One-part anti-aging epoxy resin composition for rtm molding

A technology of epoxy resin and hydantoin epoxy resin, which is applied in the field of one-part epoxy resin composition for RTM molding, can solve the problems of high reject rate and slowness of products, and achieve low viscosity, good manufacturability and stability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

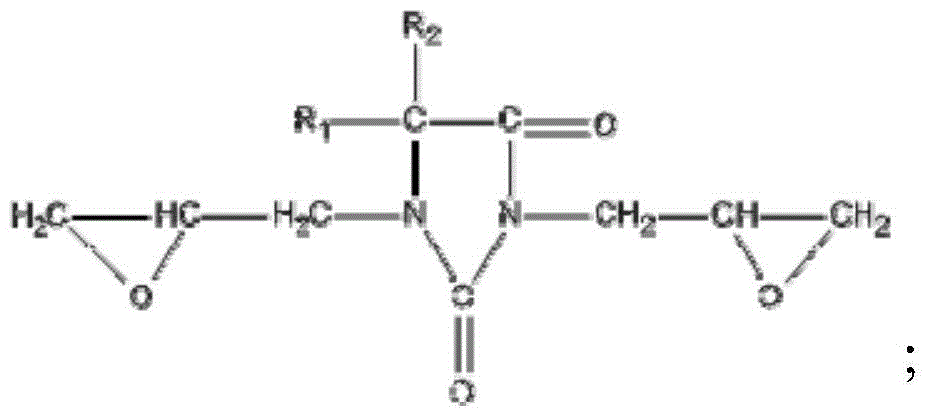

Method used

Image

Examples

Embodiment 1

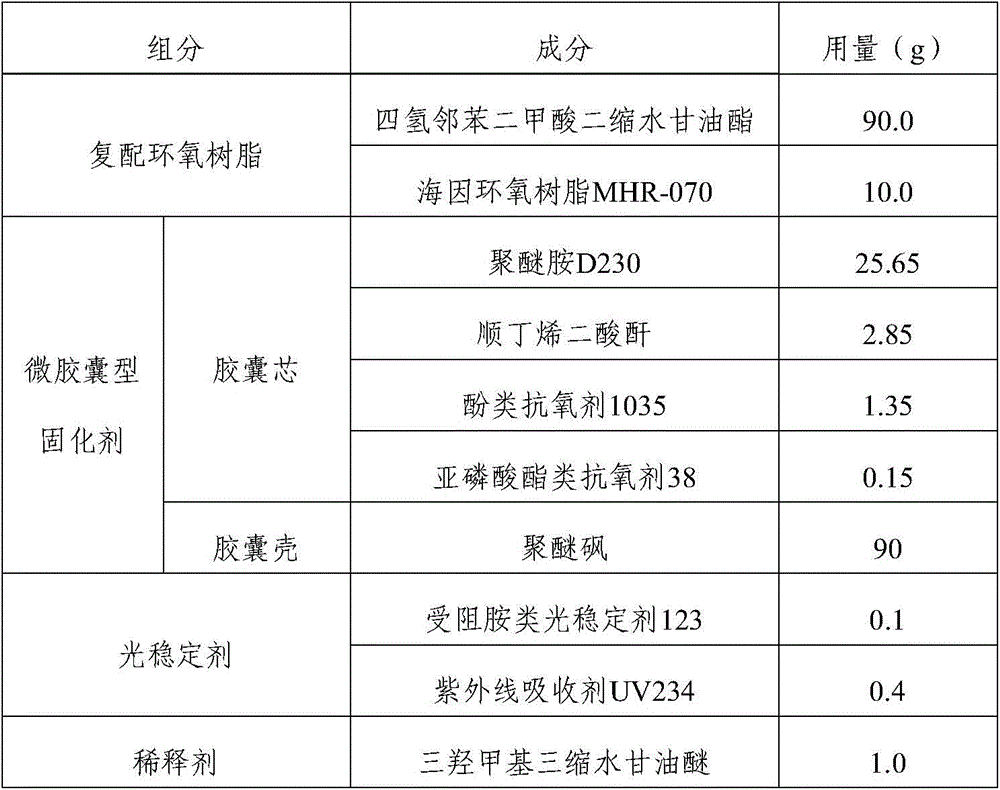

[0030] 1. The composition of the composition: as shown in Table 1; the viscosity of the composition was tested with an NDJ-8S rotational viscometer, and the viscosity at 25°C was 389mPa·s;

