Rotary high-temperature superconducting-tube pyrogasification furnace for garbage

A high-temperature superconducting, pyrolysis gasification technology, applied in the direction of drum gasifier, gasification process, gasification device details, etc., to achieve high efficiency, curb production and emissions, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

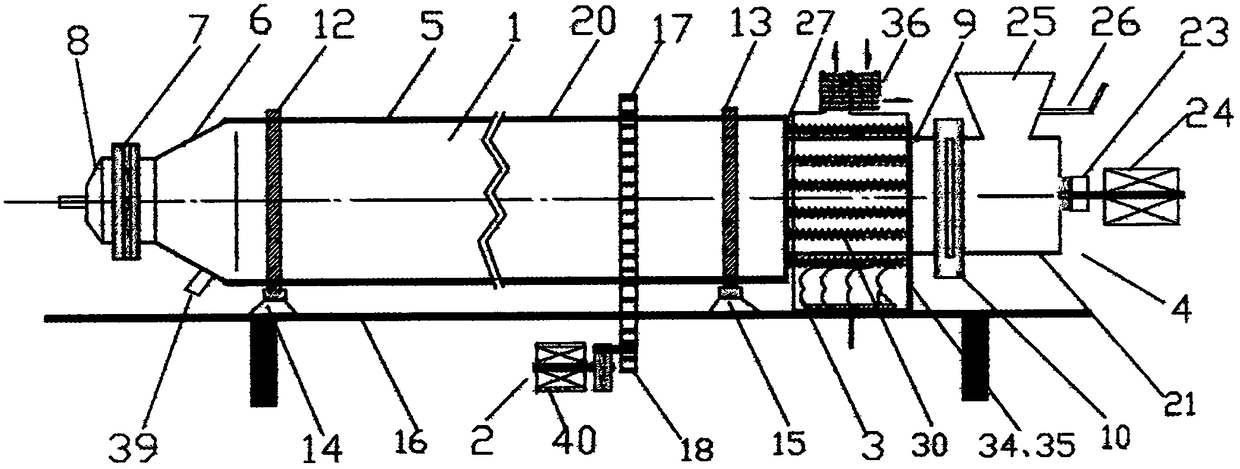

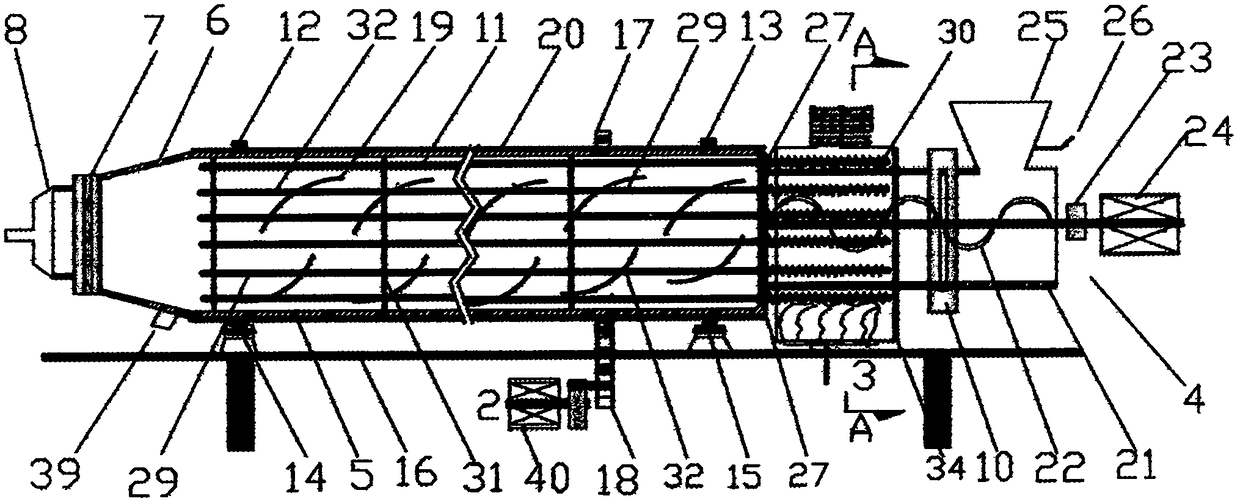

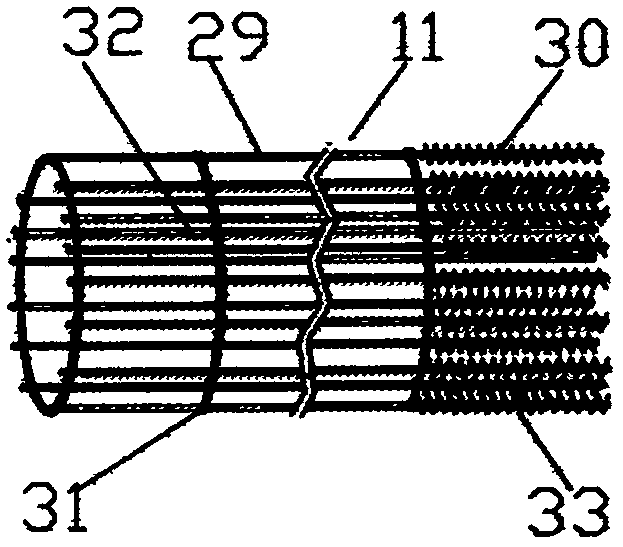

[0027] A rotary high-temperature superconducting garbage pyrolysis gasifier is composed of four parts: a cylindrical rotary furnace body 1, a rotary furnace body driver 2, a heater 3 and a feeder 4. It is characterized in that the cylindrical rotary furnace body 1 is composed of a cylindrical shell 5, an air outlet 8 connected with the left end 6 of the cylindrical shell 5 through a sealing ring 7, and a feeder connected with the right end 9 of the cylindrical shell 5 through a sealing ring 10 4 and the squirrel-cage superconducting heat exchanger 11 installed in the cylindrical shell 5 constitute. Roller belts 12 and 13 are installed at both ends of the cylindrical rotary furnace body 1, and the roller belts are placed in the respective rolling grooves 14 and 15, and the cylindrical rotary furnace body 1 is assembled in a horizontal state through the rolling belts and the rolling grooves. On the body of furnace support 16. A gear ring 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com