Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Avoid lumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

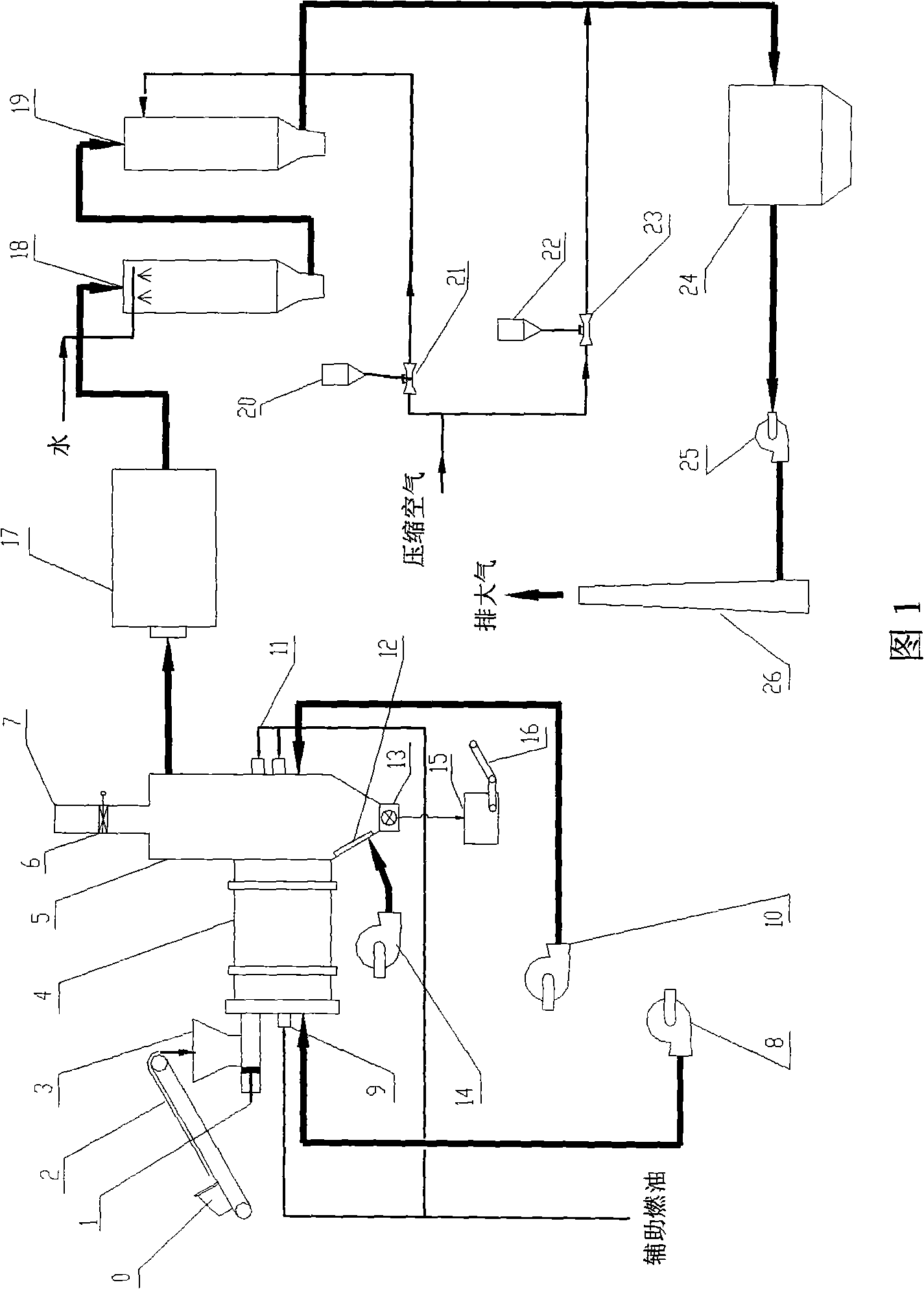

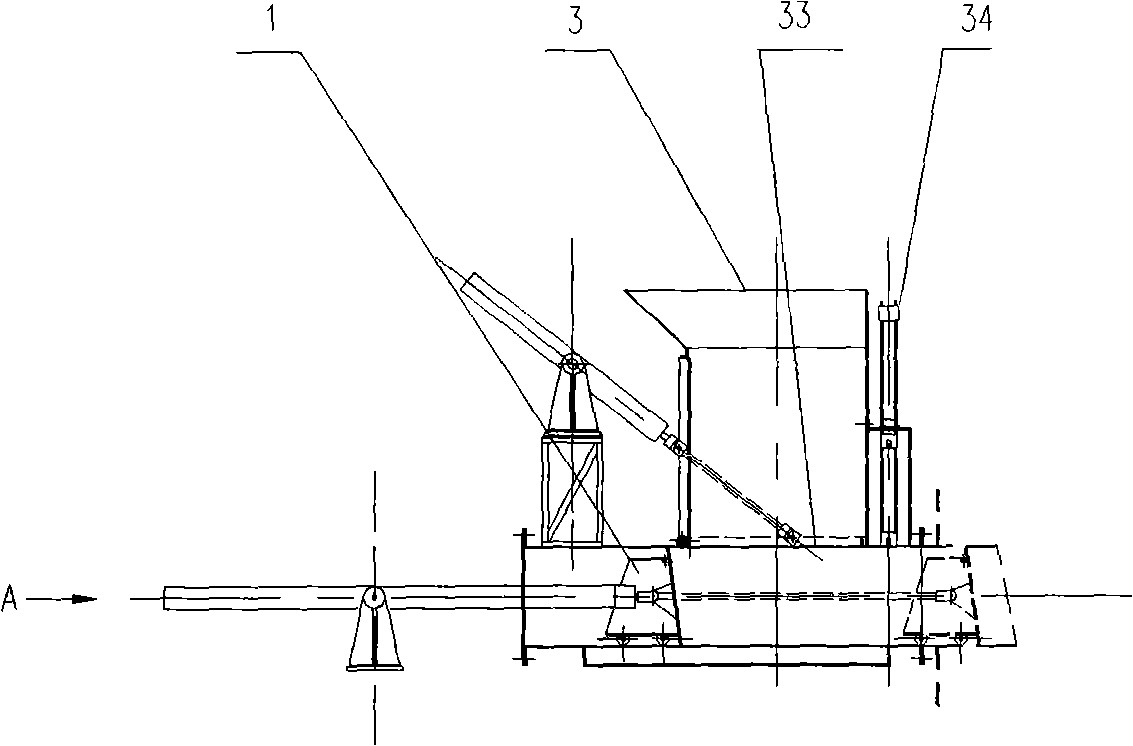

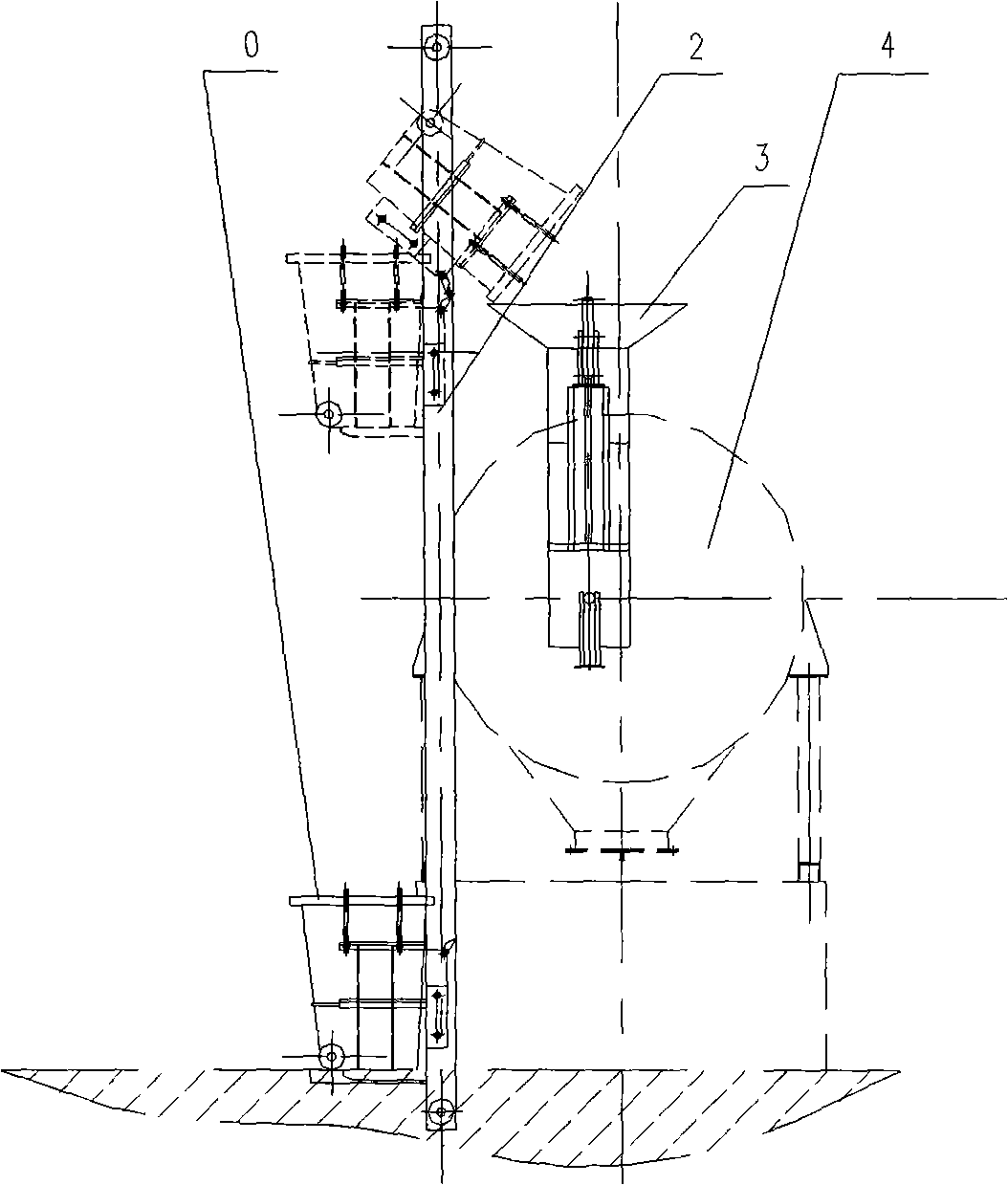

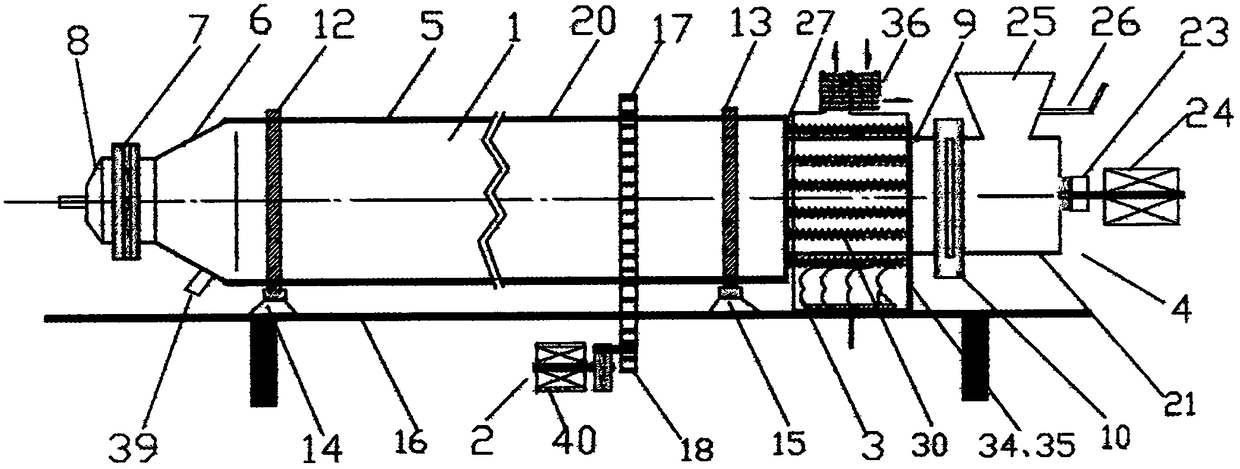

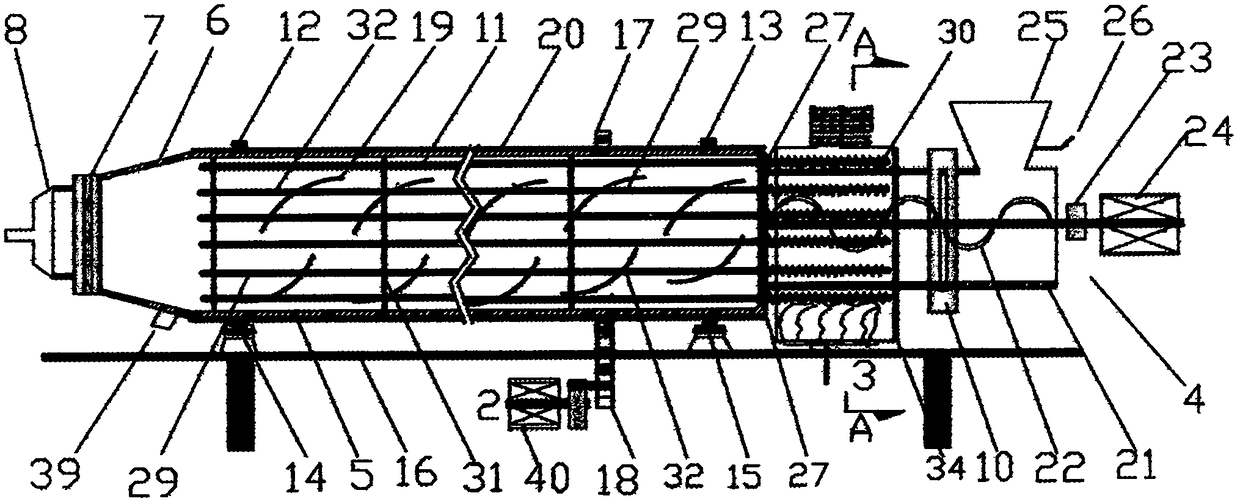

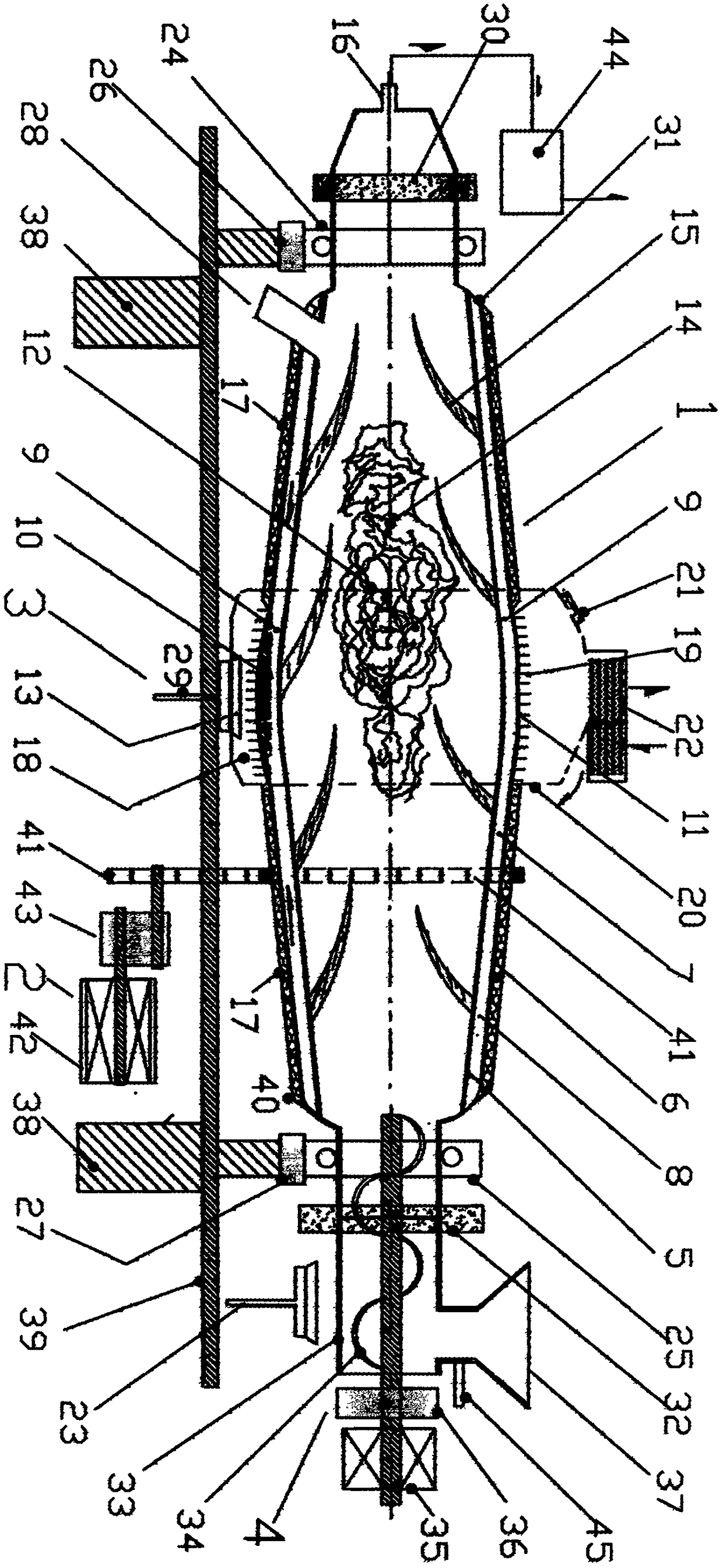

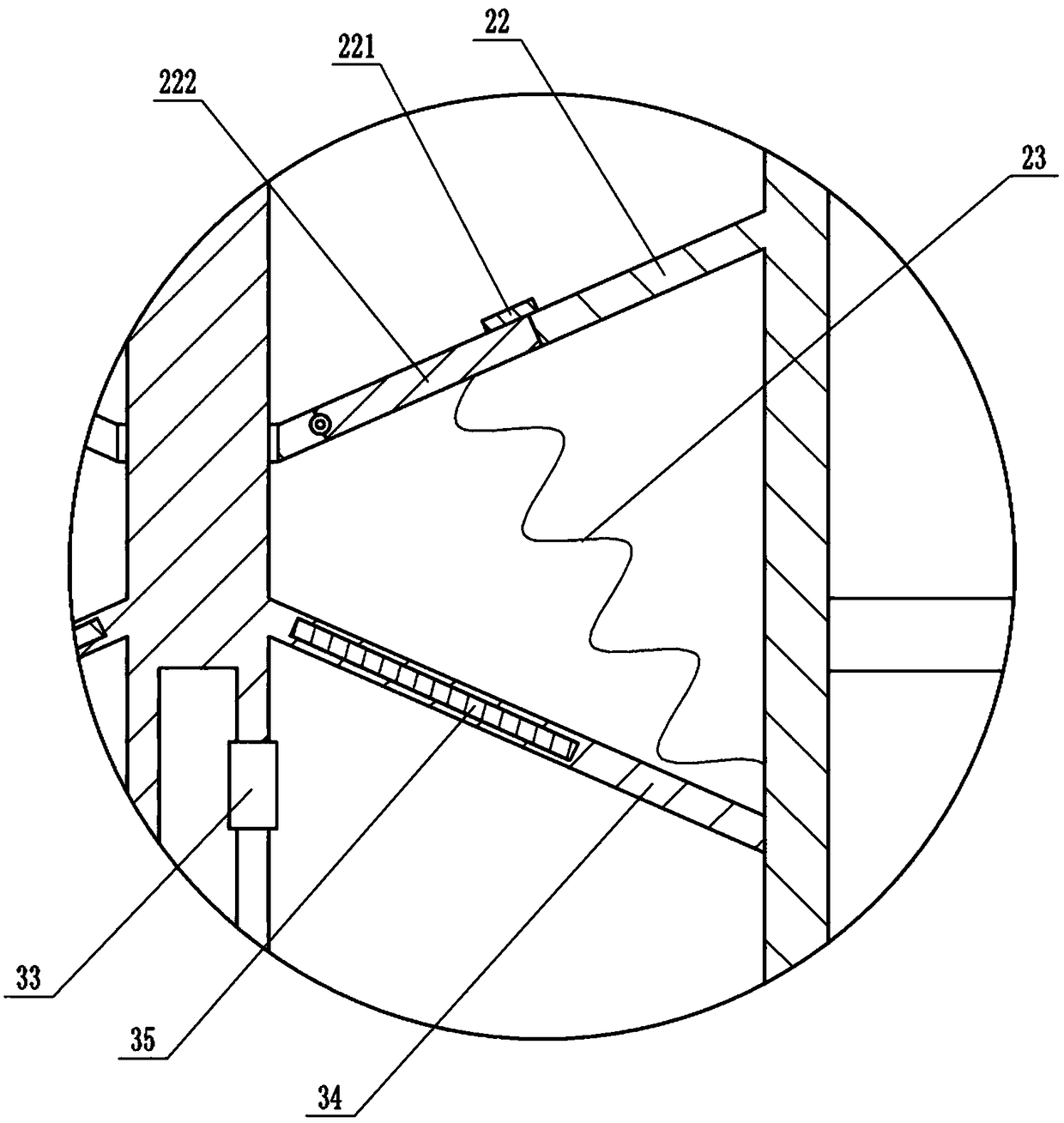

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

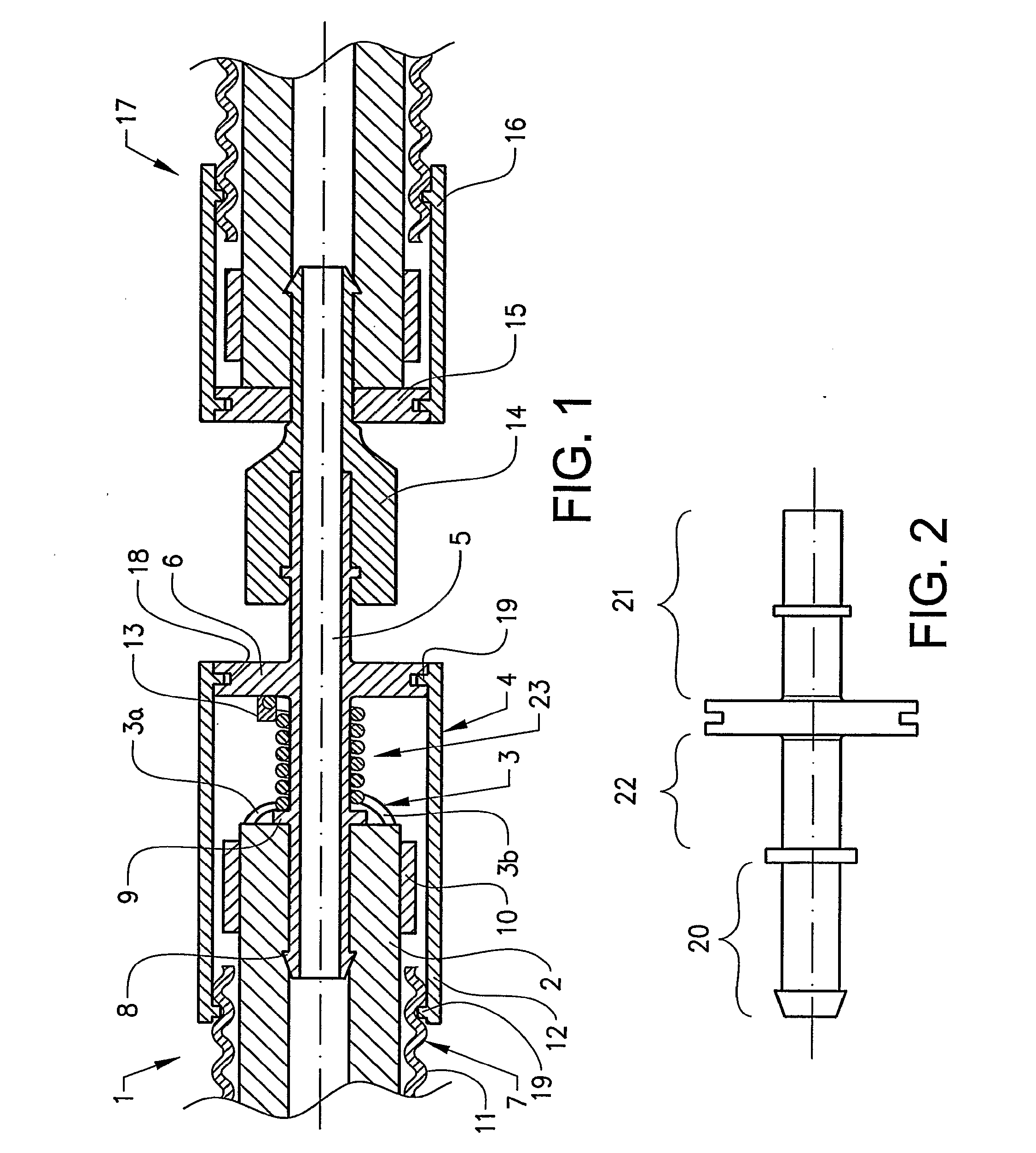

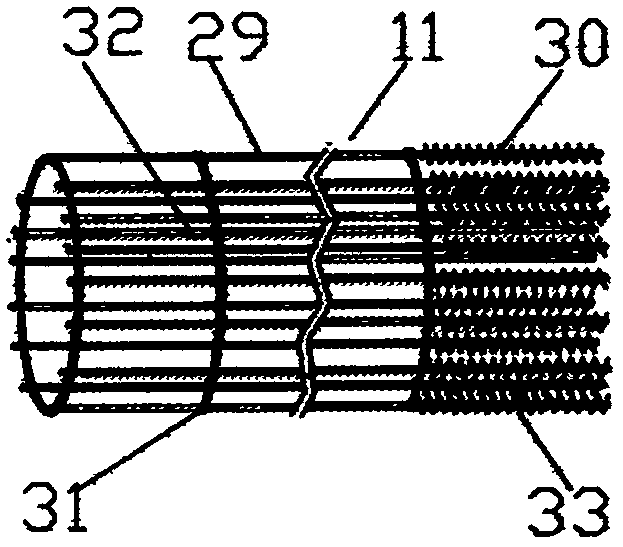

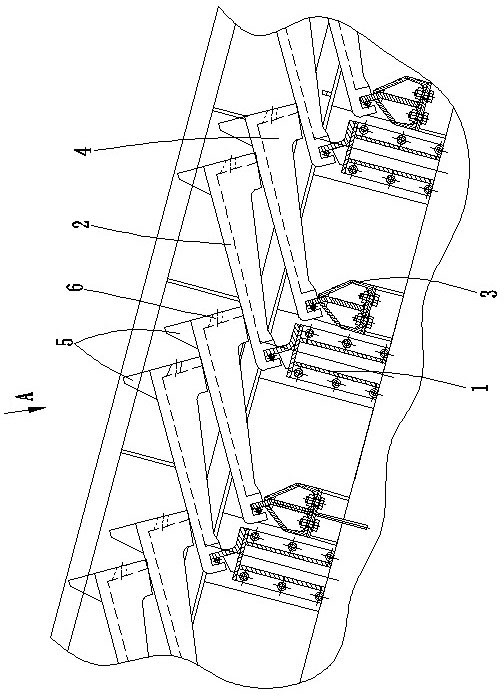

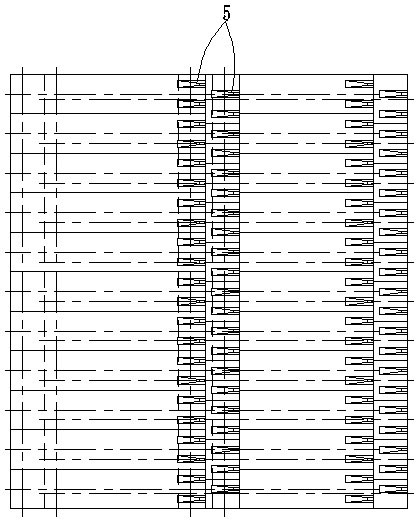

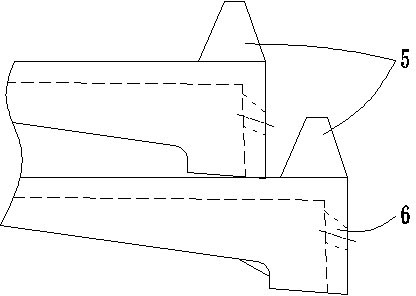

Electrically heatable coupling and an encased fluid hose with an electrically heatable coupling

InactiveUS20070176418A1Avoid lumpsImprove corrosion resistancePipe heating/coolingPipe elementsCouplingElectrical and Electronics engineering

The invention relates to a coupling (5) for fluid, comprising a first connecting section (20) for connection to a fluid hose (2) and a second connecting section (21) for connection to an opposing coupling (14), in which the coupling (5) also comprises a heating section (22) intended for a heating means (23). The object of the invention is to provide a heated coupling for use together with an electrically heated, encased fluid hose. The invention also relates to an encased fluid hose (1) connected to a coupling (5) comprising a heating section (22).

Owner:VOLVO LASTVAGNAR AB

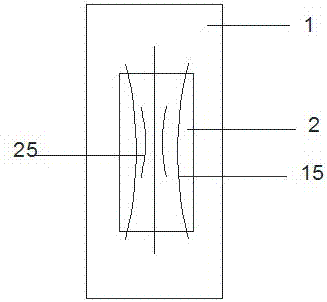

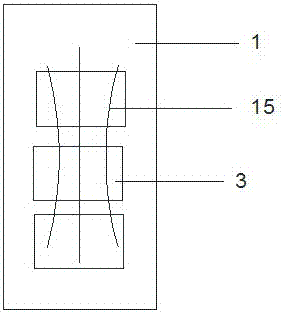

Window portion with an adjusted rate of wear

InactiveUS6860793B2Easy to wearAvoid lumpsSemiconductor/solid-state device manufacturingLapping machinesEngineering

