Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid abnormal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling and regenerating PCB (Printed Circuit Board) acidic and alkaline etching waste liquid

InactiveCN103789769AAvoid abnormal qualityPhotography auxillary processesProcess efficiency improvementLiquid wasteElectrolysis

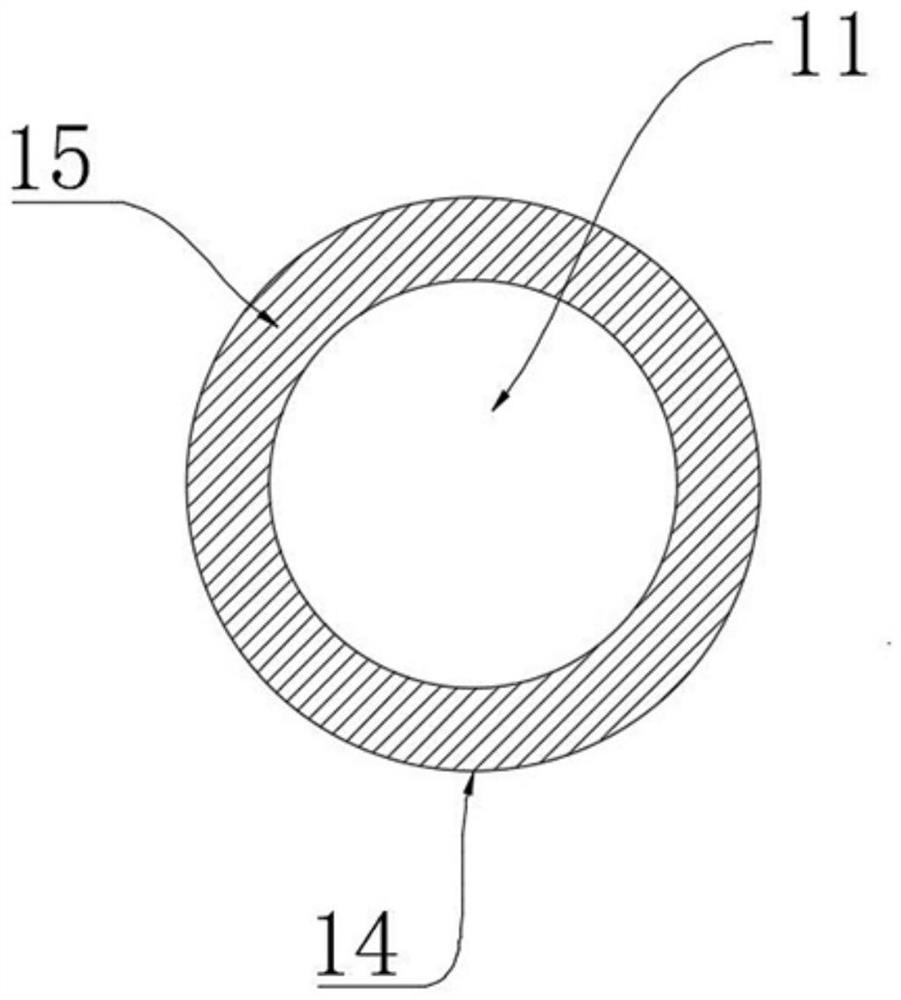

The invention provides a method for recycling and regenerating PCB (Printed Circuit Board) acidic and alkaline etching waste liquid. The method comprises the following steps: feeding acidic and alkaline etching waste liquid and an alkaline extracting agent into a centrifugal extraction system under the driving of power in a ratio of 1:4, and mixing, agitating and separating, wherein copper ions of the separated etching liquid are reduced to be lower than 50g / L and thus the acidic and alkaline etching waste liquid is regenerated; blending the regenerated acidic and alkaline etching waste liquid and returning back to a production line for cyclic utilization; after separating, feeding the extracting agent into a centrifuging water washing groove; after washing with water, feeding the extracting agent into a centrifugal backwashing groove, mixing with 190g / L dilute sulfuric acid and stirring so that the extracted copper ions are converted into copper sulfate; conveying the copper sulfate into a centrifugal electrolysis system, and producing a pipe type electrolysis copper pipe under the effect of direct current, wherein the copper content of the copper pipe is 99.95%; and after backwashing, conveying the extracting agent into an extracting agent chamber for cyclic utilization. With the adoption of the method, the problems in the prior art that the extracting agent is easy to lose, sulfate ions easily enter regenerated liquid, an electrolytic bath is likely to generate short circuit in the operation process, the occupied area of equipment is large can be solved.

Owner:WUXI RUISIKE ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

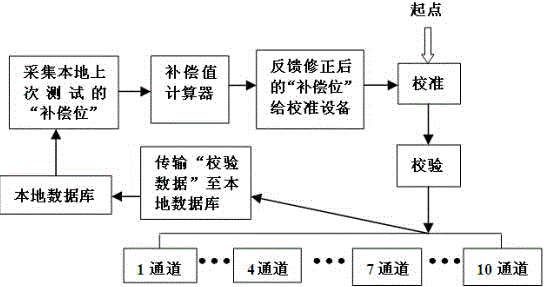

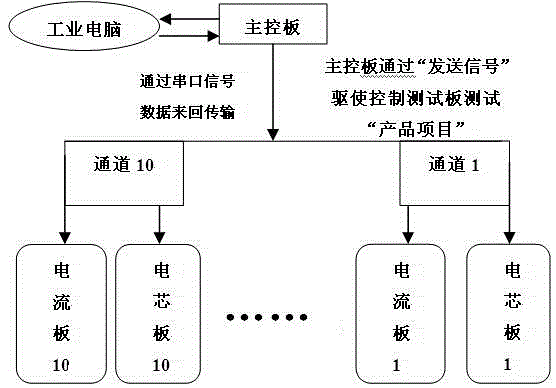

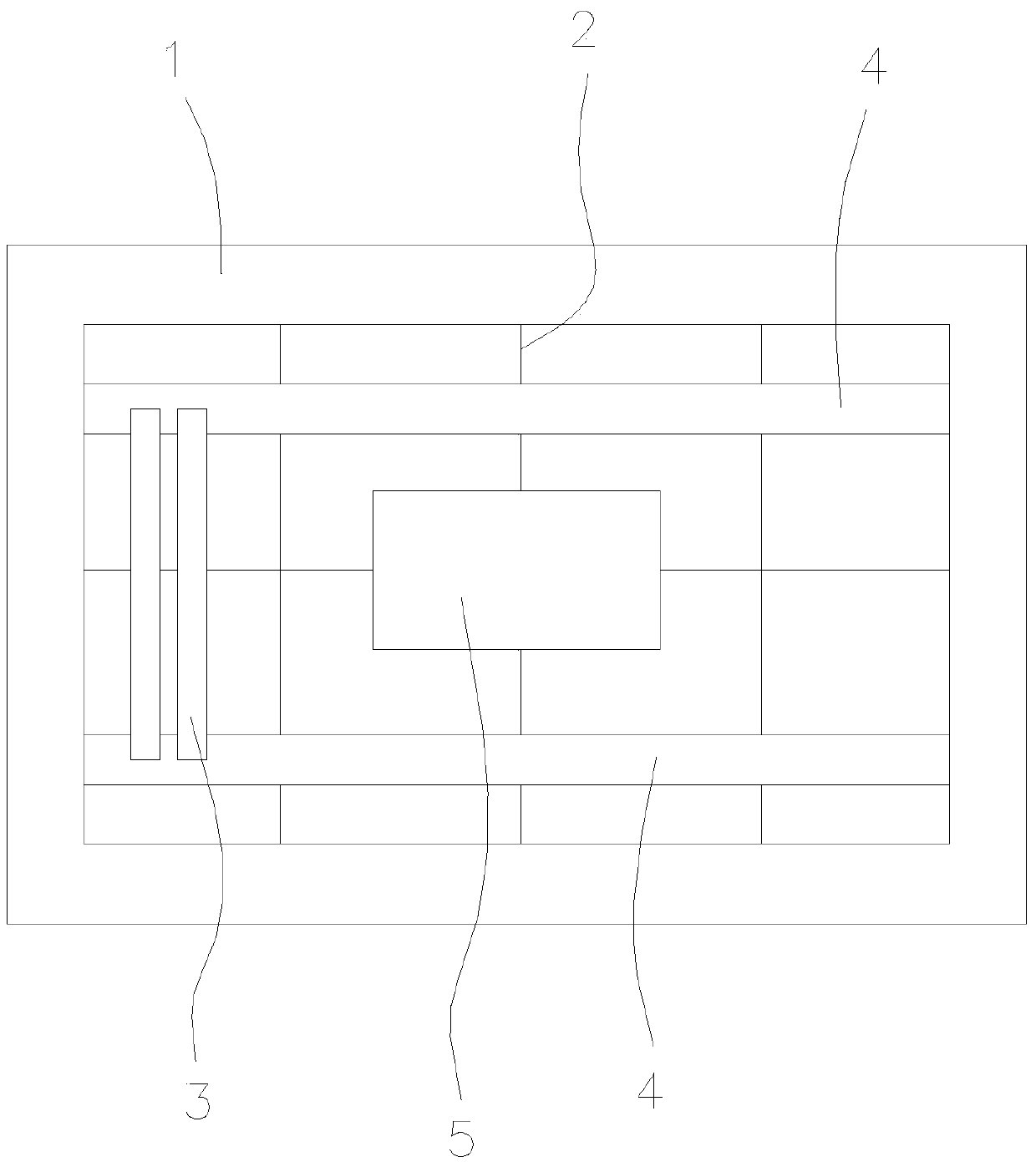

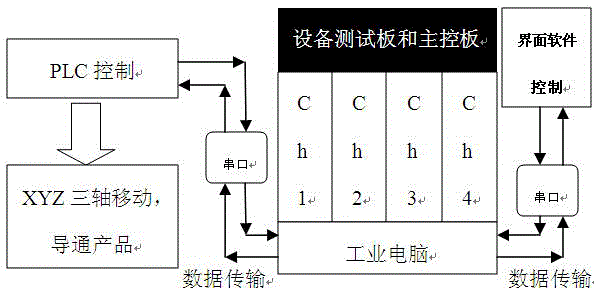

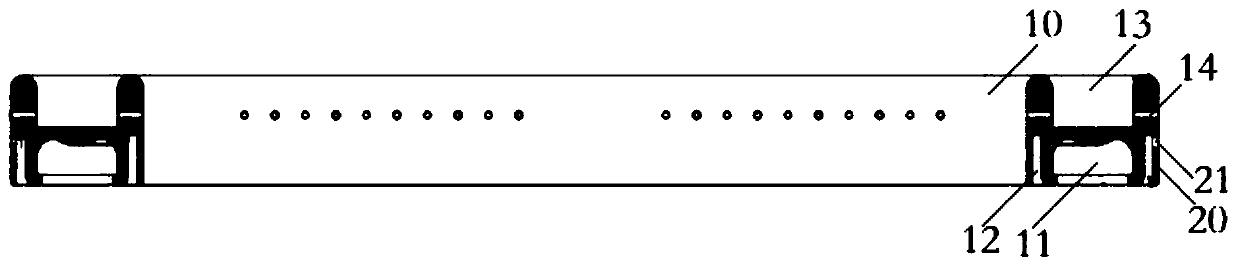

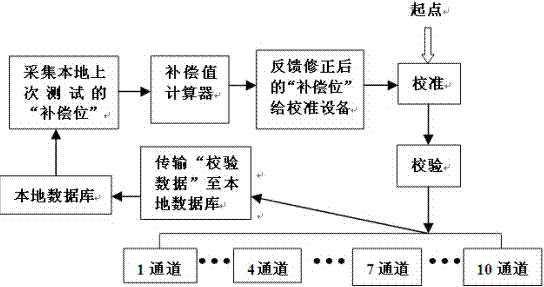

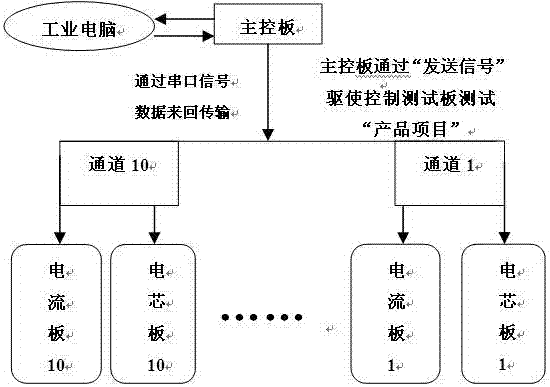

Multichannel calibration and verification device and method for multiple sections of electric-quantity management ICs

ActiveCN104133185AImprove scalabilityExpand the scope of testingElectrical measurementsTest efficiencyComputer module

The invention provides a multichannel calibration and verification device and method for multiple sections of electric-quantity management ICs. The method mainly controls a plurality of channel test boards through a main control board to test the multiple sections of electric-quantity management ICs and in a test process, a localized closed-loop correction method is adopted to calibrate voltage and current precision of the multiple sections of electric-quantity management ICs. Moreover, through adoption of a channel self-detection module, precision calibration is carried out on cell boards and current boards of the channels of the device so that precision calibration of a voltage and current reference source of the device is realized and stability of the reference source of the device is ensured. The method also uses a channel combination module according to practical needs to combine the plurality of channels into large channels so as to meet test demands of the multiple sections of electric-quantity management ICs. The method uses a method of using the plurality of channels to carry out parallel tests simultaneously so that test efficiency of the multiple sections of electric-quantity management ICs is improved, expandability of the multichannel calibration and verification device is strengthened, demands that users configure the channels flexibly according to practical conditions can be met and user use cost is reduced.

