Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about "Lubrication for crankcase compression engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

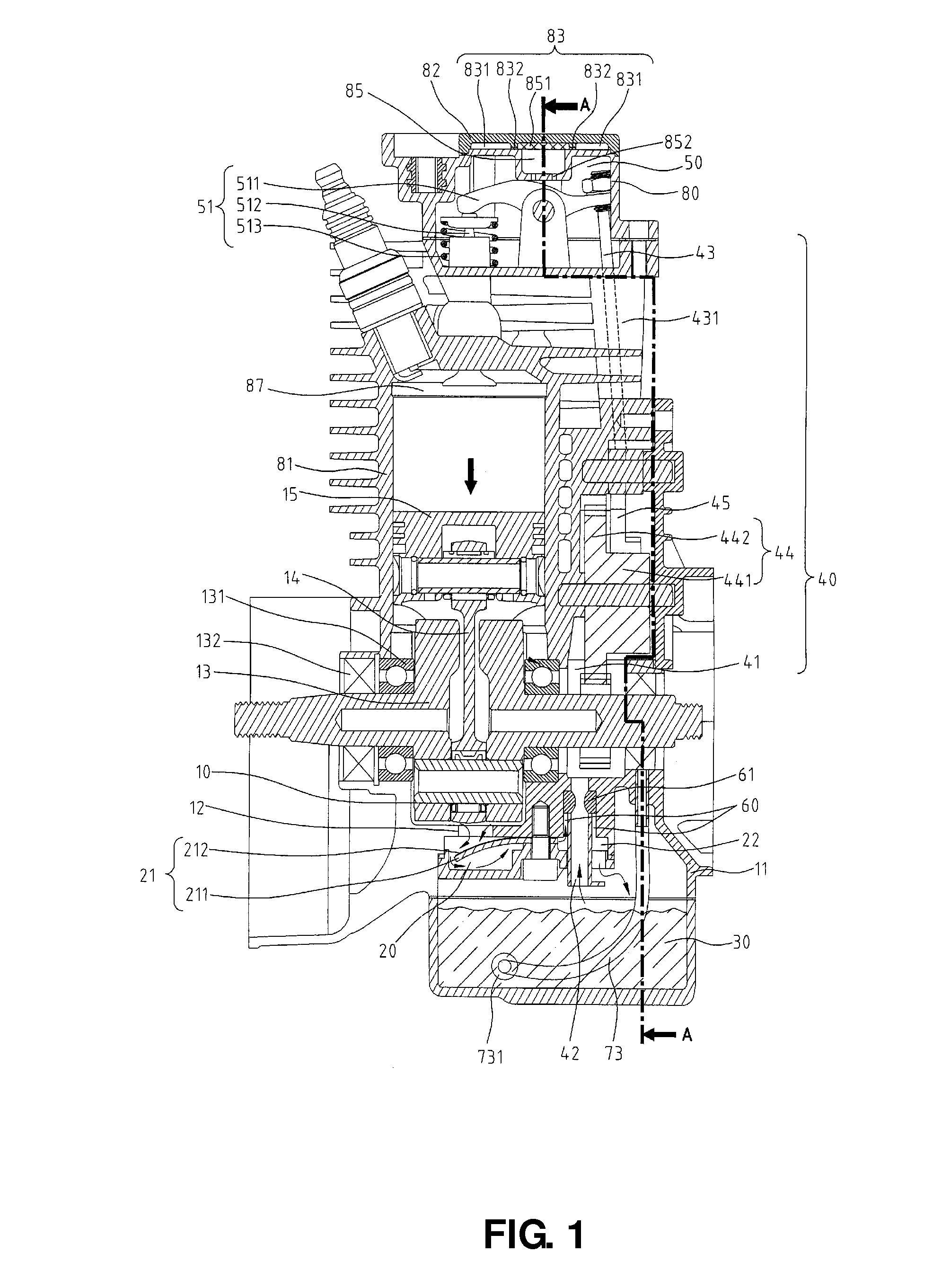

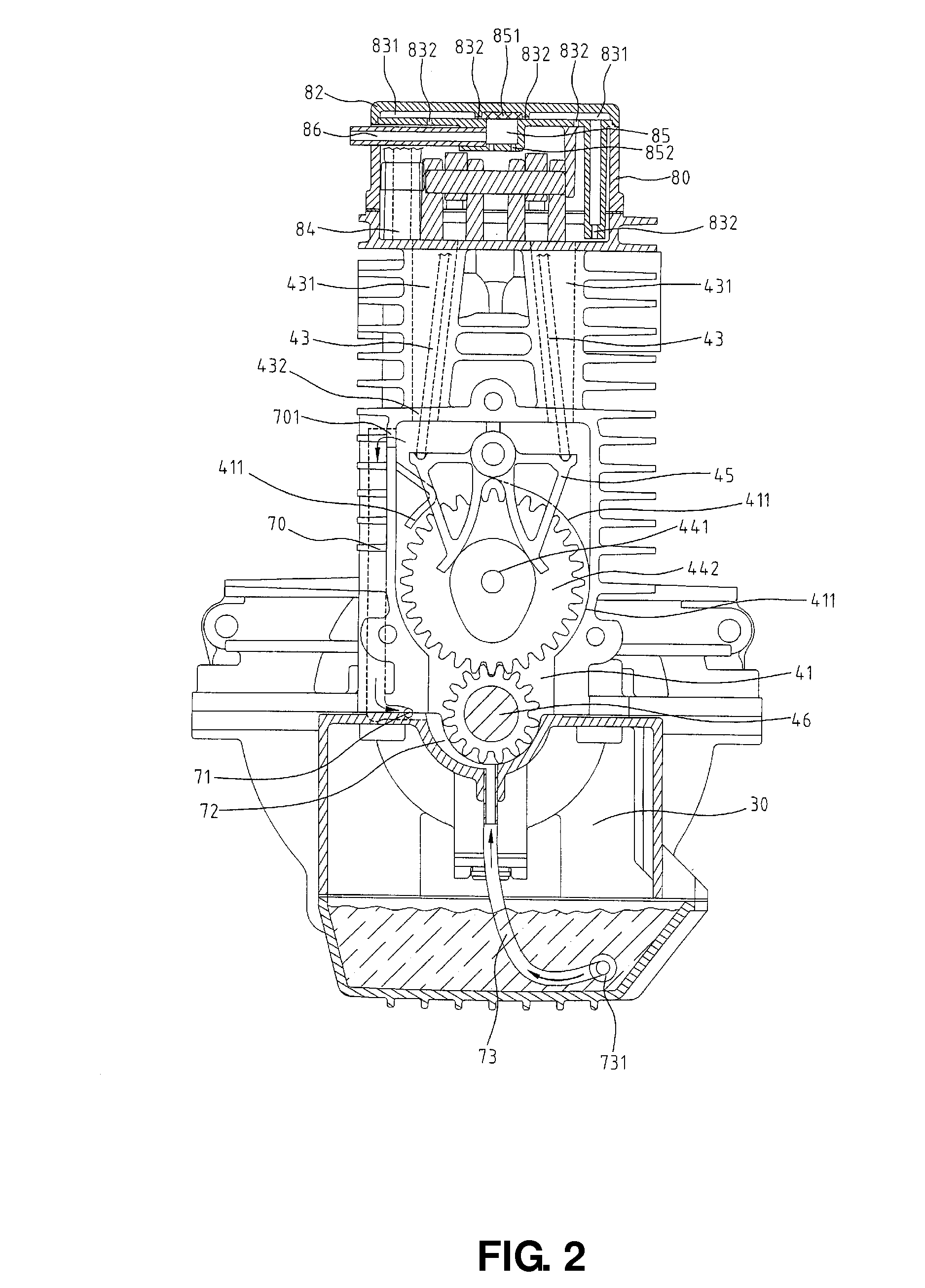

Lubrication system for an engine

ActiveUS20090013959A1Fully lubricatedCombustion enginesPressure lubricationFour-stroke engineEngineering

A lubrication system for a small lightweight four-stroke engine is disclosed. The lubrication system, provided with a weight at one end of a flexible oil tube inserted into an oil reservoir, is capable of providing a sufficient lubrication to components of the engine which may operate in a horizontal posture, a vertical posture, or any posture therebetween.

Owner:LIN SZU LIANG

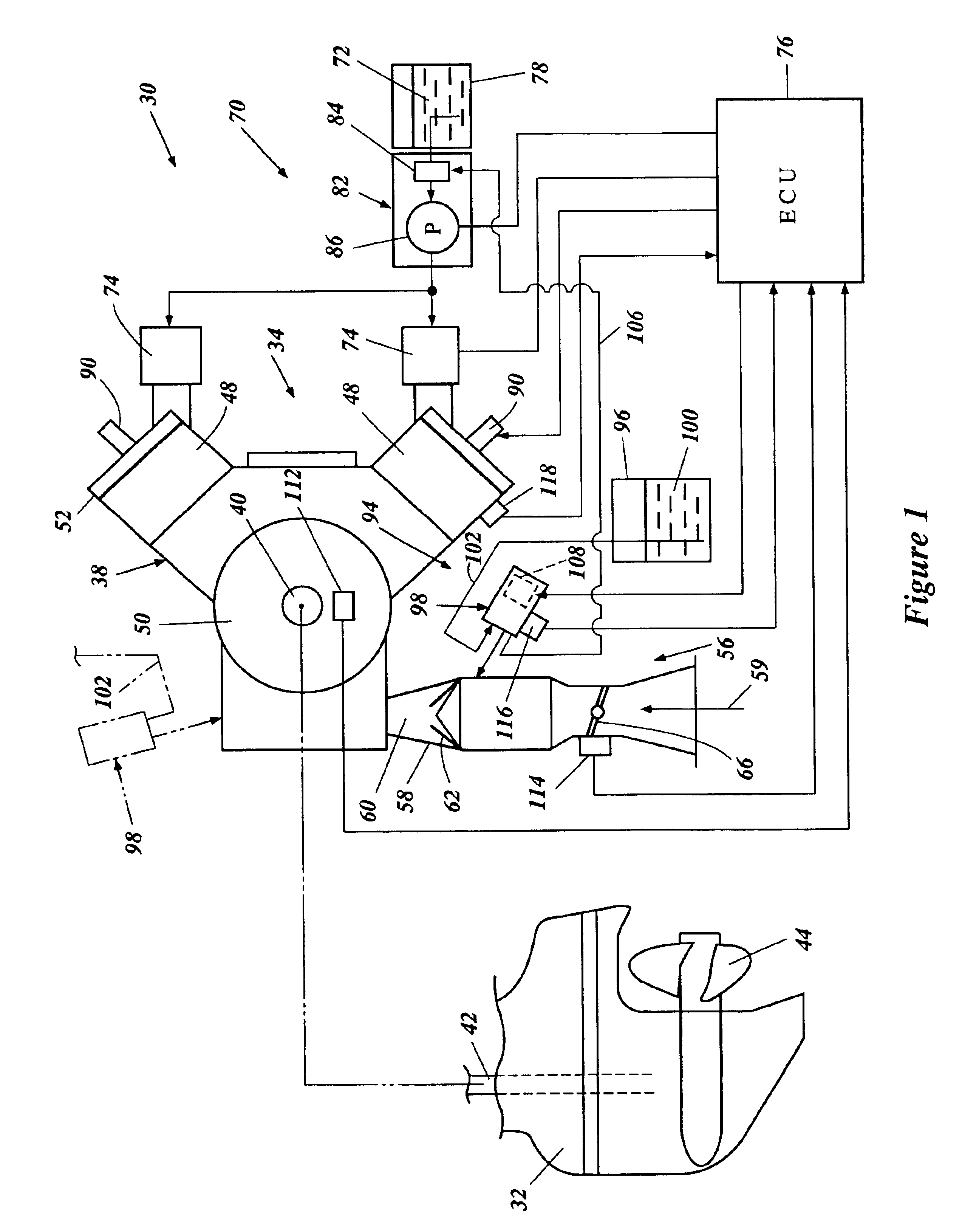

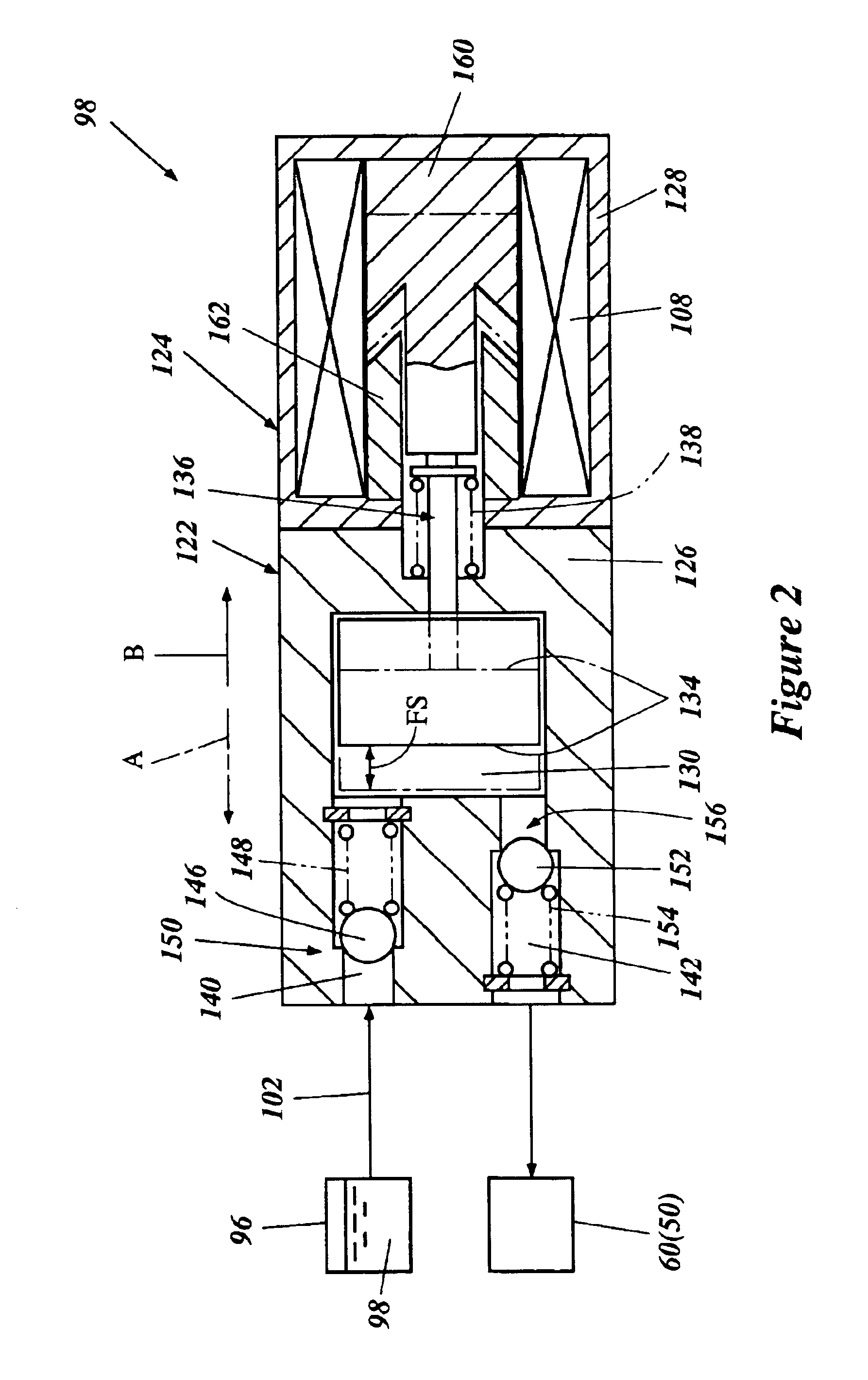

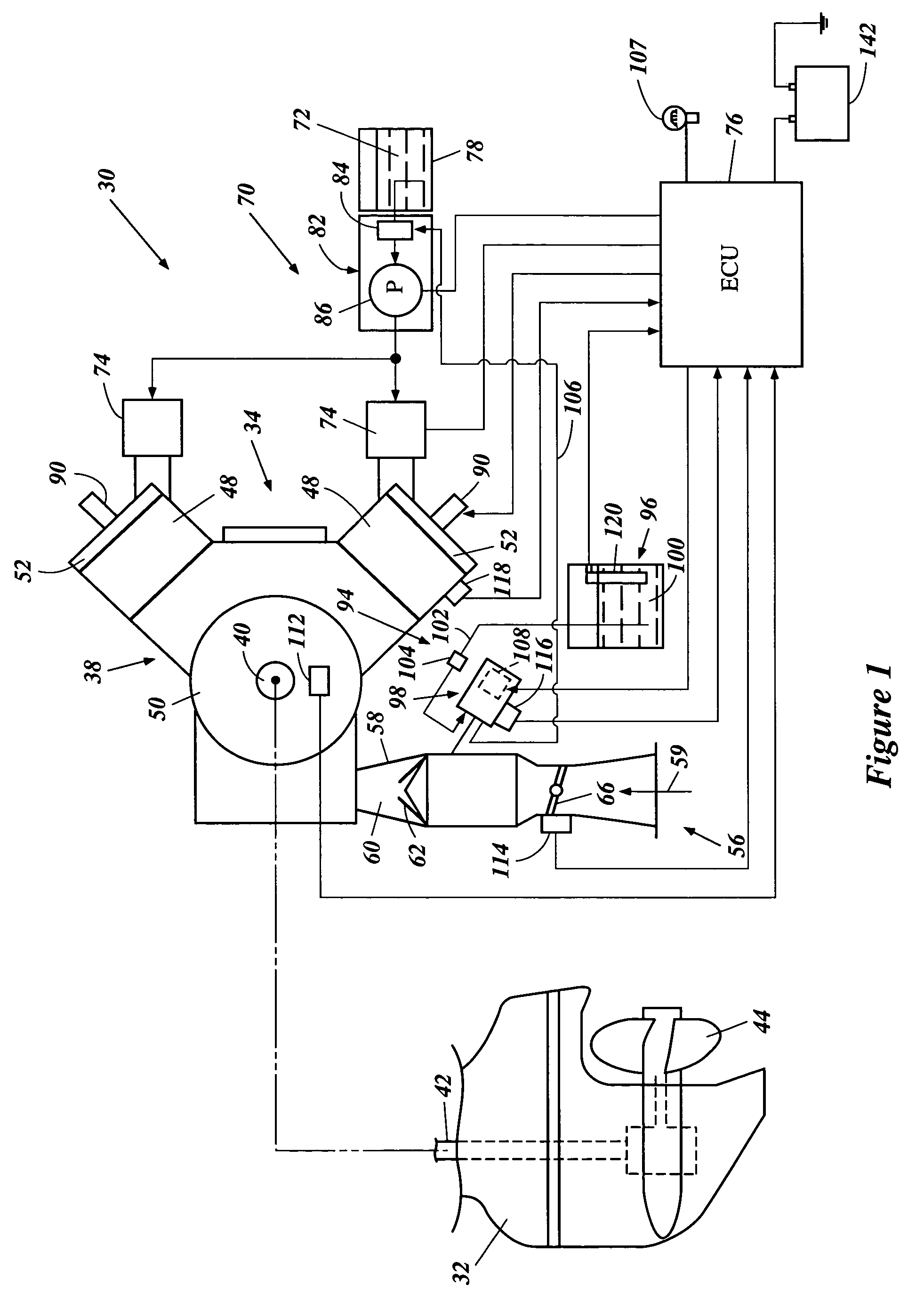

Oil injection lubrication system and methods for two-cycle engines

InactiveUS6422183B1Reduced deposit formationAvoid corrosionCombustion enginesEngine operating parametersSolenoid valveControl signal

The present invention provides an improved oil injection lubrication system for two-cycle engines. The system includes a variable output oil pump, the output of which can be varied in relation to the throttle level. The system also includes a solenoid valve unit containing a plurality of solenoid valves that regulate the flow of oil from the oil pump to each cylinder. The electronic control unit sends control signals to the solenoid valve unit to regulate the flow of oil based upon factors relating to the operation of the engine in accordance with a control scheme. The factors may include those that apply to all of the engine's cylinders (i.e., do not vary between the cylinders), such as intake air temperature, atmospheric pressure, battery voltage, engine break-in period, and load frequency among others.

Owner:SANSHIN KOGYO CO LTD

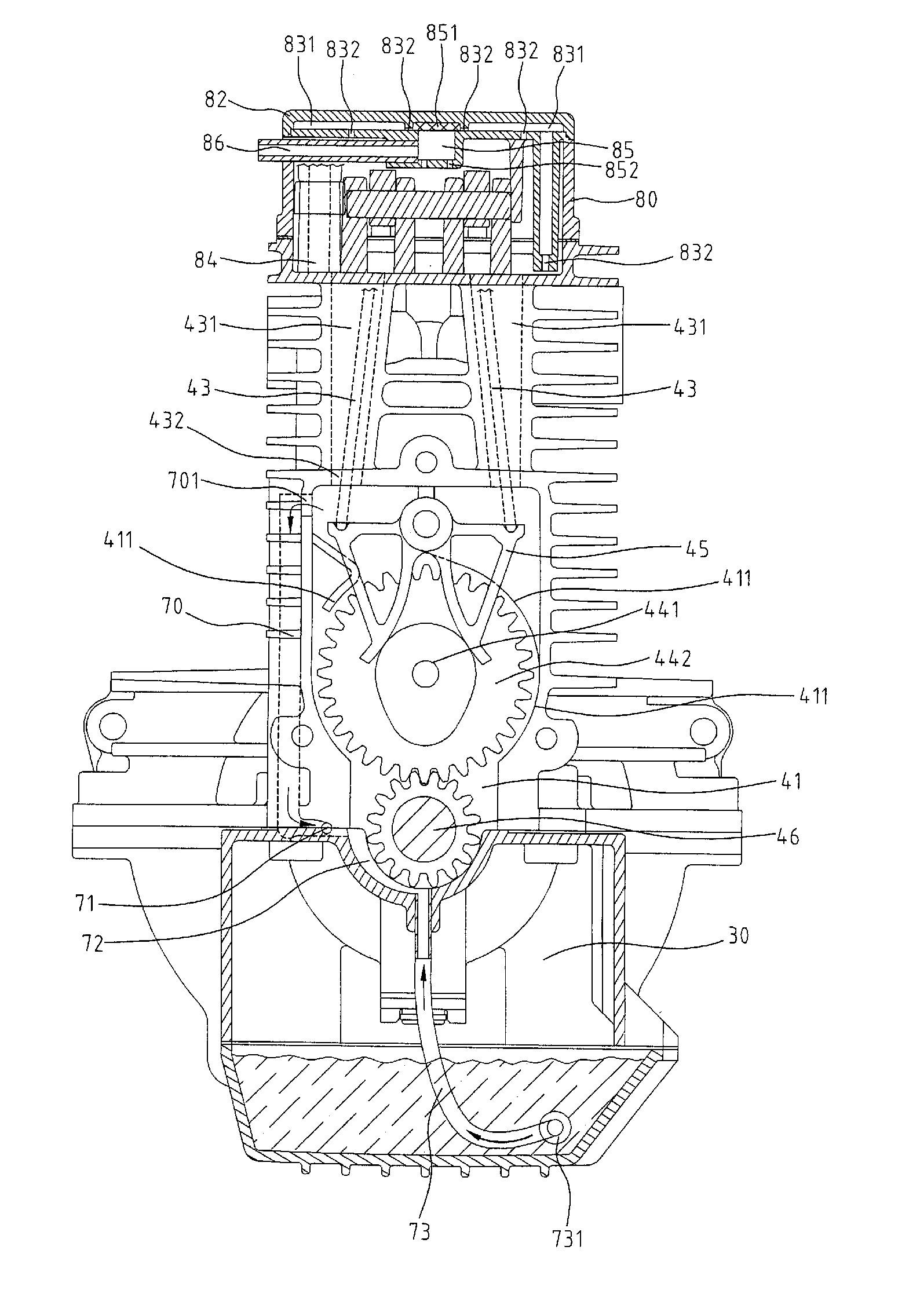

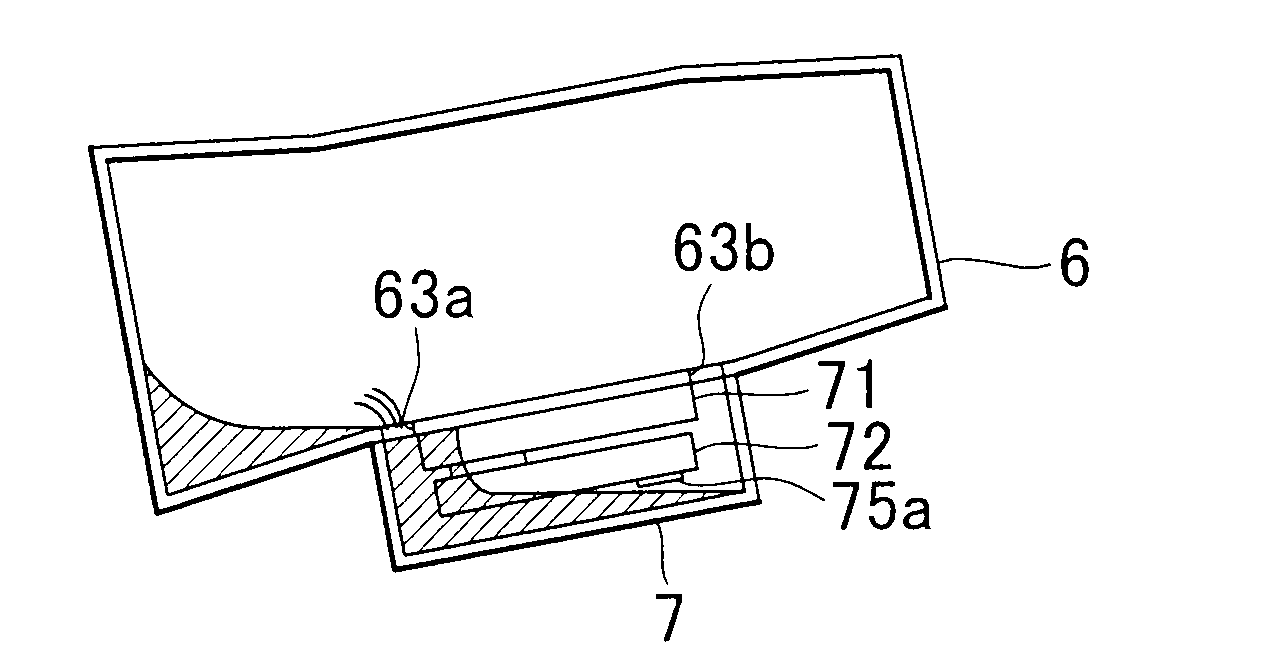

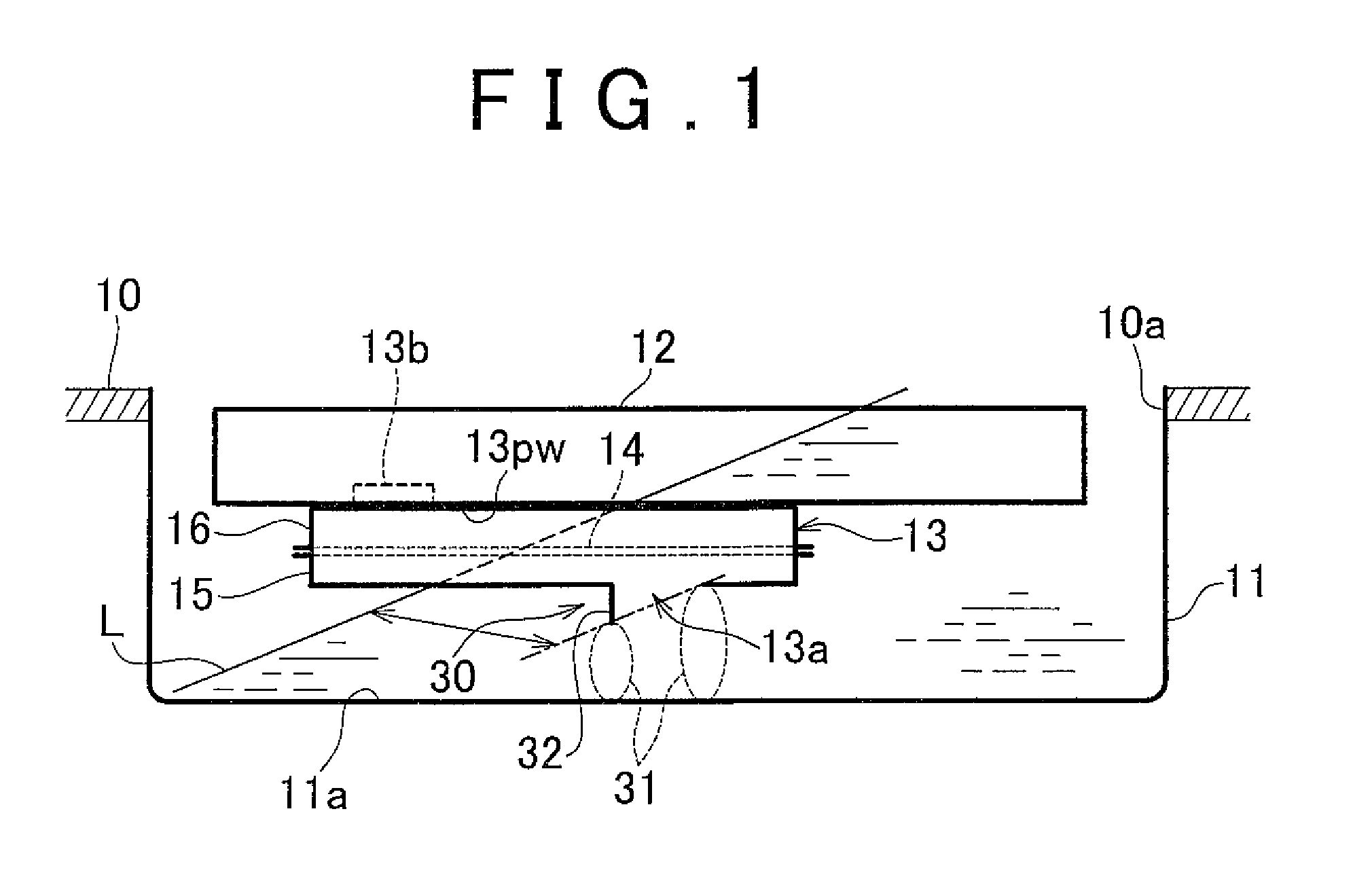

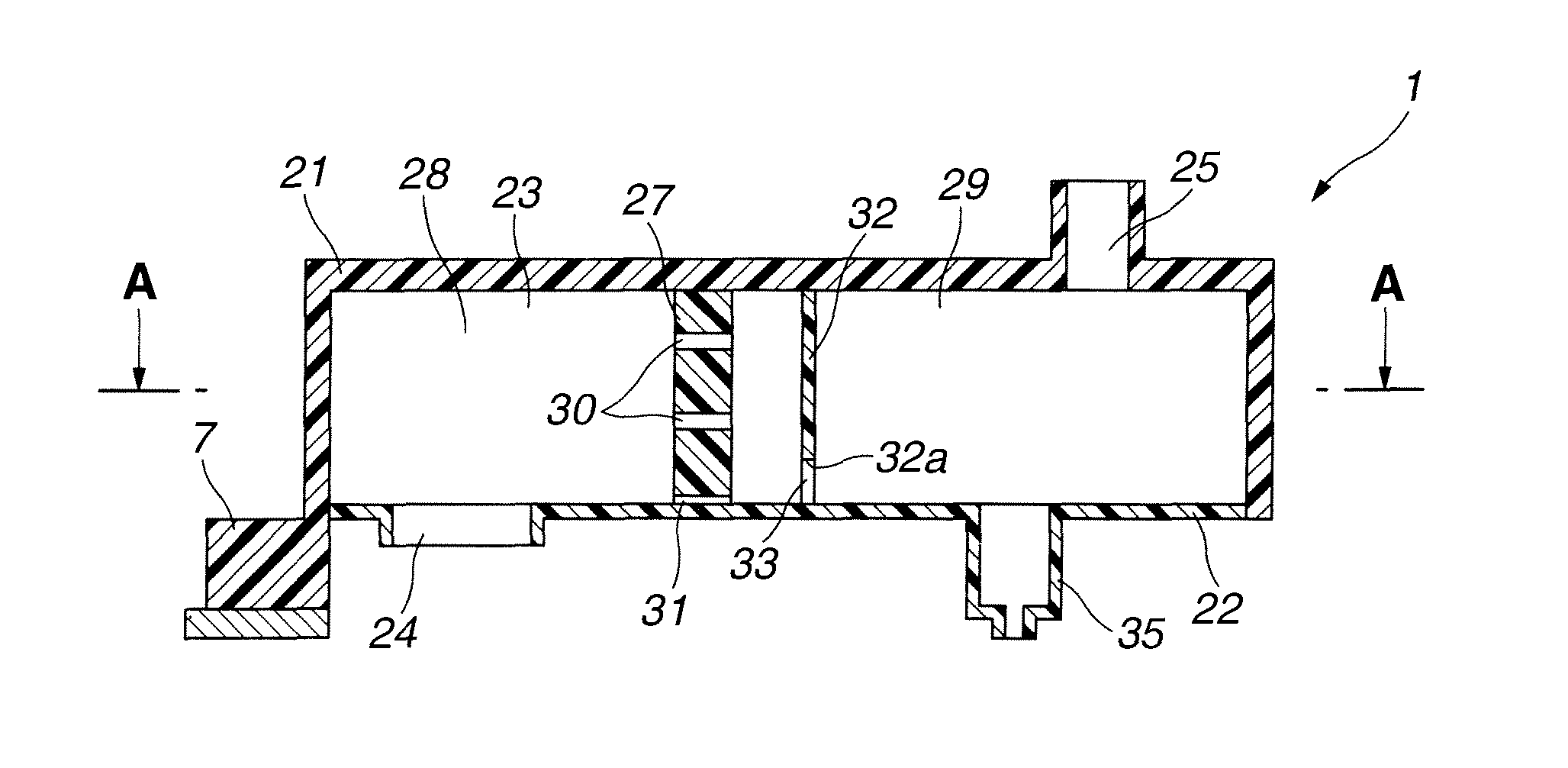

Oil lubricating structure

An oil lubricating structure includes a main body case having a housing chamber in which an element requiring a supply of oil is housed, an oil reservoir which is provided below the main body case and has an oil chamber in which oil collects, an oil supply portion which has an inlet port through which oil is drawn in from the oil chamber and which supplies oil collected in the oil chamber to the element requiring a supply of oil through the inlet port, and a duct member provided in the oil chamber. An oil return hole is provided which is formed in a bottom surface of the main body case toward the front of the oil reservoir and through which oil returns to the oil reservoir from the main body case. One end portion of the duct member is connected to the oil return hole and the other end portion of the duct member is positioned farther to the rear than the inlet port.

