Plastic thin film raw material mixing machine

A plastic film and mixer technology, applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve problems such as single function, achieve uniform mixing, full mixing, and prevent the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below based on the drawings.

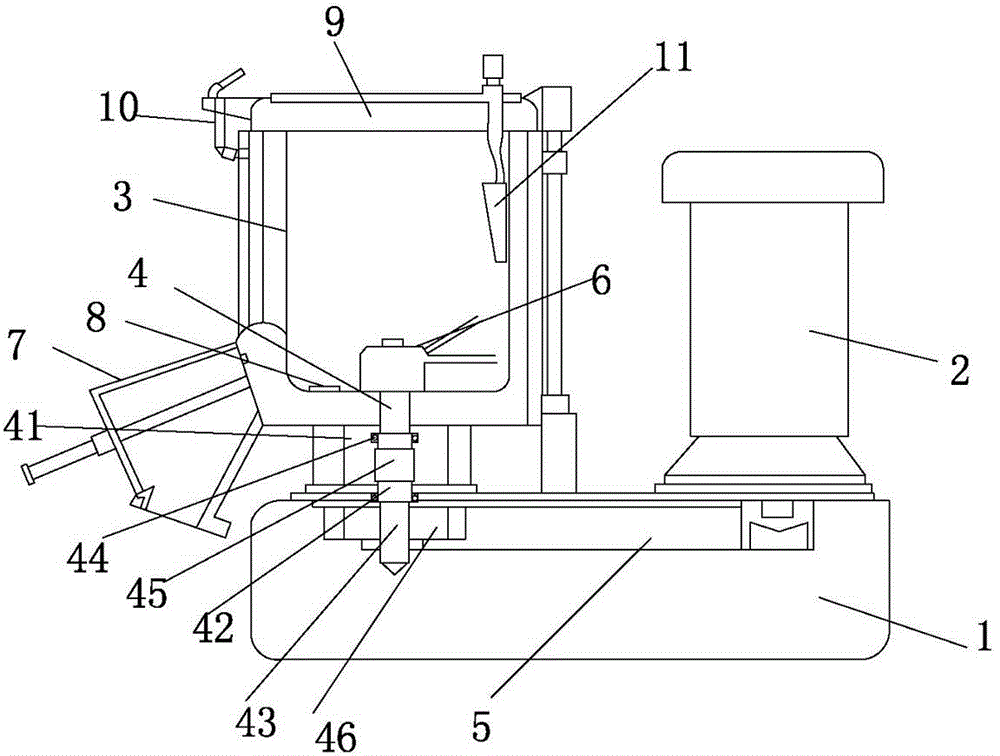

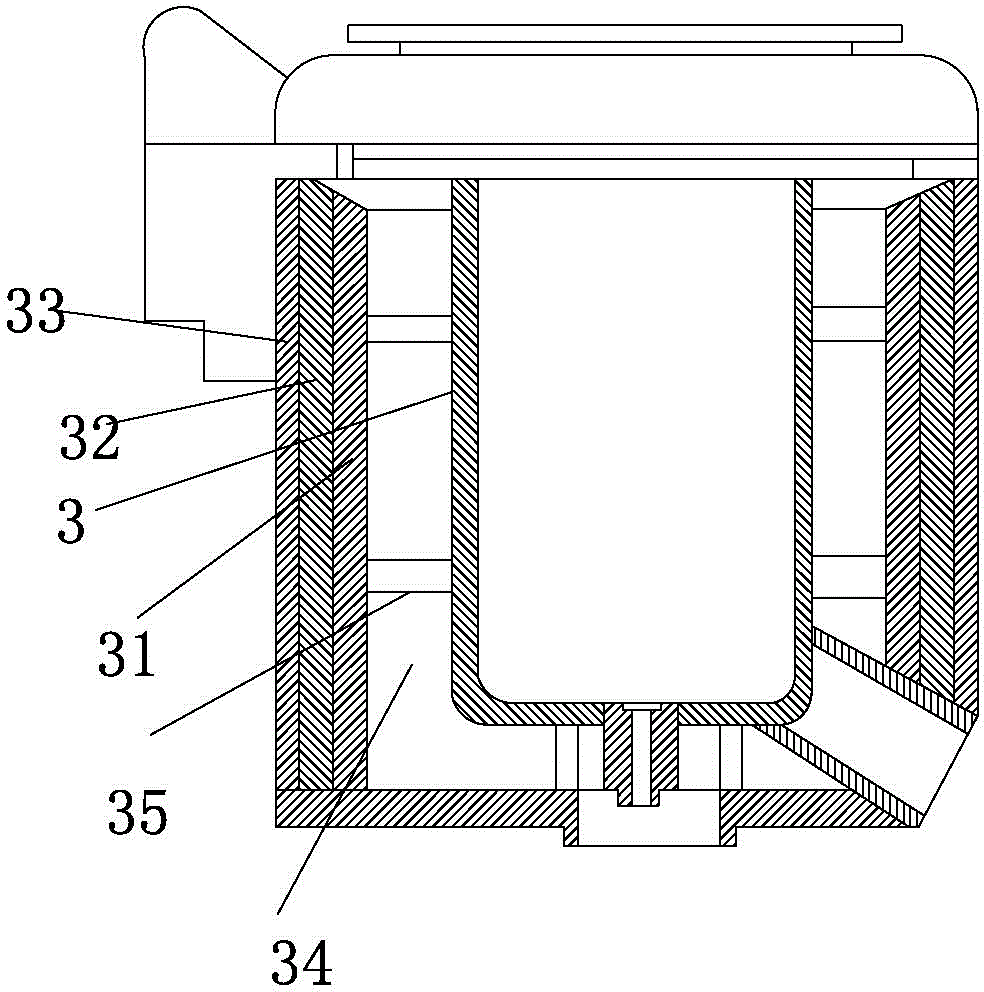

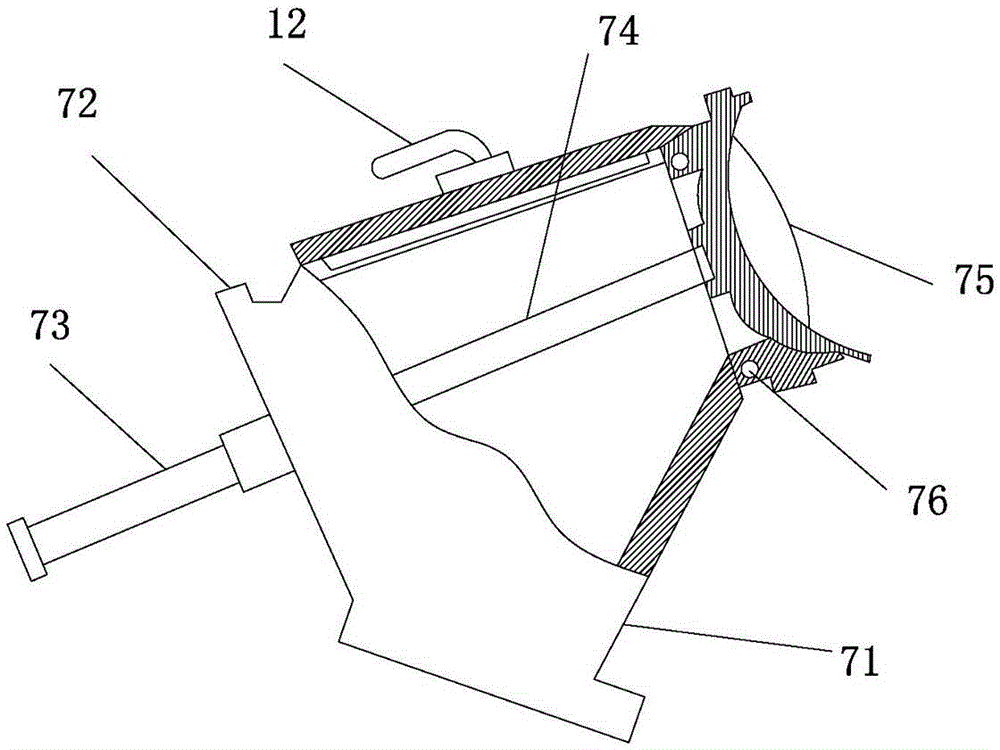

[0019] Such as figure 1 with figure 2 As shown, a plastic film raw material mixer includes a base 1, a motor 2 and a mixing chamber 3 are provided on the base 1, a transmission device 4 is provided at the bottom of the mixing chamber 3, and the lower end of the transmission device 4 passes through a transmission belt 5 and the motor 2 The output shaft is connected, the upper end of the transmission device 4 extends into the mixing chamber 3, the upper end of the transmission device 4 is provided with a stirring paddle 6, and the side walls of the mixing chamber 3 are successively provided with a jacket layer 31, an insulation layer 32 and a jacket 33 from the inside to the outside. There is a cavity 34 containing water vapor or cooling water between the jacket layer 31 and the side wall of the mixing chamber 3, and a discharge device 7 is provided on the outside of the mixing chamber 3.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com