Owner:HUIZHOU BLUEWAY ELECTRONICS

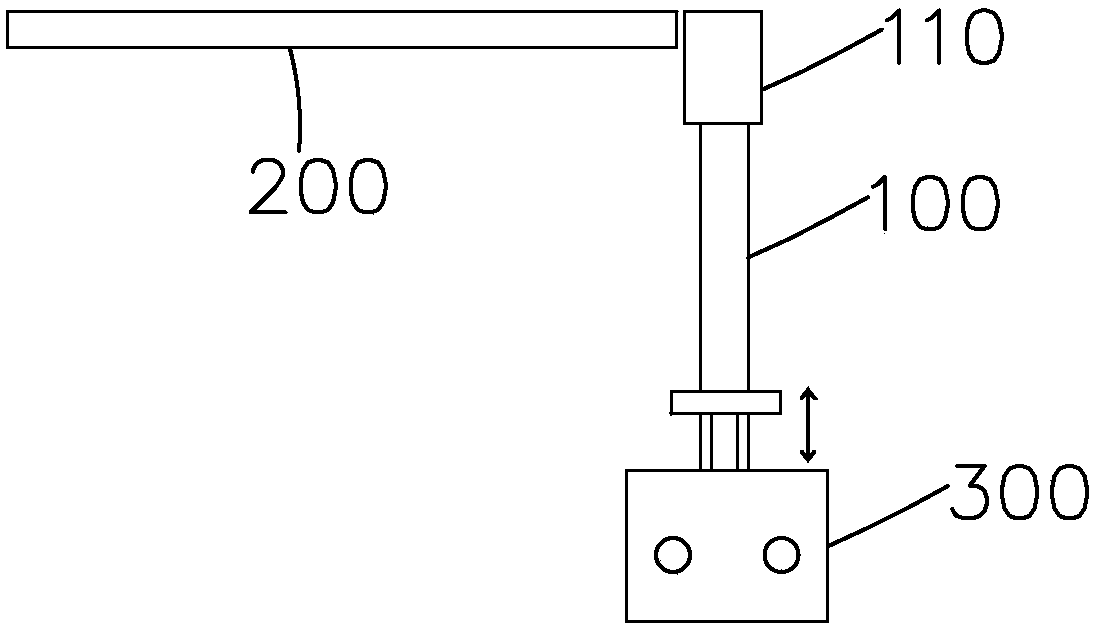

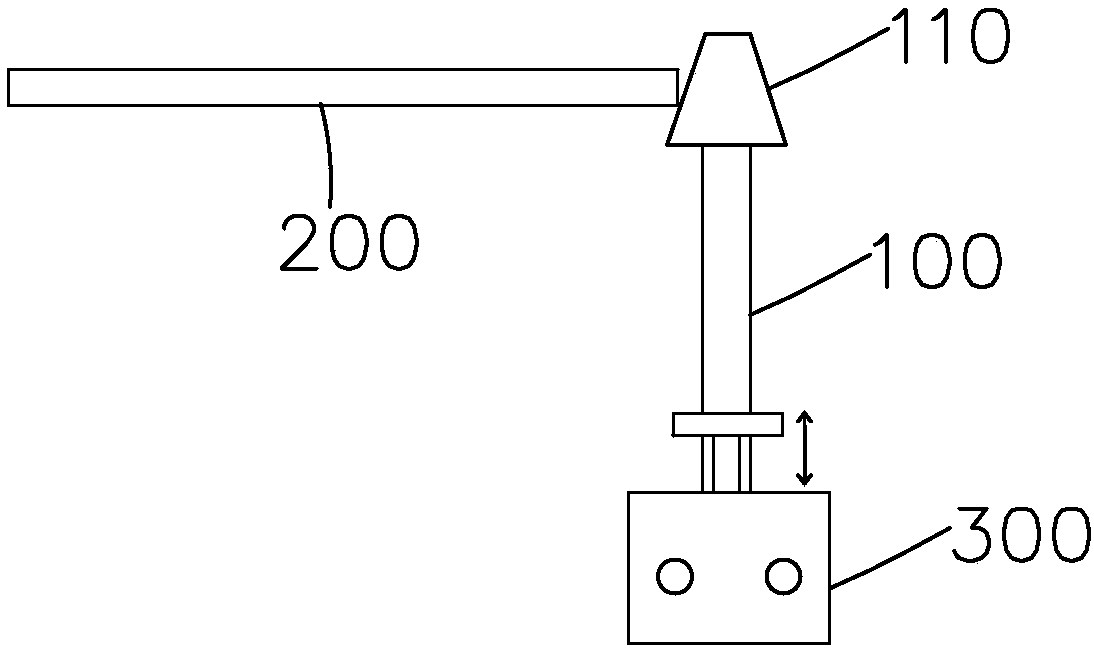

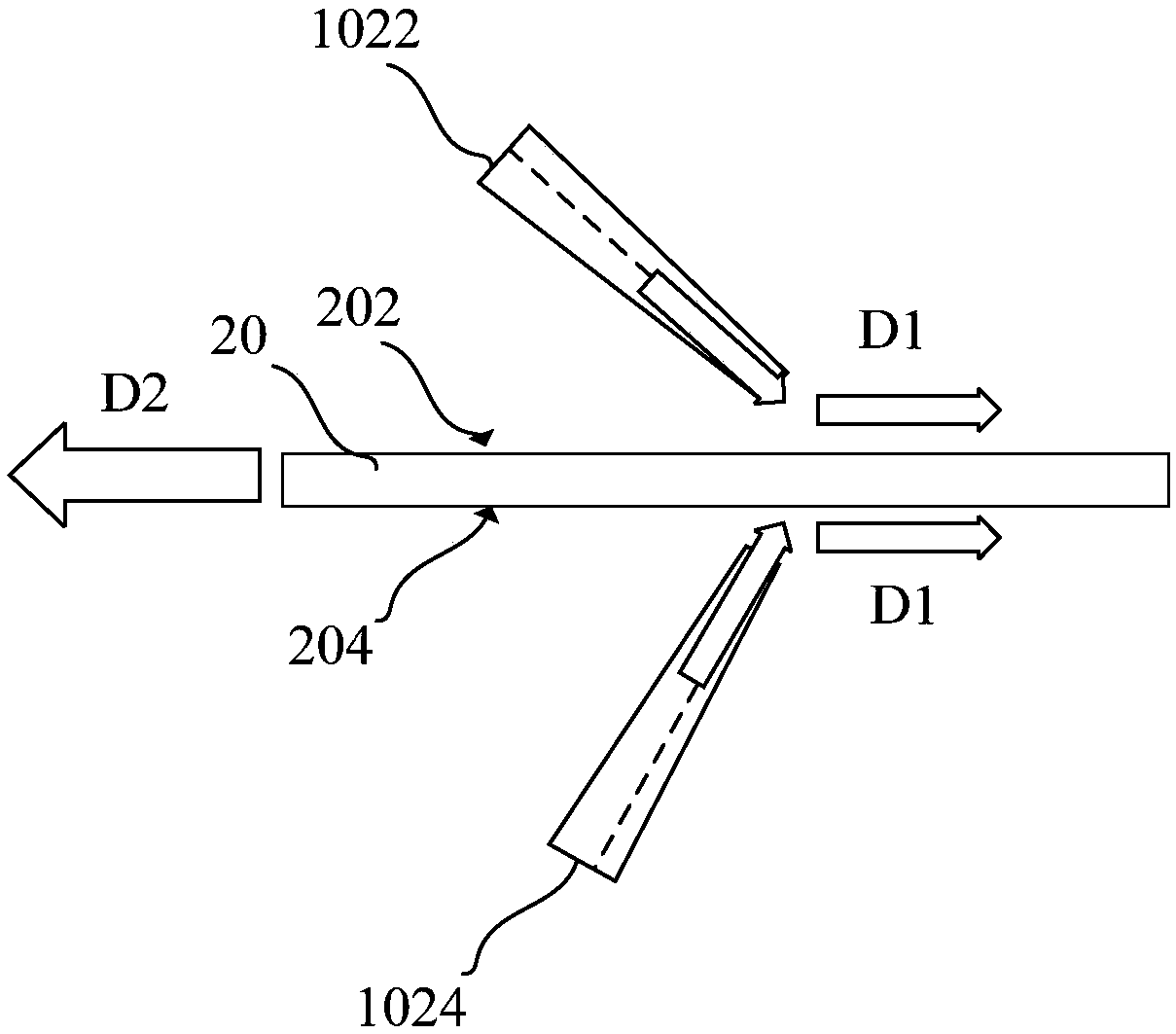

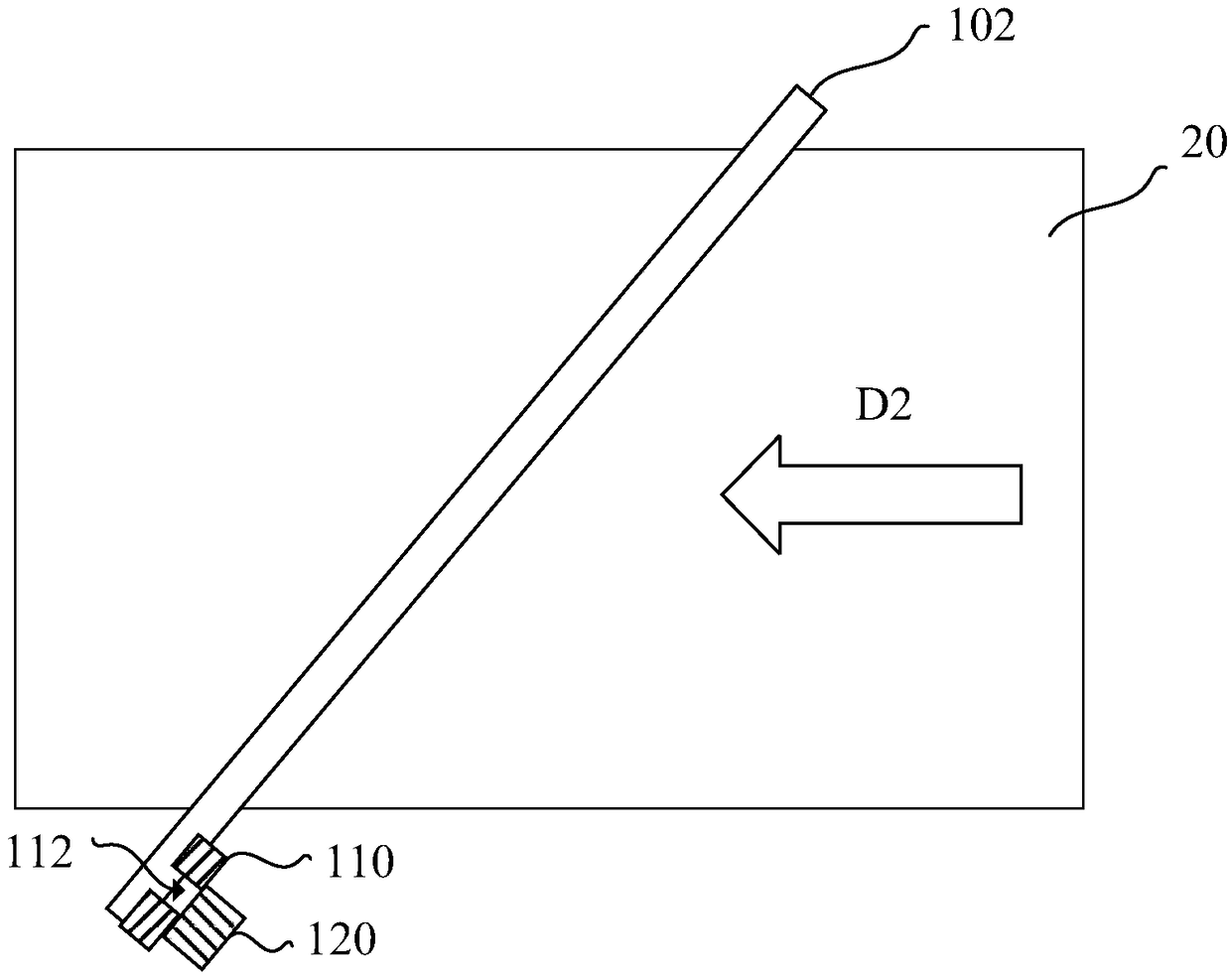

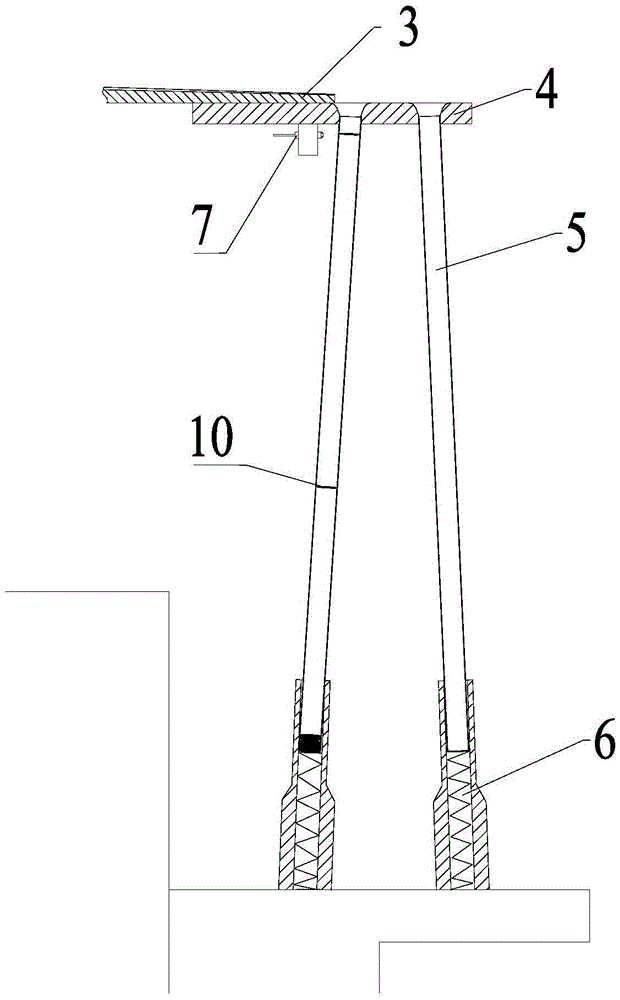

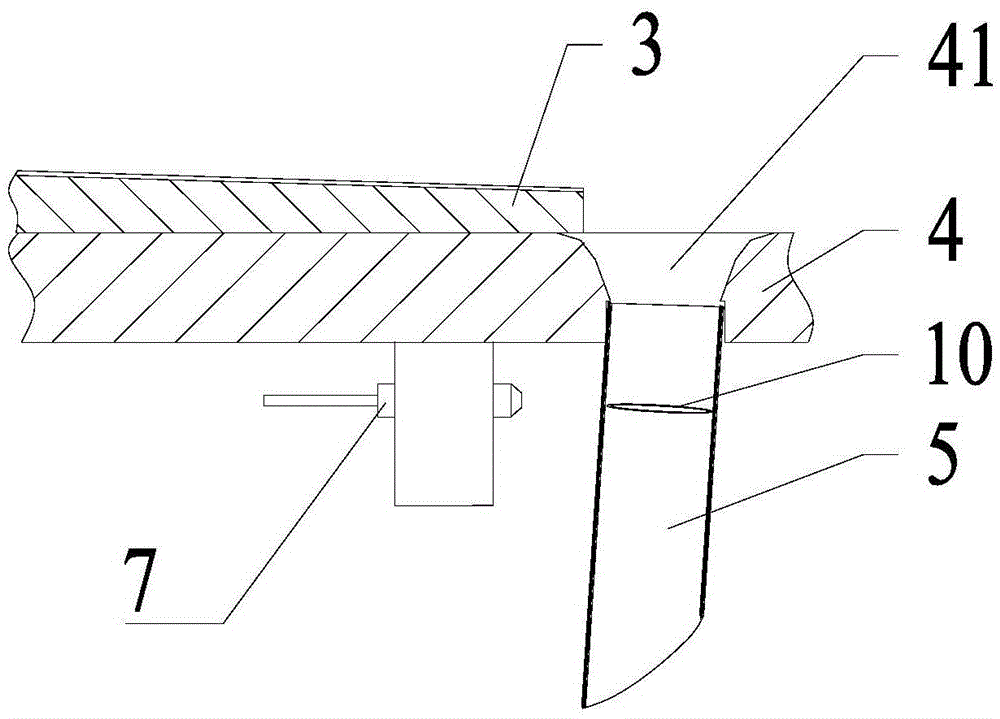

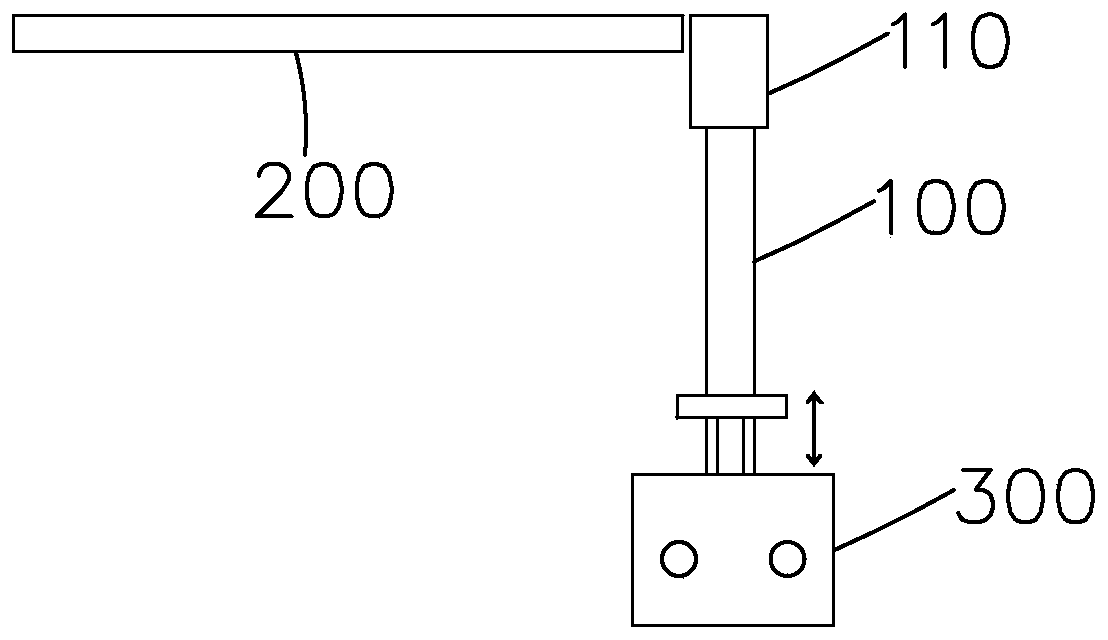

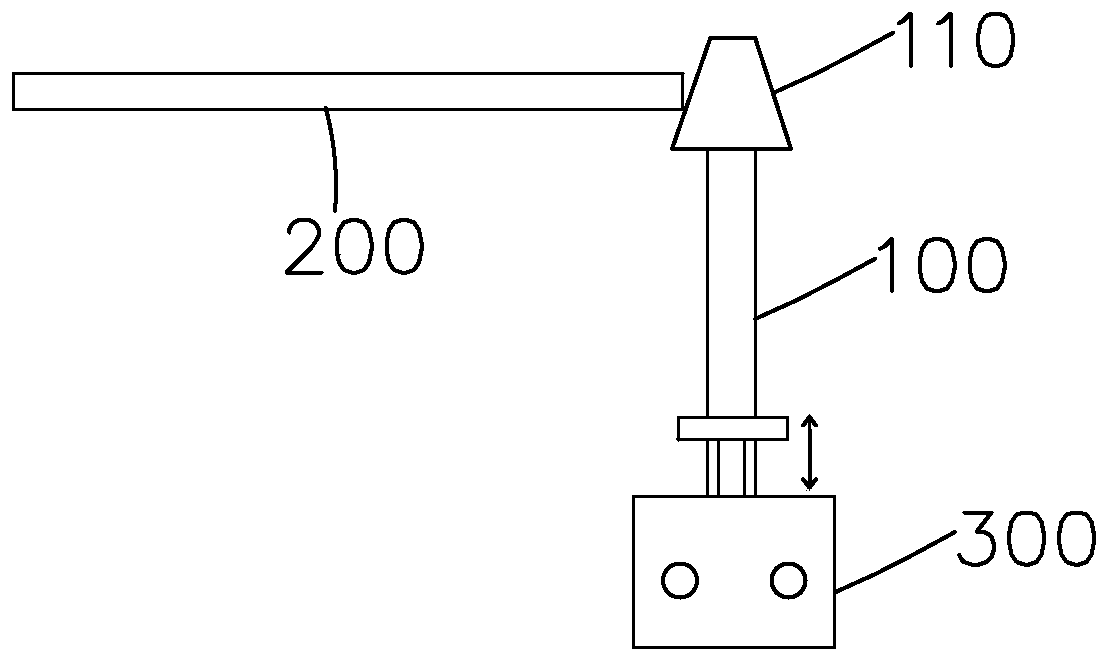

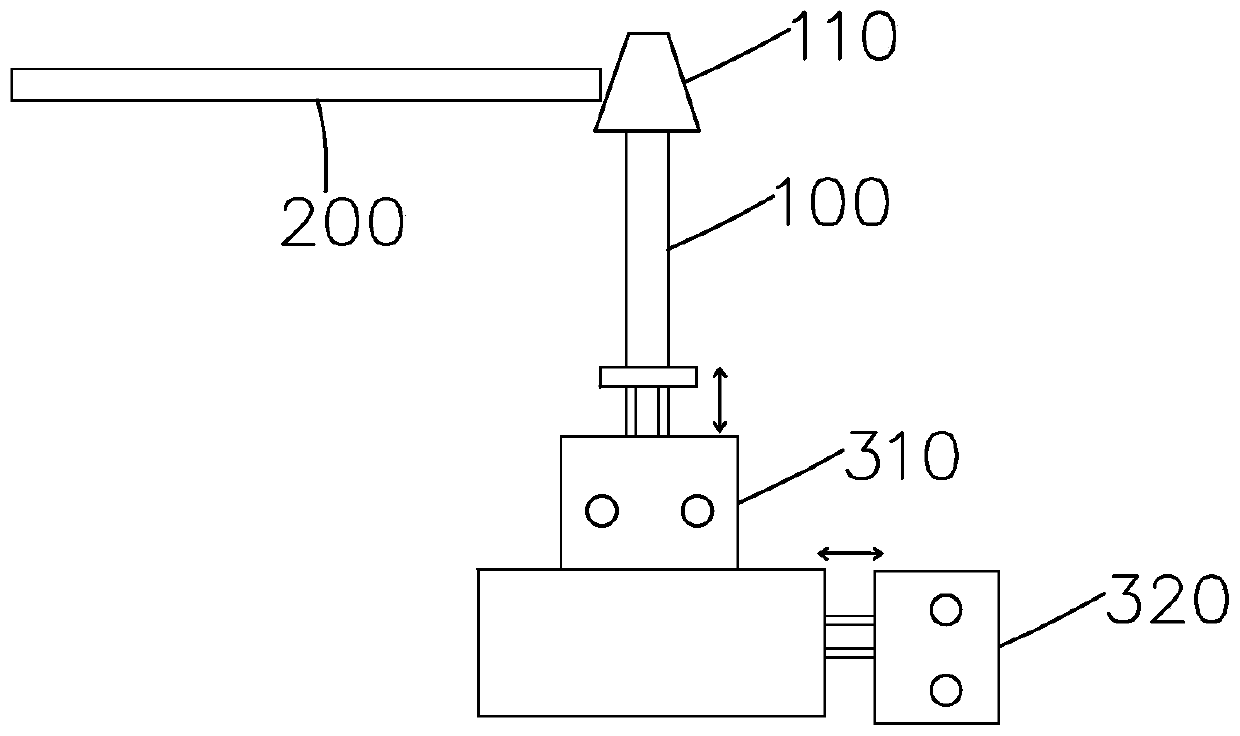