Owner:TOYOTA JIDOSHA KK +1

Active gas turbine lubrication system flow control

A lubrication system is provided for an aircraft turbine machine, the lubrication system being controlled by a closed-loop logic arrangement, wherein the oil pressure of a lubricant circulated therein is monitored and altered according to attitude data, acceleration data, operating mode data, or some combination thereof contained in a signal received from an airframe flight controller and according to a oil pressure signal and an oil temperature signal. The logic responsively provides a supply pump speed control signal, according to a predetermined target oil pressure value selected to correspond to the data contained in the signals. The target value may be continuously compared to the present oil pressure value and the present oil pressure adjusted by sending a motor control signal to the supply pump and a valve flow control signal to a flow control valve that conditionally allows oil from the outlet side of the supply pump to be fed back to its inlet side.

Owner:HONEYWELL INT INC

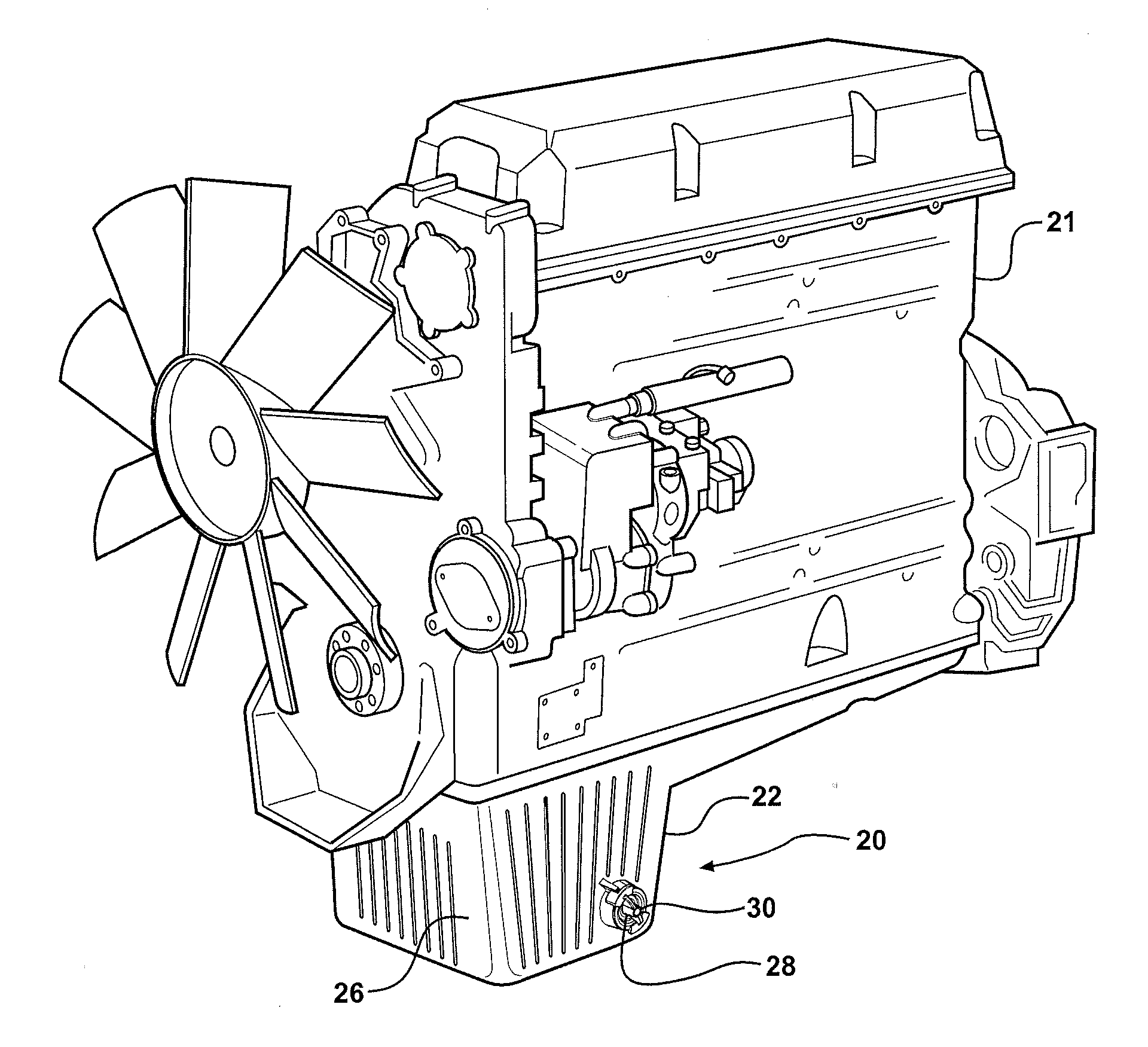

Oil supply system for an engine

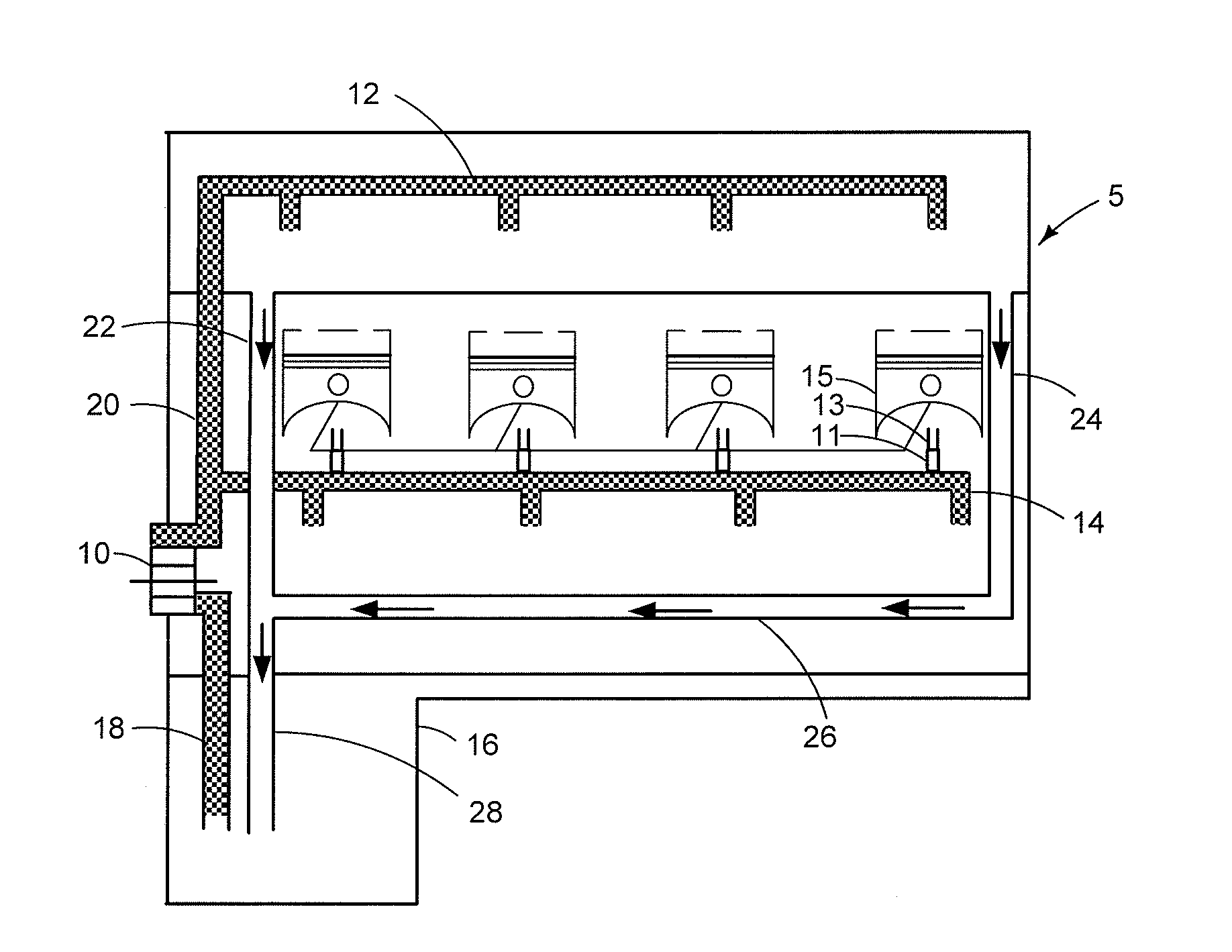

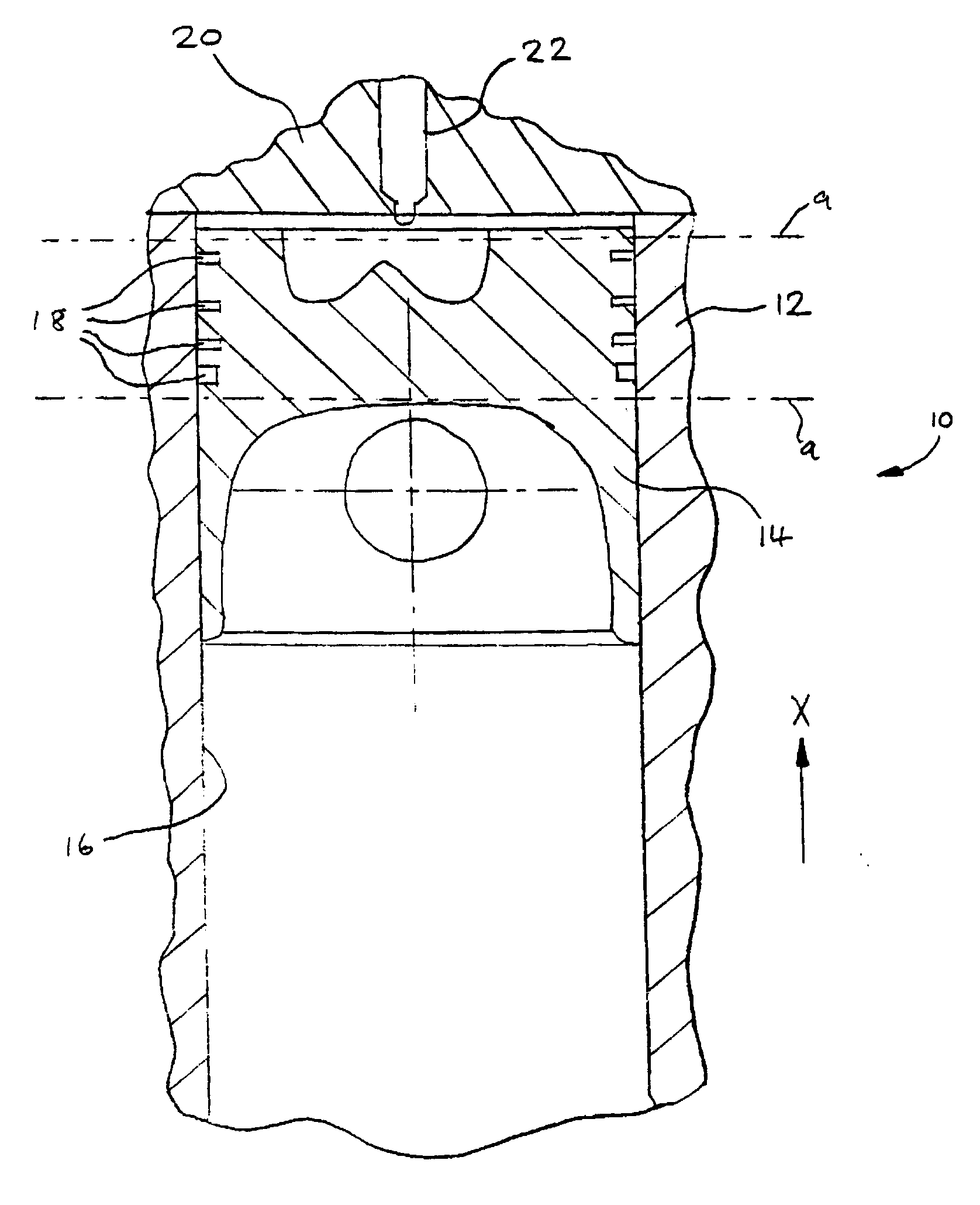

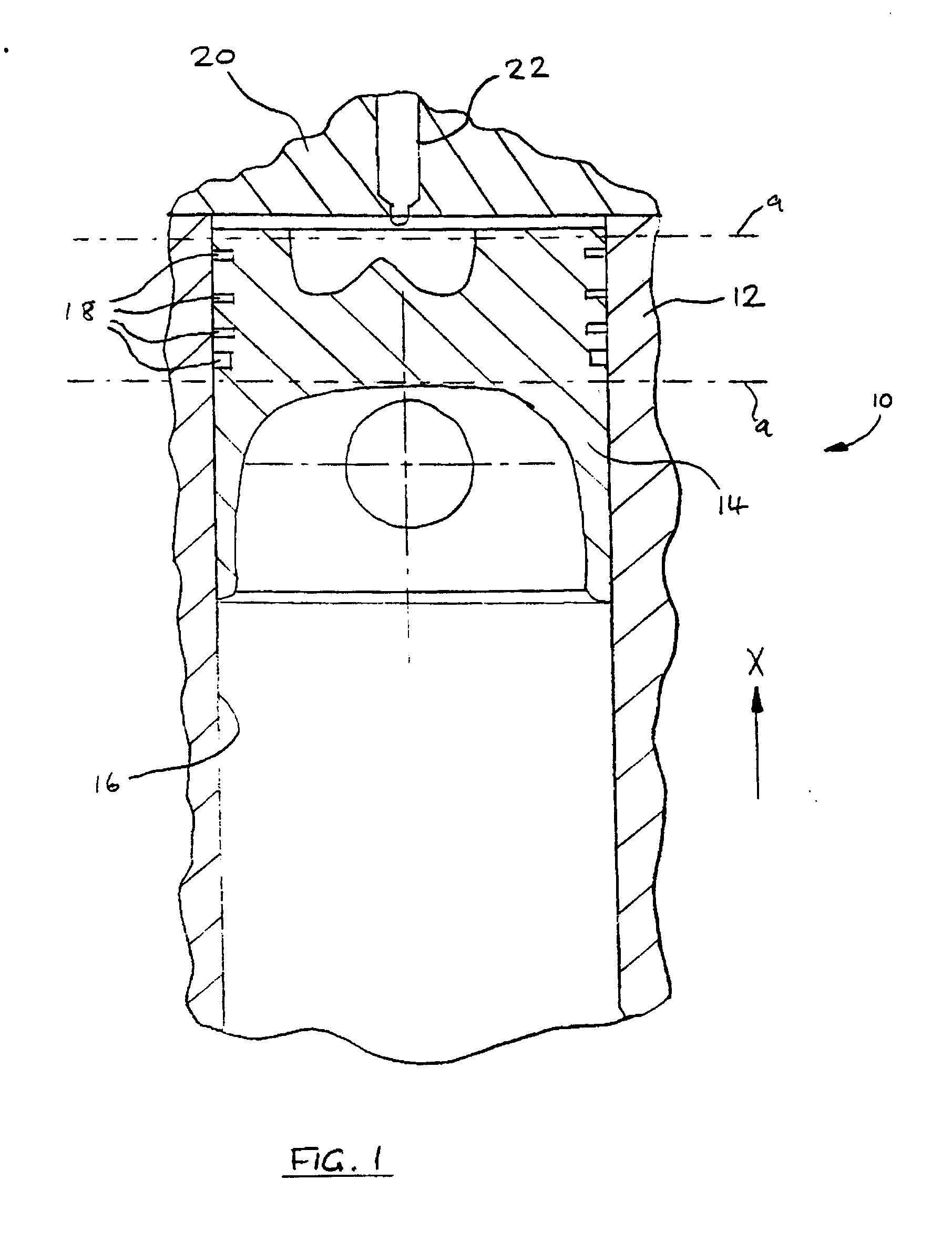

ActiveUS20110283968A1Reduce fuel usageLiquid coolingLubrication of auxillariesInternal combustion enginePiston

An oil supply system for a reciprocating piston internal combustion engine is disclosed in which the supply of oil to piston cooling jets is controlled by pressure operated valves designed to open at a pre-defined valve opening pressure. The pressure of oil supplied by a pump is controlled to be below this pre-defined valve opening pressure during operation of the engine in which piston cooling is not required, and the pressure of oil is controlled to above the pre-defined valve opening pressure when piston cooling is required. The control of the pump is by an electronic control unit based upon a combination of engine speed and engine load.

Owner:FORD GLOBAL TECH LLC

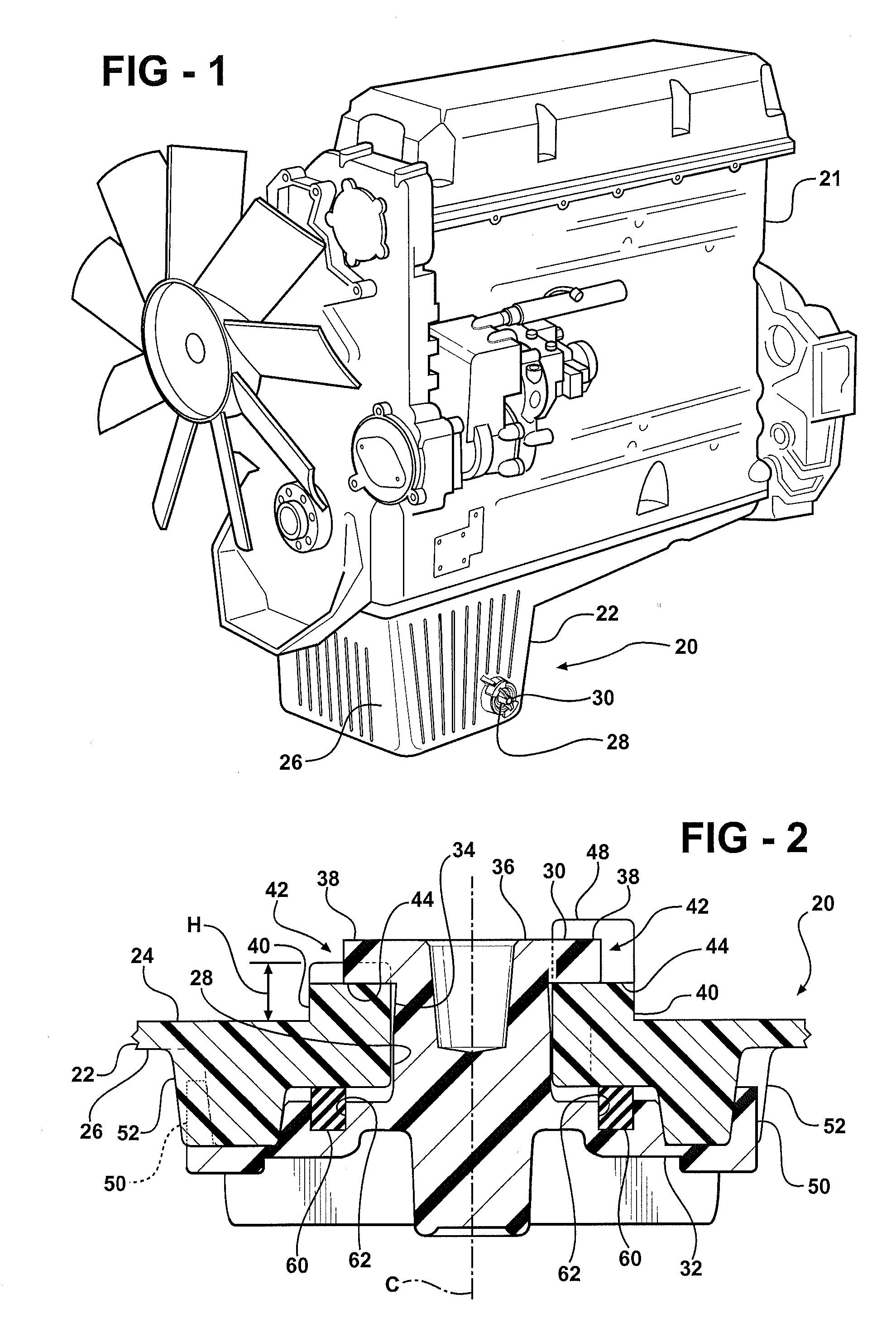

Fluid reservoir assembly

A fluid reservoir assembly having a pan defining a drain opening and a plug disposed therein is disclosed. The pan includes a pair of ramps disposed on an inner surface thereof adjacent the drain opening. The plug includes a pair of wings in engagement with the ramps. The ramps increase in height relative to the inner surface of the pan along a first direction of rotation about the central axis. The plug is drawn into sealing engagement with an outer surface of the pan by rotating the plug in the first direction of rotation about the central axis thereby moving the wings up the ramps. The pan includes at least one stop to prevent over-rotation of the plug. The ramps define a recess to secure the wings in a closed position.

Owner:BASF AG

Engine and a method of making same

InactiveUS20070101967A1Good oil retentionReasonable piston friction characteristicCylinder headsCylindersTop dead centerInternal combustion engine

An internal combustion engine is provided having at least one cylinder bore for slidingly supporting a piston, the cylinder bore wall of the at least one cylinder of the engine having pockets formed therein for retaining lubricant to reduce friction between the cylinder bore wall and piston. The pockets are elongate and have axes which are substantially parallel to the axis of the cylinder bore. The pockets are located at a first region supporting the piston when the piston is at its top dead center position. A method of making the cylinder is also provided.

Owner:FORD GLOBAL TECH LLC

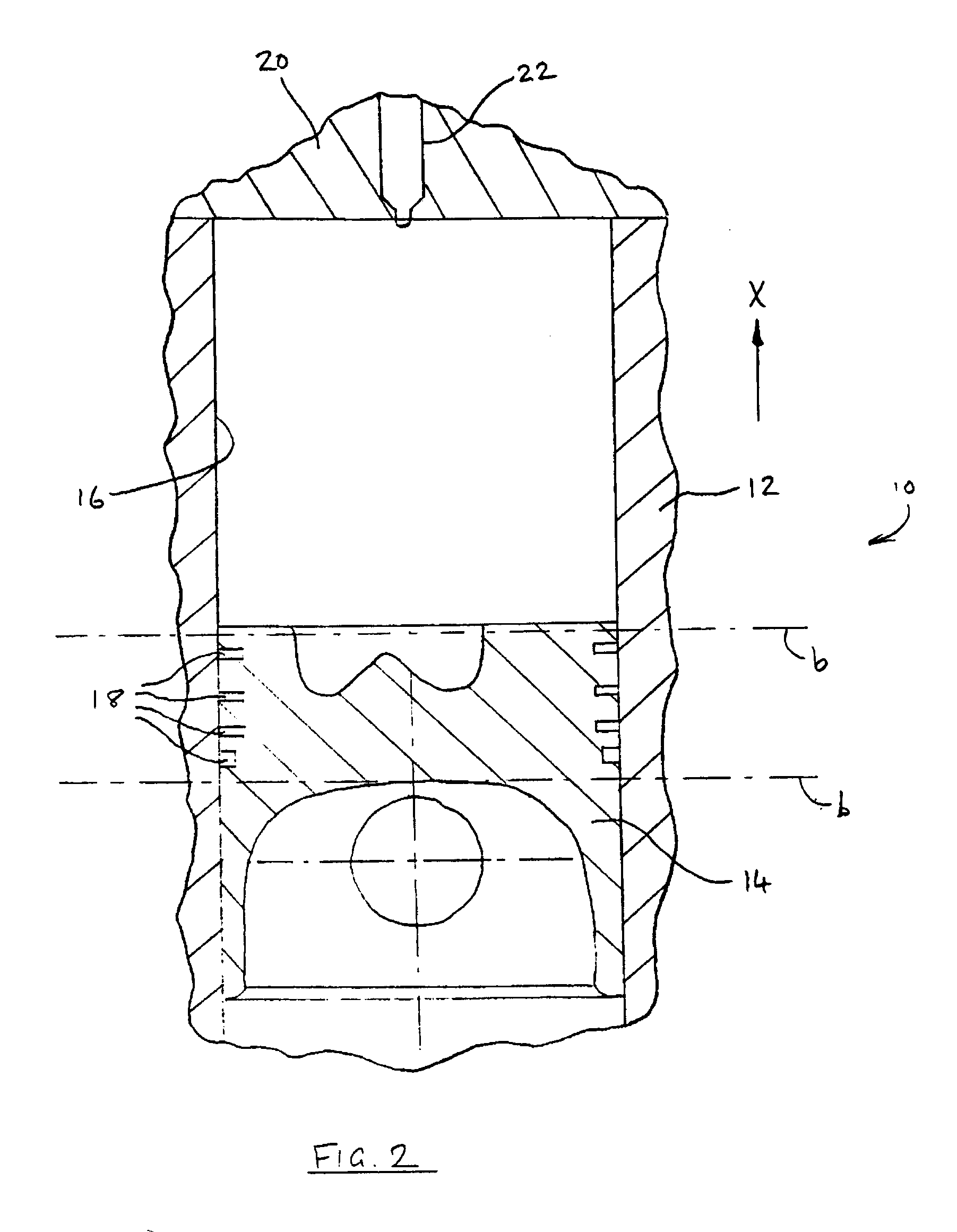

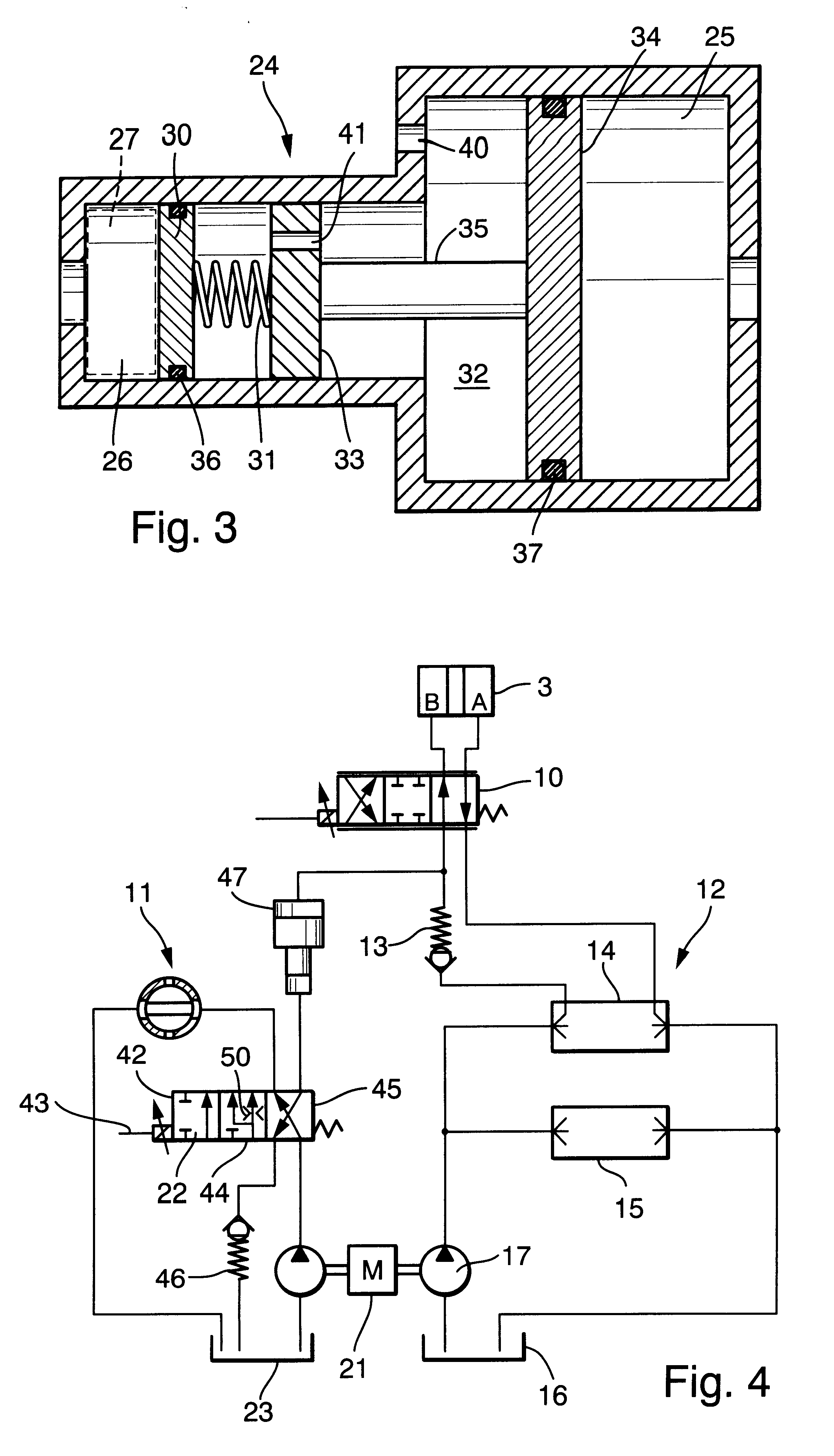

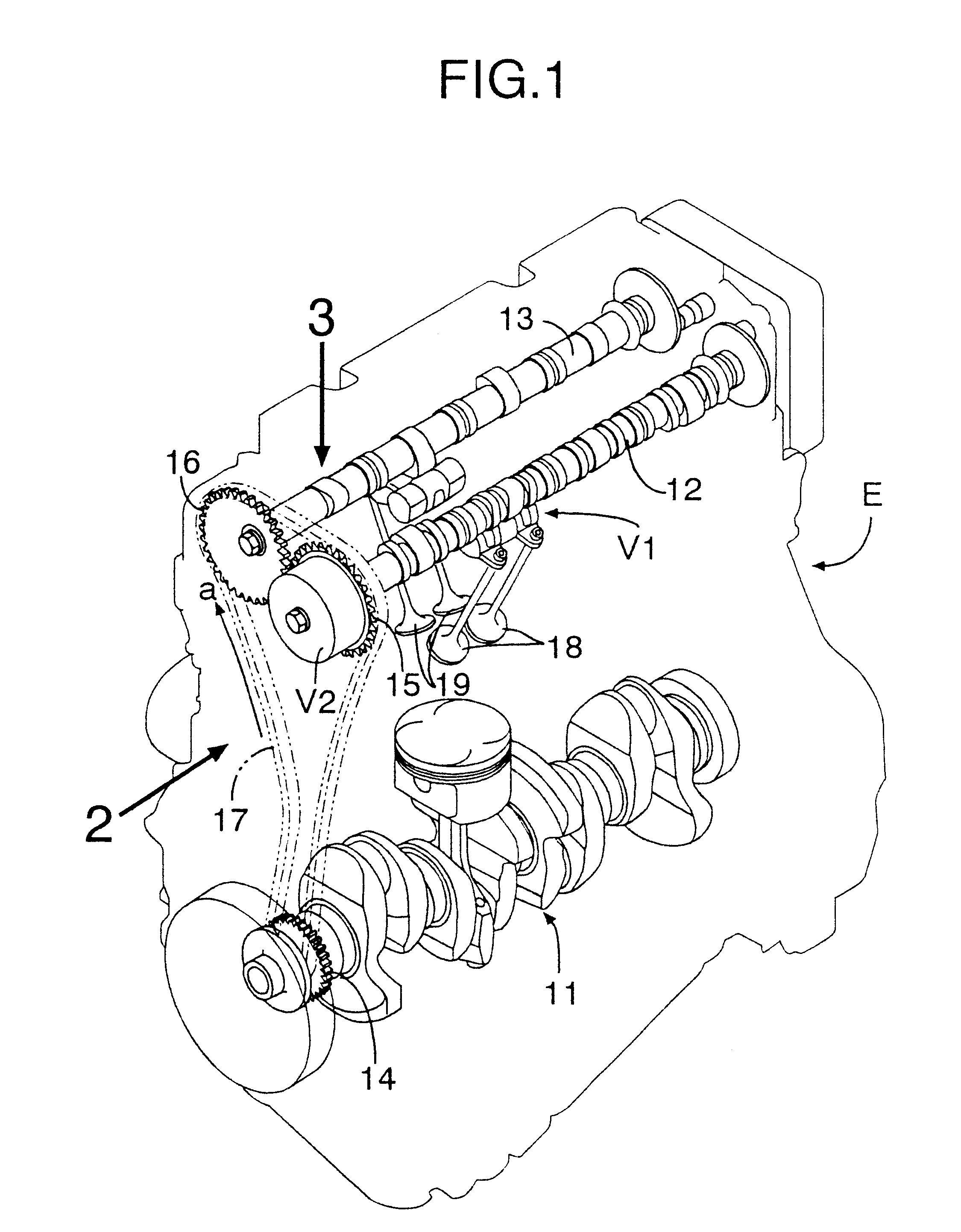

Apparatus for angular adjustment of camshafts relative to crankshafts in combustion engines

An apparatus for varying the phase of the camshaft in the combustion engine of a motor vehicle has an adjuster which is connected to the camshaft and is operable to adjust the phase of the camshaft prior and subsequent to starting of the engine. To this end, the adjuster is connected with a hydraulic drive system which can operate the adjuster while the engine is idle. Once the engine is started, the drive system receives pressurized fluid from the lubricating circuit of the engine. Prior to starting of the engine, the drive system receives pressurized fluid from a source other than the lubricating circuit or from a source which is provided in addition to the lubricating circuit. The other source is preferably the hydraulic circuit of the power steering system (such as a speed-sensitive power steering system) of the motor vehicle.

