A system for extracting vanadium and preparing vanadium pentoxide from vanadium-chromium-silicon-containing leaching solution and its treatment method

A vanadium pentoxide and leaching solution technology, which is applied in the preparation of vanadium compounds, vanadium oxide, chemical instruments and methods, etc., can solve the problems of large initial investment, affecting purity, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

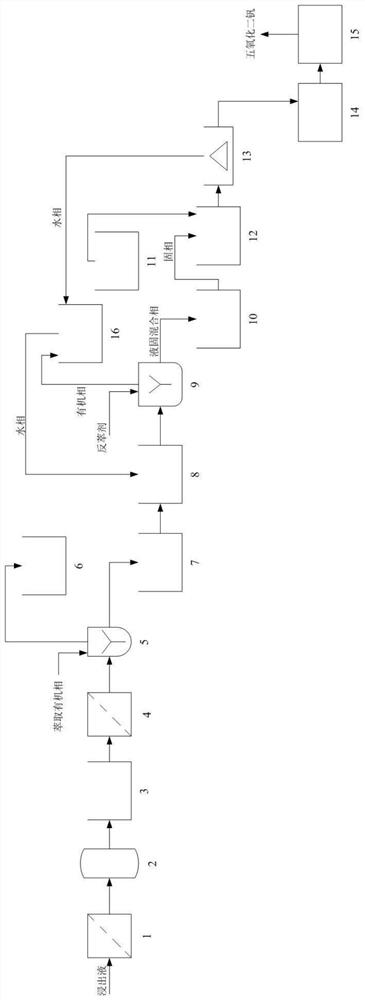

[0128] This embodiment provides a system and a treatment method for extracting vanadium and preparing vanadium pentoxide from a vanadium-chromium-silicon-containing leach solution:

[0129] The system sequentially includes an impurity removal system, an extraction system, a stripping vanadium precipitation system, a washing system and a calcination system.

[0130] Wherein, the impurity removal system includes the first filter 1, the impurity removal reaction kettle 2, the impurity removal liquid static tank 3 and the second filter 4 connected in sequence, the liquid outlet of the second filter 4 and the material of the extraction system The entrance is connected.

[0131] The extraction system comprises a centrifugal extractor 5, a raffinate storage tank 6 and a vanadium-rich organic phase storage tank 7, the raffinate outlet of the centrifugal extractor 5 is connected to the inlet of the raffinate storage tank 6, and the centrifugal The organic phase outlet of the extractor...

Embodiment 2

[0145] This embodiment provides a system and a treatment method for extracting vanadium and preparing vanadium pentoxide from a vanadium-chromium-silicon-containing leach solution:

[0146] The system is the same as that in Example 1.

[0147] The processing method of the above system is:

[0148] (1) After the leaching solution containing vanadium, chromium and silicon is filtered by the first filter 1, 500mL of the leaching solution containing pentavalent vanadium, hexavalent chromium and silicon is sent to the impurity removal reaction kettle 2, and after constant temperature heating to 60°C, add 5.86 Al of g 2 (SO 4 ) 3 and 0.751 g of CaCl 2 Carry out desiliconization treatment, stir and react for 40 minutes, cool to room temperature and adjust the pH value to 7.7 with sulfuric acid, and then stir for 10 minutes, then send it to the impurity removal liquid standing tank 3 and let it stand for 2 hours, and after the second filter 4 is centrifugally separated and filtere...

Embodiment 3

[0156] This embodiment provides a system and a treatment method for extracting vanadium and preparing vanadium pentoxide from a vanadium-chromium-silicon-containing leach solution:

[0157] The system is the same as that in Example 1.

[0158] The processing method of the above system is:

[0159] (1) After the leaching solution containing vanadium, chromium and silicon is filtered by the first filter 1, 1000 mL of the leaching solution containing pentavalent vanadium, hexavalent chromium and silicon is sent to the impurity removal reaction kettle 2, and after the constant temperature is heated to 70 ° C, 1.056 g Al(OH) 3 and 0.7g CaCl 2 Carry out desiliconization treatment, stir and react for 50 minutes, cool to room temperature and adjust the pH value to 8.0 with sulfuric acid, and then stir for 10 minutes, then put it into the impurity removal liquid standing tank 3 and let it stand for 3 hours, and after centrifugal separation and filtration by the second filter 4, Obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com