Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Avoid Burst Accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil and gas pipeline intelligent internal detection device based on multi-module combined location

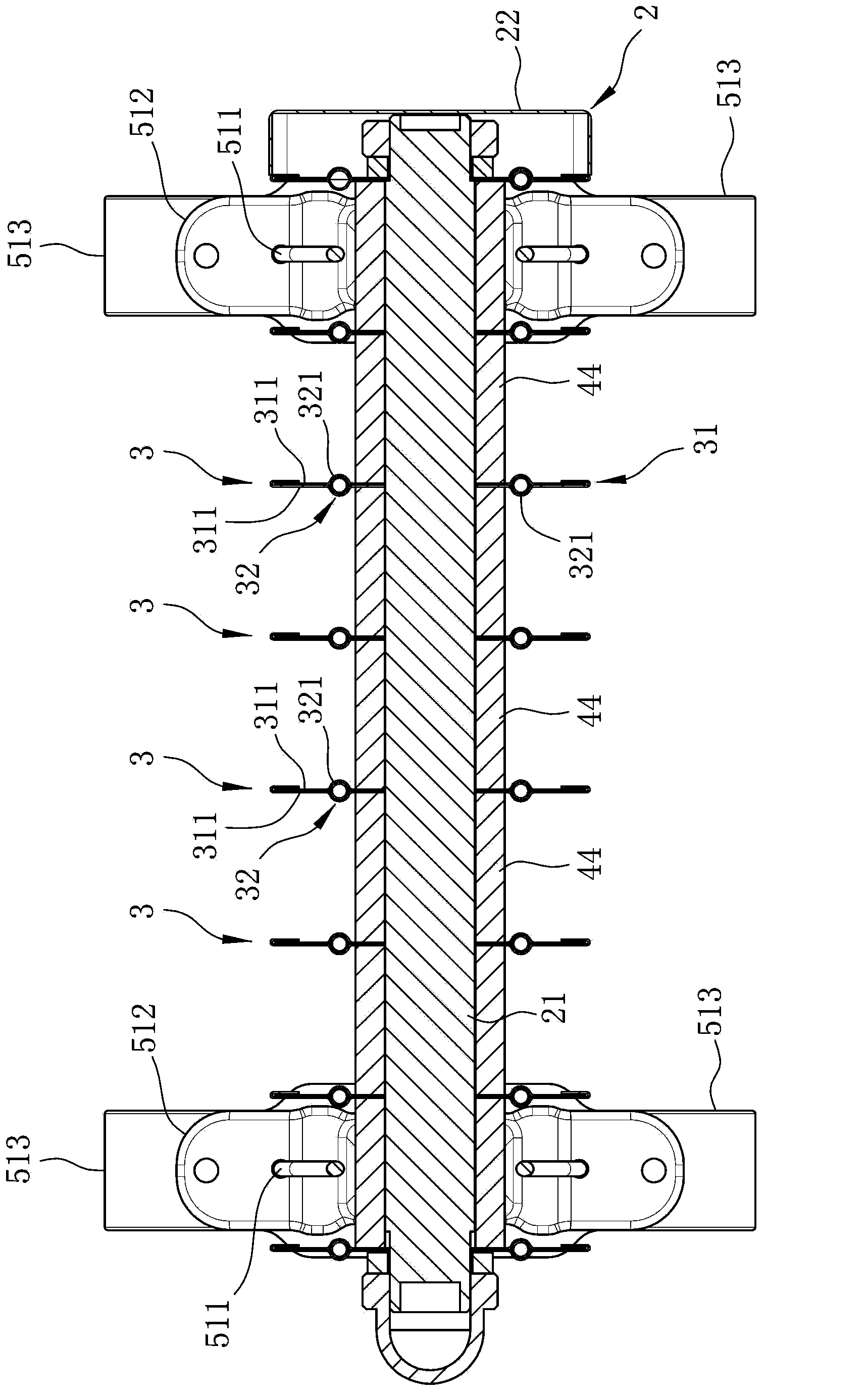

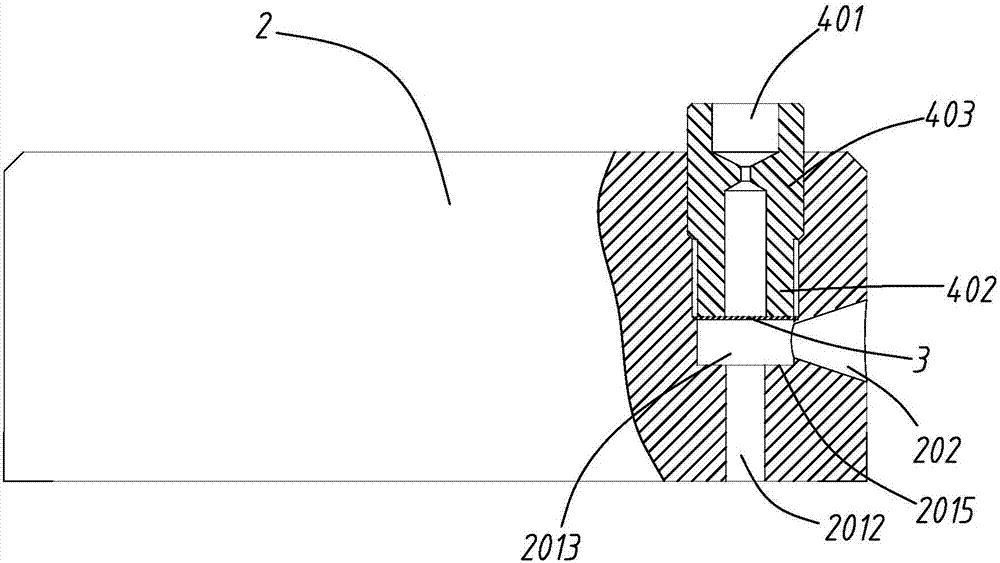

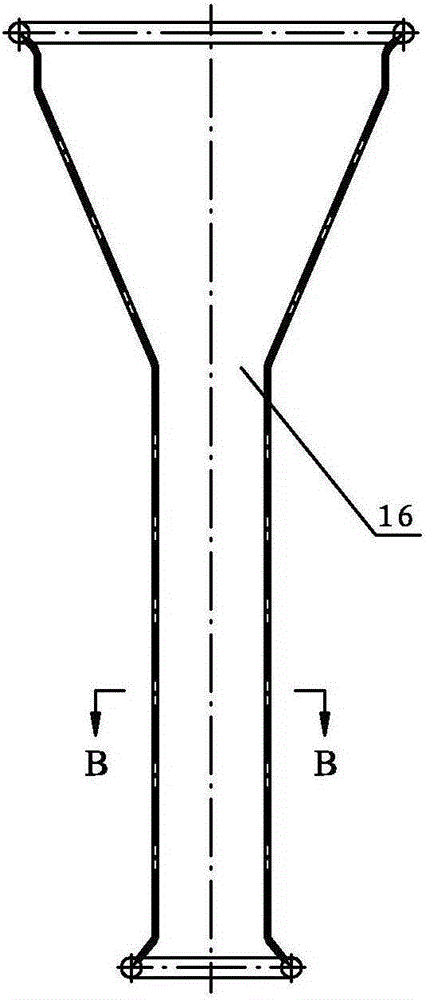

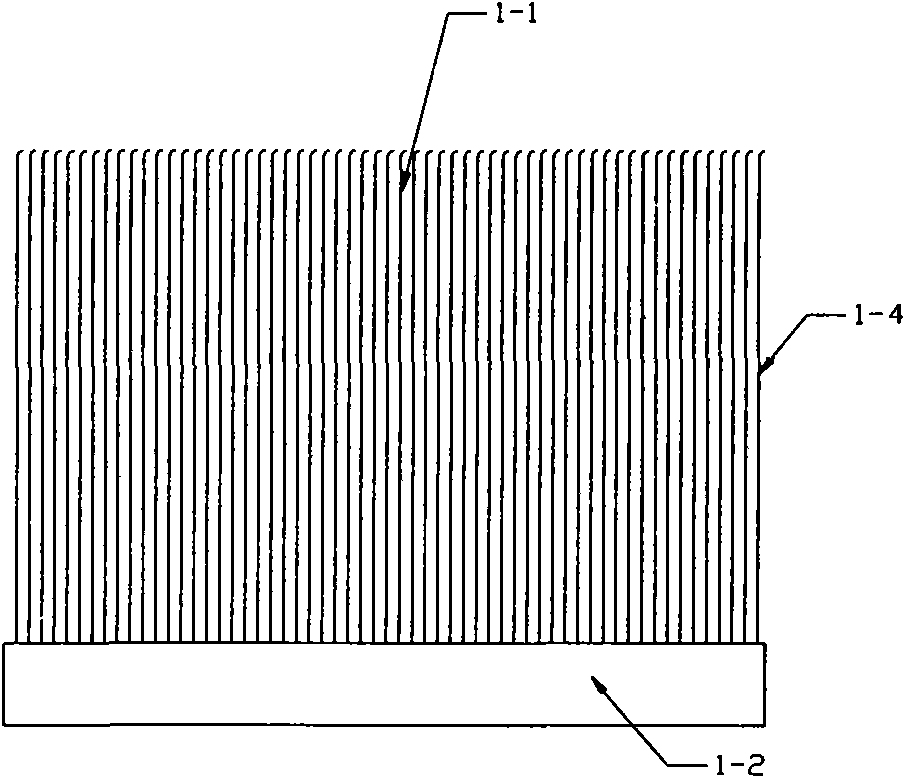

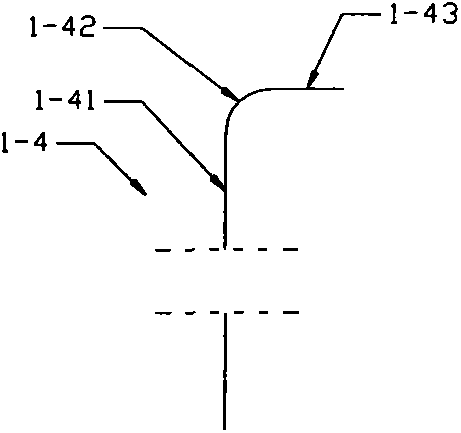

ActiveCN103470959AReduce resistancePrevent pulling outPipeline systemsSpeed control systemElectromagnetic pulse

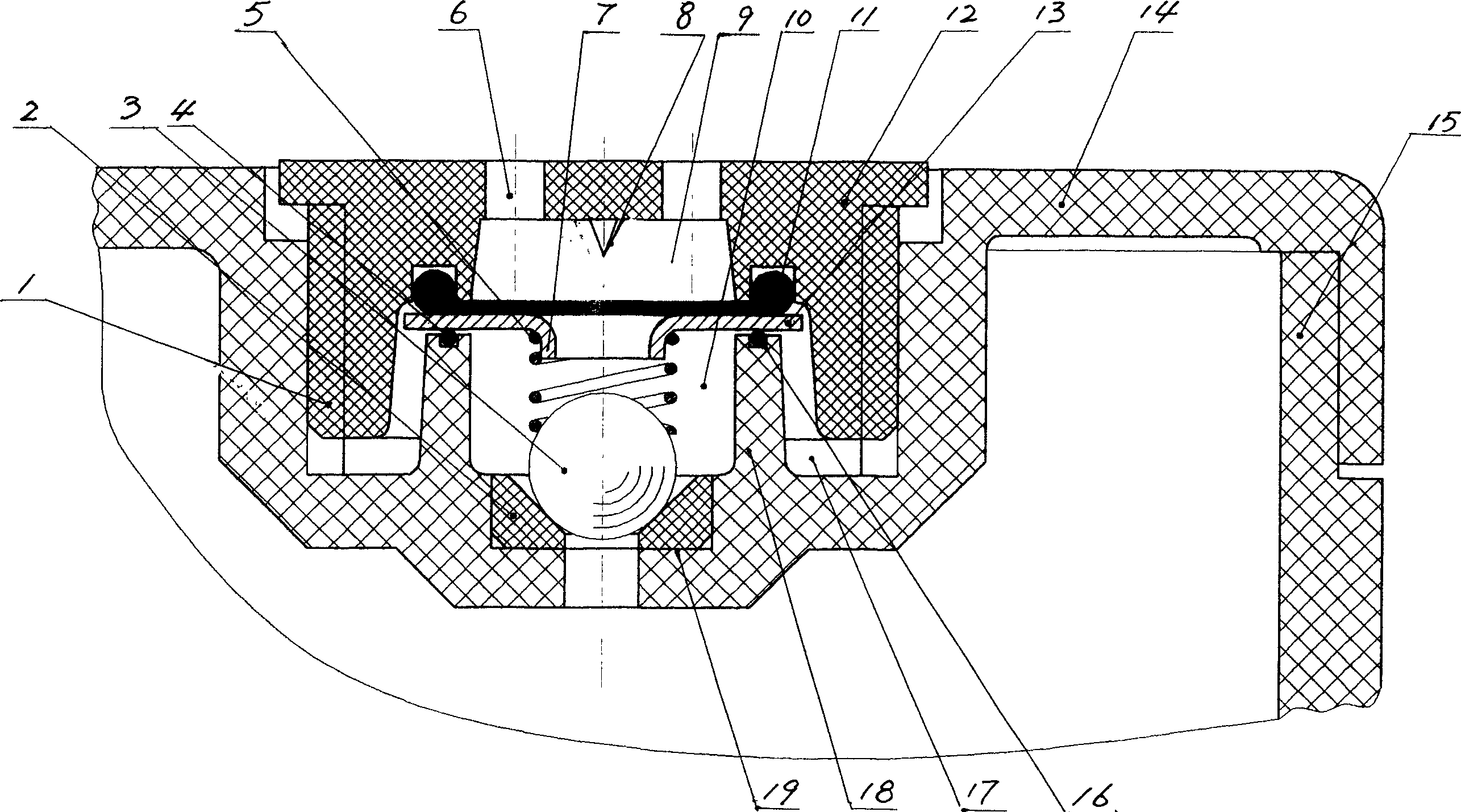

The invention discloses an oil and gas pipeline intelligent internal detection device based on multi-module combined location. The device comprises an internal detector arranged inside an oil and gas pipeline and a floor marker arranged outside the oil and gas pipeline. The internal detector comprises a driving system, a magnetic leakage detecting system, a speed control system, a distance measuring system and a low frequency emitting system, wherein the driving system, the magnetic leakage detection system, the speed control system, the distance measuring system and the low frequency emitting system are relatively fixedly connected together; the floor marker at least comprises a low frequency receiving system; the low frequency emitting system is used for sending detection results obtained by the magnetic leakage detection system out of the oil and gas pipeline; the low frequency receiving system is used for receiving low frequency electromagnetic pulse signals transmitted by the low frequency emitting system. The oil and gas pipeline intelligent internal detection device based on the multi-module combined location can timely obtain the detection data of the pipeline detector and analyze the detection data and accordingly rapidly determine the defect conditions of the pipeline.

