Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about "Material removal/addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

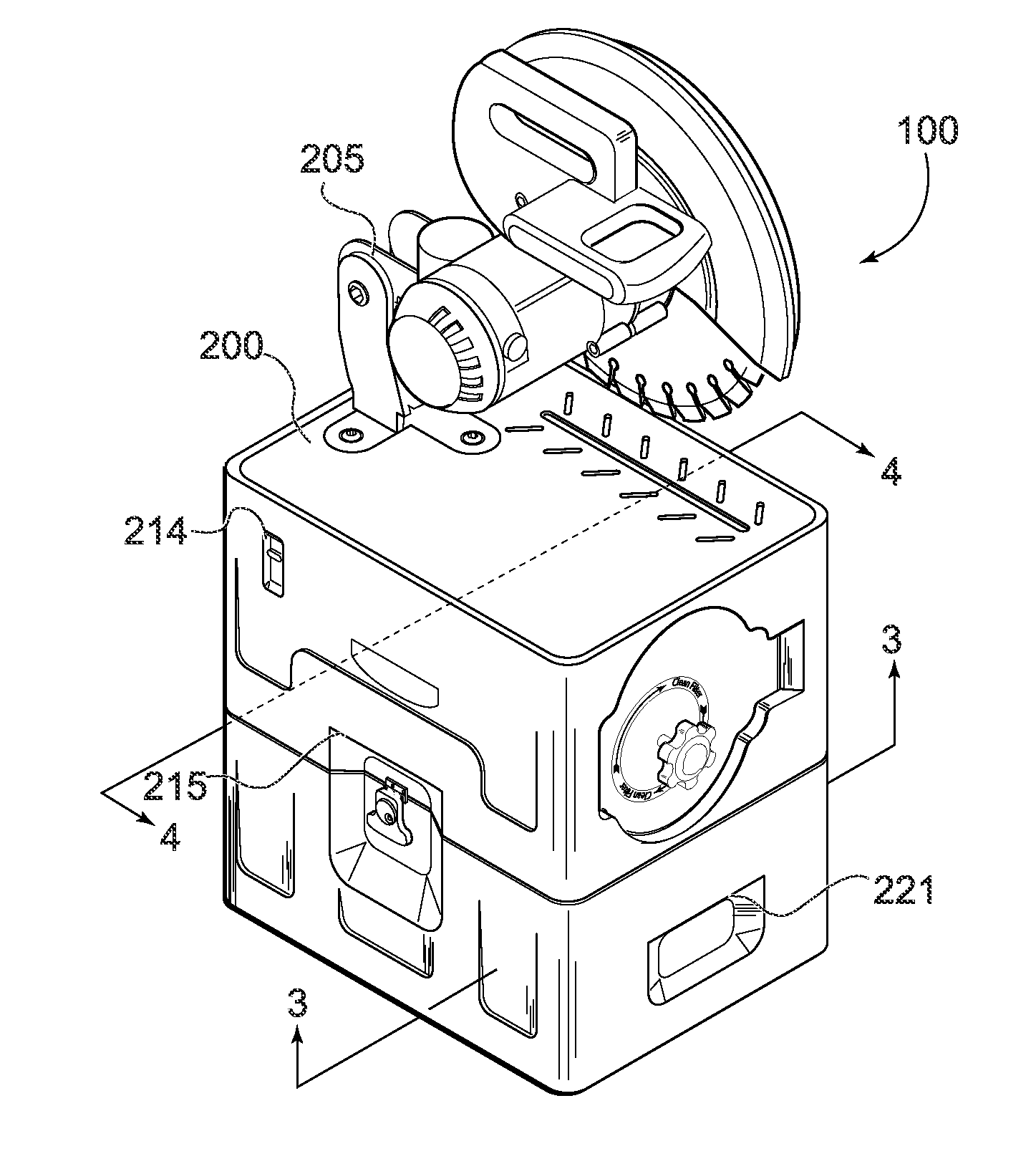

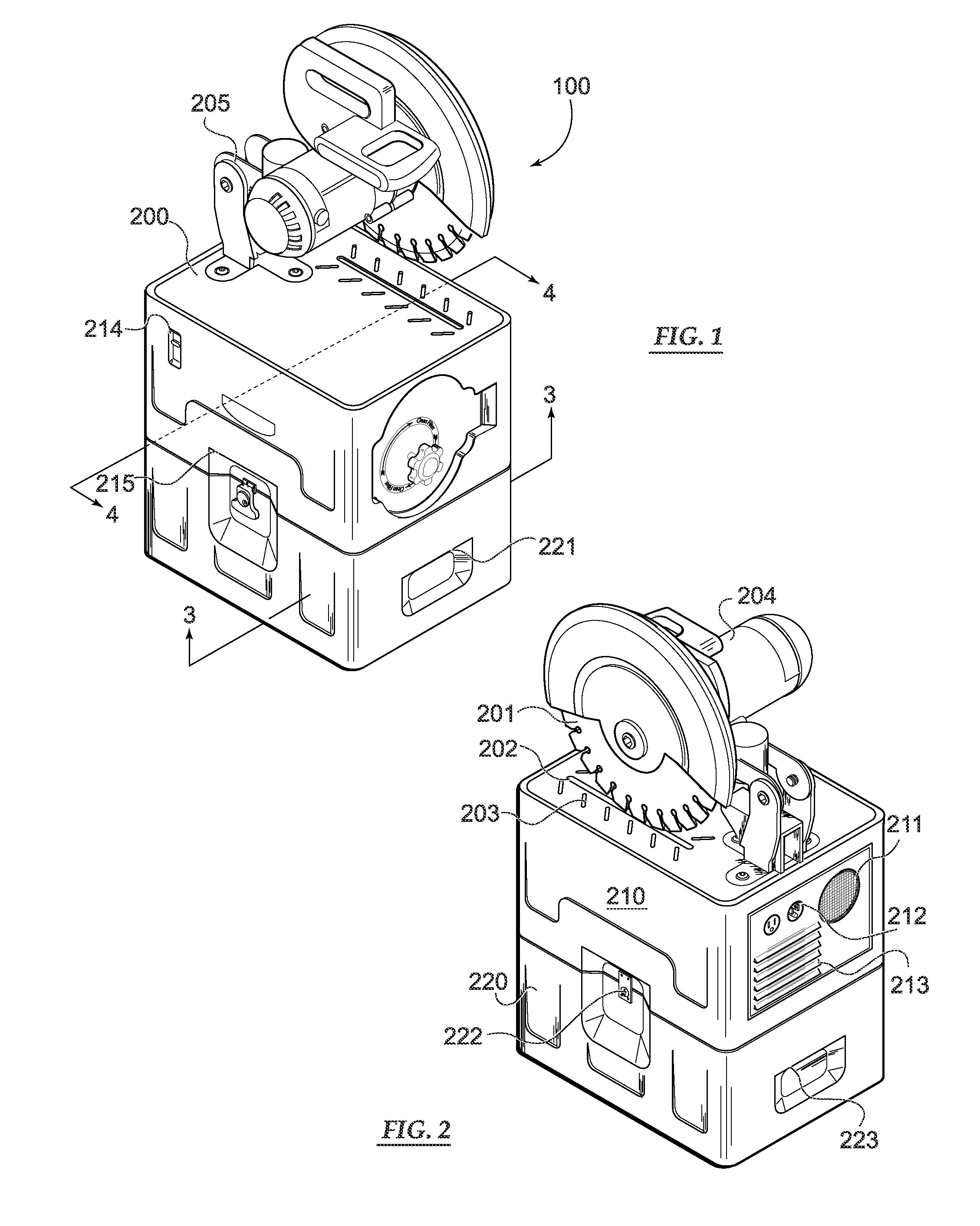

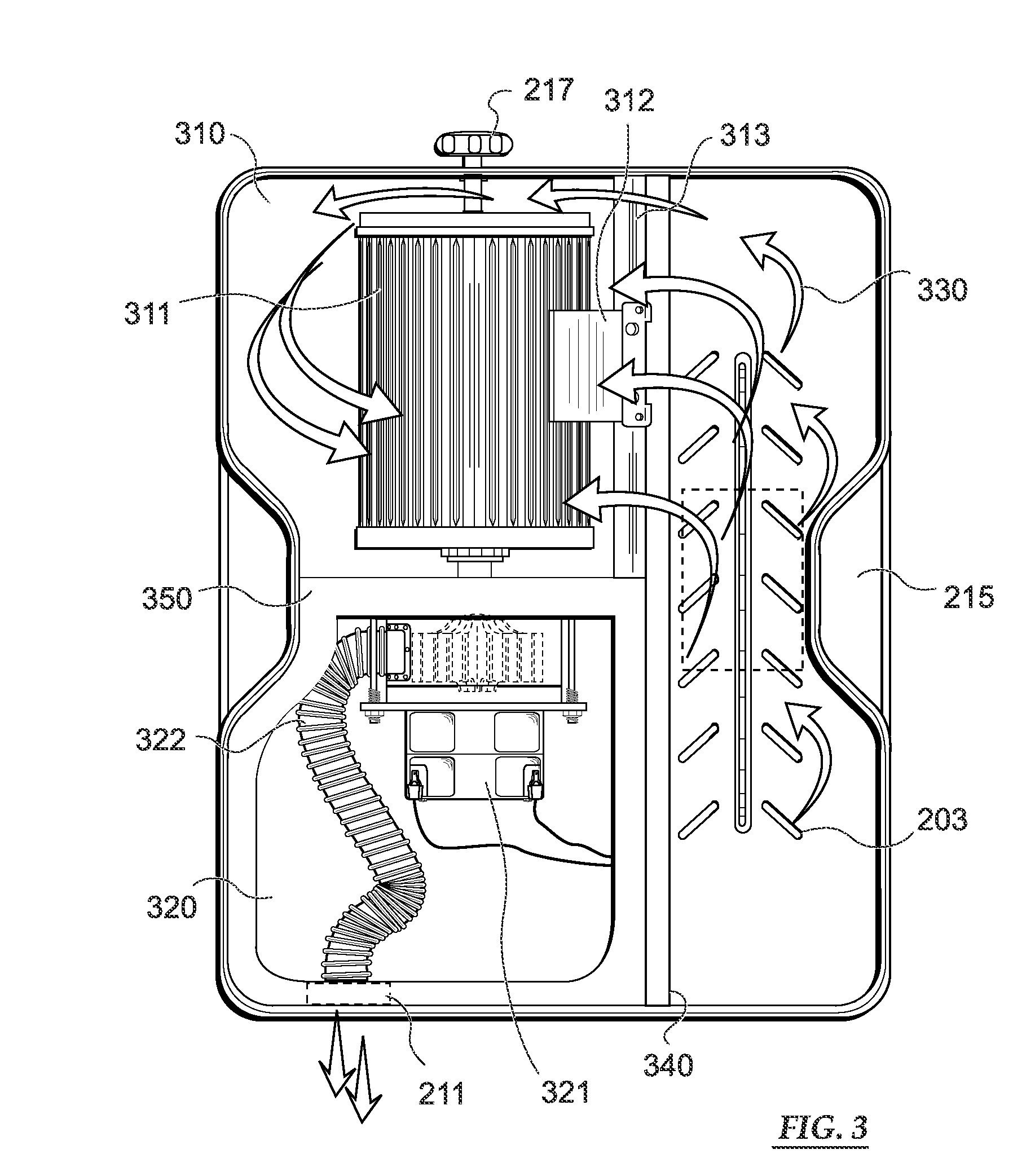

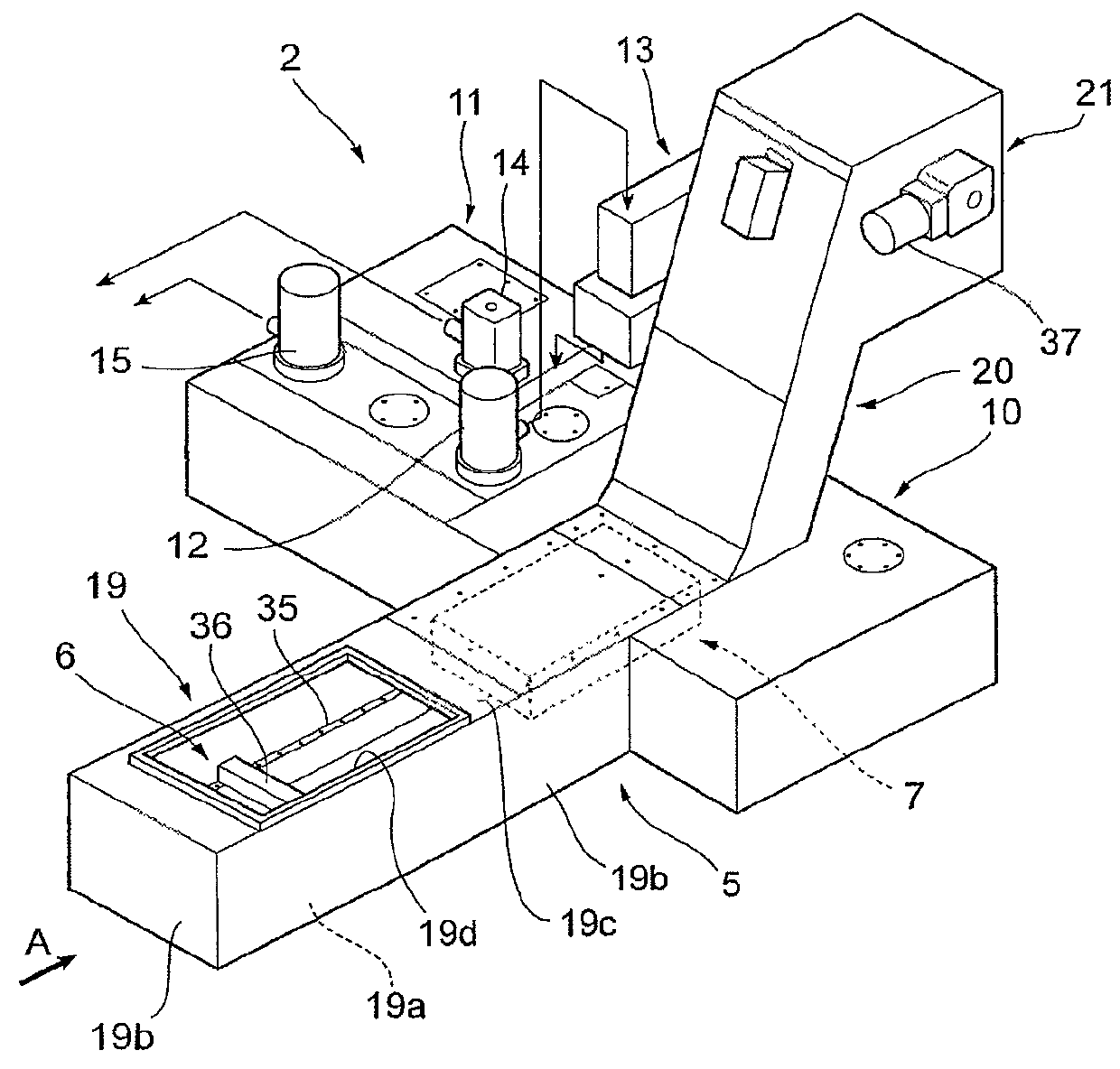

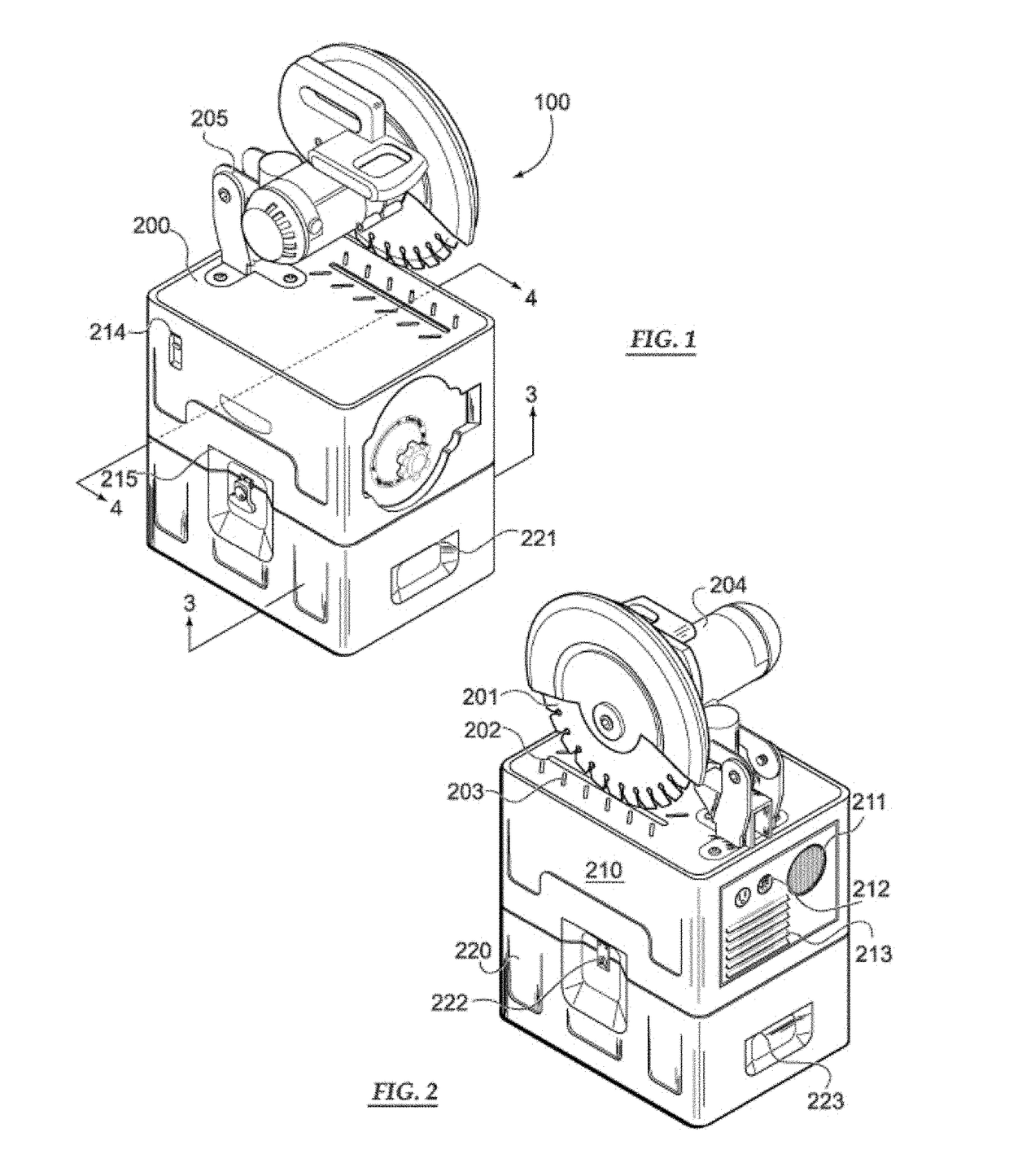

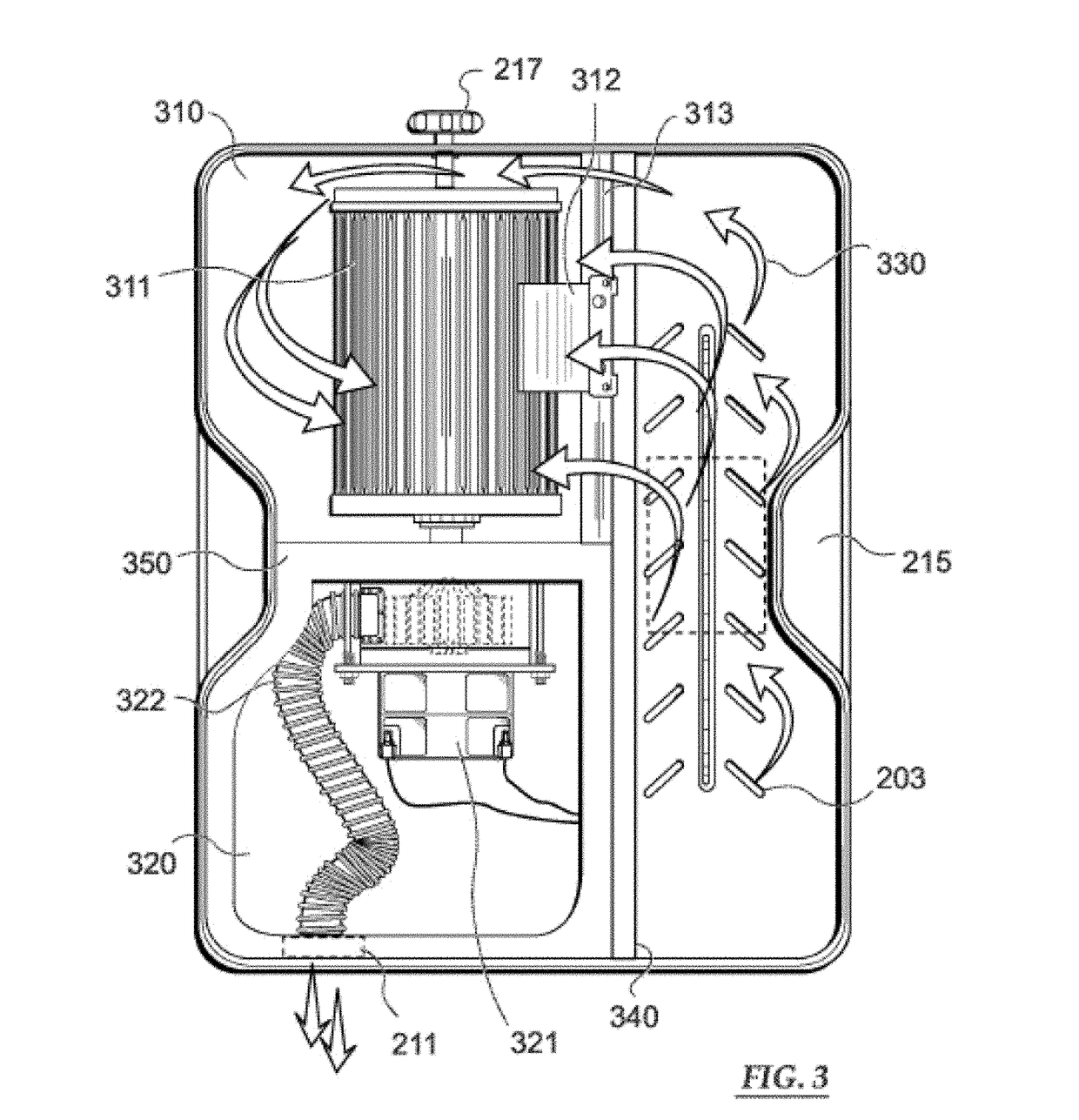

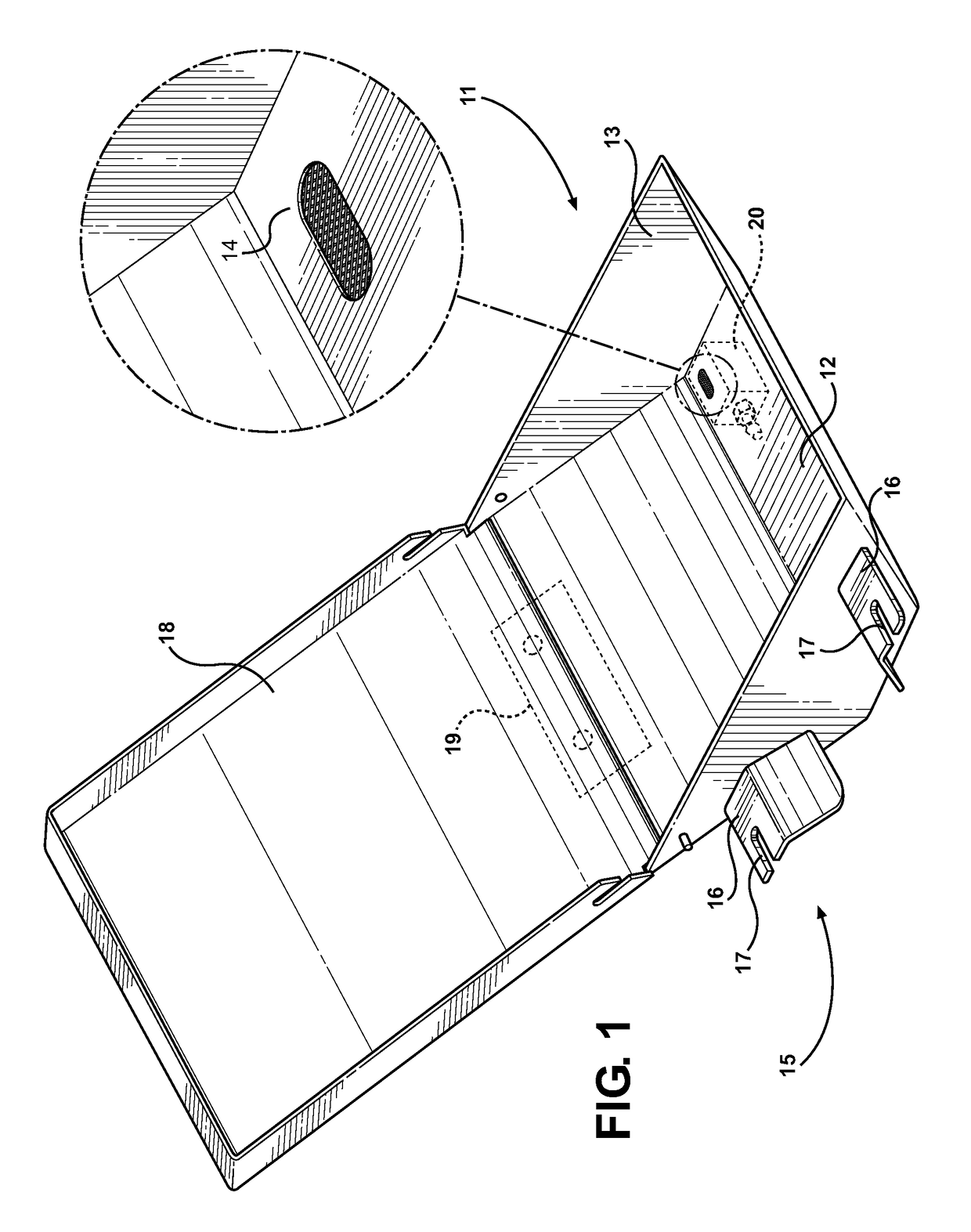

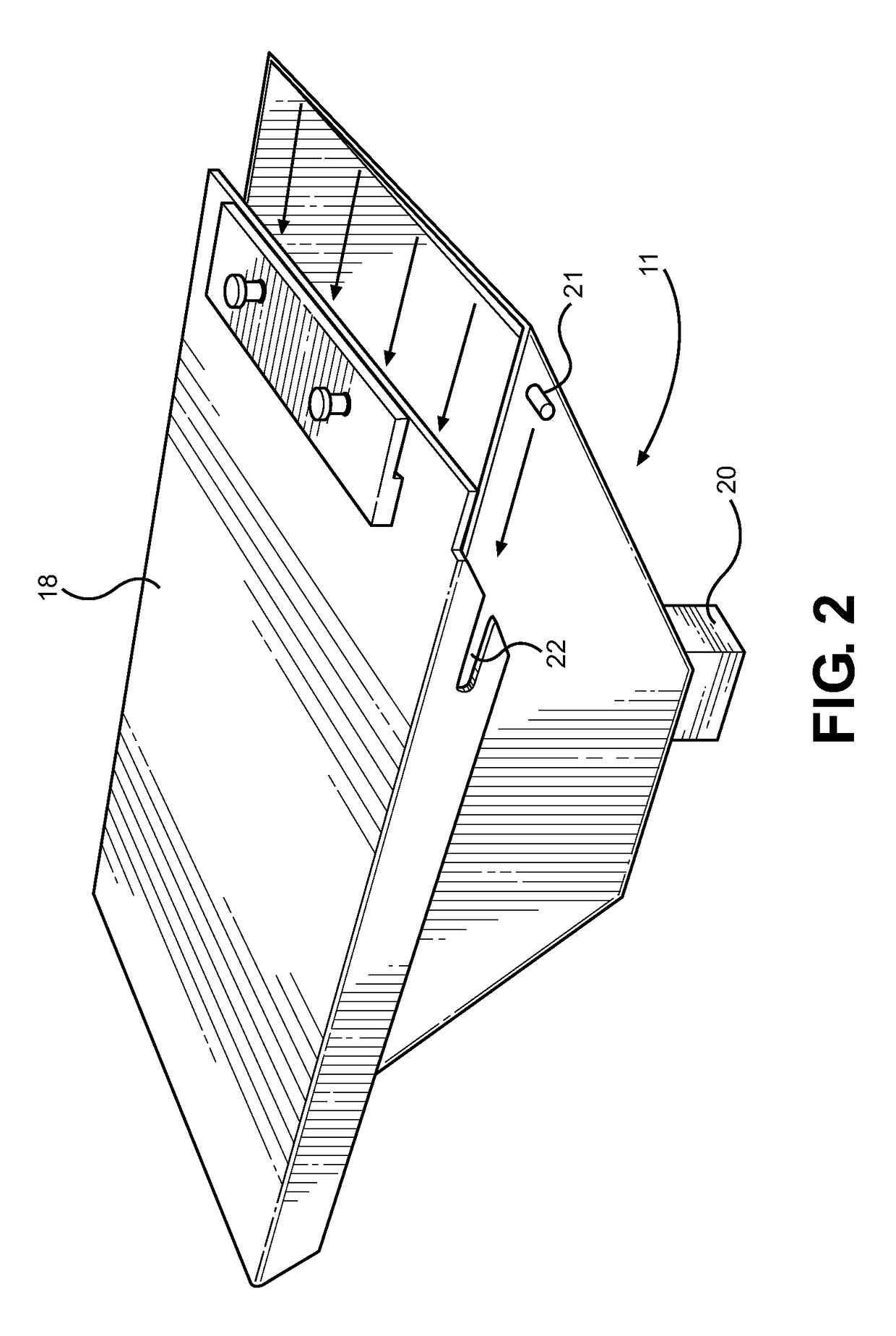

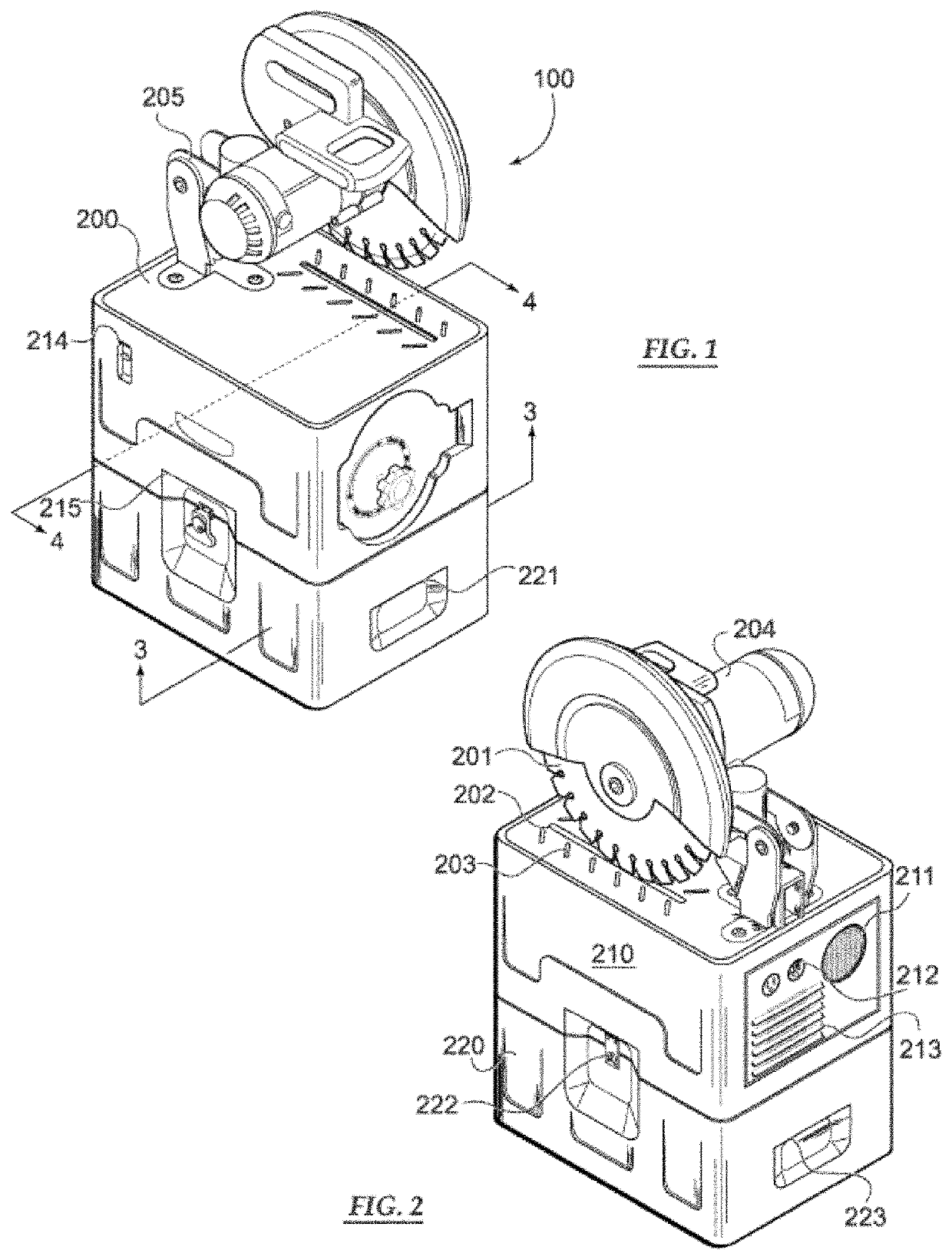

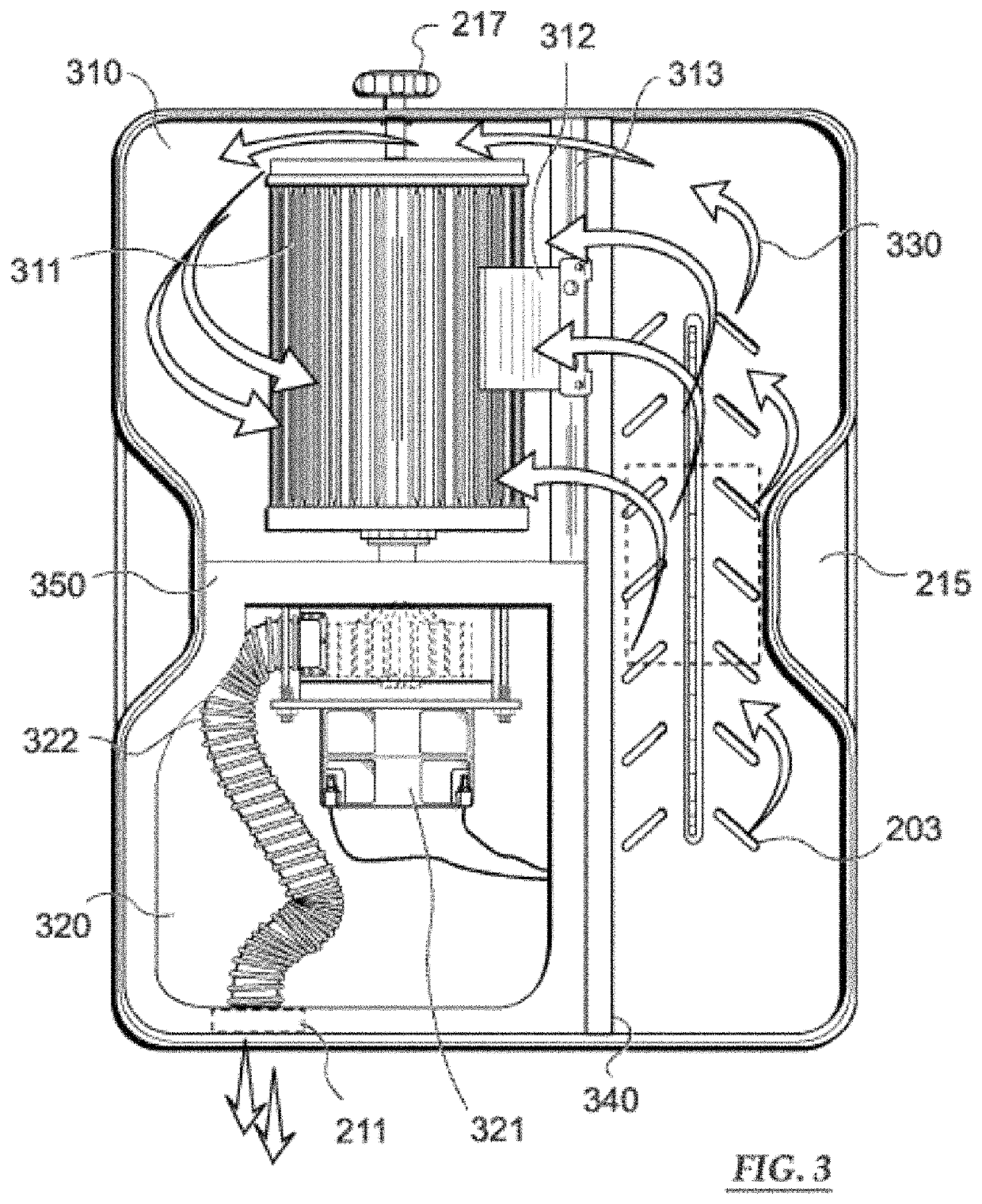

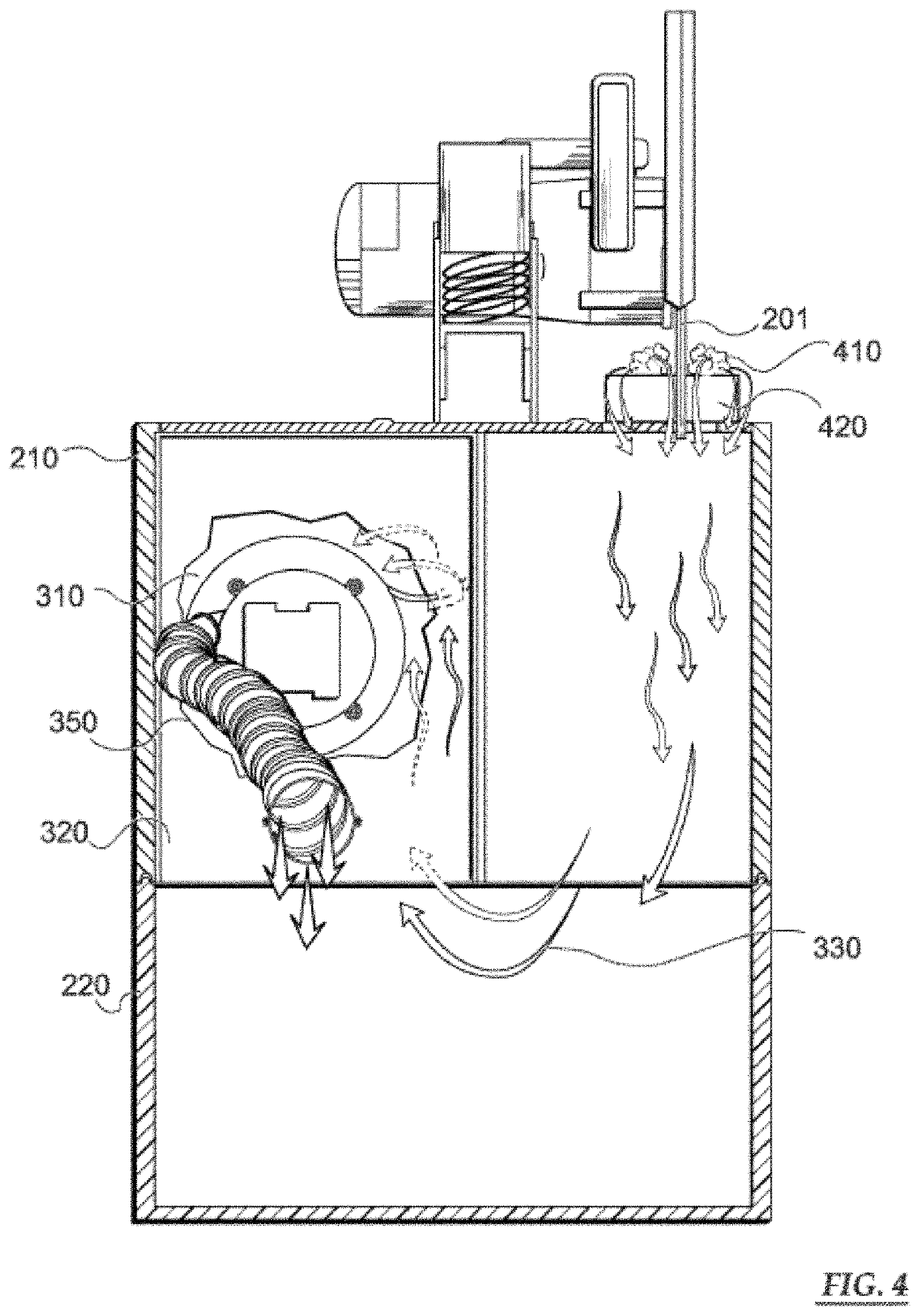

Chop Saw with Dust Collection System

ActiveUS20100116261A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesParticulatesCircular saw

A chop saw, grinding wheel, or like apparatus is disclosed herein also incorporated to an easily portable dust collection system. In a preferred embodiment, a worktable is provided with a center slot for receiving a circular saw blade. A negative pressure and resulting air flow is provided at the center slot to capture particulate matter as a byproduct of cutting the workpiece. Side slots are also disclosed to assist in particulate collection. A unique filter chamber having a cylindrical filter is additionally provided to remove dust from air and discharge the filtered air at a lateral side of the apparatus. A filter cleaning knob is additionally disclosed to assist in cleaning the filter. Of the beneficial aspects of the chop saw with dust collection system is its portability being one integral unit and the dust filter being easily cleaned and maintained.

