Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Vanadium compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

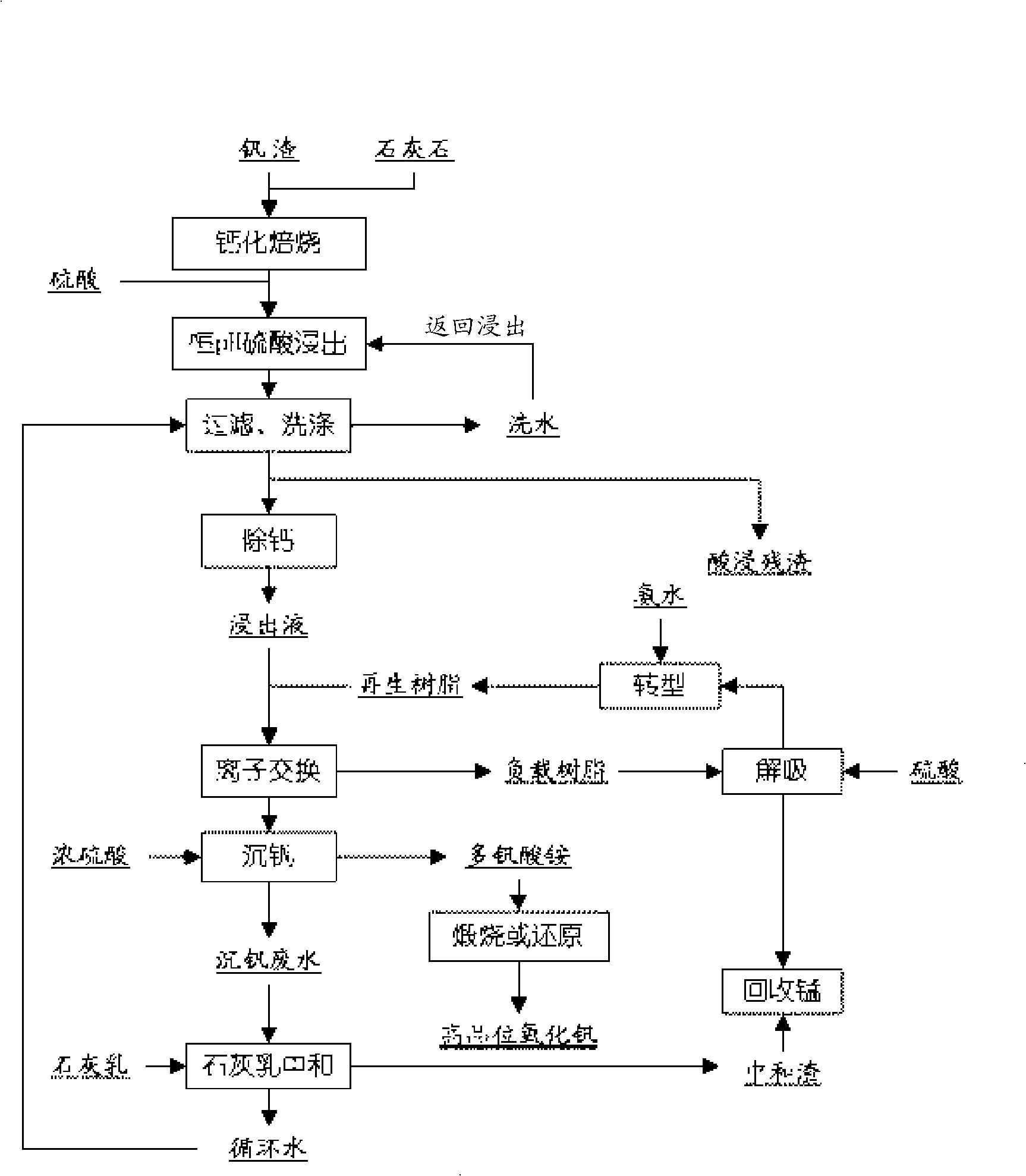

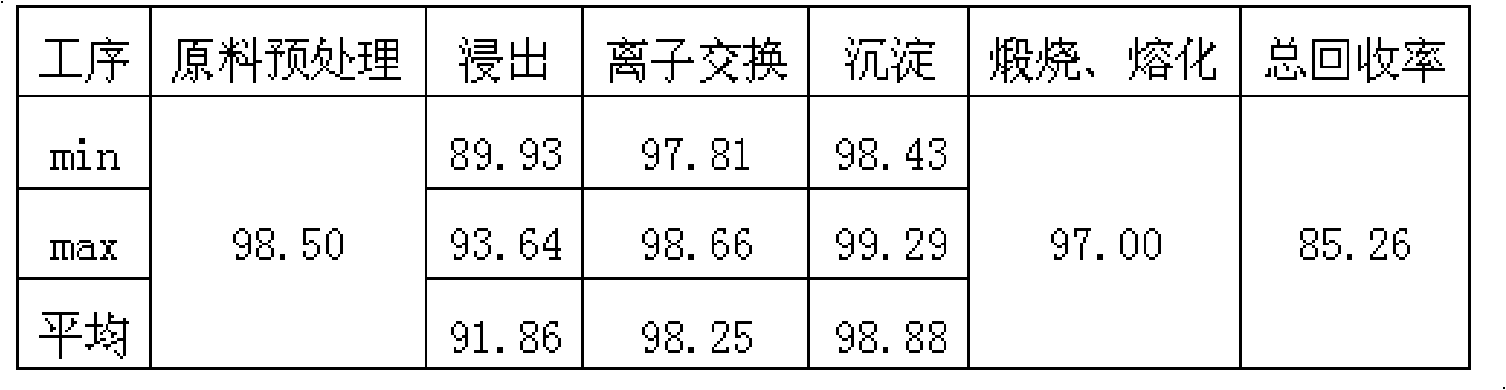

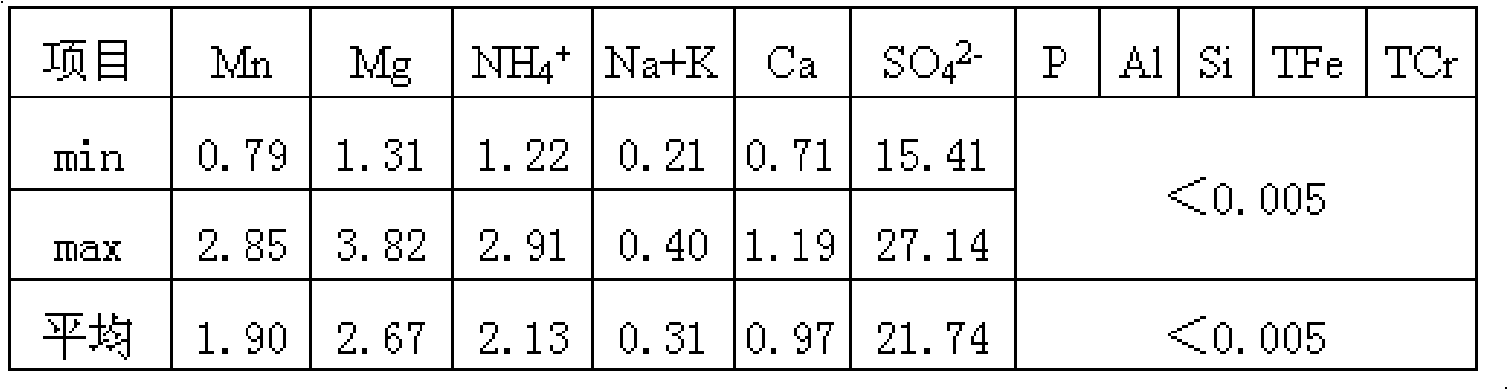

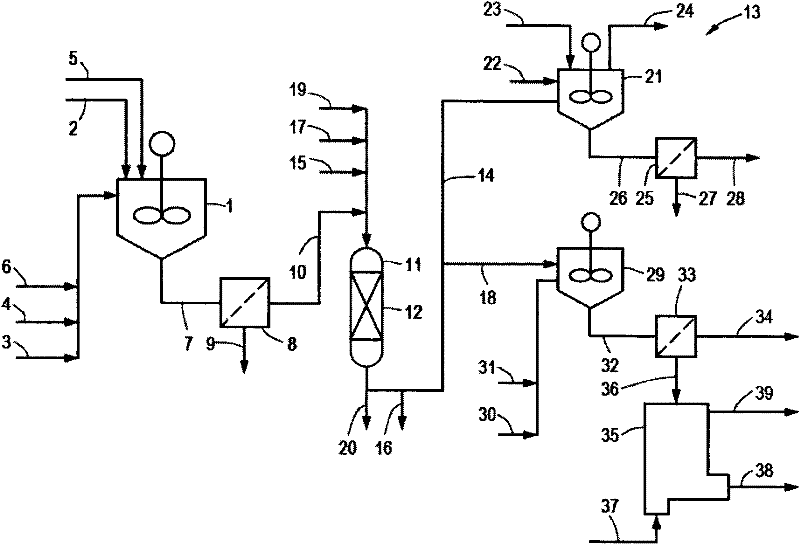

Process for producing vanadium oxide for implementing wastewater circulation with ionic exchange

ActiveCN101402470ASolve difficult environmental problemsQuality improvementVanadium compounds preparationVanadium oxidesEmission standardIon exchange

The invention relates to a method for producing vanadium oxide by utilizing ion exchange to realize wastewater circulation and belongs to the field of the extraction of the vanadium oxide. The technical problem which is solved by the invention is to provide a method for producing the vanadium oxide, in which a high-quality vanadium product can be obtained and the problems that vanadium extraction wastewater reaches the emission standard and is recycled are thoroughly solved. The method for producing the vanadium oxide comprises the following steps: the vanadium oxide is prepared by the steps of the preparation of raw materials, calcification and roasting, infiltration, solid-liquid separation, ion exchange and impurity removal, vanadium precipitation, calcination and deamination or deoxidation and other steps; and the vanadium extraction wastewater is subjected to neutralizing treatment by using lime cream and returns a system for recycling, thereby realizing the zero emission of the wastewater. The method also improves the reclaiming rate of vanadium which is higher than that of the current process, and reduces production cost. The method is combined with other technologies to convert residue and other wastes after vanadium extraction into secondary resource for reutilization, thereby realizing clean production.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