Owner:BEIJING APC PETROCHEM TECH

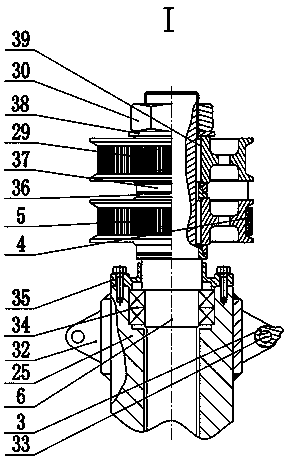

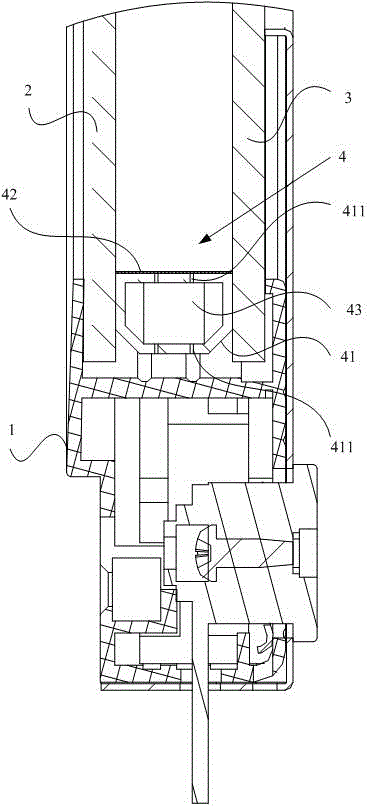

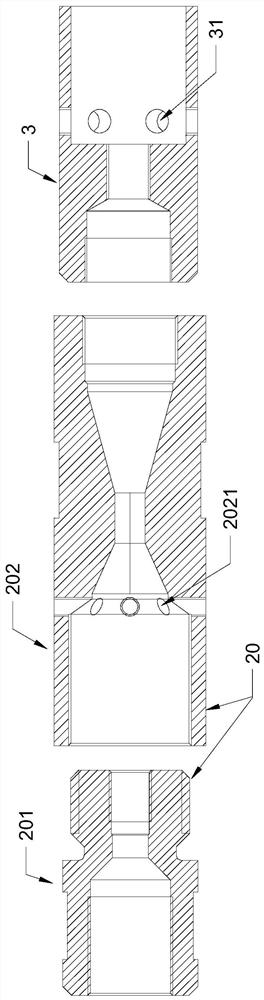

Mechanical tube cleaner speed controller

InactiveCN103551350ATo overcome the shortcomings of excessive delay of the speed controllerAdapt to speed changesHollow article cleaningAppliance componentEngineering

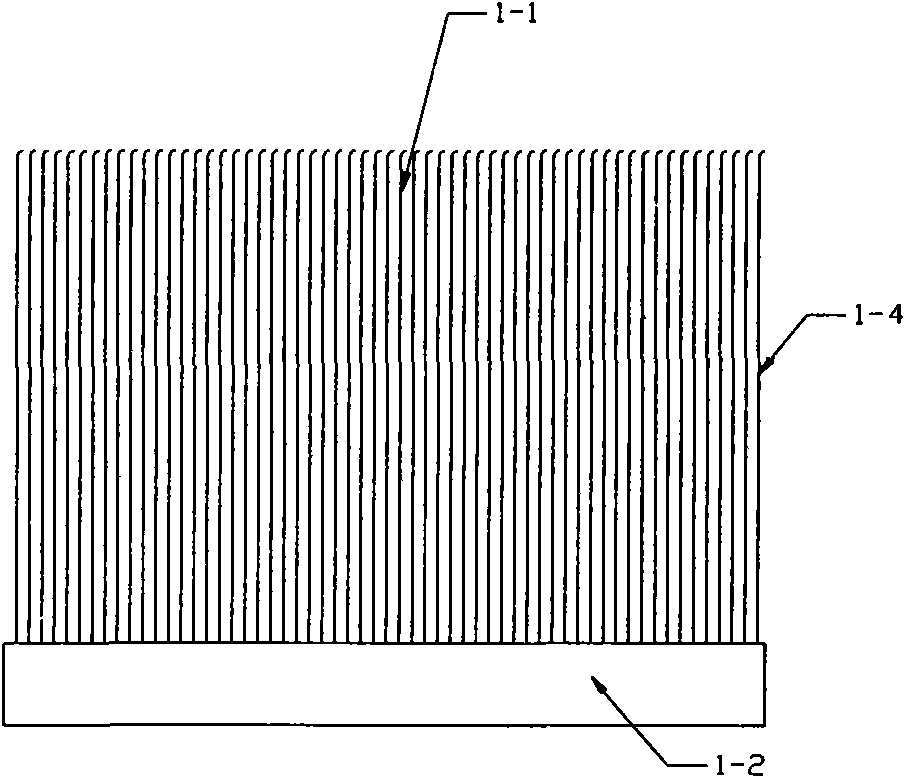

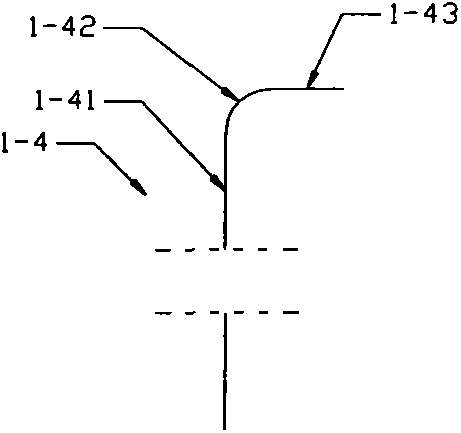

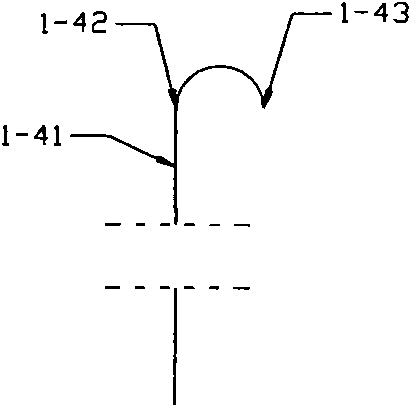

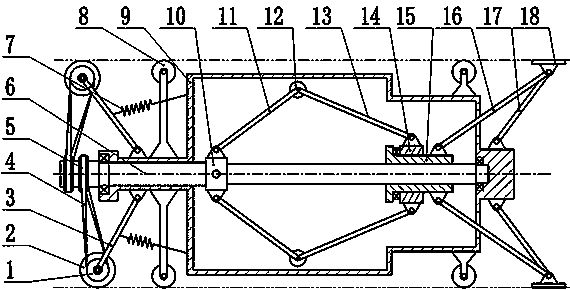

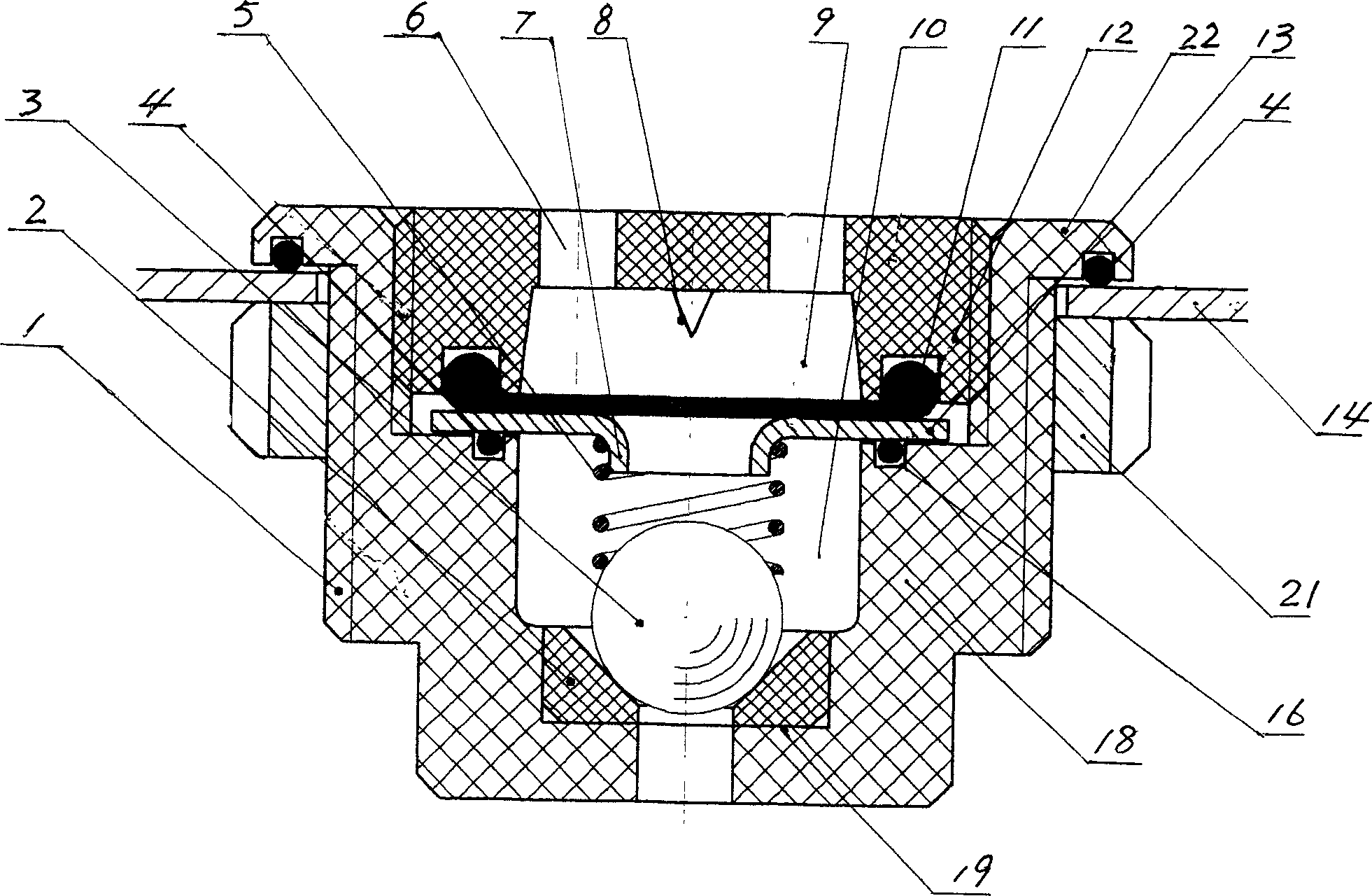

The invention relates to a mechanical speed controller used for controlling running speed of a tube cleaner and a defect detection device in a pipe cleaning and defect detection process of natural gas pipes on active service and a pressure test and discharging process of pipelines under construction. The controller can control the speed of the tube cleaner to be in a certain range and solve the problem that the existing tube cleaner is impacted due to the fact that the speed cannot be controlled and a detector is inaccurate in detection due to the fact that the speed is too high. Four support wheels are arranged at two ends of a barrel body respectively, and two speed collection wheels are symmetrically arranged on two sides of the barrel body through support rods and connected through a spring. A belt wheel A is coaxially installed on the speed collection wheels and connected with a belt wheel B on the end portion of a central shaft through a belt. A sleeve is installed in the middle section of the central shaft, a fixed barrel is installed on the tail section, and a rotating barrel is sleeved on the outside of the fixed barrel. One end of a connection rod A and one end of a connection rod B are hinged to a mass block, the other ends of the connection rod A and the connection rod B are connected with the sleeve and the rotating barrel respectively, a connection rod C is connected with the end portion of the fixed barrel and a friction block, and a connection rod D is connected with the end portion of the barrel body and a friction block. The speed controller is simple in structure, free of delaying, safe and reliable and has no electric appliance components.