Owner:JPL GLOBAL

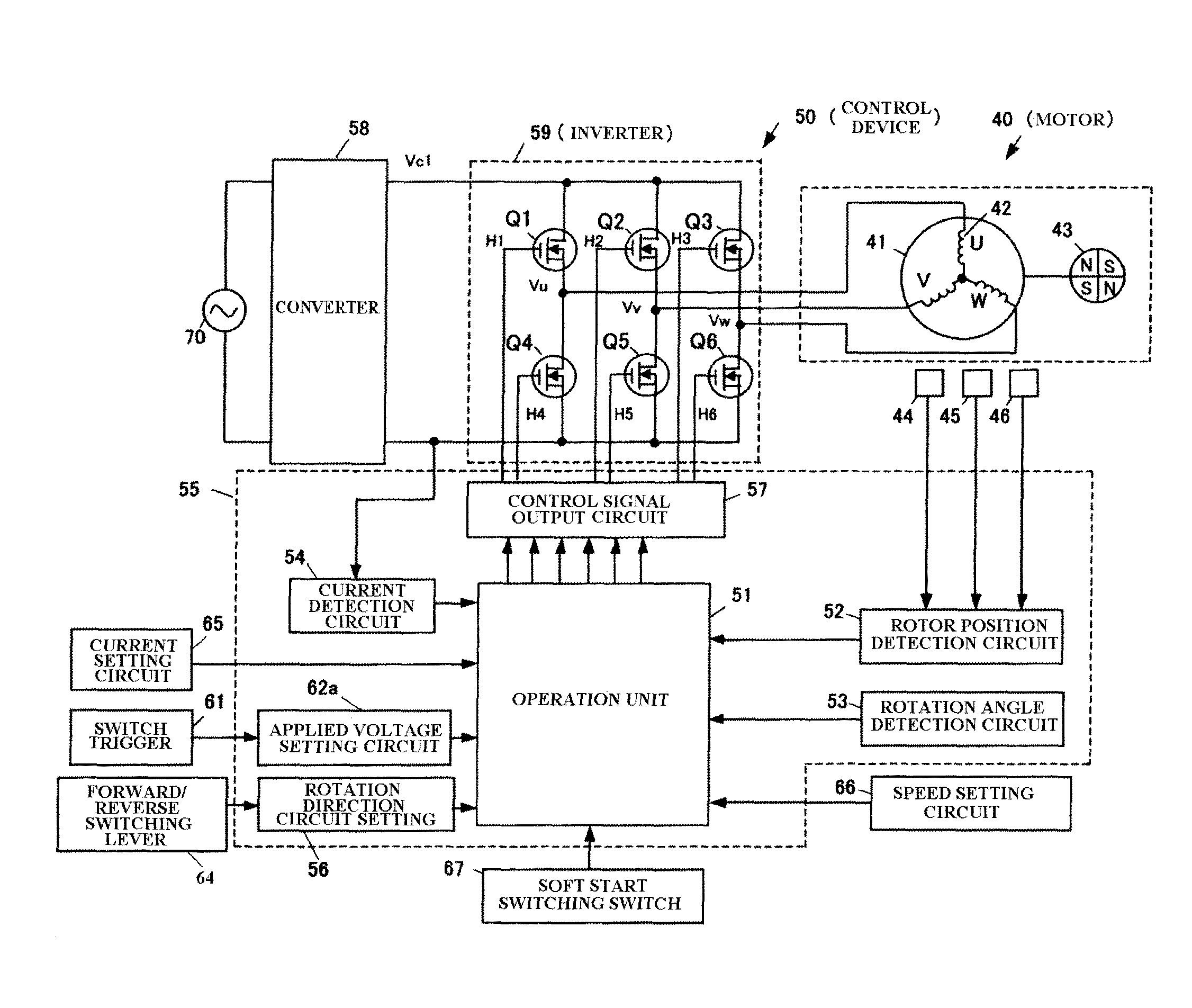

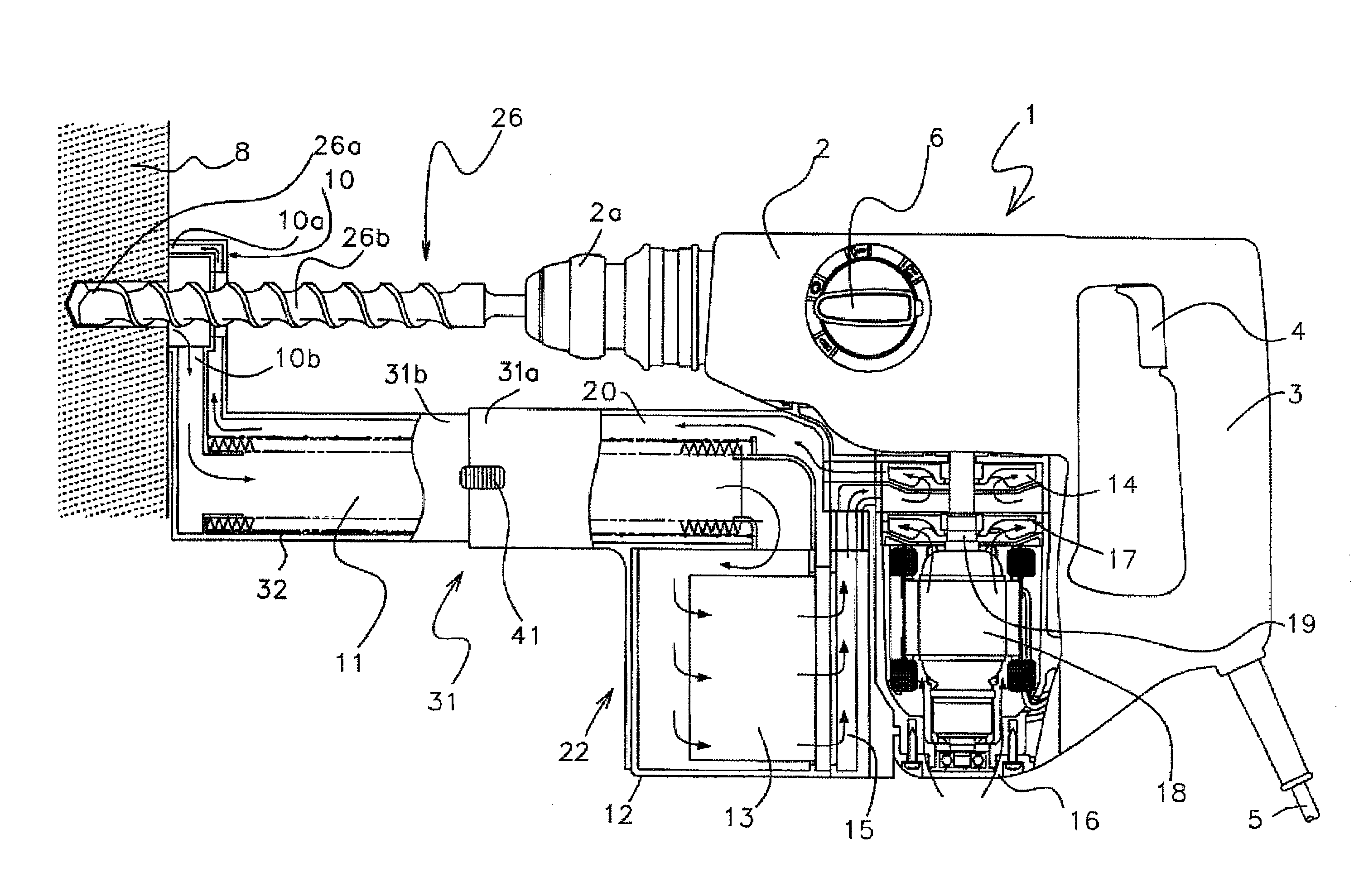

Electric boring tool

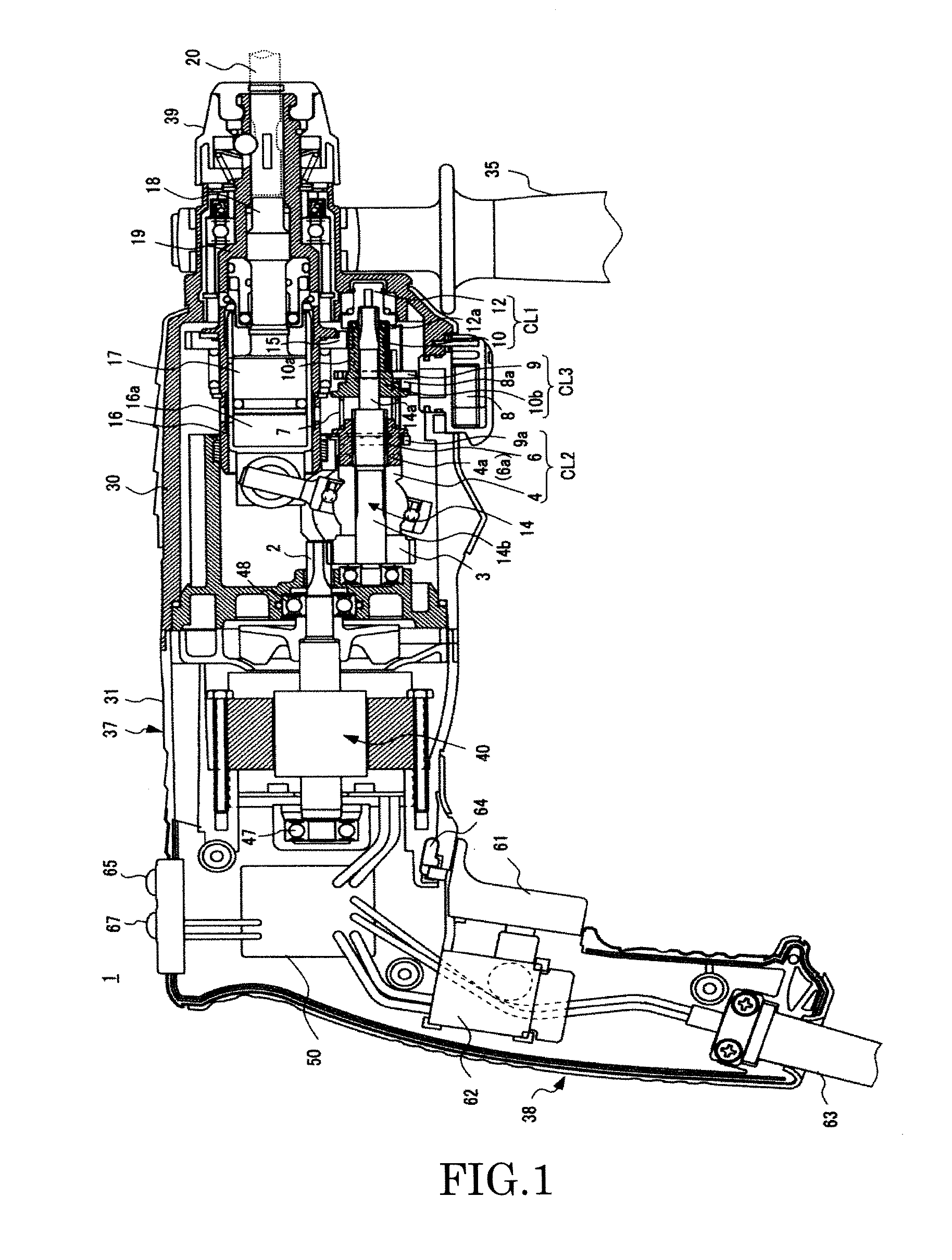

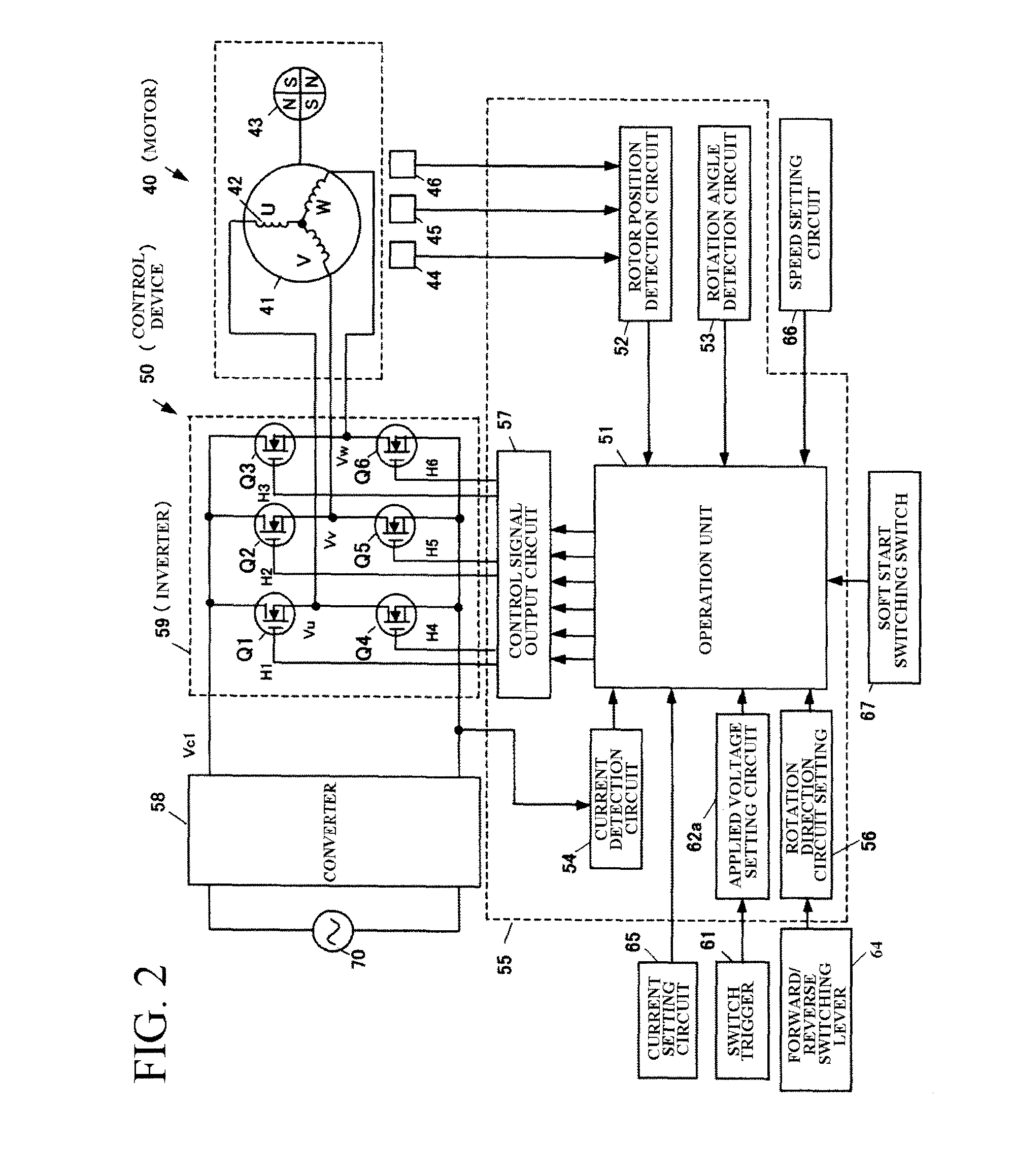

InactiveUS9314855B2Prevent and ease damageMotor control for very low speedsDC motor speed/torque controlPower flowMotor control

An electric boring tool comprises an electric motor, a switch trigger, a tip tool driven by driving force of the electric motor, a power transmission mechanism for transmitting the driving force of the electric motor to the tip tool as rotational force and / or hammer force, and a motor control unit for controlling speed of the electric motor in response to an extent of pulling of the switch trigger. The motor control unit subjects the electric motor to low speed control after the electric motor is started up, and controls the speed of the electric motor in response to the extent of pulling of the switch trigger when the load current of the electric motor is set value or greater during the low speed control.

Owner:KOKI HLDG CO LTD

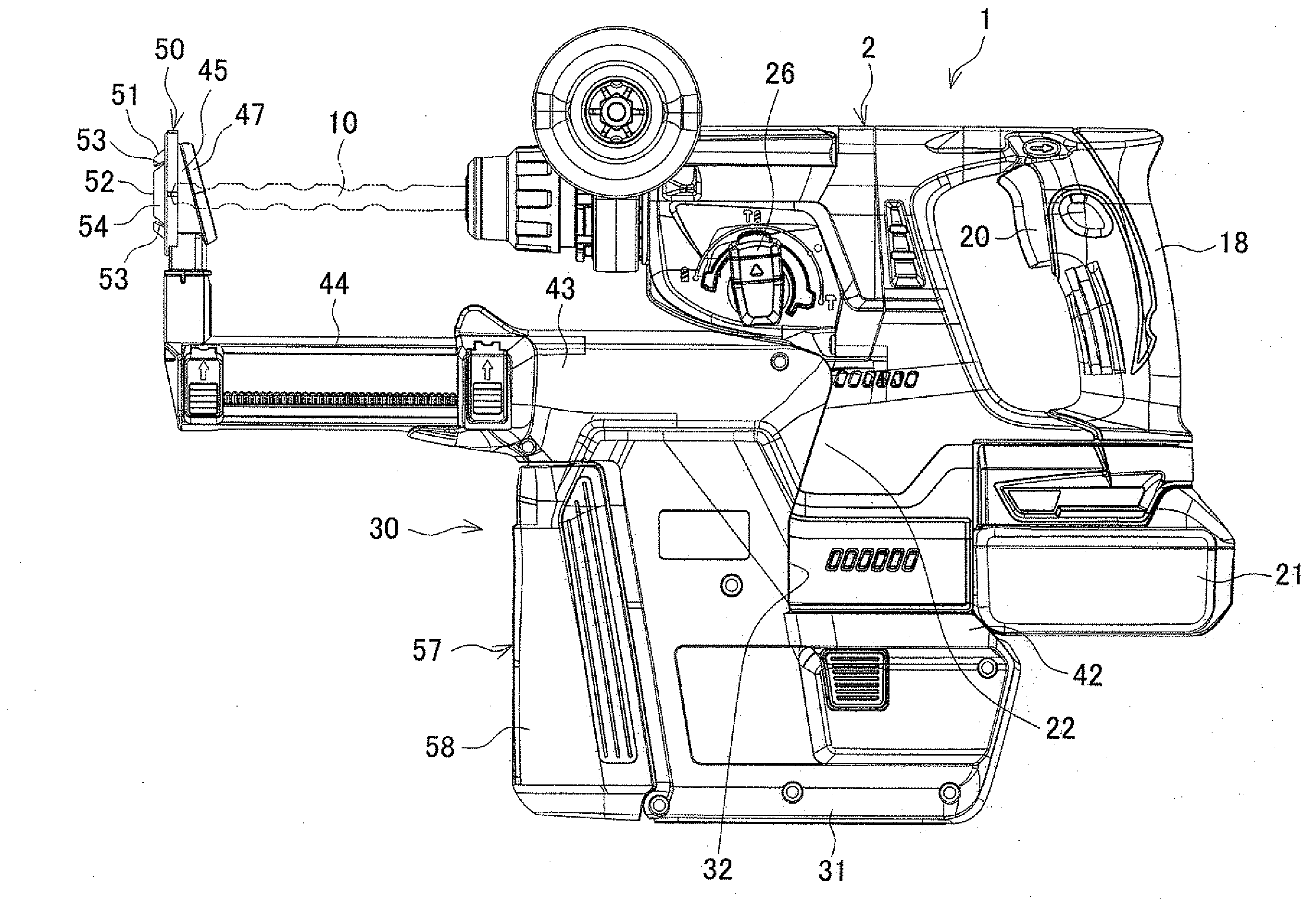

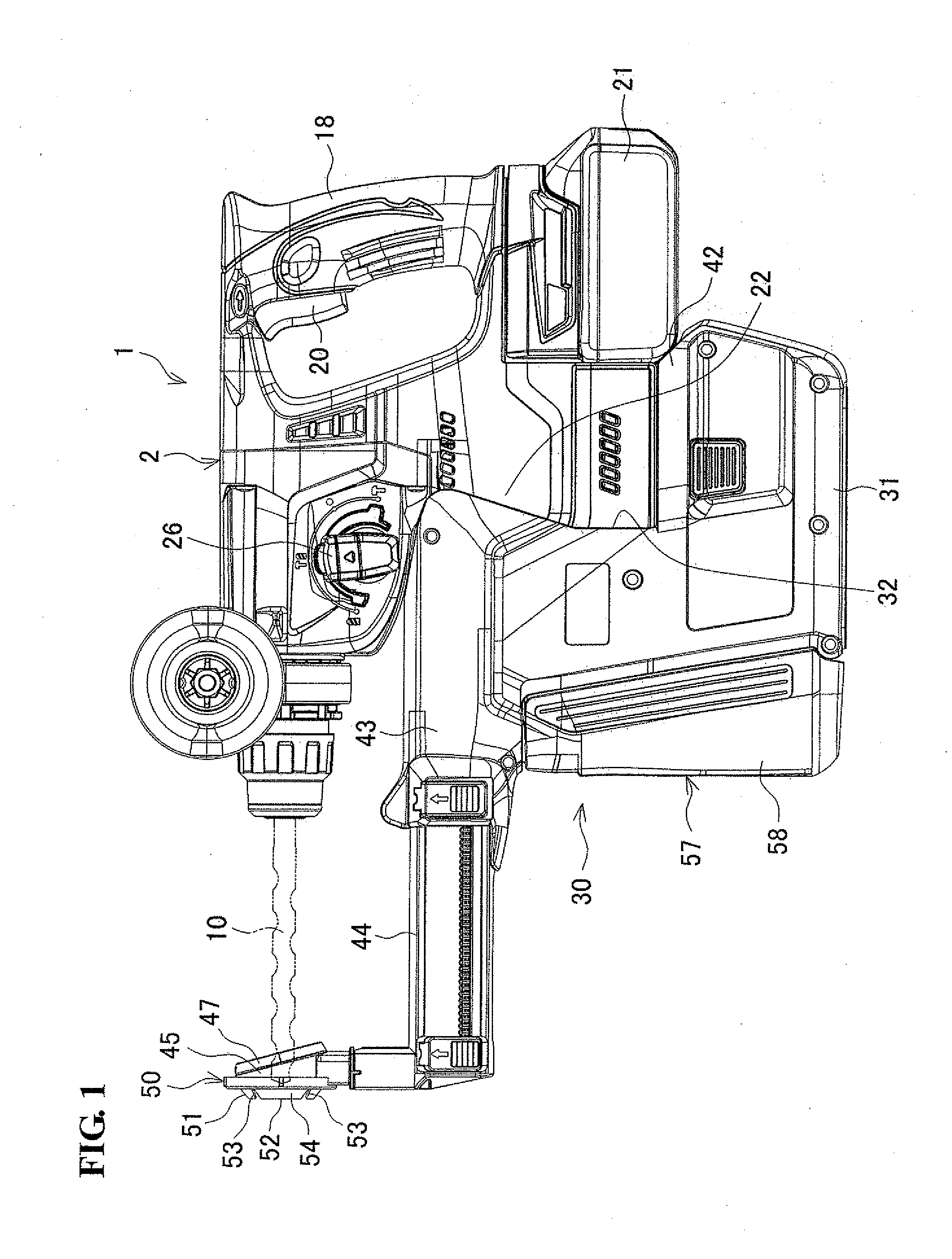

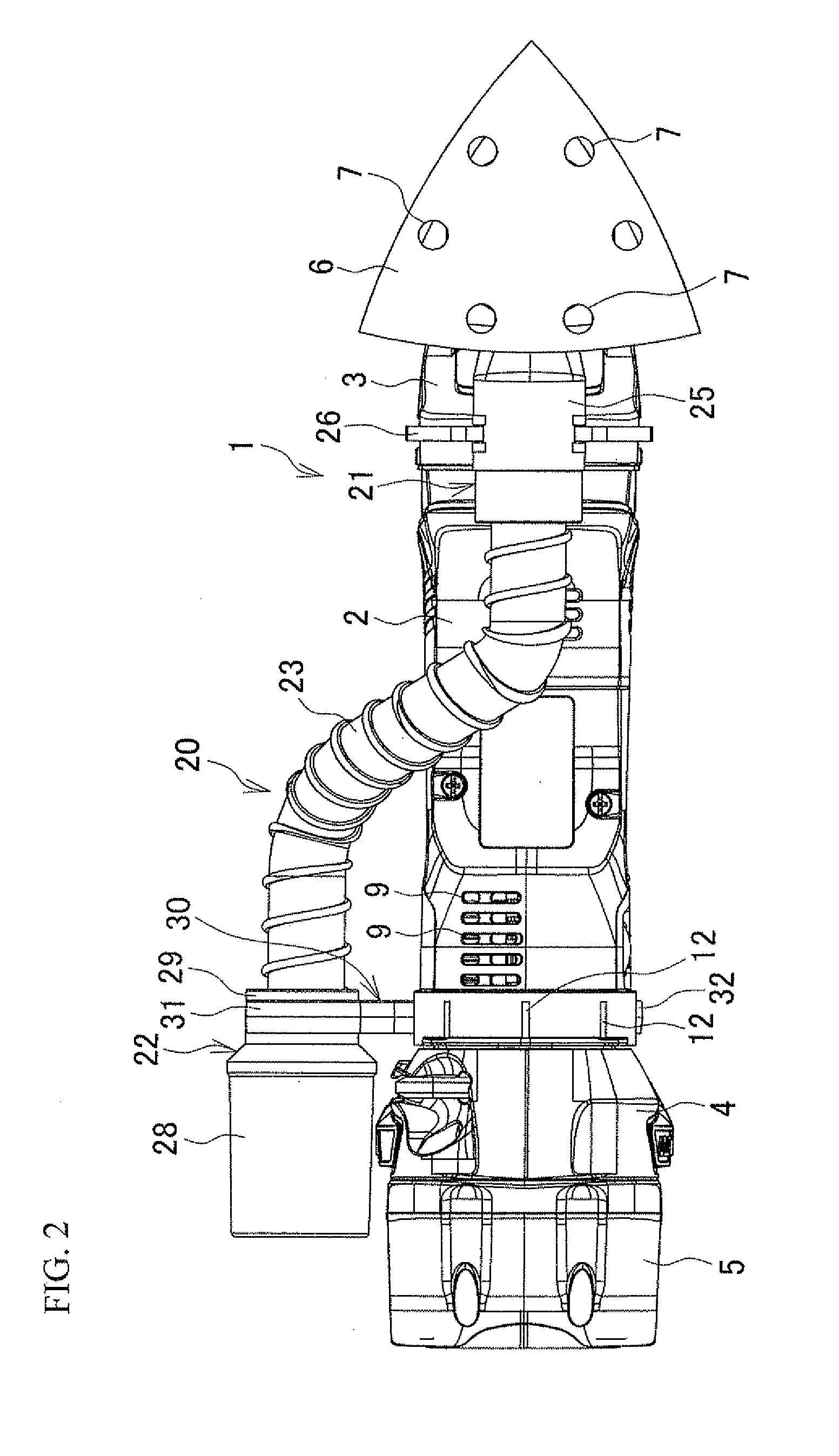

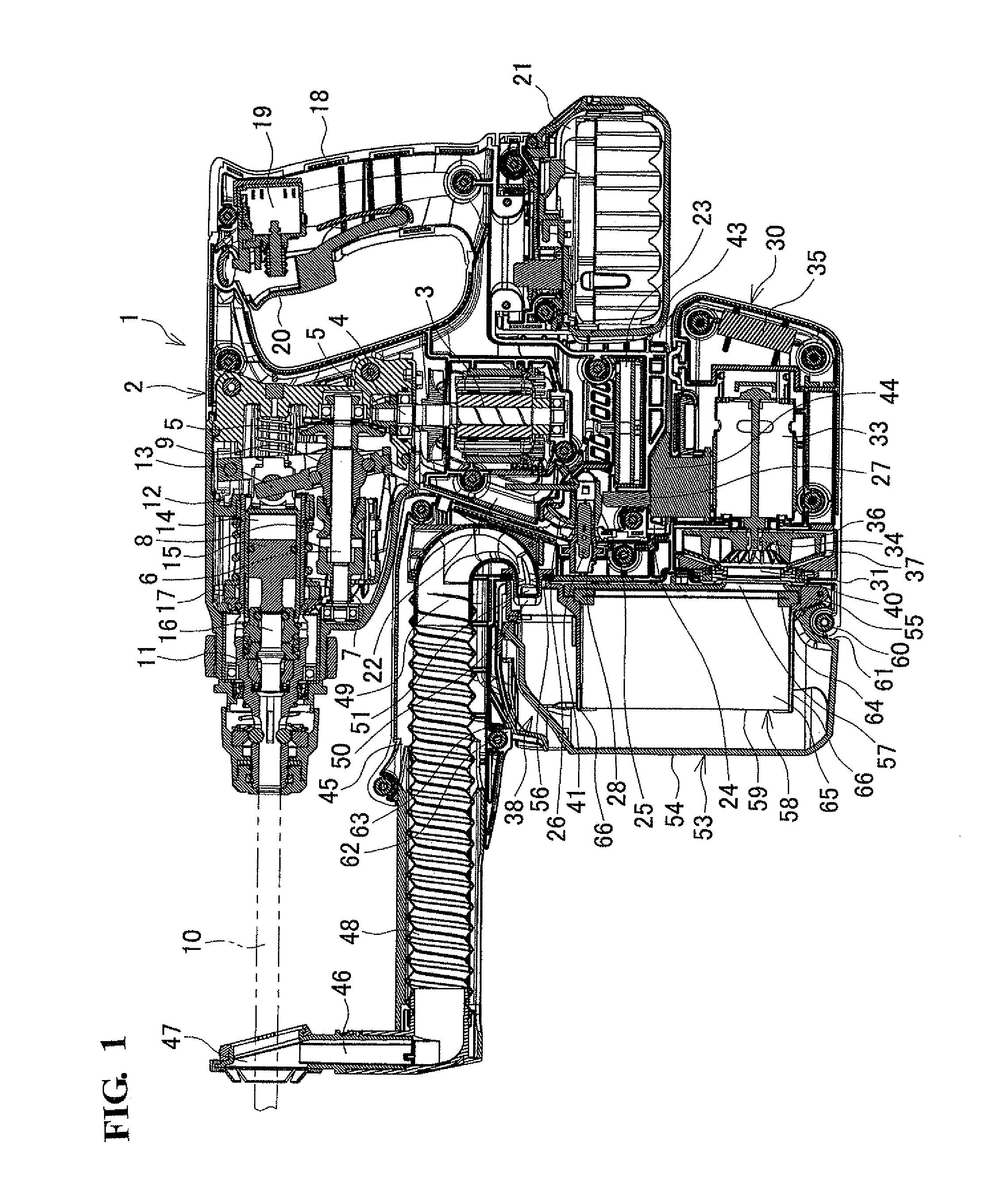

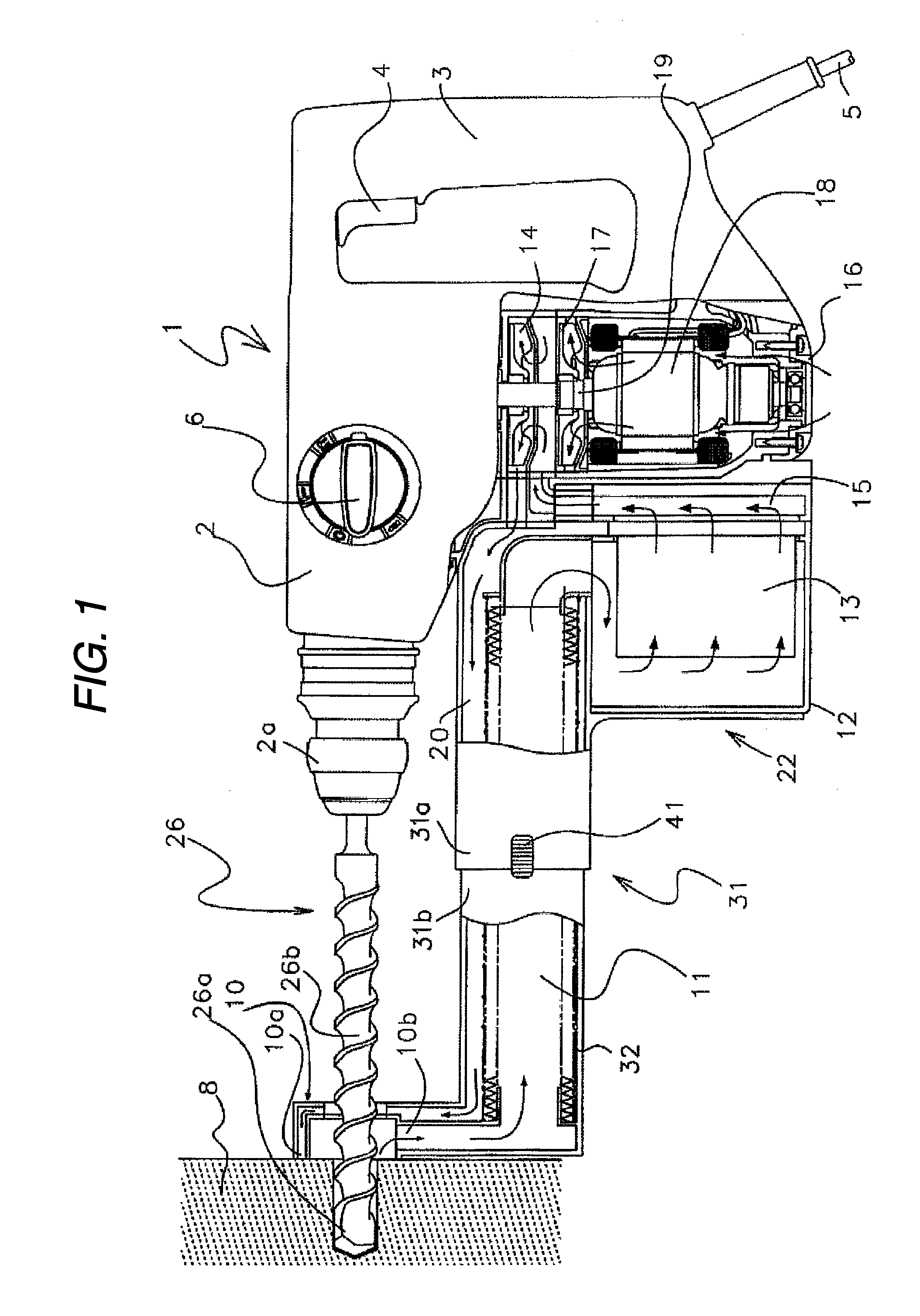

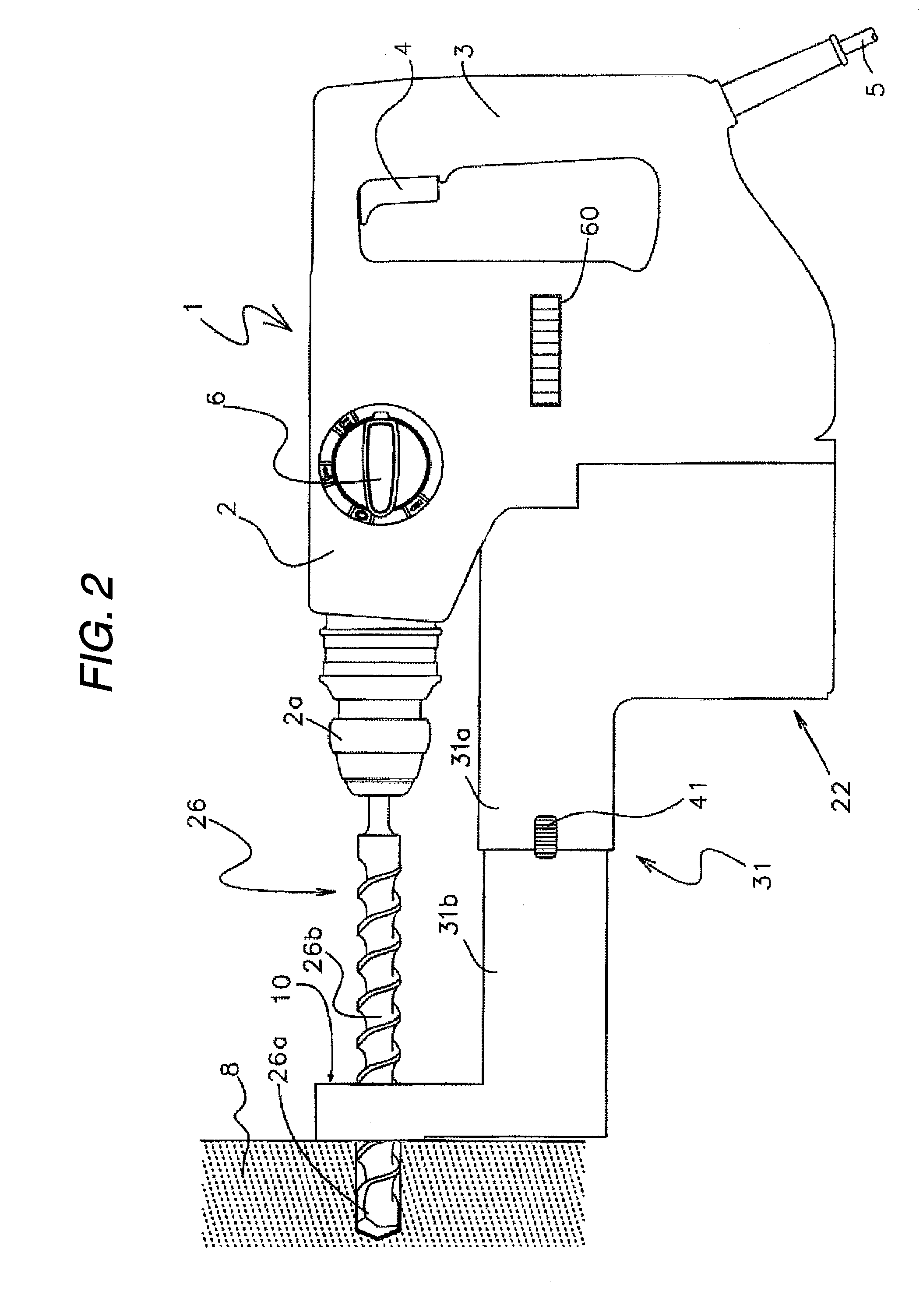

Power tool dust collecting device and power tool

ActiveUS20130055523A1Suitable dust collecting efficiencyKeep the flowCleaning filter meansSuction filtersEngineeringPower tool

In a power tool dust collecting device, a blocking ring that is subject to elastic deformation upon contact with a workpiece surface for blockage between a suction head and the workpiece surface is provided to the front surface of the suction head to be brought into contact with the workpiece surface. The blocking ring has a ventilating portion (a V-shaped slit) that ensures the flow of air to the suction head regardless of whether the elastic deformation has occurred.