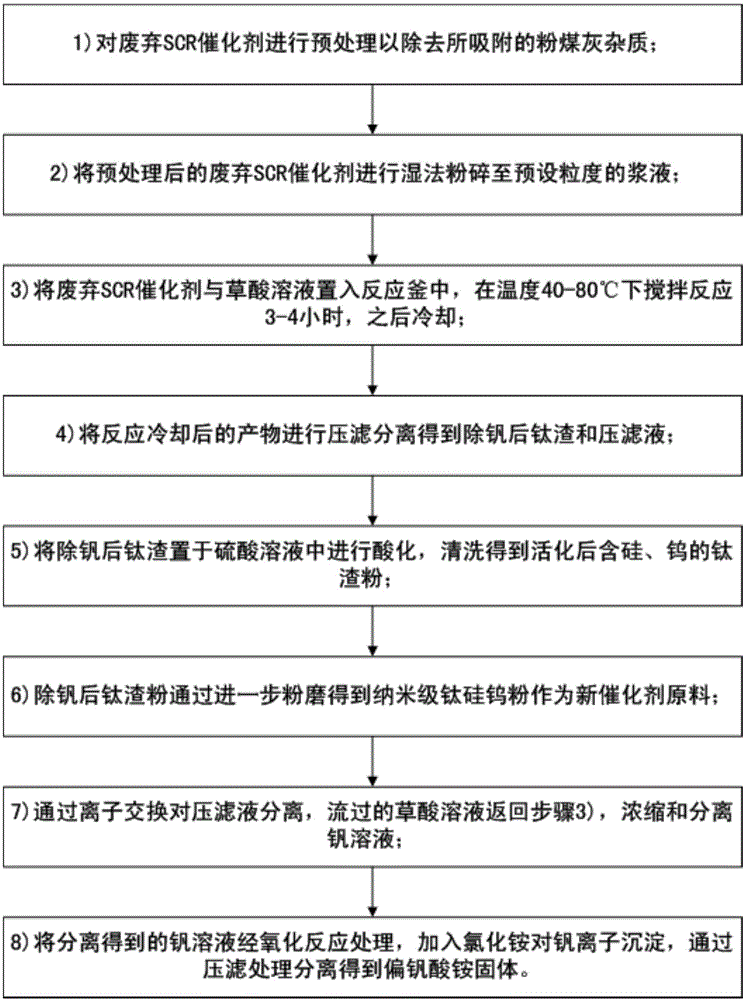

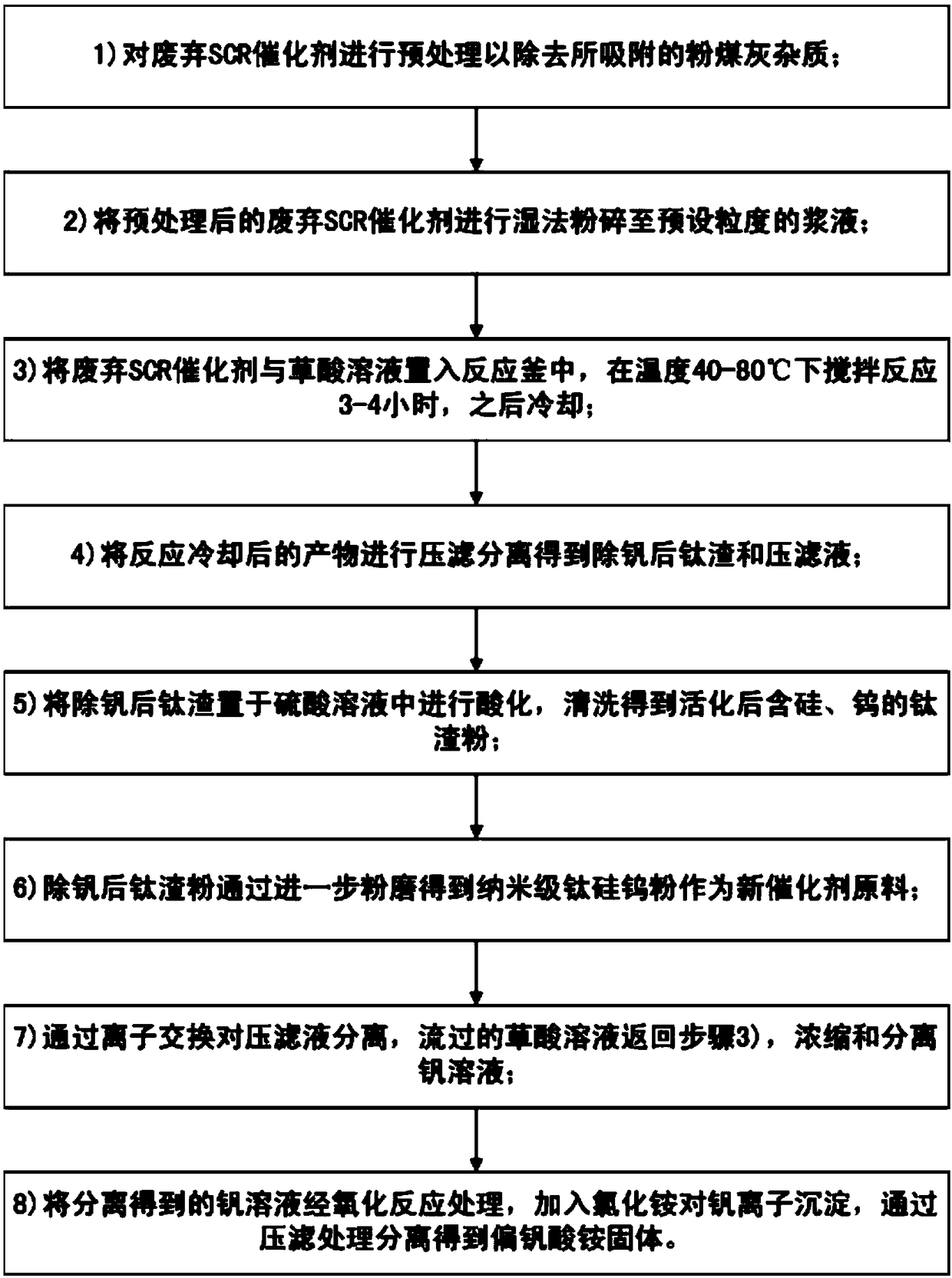

Method for extraction of vanadium from waste SCR catalyst and preparation of activated titanium silicon tungsten powder

ActiveCN106521160ASolve harmless disposalTo achieve the purpose of resource reuseCatalyst regeneration/reactivationVanadium compounds preparationOxalateSlurry

The invention discloses a method for extraction of failure vanadium from a waste SCR catalyst and preparation of activated titanium silicon tungsten powder for making a new denitration catalyst. The method includes: conducting pretreatment on a waste SCR catalyst, performing wet grinding to obtain a slurry, and adding an oxalic acid solution to carry out leaching reaction; carrying out filter-press separation to obtain tungsten silicon-containing titanium slag powder and press filtrate, then performing cleaning, activation, and fine grinding to obtain nanoscale titanium silicon tungsten powder; separating the press filtrate, recovering oxalic acid and returning the recovered oxalic acid to leaching reaction, adding an oxidizing agent into the separated liquid to carry out precipitation reaction so as to obtain ammonium metavanadate precipitate, and conducting filtering and separation to obtain ammonium metavanadate solid. The method provided by the invention uses oxalic acid for reaction under a normal temperature condition, can separate failure vanadium salt from the SCR catalyst, utilizes acid to activate other components and then performs fine grinding and other treatments so as to obtain the raw material for preparation of a new denitration catalyst. The process provided by the invention has the characteristics of low technological investment requirement and low energy consumption, effectively solves the harmless treatment problem of the SCR catalyst, and realizes recycling of resources.

Owner:安徽思凯瑞环保科技有限公司

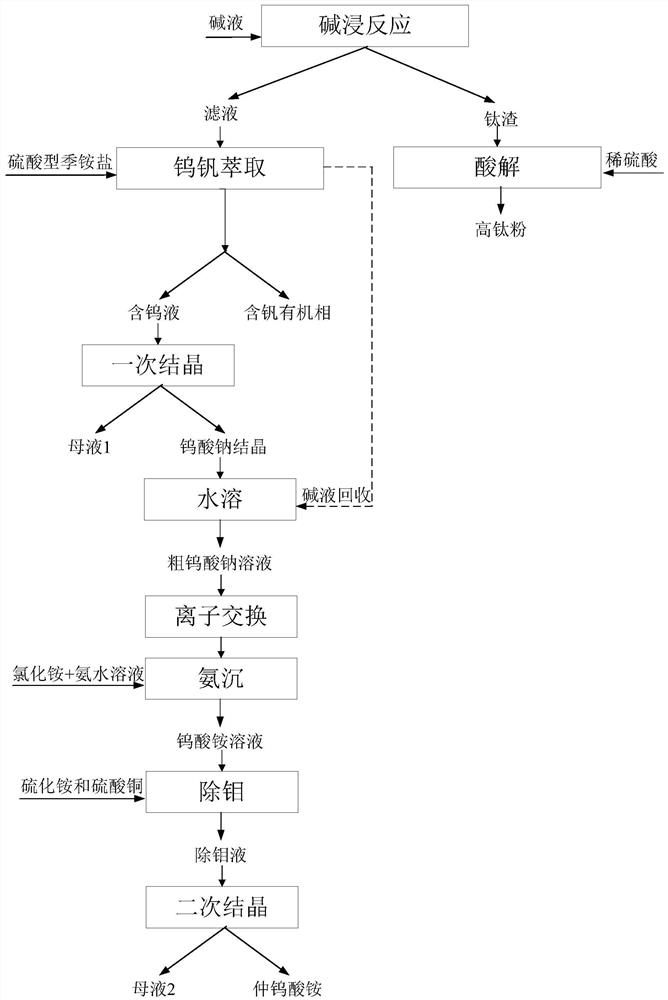

Process for reclaiming honeycomb SCR waste catalyst

ActiveCN105621483AFairly technologically advancedQuite practicalTungsten compounds preparationVanadium compounds preparationAmmonium paratungstateIon exchange

Owner:TIANCHANG GAOPENG EXPERIMENT EQUIP

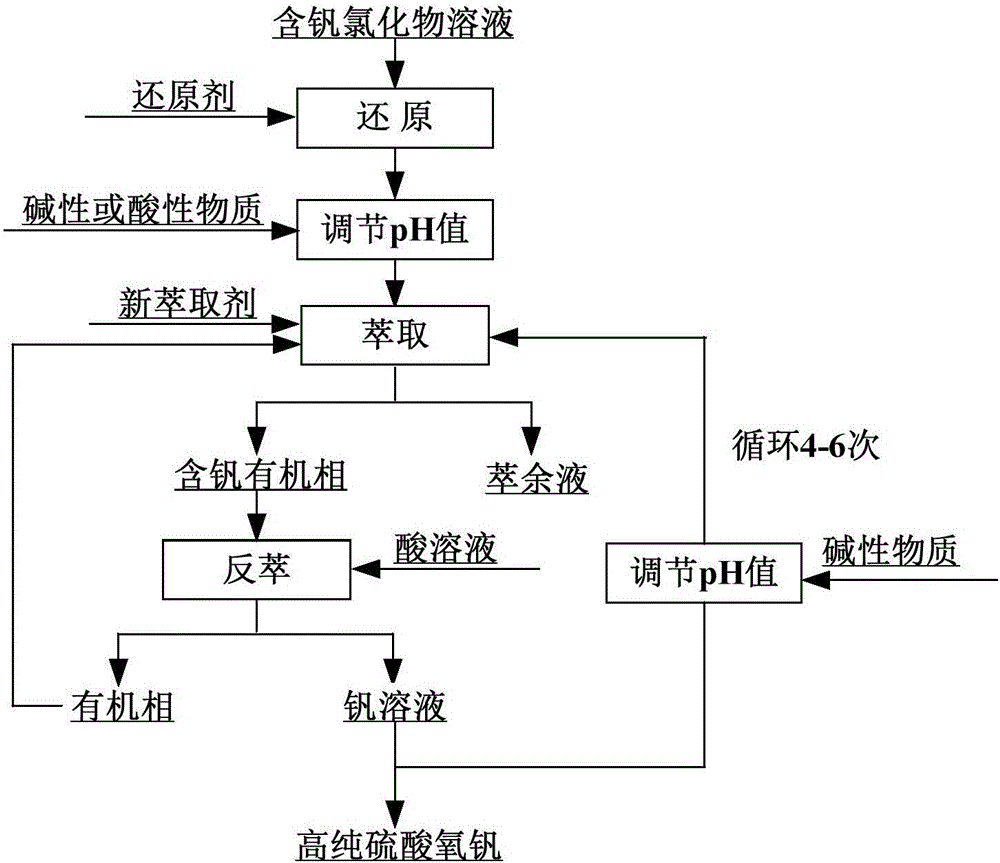

Method for preparing vanadyl sulfate by use of vanadium-containing chloride solution

InactiveCN106395899AAvoid energy consumptionAvoid pollutionVanadium compounds preparationMagnetiteVanadyl sulfate

The invention belongs to the field of wet-process metallurgy and particularly relates to a method for preparing vanadyl sulfate by use of a vanadium-containing chloride solution. The method comprises the following steps: 1) heating and reducing the vanadium-containing chloride solution, thereby obtaining a reduction solution; 2) regulating the pH value of the reduction solution to 0-2; 3), performing extraction, thereby obtaining a vanadium-loaded organic phase; 4) performing reverse extraction, thereby obtaining a vanadium solution; 5) regulating the pH value of the vanadium solution to 1-3; 6) extracting the solution, thereby obtaining the vanadium-loaded organic phase; 7) performing reverse extraction, thereby obtaining a vanadyl sulfate solution; and 8) absorbing the vanadyl sulfate solution by use of an adsorbent, thereby obtaining a vanadyl sulfate solution final product. According to the method, HCl leaching liquid containing vanadium resources, such as titaniferous magnetite and an SCR dead catalyst are utilized as raw materials, and an extraction-reverse extraction-deep impurity removal method is adopted, so that the method provided by the invention is capable of directly preparing high-purity anadyl sulfate from the vanadium-containing chloride solution, and has the advantages of short process and low cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of high-purity vanadyl sulfate solution

ActiveCN106745248AHigh purityIncrease profitVanadium compounds preparationVanadium CompoundsWater insoluble

The invention provides a preparation method of high-purity vanadyl sulfate. The method comprises the following steps: selecting a strong alkali solution for dissolving vanadium salts or vanadium compounds, removing impurities, filtering and adjusting a pH value of the solution to 1.5-5.0, then adding high-reducibility sulfuric acid compounds and phosphate diester precipitation preventing agents to obtain a tetravalent vanadium compound solution; enabling an alum solution and the tetravalent vanadium compound solution to fully react and generate water-insoluble tetravalent vanadium compound solid powder; washing the tetravalent vanadium compound solid powder with deionized water or distilled water, then carrying out solid-liquid separation; drying and firing the washed tetravalent vanadium compound solid powder, and then dissolving the tetravalent vanadium compound solid powder in a dilute sulfuric acid solution to obtain a water-soluble high-purity vanadyl sulfate solution. The method is capable of effectively removing various impurities in the vanadium salts or the vanadium compounds, fully reducing pentavalent vanadium compounds to tetravalent vanadium compounds and obtaining the high-purity vanadyl sulfate solution; the method is high in utilization rate of vanadium, short in technological process, low in cost and free of by-products; the large-scale production is easy to implement.