Owner:ATLAS FAHRZEUGTECHN GMBH

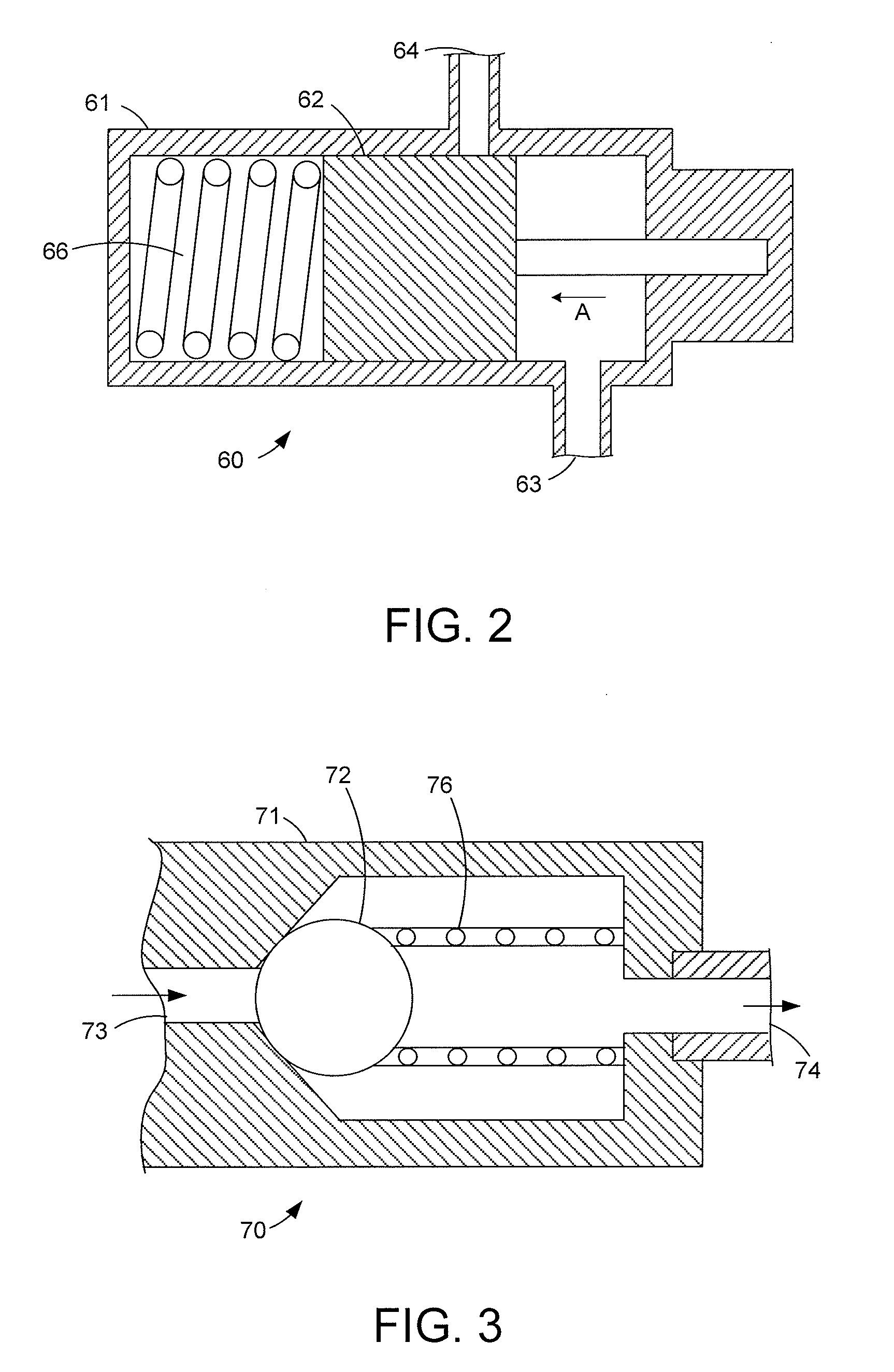

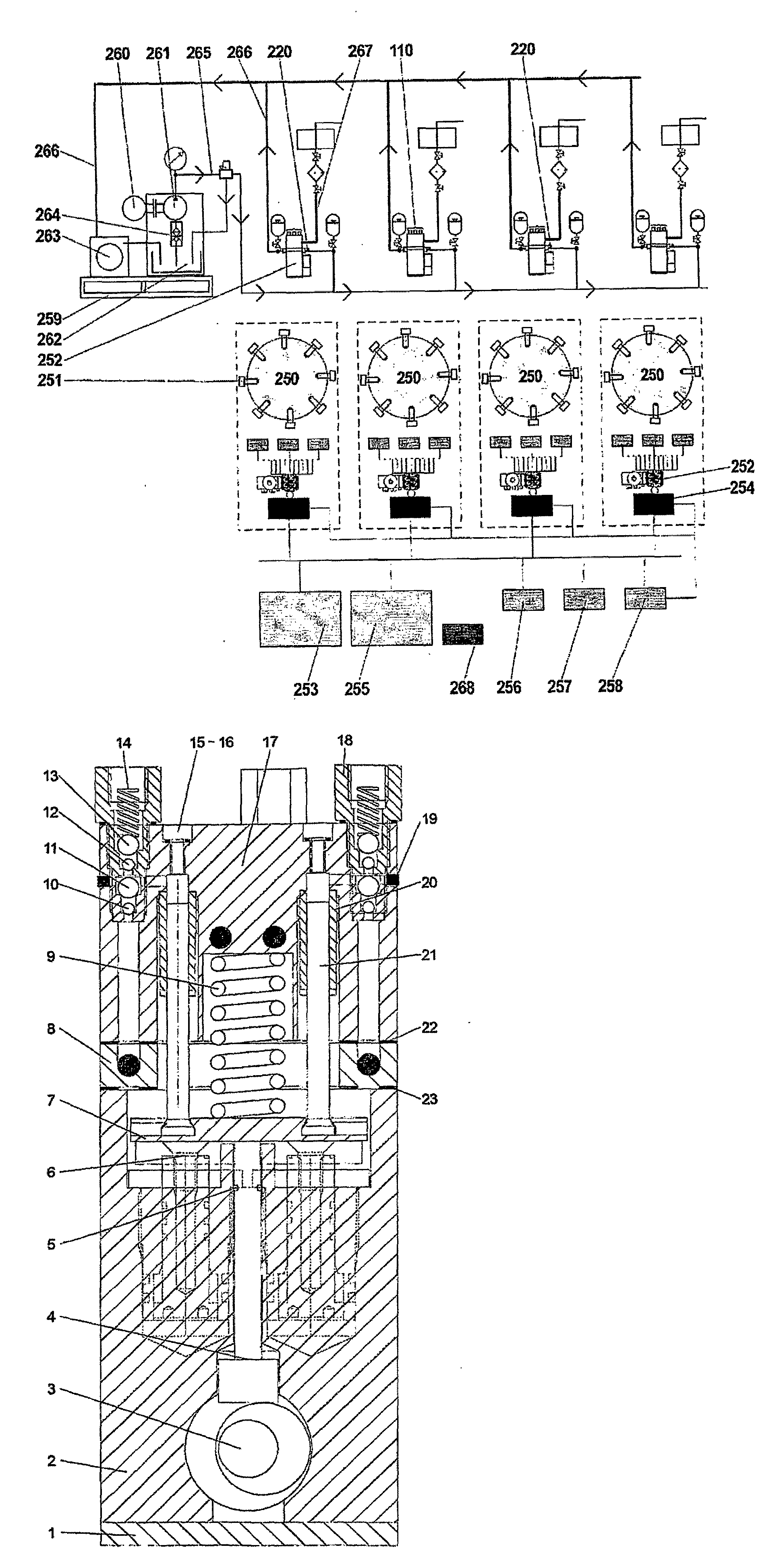

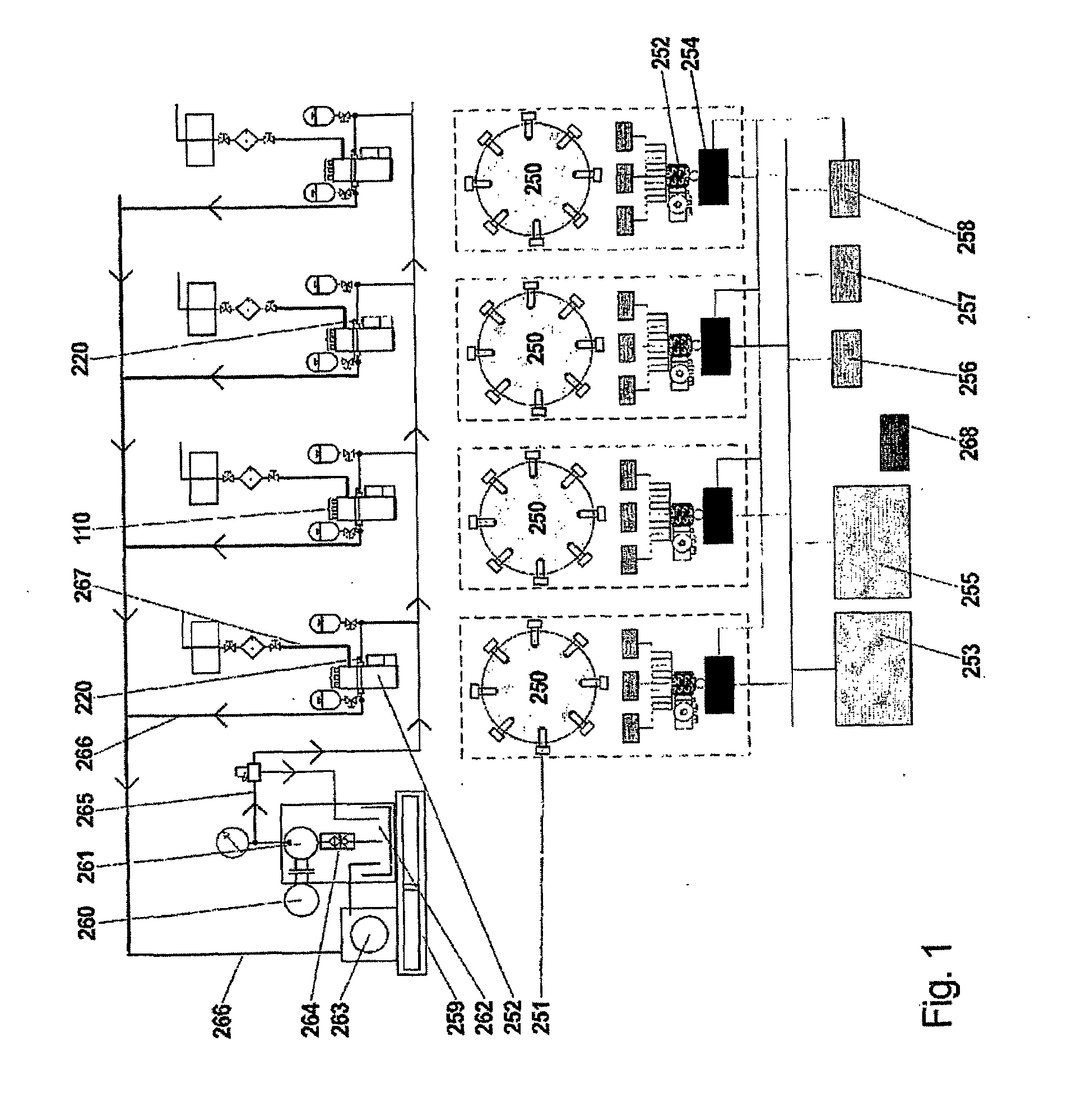

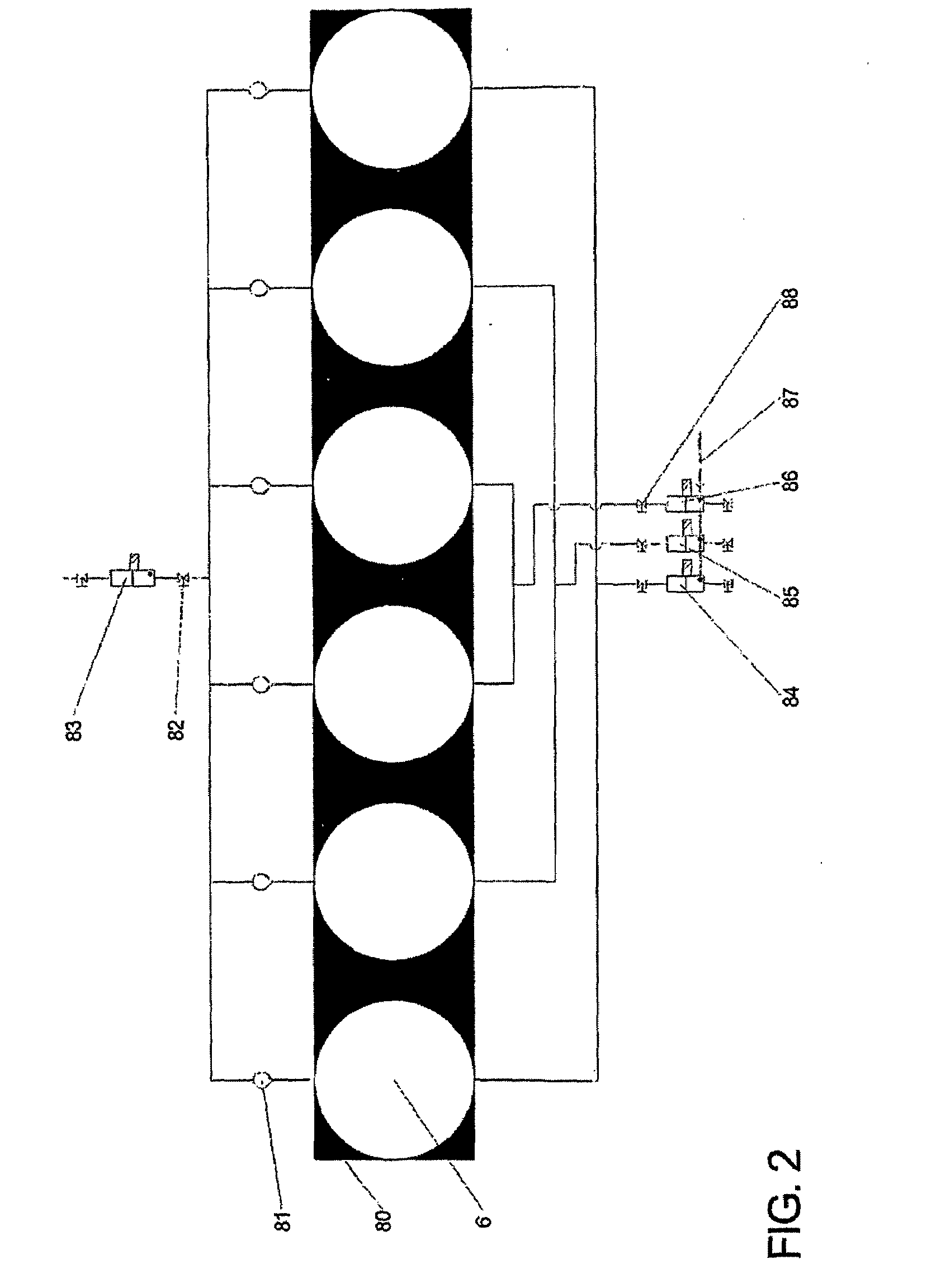

Lubricating apparatus for a dosing system for cylinder lubrication oil and method for dosing cylinder lubricating oil

ActiveUS20100006056A1Easy to adjustEasy to replaceLubrication of auxillariesPropulsion power plantsHydraulic cylinderEngineering

There is disclosed a method and a hydraulic lubricating apparatus for dosing cylinder lubricating oil. The dosing system includes a supply line and a return line connected with the lubricating apparatus via each one or more valves for supplying hydraulic oil, a central hydraulic oil feed pump connected with hydraulic cylinders, each having a hydraulic piston and which may be subjected to pressure by hydraulic oil via the supply line, a number of injection units corresponding to a multiple of the cylinder number in the engine and which are connected with each their dosing cylinder with a dosing piston and a supply line for cylinder lubricating oil. In order to provide a system which is reliable and cheap and where there is no risk of disruptions, even if a hydraulic cylinder fails, the lubricating apparatus is designed with a distributor plate which at one side is in contact with the dosing pistons and which at its other side is in contact with two or more hydraulic pistons for displacing the distributor plate for activating the dosing pistons.

Owner:HANS JENSEN LUBRICATORS

Rotary feed-through

InactiveUS6929099B2Easy constructionReduce wearAdjustable jointsMachines/enginesLine tubingContact pressure

A rotary feed-through, which contains a hollow shaft, which is supported in a first housing part so that it can rotate, with a first sealing surface and a sealing bushing, which is arranged rotationally fixed within a second housing part and which is coaxial with the hollow shaft, with a second sealing surface for contact to the first sealing surface. In order to also enable lower leakage losses, in addition to less wear, with the supply of cooling lubricants and compressed air, the second housing part contains a first lateral supply channel, which can be attached to a coolant supply line or a compressed air supply line, for the supply of cooling lubricant or compressed air via at least one radial opening of the sealing bushing and a second supply channel, which is charged during the supply of cooling lubricant, for the supply of cooling lubricant to a pressure piston, which closes the rear end of the sealing bushing, to increase the contact pressure of the sealing surfaces.

Owner:OTT JAKOB & SPANNTECHN

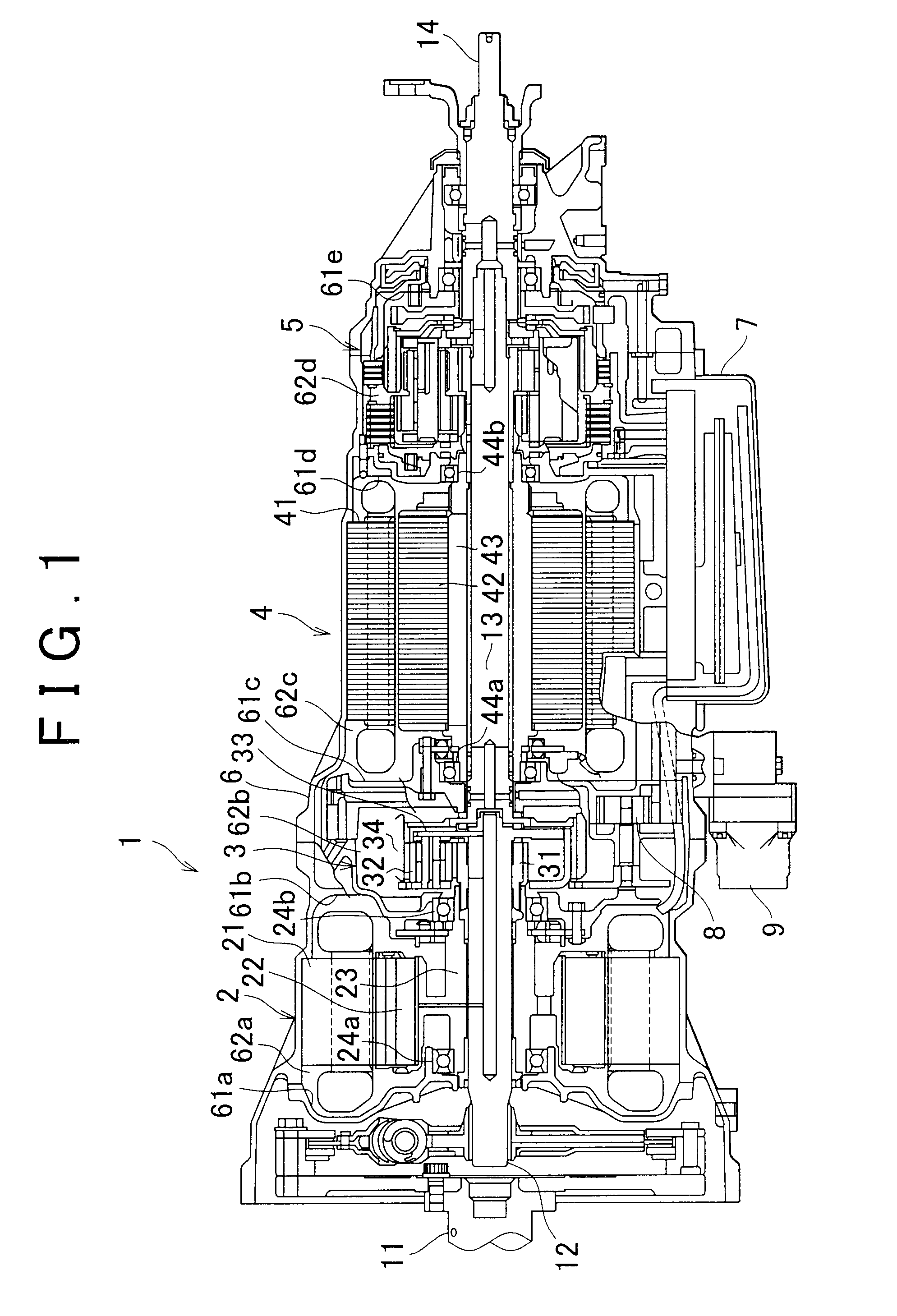

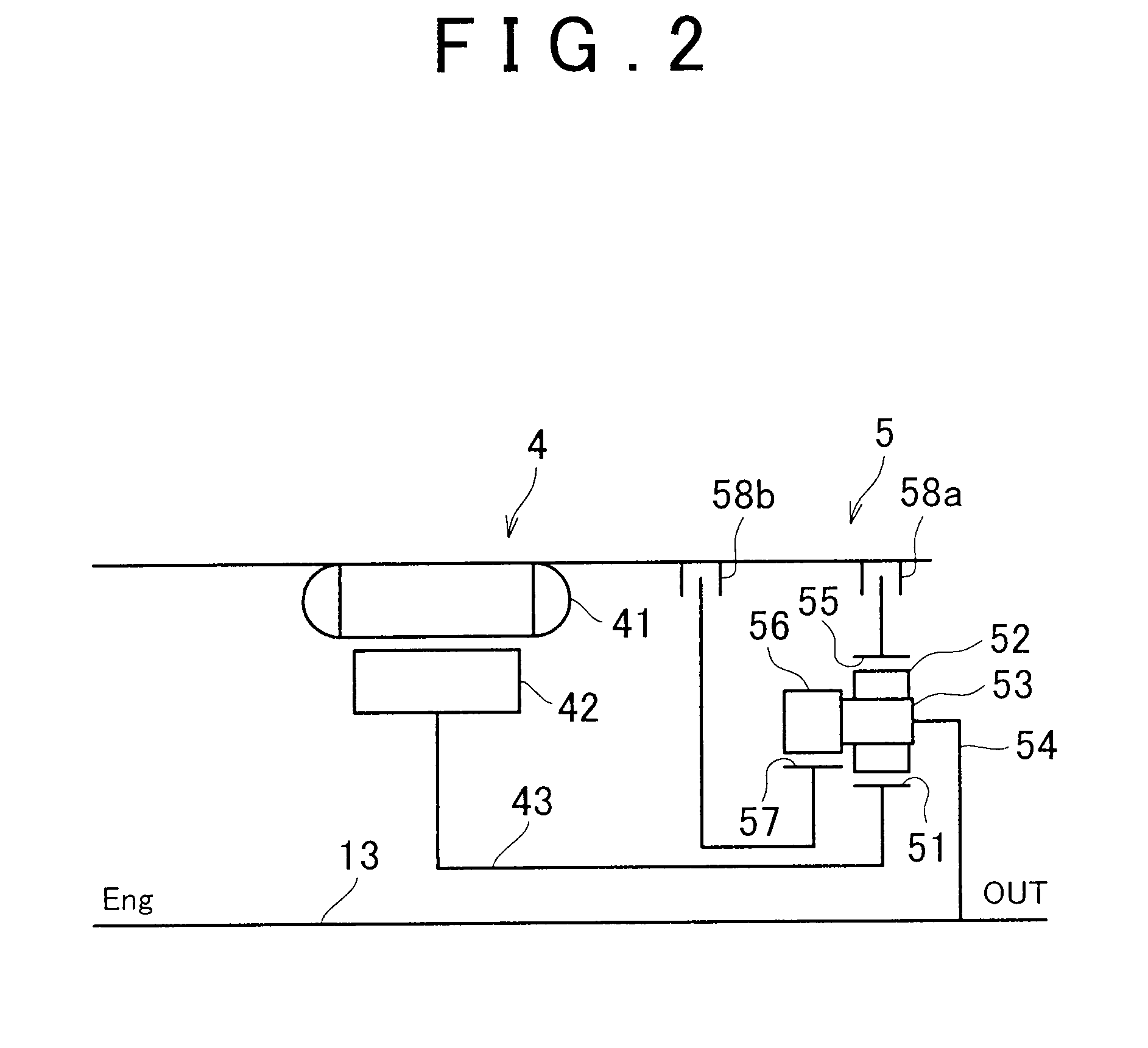

Lubricating oil supplying system for internal combustion engine

InactiveUS7331323B2Simplifying the hydraulic circuitAvoid developmentEqualizing valvesSafety valvesControl signalExternal combustion engine