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

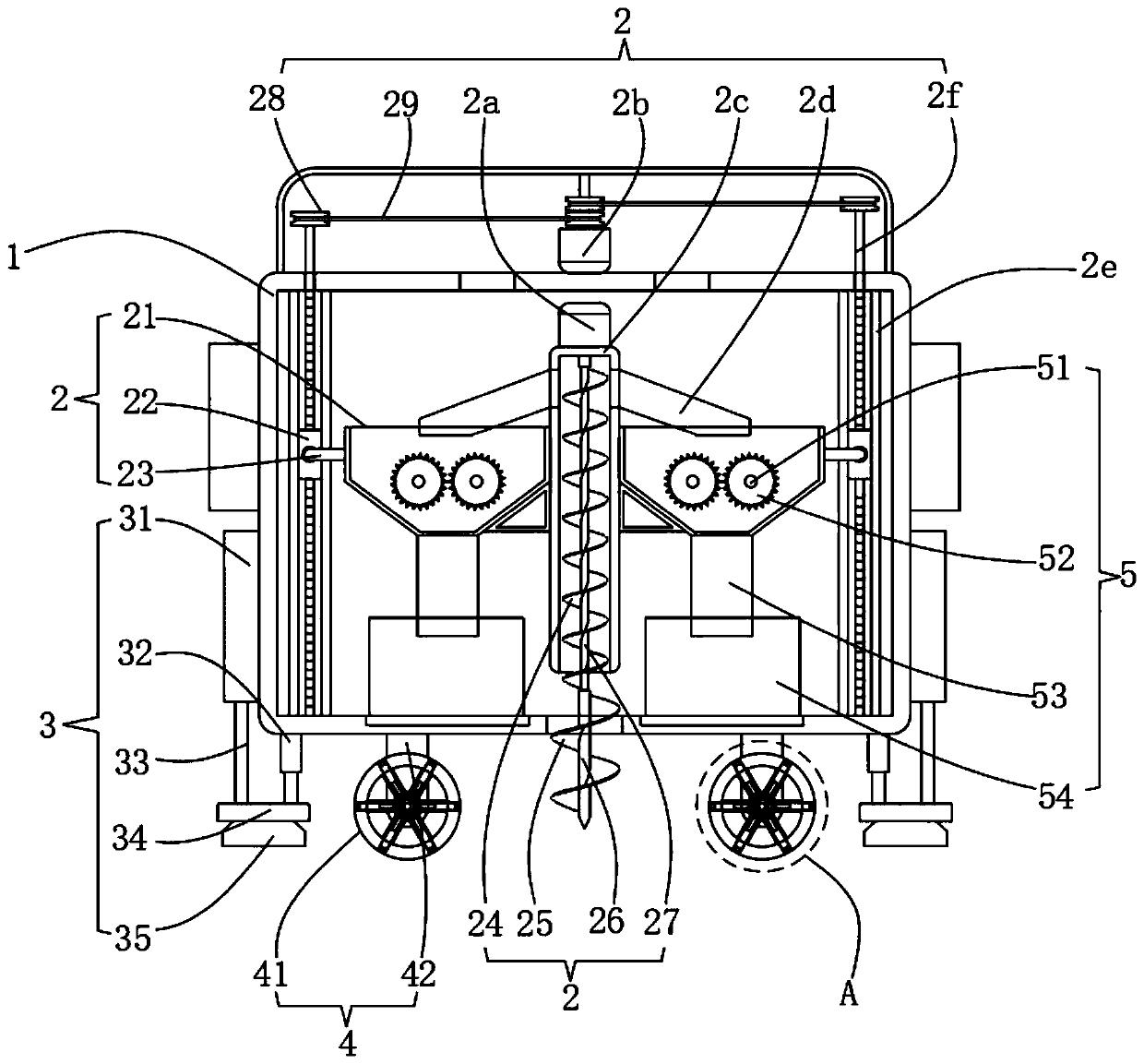

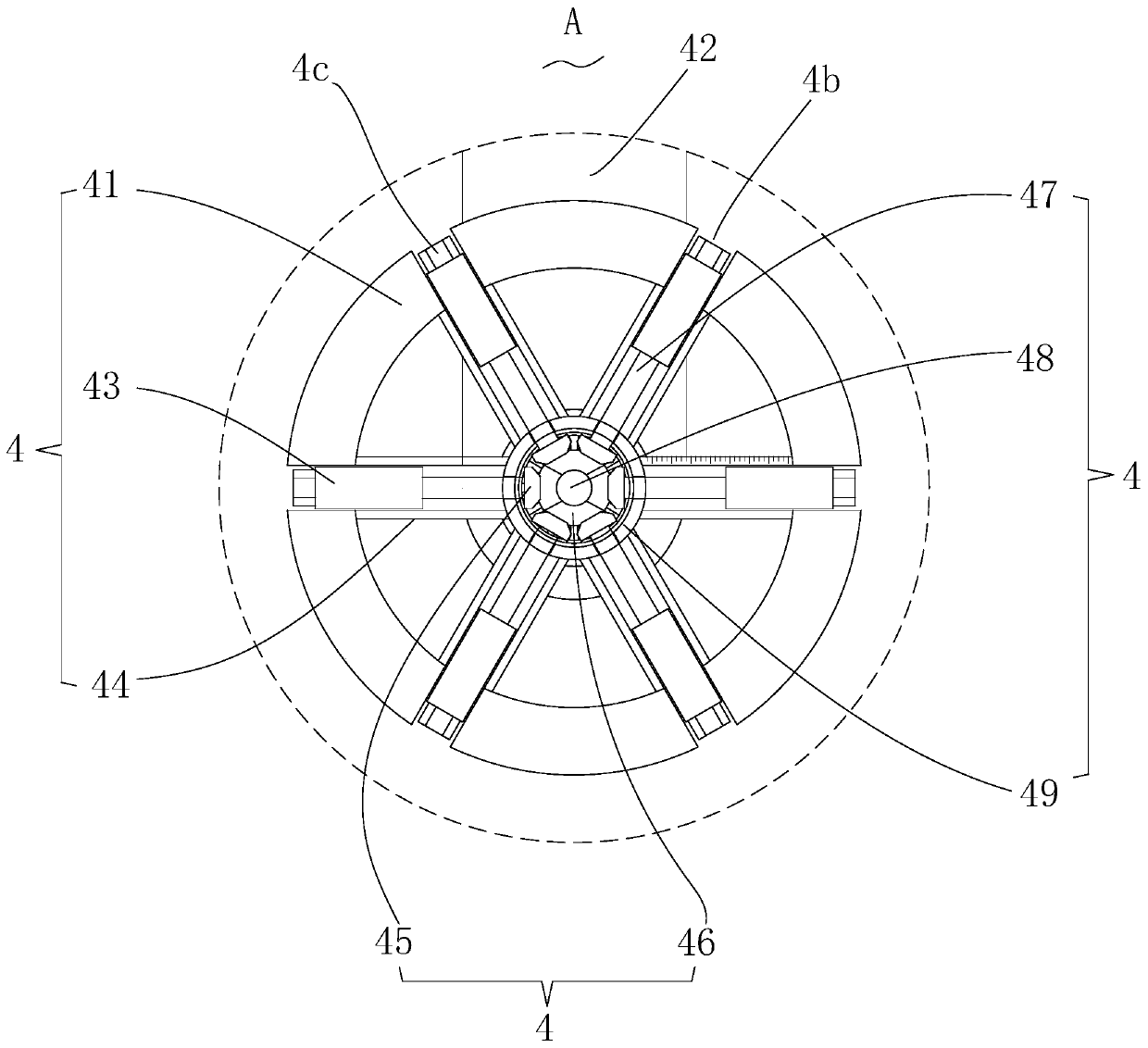

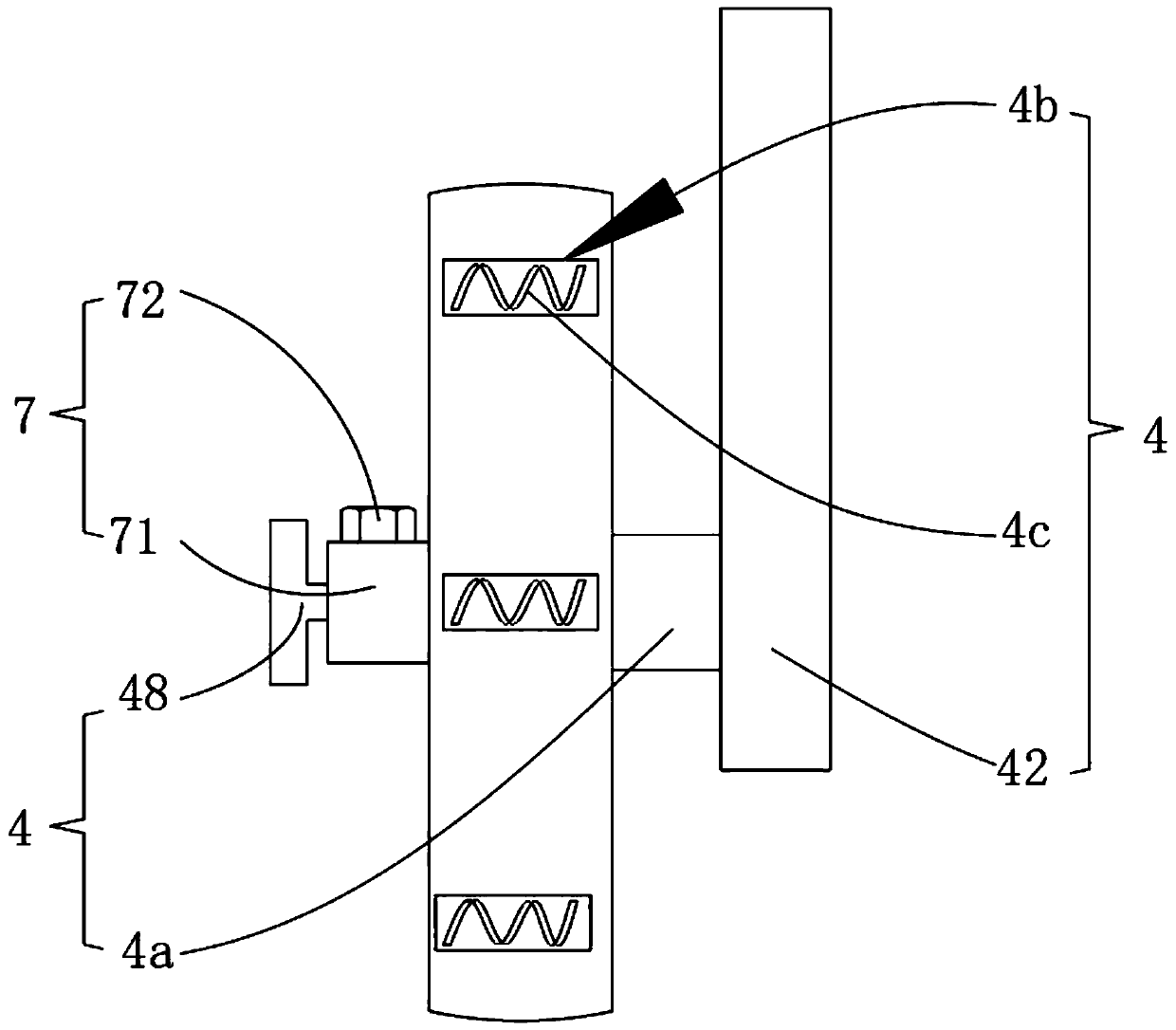

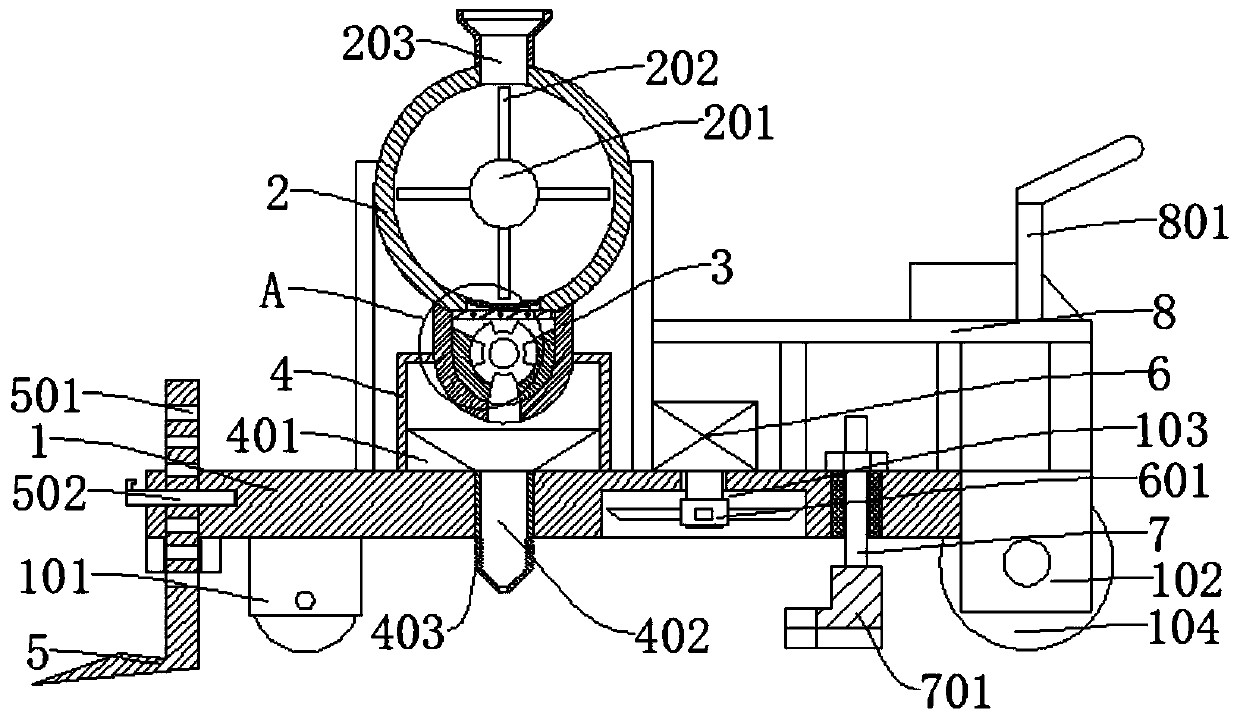

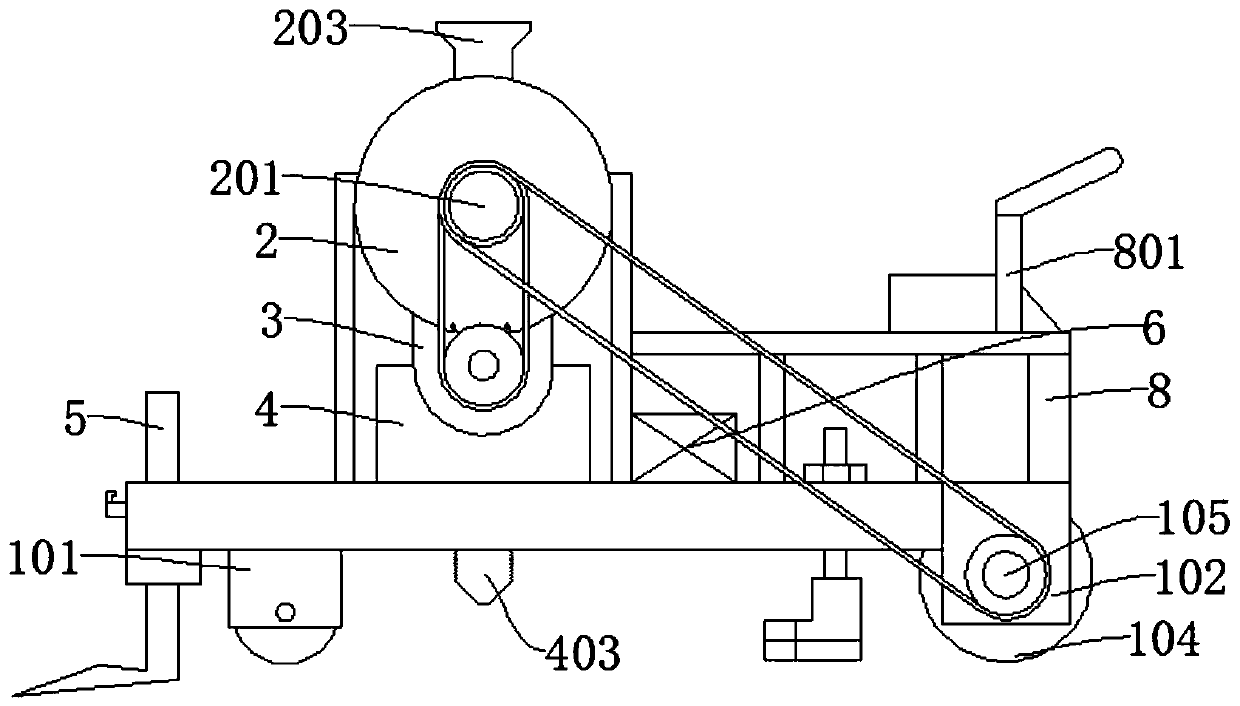

Soil sampling and detecting device

InactiveCN111537273AImprove gripIncrease contact frictionWithdrawing sample devicesPreparing sample for investigationAgricultural scienceThreaded pipe

The invention provides a soil sampling and detecting device. The soil sampling and detecting device comprises a box body, a soil sampling mechanism, a supporting adjusting mechanism, a movable adjusting mechanism, a crushing and detecting mechanism, an auxiliary operating mechanism and a limiting mechanism. The movable adjusting mechanism suitable for adjusting and transferring different road surfaces is connected with the bottom of the box body and comprises a hub, a supporting plate, a rectangular inner threaded pipe, a rectangular sleeve, a first bevel gear, a second bevel gear, an outer threaded rod, a T-shaped rotating rod, a circular box, a third rotating shaft and a bent plate. According to the soil sampling and detecting device provided by the invention, the form of the corresponding hub needs to be adjusted in the transferring process for pushing and transferring; the device can be suitable for rolling of different types of road surfaces; and when the road condition of the soil conveying road surface is poor, transferring can be conducted in a manual carrying mode; time and labor are saved in the operation process; the working efficiency is improved; the device is suitablefor transferring of two kinds of road surfaces; and the application range of the transferring process is widened.