Owner:SOUTHWEST PETROLEUM UNIV

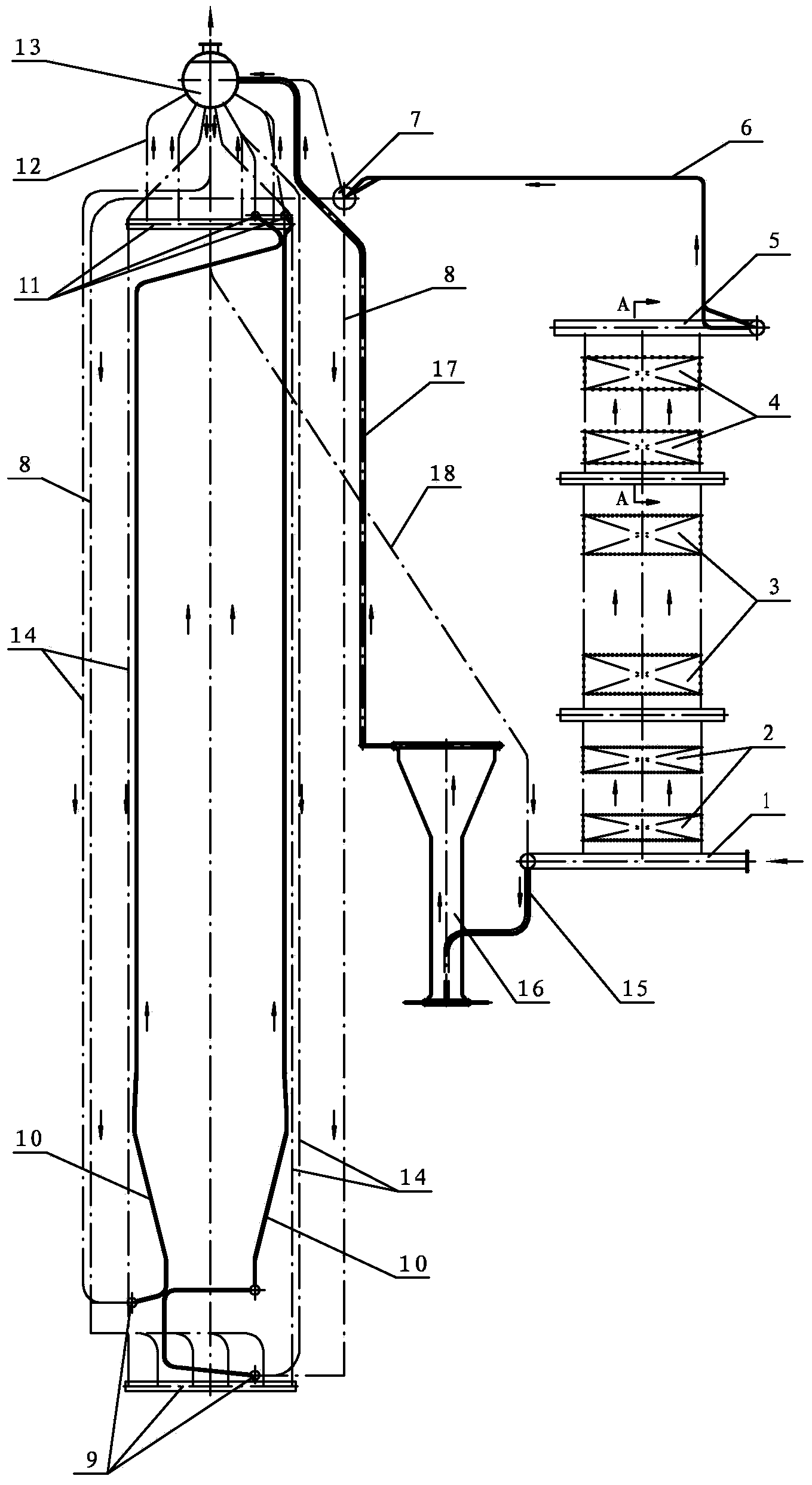

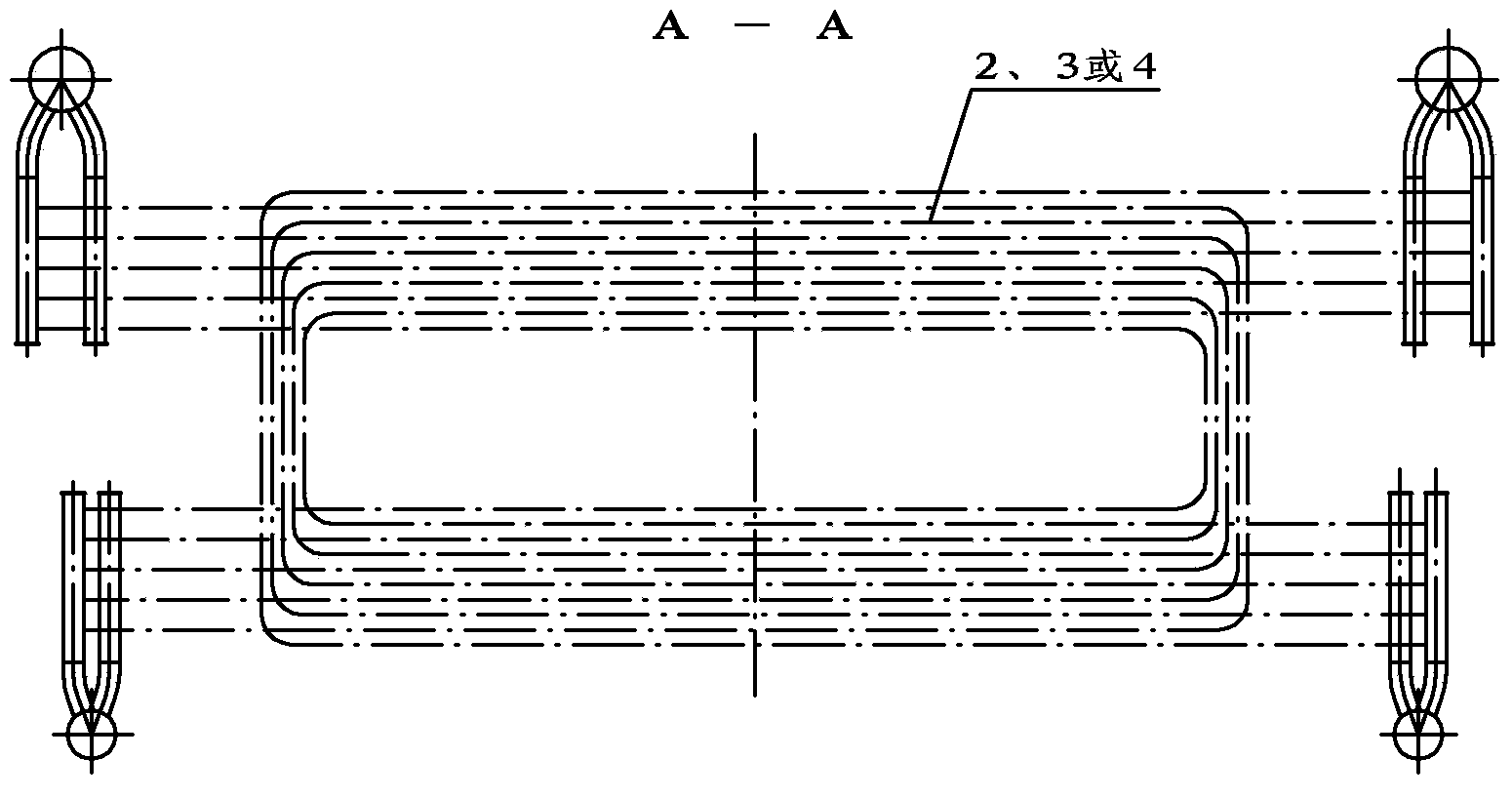

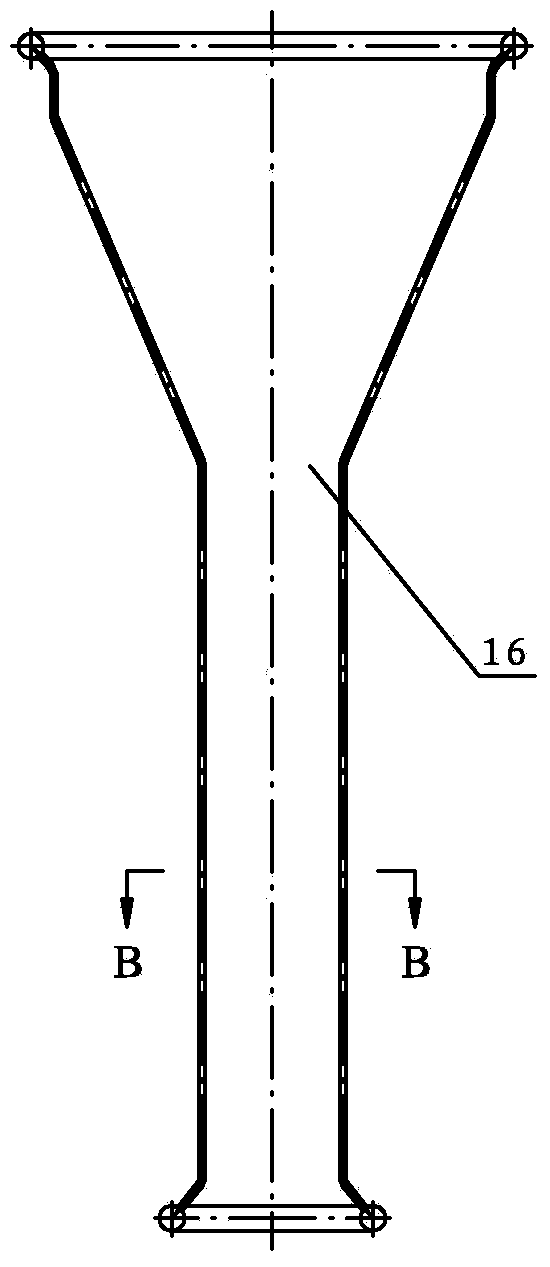

Forced water circulation high-capacity hot water boiler of circulating fluidized bed

ActiveCN103644648AImplement security requirementsAvoid damageFluidized bed combustionWater heatersWater circulationHearth

The invention discloses a forced water circulation high-capacity hot water boiler of a circulating fluidized bed, which relates to a hot water boiler of a fluidized bed, and aims to ensure water circulation safety and power failure protection of a high-capacity hot water boiler of a circulating fluidized bed. A water supply distribution header is connected with lower coal economizers; the lower coal economizers, middle coal economizers and upper coal economizers are sequentially connected with one another; the upper coal economizers are connected with a coal economizer upper header; the coal economizer upper header is connected with a collection water bag by a coal economizer coating pipe; the collection water bag is connected with water cooling wall lower headers by a descending pipe; the water cooling wall lower headers are connected with a hearth water cooling wall; the hearth water cooling wall is connected with water cooling wall upper headers; the water cooling wall upper headers are connected with a boiler cylinder by extraction pipes; the water supply distribution header is connected with a separator water cooling sleeve by a water cooling sleeve water intake pipe; the separator water cooling sleeve is connected with the boiler cylinder by a water cooling sleeve water outlet pipe; the boiler cylinder is connected with the water cooling wall lower headers by communicating pipes, and is connected with the water supply distribution header by a power failure water supply pipe. The forced water circulation high-capacity hot water boiler provided by the invention is applied to large concentrated heat supply and warming.

Owner:哈尔滨红光锅炉总厂有限责任公司

Chemical cleaning system and method for oxide skin of power station superheater or reheater

The invention relates to a chemical cleaning system and method for the oxide skin of a power station superheater or reheater. The system comprises a cleaning power platform, wherein the cleaning power platform is connected with the system inlet of the power station superheater or reheater through a liquid inlet pipeline, and is connected with the system outlet of the power station superheater or reheater through a liquid returning pipeline, so that circular cleaning is realized for the power station superheater or reheater; corrosion on-line monitoring equipment and a heater are arranged on the liquid inlet pipeline; the corrosion on-line monitoring equipment is used for monitoring the corrosion rate of the superheater or reheater in real time during a chemical cleaning period, so that excessive corrosion of the superheater or reheater is prevented; the heater is used for heating cleaning liquid; dead-end pipe on-line monitoring equipment which is used for monitoring the pipe flowing state of the superheater or reheater in real time is arranged in the pipe of the power station superheater or reheater; and the invention further discloses the cleaning method. By using the system and method disclosed by the invention, the oxide skin of the power station superheater or reheater is completely removed; pipe bursting risk is lowered during the operation period of the power station superheater or reheater is lowered; and meanwhile, the heat conduction efficiency of the power station superheater or reheater is improved, so that safe and economical operation of a power station is ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Solar Automatic soaking and gathering-heat pipe, slot-typed assembly, thermal power generating system and craft

ActiveCN103115445AUp and down evenlyBreak laminar flowSolar heating energyFrom solar energyPower stationEngineering

The invention relates to a solar automatic soaking and gathering-heat pipe, a slot-typed assembly, a thermal power generating system and a craft. The solar automatic soaking and gathering-heat pipe comprises a glass tube and an absorption tube which is installed inside the glass tube and is coated with an endothermic layer. Vacuum is arranged between the glass tube and the absorption tube. The solar automatic soaking and gathering-heat pipe is characterized in that segregation board which is used for enabling fluid to turn flow up and down alternatively in the absorption tube and is installed inside the inner chamber of the absorption tube. The segregation board is in a heliciform and is fixed in the absorption tube enabling the solar automatic soaking and gathering-heat pipe to be filled with water to heat directly without the worry of booster. Meanwhile, the electrical power generating system and the craft through photo-thermal supplementary electricity generation enables the photo-thermal supplementary power station to be unaffected by the weather so that the electricity can be generated steadily at night or when the sunlight is inadequate. Energy conservation and environment protection can be achieved.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Method for directly treating air cooling drum boiler unit water supply

ActiveCN1945115AReduce depositionAdd lessSteam boilersSteam boilers componentsFlow-accelerated corrosionCorrosion

The present invention relates to boiler feed water treating technology, and is especially water treating method for directly air cooled steam drum boiler. Under the reductive condition, the condensed water from the condensing water tank is added with ammonia before entering the boiler directly under the condition of closing the oxygen discharging door of deaerator and the water hydrogen conductivity is controlled below 0.2microS / cm. In case of poor water quality, the oxygen discharging door is opened to convert into reductive mode. The present invention alters the traditional concept that dissolved oxygen will result in corrosion, and has double compact oxide film formed on surface of metal to inhibit the flow corrosion in thermal system, fine treatment of condensed water for long running time, no use of carcinogenic hydrazine and lowered ammonia adding amount for environment protection and health, and raised equipment utilization.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

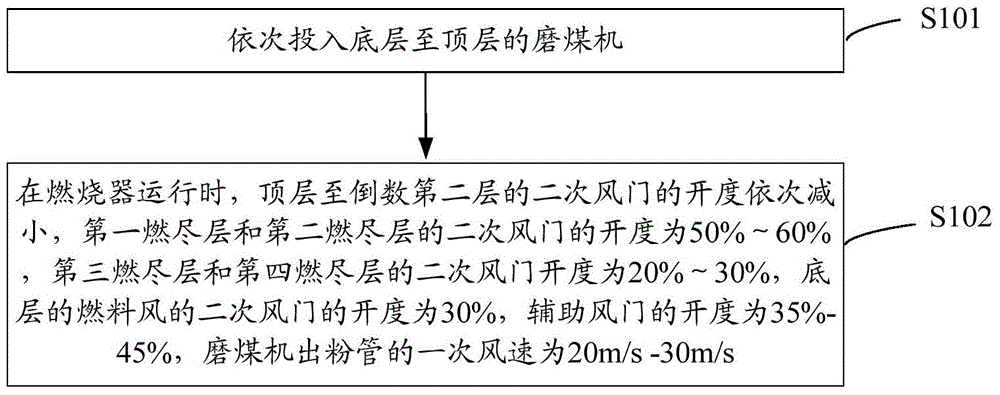

1050 MW ultra-supercritical pulverized coal boiler anti-overtemperature control method

ActiveCN104791839AReduce the temperaturePrevent fallingFuel supply regulationBoiler controlCombustorAir volume

