Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195results about "Mechanical automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

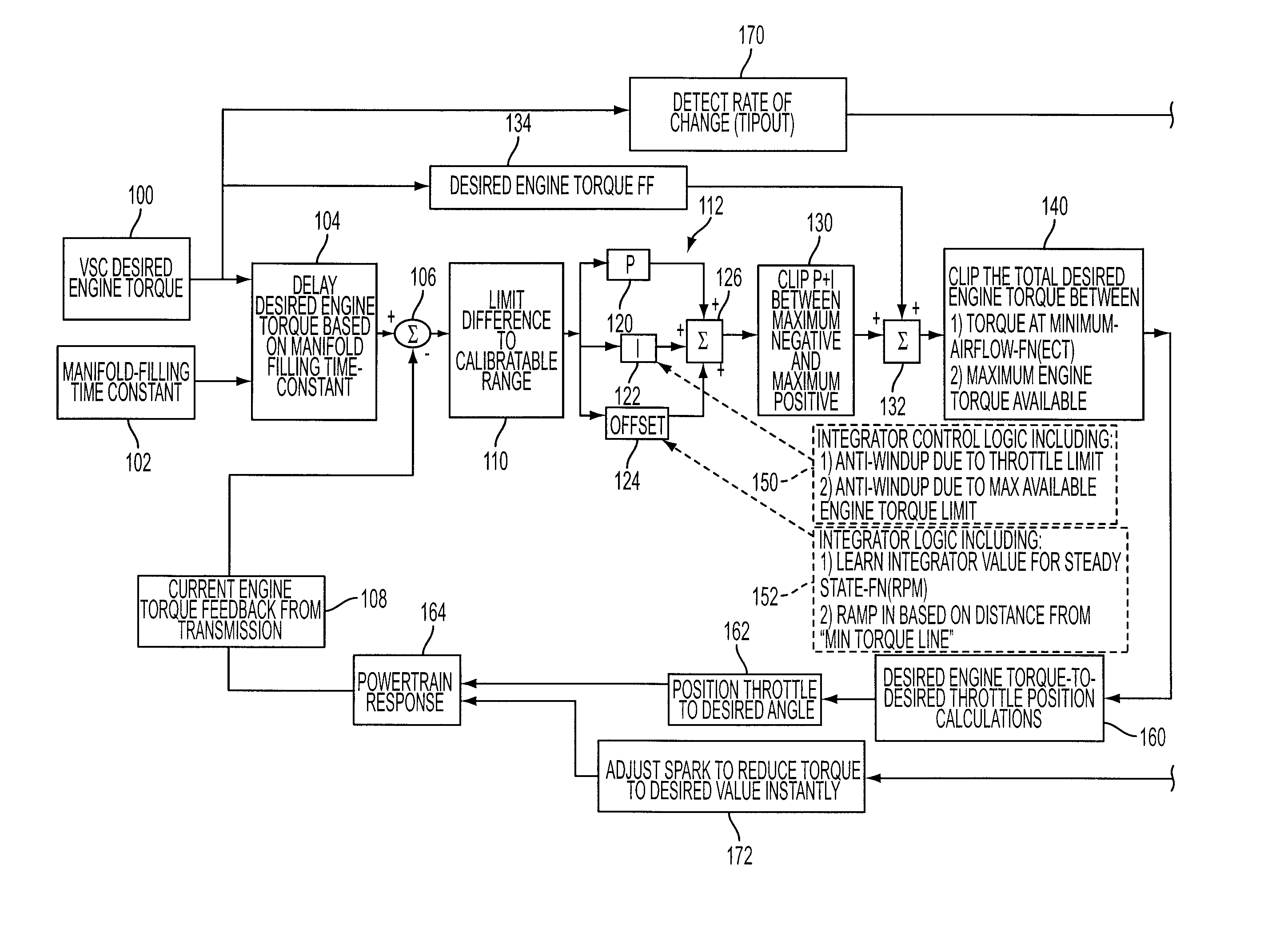

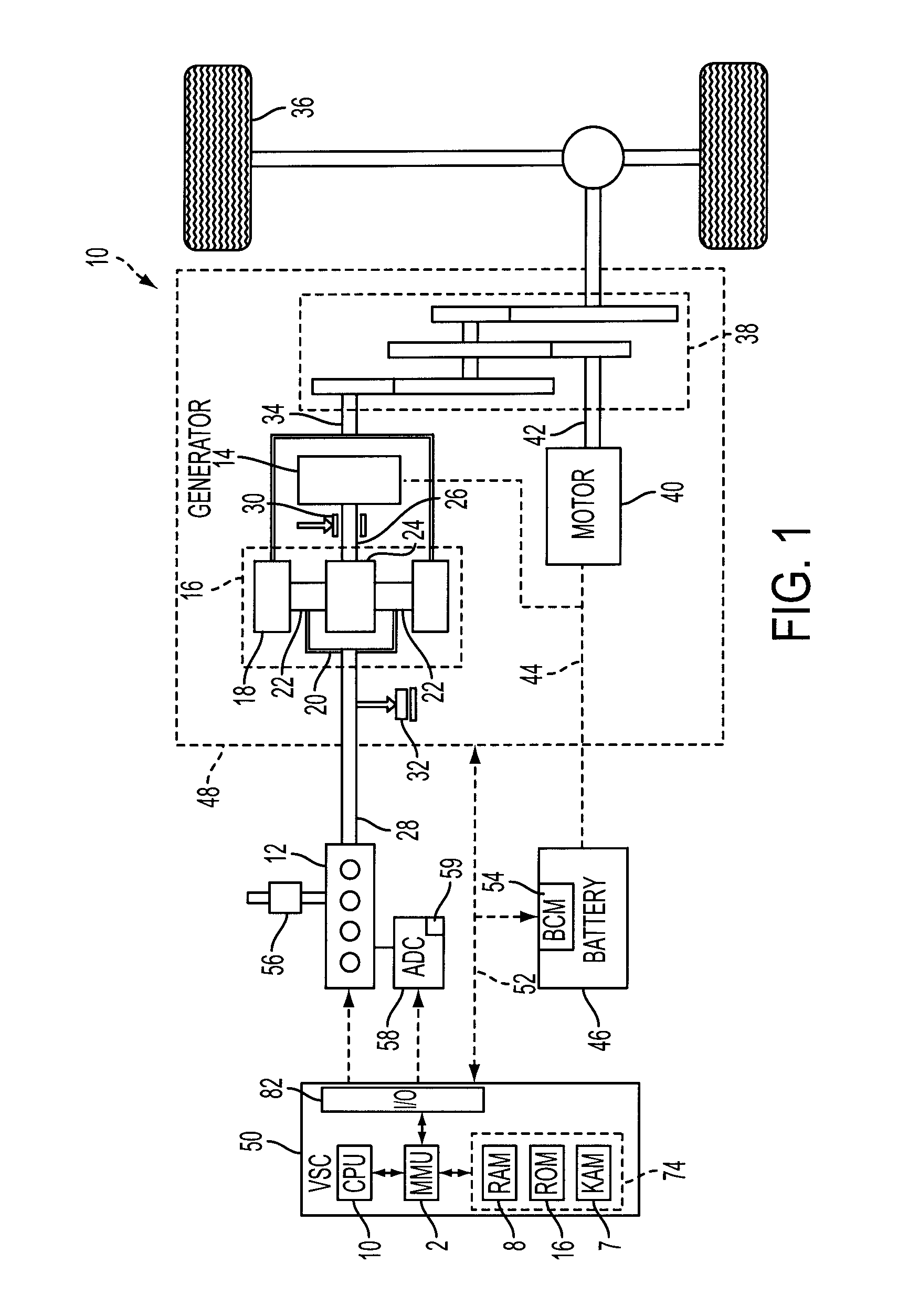

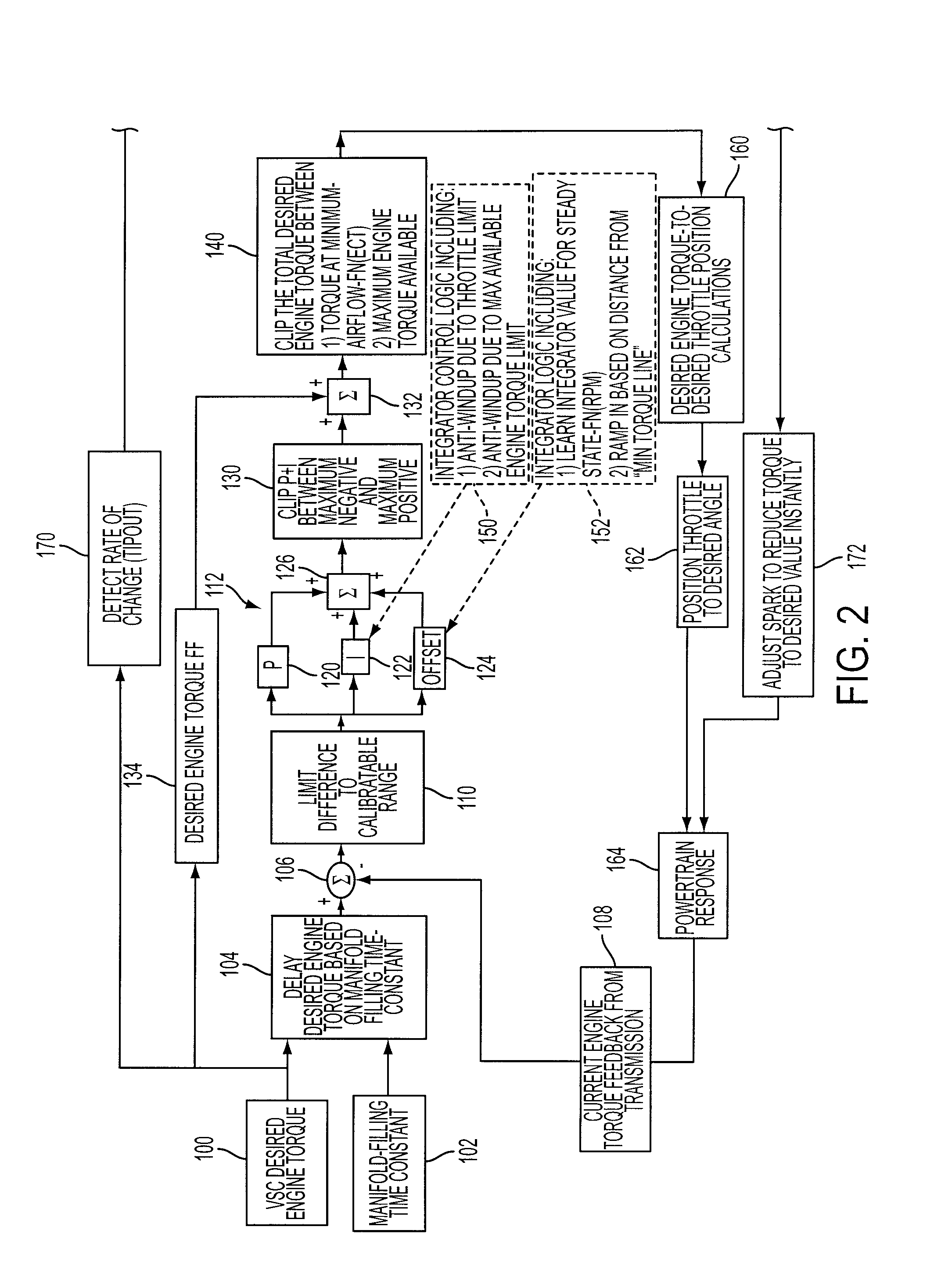

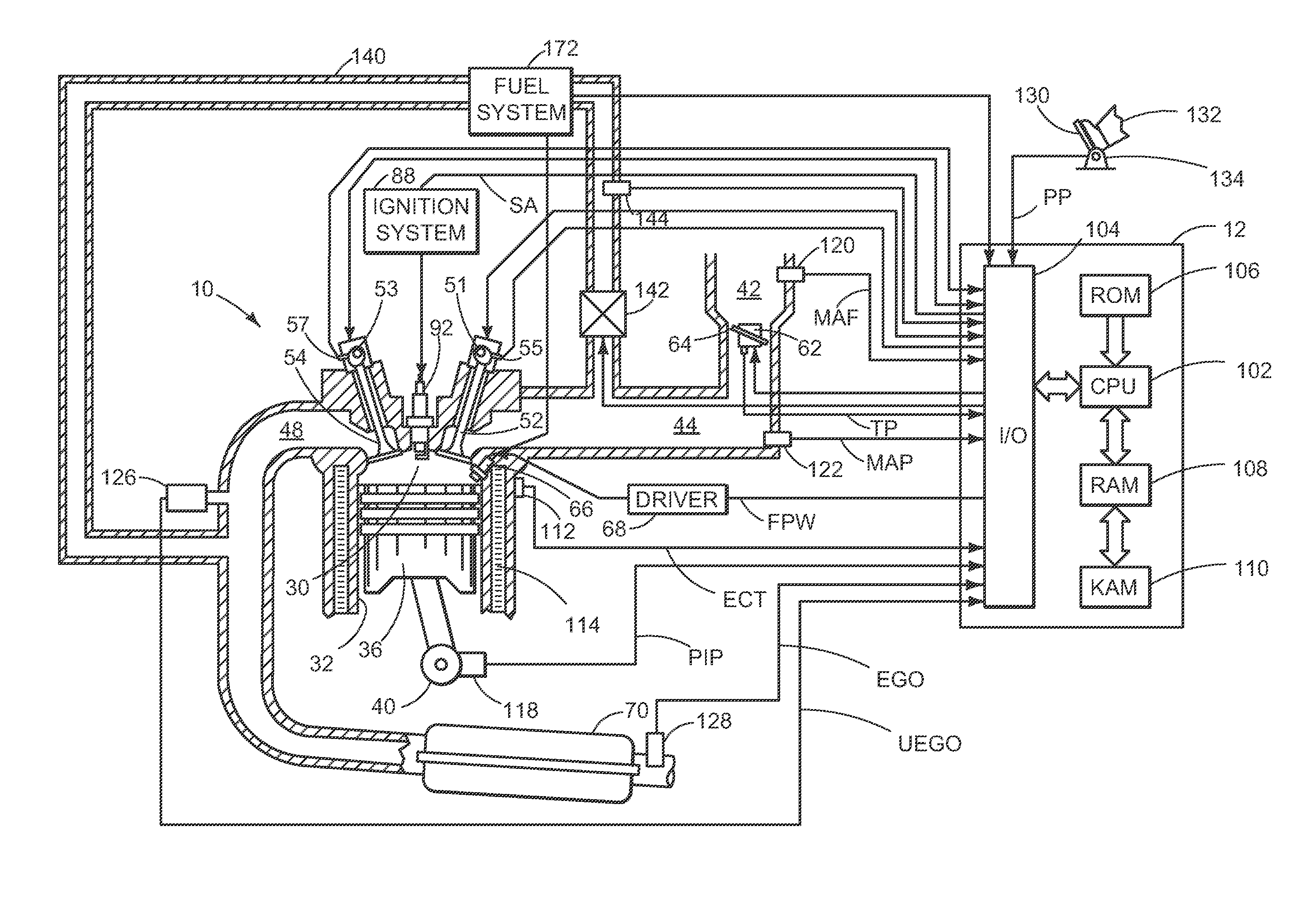

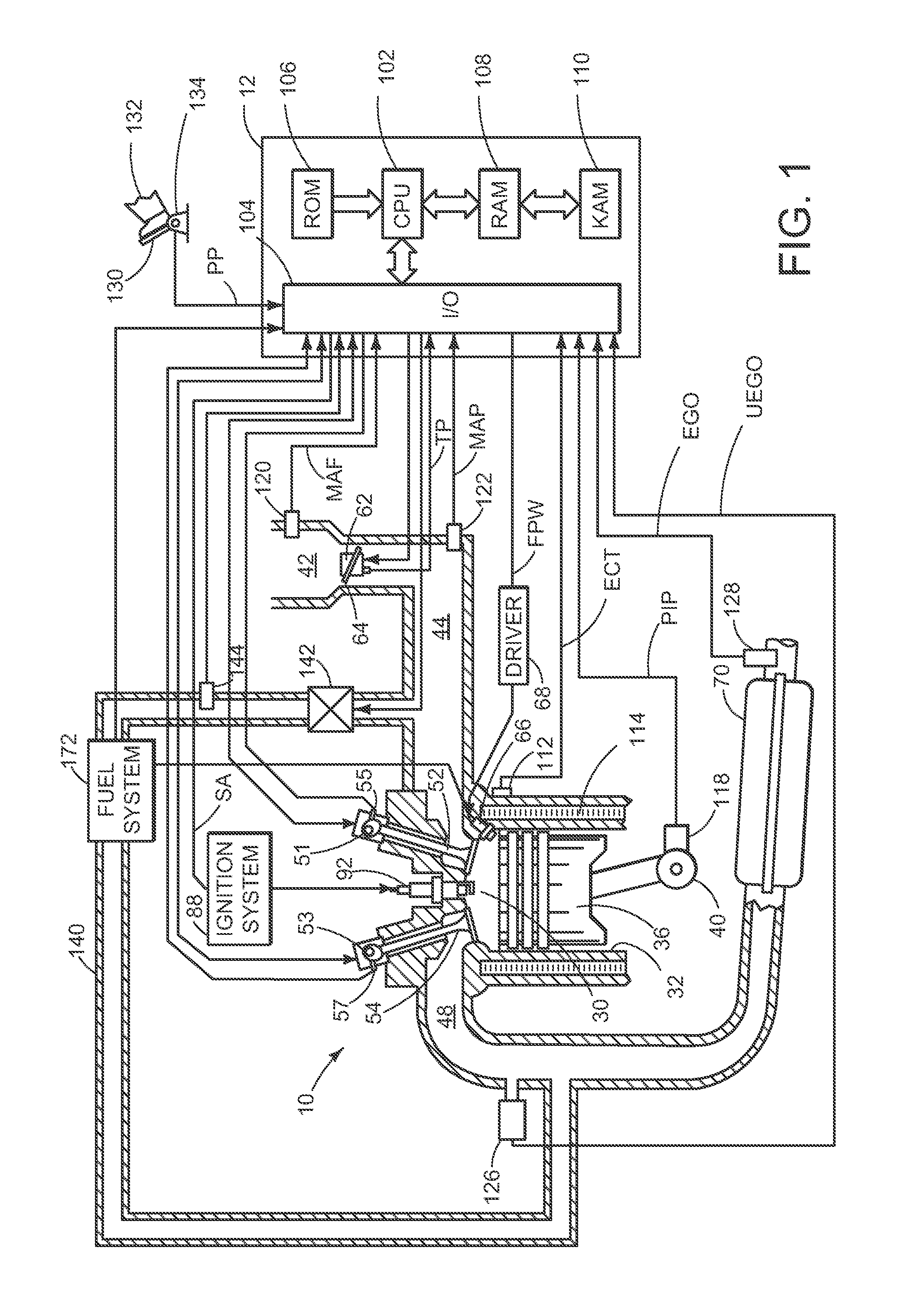

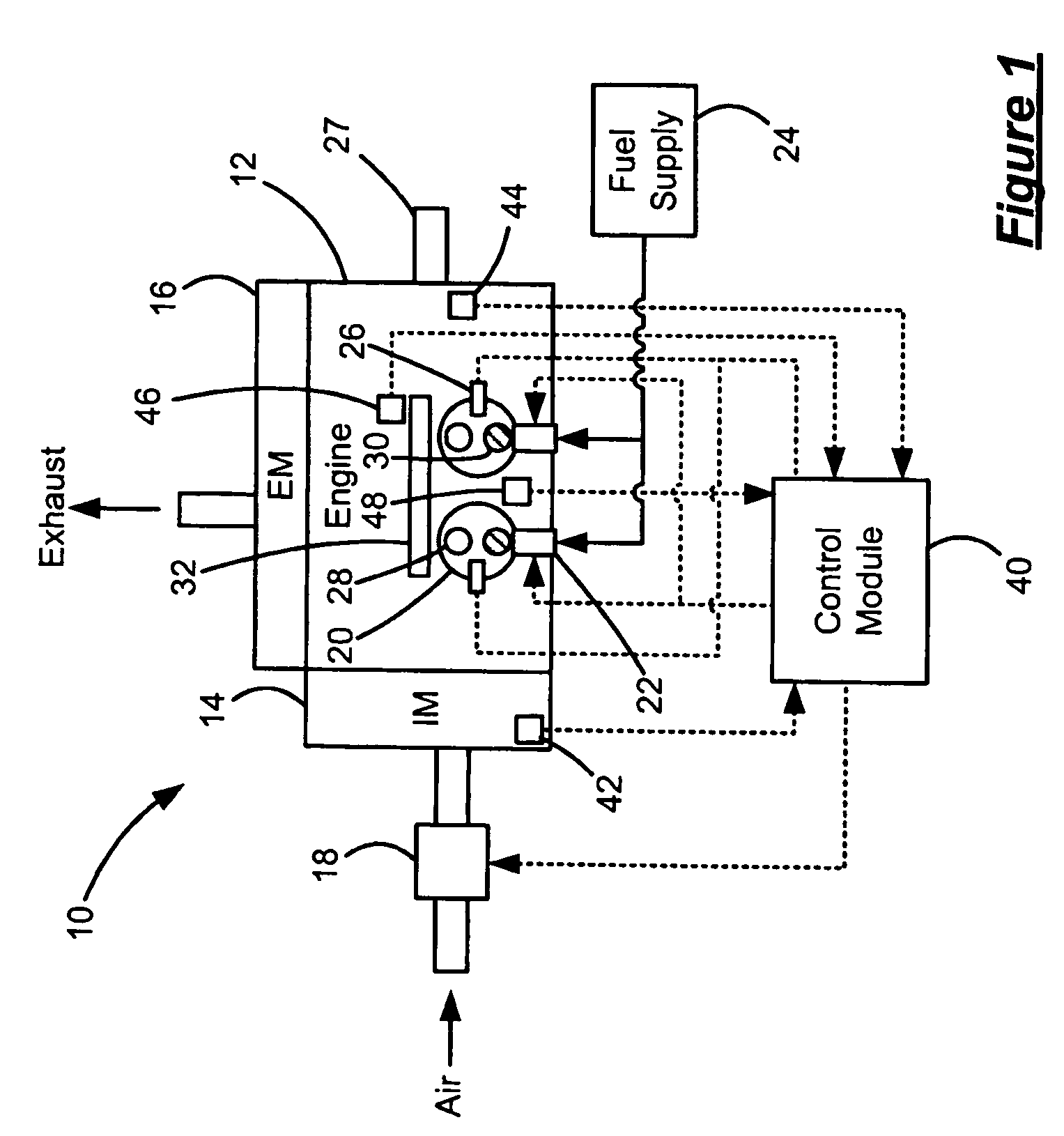

Torque-based powertrain control for vehicles

ActiveUS7275518B1Prevent over-chargingImproved torque controlElectrical controlInternal combustion piston enginesEngineeringPowertrain control

A system and method for controlling a vehicle powertrain having an internal combustion engine include determining a difference between a desired engine torque and a current engine torque, adjusting the difference based on a stored torque offset corresponding to a current engine speed, and controlling the engine to produce a torque corresponding to the adjusted torque difference. The stored torque offset is adjusted when the engine is operating in a predetermined engine speed range based on a steady-state difference between the desired and current engine torque to reduce the steady-state difference to zero. The adjusted torque difference may be limited by a maximum-engine-torque-available parameter and a minimum-engine-torque-available parameter, which is based on an operating temperature, such as the engine coolant temperature. The system and method may also include controlling spark to rapidly reduce current engine torque to the adjusted torque difference value.

Owner:FORD GLOBAL TECH LLC

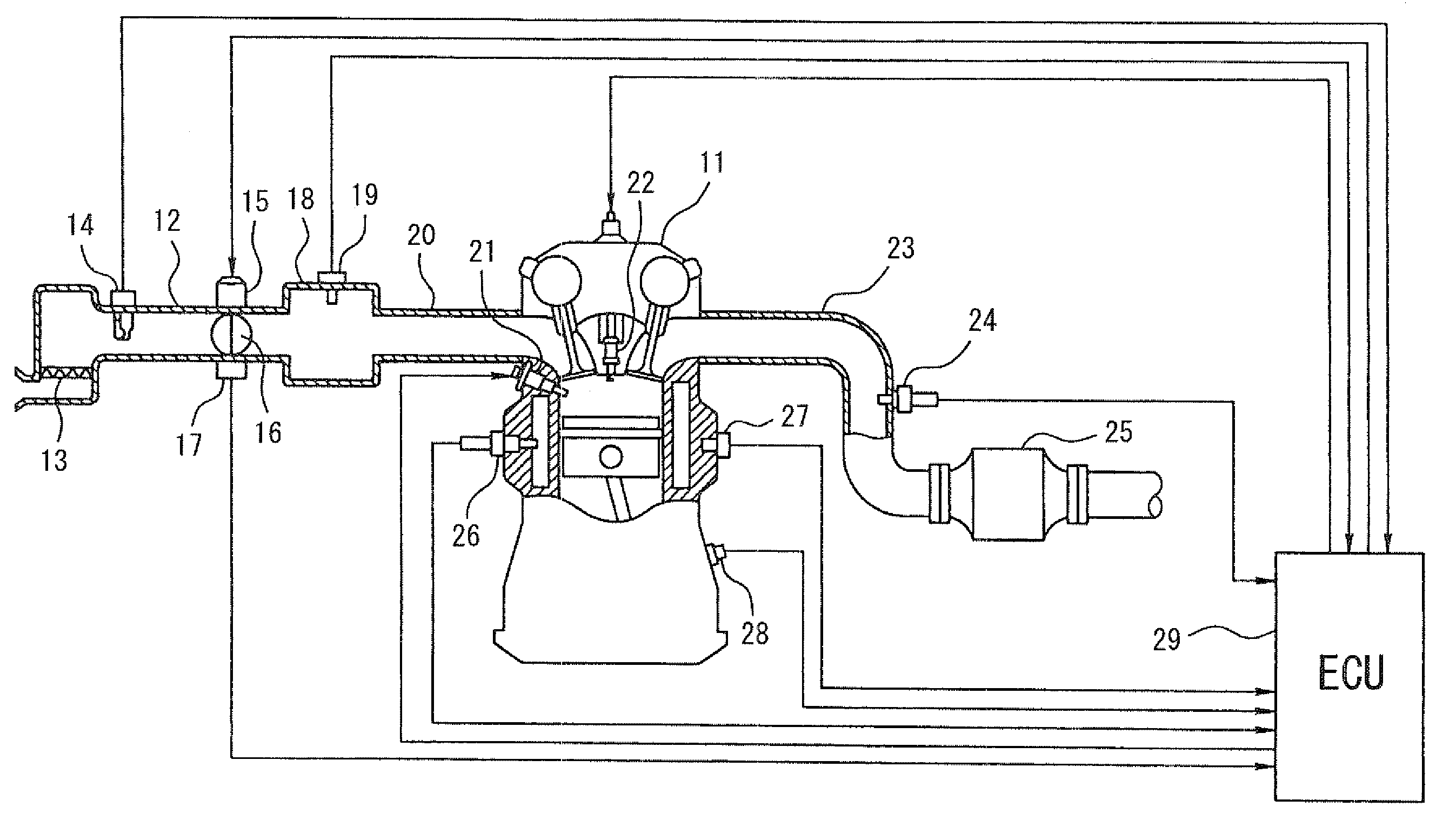

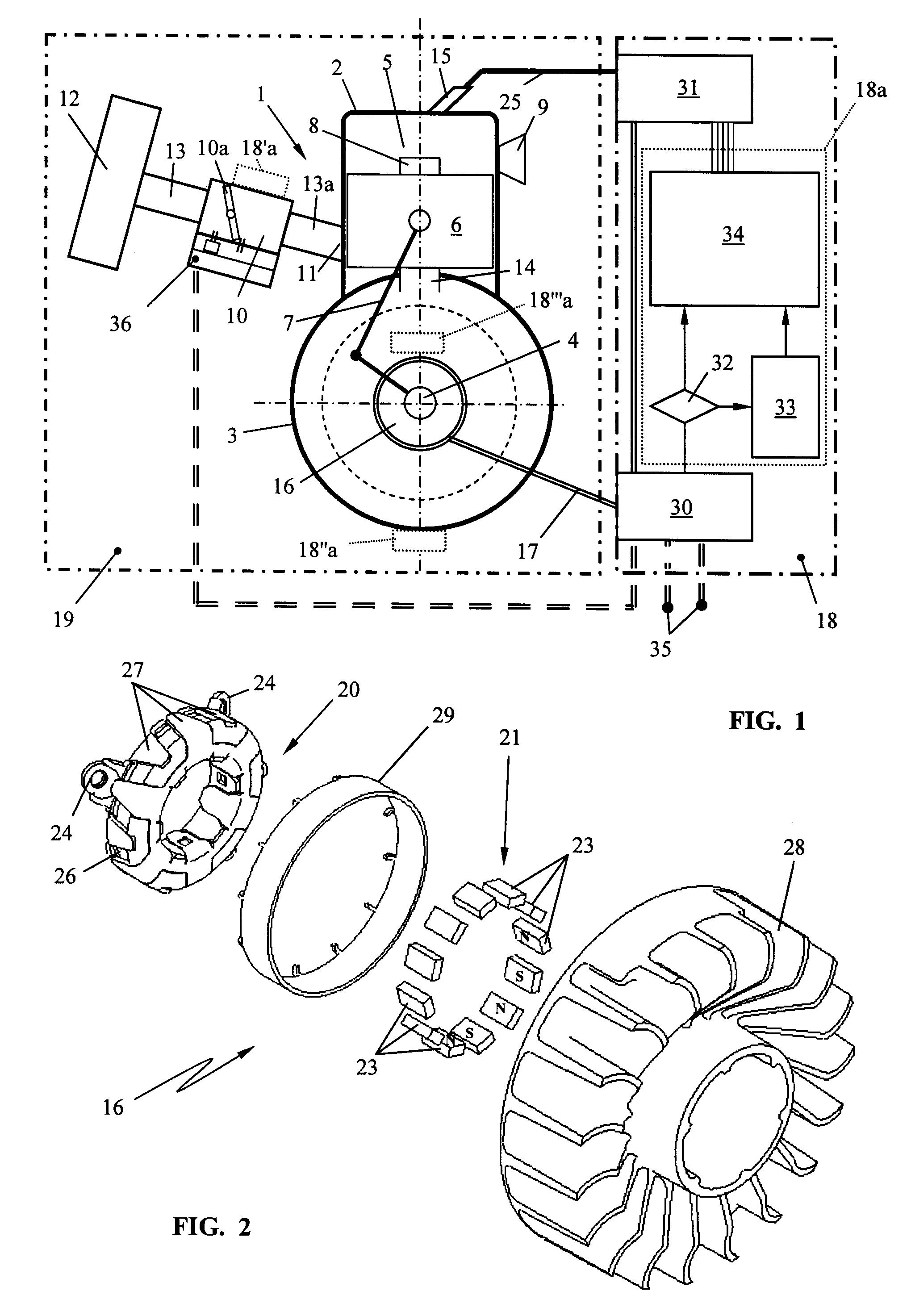

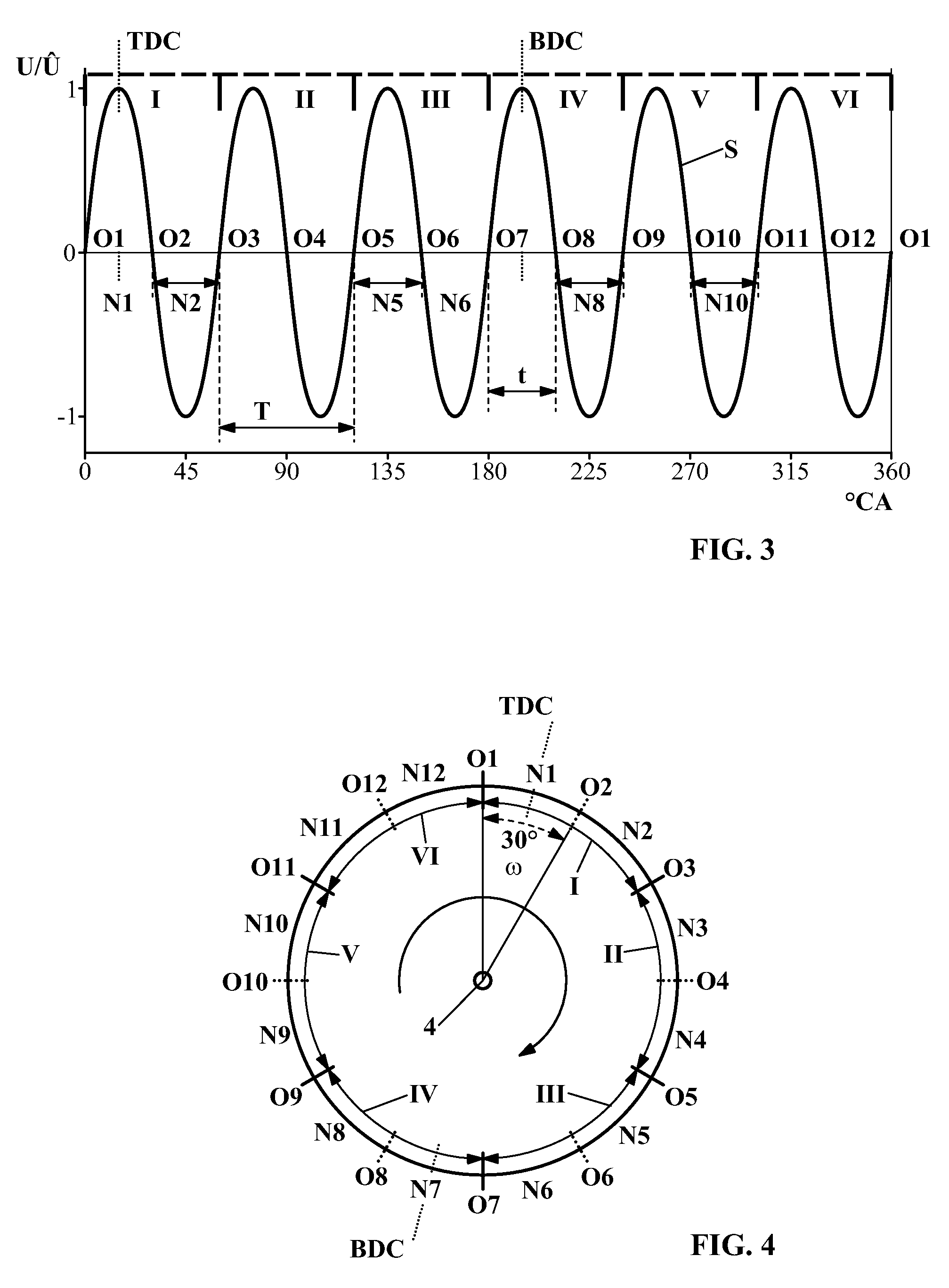

Engine timing control with intake air pressure sensor

InactiveUS7225793B2Reduce complexityLow costElectrical controlVolume/mass flow by thermal effectsExternal combustion engineInlet valve

An engine control apparatus is disclosed for determining crankshaft position and engine phase of an internal combustion engine through monitoring intake air pressure fluctuations. The opening of the intake valve is mechanically linked to the crankshaft position of an engine. When the intake valve opens it creates air pressure fluctuations in the air induction system of the engine. The control apparatus is configured to determine intake air pressure fluctuations indicative of an intake air event and thus a particular crankshaft position, and their corresponding period of the engine cycle. The controller then uses this information to determine crankshaft speed and position for the purpose of fuel injection and ignition timing of the internal combustion engine. Engine phase is also determined on four-stroke engines. The engine may also include a crankshaft position sensor in combination with monitoring intake air pressure fluctuations to increase resolution in determination of crankshaft position. A circuit is provided for simultaneously measuring intake temperature using a single bridge type pressure sensor in order to calculate air mass flow rate.

