Friction plate clutch

A friction plate and clutch technology, applied in the field of friction plate clutches, can solve the problems of friction transmission pair friction plate burning, damage to engine-related components, and tensile strength bursting, etc., to avoid threaded hole damage, accelerate full flow, improve The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

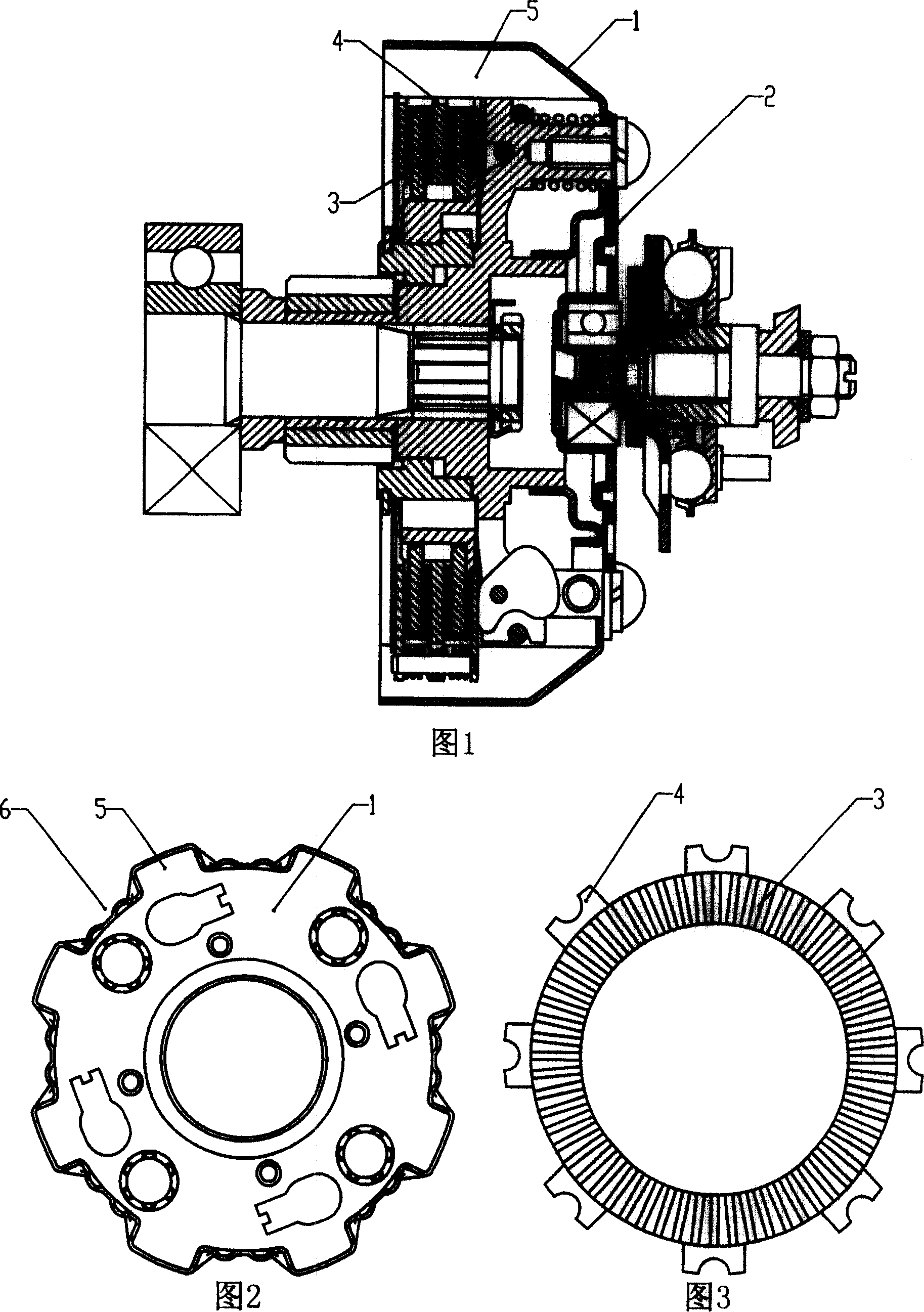

[0016] Embodiment: as shown in Fig. 1, Fig. 2 and Fig. 3, the friction disc clutch of the present invention is provided with a chute 5 adapted to the outer teeth 4 on the active friction disc 3 on its outer cover 1, and the outer cover 1 adopts cold Rolled steel plate is made, and the outer cover 1 of continuous overall structure is made by stamping and stretching. A groove 6 extending along the axial direction of the outer cover 1 is provided on the circumference of the outer contour of the outer cover 1 to make the outer shape of the outer cover 1 form an impeller shape. The chute 5 adopts an integral structure formed by stamping and stretching and the periphery of the chute 5 is closed and forms a continuous integral structure with the outer contour of the outer cover 1, and grooves are naturally formed between the periphery of the contour of the chute 5 formed by adjacent stamping and stretching 6. Further improve the strength of the outer cover 1 of its overall structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com