[0031] Table 1: Composition of the compositions

[0032]

[0033] 2. Preparation of RTM molding epoxy resin:

[0034] (1) The reaction exothermic curve of the composition was tested by differential scanning calorimetry, and the heating rate was measured at 5°C / min and 15°C / min, and the gel temperature was 67°C and the curing temperature was 90°C by extrapolation , the post-curing treatment temperature is 125°C;

[0035] (2) After stirring the composition evenly, place it in a vacuum drying oven to remove air bubbles; pour it into a closed mold, and cure it according to the following procedure: 67°C for 1 hour, 90°C for 2 hours, and 125°C for 2 hours, that is Get RTM molding epoxy resin.

[0036] 3. Performance testing of molded epoxy resin:

[0037] (1) Differential scanning calorim...

Embodiment 2

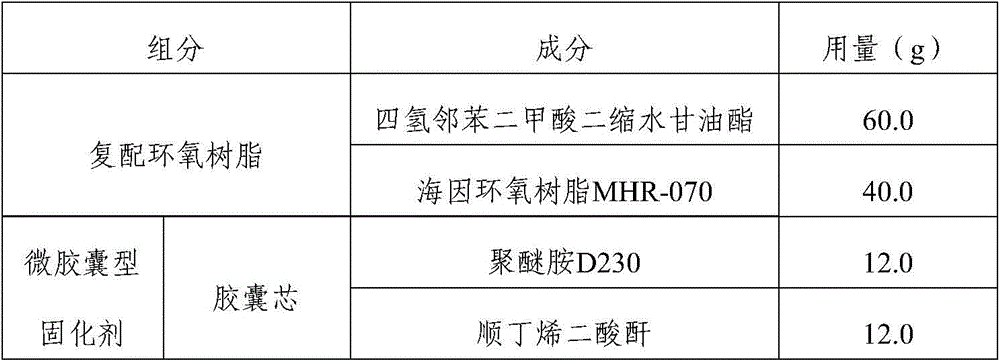

[0041] 1. Composition composition: as shown in Table 2; the viscosity of the composition was tested with an NDJ-8S rotational viscometer, and the viscosity at 25°C was 390mPa·s;

[0042] Table 2: Composition of the compositions

[0043]

[0044]

[0045] 2. Preparation of RTM molding epoxy resin:

[0046] (1) The reaction exothermic curve of the composition was tested by differential scanning calorimetry, and the heating rate was measured at 5°C / min and 15°C / min, and the gel temperature was 67°C and the curing temperature was 90°C by extrapolation , the post-curing treatment temperature is 125°C;

[0047] (2) After stirring the composition evenly, place it in a vacuum drying oven to remove air bubbles; pour it into a closed mold, and cure it according to the following procedure: 67°C for 1 hour, 90°C for 2 hours, and 125°C for 2 hours, that is Get RTM molding epoxy resin.

[0048] 3. Performance testing of molded epoxy resin:

[0049] (1) Differential scanning calori...

Embodiment 3

[0053] 1. Composition composition: as shown in Table 3; the viscosity of the composition was tested with an NDJ-8S rotational viscometer, and the viscosity at 25°C was 484mPa·s;

[0054] Table 3: Composition of the compositions

[0055]

[0056] 2. Preparation of RTM molding epoxy resin:

[0057] (1) The reaction exothermic curve of the composition was tested by differential scanning calorimetry, and the heating rate was measured at 5°C / min and 15°C / min, and the gel temperature was 65°C and the curing temperature was 89°C by extrapolation , the post-curing treatment temperature is 110°C;

[0058] (2) After stirring the composition evenly, place it in a vacuum drying oven to remove air bubbles; pour it into a closed mold, and cure it according to the following procedure: 65°C for 1 hour, 89°C for 2 hours, and 110°C for 2 hours, that is Get RTM molding epoxy resin.

[0059] 3. Performance testing of molded epoxy resin:

[0060] (1) Differential scanning calorimetry (DSC m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com