Owner:苏波

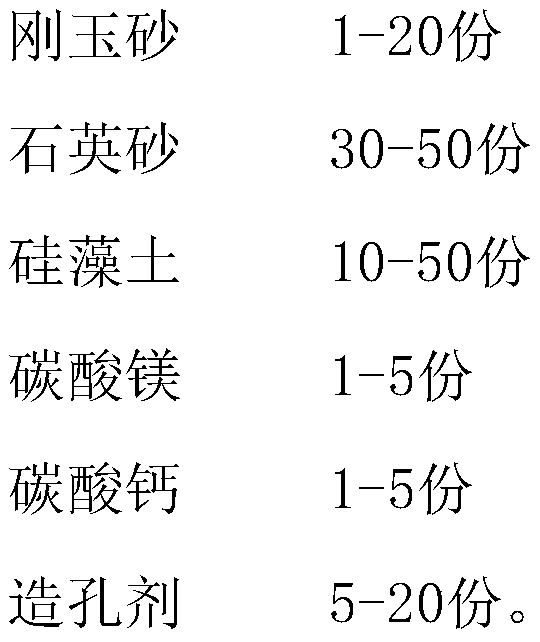

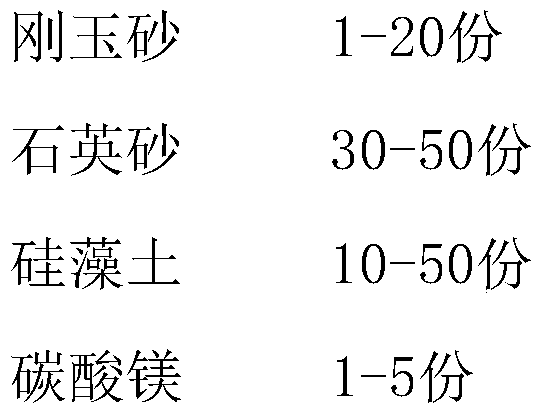

Porous ceramic heating body and preparation method thereof

InactiveCN110981454AHigh strengthImprove performanceTobaccoCeramicwareElectronic cigaretteSilicon dioxide

The invention relates to the technical field of electronic cigarettes, in particular to a porous ceramic heating body and a preparation method thereof. The porous ceramic heating body comprises a porous ceramic matrix and a metal heating element. The porous ceramic matrix comprises the following raw materials in parts by weight: 1-20 parts of emery, 30-50 parts of quartz sand, 10-50 parts of diatomite, 1-5 parts of magnesium carbonate, 1-5 parts of calcium carbonate and 5-20 parts of a pore forming agent. The porous ceramic heating body is novel in structure, high in product porosity and highin strength; the metal heating element is not oxidized; the diatomite forms gaps under the action of the pore forming agent, so the porosity of the produced porous ceramic heating body is guaranteed;magnesium carbonate and calcium carbonate can decompose a part of carbon dioxide gas under a high-temperature condition, so porosity is improved; and magnesium oxide and calcium oxide generated afterhigh-temperature decomposition form aluminosilicate together with silicon dioxide and aluminum oxide, so the inter-binding property of material particles is improved, and the structural stability andstrength of the porous ceramic matrix are improved.

Owner:KEY MATERIAL

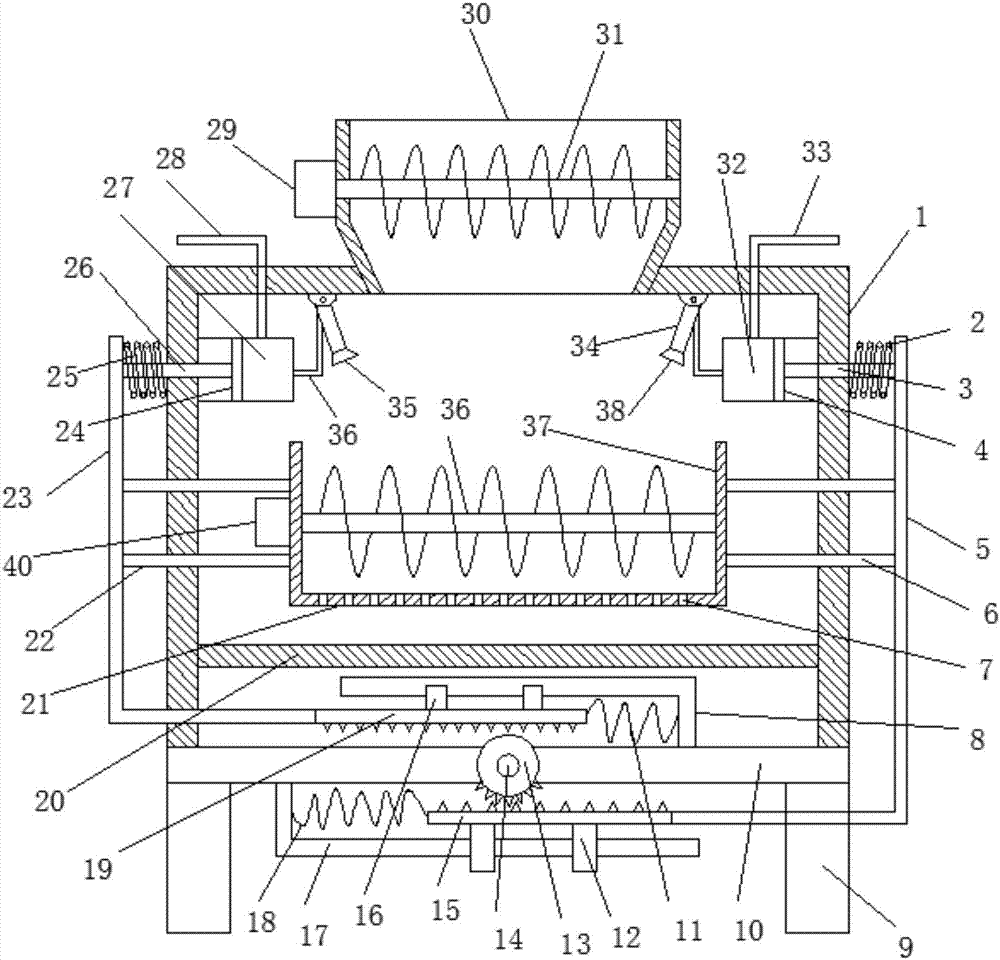

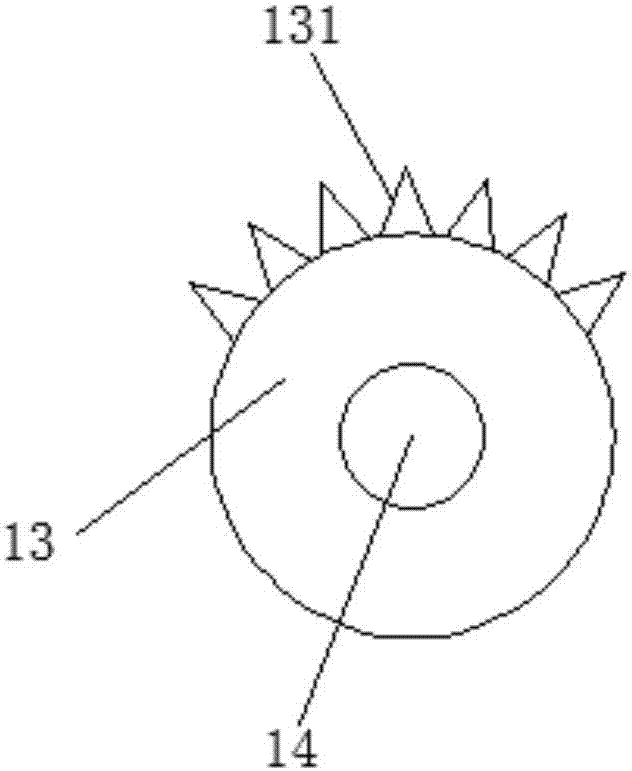

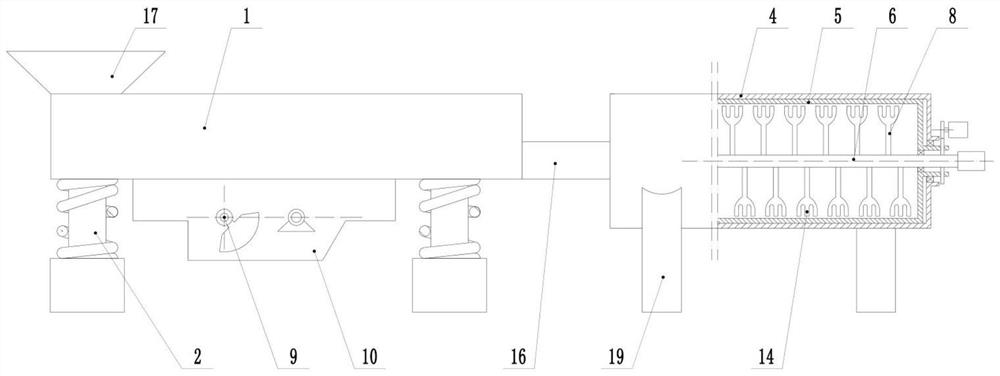

Atomizing, oil-spraying and mixing device for feed production and processing

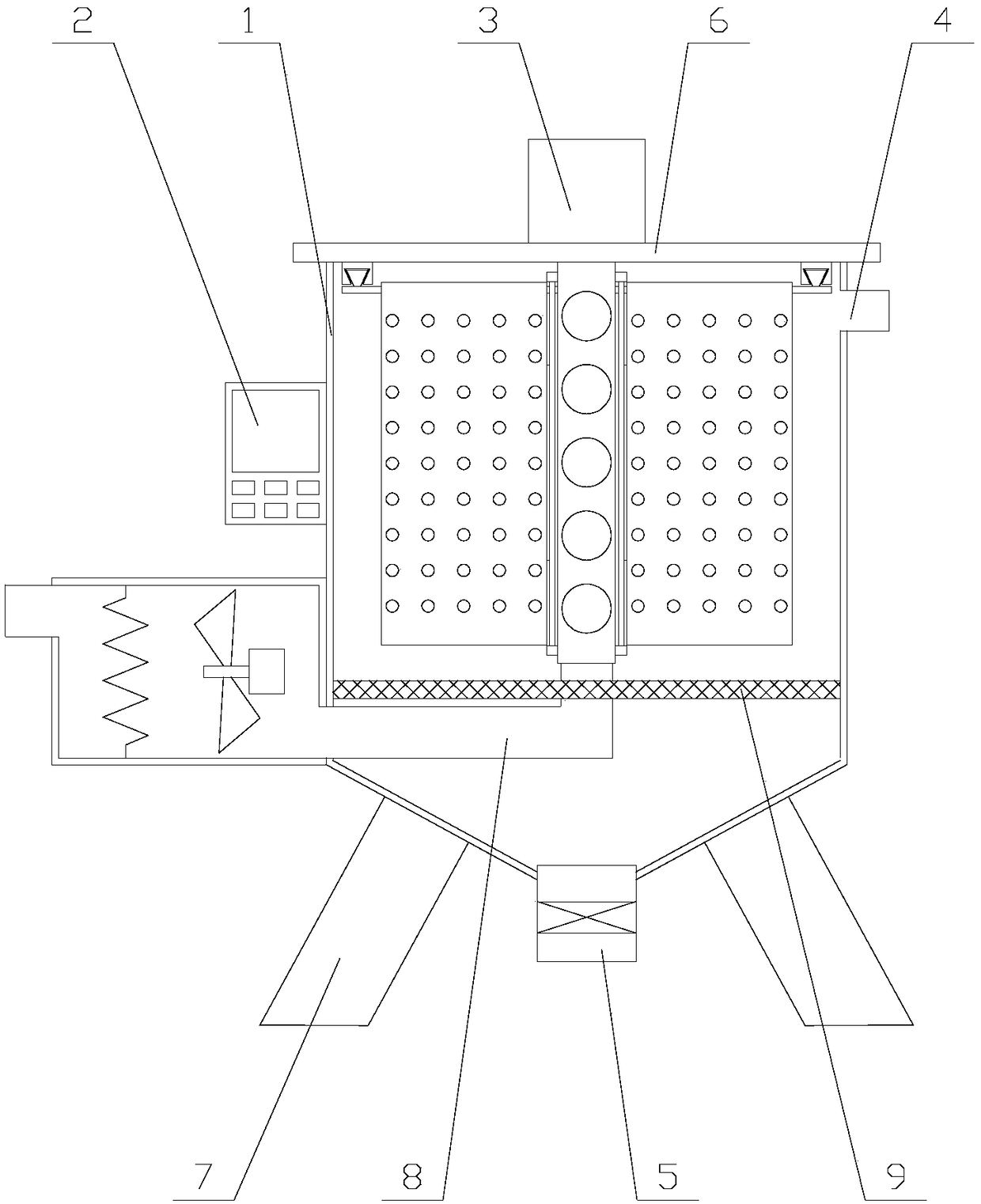

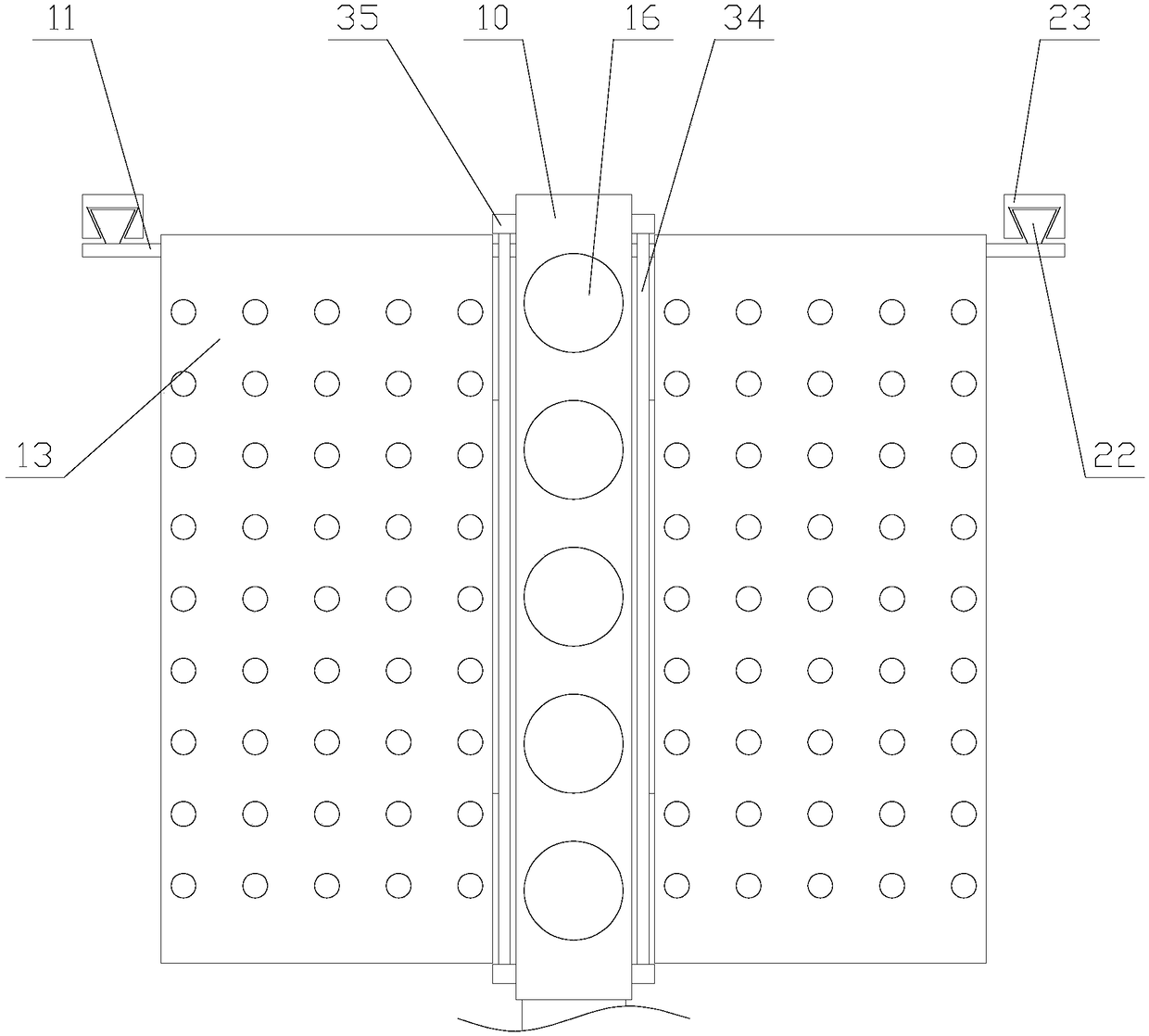

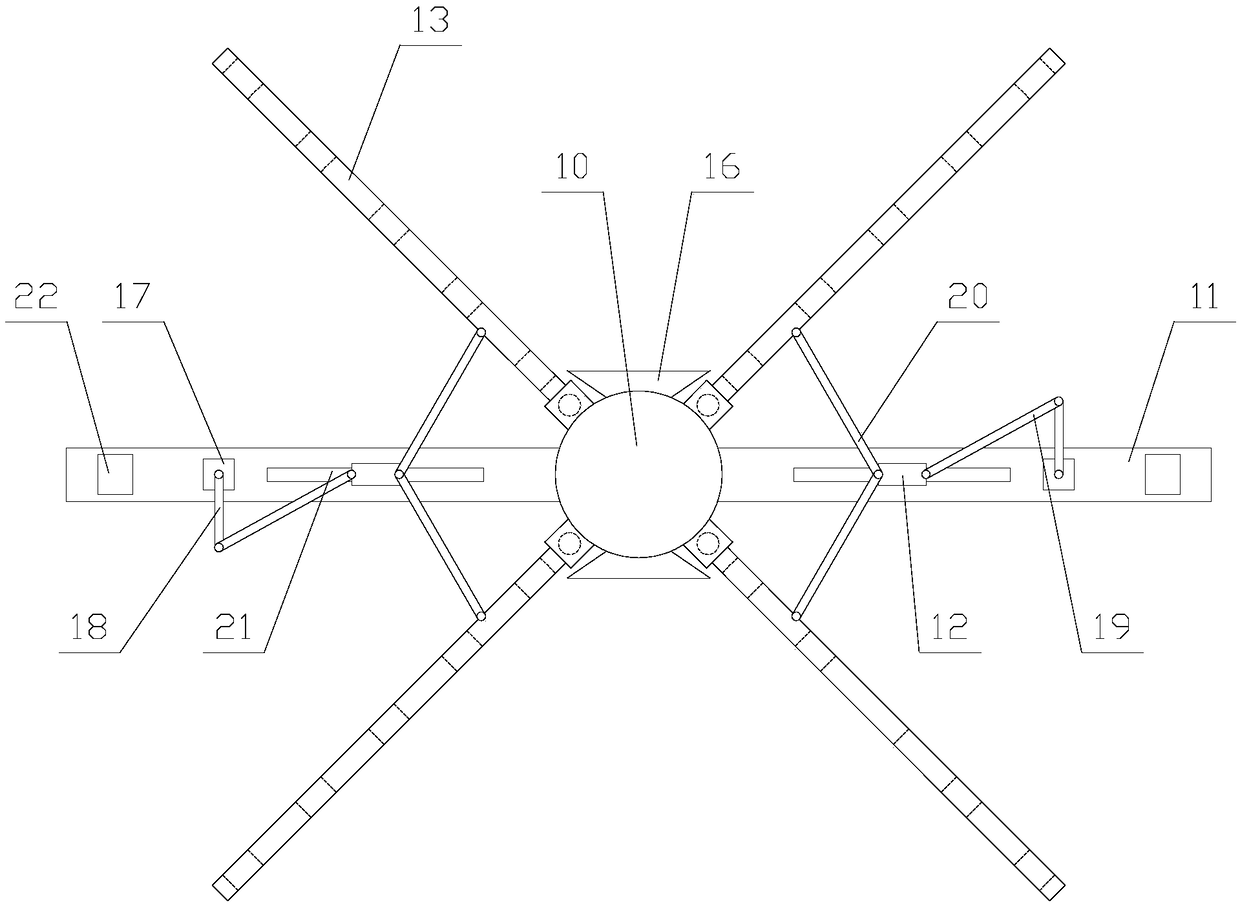

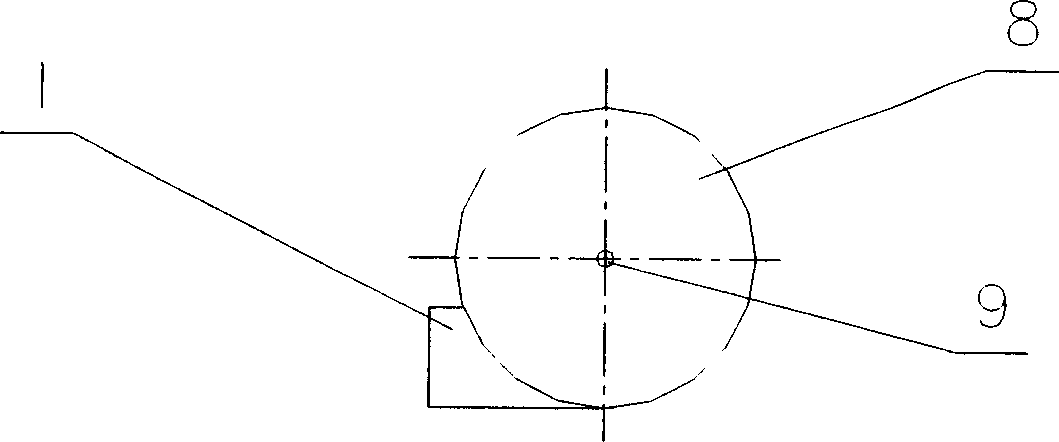

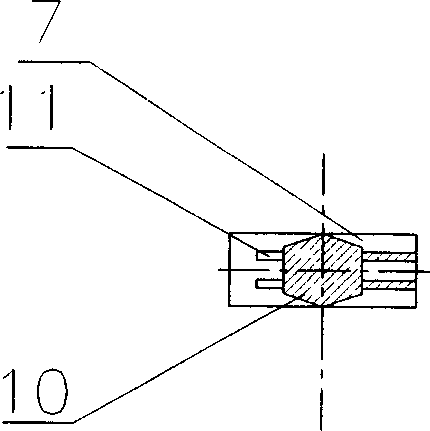

PendingCN107536087AEfficient crushingAvoid lumpsShaking/oscillating/vibrating mixersFeeding-stuffRotational axisEngineering

The invention discloses an atomizing, oil-spraying and mixing device for feed production and processing. The atomizing, oil-spraying and mixing device comprises a supporting seat, wherein a mixing boxis mounted at the upper end of the supporting seat; a rotating shaft is mounted in the middle of the supporting seat; a rotating wheel is mounted in the middle of the rotating shaft; a first gear rack is engaged with the upper end of the rotating wheel; a first guiding block is mounted in the middle of the upper end of the first gear rack; a first guiding rod is connected to the upper end of thefirst guiding block; a left swinging rod is connected to the left end of the first gear rack; a left connecting rod is mounted in the middle of the right end of the left swinging rod; a second gear rack is engaged with the lower end of the rotating wheel; a second guiding block is connected to the middle of the lower end of the second gear rack; a second guiding rod is connected to the middle of the second guiding block; a right swinging rod is connected to the right end of the second gear rack; and a right connecting rod is connected to the middle of the left end of the right swinging rod. According to the atomizing, oil-spraying and mixing device disclosed by the invention, the left and right movement of a mixing frame is realized, and the mixing effect of oil and a feed is improved; andbesides, the feed is efficiently crushed by the action of a crushing shaft and a mixing shaft, so that agglomeration of the feed is avoided and the quality of the feed is improved.