Owner:ELECTROJET TECH INC

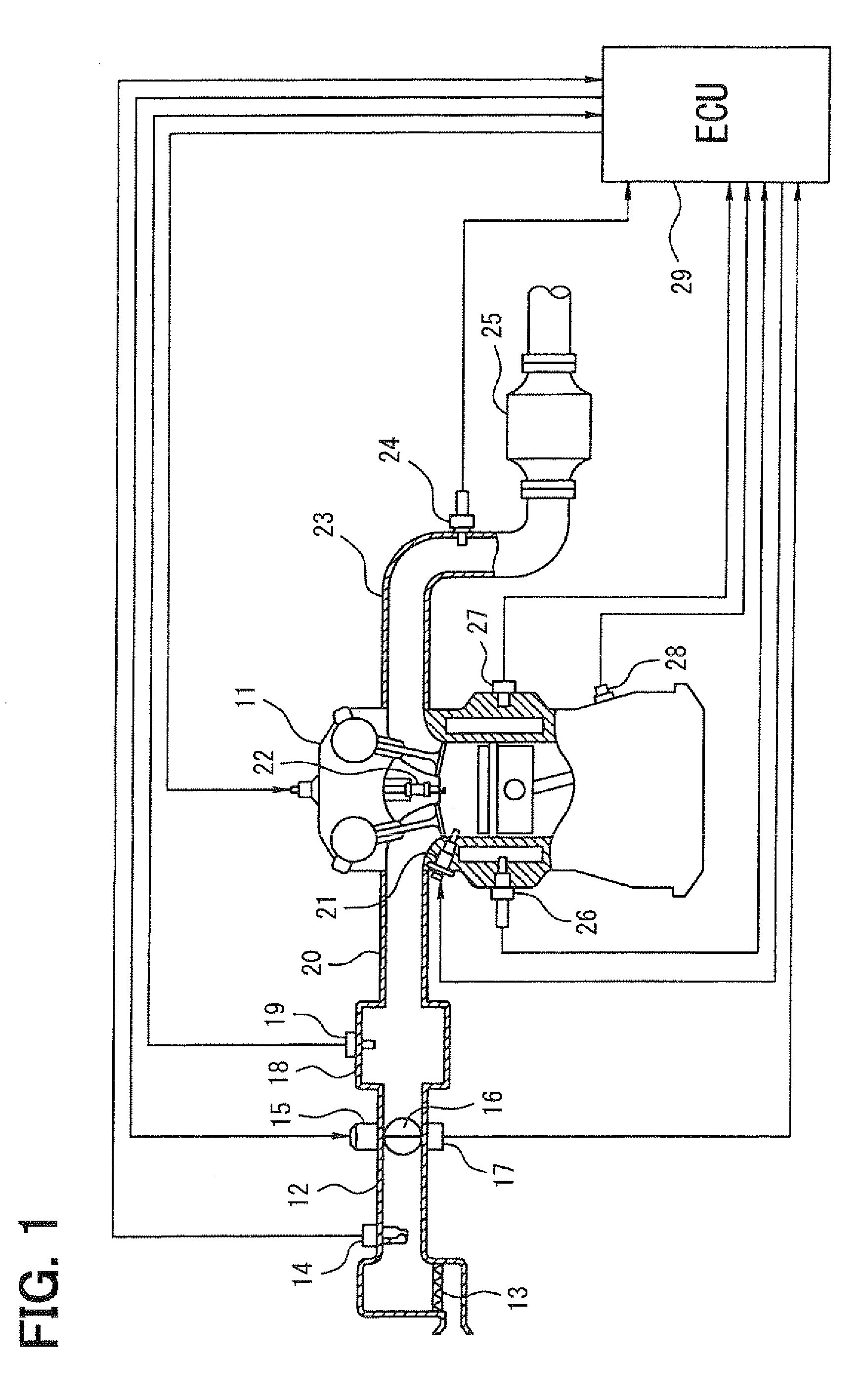

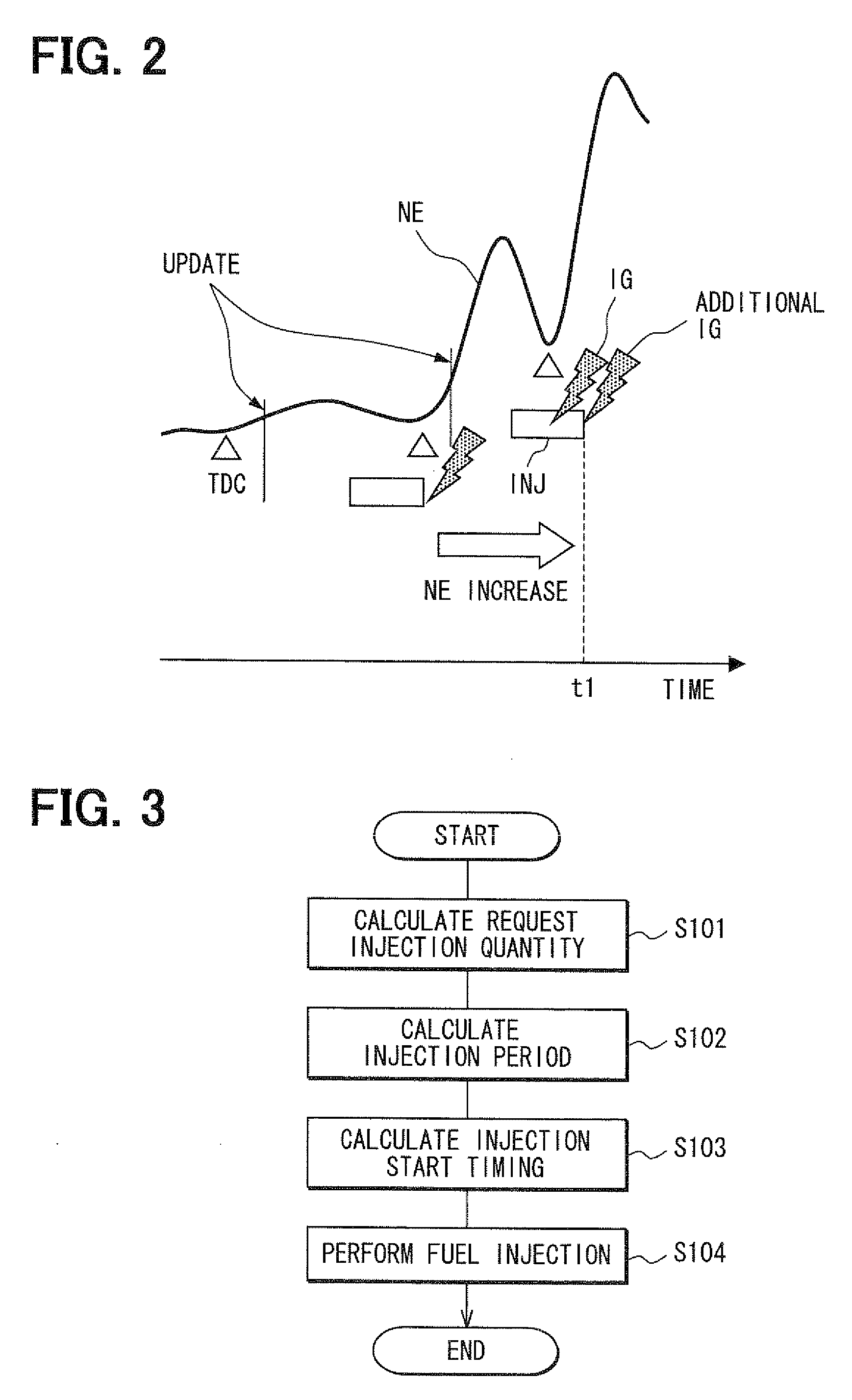

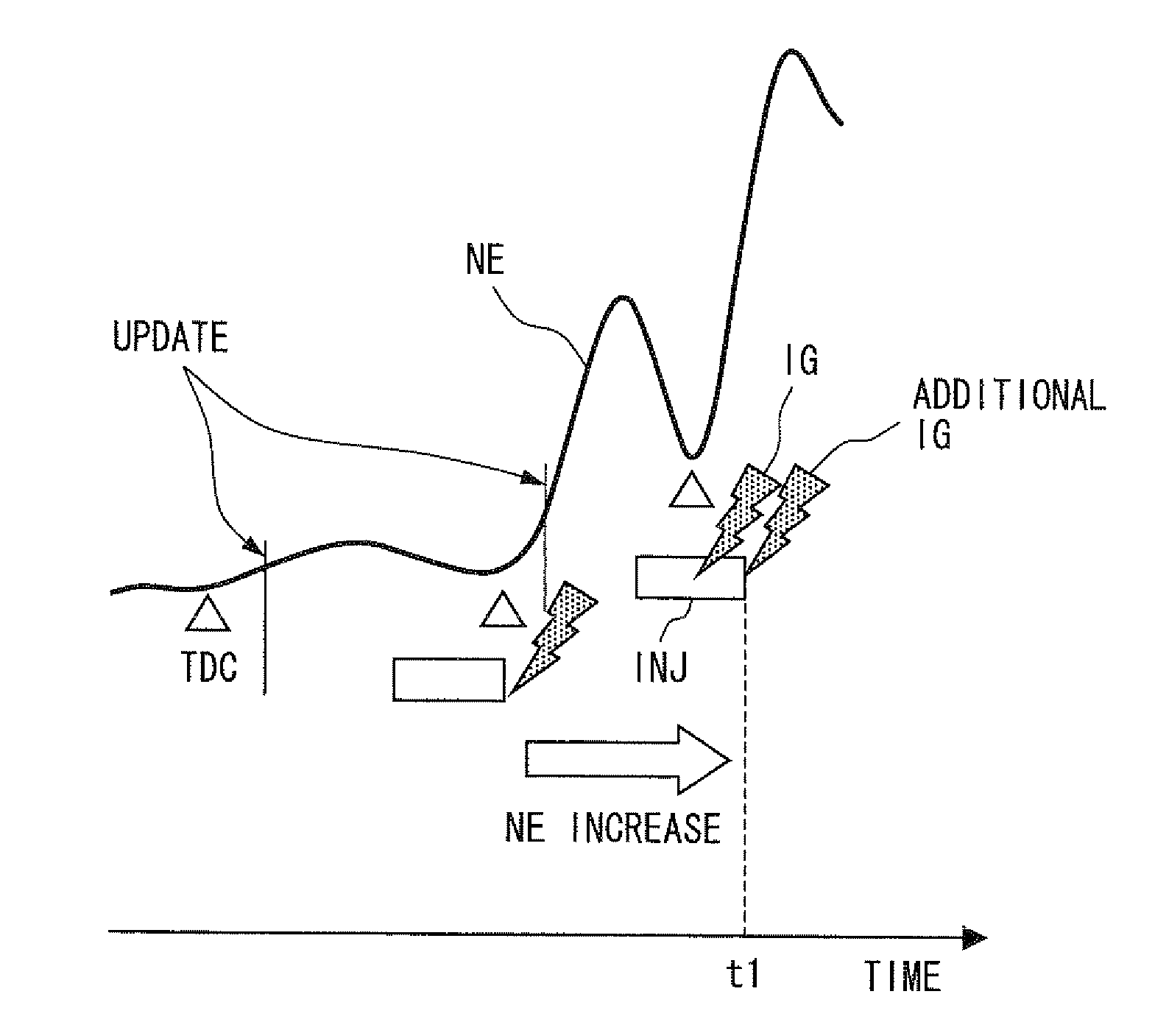

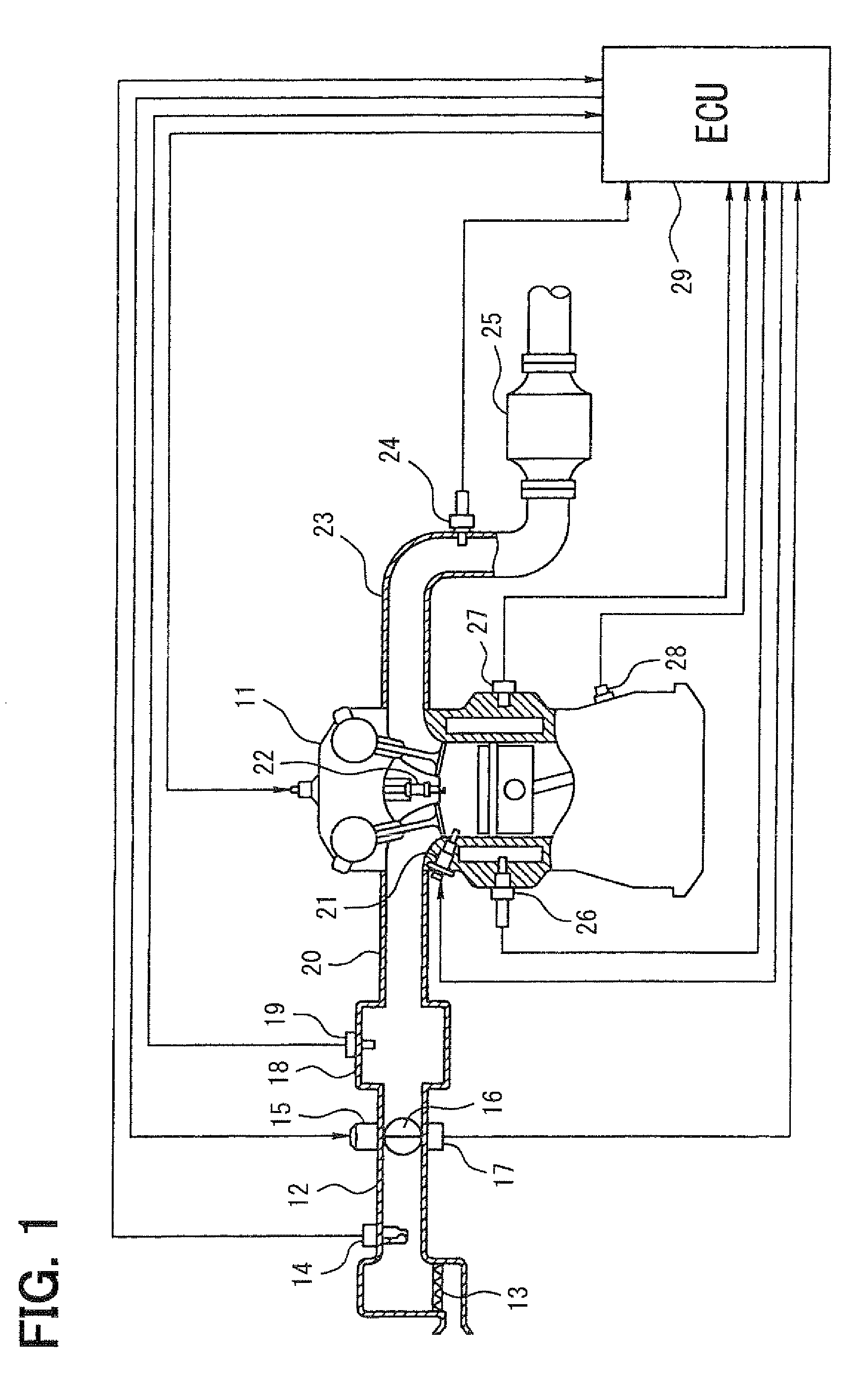

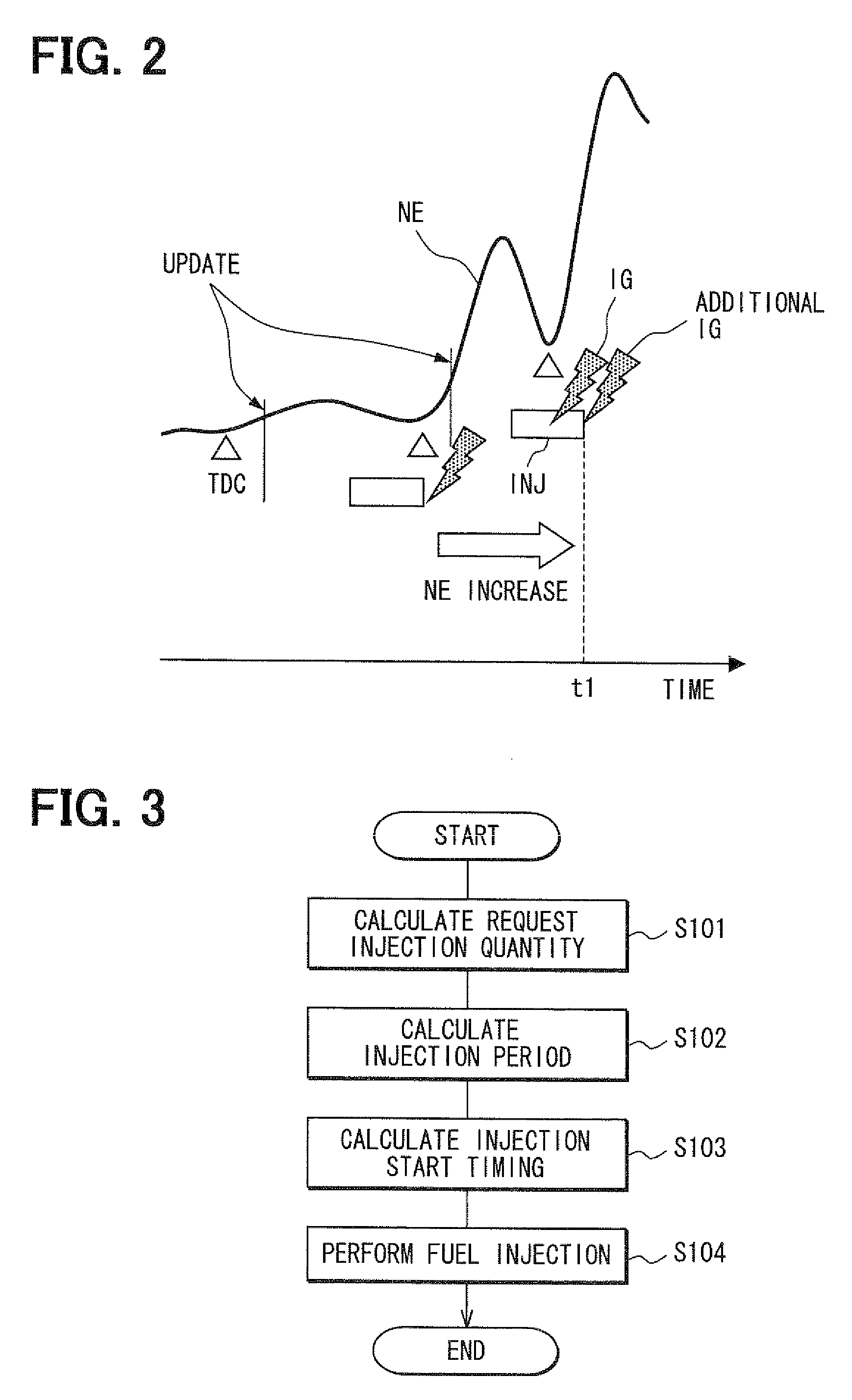

Control device of direct injection internal combustion engine

InactiveUS20090118986A1Increase rotation speedAvoid incomplete combustionElectrical controlDigital data processing detailsEngineeringIgnition timing

When engine rotation speed is increasing in a compression stroke injection mode, a control device determines that a crank angle at injection end timing of an injector deviates toward a delayed crank angle side and performs additional ignition at timing when (or immediately before or after) a crank angle at actual injection end timing of the injector of a present injection cylinder is reached. Thus, even when the crank angle at the injection end timing deviates toward the delayed crank angle side with respect to preset original ignition timing, a combustion state can be stabilized by performing the additional ignition at timing, at which a suitable stratified mixture gas is formed in a cylinder, through the execution of the additional ignition at the timing substantially the same as the actual injection end timing.