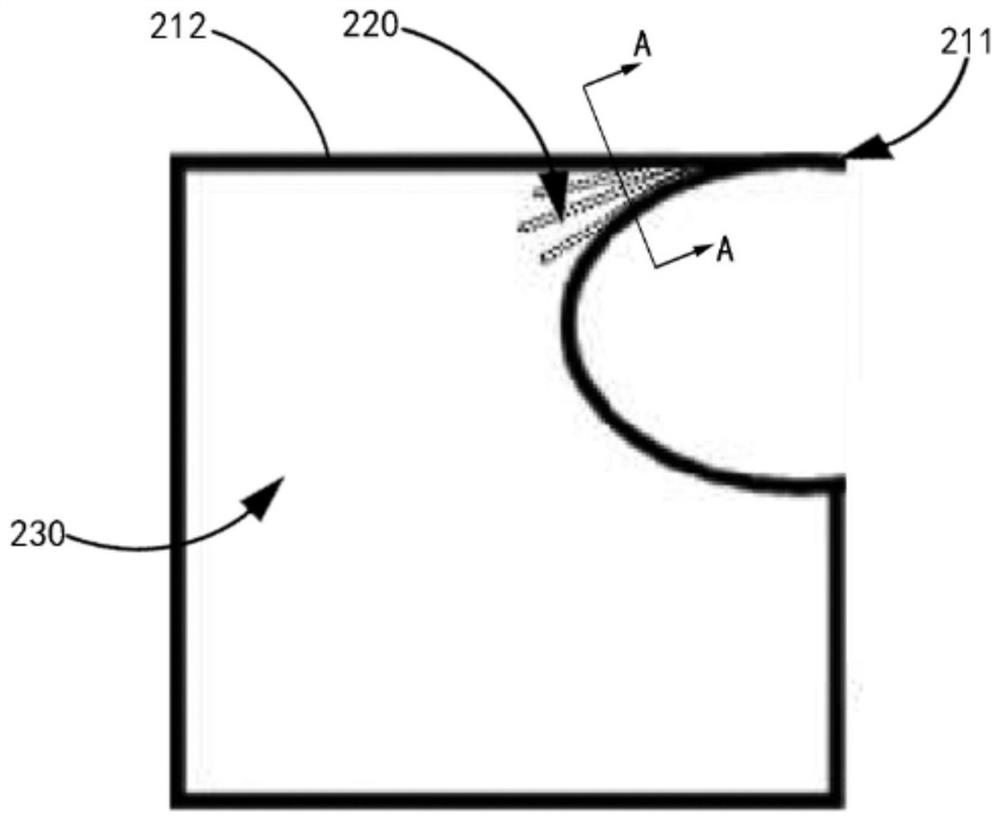

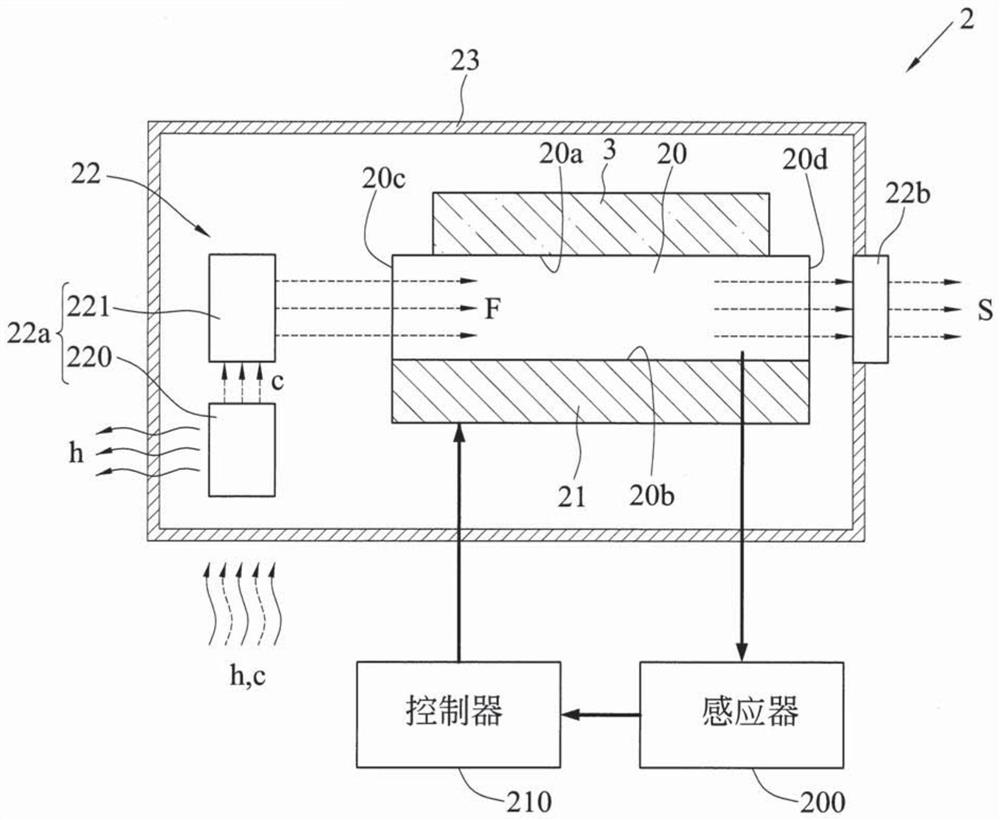

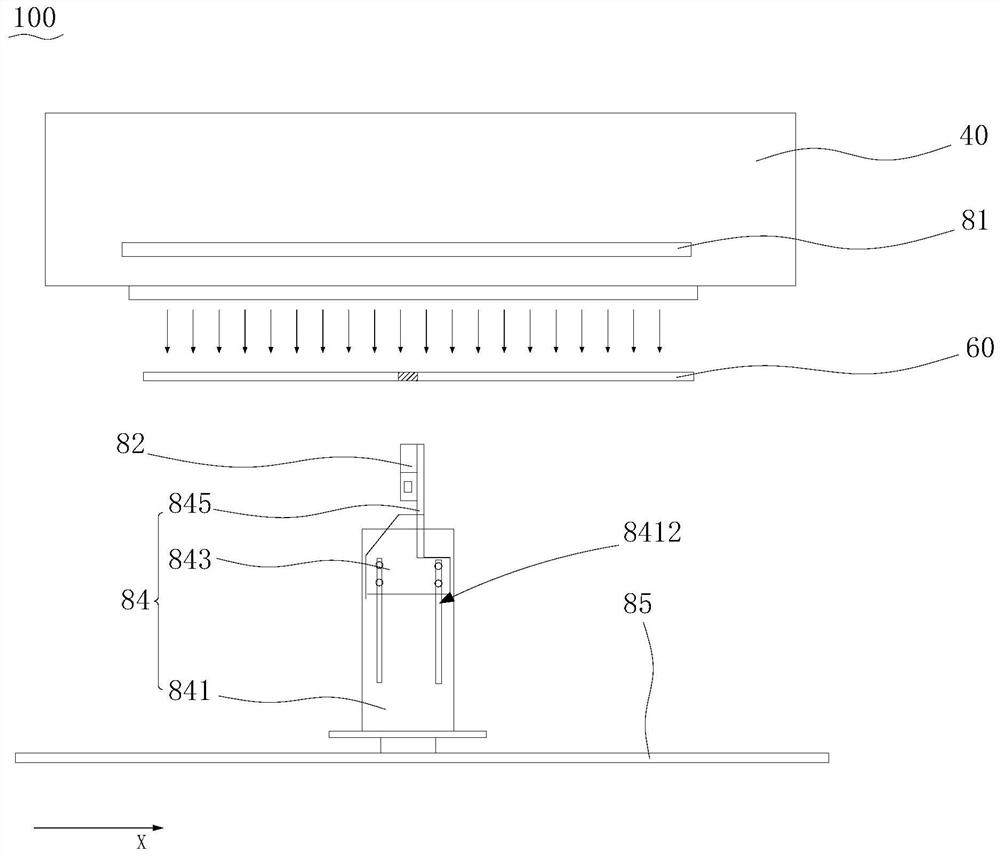

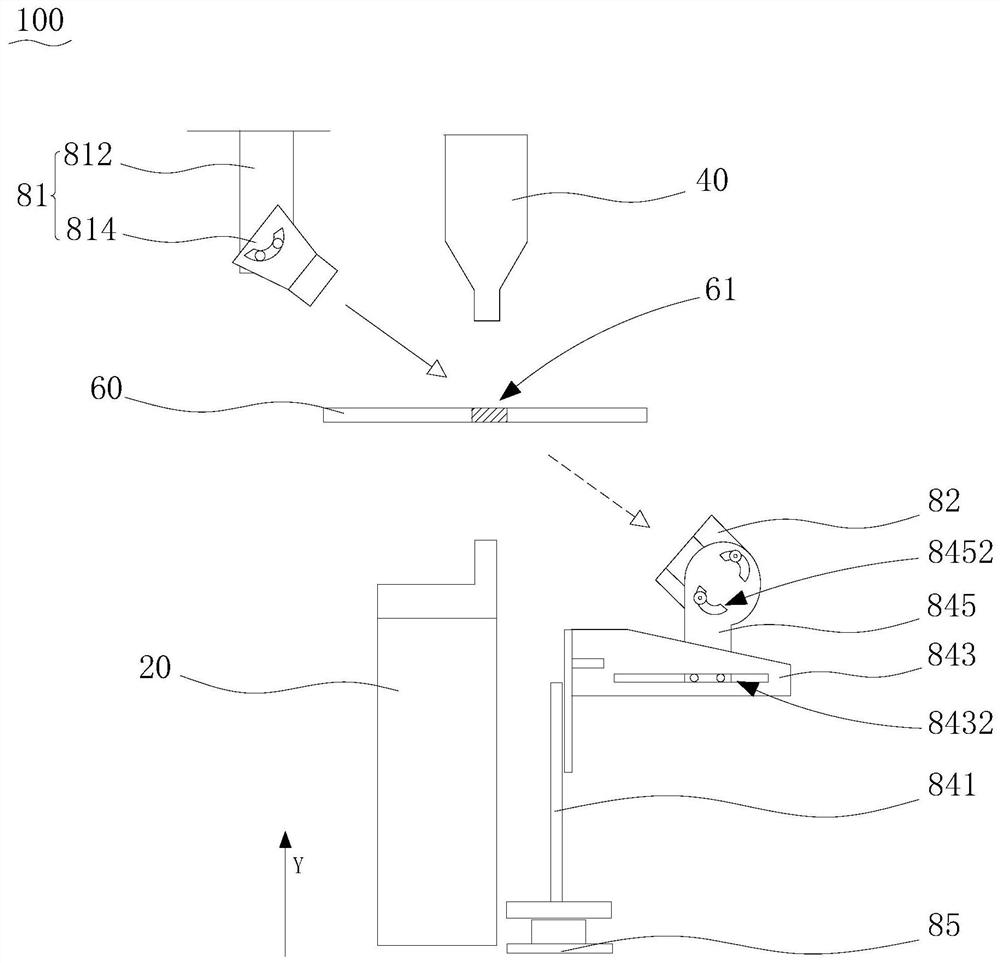

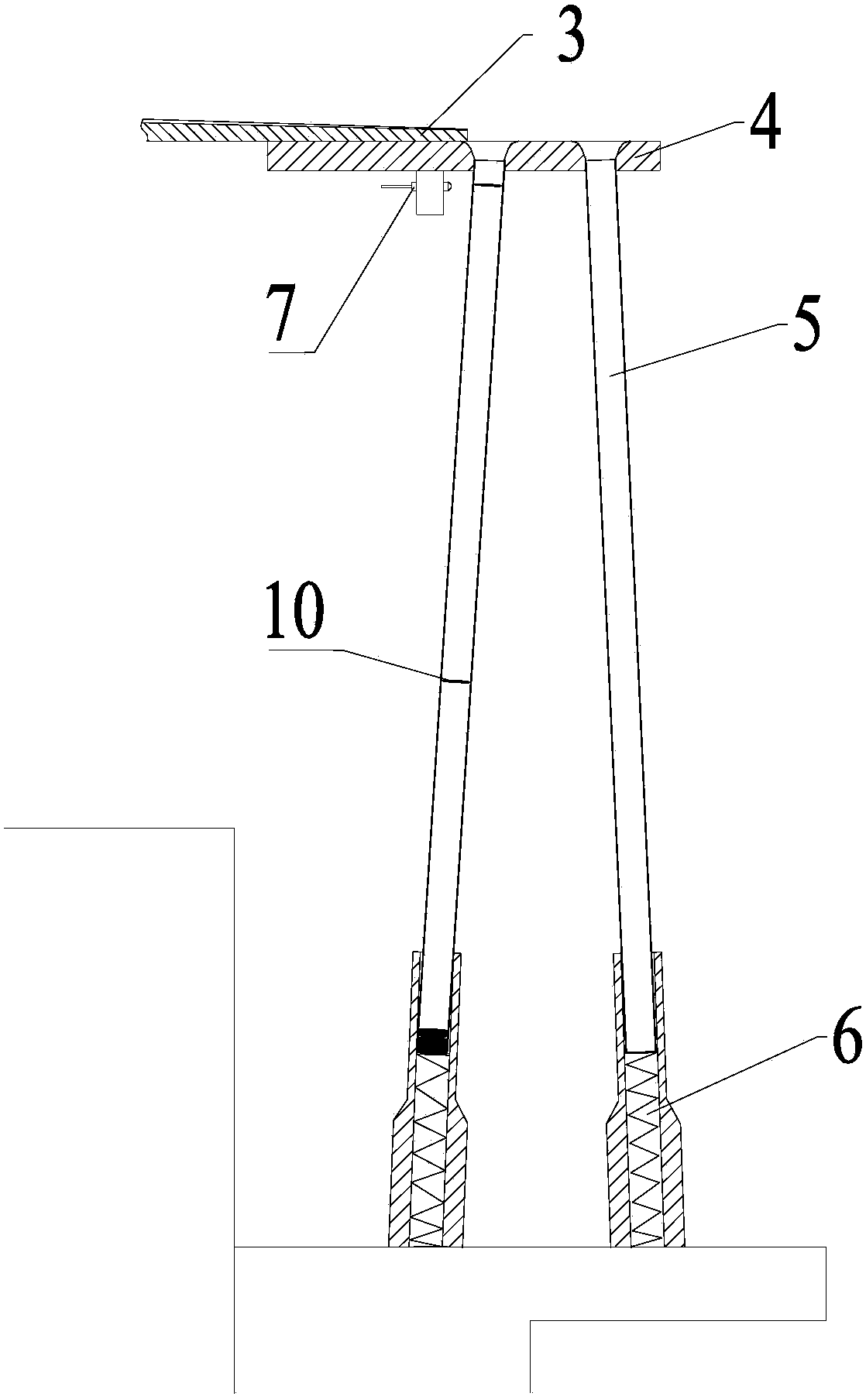

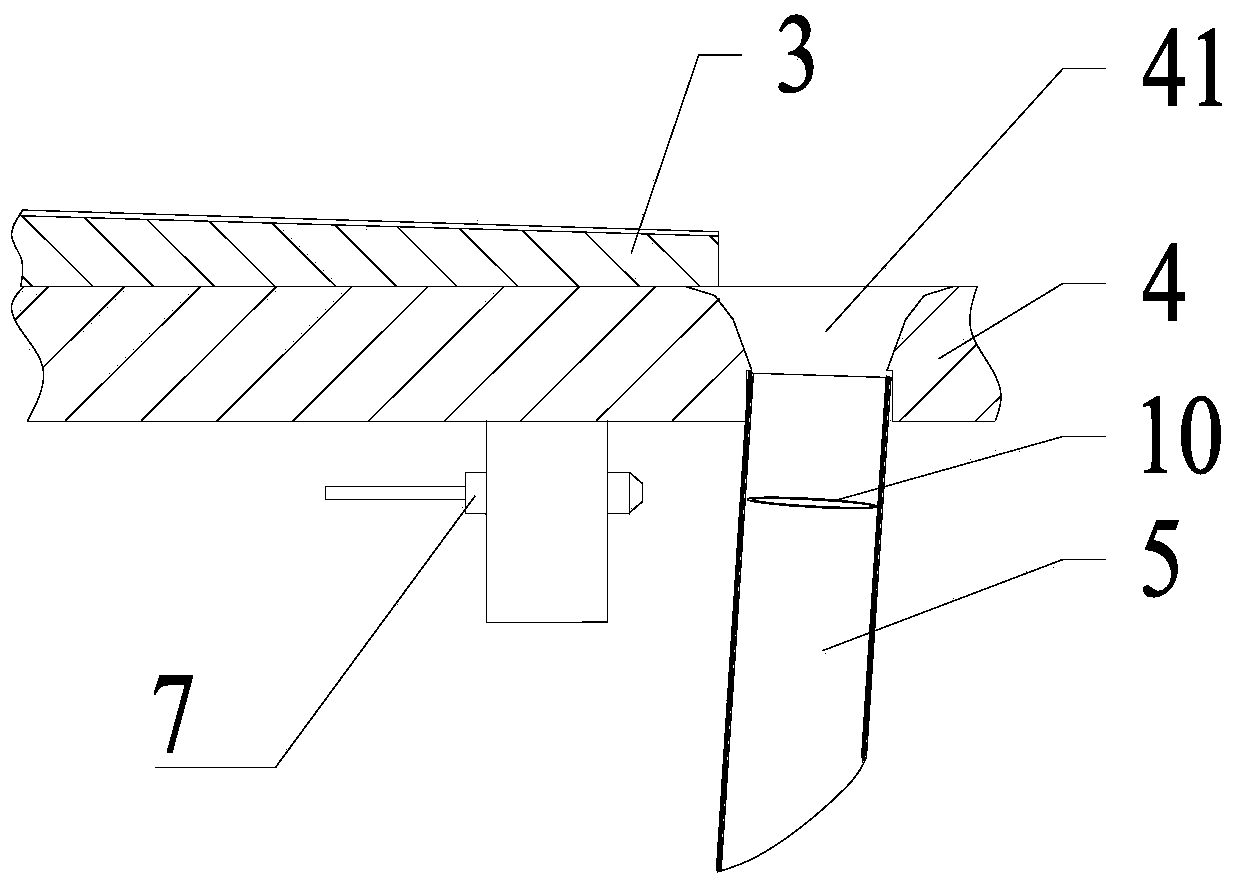

Positioning pin mechanism, substrate conveying device and substrate conveying method

ActiveCN108557472AAvoid abnormal qualityReduce design costCharge manipulationConveyor partsEngineeringPiston rod

