Air knife device for drying substrate

An air knife and substrate technology, which is used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above and other objectives, features, and advantages of the present disclosure more comprehensible, preferred embodiments of the present disclosure will be exemplified below in detail with reference to the attached drawings. Furthermore, the direction terms mentioned in this disclosure, such as up, down, top, bottom, front, back, left, right, inside, outside, side layer, surrounding, center, horizontal, transverse, vertical, longitudinal, axial , radial direction, the uppermost layer or the lowermost layer, etc., are only directions for referring to the attached drawings. Therefore, the directional terms used are used to explain and understand the present disclosure, but not to limit the present disclosure.

[0021] In the figures, structurally similar units are denoted by the same reference numerals.

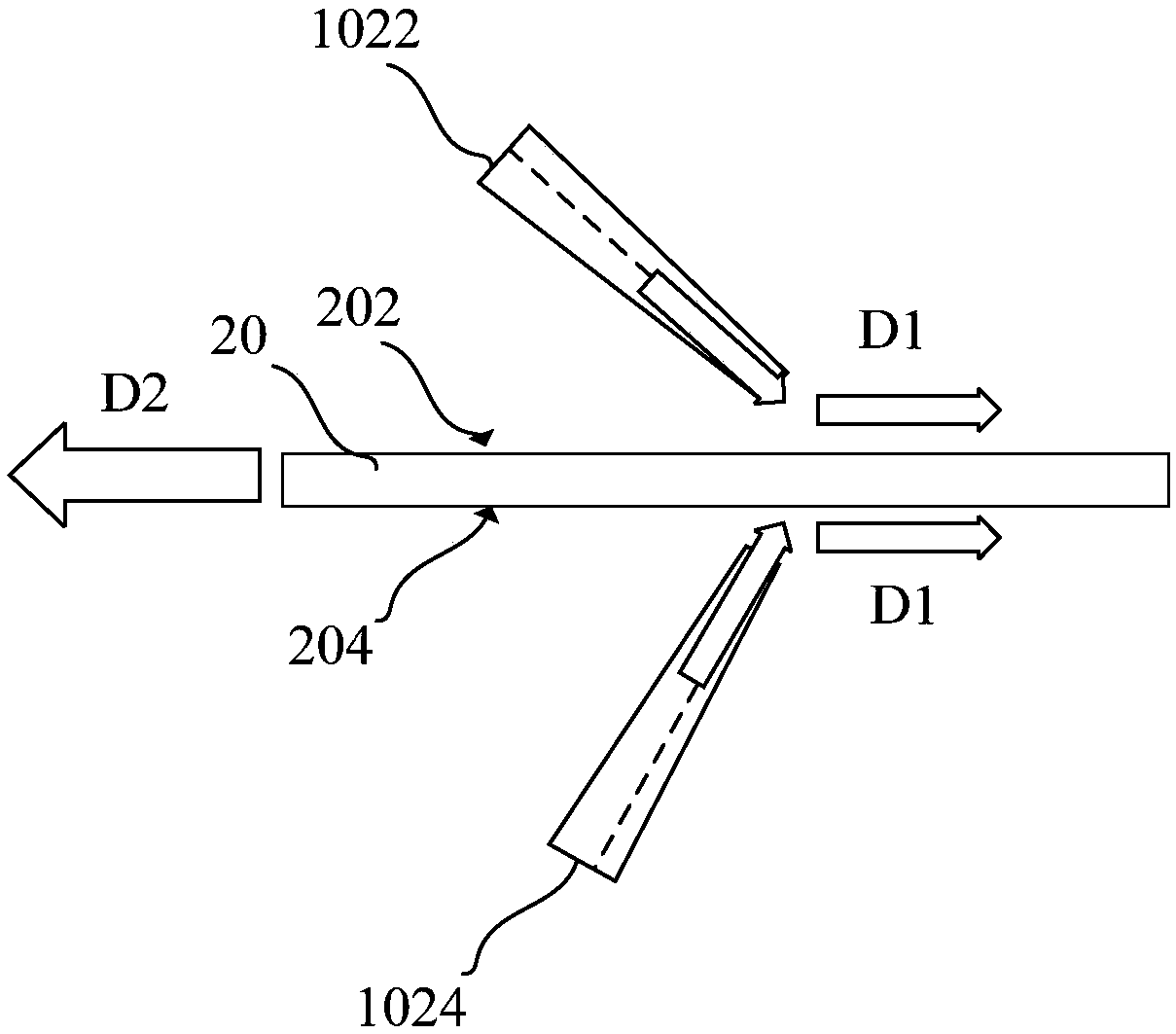

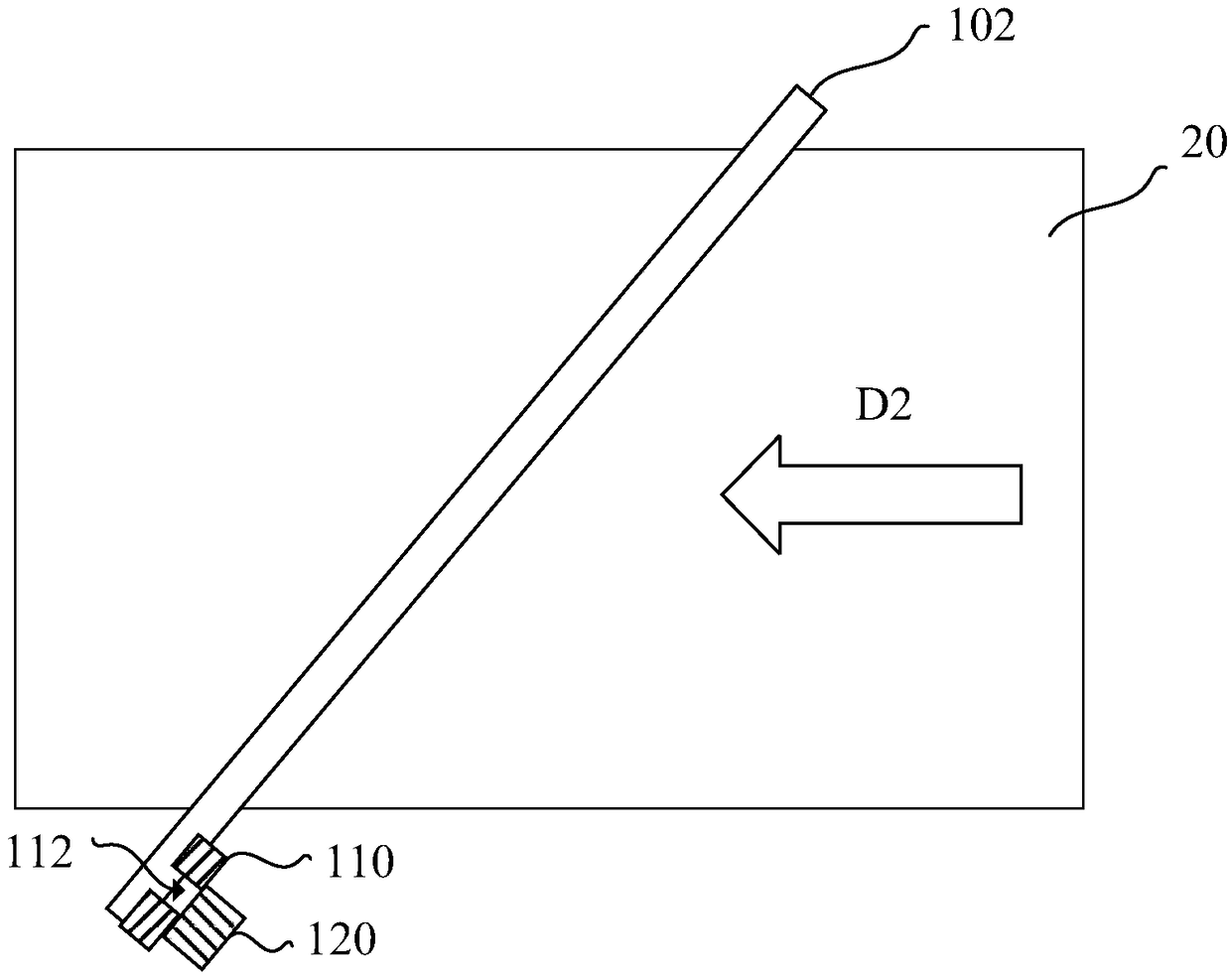

[0022] refer to figure 1 and figure 2 , figure 1 A schematic diagram showing the structure of an air knife device according to an embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com