Owner:DENSO CORP

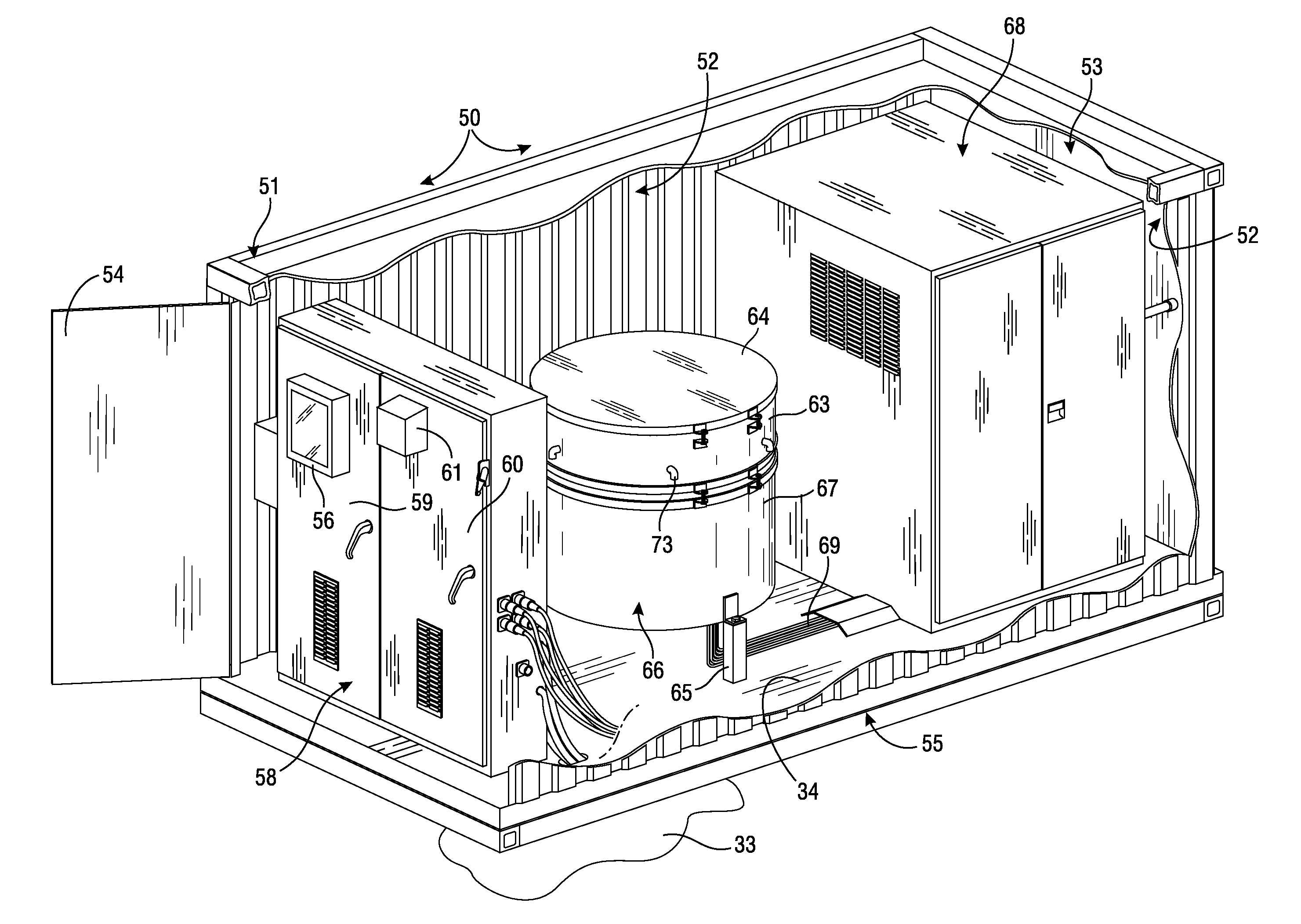

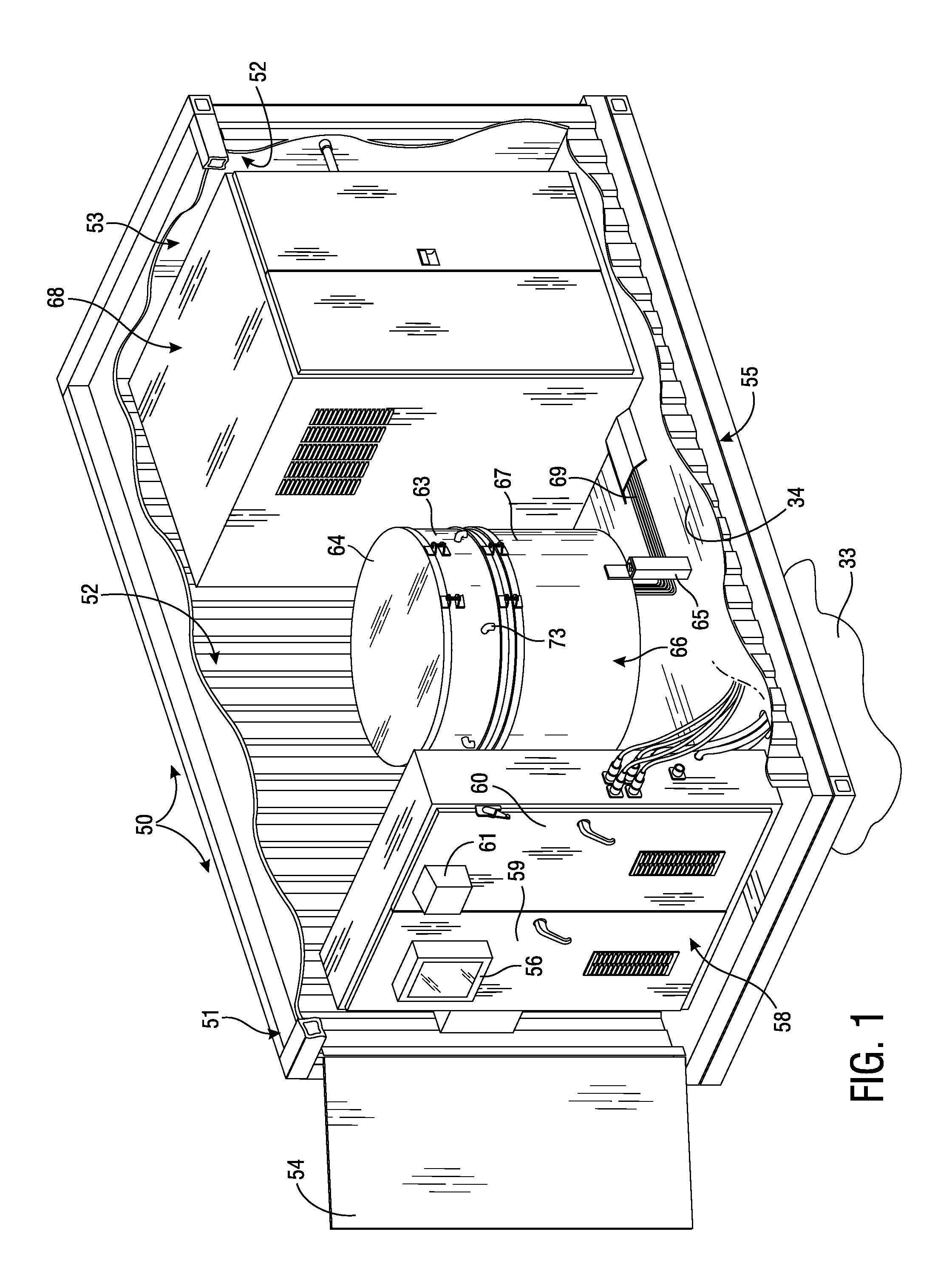

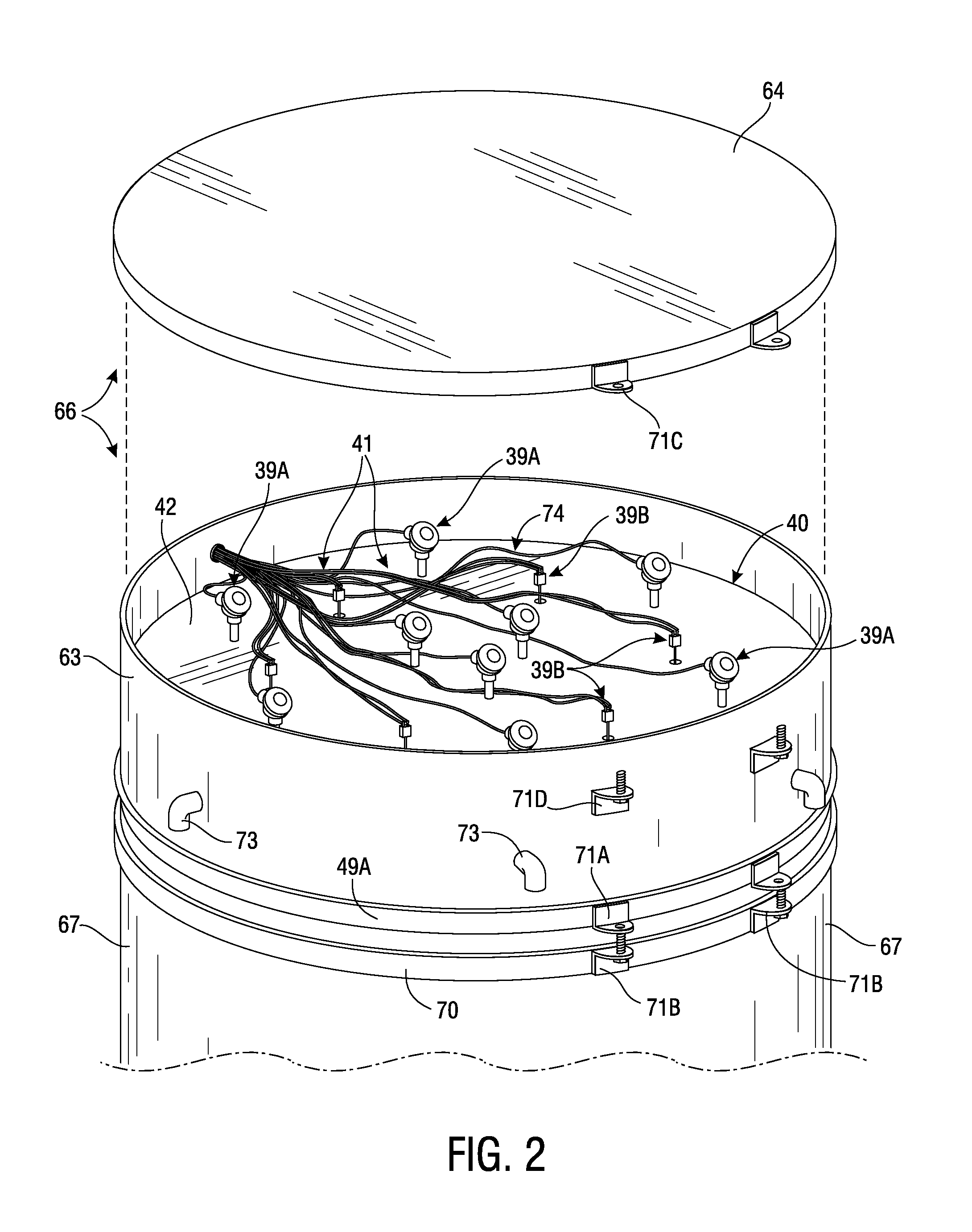

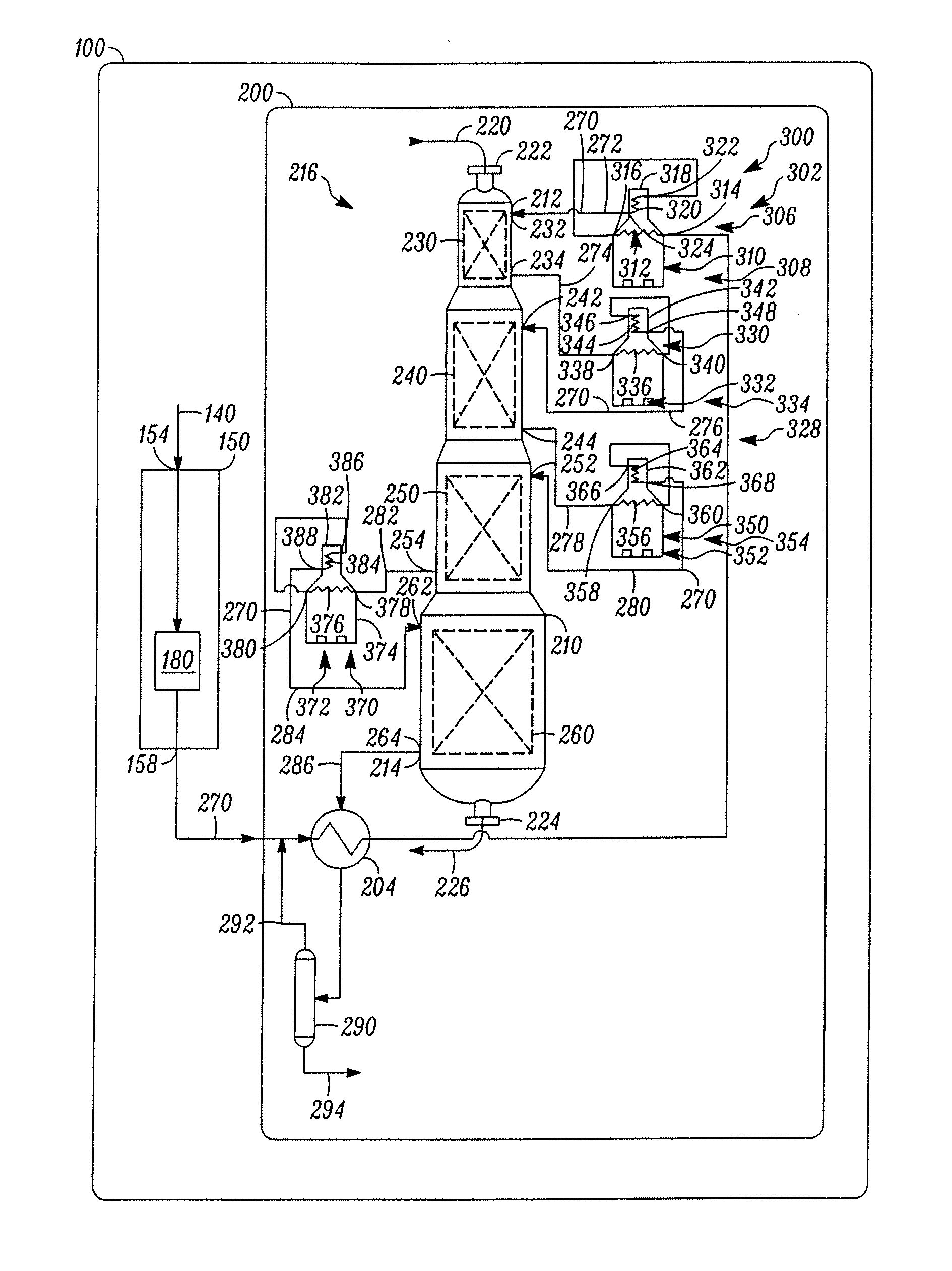

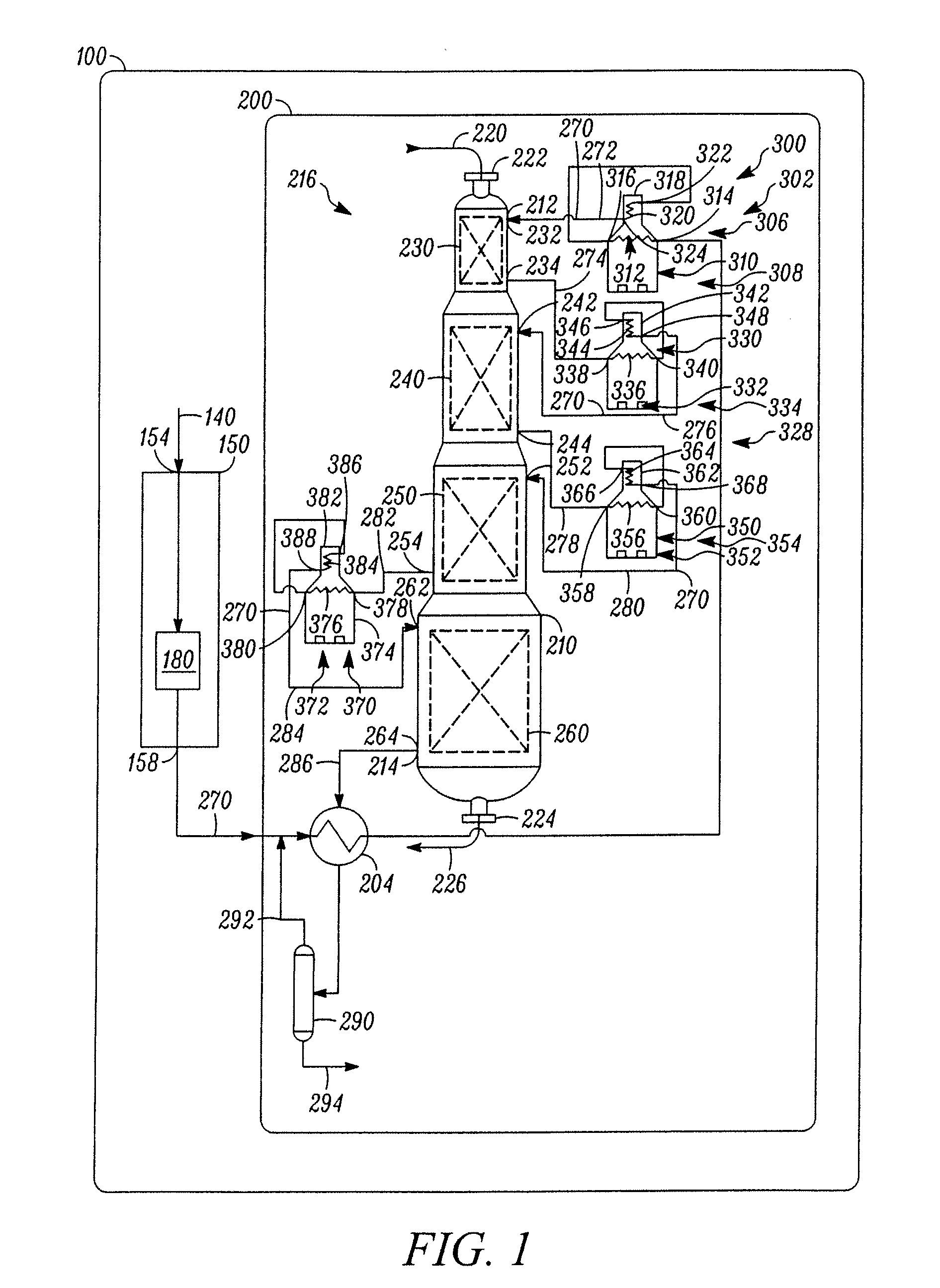

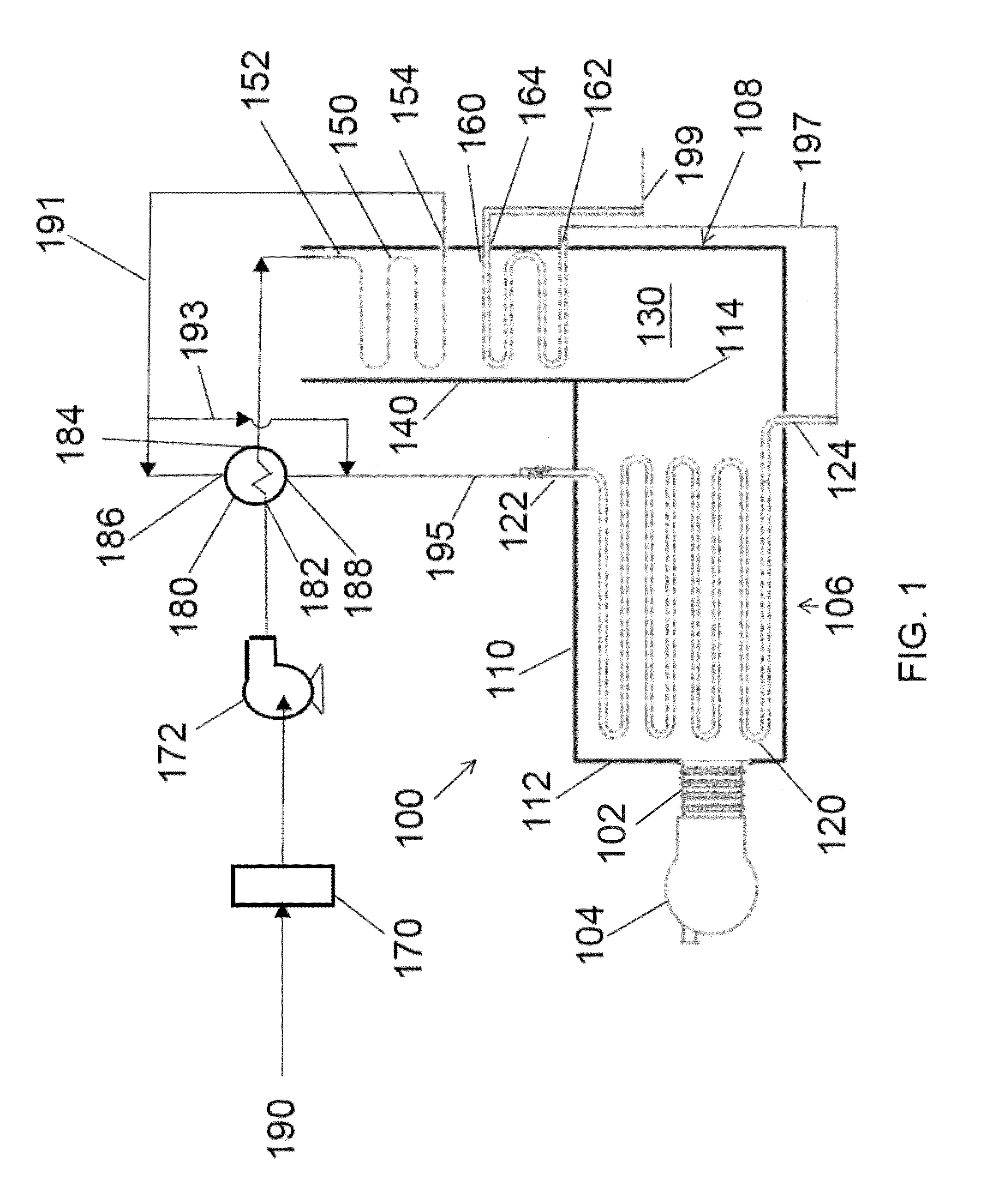

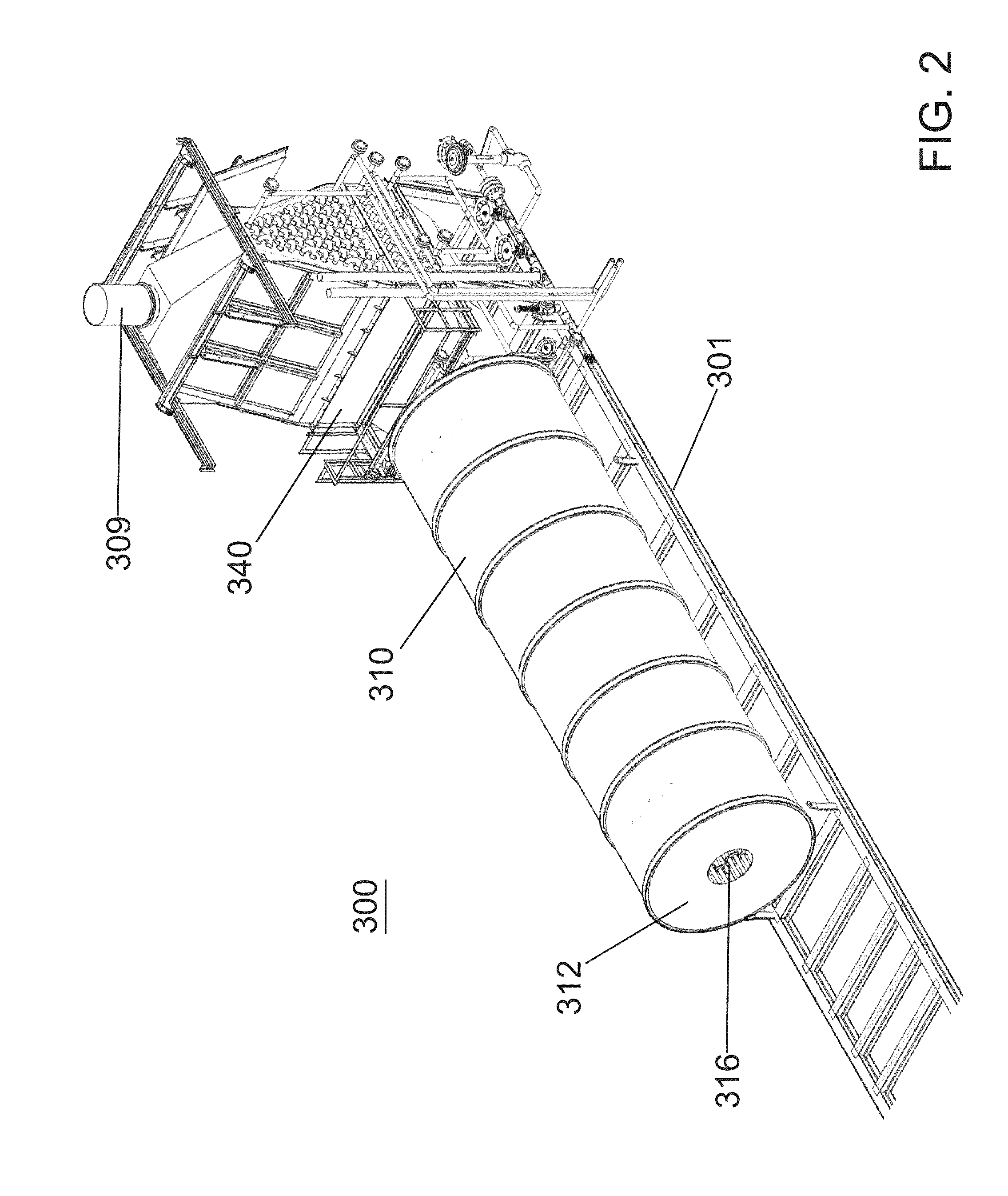

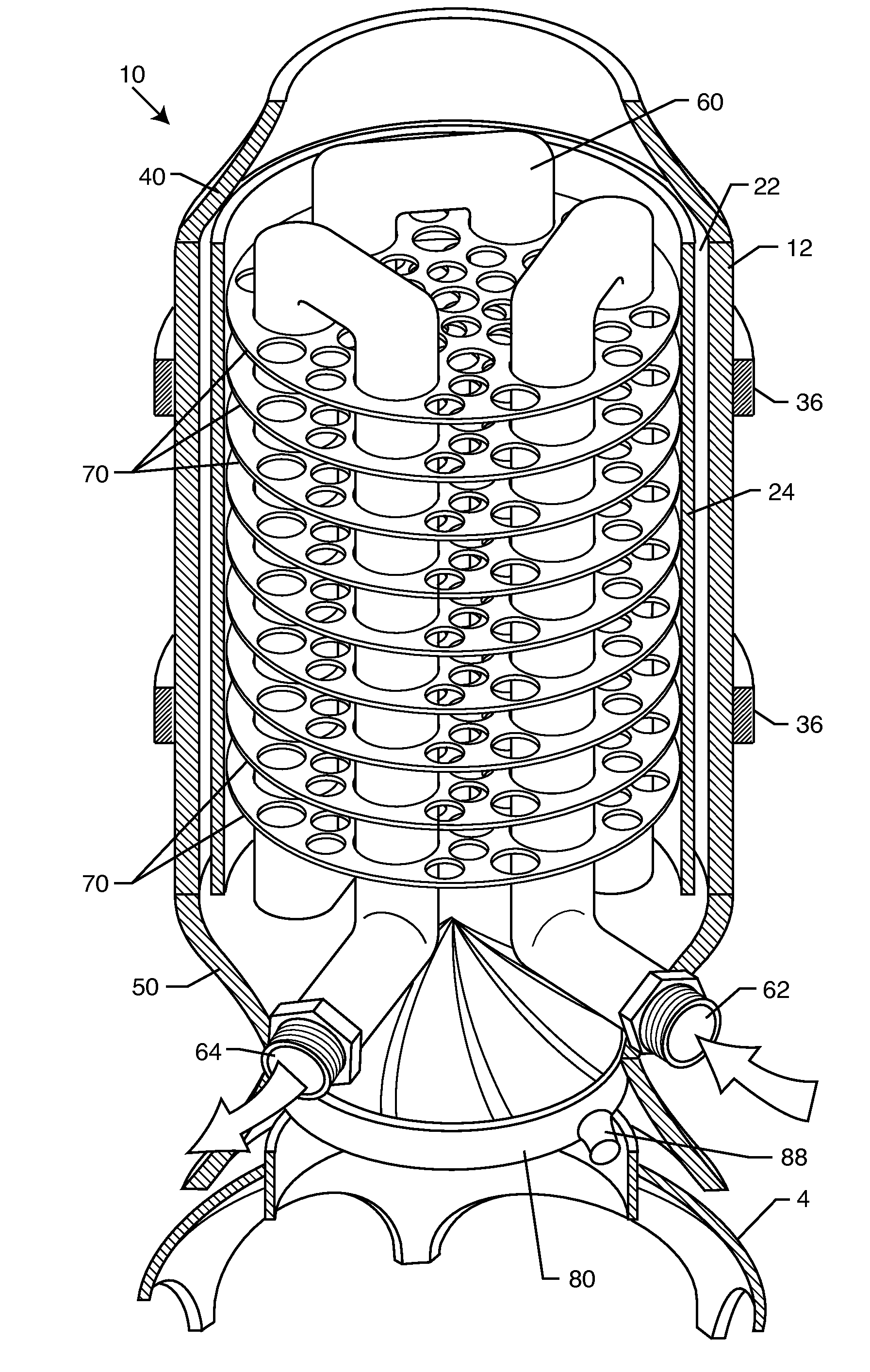

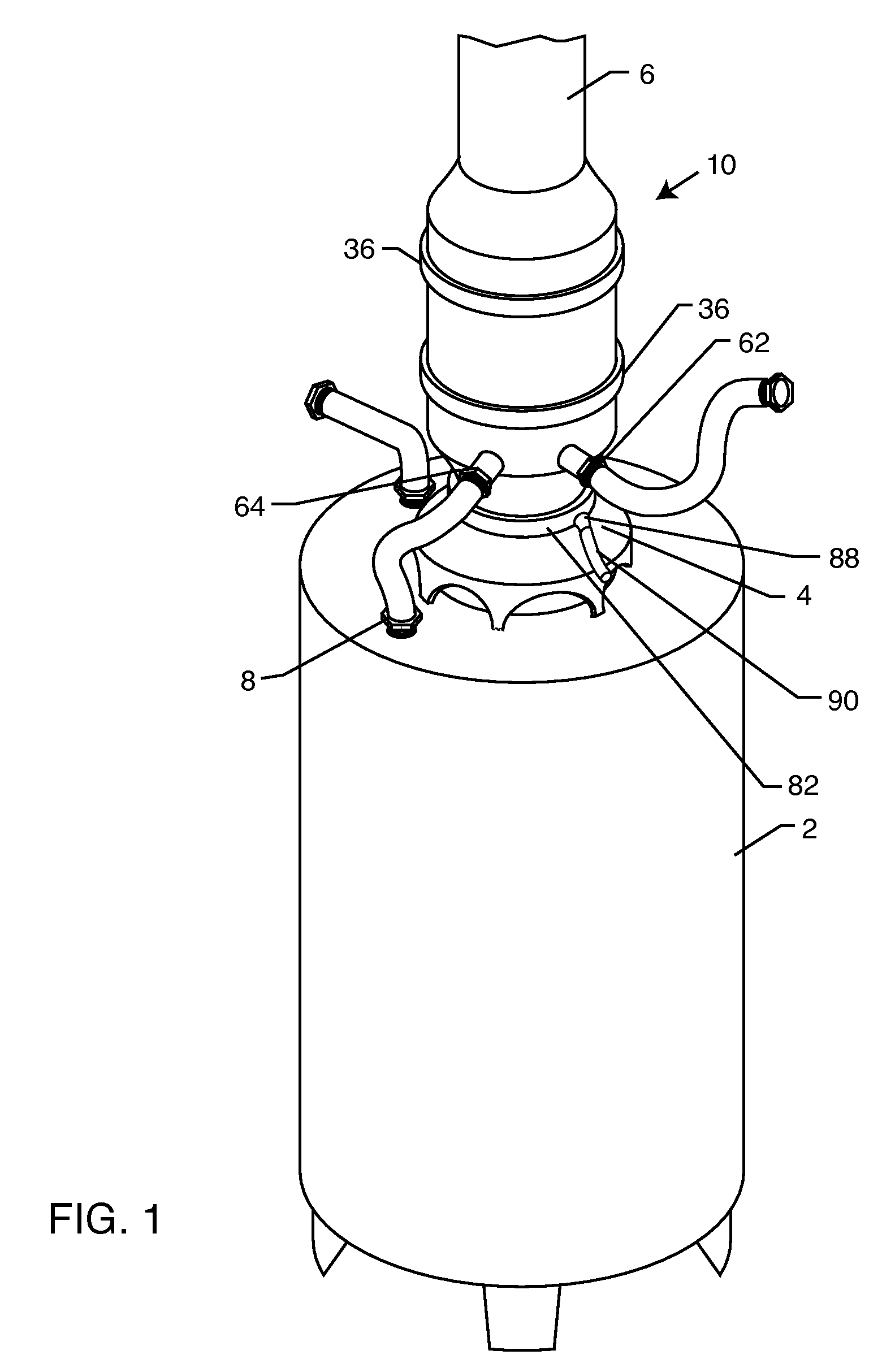

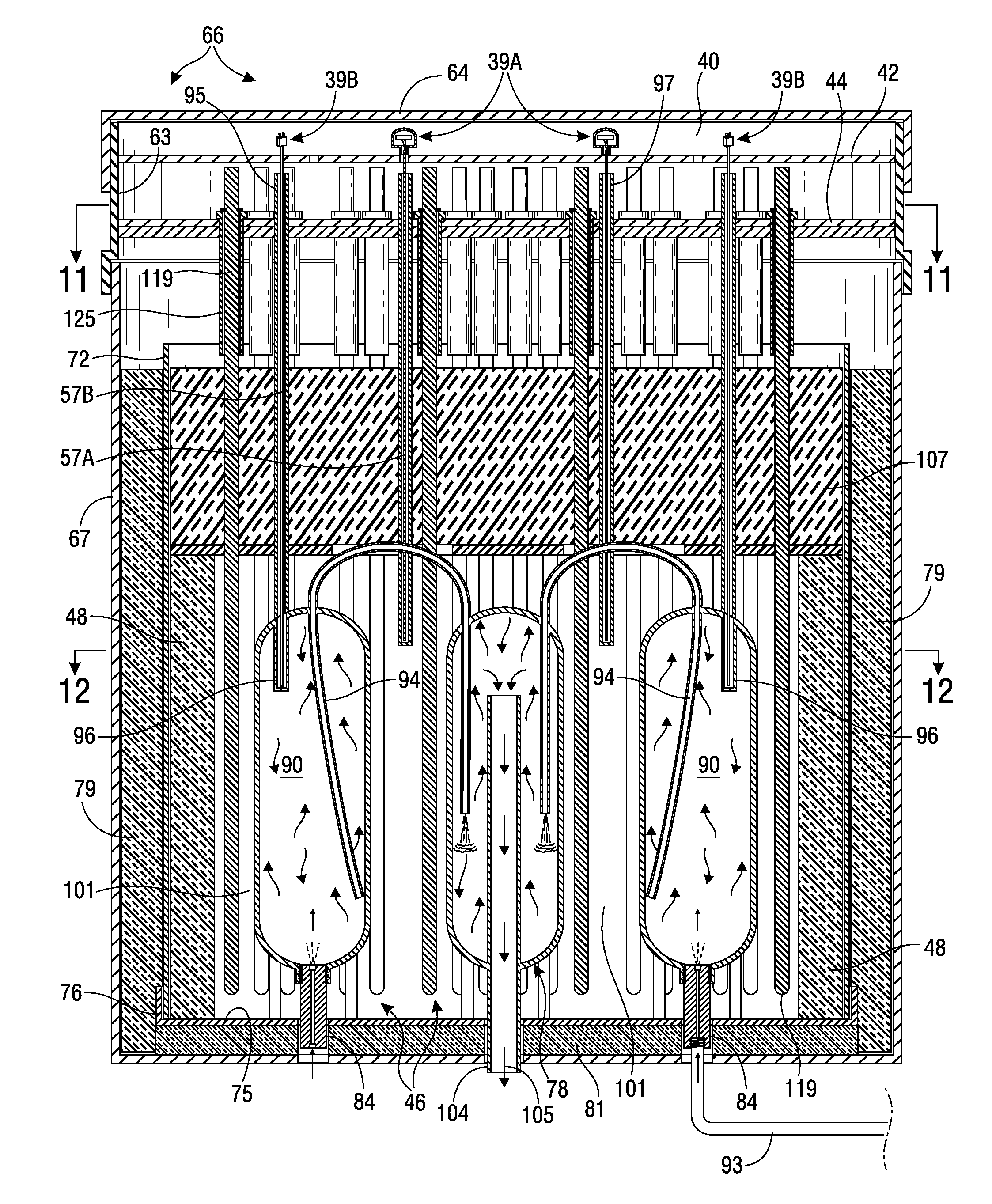

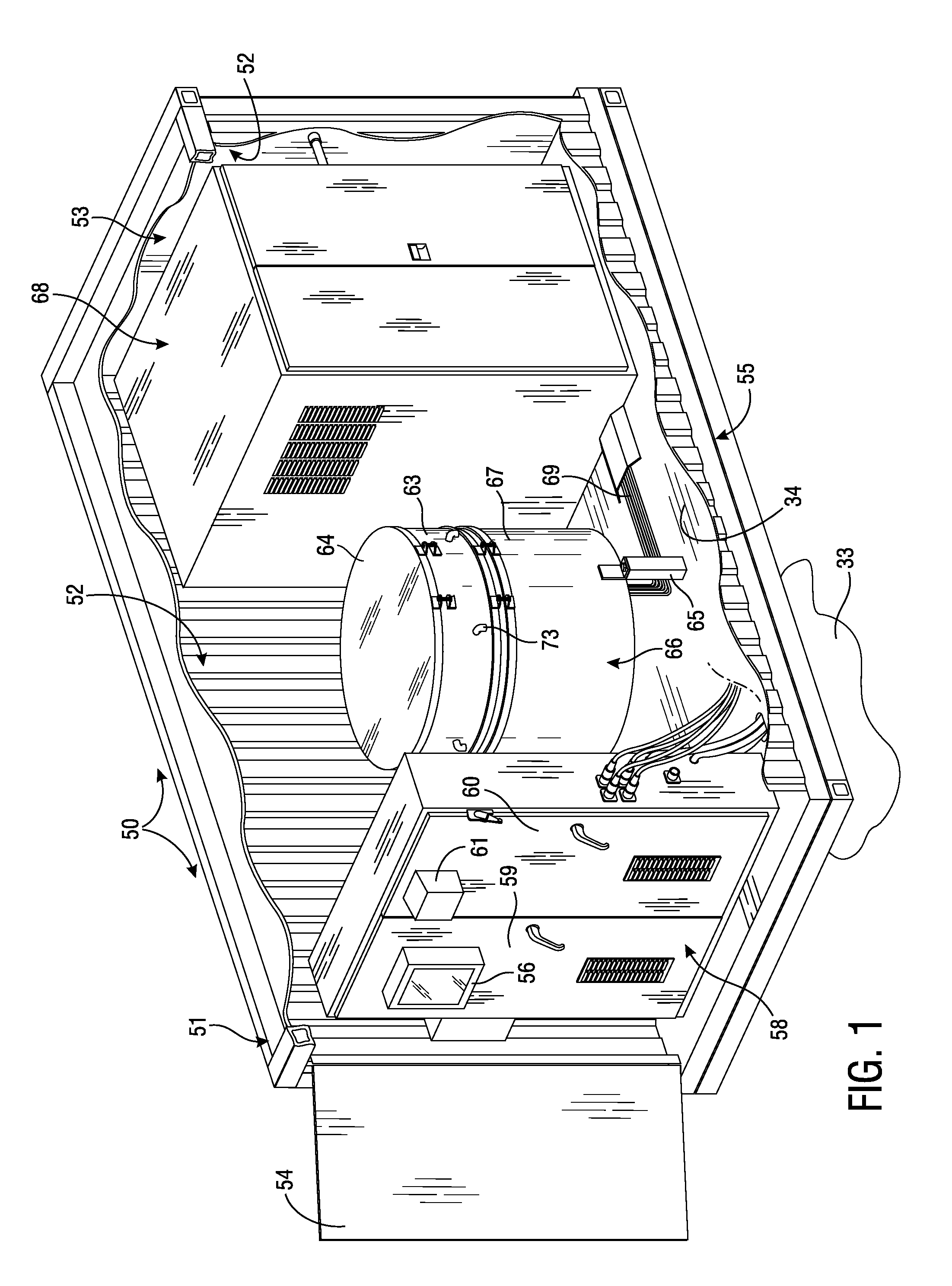

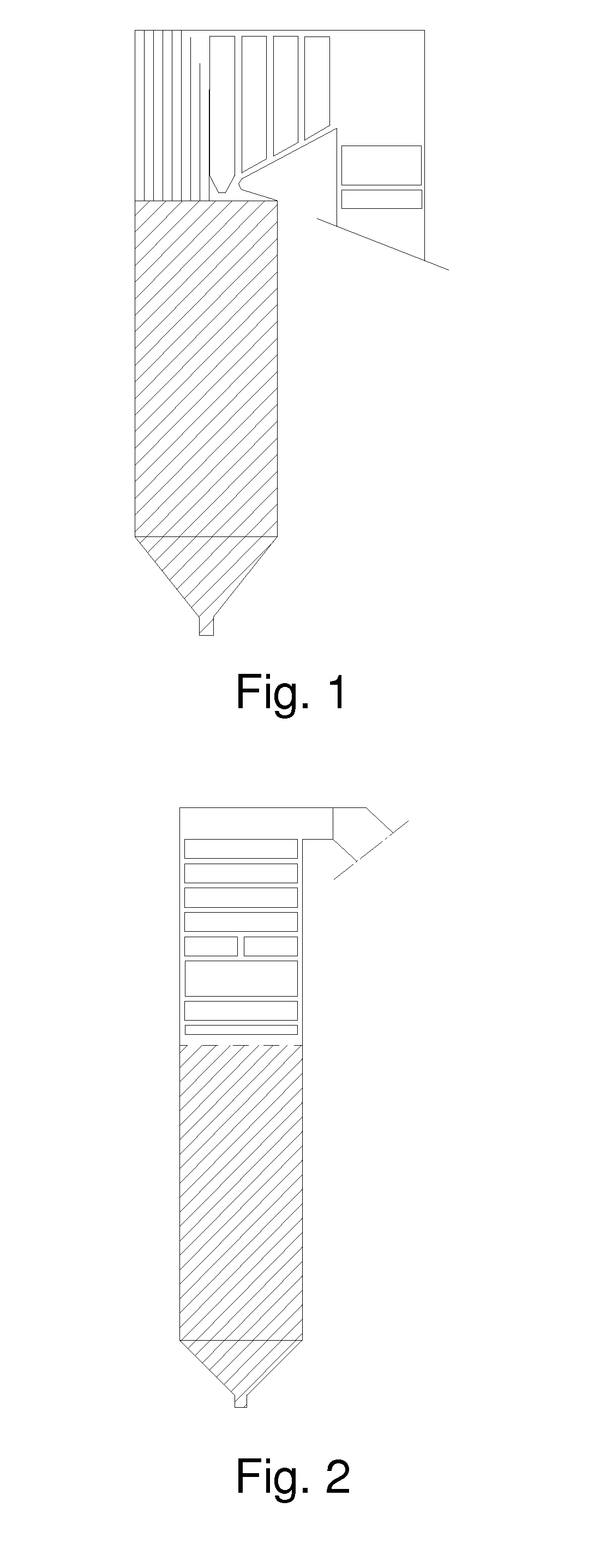

Methods for Super Heated Steam Generation

InactiveUS20130136435A1Increase superheatAccurate monitoringMachines/enginesFlash steam boilersEngineeringSuperheated steam

Modularized, superheated steam generators comprise a steam module (46), a thermocouple module (41), and an electrode module (45) assembled within a containment enclosure (66). The multi-stage steam module (46) comprises a plurality of first stage pressure vessels (77) surrounding and feeding a second stage pressure vessel (78). The steam module (46) is coaxially surrounded by insulation (48) disposed within a cylindrical shroud (72). The electrode module (45) radiantly heats the steam module with resistive heating elements (119). The thermocouple module (41) includes thermocouples monitoring first stage temperatures within and between pressure vessels (77). PLC computer SCADA software (600) operates the generators. Thermocouple data is analyzed to control heater temperatures, the water feeding system (340), and outputted steam temperature. PLC software (600) provides operating logic (602) establishing a start up subroutine (602), a ramp up subroutine (603), a steady state subroutine (605), and a shut down subroutine (606).

Owner:TRIMETEOR OIL & GAS CORP

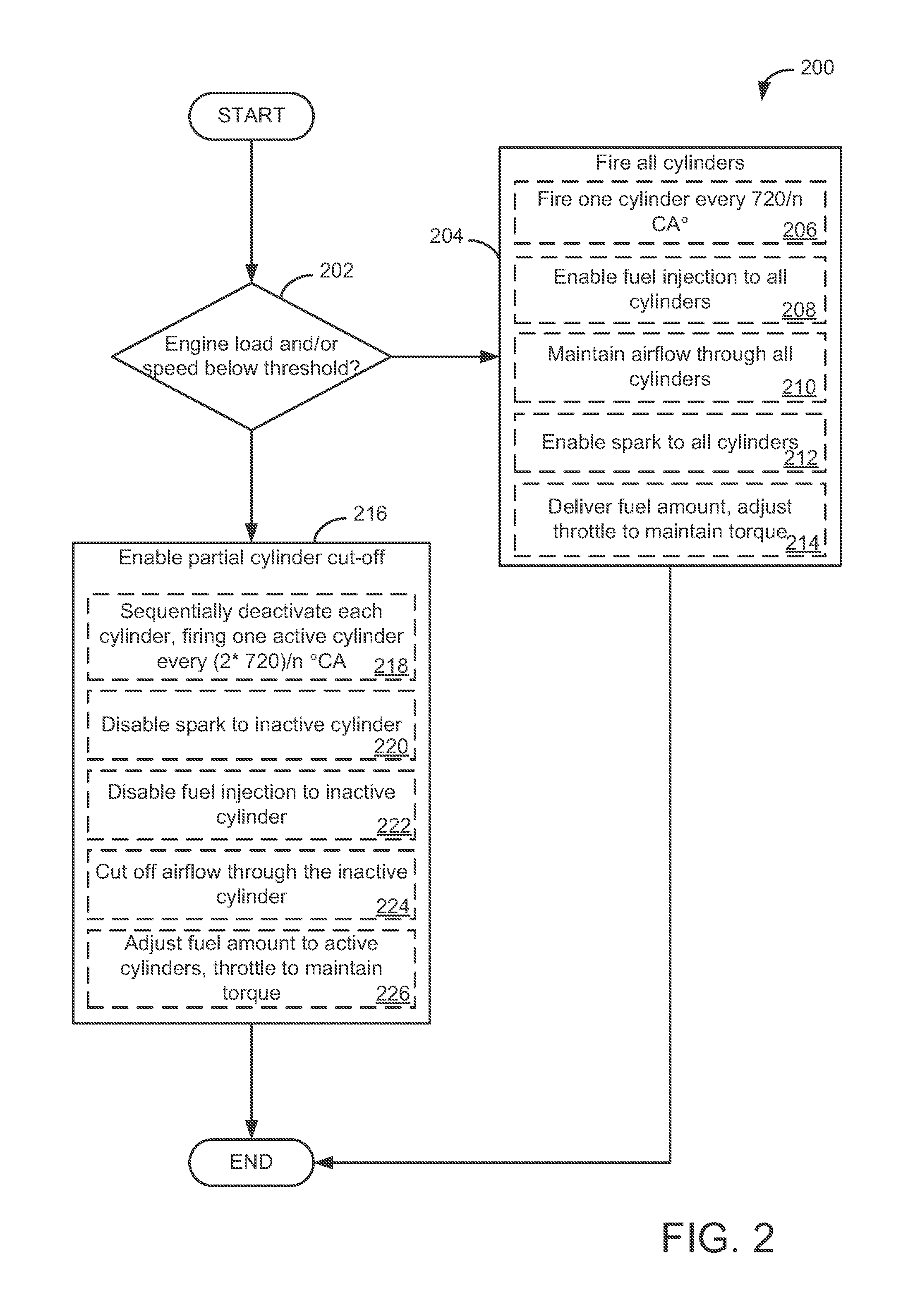

Multi-cylinder internal combustion engine and method for operating a multi-cylinder internal combustion engine

ActiveUS8944026B2Electrical controlNon-fuel substance addition to fuelExternal combustion engineEngineering

A method for partial cylinder cutoff is provided. The method comprises operating a multi-cylinder internal combustion engine with applied ignition, in which an odd number n of cylinders is arranged in line, and during partial-load operation when engine load is below threshold, enabling a partial cutoff of the cylinders, the partial cutoff comprising operating each cylinder only intermittently such that each cylinder is fired and cut off in turn at an interval of (2*720° CA) / n.