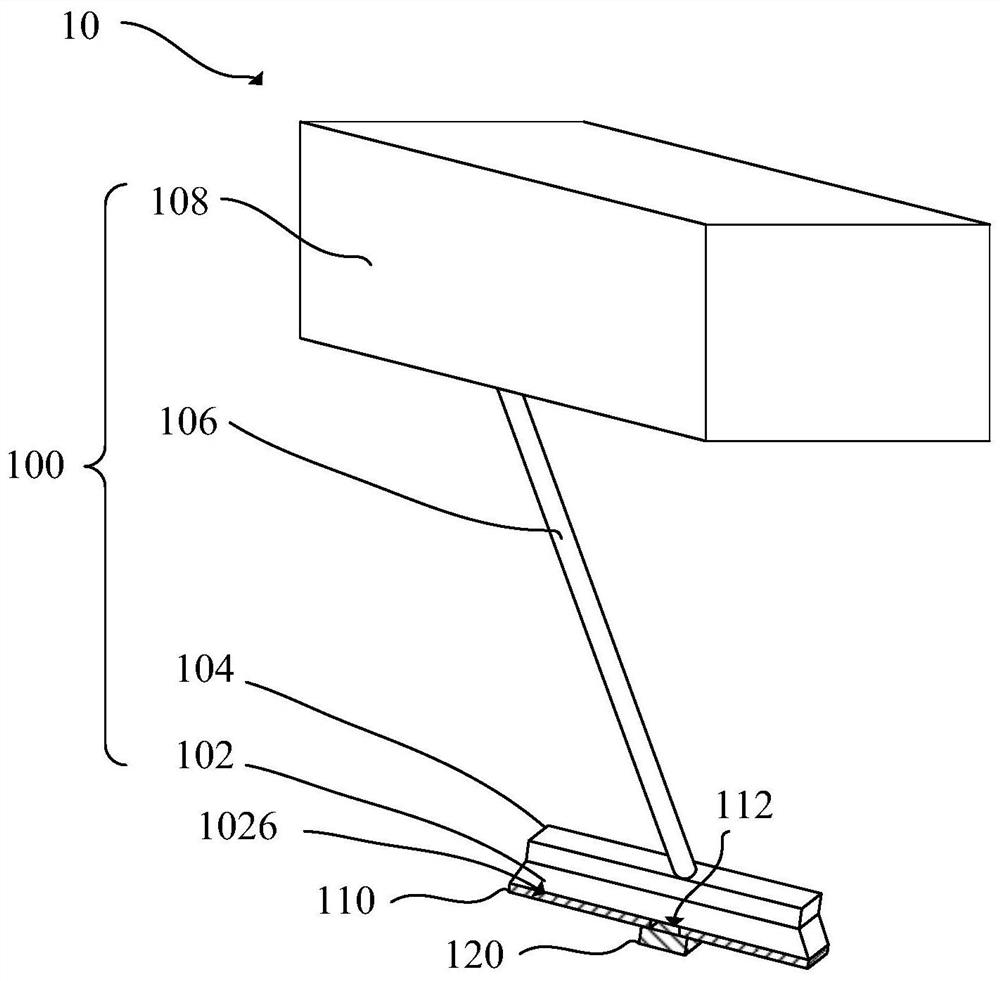

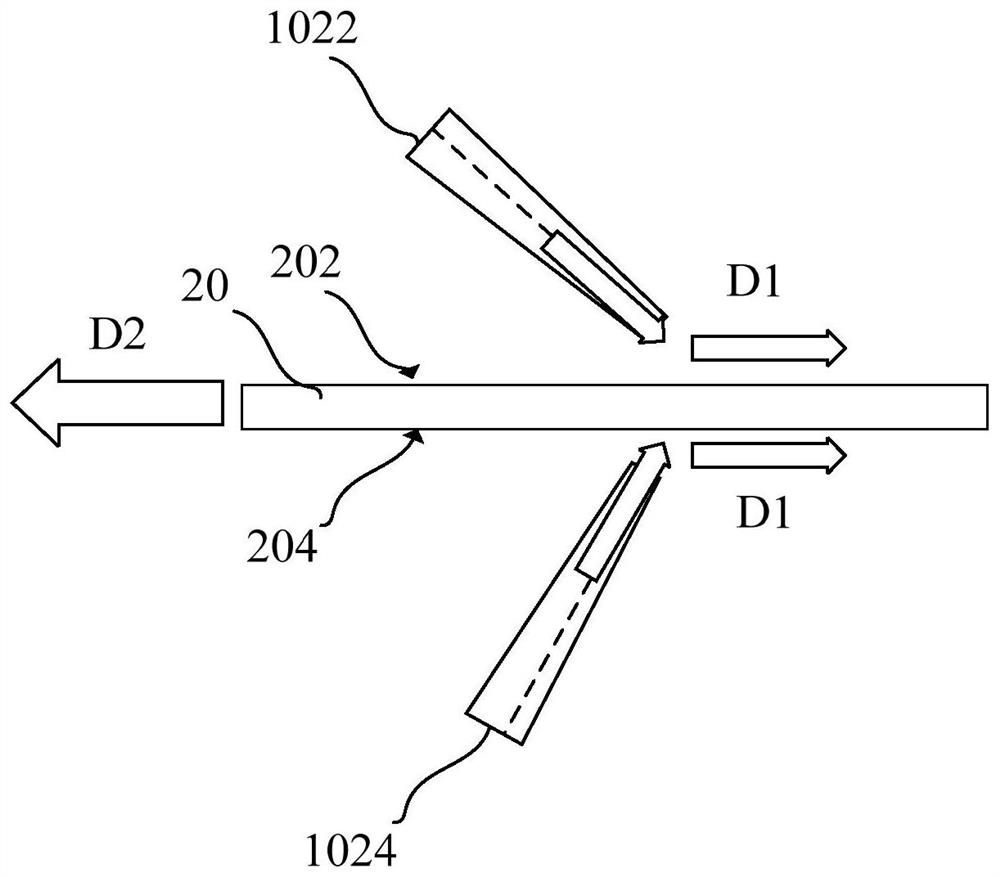

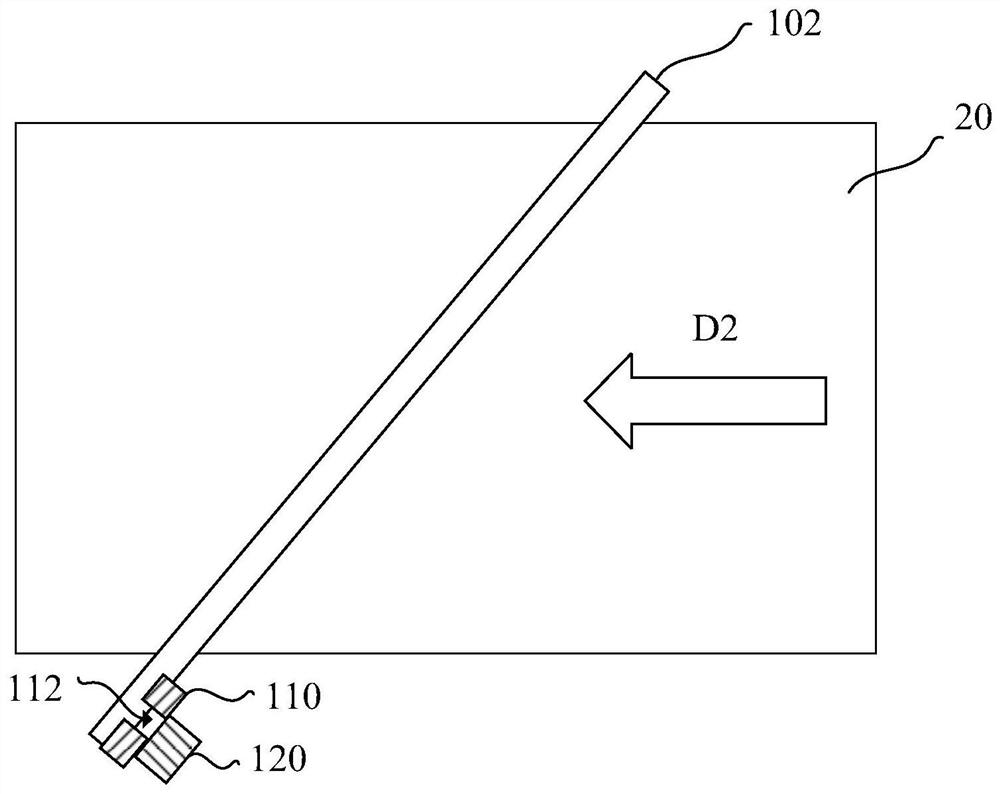

The invention provides a positioning pin mechanism, a substrate conveying device and a substrate conveying method. The positioning pin mechanism comprises a positioning pin and a cylinder driving thepositioning pin to move; the cylinder comprises an obliquely arranged cylinder body and a piston rod telescopically arranged in the cylinder body, and therefore the positioning pin can be driven by the cylinder to shift in the horizontal direction and the vertical direction at the same time, the design cost can be reduced, and it can be effectively avoided that in the substrate positioning process, because the positioning pin abrades and scratches a substrate, quality abnormity is caused.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Aluminum substrate resistance welding screen making method for preventing photosensitive slurry from falling off

ActiveCN105517366AImprove the problem of easy falling offAvoid abnormal qualityNon-metallic protective coating applicationDirectly printed exposure masksSpray coatingPulp and paper industry

An aluminum substrate resistance welding screen making method for preventing photosensitive slurry from falling off comprises the following steps: (1) using double-sided adhesive to paste a PET protective film to each of the positions, corresponding to the running tracks at the two ends of a scraper, on the front of a screen mesh; (2) applying glue water to the positions, corresponding to the PET protective films, on the back of the screen mesh, and naturally drying the glue water for a period of time after glue water applying to make the PET protective films cured on the screen mesh; (3) before photosensitive slurry is applied, adding boiling oil water to the photosensitive slurry according to the ratio of 30ml boiling oil water to 1kg photosensitive slurry, manually stirring the boiling oil water and the photosensitive slurry, and letting the mixture stand for a period of time; (4) spray-coating a given photosensitive slurry applying position of the screen mesh with the photosensitive slurry added with boiling oil water; and (5) after the photosensitive slurry is applied, baking the screen in an oven for a period of time to make the photosensitive slurry cured on the screen mesh. By using the method, the problem that the photosensitive slurry on the mesh in the positions of the two ends of the scraper is easy to fall off is improved effectively, the product quality is improved, and the service life of the screen is increased.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

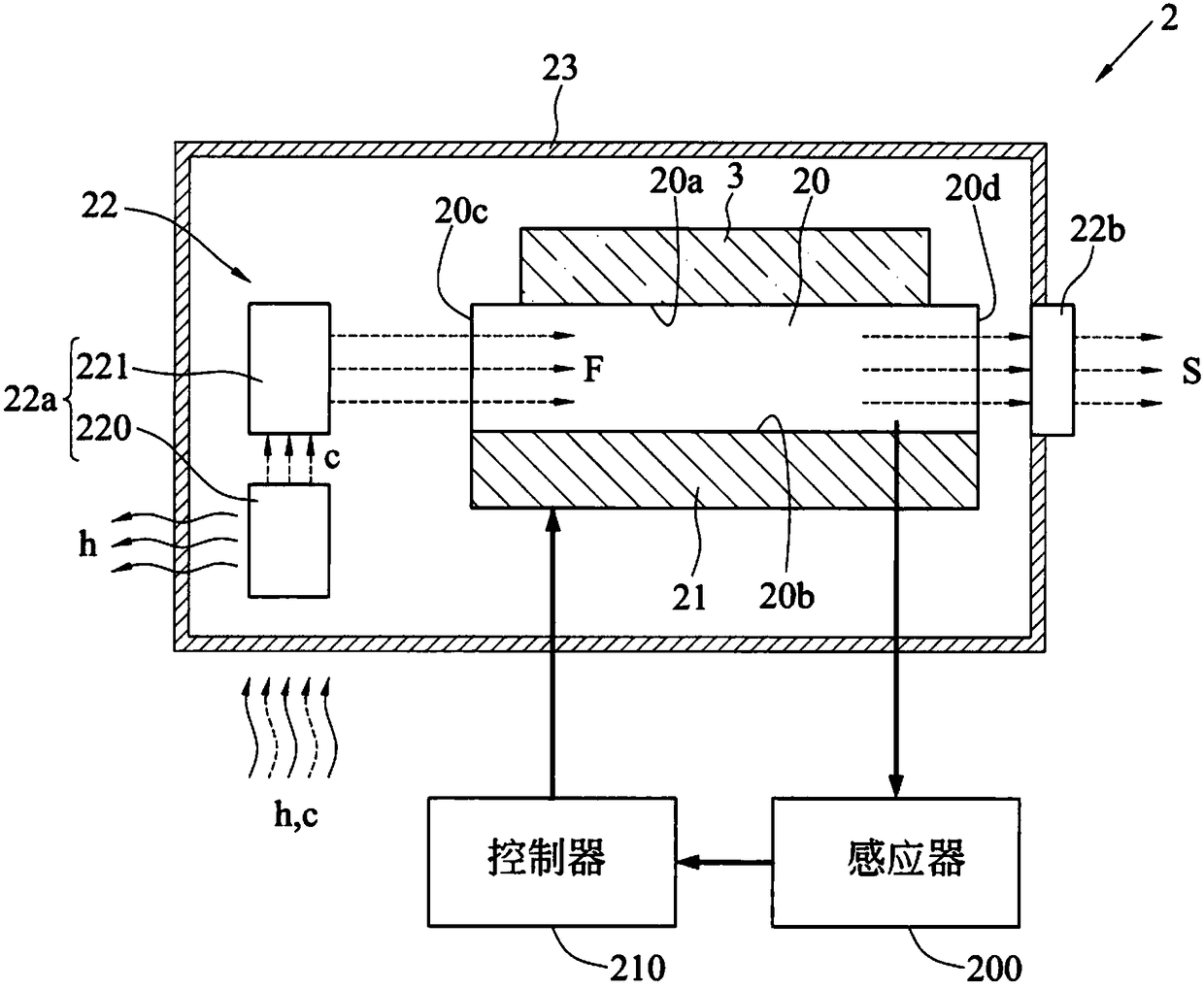

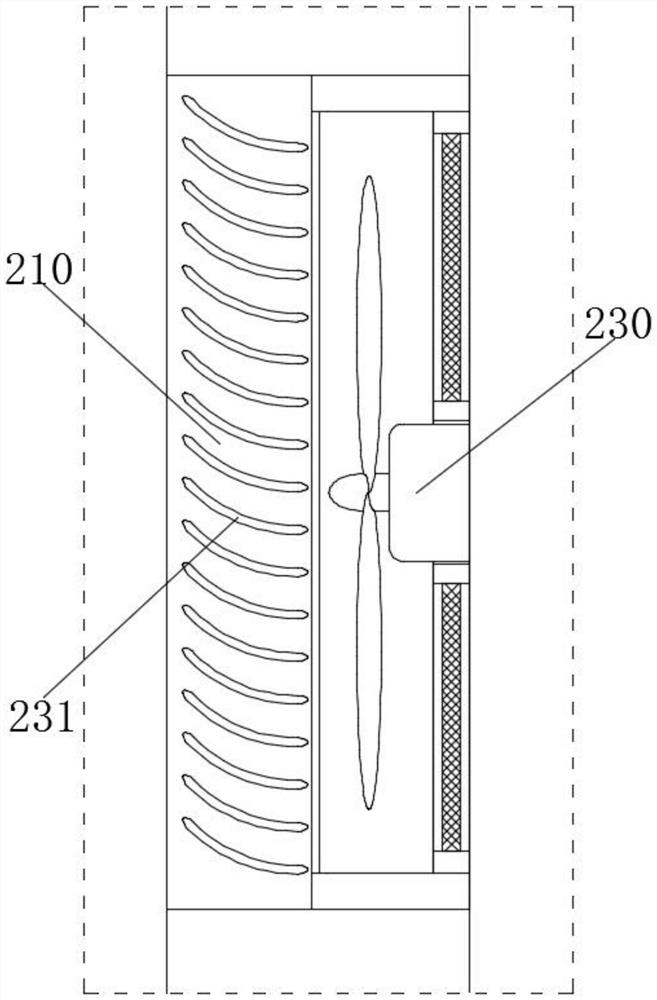

Air knife device for drying substrate

ActiveCN108847398AAccurate detection of air volume changesTimely detection of blockage problemsSemiconductor/solid-state device manufacturingAir volumeAir knife

The invention provides an air knife device for drying a substrate. The air knife device comprises an air knife assembly, a movable telescopic baffle piece and a movable sensor. The air knife assemblycomprises an air knife air nozzle assembly, a pipeline connected with the air knife air nozzle assembly, an air supply device connected with the pipeline, and an adjusting device for controlling the wind power intensity of the air knife air nozzle assembly. The air knife air nozzle assembly comprises a first air knife air nozzle and a second air knife air nozzle, wherein the first air knife air nozzle and the second air knife air nozzle are used for blowing the two surfaces of the substrate respectively. The movable telescopic baffle piece is movably and telescopically arranged at the air outlet of the air knife air nozzle assembly. The movable sensor is movably arranged on the movable telescopic baffle piece, so as to detect the air outlet quantity of the air knife air nozzle assembly ata specific position. By virtue of the movable telescopic baffle piece and the movable sensor, the air volume changes of all positions of the air knife air nozzle assembly can be accurately detected, and the blockage problem of the air knife air nozzle assembly can be found in time, so that the phenomenon that the quality of the substrate product is abnormal due to blockage of the air knife air nozzle assembly is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

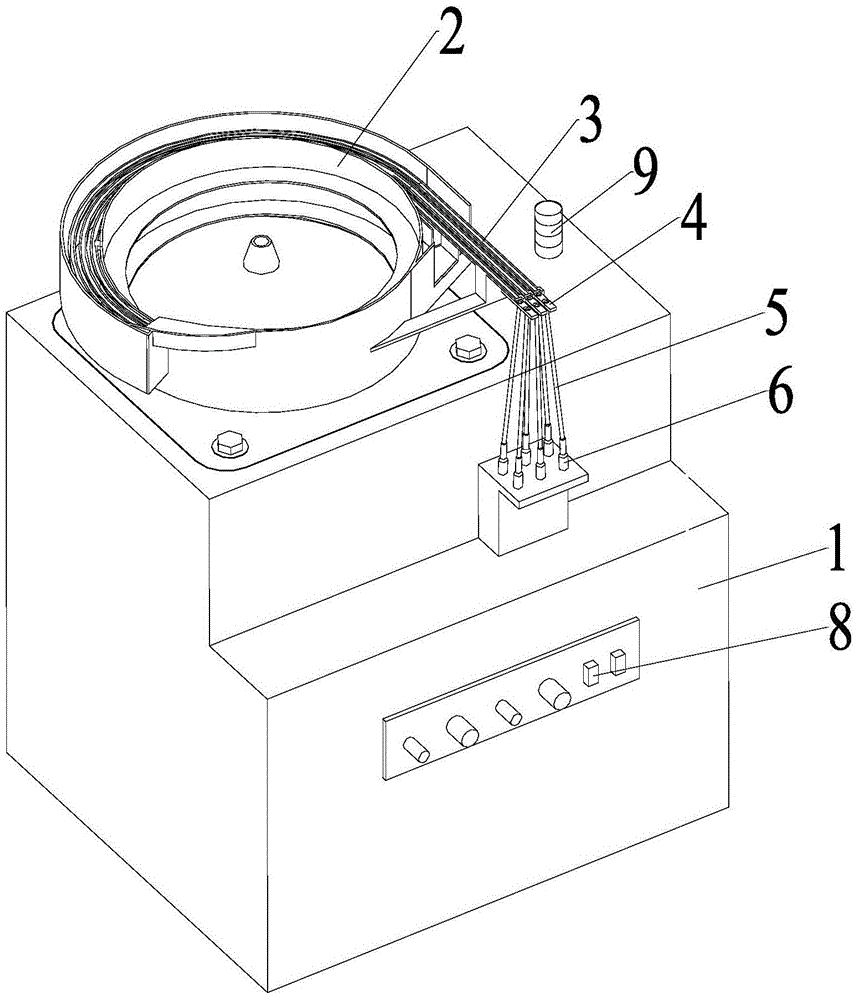

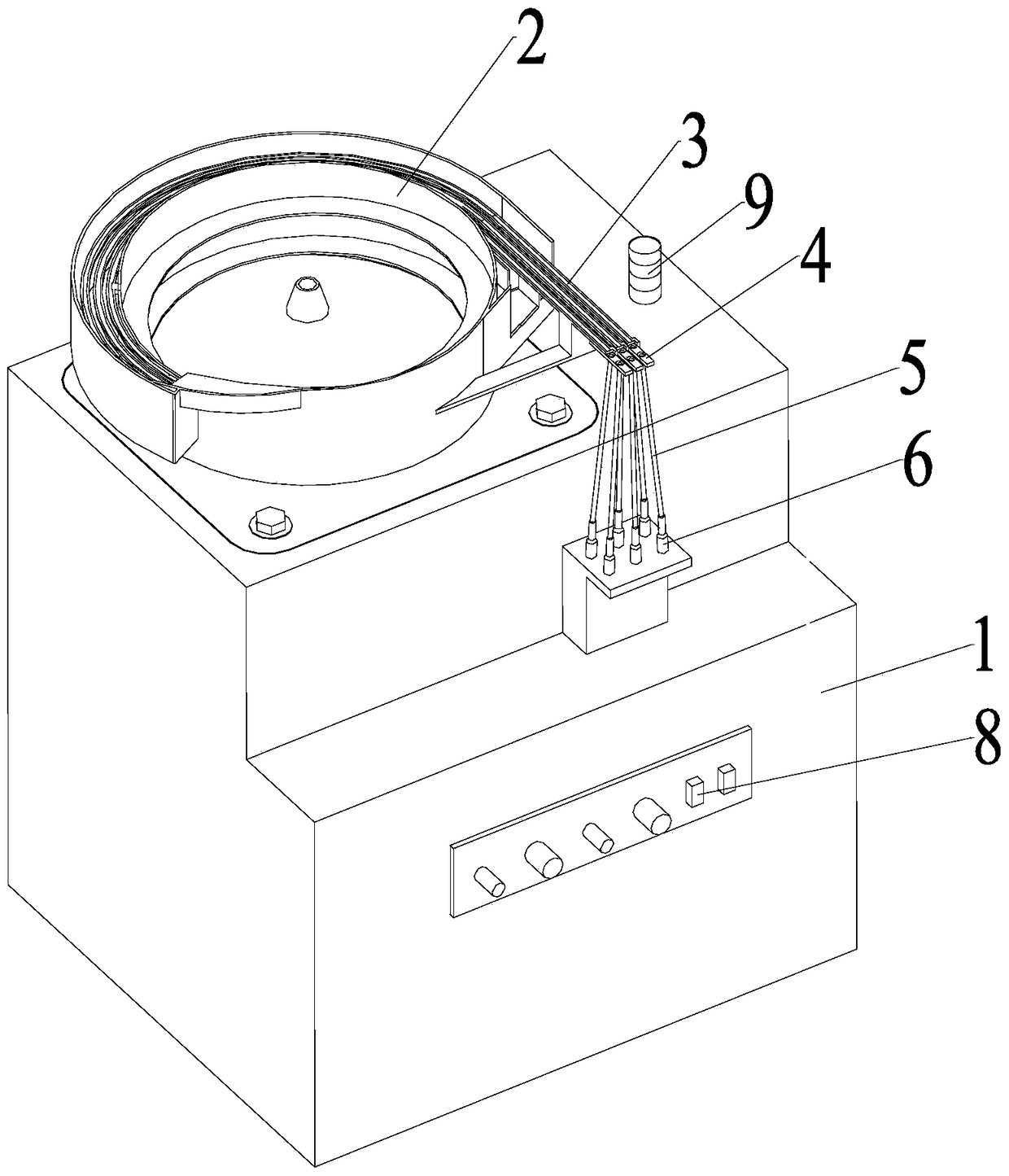

Automatic packing equipment of vibrating diaphragm

ActiveCN105480478ASimple structureEasy to operatePackaging automatic controlEngineeringMechanical engineering

The invention is suitable for the technical field of automatic packing, and provides automatic packing equipment of a vibrating diaphragm. The automatic packing equipment comprises a frame; a vibrating disc is arranged on the frame; multiple slide ways are formed in a discharge port of the vibrating disc; guide plates capable of sliding are arranged below each slide way; at least two guide holes are formed in the guide plates; limiting grooves are formed in the lower part of each guide hole; the tops of packing pipes are sleeved in the limiting grooves; an elastic bracket is arranged on the frame below the packing pipes; and the elastic bracket supports and guarantees the tops of the packing pipes to be sleeved in the limiting grooves. The automatic packing equipment realizes automatic arrangement and automatic packing of the vibrating diaphragm through the setting of the vibrating disc and guide devices, is additionally provided with counting and warning devices, is simple in structure and convenient to operate, improves the production efficiency, and prevents the generation of quality abnormality.