Owner:HITACHI LTD

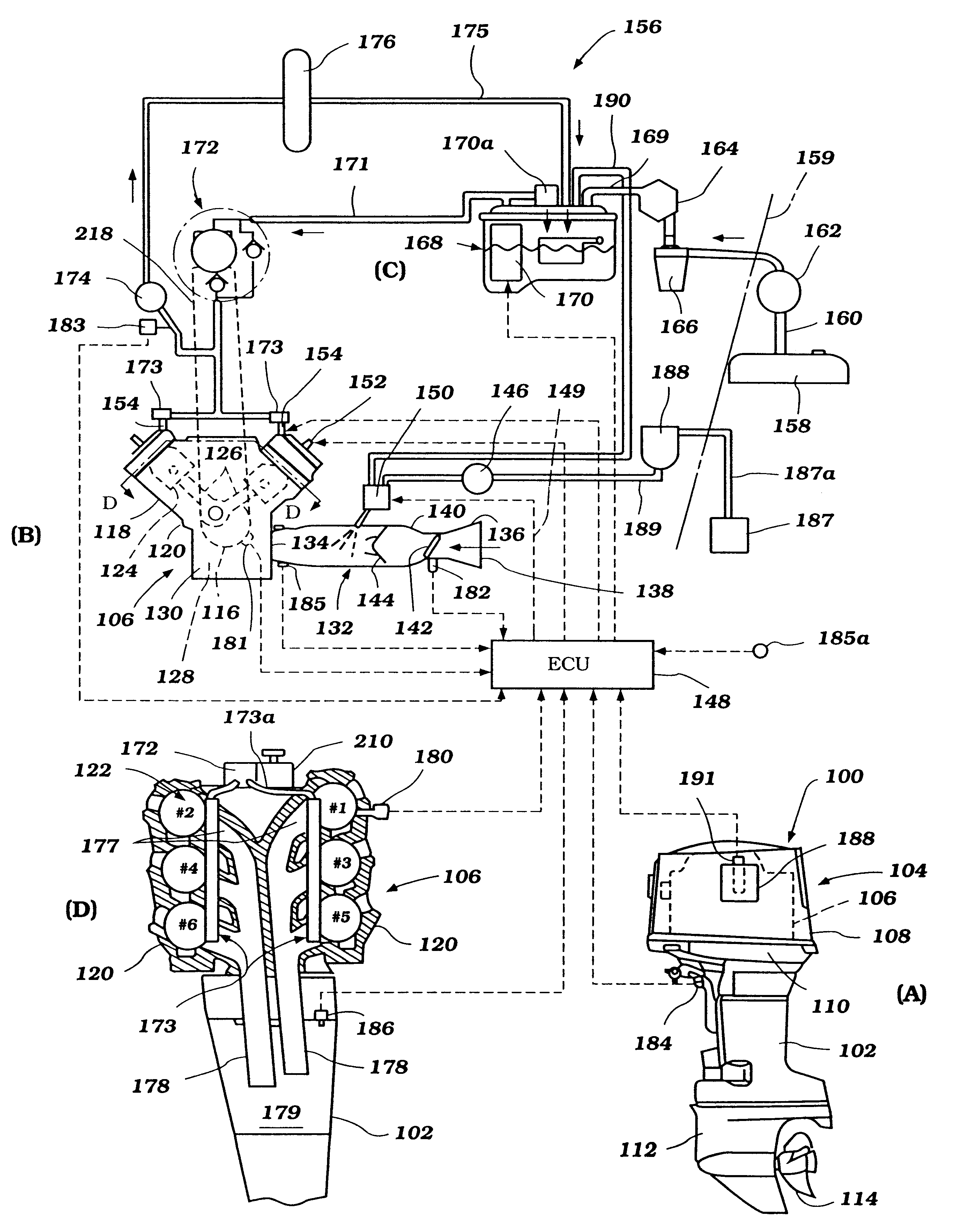

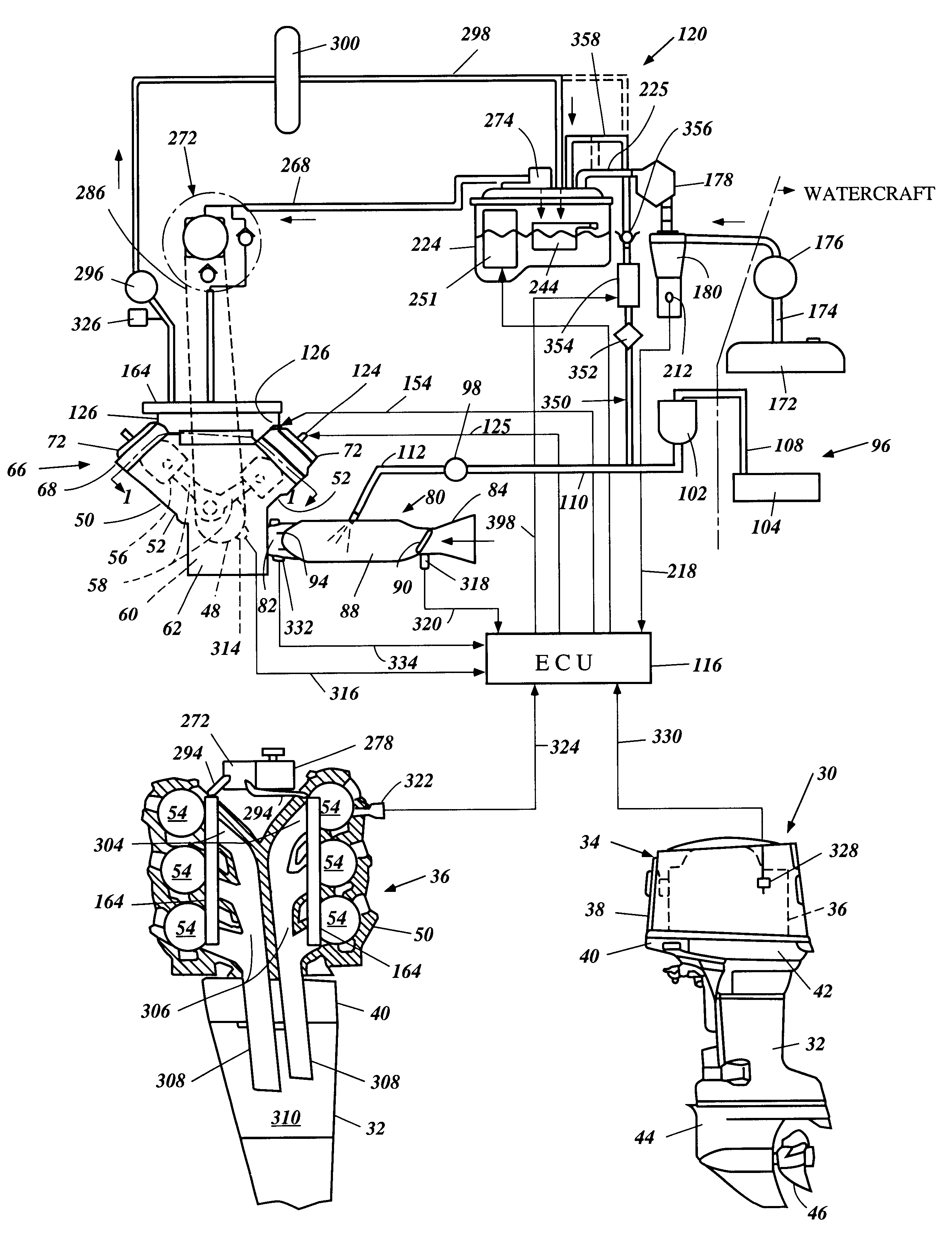

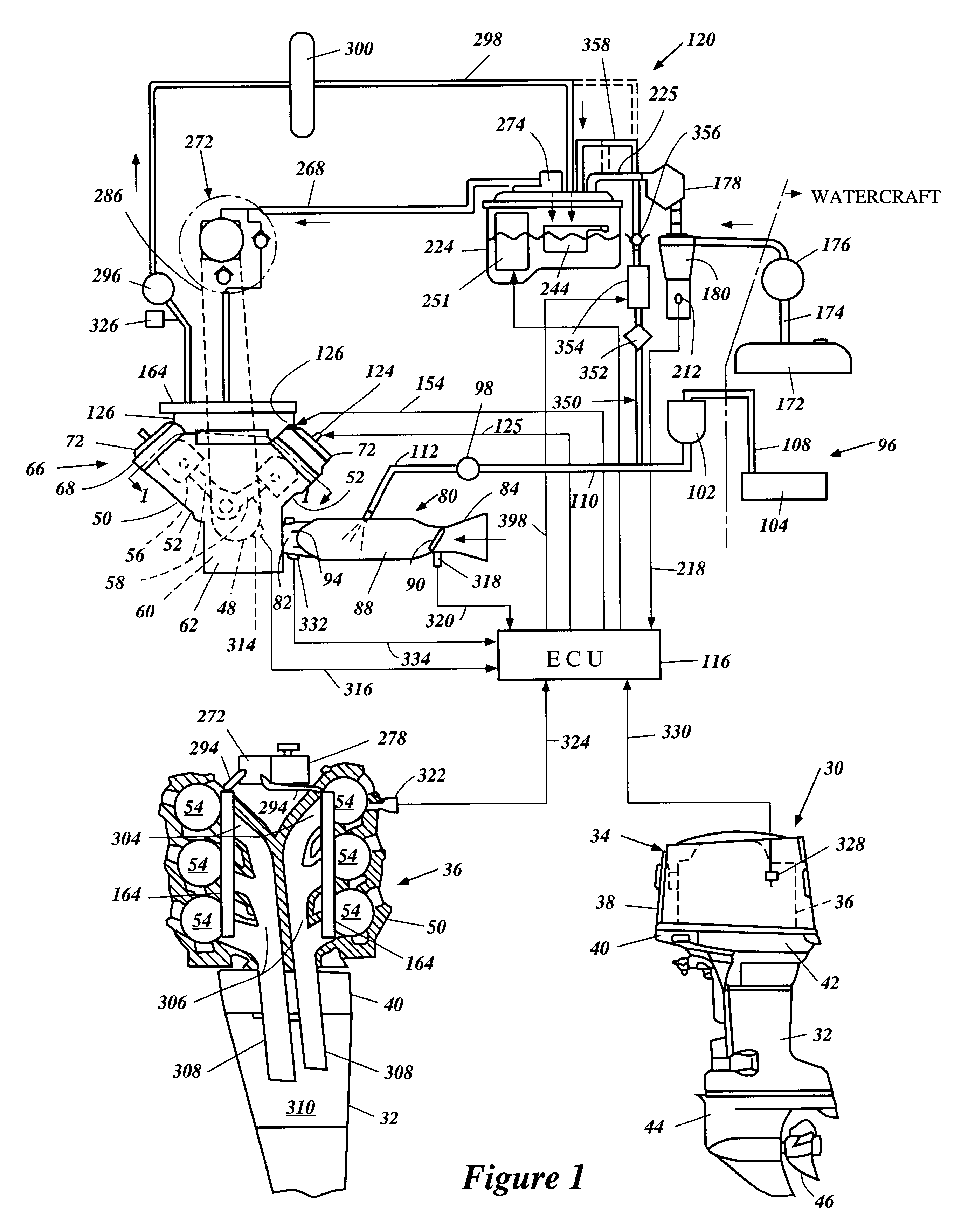

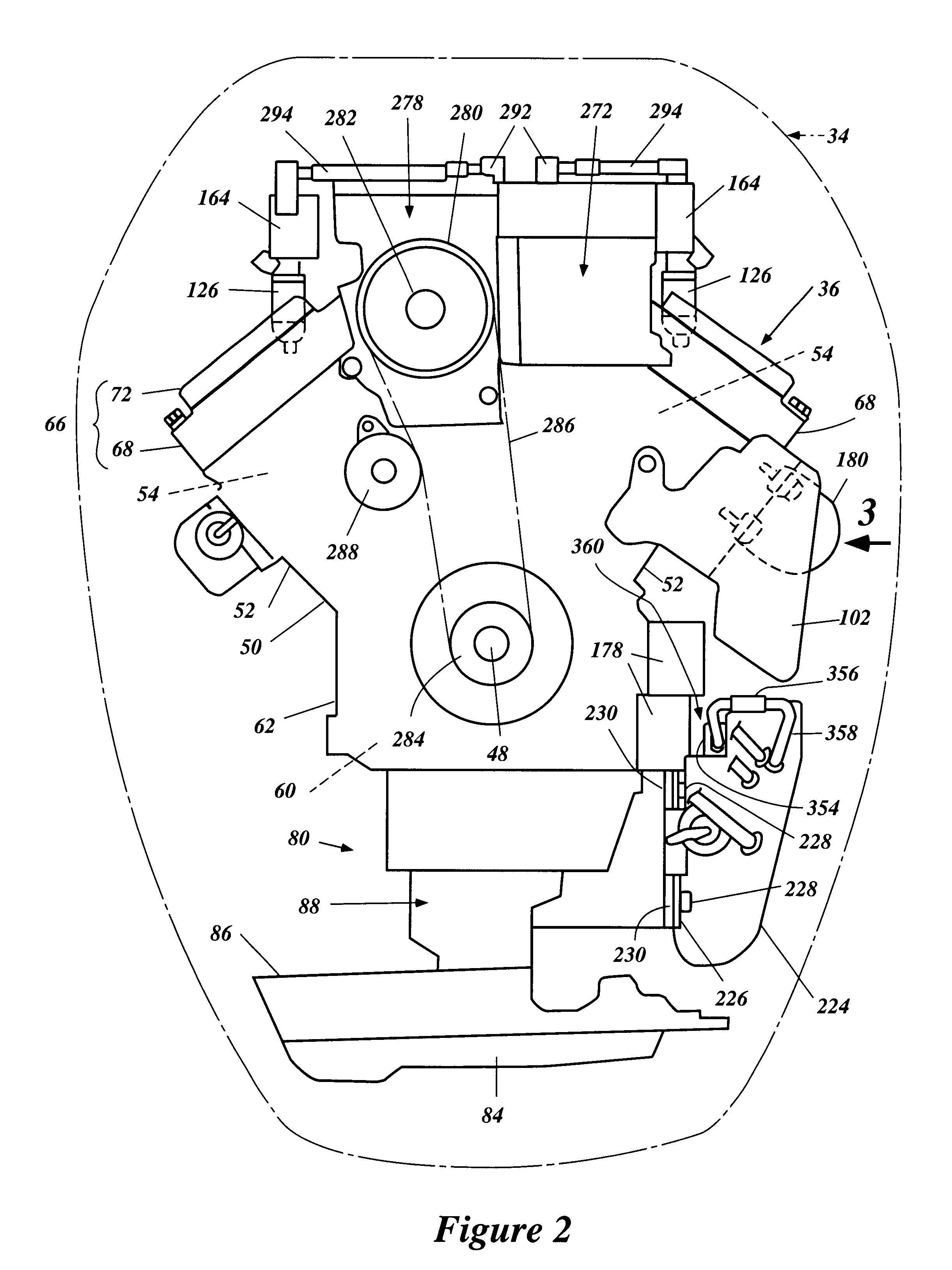

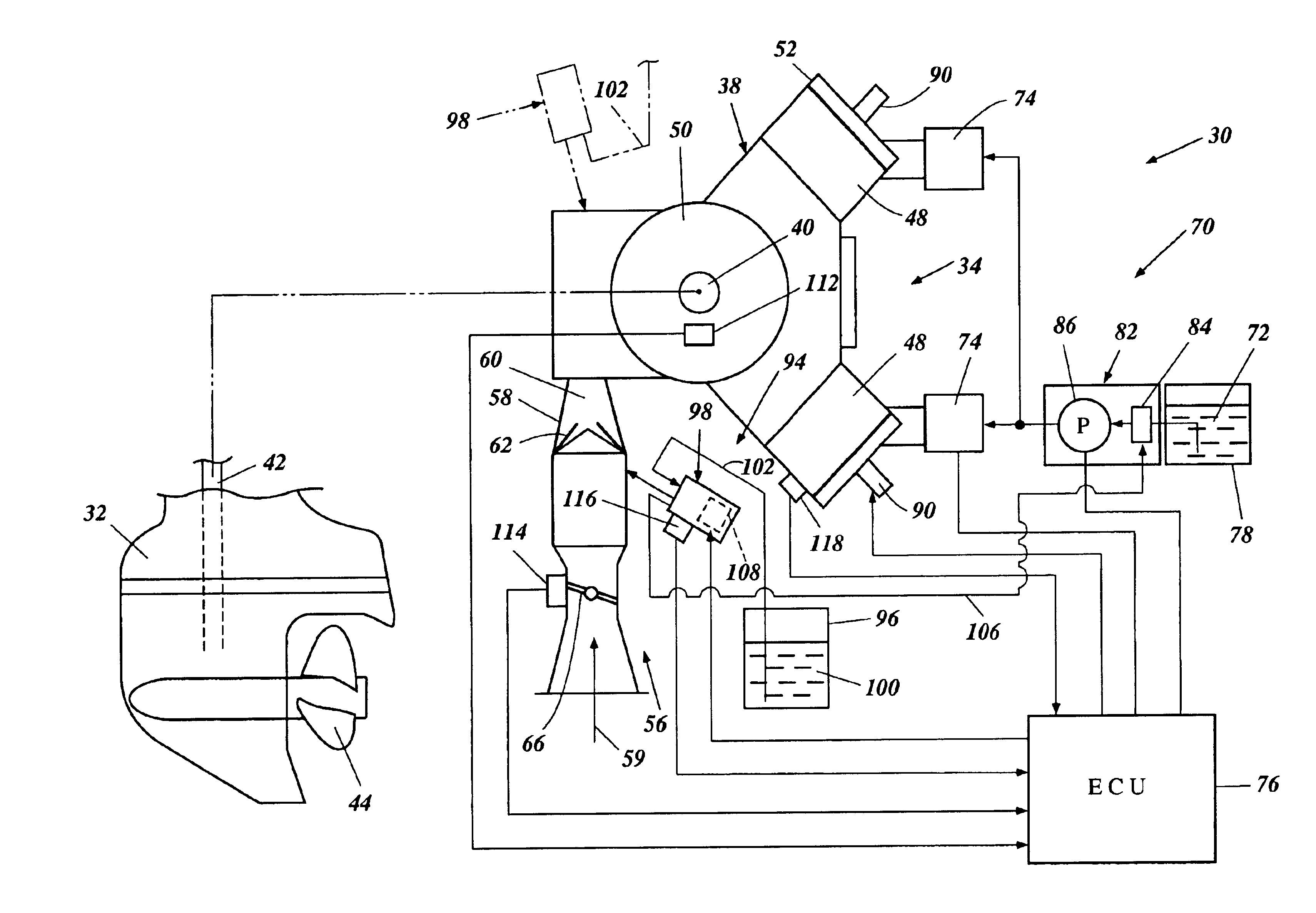

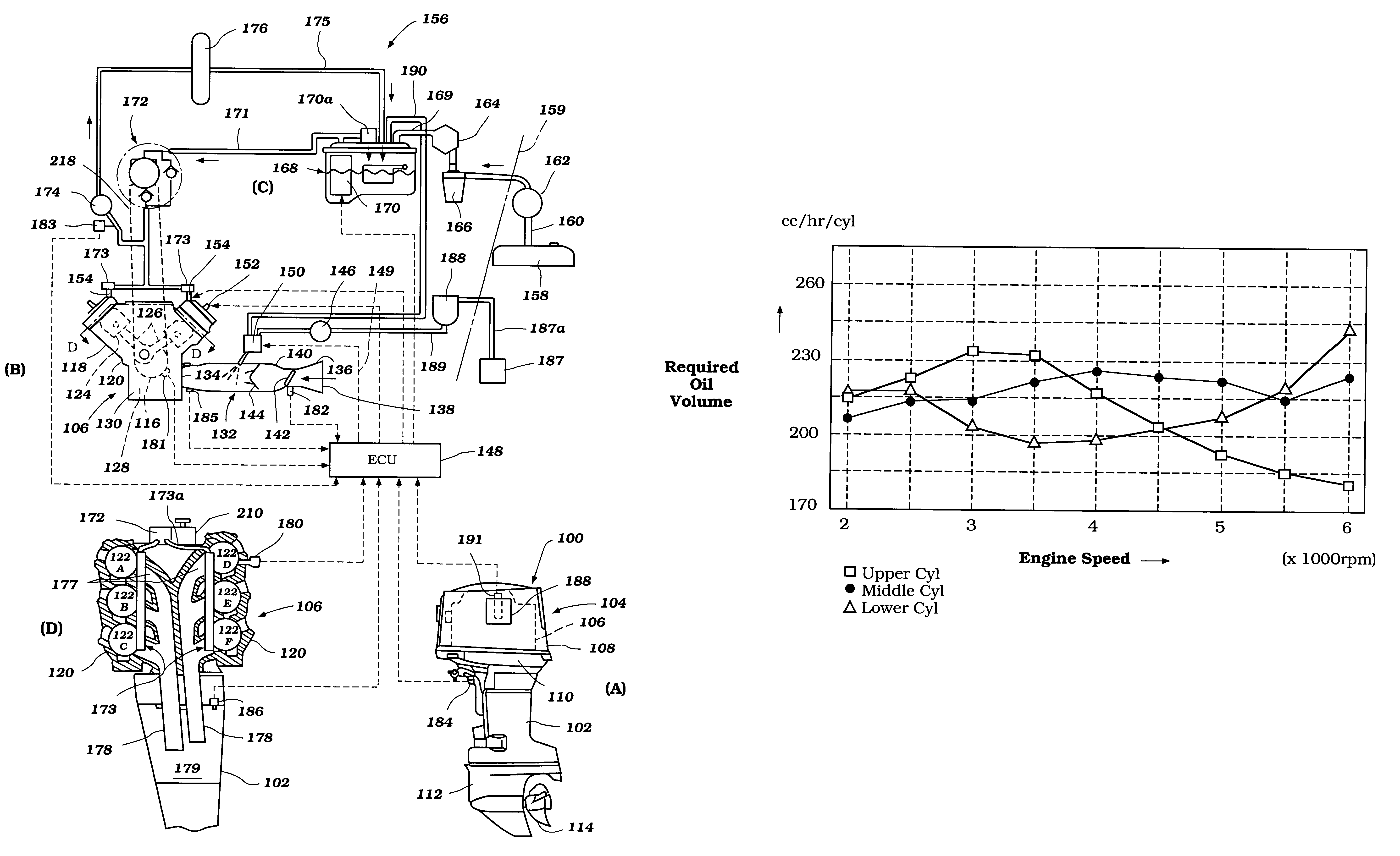

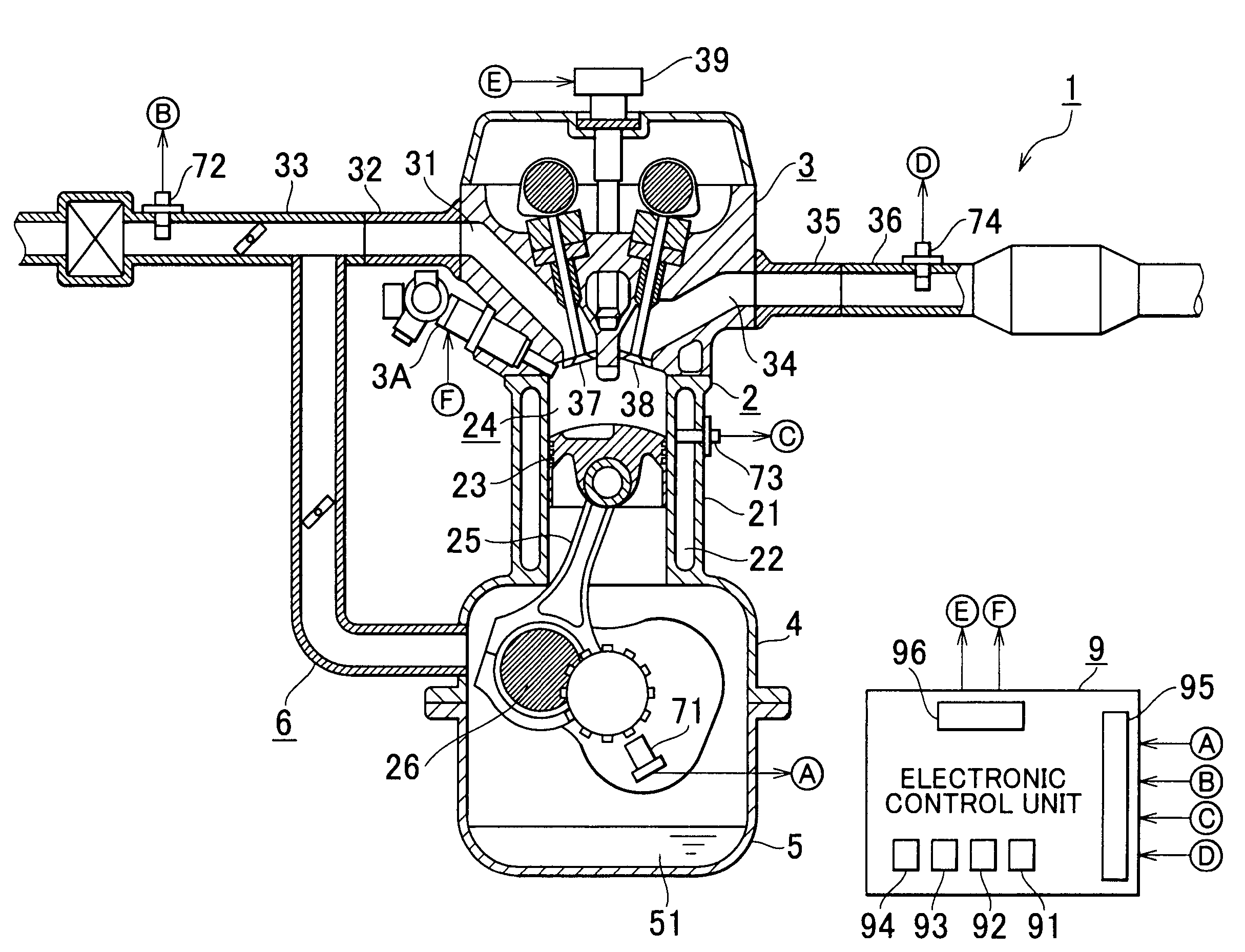

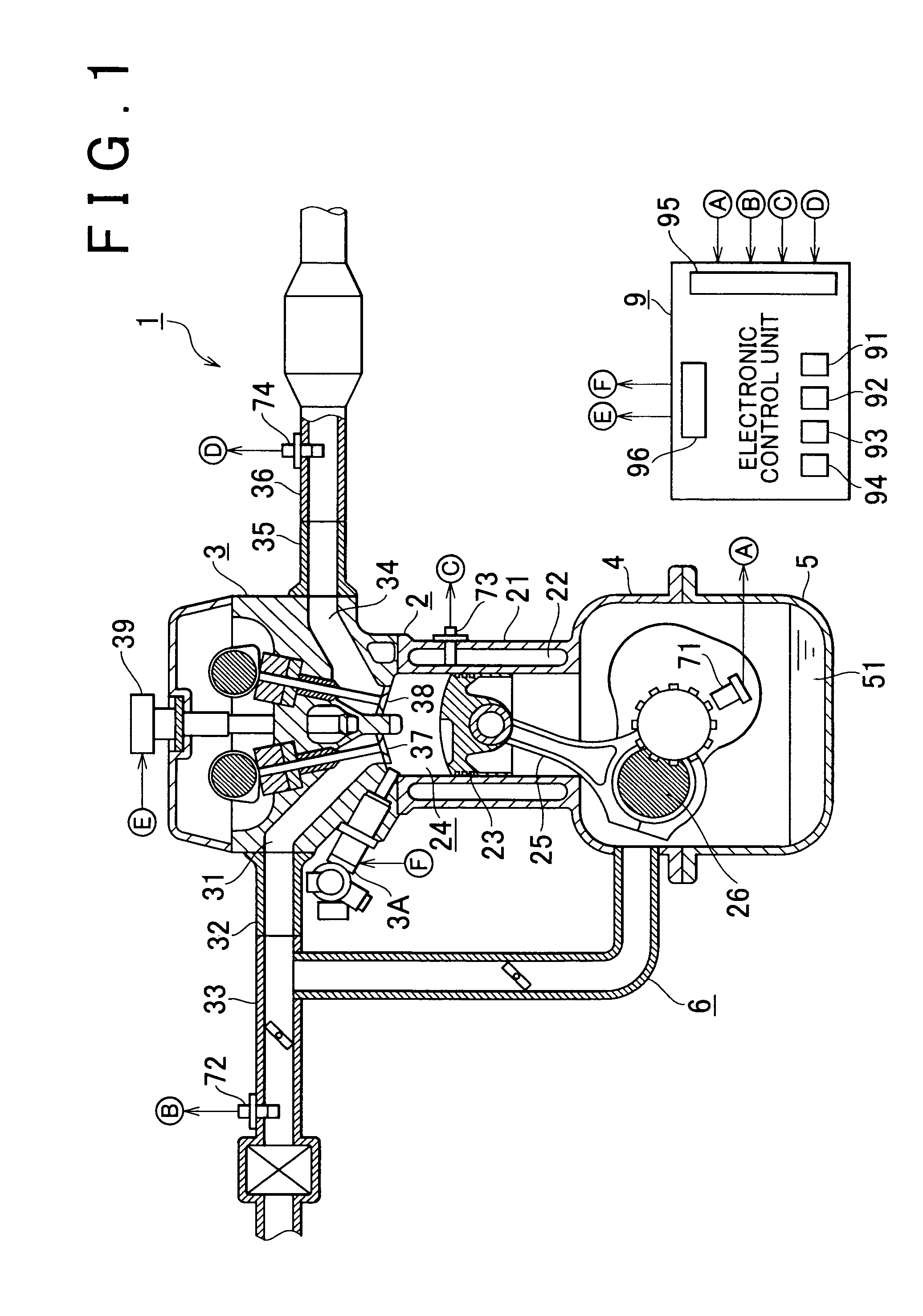

Fuel injection system for marine engine

A fuel injection system for a marine engine includes an improved construction that, by the introduction of lubricant into the fuel, inhibits components of the system from rusting in the event that water, particularly salt water, is mixed with the fuel. The engine includes a lubricant delivery system to deliver lubricant to at least one portion of the engine that needs lubrication. A premix lubricant pump is provided for supplying lubricant with the fuel injection device from the lubricant delivery system so as to mix the part of the lubricant to the fuel. An ECU controls an amount of the part of the lubricant so as to be in a proper and extremely small range.

Owner:SANSHIN KOGYO CO LTD

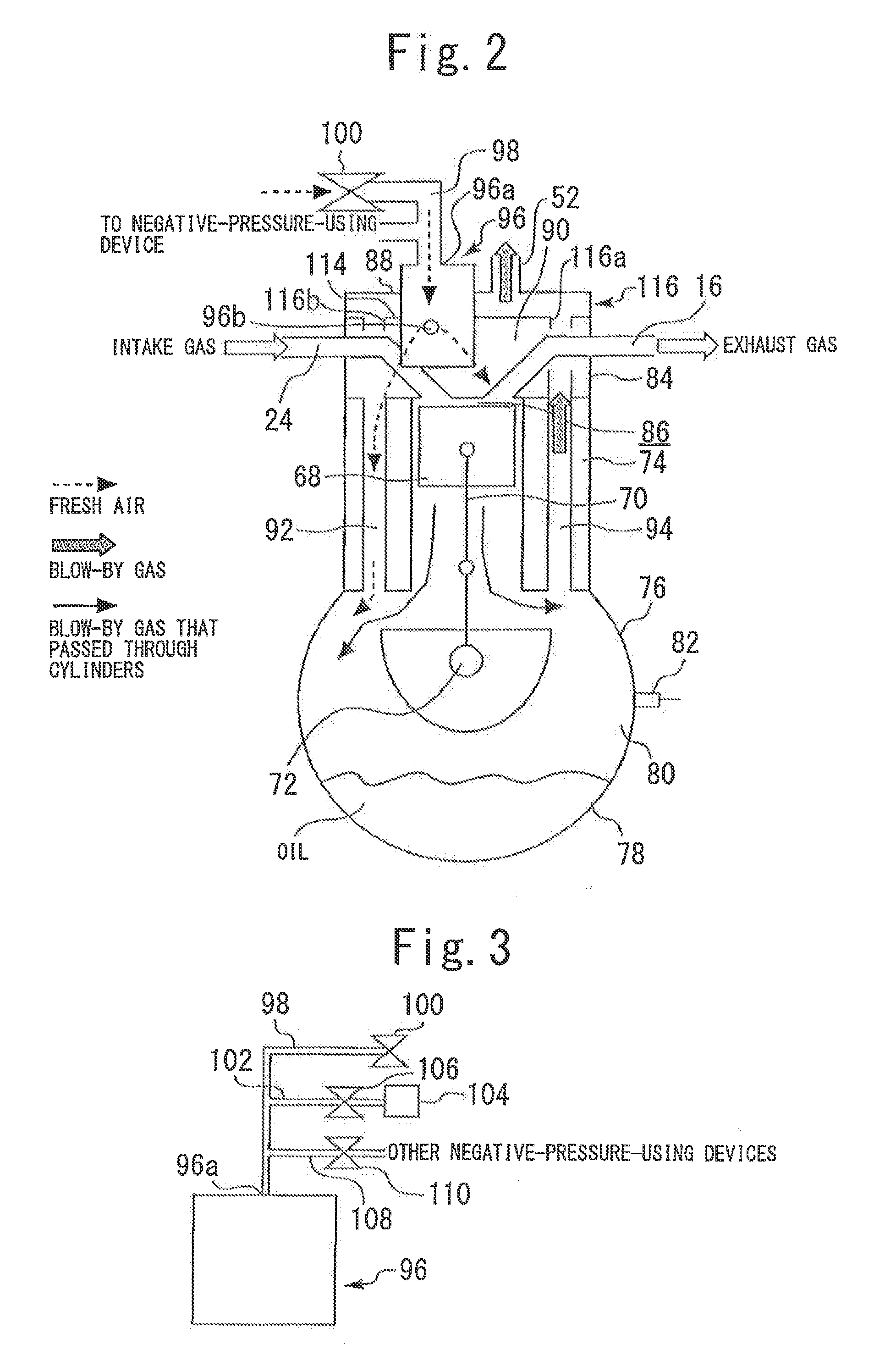

Supercharged internal combustion engine

InactiveUS20140326225A1Prevent buildupRotary/oscillating piston combinations for elastic fluidsElectrical controlInterior spaceImpeller

A supercharged internal combustion engine of the present invention is provided with a turbocharger (18) having a compressor (18b) in an air intake passage (24), a communication passage (52) connected between an upstream-side portion of the air intake passage (24) on the upstream side of a compressor impeller (18b3) and an internal space (90) of the internal combustion engine (10), and an oil supply apparatus (96, 98, 100) that supplies oil to an internal passage in the compressor (18) through which intake air flows. When a deposit buildup operation condition under which there is a concern of a buildup of a deposit in the compressor (18) is met, the oil supply apparatus (96, 98, 100) increases the amount of oil supplied to the internal passage compared with the amount of oil supplied when the deposit buildup operation condition is not met.