Owner:MAKITA CORP

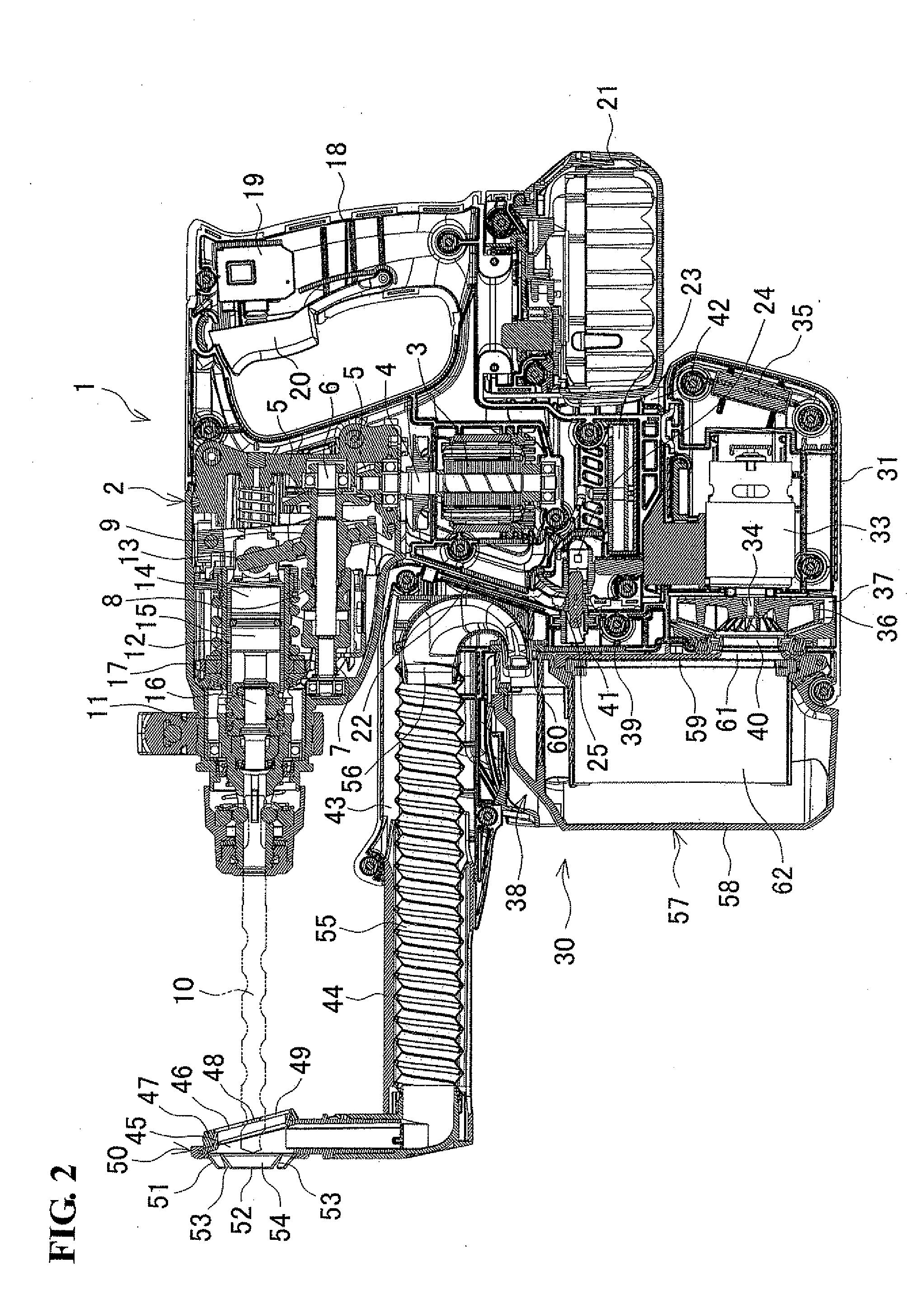

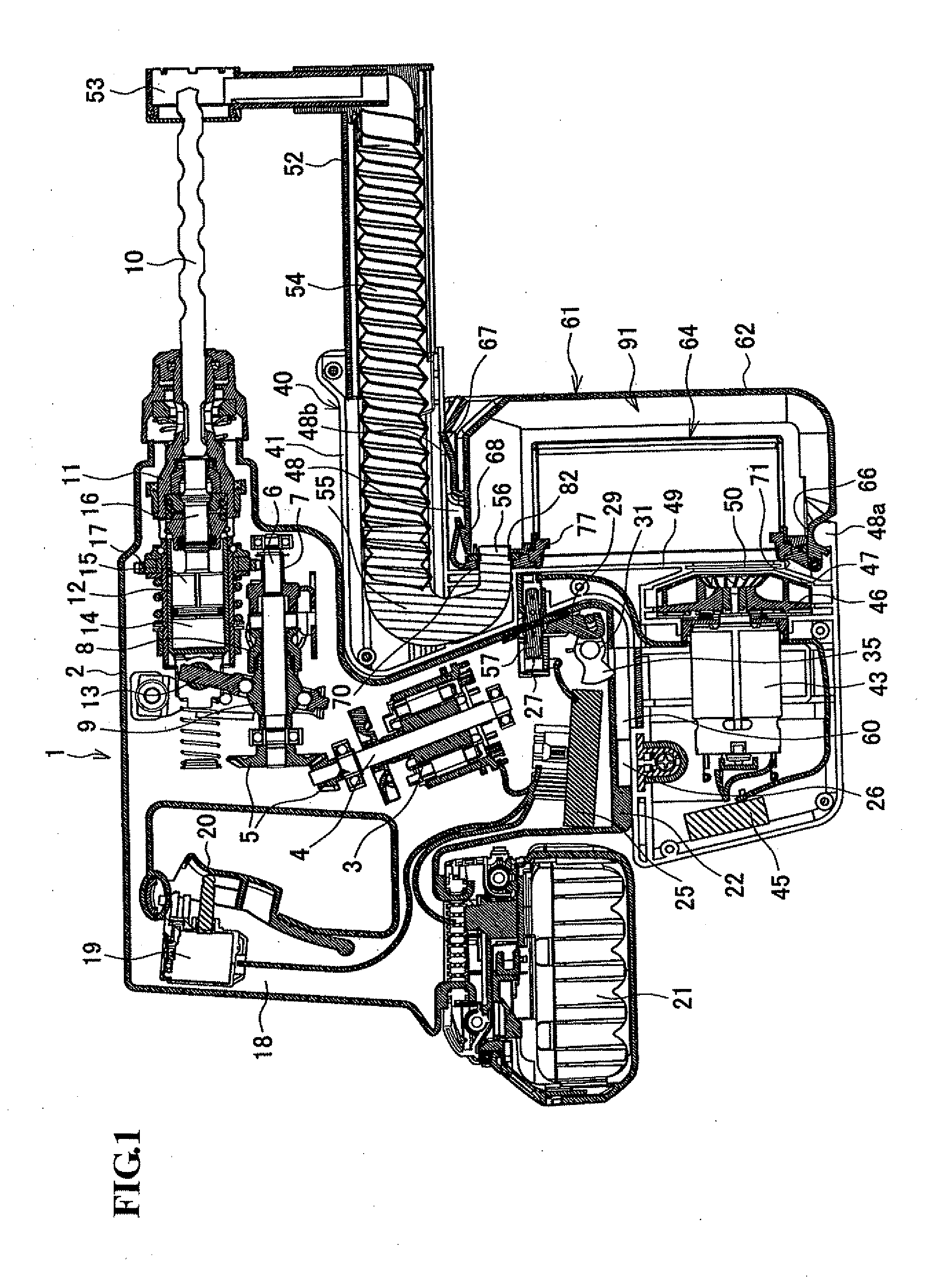

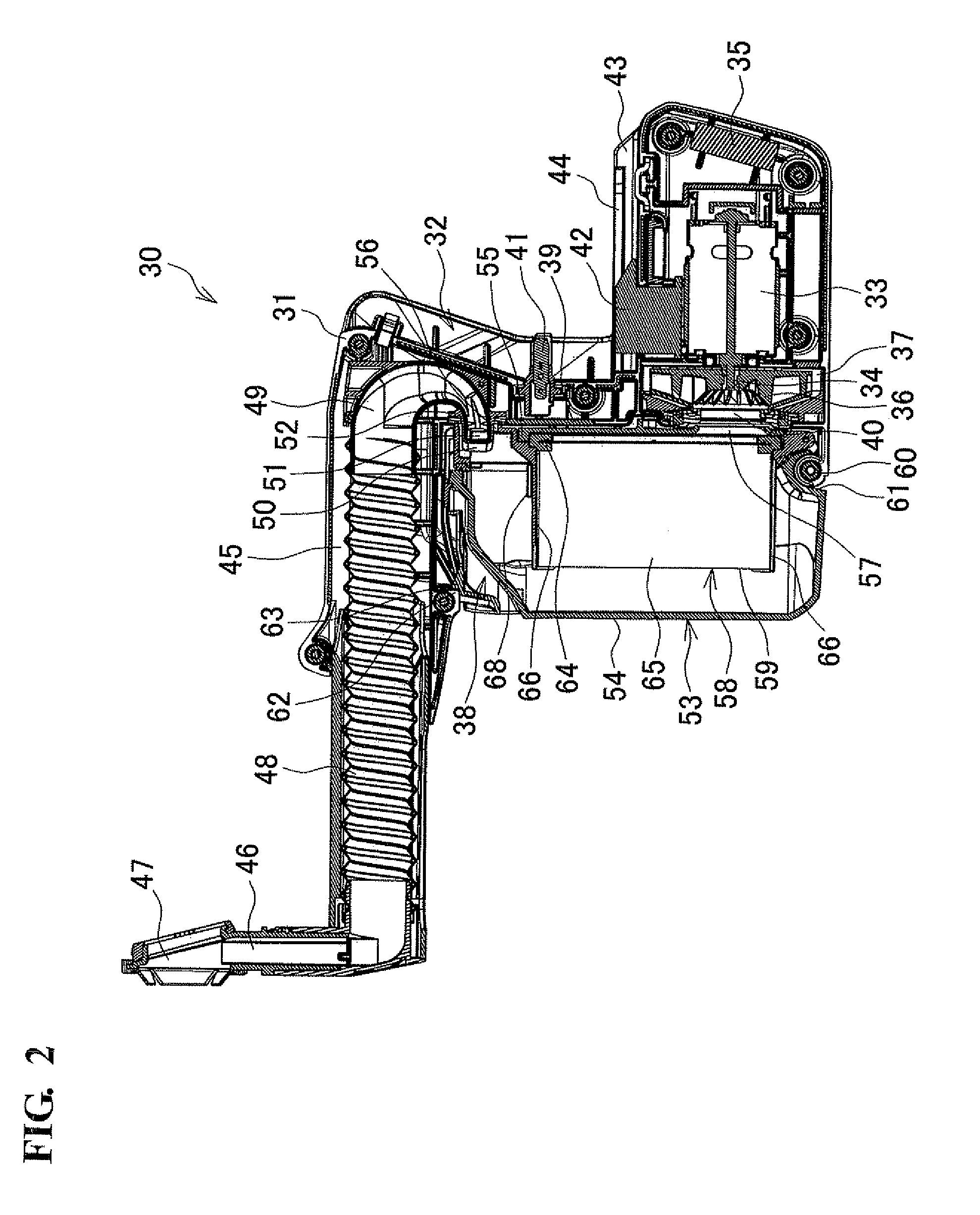

Dust collecting device and electric tool equipped with dust collecting device

ActiveUS20110226499A1Easy to discardImprove usabilityCleaning filter meansSuction filtersEngineeringPre filtering

Owner:MAKITA CORP

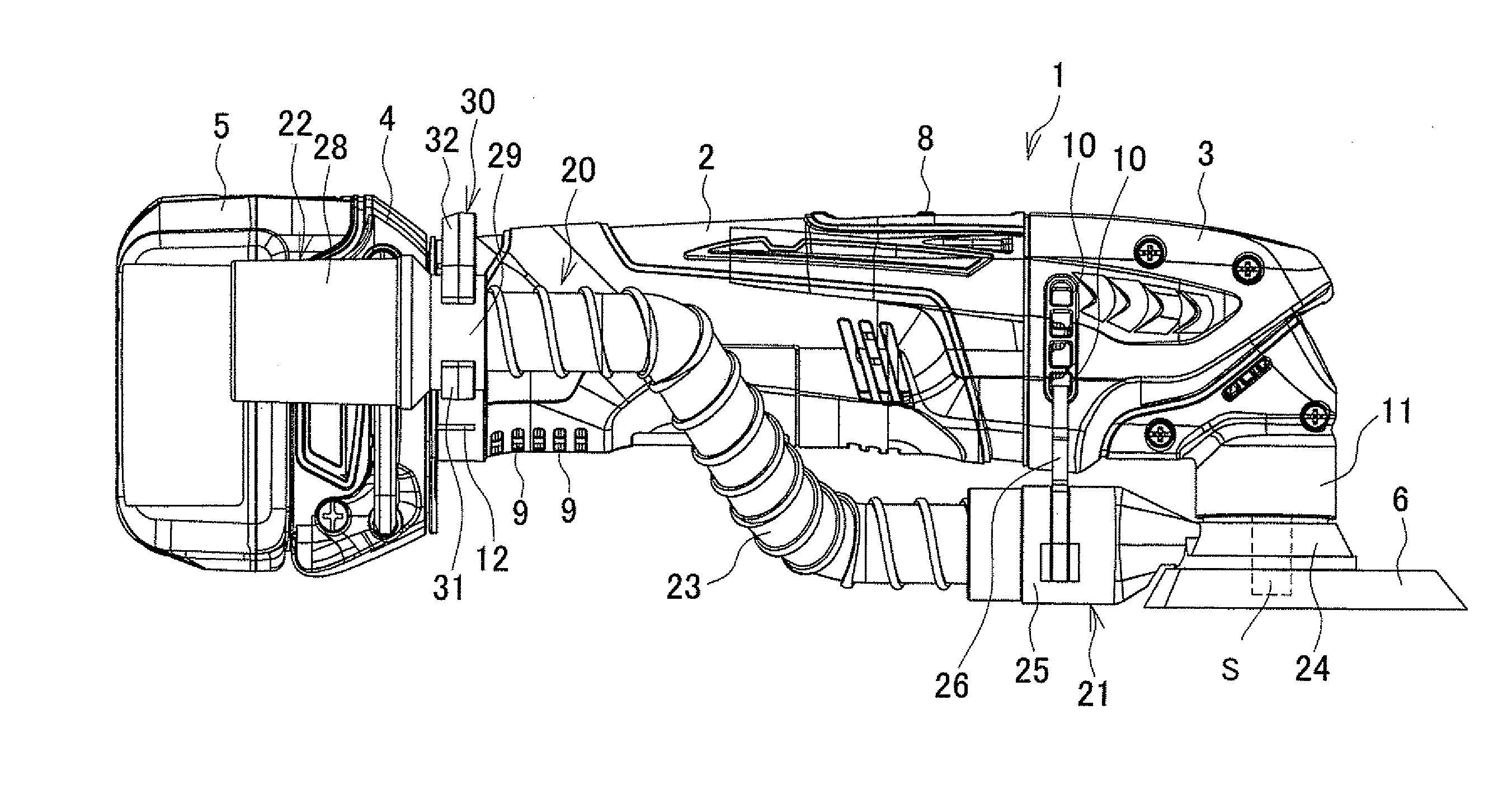

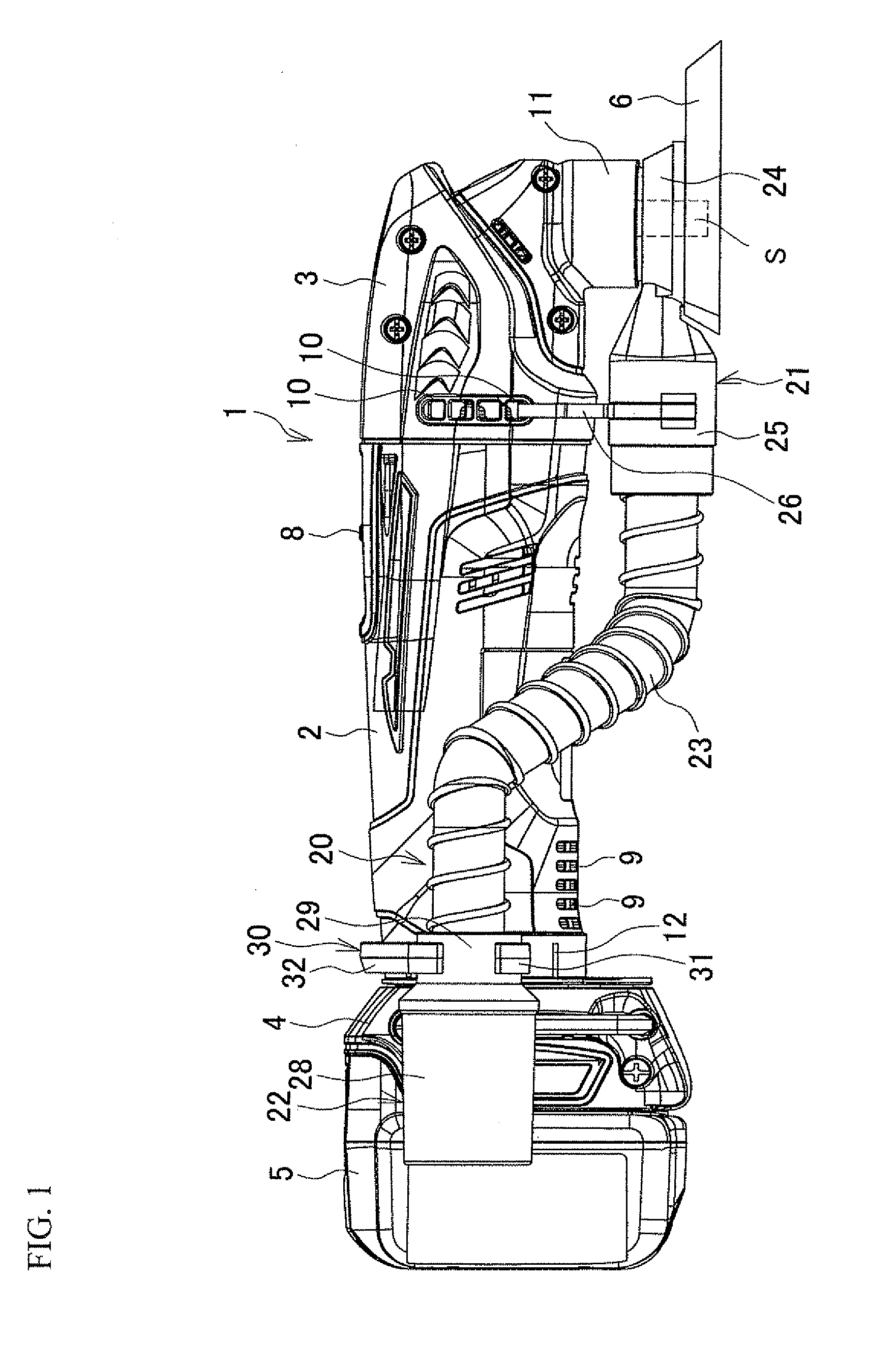

Dust collecting attachment for electric power tool and electric power tool

ActiveUS20130115863A1Stable connection of pipePrevent disengagementWindow cleanersVehicle cleaningSanderElectric power system

A dust collecting attachment that is mounted on a sander includes a suction portion mounted on a portion of a front housing where an output shaft projects, a flexible hose having a front end of the flexible hose connected to the suction portion, a discharge portion connected to a rear end of the flexible hose and a changeable member placed on both a motor housing and the discharge portion. The changeable member allows the discharge portion to be mounted at any position around an axis of the motor housing.

Owner:MAKITA CORP

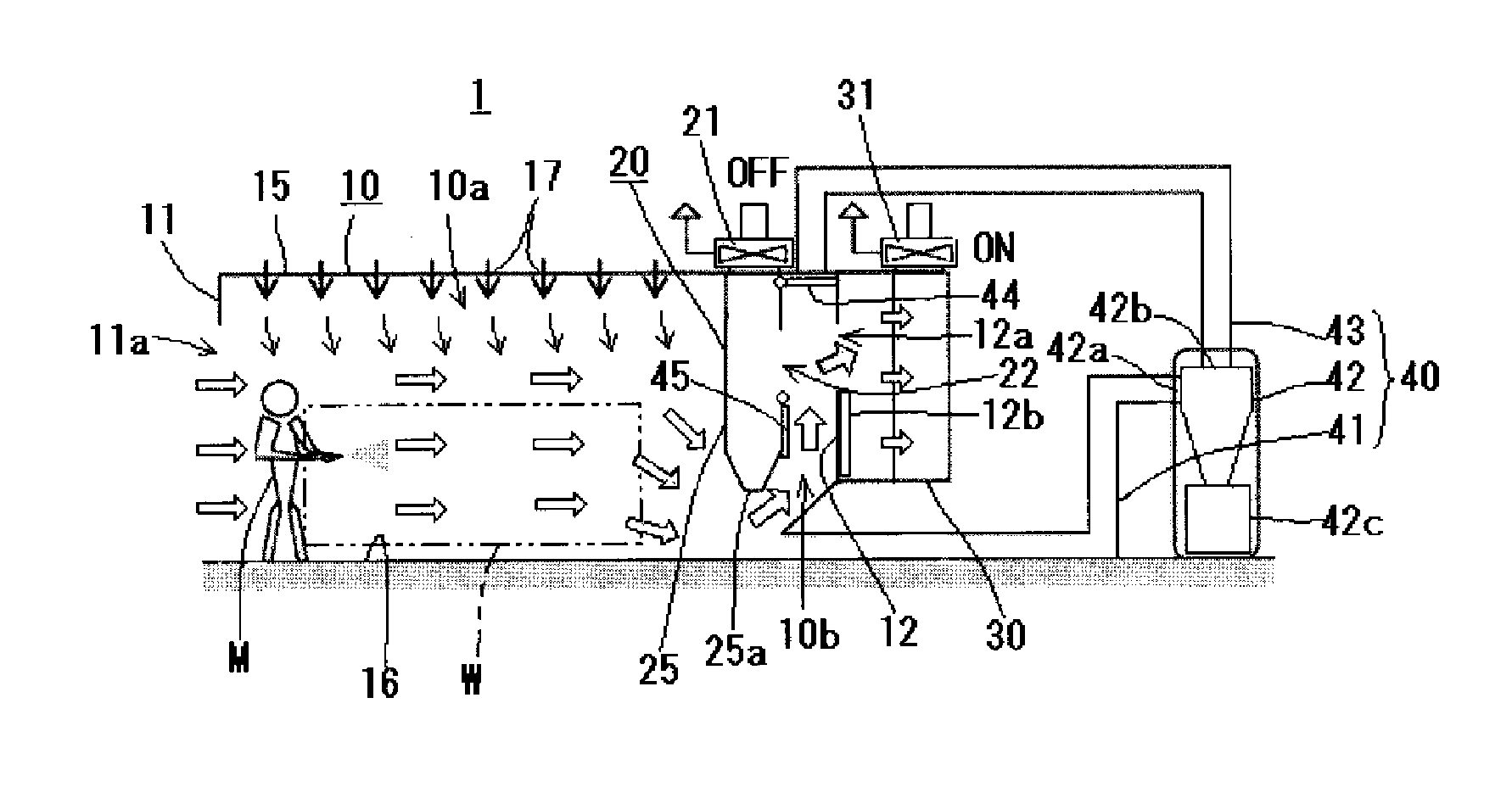

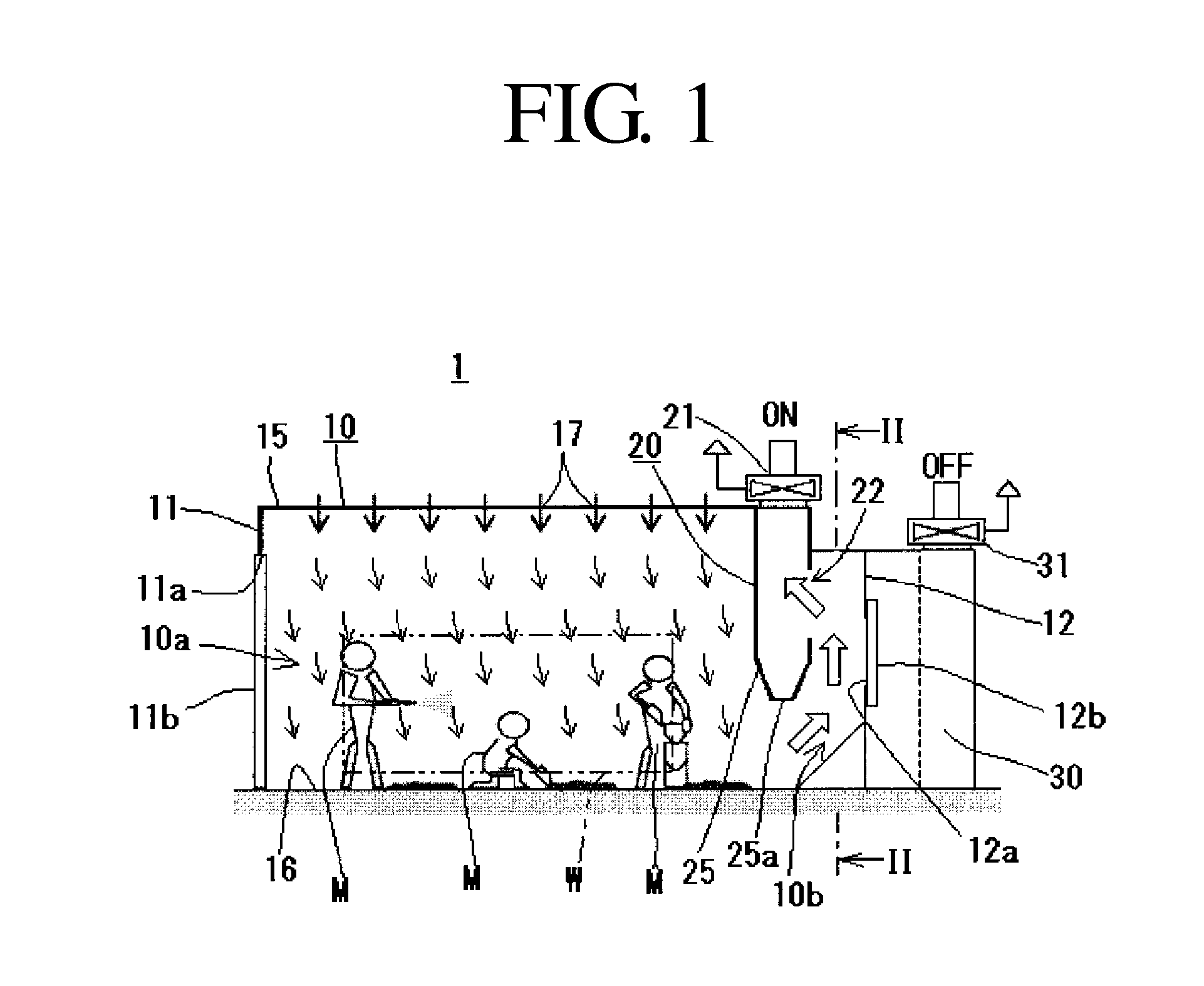

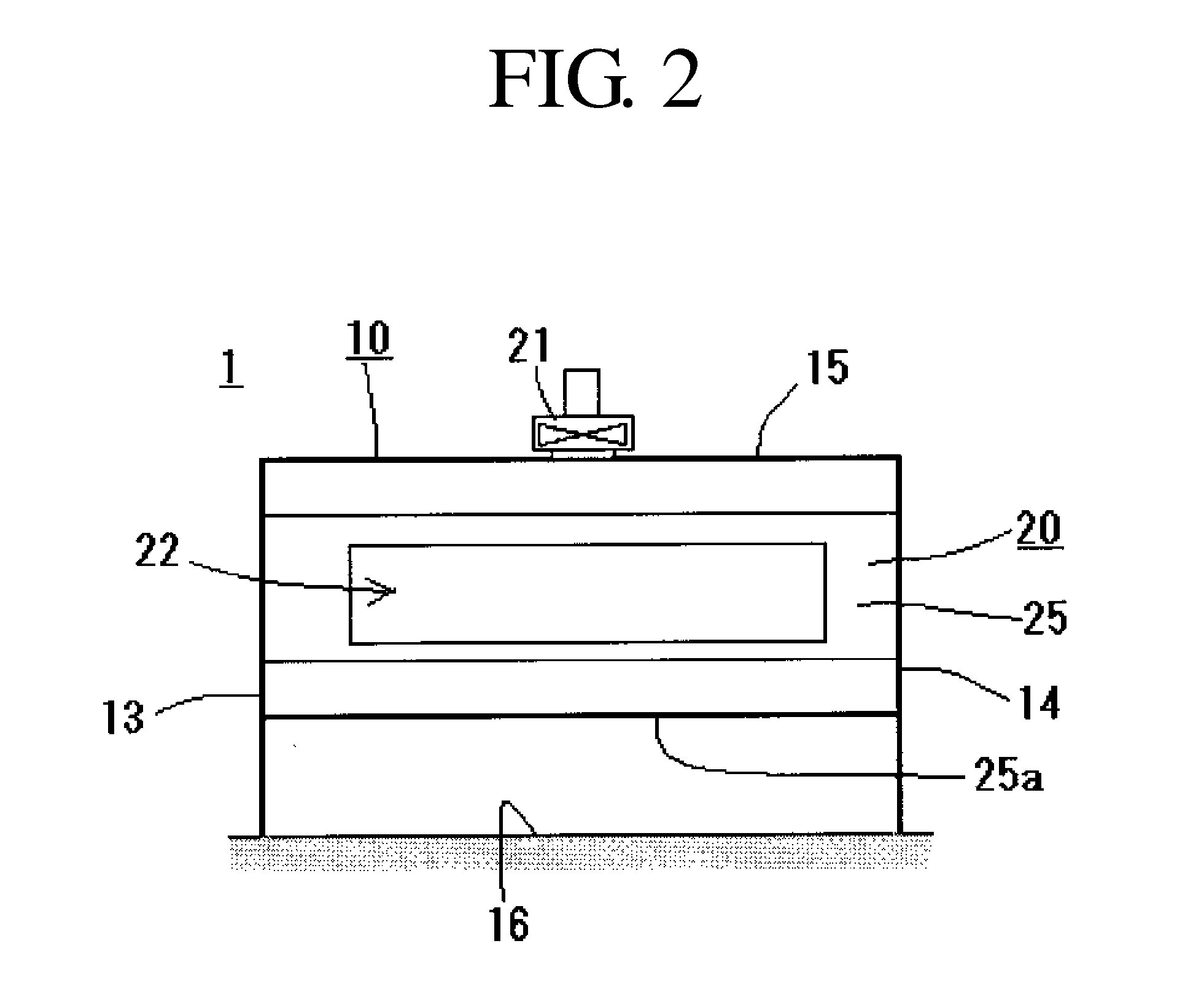

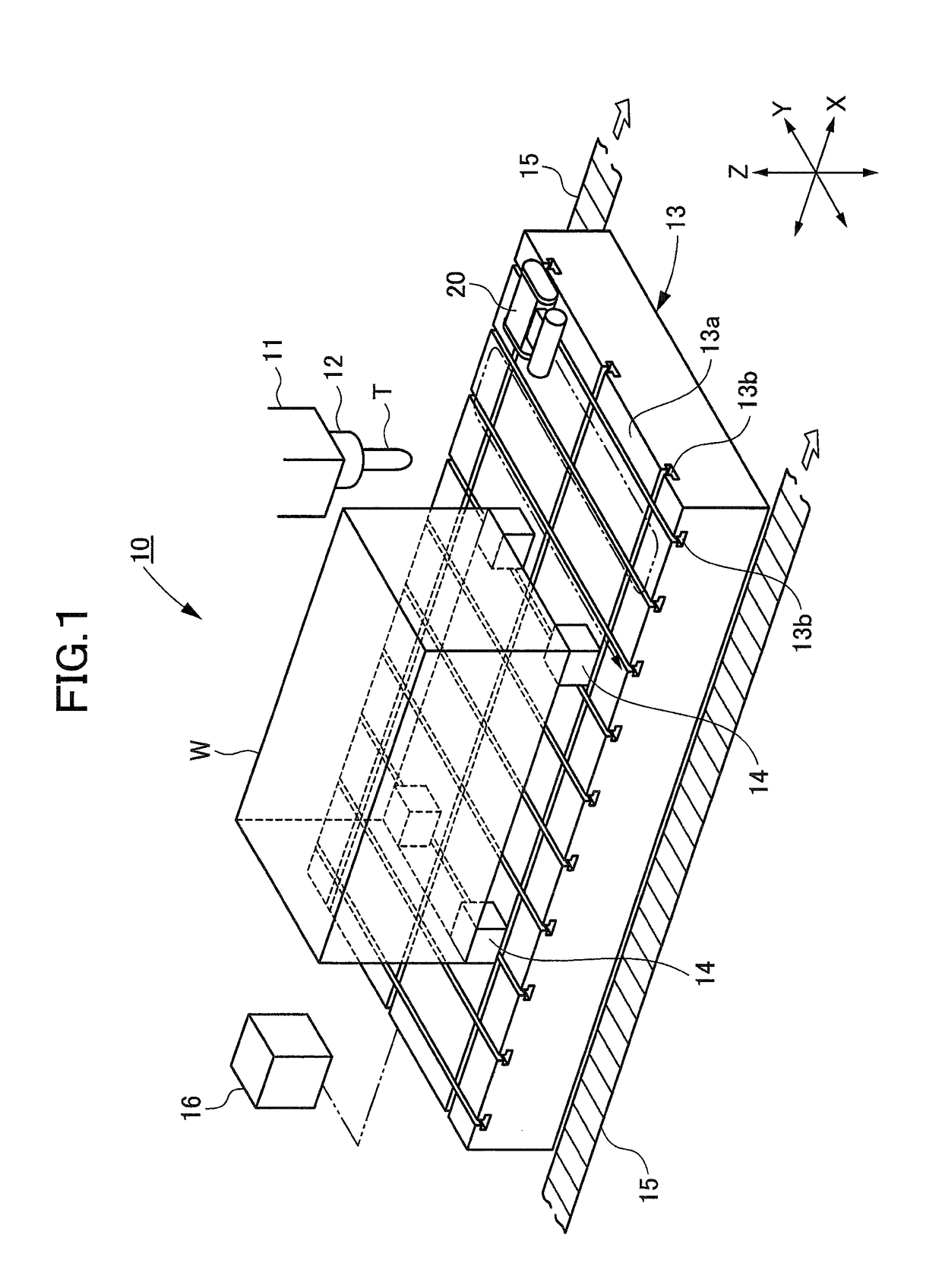

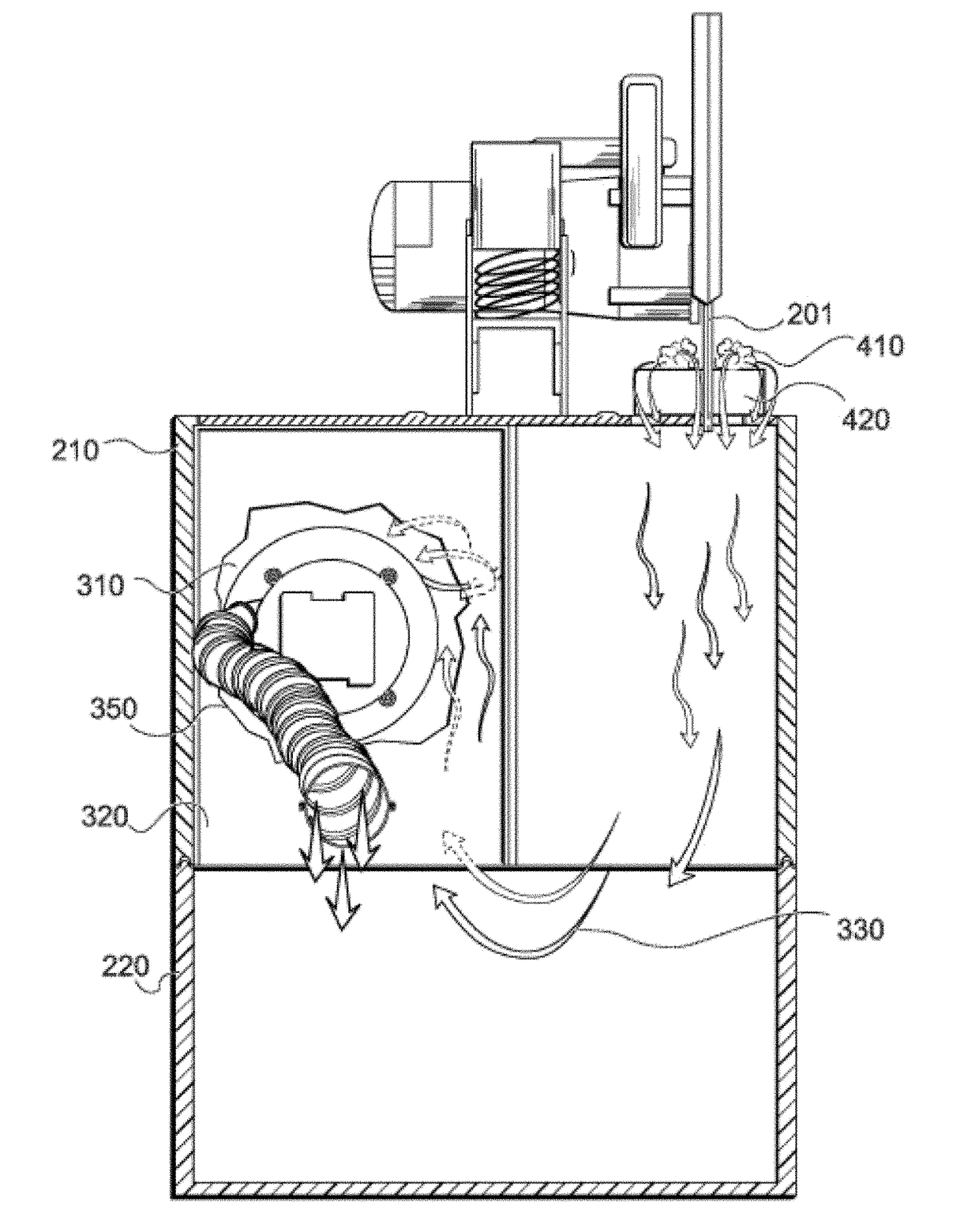

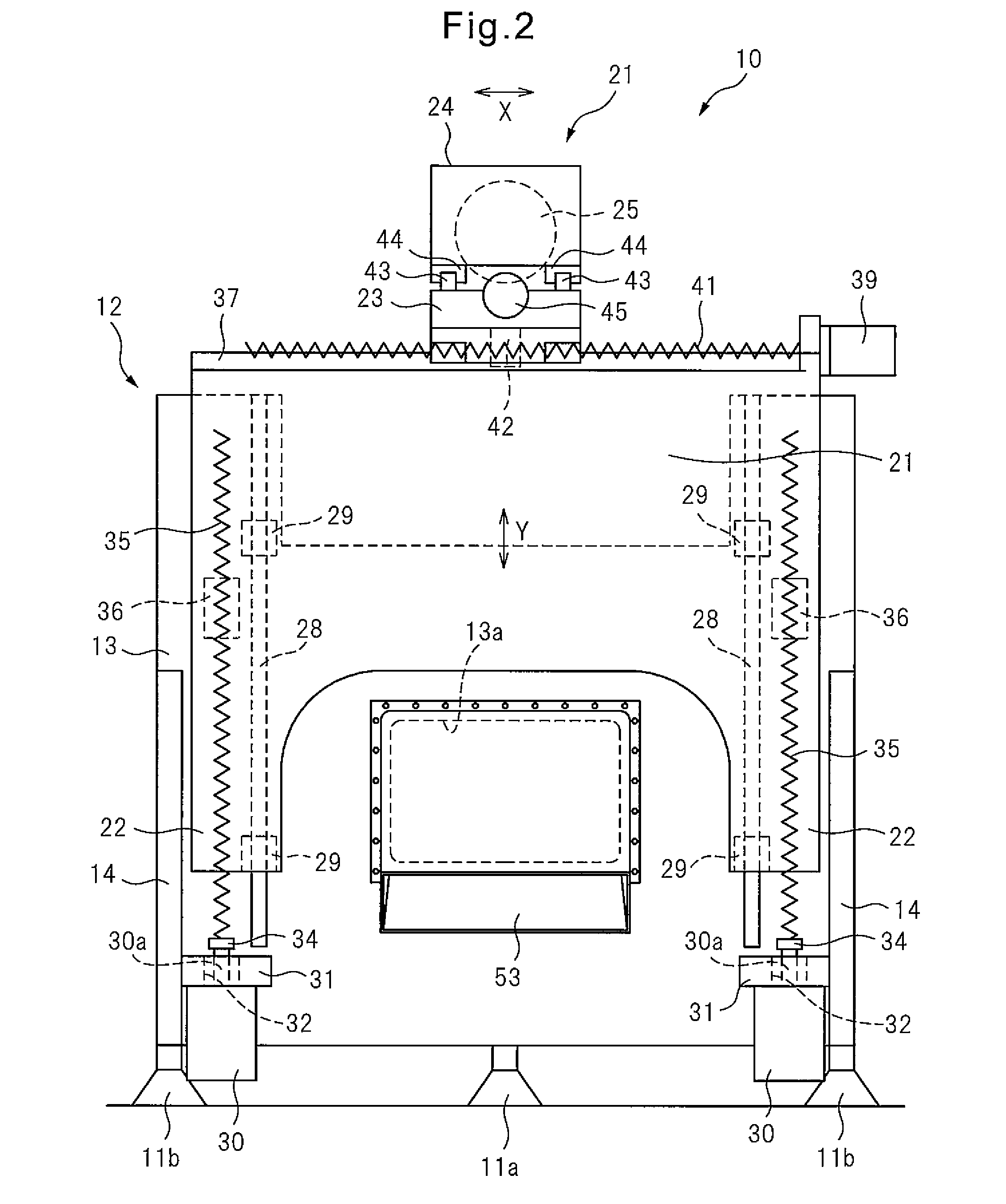

Blasting Chamber

InactiveUS20110034119A1Avoid pollutionMechanical apparatusLighting and heating apparatusWorking spaceWaste management

A blasting chamber capable of conducting painting on a workpiece subsequent to a blasting process in the same working chamber is provided. A dust collection unit 20 that ventilates a main unit 10 during blasting work and a ventilation unit 30 that ventilates a main unit during a painting step are provided. A side wall 11 of the main unit is provided with an entrance 11a and an opening-and-closing member 11b that opens / closes the entrance, the dust collection unit is provided so as to project from a roof panel 15 to a floor panel 16 at a position closer to an other side wall 12 that is opposed to this side wall so as to partition the interior of the main unit, and a working space 10a and a ventilation duct 10b are defined in the main unit. A roof panel 15 above a working space has air suction holes 17 formed therein, and an intake opening 22 that communicates between the dust collection unit and the ventilation duct is provided. The side wall is provided with an opening 12a that communicates between the ventilation unit and the ventilation duct, and during the blasting process, ventilation is conducted with the dust collection unit with the entrance closed, and during painting, ventilation is conducted with the ventilation unit with the entrance opened.

