Curing agent sustained release capsule for gas injection channeling prevention, channeling prevention agent and preparation method of curing agent sustained release capsule

A slow-release capsule and curing agent technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of contradictory wellbore injectability and plugging performance, large fracture and hole size, short validity period, etc., and achieve excellent Wellbore injectability, extended curing time, and good wellbore injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0030] The coating agent, curing agent and hollow glass microspheres are configured according to the proportions of Examples 1-7 in Table 1. Among them, the dry powder of the curing agent for anti-air channeling is selected from urotropine, and the particle size is 200-400 mesh; the coating agent is selected from linear Low-density polyethylene LLDPE particles, the particle size is 1-2mm; the density regulator is hollow glass microspheres, the particle size is 200-400 mesh, and the density is 0.59g / cm 3 , Compressive strength 30 ~ 70MPa.

Embodiment 1

[0031] Taking Example 1 as an example, prepare low-density curing agent sustained-release capsules according to the following methods and steps:

[0032] (1) Take by weighing 20g quality anti-channeling curing agent powder, 22.5g coating agent and 2.5g density regulator;

[0033] (2) Add the coating agent to the 120°C reaction kettle, and heat to completely melt the coating agent;

[0034] (3) Add solidifying agent and density regulator successively to the coating agent of melting and continue to stir, stop heating after making each material mix evenly;

[0035] (4) After the reactor is cooled to room temperature, the materials are taken out, pulverized and granulated to obtain low-density curing agent capsules.

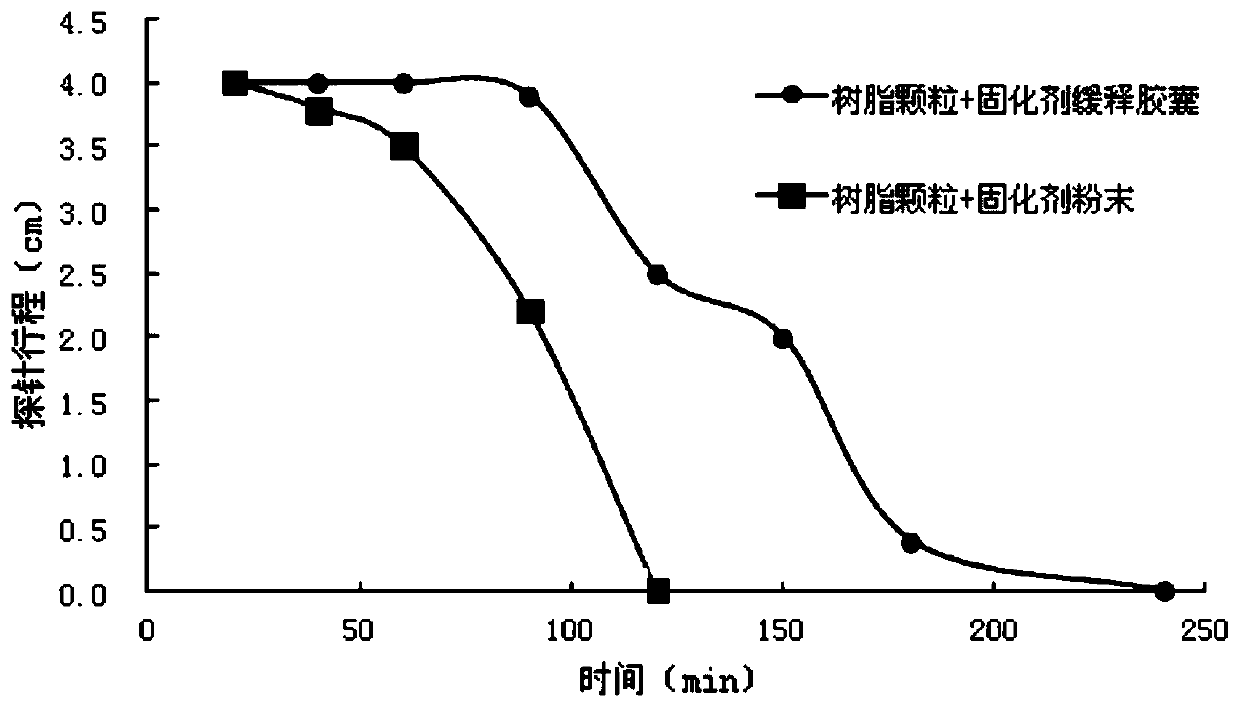

[0036] The prepared low-density curing agent capsules were subjected to a density test, a curing time test and a curing ability test.