Owner:深圳力合通科技有限公司

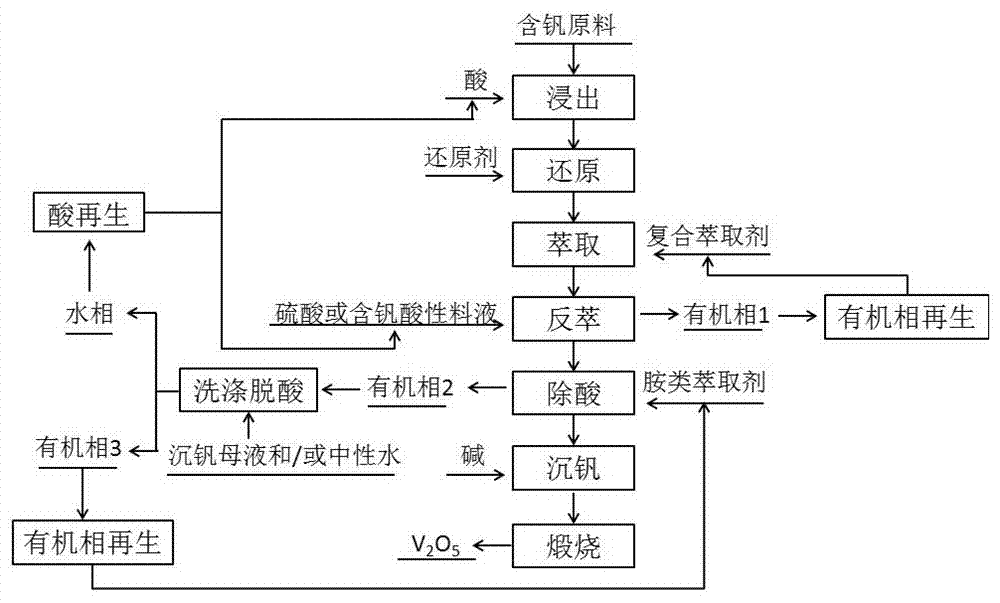

Method for preparing vanadium pentoxide through composite extraction

ActiveCN107226484AHigh extraction rateImprove extraction abilityVanadium compounds preparationVanadium oxidesPhysical chemistryPhosphoric acid

The present invention relates to a vanadium pentoxide preparation method, and provides a method for preparing vanadium pentoxide through composite extraction. The method comprises: (1) leaching; (2) reducing; (3) extracting, wherein a vanadium-containing material liquid is extracted with a composite extractant prepared from a phosphate organic matter and a modifier to prepare a vanadium-containing supported organic phase; (4) carrying out back extraction, wherein the supported organic phase is subjected to back extraction with sulfuric acid or a vanadium-containing sulfuric acid solution to prepare a vanadium-rich liquid; (5) removing acid, wherein the excess acid in the vanadium-rich liquid is extracted; (6) precipitating vanadium; and (7) calcining. According to the present invention, the vanadium is extracted with the composite extractant having strong extraction ability and strong back extraction ability, such that the vanadium extraction rate and the vanadium purity can be improved so as to improve the yield and the product of the vanadium pentoxide product, and the alkali consumption can be reduced so as to reduce the production cost.

Owner:CHONGQING KOOPPER CHEM IND

Method for preparing high-purity ammonium metavanadate from spent catalyst

ActiveCN104628032ASolve the problem of entrainmentEfficient separationVanadium compounds preparationPregnant leach solutionPhysical chemistry

The invention discloses a method for preparing high-purity ammonium metavanadate from a spent catalyst, which comprises the following steps: dephosphorization: collecting a spent catalyst leach solution in a leaching mode, filtering the leach solution, sending into an ion-exchange dephosphorization system, and carrying out phosphorus adsorption on the spent catalyst leach solution by using a resin; molybdenum-vanadium separation: sending the dephosphorized molybdenum / vanadium-containing solution into an ion-exchange system, and carrying out molybdenum adsorption by using a resin to separate the molybdenum and vanadium; and vanadium precipitation: pumping the vanadium-containing mother solution subjected to dephosphorization and separation molybdenum into a vanadium precipitation tank, and precipitating vanadium by using a weakly alkaline ammonium salt to obtain the high-purity ammonium metavanadate product. The method has the characteristics of short process, simple technique, energy saving, environmental protection, high efficiency, low cost and the like.

Owner:DALIAN DONGTAI RESOURCE RENEWABLE

Recovery method of waste SCR denitration catalyst

ActiveCN110817944AGood removal effectImprove permeabilityAlkaline earth titanatesTungsten compounds preparationPtru catalystTungstate

The invention belongs to the field of non-ferrous metal recovery, and particularly relates to a recovery method of a waste SCR denitration catalyst. The recovery method comprises the steps of pretreatment, TiO2 separation, extraction and purification, titanium recovery, vanadium recovery, tungsten / molybdenum recovery and the like. The recovery method is capable of recycling a several precious recovery products such as V2O5, ammonium tungstate / ammonium molybdate and BaTiO3 from the waste SCR denitration catalyst. The invention provides an effective technical scheme, and efficient resource utilization of the waste SCR denitration catalyst can be realized.

Owner:北京华电光大环境股份有限公司

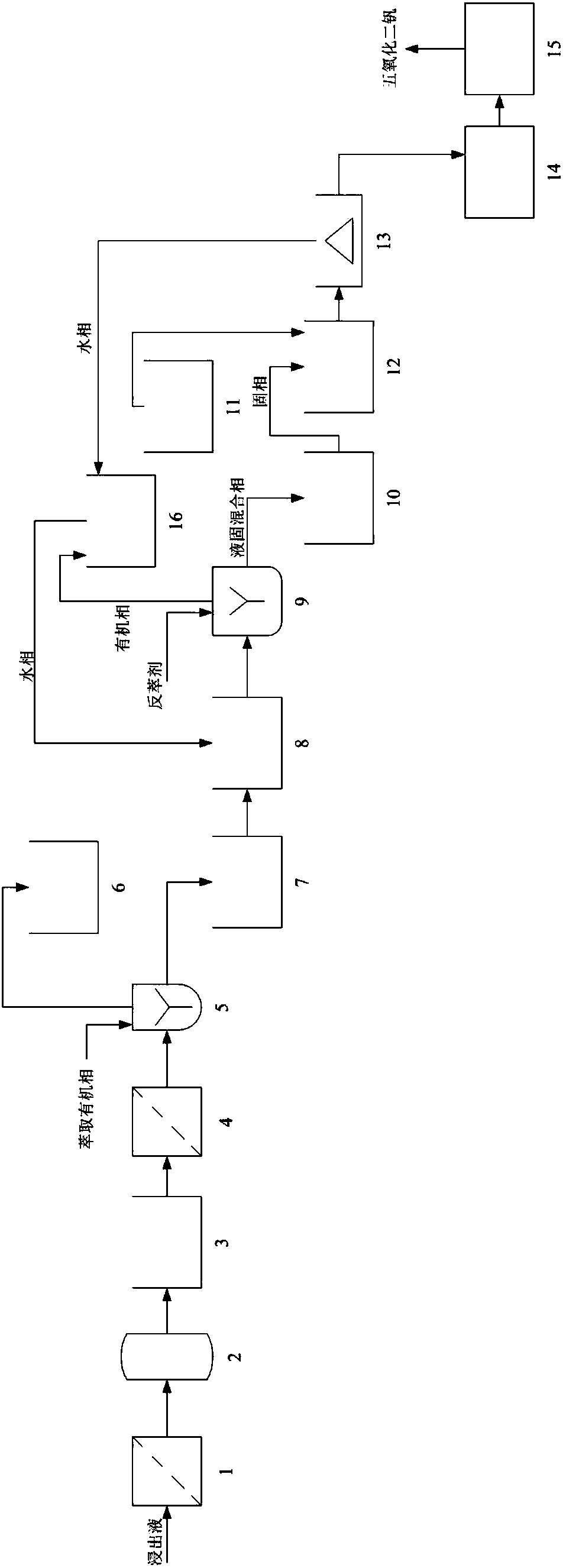

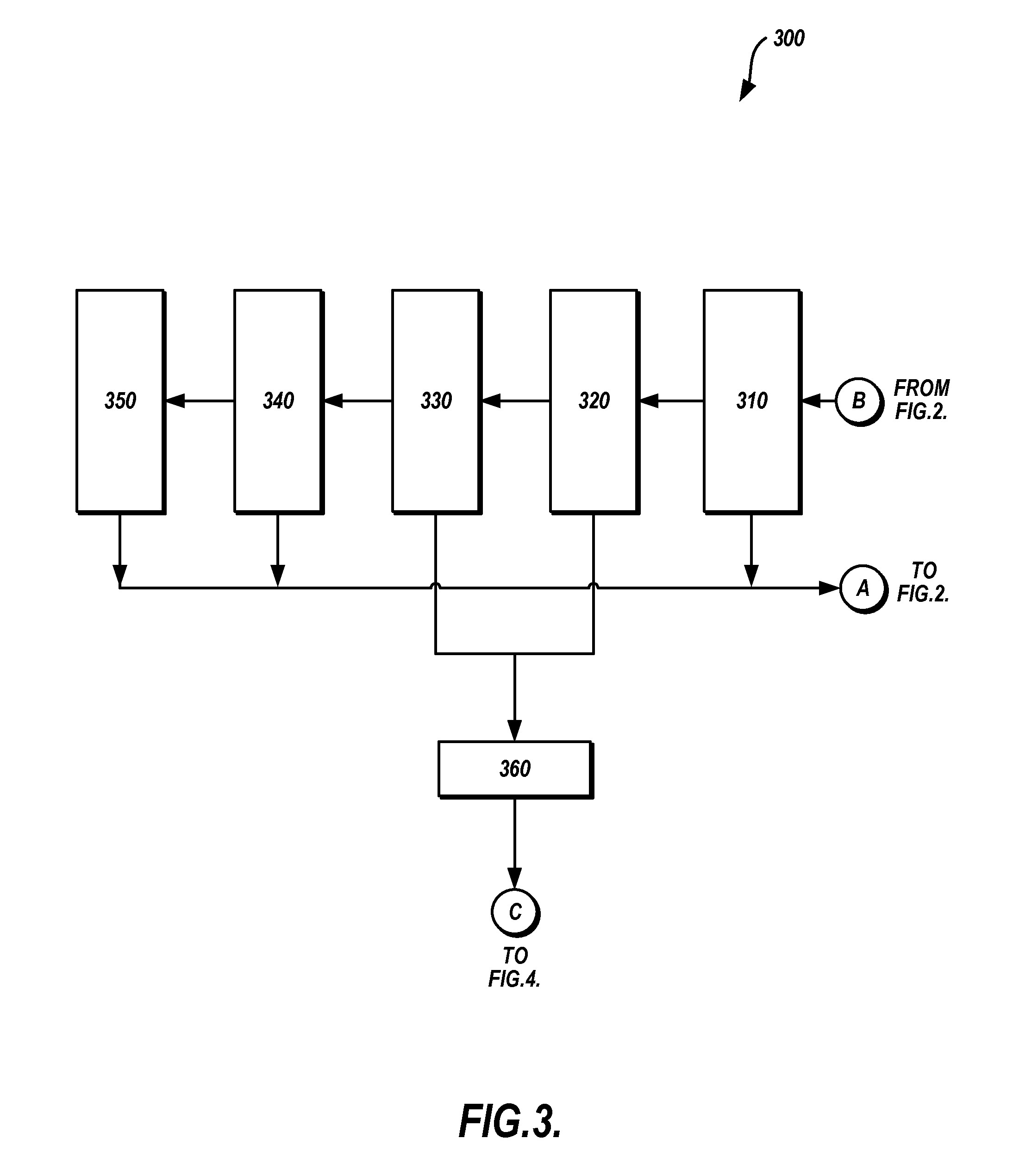

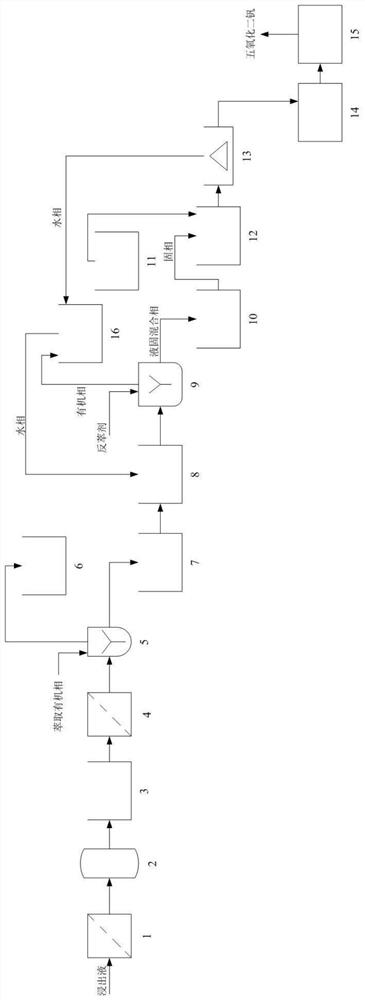

System for extracting vanadium from leachate containing vanadium, chromium and silicon and preparing vanadium pentoxide, and treatment method thereof