The invention relates to a 1050 MW ultra-supercritical pulverized coal boiler anti-overtemperature control method. According to the method, a burner burns stably by controlling the operating sequence of a coal pulverizer, the opening degrees of secondary air doors from the top layer to the last but one layer are sequentially decreased by controlling the secondary air distribution mode, the temperature of a hearth outlet is effectively decreased, distribution non-uniformity of the inner wall of a hearth is reduced, the opening degree of a secondary air door on the bottom layer is 30%, and therefore flames are supported not to rush downwards and prevented from falling into a dry bottom hopper. The primary air speed of a powder discharge pipe of the coal pulverizer ranges from 20 m / s to 30 m / s, the opening degrees of auxiliary air doors range from 35% to 45%, the secondary air volume can be reduced by increasing the primary air volume in the hearth, and the probability that secondary air impacts primary air powder on the opposite side due to the too high secondary air speed, so that wall-attached burning is caused is avoided. The control method conforms to octagonal reverse bi-tangential circle boiler power field characteristics, pulverized coal is fully burnt, and therefore the pipe explosion accident caused by overtemperature generated due to non-uniform inner wall temperature distribution is avoided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

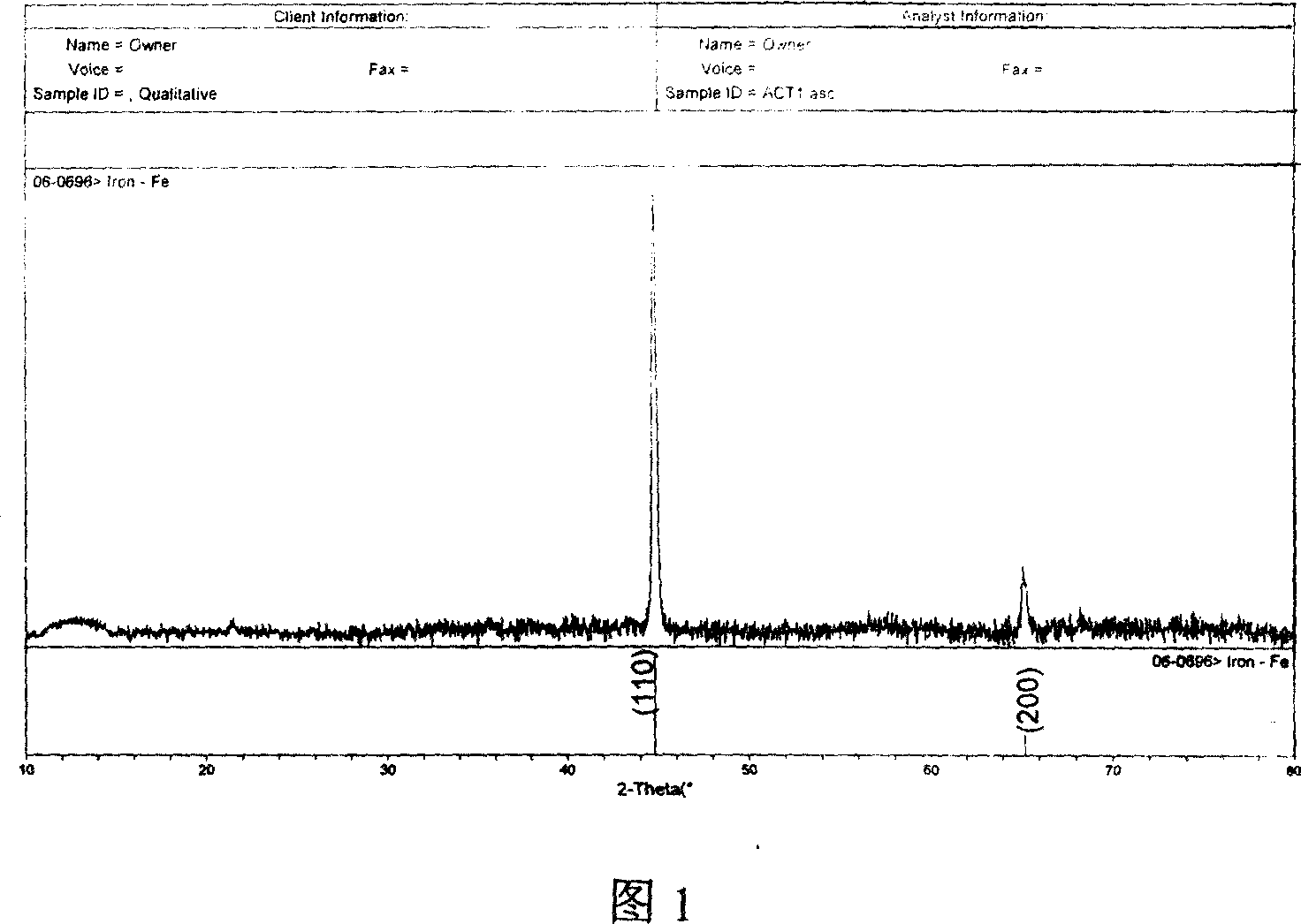

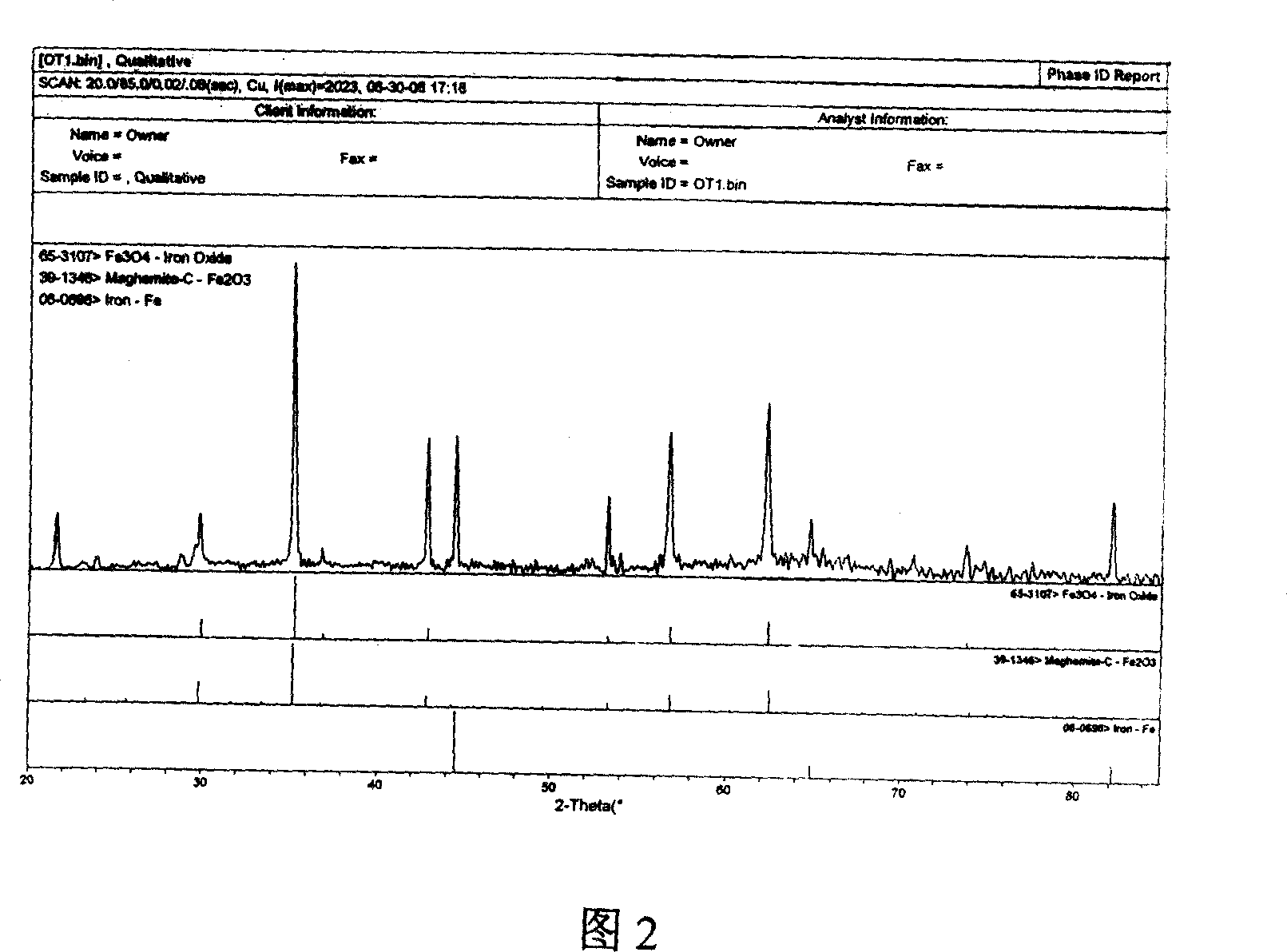

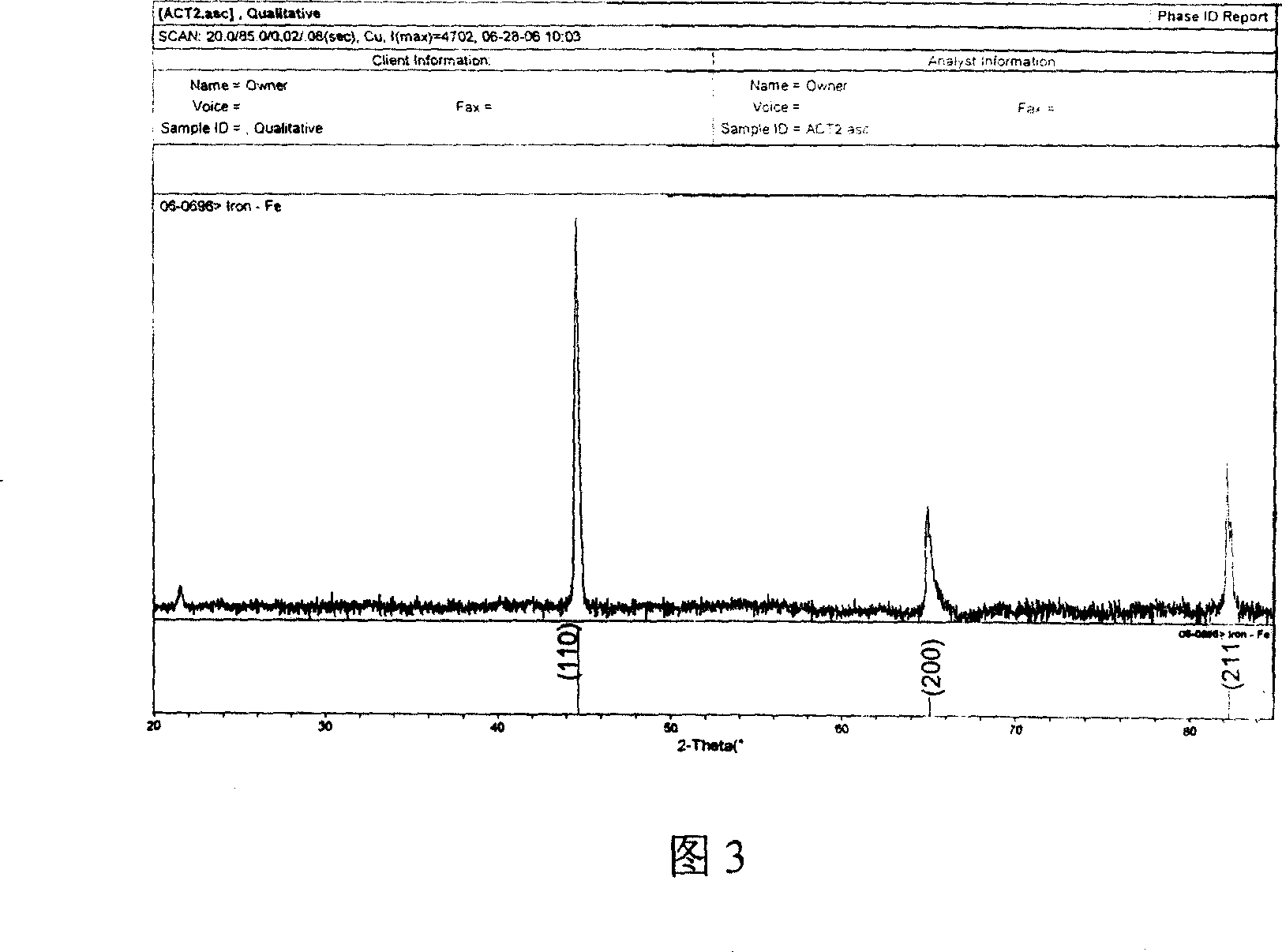

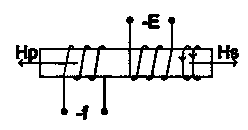

Heated surface tube inner oxide skin accumulation condition detection method

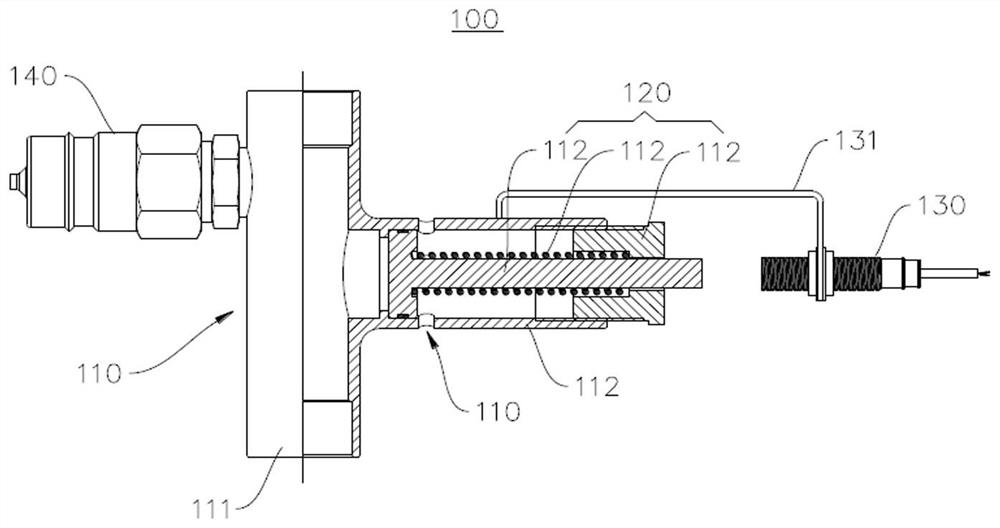

The invention discloses a heated surface tube inner oxide skin accumulation condition detection method. The method comprises the following steps: an exciting coil is wound around a heated surface tube of which the oxide skin accumulation volume is to be detected, and the coil is energized with a low-frequency alternating current of which the frequency is less than 50Hz; a measuring coil is wound around the detected heated surface tube at a position which is away from the exciting coil for a certain distance L; the induced electromotive force E of two ends of the coil described in the step2 is measured; and the measured data is compared with the test data to judge the tube inner wall oxide skin accumulation volume. The method has the advantage of convenient operation, the method can be used to perform fast detection on heated surface tube inner oxide skin accumulation volume, and the tube explosion accident of a boiler heated surface tube due to oxide skin accumulation can be prevented well.