[0037] 1. Density test

[0038] Take the coating material (particle size 1-2mm), hollow glass microspheres (particle size 200-40...

Embodiment 8-13

[0046] The coating agent, curing agent and density regulator were configured according to the component ratios of Examples 8-13 in Table 1, and the corresponding curing agent sustained-release capsules were prepared according to the component parameters and preparation conditions of Example 1.

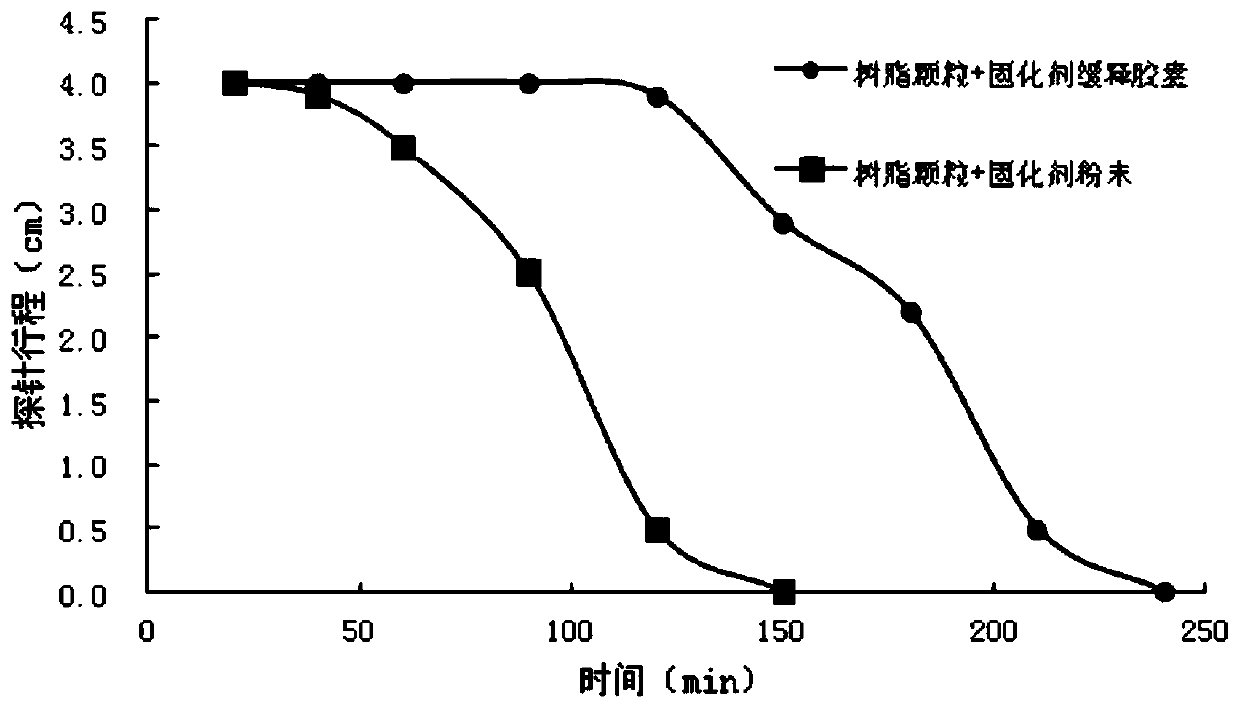