Owner:潍坊新声悦尔电子科技有限公司

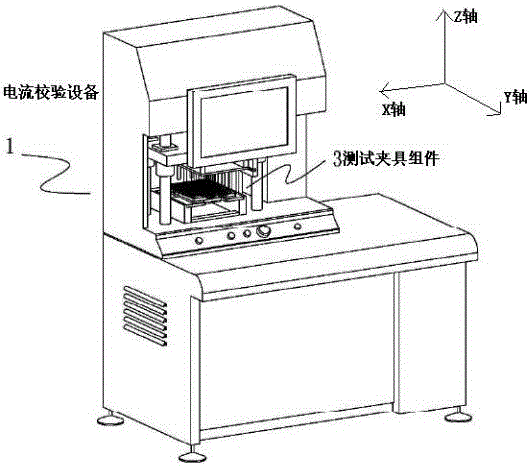

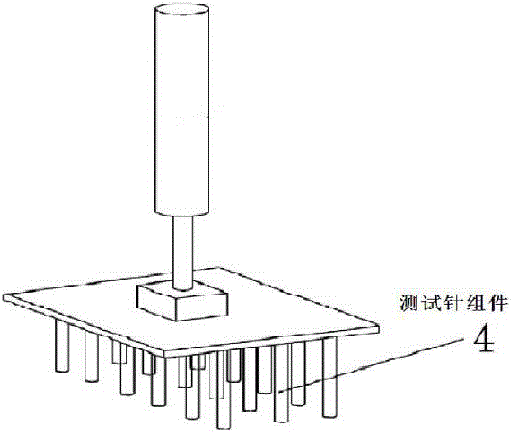

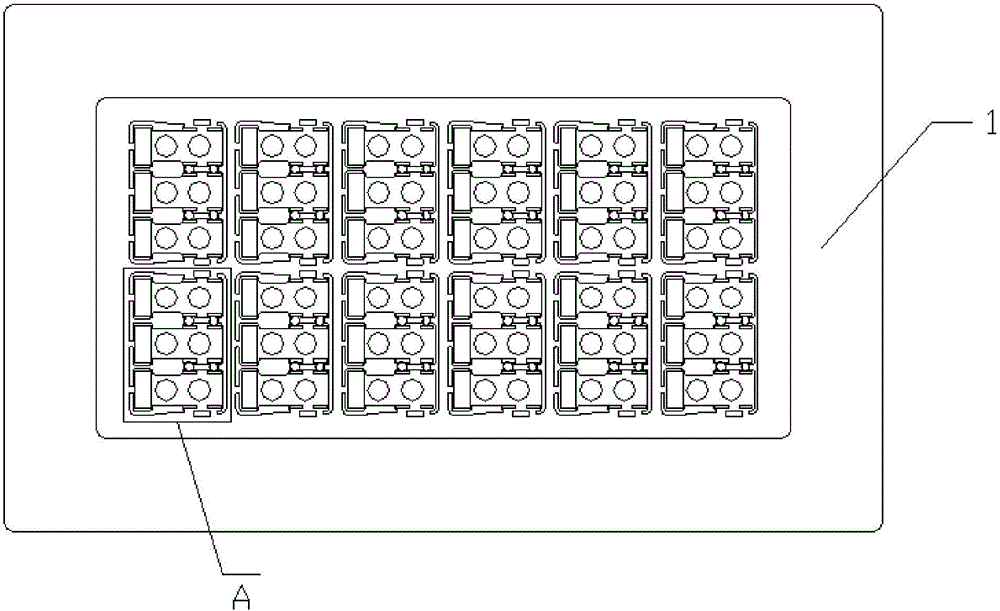

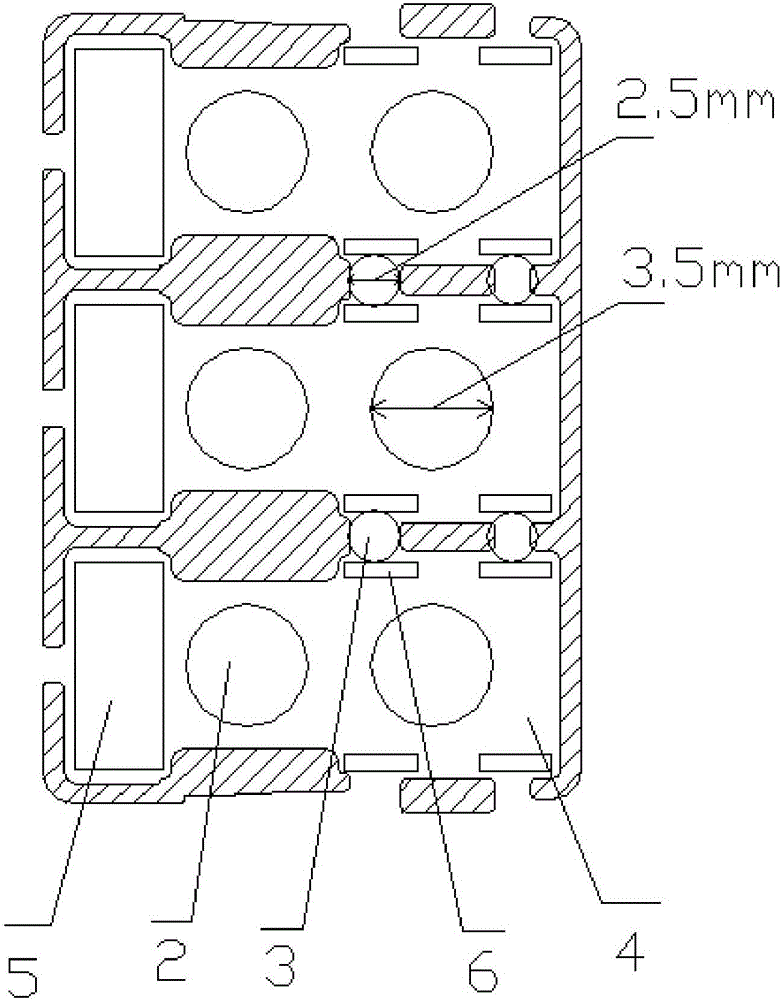

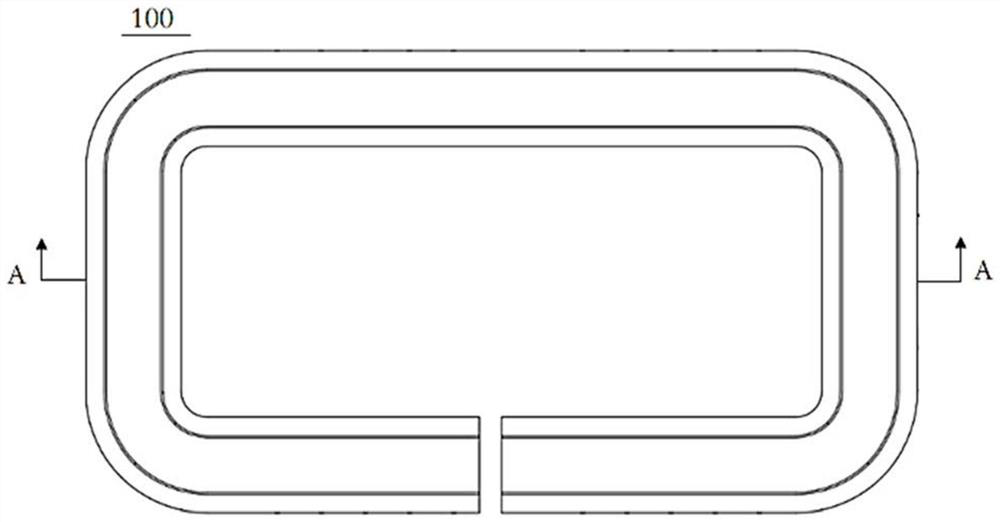

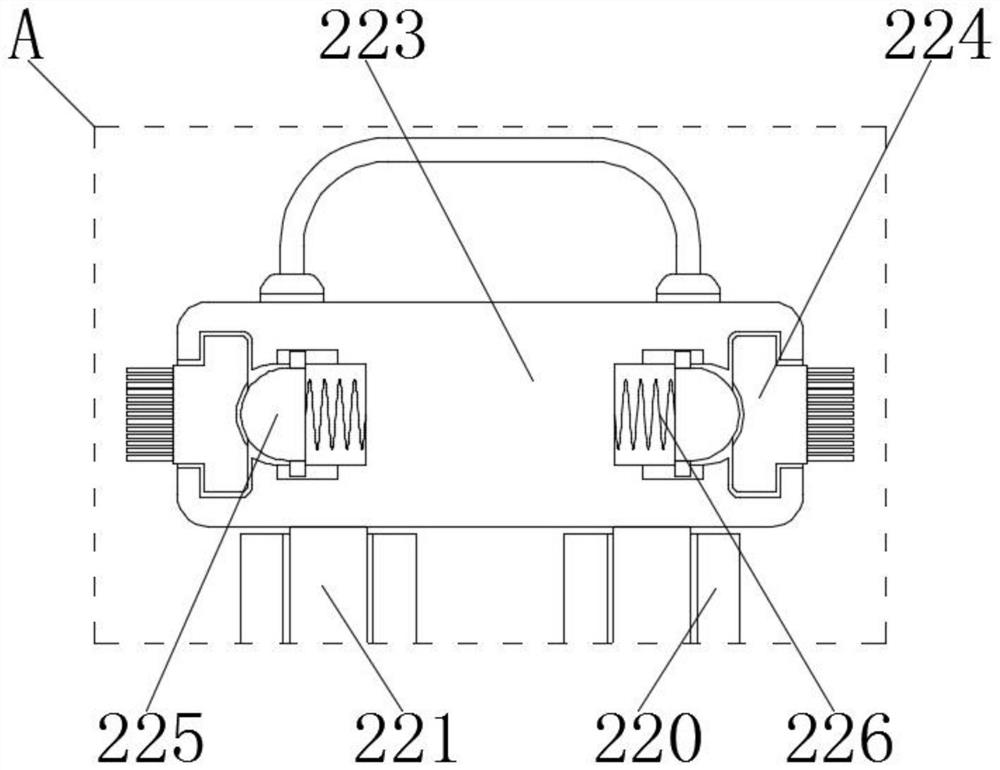

Current calibration equipment and method for charge management ICs

InactiveCN104155591AIdentify contact power statusPrevent reverse insertion and wrong insertionElectronic circuit testingUltimate tensile strengthAutomation

The invention provides current calibration equipment and a method for charge management ICs. The current calibration method of charge management IC comprises the following steps: setting a three-dimensional coordinate axis; defining plane coordinate values on every charge management ICs on testing clamp components and height coordinate values generated during rising and downward pressing a longitudinal cylinder, wherein a logic controller drives a transversal cylinder to move according to calculated space coordinate values and a certain intervals of speed and period until the most front row of the charge management ICs are positioned under testing needle components, and the longitudinal cylinder drives the testing needle components to be pressed downwards automatically and be in contact with testing points of the most front row of the charge management ICs sufficiently to calculate current precision signals of the charge management ICs with charging protection, then, the transversal cylinder moves continuously until the next row of the charge management ICs are positioned under the testing needle components; repeating the testing steps till all of the charge management ICs are tested. According to the testing manners, the stepping type and the multichannel type are adopted, so that the degree of automation of the testing equipment is improved, and the production cost and the operation labor intensity are lowered.

Owner:HUIZHOU BLUEWAY ELECTRONICS

Method for producing single PCS substrate by UV laser cutting

InactiveCN106346142AReduce reworkAvoid abnormal qualityWelding/cutting auxillary devicesAuxillary welding devicesUv laserEngineering

The invention relates to a method for producing a single PCS substrate by UV laser cutting. The method comprises the following steps: (1) selecting a specific fixture board basal plate; (2) drilling a first hole and a second hole in the fixture board basal plate; (3) performing primary depth-controlled milling in the fixture board basal plate to obtain a first milling groove; (4) performing secondary depth-controlled milling in the fixture board basal plate to obtain a second milling groove; (5) milling the periphery of the fixture board basal plate to obtain a fixture board finished product; (6) fixing a cut substrate on the fixture board, and positioning a single PCS substrate in the first milling groove and the second milling groove; (7) correcting the energy of UV laser equipment to position a cut substrate; and (8) performing UV laser treatment on the cut substrate to obtain a single PCS substrate, taking the substrate and placing. By adopting the method, the equipment utilization rate can be improved, the capacity and quality can be improved, and the cost can be reduced.

Owner:江苏弘信华印电路科技有限公司

Silicone strip anti-falling device and laminator

ActiveCN110473931BAvoid abnormal qualityFinal product manufacturePhotovoltaic energy generationPolymer scienceEngineering

The invention provides a silicone strip anti-falling device and a laminator, which are used in the laminator, and are characterized in that they include a carrier, and the first end of the carrier is provided with a first chamber and a second chamber with one end open chamber, the first chamber is used to install the first silica gel strip, and there are two second chambers, the two second chambers are respectively arranged on both sides of the first chamber, and the two The second chamber is respectively used to fix the two sides of the second silica gel strip. The silicone strip anti-falling device according to the embodiment of the present invention can fix the two silica gel strips, and the second silica gel strip can wrap and fix the first silica gel strip, which effectively prevents the silica gel strips from falling off after the surface aging due to the increase in the service cycle. The problem of abnormal quality caused by air bubbles in components.