Owner:TOYOTA JIDOSHA KK

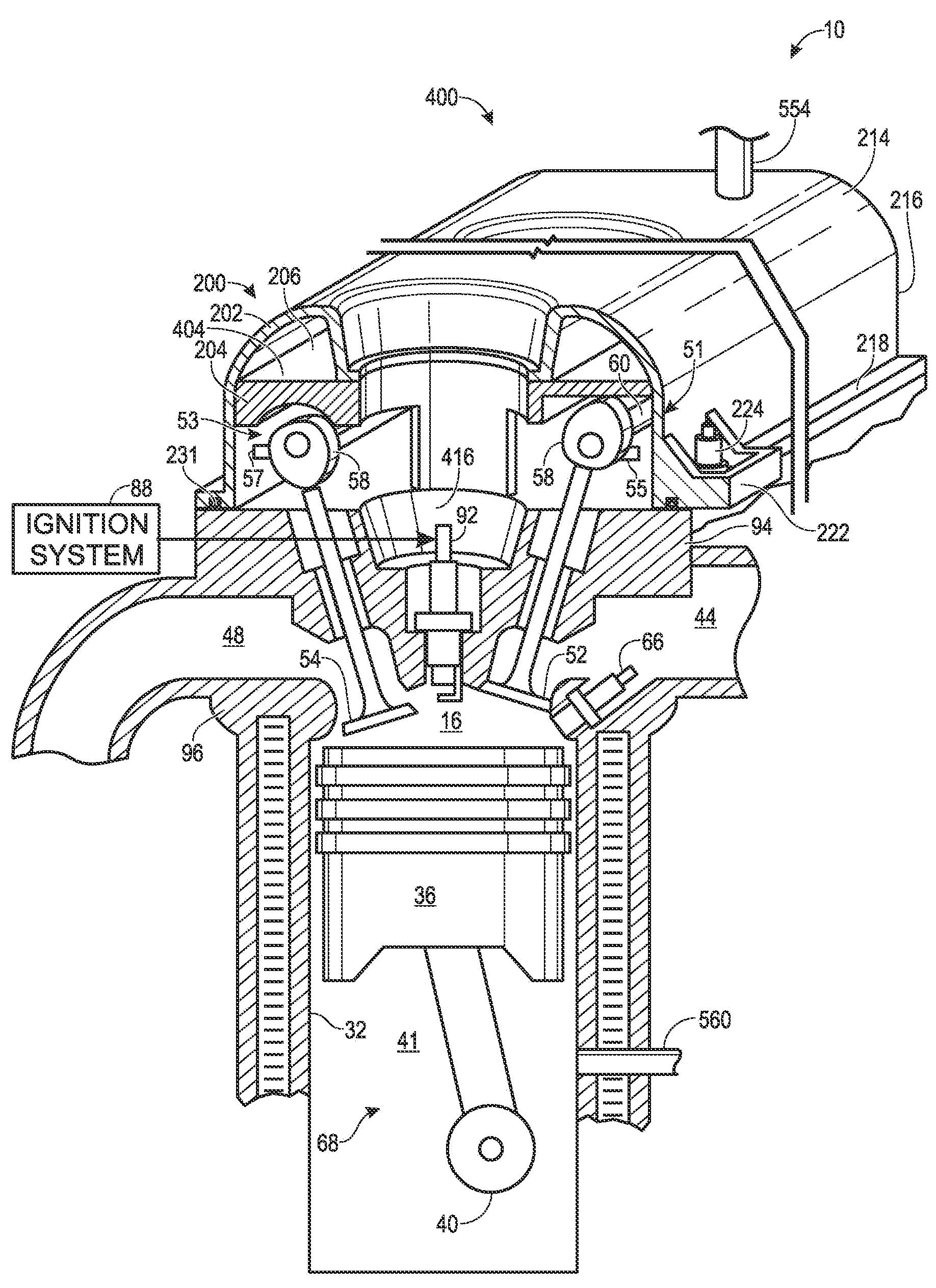

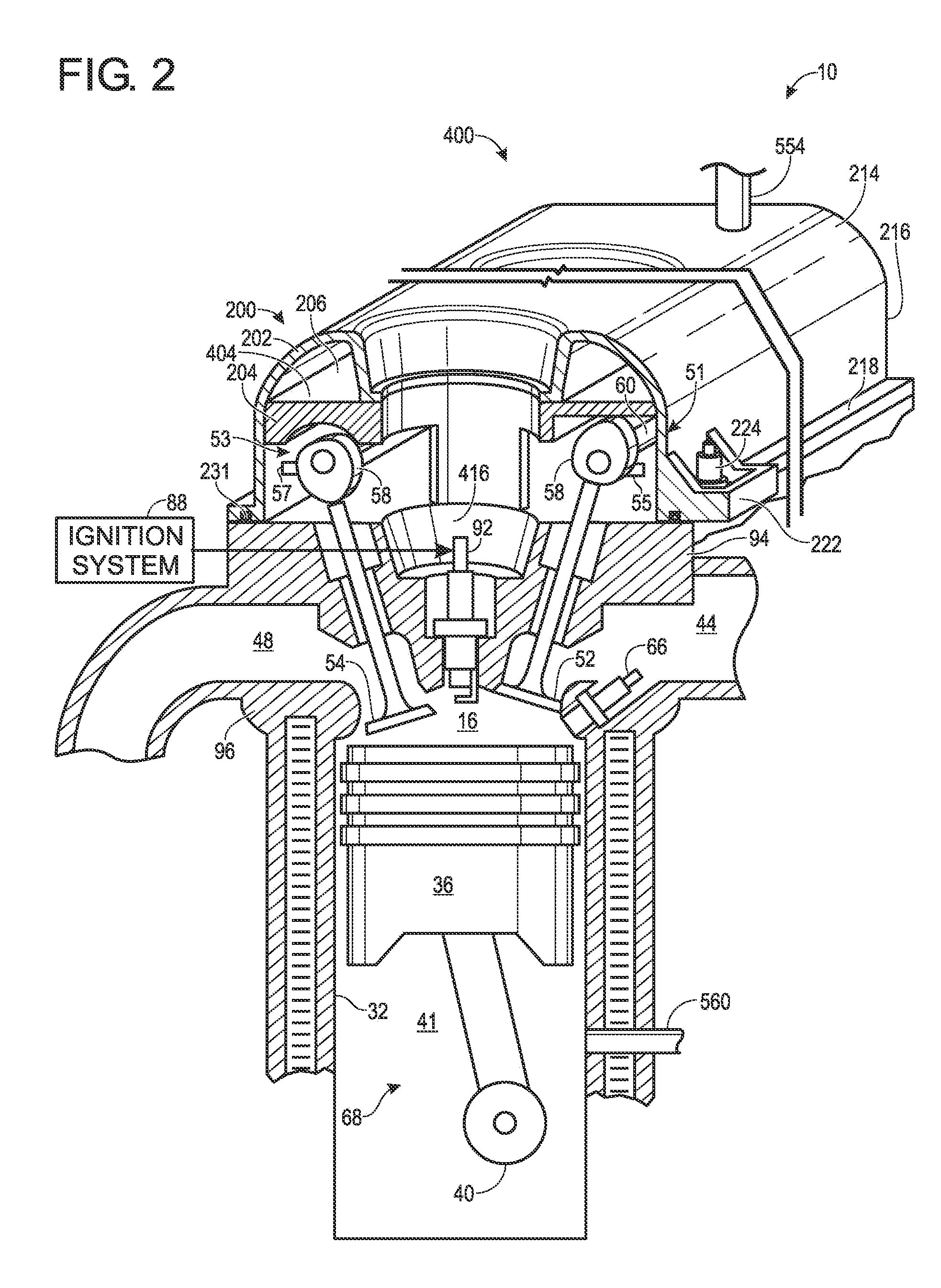

Multi-location fuel injection system

ActiveUS7168401B2Lower emission levelsSacrificing a potential peak horsepowerCombustion enginesLow pressure fuel injectionExhaust valveCrankcase

Owner:ARCTIC CAT

Internal combustion engine with oil temperature sensor

InactiveUS20050092283A1Reduce the heating effectAccurate temperatureExhaust apparatusCylinder headsDegrees of freedomCylinder block

The invention relates to an engine arrangement that increases the degree of freedom of the engine state sensor while decreasing the size of the engine body. More specifically, the engine is formed with a chamber for housing a valve train and serving dually as a return oil path of the lubricating oil after having lubricated the valve train. The engine includes an oil temperature sensor partially exposed on one side of a cylinder block and an exhaust pipe partially exposed on the opposite side of the cylinder block.

Owner:HONDA MOTOR CO LTD

Oil suction system

ActiveUS8292036B2Easy constructionAvoid drawingGearboxesGear lubrication/coolingEngineeringLiquid surfaces

In an oil suction system for drawing up oil stored in an oil reservoir through a strainer, the oil reservoir is constructed such that, when the liquid surface of the oil is inclined due to movement of the stored oil, the level of the liquid surface close to the suction port varies in accordance with a plurality of directions of inclination of the liquid surface, and the level of the liquid surface close to the suction port is lower in a particular direction as one of the directions of inclination of the liquid surface than those in the other directions of inclination, and an inflow resistance portion is provided at a lowered liquid-level side of the suction port on which the liquid level is lowered when the oil surface is inclined in the particular direction, for increasing the resistance to flow of the oil from the lowered liquid-level side toward the suction port, to be larger than the resistance to flow of the oil from a raised liquid-level side of the suction port on which the liquid level is raised due to inclination in the particular direction, toward the suction port.

Owner:TOYOTA JIDOSHA KK

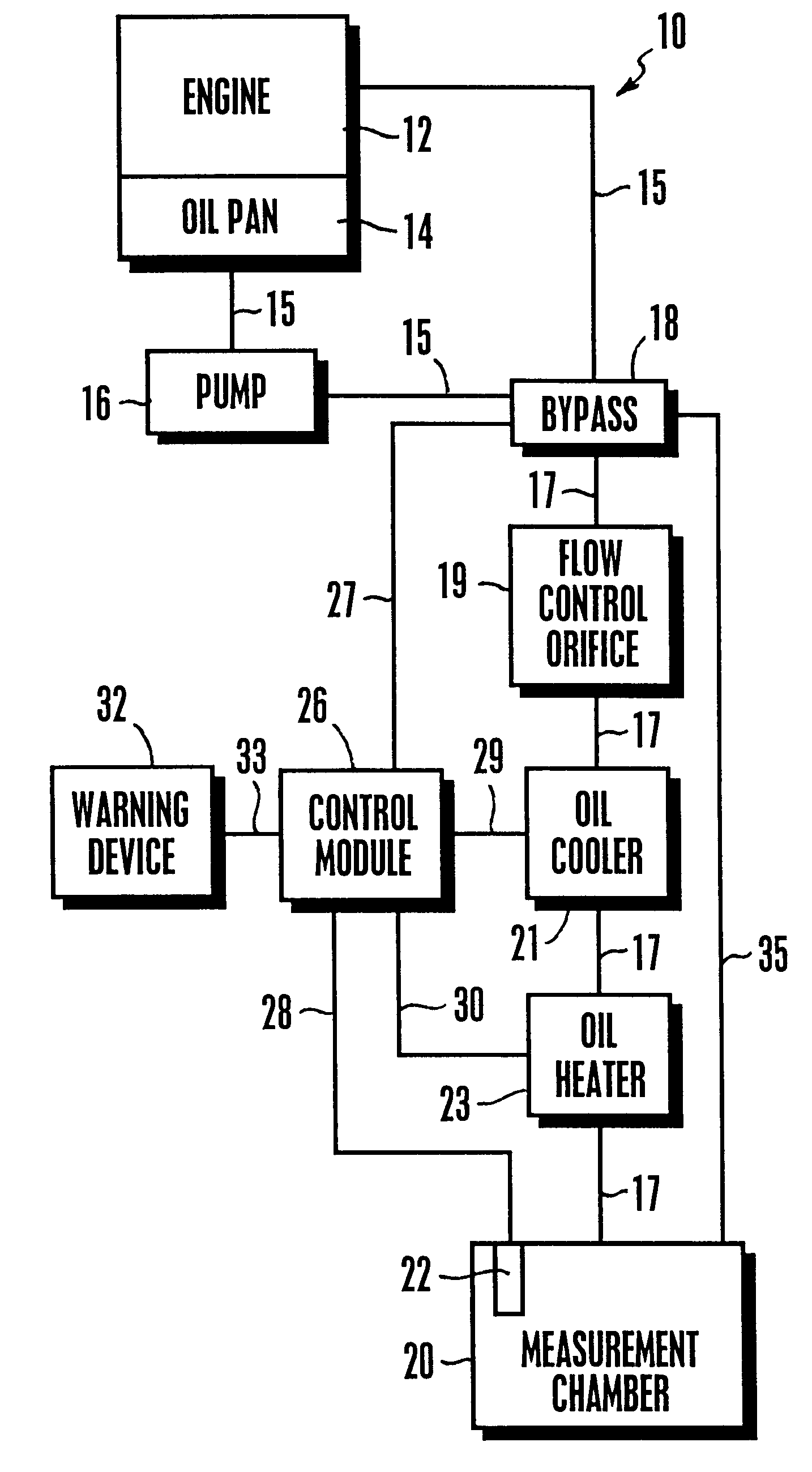

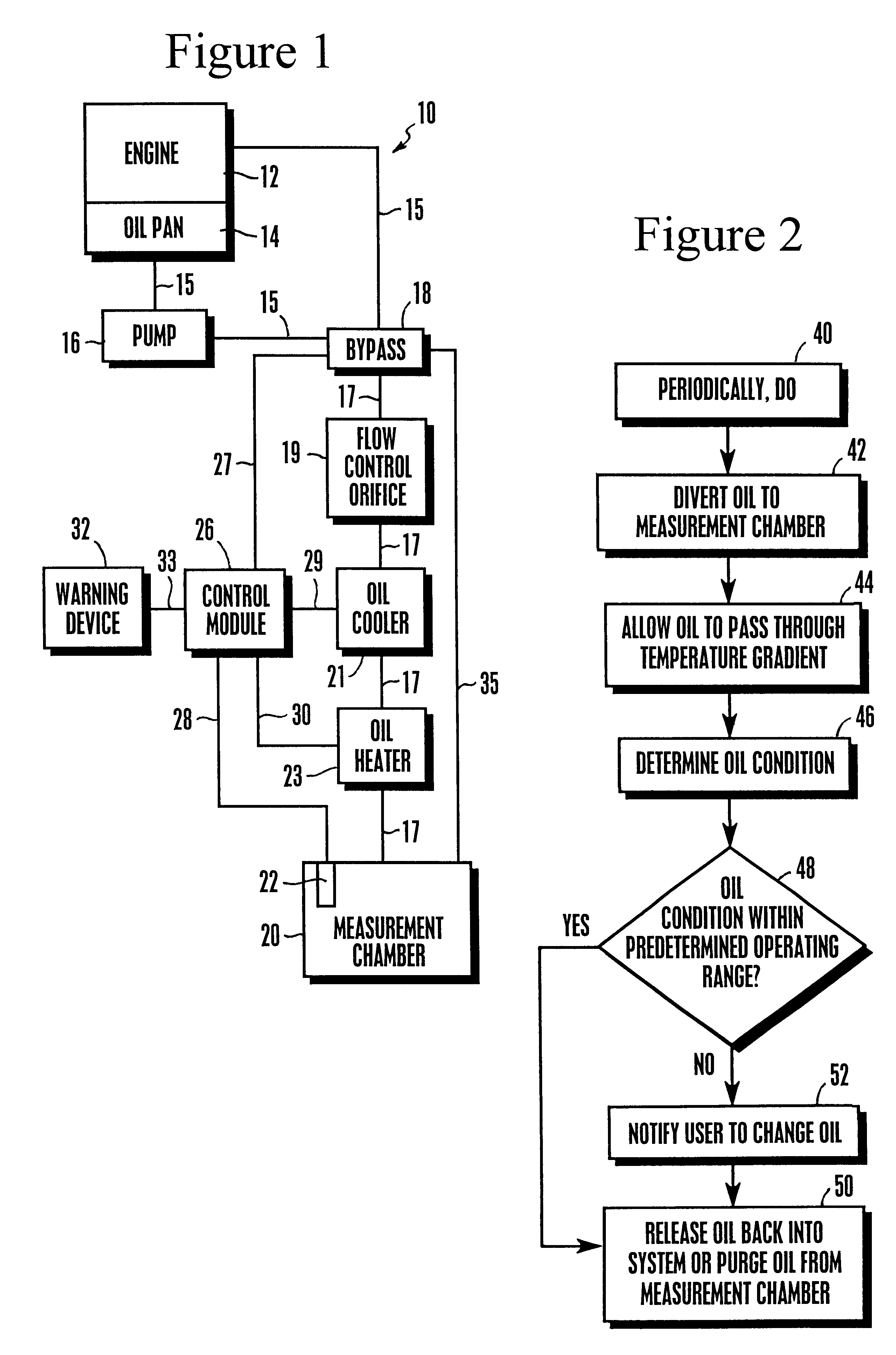

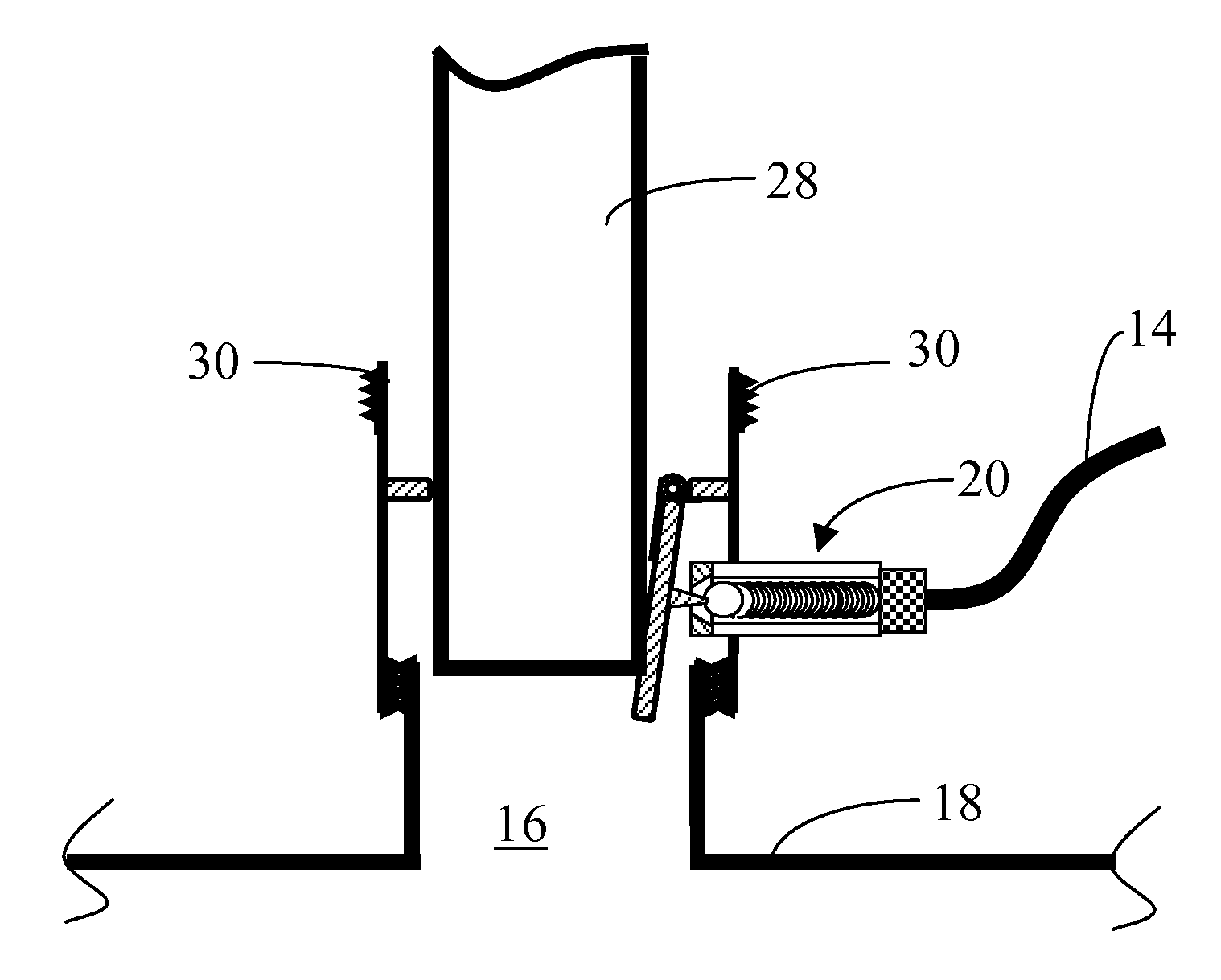

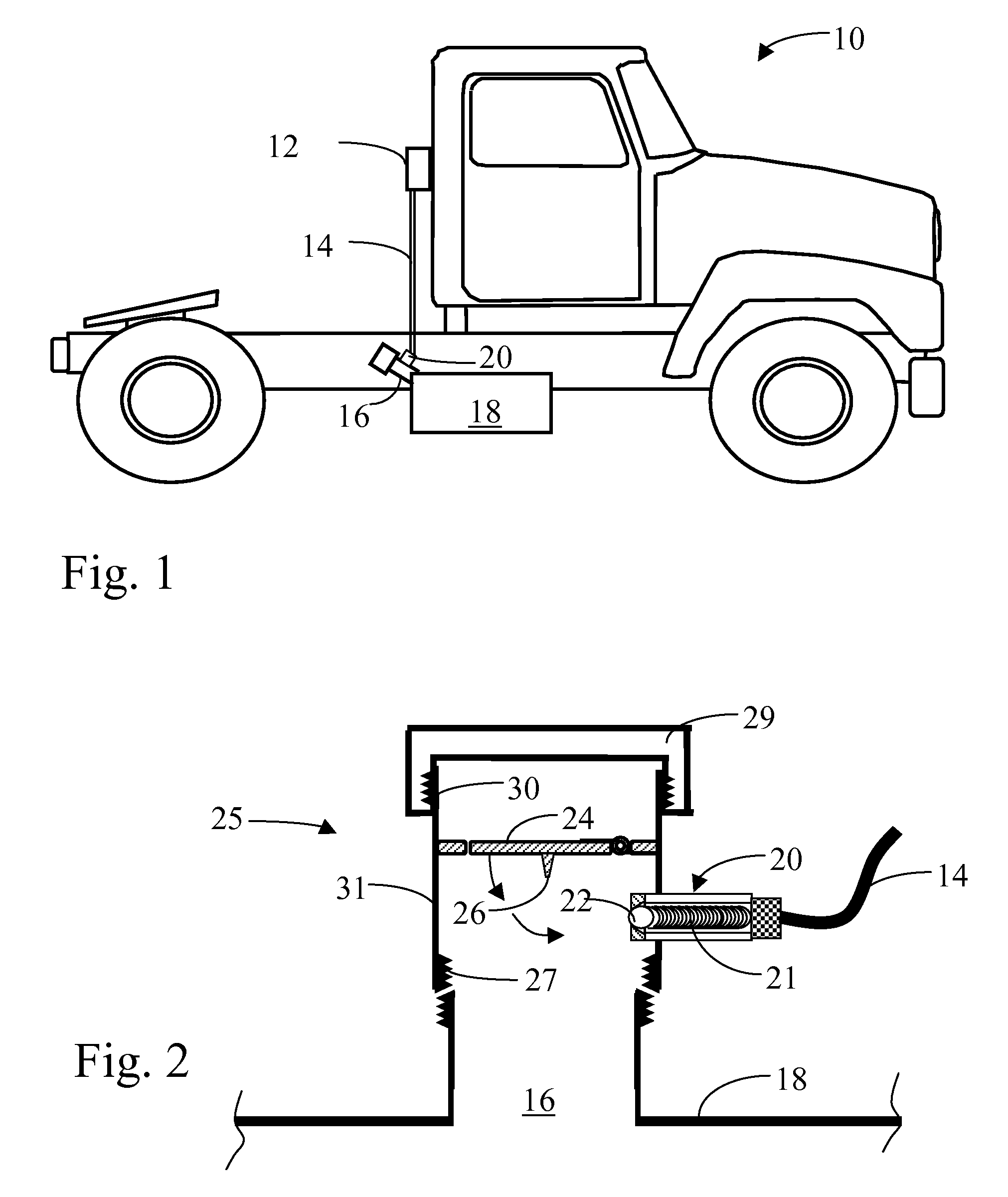

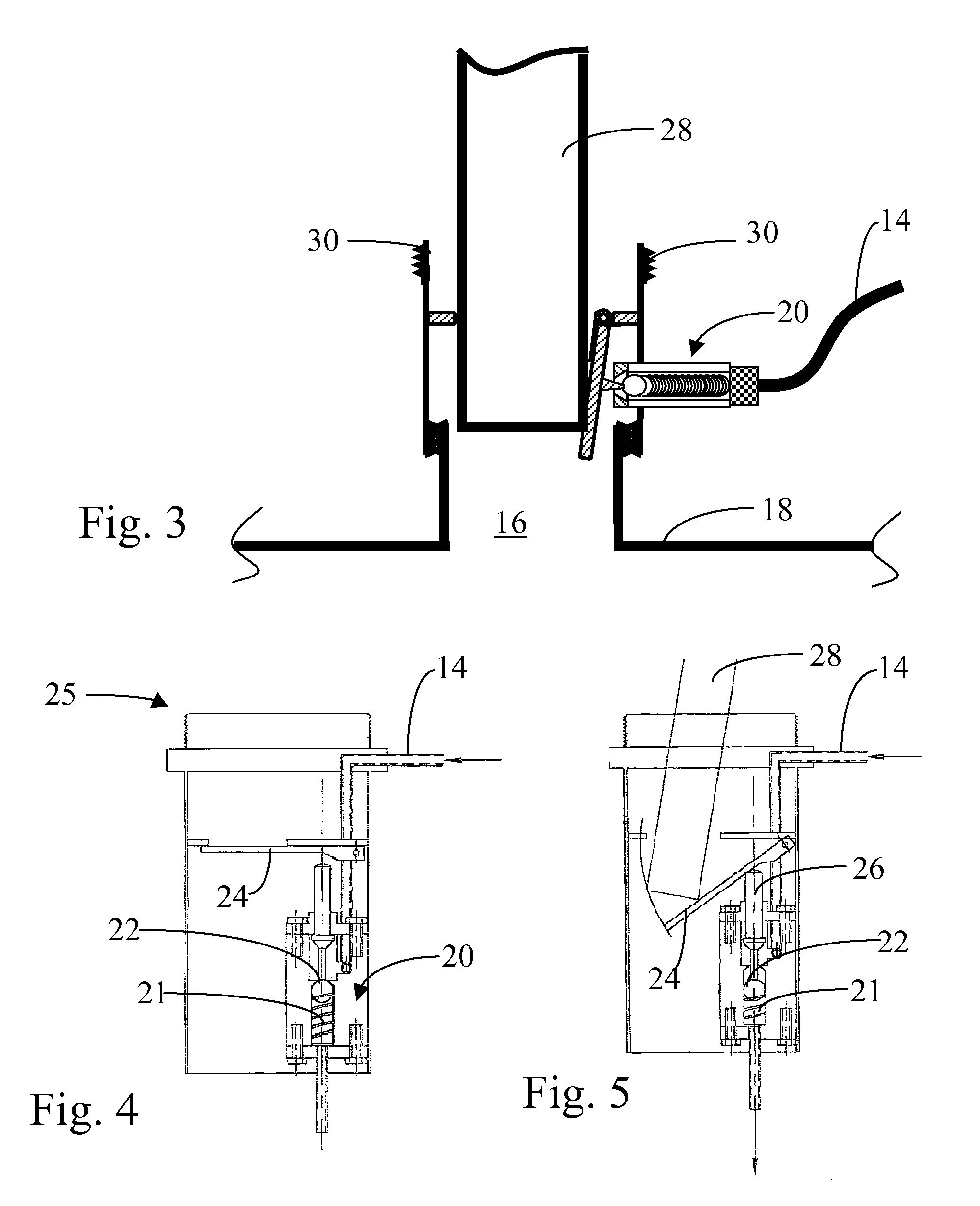

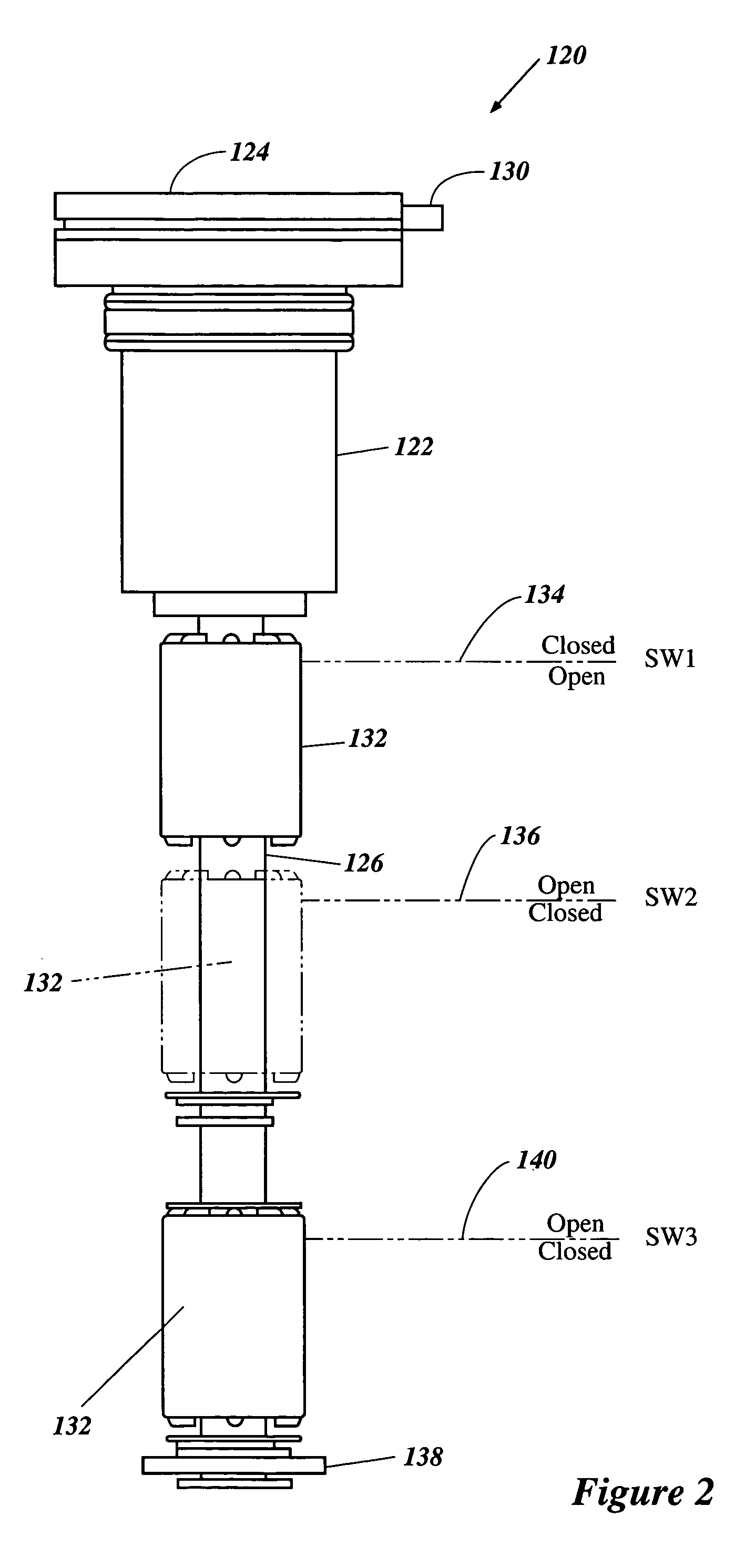

System and method for measuring oil condition in large engines

A system for measuring oil condition in large engines includes a bypass valve that is installed in a lubrication system along a fluid line between an oil pan and an engine. The bypass valve communicates with a measurement chamber and when energized by a control module, the bypass valve diverts oil from the lubrication system to the measurement chamber. An oil condition sensor is disposed within the measurement chamber and is used to determine the condition of the oil that is diverted to the chamber. After the condition of the oil is determined, the bypass valve is energized to release the oil from the measurement chamber back into the lubrication system.