ActiveCN108298581AGuaranteed uptimeLow costVanadium compounds preparationLiquid solutions solvent extractionRaffinateCalcination

The invention provides a system for extracting vanadium from leachate containing vanadium, chromium and silicon and preparing vanadium pentoxide, and a treatment method thereof. The system sequentially comprises an impurity removal system, an extraction system, a stripping vanadium precipitation system, a washing system and a calcination system. The system and the method are characterized in thatdetailed studying of silicon, aluminum, chromium and other elements easily precipitating in the vanadium pentoxide product is carried out, different polymer forms of vanadium, chromium, silicon, aluminum and other impurities in an extraction feeding liquid, an impurity removal solution and raffinate are quantitatively detected through chemical regulation and device enhancement, and the structure of a extracted complex is detected, so the extraction mechanism of the vanadium, chromium, silicon and aluminum is scientifically predicated based on the result of quantitative experiment test studying; and the system is formed through chemical regulation impurity removal, an enhanced centrifugal extraction equipment and stripping quantification control and other measures in order to realize the preparation of low-chromium, low-silicon, low-aluminum and high-purity vanadium pentoxide product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Production of high-grade synthetic rutile from low-grade titanium-bearing ores

The present invention relates to a two-stage leaching process using concentrated hydrochloric acid that upgrades a variety of inferior quality titanium-iron ores into premium titanium concentrate and iron oxide products. The ground ore is leached with two separate quantities of hydrochloric acid after which the dissolved titanium is precipitated from the filtered liquor by hydrolysis. The still soluble iron chlorides are then optionally subjected to oxyhydrolysis to recover iron oxide and HCl. The process was developed for low-grade ores (under 12% TiO2), and can be naturally applied advantageously to higher grade titanium-bearing ores.

Owner:FFK TECH INC

Method for recovering high-purity vanadium from spent vanadium electrolyte

InactiveCN111484076AEasy to operateReduce recycling costsVanadium compounds preparationVanadium oxidesElectrolytic agentIon exchange

The invention discloses a method for recovering high-purity vanadium from a spent vanadium electrolyte, and the method comprises the following steps: adding an oxidant into the spent vanadium electrolyte to oxidize vanadium ions in the electrolyte into pentavalent ions, wherein the oxidant is formed by mixing sodium persulfate and potassium permanganate in a mass ratio of 1: (1.9-2.8); then adjusting the pH value of the electrolyte to 2-5; carrying out elution treatment on the filtrate by adopting ion exchange resin; adding a vanadium precipitation agent into the eluted electrolyte to obtain asolid precipitate, wherein the vanadium precipitation agent comprises (NH4)2S2O8 and (NH4)2SO4 in a mass ratio of (1-5): 2; and finally, washing the obtained solid precipitate with a vanadium precipitation agent aqueous solution and deionized water in sequence, drying, and carrying out high-temperature roasting treatment to obtain a vanadium pentoxide solid with the purity of 95% or above. The recycling process is high in operability, large equipment is not needed, and the recycling cost is low.

Owner:承德新新钒钛储能科技有限公司

Method for preparing high-purity ammonium polyvanadate

ActiveCN110092419AHigh purityAvoid excessive consumptionVanadium compounds preparationChelating resinImpurity

The invention relates to a method for preparing high-purity ammonium polyvanadate. The method comprises the following steps: adding ferrous sulfate to a vanadium-containing solution, and performing stirring for a reaction; adding a silicon precipitating agent after the reaction is completed, performing stirring for a reaction, and carrying out solid-liquid separation; primarily adsorbing a solution obtained after the solid-liquid separation by using aminophosphoric acid resin; secondarily adsorbing the solution by using iminodiacetic acid chelated resin after the primary adsorption is completed; and adding ammonium sulfate to the secondarily adsorbed solution to precipitate vanadium, and performing solid-liquid separation to obtain the ammonium polyvanadate product. The method removes chromium, iron, magnesium, aluminum, silicon and other impurity elements in the vanadium-containing solution through process improvement and reagent control, and allows the ammonium polyvanadate product with a purity of above 99.9% to be obtained; and the high-purity ammonium polyvanadate product can be used to prepare other high-purity vanadium products, and has a good application prospect when applied to fields of metallurgy, aerospace, chemistry, batteries, pigments, glass, optics, medicines and the like.

Owner:承德燕北冶金材料有限公司

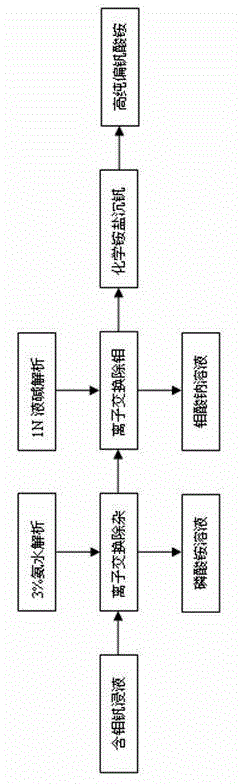

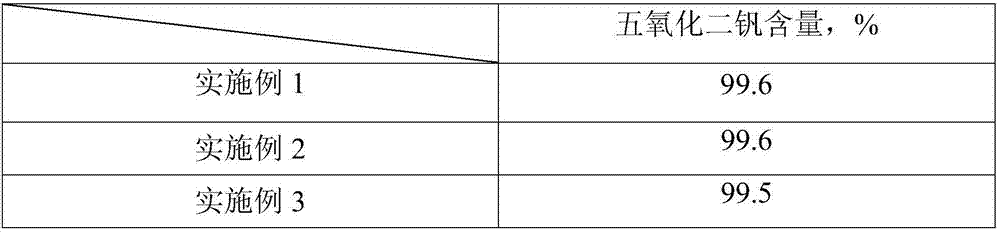

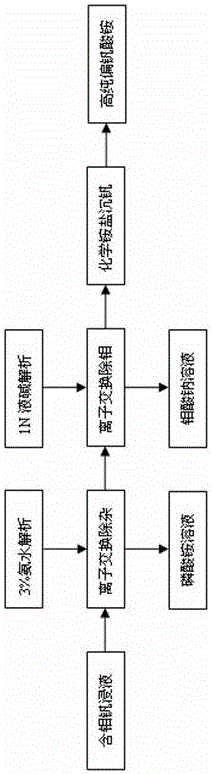

Preparation method of high-purity vanadium oxide

InactiveCN107285382AHigh purityVanadium compounds preparationVanadium oxidesIon-exchange resinVanadate

The invention discloses a method for preparing high-purity vanadium pentoxide. The preparation method comprises: (1) dissolving industrial-grade ammonium metavanadate in an alkali solution, and performing vanadium adsorption through an alkaline anion exchange resin; (2) ) analyzing the adsorbed basic anion exchange resin to obtain a vanadium-containing solution; (3) contacting the vanadium-containing solution with an acidic cation-exchange resin to obtain a purified vanadium-containing solution; (4) adding the purified The vanadium-containing solution is added with a vanadium precipitation agent to obtain primary ammonium metavanadate; (5) the primary ammonium metavanadate is recrystallized, washed, and dried to obtain high-purity ammonium metavanadate; (6) the high-purity ammonium metavanadate is Ammonium metavanadate is calcined to obtain high-purity vanadium pentoxide. The purity of the vanadium pentoxide of the present invention can reach more than 99.5%.

Owner:WUHU RENBEN ALLOY

The production of high-grade synthetic rutile from low-grade titanium-bearing ores

InactiveCN106232840AWidely availableChlorine/hydrogen-chloride purificationFerric oxidesIronstoneHydrolysis

The present invention relates, first, to a two-stage leaching process using concentrated hydrochloric acid wherein ground ore is leached with two separate quantities of hydrochloric acid at different temperatures. Second, the invention relates to a one-step leaching process using concentrated HCl and a fixed acid to ore ratio to prevent hydrolysis of titanium. Afterwards the dissolved titanium is precipitated from the filter liquor by hydrolysis and the still soluble iron chlorides are then optionally subjected to oxyhydrolysis to recover iron oxide and HCl. The process was developed for low-grade ores (under 12% Ti02), and can naturally be applied advantageously to higher grade titanium-bearing ores, that upgrades a variety of inferior quality titanium-iron ores into premium titanium concentrate and iron oxide products.