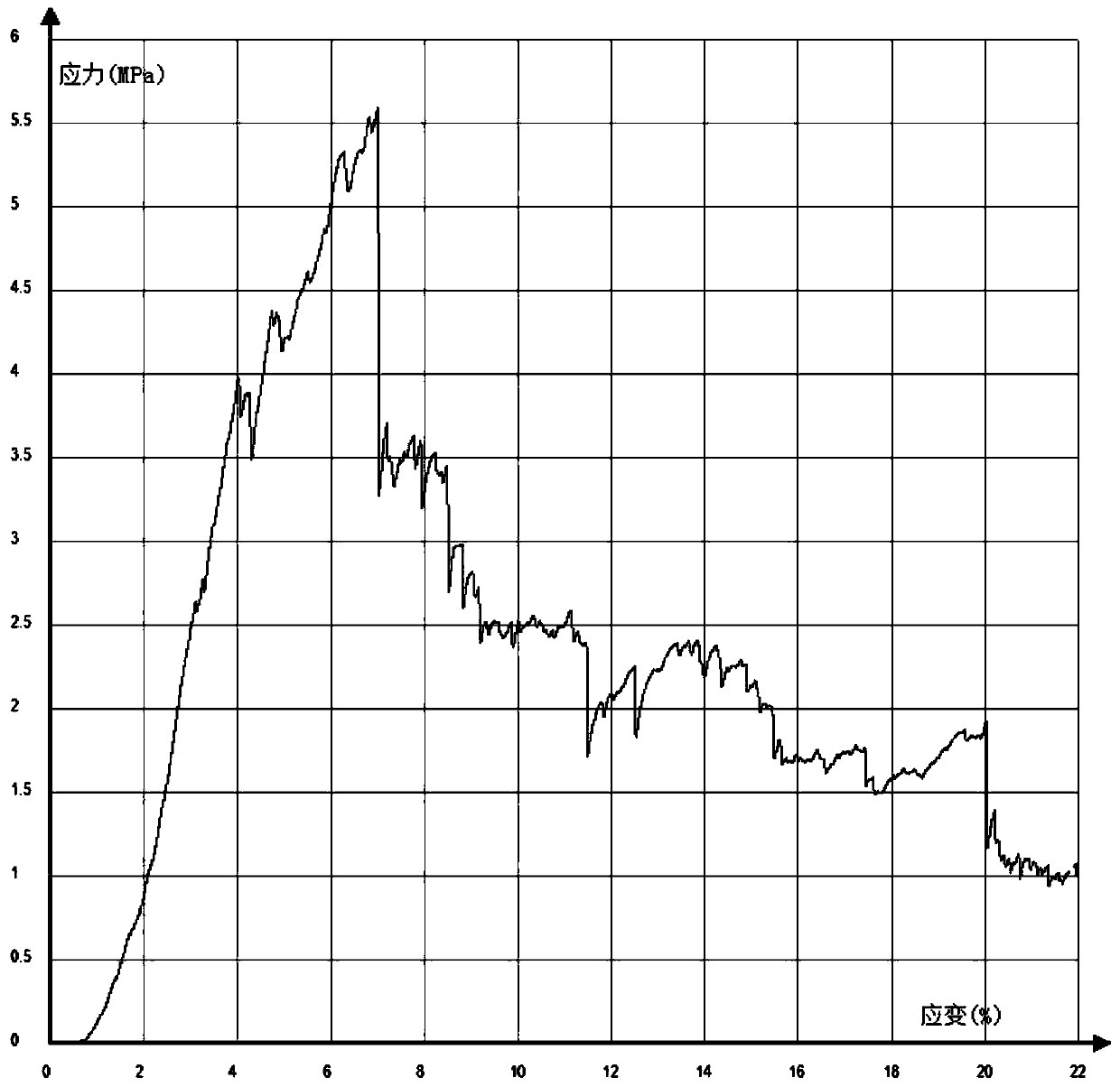

[0047] And the solidifying agent capsule prepared is carried out density test, curing time test and curing ability test according to the test procedure of embodiment 1, and difference is in test condition, thermosetting resin: the mass ratio of curing agent slow-release capsule is 100:8, test The temperature was 115°C. The results are shown in Table 1, wherein the test curve of Example 13 is shown in Figure 3-4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com