Owner:DELPHI TECH INC

Gravity feed ball-in-seat valve with extension unit for dosing fuel additives

InactiveUS7216681B2Easy to operateEmission reductionLiquid fillingCombustion enginesFuel tankEngineering

A simple, reliable system is provided for automatically dosing vehicle fuel tanks with a fuel additive, particularly a concentrate containing a fuel borne catalyst (FBC), using gravity as the means of injection, preferably with no electronics or complex mechanical parts. The system includes a supply line for feeding fuel additive by gravity from an additive reservoir and opening into a filler spout of a fuel tank, a ball-in-seat valve at the end of the supply line biased in normally closed position and operable to an open position by mechanically pressing a release on the ball-in-seat valve, and a pivotable lever positioned within the filler spout and including a projection capable of mating with the ball-in-seat valve release upon pivotable movement. Upon insertion of a filler hose into the filler spout, the filler hose moves the lever and projection to press the release on the ball-in-seat valve thereby dispensing additive.

Owner:CLEAN DIESEL TECHNOLOGIES

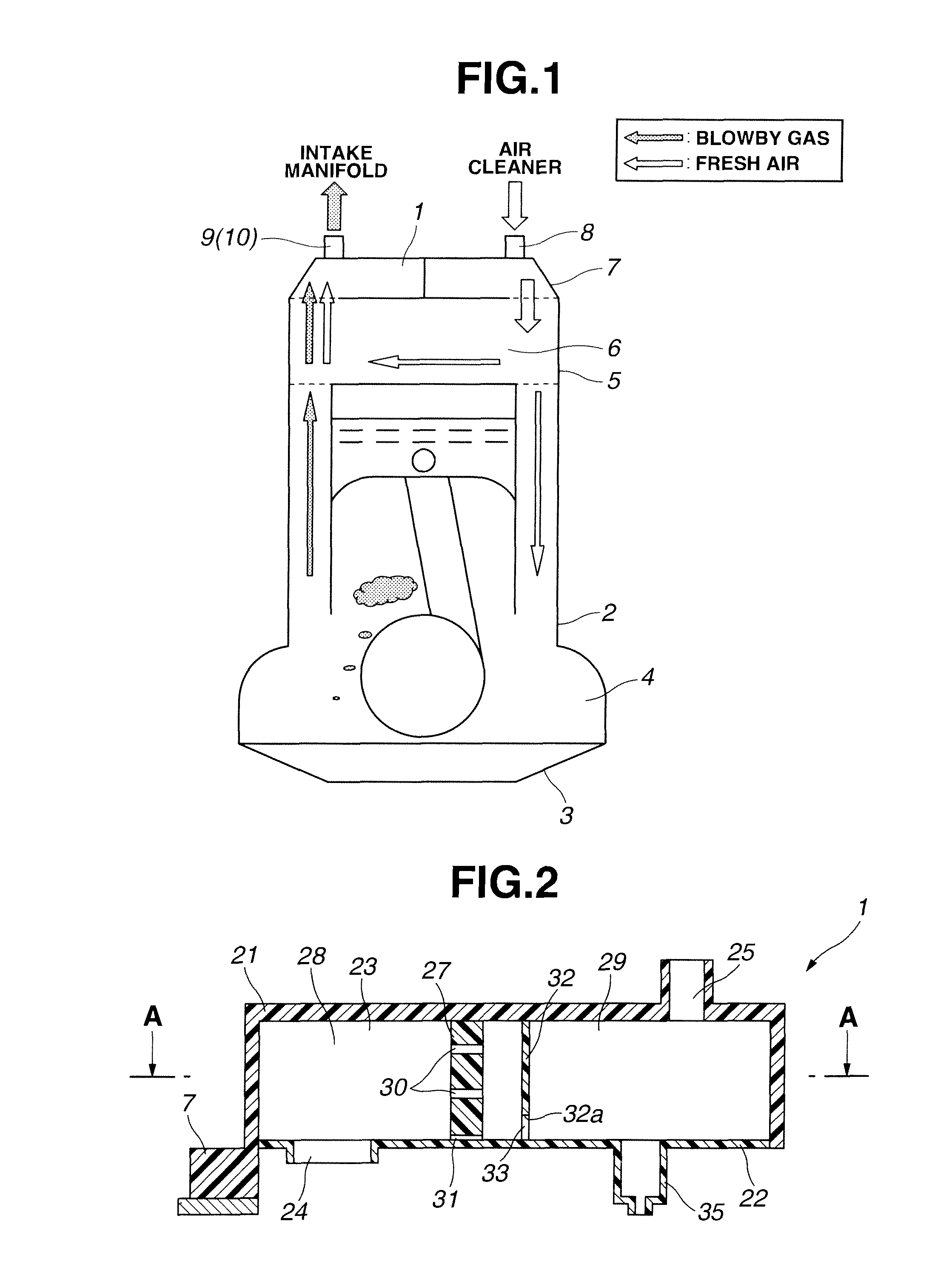

Structural oil baffle for engine covers

ActiveUS20100147235A1Improve structural rigidityReducing cover surface vibrationCasingsValve drivesCylinder headOil separation

An oil baffle, a system, and a method are disclosed for separating a gaseous component from oil in a blow-by vapor for an internal combustion engine. An example system may include a cam cover configured to be mounted on a cylinder head. The system may also include an oil baffle that may have a generally planar body with a first face and a second face opposite the first face. The first face may be coupled to the cam cover and may define an oil separation chamber between the cam cover and the first face. The oil baffle may include one or more stiffening members coupled to and extending from and substantially normal to the second face.

Owner:FORD GLOBAL TECH LLC

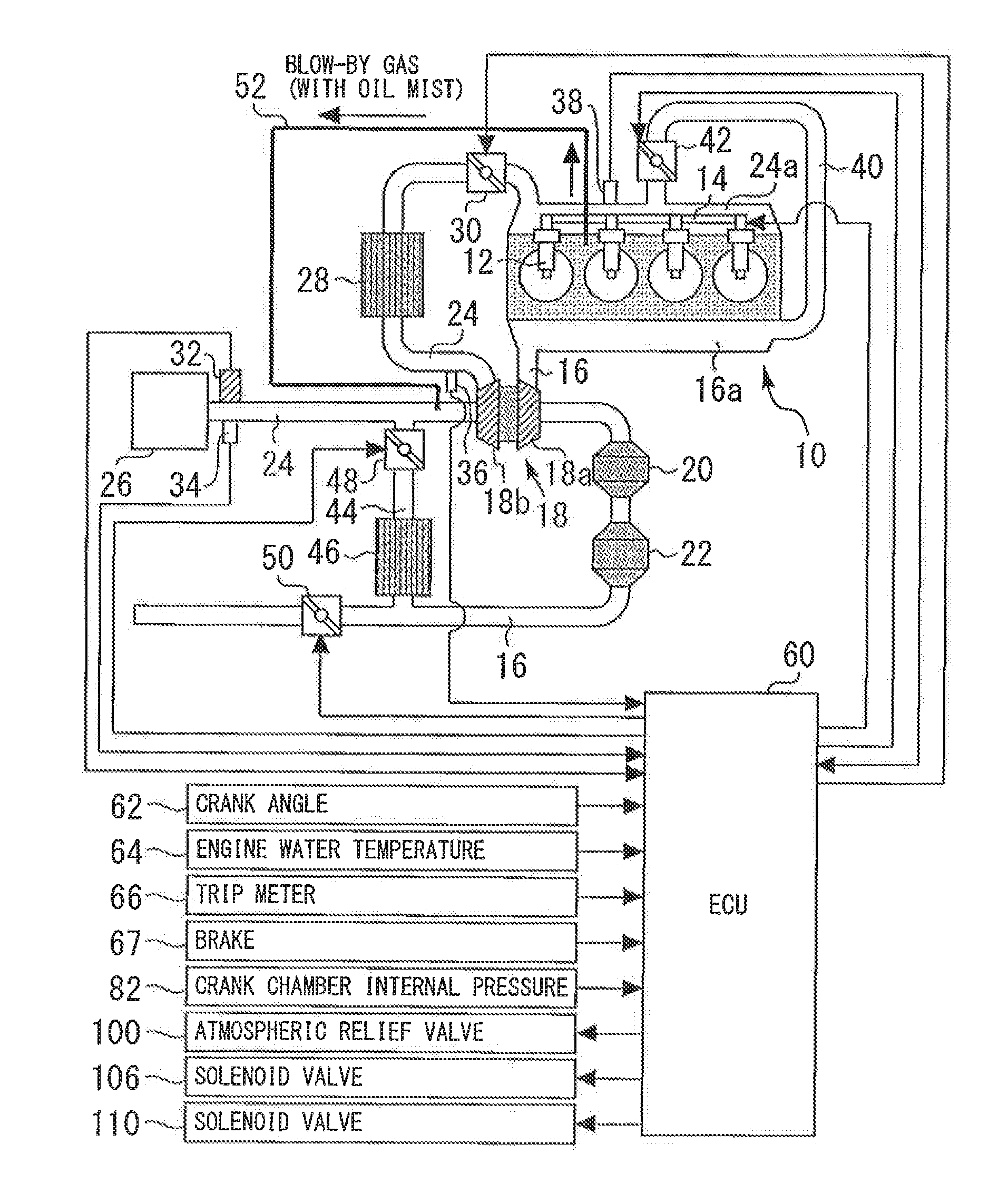

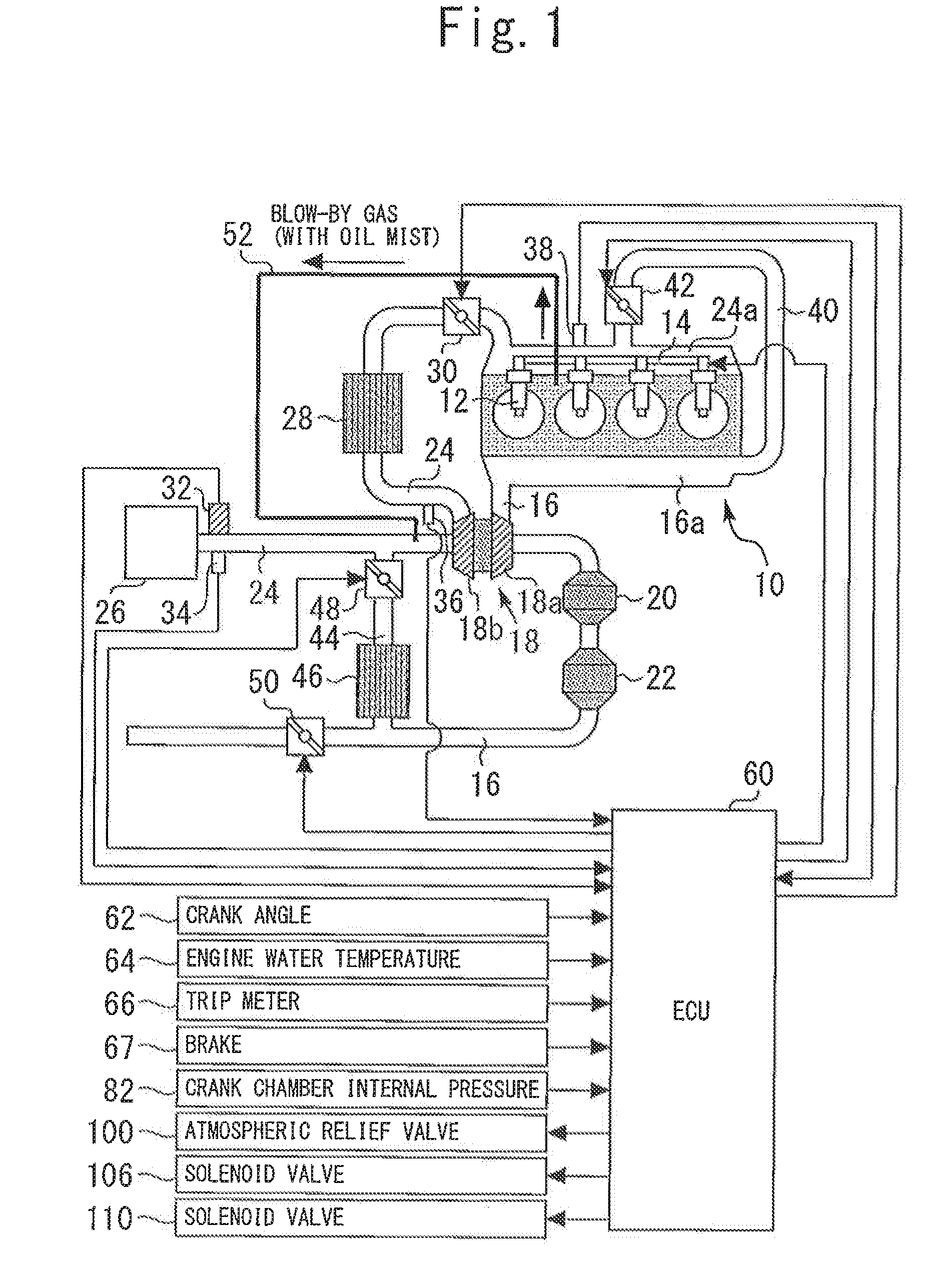

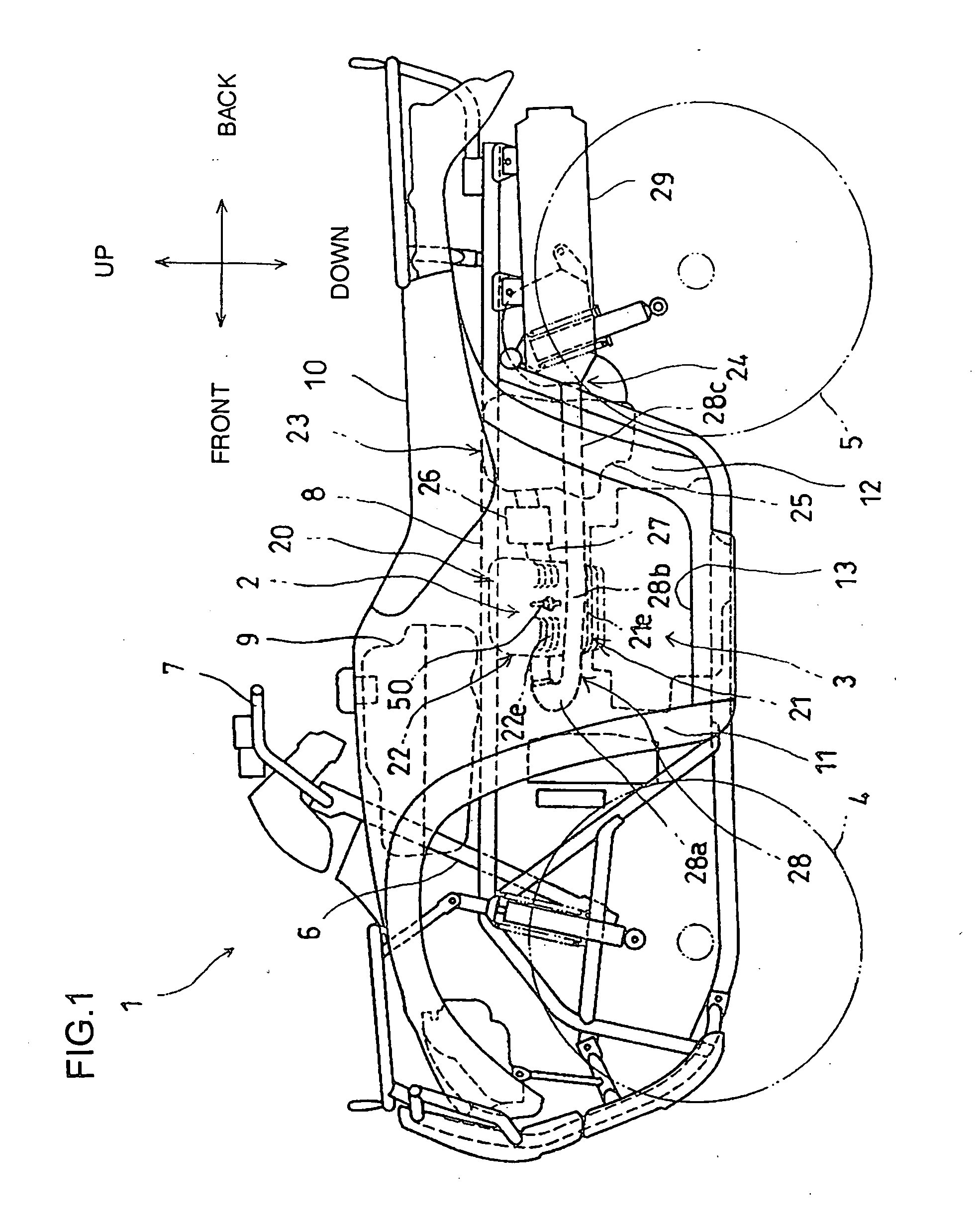

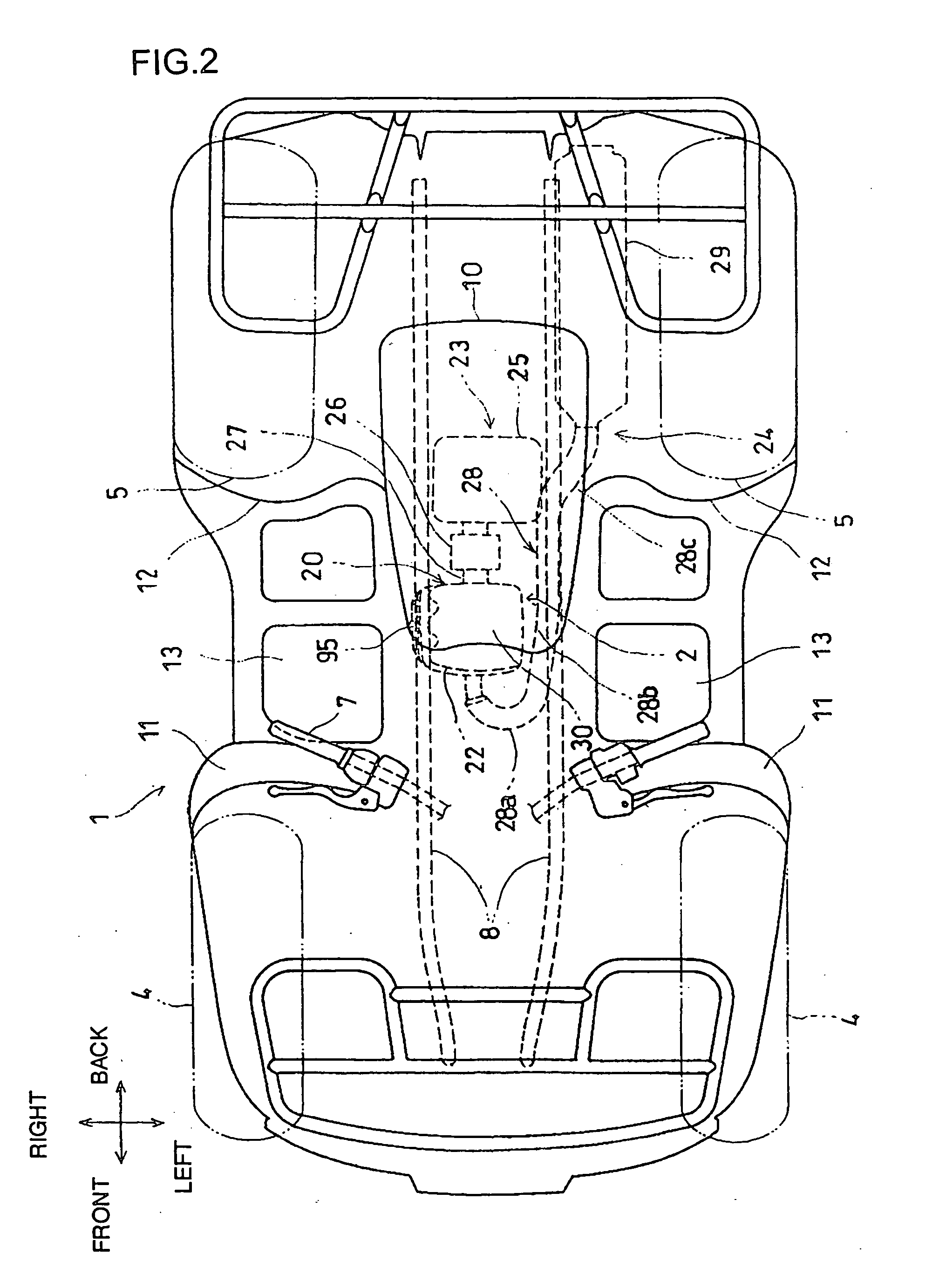

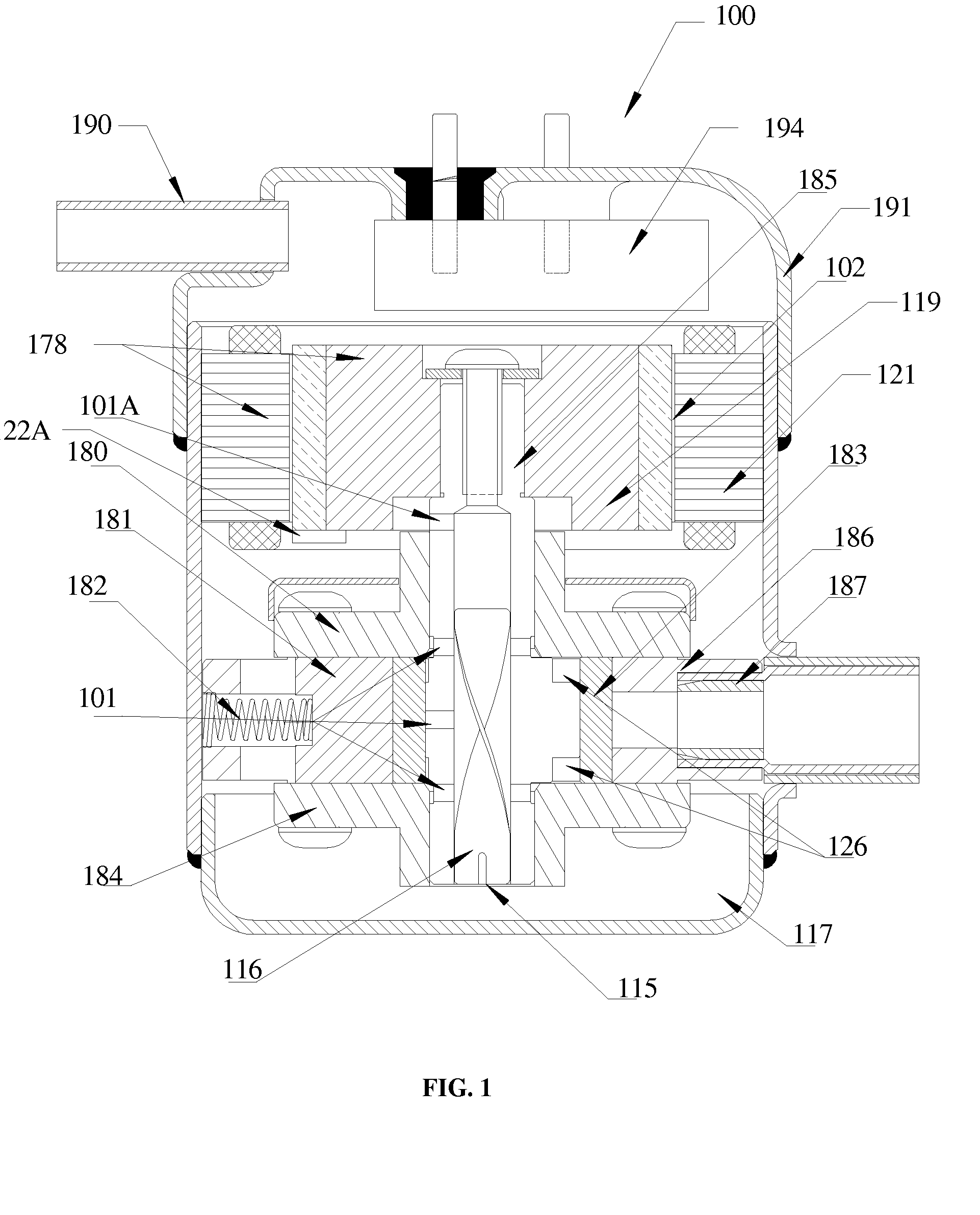

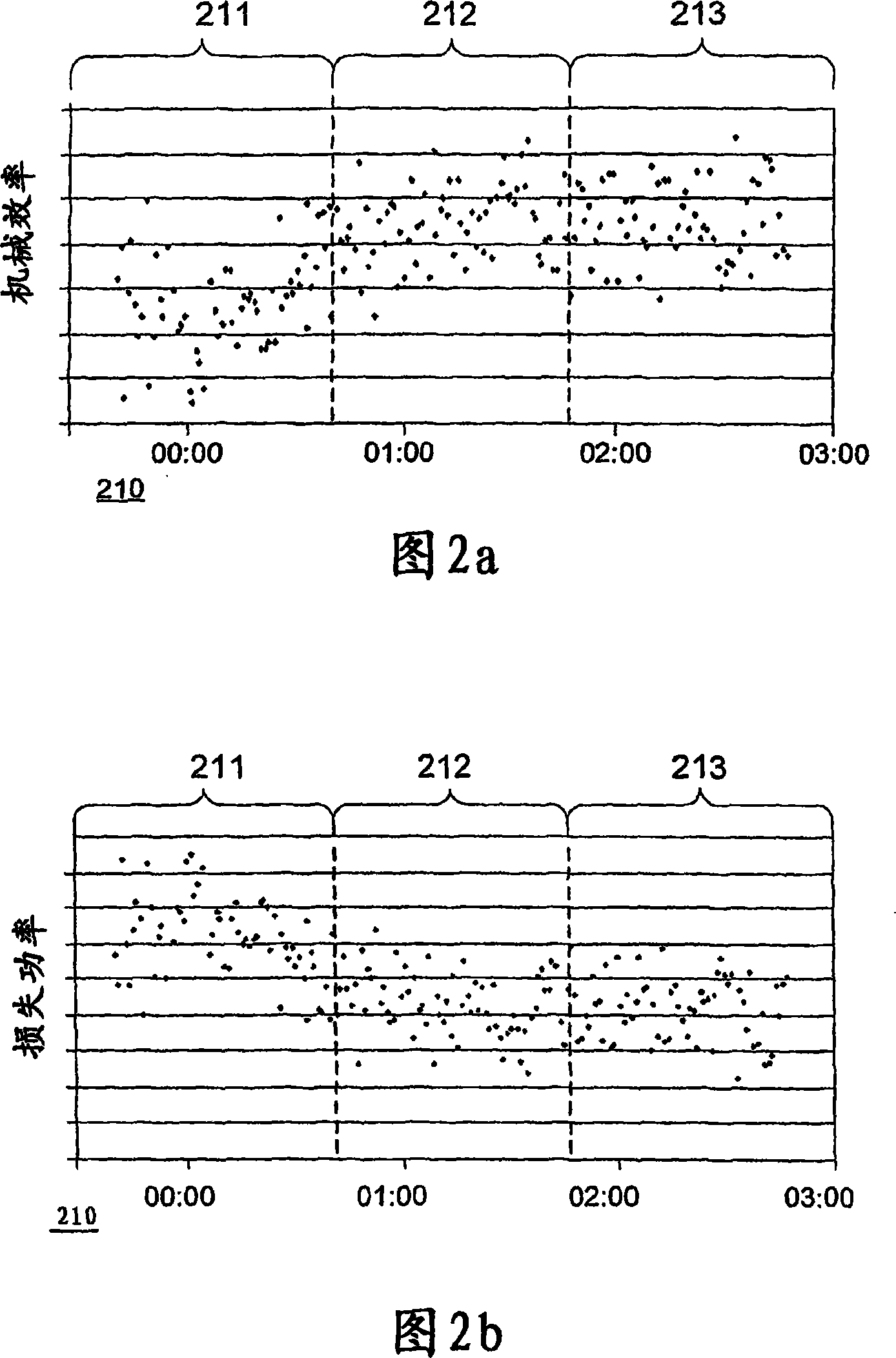

Lubrication system for two-cycle engine

An engine has a lubrication system configured to lubricate at least a portion of the engine with lubricant. The lubrication system has a lubrication pump that periodically pressurizes the lubricant toward the portion of the engine. A first sensor senses an engine speed. A second sensor senses an engine load. A third sensor senses a temperature of the lubricant or the engine. A control device controls the lubrication pump. The control device determines a frequency of periodic pressurization by the lubrication pump based upon outputs from the first and second sensors. The control device determines a pressurization time of the lubrication pump based upon at least one of outputs from the first, second and third sensors.