Owner:ZHENGZHOU UNIV

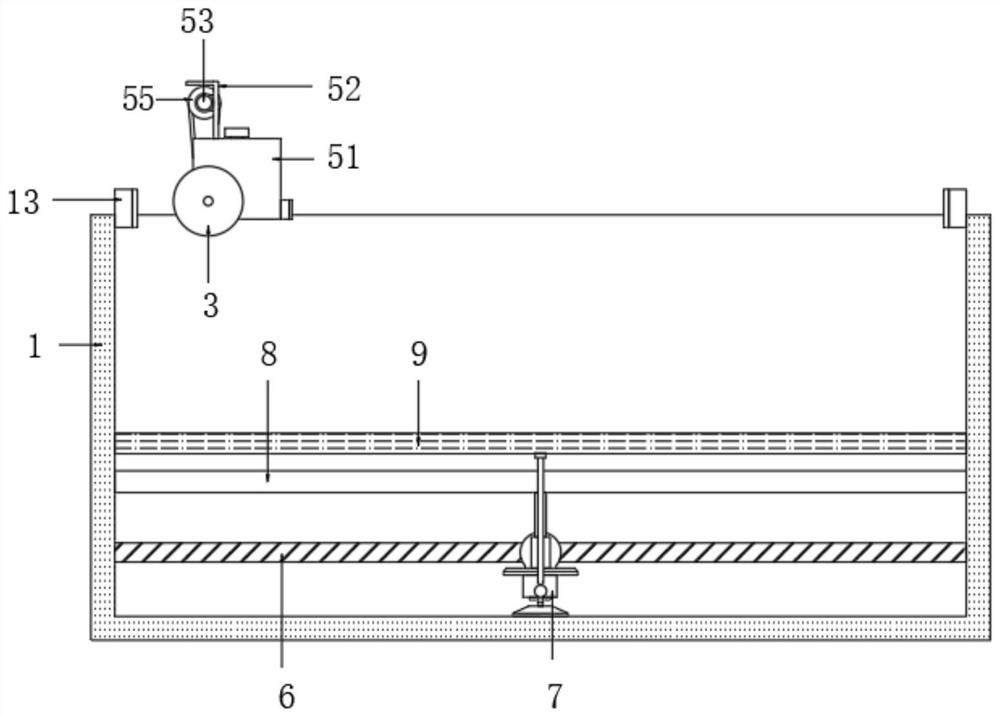

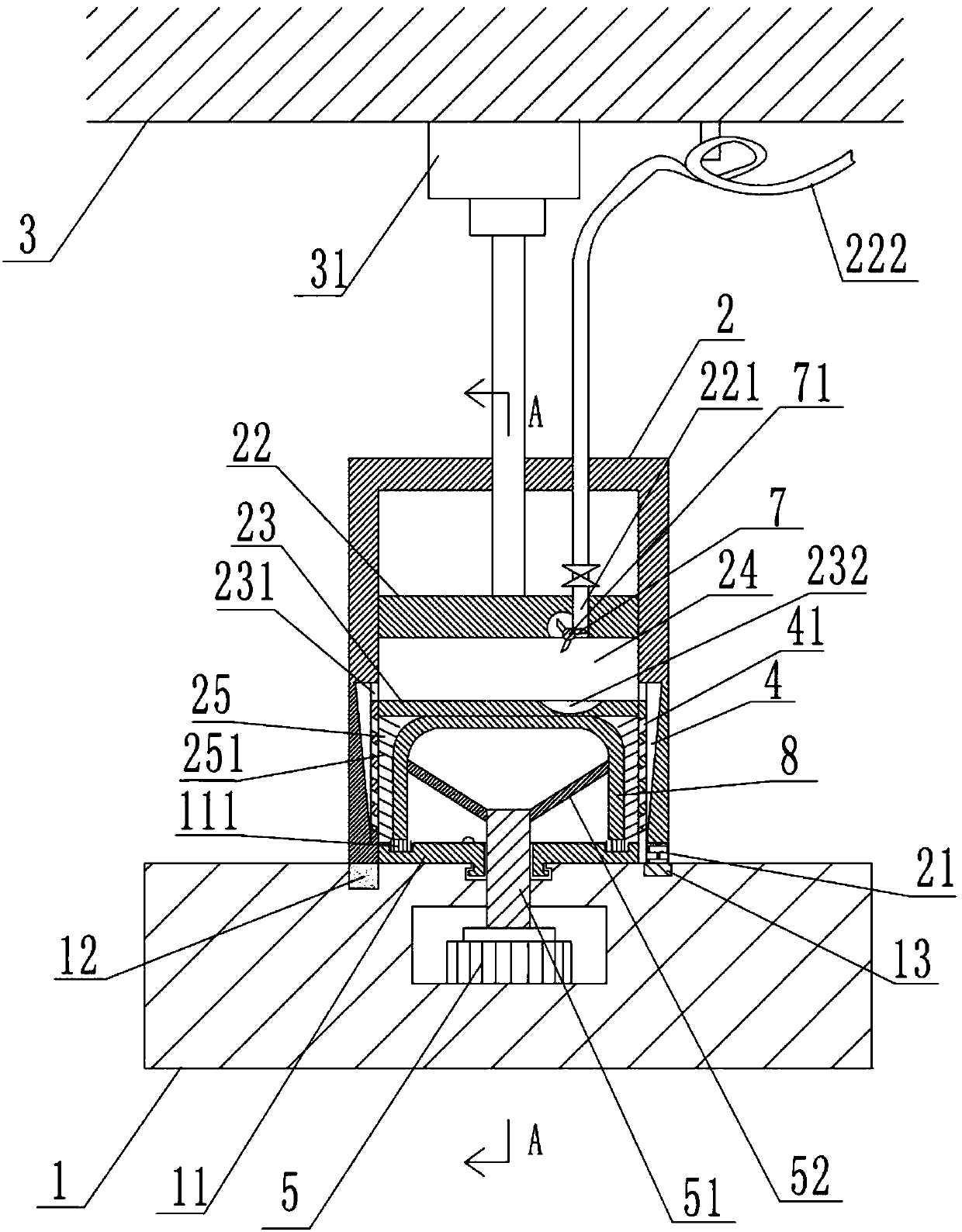

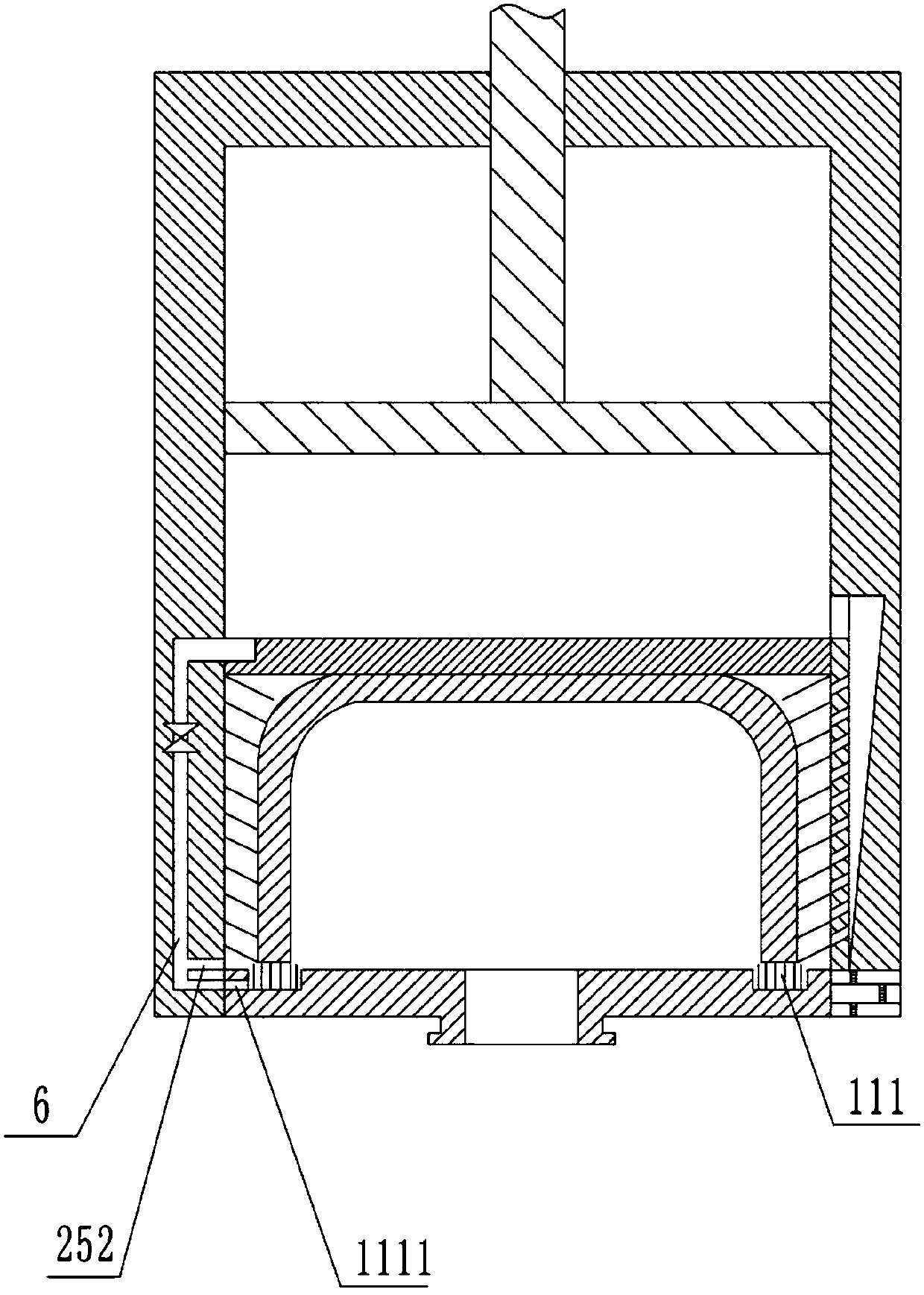

Aerobic reaction device used for garbage composting

InactiveCN108794084AEasy outflowRealize looseClimate change adaptationOrganic fertilisersLitterEngineering

The invention relates to an aerobic reaction device used for garbage composting. The device comprises a reactor, a controller, an oxygen supply mechanism, a first motor, an exhaust pipe, a drainage pipe, a cover board and a plurality of supporting legs, wherein an oxygen supply pipe, a screen and a stirring mechanism are arranged in the reactor, the stirring mechanism comprises a rotating pipe andtwo stirring assemblies, each stirring assembly comprises a side board, a reciprocating unit, a reciprocating block and two stirring units, the stirring units comprise hinge units, supporting rods and stirring boards, a ventilation mechanism is arranged in the rotating pipe, and the ventilation mechanism comprises a lifting assembly, a lifting block and a plurality of ventilation assemblies. According to the aerobic reaction device used for garbage composting, through the first motor, the stirring mechanism is driven to run, so that a raw material is clamped in a rotating process of the stirring boards, the flowing of garbage out of through holes is convenient, the garbage is loosened, composting is promoted, and garbage blocking is avoided; moreover, through the ventilation mechanism, the oxygen conveying position is changed, so that the garbage at various positions can all be subjected to full composting reaction, and the practicability of the device is improved.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

PPS with low dielectric coefficient

InactiveCN109705577AImprove high temperature resistanceImprove mechanical propertiesGlass fiberHigh density

The invention discloses PPS with a low dielectric coefficient, and relates to the technical field of plastics. The PPS is prepared by the following steps: particles of a PPS toughening agent are ground into powder by a material grinding machine, then sieving is performed by using a high-density sieve, and sieved toughening agent powder is retained for standby application; after the material is processed, PPS resin, hollow glass microbeads, the PPS toughening agent powder and low-dielectric-coefficient glass fibers are added into a high-speed material-mixing machine in proportion, and mixing isperformed; and after the mixing is completed, the material is taken out and put into a plastic extruding machine, and extrusion molding is performed. The PPS with the low dielectric coefficient provided by the invention has excellent high-temperature resistance and mechanical properties, and shows stable dielectric properties in a wide range from -40 to 120 DEG C; and the PPS is utilized as a substrate, the dielectric coefficient is reduced to less than 3 to meet market demand by means of a modification manner (that is, cooperation of the hollow glass microbeads, the low-dielectric-coefficient glass fibers and the PPS toughening agent is utilized), at the same time, good toughness and strength are maintained, and the high-temperature resistance is strong.

Owner:江苏欧瑞达新材料科技有限公司

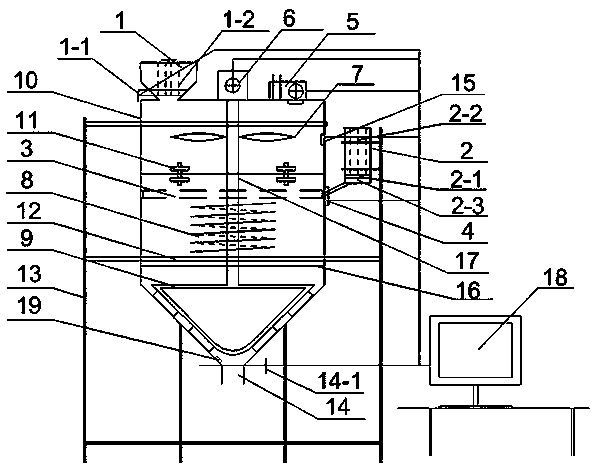

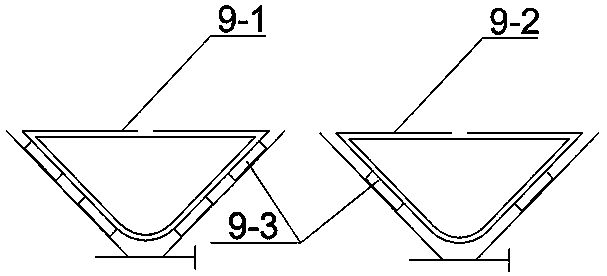

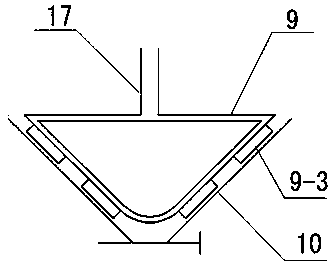

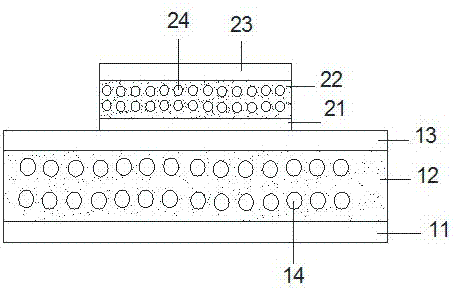

Reaction tower for stack gas desulfurization of dry type circulating fluid bed

ActiveCN1795968ARaise the ratioPre-separation implementationDispersed particle separationFluidized bedFlue gas

The invention relates to a dry circulating fluidized bed flue gas desulfurization reaction tower, belonging to the field of flue gas purification technology. Said invention includes tower body and flue gas inlet, flue gas outlet, spraying water inlet and spraying powder outlet which are connected with the tower body. Said tower body is composed of upper and lower two sections which are connected by means of designed Venturi section. The lower section of said tower body is preseparation chamber with buffer action, the connection form of the preseparation chamber and the described flue gas inlet adopts a tangetial gas-feeding turnable type structure, the bottom portion of preseparation chamber is equipped with a conical ash-falling mouth. The upper section of said tower body is a straight barrel section; the lower portion of said straight barrel section is connected with the described spraying powder inlet and spraying water inlet placed over the spraying powder inlet. In the interior of upper portion of said straight barrel section an internal separation member with inertial separation action is mounted, and the described flue gas outlet is placed over the internal separation member and connected with outer wall of said straight barrel section.

Owner:TSINGHUA UNIV +1

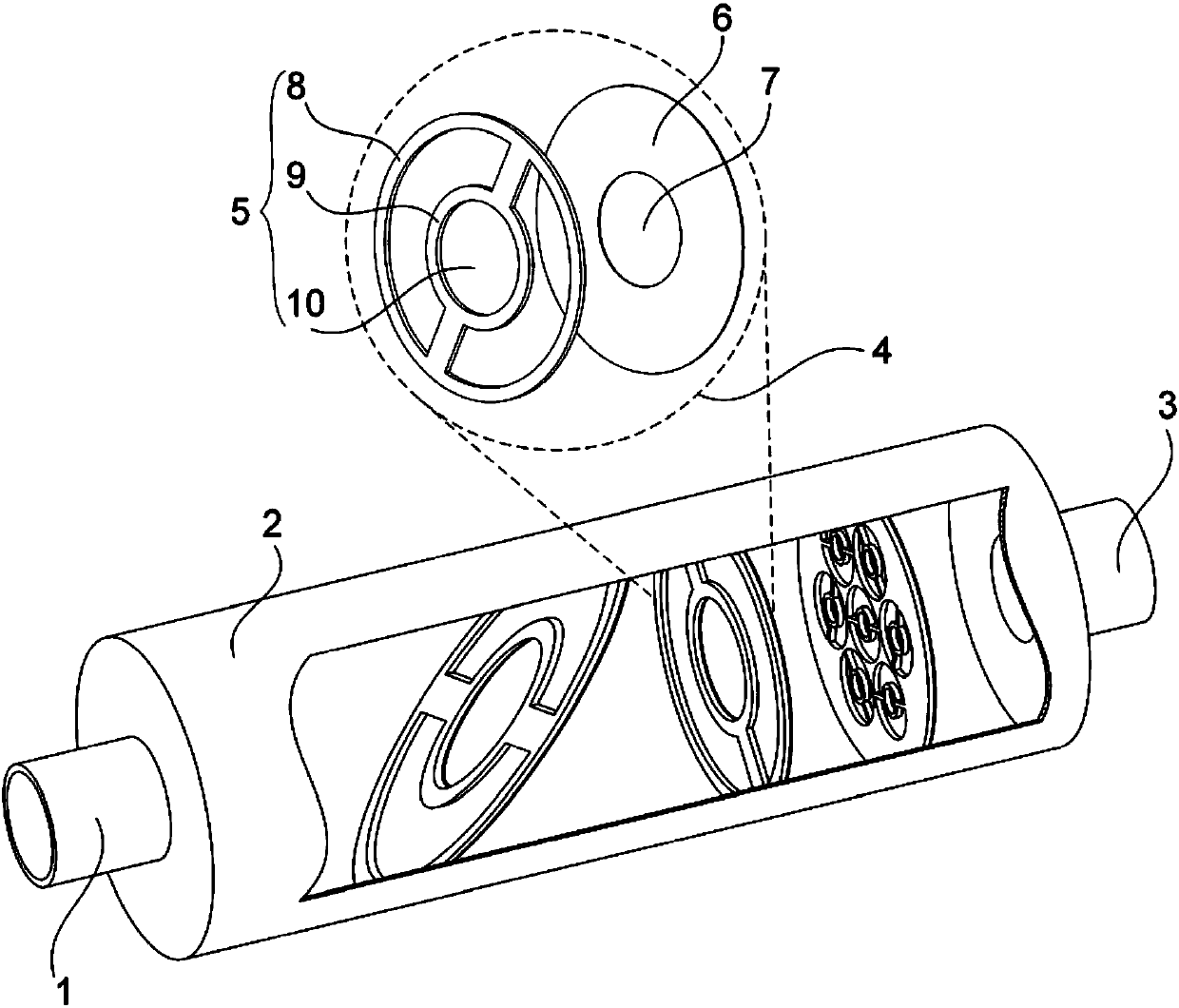

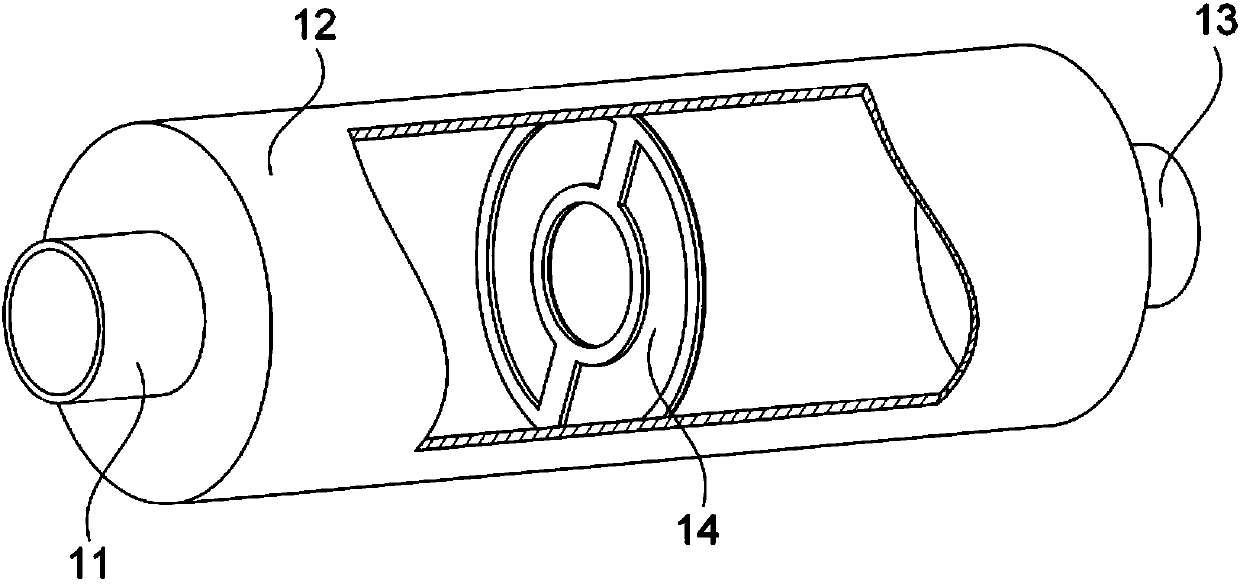

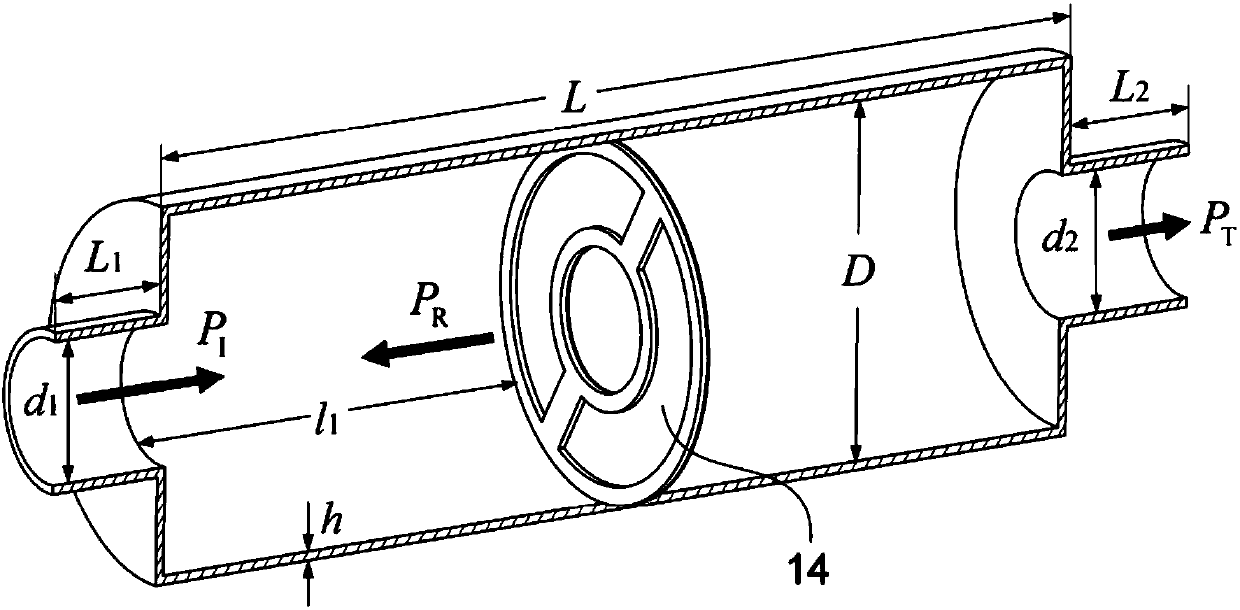

Baffled acoustic metamaterial silencer, and preparation and assembling methods thereof

ActiveCN107633838AExcellent low frequency anechoic bandwidthExcellent noise reductionSound producing devicesEngineeringHeat transfer efficiency

The invention relates to a silencer comprising an inlet pipe, an outlet pipe, a hollow expansion cavity formed between the inlet pipe and the outlet pipe, and a perforated acoustic metamateiral bafflearranged vertically or obliquely at the internal cross section of the hollow expansion cavity. The a perforated acoustic metamateiral baffle includes a frame; a constraint body in rigid connection with the frame is arranged inside the frame; a thin film covers the surface of the frame; and through holes are formed in the constraint body and the thin film. In addition, the invention also relates to an improved silencer; and occurrence of standing wave damping valley of the traditional resistant silencer is avoided and the good low-frequency noise elimination effect is realized. In addition, according to another embodiment, the invention also relates to an improved silencer, so that a problem of the direct contact between the sound absorption material and the fluid is solved. And accordingto another embodiment, the invention also relates to a silencer for improving the heat transfer efficiency of the fluid medium at the two sides of the hole by using vibration of a perforated acousticmetamateiral baffle. Besides, the invention also provides a method for frequency modulation and preparation of a perforated acoustic metamateiral baffle and a method of assembling the silencer. The silencer has characteristics of compact structure, simple process, stable performance, and long service life.