Owner:FFK TECH INC

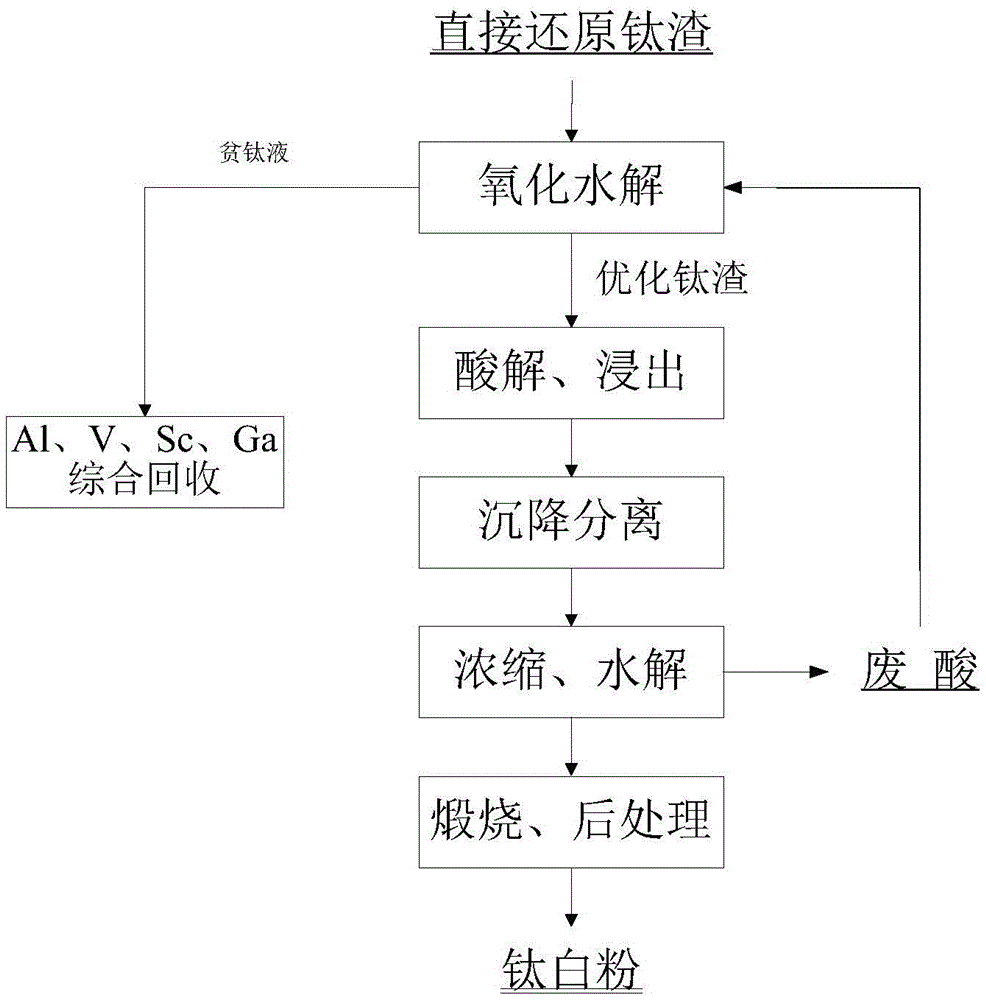

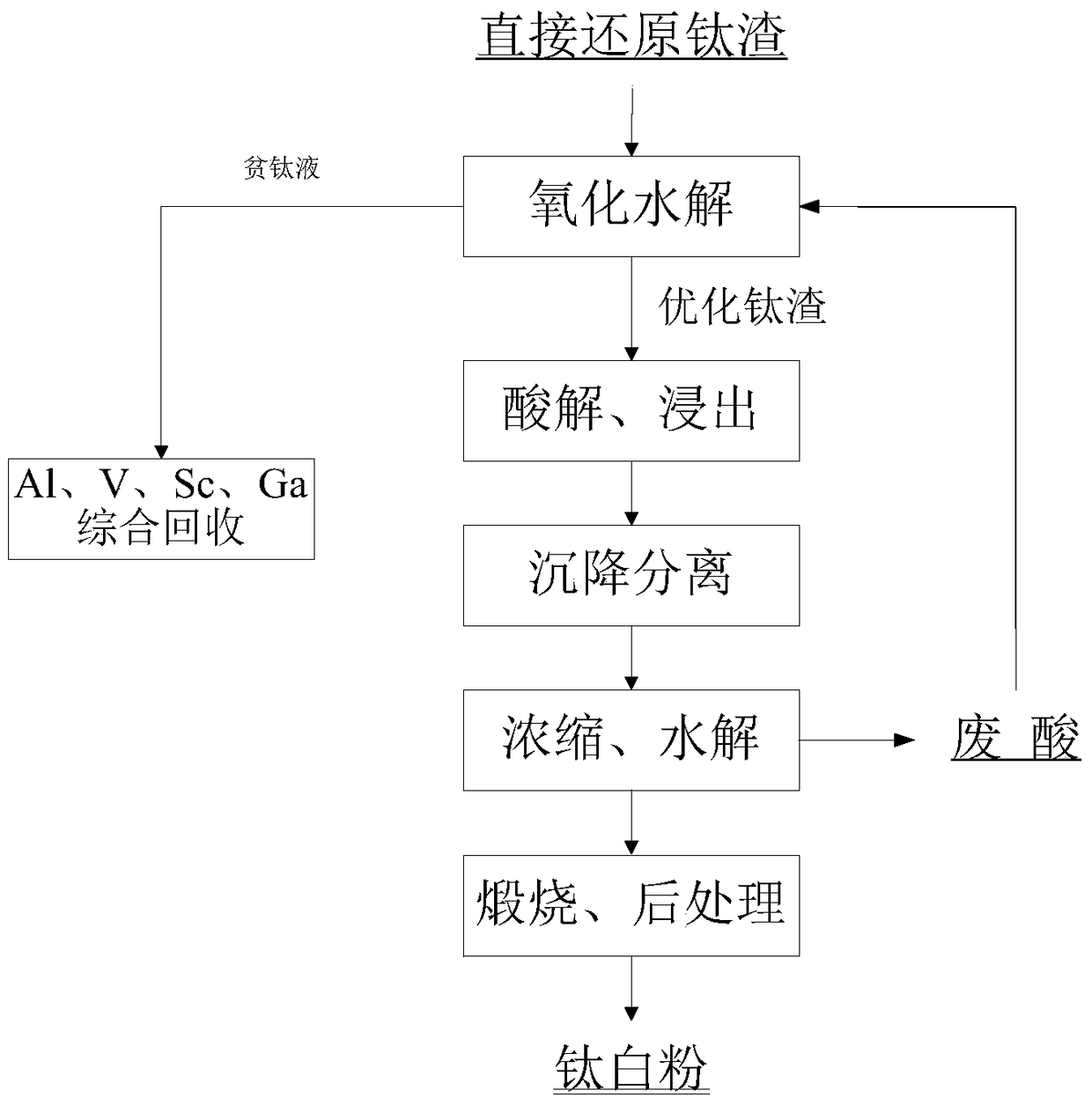

Comprehensive utilization method of waste acids of titanium dioxide industry

ActiveCN106882839ASolving RecyclingAchieve recyclingVanadium compounds preparationAllium/indium/thallium compounds preparationsIon exchangeHydrolysis

The invention discloses a comprehensive utilization method of waste acids of the titanium dioxide industry, relates to a method of comprehensively utilizing and recovering waste acids of the titanium dioxide industry and directly producing sulfuric acid method titanium dioxide from non-blast furnace titanium slag, and belongs to the technical field of titanium non-acid treatment. Titanium slag generated through direct reduction of vanadium-titanium magnetite ores is taken as the raw material, neutralizing agent, and capturing agent of titanium hydrolysis and precipitation, through oxidation and hydrolysis, titanium in the waste acids of the titanium dioxide industry is precipitated and enriched in the optimized titanium slag; at the same time, rare metals such as vanadium, scandium, and the like, is extracted and dissolved in the solution so as to obtain a titanium poor solution containing rare metals such as vanadium, scandium, and the like, the titanium poor solution is extracted or subjected to ion exchange so as to recover vanadium, scandium, and the like; the optimized titanium slag is applied to titanium dioxide production through a sulfuric acid method; and the waste acids generated during the titanium dioxide production are returned and cyclically used. The problems of waste acid discharge and environmental pollution of sulfuric acid method titanium dioxide production are radically solved; and the provided method has the advantages that the titanium dioxide product quality is good, the titanium recovery rate is high, and rare elements such as vanadium, scandium, and the like, can be comprehensively recovered.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