Owner:FORD GLOBAL TECH LLC

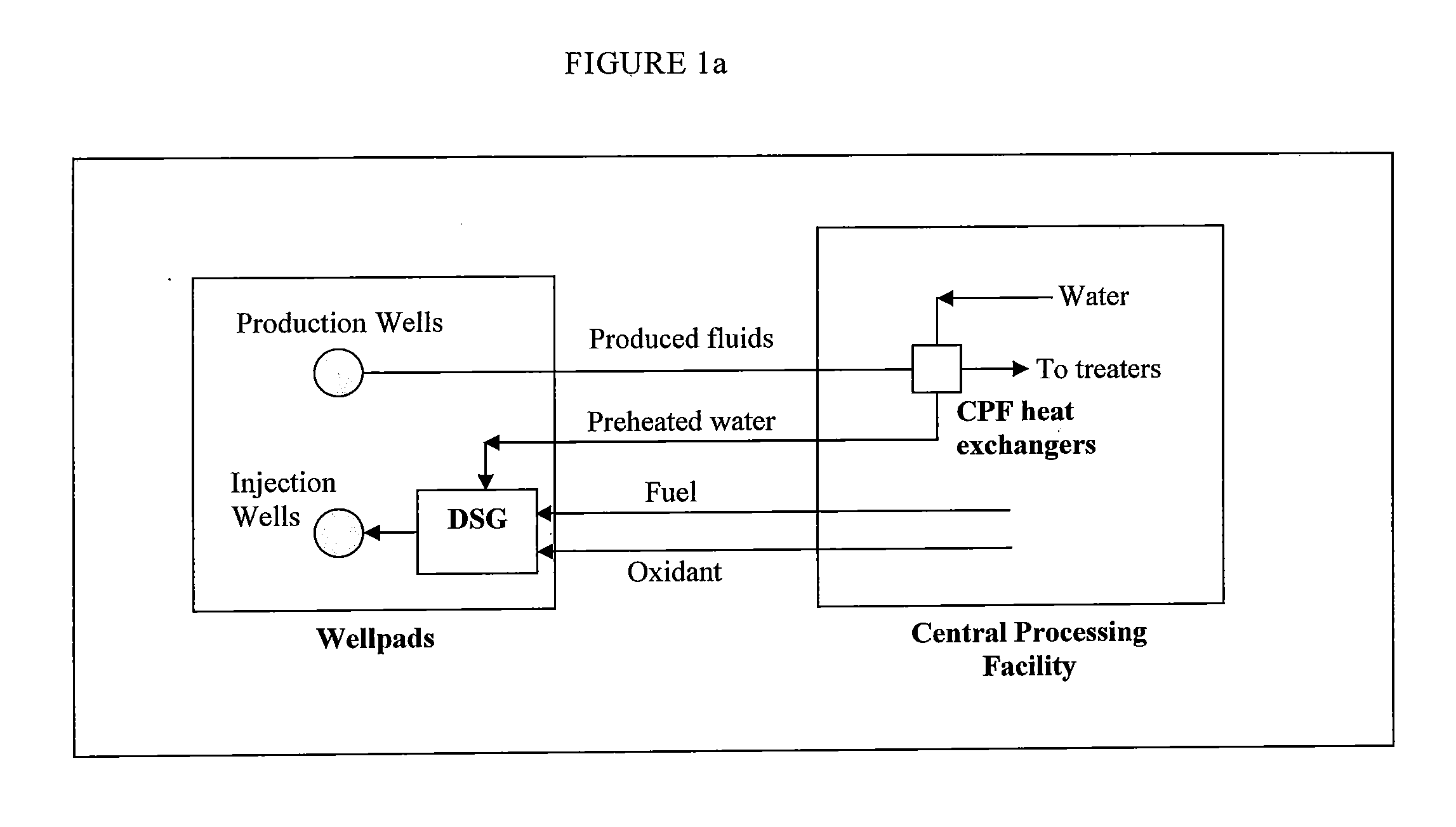

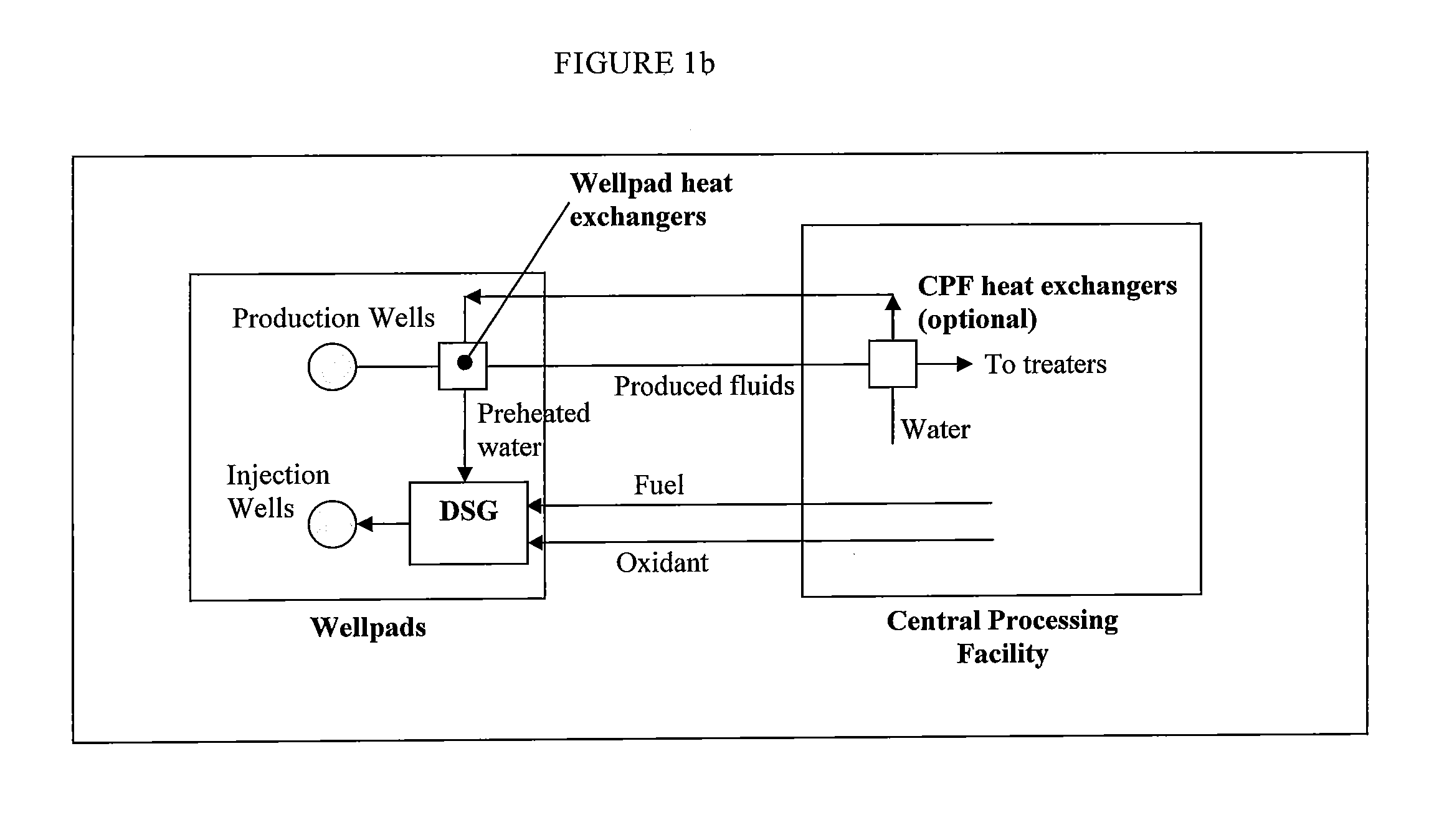

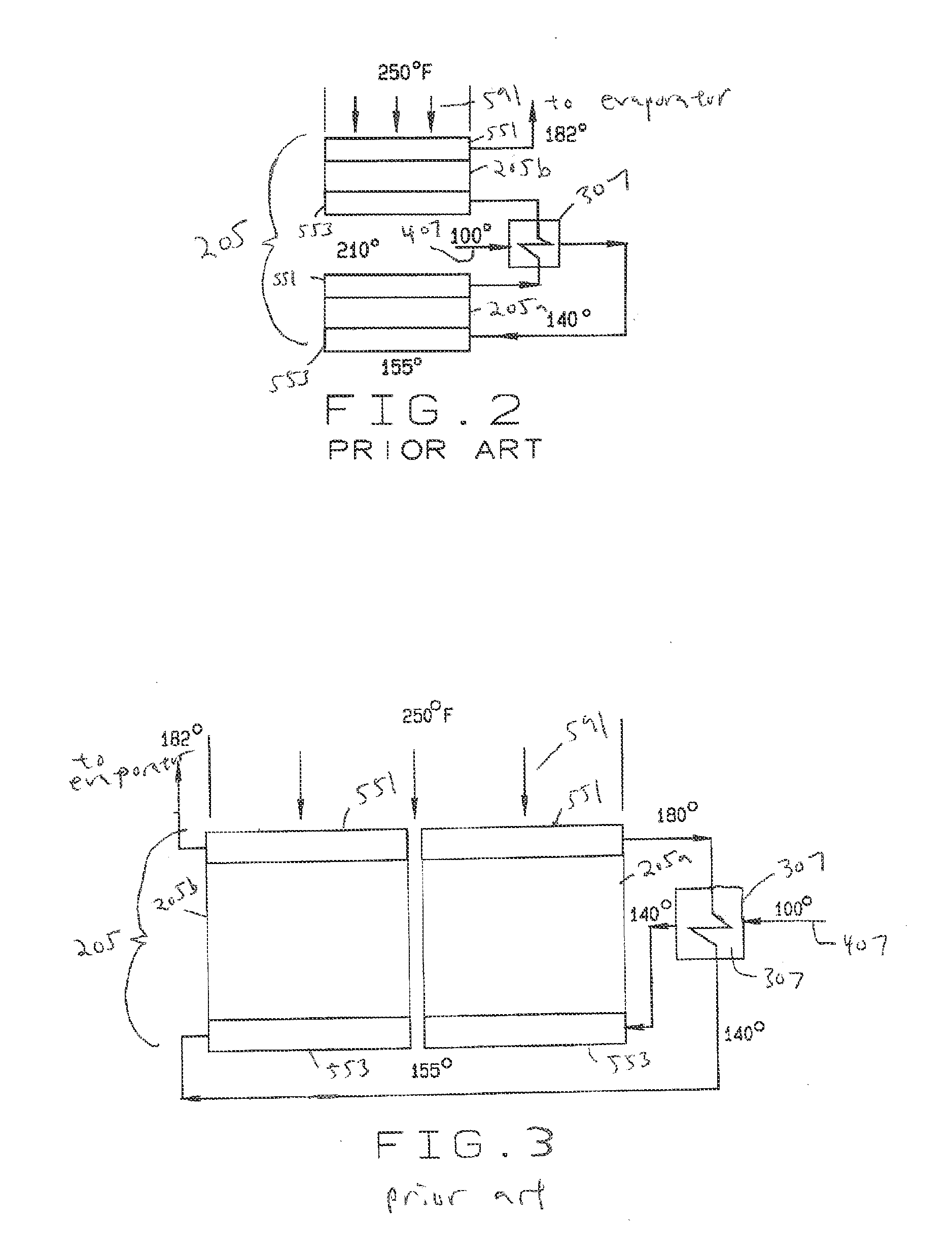

Heat recovery method for wellpad sagd steam generation

InactiveUS20130068458A1More energy can be savedCost-effectiveValve members for heating/coolingInsulationRecovery methodAs Directed

The invention provides a method of recovering heat from hot produced fluids at SAGD facilities that utilize wellpad steam generation such as Direct Steam Generators (DSG).

Owner:CONOCOPHILLIPS CO

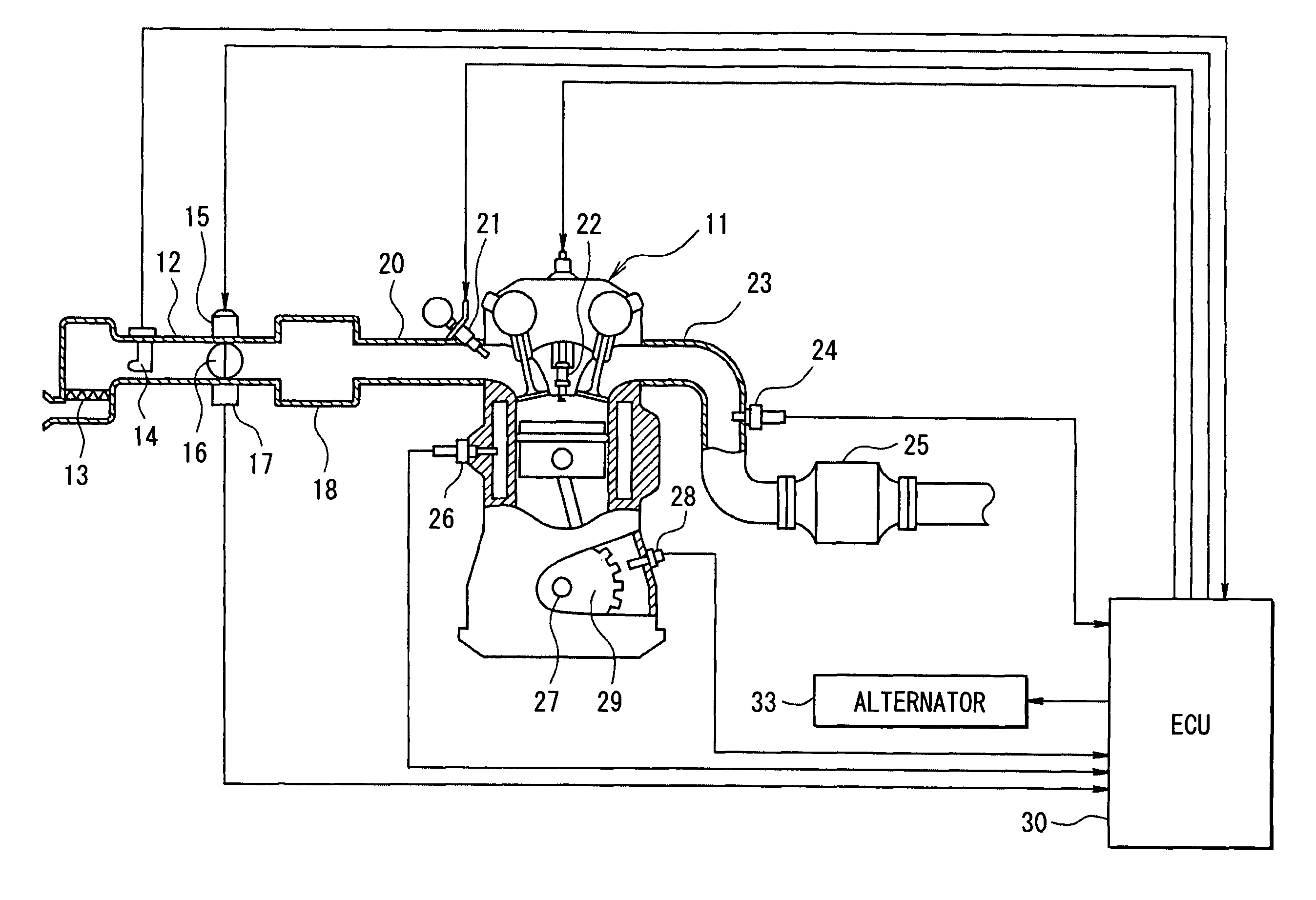

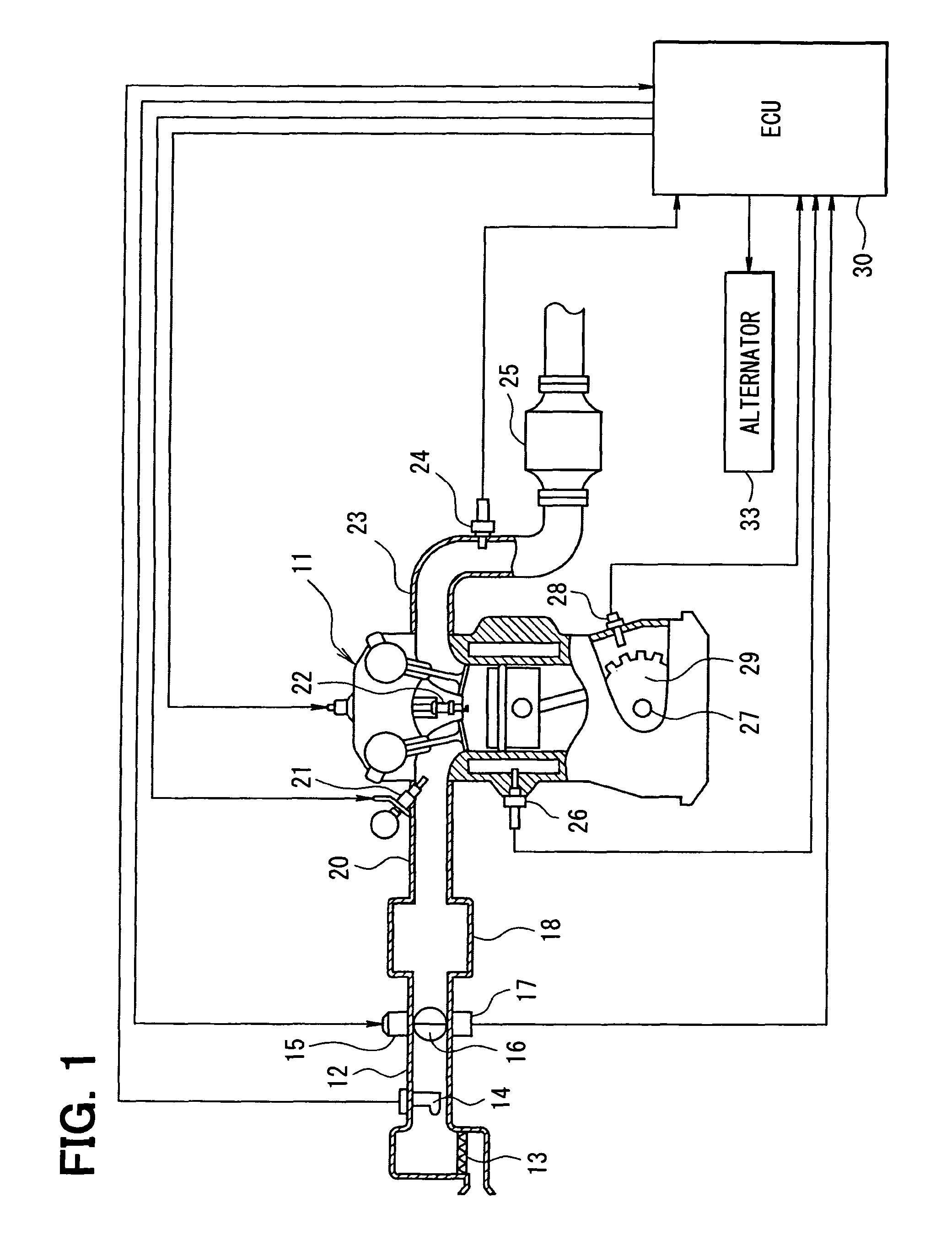

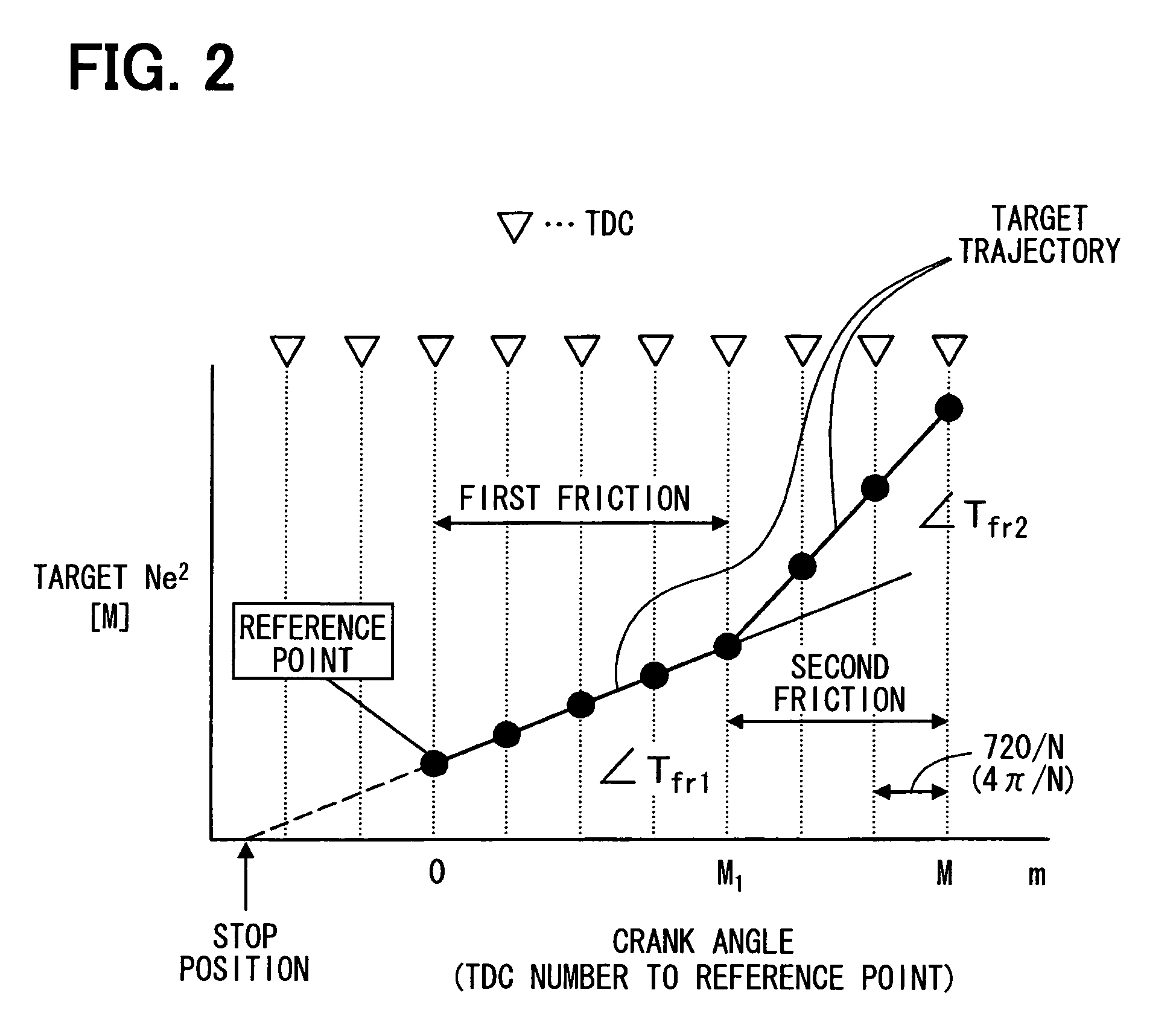

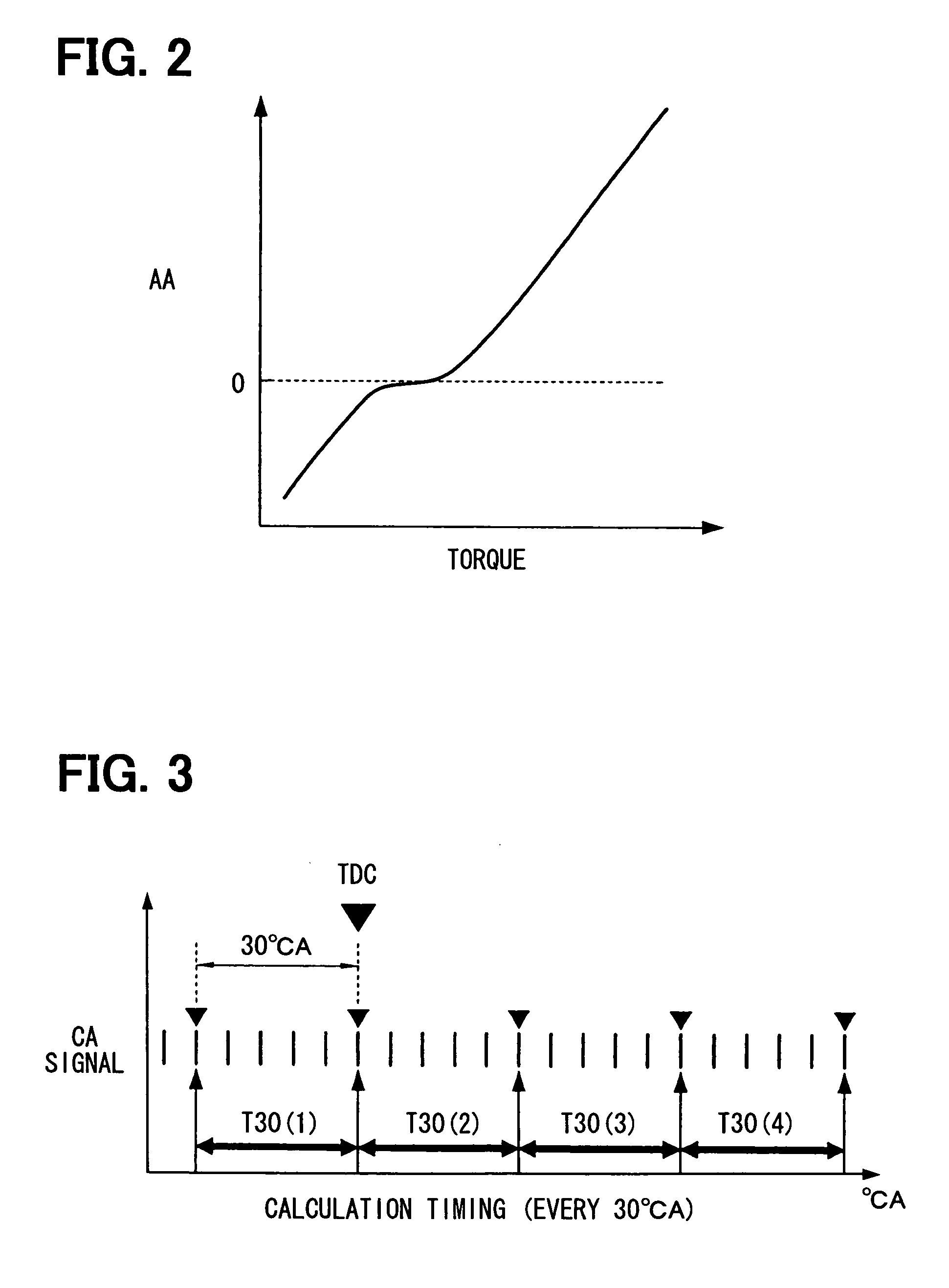

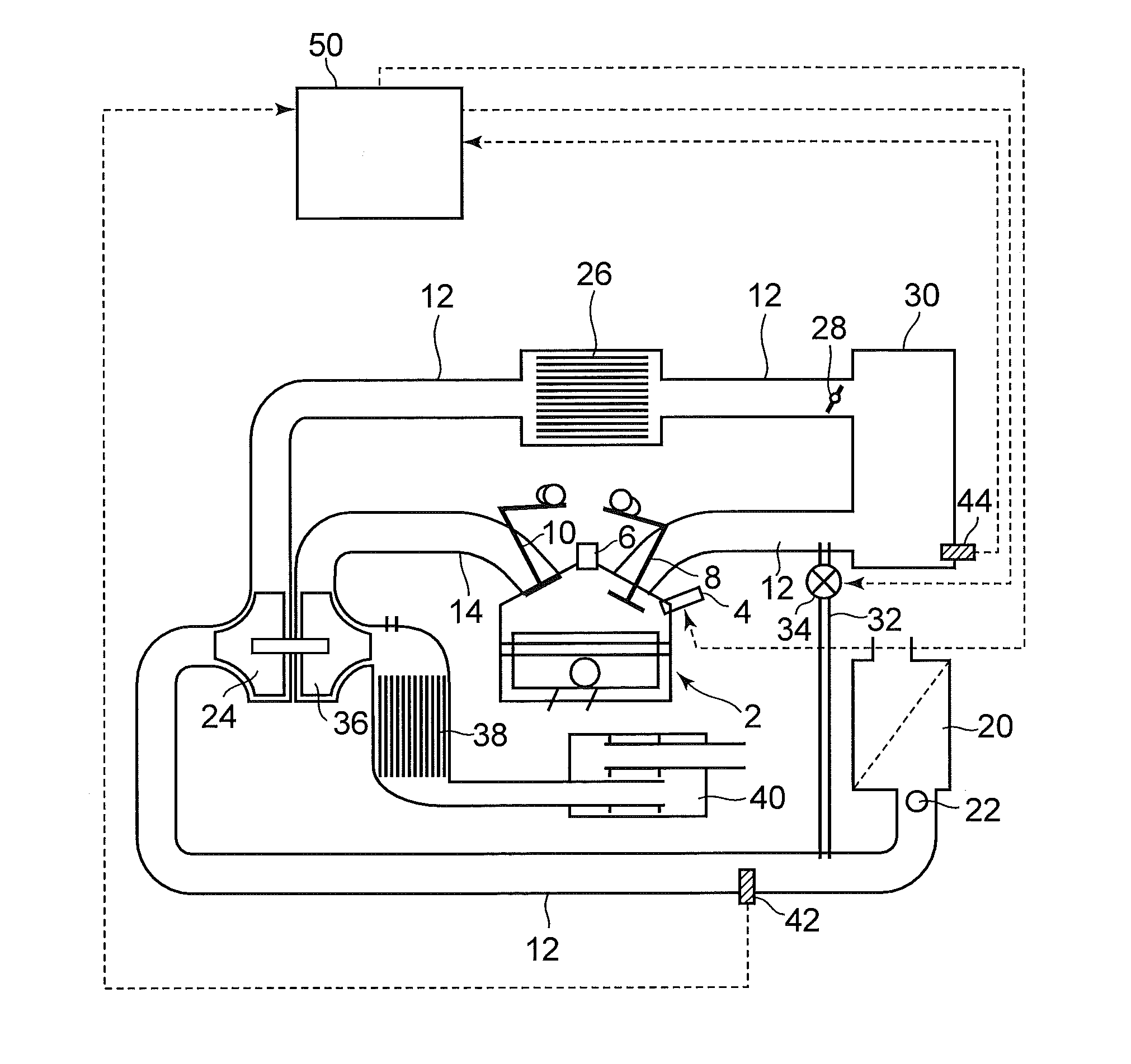

Engine automatic stop-start controller

InactiveUS7848875B2Accurate inductionAnalogue computers for vehiclesElectrical controlControl theoryFuel supply

A first ignition cylinder that performs ignition first is set based on an engine stop position in automatic start. Existence / nonexistence of a misfire in the first ignition cylinder is determined based on whether a difference ΔNe between engine rotation speed at a predetermined crank angle in an interval from timing immediately before the ignition to timing immediately after the ignition of the first ignition cylinder (e.g., at TDC of first ignition cylinder) and engine rotation speed at a predetermined crank angle before ignition of a second ignition cylinder (e.g., at TDC of second ignition cylinder) is equal to or smaller than a predetermined misfire determination threshold value Nef. When misfire time number of the first ignition cylinder exceeds a predetermined value, fuel supply to the first ignition cylinder is prohibited and the automatic start is started from the second ignition cylinder.

Owner:DENSO CORP

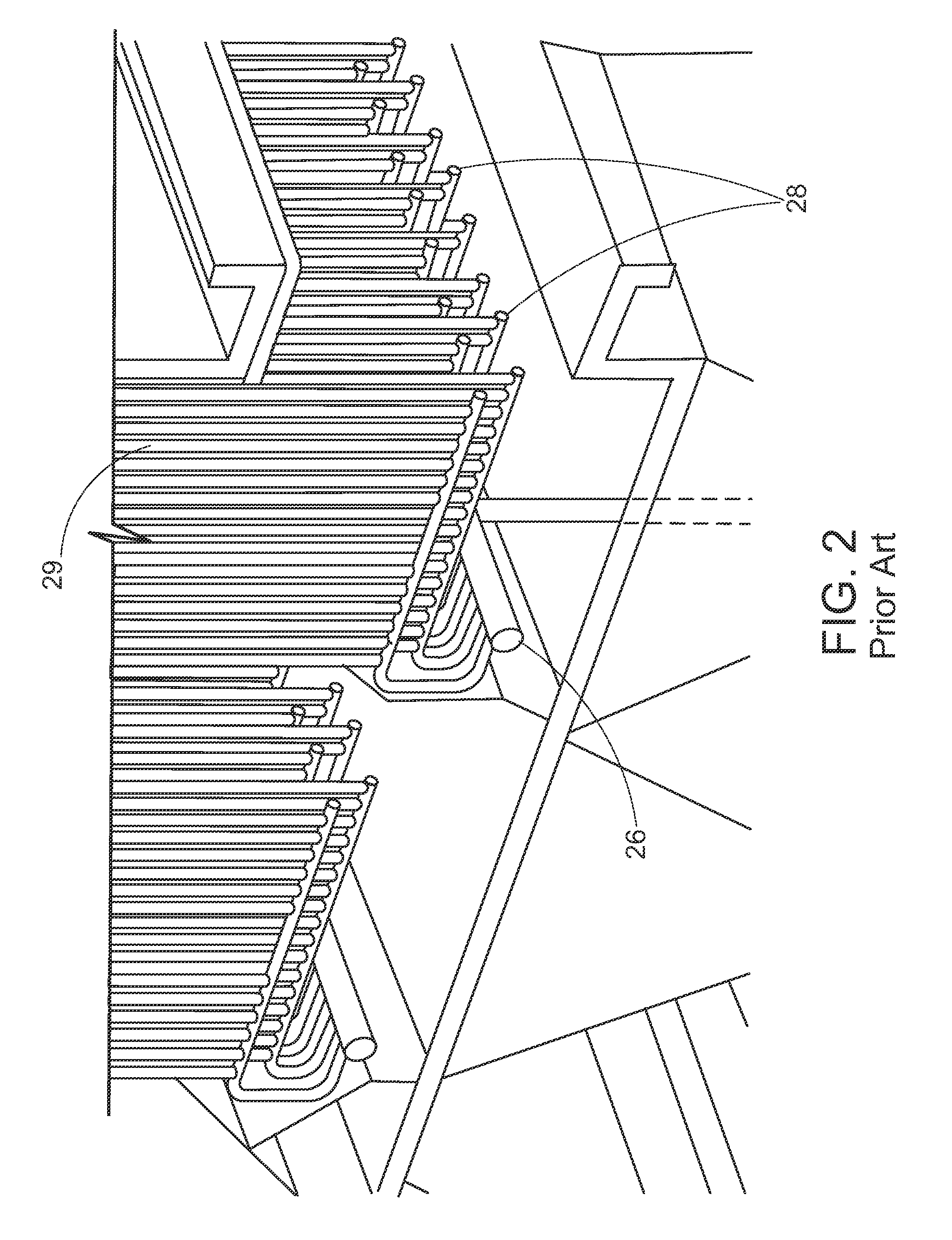

Fired heater for a hydrocarbon conversion process

ActiveUS8282814B2Low costShorten the timeThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonEngineeringInlet manifold

One exemplary embodiment of the present invention can be a fired heater for a hydrocarbon conversion process. The fired heater includes inlet and outlet headers or manifolds, a set of heater tubes with each heater tube having an inlet and an outlet, at least one restriction orifice adjacent the inlet of at least one heater tube. The restriction orifice may be within the inlet manifold and adjacent the inlet of a heater tube, or between the inlet manifold and the inlet to the heater tube. A process may include passing a hydrocarbon stream through the fired heater described herein during the course of operating a hydrocarbon conversion process.

Owner:UOP LLC

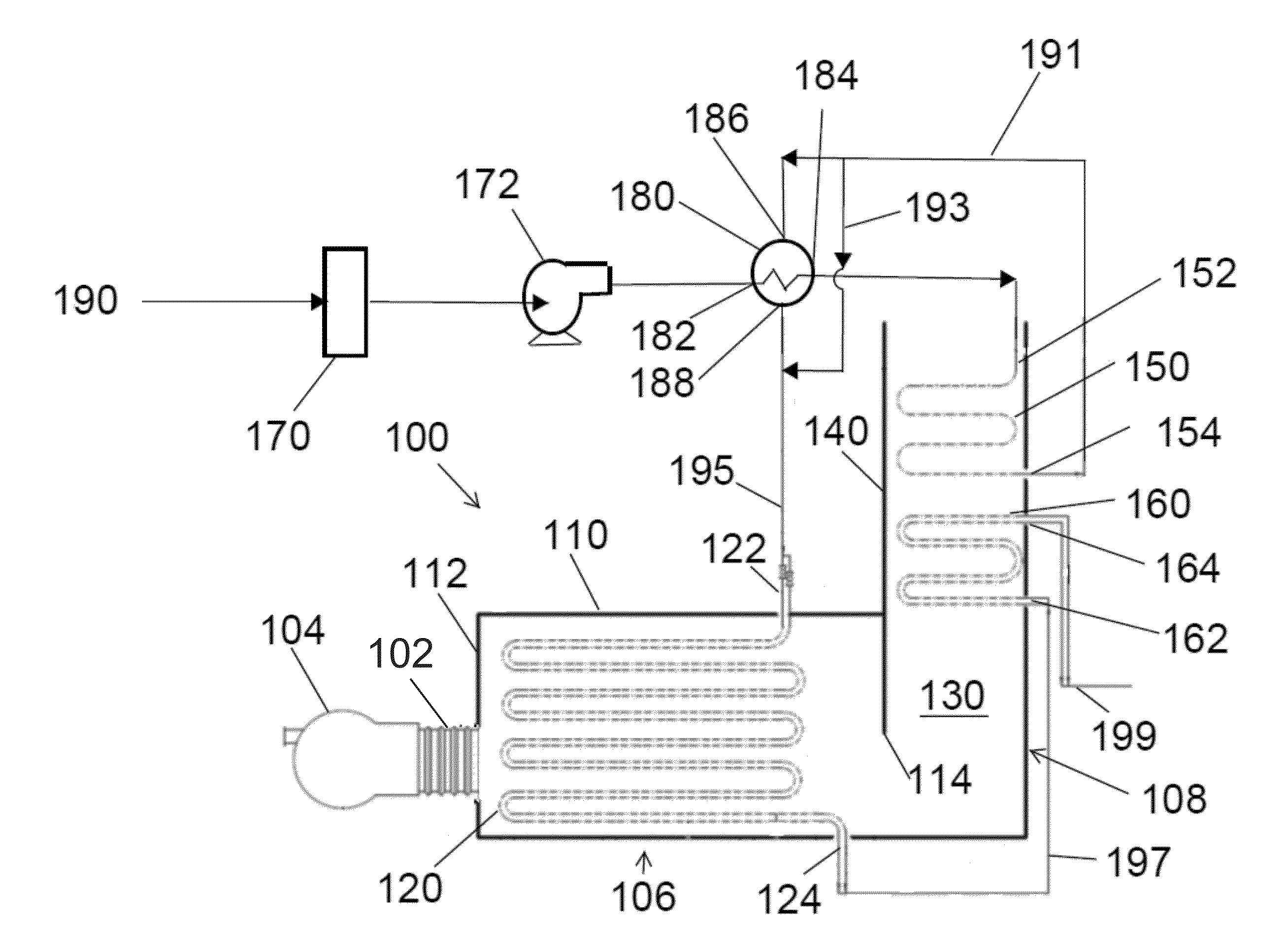

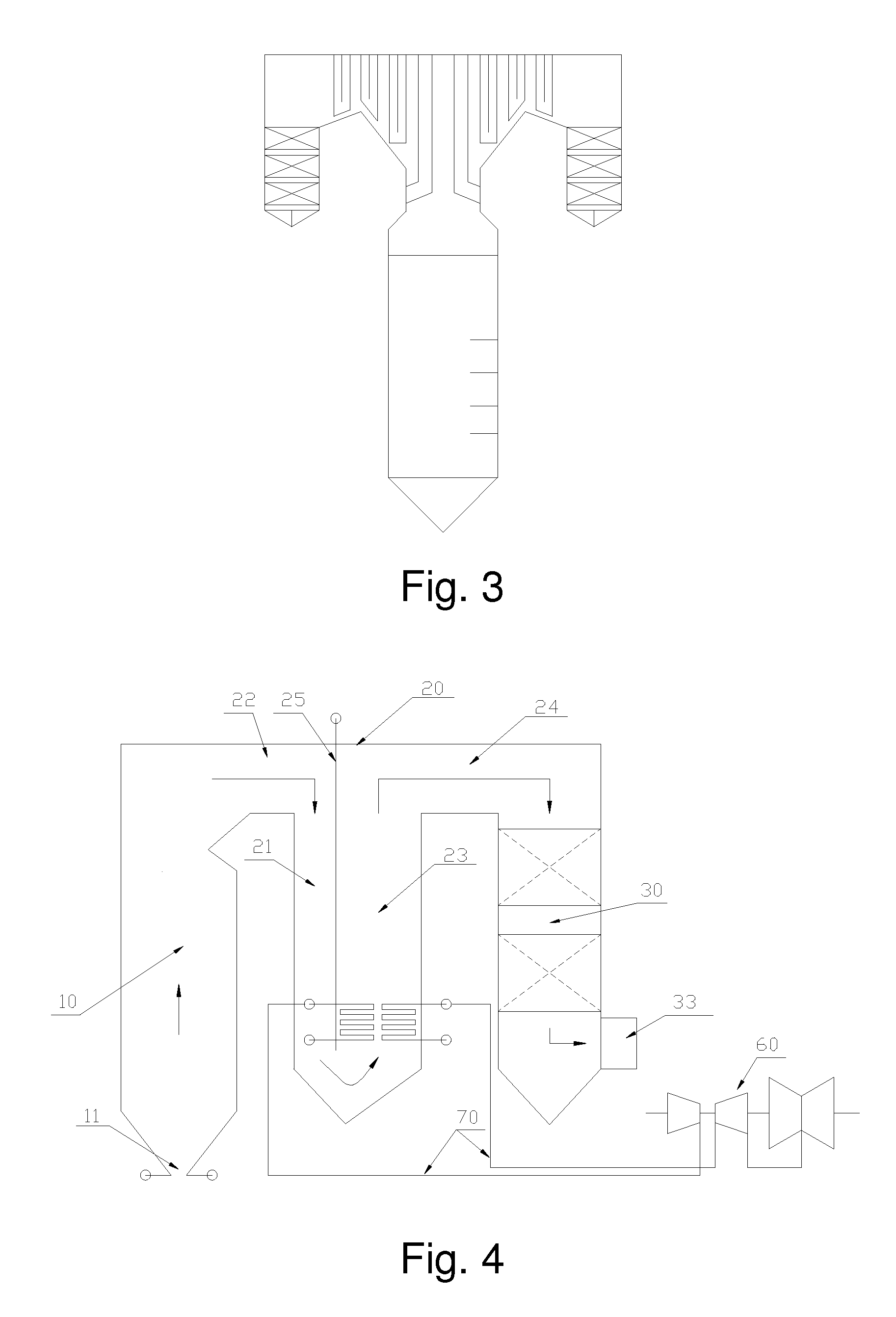

Small supercritical once-thru steam generator

A small supercritical once-through steam generator (OTSG) includes a radiant section with a furnace coil, and a convection section downstream of the radiant section that includes a superheater which is fluidically connected to the furnace coil. Optionally, the OTSG is devoid of a steam separator. An economizer can also be included downstream of the superheater. Supercritical steam can be generated using the OTSG, for use, among other things, in enhanced oil recovery applications.