Owner:STATE GRID CORP OF CHINA +2

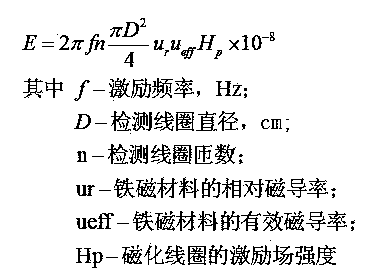

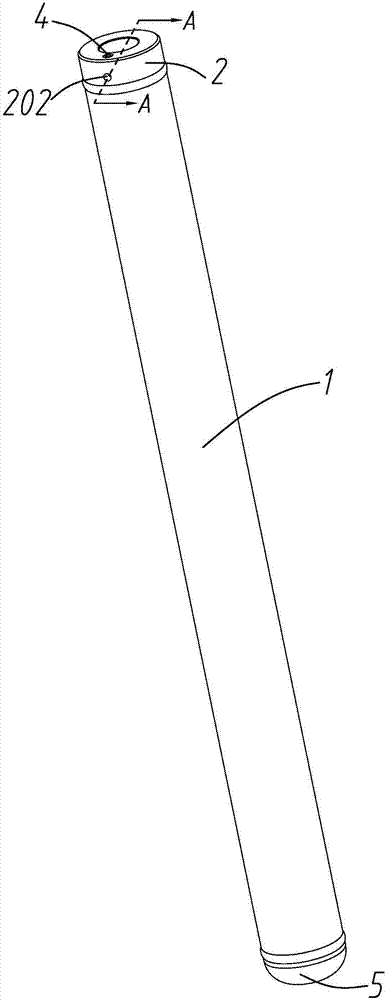

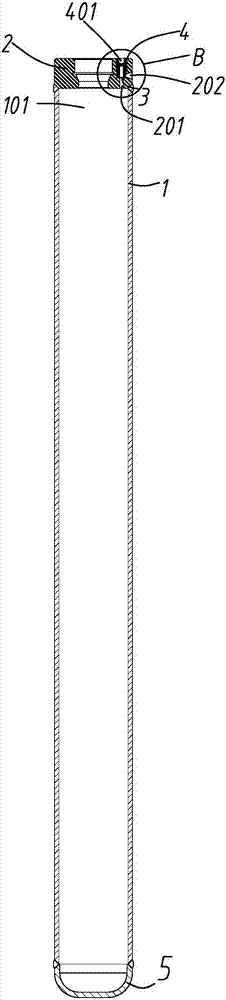

Solar energy heat collector

InactiveCN101377358AIncrease profitImprove conversion rateSolar heating energySolar heat devicesThermodynamicsHeat conducting

The invention discloses a solar energy collector device which has high energy absorption rate and is capable of effectively utilizing solar energy. The invention comprises an outer housing (1), a heat pipe (2), a focusing convex lens (3) and a focusing concave reflector (4), wherein, the heat pipe (2), the focusing convex lens (3) and the focusing concave reflector (4) are all arranged in the outer housing (1); the focusing convex lens (3) and the focusing concave reflector (4) are both stripe-shaped, and are arranged in parallel to the heat pipe (2) in the lengthwise direction; the focuses of the focusing convex lens (3) and the focusing concave reflector (4) are linear, and the focus links superpose with the axis (C) of the heat pipe (2); and heat-conducting medium is arranged in the heat pipe (2). The invention can be widely used to the technical field of solar energy utilization.

Owner:ZHUHAI HUISHENG ENERGY SOURCE TECH DEV

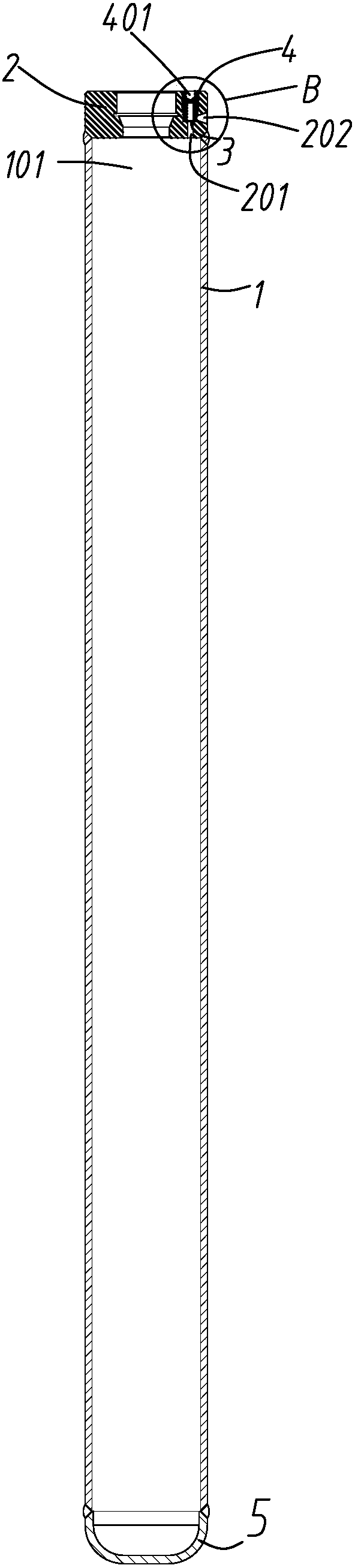

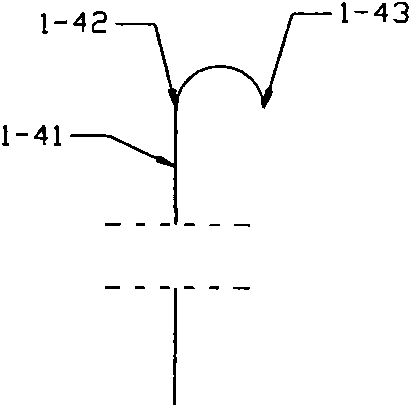

Safety valve for lithium ion cell

InactiveCN1688041AAvoid Burst AccidentsPlay a role of security protectionSecondary cellsCell component detailsEngineeringSafety valve

This invention discloses a safety valve mounted on the orifice of the Li ionic battery shell including a battery top cover with a seat at the middle sealed-in with the cover. A central hole is set on the seat, and the diameter of the upper section is greater than that of the lower to form circle stage at the middle, a valve plug, a spring and a wafer are set in the central hole from the bottom to the top on the circle stage. A central hole is on the wafer, its edge is sealed-in with the central orifice of the valve seat, a rubber film is on the wafer, its surrounding is sealed-in with the wafer, a cover with an air gate at the center is set on the rubber film and downward center is set at the air gate, the peak of the center is in a gap with the film.

Owner:汤国江

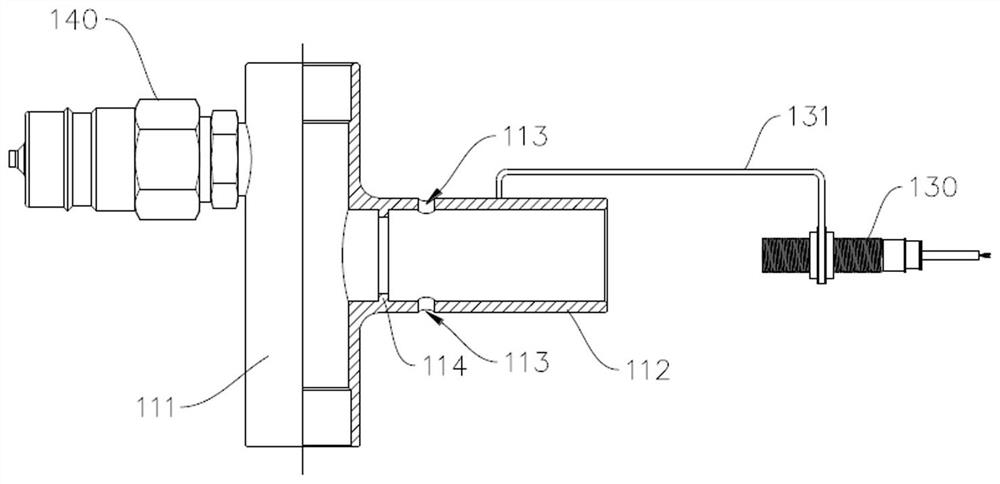

PCCP (prestressed concrete cylinder pipe) pipe broken wire detection equipment based on orthogonal electromagnetic principle

InactiveCN110346838ARealize non-destructive testingImprove efficiencyElectric/magnetic detectionAcoustic wave reradiationPre stressEngineering

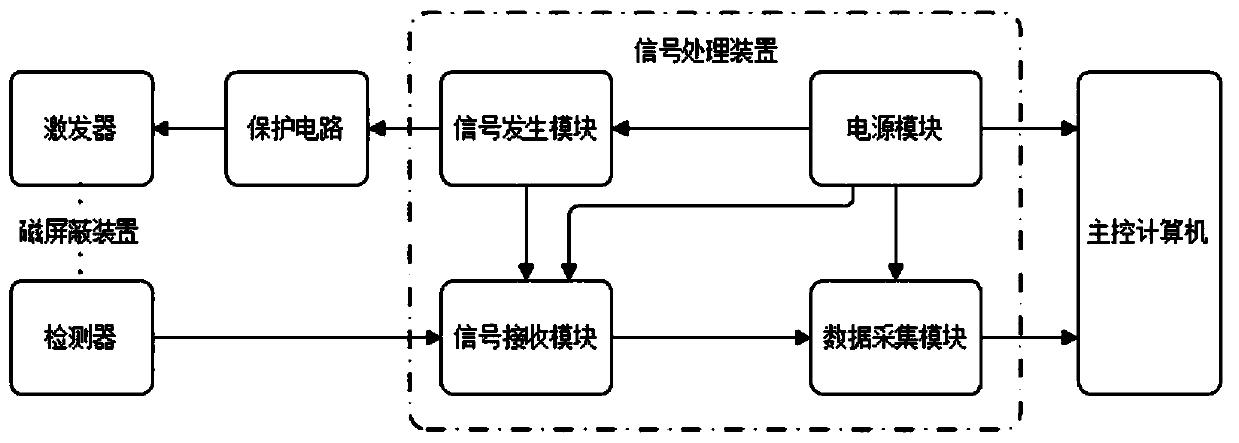

The invention discloses PCCP (prestressed concrete cylinder pipe) pipe broken wire detection equipment based on an orthogonal electromagnetic principle. The equipment comprises an exciter, a detector,a protection circuit, a signal processing device and a moving device, wherein the moving device is convenient for carrying the detection device; the exciter and the detector are orthogonally arranged; the protection circuit is used for protecting the exciter; the exciter is driven by a low-frequency sinusoidal signal to generate an alternating magnetic field, and the detector is used for receiving a magnetic field signal caused by an induced current in a steel wire; the signal processing device is used for extracting and amplifying weak electromagnetic signals and judging the positions and the number of broken wires. By means of internal electromagnetic nondestructive detection, the corrosion and breakage conditions of the prestressed steel wire can be checked in a targeted mode, and thehealth condition of the PCCP pipe is evaluated.

Owner:天津精仪精测科技有限公司

Decoking and coal-saving additive for supercritical or super-supercritical boiler

ActiveCN103215101AQuick smashGood defocusing effectSolid fuelsFuel additivesCupric nitrateDodecylsulfonic acid

The invention discloses a decoking and coal-saving additive for a supercritical or super-supercritical boiler. The additive comprises the components in percentage by weight as follows: 8.5-12.3% of magnesium nitrate, 5.0-7.2% of cupric nitrate, 6.0-8.5% of ammonium chloride, 1.2-2.5% of ammonium bicarbonate, 2.3-3.6% of boric acid, 1.5-2.0% of sodium dodecyl sulfate, 1.2-2.8% of modified nano ceramic powder dissolved in water, 1.2-2.2% of stabilizer and the balance of water. The additive provided by the invention has the advantages that 1, the additive is simple to operate and small in use level; 2, the decoking effect is good, and coke blocks can be quickly smashed; 3, the additive is less in environmental pollution, less in heavy metal salt content and less in smoke carried and generated by combustion and heavy metal; 4, the using safety of the boiler can be improved, and after coking of the boiler, the additive is quickly used to effectively prevent tube explosion of the boiler, and meanwhile to prevent large coking blocks from falling into a submerged chain conveyor to lead to major accident of chain breakage of the submerged chain conveyor; and 5, the additive is safe and non-toxic and does not harm the human body.