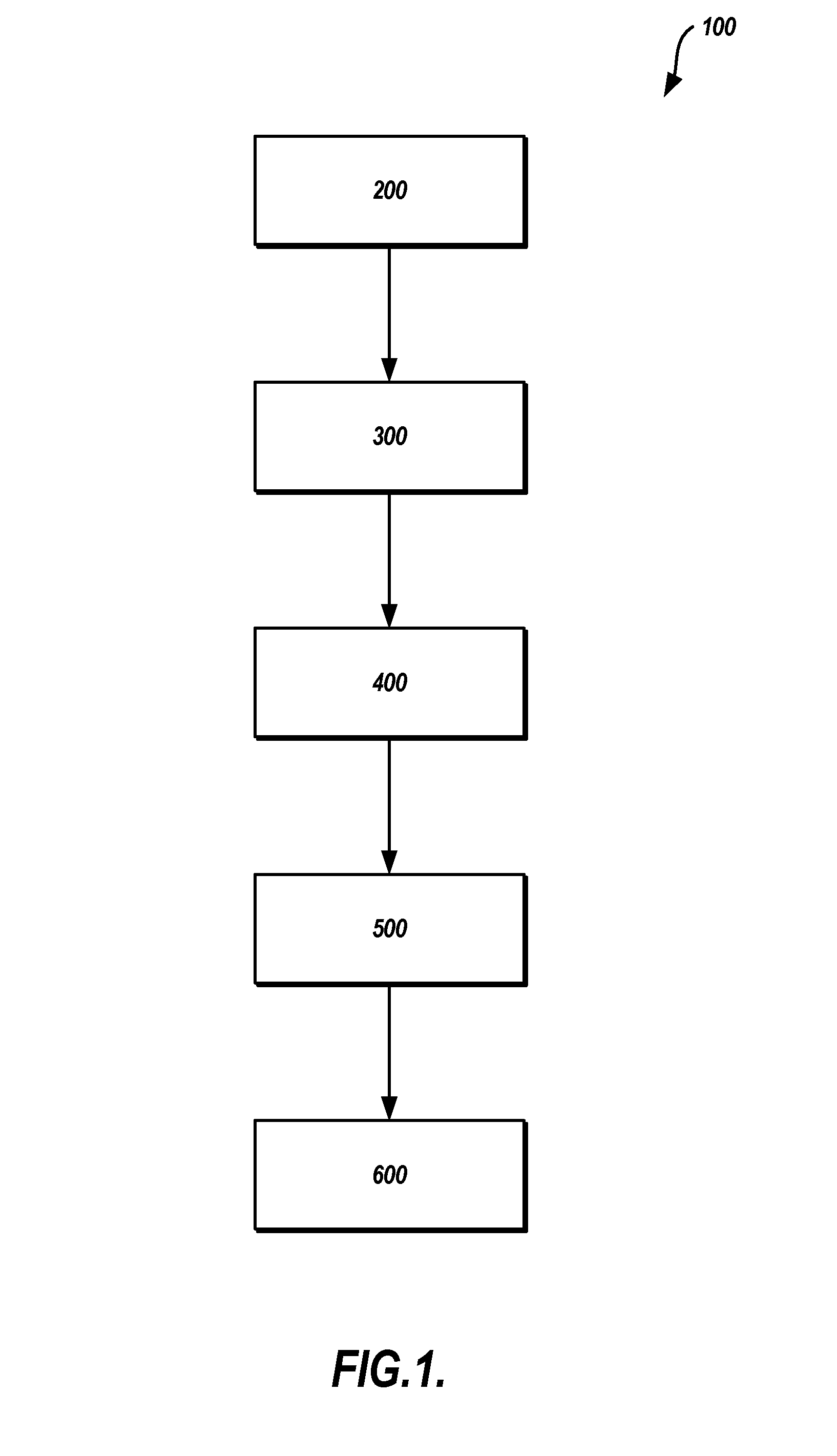

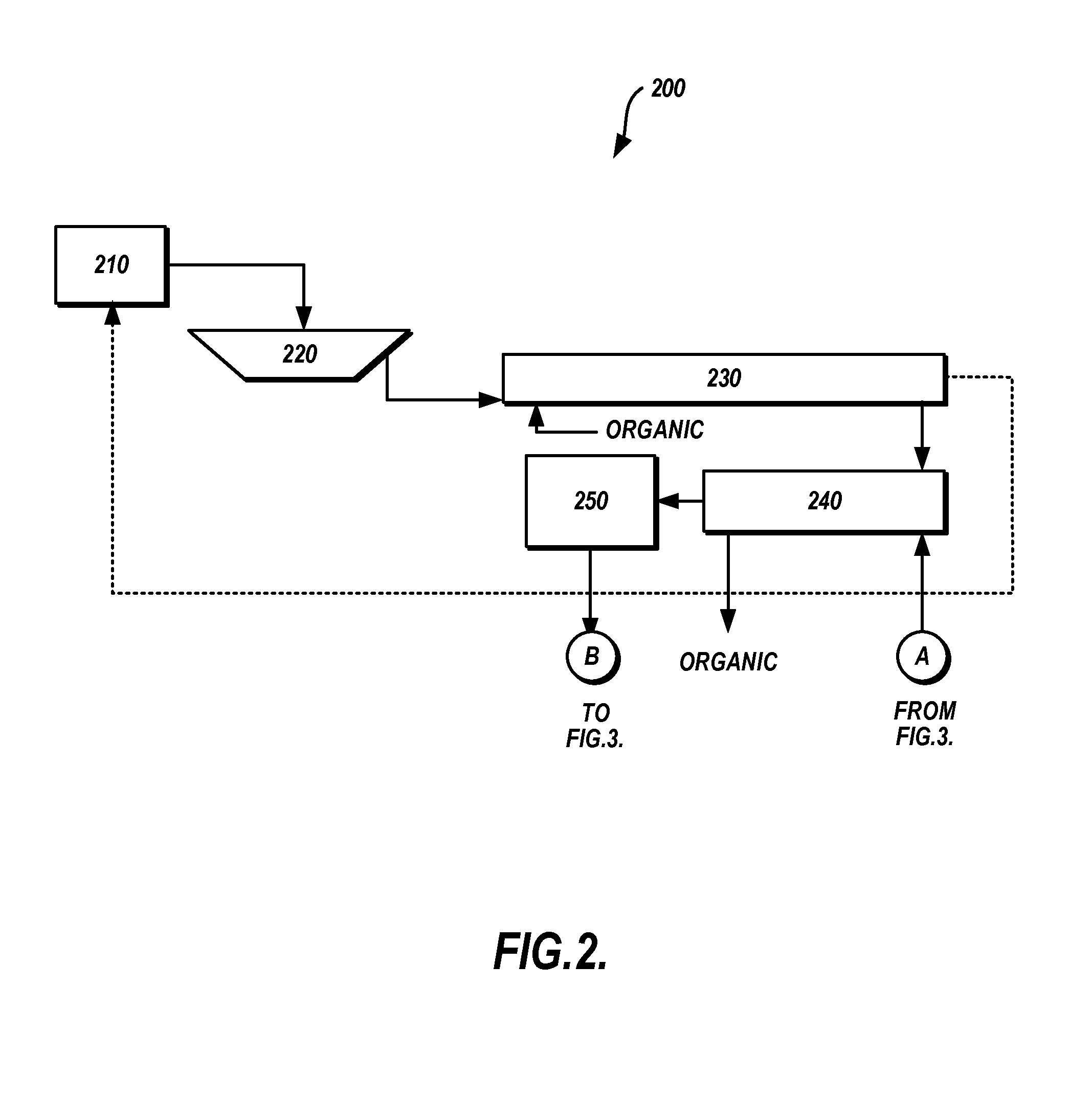

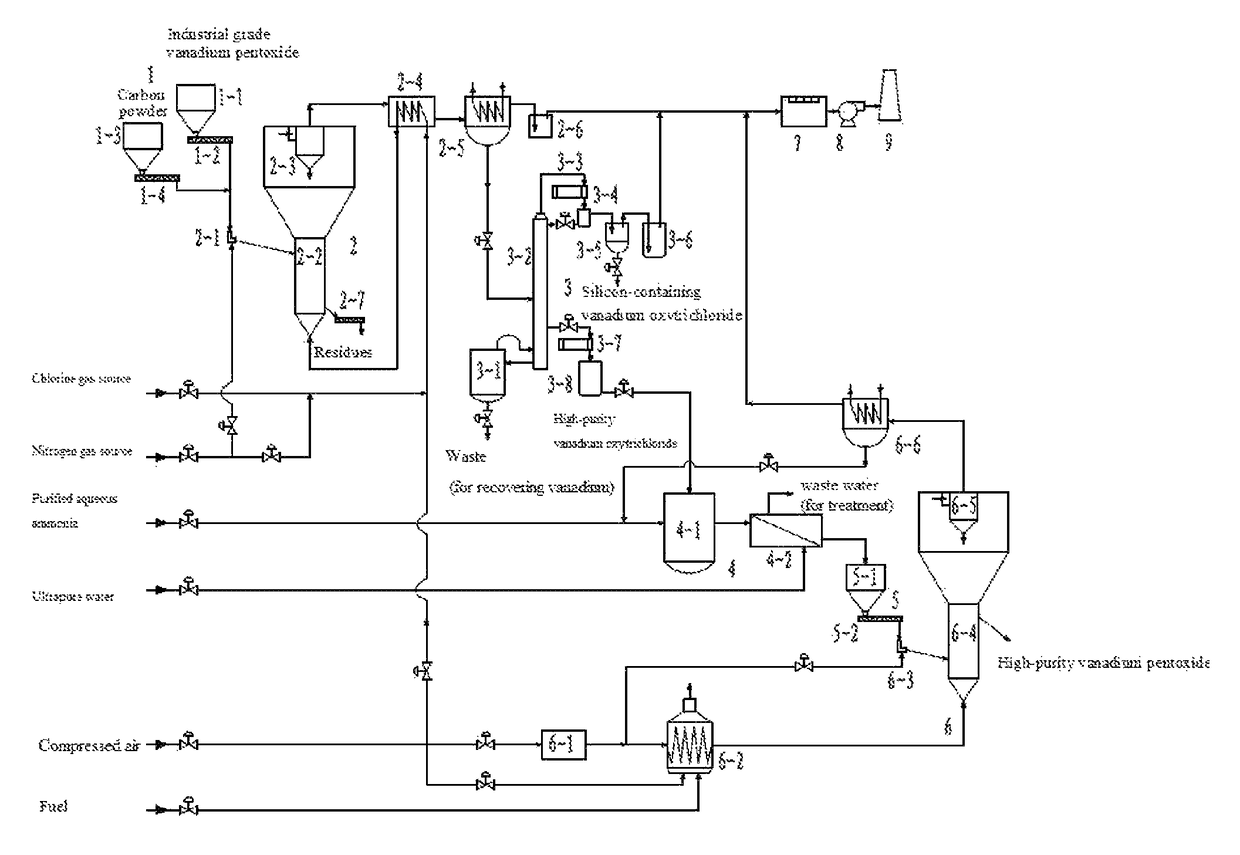

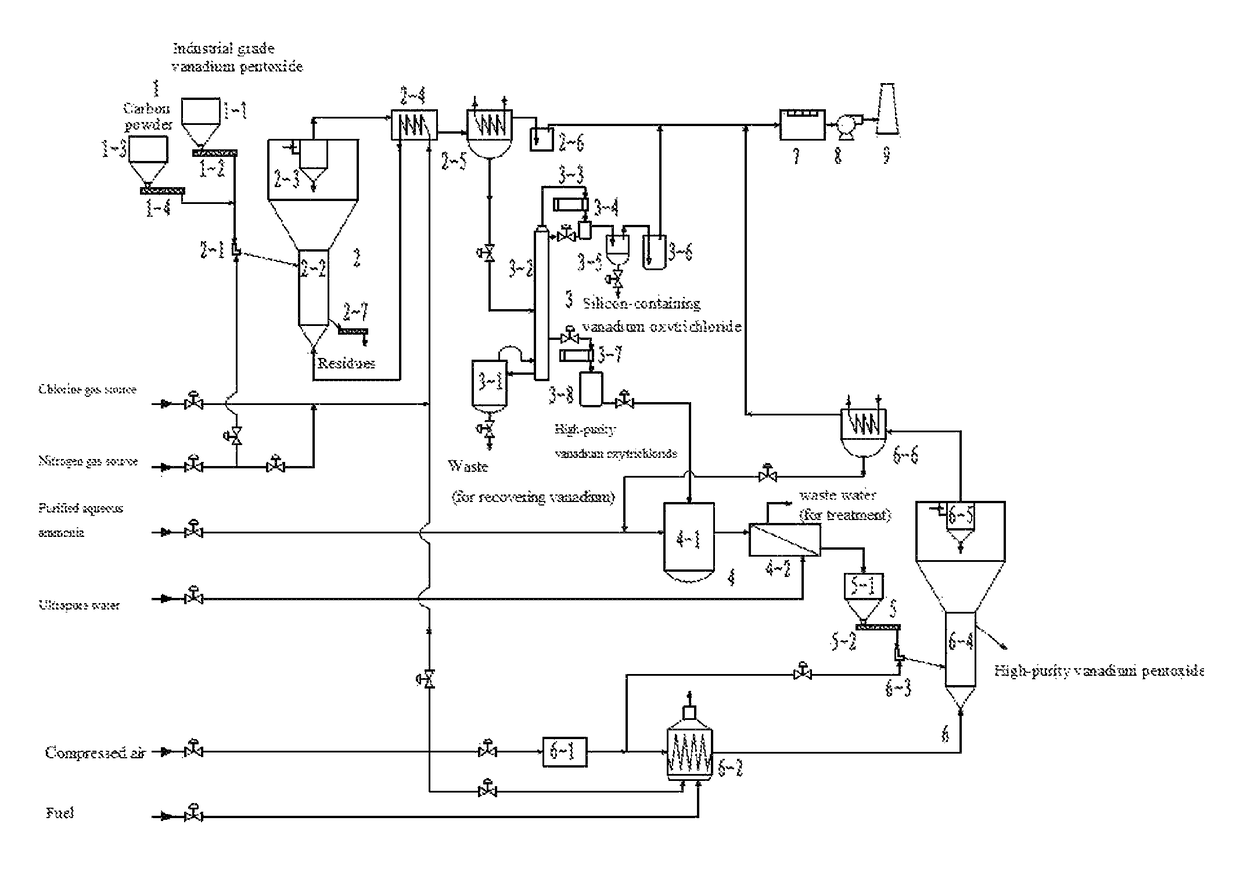

System and Method for Preparing High-Purity Vanadium Pentoxide Powder

ActiveUS20180022616A1Improve calcination decomposition efficiencyGood choiceDistillation in boilers/stillsChemical liquid solidificationTechnical gradeVanadium oxytrichloride

The present invention provides a system and method for preparing high-purity vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is subjected to purification by rectification, ammonium salt precipitation and fluidized calcination, thereby obtaining high-purity vanadium pentoxide, wherein the ammonia gas produced during calcination is condensed and then recycled for ammonium salt precipitation. The system and method have advantages of favorable adaptability to raw material, less pollution, low energy consumption in production, low operation cost, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Vanadyl-sulfate electrolyte preparation method applied to full-vanadium flow cell

InactiveCN104319413AAchieve mass productionSimple processRegenerative fuel cellsVanadium compounds preparationIonDistillation

The invention relates to a preparation method for battery electrolyte, especially relates to a vanadyl-sulfate electrolyte preparation method applied to a full-vanadium flow cell. Compared with the prior art, the method takes vanadyl-sulfate solution, obtained through a conventional method for extracting vanadium from vanadium slags and stone coal, as an object. The pH value of the solution is adjusted through alkali metal or alkaline-earth metal oxides or hydroxides. The separation of vanadium and iron ions is achieved through revivification and a method of multi-segment multi-stage counter-current extraction. The concentration of vanadyl sulfate is adjusted through distillation, and a vanadyl sulfate electrolyte is manufactured directly. The method is simple in technology, is low in cost, and achieves scale production.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

Process for the extraction of specific transition metals with gaseous HCL

A process is disclosed for separation and recovery of vanadium, molybdenum, iron, tungsten, cobalt and nickel from alumina-based materials, mattes, ores, manufacturing by-products and waste. These elements are oxidized. The oxides are reacted with gaseous HCl to form volatile chloride-bearing compounds that subsequently sublimate. The volatile compounds are condensed in a downward-stepped thermal gradient that allows collection of moderate to high purity compounds of individual elements with exception of a nickel-cobalt co-condensate. Nickel is separated from cobalt by precipitation of nickel chloride from concentrated HCl pressurized with gaseous HCl.