Owner:FUJI MFG CO LTD

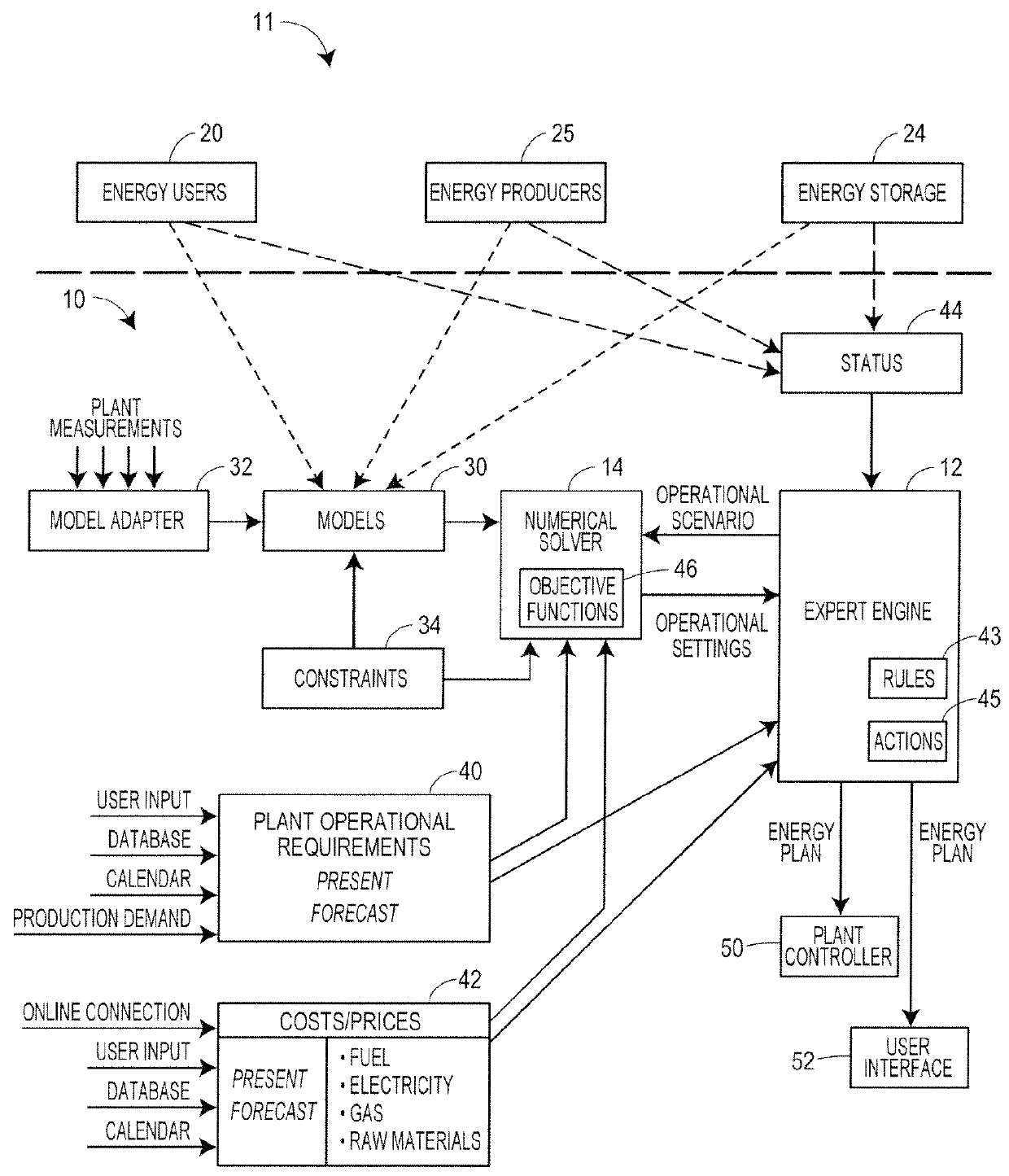

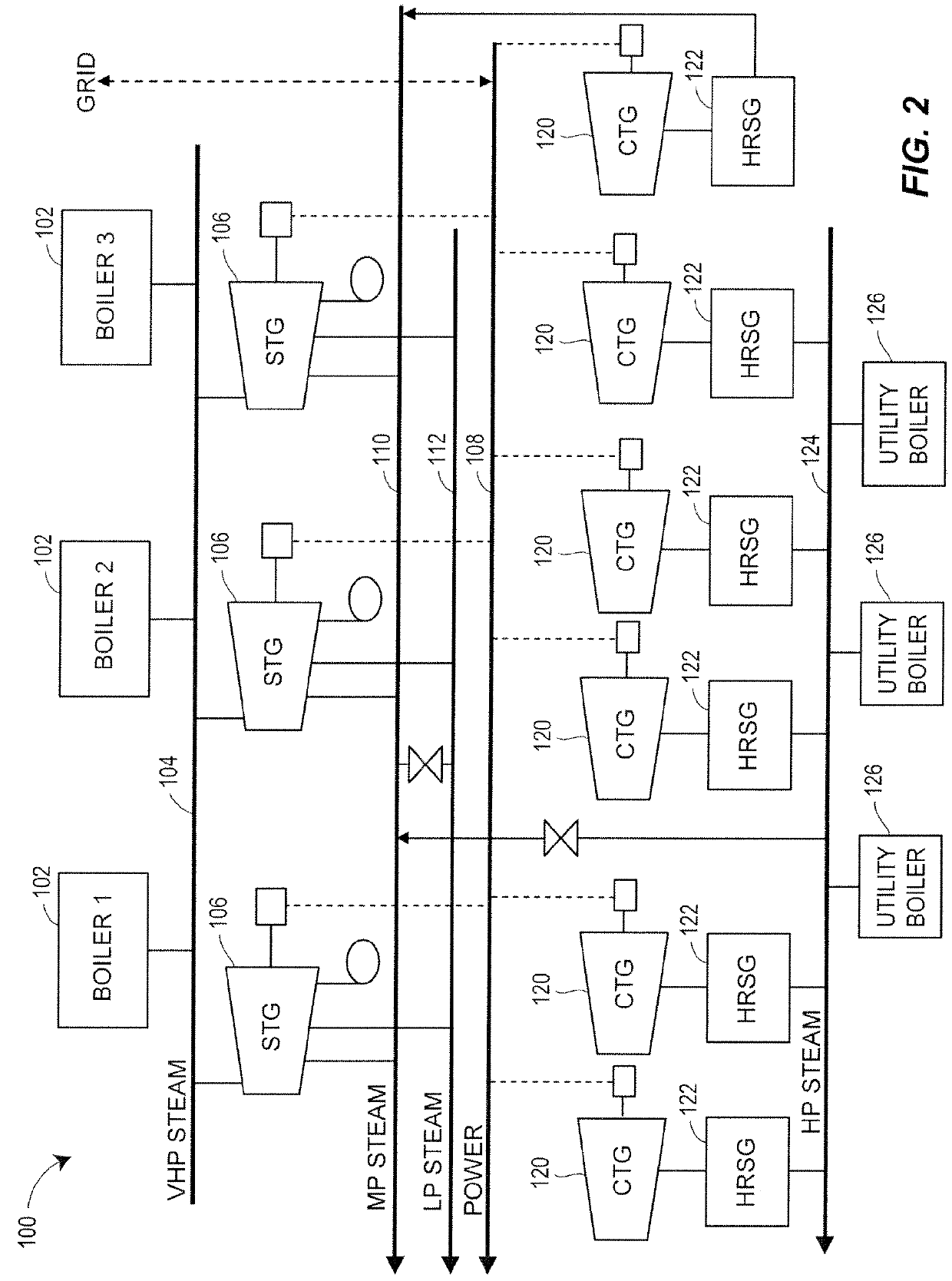

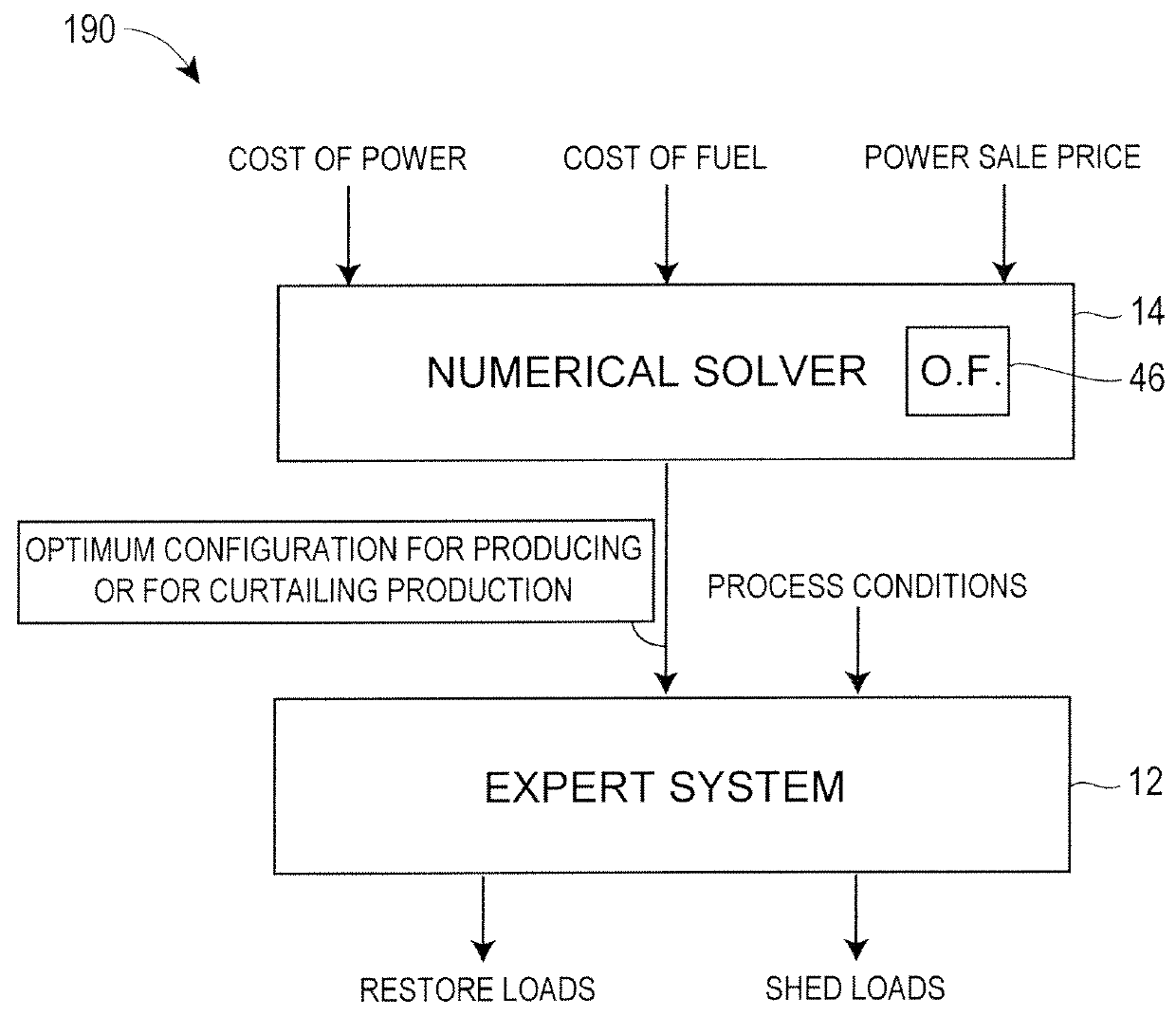

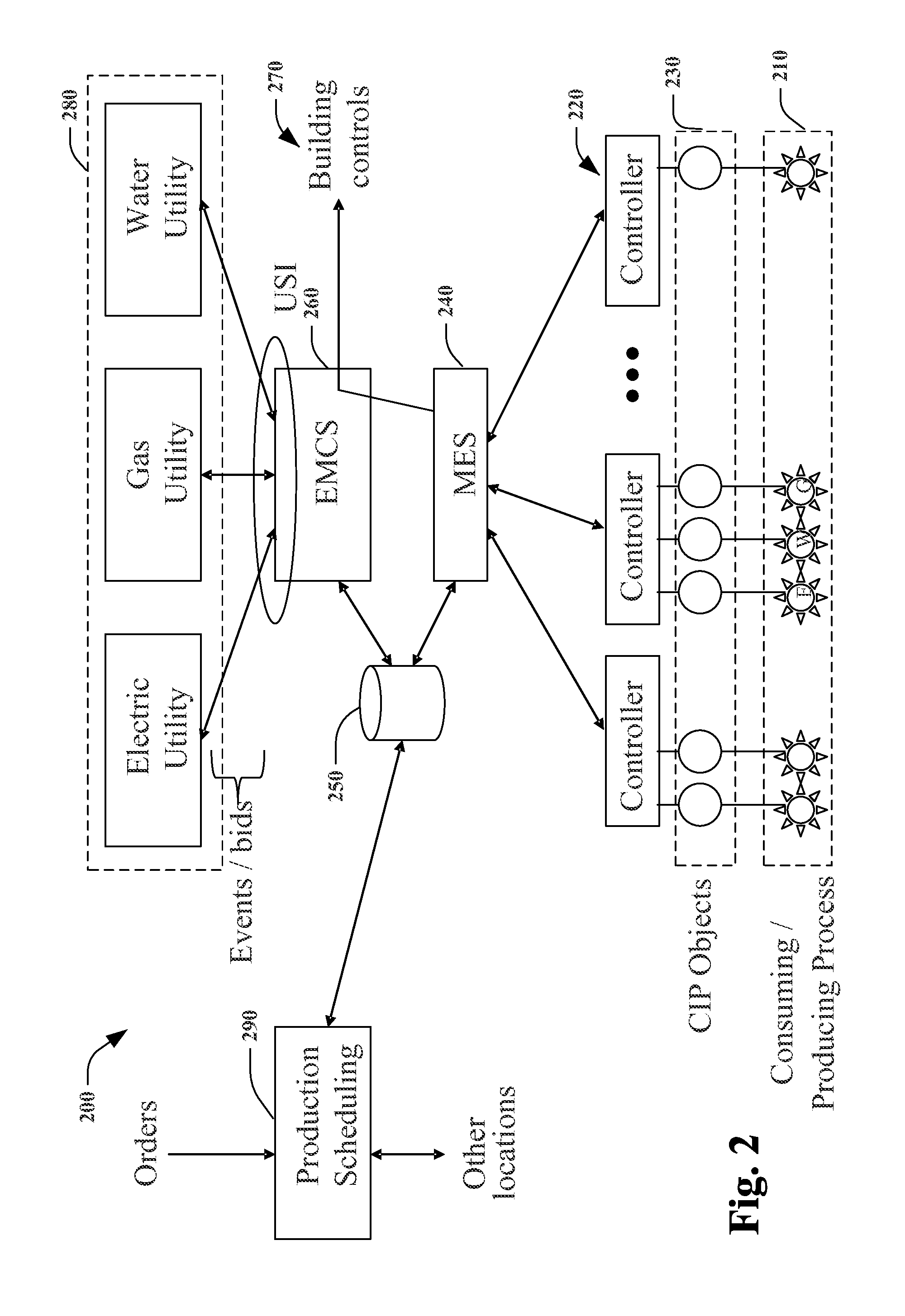

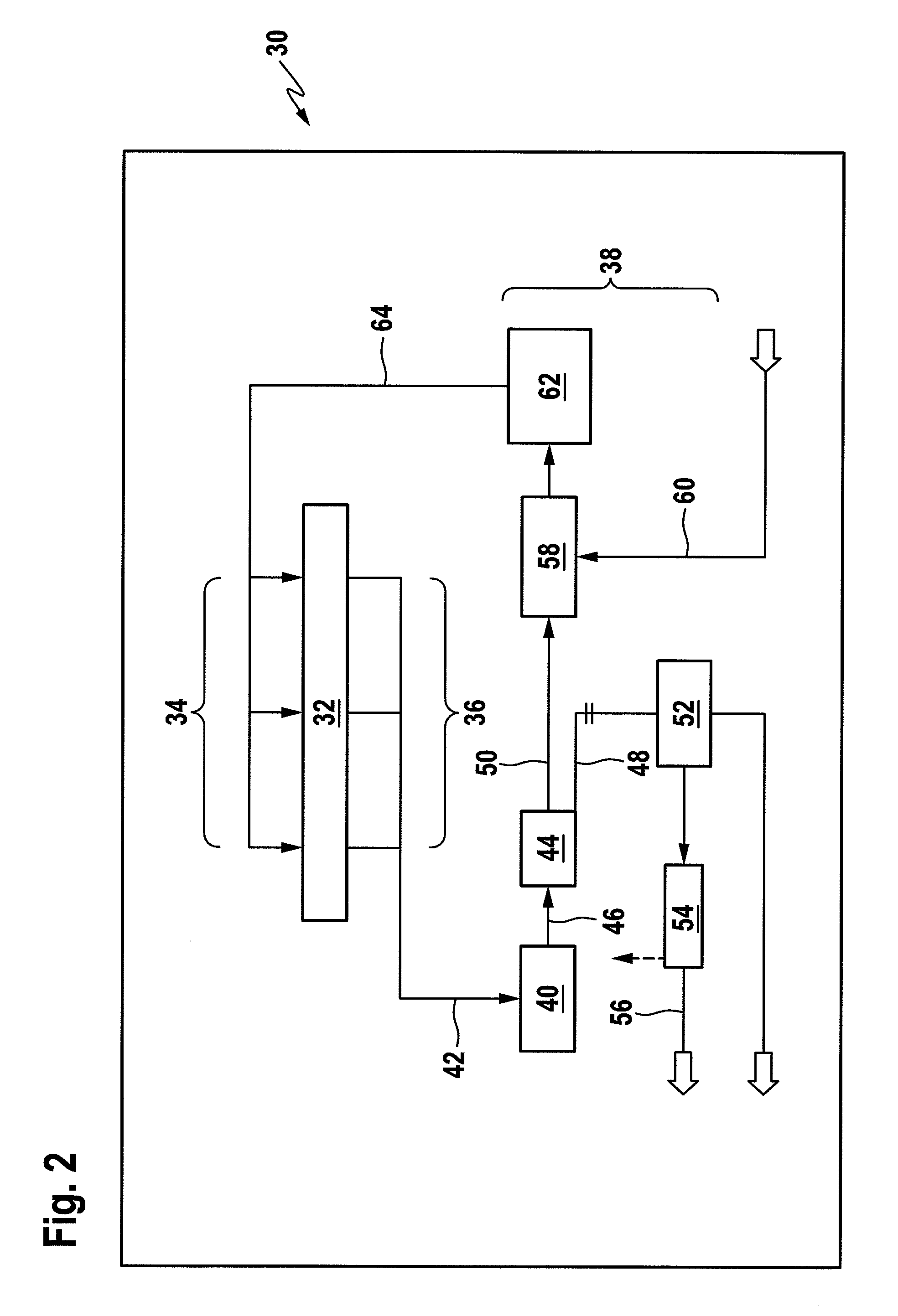

Energy management system

ActiveUS9335748B2Reduce and optimize energy costLow costTechnology managementTotal factory controlOperational systemEngineering

An energy management system uses an expert engine and a numerical solver to determine an optimal manner of using and controlling the various energy consumption, producing and storage equipment in a plant / communities in order to for example reduce energy costs within the plant, and is especially applicable to plants that require or that are capable of using and / or producing different types of energy at different times. The energy management system operates the various energy manufacturing and energy usage components of the plant to minimize the cost of energy over time, or at various different times, while still meeting certain constraints or requirements within the operational system, such as producing a certain amount of heat or cooling, a certain power level, a certain level of production, etc. In some cases, the energy management system may cause the operational equipment of the plant to produce unneeded energy that can be stored until a later time and then used, or that can be sold back to a public utility, for example, so as to reduce the overall cost of energy within the plant.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

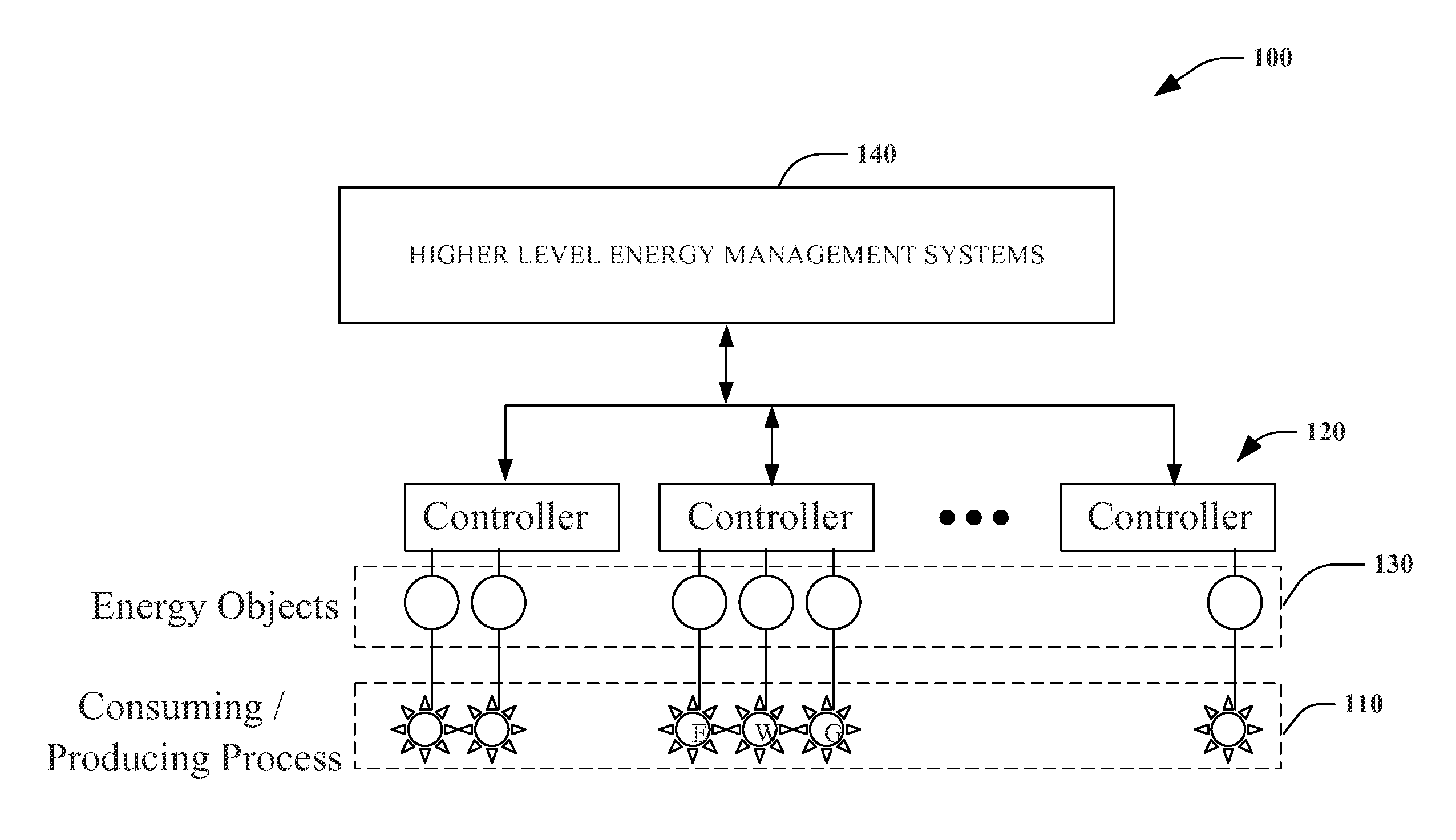

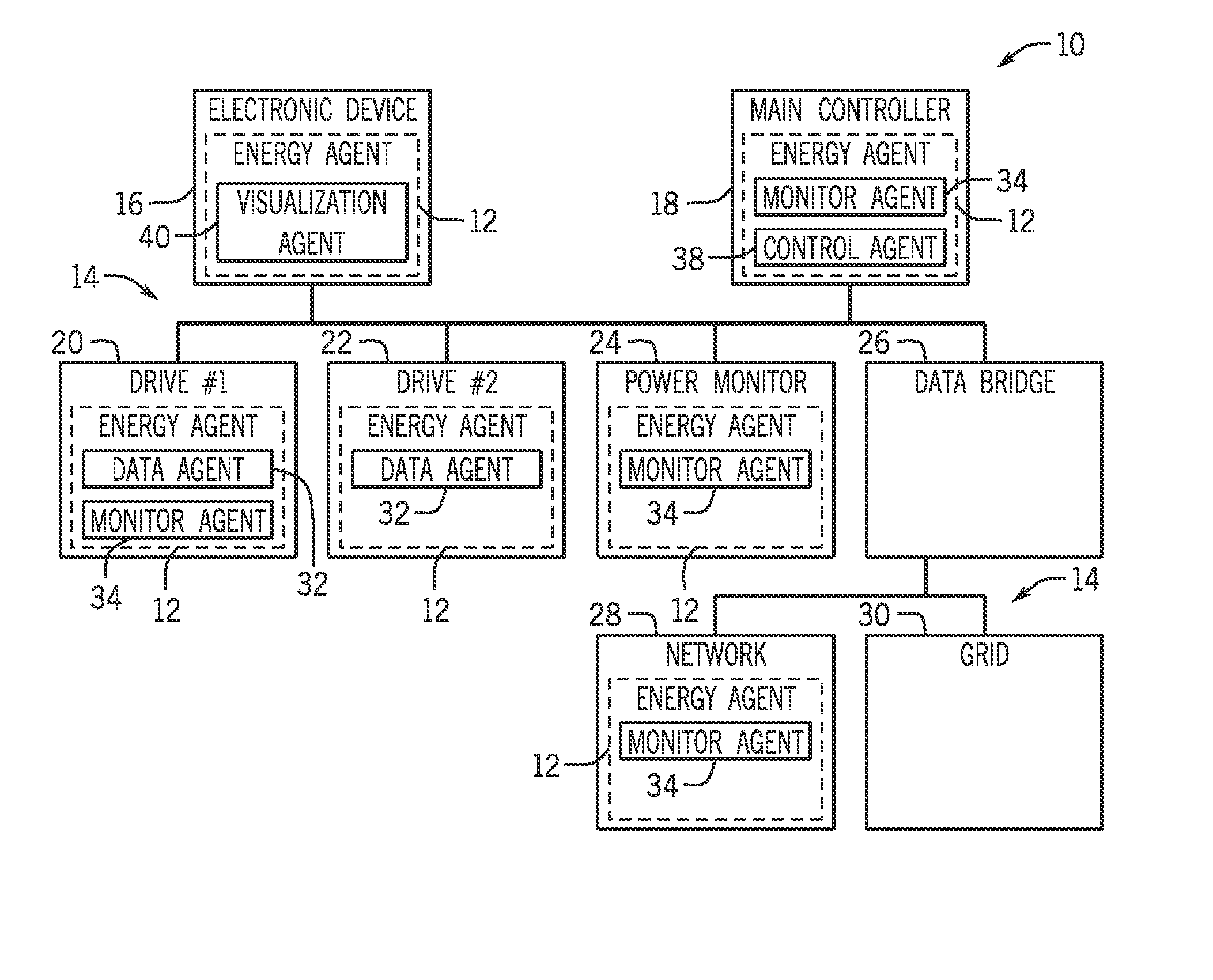

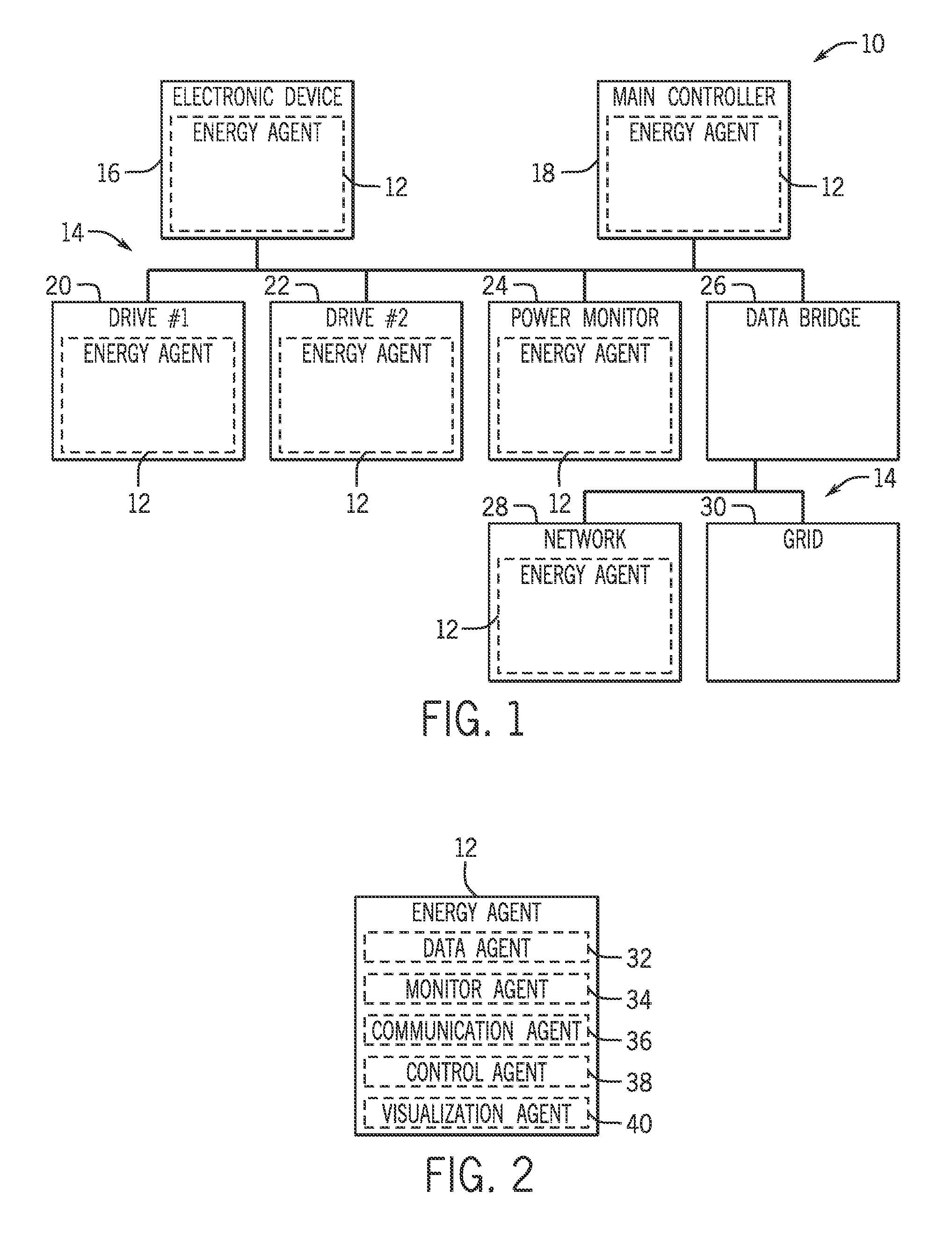

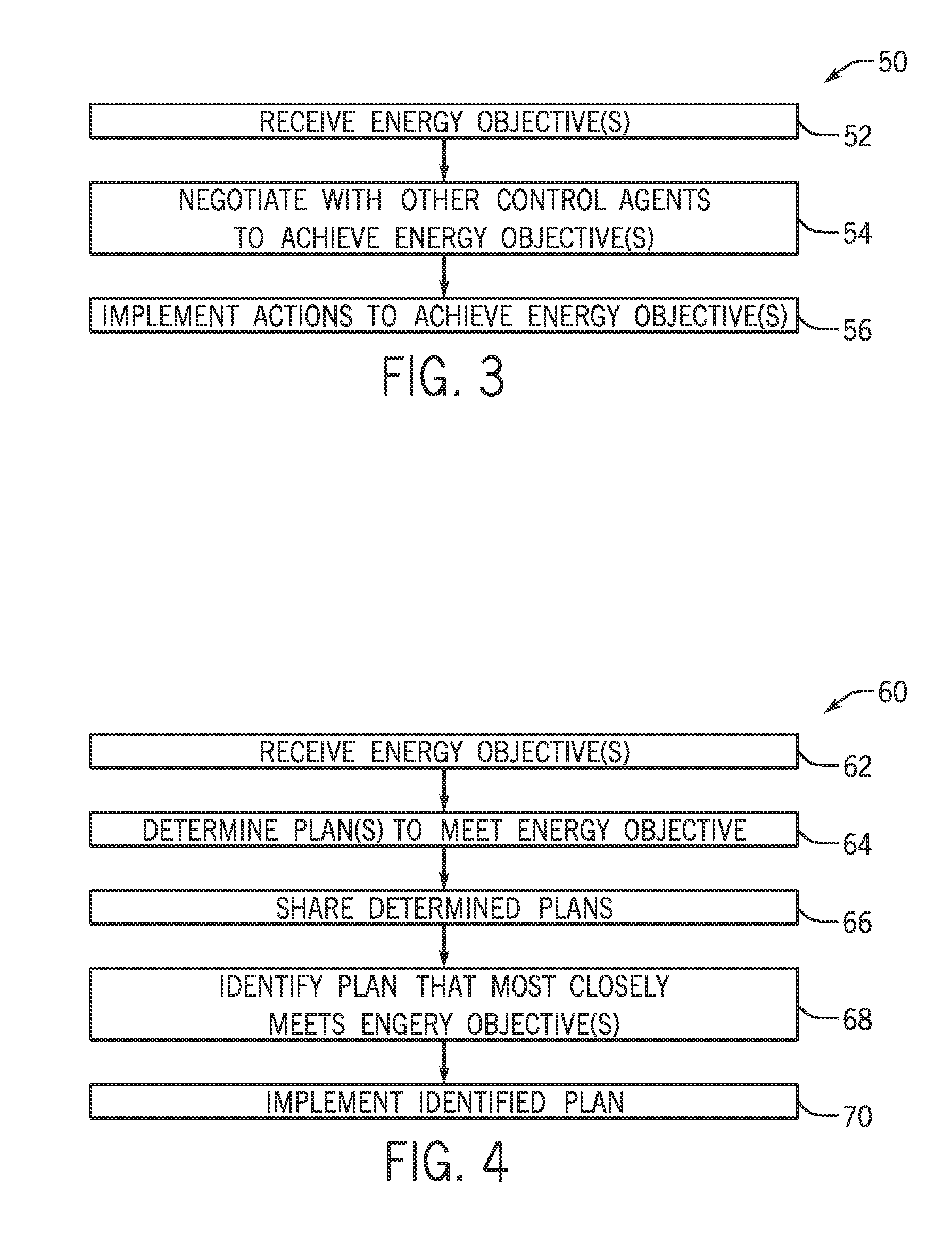

Industrial control energy object

ActiveUS9274518B2Efficient use of energyEfficient managementLevel controlCircuit arrangementsMonitoring and controlProcess engineering

An energy object extension to an industrial protocol having a comprehensive suite of attributes, messages and services utilized for the monitoring and control of energy consuming or producing resources by a manufacturing automation application is provided. The energy object includes an identifier associated with an energy resource that is associated with a manufacturing automation application and an energy type associated with the energy resource. This includes a measurement characteristic associated with the energy resource to facilitate energy management by the manufacturing automation application.

Owner:ROCKWELL AUTOMATION TECH

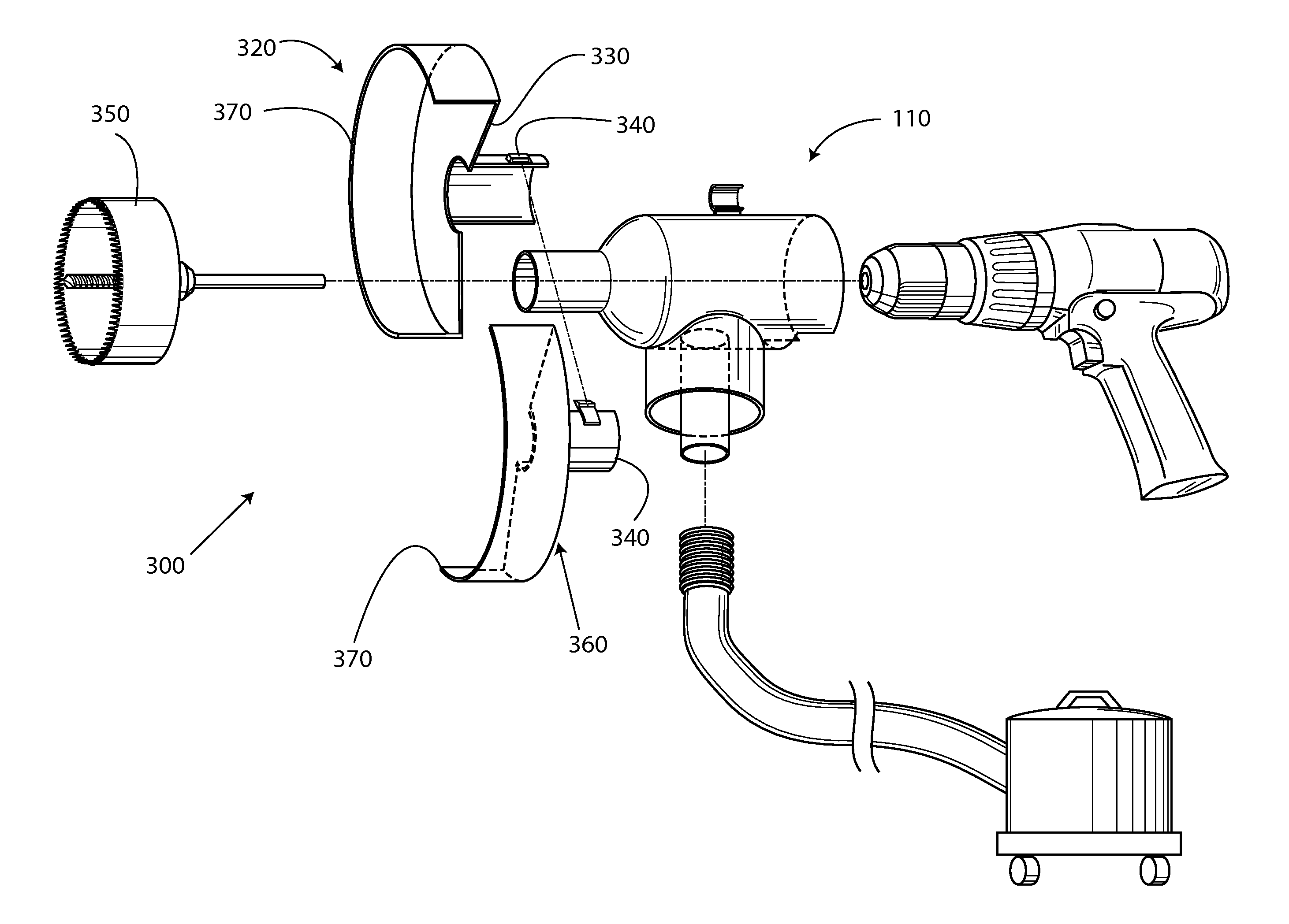

Dust free drill system

Hammer drills and similar devices have an ongoing dust and debris problem that is solved by a protector device covering the drill in a main body protector shielding a user from the materials. The protector device has an evacuation region on its underside with multi dimensional adapters for attaching hoses of varying sizes. Additionally, an insertable collapsible accordion cylinder assists in covering the debris falling from different size drills being used. A second embodiment has a circular saw dust protector attachment arranged as two half moons or ¼ moon and ¾ moon having a central cylinder at their respective tops that are to be held together with a mechanical latch.

Owner:SULLIVAN MARK D

Method and system for manufacturing wafer-like slices from a substrate material

InactiveUS20100170495A1Thorough removalIncrease productionSolid sorbent liquid separationCation exchangersIonic strengthElectrical resistivity and conductivity

The present invention relates to a method and a system for manufacturing wafer-like slices from a body of a substrate material, especially for use in the manufacture of semiconductor devices.The method comprises providing a slicing device with a cutting wire equipped on its surface with abrasive particles; providing an aqueous cooling and lubricating fluid, said fluid having an ionic strength corresponding to an electrical conductivity of about 30 μS / cm or less; cutting said body with said cutting wire into slices while dispensing said cooling and lubricating fluid into a kerf area where said cutting wire contacts and cuts said body, said cooling and lubricating fluid promoting removal of powdered substrate material from said kerf area resulting in spent fluid; and removing said spent fluid from said cutting device and recovering said powdered substrate material from said spent fluid.The system comprises a slicing device provided with a cutting wire, said cutting wire being equipped on its surface with abrasive particles, said slicing device comprising a dispensing unit for delivering a cooling and lubricating fluid to a kerf area where said cutting wire contacts and cuts said body; wherein said fluid promotes removal of powdered substrate material from said kerf area resulting in spent cooling and lubricating fluid; a draining unit for removing said spent fluid from said slicing device; and a fluid reclamation device for treating said spent fluid, said reclamation device comprising a first filtering unit for separating and recovering said powdered substrate material from said spent fluid and providing a reusable fluid.