Owner:JA XINGTAI SOLAR CO LTD

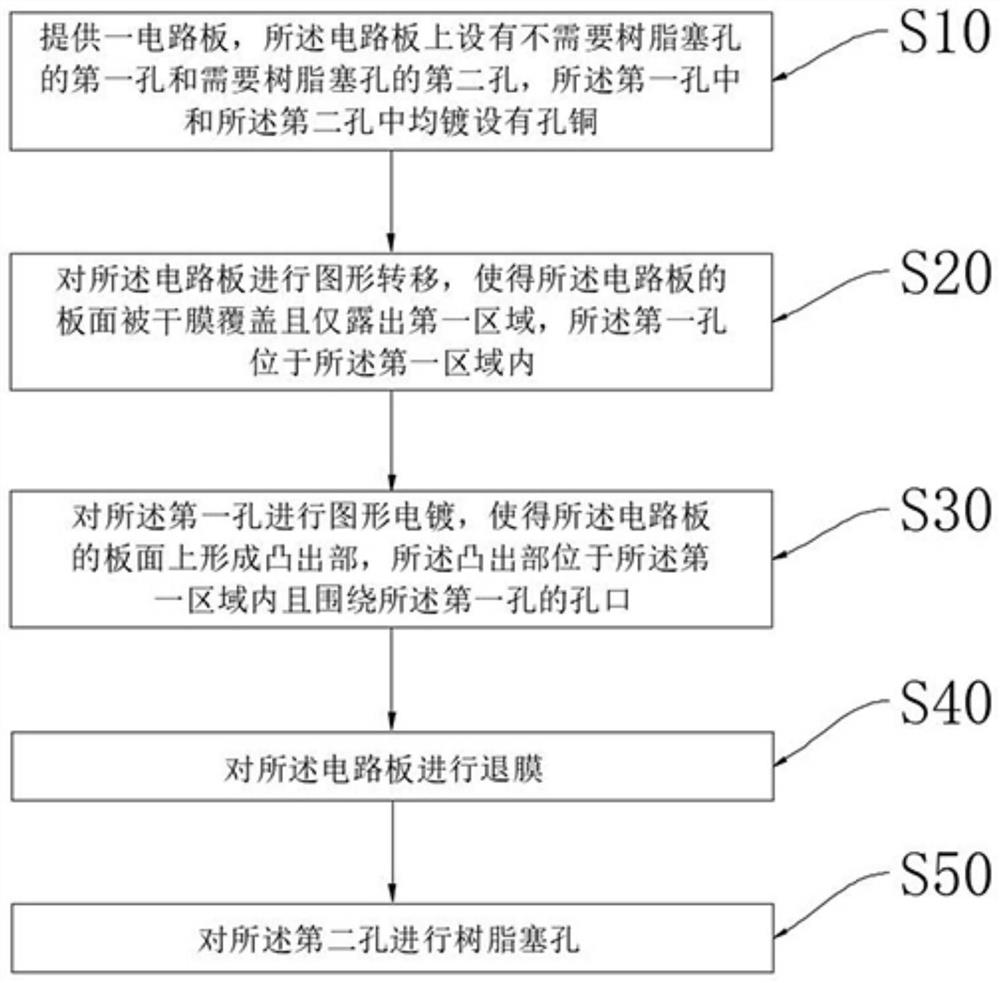

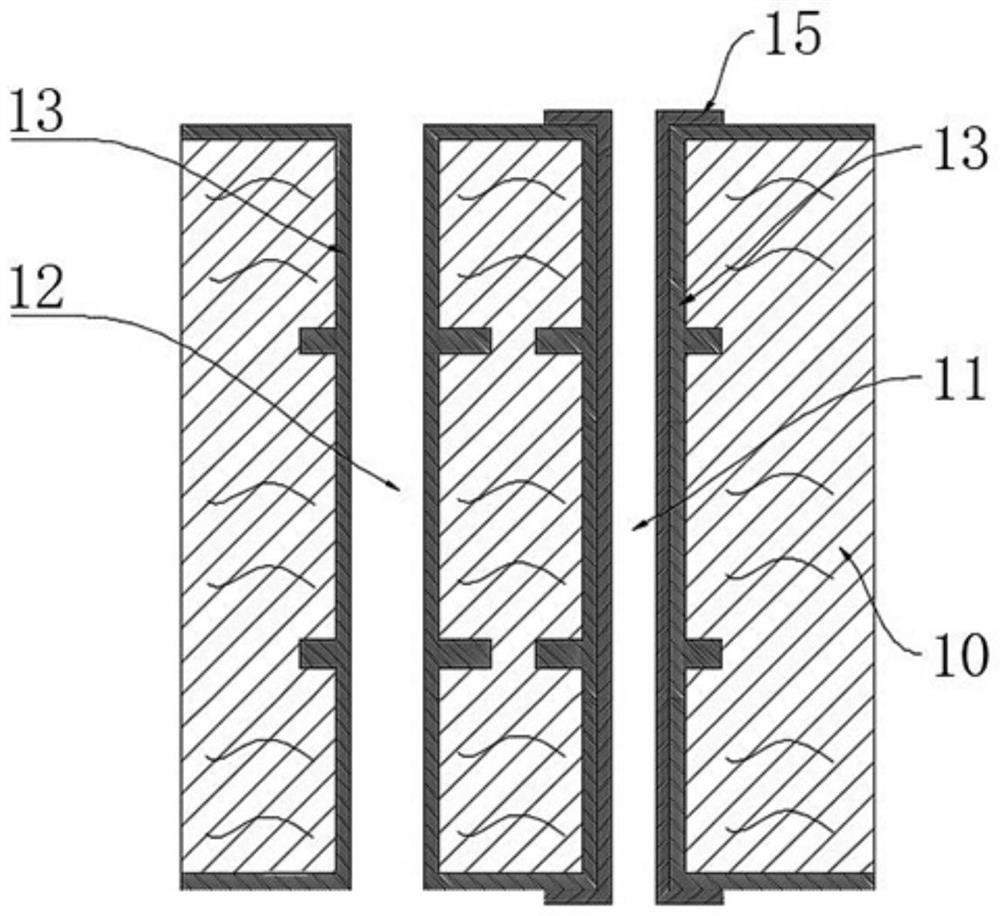

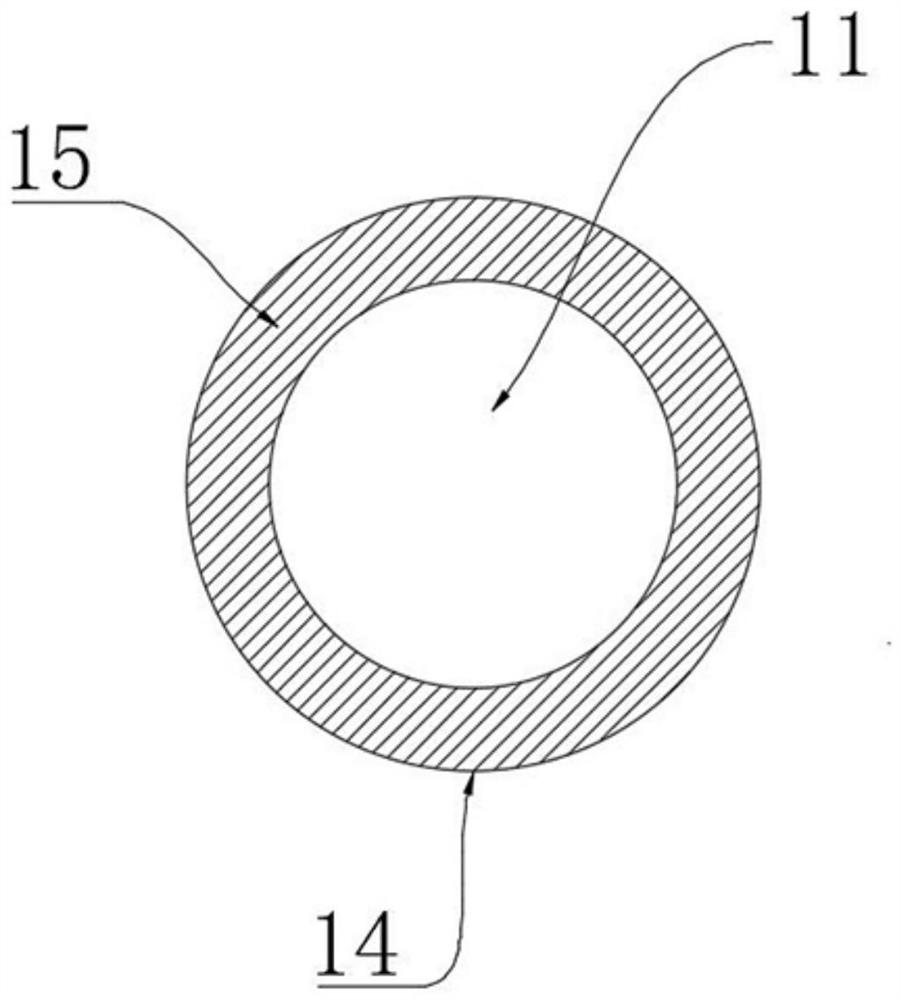

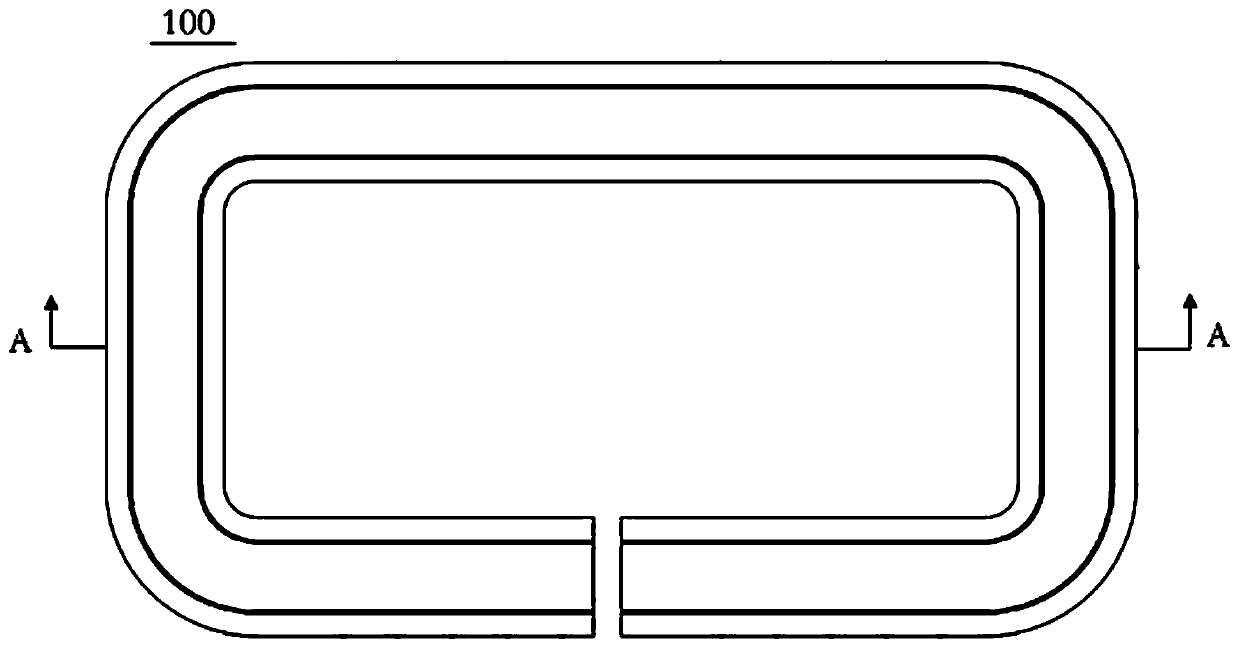

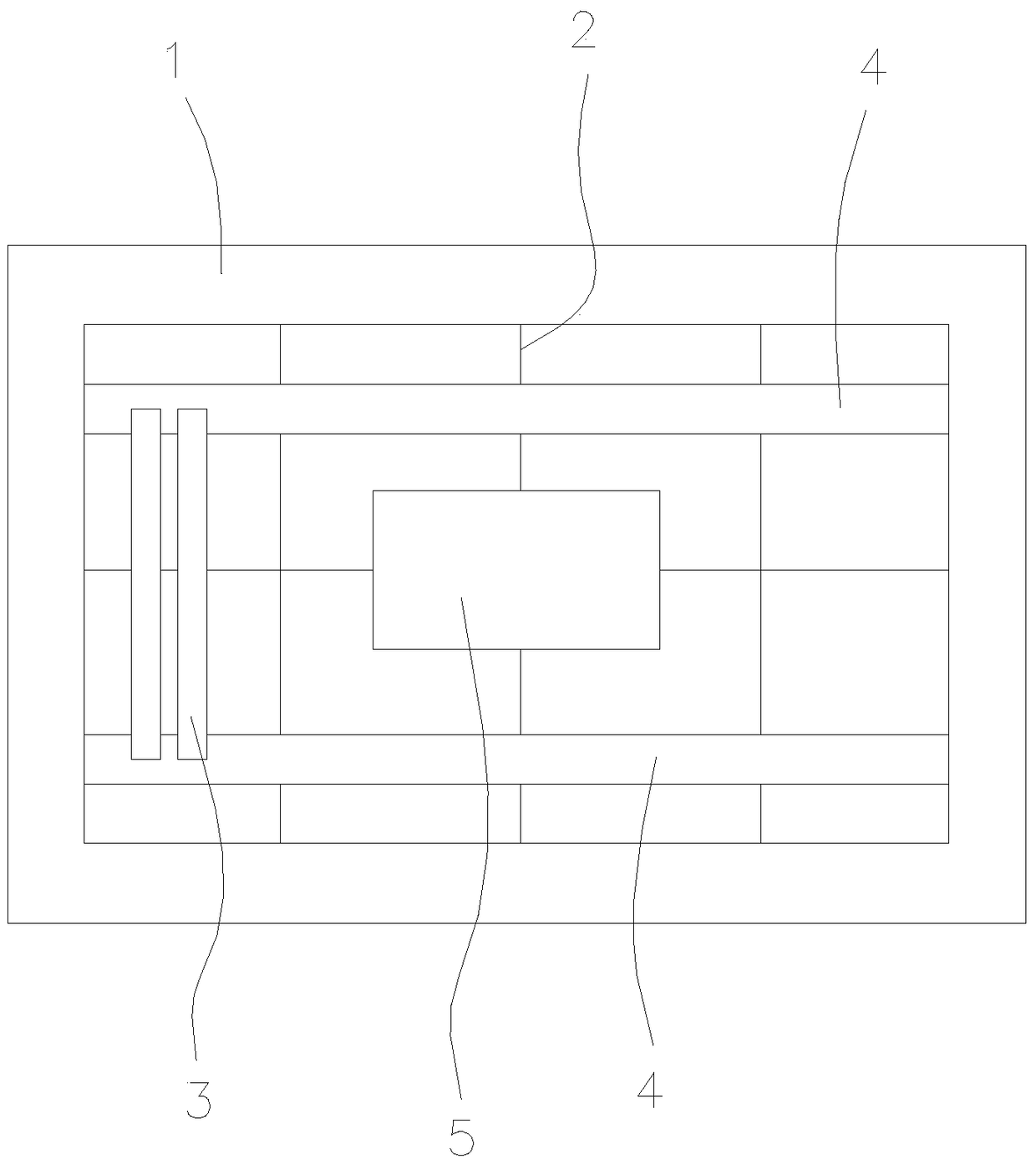

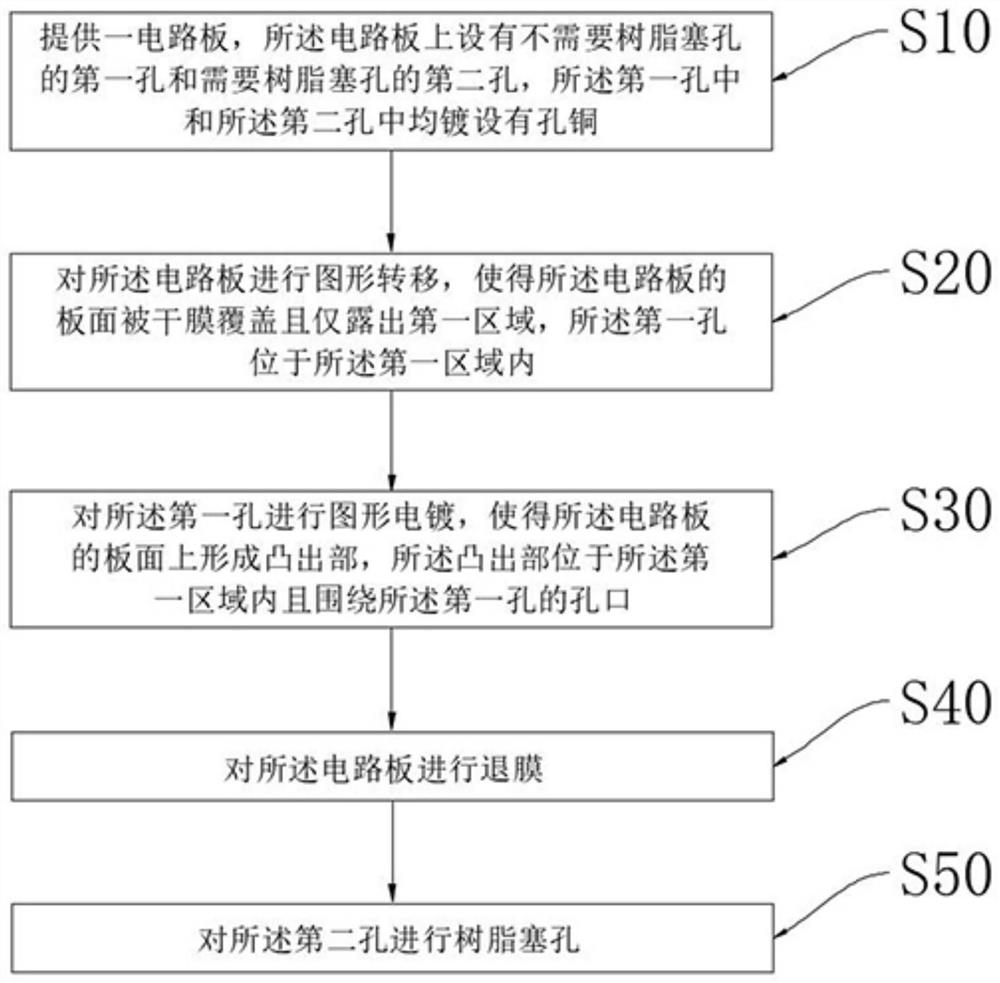

Method and circuit board for selective resin plugging

ActiveCN113260151BPrevent penetrationAvoid abnormal qualityPrinted circuit aspectsPrinted element electric connection formationManufacturing technologyEngineering

The invention is applicable to the technical field of circuit board manufacturing technology, and provides a method for selectively plugging holes with resin and a circuit board. The method for selectively plugging holes with resin includes: providing a circuit board with a first hole that does not require a resin plug hole and a second hole that requires a resin plug hole, the first hole neutralizing all the holes. The second holes are all plated with hole copper; the pattern is transferred to the circuit board, so that the board surface of the circuit board is covered by dry film and only the first area is exposed, and the first hole is located in the first hole. area; perform pattern plating on the first hole, so that a protruding part is formed on the board surface of the circuit board, and the protruding part is located in the first area and surrounds the opening of the first hole; Perform film stripping on the circuit board; perform resin plugging on the second hole. The invention also provides a circuit board. The invention can prevent the resin ink from penetrating into the through holes that do not need the resin plug holes, and avoid the abnormal quality.

Owner:SHENZHEN KINWONG ELECTRONICS

Silicone strip anti-falling device and laminating machine

ActiveCN110473931AAvoid abnormal qualityFinal product manufacturePhotovoltaic energy generationEngineeringSilica gel

The invention provides a silicone strip anti-falling device and a laminating machine. The device is used for the laminating machine. A bearing component is included. A first end of the bearing component is provided with a first chamber with an open end and second chambers. The first chamber is used to install a first silicone strip. There are two second chambers, the two second chambers are arranged on two sides of the first chamber, and the two second chambers are used for fixing two side edges of a second silicone strip. The silicone strip anti-falling device can fix the two silicone strips,and the second silicone strip can wrap and fix the first silicone strip, which effectively avoids a problem that the silicone strip falls off after a surface is aged due to increase of a service cycle so as to cause the components to appear air bubbles and abnormal quality.

Owner:JA XINGTAI SOLAR CO LTD

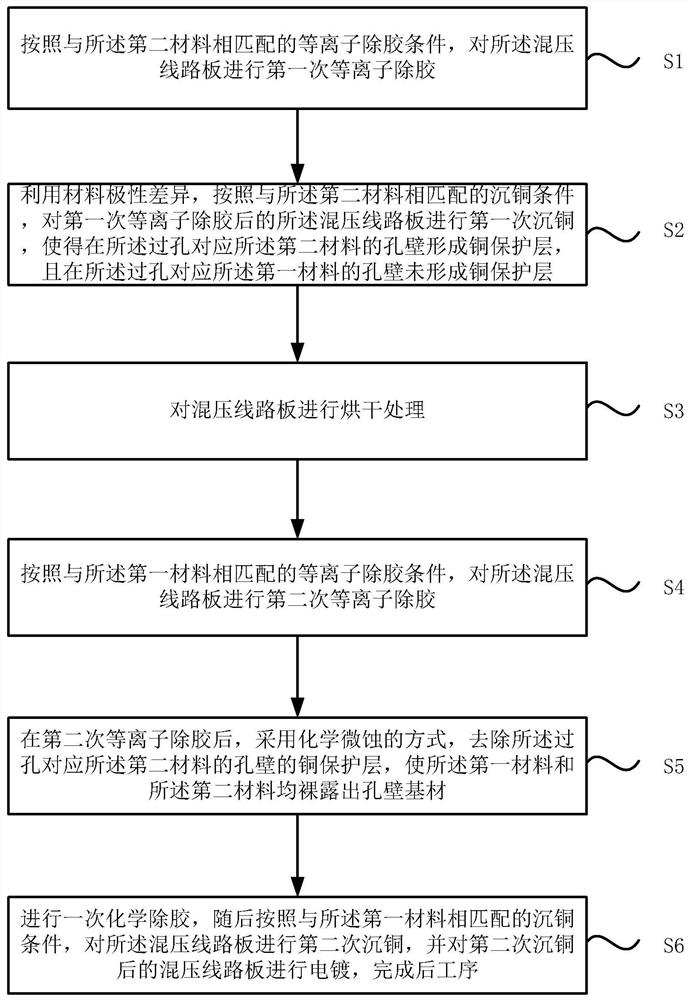

Plasma degumming method for mixed-pressed circuit board

PendingCN113423178AAvoid abnormal qualityGood degumming effectConductive pattern polishing/cleaningProtection layerChemical engineering

The invention discloses a plasma degumming method for a mixed-pressed circuit board. The method comprises the steps of: carrying out primary plasma degumming on a laminated board which is obtained through the mixed pressing of two materials with different degumming difficulties and a via hole through machining, forming a copper protection layer on the hole wall corresponding to the material with small degumming difficulty according to the polarity difference of the two materials, wherein a copper protection layer is not formed on the hole wall corresponding to the material with high degumming difficulty, then carrying out secondary plasma degumming, removing the copper protection layer, and completing copper deposition and electroplating coordinated with chemical degumming. Therefore, selective degumming be carried out on different types of materials, various quality abnormities can be effectively avoided, and a good degumming effect and a good metallization effect are ensured.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