Owner:METALS RECOVERY TECH

Vanadium oxide purification process

Owner:PROPHECY DEV CORP

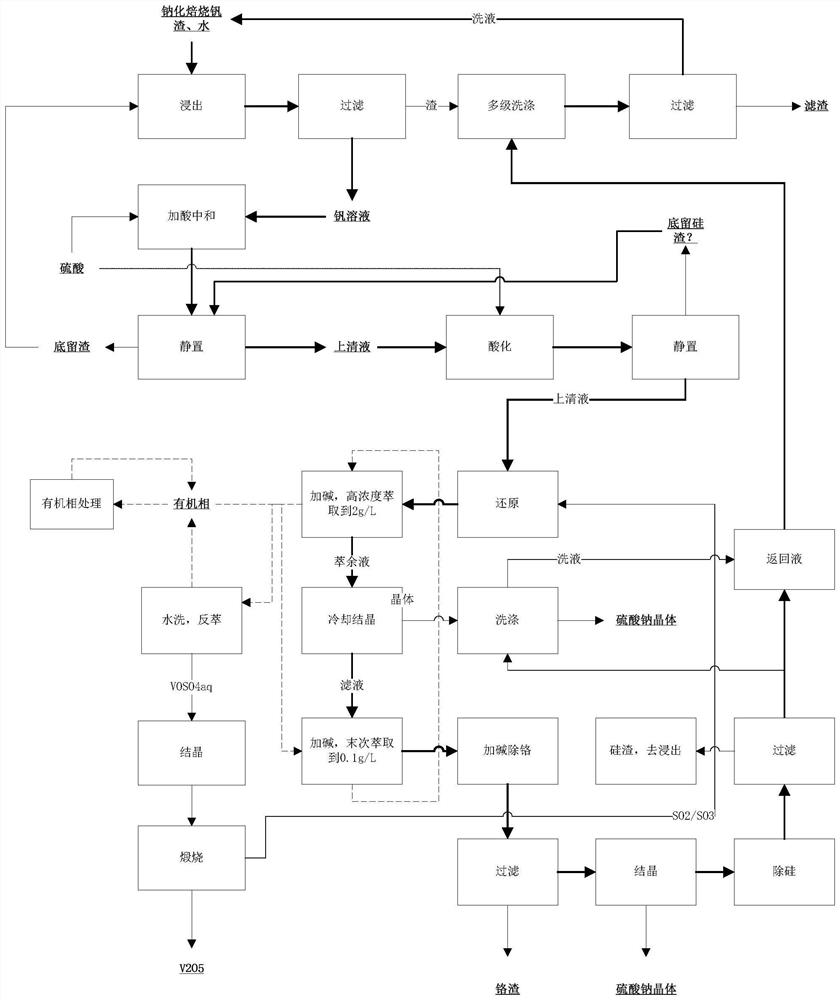

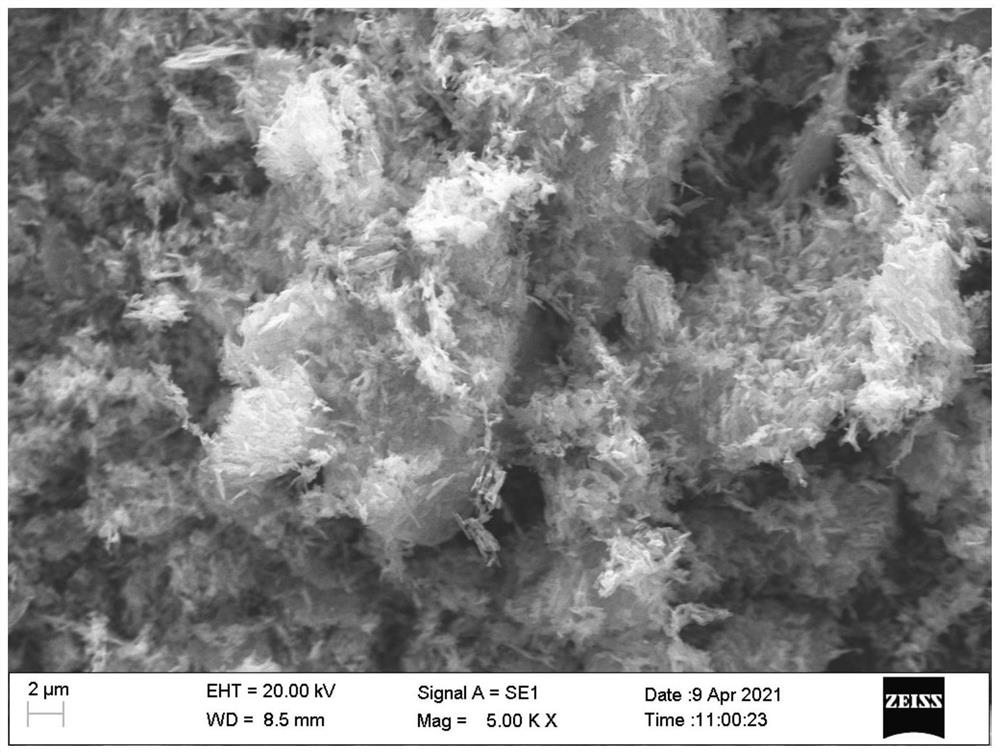

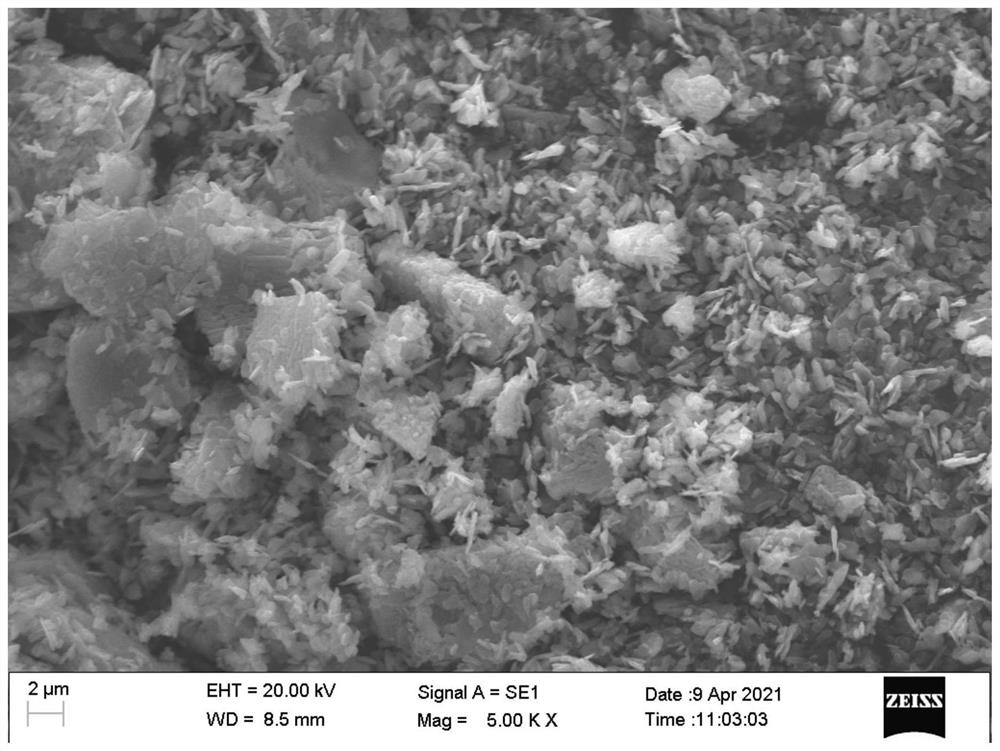

Vanadium pentoxide as well as ammonium-free preparation method and application thereof

ActiveCN114231758AReduce dosageReduce ammonium removal operationsVanadium compounds preparationVanadium oxidesVanadyl sulfateRaffinate

The invention provides vanadium pentoxide as well as an ammonium-free preparation method and application thereof. The ammonium-free preparation method of vanadium pentoxide comprises the following steps: step 1, sodium salt roasting: uniformly mixing sodium carbonate and a vanadium-containing raw material, putting the mixture into a furnace kiln, and carrying out high-temperature oxidation roasting to convert vanadium into water-soluble sodium vanadate; step 2, leaching and filtering: dissolving a material obtained by calcining in the step 1 in water, and filtering to obtain a sodium vanadate leaching solution and waste residues; step 3, adding acid to remove impurities; adding a reducing agent, and reducing vanadium to tetravalent to obtain a mixed solution of tetravalent vanadium and sodium sulfate; step 4, extracting vanadium through extraction-reverse extraction: carrying out a liquid-liquid extraction-reverse extraction method by using an extracting agent to obtain a vanadyl sulfate solution and raffinate containing sodium sulfate; 5, crystallizing to obtain vanadyl sulfate crystals; and step 6, calcining and decomposing vanadyl sulfate to obtain vanadium pentoxide. The method is low in production cost, and the product vanadium pentoxide has smaller granularity and larger specific surface area.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

A system for extracting vanadium and preparing vanadium pentoxide from vanadium-chromium-silicon-containing leaching solution and its treatment method

ActiveCN108298581BReduce silicon contentReduced silicon and aluminum contentVanadium compounds preparationLiquid solutions solvent extractionPregnant leach solutionPhysical chemistry

The invention provides a system for extracting vanadium from a vanadium-chromium-silicon-containing leaching solution and preparing vanadium pentoxide and a treatment method thereof. The system sequentially includes an impurity removal system, an extraction system, a stripping vanadium precipitation system, and a washing system and calcination system. On the basis of the prior art, the system and method of the present invention have carried out careful research on elements that are easy to deposit in vanadium pentoxide products such as silicon, aluminum and chromium, and through chemical regulation and equipment strengthening, the extraction stock solution, The different polymerization states of impurities such as vanadium-chromium-silicon-aluminum in the impurity removal liquid and raffinate were quantitatively detected, combined with the structure of the extract, based on the quantitative experimental test results, the extraction mechanism of vanadium-chromium-silicon-aluminum was scientifically predicted, and Through chemical regulation and removal of impurities, strengthening of centrifugal extraction equipment and quantitative control of back extraction, a system is formed to realize the preparation of low-chromium, low-silicon, low-aluminum, high-purity vanadium pentoxide products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method for extracting vanadium from waste scr catalyst and preparing activated titanium silicon tungsten powder

ActiveCN106521160BCatalyst regeneration/reactivationVanadium compounds preparationActivation methodSlurry

The invention discloses a method for extraction of failure vanadium from a waste SCR catalyst and preparation of activated titanium silicon tungsten powder for making a new denitration catalyst. The method includes: conducting pretreatment on a waste SCR catalyst, performing wet grinding to obtain a slurry, and adding an oxalic acid solution to carry out leaching reaction; carrying out filter-press separation to obtain tungsten silicon-containing titanium slag powder and press filtrate, then performing cleaning, activation, and fine grinding to obtain nanoscale titanium silicon tungsten powder; separating the press filtrate, recovering oxalic acid and returning the recovered oxalic acid to leaching reaction, adding an oxidizing agent into the separated liquid to carry out precipitation reaction so as to obtain ammonium metavanadate precipitate, and conducting filtering and separation to obtain ammonium metavanadate solid. The method provided by the invention uses oxalic acid for reaction under a normal temperature condition, can separate failure vanadium salt from the SCR catalyst, utilizes acid to activate other components and then performs fine grinding and other treatments so as to obtain the raw material for preparation of a new denitration catalyst. The process provided by the invention has the characteristics of low technological investment requirement and low energy consumption, effectively solves the harmless treatment problem of the SCR catalyst, and realizes recycling of resources.

Owner:安徽思凯瑞环保科技有限公司

A method for comprehensive utilization of titanium dioxide waste acid

ActiveCN106882839BSolving RecyclingAchieve recyclingVanadium compounds preparationAllium/indium/thallium compounds preparationsIon exchangeHydrolysis

The invention discloses a comprehensive utilization method of waste acids of the titanium dioxide industry, relates to a method of comprehensively utilizing and recovering waste acids of the titanium dioxide industry and directly producing sulfuric acid method titanium dioxide from non-blast furnace titanium slag, and belongs to the technical field of titanium non-acid treatment. Titanium slag generated through direct reduction of vanadium-titanium magnetite ores is taken as the raw material, neutralizing agent, and capturing agent of titanium hydrolysis and precipitation, through oxidation and hydrolysis, titanium in the waste acids of the titanium dioxide industry is precipitated and enriched in the optimized titanium slag; at the same time, rare metals such as vanadium, scandium, and the like, is extracted and dissolved in the solution so as to obtain a titanium poor solution containing rare metals such as vanadium, scandium, and the like, the titanium poor solution is extracted or subjected to ion exchange so as to recover vanadium, scandium, and the like; the optimized titanium slag is applied to titanium dioxide production through a sulfuric acid method; and the waste acids generated during the titanium dioxide production are returned and cyclically used. The problems of waste acid discharge and environmental pollution of sulfuric acid method titanium dioxide production are radically solved; and the provided method has the advantages that the titanium dioxide product quality is good, the titanium recovery rate is high, and rare elements such as vanadium, scandium, and the like, can be comprehensively recovered.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

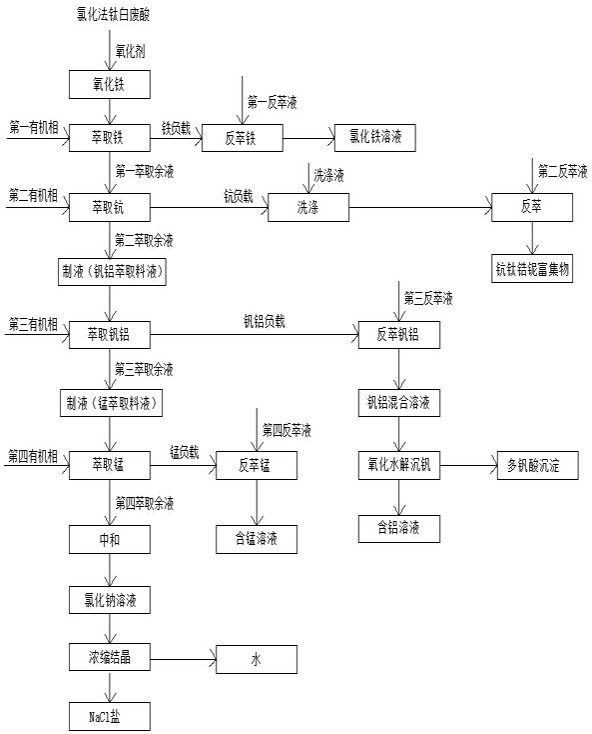

Method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction

ActiveCN112429780AAchieve recyclingIncrease valueTreatment involving filtrationWater/sewage treatment by neutralisationTitanium zirconiumNiobium

The invention discloses a method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction. The method comprises the following steps: S1, adding a first organic phase into the chlorination-process titanium dioxide waste acid to obtain a first extraction raffinate and an iron load, and carrying out back extraction on the iron load to obtaina ferric chloride solution; S2, adding a second organic phase into the first extraction raffinate to obtain second extraction raffinate and a scandium-titanium-zirconium-niobium load; S3, carrying outback extraction on the scandium load to obtain a scandium-titanium-zirconium-niobium enriched product; S4, adjusting the pH value of the second extraction raffinate to prepare a liquid; S5, adding athird organic phase after liquid preparation to obtain a vanadium-aluminum load and a third extraction raffinate; S6, carrying out back extraction on the vanadium-aluminum load to obtain a vanadium-aluminum mixed solution; S7, adjusting the pH value of the third extraction raffinate to prepare a liquid; S8, after liquid preparation, adding a fourth organic phase into manganese extraction feed liquid to obtain a manganese load and a fourth extraction raffinate, and carrying out back extraction on the manganese load to obtain a manganese-containing solution; and S9, neutralizing the fourth extraction raffinate, carrying out filtering, then performing concentrating and crystallizing to obtain NaCl edible salt and water, and recycling the NaCl edible salt and water.