Owner:黄礼范

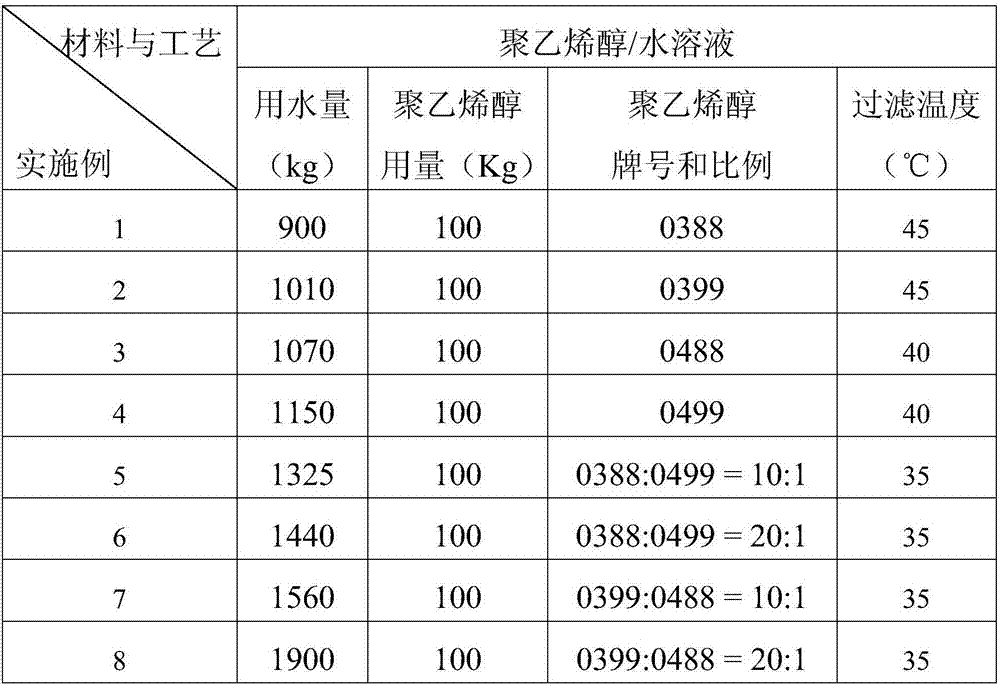

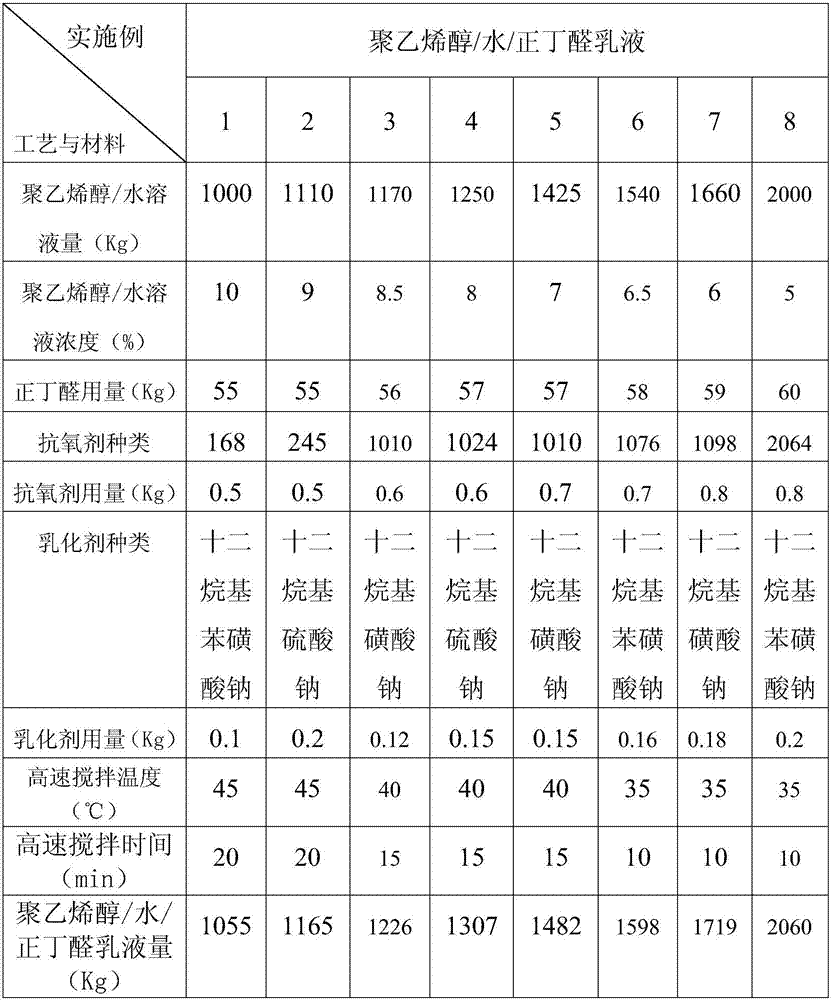

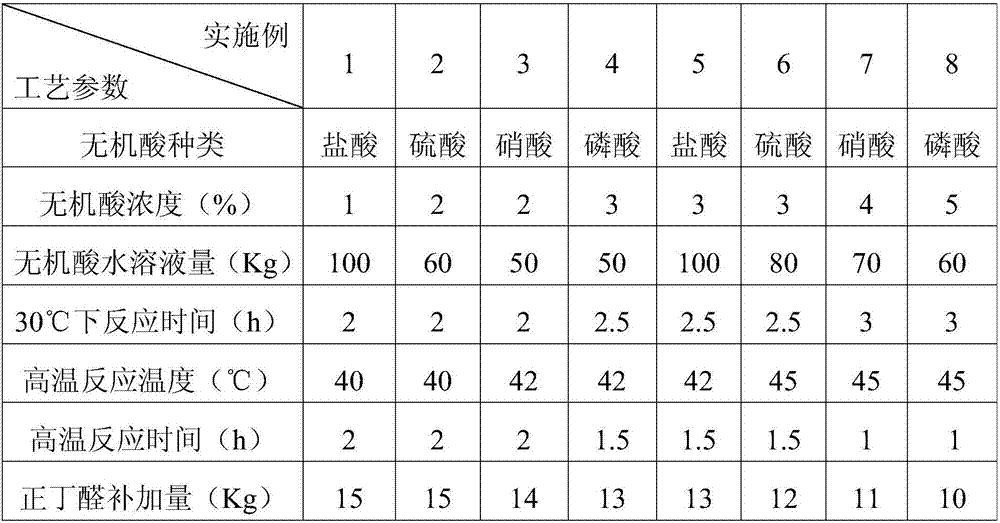

Synthetic method of low-viscosity polyvinyl butyral resin

The invention discloses a synthetic method of low-viscosity polyvinyl butyral resin. The synthetic method is characterized by comprising the following steps: mixing low-viscosity polyvinyl alcohol with water for dissolving, adding n-butanal, an antioxidant and an emulsifying agent at 35-45 DEG C, carrying out high-speed stirring, dropwise adding an inorganic acid water solution, heating to 30 DEG C for reacting for 2-3h, heating to 40-45 DEG C, and replenishing n-butanal for reacting to obtain slurry; and adjusting the pH value with an alkaline liquid, washing, dehydrating and drying, so as to obtain the low-viscosity polyvinyl butyral resin. The resin has the performance as follows: the viscosity of a 10% polyvinyl butyral resin-ethanol solution is 10mPa.s-50mPa.s, the hydroxyl content is 12%-17%, the aldehyde acetal group content is 75%-85%, and the acetyl content is less than 3%. The prepared low-viscosity polyvinyl butyral resin can be applied to the fields of ink, coatings, adhesives and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

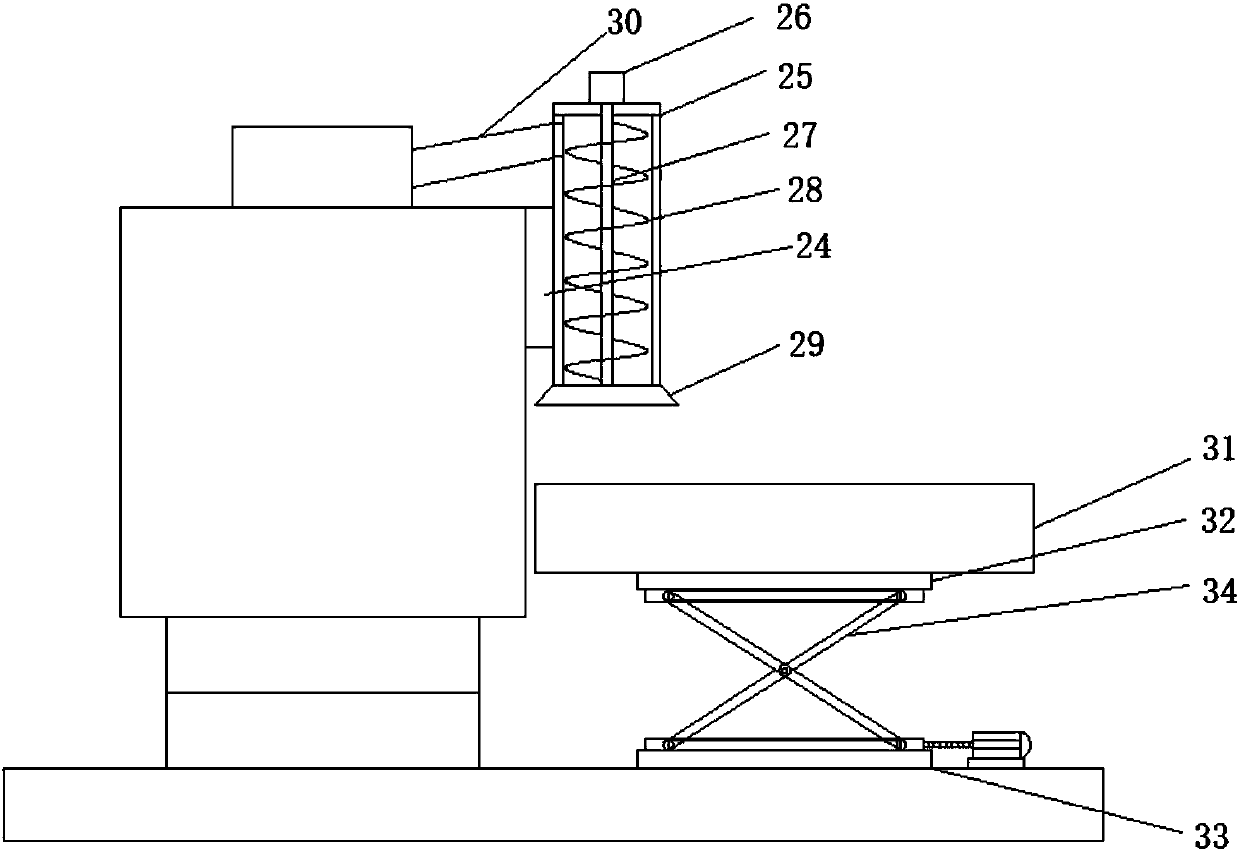

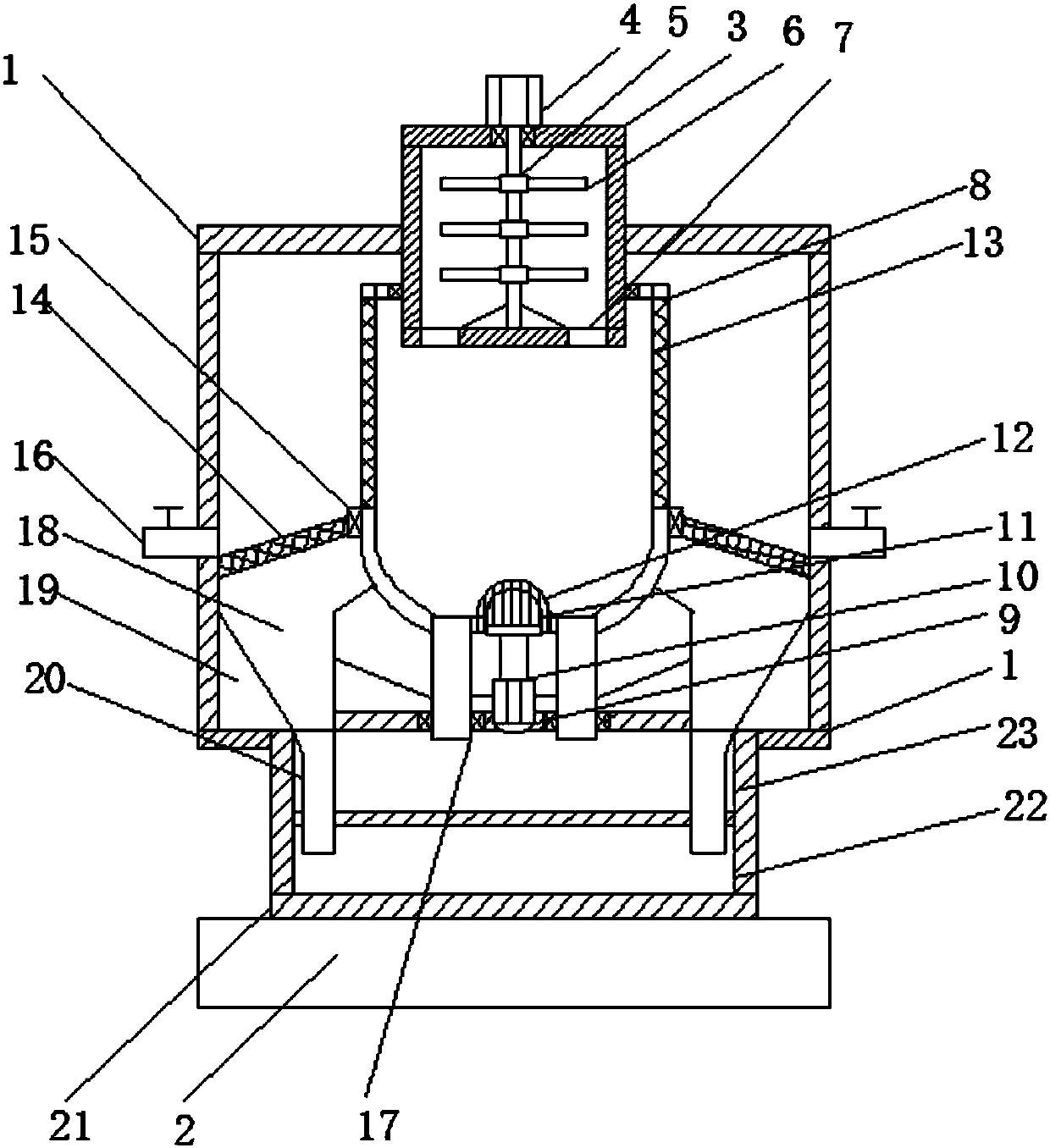

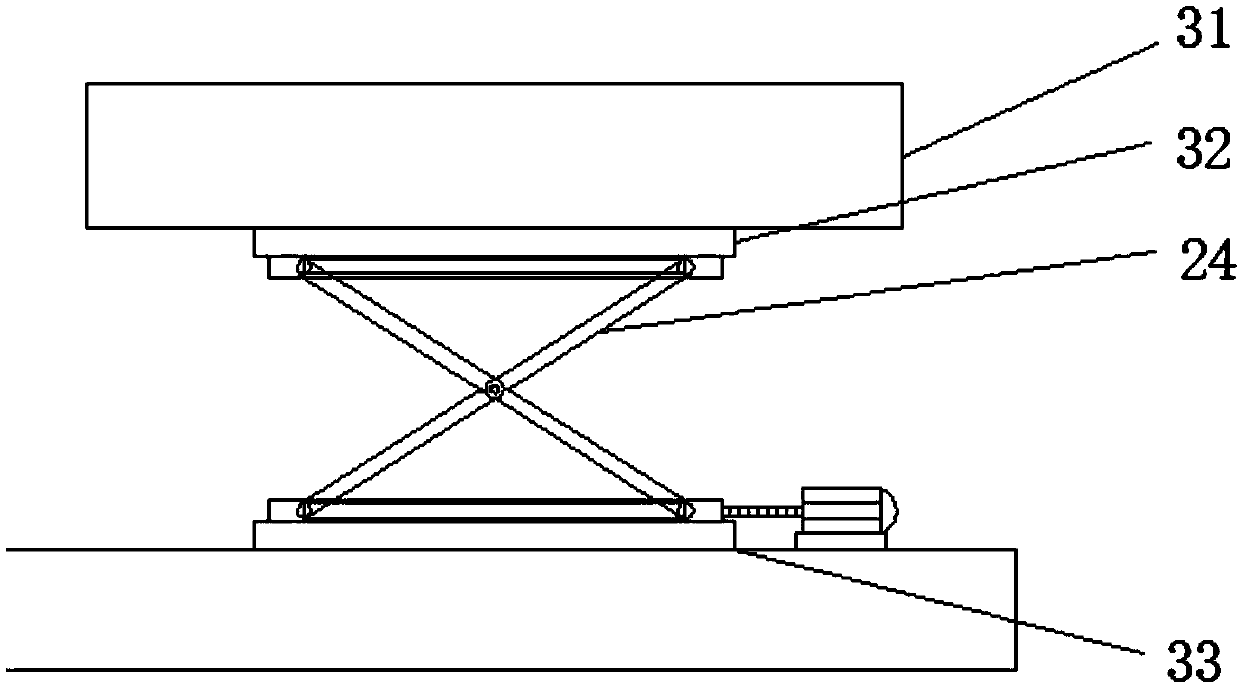

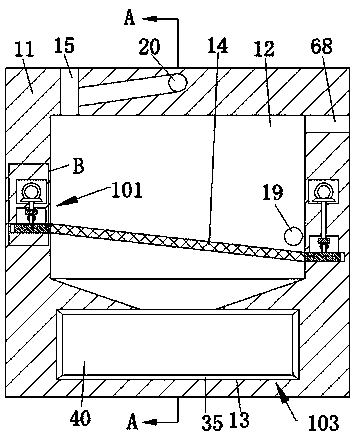

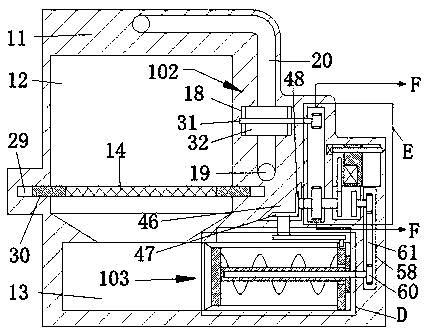

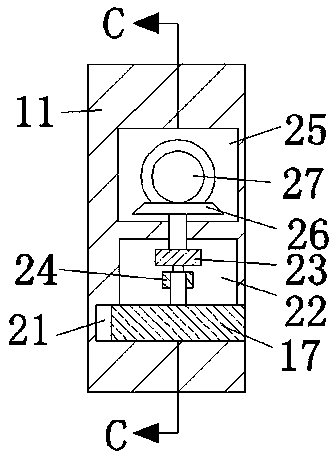

Automatic rock-like sample stirrer capable of preventing dust and uniformly stirring and stirring method

ActiveCN111001350AIncrease pressureResidue reductionMixing methodsTransportation and packagingRotational axisElectric machine

The invention discloses an automatic rock-like sample stirrer capable of preventing dust and uniformly stirring and a stirring method. The stirrer comprises a support for supporting and fixing a cylinder body; a pressurizing / pressure-relieving valve is arranged at the top of the cylinder body; a rotating shaft is mounted on the central axis of the cylinder body; the upper end of the rotating shaftis connected with an output shaft of a rotating motor; a stirring device and a threaded stirrer are fixed to the rotating shaft from top to bottom, the inclination direction of fan blades of the threaded stirrer is opposite to that of the stirring device, a solid storage hopper is arranged at the top of the cylinder body, an annular nozzle is installed on the inner wall of the cylinder body between the threaded stirrer and the stirring device, a discharge port is formed in the bottom center of the cylinder body; and a solid particle electric control sensor is arranged at a position, close tothe stirring device, in the cylinder body. According to the stirrer, dust is prevented from escaping, the stirring uniformity can be improved in the stirring process, powder lumps are prevented, automatic integration of feeding and stirring is achieved, the sample preparation efficiency and precision are improved, sample residues are reduced, and the sample quality is guaranteed.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

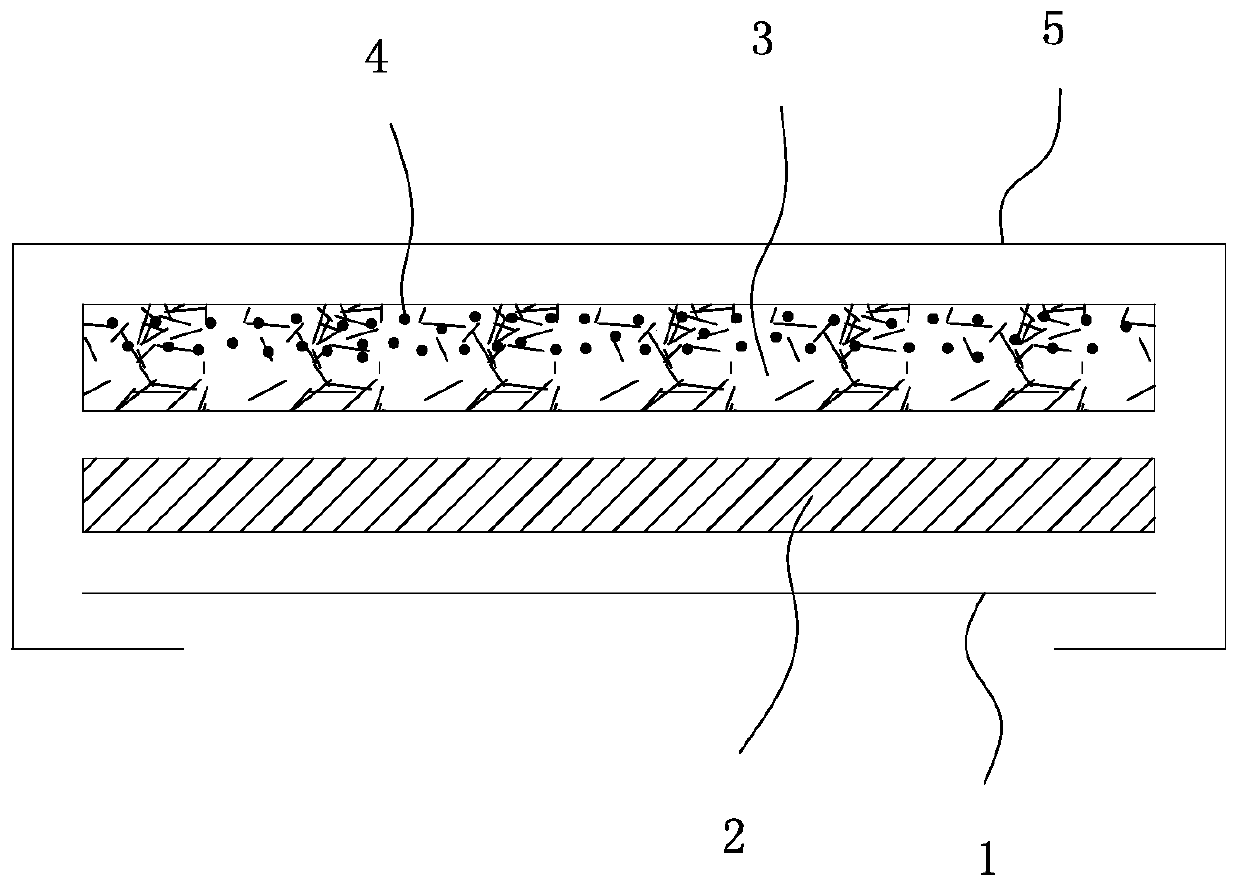

High absorptivity diaper core

InactiveCN106963562AImprove breathabilityImprove absorption and utilizationAbsorbent padsBandagesEngineeringPolymer

The invention discloses a high absorptivity diaper core. The core comprises a lower core, the lower core comprises first wood pulp dust-free paper, first fluffy cotton and first hydrophilic non-woven fabric which are pressed from top to bottom and formed, a first polymer layer is arranged in the first fluffy cotton in a clipped mode, the first polymer layer comprises first polymer water absorbent beads distributed evenly, the upper surface of the first hydrophilic non-woven fabric is provided with an upper core, the surface area of the upper core is 1 / 7 -2 / 3 of the surface area of the lower core, an adhesion layer is connected between the first hydrophilic non-woven fabric and the upper core, the upper core is adhered to the lower core, the upper core is smaller than the lower core, and therefore the thickness of the middle area of a diaper is increased, absorption quantity demanded of the middle portion of the core can be ensured, the thickness of the lower core can be reduced at the same time, the periphery of which the usage rate is low is light and thin, the permeability of the core is improved, and the usage amount of row materials of the core is saved, the middle portion of the core is centralized at the same time, and the absorption and utilization rate of the core can be improved.