Owner:PALL CORP

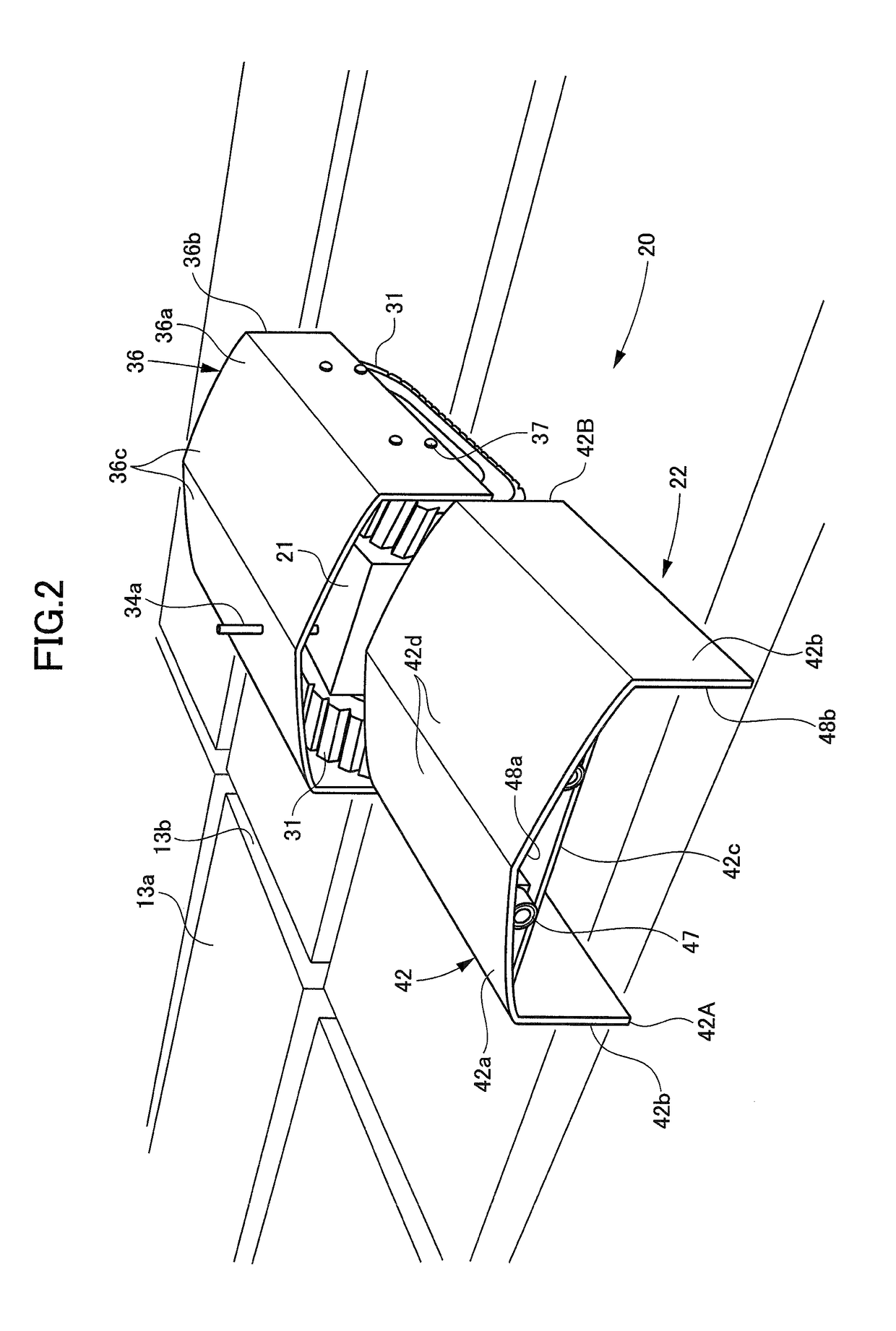

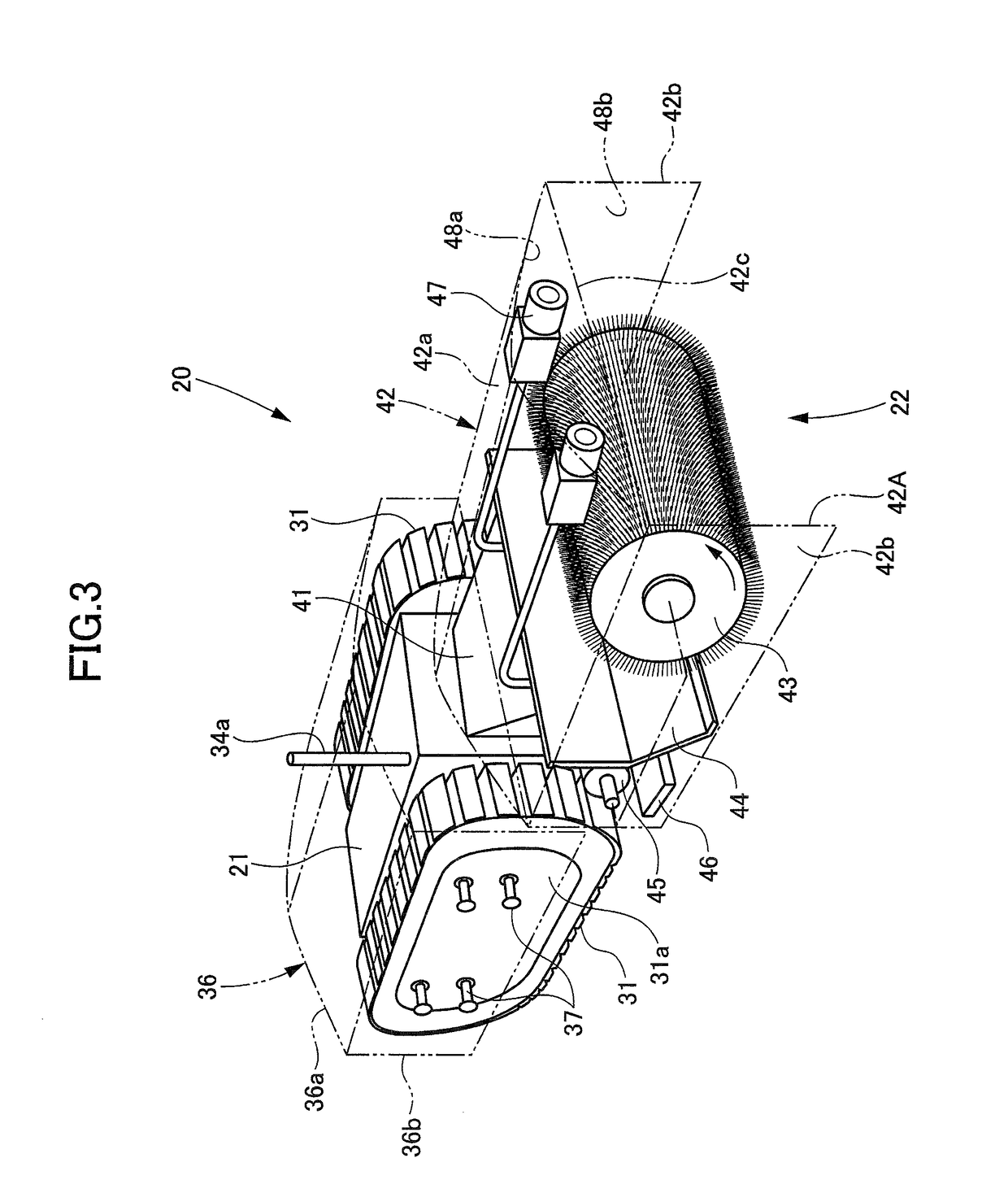

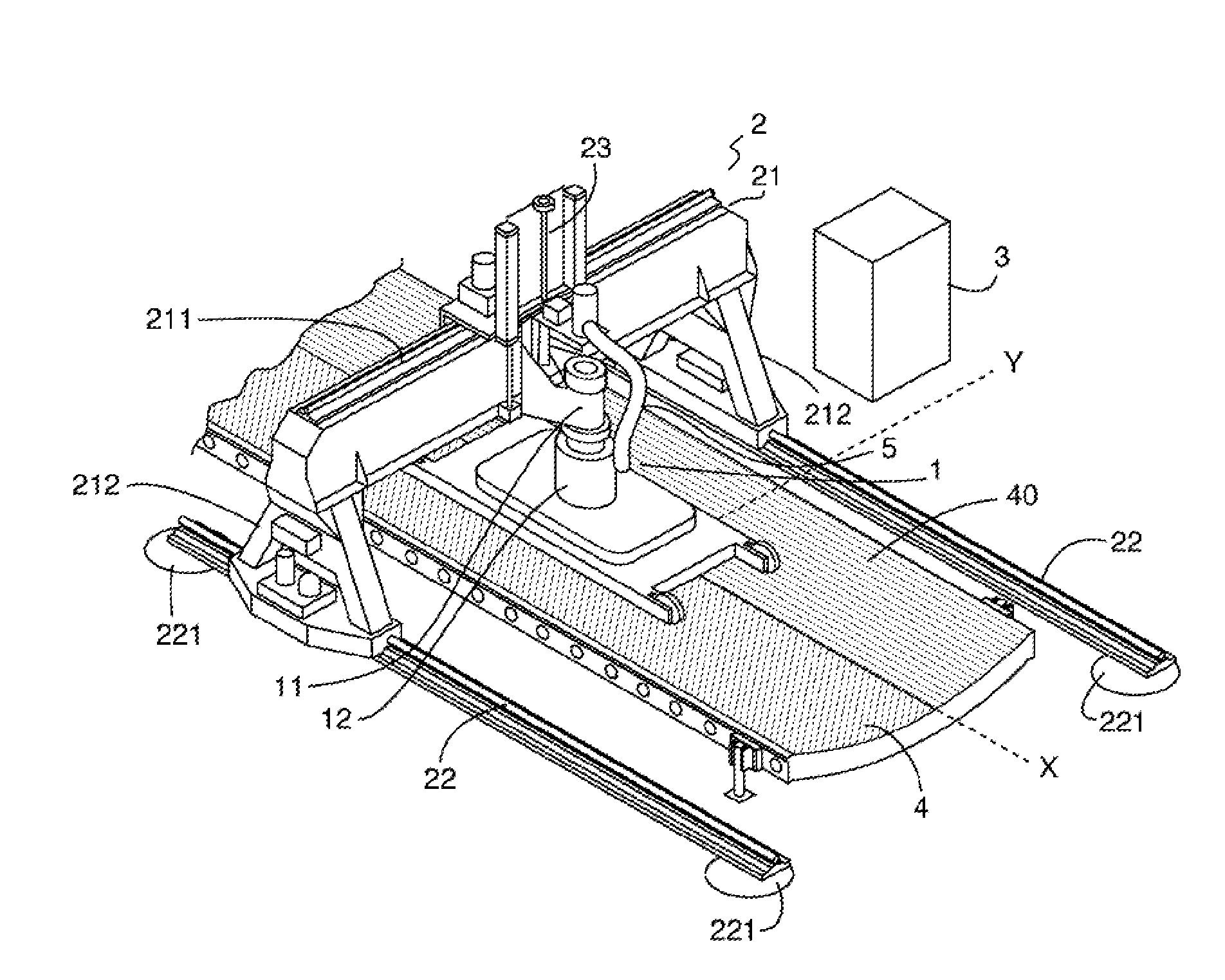

Chip sweeping robot

There is provided a chip sweeping robot which is capable of possessing adaptability to various machine tools and automatically sweeping a wide range efficiently. To this end, a chip sweeping robot configured to sweep chips, which are scattered on an upper surface of a table of a machine tool at the time of machining a workpiece attached to the table, by traveling in accordance with a travel route set on the upper surface, includes: a robot body which autonomously travels on the upper surface; a rotating brush which sweeps the chips out forward in a traveling direction by being rotated from a lower side to an upper side forward in the traveling direction; and a blade which scoops out the chips, which pass through the rotating brush, forward in the traveling direction and sends the chips to a rotating region of the rotating brush.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

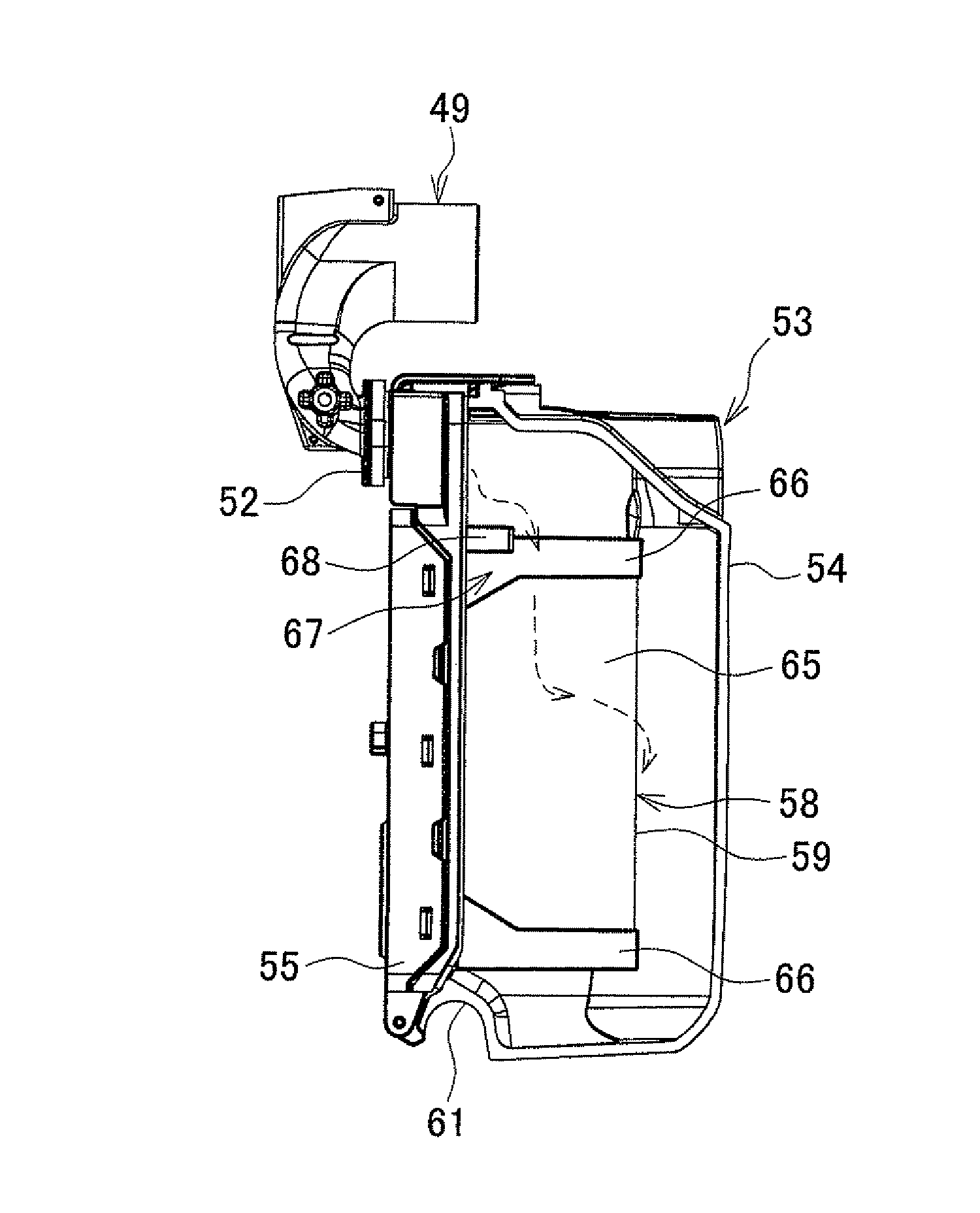

Dust collection device for power tool and power tool

ActiveUS9108284B2Efficiency longProlong lifeAuxillary pretreatmentPortable percussive toolsPower toolHammer drill

In a dust collection device attached to a hammer drill, a filter is provided in a dust box at a position at which the filter covers an outlet provided on a rear face of a lid body, in a state such that a filter surface projects into the dust box from the rear face of the lid body. A space is formed between an inner face of a box main body and a side face of the filter that is adjacent to the filter surface. Air outlets are provided to guide air, which flows in through an inlet, toward the space.

Owner:MAKITA CORP

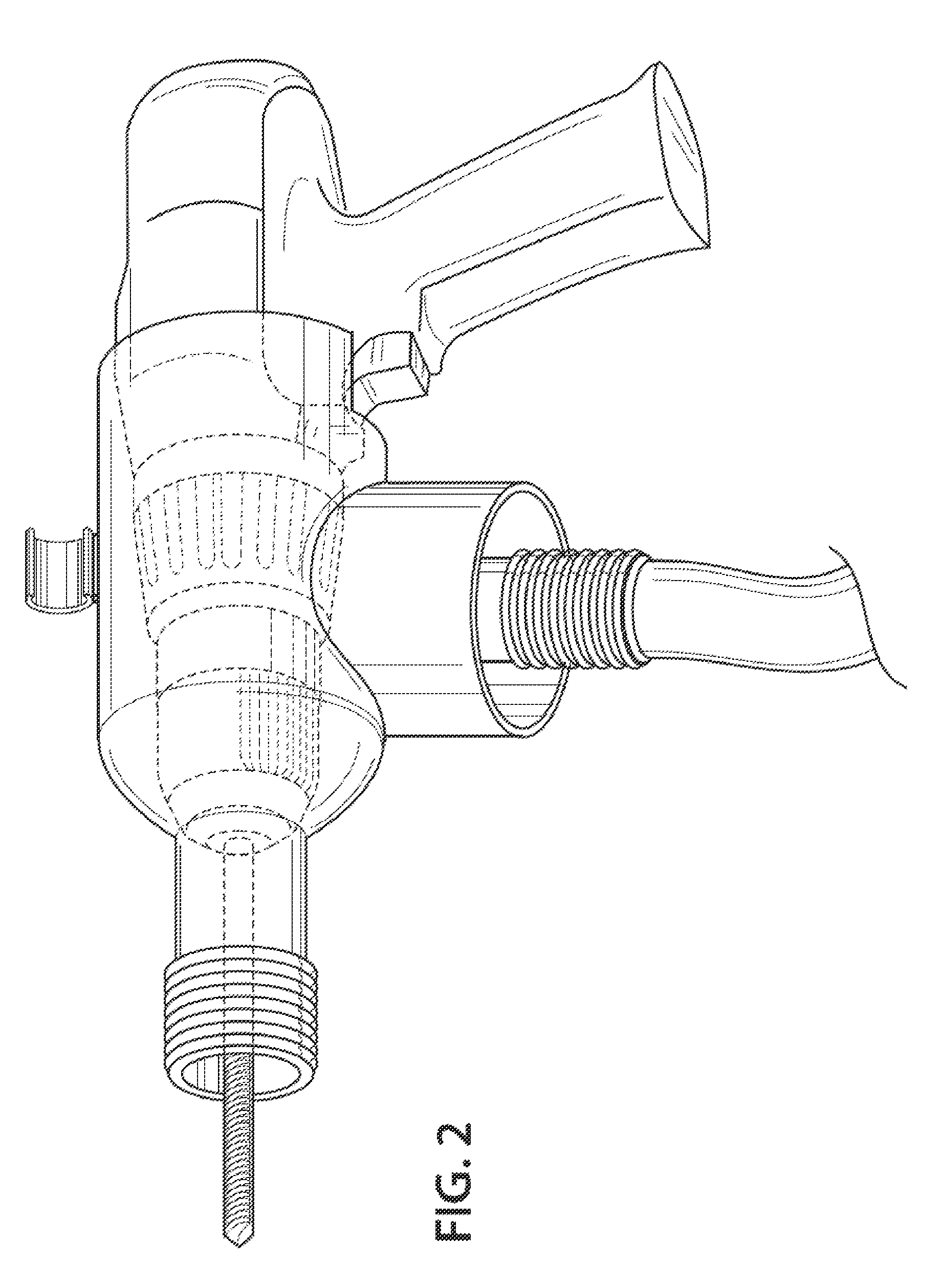

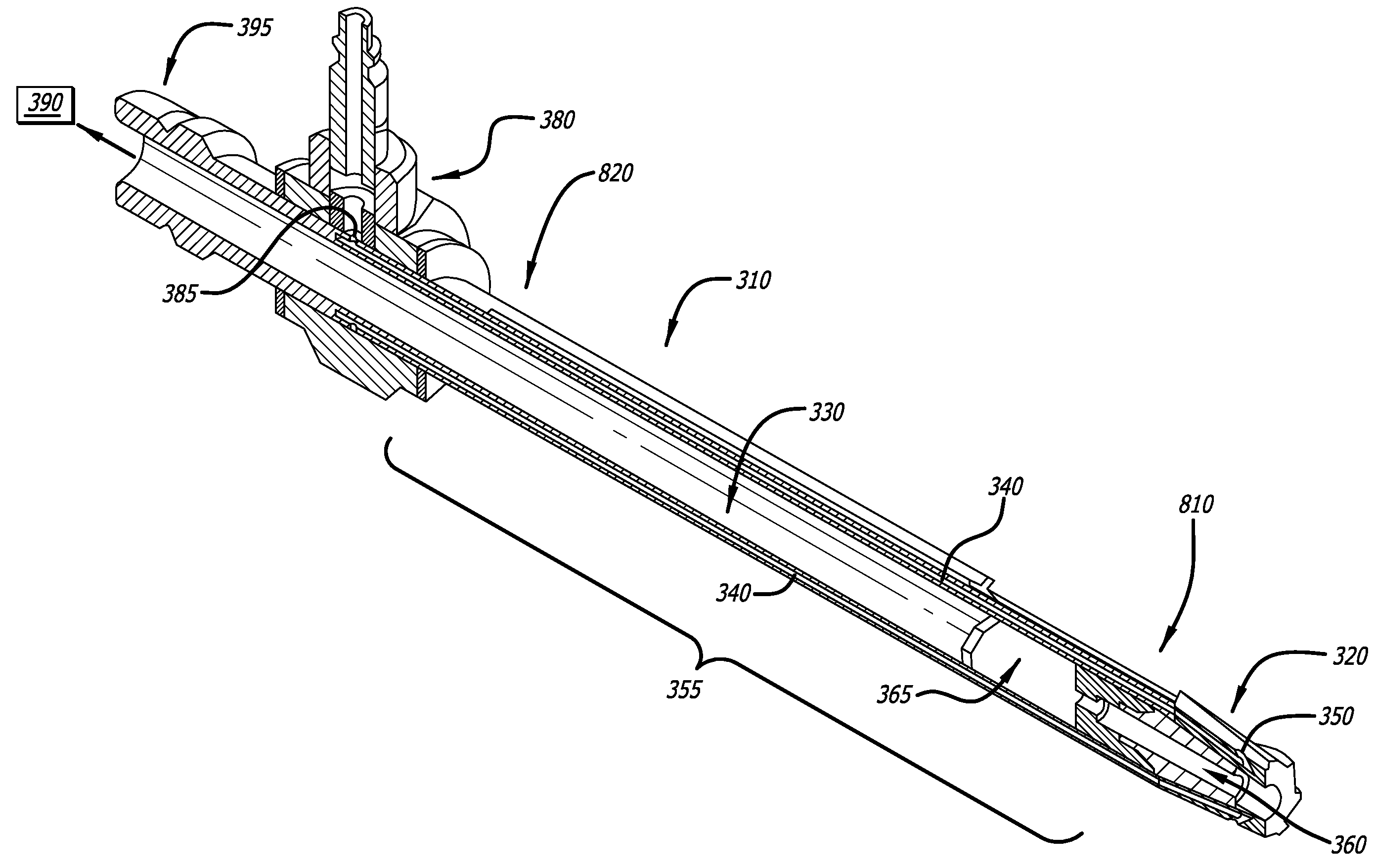

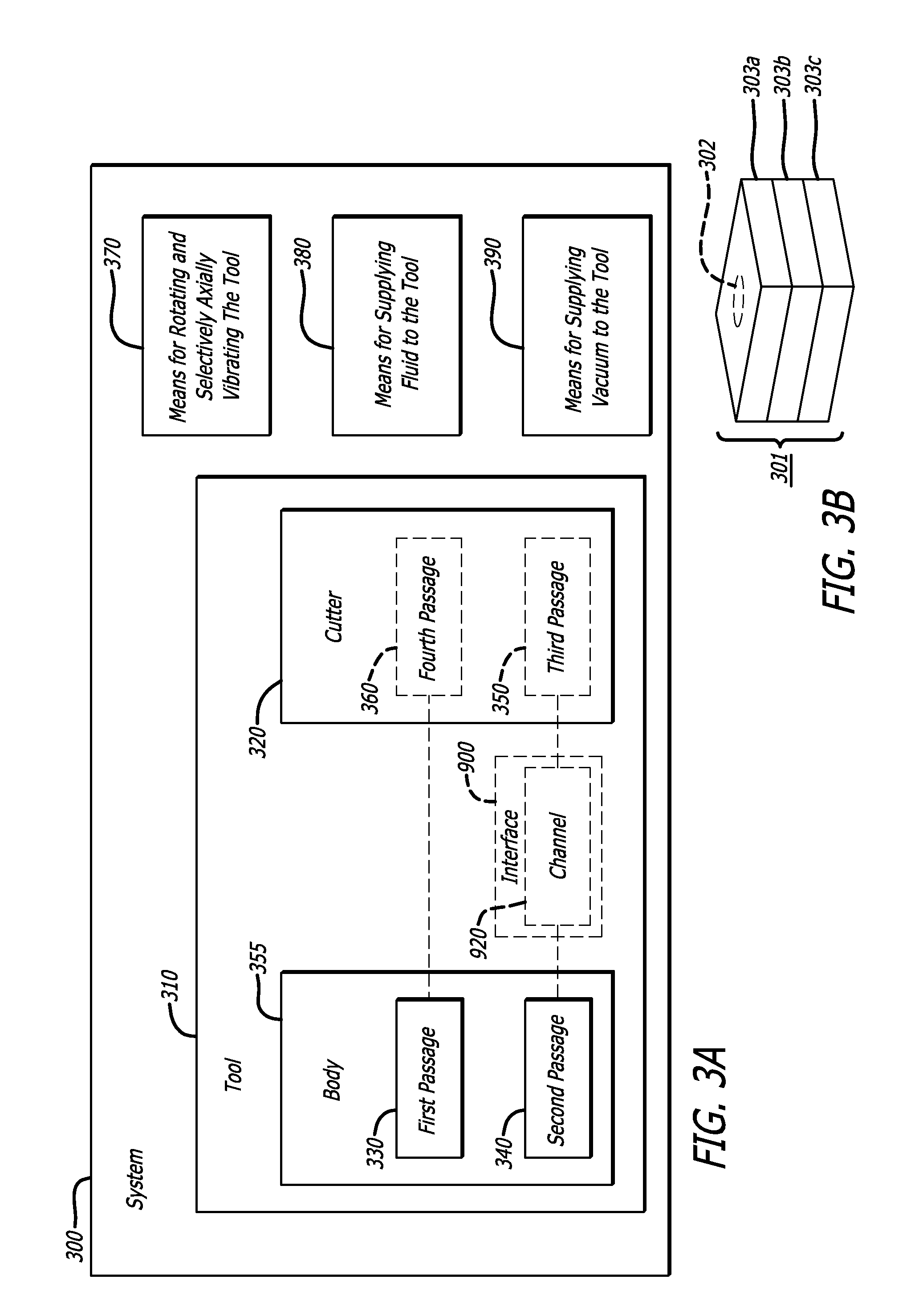

Fluid-fed vacuum cutters

In one aspect of the disclosure, a system for processing a location of a workpiece is disclosed. The system includes a tool, including a first passage, configured to supply a vacuum to the location, and a second passage formed along the first passage, where the second passage is configured to supply a fluid to the location. The system also includes means for rotating and selectively axially vibrating the tool, means for supplying the fluid to the tool, and means for supplying the vacuum to the tool.

Owner:THE BOEING CO

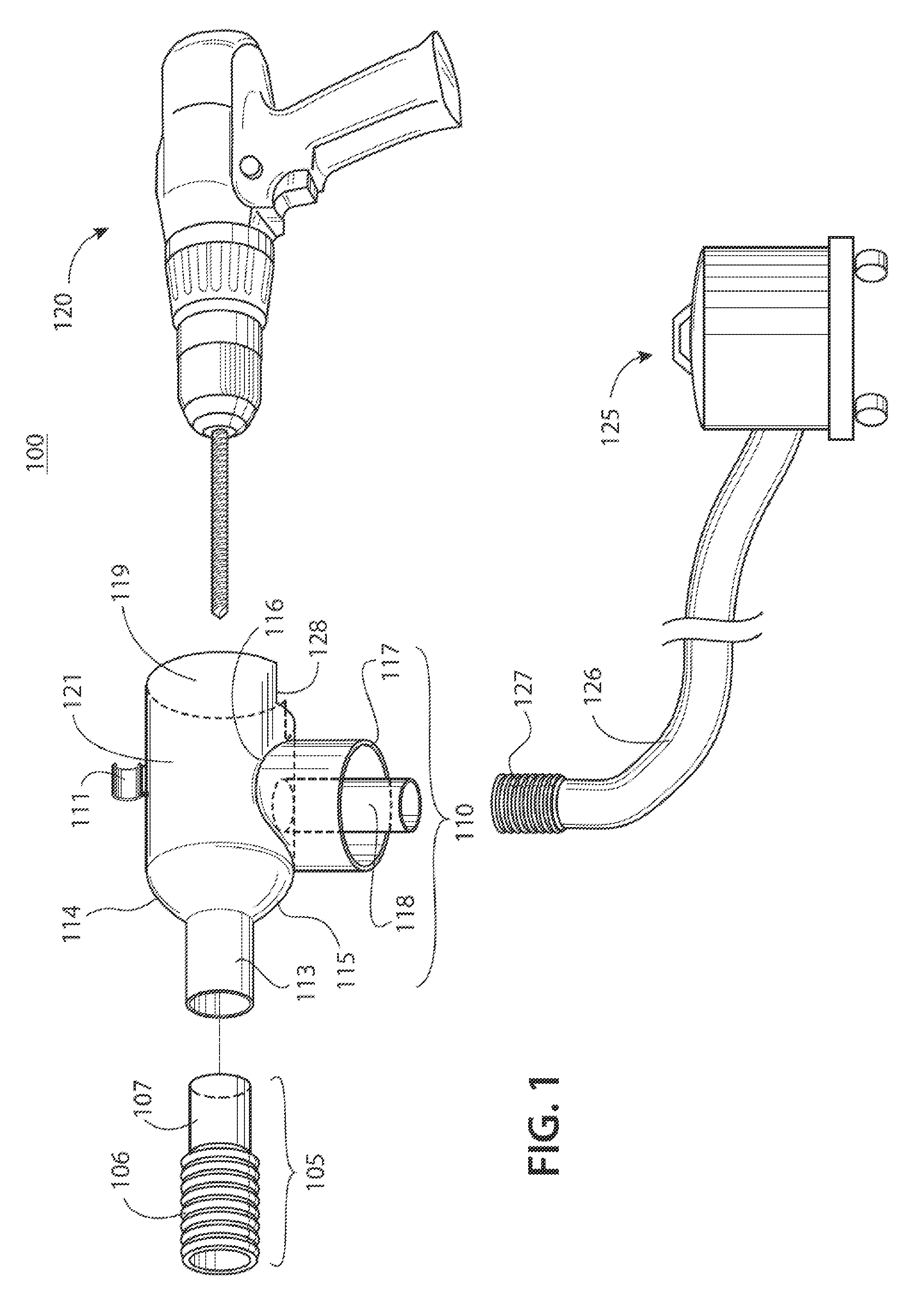

Retractable drill mounted dust collector

InactiveUS8529170B2Prevent and reduce marringPrevent and reduce and damageThread cutting feeding devicesMaterial removal/additionEngineeringSoft materials

A retractable dust containment device includes a forward ring, a collapsible cylindrical center portion, a stretchable rear cover, and draw strings. The forward ring is made from or covered by a plastic or soft material to prevent or reduce marring or damage to a work surface. The center portion includes a spring element pushing the forward ring away from the rear cover, and is enclosed by material to contain dust. The rear cover is a rubber like material and includes a window sized to allow a chuck and rotating drill elements to pass through and seat a non-rotating nose of the drill in the window. Draw strings pass through guides on the perimeter of the rear cover, attach to the forward ring, and are joined behind the rear cover, allowing the forward ring to be drawn to the rear to allow clear viewing on the work surface.

Owner:EVERINGTON JR ERNEST

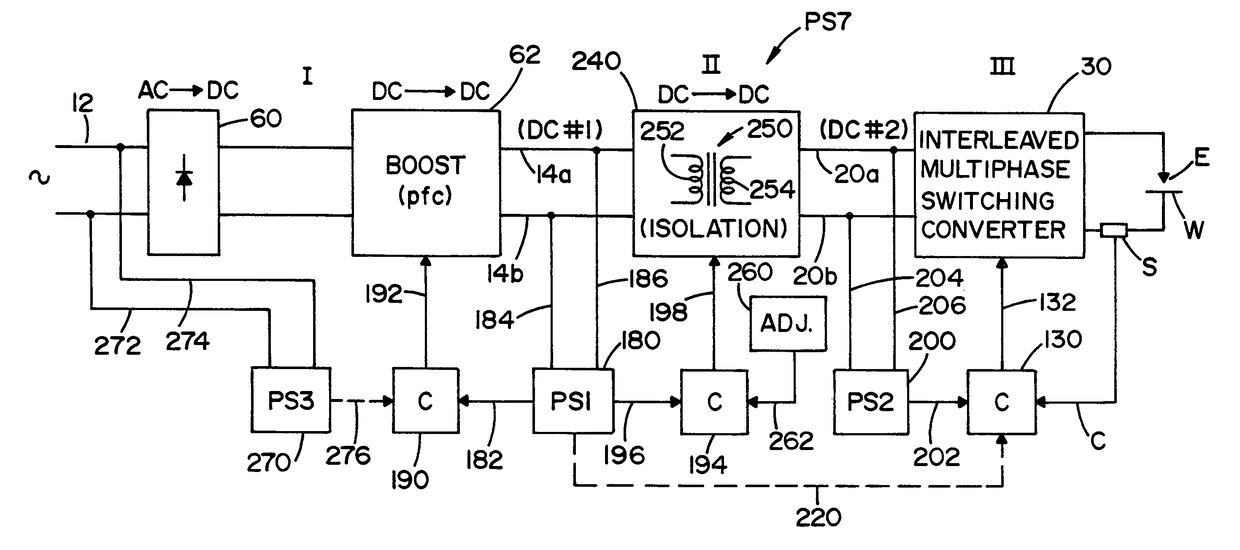

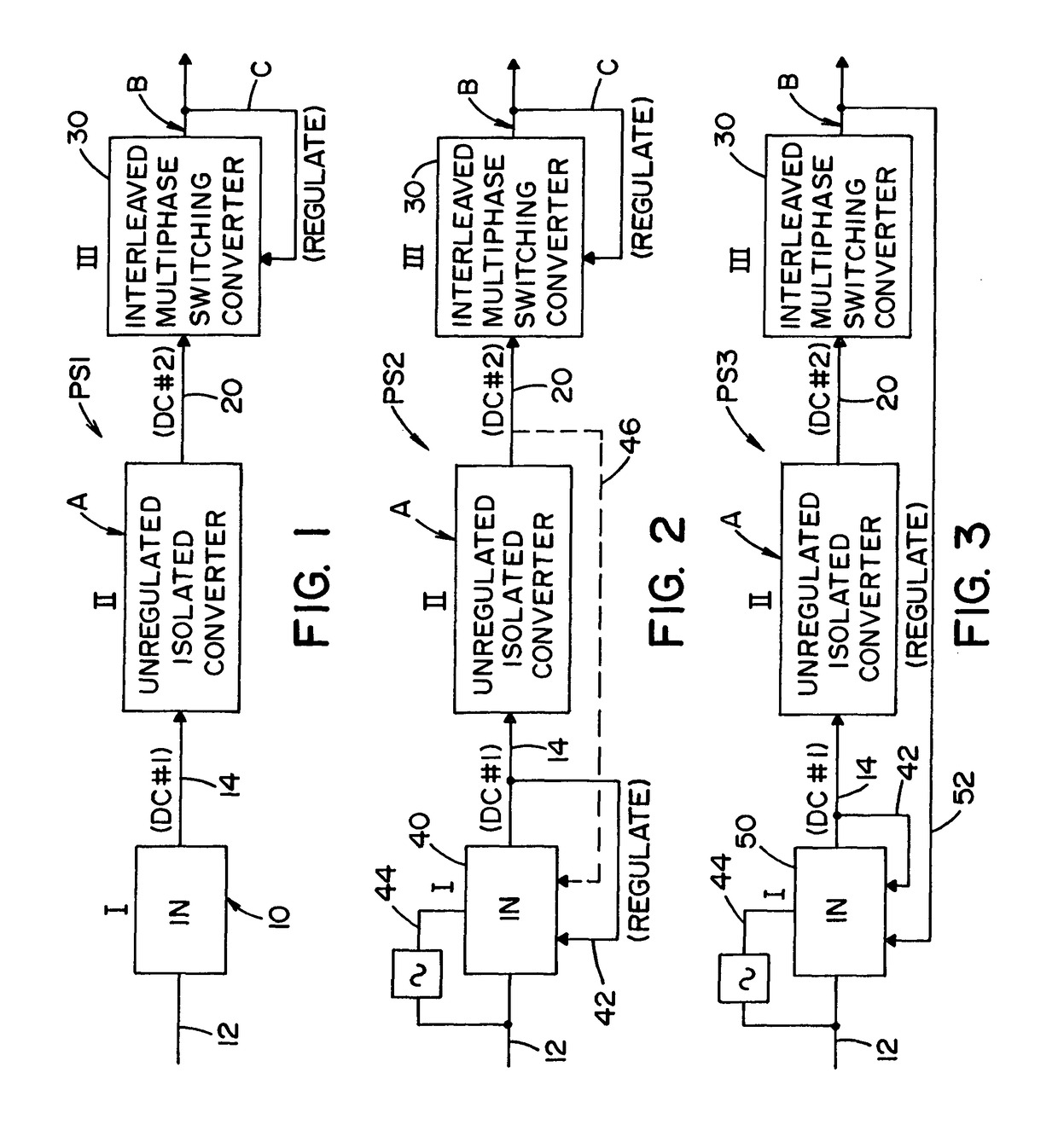

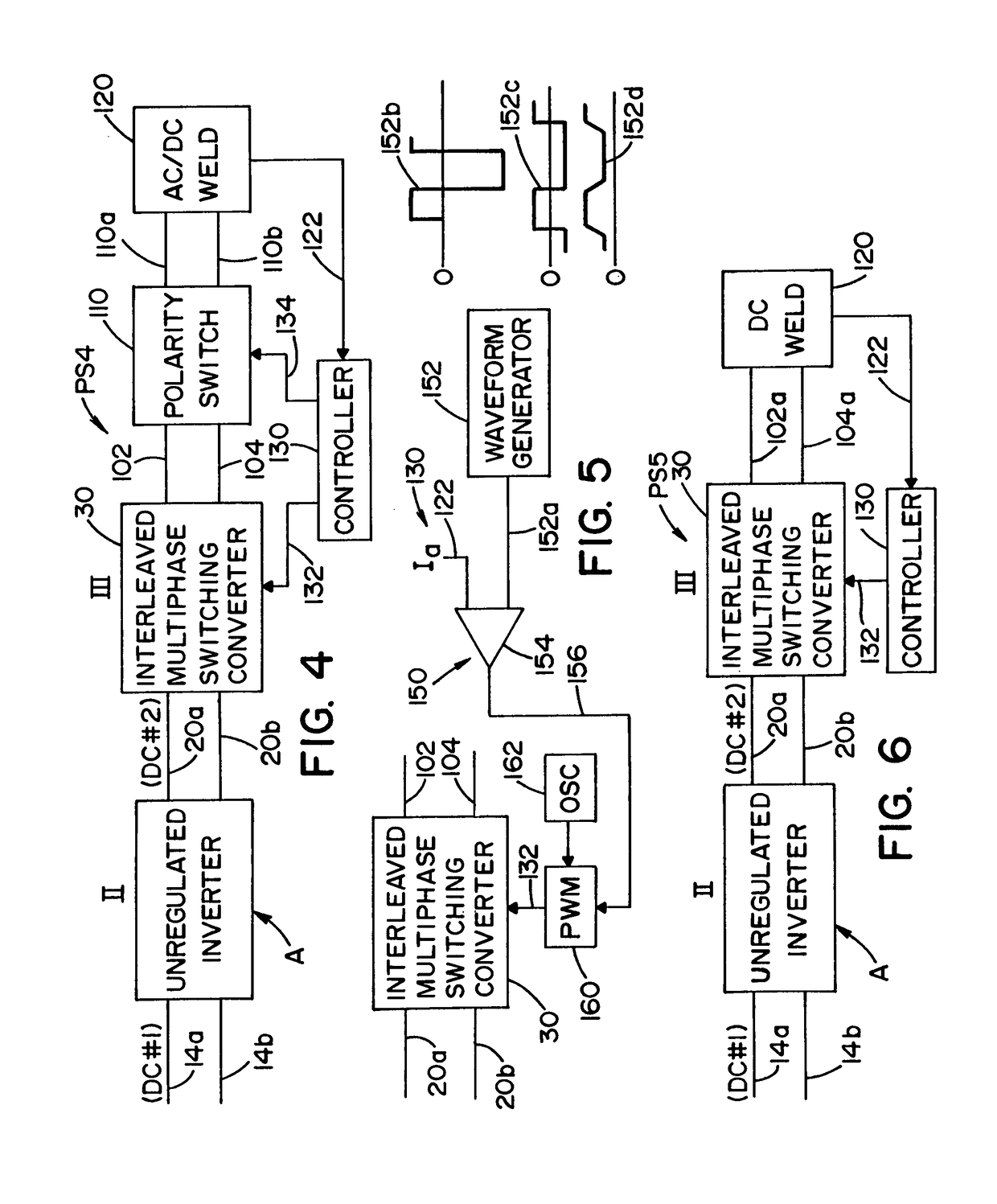

Chopper output stage for arc welder power source

ActiveUS9647555B2Significantly degrading system efficiencyWithout unduly adding to system costConversion with intermediate conversion to dcArc welding apparatusEngineeringElectrical and Electronics engineering

Power sources are disclosed for electric arc welding or cutting processes, in which an interleaved multiphase switching converter is provided with a plurality of converter power circuits to convert a DC signal to a regulated signal suitable for welding.

