Polyvinyl chloride plastisol and preparation method and application thereof

A technology of polyvinyl chloride and plastisol, applied in the field of polyvinyl chloride plastisol and its preparation and application, can solve the problems of polluting the environment, difficulty in unification, etc., achieve good compatibility, improve strength, and avoid the effects of early curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

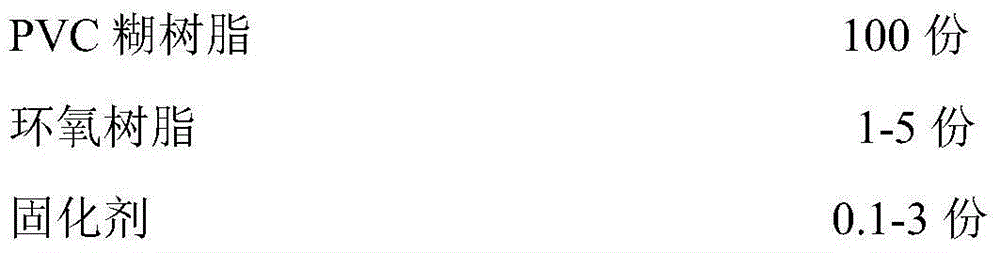

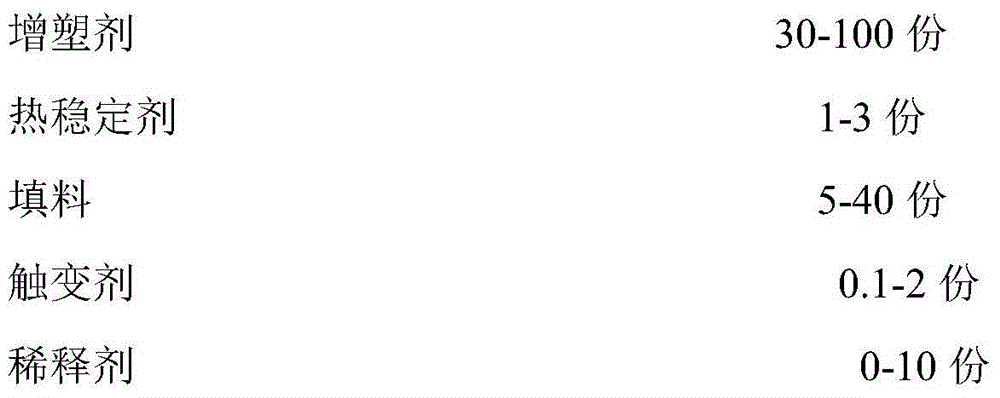

Method used

Image

Examples

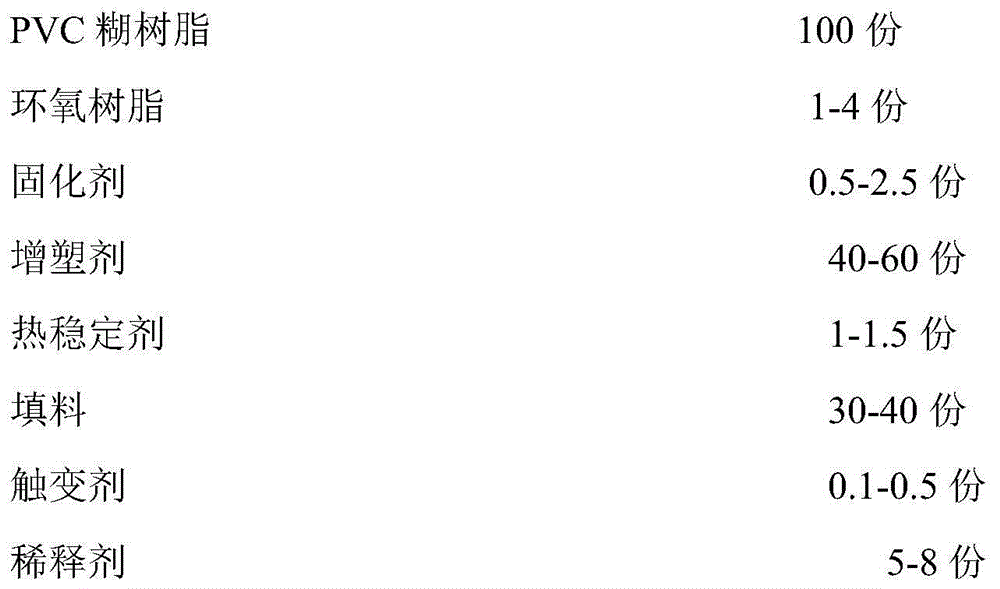

Embodiment 1

[0035] Add each component according to the portion in the table.

[0036] The PVC paste resin resin is an emulsion polymerization resin with a degree of polymerization of 1000, the plasticizer is dioctyl phthalate, the epoxy equivalent of the epoxy resin is 200, the heat stabilizer is organotin, the filler is light calcium carbonate, and the contact The variable agent is nano-silica, and the diluent is C 12 isoparaffins.

[0037] The preparation method of the curing agent is as follows: under stirring at 20° C., liquid hexahydrophthalic anhydride is added dropwise to liquid xylene polyamine under the protection of inert gas, and the reaction is carried out for 3 hours. At room temperature, the components are mixed and fully dispersed, vacuum defoamed for 3 hours and then matured for 24 hours to prepare a plastisol, and the functional group ratio of the liquid acid anhydride to the polyamine is 1:2;

[0038] After the plastisol was cured at 135° C. for 10 min, the strength of...

Embodiment 2

[0040] Add each component according to the portion in the table. The PVC paste resin resin is an emulsion polymer resin with a degree of polymerization of 1200, the plasticizer is diisodecyl phthalate, the epoxy resin epoxy equivalent is 180, the heat stabilizer is organotin, and the filler is light calcium carbonate. Thixotropic agent is nano-silica, diluent is C 14 isoparaffins. The preparation method of the curing agent is as follows: under stirring at 25° C., liquid methyltetrahydrophthalic anhydride is added dropwise to isophorone polyamine under the protection of inert gas, and the reaction is carried out for 2 hours. At room temperature, the components are mixed and fully dispersed, vacuum defoamed for 2 hours and then matured for 24 hours to prepare a plastisol, and the functional group ratio of the liquid acid anhydride to the polyamine is 1:2;

[0041] After the plastisol was cured at 140° C. for 5 minutes, the strength of the cured product was 5.5 MPa, and the elo...

Embodiment 3

[0043] Add each component according to the portion in the table. The PVC paste resin resin is an emulsion polymer resin with a degree of polymerization of 1300, the plasticizer is diisobutyl phthalate, the epoxy resin epoxy equivalent is 250, the heat stabilizer is organotin, and the filler is light calcium carbonate. Thixotropic agent is nano-silica, diluent is C 18 isoparaffins. The preparation method of the curing agent is as follows: at 20° C. under stirring, under the protection of inert gas, liquid methyl hexahydrophthalic anhydride is added dropwise with diethyl tripress, and the reaction is carried out for 2 hours. At room temperature, the components are mixed and dispersed uniformly, vacuum defoamed for 3 hours and then aged for 12 hours to prepare a plastisol. The functional group ratio of liquid acid anhydride and polyamine is 1:2;

[0044] After the plastisol was cured at 135° C. for 7 minutes, the strength of the cured product was 4.5 MPa, and the elongation wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com