Rigid polyurethane foam plastic with constant temperature function and preparation method thereof

A technology of rigid polyurethane and foam plastics, applied in the field of foam plastics, can solve the problems of toughness, tensile and shear strength, and thermal insulation performance degradation, affecting the mechanical strength and quality stability of foam plastics, high raw material costs, transportation and installation costs, etc. , to achieve the effect of fast expansion speed, prolonging the anti-flammability time and high expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

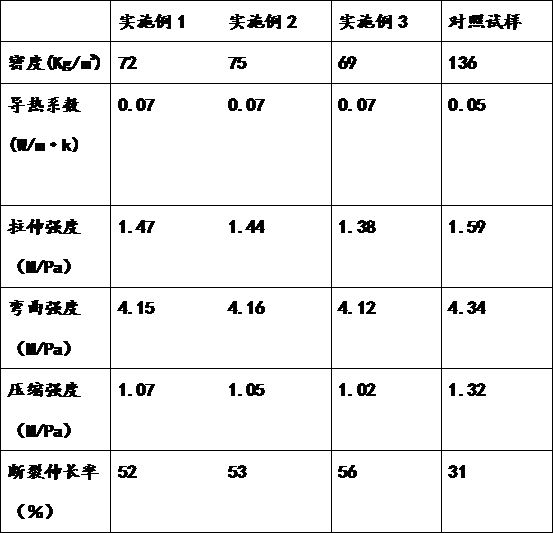

Examples

Embodiment 1

[0034] The rigid polyurethane foam with constant temperature function provided by the invention is composed according to the following components by weight:

[0035] 70 parts by weight of polyisocyanate;

[0036] 80 parts by weight of polyol;

[0037] Foaming agent 4 parts by weight;

[0038] 0.5 parts by weight of catalyst;

[0039] 1 part by weight of cell opener;

[0040] 1 part by weight of foam stabilizer;

[0041] 1 part by weight of crosslinking agent;

[0042] 1 part by weight of external blowing agent;

[0043] 5 parts by weight of phase change heat storage material;

[0044] 3 parts by weight of expanded graphite.

[0045] Further, the phase change heat storage material is CaCl 2 .6H 2 O.

[0046] Further, the polyisocyanate is one or more mixtures of toluene diisocyanate (TDI), diphenylmethane diisocyanate (MDI) or polymethylene polyphenyl polyisocyanate (PAPI).

[0047] Further, the polyol is polyester polyol or polyether polyol.

[0048] Further, the c...

Embodiment 2

[0056] Rigid polyurethane foam with constant temperature function, according to the composition of the following components by weight:

[0057] 90 parts by weight of polyisocyanate;

[0058] 50 parts by weight of polyol;

[0059] Foaming agent 10 parts by weight;

[0060] Catalyst 1 weight part;

[0061] 5 parts by weight of cell opener;

[0062] 2 parts by weight of foam stabilizer;

[0063] 2 parts by weight of crosslinking agent;

[0064] 3 parts by weight of external blowing agent;

[0065] 10 parts by weight of phase change heat storage material;

[0066] 7 parts by weight of expanded graphite.

[0067] Further, the phase change heat storage material is CaCl 2 .6H 2 O.

[0068] Further, the polyisocyanate is one or more mixtures of toluene diisocyanate (TDI), diphenylmethane diisocyanate (MDI) or polymethylene polyphenyl polyisocyanate (PAPI).

[0069] Further, the polyol is polyester polyol or polyether polyol.

[0070] Further, the catalyst is bis-dimethylam...

Embodiment 3

[0078] Rigid polyurethane foam with constant temperature function, according to the composition of the following components by weight:

[0079] 80 parts by weight of polyisocyanate;

[0080] 70 parts by weight of polyol;

[0081] Foaming agent 7 parts by weight;

[0082] 0.7 parts by weight of catalyst;

[0083] 3 parts by weight of cell opener;

[0084] 1.5 parts by weight of foam stabilizer;

[0085] 1.5 parts by weight of crosslinking agent;

[0086] 2 parts by weight of external blowing agent;

[0087] 7 parts by weight of phase change heat storage material;

[0088] 5 parts by weight of expanded graphite.

[0089] Further, the phase change heat storage material is CaCl 2 .6H 2 O.

[0090] Further, the polyisocyanate is one or more mixtures of toluene diisocyanate (TDI), diphenylmethane diisocyanate (MDI) or polymethylene polyphenyl polyisocyanate (PAPI).

[0091] Further, the polyol is polyester polyol or polyether polyol.

[0092] Further, the catalyst is bis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com