Owner:LINCOLN GLOBAL INC

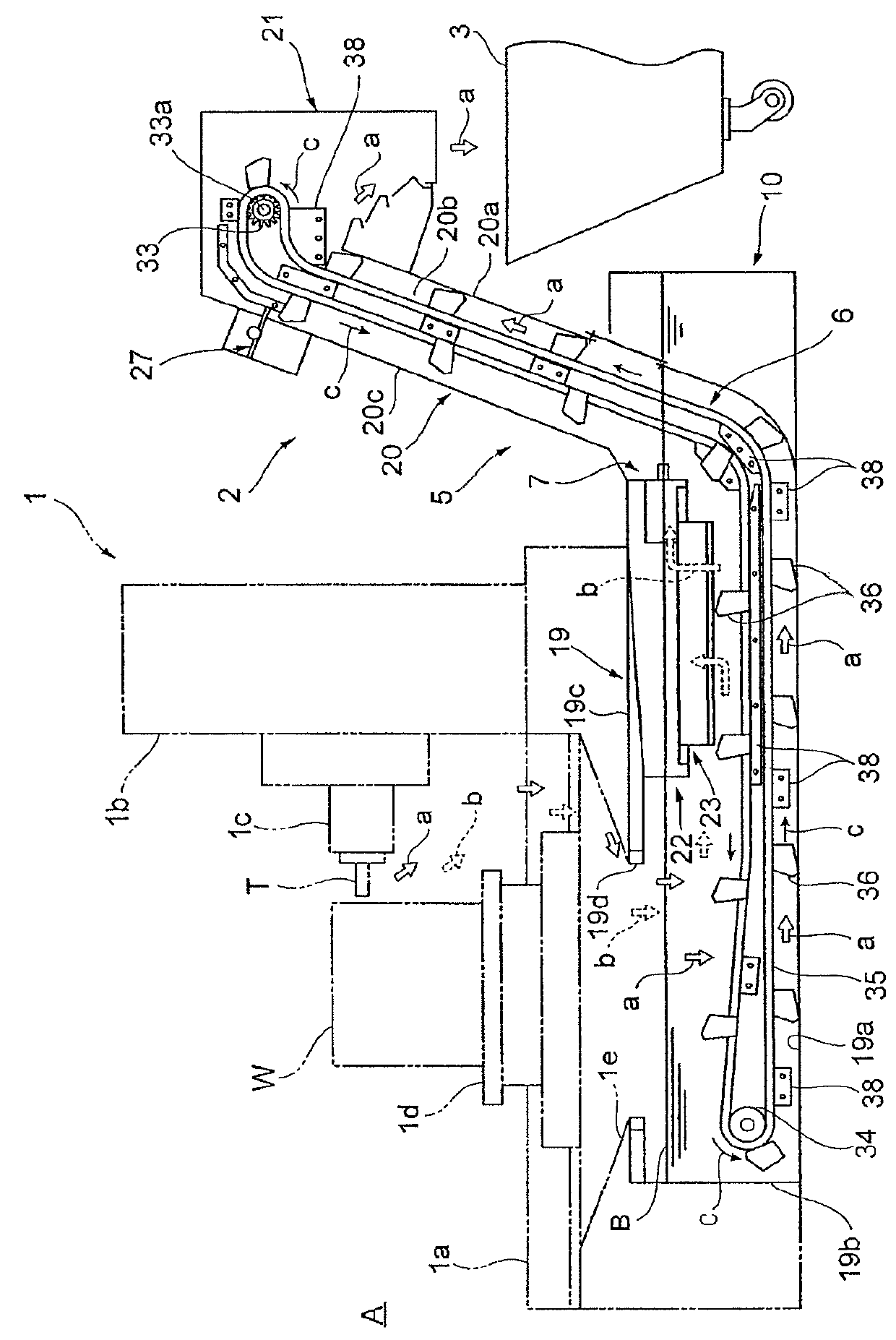

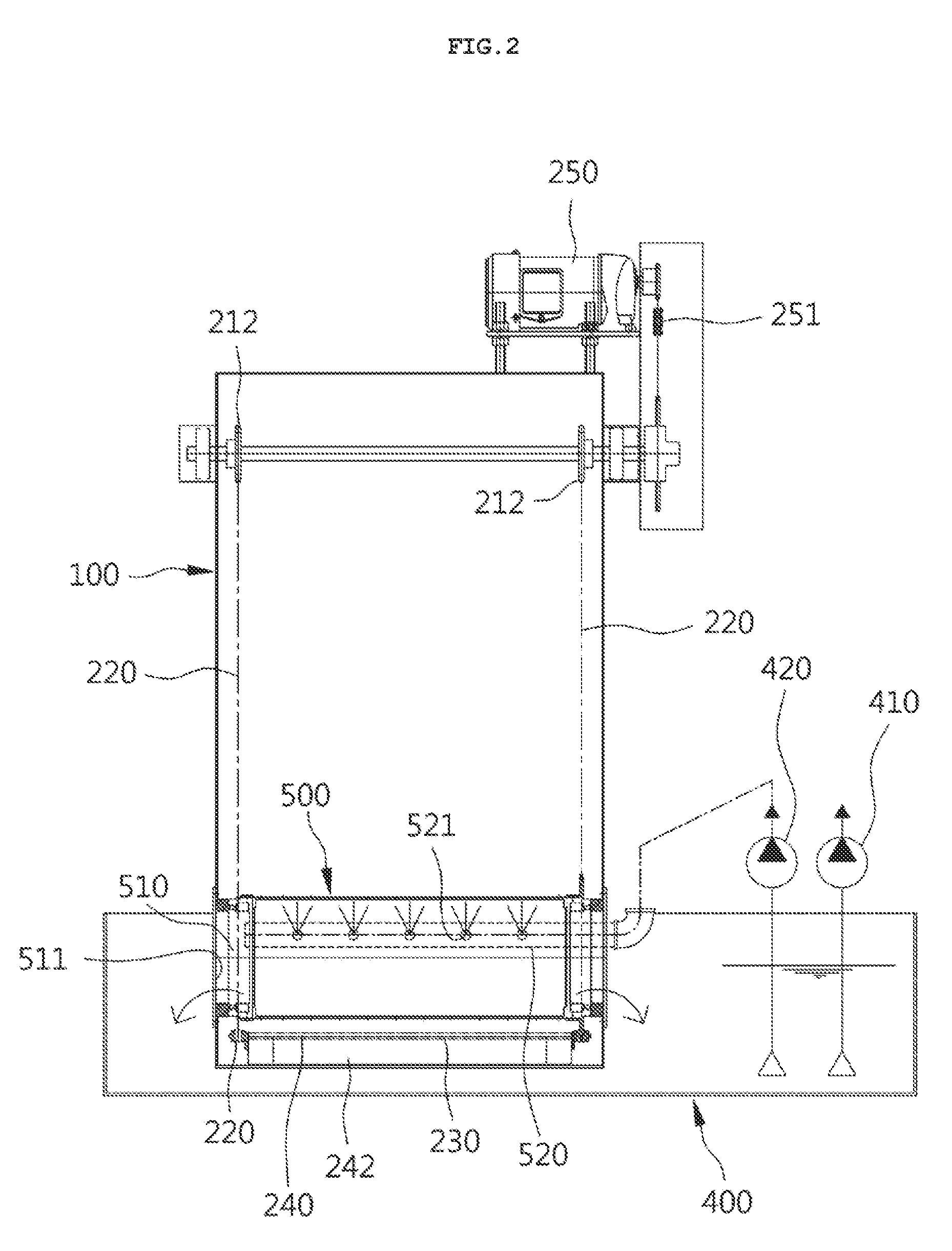

Chip disposal device of machine tool

InactiveUS9339907B2Increase collection rateA large amountCleaningMaterial removal/additionEngineeringMachine tool

Owner:DMG MORI CO LTD

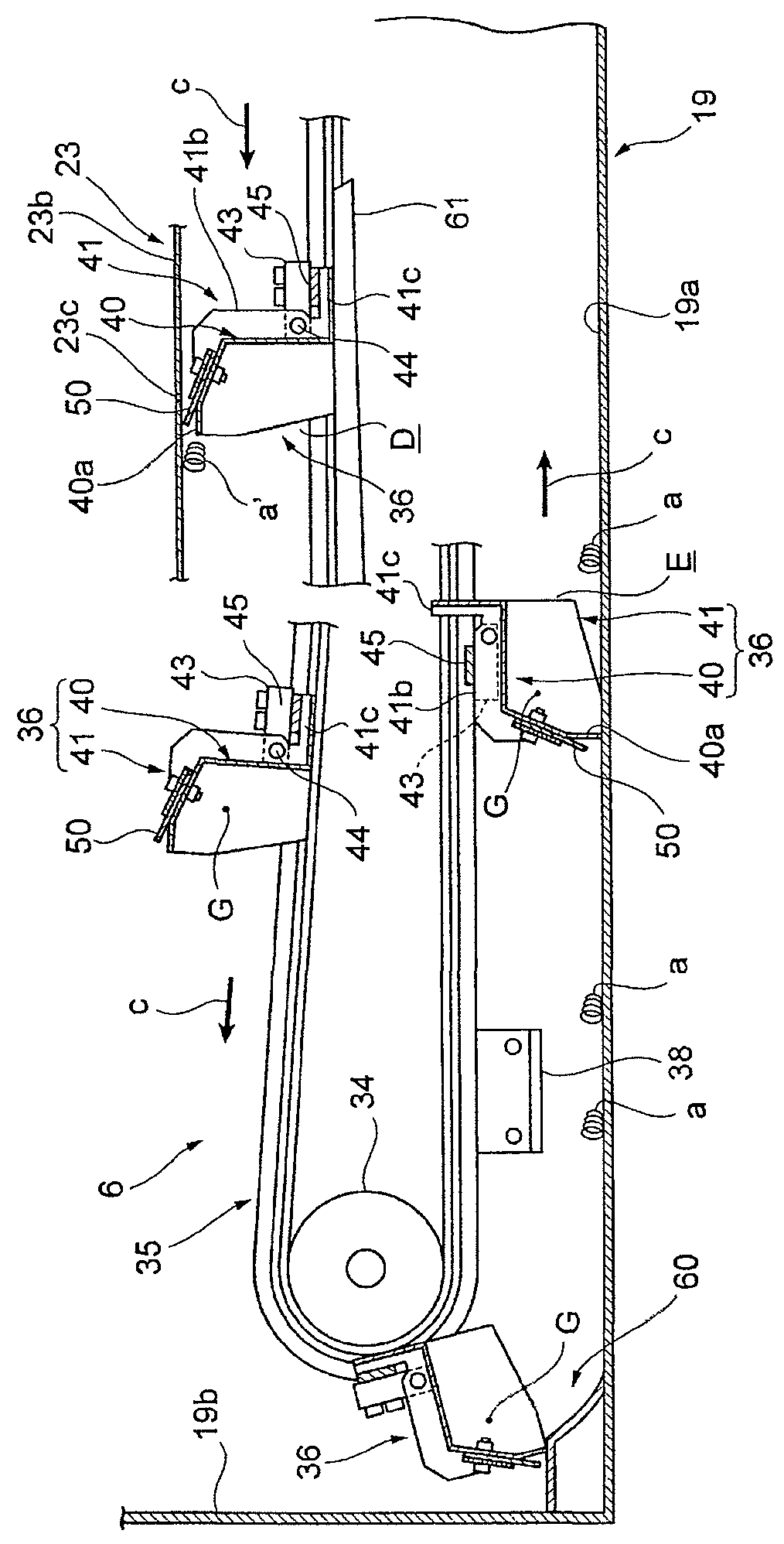

Conveyer apparatus for discharging chips

A conveyer apparatus for discharging chips is disclosed herein. The conveyer apparatus includes a tank body, a conveyer unit, and an opening / closing unit. The tank body is configured such that the tank body is configured in the form of a container body, an inlet is formed in the top surface of one side of the tank body, and a chip outlet is formed in the bottom surface of the remaining side of the tank body. The conveyer unit is installed in the form of a caterpillar spaced apart from the inner walls of the tank body, and has at least one opening so that the inner and outer spaces of the conveyer unit communicate. The opening / closing unit is installed to block the opening, and operates so as to open the opening when the corresponding opening passes through a surface opposite the inner bottom surface of the tank body.

Owner:O SUNG MECHATRONICS

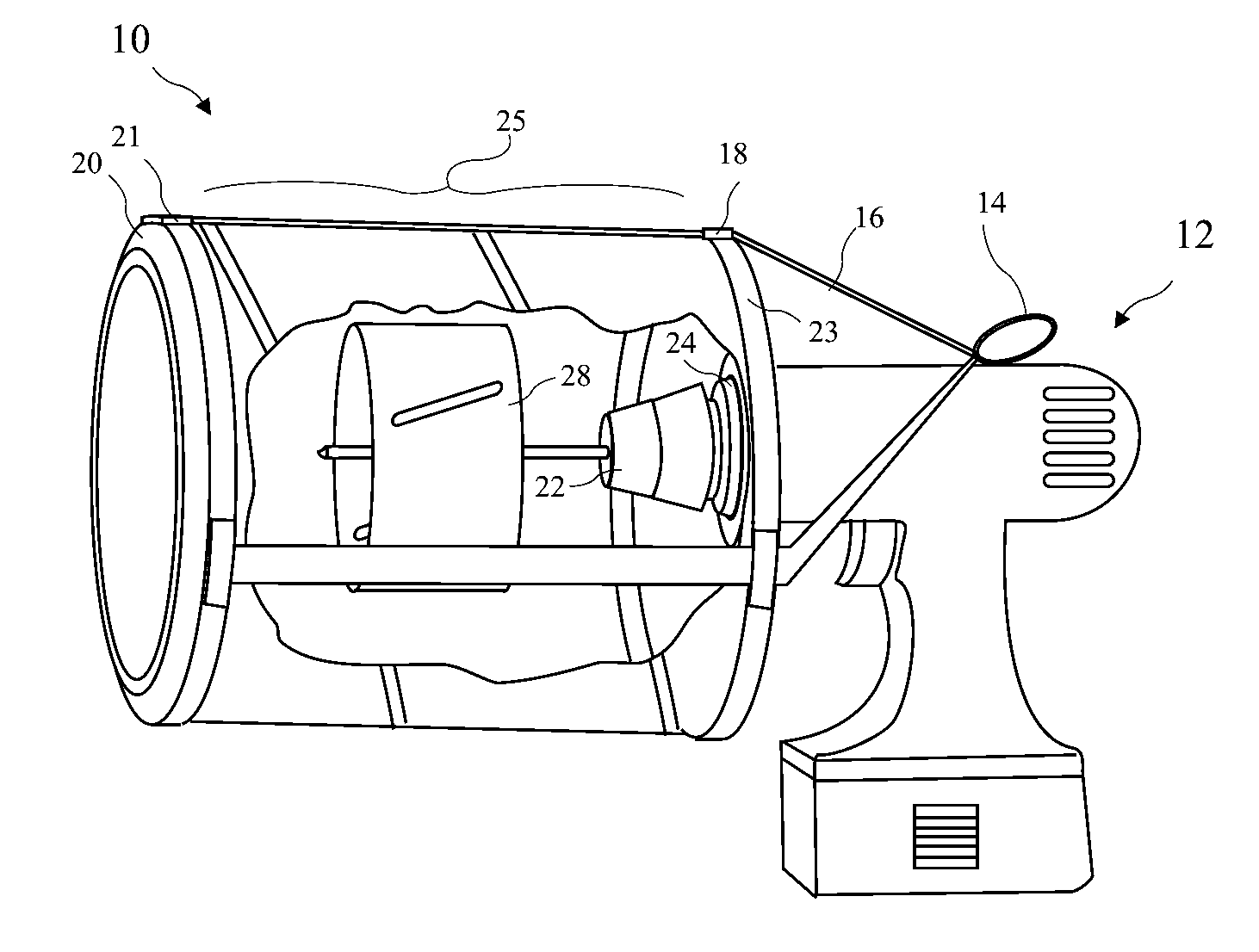

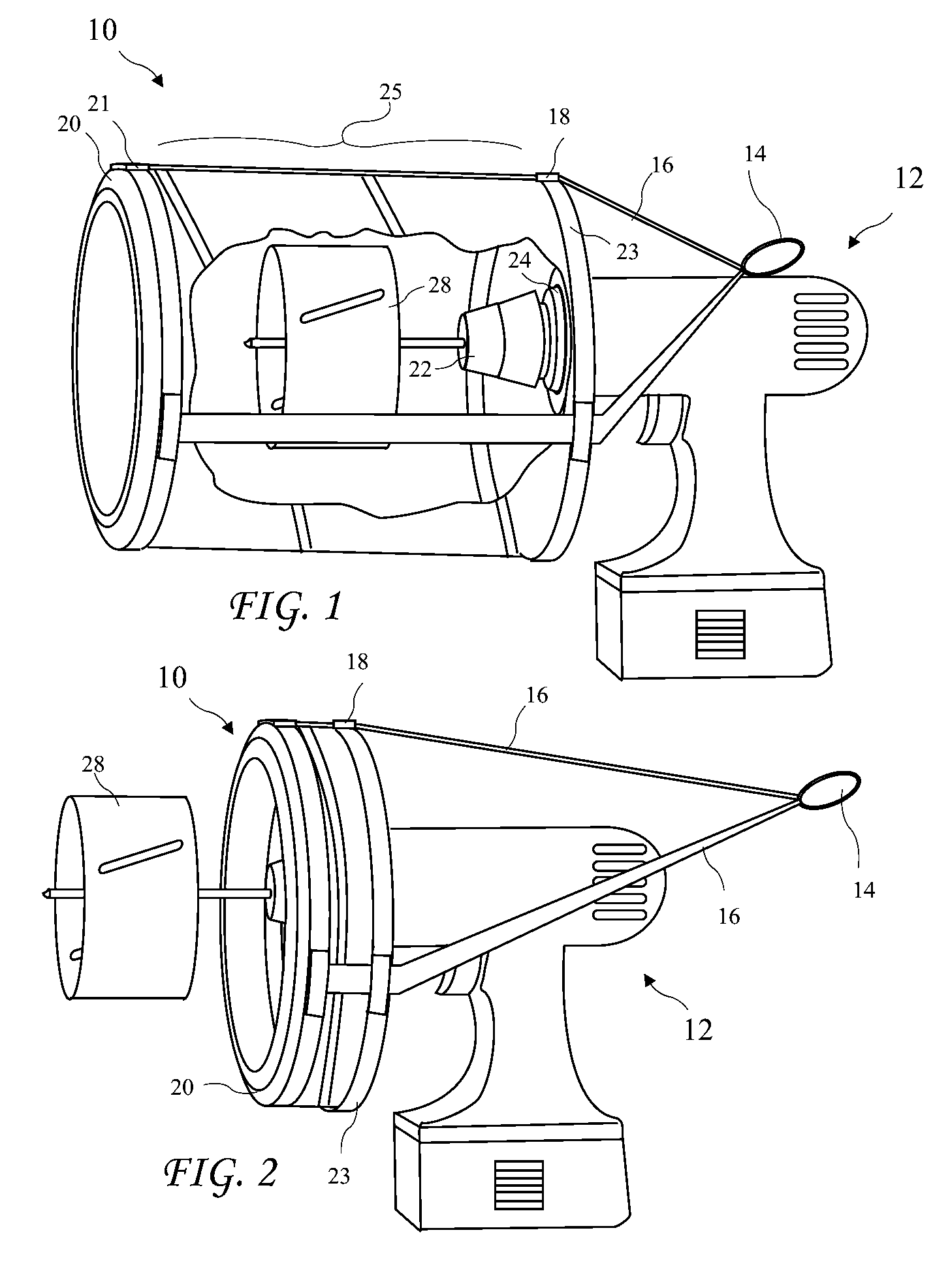

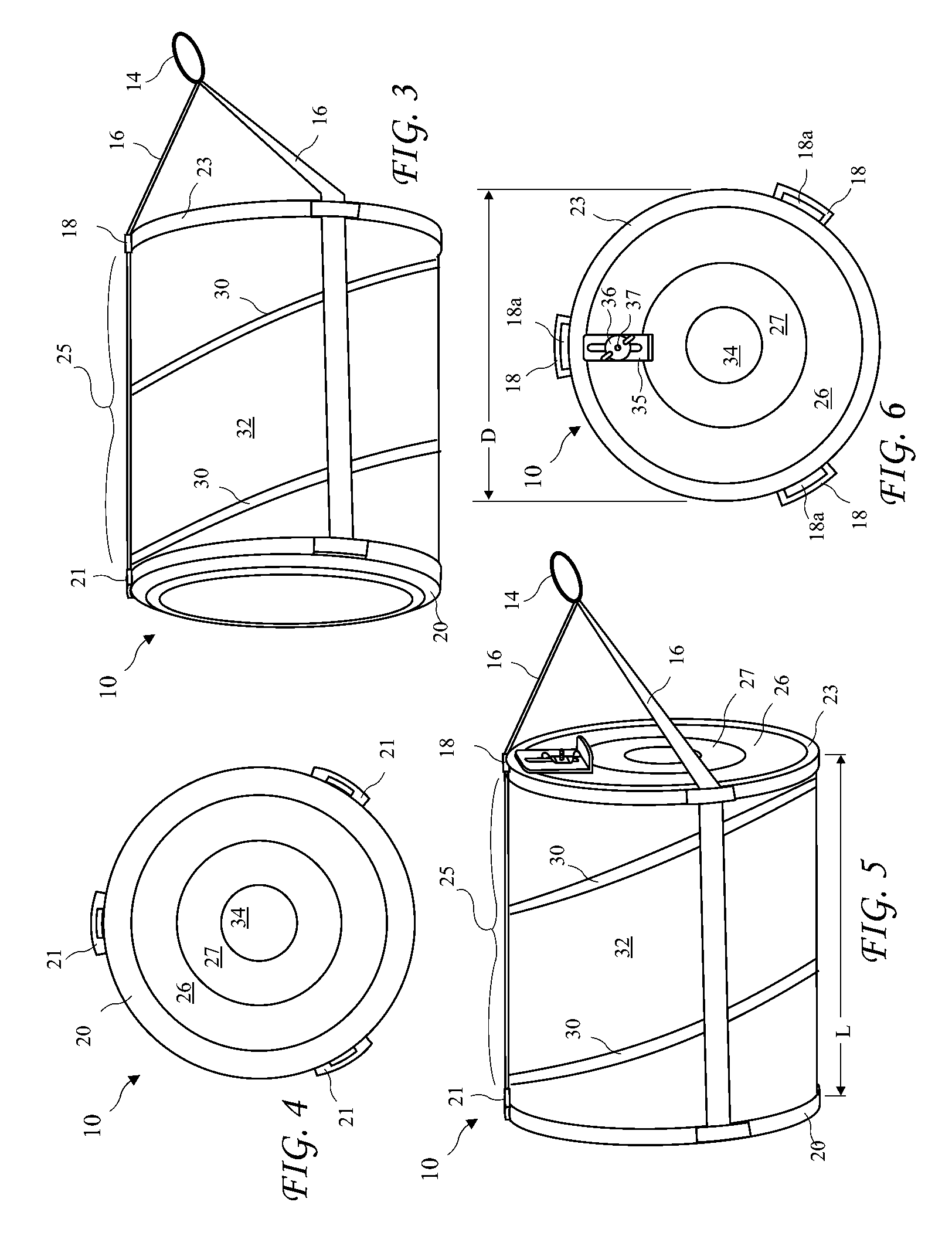

Rotatable filter system and methodology

ActiveUS20170282407A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesFilter systemWaste management

Owner:JPL GLOBAL

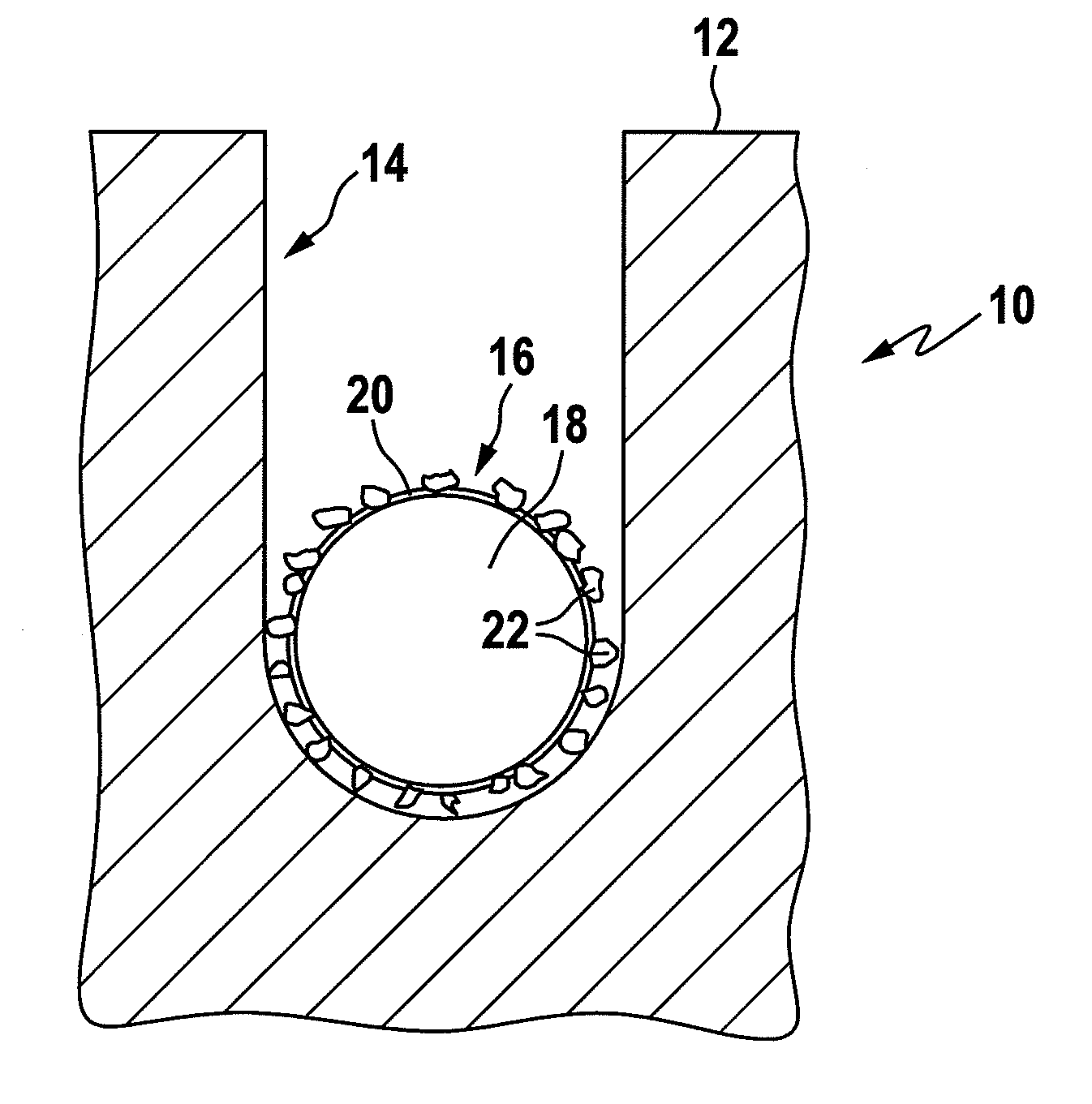

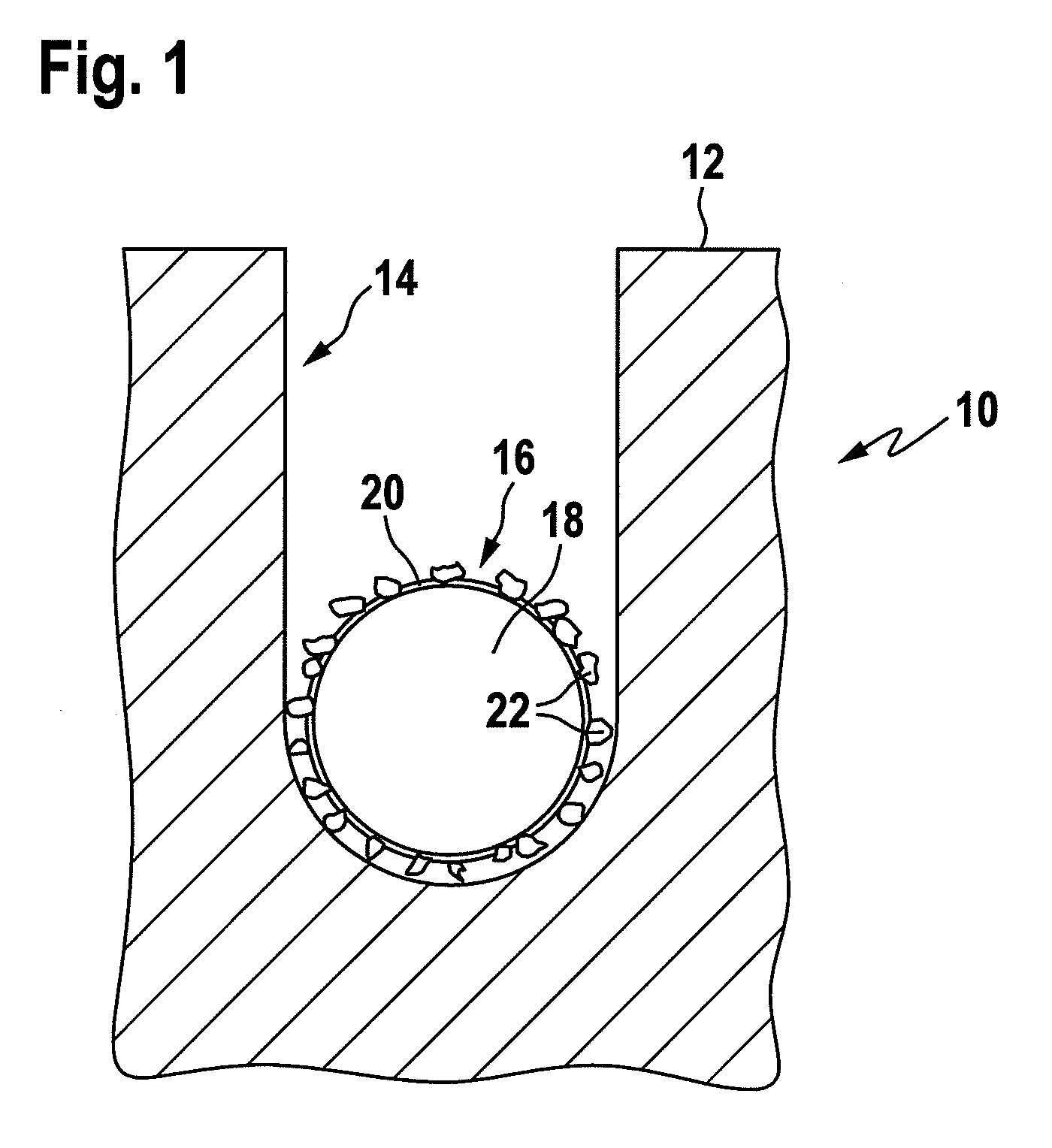

Dust extraction device for a rotary power tool

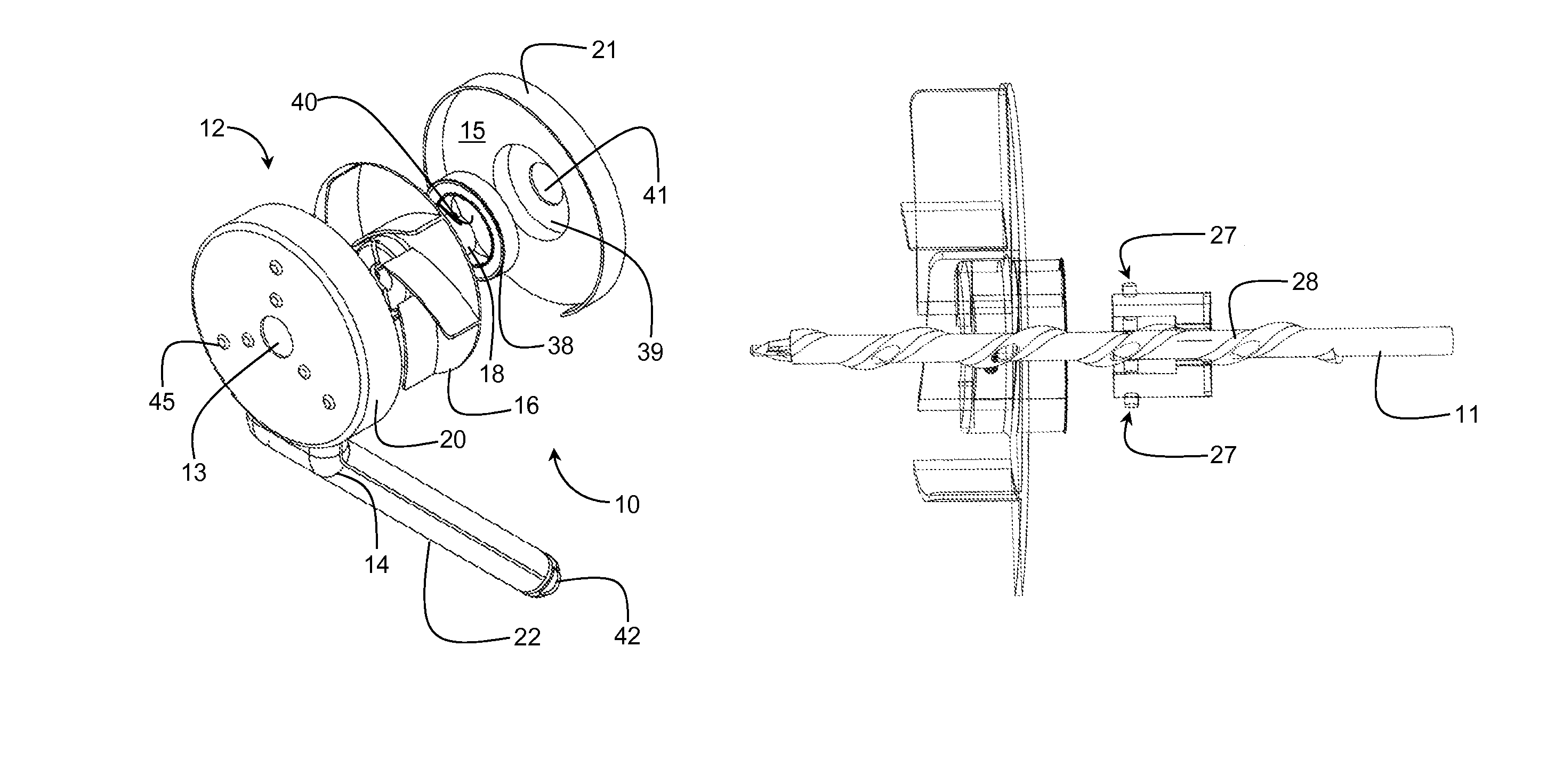

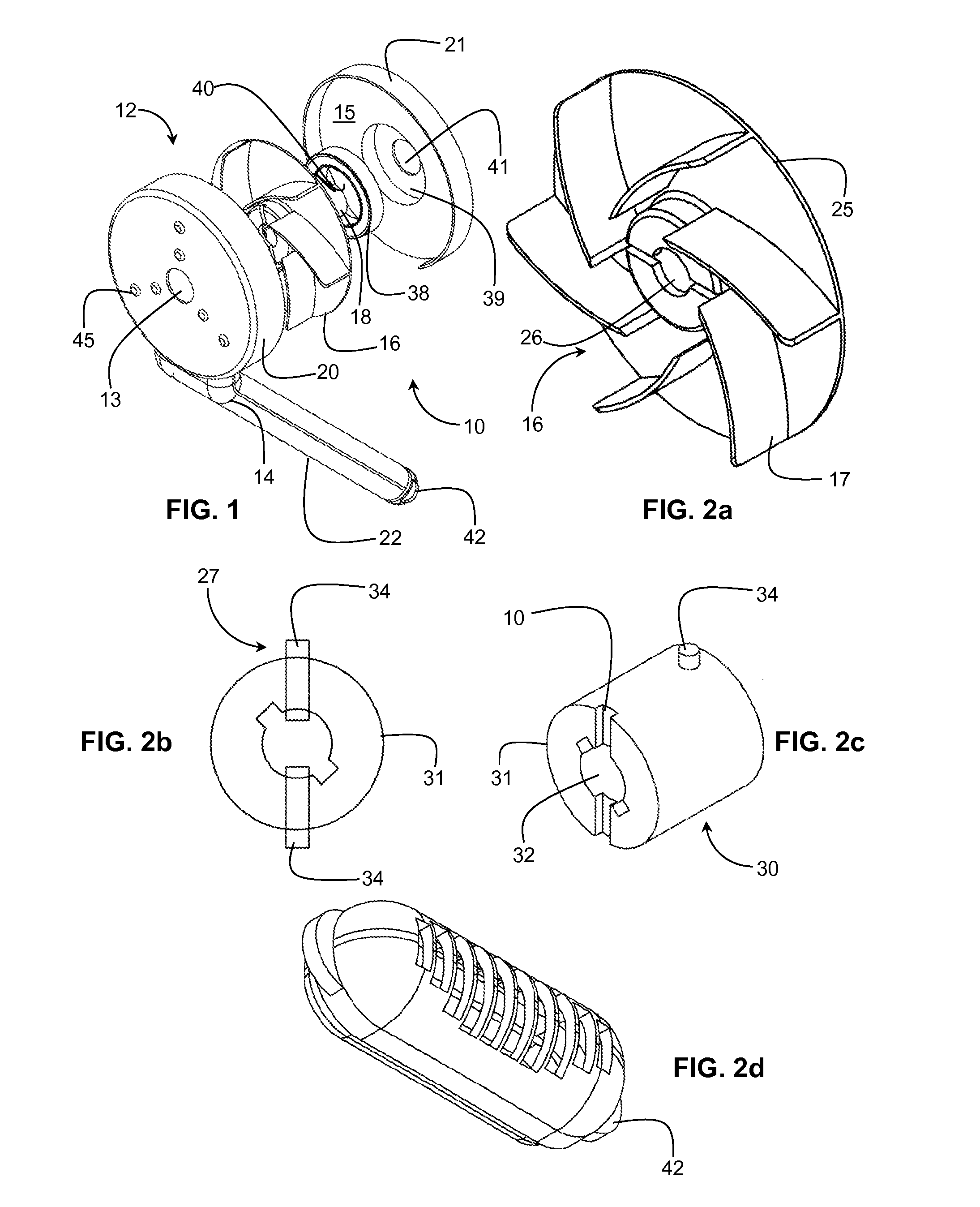

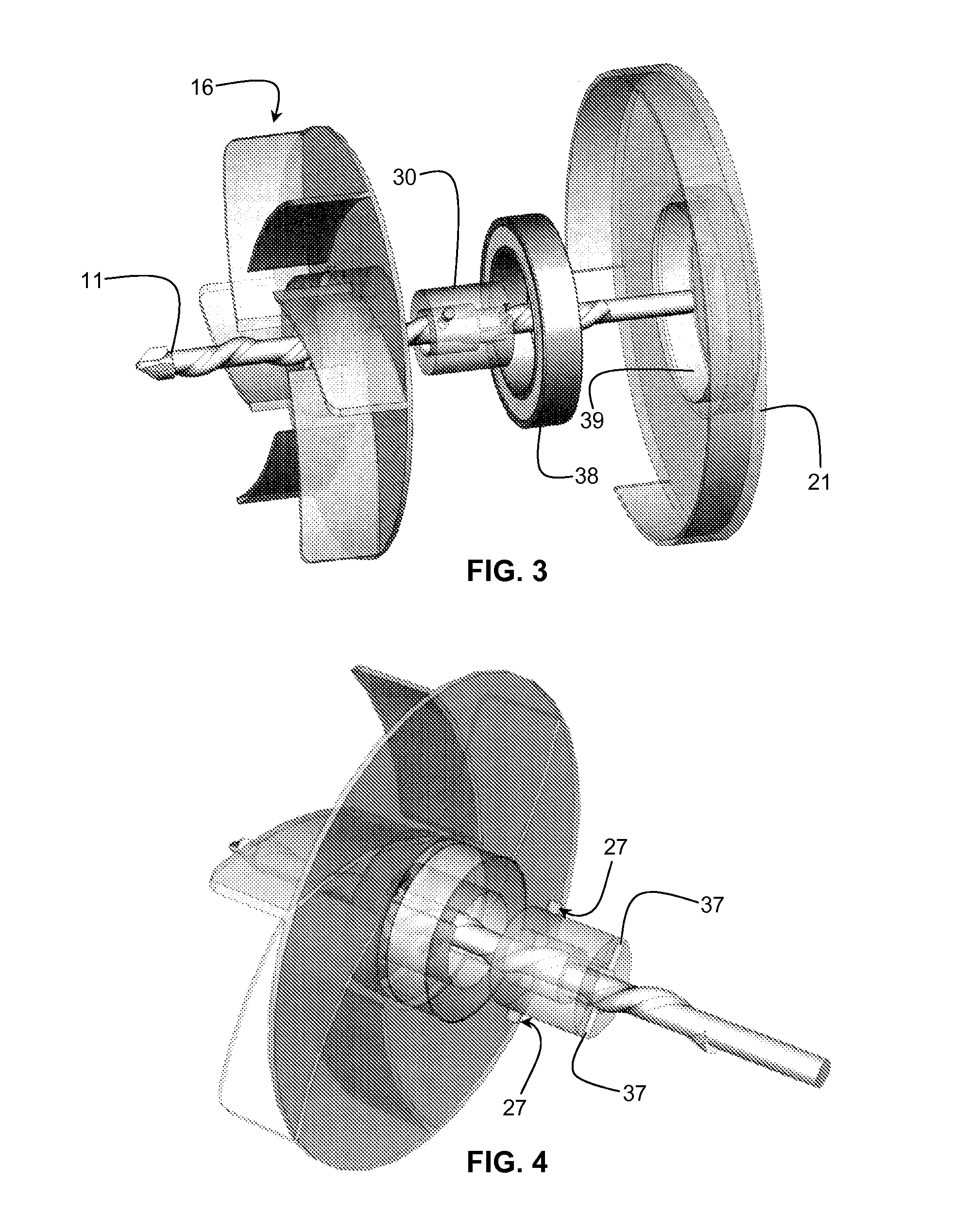

InactiveUS9399272B2Avoid the needIncrease forceMetal working apparatusPortable drilling machinesImpellerEngineering

A dust extraction device (10) for a rotary power tool having an elongate rotating drill bit (1) for operating on a work surface includes a casing (12) having an inlet (13) and an outlet (14) and defining an interior cavity (15). A fan element (16) having a plurality of impellers (17) and a central hub (18) is adapted for rotation within and independent of the casing for inducing air flow within the casing from the inlet to the outlet when the fan element rotates, the hub being adapted for engaging the drill bit (11) in a manner that permits rotation of the hub as well as axial movement of the drill bit relative to the hub during rotation of the drill bit. Rotation of the drill bit results in air flow to remove debris from the work surface to the outlet without rotating the casing.