Owner:湖南省湘电试验研究院有限公司 +2

Anti-pipe-blocking detection device, spraying device, pipeline material recycling method and pipeline cleaning method

InactiveCN112268224ASimple processSimple structurePipeline systemsLiquid spraying apparatusElastomerStructural engineering

The invention provides an anti-pipe-blocking detection device, a spraying device, a pipeline material recycling method and a pipeline cleaning method. The anti-pipe-blocking detection device comprisesa valve body, an adjusting assembly and a proximity switch; the valve body is provided with a passage for connecting a to-be-detected pipeline and a branch communicating with the passage; the adjusting assembly is assembled in the branch, and the adjusting assembly comprises a piston matched with the branch, an elastic body acting on the piston and an end cover connected to the end of the branchin the mode of being capable of moving relative to the branch; and the proximity switch is assembled on the valve body and is arranged corresponding to the piston. The anti-pipe-blocking detection device is simple in structure, a related hydraulic system does not need to be additionally arranged, the pressure in the to-be-detected pipeline can be continuously adjusted, the pressure relief can be conducted on the pipeline in time when pipe blockage occurs, and pipe explosion accidents are avoided; according to the spraying device, residual materials in the pipeline can be collected back to a material barrel, and materials are saved; and the pipeline can be cleaned, the damage to devices due to material solidification is avoided, and therefore the service life is prolonged.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Hollow glass door and manufacturing method thereof

InactiveCN106567650AImprove safety and reliabilityNo moistureSealing arrangementsUnits with parallel planesAmbient pressureEngineering

The invention provides a hollow glass door and a manufacturing method thereof. The hollow glass door include a frame, an outer glass plate, an inner glass plate, and an air pressure balancing assembly; the outer glass plate and the inner glass plate are arranged on the frame; the air pressure balancing assembly includes a sealing partition bar and waterproof breathable film; the sealing partition bar is clamped between the outer glass plate and the inner glass plate; a plurality of vent holes are formed in the sealing partition bar; the waterproof breathable film is pasted on the sealing partition bar and covers the vent holes; the vent holes are covered by the waterproof breathable film; in actual use, when the pressure of a cavity formed between the glass plates is not equal to the ambient pressure, outside air can flow between the cavity and the outside environment through the vent holes, and then the air pressure in the hollow glass door and the air pressure outside the hollow glass door can be balanced, glass burst accidents due to over-high pressure difference can be avoided, and the safety and reliability of the hollow glass door can be improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

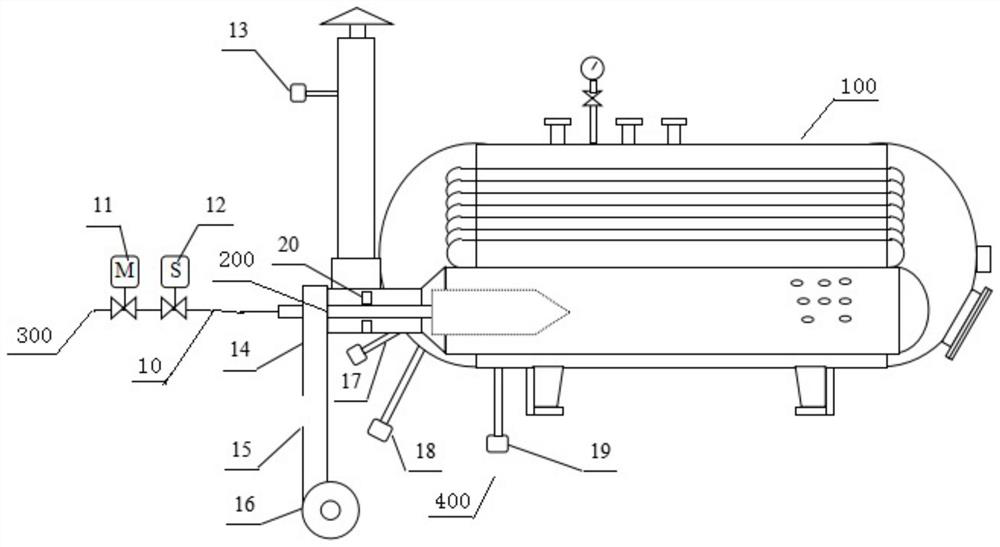

High-pressure high-temperature hot-water supply device

InactiveCN105865016ARaise base temperatureIncrease temperatureWater heatersCombustion chamberWarm water

The invention relates to a high-pressure high-temperature hot-water supply device comprising a preheating tank, a combustion chamber, a combustor, a heating coil, an exhaust pipe, an exhaust fan, a high-pressure pump and an electric controller. A cool-water inlet and a warm-water outlet are arranged in the preheating water tank, a warm-water inlet and a high-pressure high-temperature hot-water outlet are arranged in the heating coil, the warm-water outlet in the preheating water tank is connected with the high-pressure pump through a pipeline, a pipeline arranged on the water outlet of the high-pressure pump is connected with the warm-water inlet in the heating coil, the combustion chamber is of a semi-closed chamber, and the heating coil and the combustor are jointly arranged in the combustion chamber in a top-and-bottom corresponding manner; the exhaust pipe is entirely embedded in the preheating water tank, one end of the exhaust pipe is led in through the bottom of the preheating water tank while the other end is led out through the side wall of the preheating water tank, and the exhaust fan is arranged at the leading-out end of the exhaust pipe; a water return opening is arranged in the preheating water tank and is communicated with a pressure relief opening arranged at the position of the high-pressure high-temperature hot-water outlet through a water return pipe, and a pressure relief valve is arranged on the water return pipeline. The high-pressure high-temperature hot-water supply device is high in heat utilization, short in heating time and good in safety performance.

Owner:任福杰

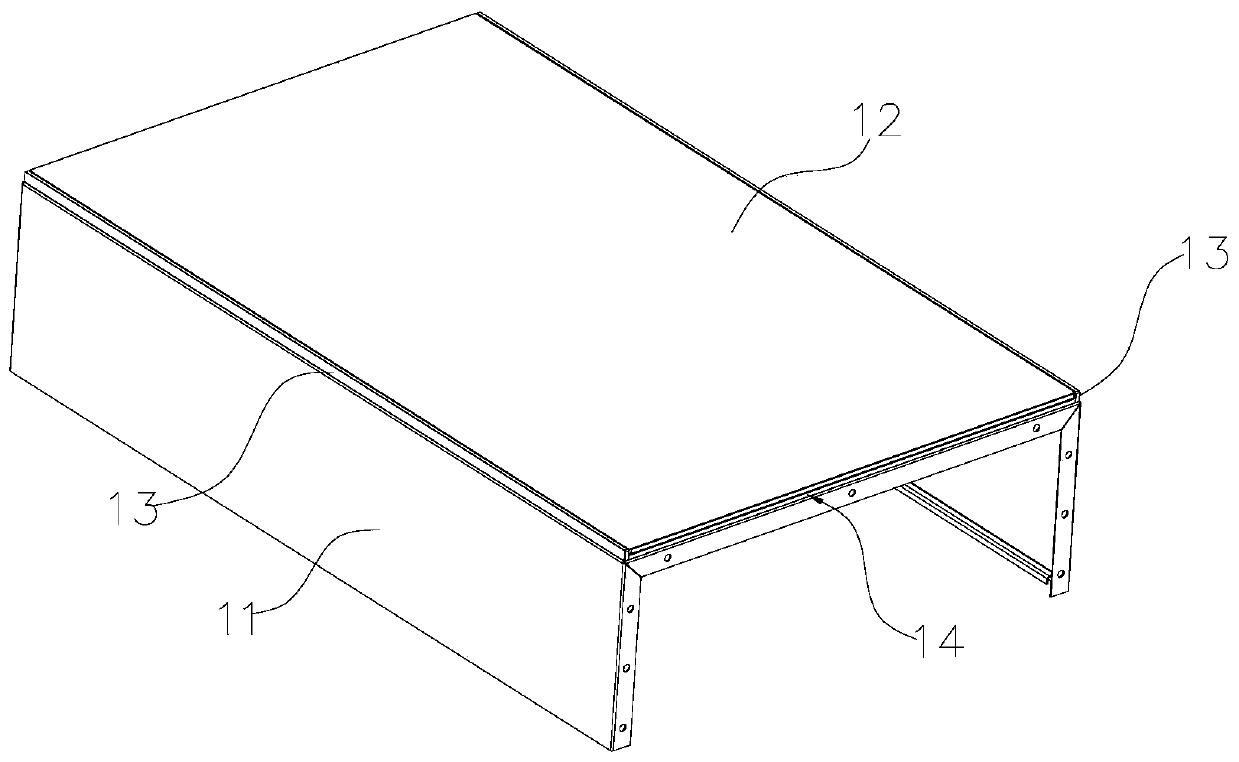

Water heater surface cover component bonding tool

ActiveCN111456989AEasy to placeAvoid scratchesMaterial gluingClassical mechanicsStructural engineering

The invention relates to a water heater surface cover component bonding tool. A water heater surface cover component comprises a glass surface board component and a surface cover body; and the tool comprises an operating frame with a workbench, a vertical frame, a bonding frame and opening and closing positioning components. According to the tool, the surface cover body is positioned through a floating positioning pin on a positioning plate, and the glass surface board component is positioned through the opening and closing positioning components on the two sides, so that the water heater surface cover component to be bonded is positioned, and the accuracy of bonding is ensured; in addition, the floating positioning pin can provide a certain buffering force in the process of downwards pressing the glass surface board component through a pressing plate so that the burst accident, caused by a downward pressing force of a pressing plate component, of a glass surface board can be avoided to a certain extent; and meanwhile, a gap is reserved between each opening and closing positioning component and the corresponding side surface of the surface cover body during bonding so that the scratch, caused by inward pressure of the opening and closing positioning components, on the side surfaces of the surface cover body can be avoided, and the attractiveness of the product appearance is ensured.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Heating device

InactiveCN104214816AHigh speedReduce power consumptionLighting and heating apparatusSpace heating and ventilation detailsEngineeringHigh pressure

The invention relates to a heating device. The heating device comprises a heating unit and a plurality of heat generating units. Each heat generating unit comprises a heat generating mechanism arranged on the heating unit and a heat conduction mechanism, each heat generating mechanism and the heating unit are correspondingly arranged, the heat conduction mechanisms are filled with superconduction media, and the superconduction media of the heat conduction mechanisms can transfer heat energy provided by the heating unit to the heat generating mechanisms for emission. The heat conduction mechanisms filled with the superconduction media capable of achieving constant-temperature heat exchange at the middle temperature are adopted, the heat energy of the heating unit is transferred to the heat generating mechanisms for emission, the room warming speed is high, power consumption is small, the high pressure cannot be generated by over-high temperature, and cracking accidents can be avoided.

Owner:台湾珈诚超导能源科技股份有限公司 +1

Hollow glass door and manufacturing method thereof

InactiveCN106196855AImprove safety and reliabilityEnsure air pressure balanceDomestic cooling apparatusLighting and heating apparatusEngineeringAtmospheric pressure

The invention provides a hollow glass door and a manufacturing method thereof. The hollow glass door comprises a door frame, an outer glass panel and an inner glass panel. The outer glass panel and the inner glass panel are mounted on the door frame. The hollow glass door further comprises a spacing assembly which comprises a spacer and a waterproof gas-permeable membrane. The spacer is clamped between the outer glass panel and the inner glass panel in a sealing mode. A plurality of air holes are formed in the spacer, and the waterproof gas-permeable membrane is attached to the spacer and covers the air holes. The air holes are covered through the waterproof gas-permeable membrane; and during the practical using process, when the pressure of a cavity formed between the glass panels is not equal to the outside pressure, outside air can flow between the cavity between the glass panels and the outside environment through the air holes, so that the air pressure balance inside and outside the hollow glass door is guaranteed, glass bursting accidents due to large inside and outside pressure differences are avoided, and the safe reliability of the hollow glass door is improved.

Owner:QINGDAO HAIER SPECIAL ICEBOX

A remote automatic monitoring system for secondary water supply

ActiveCN112202912BImplementation statusAchieve securityClosed circuit television systemsIndividual entry/exit registersWater flowMonitoring system

The invention discloses a remote automatic monitoring system for secondary water supply. The sensor monitors the water flow information of the outlet pipe; equipped with a video acquisition module to obtain video information around the secondary water supply equipment, equipped with a pressure sensor to monitor the water pressure information in the outlet pipe, when the water pressure information / water flow information exceeds the preset water pressure threshold / When the preset water flow threshold reaches the preset time, the alarm module is controlled to issue an alarm, which realizes the remote status monitoring and safety monitoring of the secondary water supply equipment, and improves the safety of the equipment; the timing module and the water level sensor realize the timing and quantitative water addition of the secondary water supply equipment. Function, reduce manpower input and improve work efficiency; access control management module is used to manage the entry and exit of personnel, which improves the safety of secondary water supply equipment.

