sprue gate is communicated with the cavity, the mold base around the sprue gate is further provided with the plurality of electric-heating rods. According to the above mode, the sudden temperature dropping of the molten material is prevented in the sprue process, thereby preventing the molten material from curing in advance to cause the blocking so as to improve the quality of the formed product.

Owner:SUZHOU GUANGXING MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com