Owner:广东恒一实业有限公司

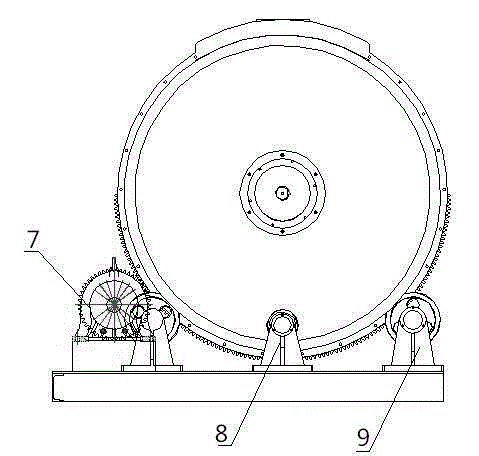

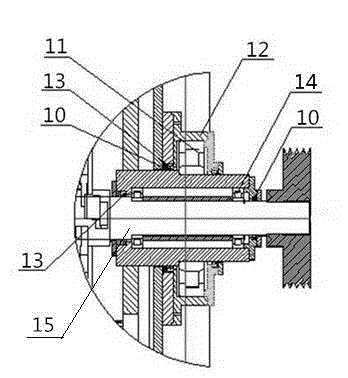

Rotary high-temperature superconducting-tube pyrogasification furnace for garbage

InactiveCN109423339AHigh pyrolysis gasification efficiencyImprove thermal conductivityGasification processes detailsRotary drum/kiln gasifiersFurnace temperatureSocial benefits

The invention relates to a rotary high-temperature superconducting-tube pyrogasification furnace for garbage. The rotary high-temperature superconducting-tube pyrogasification furnace is composed of four parts, i.e., a circular cylinder rotary furnace body, a rotary furnace body driver, a heater and a feeding machine. The rotary high-temperature superconducting-tube pyrogasification furnace is characterized in that the inner wall of the circular cylinder rotary furnace body is filled with metal stirring plates and a high-temperature mouse-cage-type superconducting heat transmitter. The heateruses gas produced by the cracking furnace for heating the superconducting-tube evaporation section of the high-temperature mouse-cage-type superconducting heat transmitter in the exterior of the furnace body, and generated radiant heat can be rapidly transmitted to garbage stirred in the furnace via high-temperature superconducting heat-transmitting pipes, thereby completing rapid, high-efficiencyand continuous pyrogasification of the garbage. The pyrogasification furnace provided by the invention has high temperature and balanced furnace temperature, so the dangers of bonding, bulging, block-forming and coking of the garbage caused by local overheating in the furnace are effectively solved, the generation of flue gas is avoided, pollution of harmful substances released by cracked substances to the environment are shielded, and the generation of dioxin is suppressed; and solid residues produced after cracking can be used as a chemical raw material for manufacturing of active carbon, and social benefits and economic benefits are significantly improved.

Owner:西安美润环保工程技术有限公司 +1

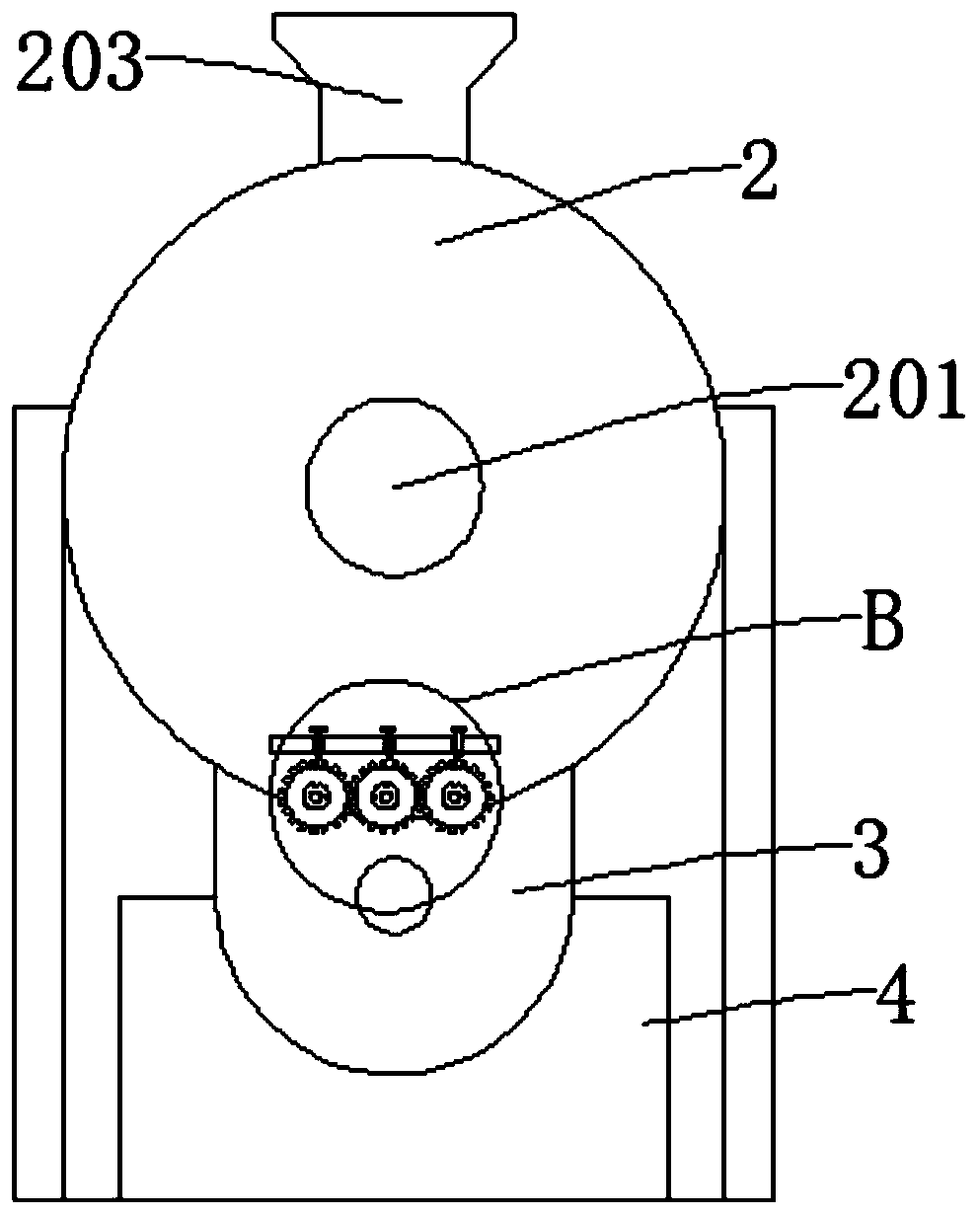

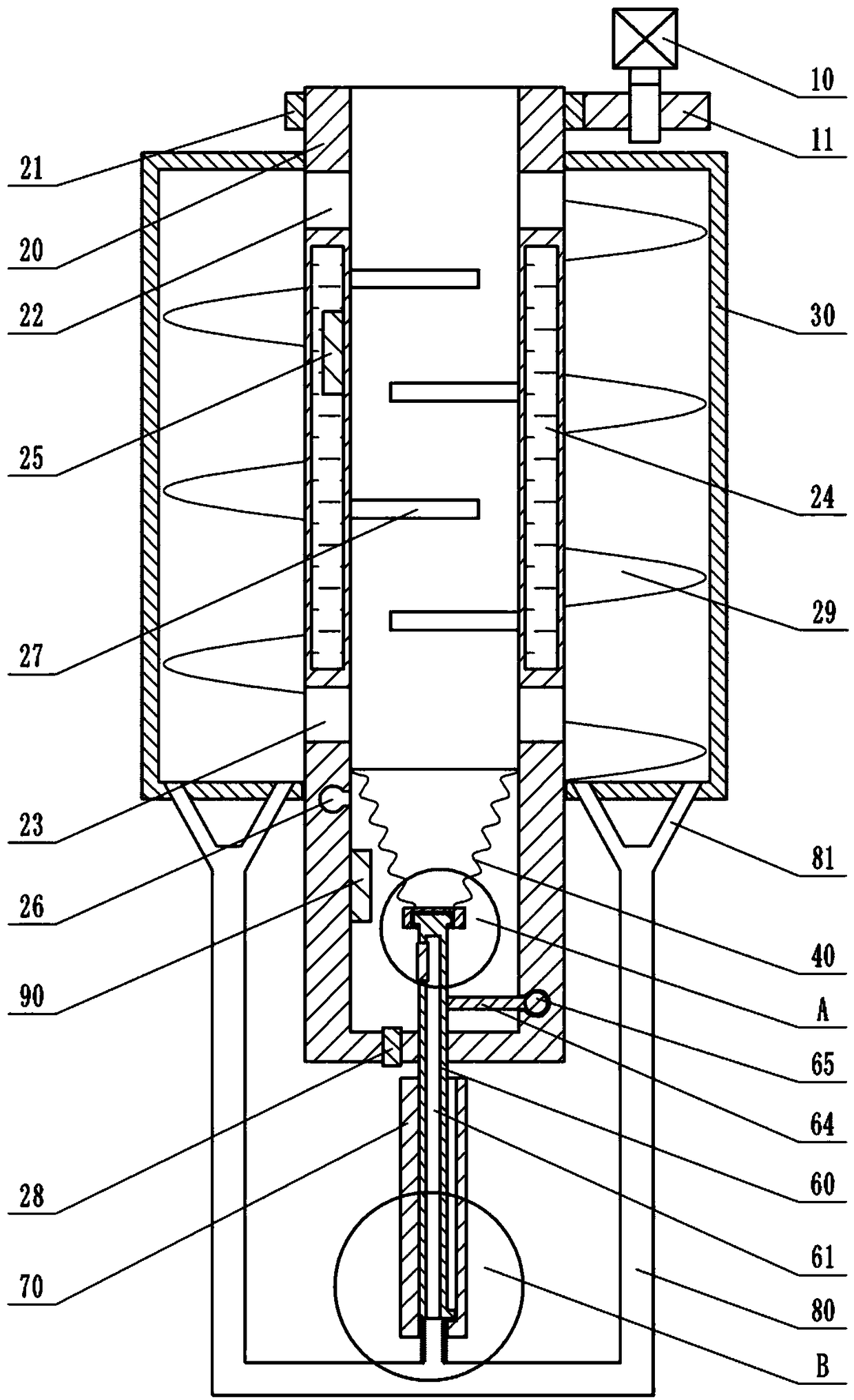

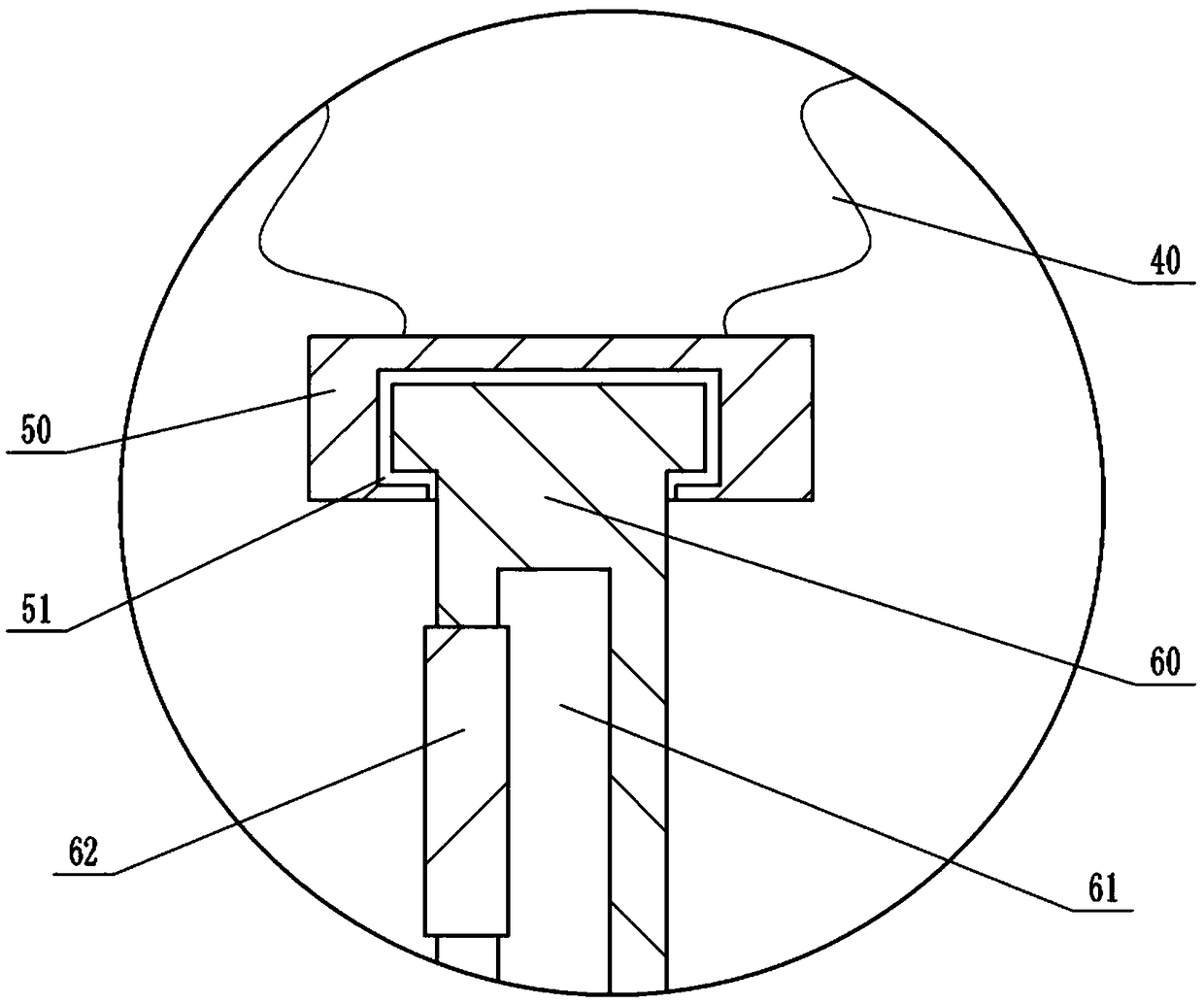

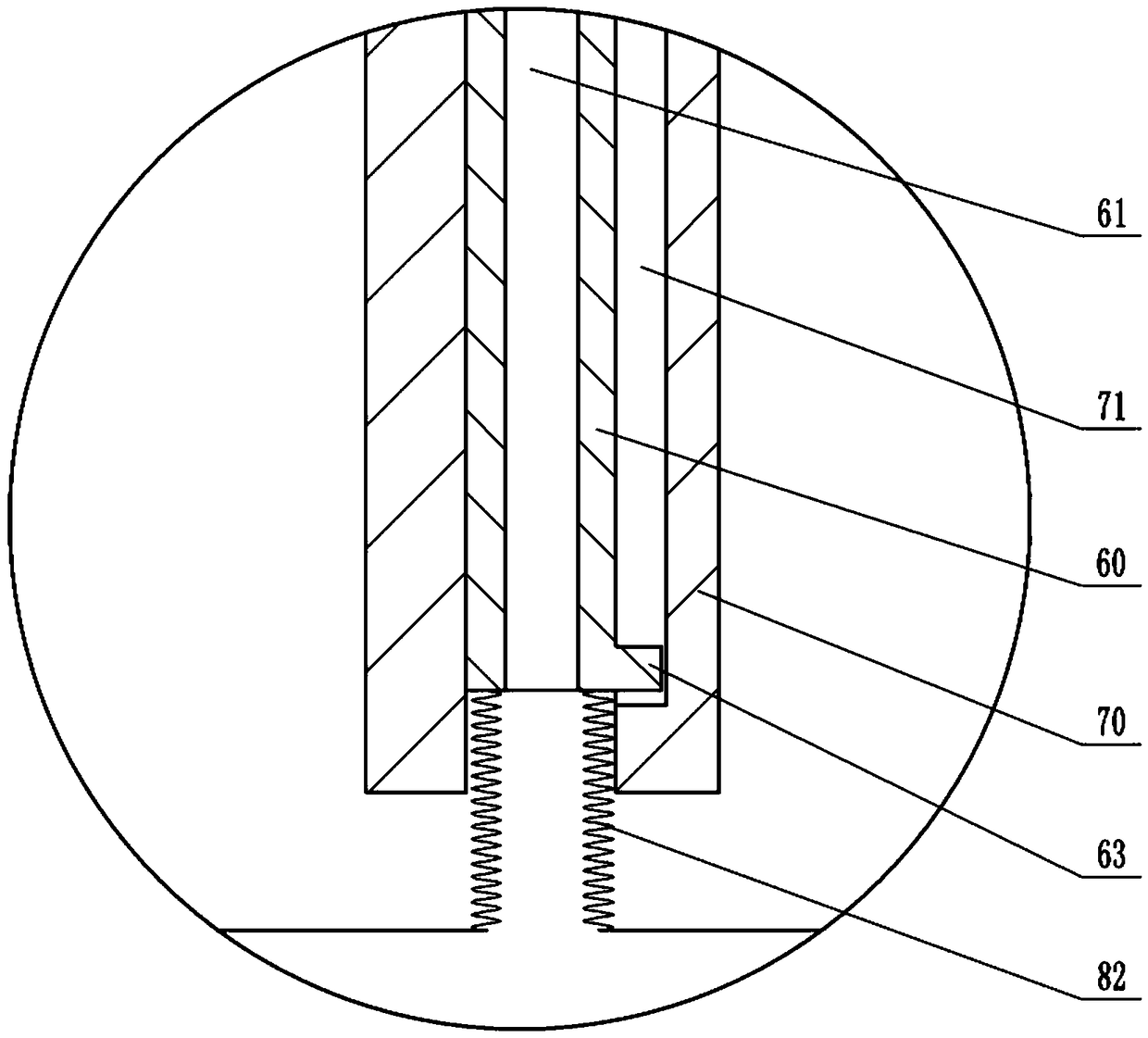

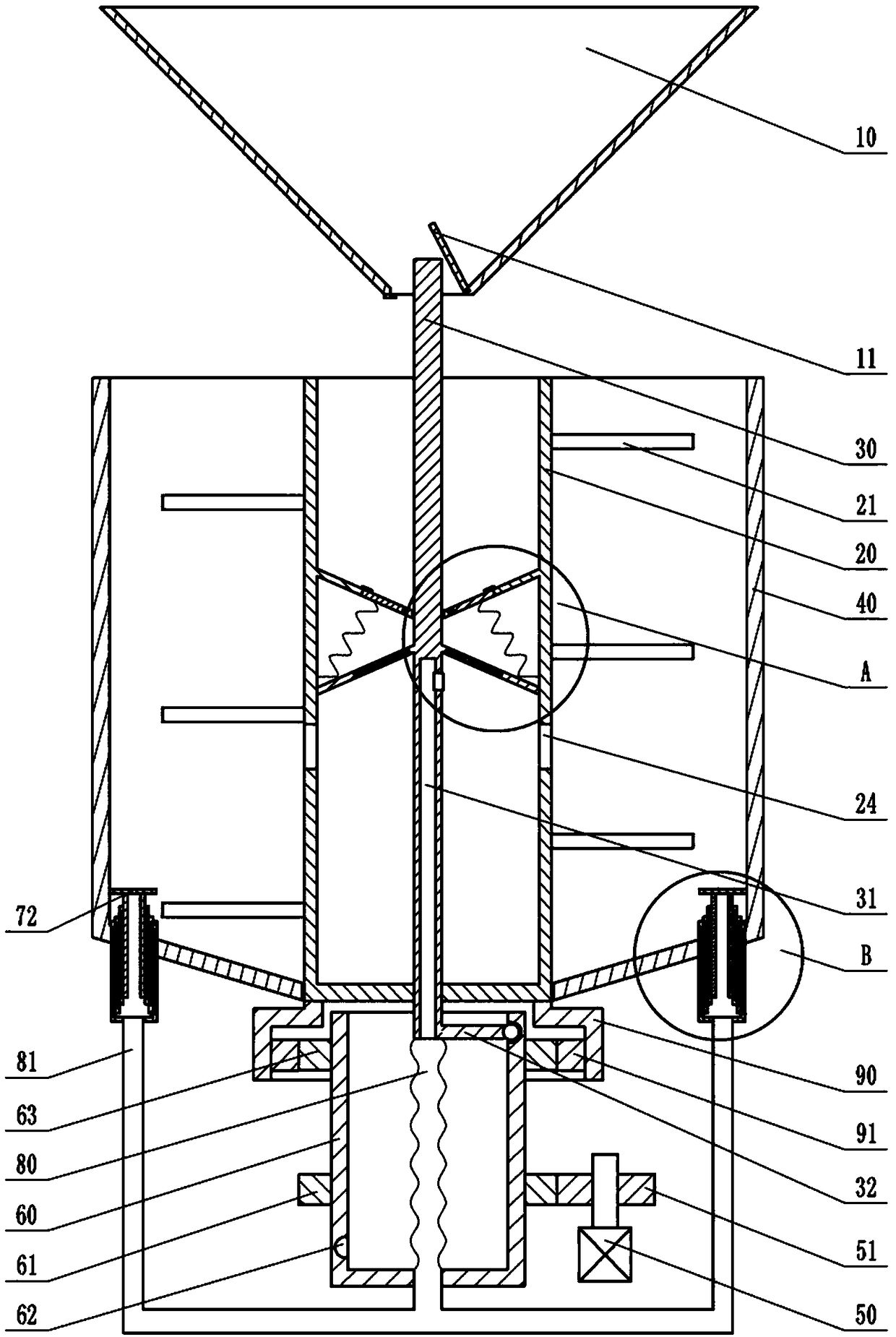

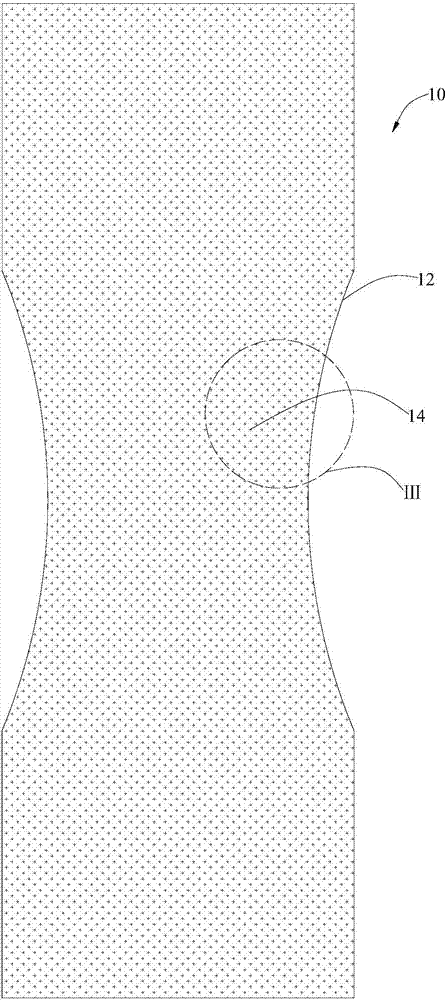

Bipyramid rotary superconducting waste cracking furnace

InactiveCN109424963AConducive to continuous cracking and gasificationLarge capacity reductionIncinerator apparatusActivated carbonFlue gas