Owner:THE BABCOCK & WILCOX CO

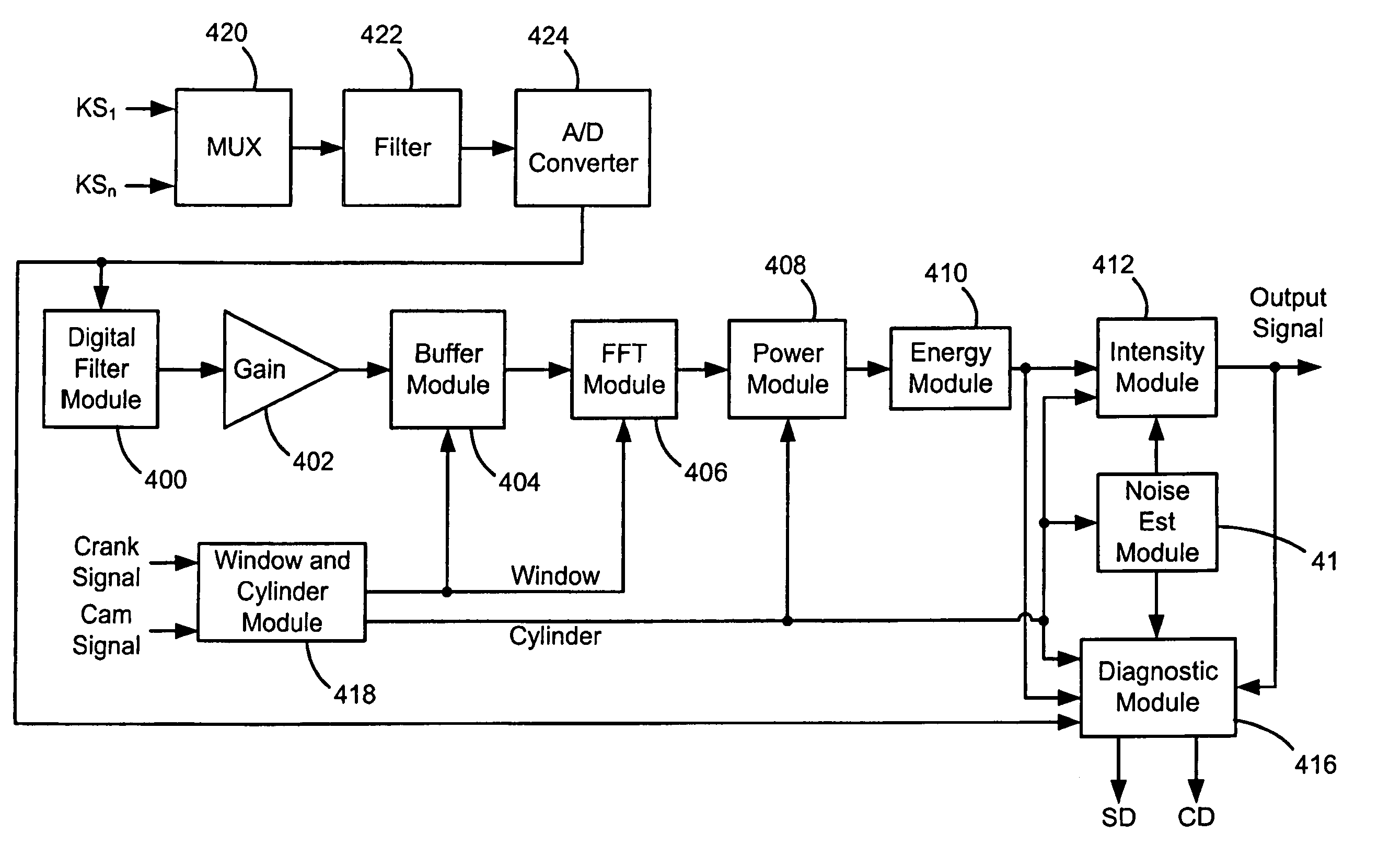

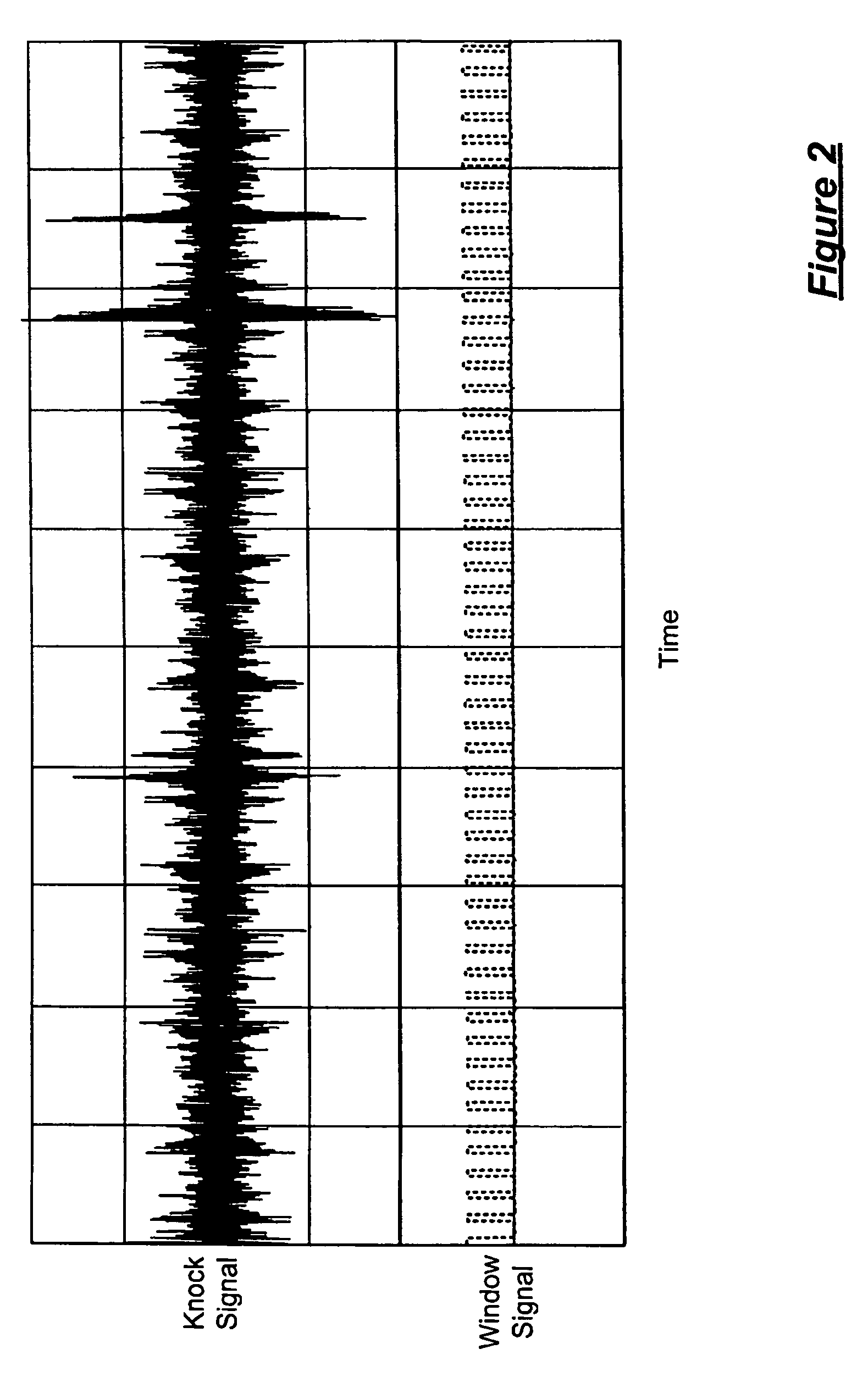

DSP-based engine knock detection including knock sensor and circuit diagnostics

ActiveUS7222607B2Internal combustion piston enginesEngine controllersEnergy basedAutomotive engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

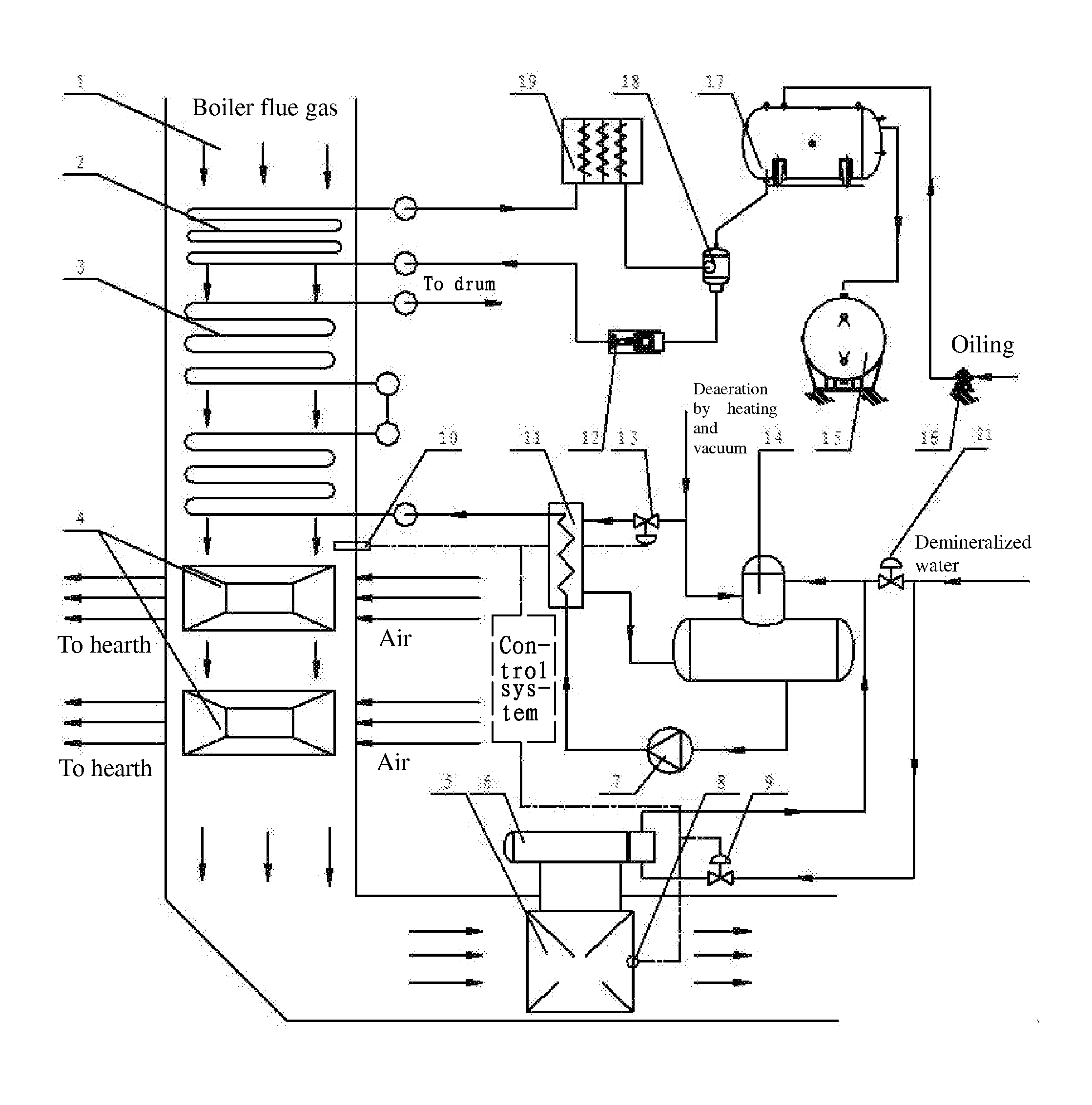

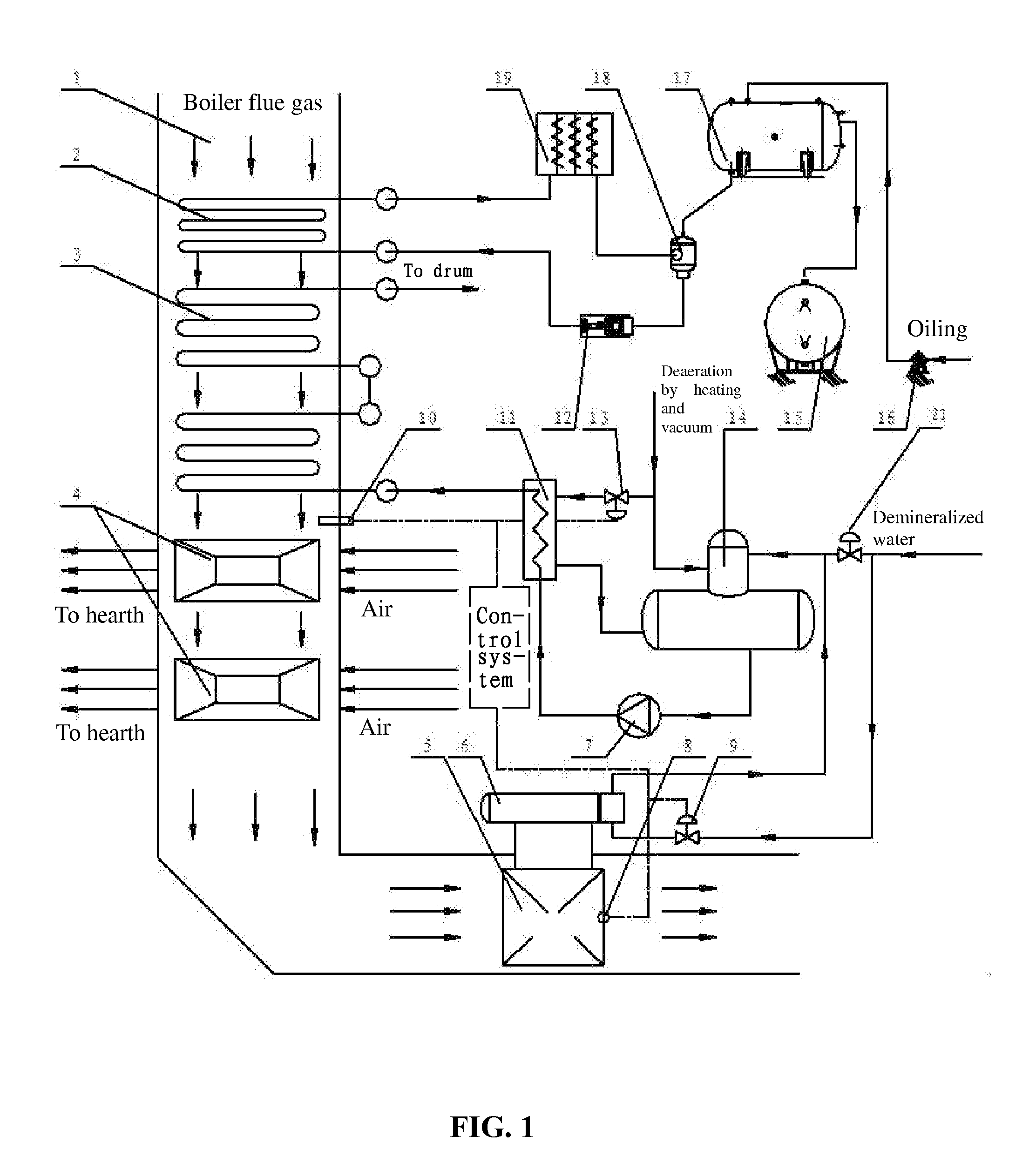

Heating system for heating heat-transfer oil usingboiler flue gas

InactiveUS20140007823A1Efficient outputLower furnace temperatureIndirect heat exchangersMachines/enginesAir preheaterFlue gas

A heating system for heating heat-transfer oil using exhaust heat of boiler flue gas. The system includes: a flue, an economizer, an air preheater, and a heat-transfer oil heater. The economizer and the air preheater are disposed in the flue along the flow direction of the flue gas. The heat-transfer oil heater is disposed inside the flue in front of the economizer and is connected to a heat consumption device via a first circulating pipe. The circulating pipe is equipped with a circulating pump.

Owner:SHANGHAI FUBO ENVIRONMENTAL PROTECTION EQUIP

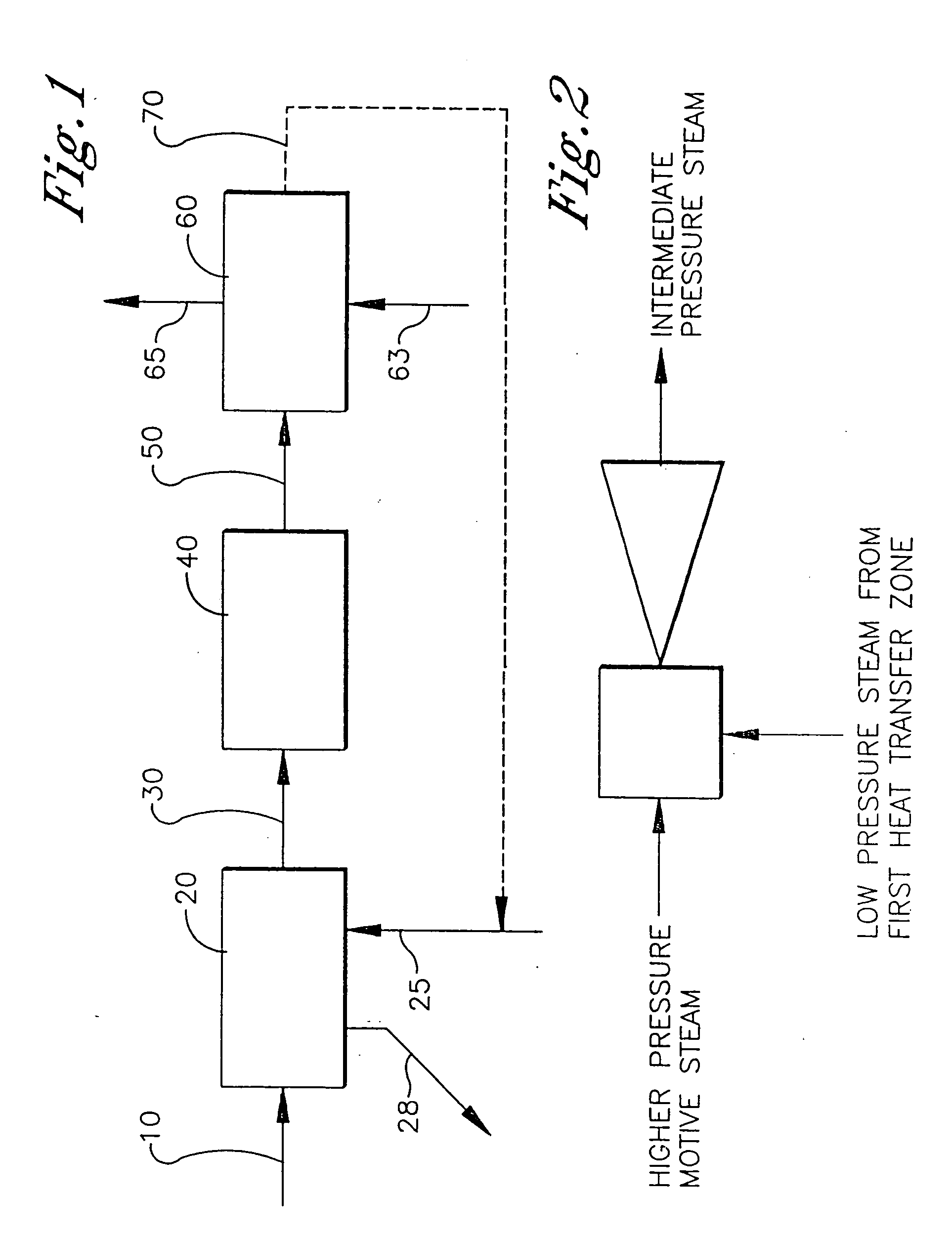

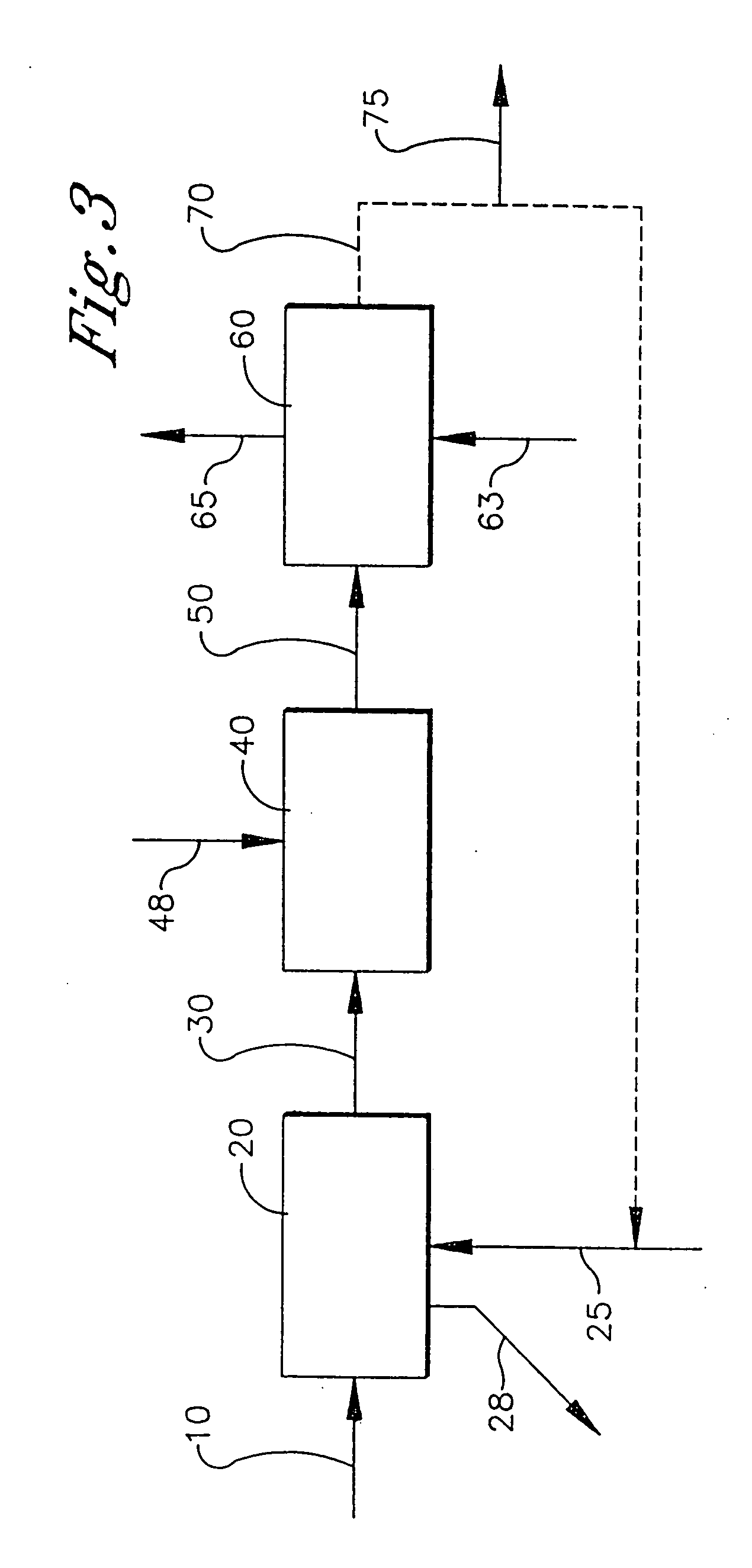

Steam recompression in carboxylic acid processes

Disclosed is a method for the re-compression of process generated steam to create a higher pressure steam that is useful as a heating medium in other parts of a carboxylic acid production process or, in general utilized in another process. The invention comprises the following basic steps: (a) recovering thermal energy from at least a portion of the high temperature process stream resulting from an aromatic carboxylic acid production process in a first heat transfer zone to produce a low pressure stream; (b) subjecting the low pressure steam to a compression zone to generate an intermediate pressure steam; (c) utilizing the intermediate pressure steam as a heating medium, specifically within other parts of the carboxylic acid process or generally in another process thereby generating steam condensate; and (d) optionally, recycling all or part of the steam condensate to the second heat transfer zone for low pressure steam generation.