Owner:HAVIV LIOR

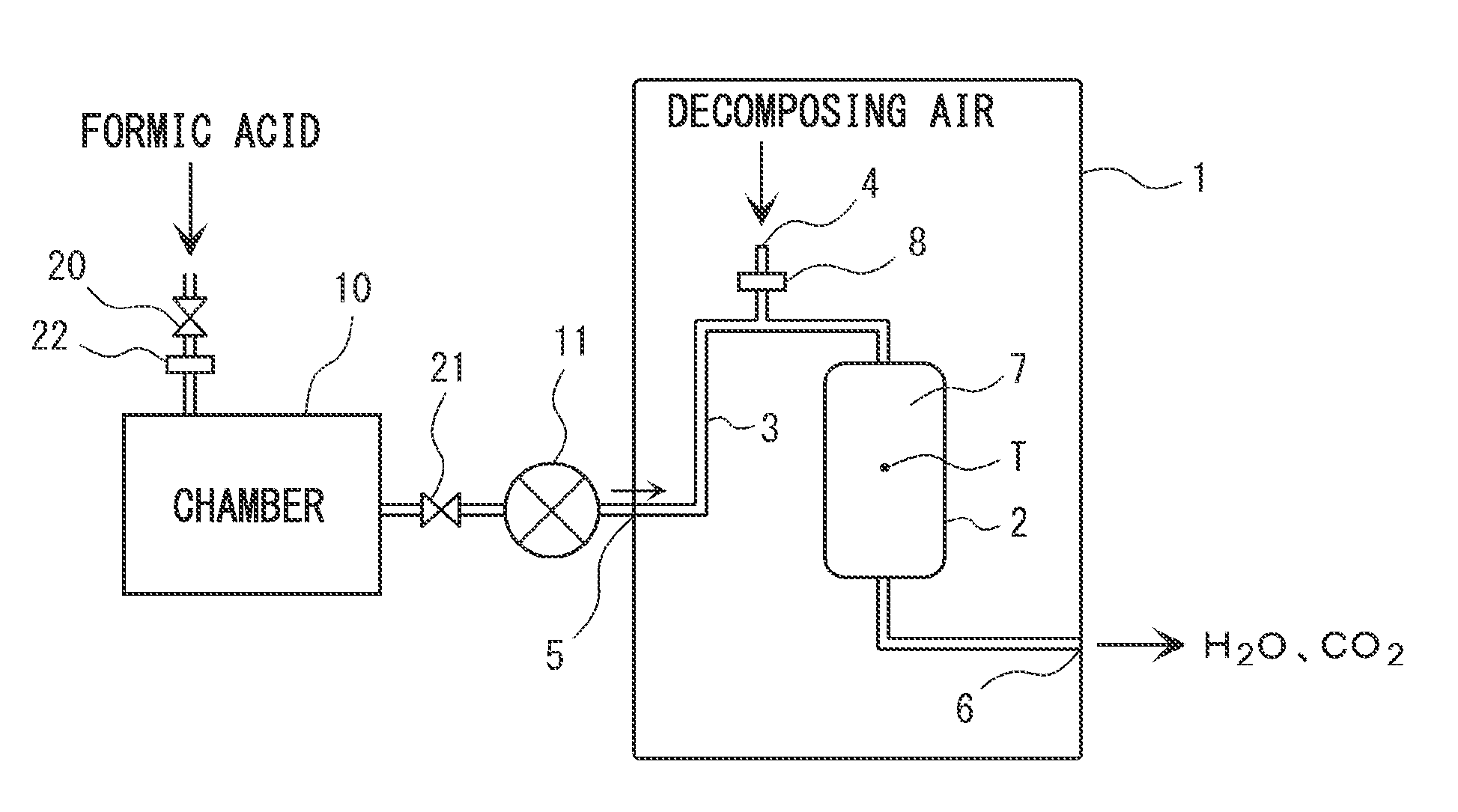

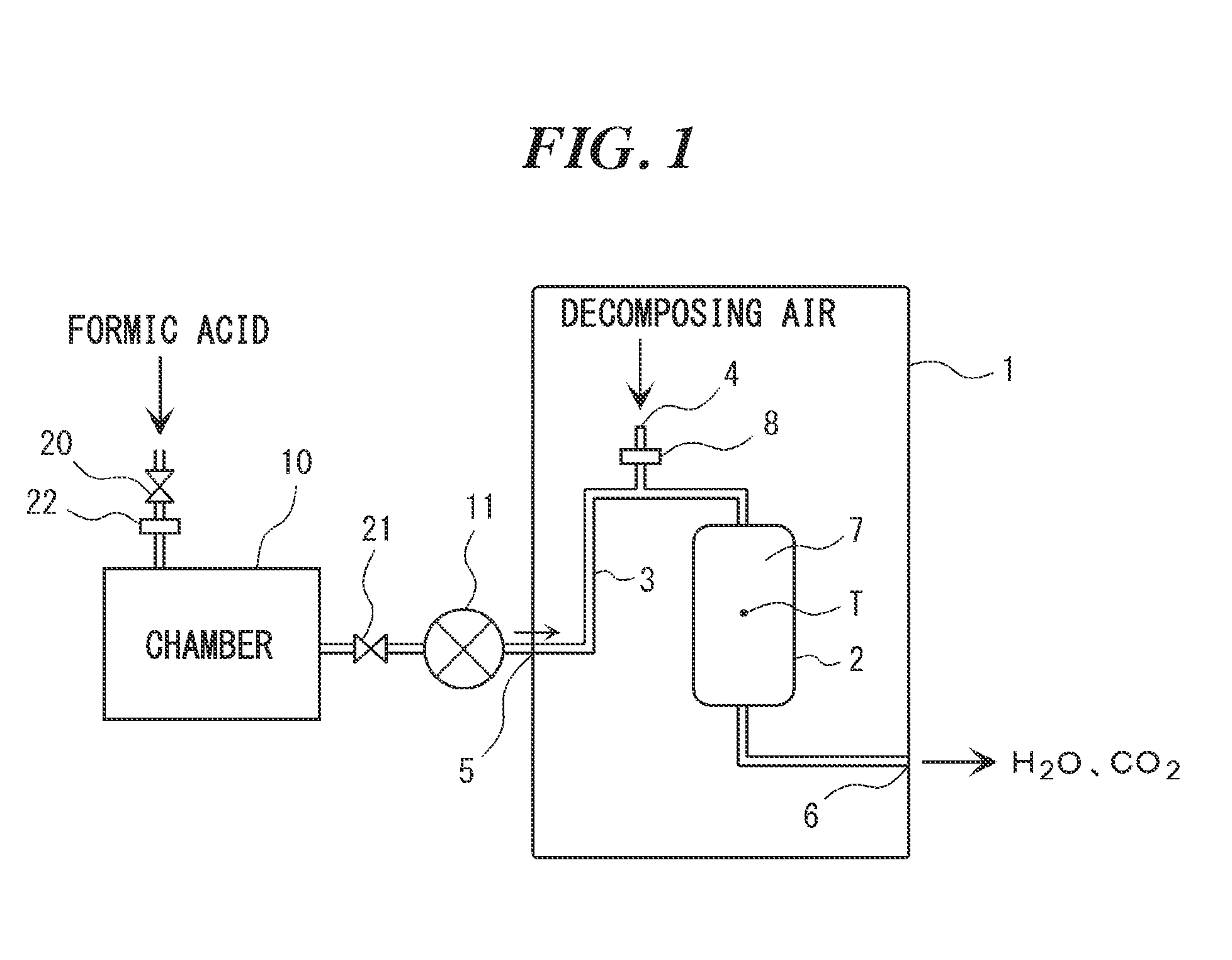

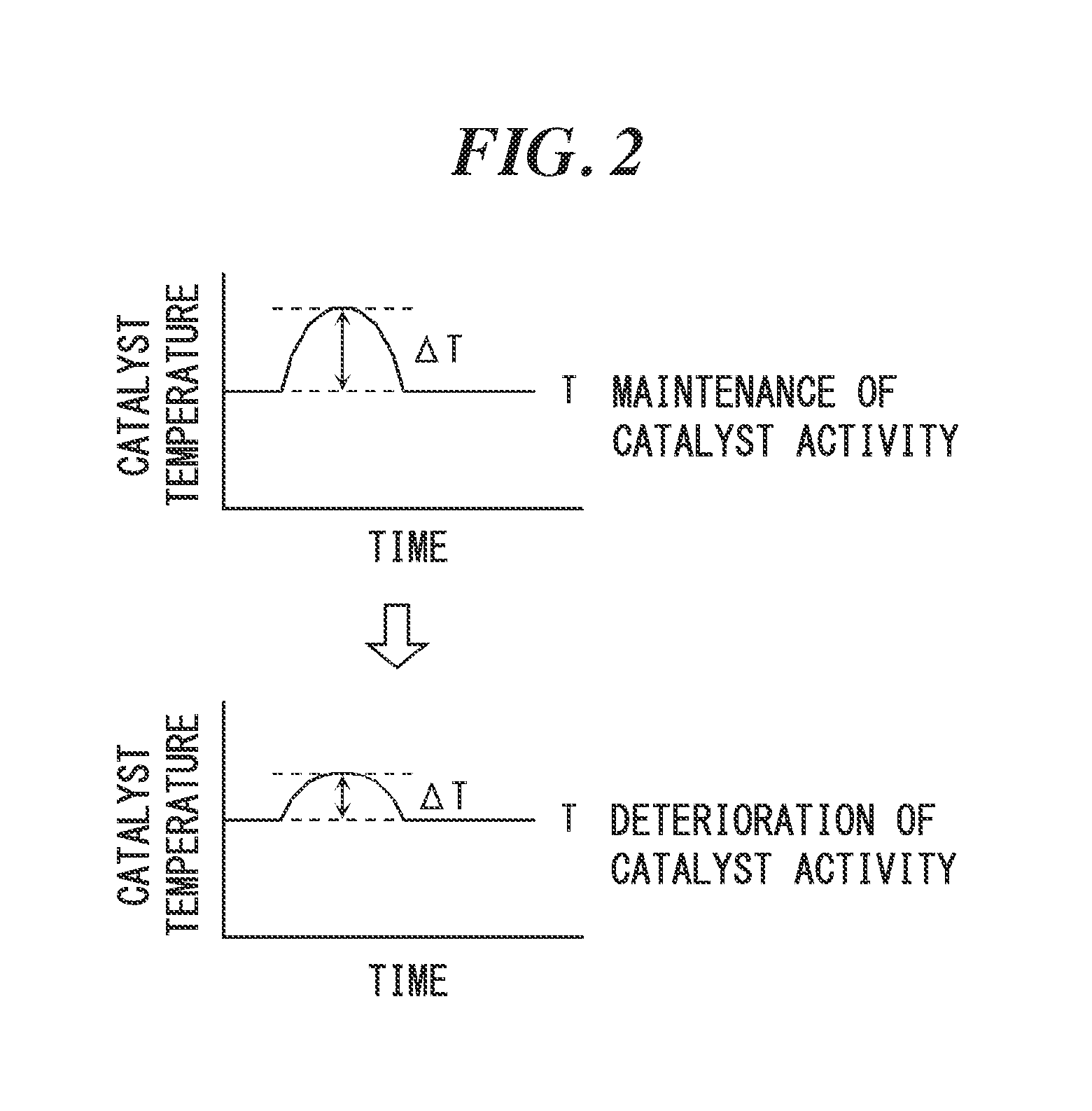

Formic acid decomposition apparatus and formic acid decomposition method

InactiveUS20160220955A1Quick breakdownProcess safetyGas treatmentDispersed particle separationDecompositionExhaust fumes

To provide a formic acid decomposition apparatus and method, which can dispose of formic acid safely and quickly and determine the activity of a filled catalyst. The apparatus is for decomposing formic acid contained in exhaust gas exhausted from a soldering apparatus in which a surface oxide film is reduced with formic acid, into water and carbon dioxide. The apparatus has a formic acid decomposition part in which a formic acid decomposition catalyst is filled; a gas introduction pipe for introducing gas containing formic acid into the decomposition part; and a gas introduction unit for introducing oxygen or gas containing oxygen into the decomposition part. In the apparatus, the activity of the catalyst is determined on the basis of an amount of change of a catalyst temperature by heat generation during a decomposition reaction of formic acid. The method includes mixing exhaust gas containing formic acid exhausted from the soldering apparatus, and oxygen or gas containing oxygen such that a molar ratio of formic acid and oxygen (oxygen / formic acid) is 1.5 or more, and allowing the mixed gas to react in the presence of the catalyst to decompose formic acid into water and carbon dioxide.

Owner:ORIGIN ELECTRIC CO LTD

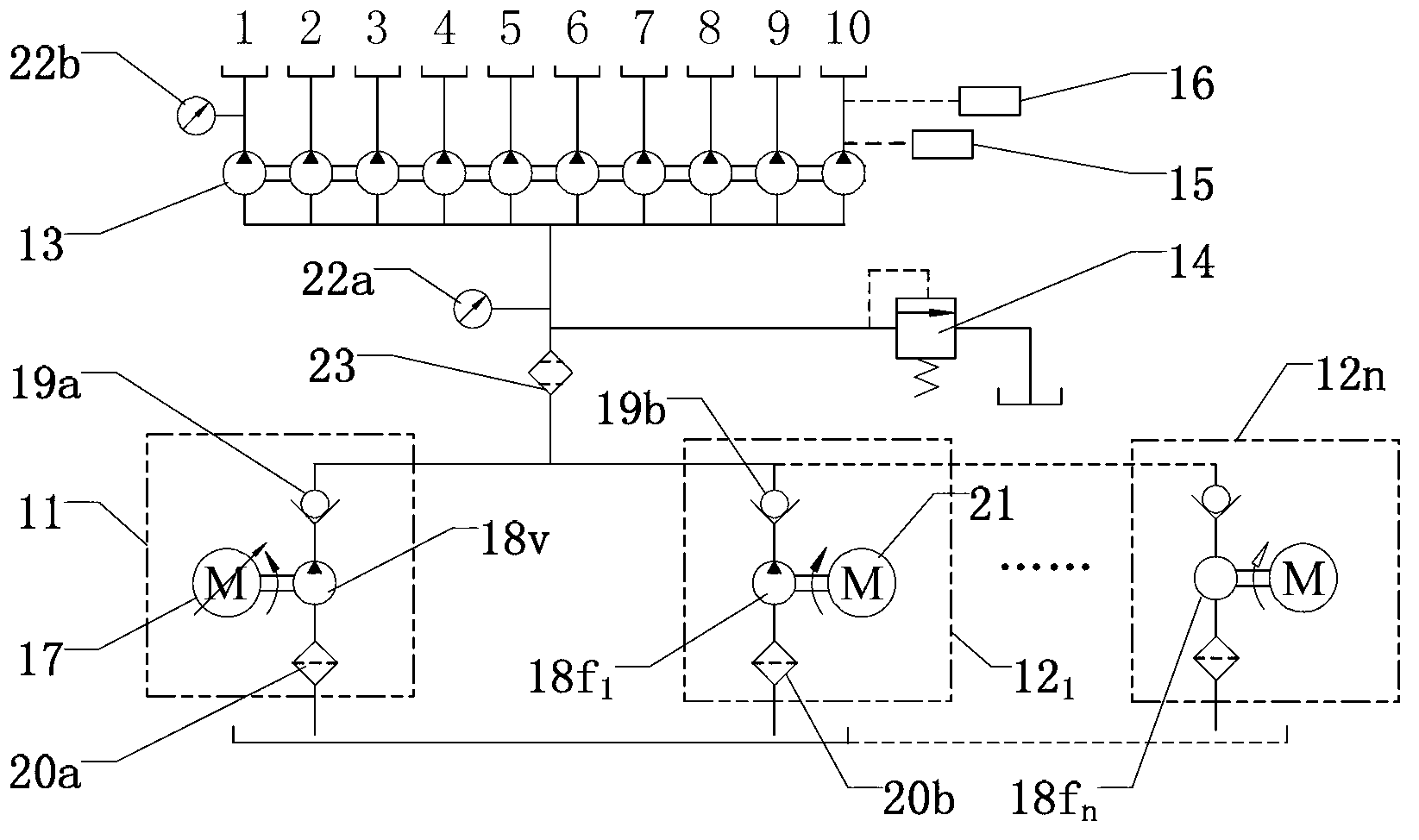

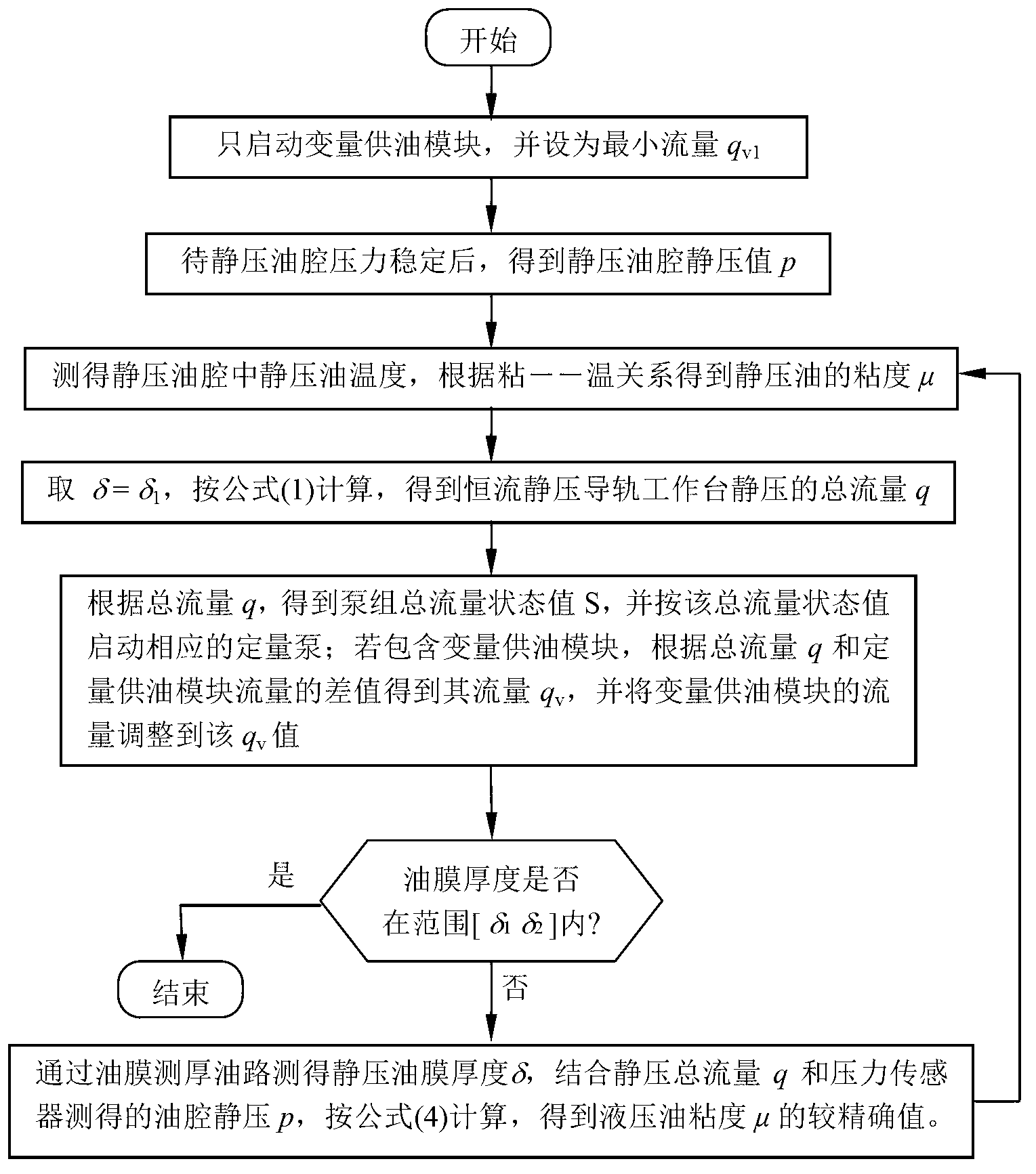

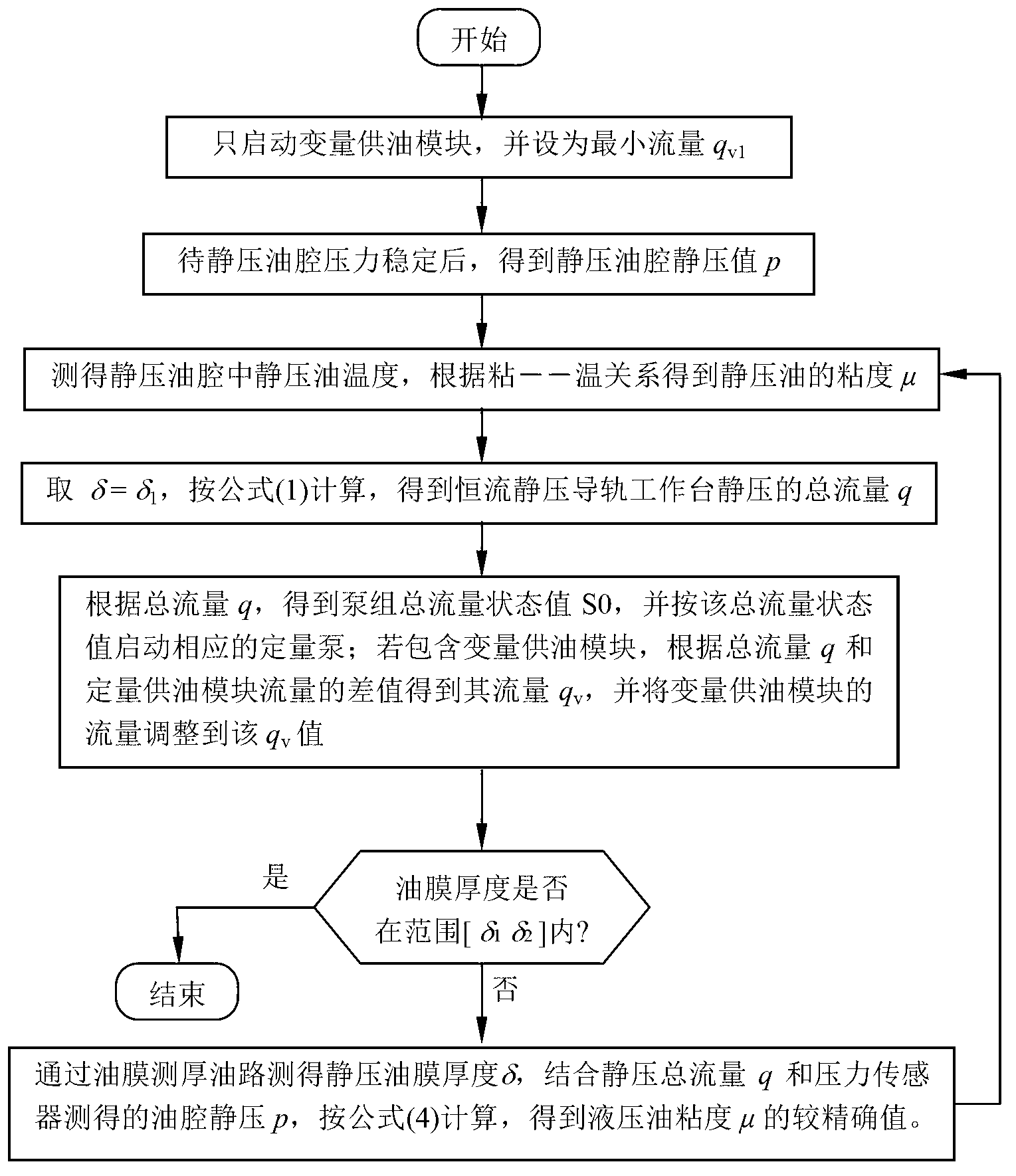

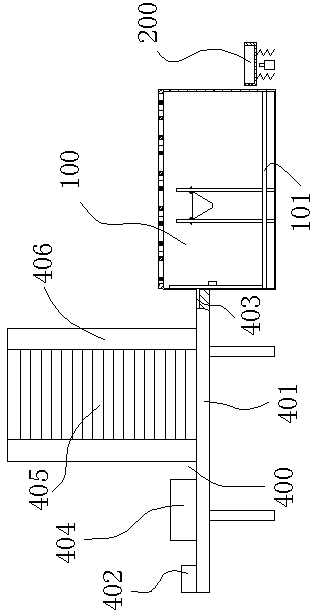

Self-adoption multi-oil chamber constant static pressure system with big flow variation range

ActiveCN102975031AThe degree of pollution is not highReduce maintenance costsLarge fixed membersMaterial removal/additionMetering pumpDistributor

The invention relates to a self-adoption multi-oil chamber constant static pressure system with a big flow variation range. The self-adoption multi-oil chamber constant static pressure system with the big flow variation range is composed of a variable oil supply module and a quantitative oil supply module or a plurality of quantitative oil supply modules. The variable oil supply module and the quantitative oil supply module are composed of a variable frequency motor, a motor, a metering pump, a one-way valve and an oil filter. An overflow valve is arranged between the variable oil supply module, the quantitative oil supply modules and a multi-point gear oil distributor. A pressure gage and a pressure sensor are arranged between the multi-point gear oil distributor and a work table constant static pressure guide rail. A static pressure oil chamber of the constant static pressure guide rail is provided with a temperature sensor. The variable oil supply module provides minimum flow required by a work table static pressure system and a certain flow range. The flow of the quantitative oil supply module is fixed and the value of the flow of the quantitative oil supply module is no less than flow changing value of the variable oil supply module and is used for expanding the flow variation range of the variable oil supply module. Therefore load bearing and automatic adjustment of a lifting range of the work table when a temperature variation range is large are achieved and reliable and stable rotation precision of the work table is guaranteed.

Owner:WUHAN HEAVY MACHINE TOOL GRP

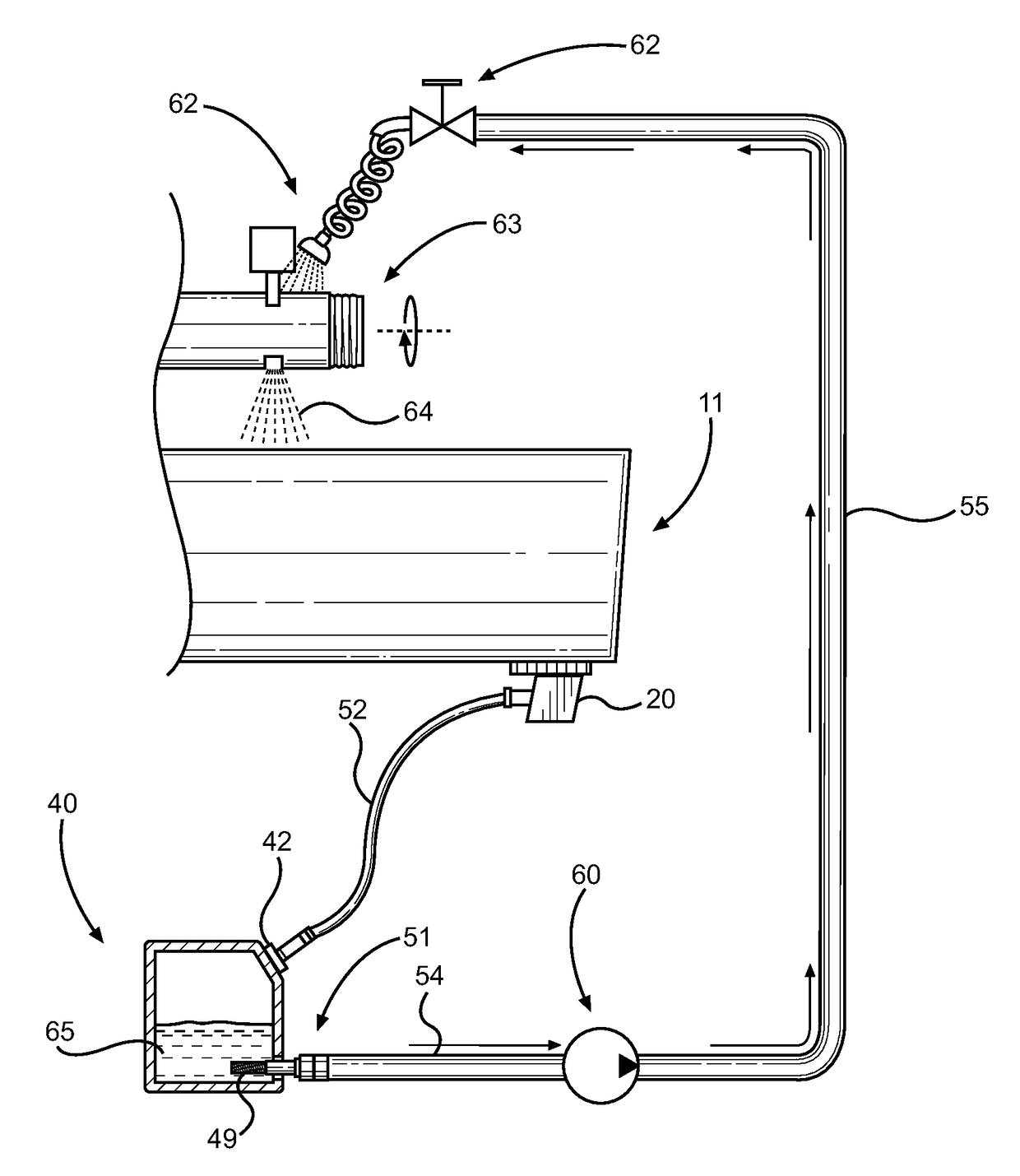

Fluid lubricant and material shavings recapture system for a cutting operation

InactiveUS10112136B2Sufficient clearanceLoose filtering material filtersCartridge filtersCouplingClosed loop

A system for collecting shaving remnants and excess lubrication fluids emanating from a mechanical cutting machine, comprising a catch basin, drain filter, quick connection couplings, fluid reservoir, and pump system for reticulating captured lubricating fluid. The catch basin securely fastens to a cutting machine, while the removable backsplash is deployed at an upstanding angle relative to the catch basin in order to capture superfluous materials liberated from a pipe threading, reaming or cutting tool work piece. The backsplash doubles as a sealable lid capable of retaining the contents of the catch basin eliminating unwanted spillage and allowing for safe transport. The fluid is filtered and collected within the fluid reservoir, whereafter a pump draws the oil through a second filter element to reuse the lubricating fluid in the tool operation to create a closed loop system. Quick connect fittings compartmentalize the system to prevent leaks during maintenance or service.

Owner:ENVIRO FAB LLC

Drilling tool with dust collector

InactiveUS8529169B2Efficient collectionPrevent leakageThread cutting feeding devicesBoring/drilling componentsDust collectorDrill bit

According to the invention, a drilling tool includes: a motor; a transmission drive unit for transmitting a rotation force of the motor to rotate a drill bit; and a dust collector for collecting dust produced from a workpiece drilled by the drill bit, wherein the dust collector is provided with a pierced portion pierced by the drill bit, a dust collection port for sucking the produced dust and its surrounding air, and a blowoff port for blowing air against a vicinity of the piercing drill bit.

Owner:KOKI HLDG CO LTD

Soldering tin melting furnace

ActiveCN103121140AAvoid crossingAvoid meltingMaterial removal/additionSolder feeding devicesWaste materialElectric wire

The invention discloses a soldering tin melting furnace which comprises a heat-resisting cavity, wherein a first heating wire is arranged inside the heat-resisting cavity, a waste-material-recycling disc is arranged beside the heat-resisting cavity, a heat-resisting support is further arranged in the heat-resisting cavity and is provided with a big-end-up cone-shaped shell, and a second through hole is arranged at the bottom of the cone-shaped shell. The soldering tin melting furnace can prevent plastic coated outside wires from penetrating through the second through hole and effectively prevent the plastic from being melted in soldering tin liquid, improves error-tolerant rates in work and ensures that workers feel relaxed to work, and due to the fact that the cone-shaped shell is arranged, safety can be effectively improved, and hands of the workers can be prevented from being scalded.

Owner:NINGBO HENGSHENG ELECTRIC

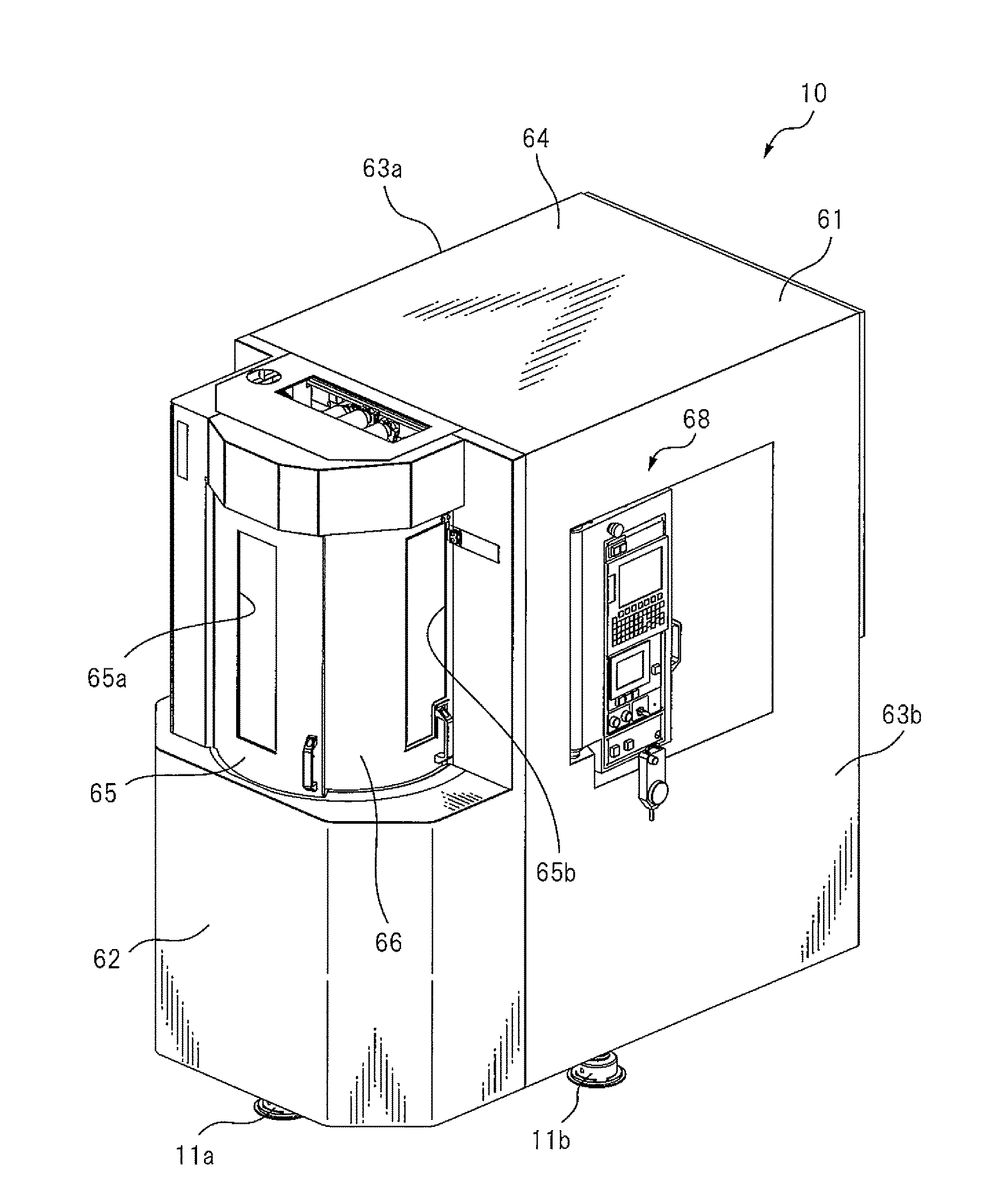

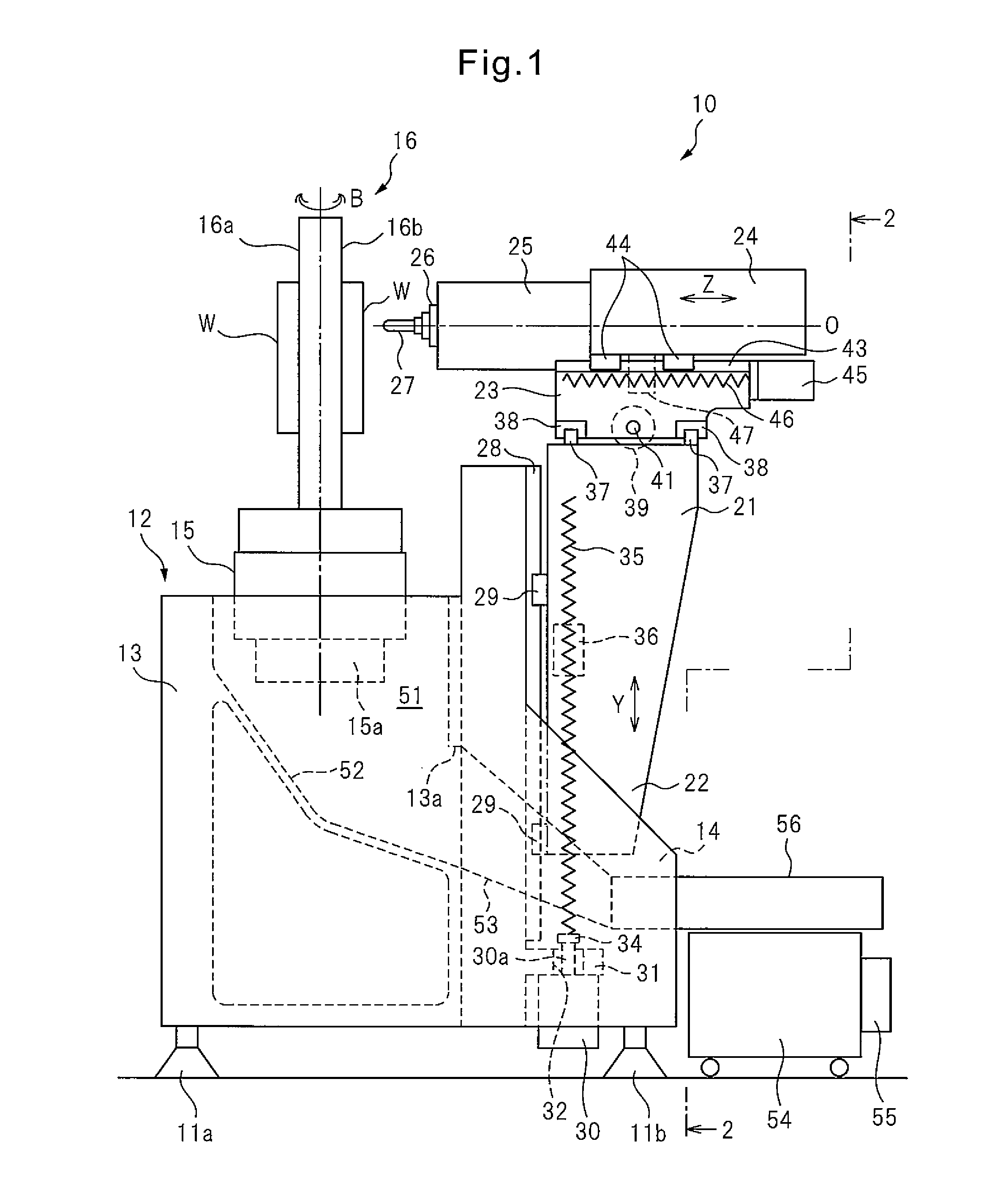

Machine tool

ActiveUS9539688B2Ensure safety efficiencyProduction and the safety are ensuredAutomatic/semiautomatic turning machinesAuxillary equipmentMachine toolMachining fluid

A work-machine splash guard for enclosing a space for machining a workpiece, and preventing the spraying of chips and machining fluid, is equipped with: a front-surface door for opening and closing in the horizontal direction via an arc-shaped movement, and positioned on the front-surface side of the work machine; a side-surface door for opening and closing by performing an arc-shaped movement that is concentric with the front-surface door, and overlapping with the front-surface door; and door-locking switches for selectively allowing the opening / closing of the front-surface door and the side-surface door according to an opening / closing pattern.