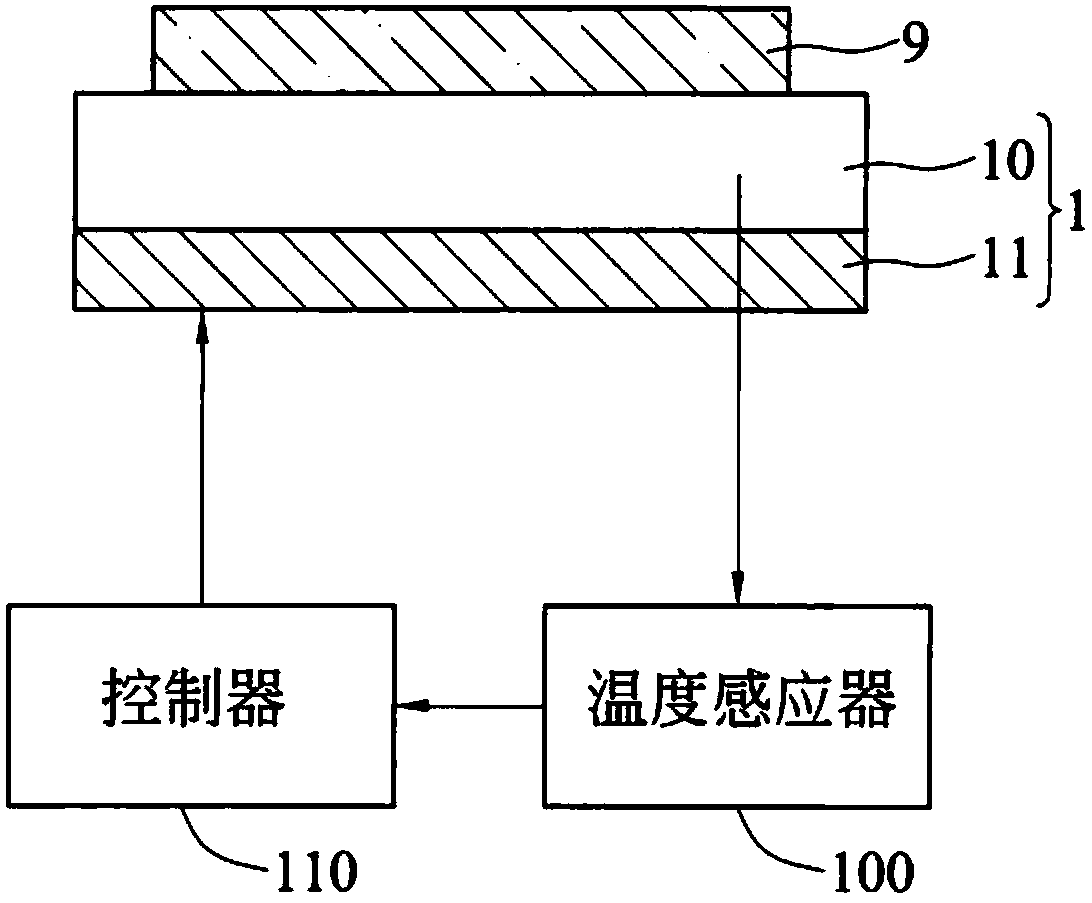

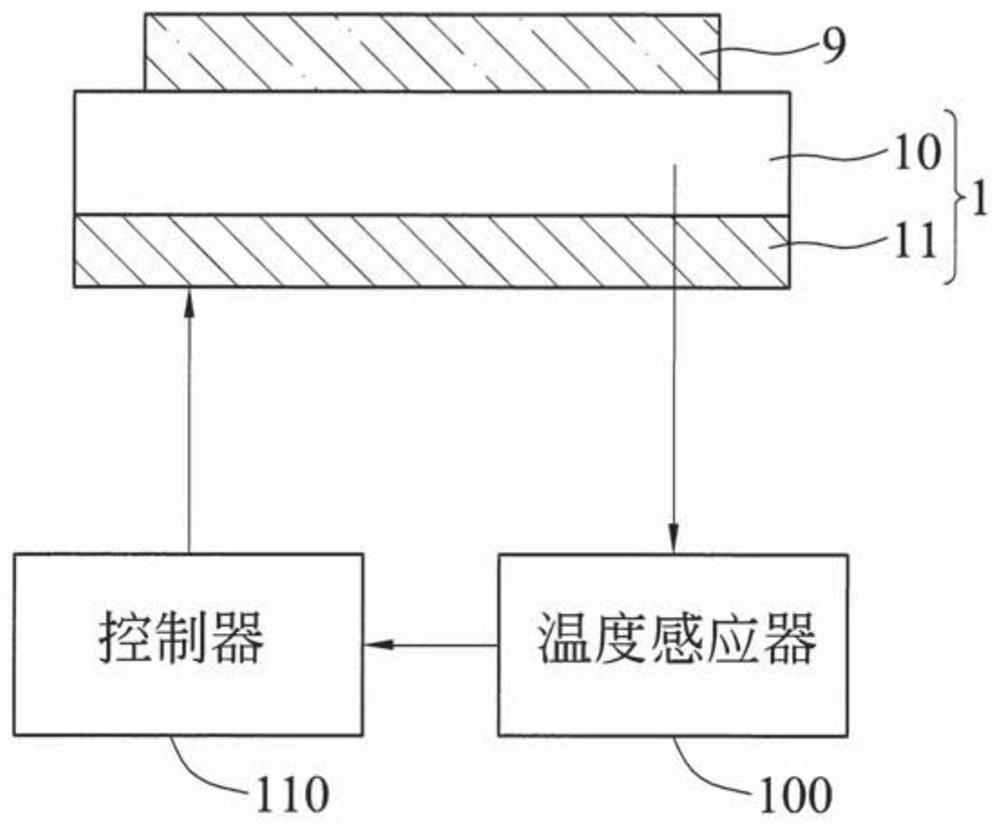

Detecting apparatus

ActiveCN108417503AAvoid abnormal qualityImprove cooling effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCooling effectElectronic component

A detecting apparatus is provided. The apparatus provides a better cooling effect by supplying gas to a carrying device for carrying an electronic component to be tested through a gas supply device toperform cooling, instead of cooling the existing ambient temperature.

Owner:SILICONWARE PRECISION IND CO LTD

Positioning pin mechanism, substrate transfer device and substrate transfer method

ActiveCN108557472BAvoid abnormal qualityReduce design costCharge manipulationConveyor partsClassical mechanicsCylinder block

The invention provides a positioning pin mechanism, a substrate conveying device and a substrate conveying method. The positioning pin mechanism comprises a positioning pin and a cylinder driving thepositioning pin to move; the cylinder comprises an obliquely arranged cylinder body and a piston rod telescopically arranged in the cylinder body, and therefore the positioning pin can be driven by the cylinder to shift in the horizontal direction and the vertical direction at the same time, the design cost can be reduced, and it can be effectively avoided that in the substrate positioning process, because the positioning pin abrades and scratches a substrate, quality abnormity is caused.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Magnetic core bonding method

The invention relates to the field of manganese zinc ferrite magnetic core production, in particular to a magnetic core bonding method. The magnetic core bonding method comprises the following steps: decomposing a magnetic core which has a special shape and cannot be directly produced into a plurality of products which are simple in shape and easy to produce, wiping the surfaces of the products by using cotton cloth dipped with alcohol, evenly smearing glue on the portions, needing to be bonded, of products, brushing the portions, needing to be bonded, of the products by using a copper wire brush, aligning and attaching the bonding faces of the two sets of products needing to be bonded, and enabling the two sets of bonded products to stand in a dry and clean environment to be cured. In the actual use process, the step of glue blending is omitted, actual operation is easier and more convenient, resource waste and abnormal product quality caused by glue blending errors are effectively avoided, the actually bonded product is more resistant to high temperature and high pressure, the efficiency of the production process is effectively improved, and manpower and material resources are saved.

Owner:WUXI SPINEL MAGNETICS

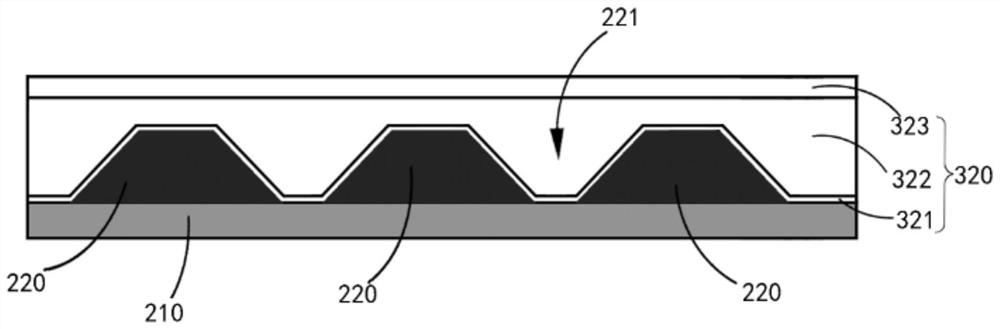

Display substrate and preparation process of display substrate

ActiveCN110379933BAvoid abnormal qualitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneStructural engineering

Owner:BOE TECH GRP CO LTD +1

Testing Equipment

ActiveCN108417503BAvoid abnormal qualityImprove cooling effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingThermodynamicsCooling effect

A detecting apparatus is provided. The apparatus provides a better cooling effect by supplying gas to a carrying device for carrying an electronic component to be tested through a gas supply device toperform cooling, instead of cooling the existing ambient temperature.

Owner:SILICONWARE PRECISION IND CO LTD

Device and method for multi-channel calibration and verification of multi-energy-saving power management IC

ActiveCN104133185BImprove scalabilityExpand the scope of testingElectrical measurementsTest efficiencyClosed loop

The invention provides a multichannel calibration and verification device and method for multiple sections of electric-quantity management ICs. The method mainly controls a plurality of channel test boards through a main control board to test the multiple sections of electric-quantity management ICs and in a test process, a localized closed-loop correction method is adopted to calibrate voltage and current precision of the multiple sections of electric-quantity management ICs. Moreover, through adoption of a channel self-detection module, precision calibration is carried out on cell boards and current boards of the channels of the device so that precision calibration of a voltage and current reference source of the device is realized and stability of the reference source of the device is ensured. The method also uses a channel combination module according to practical needs to combine the plurality of channels into large channels so as to meet test demands of the multiple sections of electric-quantity management ICs. The method uses a method of using the plurality of channels to carry out parallel tests simultaneously so that test efficiency of the multiple sections of electric-quantity management ICs is improved, expandability of the multichannel calibration and verification device is strengthened, demands that users configure the channels flexibly according to practical conditions can be met and user use cost is reduced.

Owner:HUIZHOU BLUEWAY ELECTRONICS

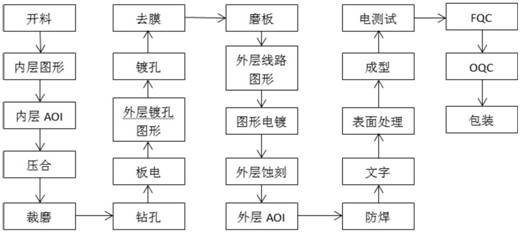

Method for manufacturing circuit board with uniformly plated holes

PendingCN113068327AImprove plated hole effectAvoid abnormal qualityPrinted element electric connection formationDrill holeSmall hole

The invention discloses a method for manufacturing a circuit board with uniformly plated holes, and the method sequentially comprises the following steps: carrying out the pre-process treatment, and forming a multi-layer circuit board; performing drilling and copper plating: presetting a hole plating area and a hole non-plating area on the circuit board, performing hole drilling in the hole plating area, and performing copper plating on the circuit board after hole drilling; carrying out the hole plating and patterning of the outer layer: determining a to-be-plated hole needing to be plated in a plurality of holes formed by drilling, and performing windowing on the position of the to-be-plated hole, wherein the windowing size is larger than the single side of the to-be-plated hole; performing windowing on the non-plated hole area to form a plurality of exposed dispersed current pads; performing hole plating: thickening the hole copper in the to-be-plated hole; performing board grinding: grinding the plated hole opening and the dispersed current pad, so that the board surface of the circuit board is flat; and carrying out post-process treatment. According to the invention, the hole plating effect is good, the problems of small hole size, hole blockage or plate burning are avoided, the current dispersion pad plays a role in dispersing current, uniform electroplating during hole plating is ensured, and the product quality is improved.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

Detection device and orthobaric equipment

InactiveCN112002231AAvoid abnormal qualityProcess stabilityLaminating printed circuit boardsOptically investigating flaws/contaminationLight sensingEngineering

The invention relates to a detection device and orthobaric equipment. The equipment comprises a working platform which is used for bearing a to-be-pressed part, an orthobaric mechanism which is arranged above the working platform, a buffer component which is arranged between the working platform and the orthobaric mechanism, a detection device and a control device, wherein the detection device comprises a light source and a light sensing unit, the light source is located on one side of the buffer component and used for emitting detection light irradiating the pressing area of the buffer component, the light sensing unit is located on the side, deviating from the light source, of the buffer component and used for sensing detection light, the control device is coupled to the detection deviceand the orthobaric mechanism, and the control device is configured to control the orthobaric equipment to be switched between the machining state and the shutdown state according to the detection result of the light sensing unit. According to the orthobaric equipment, if the buffer component after being pressed is broken, the detection light emitted by the light source irradiates the light sensing unit through the gap generated after the buffer component is broken, the orthobaric equipment can stop running according to the detection result of the light sensing unit, and large-scale quality abnormity is avoided.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

A method for making an aluminum substrate solder resist screen plate to prevent photosensitive paste from falling off

ActiveCN105517366BImprove the problem of easy falling offAvoid abnormal qualityNon-metallic protective coating applicationDirectly printed exposure masksResistAdhesive

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

Selective resin hole plugging method and circuit board

ActiveCN113260151APrevent penetrationAvoid abnormal qualityPrinted circuit aspectsPrinted element electric connection formationPolymer scienceEngineering

The invention is suitable for the technical field of circuit board manufacturing processes, and provides a selective resin hole plugging method and a circuit board. The selective resin hole plugging method comprises the steps that a circuit board is provided, a first hole which does not need resin hole plugging and a second hole which needs resin hole plugging are formed in the circuit board, and hole copper is plated in the first hole and the second hole; pattern transfer is carried out on the circuit board, so that the board surface of the circuit board is covered by a dry film, only a first area is exposed, and the first hole is located in the first area; pattern electroplating is conducted on the first hole, so that a protruding part is formed on the board face of the circuit board, and the protruding part is located in the first area and surrounds an opening of the first hole; film stripping is conducted on the circuit board; and resin hole plugging is conducted on the second hole. The invention also provides a circuit board. The resin ink can be prevented from permeating into the through hole which does not need resin plugging, and the quality abnormity is avoided.

Owner:SHENZHEN KINWONG ELECTRONICS

Decolorization of Acetyl Chloride and Application of Acidic Strong Oxidizer in Acetyl Chloride Decolorization

ActiveCN108117487BAvoid abnormal qualityImprove use valueOrganic compound preparationCarboxylic compound preparationSimple Organic CompoundsAcetyl chloride

The invention discloses a decolorization method of acetyl chloride. The decolorization method comprises the following steps: S1: adding a strong acid oxidant to the discolored acetyl chloride while stirring at the temperature not higher than 45 DEG C; controlling the mass ratio of the strong acid oxidant and acetyl chloride to be (1: 250) to (1:1000); S2: rising the temperature until fractions occur, and performing a total reflux reaction; S3: after the total reflux reaction is finished, distilling to be cutoff at the temperature not higher than 85 DEG C. The invention further discloses application of the strong acid oxidant to decolorization of acetyl chloride. The method disclosed by the invention can remove organic compounds containing unsaturated bonds and more active in properties inacetyl chloride to effectively prevent the discoloration of acetyl chloride in transportation and storage to improve use values of acetyl chloride.

Owner:湖北新蓝天新材料股份有限公司

Air Knife Device for Drying Substrates

ActiveCN108847398BAccurate detection of air volume changesTimely detection of blockage problemsSemiconductor/solid-state device manufacturingAir volumeEngineering

The invention provides an air knife device for drying a substrate. The air knife device comprises an air knife assembly, a movable telescopic baffle piece and a movable sensor. The air knife assemblycomprises an air knife air nozzle assembly, a pipeline connected with the air knife air nozzle assembly, an air supply device connected with the pipeline, and an adjusting device for controlling the wind power intensity of the air knife air nozzle assembly. The air knife air nozzle assembly comprises a first air knife air nozzle and a second air knife air nozzle, wherein the first air knife air nozzle and the second air knife air nozzle are used for blowing the two surfaces of the substrate respectively. The movable telescopic baffle piece is movably and telescopically arranged at the air outlet of the air knife air nozzle assembly. The movable sensor is movably arranged on the movable telescopic baffle piece, so as to detect the air outlet quantity of the air knife air nozzle assembly ata specific position. By virtue of the movable telescopic baffle piece and the movable sensor, the air volume changes of all positions of the air knife air nozzle assembly can be accurately detected, and the blockage problem of the air knife air nozzle assembly can be found in time, so that the phenomenon that the quality of the substrate product is abnormal due to blockage of the air knife air nozzle assembly is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