Owner:ALPEK POLYESTER SA DE CV

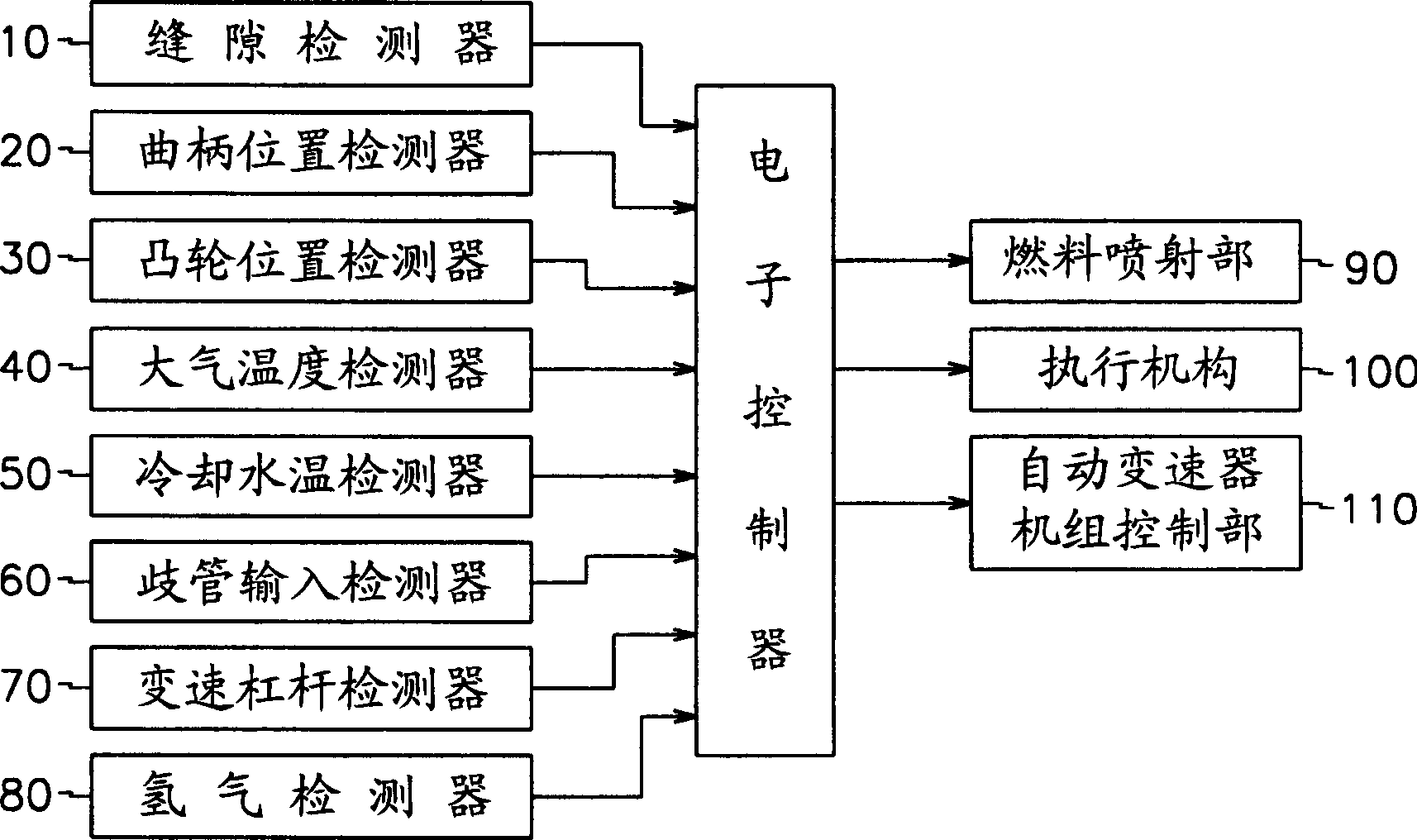

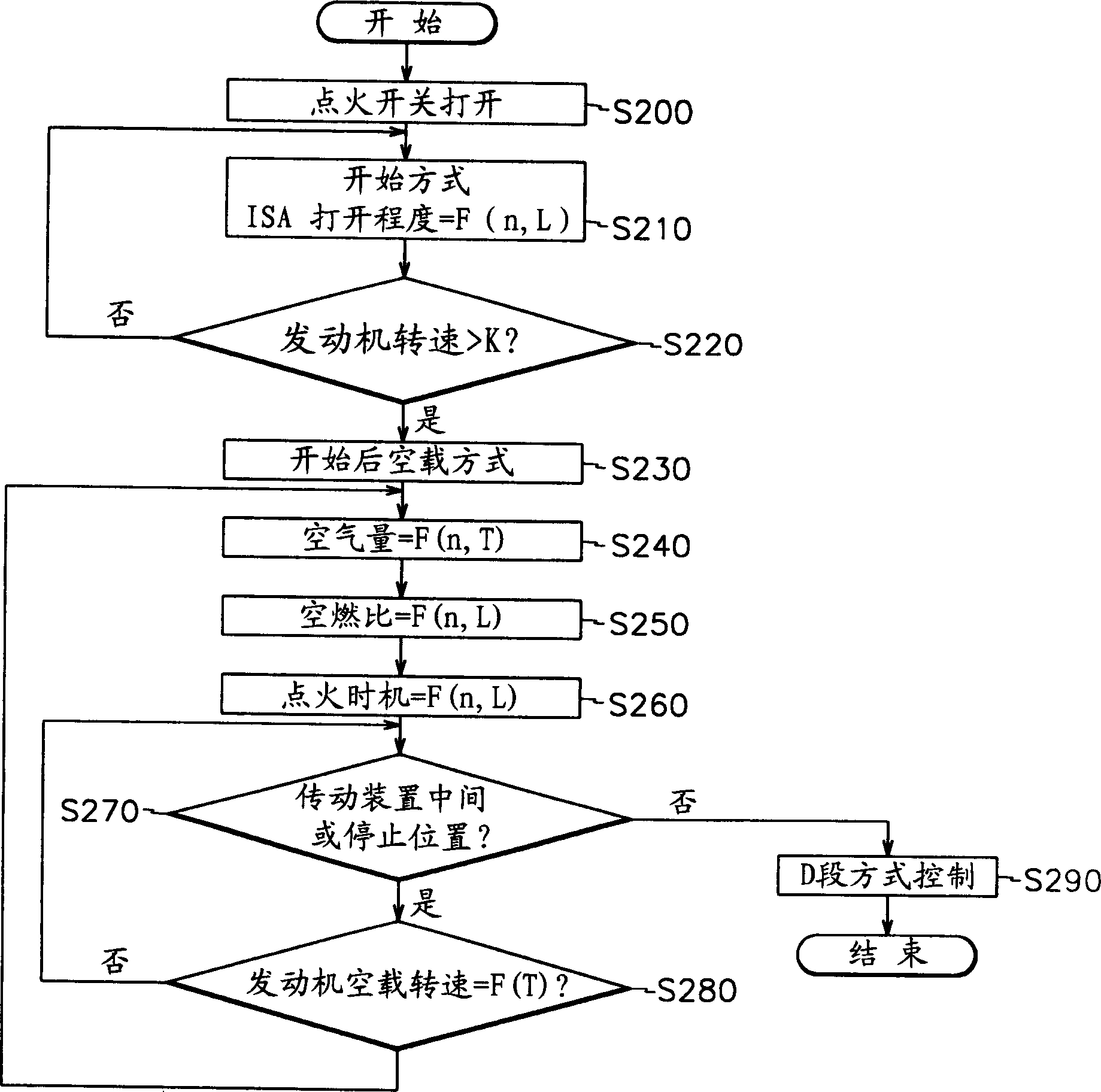

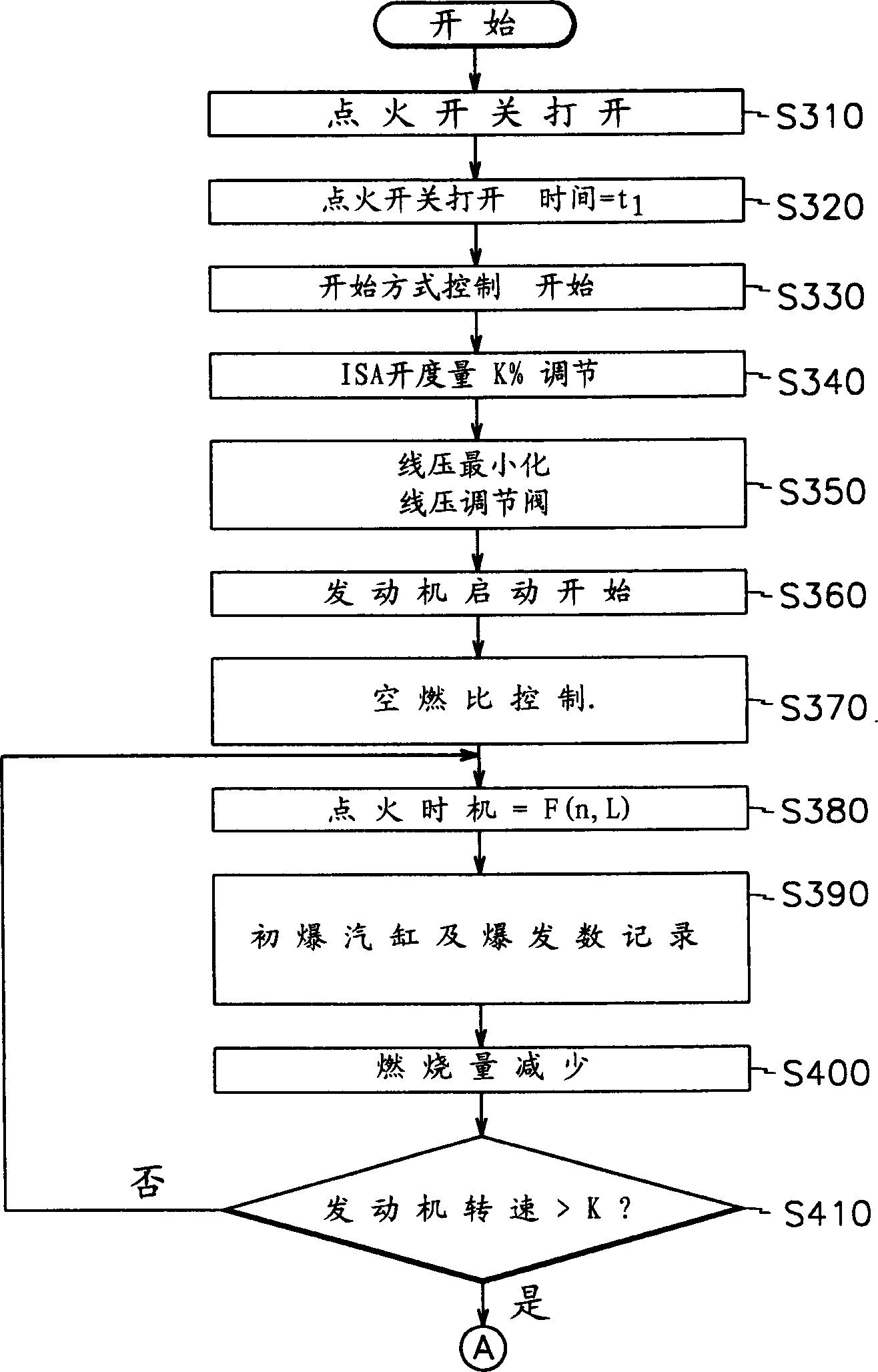

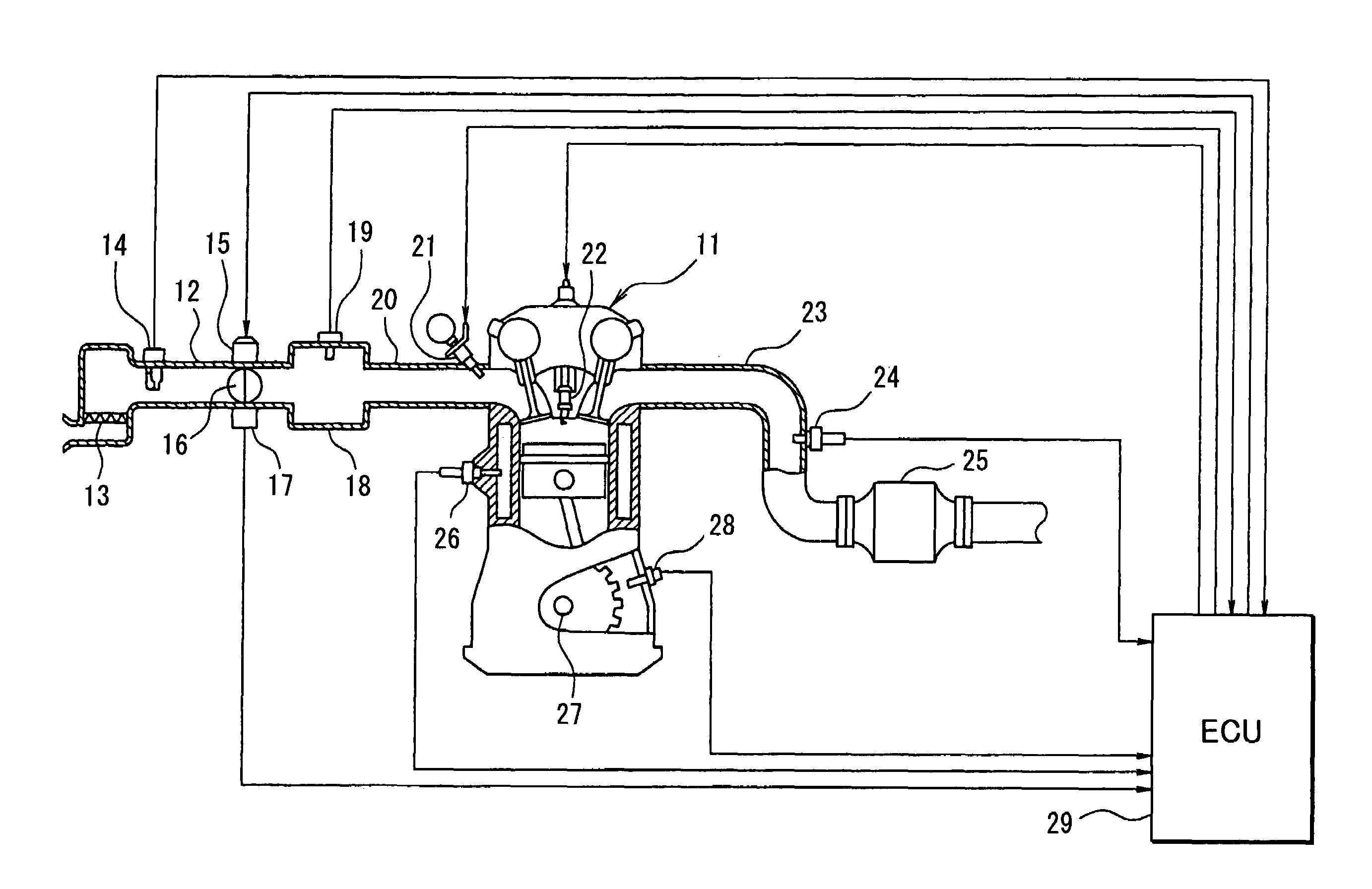

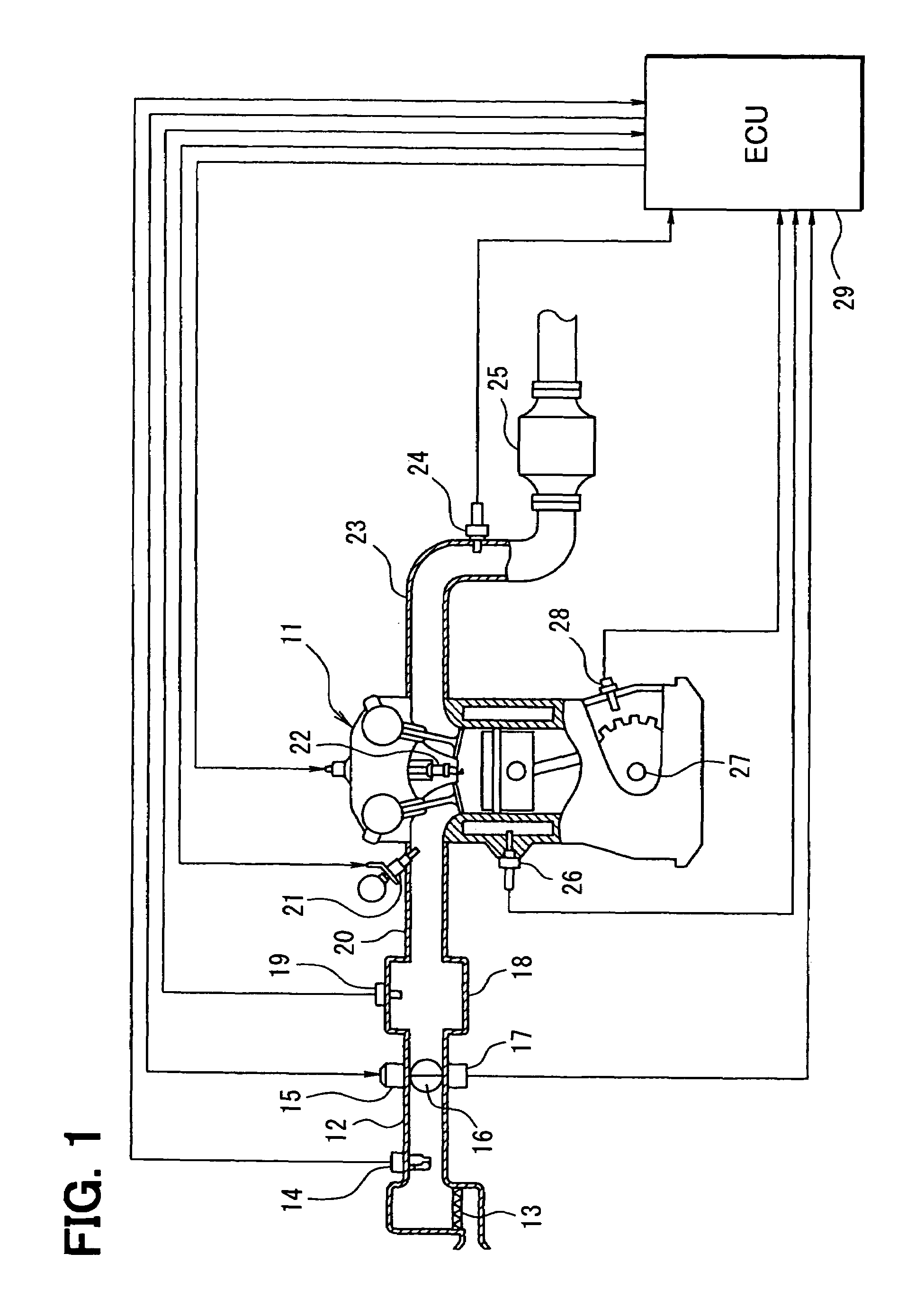

Method for control of engine to reduce exhaust gas during cold starting and idling of car

InactiveCN1386972AGuaranteed to minimizeGuaranteed to minimize the amount of hydrocarbon exhaustElectrical controlInternal combustion piston enginesAir volumeIgnition timing

An engine control method for reducing exhaust gas during cold start and idling of an automobile. The method is divided into four stages: 1. Turn on the ignition device switch to enter the starting state, control the amount of inhaled air to make the air-fuel ratio become lean, and control the engine to be at No-load state; 2. The engine starts to start, and the second stage of controlling the air-fuel ratio and delaying the ignition timing according to the engine speed and engine load; 3. If the engine speed formed by the first and second stage control is greater than the target speed, it will enter after the start In the no-load mode, output the air volume according to the detected rotational speed and cooling water temperature, and at the same time control the air-fuel ratio and the third stage of delayed ignition timing according to the changing engine rotational speed and load; 4. In the third stage, control the formed engine rotational speed. If the rotational speed is less than the target speed, the current shifting stage is converted into a driving shifting stage, and enters the driving mode, and the fourth stage of engine control is formed according to the corresponding mode.

Owner:HYUNDAI MOTOR CO LTD

Controller of internal combustion engine

ActiveUS7448360B2Easy to controlSmooth startAnalogue computers for vehiclesElectrical controlCombustionTop dead center

Owner:DENSO CORP

Energy re-claimer

An energy re-claimer is provided for preheating water prior to the water entering a conventional residential, commercial or industrial gas water heater. The energy re-claimer is mounted on top of the water heater between the draft diverter and the hot air flue. The energy re-claimer is preferably a double wall construction that is larger in diameter than the draft diverter and hot air flue in order to allow normal passage of hot air through the system; however, a single wall construction may also be used. Tap water enters a pipe inside the double wall construction and is heated prior to being directed through the water heater. The pipe may be constructed of a number of straight lengths connected by returns or may be in the form of a single straight section connected to a coil made of connected curving sections that surround the axis of the energy re-claimer. A condensation collector may be provided between the draft diverter and the energy re-claimer to collect any condensation that may form as a result of cooling gases and prevent the condensate from falling into the water heater where it could extinguish the flame.

Owner:JIMENEZ JESUS MARTINEZ

Control apparatus for internal combustion engine

ActiveUS20160047339A1Reduce the amount requiredReduce torqueElectrical controlInternal combustion piston enginesWastegateExternal combustion engine

An engine includes a turbocharger, an air bypass valve, a wastegate valve, and an EGR apparatus. The engine also includes an ISC passage that connects an upstream side and a downstream side of a throttle valve in an intake passage, and an ISC valve that adjusts an amount of air flowing through the ISC passage. A control apparatus for the engine performs valve opening control to set an opening of an ISC valve at a larger opening than a reference opening when a required torque required by the engine is smaller than an estimated torque that can be generated by the engine, and closes the air bypass valve and the wastegate valve for a fixed period following completion of the valve opening control when an EGR valve of a low pressure EGR apparatus is opened during execution of the valve opening control.

Owner:TOYOTA JIDOSHA KK

Control device of direct injection internal combustion engine

InactiveUS7747379B2Increase rotation speedAvoid incomplete combustionDigital data processing detailsAutomatic initiationsEngineeringIgnition timing

When engine rotation speed is increasing in a compression stroke injection mode, a control device determines that a crank angle at injection end timing of an injector deviates toward a delayed crank angle side and performs additional ignition at timing when (or immediately before or after) a crank angle at actual injection end timing of the injector of a present injection cylinder is reached. Thus, even when the crank angle at the injection end timing deviates toward the delayed crank angle side with respect to preset original ignition timing, a combustion state can be stabilized by performing the additional ignition at timing, at which a suitable stratified mixture gas is formed in a cylinder, through the execution of the additional ignition at the timing substantially the same as the actual injection end timing.

Owner:DENSO CORP

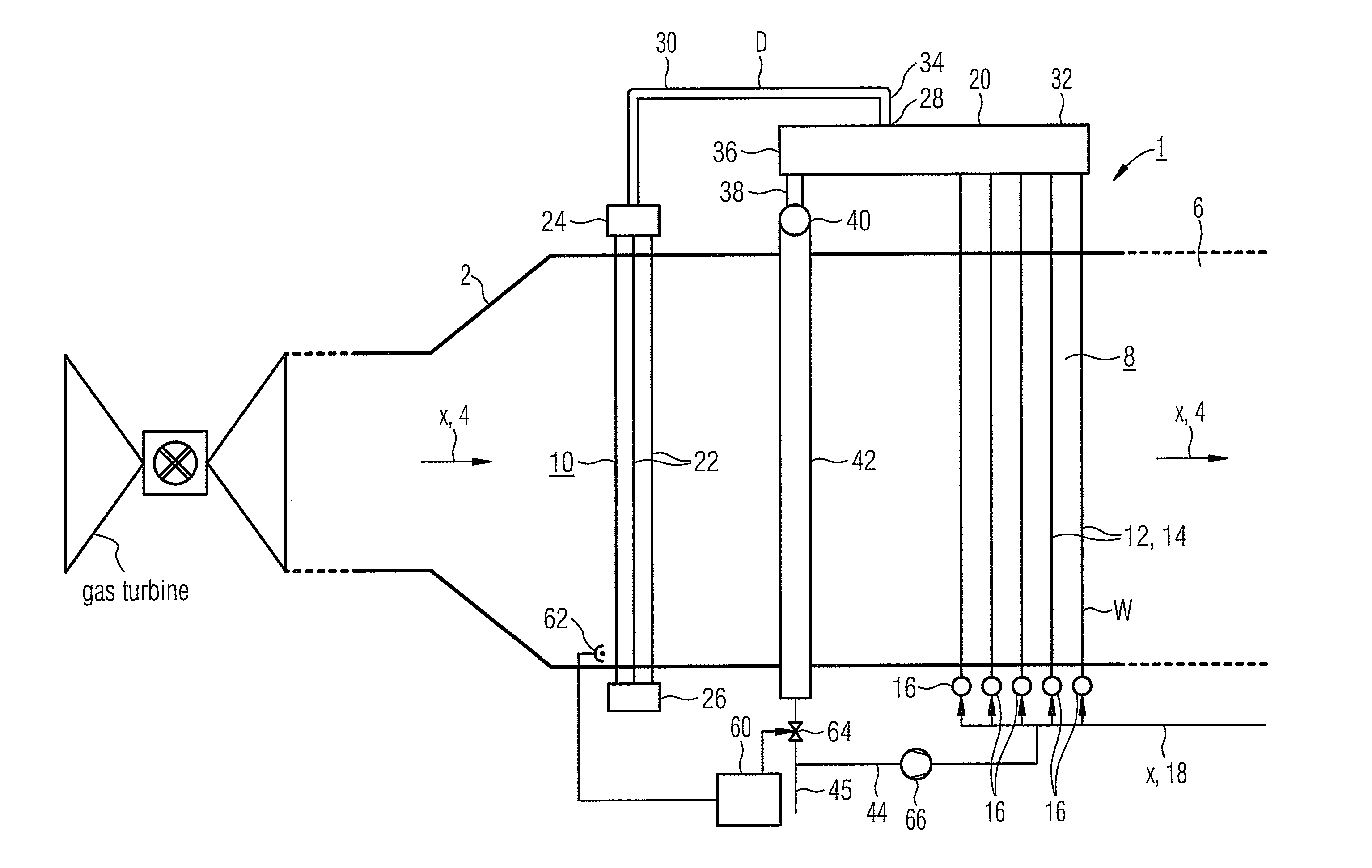

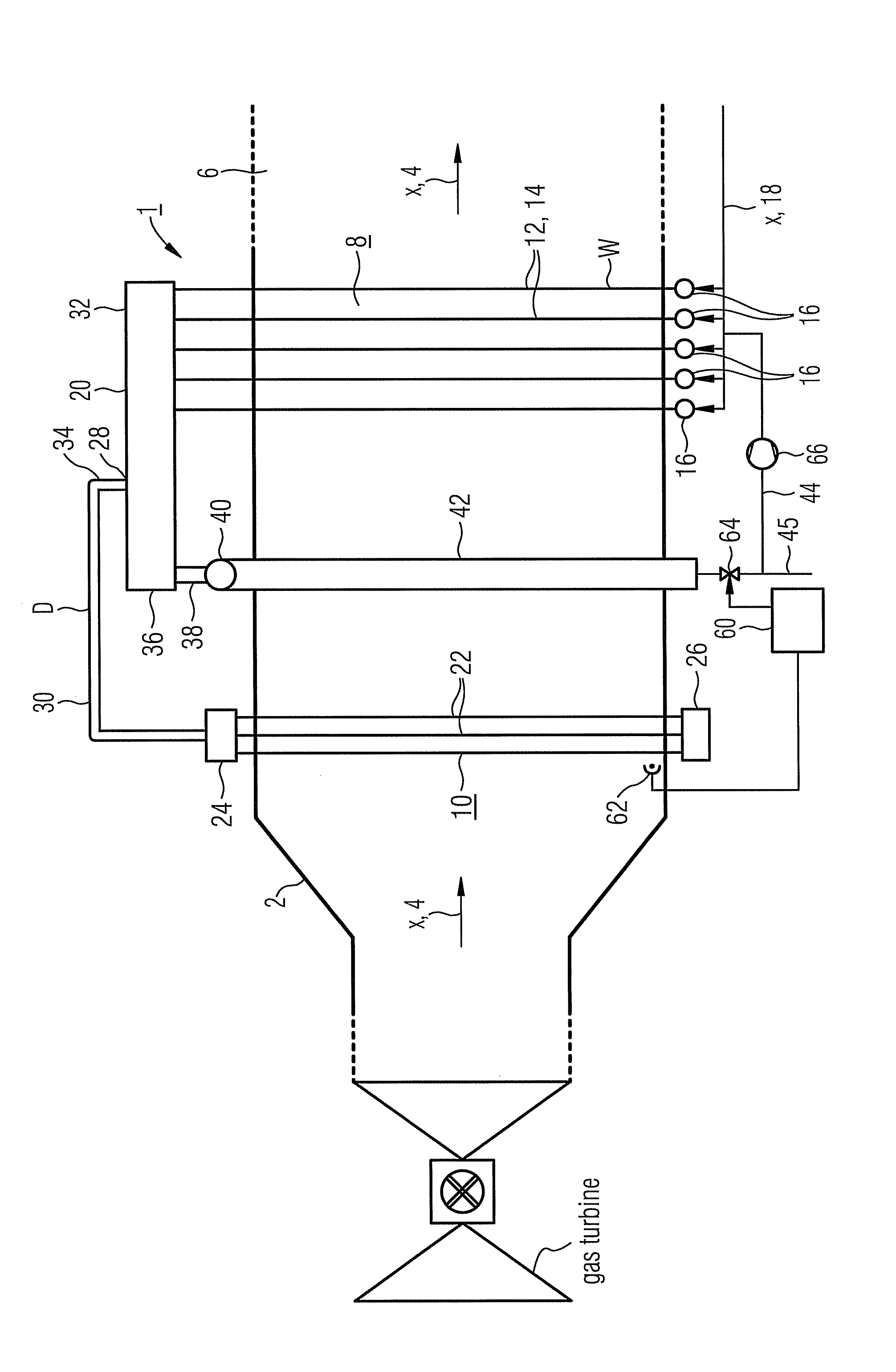

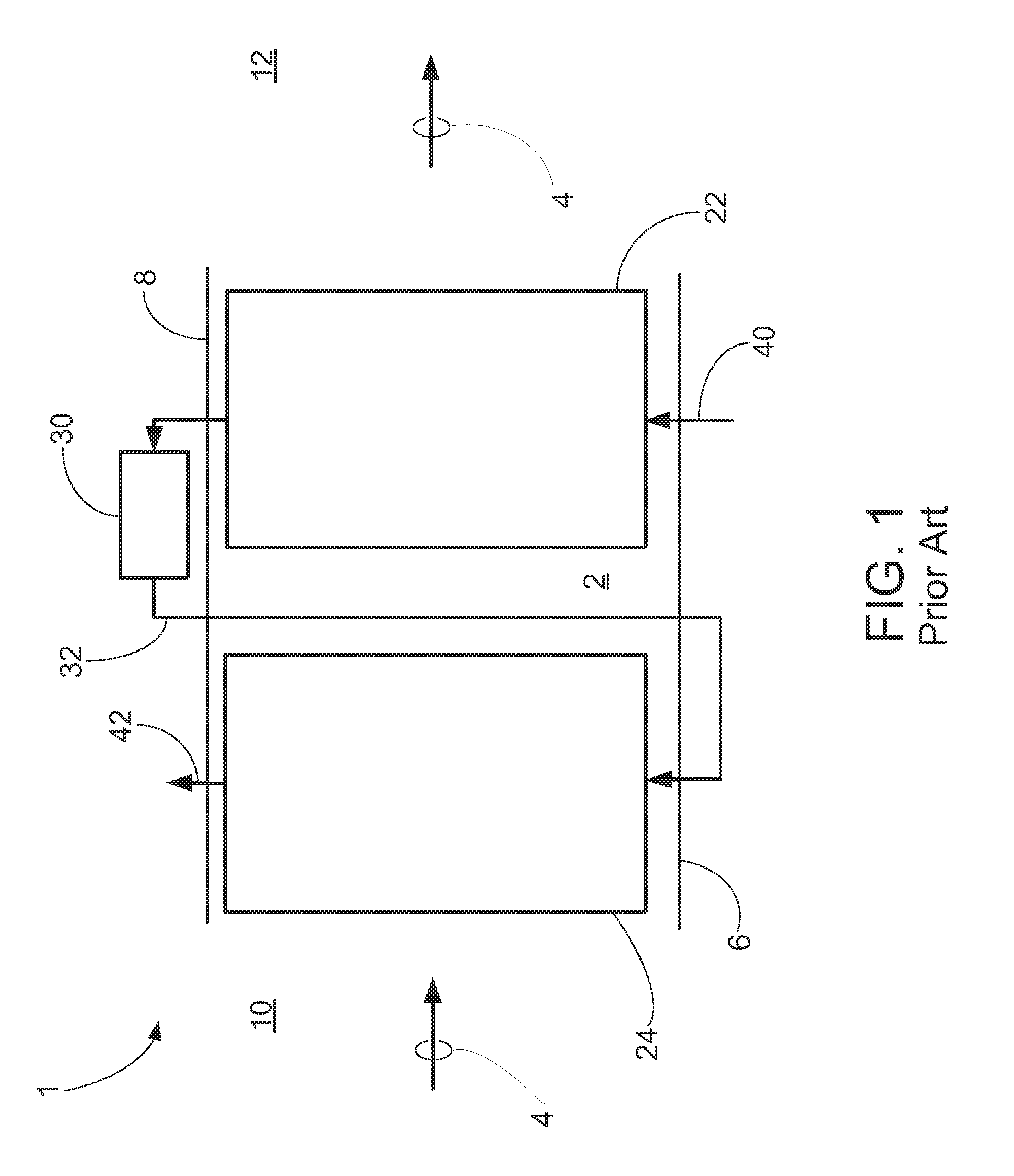

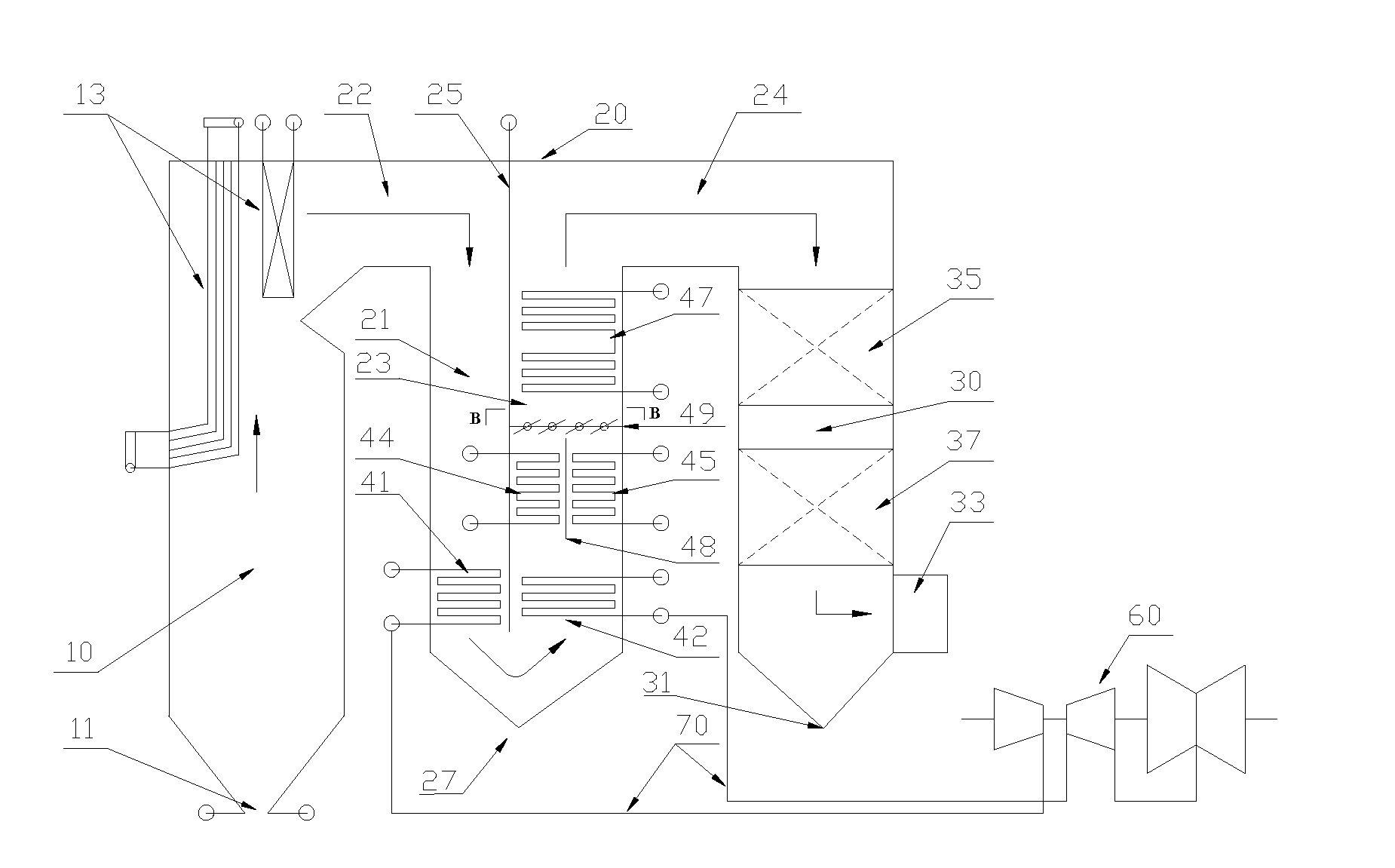

Steam generator in horizontal constructional form

ActiveUS7628124B2Improve operational flexibilityReliable water separationSteam separation arrangementsMachines/enginesEngineeringDust collector

The invention relates to a steam generator whose continuously heating evaporator surface is arranged in a hot gas channel for a hot gas passage in a substantially horizontal direction and which comprises a plurality of steam generating pipes passed through by flowing medium, wherein a plurality of output collectors which are mounted downstream of certain steam generating pipes, on the side of flowing medium, are oriented in the longitudinal direction thereof substantially parallel to the hot gas direction. The invention improves the steam generator such that it is possible to attain a high operational flexibility, a particularly reduced start- and load-alternation time, including starting operation or light load phases and to maintain a low-cost production. Each output collector comprises an integrated water separating element by means of which said collector is connected, on the side of flowing medium, to a plurality of downstream arranged overheating pipes of an overheating surface.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

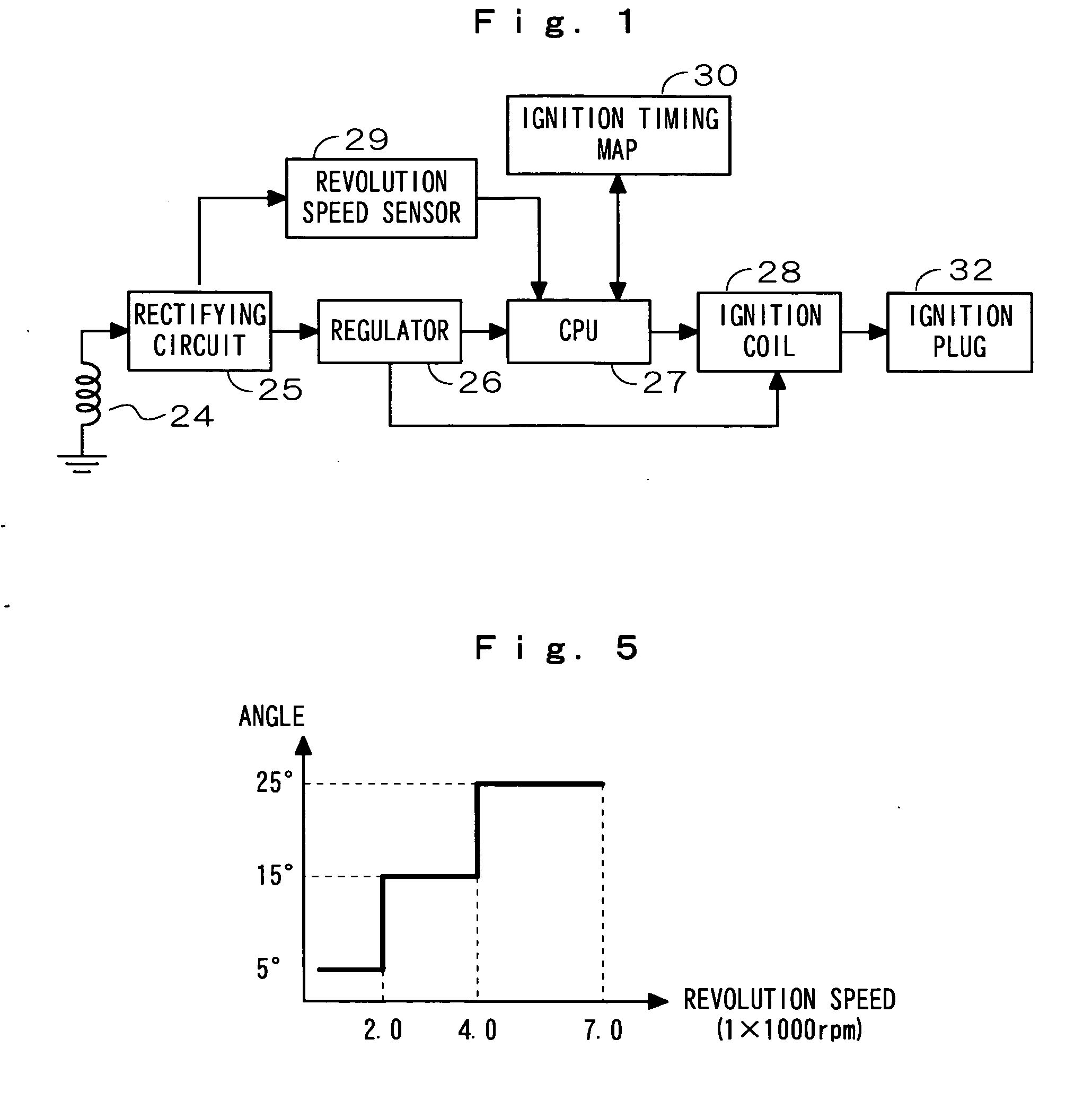

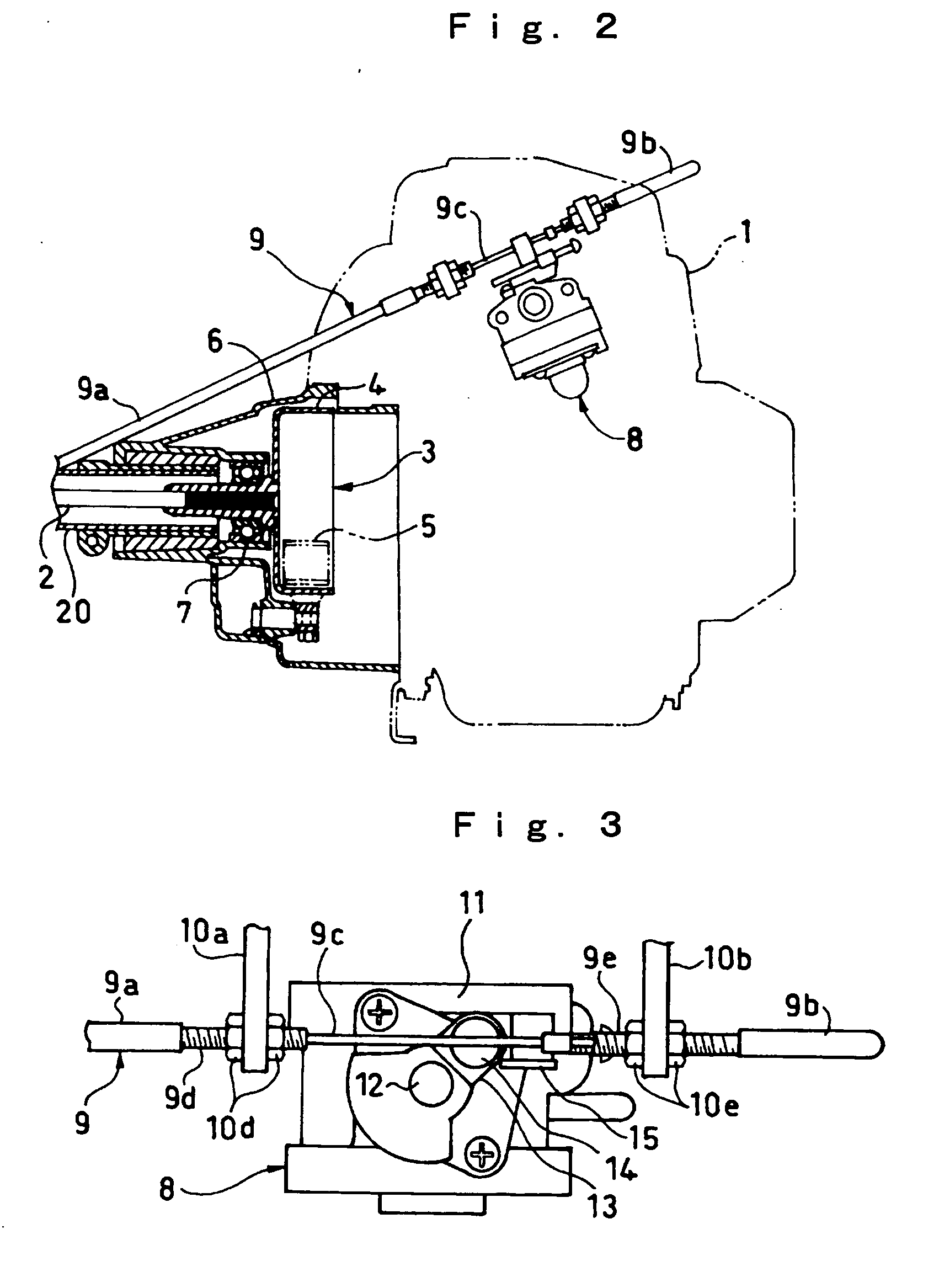

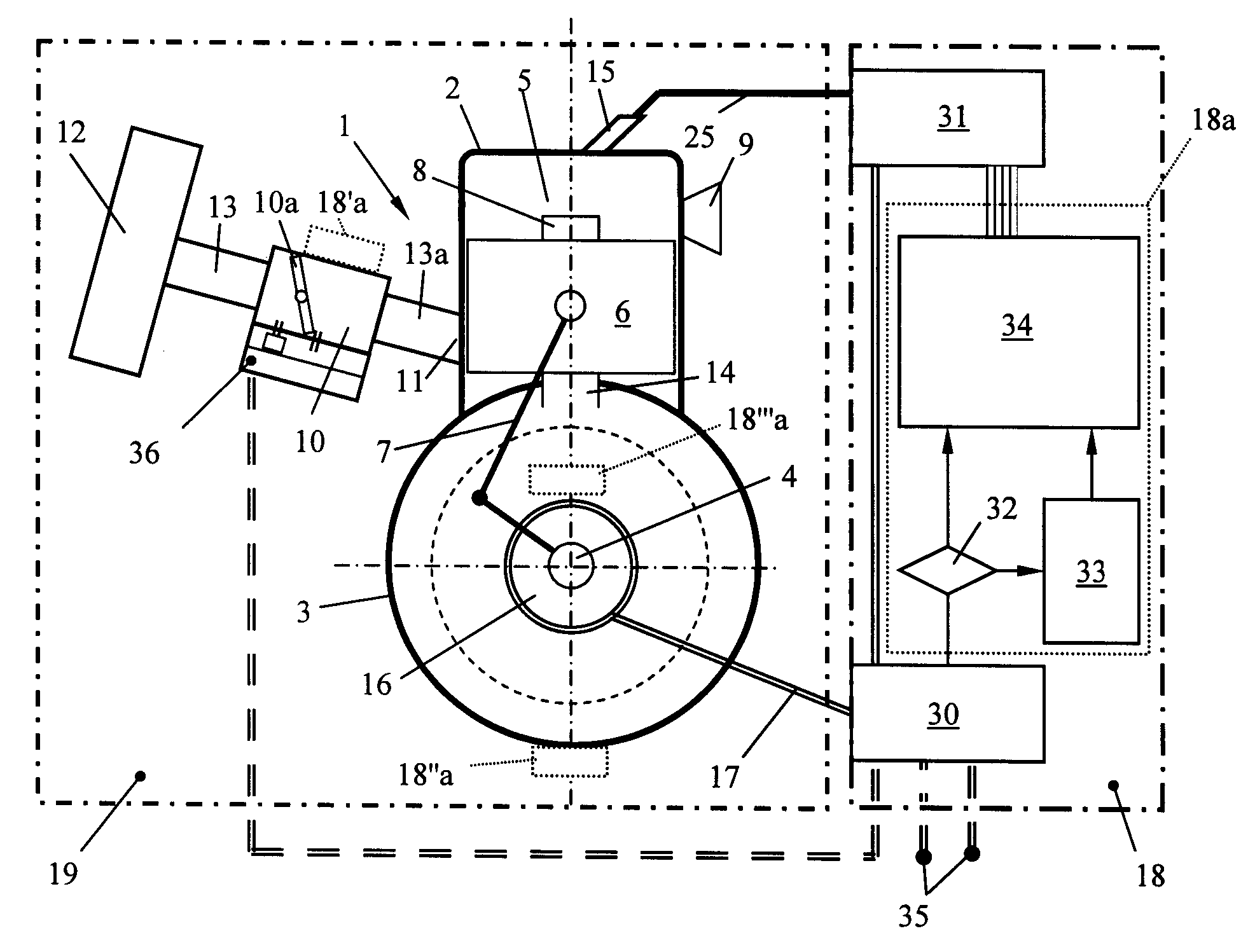

Engine revolution controller of working machine

InactiveUS20070125341A1Maintenance of such closeSuppress increaseElectrical controlInternal combustion piston enginesIgnition timingThrottle opening

In an engine of a working machine having no governor mechanism, the engine revolution speed is controlled such that the revolution speed can stably be maintained irrespective of the variation in load without adjusting the throttle opening to exploit the full potential of the engine. Since an engine 1 does not have the governor mechanism, an operator adjusts the throttle opening and controls the engine revolution speed. A map in which ignition timing (amount of angle of lead) is set by means of functions of the engine revolution speed is stored in an ignition timing map 30. The map 30 is set such that the engine revolution speed is equal to or higher than a value to be controlled (e.g. 7000 rpm), and the ignition timing is lagged as compared with a case in which the engine revolution speed is lower than the value to be controlled.