Owner:MAKINO MILLING MASCH CO LTD

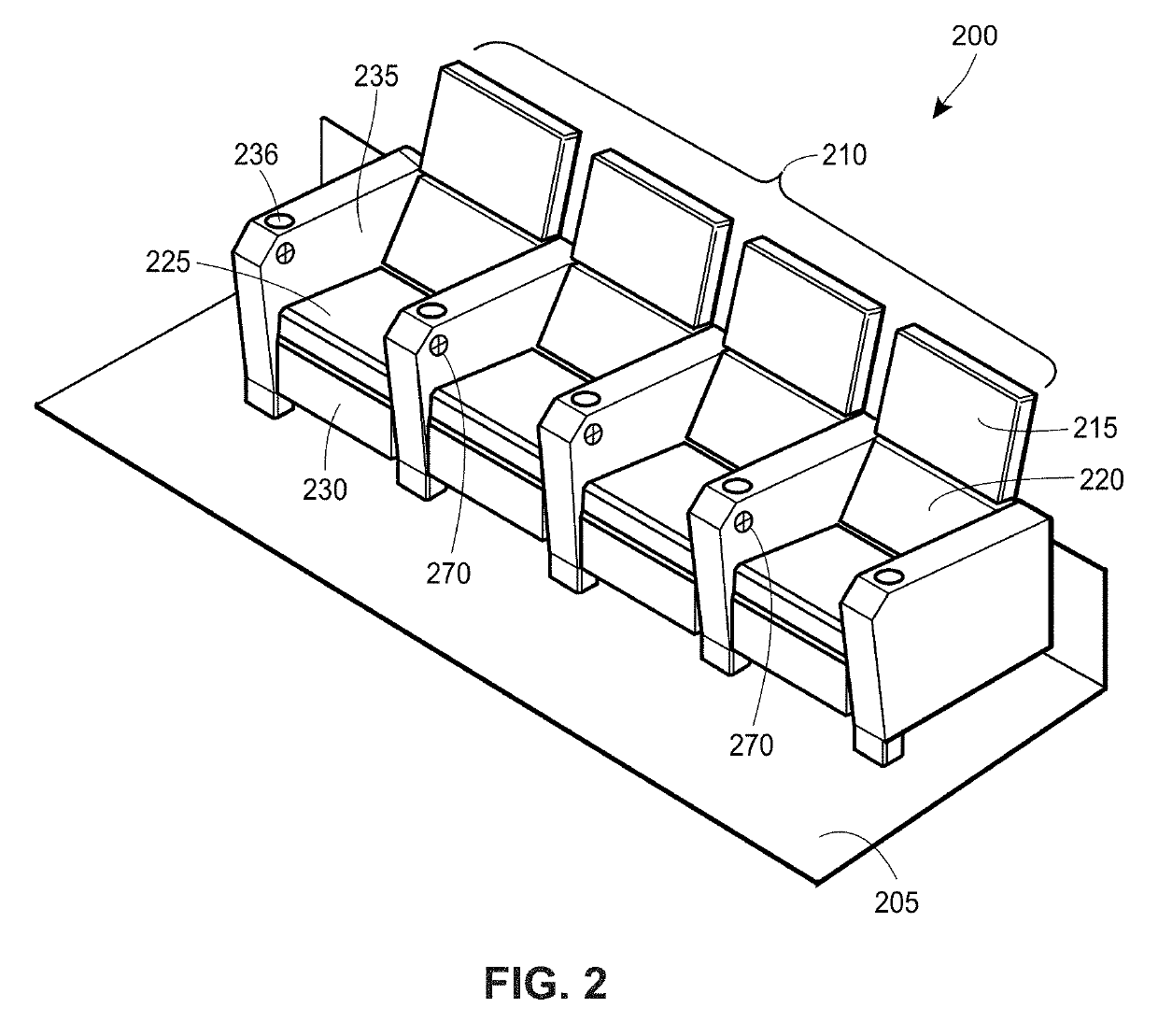

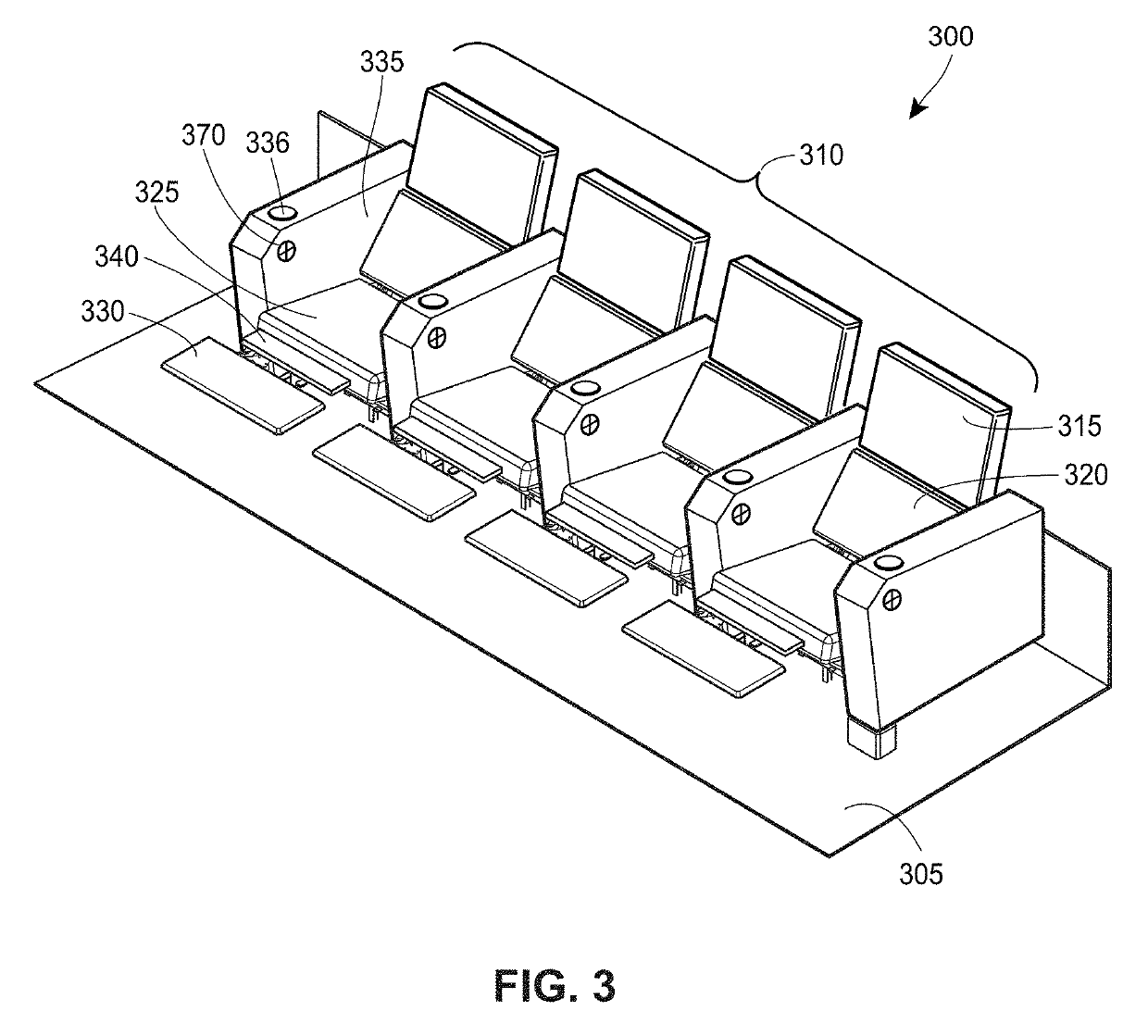

Powered chairs for public venues, assemblies for use in powered chairs, and components for use in assemblies for use in powered chairs

Owner:TELESCOPIC SEATING SYST LLC

Rotatable filter system and methodology

ActiveUS10543622B2Increase usable surface areaMinimise currentMetal sawing devicesMetal sawing accessoriesFilter systemEngineering

Owner:JPL GLOBAL

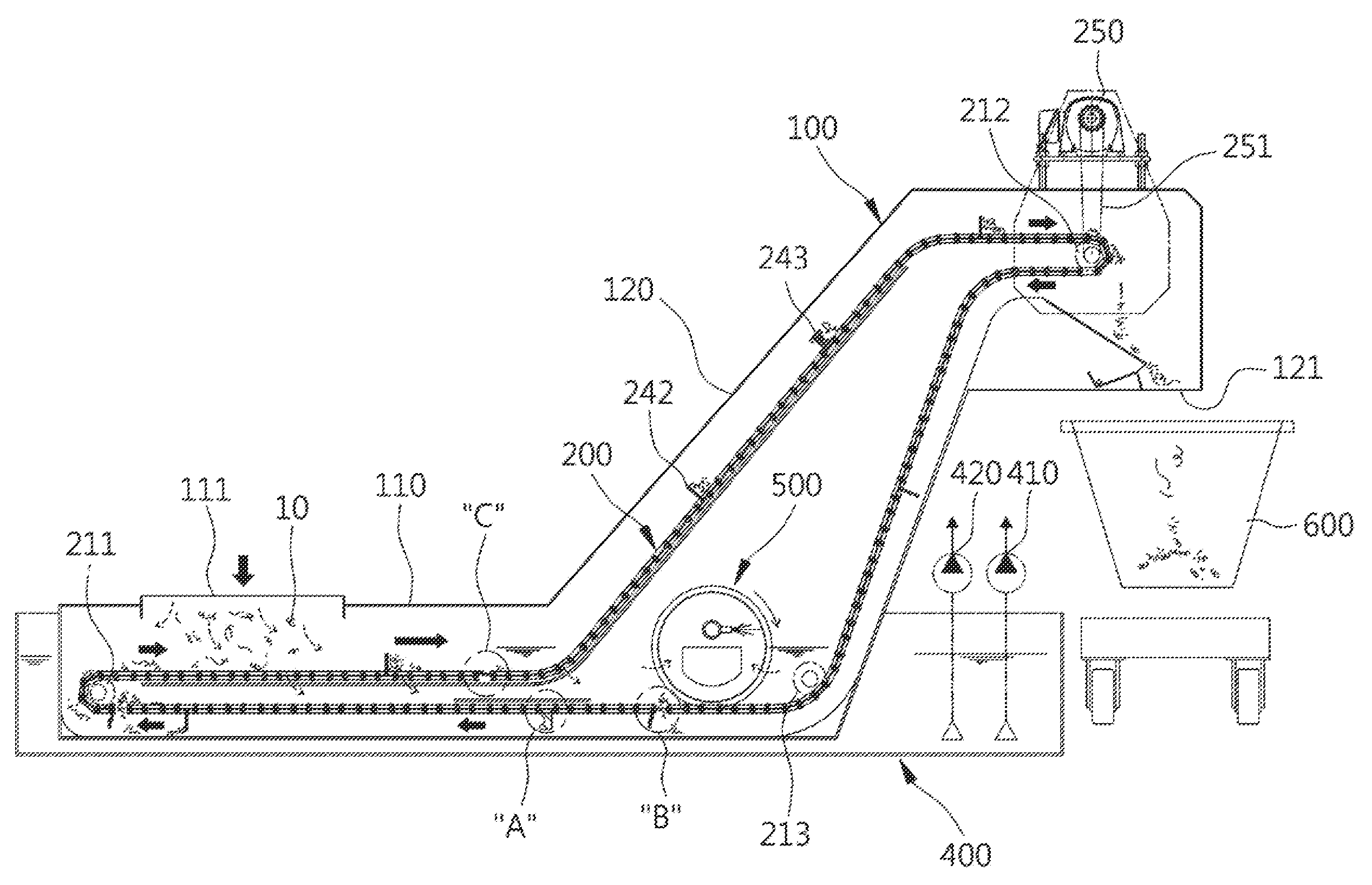

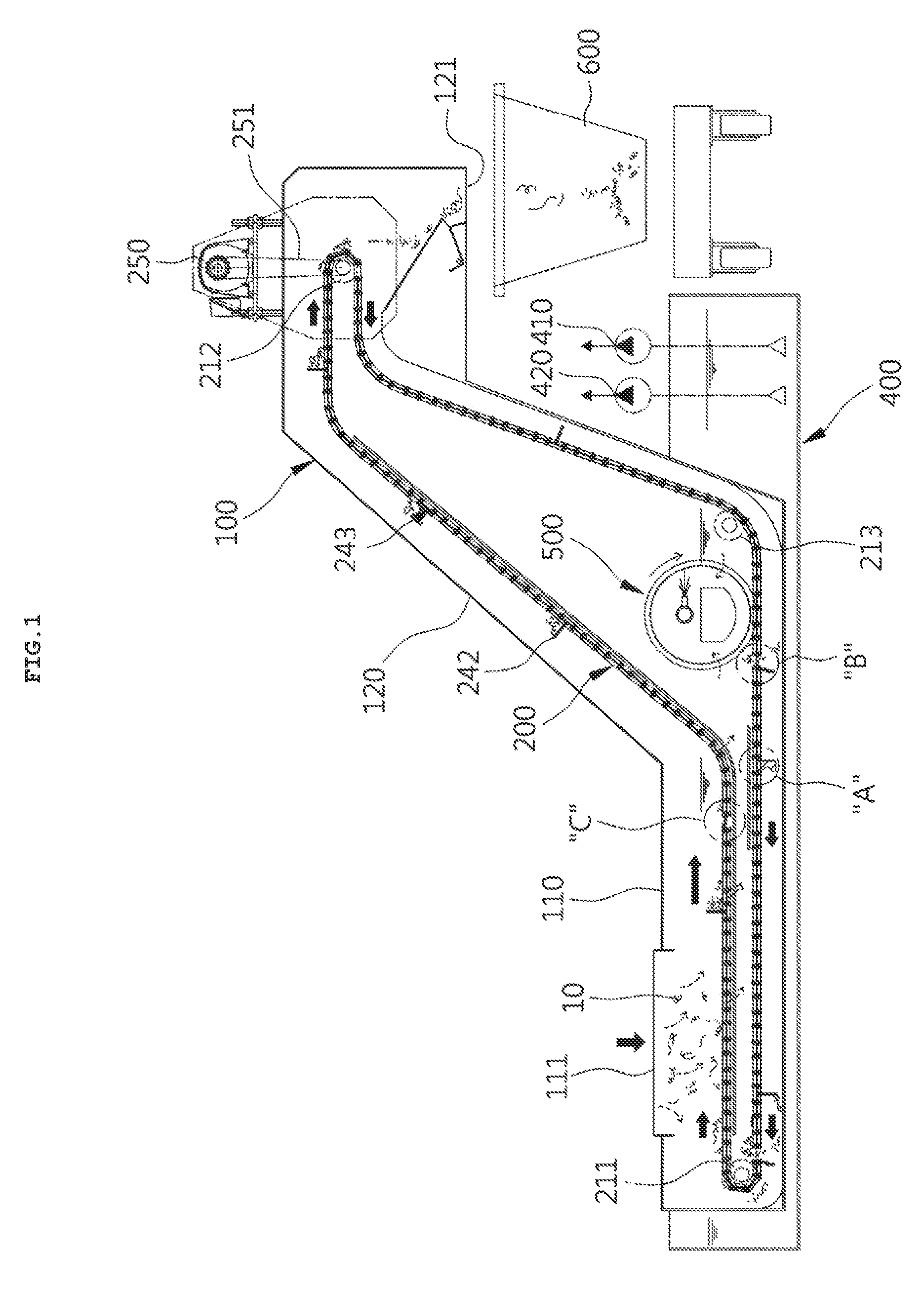

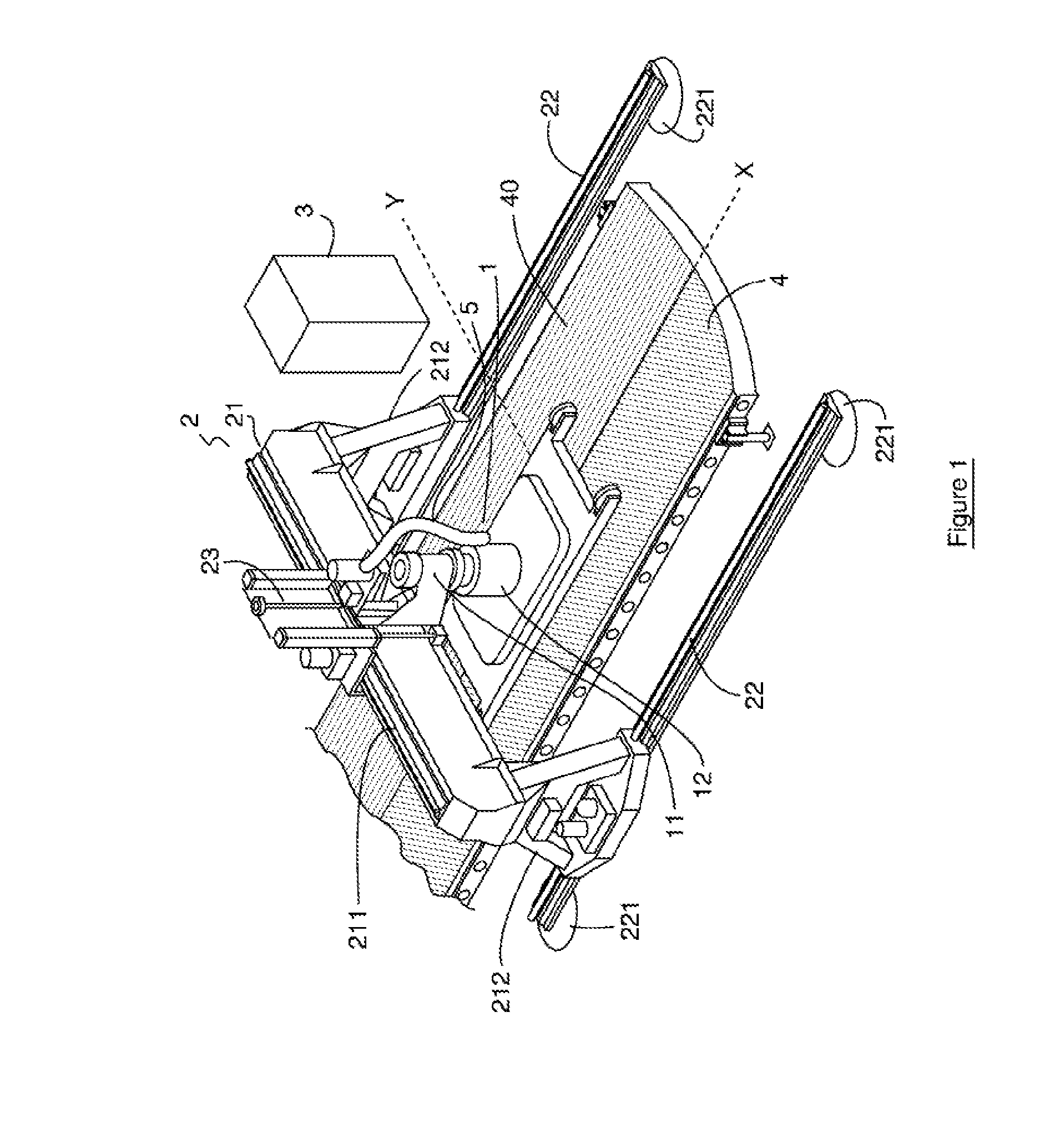

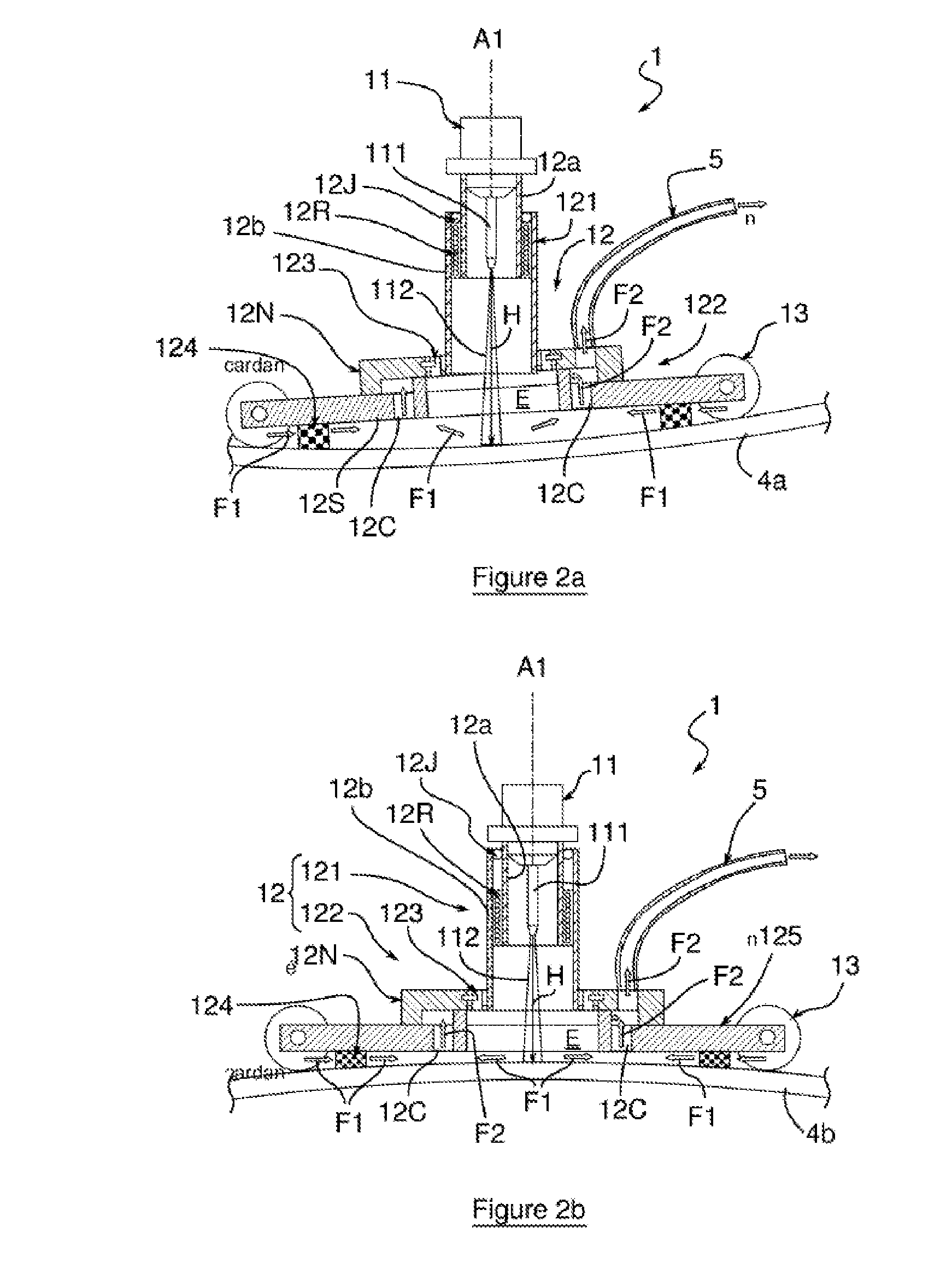

Method for recovering machining waste by input of energy and machining machine comprising a waste recovery system

ActiveUS20160229030A1Great suctionReserved functionAbrasive machine appurtenancesAbrasive blasting machinesPorosityEnergy recovery

The invention relates to implement the sealing, porosity and sweeping functions, combined. For this purpose, the present invention proposes to confine the waste and to suction the waste at the ejection head by means of a sufficiently flexible connection, such as to remain in contact with the machining area. According to an embodiment, a portable machining machine (1) operated by a pressurized jet (112) includes a waste recovery system (5), an injection head (11) which is provided with a nozzle (111) having an axis (A1) that is substantially perpendicular to the surface to be machined (4a) and which is driven by a digitally controlled two-axle guide system, the ejection head (11) being extended by an enclosure (12) to the surface area to be machined (4a). In addition, the enclosure (12) comprises a tubular portion (121) consisting of two walls (12a, 12b) which slide coaxially along the axis (A1) and a double-pivot articulation device (123). The enclosure (12) has a porous annular wall (124) in a plane substantially perpendicular to the axis (A1) of the nozzle (111), said annular wall (124) having sufficient resilience to keep the enclosure (12) in permanent sealing contact with the surface to be machined (4; 4a, 4b).

Owner:JEDO TECH

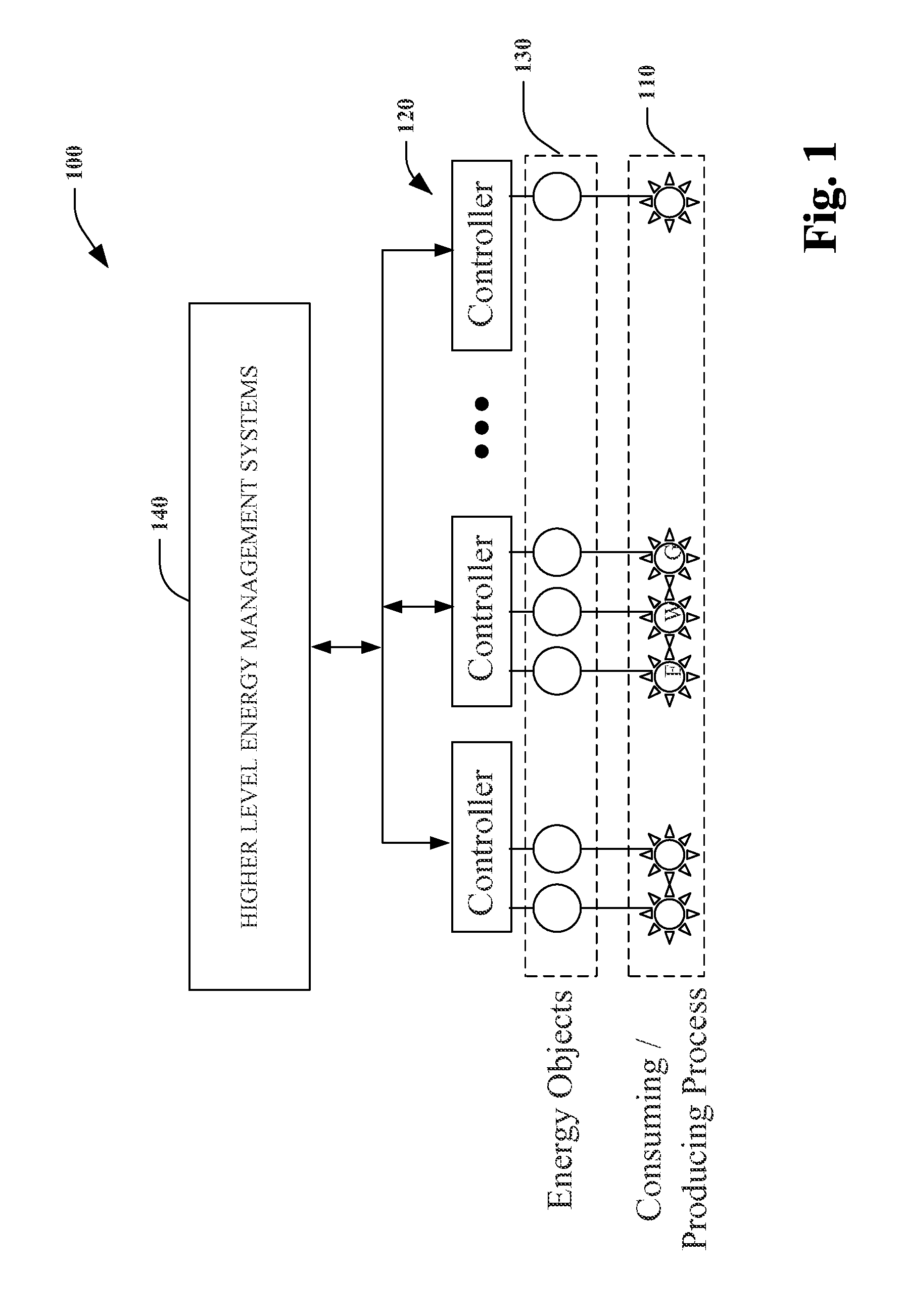

Extensible energy management architecture

An energy management system may include a plurality of industrial automation devices and a first energy agent embedded within an industrial automation device of the plurality of industrial automation devices. The first energy agent may monitor one or more energy properties that correspond to the industrial automation device. Also, the first energy agent may adjust one or more operations of the industrial automation device based at least in part on the energy properties and an energy objective.

Owner:ROCKWELL AUTOMATION TECH

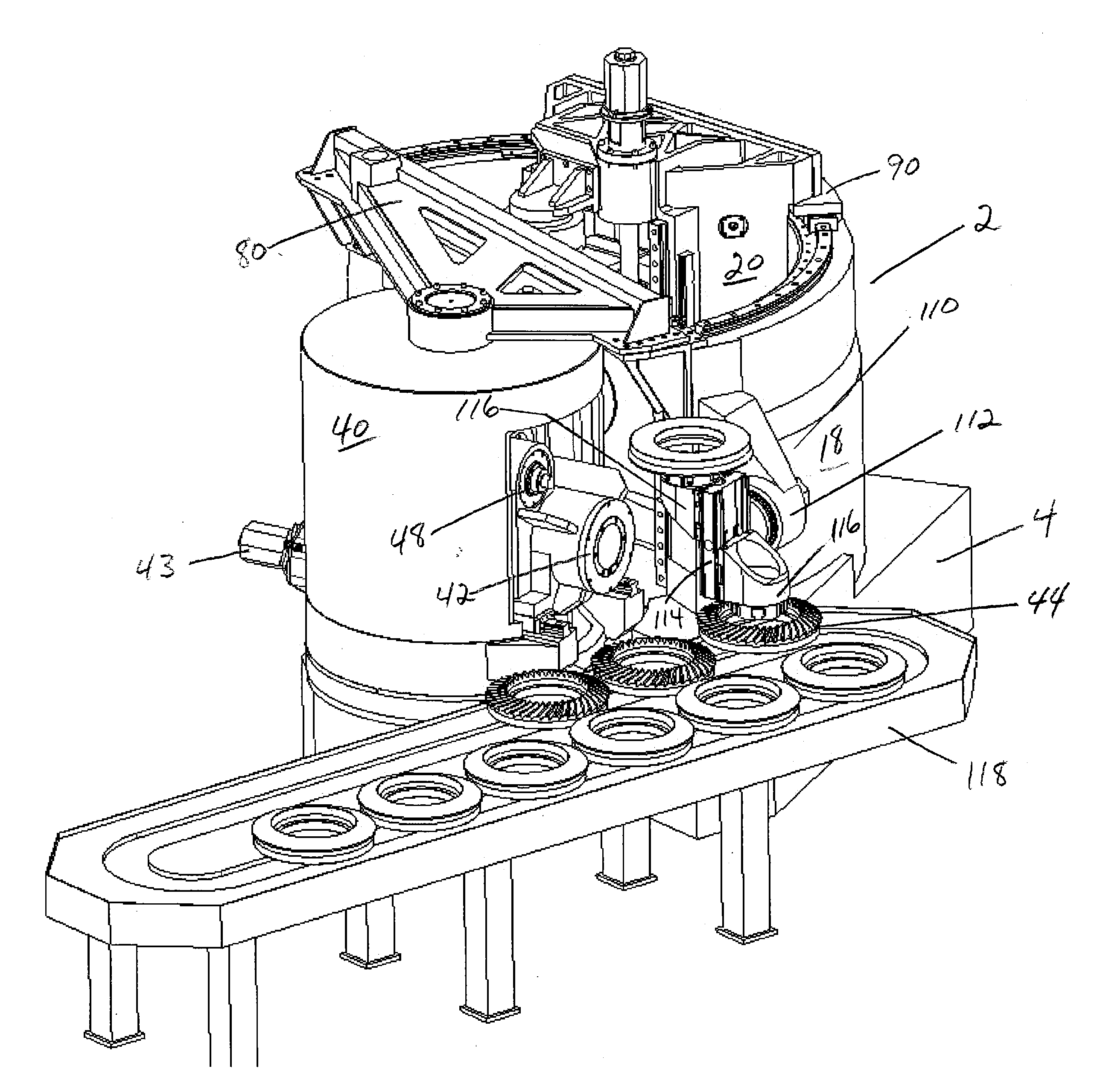

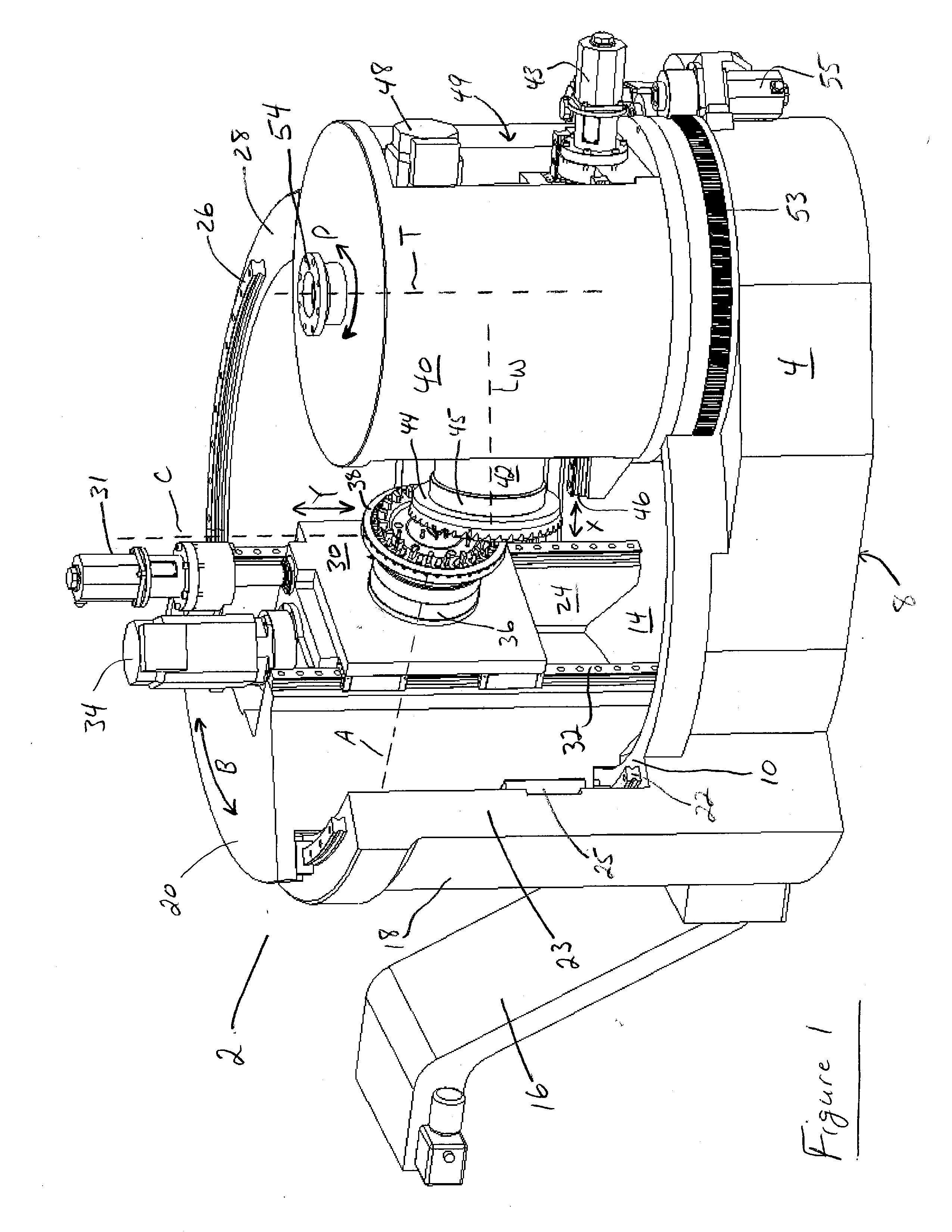

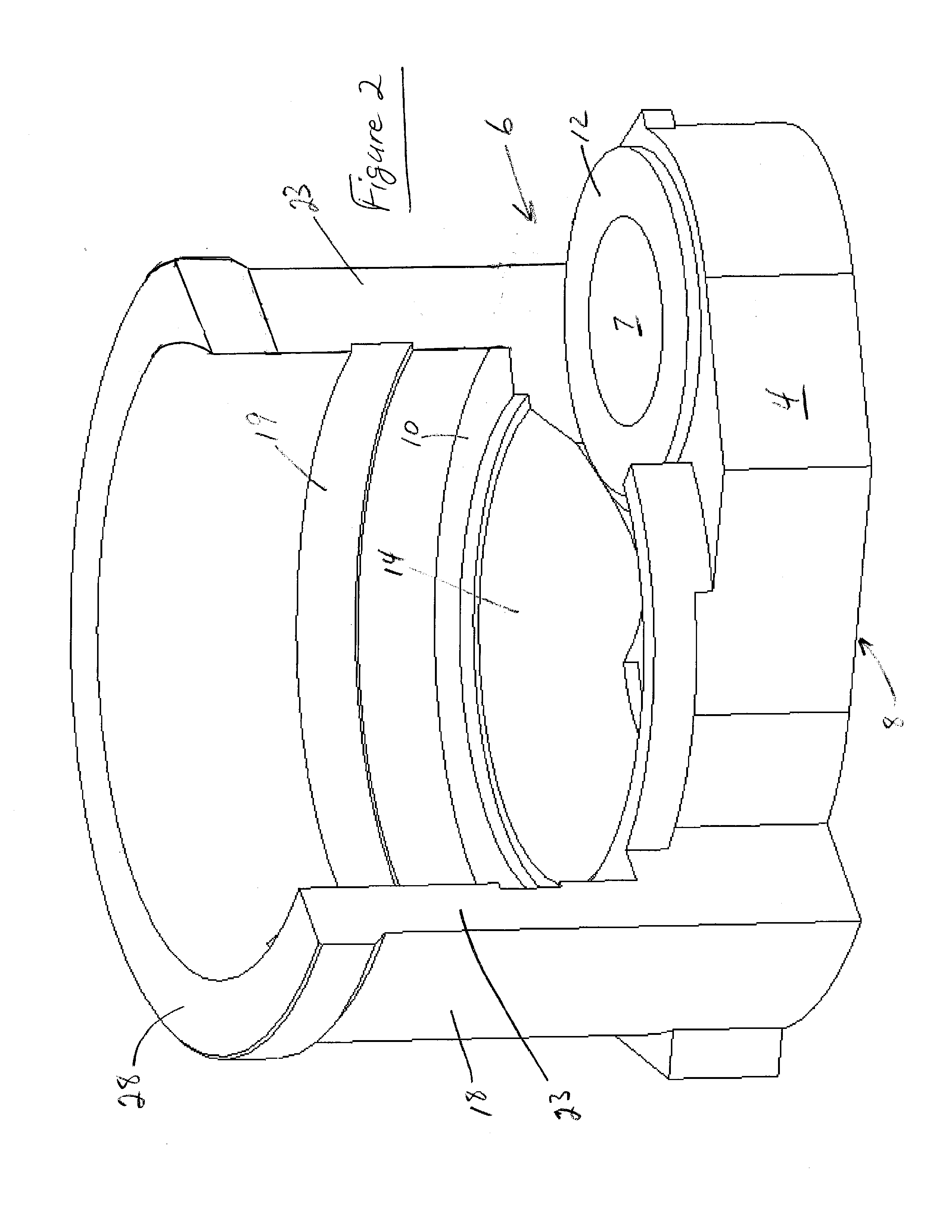

Gear processing machine

A machine tool comprising a machine base having a first side comprising a first planar surface and a machine column movable along an arcuate path on the first planar surface. The machine further comprises a first spindle movable in a first linear direction and being rotatable about a first axis of rotation. The machine further comprises a machine turret located on a second planar surface of the machine base first side. The machine turret is angularly movable about a pivot axis. The machine turret includes a second spindle positioned within the turret with the second spindle being rotatable about a second axis of rotation and being movable in a second linear direction.

Owner:GLEASON WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com