Owner:XINGAN ANHUI ELECTRIC LTD BY SHARE LTD

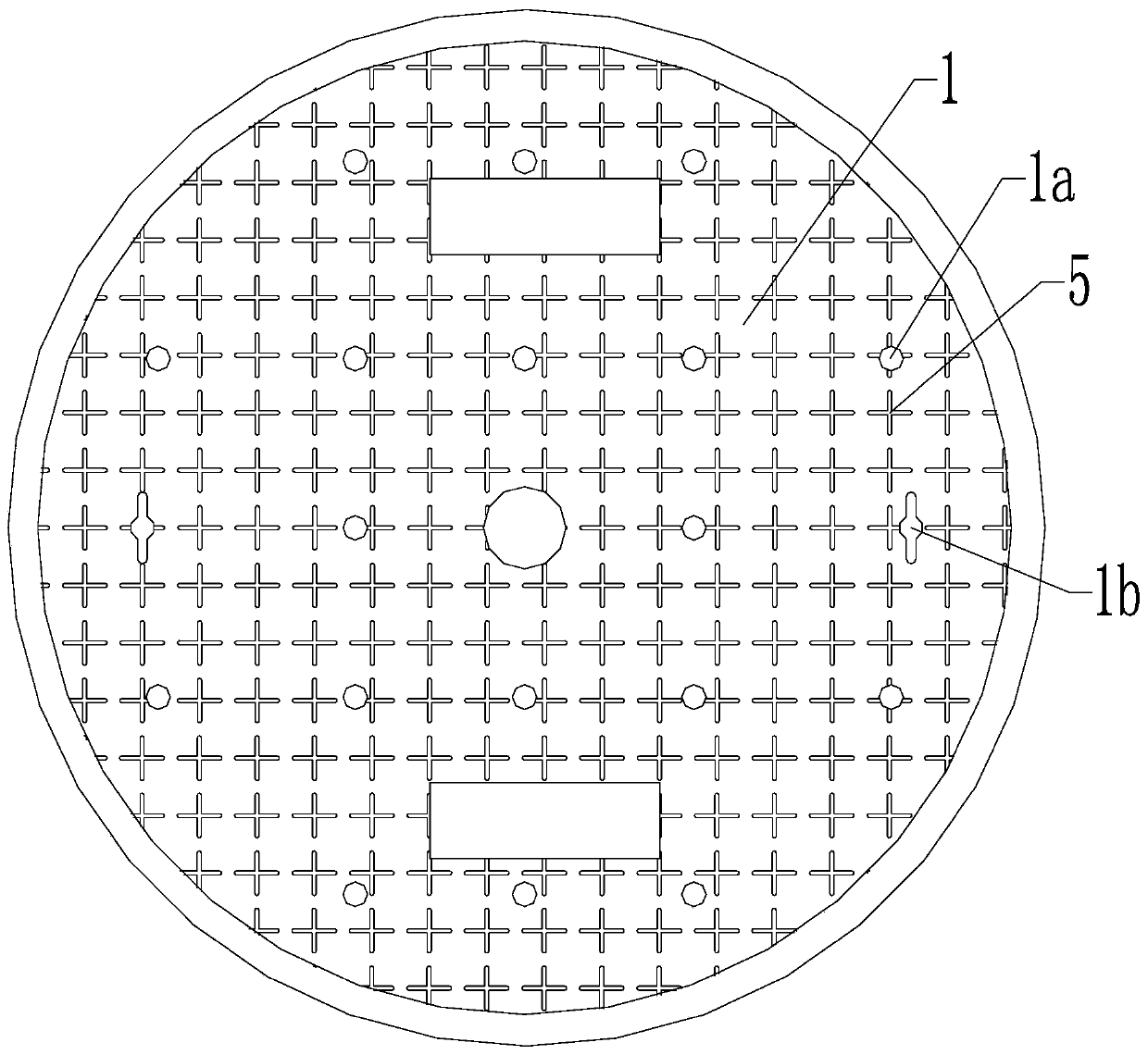

Sewer well lid and well lid assembly

ActiveCN111003967ADoes not affect bearing capacityExtended service lifeArtificial islandsUnderwater structuresSewerageCivil engineering

The invention discloses a sewer well lid. According to the sewer well lid, eighteen gas-permeable holes are dispersedly formed in a well lid body to automatically disperse biogas in a sewer from the gas-permeable holes, so that high-concentration biogas is effectively prevented from remaining in the sewer, and pipe explosion accidents are avoided; the components and the production process of the well lid are redesigned, the bearing capacity of the well lid is not affected even if a large number of gas-permeable holes are formed, actually the load of the well lid reaches up to 60 tons through the new components and the new process, and the load of the conventional well lid on the market is only about 40 tons, so that the service life of the well lid is remarkably prolonged; and the invention further provides a well lid assembly comprising the well lid, and an anti-falling net is arranged on the well seat of the well lid assembly, so that people are prevented from falling into a well accidentally after the well lid is opened so as to improve the safety of the well seat assembly.

Owner:重庆振坤达交通设施有限公司

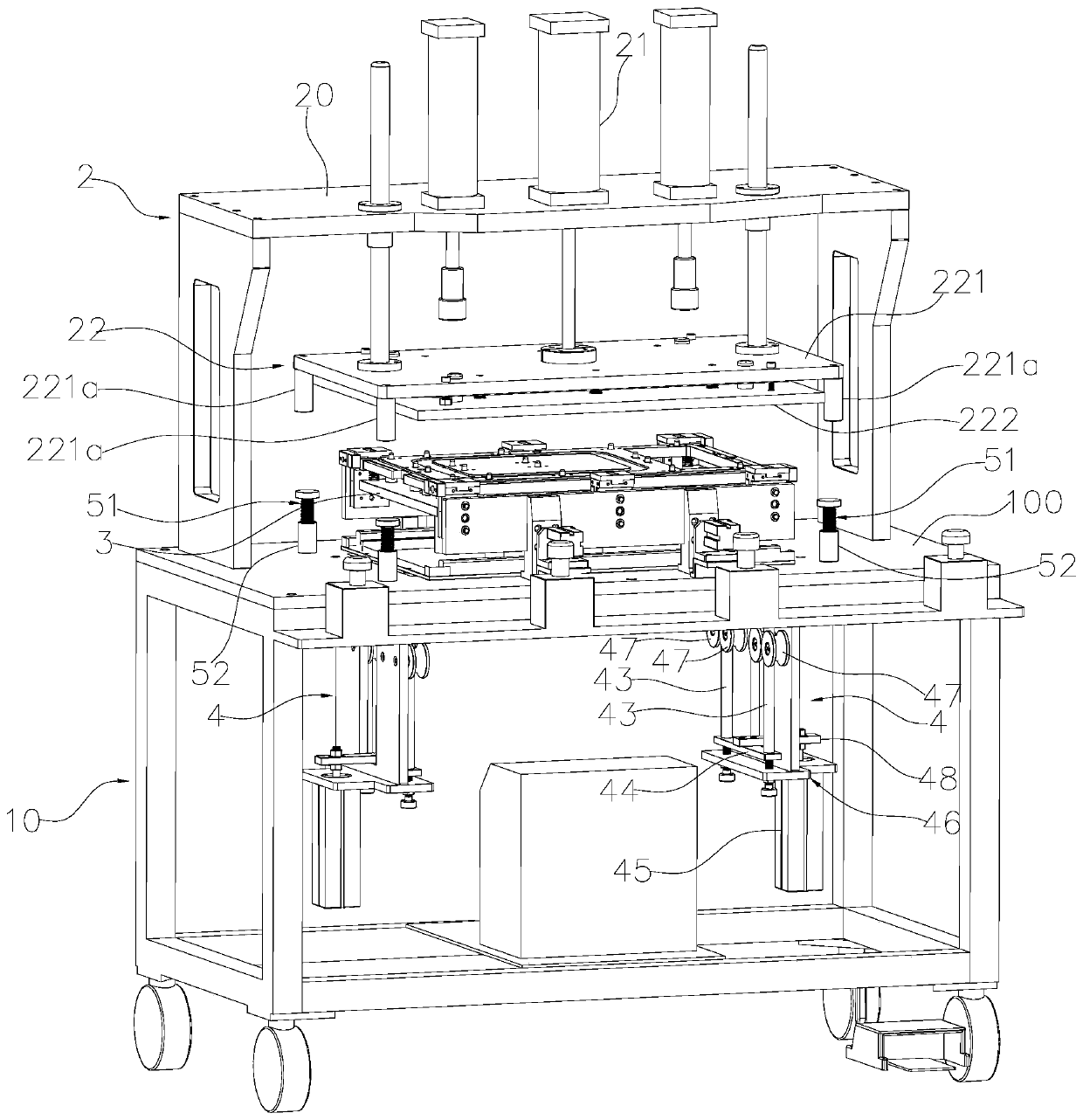

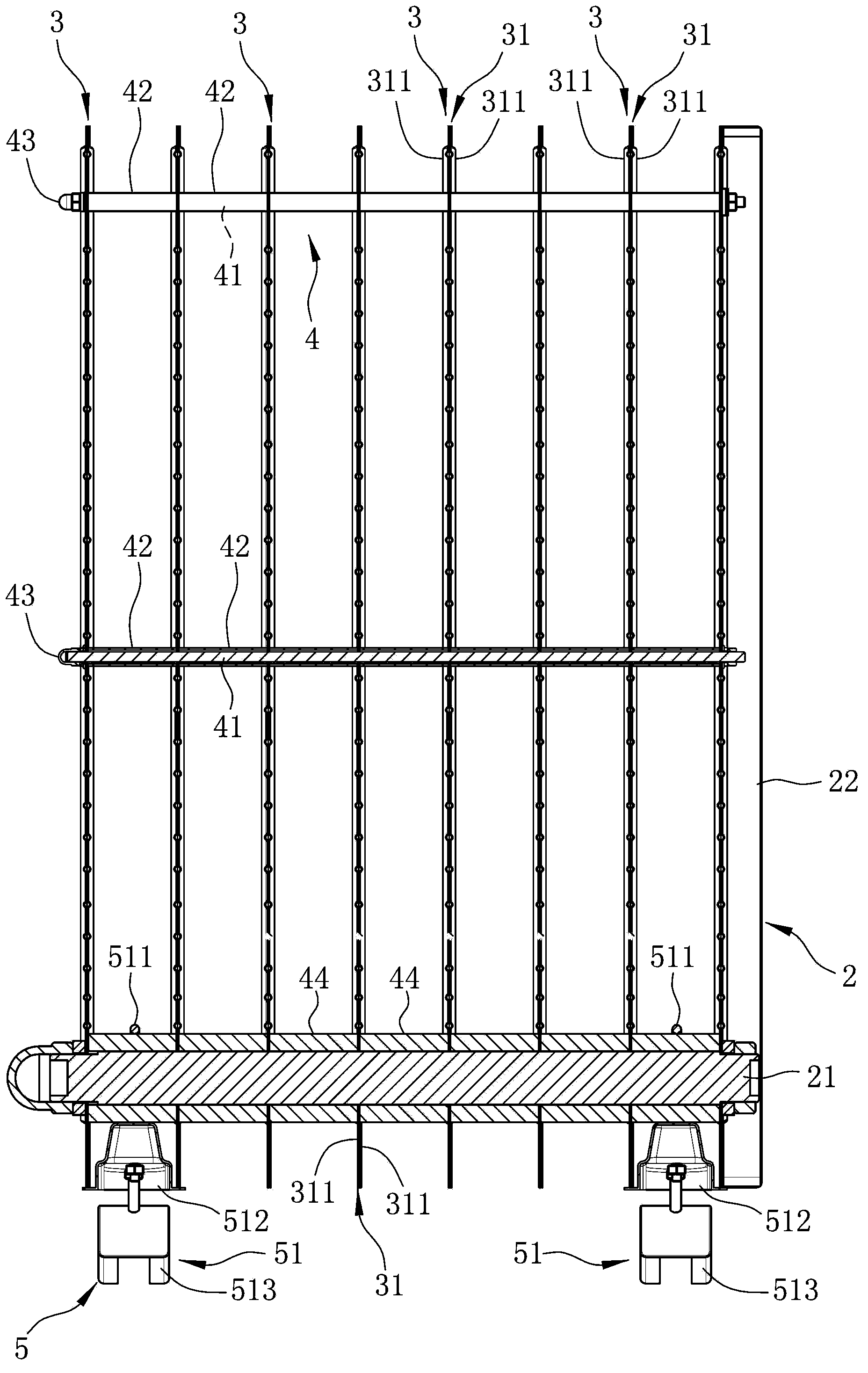

Phototube test automation device and method

PendingCN114355145AReduce the possibility of electric shockSame placementIndividual semiconductor device testingTemperature controlControl power

The invention belongs to the field of detection devices, and particularly relates to a photoelectric tube test automation device and method.The photoelectric tube test automation device comprises a combination table, power devices are symmetrically arranged on the front side and the rear side of the outer surface of the combination table, conductors are fixedly connected to the left sides of the outer surfaces of the power devices, and a supporting frame is fixedly connected to the right side of the outer surface of the combination table; the right side of the supporting frame is fixedly connected with a control power source through a connecting wire. The device can detect each processed to-be-detected pipe body in a flow mode, compared with manual detection, the possibility that an operator gets an electric shock when the to-be-detected pipe body is broken down due to unqualified quality is effectively reduced, the device can be remotely operated by the operator in the process of detecting the to-be-detected pipe body in a power-on mode, the detection conditions of all the to-be-detected pipe bodies are the same, and the detection efficiency is improved. Namely, the electrified parts and the placement positions are the same, and the temperature control conditions are the same, so that the test environment is more reliable, and the problem of test result deviation caused by unfixed electrified positions during manual detection is avoided.

Owner:淮安昕锐至新光电科技合伙企业(有限合伙)

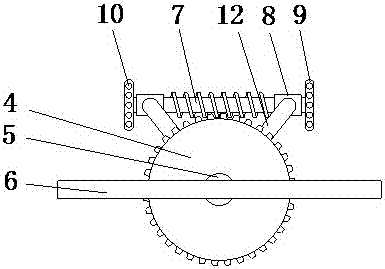

Cleaning device for thermal equipment

InactiveCN107321675AEasy to cleanAvoid Burst AccidentsHollow article cleaningCleaning using liquidsAgricultural engineeringMotor shaft

The invention discloses a cleaning device for thermal equipment, which comprises a casing, the front of the casing is fixedly connected with a motor, and the rear end of the rotating shaft of the motor passes through the casing and extends to the inside of the casing to be movably connected with a rotating shaft. The rear end of the rotating shaft is movably connected with a bearing, the back of the bearing is fixedly connected with a tooth block, the bottom of the tooth block is fixedly connected with a connecting block, the inside of the housing is fixedly connected with a fixed rod, and the fixed rod The front of the tooth block is fixedly connected with the back of the connection block, and the surface of the tooth block is engaged with a threaded rod. The invention makes the thermal equipment easy to clean by arranging the motor, the rotating shaft, the bearing, the gear block, the connecting block, the fixed rod, the threaded rod, the bearing sleeve and the V-shaped block. Inhomogeneous mixing of substances can cause pipe burst accidents caused by local damage to thermal equipment, which is beneficial to people's use.

