Porous ceramic heating body and preparation method thereof

A porous ceramic and heating body technology, applied in the field of electronic cigarettes, can solve the problems of poor resistance to cold and heat shock, low softening temperature, easy oxidation of heating wires, etc., and achieve stable performance, high product quality, and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

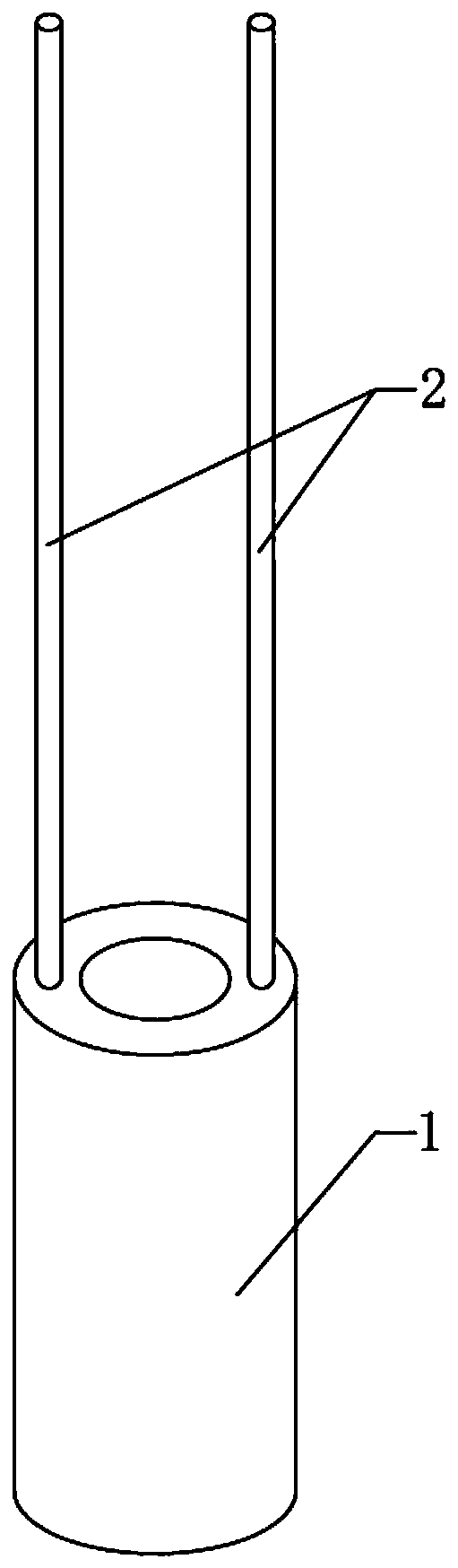

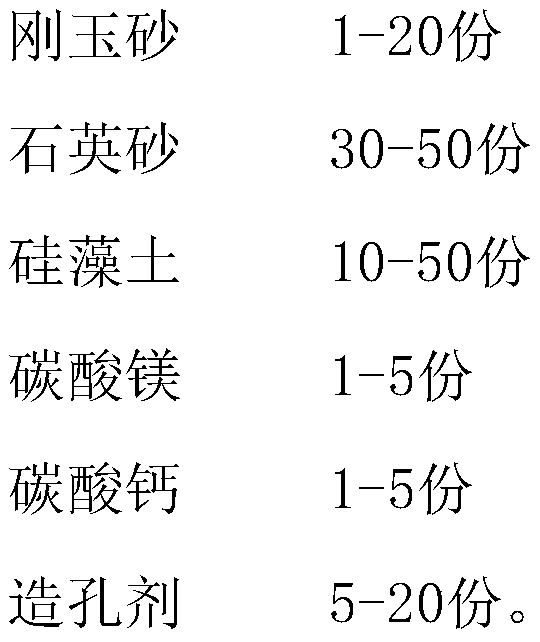

[0034] See attached figure 1 , A porous ceramic heating body, comprising a porous ceramic substrate and a metal heating element embedded in the porous ceramic substrate, the porous ceramic substrate including the following raw materials by weight:

[0035]

[0036] The mesh number of the corundum sand is 100 mesh, the mesh number of the quartz sand is 100 mesh, and the mesh number of the diatomite is 100 mesh.

[0037] The pore former is starch.

[0038] The metal heating element is a nickel-iron heating wire or a nickel-iron heating sheet.

[0039] The porosity of the porous ceramic substrate is 40%, and the pore diameter of the pores is 1-60 μm.

[0040] A method for preparing the porous ceramic heating body as described above includes the following steps:

[0041] (1) Drying and ball milling: According to parts by weight, each raw material is baked and dried, and then 0.5% oleic acid is added for ball milling to prepare a mixture;

Embodiment 2

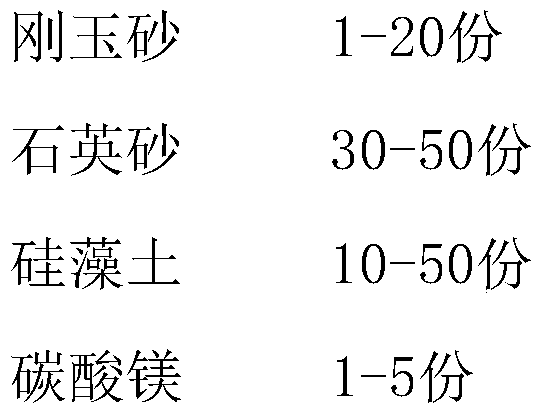

[0052] A porous ceramic heating body includes a porous ceramic substrate and a metal heating element embedded in the porous ceramic substrate, and the porous ceramic substrate includes the following raw materials by weight:

[0053]

[0054] The mesh number of the corundum sand is 200 mesh, the mesh number of the quartz sand is 200 mesh, and the mesh number of the diatomite is 200 mesh.

[0055] The pore former is wood chips.

[0056] The metal heating element is a nickel-chromium heating wire or a nickel-chromium heating sheet.

[0057] The porosity of the porous ceramic substrate is 50%, and the pore diameter of the pores is 20 μm.

[0058] A method for preparing the porous ceramic heating body as described above includes the following steps:

[0059] (1) Drying and ball milling: According to parts by weight, each raw material is baked and dried, and then 0.6% oleic acid is added for ball milling to obtain a mixture;

[0060] (2) Preparation of wax slurry: dry the mixture after ball mil...

Embodiment 3

[0070] A porous ceramic heating body includes a porous ceramic substrate and a metal heating element embedded in the porous ceramic substrate, and the porous ceramic substrate includes the following raw materials by weight:

[0071]

[0072]

[0073] The mesh number of the corundum sand is 350 mesh, the mesh number of the quartz sand is 350 mesh, and the mesh number of the diatomite is 350 mesh.

[0074] The pore forming agent is plastic particles; the plastic particles are PMMA.

[0075] The metal heating element is a nickel-chromium heating wire or a nickel-chromium heating sheet.

[0076] The porosity of the porous ceramic substrate is 55%, and the pore diameter of the pores is 30 μm.

[0077] A method for preparing the porous ceramic heating body as described above includes the following steps:

[0078] (1) Drying and ball milling: According to parts by weight, each raw material is baked and dried, and then 0.8% by mass oleic acid is added for ball milling to prepare a mixture;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com