Owner:YAMAHA MARINE KK

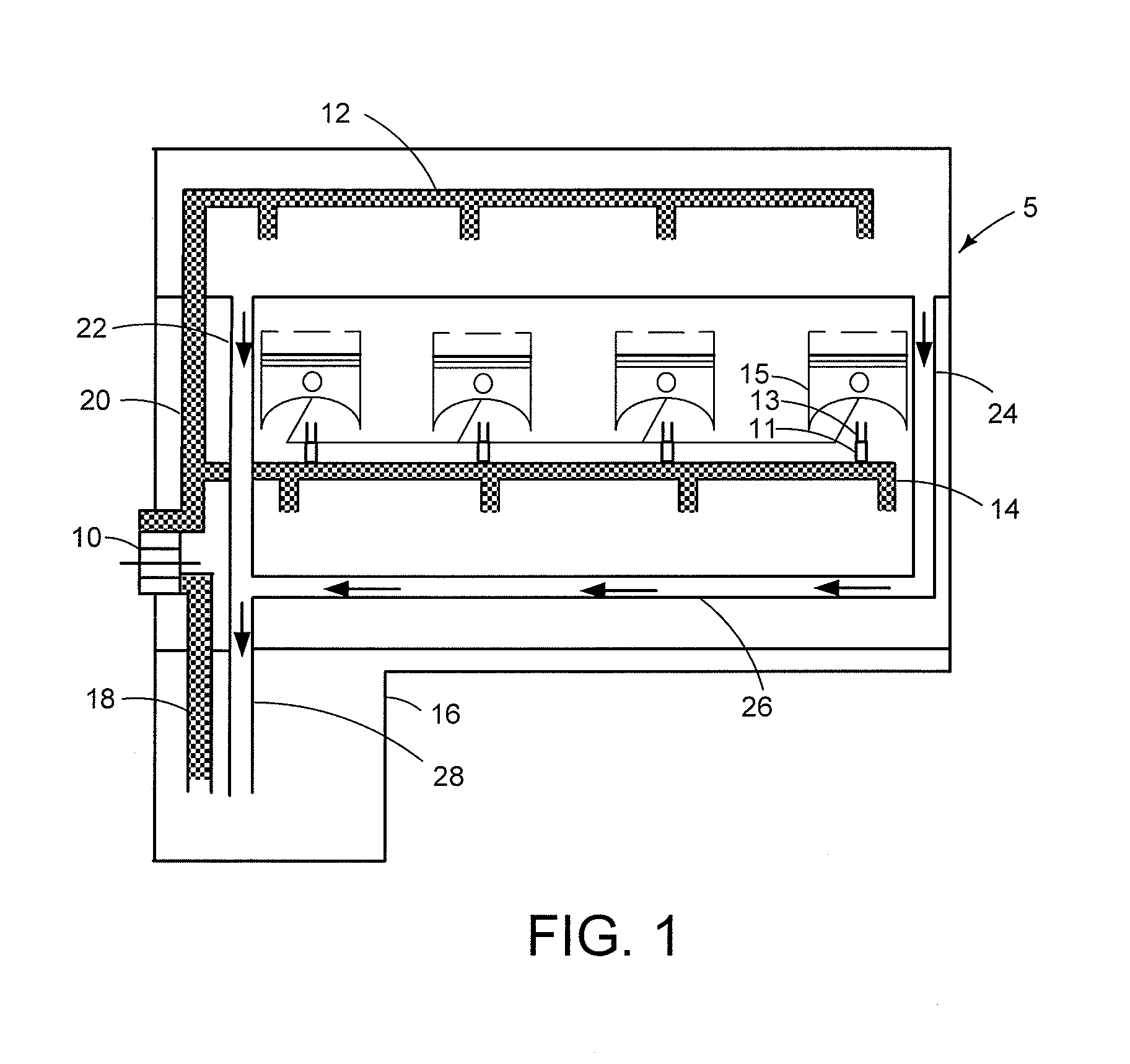

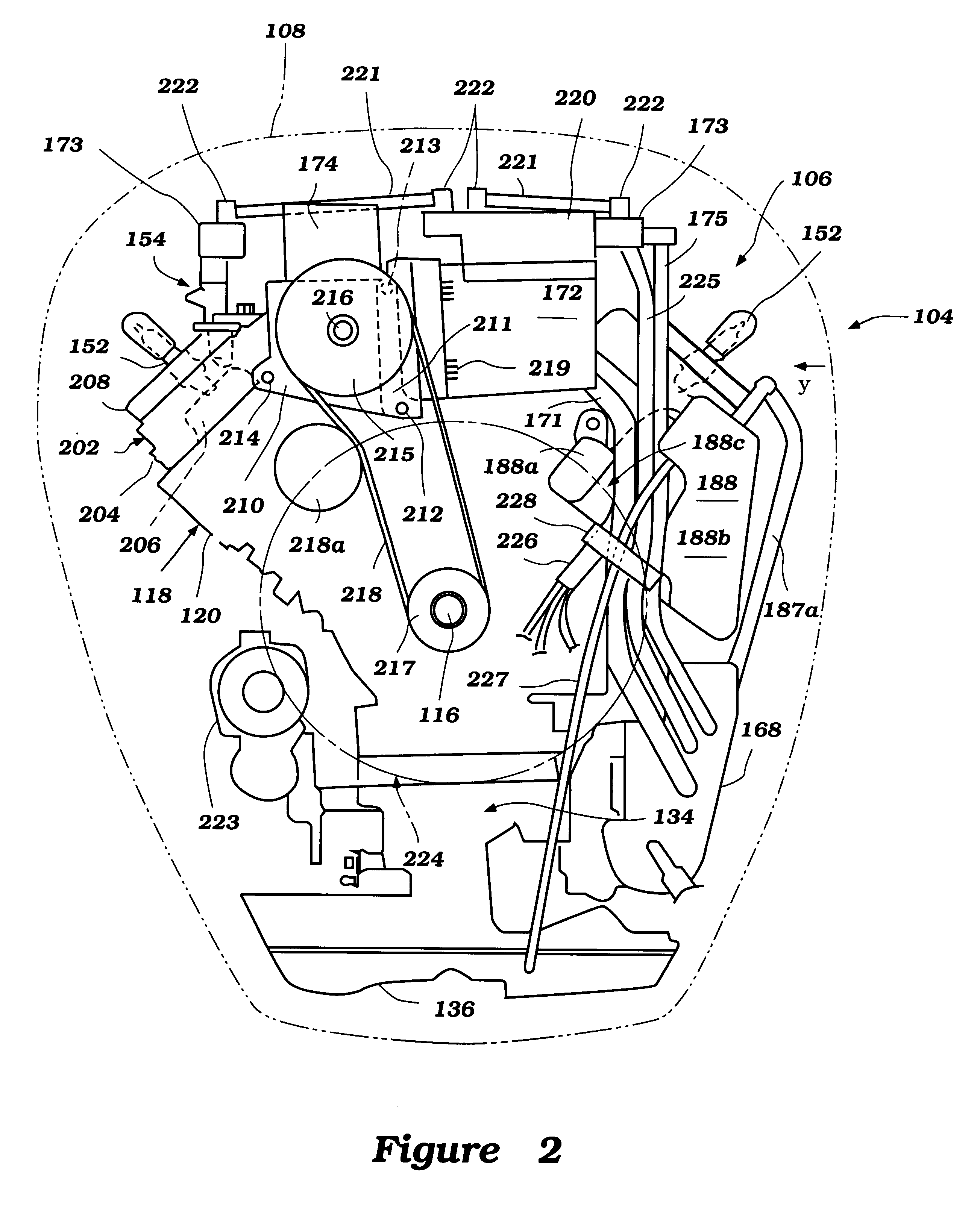

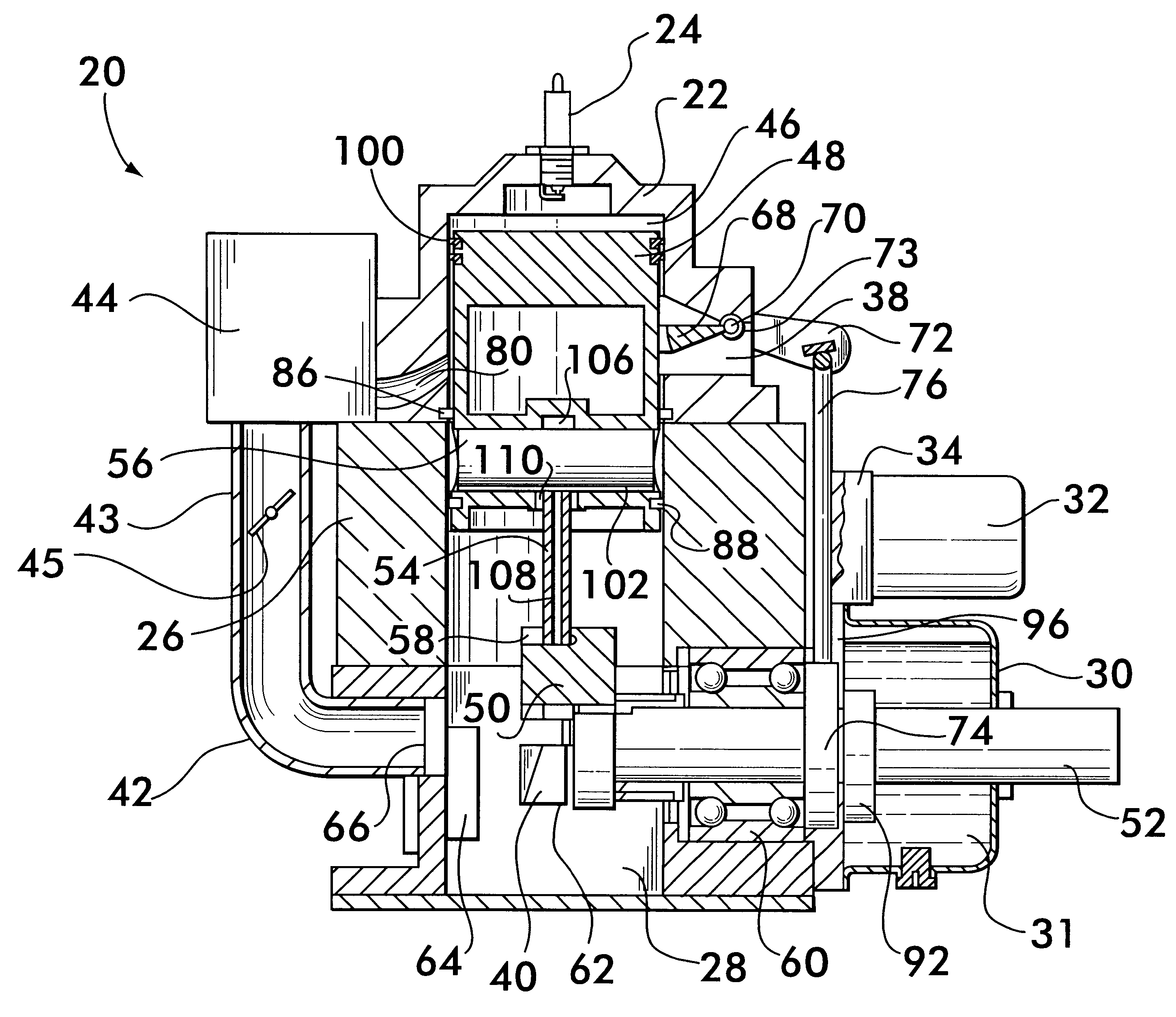

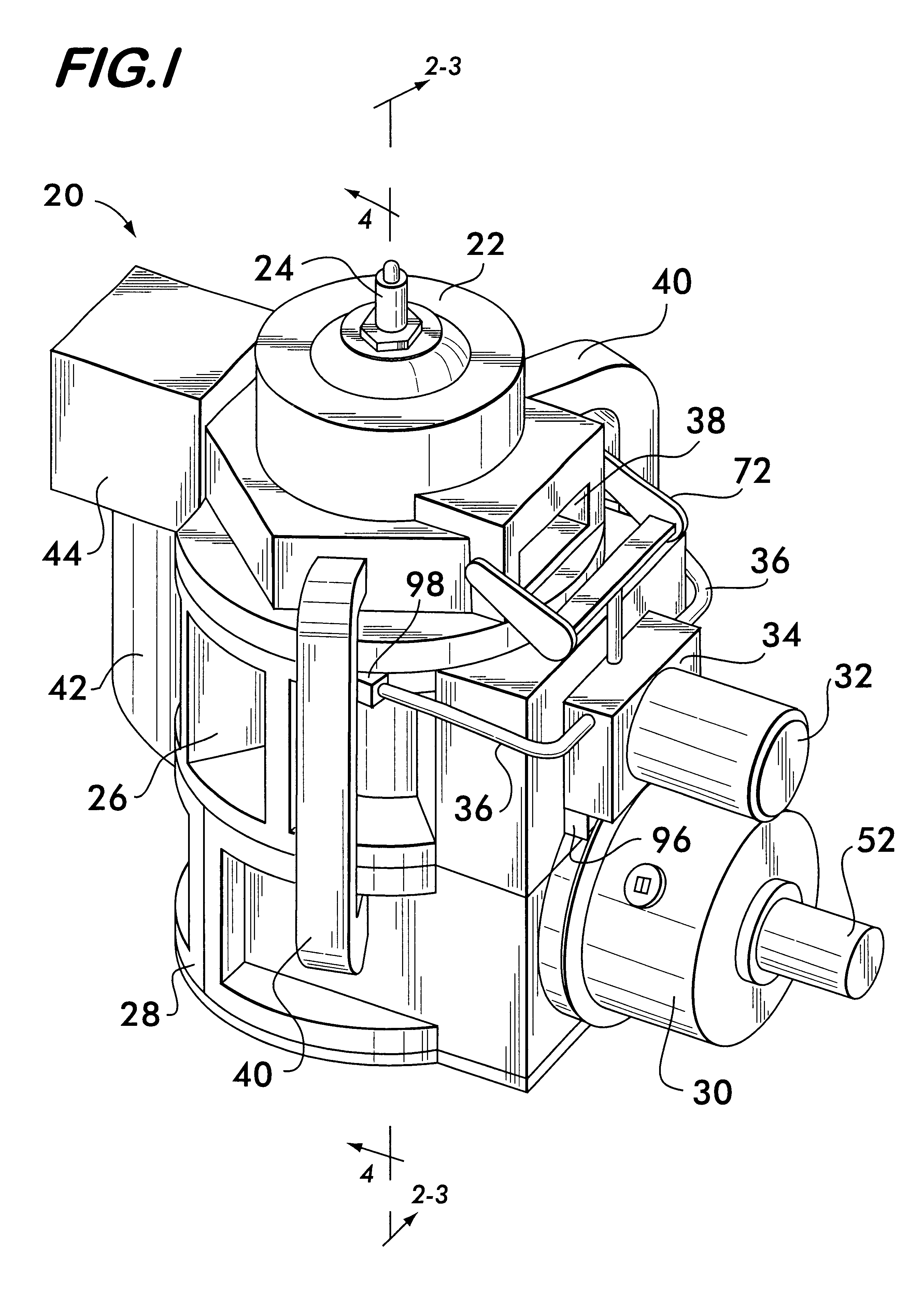

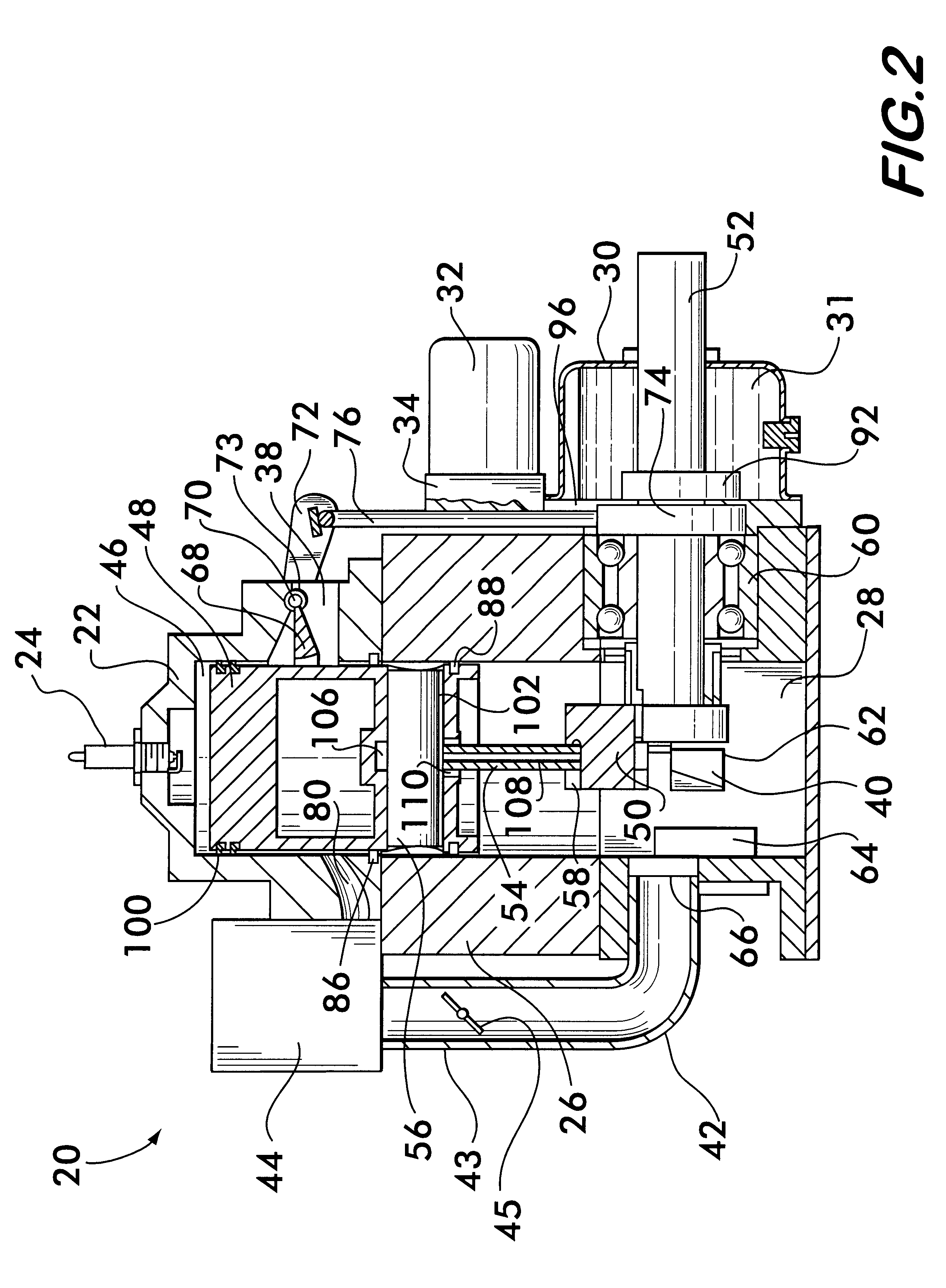

Orientation and gravity insensitive in-casing oil management system for fluid displacement devices, and methods related thereto

InactiveUS20080078618A1Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeAviationElectronics cooling

Disclosed is a pressurized internal oil management system, comprising an oil dam, at least one oil separator, at least one oil collection manifold, at least one oil pump, and one or more paths for returning the separated oil; said system integrated within the casing of a fluid displacement device to supply adequate lubrication regardless of orientations under zero to full gravity, and methods and applications related thereto. Fluid displacement devices useful herein include oil lubricated rotary or reciprocating machinery, such as compressors, expanders, pumps and engines, in the casing of which exists one or more drive mechanisms that can be utilized to operate the oil management system, in most cases without even increasing the size of the casing. The present invention is especially useful for applications where small size and low weight of the fluid displacement device or the system containing it are important, such as personal or electronic cooling systems in terrestrial mobile applications or various cooling systems in aerospace applications.

Owner:ASPEN COMPRESSOR

Oil injection lubrication system for two-cycle engines

InactiveUS6374781B1Reduced deposit formationAvoid corrosionCombustion enginesLubrication pressure controlControl signalSolenoid valve

The invention provides an improved oil injection lubrication system for two-cycle engines. The system includes a variable output oil pump, the output of which can be varied in relation to the throttle level. The system also includes a solenoid valve unit containing a plurality of solenoid valves that further regulates the flow of oil from the oil pump to each cylinder. An electronic control unit sends control signals to the soleniod valve unit to regulate the flow of oil based upon engine operating conditions in accordance with a controle scheme. The combination of the variable output oil pump and the solenoid valve unit enables the solenoid valves to be activated with a lighter duty cycle, which reduces the amount of power consumed by the solenoid valve unit.

Owner:SANSHIN KOGYO CO LTD

Lubrication supply control system

An engine has a lubrication system to lubricate at least a portion of the engine with lubricant. The lubrication system has a lubrication pump that periodically pressurizes the lubricant toward the portion of the engine. A first sensor senses an engine speed. A second sensor senses an engine load. A third sensor senses a temperature of the lubricant or the engine. A control device controls the lubrication pump. The control device determines a frequency of periodic pressurization by the lubrication pump based upon outputs from the first and second sensors. The control device determines a pressurization time of the lubrication pump based upon at least one of outputs from the first sensor, second sensor, third sensor, and a battery voltage.

Owner:YAMAHA MARINE KK

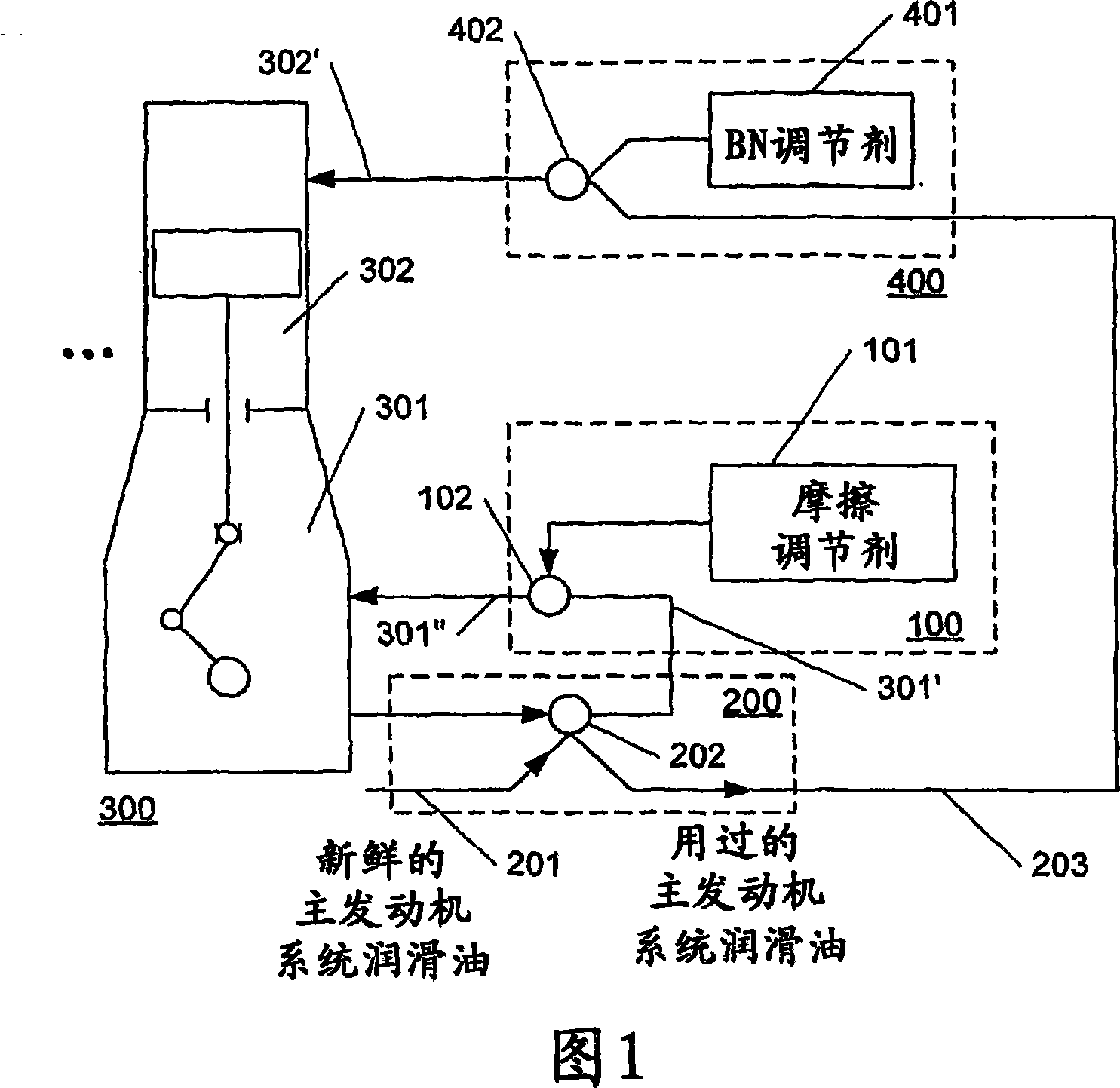

Method and system for improving fuel economy and environmental impact operating a 2-stroke engine

ActiveCN101115911AReduce frictionLong operating timeMachines/enginesLubricant compositionEngine efficiencyEnvironmental effect

The invention relates to a method and a corresponding system for reducing fuel consumption and environmental impact in a two-stroke engine, comprising the steps of obtaining system oil / consumable system oil (301') from at least one engine (300), supplying Adding (102) at least one friction modifier (101) to at least part of the resulting system oil / consumable system oil (301'), wherein the addition of the at least one friction modifier (101) reduces the resulting system The coefficient of friction of the lubricating oil / consumable system lubricating oil (301′), forming a system lubricating oil / consumable system lubricating oil (301″) with reduced friction, and combining said lubricating oil / consumable system lubricating oil with reduced friction Lubricating oil (301") is provided to said at least one engine (300). In this way, frictional losses due to system oil / consumable system oil contamination, which normally occur when the oil is used and cause a continuous reduction in engine efficiency, resulting in fuel consumption and Emissions increase. Furthermore, the invention relates to a method and a corresponding system for converting system oil / consumable system oil into cylinder oil. Finally, the invention relates to a method of using consumable system oil when said oil is converted into cylinder oil. This further allows consumable system oils to contain lower performance additive packages and / or lower additive treat ratios. Large economic savings and environmental improvements are thus obtained.

Owner:A P MOLLER AS

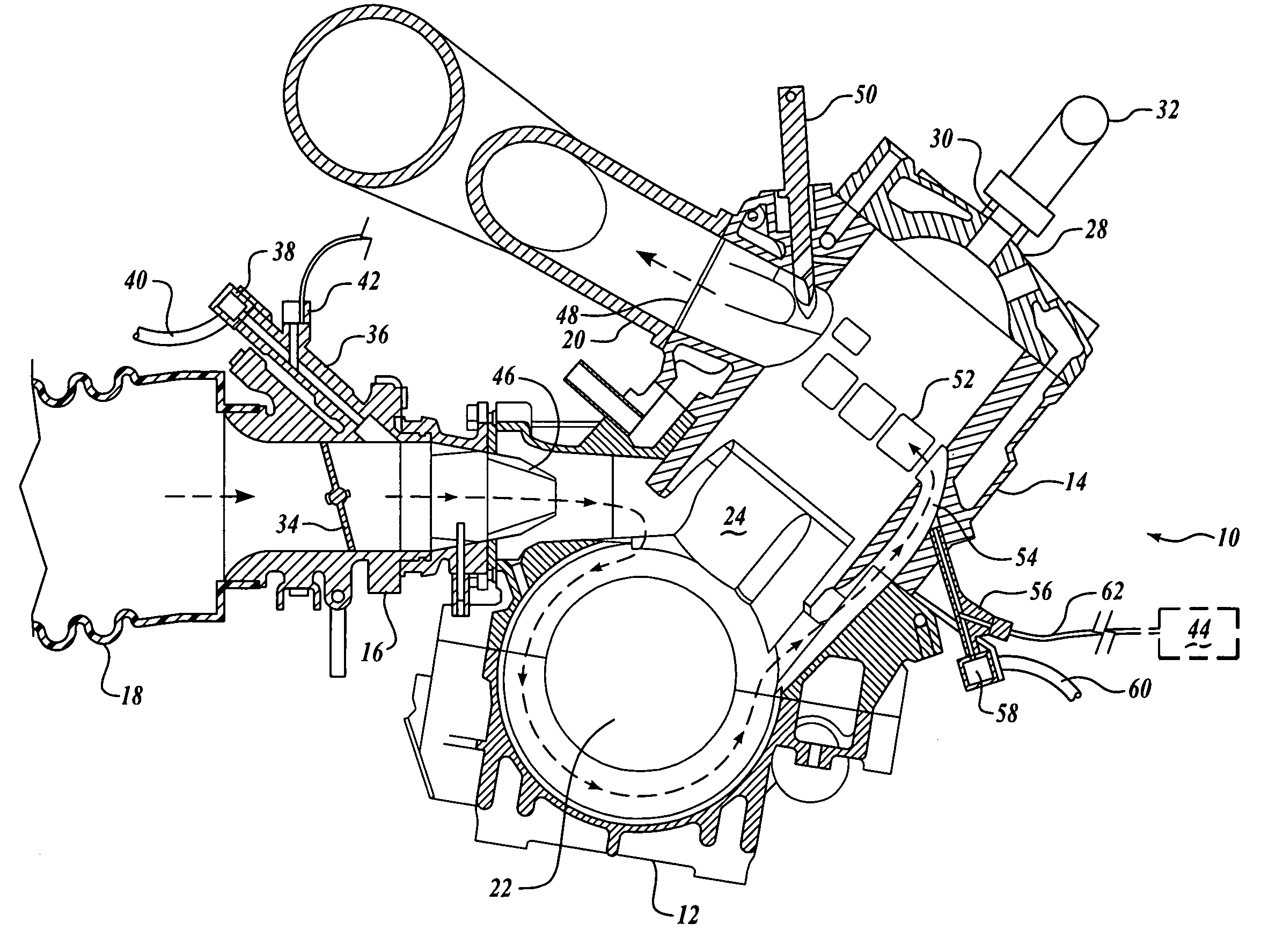

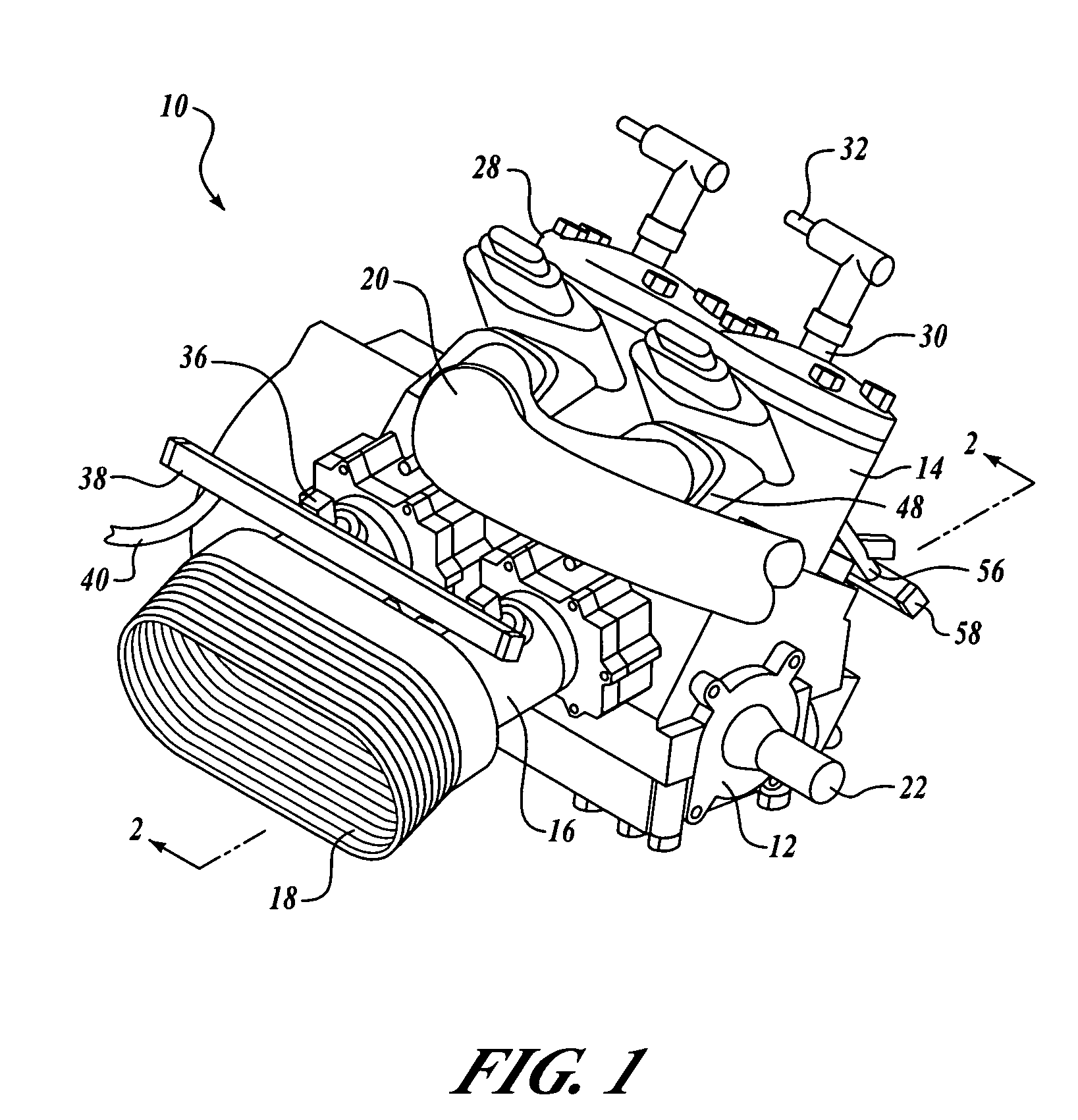

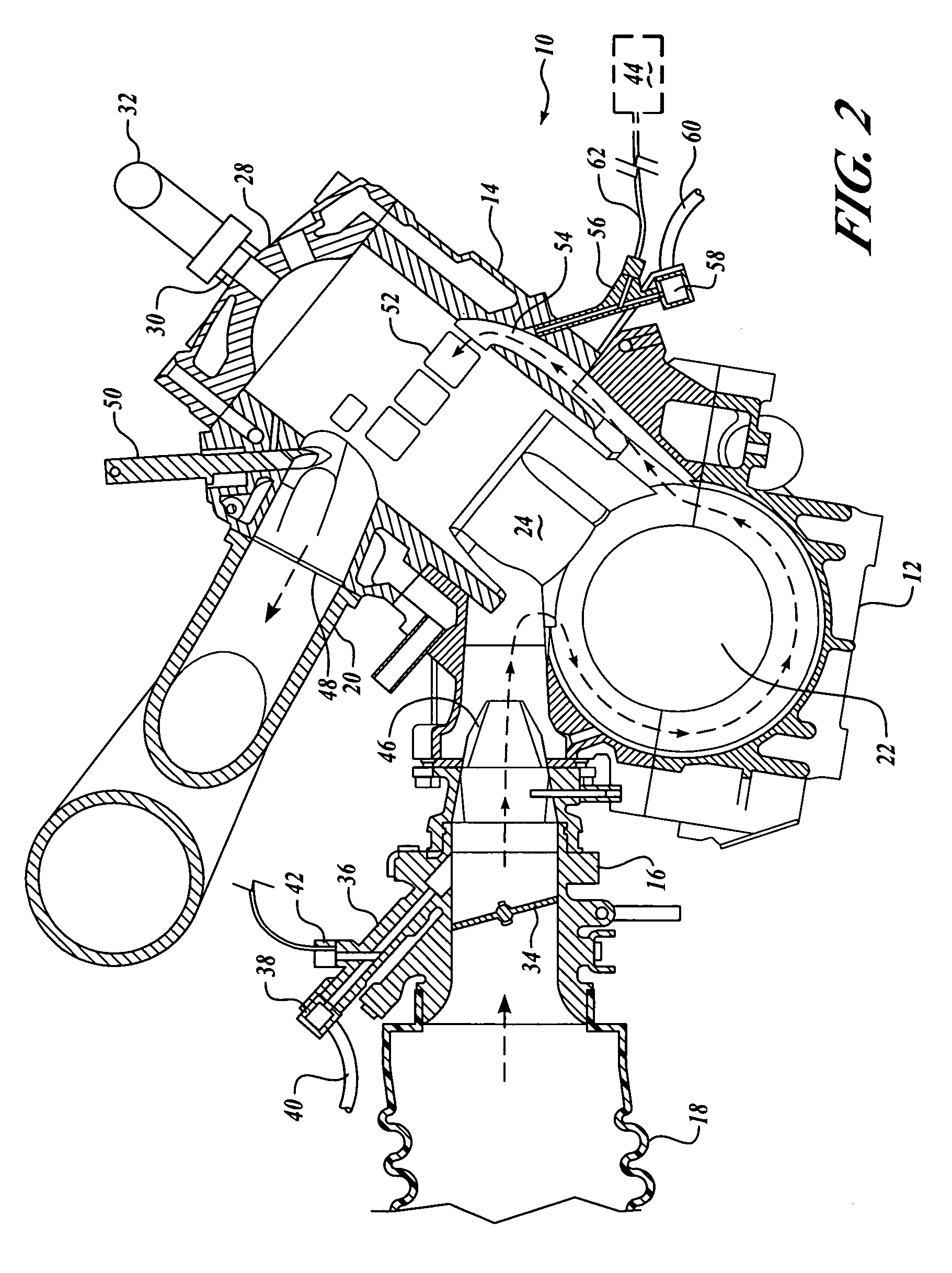

Engine with dry sump lubrication, separated scavenging and charging air flows and variable exhaust port timing

InactiveUS6397795B2Emission reductionImprove efficiencyCylinder headsOutput powerEngineeringCylinder block

An engine is disclosed having an improved lubrication system and scavenging system. An oil sleeve is positioned between the cylinder and the crankcase, the sleeve having a bore sized to receive the piston. The piston and sleeve define an annular oil space which is connected to a reservoir by oil lines. A fixed seal is positioned surrounding the piston between the cylinder and the oil sleeve. A movable seal is mounted on and surrounds the piston. On the power stroke the movable seal moves away from the fixed seal, drawing oil from the reservoir into the annular oil space. On the compression stroke, the movable seal moves toward the fixed seal, forcing the oil from the annular oil space into the piston wrist pin and through conduits to the crank and main bearings and then back to the reservoir. Separate scavenging and charging tubes connect the crankcase to the cylinder.