Owner:颜秋羊

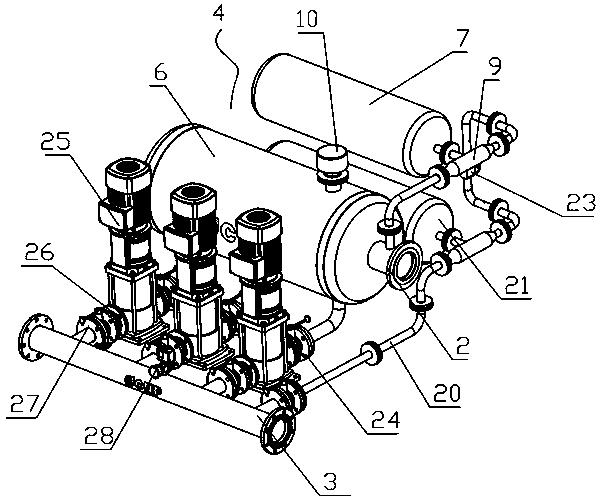

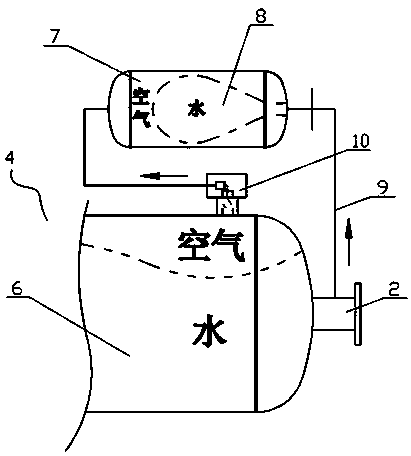

A nfwgⅢ type multi-stage tank water supply equipment

ActiveCN106400891BEffective filteringBackflow will notService pipe systemsWater mainsWater dischargeControl system

The invention discloses NFWGIII-type multistage tank body water supply equipment, which comprises a control system and a flow stabilizing tank device which is arranged between a water supply main pipe and a water discharging main pipe, wherein the flow stabilizing tank device, as a multistage tank body structure, comprises a flow stabilizing tank and a voltage supplementing tank body; a voltage supplementing capsule body is arranged in the voltage supplementing tank body; a water inlet branch pipe, which is connected to the voltage supplementing tank body, is arranged on the water supply main pipe; the water outlet of the water inlet branch pipe communicates with an opening of the voltage supplementing capsule body; the flow stabilizing tank body is connected to the voltage supplementing tank body by virtue of a negative pressure inhibiting device; the negative pressure inhibiting device is connected to the control system; and the negative pressure inhibiting device communicates with a cavity of the voltage supplementing tank body outside the voltage supplementing capsule body by virtue of a pipeline. The water supply equipment, through a cooperated operation with the multistage tank body structure, offers voltage supplementing double guarantee by virtue of the voltage supplementing capsule and gas, so that a negative-pressure inhibiting effect of municipal water supply is enhanced and the safe running of a municipal pipe network is guaranteed.

Owner:南方智水科技有限公司

Safety explosion-proof carbon dioxide cracking equipment

ActiveCN107202519BProtection against accidental blastingEasy to installBlasting cartridgesInternal pressureEngineering

Owner:湖南烈岩科技有限公司

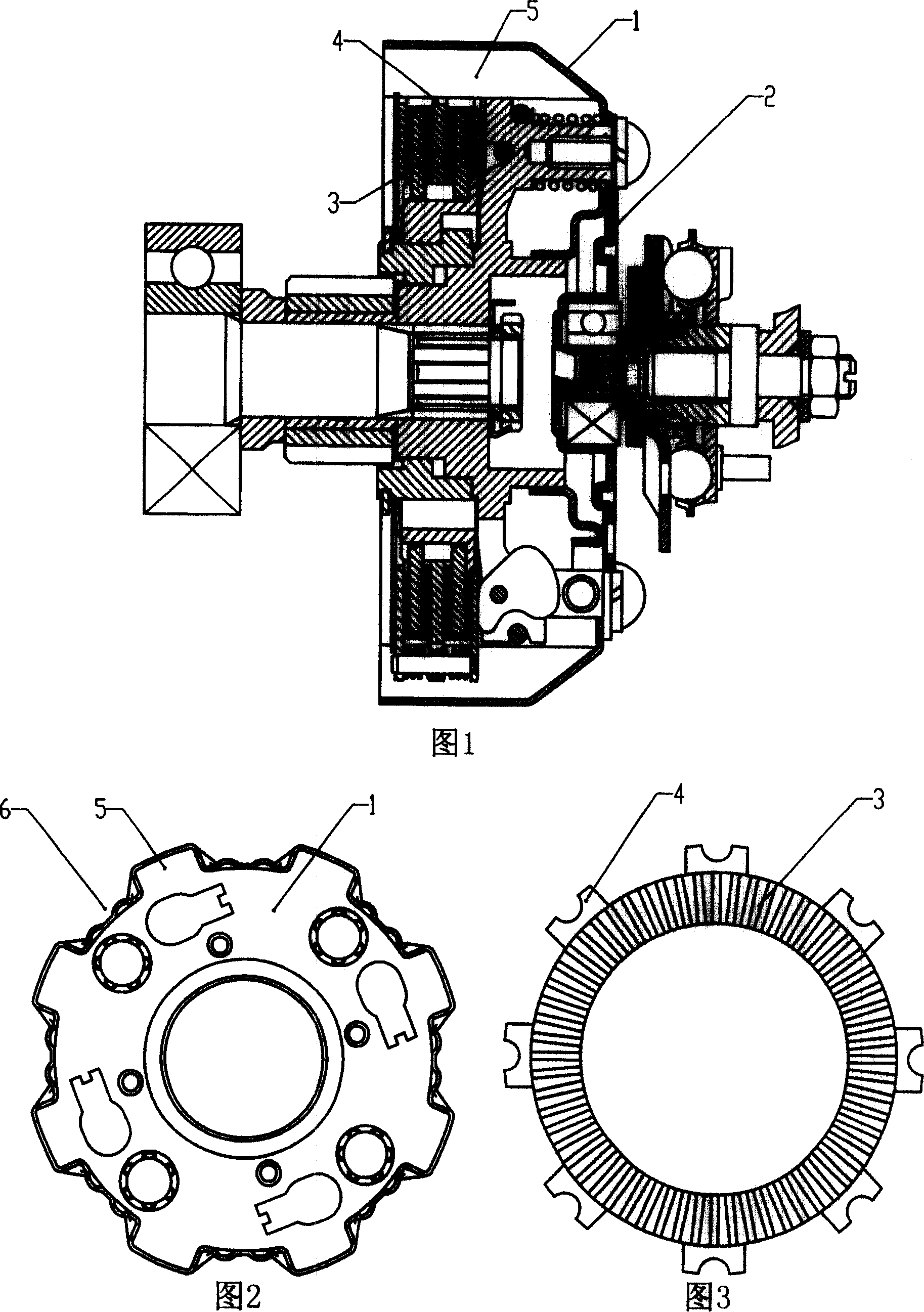

Friction plate clutch

The invention discloses a friction plate motorcycle clutch whose outer cover has high tensile strength, uneasy to crack, where the outer cover is provided with a runner adapting to external teeth on an active friction plate, and the outer cover is of a continuous integrated structure formed by punching and stretching. In addition, the circumference of outline of the external cover is provided with grooves or grooves plus through holes to make the external cover be of a vane shape, thus improving heat radiating property of the clutch, avoiding the damage to the friction plate by overhigh temperature and preventing the clutch skidding. Besides, it can be widely applied to motorcycles.

Owner:刘珍利

Flameout detection protection and re-ignition device for heating furnace

PendingCN111829191AEliminate accumulationEliminate deflagration accidentsFluid heatersElectric spark ignitersCombustible gasFlameout

The invention provides a flameout detection protection and re-ignition device for a heating furnace, and relates to the technical field of heating equipment. The technical problems that no detection means is used for fire extinguishing of the heating furnace, manual discovery is required and hidden dangers exist are solved. The flameout detection protection and re-ignition device for the heating furnace comprises a furnace body, a ventilation door and a chimney are arranged on the furnace body, and the flameout detection protection and re-ignition device further comprises a fire nozzle, a gassupply assembly and two fire extinguishing monitoring assemblies, wherein the fire extinguishing monitoring assemblies are installed in a premixing area and a flame area respectively; the device further comprises a sleeve type tee joint, a switching air valve and a high-pressure fan; a combustible gas sensor is arranged in the chimney; the self-pressurization high-energy high-frequency igniter isarranged in the furnace body and is close to the fire nozzle; and a flame stabilizer is arranged in the air inducing area. The flameout detection protection and re-ignition device disclosed by the invention has the characteristics of safety and capability of monitoring whether fire is extinguished in the heating furnace in real time and closing fuel gas in time or not.

Owner:王佐芹

Explosion-proof safety carbon dioxide cracking equipment

ActiveCN107202519AProtection against accidental blastingEasy to installBlasting cartridgesEngineeringAtmospheric pressure

The invention relates to carbon dioxide cracking devices, in particular to explosion-proof safety carbon dioxide cracking equipment. The explosion-proof safety carbon dioxide cracking equipment comprises a pipe, a liquid storage cavity is formed in the pipe, and an energy charging head is further arranged on the pipe. A pressure relief channel enabling the liquid storage cavity to communicate with the outside and a liquid charging opening communicating with the pressure relief channel are formed in the energy charging head. An explosion-proof safety sheet arranged in the pressure relief channel and used for blocking the pressure relief channel and a gas locking part which is located on the explosion-proof safety sheet and can vertically move in the pressure relief channel are further included. The explosion-proof safety sheet is adopted for preventing the accidental exploding situation of the carbon dioxide cracking equipment, pressure generated inside becomes large to be larger than pressure intensity capable of being borne by the explosion-proof safety sheet, and the explosion-proof safety sheet can crack to enable the liquid storage cavity to communicate with the outside; and air pressure in the liquid storage cavity can be released, and the cracking accident caused by increase of the internal air pressure is effectively avoided.

Owner:湖南烈岩科技有限公司

A Large Capacity Circulating Fluidized Bed Hot Water Boiler with Forced Water Circulation

ActiveCN103644648BImplement security requirementsAvoid damageFluidized bed combustionWater heatersWater circulationHearth

The invention discloses a forced water circulation high-capacity hot water boiler of a circulating fluidized bed, which relates to a hot water boiler of a fluidized bed, and aims to ensure water circulation safety and power failure protection of a high-capacity hot water boiler of a circulating fluidized bed. A water supply distribution header is connected with lower coal economizers; the lower coal economizers, middle coal economizers and upper coal economizers are sequentially connected with one another; the upper coal economizers are connected with a coal economizer upper header; the coal economizer upper header is connected with a collection water bag by a coal economizer coating pipe; the collection water bag is connected with water cooling wall lower headers by a descending pipe; the water cooling wall lower headers are connected with a hearth water cooling wall; the hearth water cooling wall is connected with water cooling wall upper headers; the water cooling wall upper headers are connected with a boiler cylinder by extraction pipes; the water supply distribution header is connected with a separator water cooling sleeve by a water cooling sleeve water intake pipe; the separator water cooling sleeve is connected with the boiler cylinder by a water cooling sleeve water outlet pipe; the boiler cylinder is connected with the water cooling wall lower headers by communicating pipes, and is connected with the water supply distribution header by a power failure water supply pipe. The forced water circulation high-capacity hot water boiler provided by the invention is applied to large concentrated heat supply and warming.

Owner:哈尔滨红光锅炉总厂有限责任公司

Intelligent internal detection device for oil and gas pipelines based on multi-mode combined positioning

ActiveCN103470959BReduce resistancePrevent pulling outPipeline systemsMaterial magnetic variablesSpeed control systemElectromagnetic pulse

The invention discloses an oil and gas pipeline intelligent internal detection device based on multi-module combined location. The device comprises an internal detector arranged inside an oil and gas pipeline and a floor marker arranged outside the oil and gas pipeline. The internal detector comprises a driving system, a magnetic leakage detecting system, a speed control system, a distance measuring system and a low frequency emitting system, wherein the driving system, the magnetic leakage detection system, the speed control system, the distance measuring system and the low frequency emitting system are relatively fixedly connected together; the floor marker at least comprises a low frequency receiving system; the low frequency emitting system is used for sending detection results obtained by the magnetic leakage detection system out of the oil and gas pipeline; the low frequency receiving system is used for receiving low frequency electromagnetic pulse signals transmitted by the low frequency emitting system. The oil and gas pipeline intelligent internal detection device based on the multi-module combined location can timely obtain the detection data of the pipeline detector and analyze the detection data and accordingly rapidly determine the defect conditions of the pipeline.

Owner:BEIJING APC PETROCHEM TECH

Device for preventing oxide skin blockage of boiler superheater and reheater and regulation and control method thereof

ActiveCN114543580AAchieve cloggingLow flow resistanceIndirect carbon-dioxide mitigationNon-rotary device cleaningThermodynamicsEngineering

The invention discloses a device for preventing oxide skin blockage of a superheater and a reheater of a boiler and a regulation and control method of the device. A sectional type inlet header corresponds to a group of single-screen heat exchange tube bundles, the group of single-screen heat exchange tube bundles comprises a plurality of single-screen heat exchange tube bundles, and each single-screen heat exchange tube bundle comprises a heat exchange tube body; the heat exchange tube body comprises a heat exchange tube inlet end, a first heat exchange tube straight-flow section, a bent tube section, a second heat exchange tube straight-flow section and a heat exchange tube outlet end; the bent pipe section comprises a bent pipe inlet end, a bent pipe horizontal section and a bent pipe outlet end; outlets of the sectional type inlet headers are communicated with the outlet header sequentially through the corresponding heat exchange pipe inlet ends, the first heat exchange pipe direct flow sections, the bent pipe inlet ends, the bent pipe horizontal sections, the bent pipe outlet ends, the second heat exchange pipe direct flow sections and the heat exchange pipe outlet ends, and the adjacent sectional type inlet headers are communicated through a two-way pneumatic adjusting valve. The device and the regulation and control method thereof can realize dredging and recovery of the oxide skin in the boiler tube bundle of the generator set.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com