Owner:HONDA MOTOR CO LTD

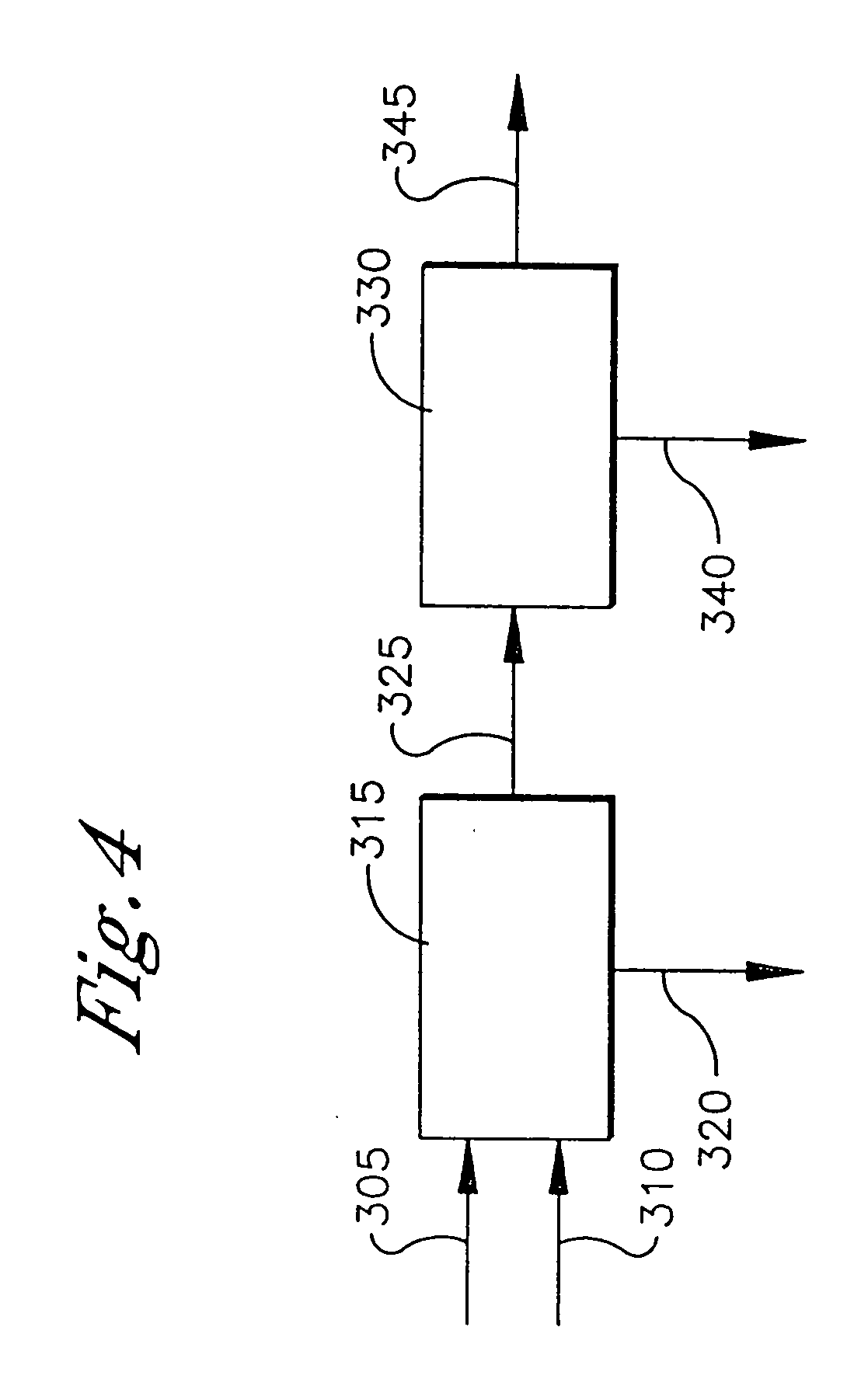

Automated Super Heated Steam Generators

InactiveUS20130136434A1Reduce heat lossImprove configurationLiquid degasificationMachines/enginesSCADAEngineering

Modularized, superheated steam generators comprise a steam module (46), a thermocouple module (41), and an electrode module (45) assembled within a containment enclosure (66). The multi-stage steam module (46) comprises a plurality of first stage pressure vessels (77) surrounding and feeding a second stage pressure vessel (78). The steam module (46) is coaxially surrounded by insulation (48) disposed within a cylindrical shroud (72). The electrode module (45) radiantly heats the steam module with resistive heating elements (119). The thermocouple module (41) includes thermocouples monitoring first stage temperatures within and between pressure vessels (77). PLC computer SCADA software (600) operates the generators. Thermocouple data is analyzed to control heater temperatures, the water feeding system (340), and outputted steam temperature. PLC software (600) provides operating logic (602) establishing a start up subroutine (602), a ramp up subroutine (603), a steady state subroutine (605), and a shut down subroutine (606).

Owner:TRIMETEOR OIL & GAS CORP

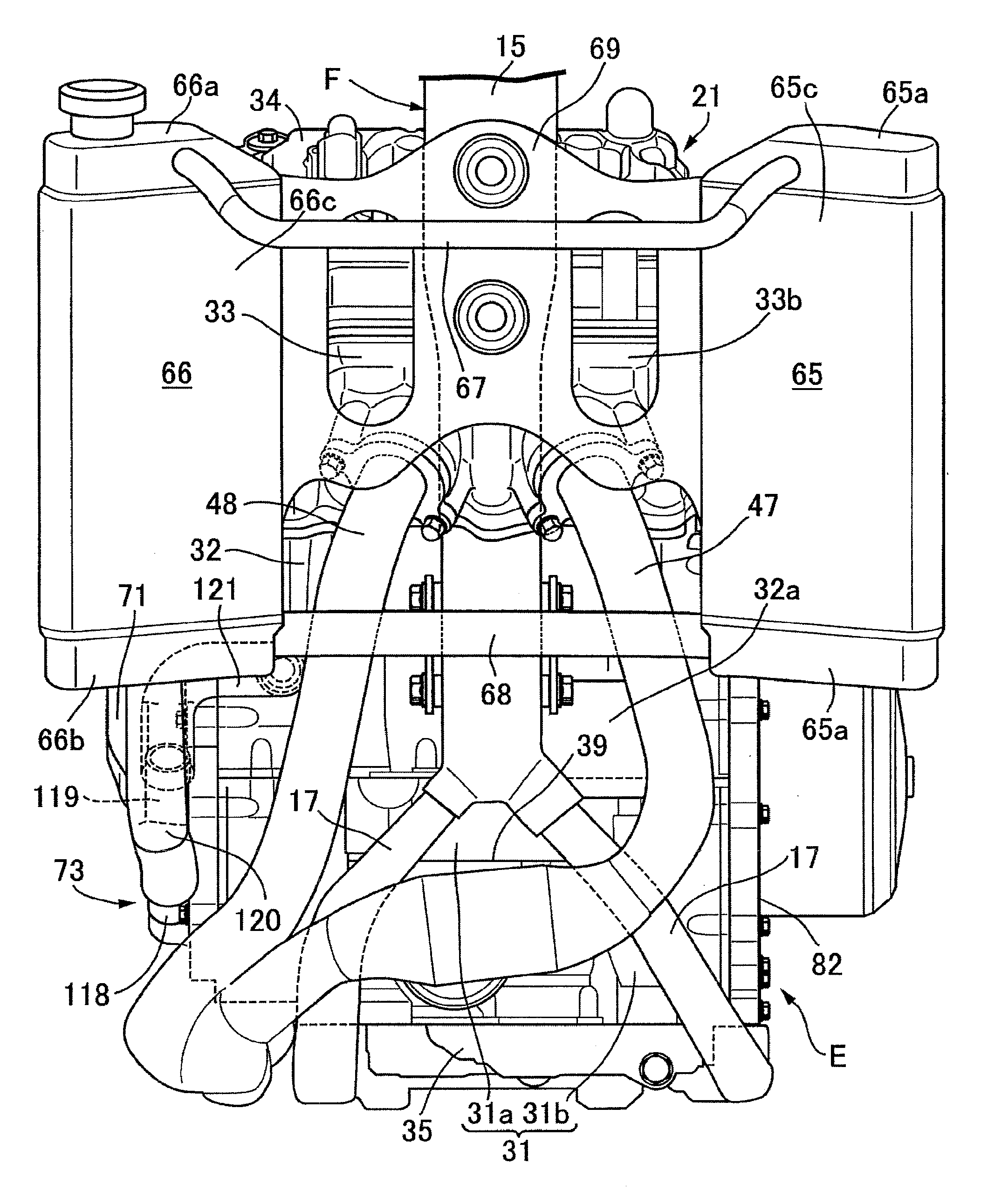

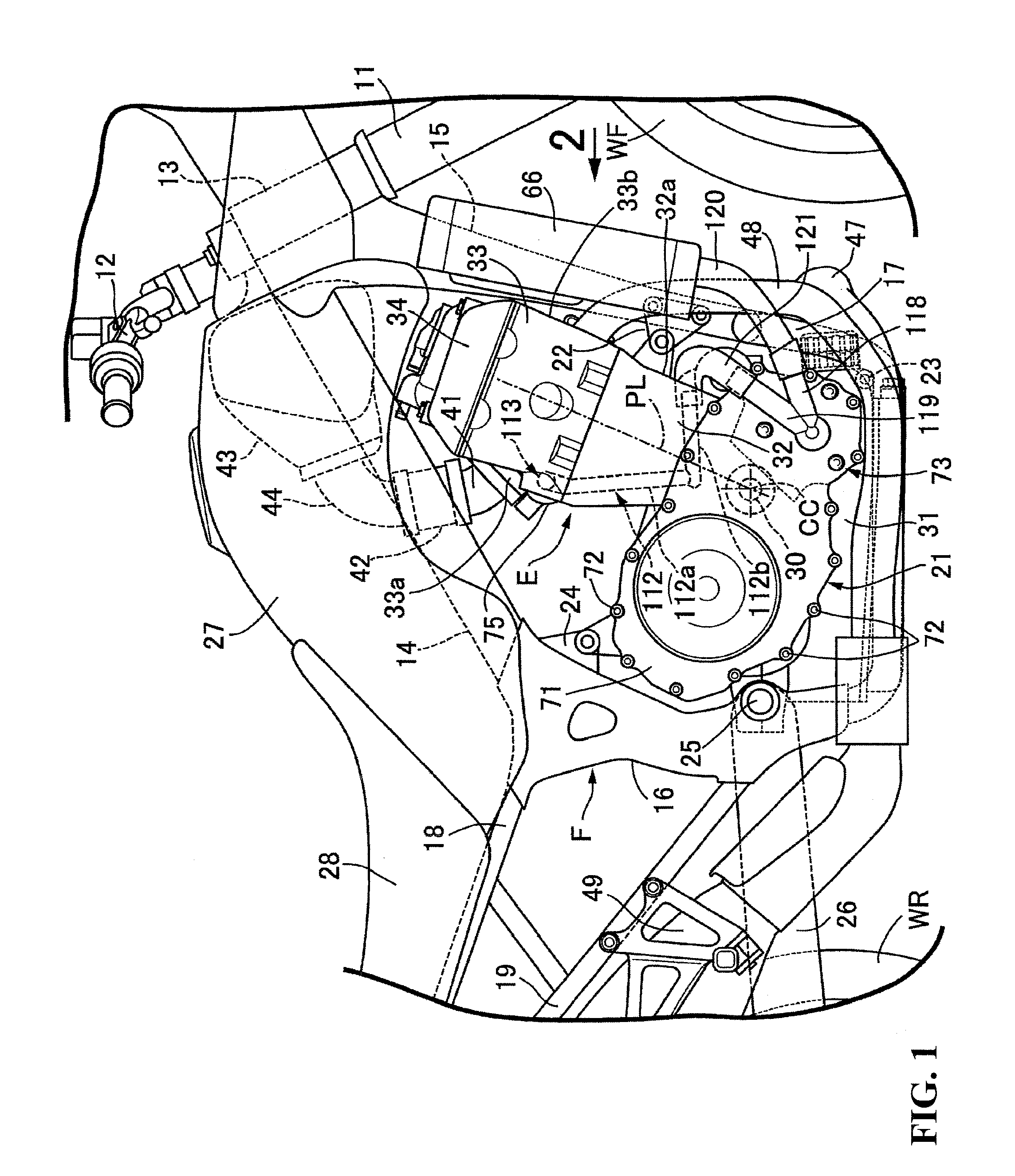

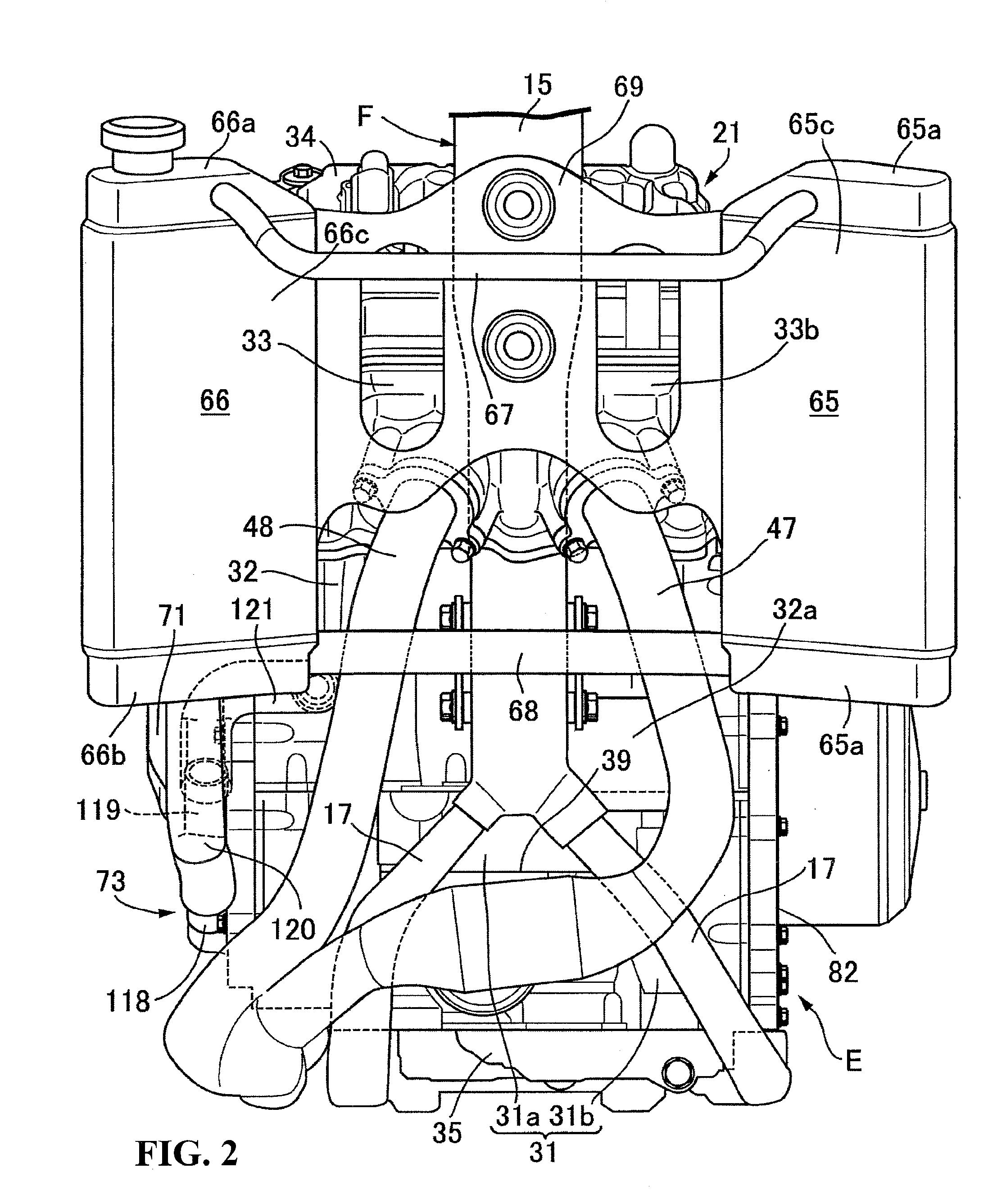

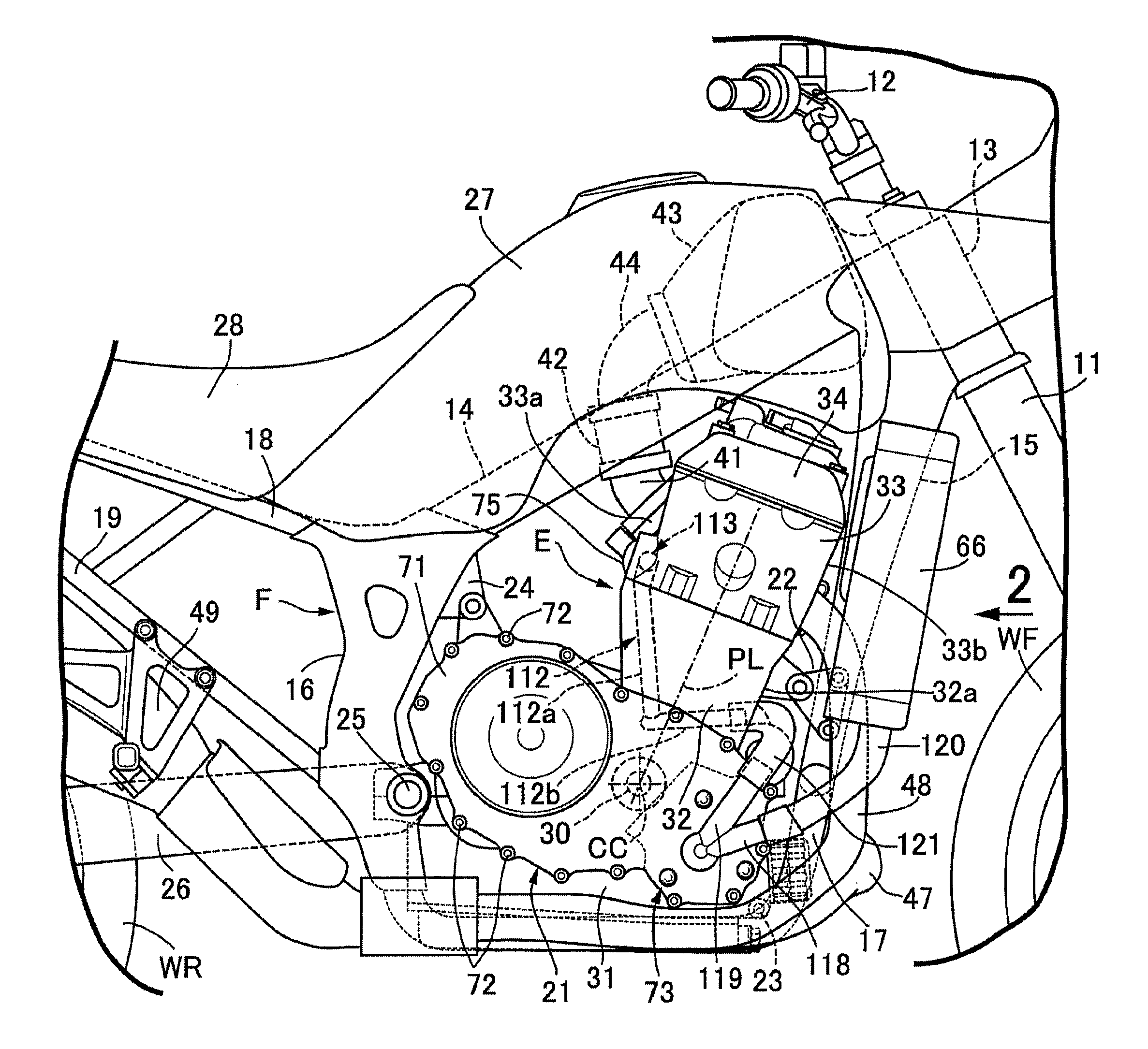

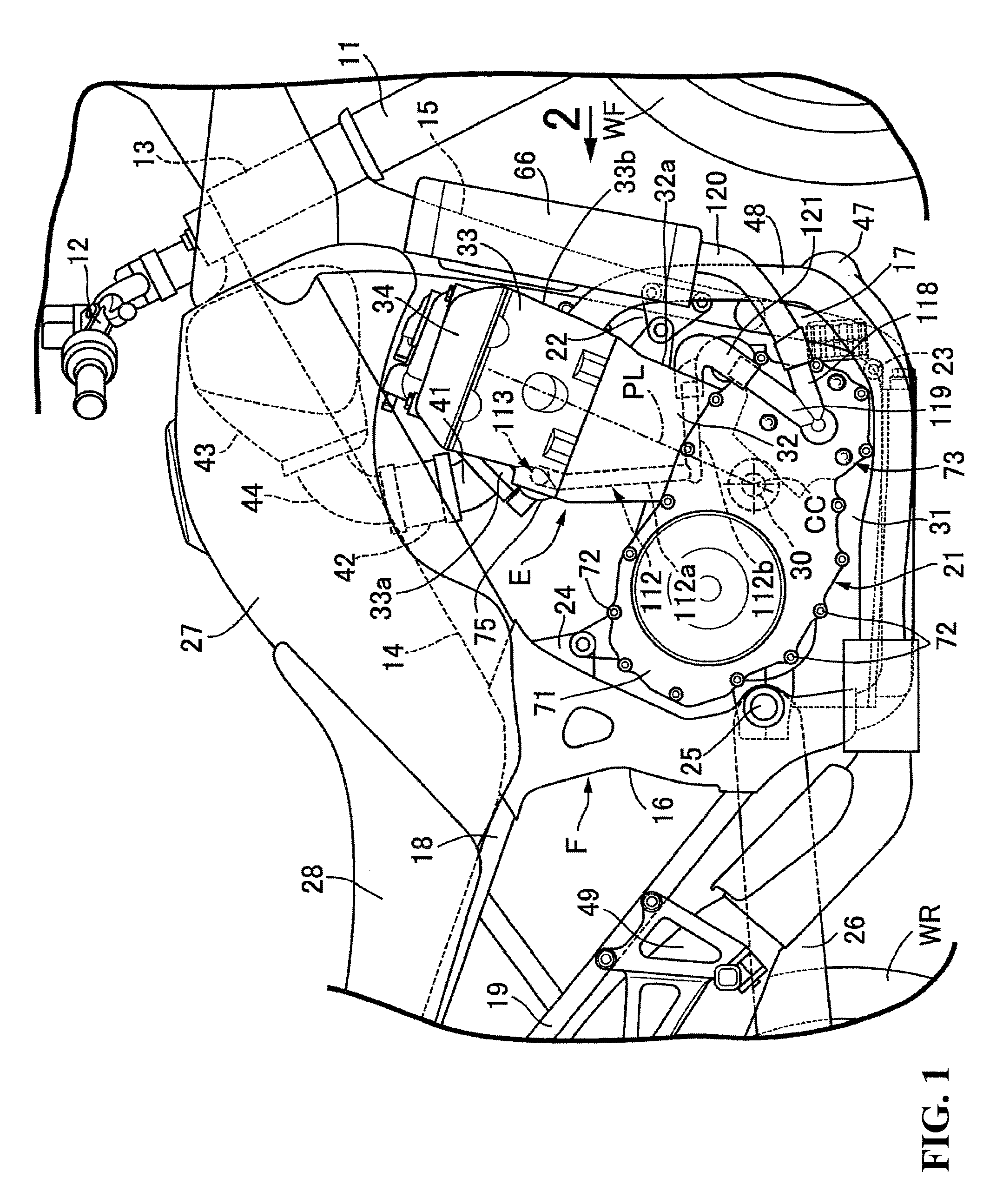

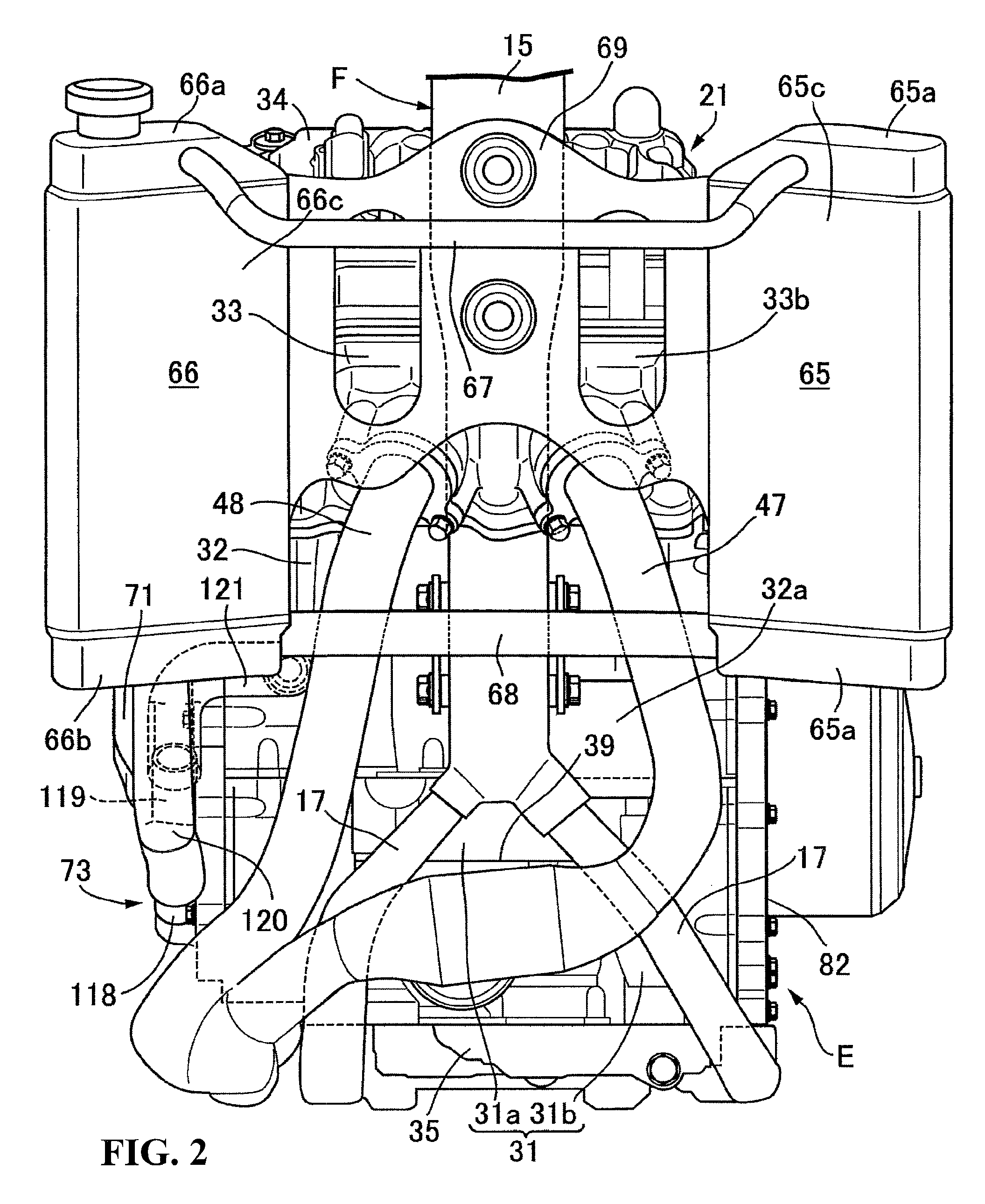

Water cooled internal combustion engine for vehicle

ActiveUS20140060465A1Good lookingSmall sizeCasingsMachines/enginesExternal combustion engineDrive shaft

A compact water cooled internal combustion engine for a vehicle wherein a water pump operated by a pump driving shaft is arranged on a crankcase cover for covering a lateral side of a crankcase, such that an axis of rotation of the water pump is coaxial with the pump driving shaft. A case member that forms a pump case of a water pump, together with a crankcase cover, and that rotatably supports a pump shaft of the water pump, is attached on an inner surface side of the crankcase cover.

Owner:HONDA MOTOR CO LTD

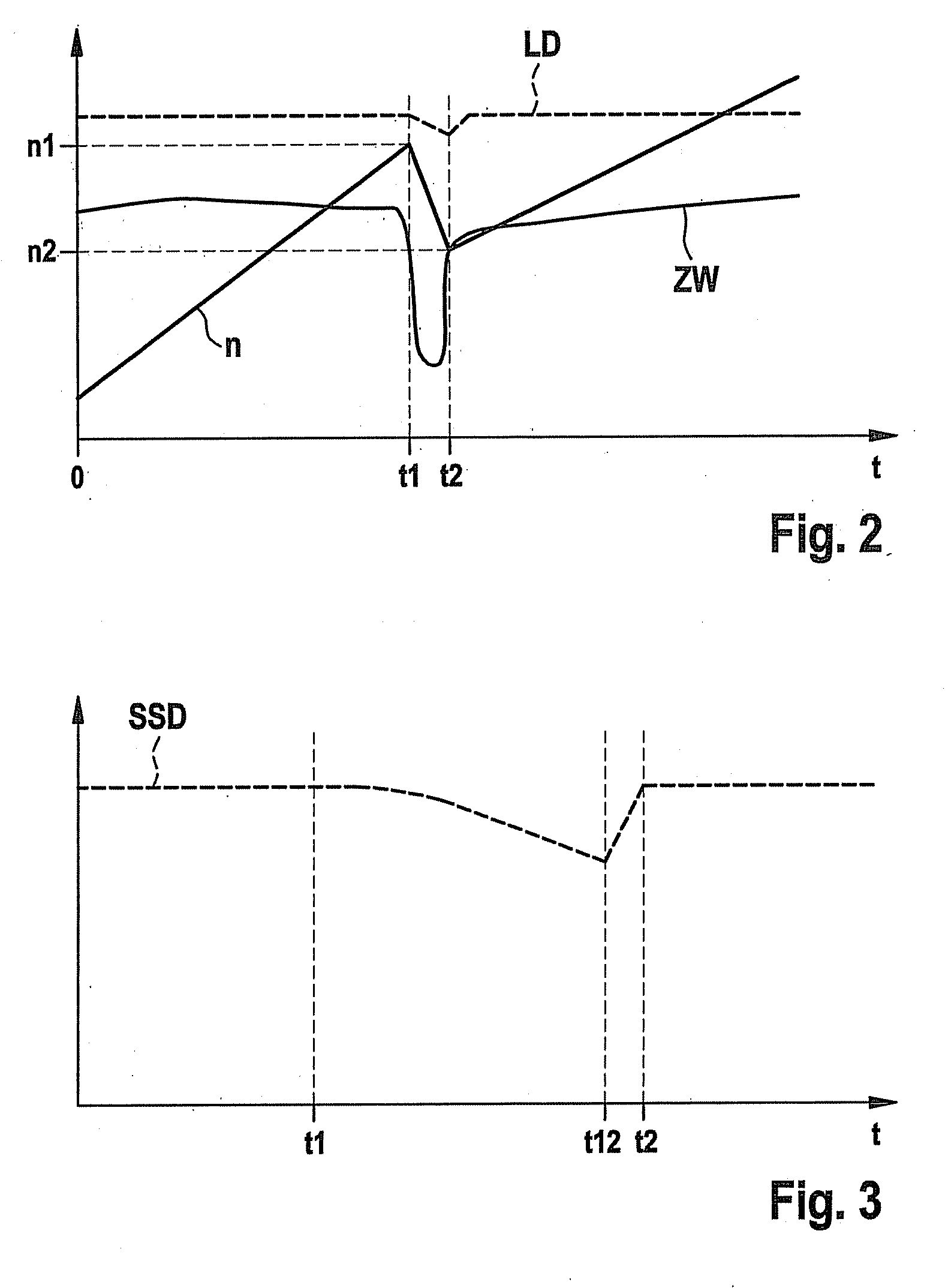

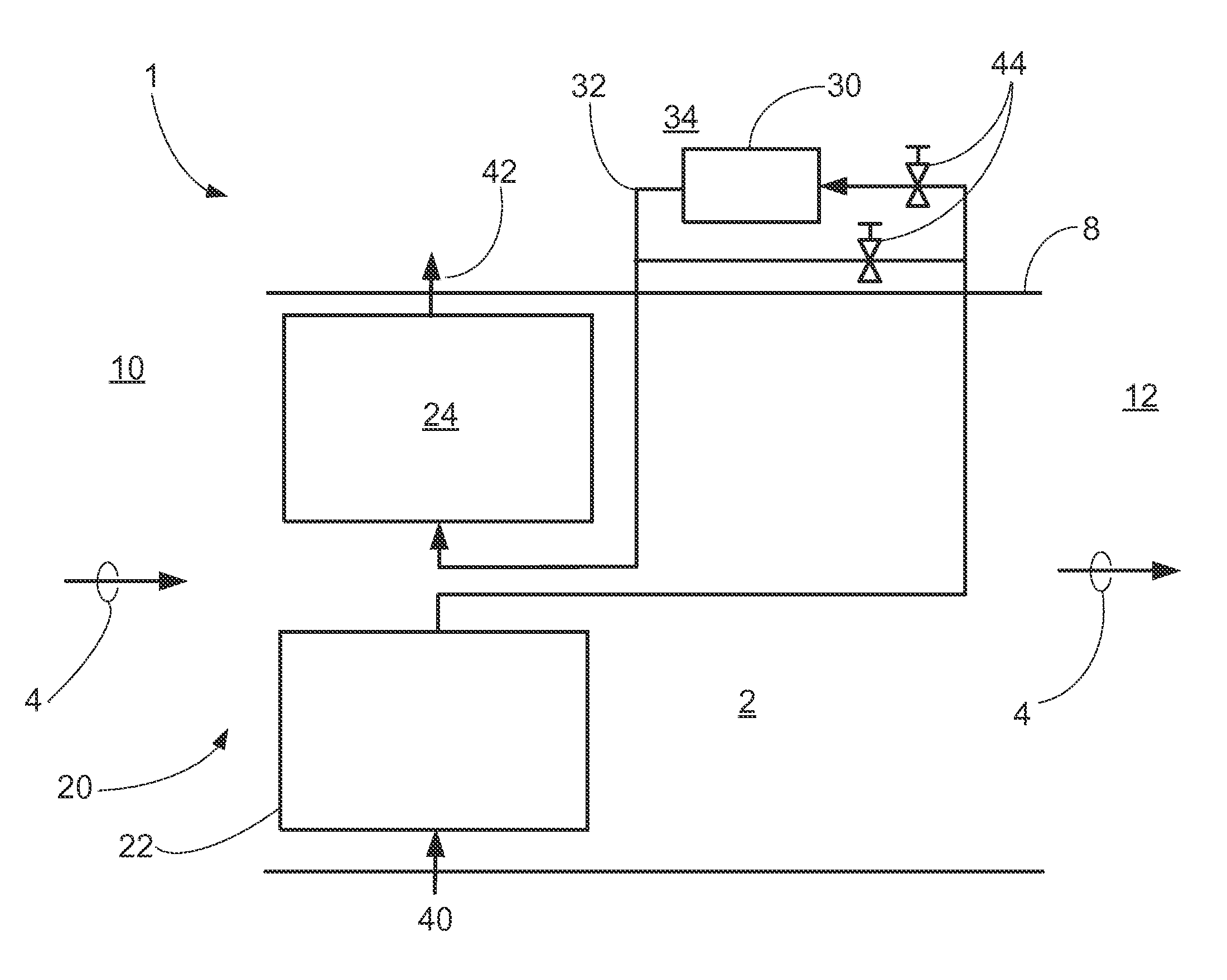

Method for operating an internal combustion engine using externally supplied ignition

InactiveUS20090157270A1Good dynamic responseElectrical controlInternal combustion piston enginesExternal combustion engineControlled combustion engine

A method for operating an internal combustion engine using externally supplied ignition, having a manually operable transmission, in which a torque produced by the internal combustion engine is able to be influenced via at least one control variable. An impending shifting process of the manual transmission and / or another operating situation of the internal combustion engine, during which a temporary lowering of the torque produced by the internal combustion engine is required and / or desired, is detected, and, as a function of the detection, the torque is lowered by changing at least one control variable of a fuel path.