The invention discloses a bipyramid rotary superconducting waste cracking furnace which is composed of a bipyramid superconducting isothermal rotary furnace body, a rotary furnace body driver, a heater and a feeding machine. The bipyramid rotary superconducting waste cracking furnace is characterized in that the bipyramid superconducting isothermal rotary furnace body is a bipyramid composite pipeisothermal superconducting rotary furnace body with two small ends and a thick middle composed of a metal inner pipe and a metal outer pipe which are concentric, the thick portion in the furnace bodyis a superconducting working medium heating pool, and a circumferential heating zone provided with heat exchange sheets is arranged on the periphery of the heating pool. The heater heats the furnacebody outside the furnace body through self-produced gas of the waste cracking furnace, produced radiant heat is rapidly and evenly transferred to waste in the rotary furnace through the circumferential heating zone, the heating pool and the bipyramid composite pipe isothermal superconducting rotary furnace body, and therefore the waste is rapidly and efficiently cracked and gasified. By means of the cracking furnace, the risk that bonding, bulging, blocking and coking are caused by local overheating of waste in the furnace is avoided, flue gas is prevented from being produced, pollution of harmful substances released by cracked materials to environment is avoided, dioxin emission is effectively restrained, and environment is protected; and cracked solid waste can be used as activated carbon for preparing chemical raw materials, and the overall economic benefits are obvious.

Owner:西安美润环保工程技术有限公司 +1

Road crack pouring machine

ActiveCN110924281AEasy accessEasy to dryRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses a road crack pouring machine, and belongs to the field of crack pouring machines. A road crack pouring machine comprises a bottom plate, the bottom of the bottom plate is rotationally connected with first rolling wheels, the outer wall of the bottom plate is connected with a fixing plate, the inner wall of the fixing plate is connected with a first rotating shaft, and the outer wall of the first rotating shaft is connected with second rolling wheels; the top of the bottom plate is connected with a stirring cylinder through a fixing rod, a stirring part is connected intothe stirring cylinder, and a discharging hole is formed in the bottom of the quantifying cylinder. A discharging box is further fixedly connected to the outer wall of the top of the bottom plate, a discharging pipe is further connected to the bottom of the discharging box, and a telescopic pipe is connected to the bottom of the discharging pipe; the bottom plate is further connected with a shovelplate in a sliding mode. According to the crack pouring device, impurities in cracks can be removed firstly, the crack pouring effect is enhanced, the cracks can be flattened in time after crack pouring, the pavement subjected to crack pouring is firmer. Meanwhile, asphalt can be stirred, the asphalt is prevented from being accumulated and solidified together, and the crack pouring device is better used.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sandstone separation device capable of conveying materials conveniently and conducting multi-stage material screening

The invention discloses a sand and stone separation device capable of conveniently conveying materials and multi-stage brushing and selecting materials. Conveying motor, the bottom end of the conveying motor is equipped with a conveying shaft, the spiral dragon is installed on the conveying shaft, and the top of the conveying cylinder is provided with a conveying pipe connected with the feeding chamber , the rear end of the base is equipped with a material box, the bottom plane of the material box is provided with an upper fixing plate, the upper plane of the base is equipped with a lower fixing plate, the upper fixing plate and the lower fixing plate There is a lifting connecting rod between them; the beneficial effect of the present invention is: through the double-stage sieving material treatment, the stones, coarse sand and fine sand are screened out separately, and separated and collected, and processed by the required building construction.

Owner:杨燕萍

White tea processing technology

The invention belongs to the technical field of tea processing and specifically discloses a white tea processing technology. The white tea processing technology comprises the following processing steps: 1) picking; 2) screening; 3) wilting: spreading tea, controlling the thickness to be 1.5-2cm, and controlling the wilting water loss rate to be 32-38%; 4) rolling: preparing a sponge ball having the diameter of 0.2-0.5cm, and embedding quartz having the particle size of 0.12-0.25cm into the sponge ball; heating the sponge ball to 58-65 DEG C; adding the heated sponge ball and the tea treated inthe step 3) into a rolling machine, wherein the mass fraction ratio of the sponge ball to the tea is controlled to be 1:(1.5-3); controlling the rolling rotation speed to be 26-32 r / min, rolling for4-6 minutes, and performing pressure-free rolling; 5) drying: drying the tea treated in the step 4) in a drying machine, controlling the temperature to be 90-96 DEG C for 6-10 minutes; spreading for cooling for 12-16 minutes after drying completion, and after-baking at an after-baking temperature of 80-88 DEG C. The white tea prepared according to the technology disclosed in the invention has thefixed shape and is strong and persistent in pekoe flavor.

Owner:ZUNYI ZHENGAN LIXIA TEA IND CO LTD

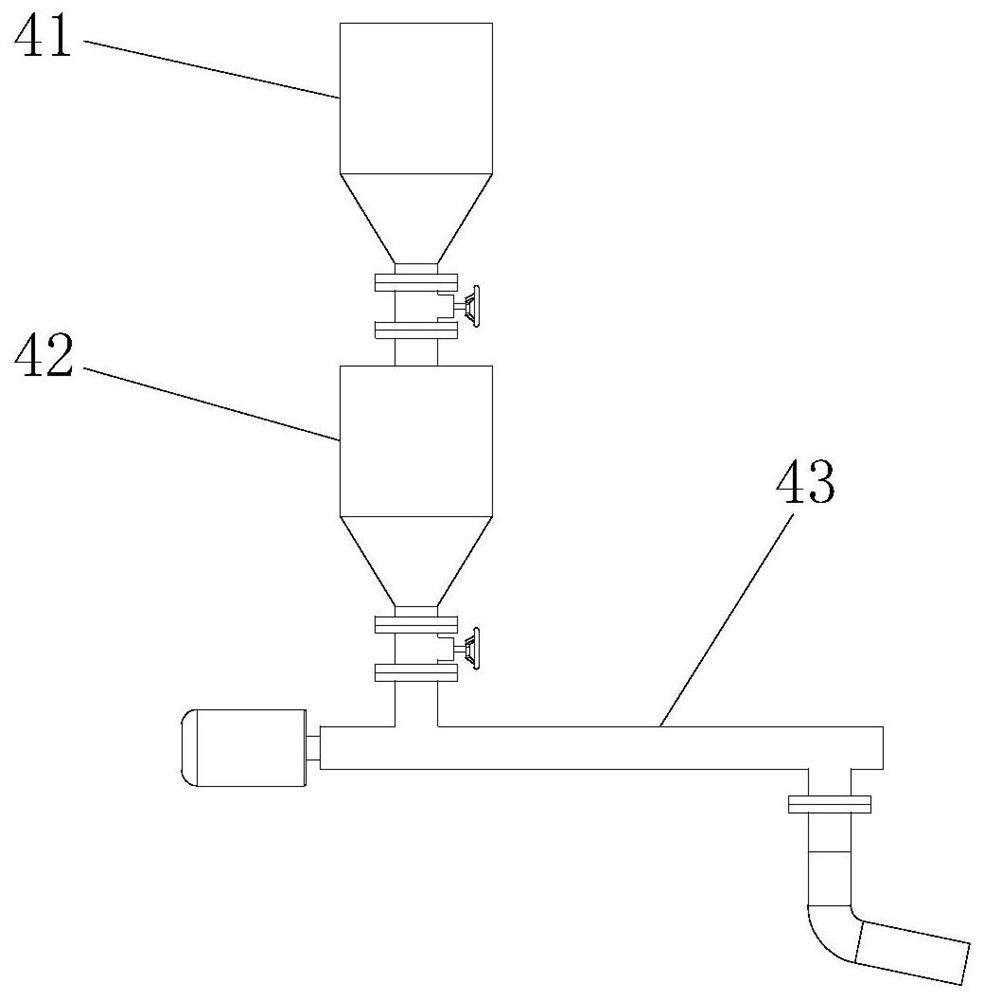

Composite fertilizer production device

PendingCN108686565ASimple structureLow costTransportation and packagingMixer accessoriesAgricultural engineeringFertilizer

The invention belongs to the technical field of fertilizer processing, and particularly discloses a composite fertilizer production device. The composite fertilizer production device comprises a powerunit, a stirring unit, a cleaning unit and a discharging unit, wherein the discharging unit comprises a hopper and an ejector rod; the hopper is hinged to a door; the stirring unit comprises an outerbarrel and an inner barrel; a stirring rod is fixed on a side wall of the inner barrel; the power unit comprises a transmission mechanism, a rotating barrel and a motor; the transmission mechanism isused for driving the rotating barrel and the inner barrel to rotate simultaneously; a closed curved groove is formed in the inner wall of the rotating barrel; a connecting rod of which one end is clamped in the curved groove is fixed on the ejector rod; the cleaning unit comprises an annular scraper blade and a telescopic mechanism; a cavity is formed in the lower portion of the ejector rod; a through opening is formed in the ejector rod; a universal joint is arranged at a connection position of a rotating center on the bottom of the rotating barrel; a corrugated tube is connected between theuniversal joint and the lower portion of the ejector rod; and an air tube is connected between the universal joint and the telescopic mechanism. By the device, the problem that excrement is attachedto the inner wall of the device and is difficult to clean can be solved.

Owner:遵义大兴复肥有限责任公司

Fire grate of incinerator with laterally arrayed fins

The invention relates to a fire grate of an incinerator with laterally arrayed fins. The fire grate is characterized in that a fixed cross beam mounted on a boundary beam penetrates through a row of slots for fixing the tail part of fire grate segments so as to form a fixed fire grate board, and a moveable cross beam mounted on a pull rod penetrates through a row of slots for moving the tail part of the fire grate segments so as to form a movable fire grate board, wherein the movable fire grate board is forward superposed with the fixed fire grate board and are arrayed at interval to form the fire grate; each fire grate segment is provided with a primary air hole; the front end of the upper surface of each fire grate segment is provided with fins; the fins on the same row of fire grate segments are laterally arranged so as to form a toothed structure; and the fins on two adjacent fire grate segments are staggered longitudinally. The fire grate can scatter, loosen, stir and mix the rubbishes in the incinerator in all directions, avoid the caking and blocking of the rubbishes on the fire grate segments, promote the drying and burning efficiency of the rubbishes and shorten the drying time. The fire grate is in favor of rapidly burning rubbish and can be used as both forwards and backwards fire grates.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Soybean meal drying roller for feed

The invention discloses a soybean meal drying roller for feed. The soybean meal drying roller comprises a pretreatment unit and a drying unit, wherein the pretreatment unit comprises a vibrating screen and a supporting column, the supporting column is arranged at the bottom of the vibrating screen, and the vibrating screen is connected with a driving mechanism; and the drying unit comprises an outer cylinder, an inner cylinder and a rotating shaft, the inner cylinder is rotatably arranged in the outer cylinder, a heating element is arranged between the inner cylinder and the outer cylinder, the rotating shaft is rotatably arranged in the inner cylinder, the rotating shaft is connected with stirring blades, and the vibrating screen communicates with an inner cavity of the inner cylinder. The vibrating screen of the pretreatment unit can drive materials to vibrate to scatter caked or clustered materials in advance so as to guarantee the later drying uniformity, the materials enter the drying unit, the inner cylinder can drive the materials to rotate, the heating element heats the inner cylinder, and the inner cylinder exchanges heat with the materials so as to dry the materials; andmeanwhile, the rotating shaft is used for driving the stirring blades to stir the materials, the material heating uniformity is guaranteed, the drying effect is enhanced, convenience is provided for subsequent feed production procedures, and the finished product quality is improved.

Owner:广东省佰益科技有限公司

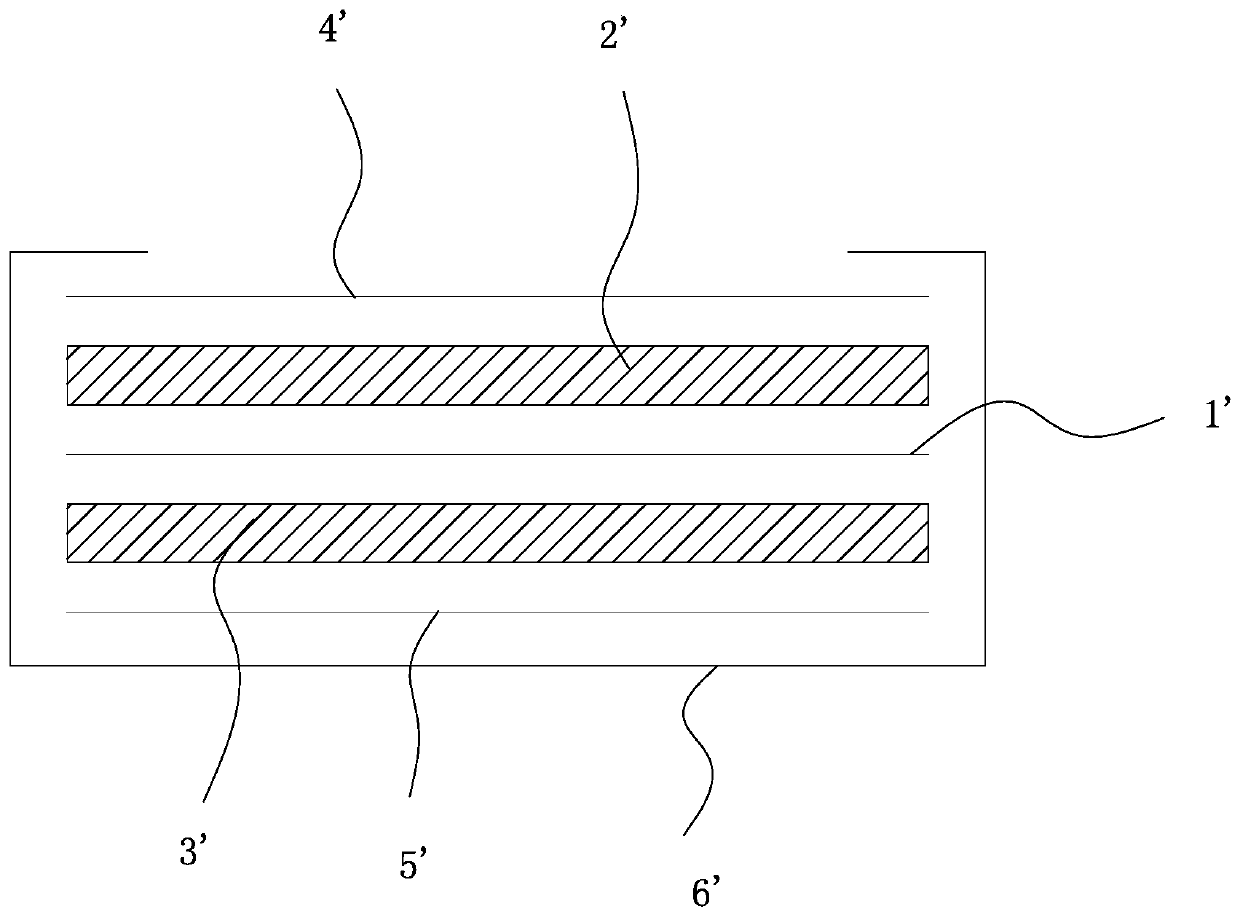

Absorbing product core body and manufacturing method thereof and absorbing product

