Road crack pouring machine

A seam filling machine and crack technology, applied in the field of seam filling machine, can solve the problems such as inability to clean up debris, unable to press in time, etc., and achieve good effect of joint filling and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

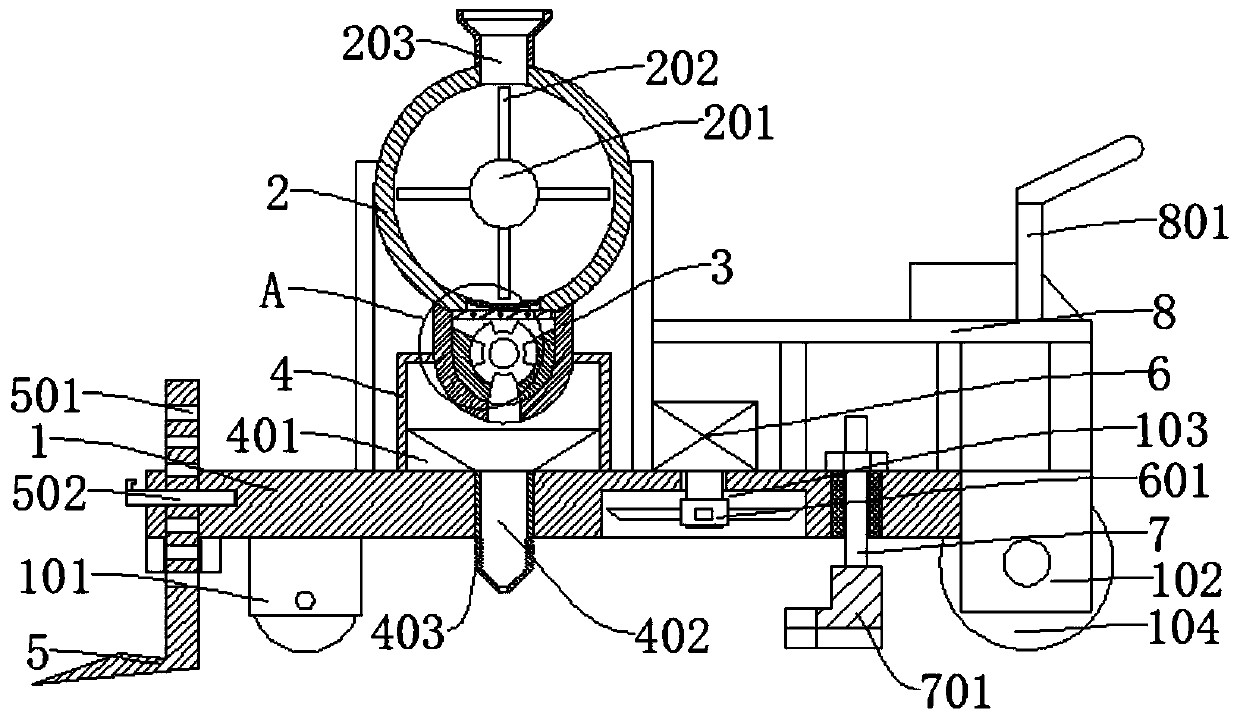

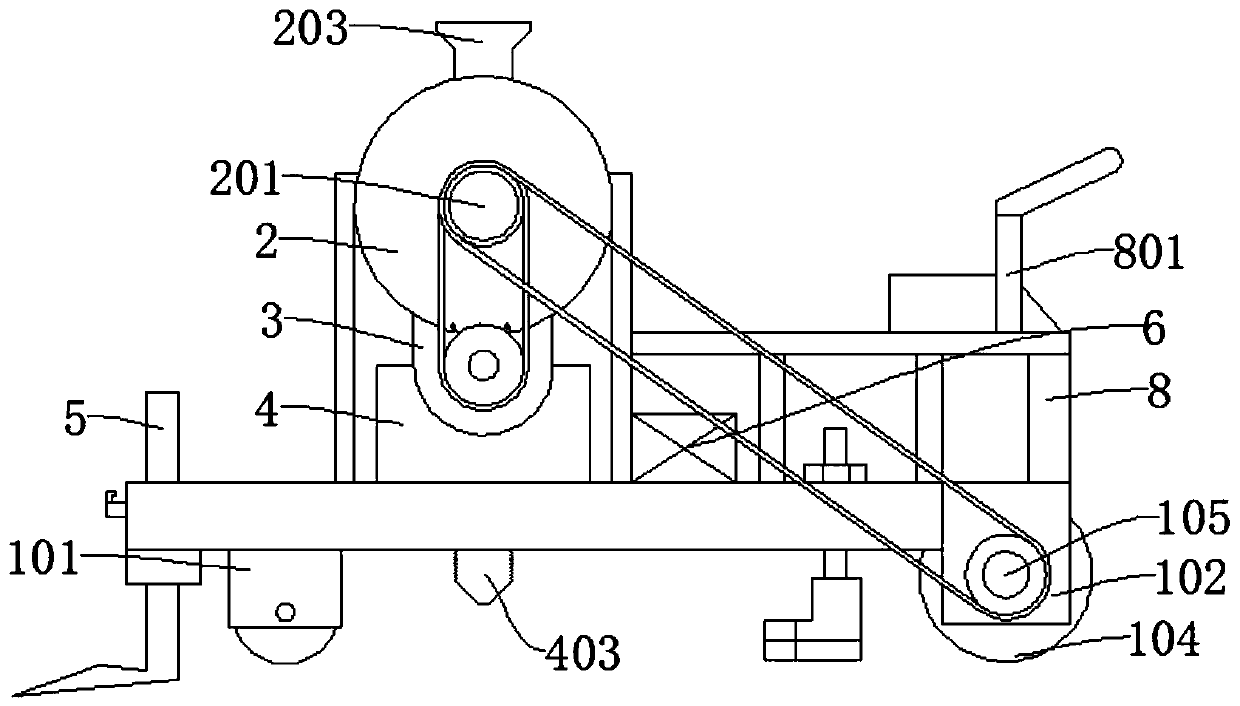

[0034] refer to Figure 1-7 , a road crack filling machine, comprising a bottom plate 1, the bottom of the bottom plate 1 is rotatably connected with a first roller 101, the outer wall of the bottom plate 1 is connected with a fixed plate 102, the inner wall of the fixed plate 102 is connected with a first rotating shaft 105, the first The outer wall of the rotating shaft 105 is connected with a second roller 104;

