Heated surface tube inner oxide skin accumulation condition detection method

A technology of heating surface tubes and oxide skins, which is applied in the direction of measuring devices, instruments, and electrical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The concrete steps of this method are as follows:

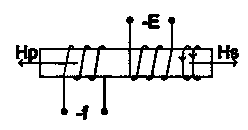

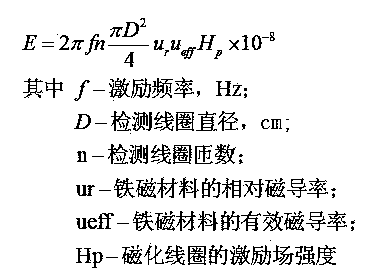

[0016] 1. Wrap the excitation coil on the heating surface tube to detect the amount of scale accumulation, and pass a low-frequency alternating current below 50 Hz to the coil. The effective penetration depth of the current is greater than the thickness of the tube wall and can penetrate the thickness of the oxide scale accumulation;

[0017] 2. Wrap the measuring coil at a certain distance L away from the exciting coil on the tube of the heating surface to be tested;

[0018] 3. Measure the induced electromotive force at both ends of the coil described in step 2;

[0019] 4. Compare the measured data with the test data to judge the amount of oxide scale accumulation on the inner wall of the pipe.

[0020] Although this method also adopts magnetic detection scale, but the magnetization mode is different, and the scope of the detected heating surface tube is also different. Using the present invention can not only dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com