Owner:SHANDONG SUN HOUSEHOLD PAPER LTD

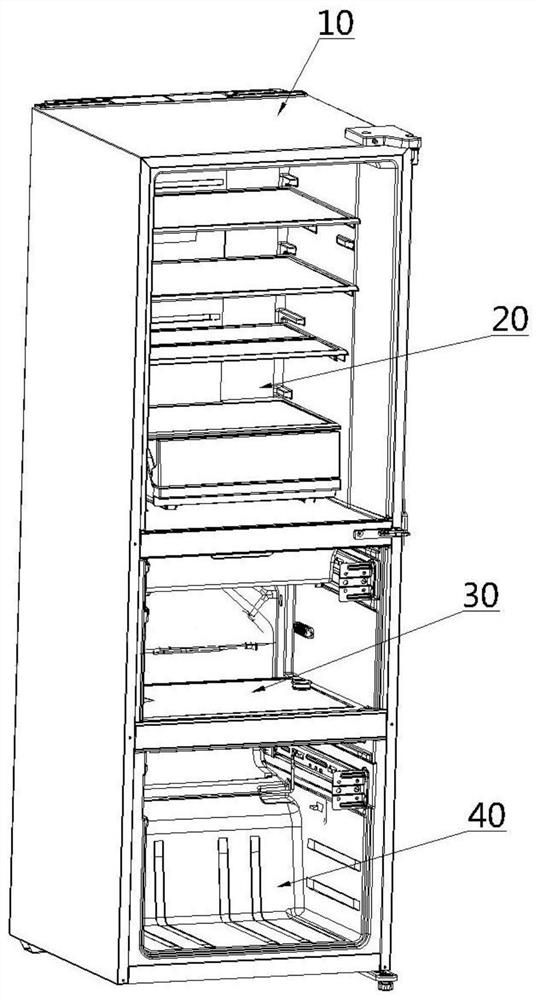

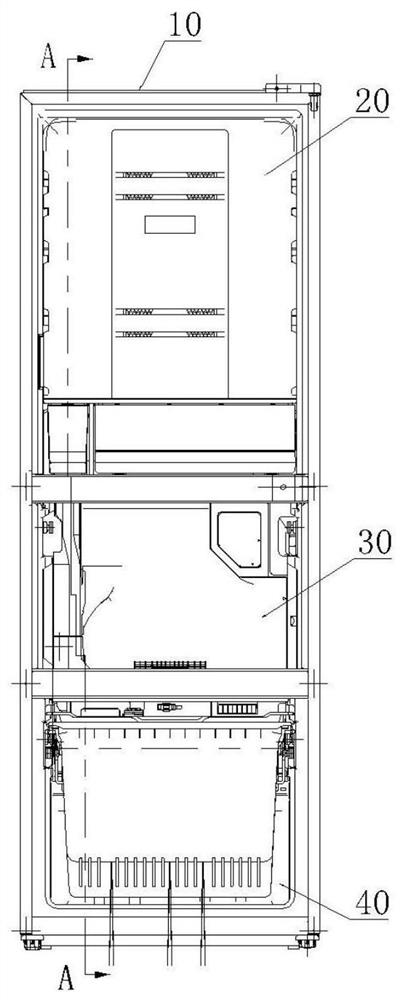

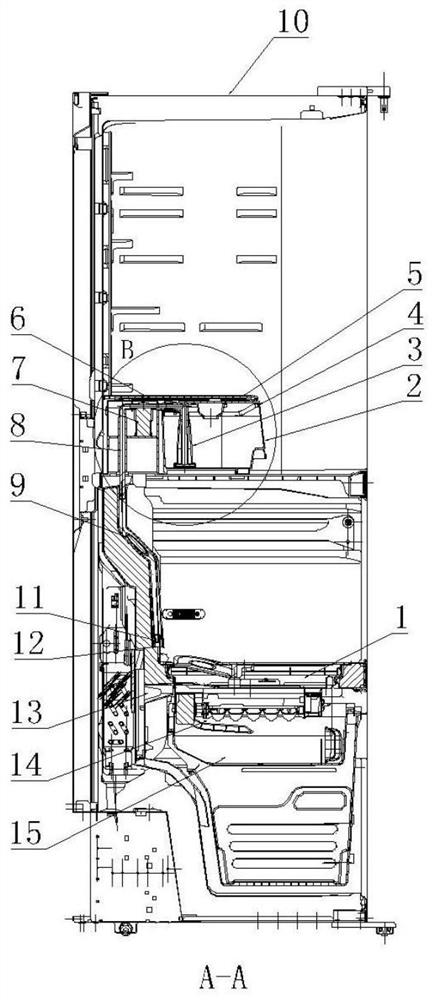

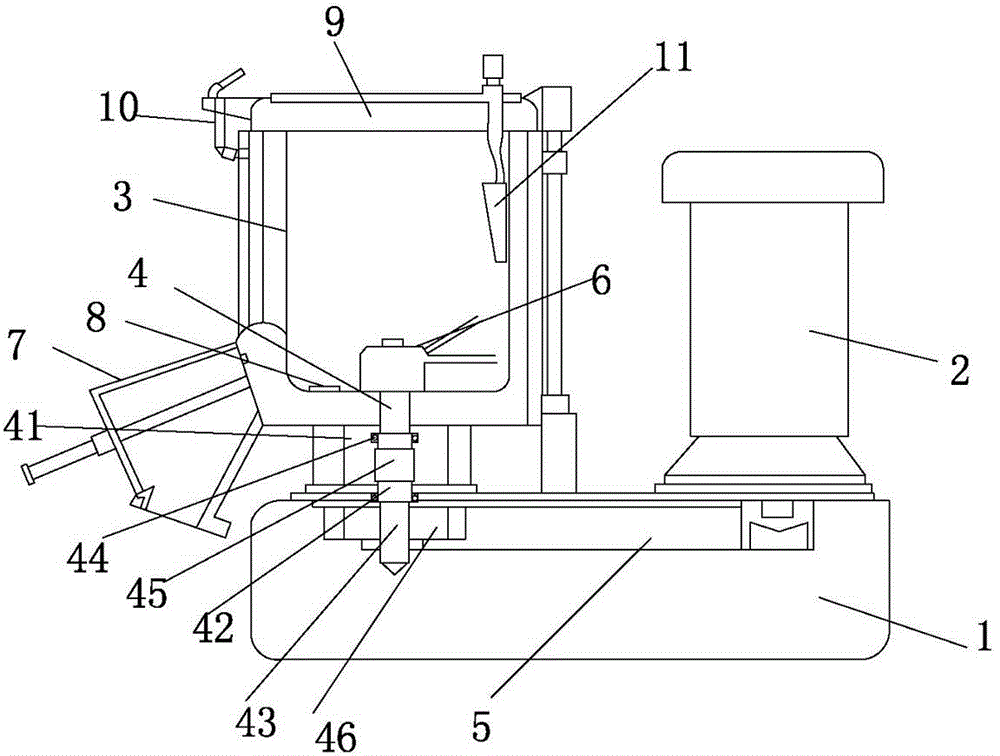

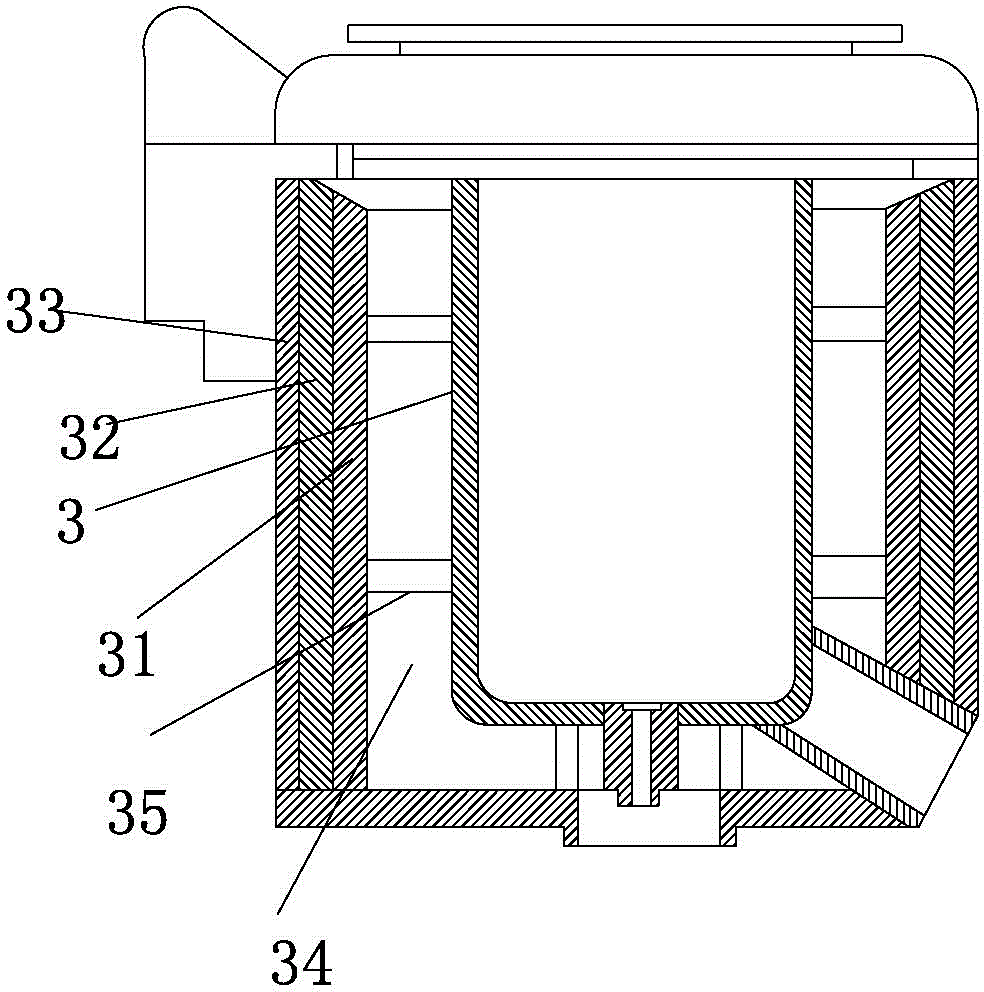

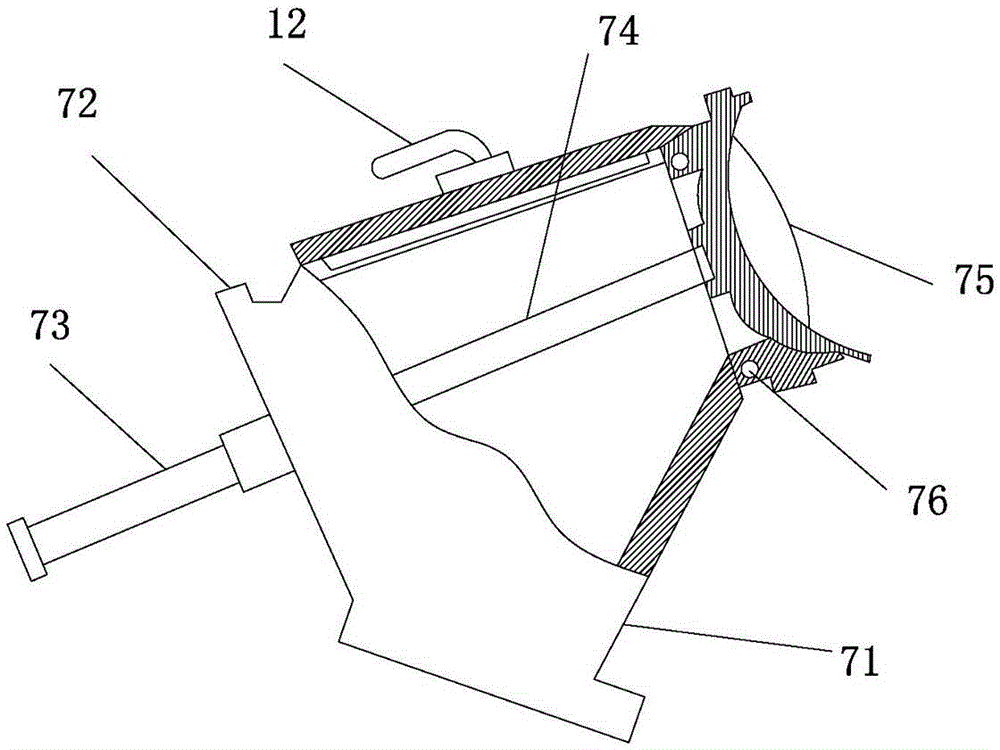

Refrigerator with ice maker and ice turning control method of ice maker

PendingCN113137820APrecise handlingEasy to cleanDomestic cooling apparatusLighting and heating apparatusIceboxEngineering

The invention discloses a refrigerator with an ice maker and an ice turning control method of the ice maker. The refrigerator comprises a refrigerator body provided with a low-temperature storage chamber, a partition plate, the ice maker, an infrared sensor and a controller; the partition plate is arranged on an inner container of the refrigerator body, and the ice maker is arranged in the low-temperature storage chamber and comprises an ice maker support arranged on the partition plate, ice cube trays detachably arranged in the ice maker support, and an ice turning motor arranged at one end of the ice maker support; and the infrared sensor is arranged on the partition plate and is used for detecting the temperature of the ice cube trays, and the controller is connected with the infrared sensor and the ice turning motor correspondingly and is used for acquiring the temperature and the ice making time detected by the infrared sensor and judging whether the ice turning motor executes ice turning operation or not according to the temperature and the ice making time detected by the infrared sensor. According to the refrigerator with an ice maker and the ice turning control method of the ice maker, the temperature of ice in the ice cube trays is directly sensed through the infrared sensor, so that the current ice making situation is accurately judged, then the ice maker is accurately controlled, the situation that ice blocks in the refrigerator are lumped due to the fact that the ice is turned over when ice making is not successful is avoided, and the ice making efficiency is greatly improved.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Plastic thin film raw material mixing machine

InactiveCN104056563AStir wellImprove mixing efficiencyRotary stirring mixersMixer accessoriesWater vaporEngineering

The invention discloses a plastic thin film raw material mixing machine which comprises a base, wherein a motor and a mixing chamber are arranged on the base; a transmission device is arranged at the bottom of the mixing chamber; the lower end of the transmission device is connected with an output shaft of the motor through a transmission belt; the upper end of the transmission device extends into the mixing chamber; a stirring paddle is arranged at the upper end of the transmission device; a clamping sleeve layer, a heat preservation layer and an outer sleeve are arranged on the side wall of the mixing chamber in sequence from inside to outside; a cavity for containing water vapor or cooling water is formed between the clamping sleeve layer and the side wall of the mixing chamber; a material discharging device is arranged on the outer side of the mixing chamber. By the adoption of the mixing chamber with a heat preservation or cooling function, when raw materials are mixed and heated, the vapor is fed into the cavity for containing the water vapor or the cooling water; after the vapor is heated, the raw materials are added into the mixing chamber, so that the mixed raw materials can be fully stirred; the stirred mixing efficiency is high, the mixing is uniform; when the high-temperature mixed raw materials are required to be cooled, the cooling water is fed into the cavity, so that the high-temperature materials can be prevented from being grouped and blocked.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Atmosphere-controllable rotary kiln and implementation method thereof

PendingCN112146433AEvenly heatedAvoid lumpsRotary drum furnacesMaintainance of heating chambersProcess engineeringContinuous flow

The invention discloses an atmosphere-controllable rotary kiln which comprises a rotary kiln body. The rotary kiln body comprises a furnace tube; stirring strips are arranged on the inner wall of thefurnace tube; a feeding mechanism is arranged at the feeding end of the rotary kiln body; a discharging mechanism is arranged at the discharging end of the rotary kiln body; the joint of the rotary kiln body and the feeding mechanism is sleeved with a kiln opening inert gas protection device; and the joint of the rotary kiln body and the discharging mechanism is sleeved with a kiln tail inert gasprotection device. The invention further discloses an implementation method of the controllable-atmosphere rotary kiln. According to the atmosphere-controllable rotary kiln and the implementation method thereof provided by the invention, the stirring strips are arranged on the inner wall of the furnace tube and can indirectly drive powder to be stirred along with the rotation of the furnace tube,so that the powder is in a continuous flowing state in the furnace tube, the whole powder is heated more uniformly, the agglomeration of the powder is avoided, the contact surface of the powder and reaction gas in the kiln is increased, the reaction is more sufficient, and the reacted powder has high purity and few impurities.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Biomass gasification furnace with anti-accumulation effect

ActiveCN110734789AAvoid lumpsFast fallWaste based fuelGranular/pulverulent flues gasificationProcess engineeringBiomass gasifier

The invention discloses a biomass gasification furnace with an anti-accumulation effect. The biomass gasification furnace comprises a gasification furnace, wherein a gasification chamber is arranged in the gasification furnace; an ash storage cavity is formed in the lower side of the gasification chamber in a communicating manner; a filter plate is arranged on the inner lower side of the gasification chamber; the filter plate has a high left part and a low right part; the left end of the upper wall of the gasification chamber is communicated with a feeding hole with an upward opening; a biomass raw material is input into the gasification chamber through the feeding hole and falls on the left end of the upper end surface of the filter plate; and shaking devices are arranged on the left sideand the right side of the filter plate. According to the invention, raw materials are shaken and circularly fall off, so efficiency reduction caused by caking of the raw materials in the gasificationprocess is prevented, and generated waste materials can quickly drop; meanwhile, the stored waste materials can be continuously scraped off and can be pushed out at a time, so reduction in storage space caused by adhering of the waste materials to the inner wall of the storage cavity is prevented and influence of storage space reduction on later use is avoided; and workers do not need to take outthe waste materials, so working intensity is reduced.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

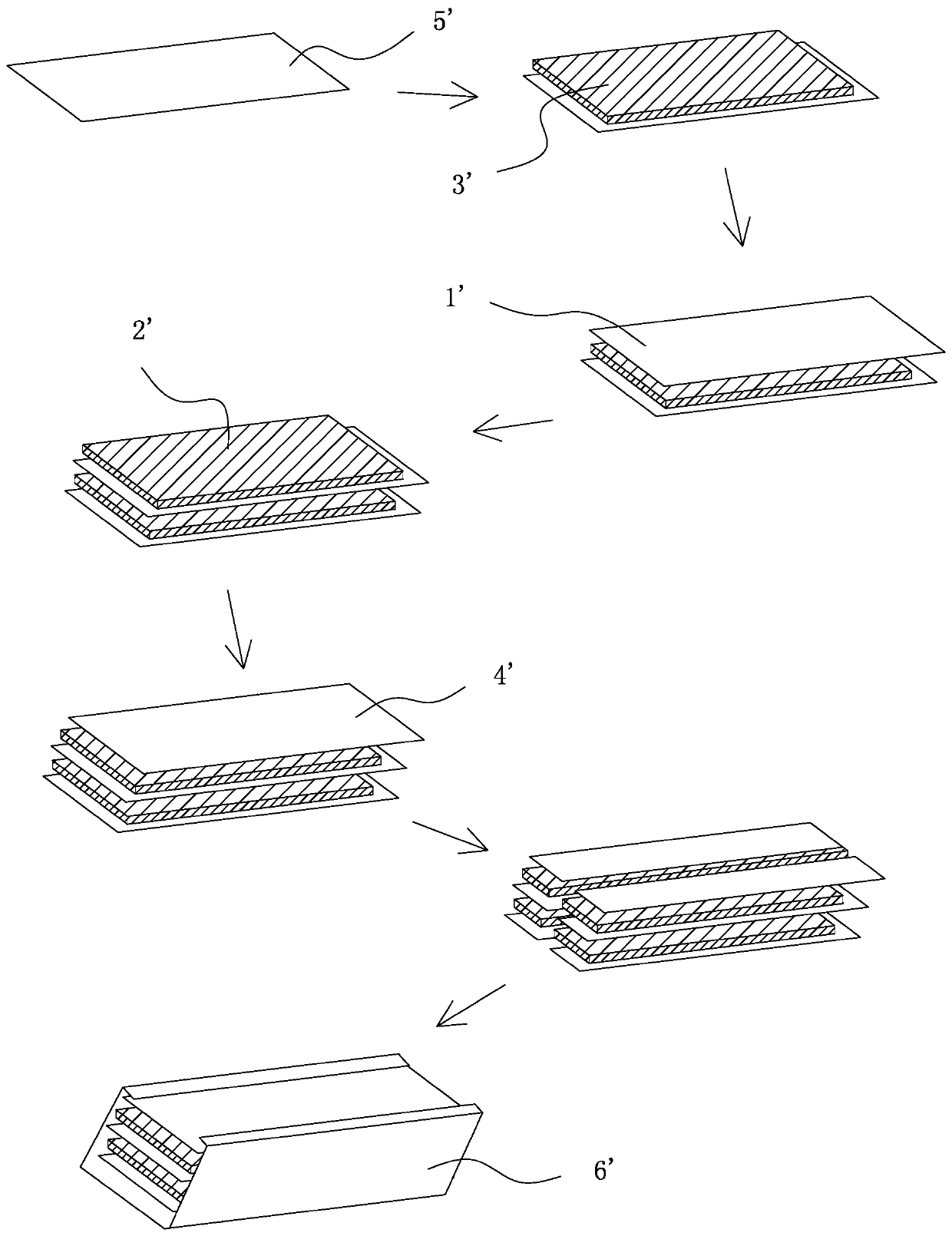

Preparation method for improved composite core

ActiveCN110547909AGuaranteed ultra-thinReduce compound processAdhesive articlesAbsorbent padsPolymer scienceNonwoven fabric

The invention relates to the field of disposable sanitary products, in particular to a preparation method for an improved composite core. The problems of a complicated processing technology and high processing cost of a composite core in the prior art are mainly solved through the preparation method. The preparation method includes the following steps: (1) preparing non-woven fabric; (2) adding apolymer water-absorbing resin material to the non-woven fabric obtained in the step (1); (3) preparing bulk non-woven fabric, and spraying the polymer water-absorbing resin material to the top surfaceof the bulk non-woven fabric; (4) compounding the lower surface of the bulk non-woven fabric on the upper surface of the product obtained in the step (2); (5) cutting the product obtained in the step(4) so as to form a single rolled material with a small width; (6) conveying the product obtained in the step (4) in a continuous mode; (7) preparing underlayer non-woven fabric, and then compoundingthe underlayer non-woven fabric with the top surface of the bulk non-woven fabric; and (8) bending the areas, which are not adhered to the bulk nonwoven fabric, at two transverse sides of the underlayer non-woven fabric obtained in the step (7) downward and inward for coating so as to adhere the areas to the two transverse sides of the lower surface of the non-woven fabric.

Owner:CHIAUS FUJIAN IND DEV

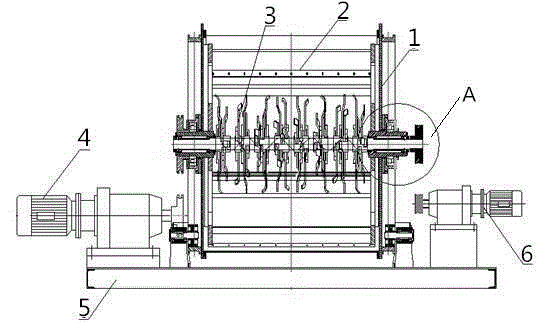

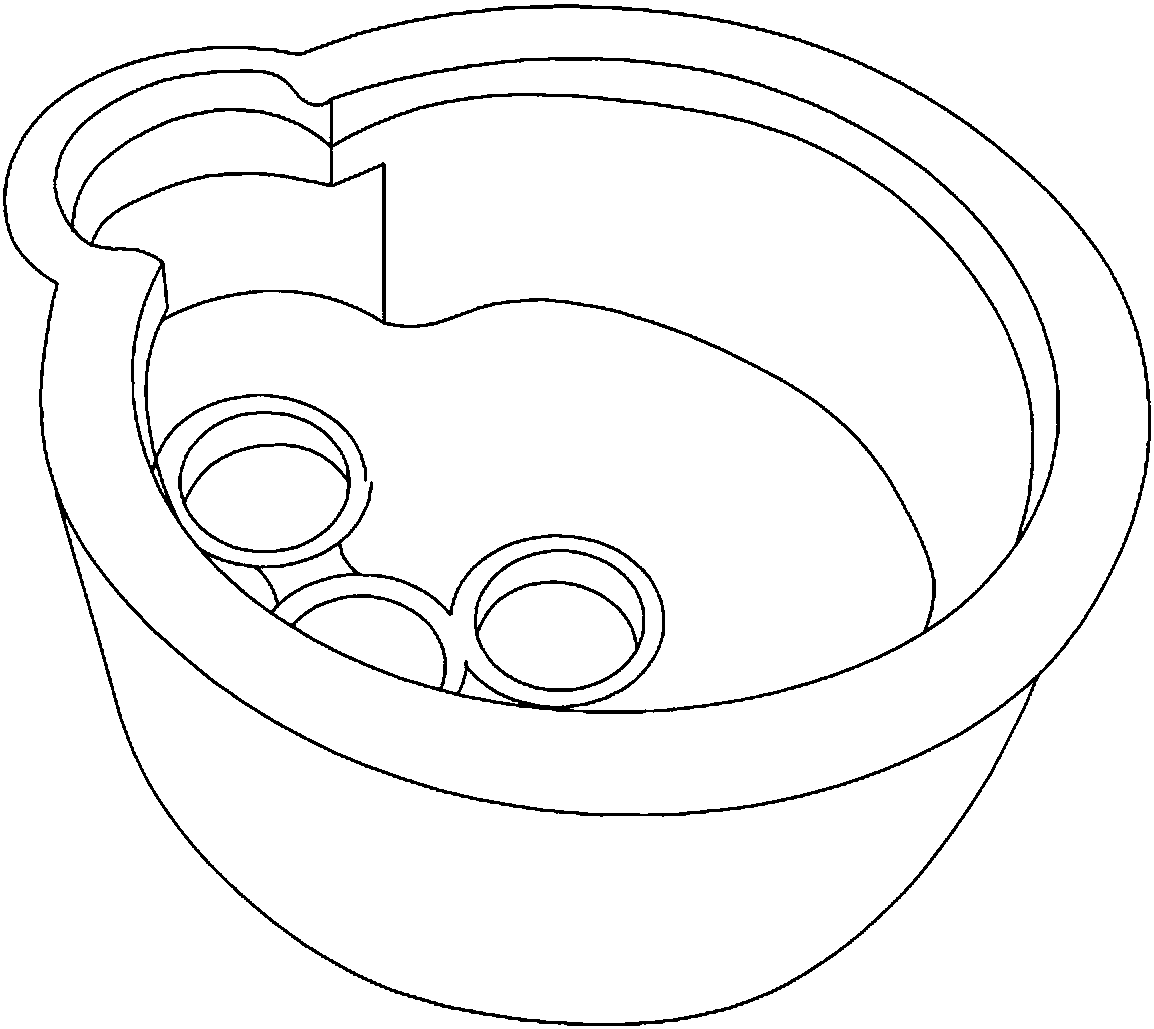

Mouse cage stirring machine

InactiveCN104874309ASolve the phenomenon of uneven mixingAvoid lumpsRotating receptacle mixersTransportation and packagingWater leakageDrive shaft

The invention discloses a mouse cage stirring machine and belongs to the technical field of stirring machines. The mouse cage stirring machine comprises a housing, a stirring mechanism and a crushing mechanism, wherein the housing is a housing of a cylindrical structure, and a rectangular material inlet-outlet is formed in the housing. A turnover mechanism for driving the housing to turn over is arranged on the side face of the housing. The stirring mechanism comprises a stirring plate and two driving plates arranged symmetrically, wherein the stirring plate is arranged between the driving plates, and the stirring mechanism is driven by a stirring machine motor. The crushing mechanism comprises a crushing cutter and a driving shaft and is fixed to the stirring mechanism through a second bearing. The mouse cage stirring machine simultaneously uses the crushing mechanism and the stirring mechanism to solve the phenomenon of uneven stirring of the stirring machine, and material blocking is avoided while stirring time is shortened. The problem that water leakage and material leakage occur on a sealing door and the end face of the stirring machine is solved through a framework oil seal and a macromolecule polyethylene ring seal.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU

Breeding equipment capable of improving growth quality and survival rate of koi carps and breeding method

InactiveCN112352726AAvoid lumpsGuaranteed individual sizeClimate change adaptationPisciculture and aquariaAnimal scienceCarp

The invention discloses breeding equipment capable of improving the growth quality and the survival rate of koi carps and a breeding method, and belongs to the technical field of koi carp breeding. The breeding equipment comprises a breeding box, guide rails are arranged at the two sides of the top of the breeding box, walking wheels are connected to the guide rails in a rolling manner, and a rotating shaft is sleeved with the two sets of walking wheels; a feeding mechanism is connected to the middle of the rotating shaft, screw rod driving mechanisms are evenly arranged on the inner wall of the breeding box, screw rods are arranged on the screw rod driving mechanisms, cleaning mechanisms are connected to the screw rods in a threaded manner, and when a water pumping pipe pumps water, waterflow and fish excrement which move fast impact blades, and therefore a driven shaft rotates; and then a cleaning shaft drives a cleaning brush to clean the fish excrement which is difficult to cleanat the bottom of the breeding box, so that the fish excrement at the bottom of the breeding box can be effectively cleaned in cooperation with the screw rod driving mechanisms, koi carp fries are prevented from living in water with high ammonia content, and the survival rate of the koi carps is effectively increased.

Owner:韩帅

Electric hoist box body outer wall spraying process

ActiveCN107931068AGuaranteed uniformityGuaranteed fixed effectPretreated surfacesCoatingsSurface layerLacquer

The invention relates to the technical field of machines or devices adopting a jetting method for coating the surface of an object or surfaces of other workpieces with liquid or other fluid, in particular to an electric hoist box body outer wall spraying process. The electric hoist box body outer wall spraying process includes the following steps of firstly, grinding, secondly, cleaning, thirdly,temperature setting, fourthly, preparing a spraying device, fifthly, priming paint spraying, sixthly, middle layer paint spraying, and seventhly, surface layer paint spraying. By means of the technical scheme, oil paint is prevented from being sprayed on the ground, and waste of the oil paint is reduced; and the adhesive force of the oil paint can also be enhanced.

Owner:河南巨人起重机集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com