Method for manufacturing circuit board with uniformly plated holes

A manufacturing method and circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, and the formation of electrical connection of printed components, can solve the problems of uneven electroplating, small aperture, burning board, etc., to ensure uniform electroplating, avoid small holes, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical solutions of the present invention in detail, the technical solutions of the embodiments of the present invention will be clearly and completely described below. Apparently, the described embodiments are some, not all, embodiments of the present invention.

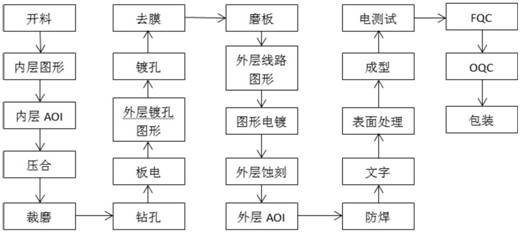

[0021] A method for manufacturing a circuit board with uniform plated holes, comprising the following steps in sequence:

[0022] The pre-process processing forms a multi-layer circuit board; the pre-process processing includes cutting, inner layer graphics, inner layer AOI, pressing and cutting and grinding in turn. Specifically, the cutting cuts multiple substrates and the subsequent pressing The substrate located in the inner layer of the circuit board is used to make the inner layer graphics, and the inner layer AOI ensures the quality, and the qualified substrates are pressed together.

[0023] Drilling and board electrical: preset plated hole area and non-plated hole area on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com