Owner:河南荣佳钪钒科技有限公司

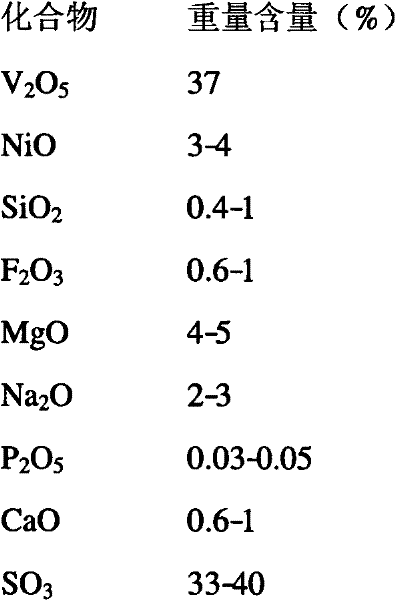

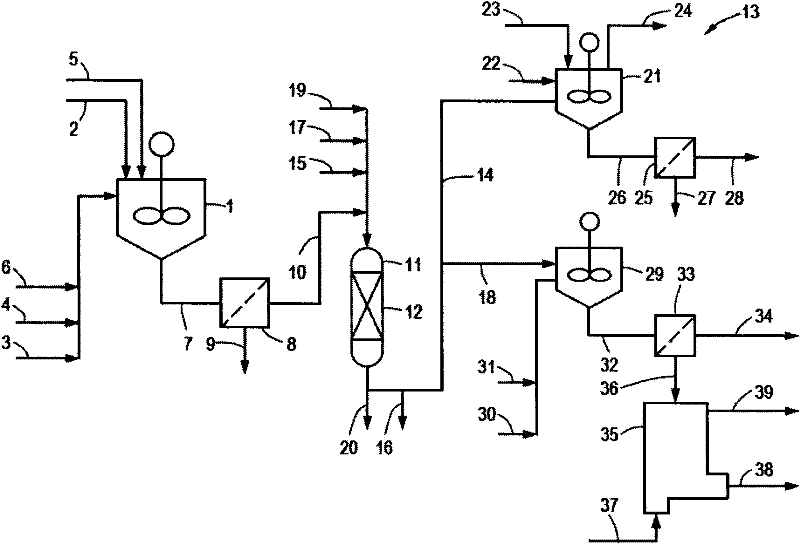

Process for preparing vanadium pentoxide from ash composition

The present invention is directed to a process for preparing vanadium pentoxide from an ash composition comprising solid ash particles, vanadium, iron and nickel compounds optionally present in an aqueous solution. The process comprises the following steps: (i) leaching the ash composition by contacting the ash composition with an acid aqueous solution at a pH of below 1, (ii) adding a reducing agent to the aqueous solution, (iii) contacting the aqueous solution obtained in step (ii) with an ion exchange resin in its H + ionic form, (iv) desorption of the vanadium compounds from the ion exchange resin rich in vanadium compounds by contacting the ion exchange resin with an aqueous solution of H 2 SO 4 to obtain an aqueous solution rich in vanadium compounds, and (v) converting and isolating the vanadium compounds as present in the aqueous solution to vanadium pentoxide.

Owner:GREENSHORES PATENT

A method for deep separation of molybdenum and vanadium in molybdenum-vanadium-containing solution

InactiveCN105692698BAchieve deep separationEasy to separateVanadium compounds preparationMolybdeum compounds preparationPotential differenceIon exchange

Owner:CENT SOUTH UNIV

Waste catalyst prepares high-purity ammonium metavanadate method

ActiveCN104628032BSolve the problem of entrainmentEfficient separationVanadium compounds preparationPregnant leach solutionIon exchange

Owner:DALIAN DONGTAI RESOURCE RENEWABLE

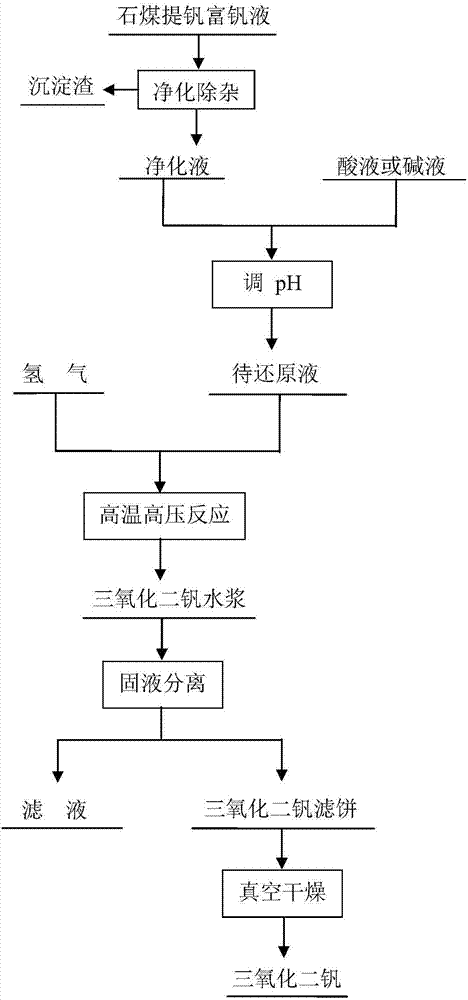

A kind of preparation method of vanadium trioxide

InactiveCN105969984BAvoid it happening againNo pollutionVanadium compounds preparationVanadium oxidesSlagHydrogen-Ion Concentrations

The invention belongs to the field of nonferrous metal metallurgy and particularly relates to a preparation method of vanadium trioxide. The preparation method comprises the following steps that (1) purification and impurity removal are conducted on vanadium-enriched liquid with the vanadium concentration being larger than 6 g / L and used for extracting vanadium from stone coal, and purification liquid and sediment slag are obtained; (2) pH regulation is conducted on the purification liquid through alkali liquid or acid liquid, and to-be-reduced liquid with the hydrogen ion concentration being 10<-4>-10<-14> mol / L is obtained; (3) under the condition that the hydrogen partial pressure is larger than 1 MPa, hydrogen and the to-be-reduced liquid are subjected to a stirring reaction in a high-temperature high-pressure reaction device for over an hour at the temperature of 50-300 DEG C, and vanadium trioxide water slurry is obtained; (4) after the vanadium trioxide water slurry is subjected to solid-liquid separation, a vanadium trioxide filter cake and filter liquid are obtained; and (5) vacuum drying is conducted on the vanadium trioxide filter cake, and vanadium trioxide is obtained. The preparation method has the advantages of being simple in technique, environmentally friendly and low in production cost.

Owner:WUHAN UNIV OF TECH

System and method for preparing high-purity vanadium pentoxide powder

ActiveUS10053371B2Improve calcination decomposition efficiencyGood choiceDistillation in boilers/stillsEnergy inputVanadium oxytrichloridePollution

The present invention provides a system and method for preparing high-purity vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is subjected to purification by rectification, ammonium salt precipitation and fluidized calcination, thereby obtaining high-purity vanadium pentoxide, wherein the ammonia gas produced during calcination is condensed and then recycled for ammonium salt precipitation. The system and method have advantages of favorable adaptability to raw material, less pollution, low energy consumption in production, low operation cost, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

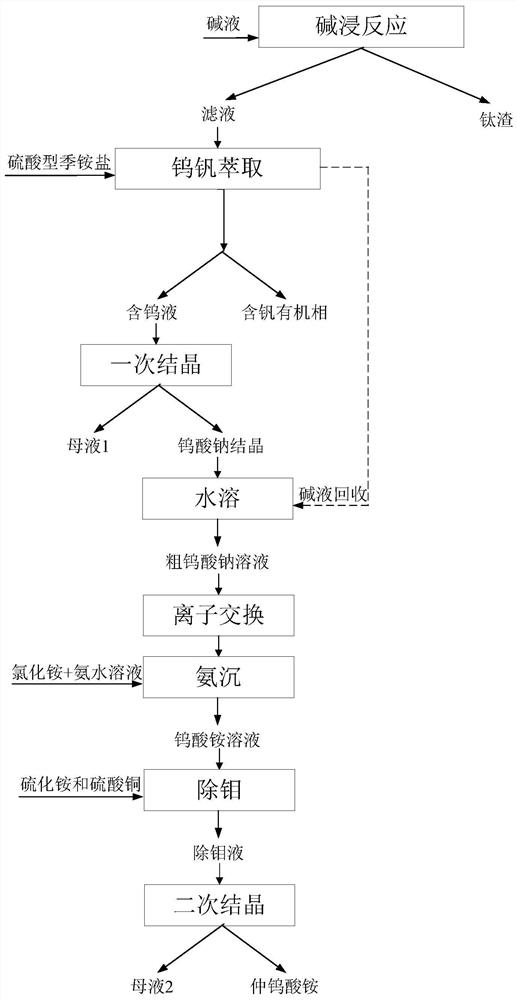

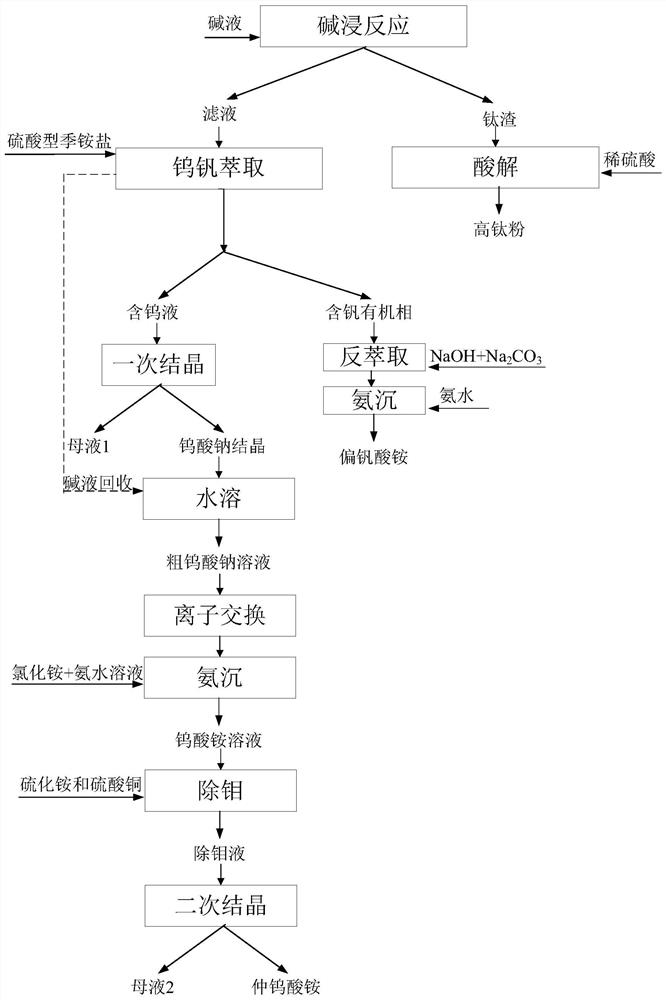

Method for recycling ammonium paratungstate by using waste SCR catalyst

PendingCN112374541AImplement extractionReduce usageTungsten compounds preparationVanadium compounds preparationPtru catalystAmmonium paratungstate

The invention discloses a method for recycling ammonium paratungstate by using a waste SCR catalyst, which is used for recycling alkali liquor after an alkaline leaching reaction is finished, so thatthe production cost is further saved, and the recycled alkali liquor is used for carrying out water-soluble operation on crystals so as to realize the extraction of ammonium paratungstate, on the basis of cyclic utilization of the alkali liquor, PH adjustment through a large amount of acid liquor is avoided, and use of harmful chemicals is effectively reduced on the basis of improving the process.

Owner:上海盈华化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com