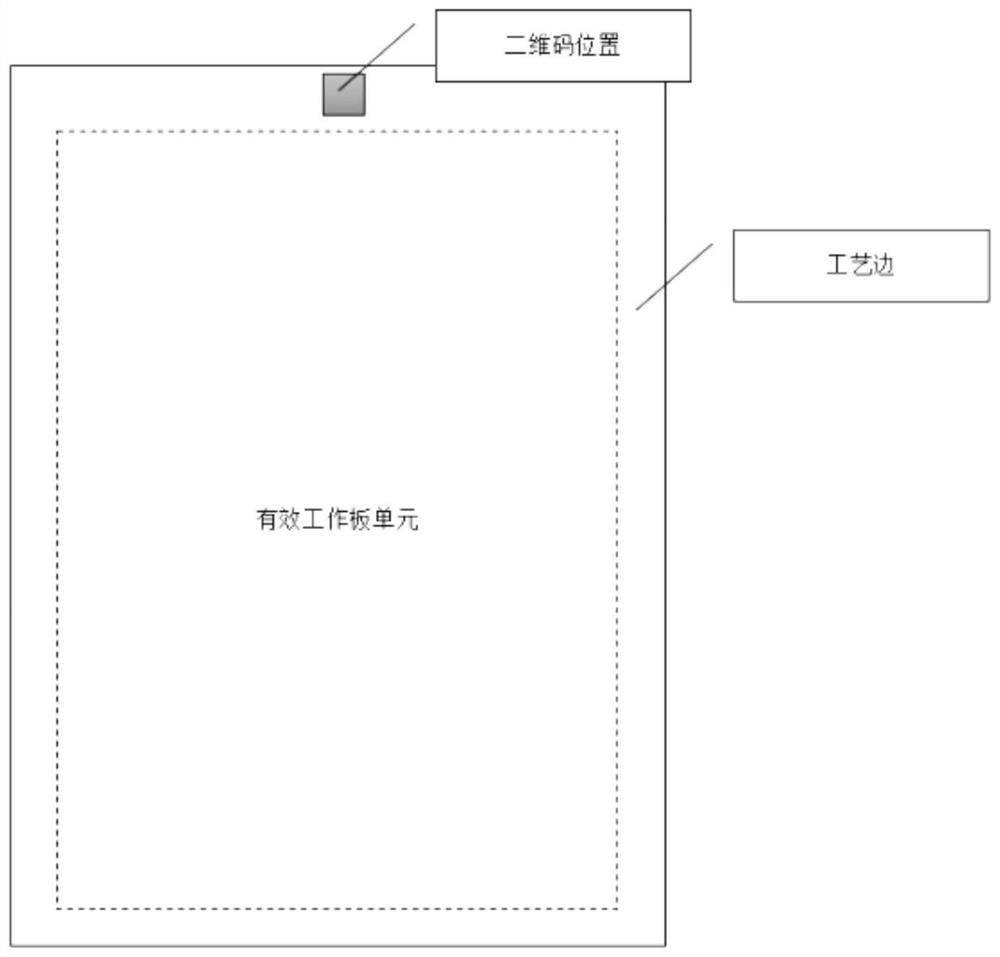

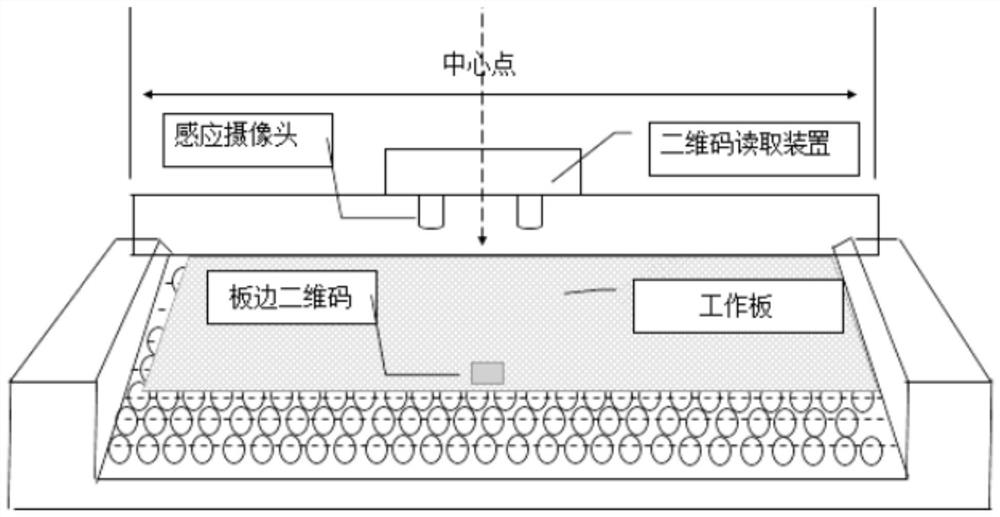

Quality abnormality detection method applied to character jet printing machines

InactiveCN110220730AExtend your lifeEasy for production inspectionStructural/machines measurementSpray nozzleWork in process

The invention discloses a quality abnormality detection method applied to character jet printing machines, and relates to the technical field. According to the method, character lines which are located in X and Y direction of a printed character are designed at a PNL plate edge remainder place; the character lines respectively penetrate through the whole printing surface; before normal charactersare produced, the character lines are firstly printed to recognize whether the ink jet points are normal or not; at a place which is 2-6 mm away from the felling of a semi-finished product, all the jet nozzles are enabled to jet ink for one time, so as to determine whether the ink jet points have the conditions such as deviation, ink scattering and ink throwing or not; at an ink jet recognition place, namely, the character lines, abnormal ink points of all the ink nozzles are displayed; when the ink jet recognition place is normal in position, the place quality is normal; and when the ink jetrecognition place is abnormal in position, the whole line in the ink jet direction of the plate is abnormal and the phenomena such as ink scattering, deviation and non-curing occur. According to the method, ink jet recognition points are designed to facilitate the production inspection and automatic equipment recognition, thereby greatly enhancing the inspection efficiency and recall factor; and judgement can be carried out for the first time when the equipment is abnormal, thereby avoiding the occurrence of the condition such as quality abnormality.

Owner:YIXING SILICON VALLEY ELECTRONICS TECH

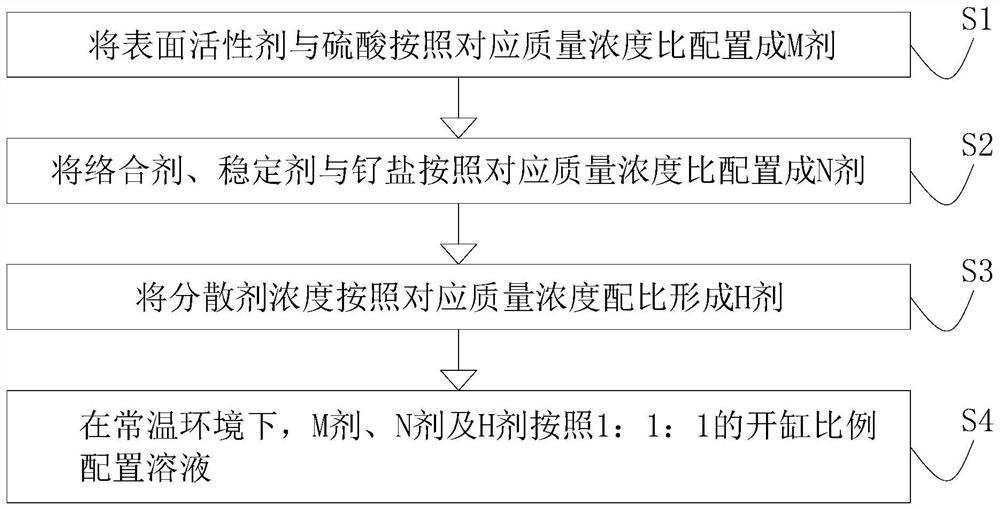

Activating solution before chemical nickel plating based on ruthenium system and preparation method of activating solution

ActiveCN114411126AImproved DippingAvoid abnormal qualityLiquid/solution decomposition chemical coatingPrinted circuit manufactureCu2 ionsActive agent

The invention discloses an activation solution before chemical nickel plating based on a ruthenium system and a preparation method of the activation solution. The activation solution comprises the following raw materials in mass concentration: 100-300 mg / L of ruthenium salt, 10000-20000 mg / L of concentrated sulfuric acid, 100-400 mg / L of a complexing agent, 10-30 mg / L of a stabilizer, 20-40 mg / L of a surfactant and 30-50 mg / L of a dispersing agent. According to the activating solution, surface treatment of chemical nickel can be achieved on a line with the line width / line distance being 2 mil / 2 mil or below, diffusion plating of an existing nickel plating process is improved, quality abnormity such as hole gold plating is solved, the copper ion tolerance of a bath solution is improved, the copper ion tolerance can be maximally improved to 200 ppm, the service life of the bath solution of the activating solution is longer, 20-30 m < 2 > of plates can be treated by each liter of bath solution, and the service life of the plates is prolonged. The activation of the ruthenium system can catalyze the chemical nickel plating of various substrates, and the binding force of the plating layer is excellent.

Owner:南雄市溢诚化工有限公司

A diaphragm automatic packaging equipment

ActiveCN105480478BSimple structureEasy to operatePackaging automatic controlEngineeringPackaging Tube

The invention is suitable for the technical field of automatic packing, and provides automatic packing equipment of a vibrating diaphragm. The automatic packing equipment comprises a frame; a vibrating disc is arranged on the frame; multiple slide ways are formed in a discharge port of the vibrating disc; guide plates capable of sliding are arranged below each slide way; at least two guide holes are formed in the guide plates; limiting grooves are formed in the lower part of each guide hole; the tops of packing pipes are sleeved in the limiting grooves; an elastic bracket is arranged on the frame below the packing pipes; and the elastic bracket supports and guarantees the tops of the packing pipes to be sleeved in the limiting grooves. The automatic packing equipment realizes automatic arrangement and automatic packing of the vibrating diaphragm through the setting of the vibrating disc and guide devices, is additionally provided with counting and warning devices, is simple in structure and convenient to operate, improves the production efficiency, and prevents the generation of quality abnormality.

Owner:潍坊新声悦尔电子科技有限公司

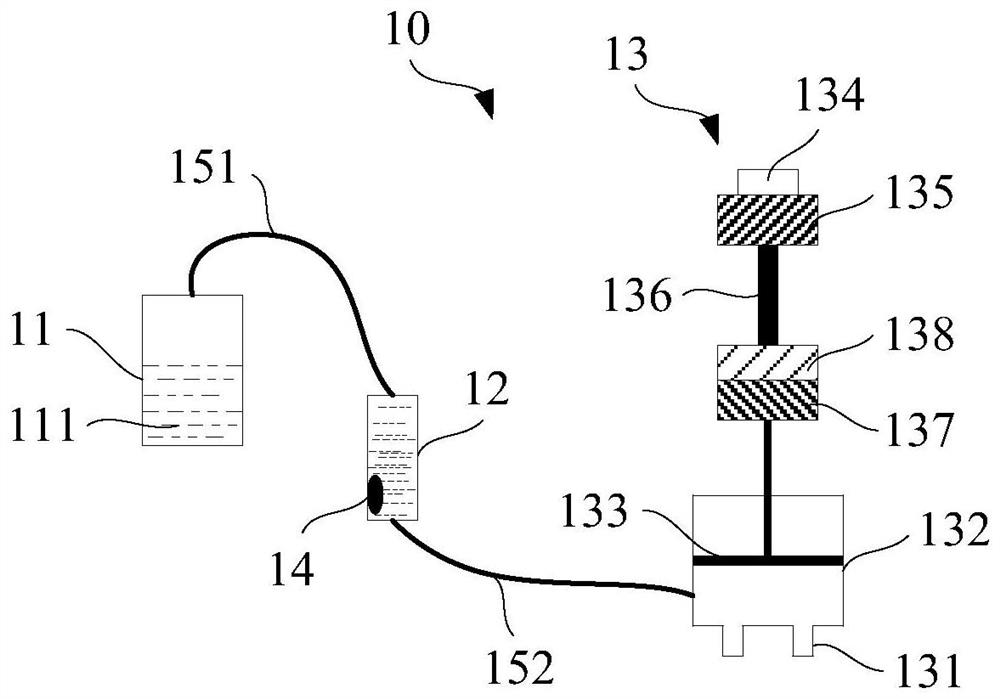

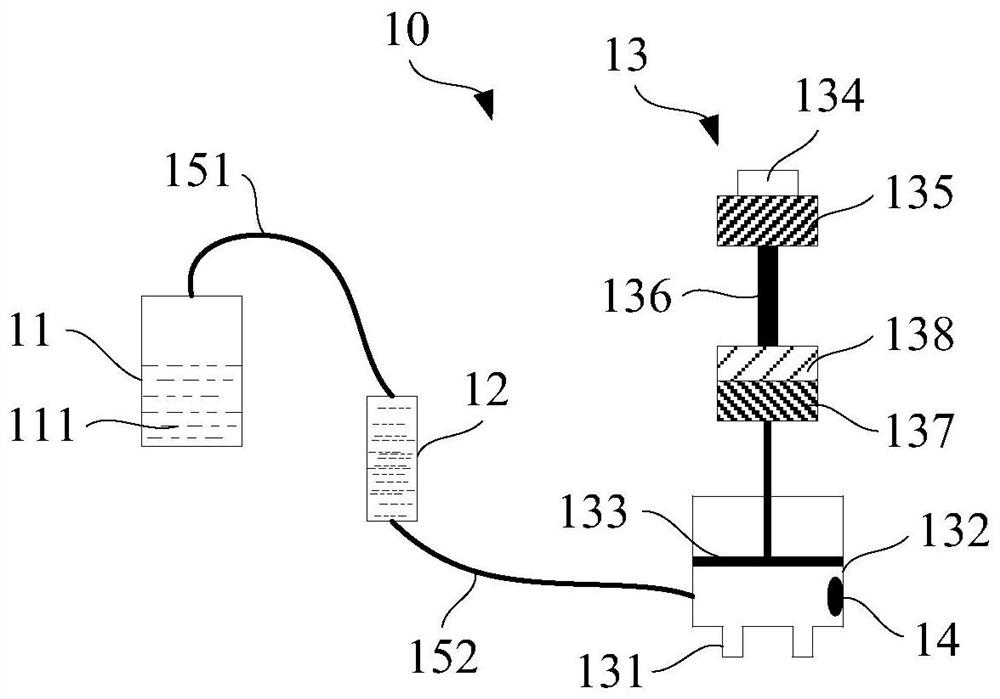

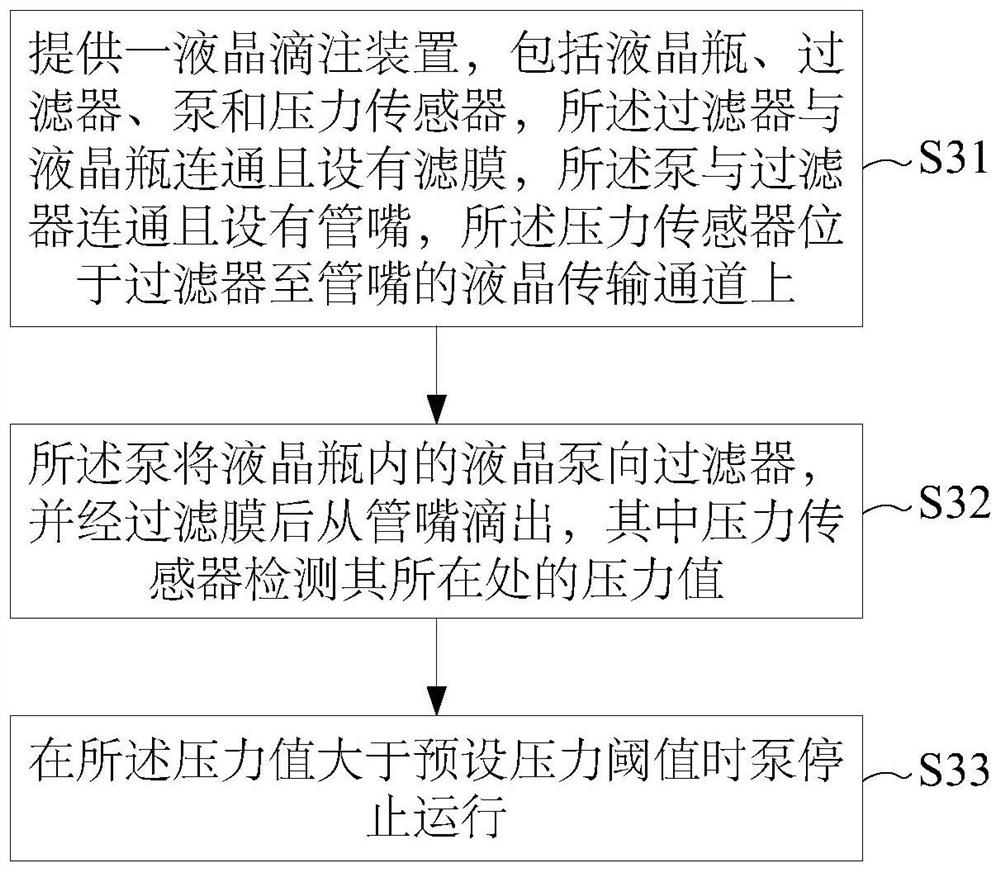

Liquid crystal dripping device and liquid crystal dripping method

ActiveCN110673404BAvoid breakingAvoid abnormal qualityNon-linear opticsLiquid crystallinePhysical chemistry

The invention discloses a liquid crystal dripping device and a liquid crystal dripping method. The liquid crystal dripping device includes: a liquid crystal bottle for containing liquid crystal; a filter connected with the liquid crystal bottle and provided with a filter membrane; a pump connected with the filter, and the pump is used to pump the liquid crystal to the filter and pass through The filter membrane drips from the nozzle of the pump; the pressure sensor, located on the liquid crystal transmission channel from the filter to the nozzle, is used to detect the pressure value at the location to allow the pump to be controlled when the pressure value is greater than the preset pressure threshold stop running. Based on this, the present invention can be beneficial to timely and effectively monitor the clogging of the filter membrane of the filter, and control the pump to stop running when the clogging of the filter membrane is detected, thereby avoiding the damage of the filter membrane and the resulting foreign matter in the liquid crystal entering into the liquid crystal panel to cause Abnormal quality phenomenon.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Decolorization method of acetyl chloride and application of strong acid oxidant to decolorization of acetyl chloride

ActiveCN108117487AAvoid abnormal qualityImprove use valueOrganic compound preparationCarboxylic compound preparationAcetyl chlorideStrong acids

The invention discloses a decolorization method of acetyl chloride. The decolorization method comprises the following steps: S1: adding a strong acid oxidant to the discolored acetyl chloride while stirring at the temperature not higher than 45 DEG C; controlling the mass ratio of the strong acid oxidant and acetyl chloride to be (1: 250) to (1:1000); S2: rising the temperature until fractions occur, and performing a total reflux reaction; S3: after the total reflux reaction is finished, distilling to be cutoff at the temperature not higher than 85 DEG C. The invention further discloses application of the strong acid oxidant to decolorization of acetyl chloride. The method disclosed by the invention can remove organic compounds containing unsaturated bonds and more active in properties inacetyl chloride to effectively prevent the discoloration of acetyl chloride in transportation and storage to improve use values of acetyl chloride.

Owner:湖北新蓝天新材料股份有限公司

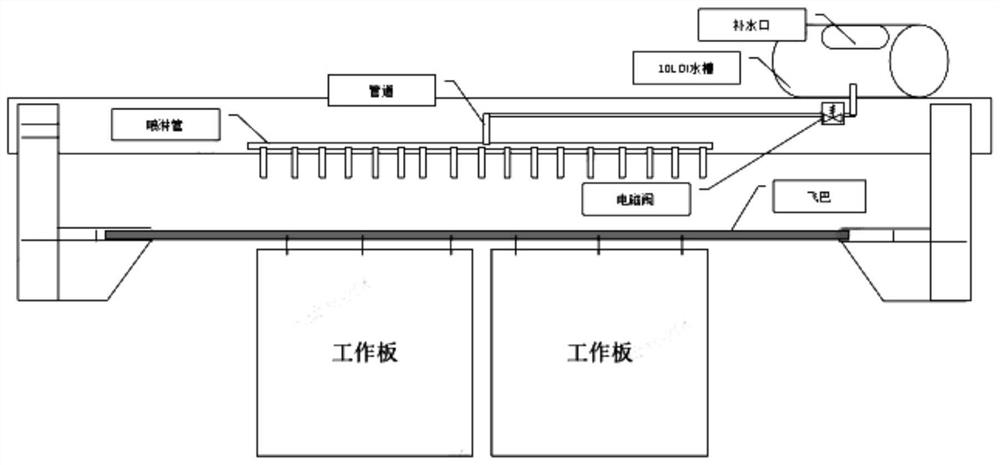

Intelligent management and control method for chemical gold process

PendingCN114690726AAvoid abnormal qualityGuaranteed qualityTotal factory controlProgramme total factory controlProcess engineeringIntelligent management

The invention discloses an intelligent management and control method for an electroless gold process, and relates to the technical field of electroless gold lines. An electroless gold thread management and control method; a post-processing management and control method; the chemical gold wire management and control method comprises the following steps of pretreatment, automatic liquid medicine adding and automatic spraying. The method has the advantages that fool-proof performance can be achieved due to flow standardization of the chemical gold process, and the situation that the next process cannot be continuously carried out when the plate does not pass through a certain step is prevented; the quality is ensured, and the abnormal quality caused by wrong dosage of manual liquid medicine adding or wrong liquid medicine adding is prevented; cost is saved, paper archives are replaced by electronic archives, paper is saved, records can be stored for a long time, and a user does not need to worry about no record after the paper archives are lost; the production information of the plate can be traced, and the production information of the plate can be collected through the two-dimensional code reading device and automatically transmitted back to the ERP system.

Owner:BOMIN ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com