Preparation method of high-purity vanadium oxide

A vanadium pentoxide, high-purity technology, applied in the field of chemicals, can solve problems such as poor purity of vanadium pentoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

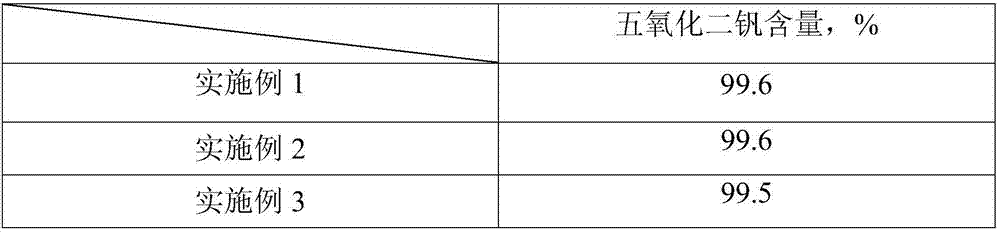

Examples

preparation example Construction

[0018] The present invention provides a kind of preparation method of high-purity vanadium pentoxide, and this preparation method comprises:

[0019] (1) Industrial grade ammonium metavanadate is dissolved in alkaline solution, and vanadium is adsorbed by basic anion exchange resin;

[0020] (2) Analyze the basic anion exchange resin after adsorption to obtain a vanadium-containing solution;

[0021] (3) contacting the vanadium-containing solution with an acidic cation exchange resin to obtain a purified vanadium-containing solution;

[0022] (4) adding a vanadium precipitation agent to the purified vanadium-containing solution to obtain primary ammonium metavanadate;

[0023] (5) recrystallizing, washing and drying the primary ammonium metavanadate to obtain high-purity ammonium metavanadate;

[0024] (6) Calcining the high-purity ammonium metavanadate to obtain high-purity vanadium pentoxide.

[0025] According to the present invention, preferably, the alkaline solution i...

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of high-purity vanadium pentoxide, and this preparation method comprises:

[0038] (1) dissolving technical grade ammonium metavanadate in the ammoniacal liquor that mass concentration is 15wt%, carries out vanadium adsorption by basic anion exchange resin, and the condition of described vanadium adsorption is: pH value is 7-8, and flow velocity is 2 times the column volume, the contact time is 60 minutes, when the vanadium content of the effluent reaches more than 2ppm, the resin is saturated and stops adsorption; wherein, the basic anion exchange resin is a gel-type anion capable of selectively adsorbing metavanadate ions exchange resin;

[0039] (2) Analyzing the basic anion exchange resin after adsorption with aqueous ammonia to obtain a vanadium-containing solution;

[0040] (3) contacting the vanadium-containing solution with an acidic cation exchange resin to obtain a purified vanadium-containing solut...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of high-purity vanadium pentoxide, and this preparation method comprises:

[0046] (1) Industrial grade ammonium metavanadate is dissolved in the sodium hydroxide solution that mass concentration is 15wt%, carries out vanadium adsorption by basic anion exchange resin, and the condition of described vanadium adsorption is: pH value is 7-8, The flow rate is 2 times the column volume, and the contact time is 60 minutes. When the vanadium content of the effluent reaches more than 2ppm, the resin is saturated and stops adsorption; wherein, the basic anion exchange resin is a gel that can selectively adsorb metavanadate ions Colloidal anion exchange resin;

[0047] (2) Analyzing the basic anion exchange resin after adsorption with aqueous ammonia to obtain a vanadium-containing solution;

[0048] (3) contacting the vanadium-containing solution with an acidic cation exchange resin to obtain a purified vanadium-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com