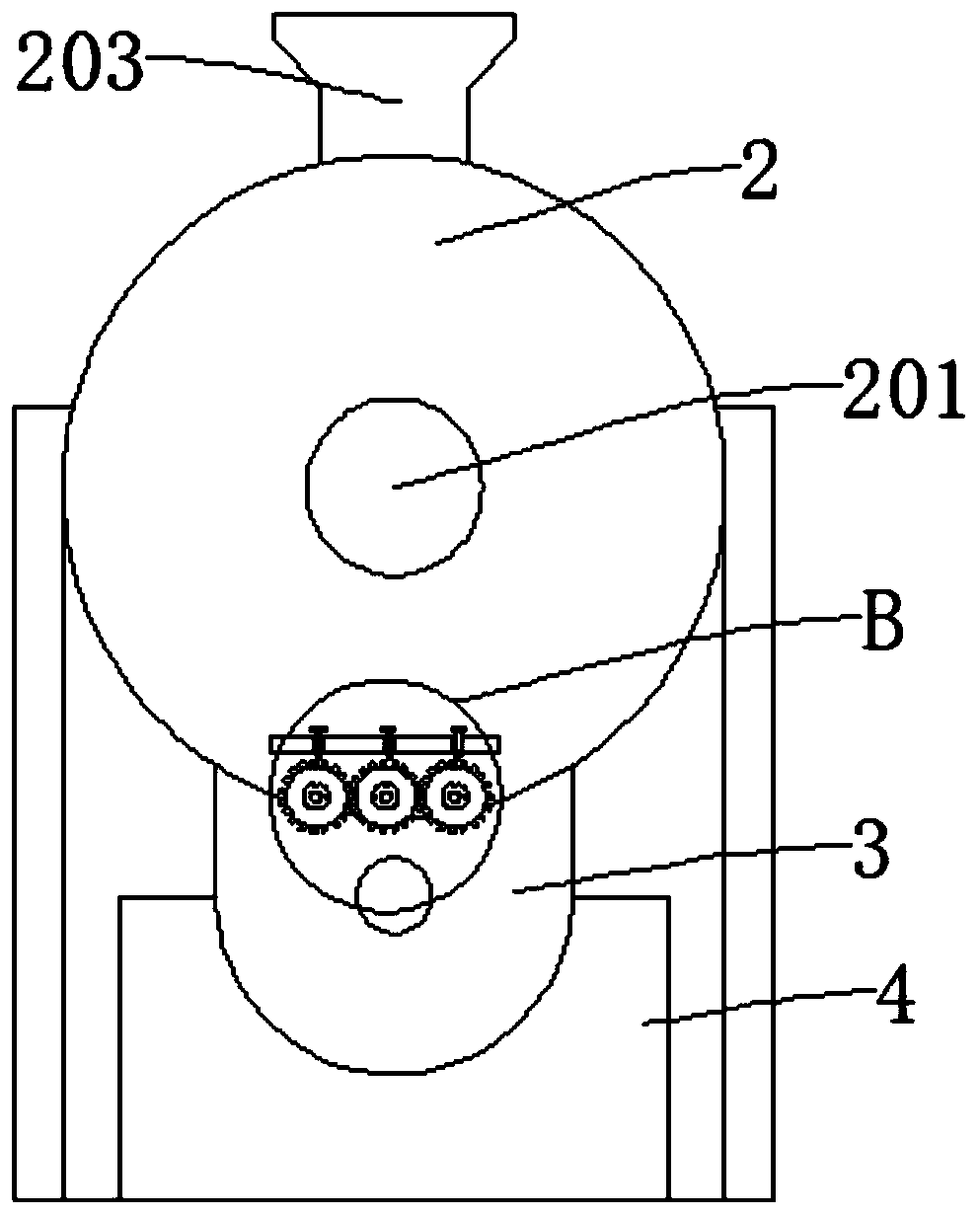

[0035] The top of the bottom plate 1 is connected with the mixing drum 2 through the fixed rod, the mixing drum 2 is connected with the stirring piece, the bottom of the mixing drum 2 is provided with a filter screen 204, and the bottom of the mixing drum 2 is also provided with a quantitative cylinder 3 connected thereto. The bottom of the quantitative cylinder 3 is provided with a discharge hole 305;

[0036] The top outer wall of the bottom plate 1 is also fixedly connected with a discharge box 4, the discharge box 4 is connected to the bottom outer wall of the...

Embodiment 2

[0040] refer to Figure 1-7 , a road crack filling machine, comprising a bottom plate 1, the bottom of the bottom plate 1 is rotatably connected with a first roller 101, the outer wall of the bottom plate 1 is connected with a fixed plate 102, the inner wall of the fixed plate 102 is connected with a first rotating shaft 105, the first The outer wall of the rotating shaft 105 is connected with a second roller 104;

[0041] The top of the bottom plate 1 is connected with the mixing drum 2 through the fixed rod, the mixing drum 2 is connected with the stirring piece, the bottom of the mixing drum 2 is provided with a filter screen 204, and the bottom of the mixing drum 2 is also provided with a quantitative cylinder 3 connected thereto. The bottom of the quantitative cylinder 3 is provided with a discharge hole 305;

[0042] The top outer wall of the bottom plate 1 is also fixedly connected with a discharge box 4, the discharge box 4 is connected to the bottom outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com