Owner:ROBERT BOSCH GMBH

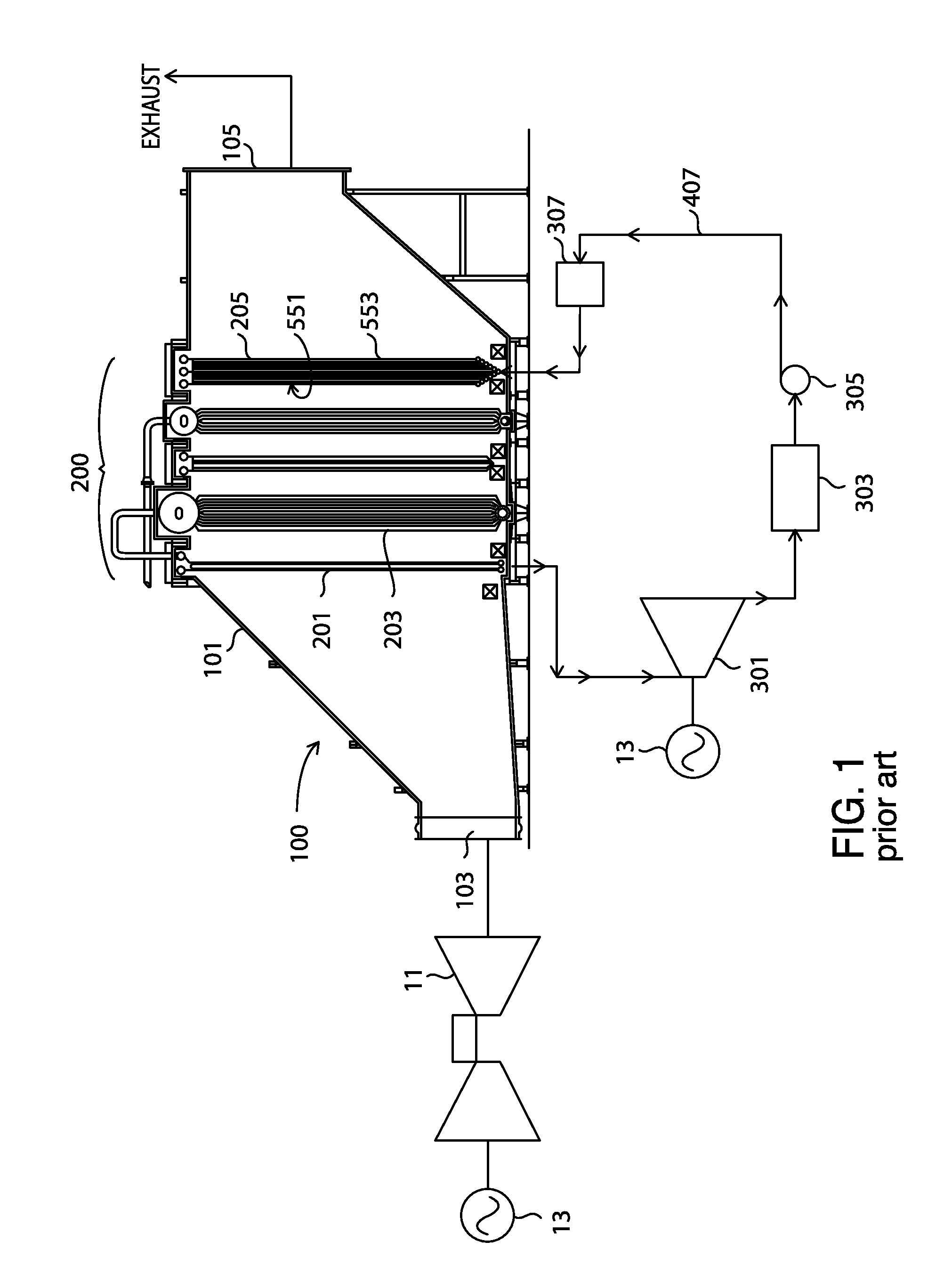

Split pass economizer bank with integrated water coil air heating and feedwater biasing

InactiveUS20130192542A1Improve thermal efficiencySmall space requirementCombustion processMachines/enginesCombustionFlue gas

An apparatus for using a water coil air heater with a single bank economizer. A boiler economizer arrangement includes an economizer bank which has separate hot pass bank and cold pass bank economizer portions in a parallel arrangement, each facing the same flow of hot flue gas. Feedwater enters the cold pass bank economizer where it is heated by the hot flue gas, and then flows to a water coil air heater away from the hot flue gas. The feedwater dissipates heat energy in the water coil air heater which may be used to heat air bound for combustion. The feedwater continues into the hot pass bank economizer portion of the economizer arrangement where it absorbs additional heat from the flue gas. The heated feedwater flows out of the economizer arrangement and may be subject to additional heating by a boiler or other heat exchanger.

Owner:THE BABCOCK & WILCOX CO

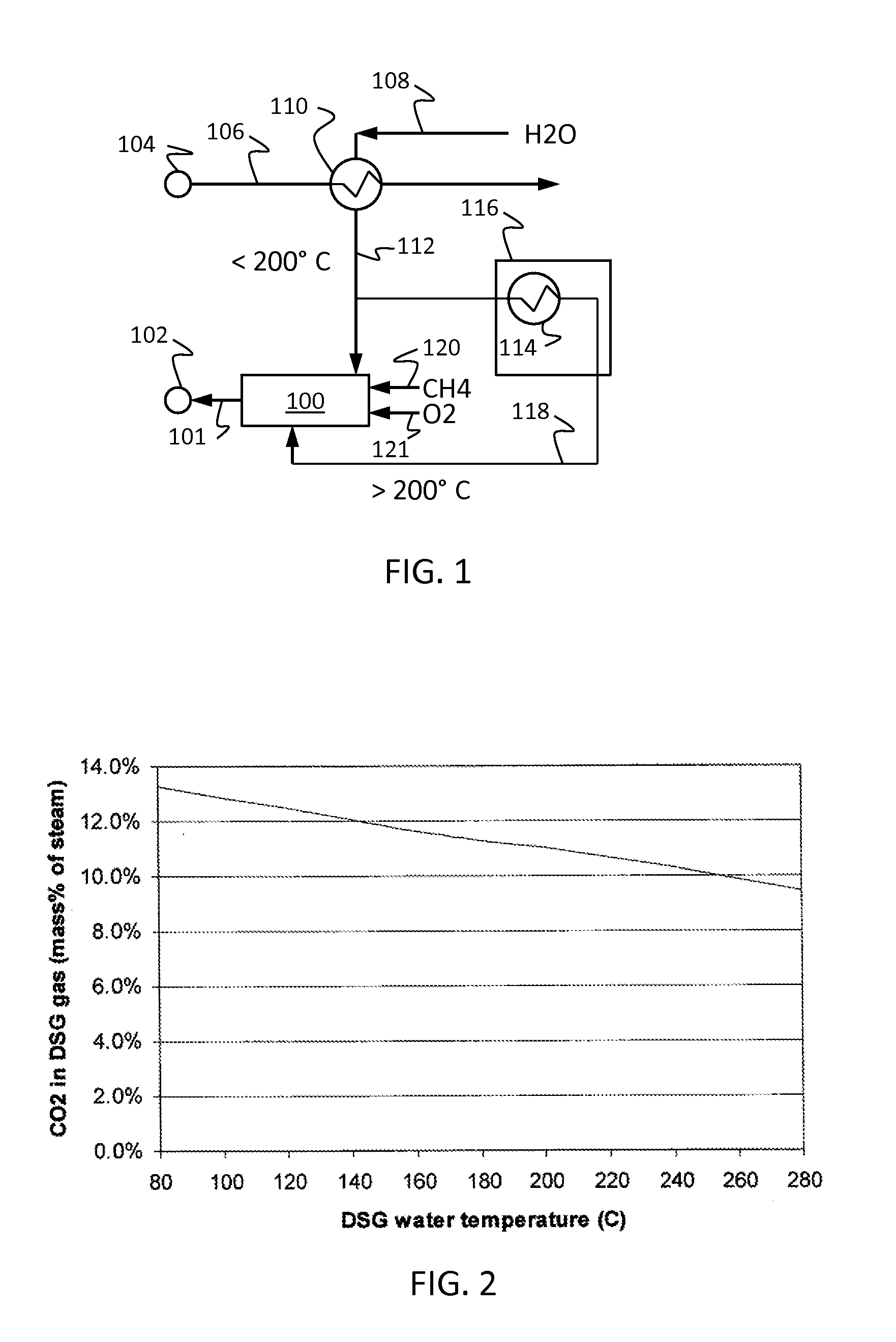

Direct steam generation co2 output control

InactiveUS20140060825A1Steam generation using pressureCombustion processEngineeringIncrease temperature

Methods and systems generate steam and carbon dioxide mixtures suitable for injection to assist in recovering hydrocarbons from oil sands based on concentration of the carbon dioxide in the mixtures as influenced by temperature of water introduced into a direct steam generator. Increasing temperature of the water to above 200° C. before introduction into the direct steam generator may utilize heat from an electrical power generation unit. Enthalpy of this preheated water impacts amount of fuel needed to burn in the direct steam generator and hence the concentration of the carbon dioxide, which may be below 11% by mass percent of the steam.

Owner:CONOCOPHILLIPS CO

M-type pulverized coal boiler suitable for ultrahigh steam temperature

ActiveUS20140033712A1Increase manufacturing costSteam turbine can be greatly reducedWater circulationFuel injection apparatusSlagFlue gas

The disclosure provides an M-type pulverized coal boiler suitable for ultrahigh steam temperature. The pulverized coal boiler comprises a hearth of which the bottom is provided with a slag hole and a tail downward flue of which the lower part is provided with a flue gas outlet. The pulverized coal boiler further comprises a middle flue communicated between the hearth and the tail downward flue, wherein the middle flue comprises an upward flue and a hearth outlet downward flue of which the bottoms are mutually communicated and the upper ends are respectively communicated with the upper end of the hearth and the upper end of the tail downward flue to form a U-shaped circulation channel. In the pulverized coal boiler provided by the disclosure, the middle flue which extends downwards and can make flue gas flow along the U-shaped circulation channel is arranged between the outlet of the hearth and the tail downward flue, so that high-temperature flue gas from the hearth can be introduced into a position with low elevation through the downward flue, and final-stage convection heating surfaces (such as a high-temperature superheater and a high-temperature reheater) can be arranged at positions with low height, and the length of ultrahigh-temperature steam pipelines between the high-temperature superheater and a steam turbine, and between the high-temperature reheater and the steam turbine can be greatly reduced. Therefore, the manufacturing cost of a boiler unit is obviously reduced.

Owner:HUANENG CLEAN ENERGY RES INST

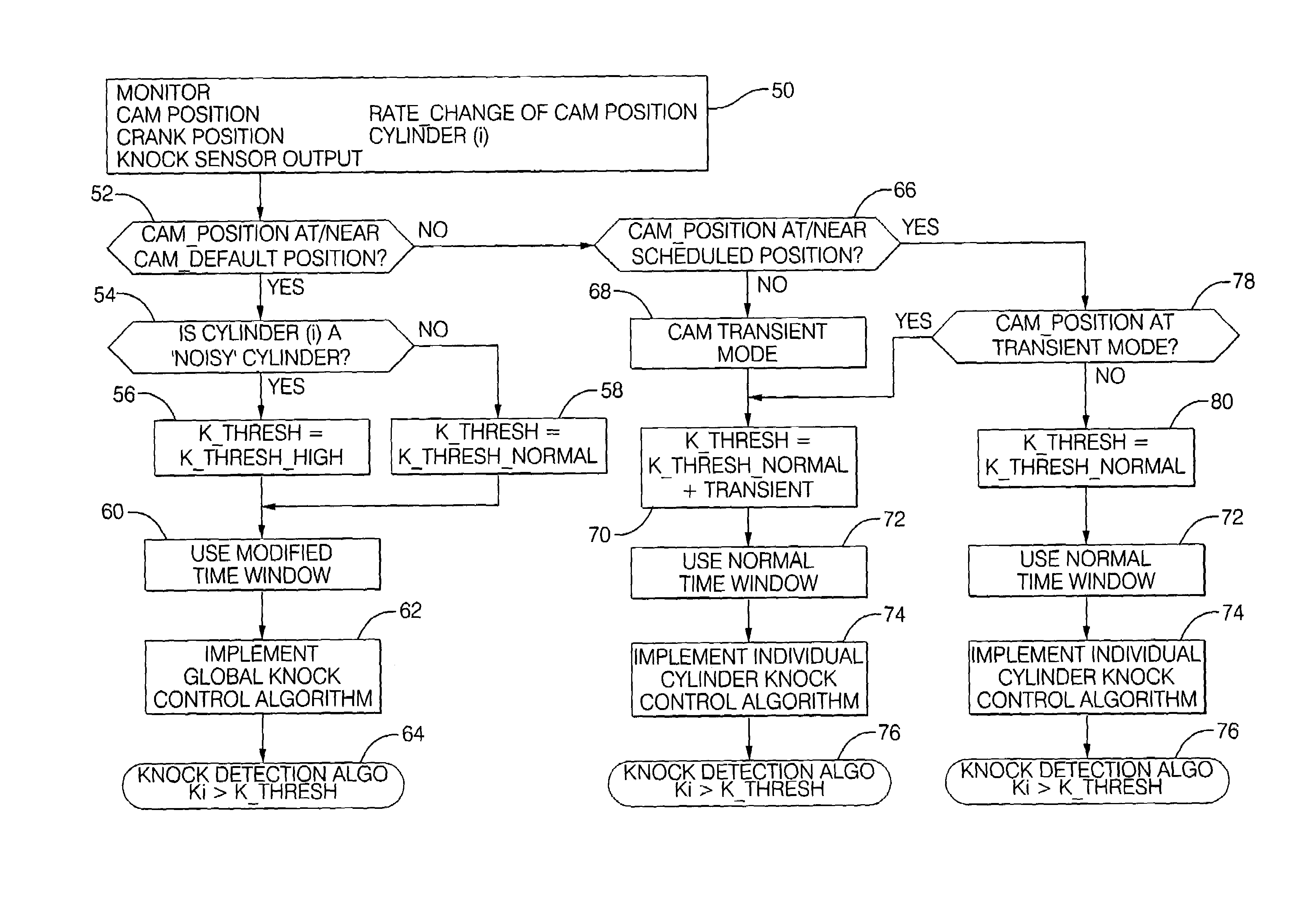

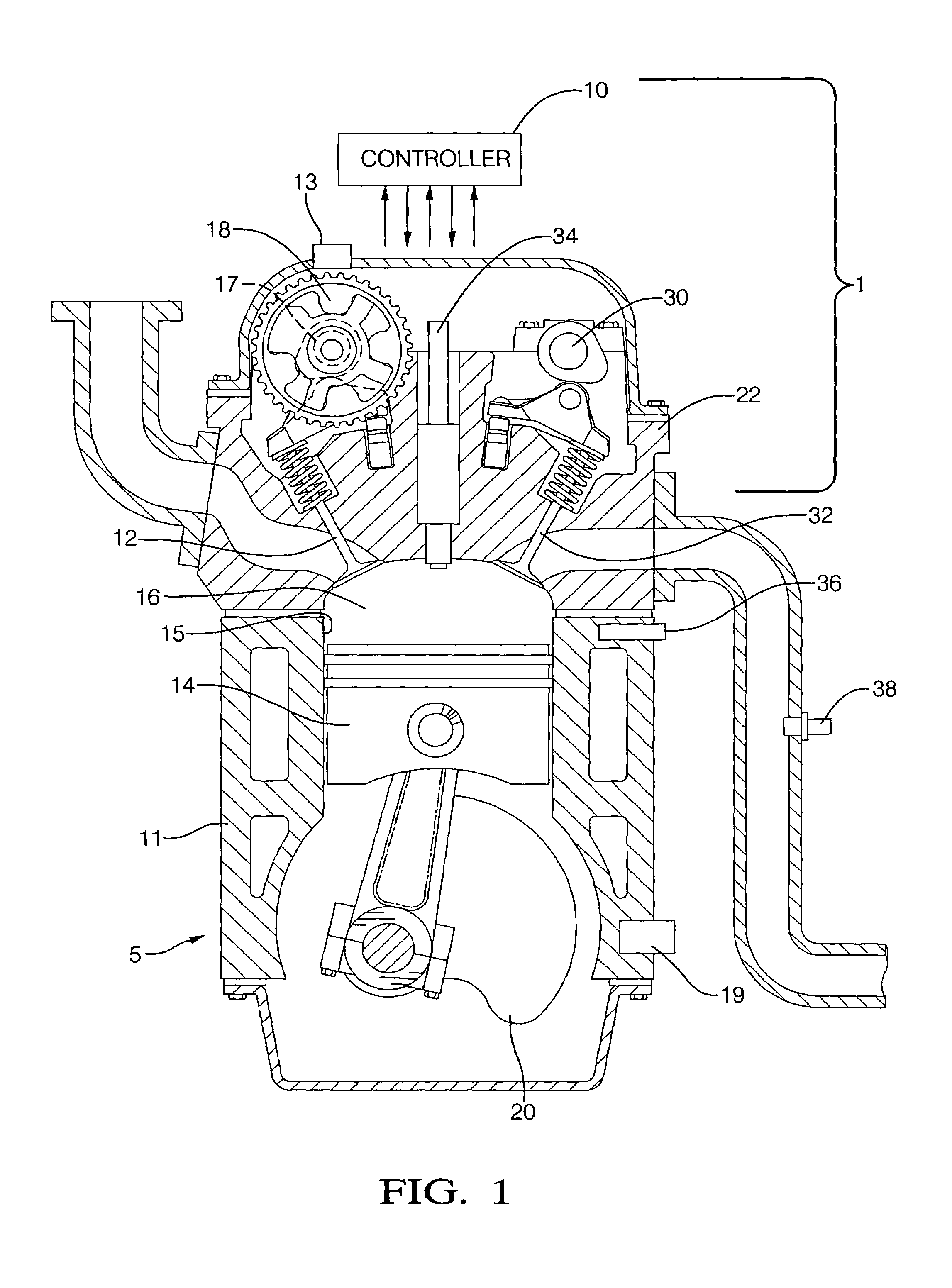

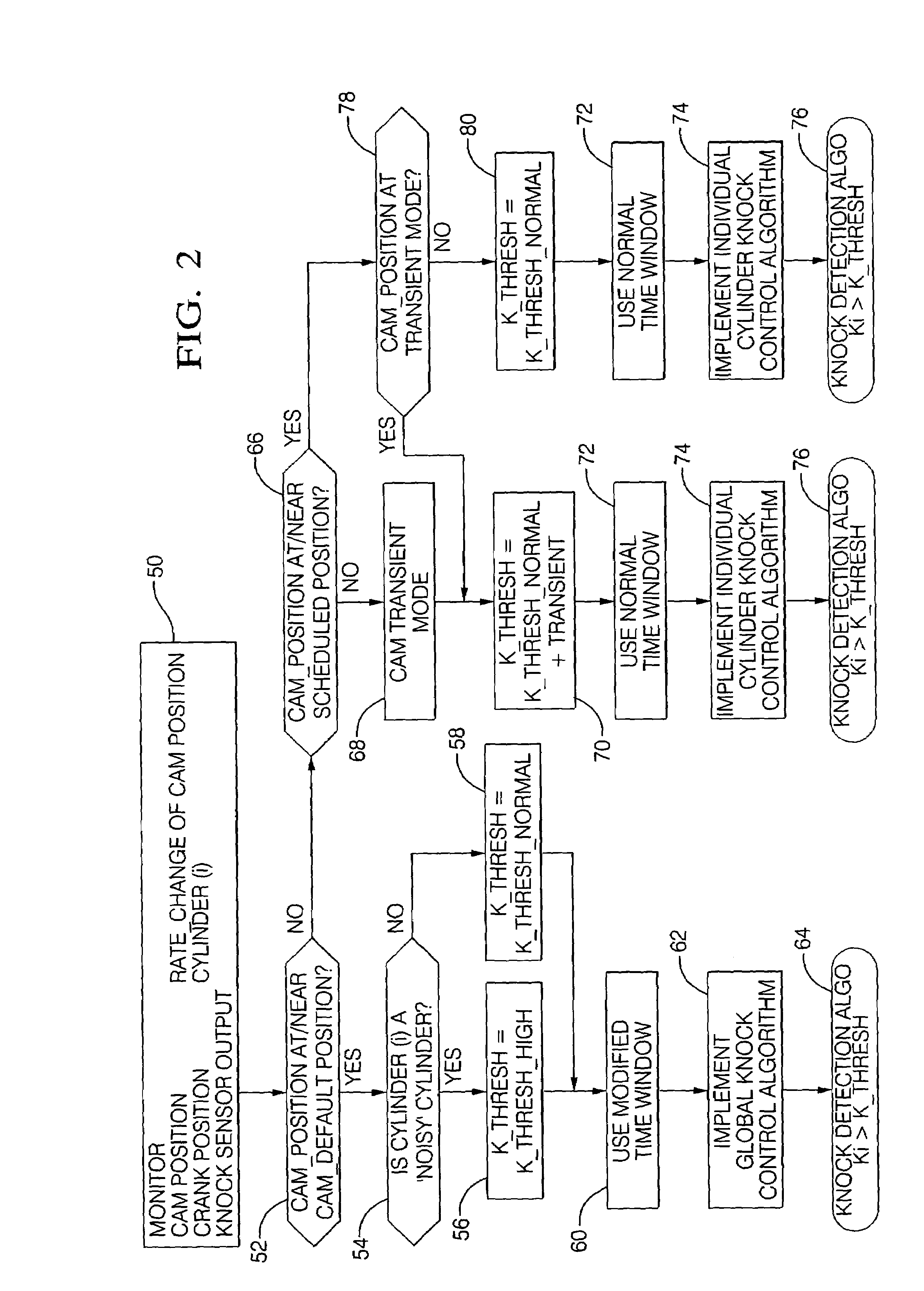

Method to control auto-ignition in an internal combustion engine equipped with variable valve timing control

A method and control system to accomplish knock control on a multi-cylinder spark-ignition internal combustion engine equipped variable cam phasing system, comprising monitoring cam position, crankshaft position, and, engine knock signal, determining cam position relative to crankshaft position, and implementing either a global cylinder knock control strategy or an individual cylinder knock control strategy, based upon whether the determined cam position relative to crankshaft position is near a default position, the determined cam position indicates the variable cam phasing system is operating in a transient mode, or, the determined cam position relative to crankshaft position is substantially different from the default position.

Owner:DELPHI TECH INC

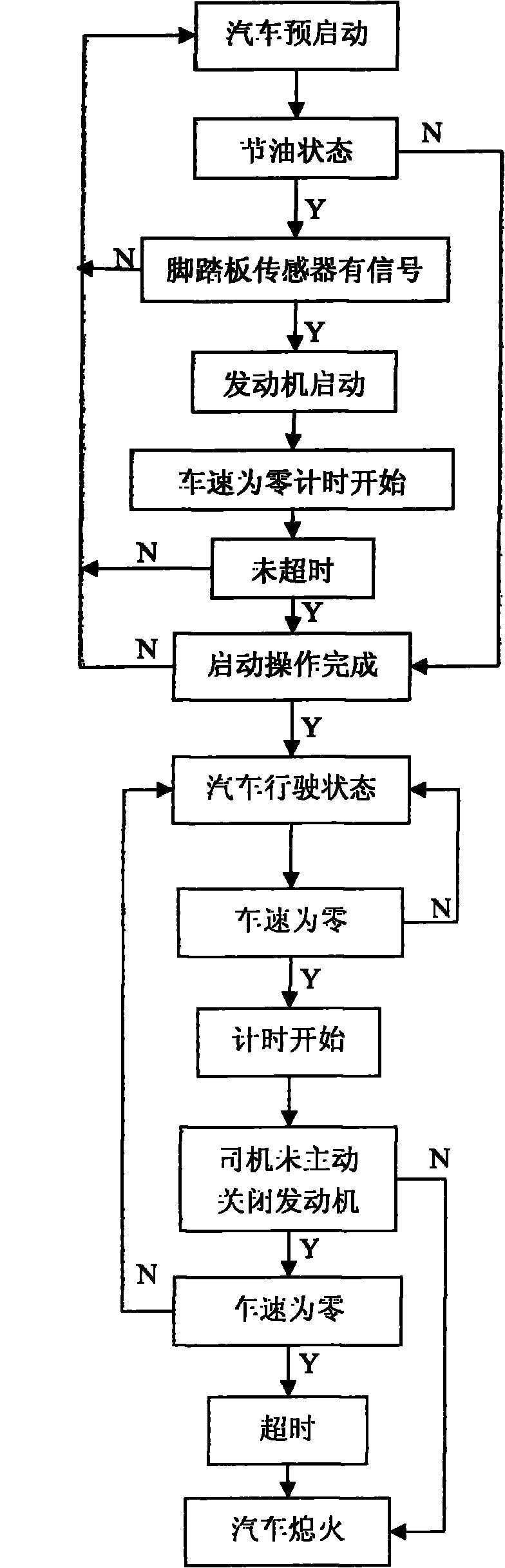

Delayed flame-out device of automobile

InactiveCN102086831AReduce lossReduce pollutionInternal combustion piston enginesIgnition automatic controlDelayed timeControl theory

The invention discloses a delayed flame-out device of an automobile, comprising a controller (1), a speed sensor (2), a timing unit (3), a voice unit (4), a man-machine interaction unit (5) and a power supply (6), wherein the controller (1) comprises a speed measurement module, a voice control module, a timing control module and a man-machine interaction control module and is respectively connected with the speed sensor (2), the timing unit (3), the voice unit (4) and the man-machine interaction unit (5); when the speed of the automobile is zero, the speed sensor (2) does not output pulses, and the controller (1) controls the timing unit (3) to carry out timing; the speed of the automobile is still zero after a preset delay time, the controller (1) of a system controls the man-machine interaction unit (5) to prompt a driver to flame out and also controls the voice unit (4) to send out prompt tones, and whether the automobile is flamed out or not is decided by the driver; countdown is carried out after an automobile owner needs to start the automobile again and stops the automobile again, and the driver manually sets different stopping delay time through the man-machine interaction unit (5).

Owner:赵若辰

Water cooled internal combustion engine for vehicle

A compact water cooled internal combustion engine for a vehicle wherein a water pump operated by a pump driving shaft is arranged on a crankcase cover for covering a lateral side of a crankcase, such that an axis of rotation of the water pump is coaxial with the pump driving shaft. A case member that forms a pump case of a water pump, together with a crankcase cover, and that rotatably supports a pump shaft of the water pump, is attached on an inner surface side of the crankcase cover.

Owner:HONDA MOTOR CO LTD

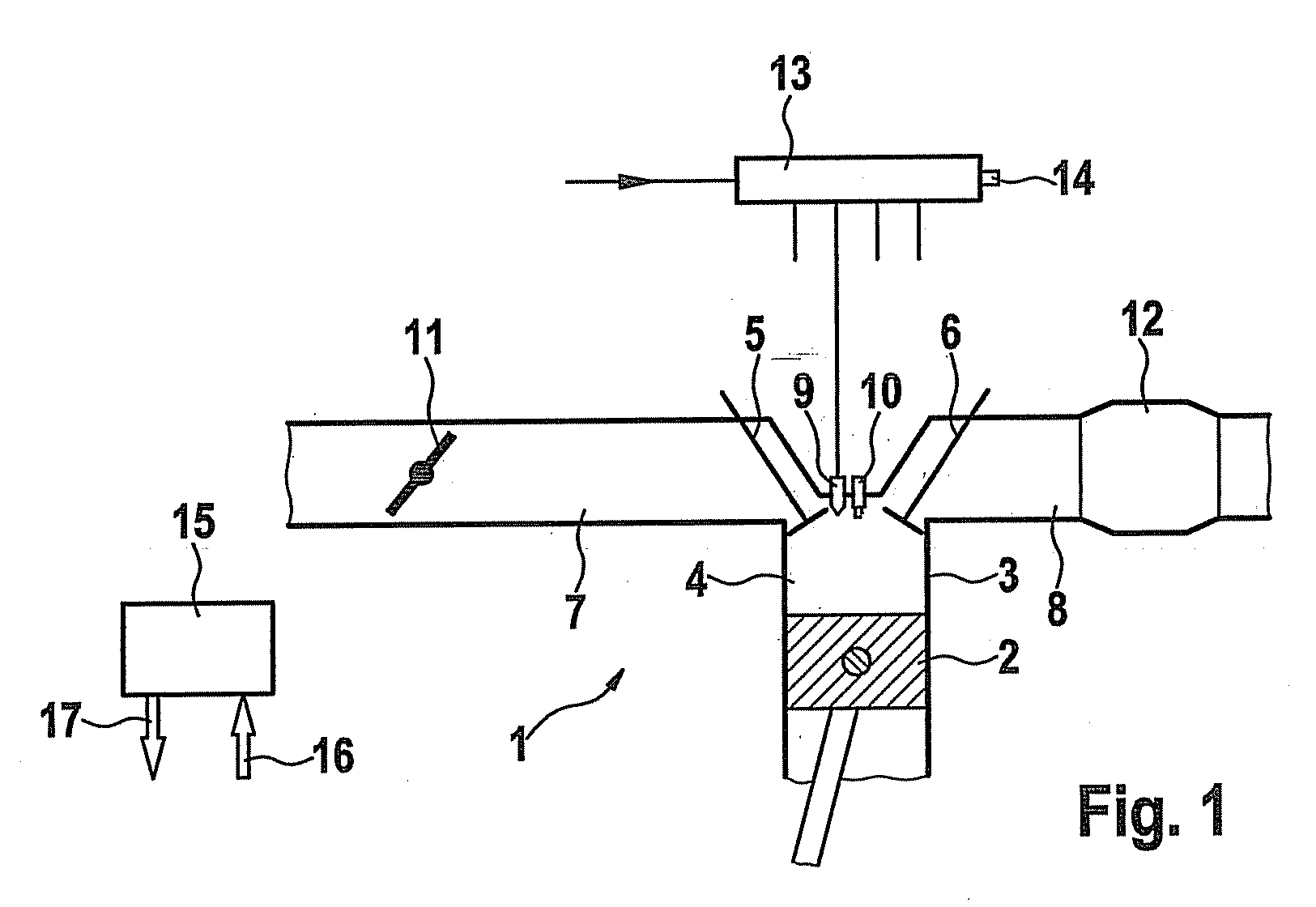

Ignition device for an internal combustion engine and method for its operation

ActiveUS7552714B2Simple configurationPrevent wrong actionGenerator for specific enginesMachines/enginesExternal combustion engineInternal combustion engine

An ignition device for a motor unit with an internal combustion engine provided with a piston, a combustion chamber with a spark plug, a crankshaft driven by the piston, an intake port supplying combustion air to the combustion chamber, an exhaust for removing combustion gases from the combustion chamber, a signal generator driven by the crankshaft and emitting for one crankshaft revolution an alternating voltage signal, has an ignition unit that triggers a spark at the spark plug at a preselectable timing. The ignition unit is a module separate from the motor unit. An alternating voltage signal generated by the signal generator is supplied to the ignition unit as an information signal sufficient for operating the internal combustion engine. The alternating voltage signal is supplied to a first unit for energy processing and to a second unit for processing information for control of the internal combustion engine.

Owner:ANDREAS STIHL AG & CO KG

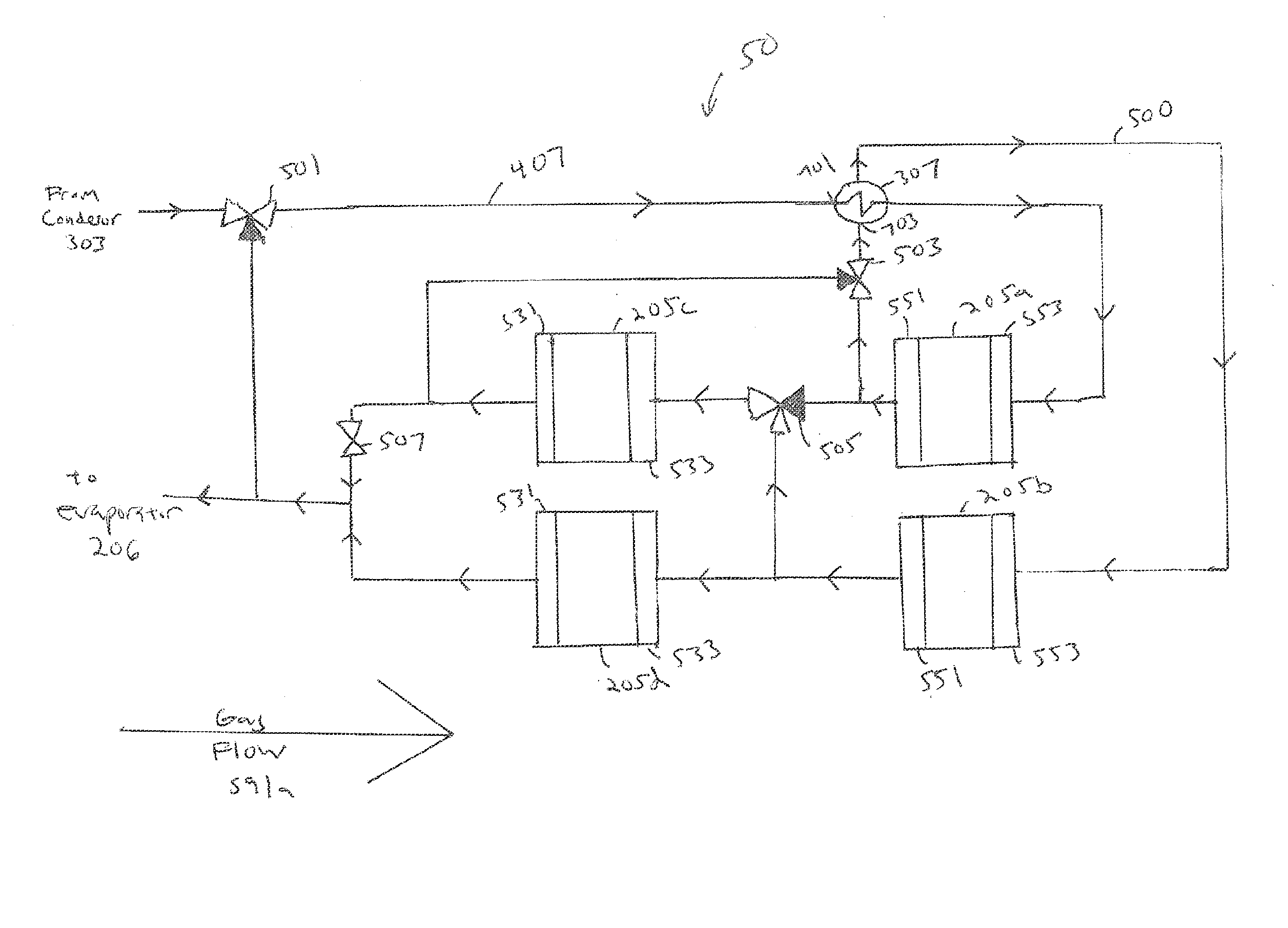

Gas-to-Liquid Heat Exchange System with Multiple Liquid Flow Patterns

Systems and methods for the design of a heat recovery steam generator (HRSG) or similar system that is designed to extract heat from hot gases flowing through a duct which utilizes an external liquid-to-liquid heat exchanger for preheating feedwater. The systems and methods allow for multiple water flow patterns to adjust the temperature of the feedwater into the gas duct.

Owner:NOOTER ERIKSEN INC

Popular searches

Automatic control Mechanical automatic control Fluid pressure measurement using ohmic-resistance variation Combustion engines Volume/mass flow by differential pressure Special data processing applications Engine testing Vehicle position/course/altitude control Position/direction control Fuel injection control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com