Owner:HARE NICHOLAS S

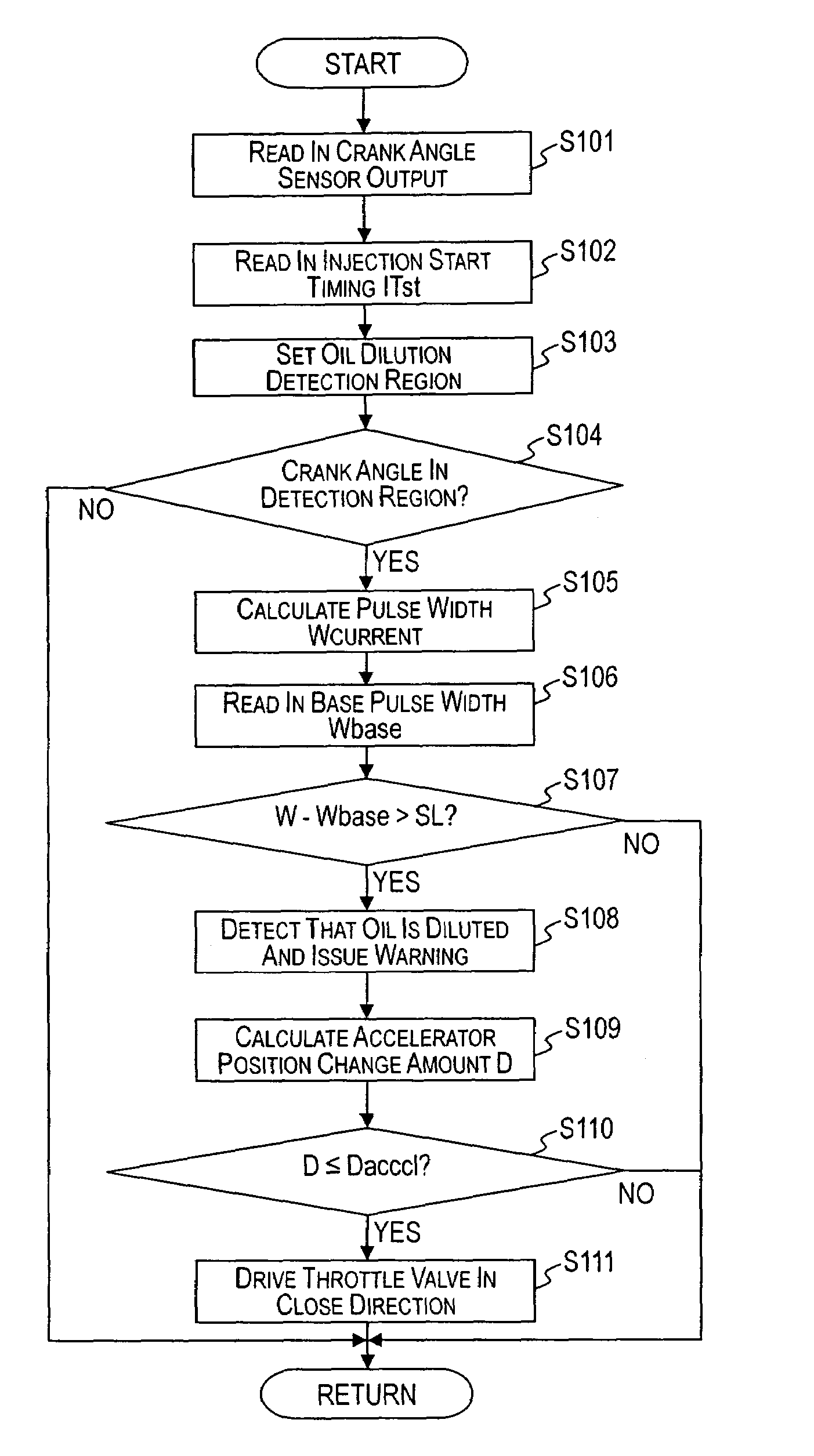

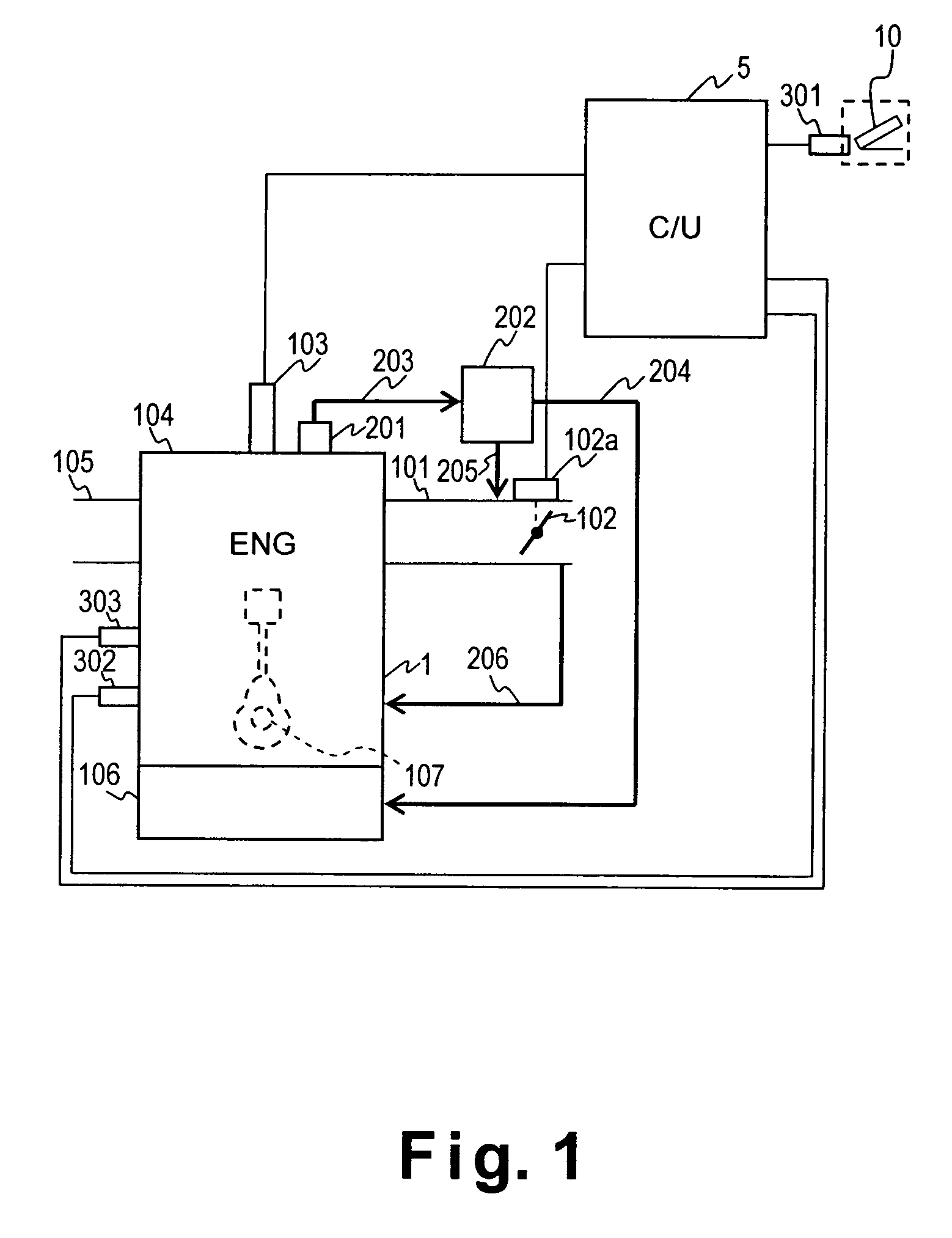

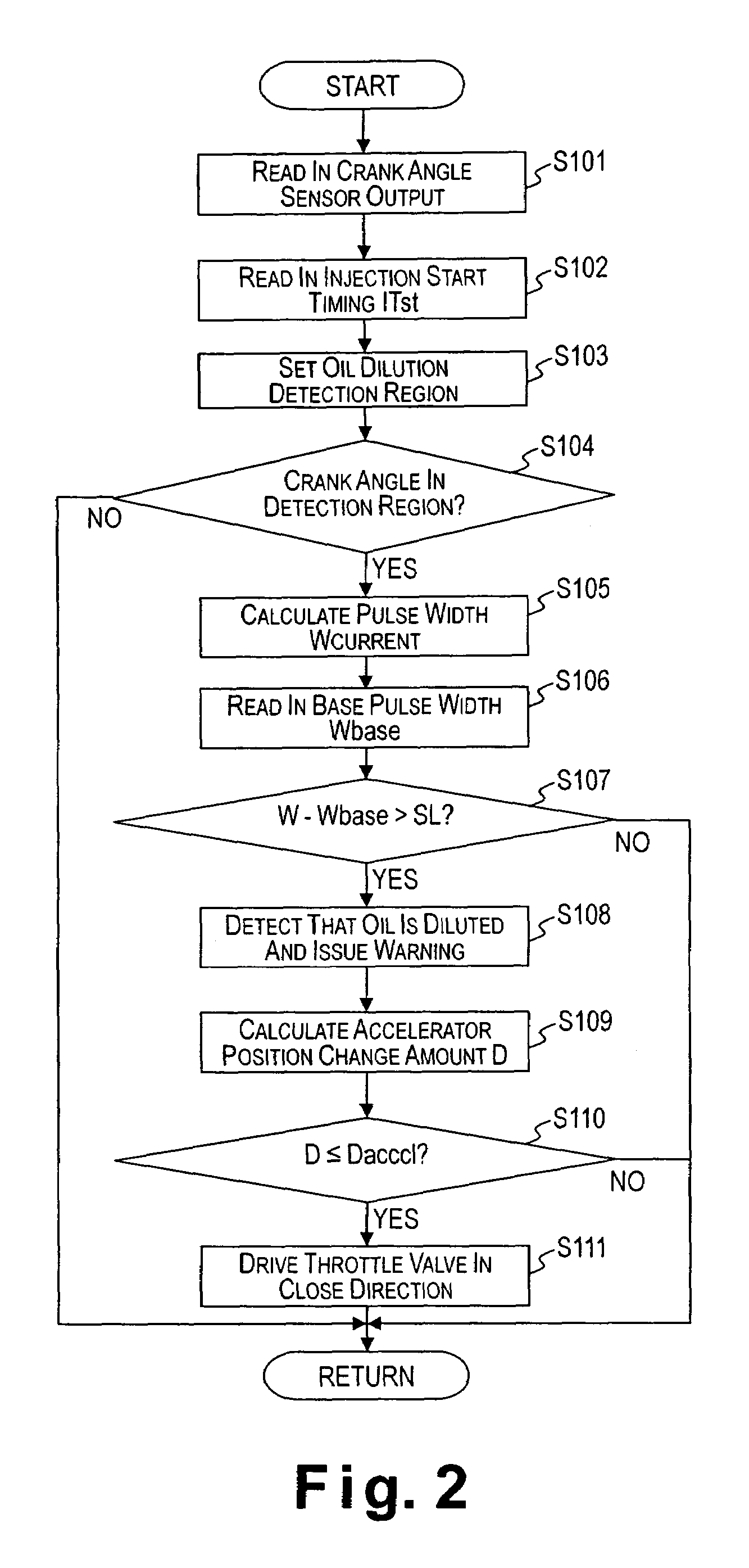

Diesel engine oil dilution managing device

Owner:NISSAN MOTOR CO LTD

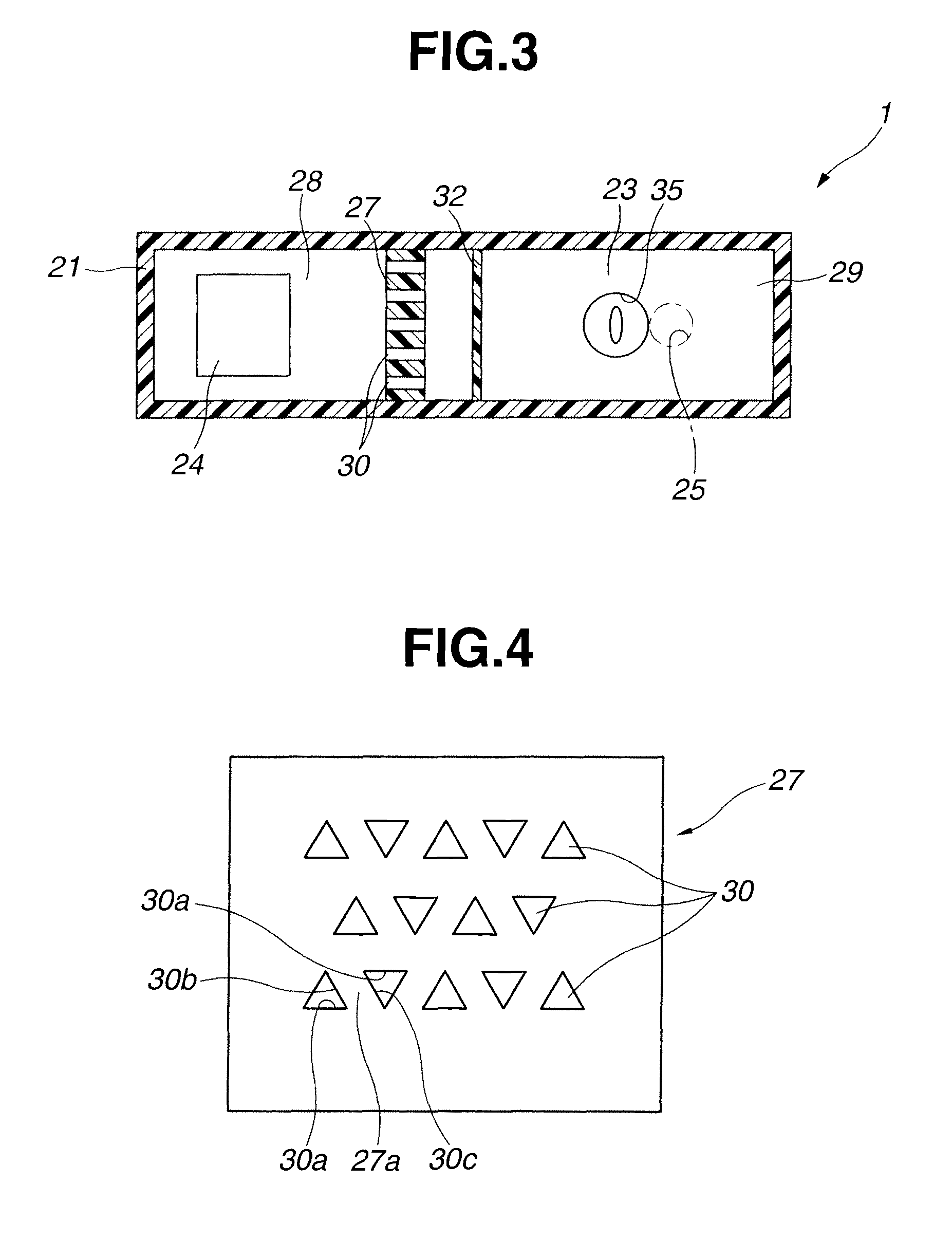

Oil separator for internal combustion engine

InactiveUS8726876B2Velocity increasesReduce the cross-sectional areaCombustion enginesPressure lubricationCylinder headExternal combustion engine

An oil separator disposed inside a cylinder head cover of an internal combustion engine. The oil separator includes a body section defining an elongate separator chamber and having a blowby gas inlet and a blowby gas outlet. A partition wall is disposed to divide the separator chamber into an inlet chamber at side of the blowby gas inlet and an outlet chamber at side of the blowby gas outlet. The partition wall is formed with a plurality of passage holes each of which is triangular in cross-section. A collision plate is disposed inside the outlet chamber and located opposite to the passage holes of the partition wall. A slit-like opening is defined by a lower section of the collision plate and communicated with a drain section for discharging oil separated from blowby gas into a valve operating chamber.

Owner:MAHLE FILTER SYST JAPAN CORP

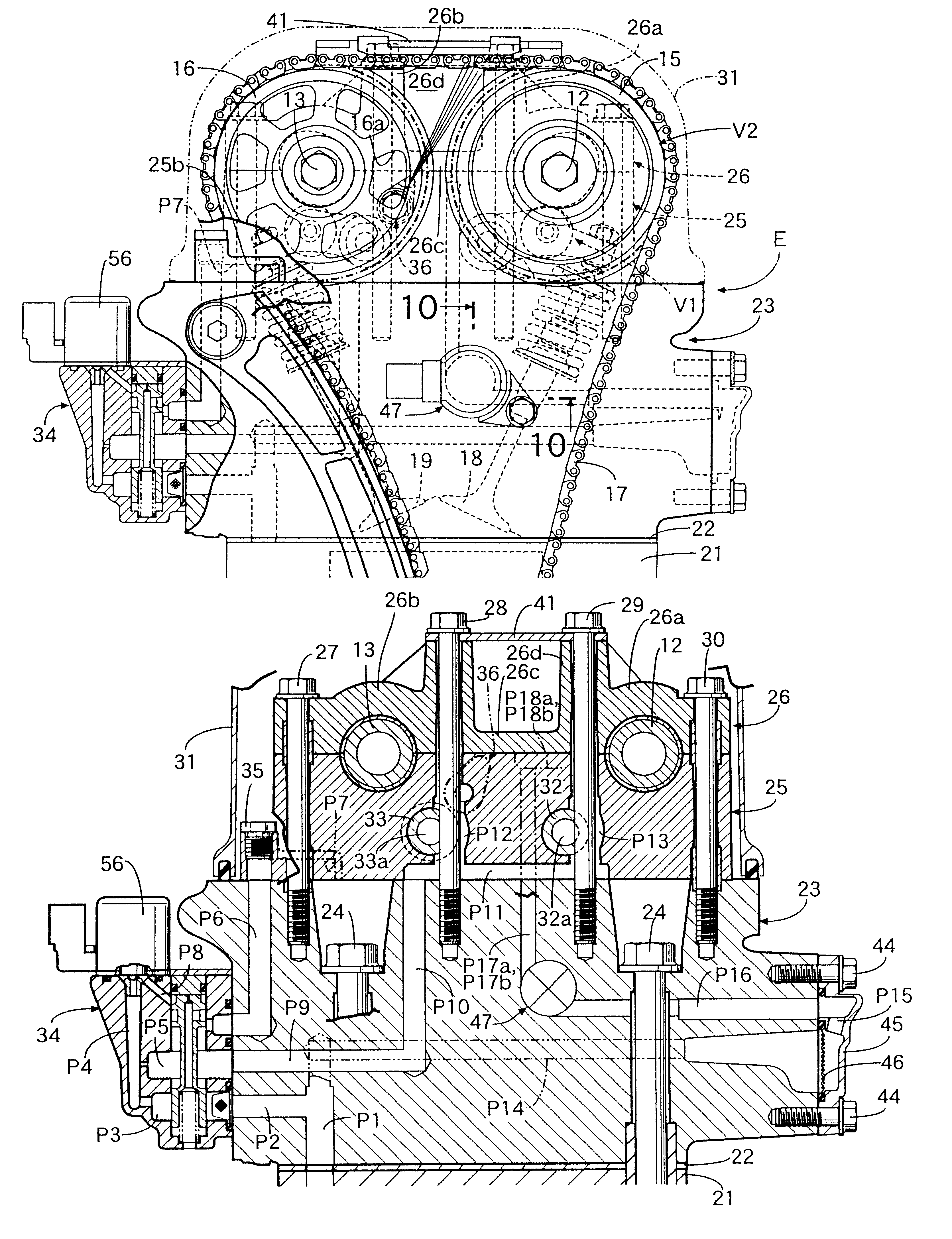

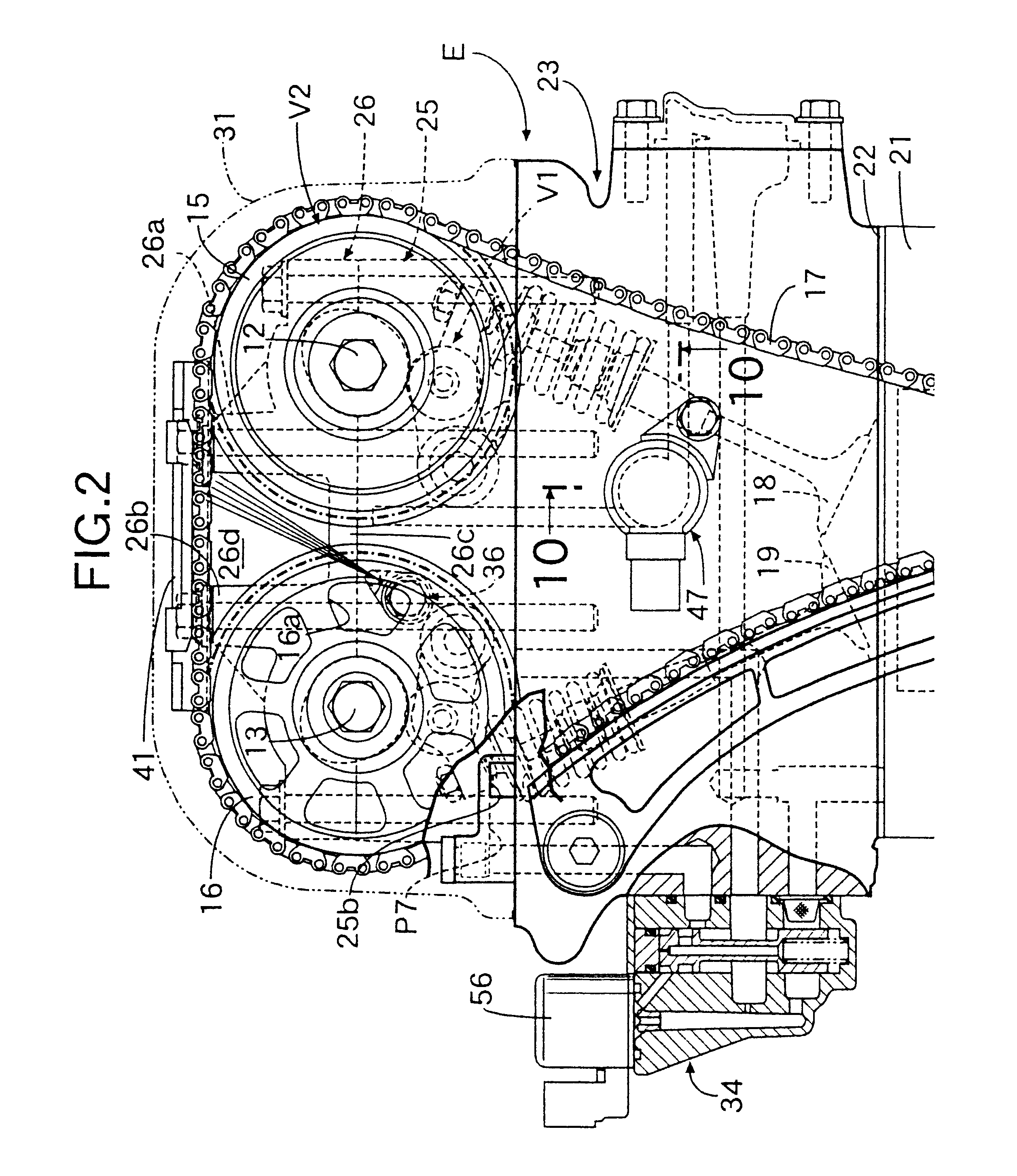

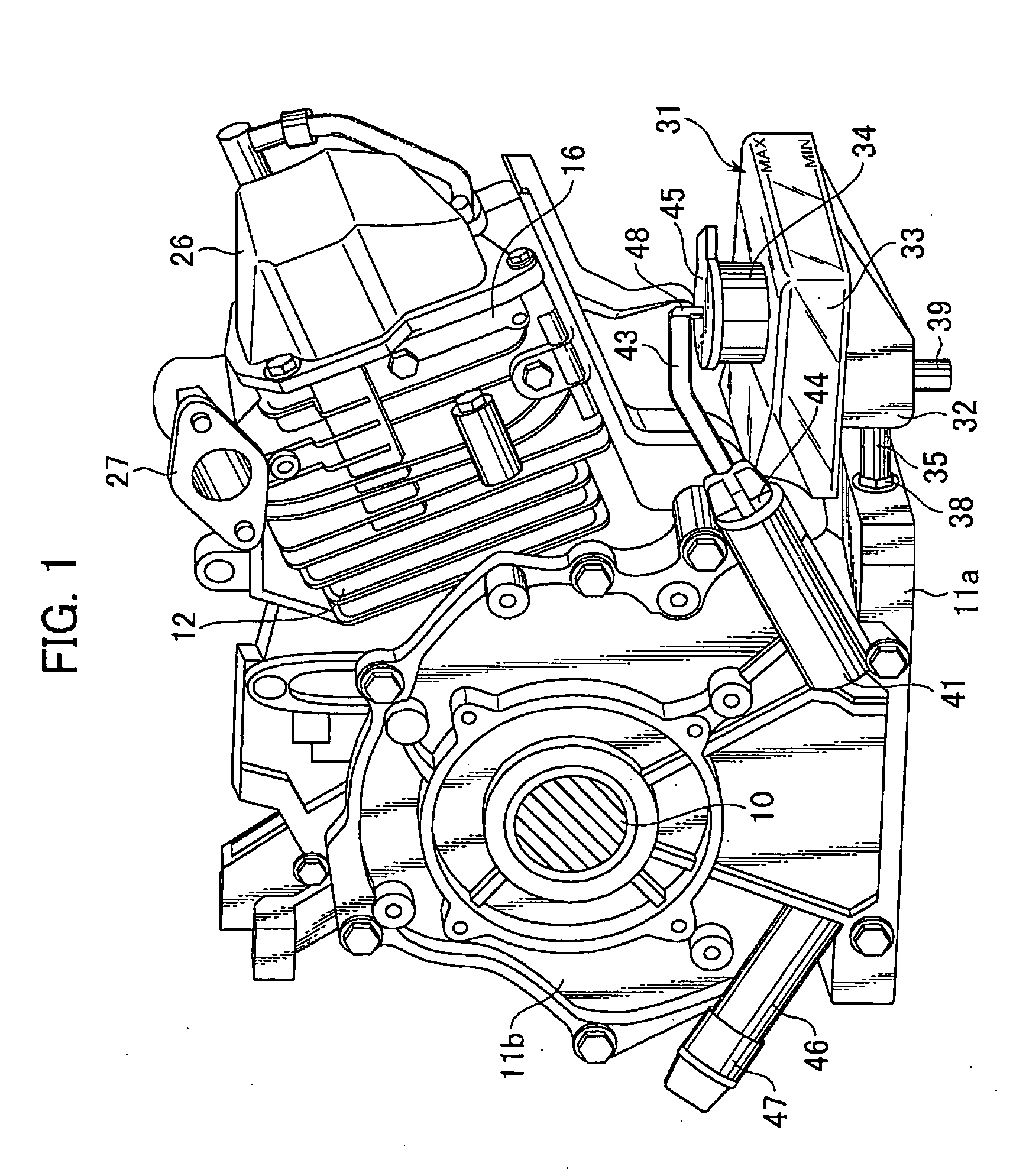

Timing chain lubricating system for engine

InactiveUS6662771B2Reduce wearIncrease supplyLubrication of auxillariesValve drivesLow speedCylinder head

Sprockets are fixed to ends of camshafts supported in a cylinder head via camshaft holders, and a timing chain is wrapped around these sprockets. An oil drain hole is provided for supplying relief oil of a hydraulic control valve to the timing chain, and an oil jet is provided for issuing a jet of oil at high pressure from the hydraulic control valve to the timing chain. When the engine is rotating at low speed oil is supplied only through the oil drain hole, and when the engine is rotating at high speed, oil is supplied through both the oil jet and the oil drain hole. The timing chain wrapped around the sprockets of the camshafts can thereby be reliably lubricated according to the operational state of the engine.

Owner:HONDA MOTOR CO LTD

Slant engine

InactiveUS20060174851A1Maintenance periodImprove performanceLubrication of auxillariesDrip or splash lubricationFuel tankCrankcase

A slant engine for a utility engine which a cylinder is attached to the crankcase with slanted with respect to the a rotational direction of a crankshaft, comprises a reservoir oil tank formed outside of the crankcase at lower portion for reserving lubricant, a communication pipe connected to bottom portions of the reservoir oil tank and the crankcase for communicating the lubricant in the crankcase and the reservoir oil tank, and a vent pipe connected to both of the reservoir oil tank and the inside of the crankcase.

Owner:SUBARU CORP

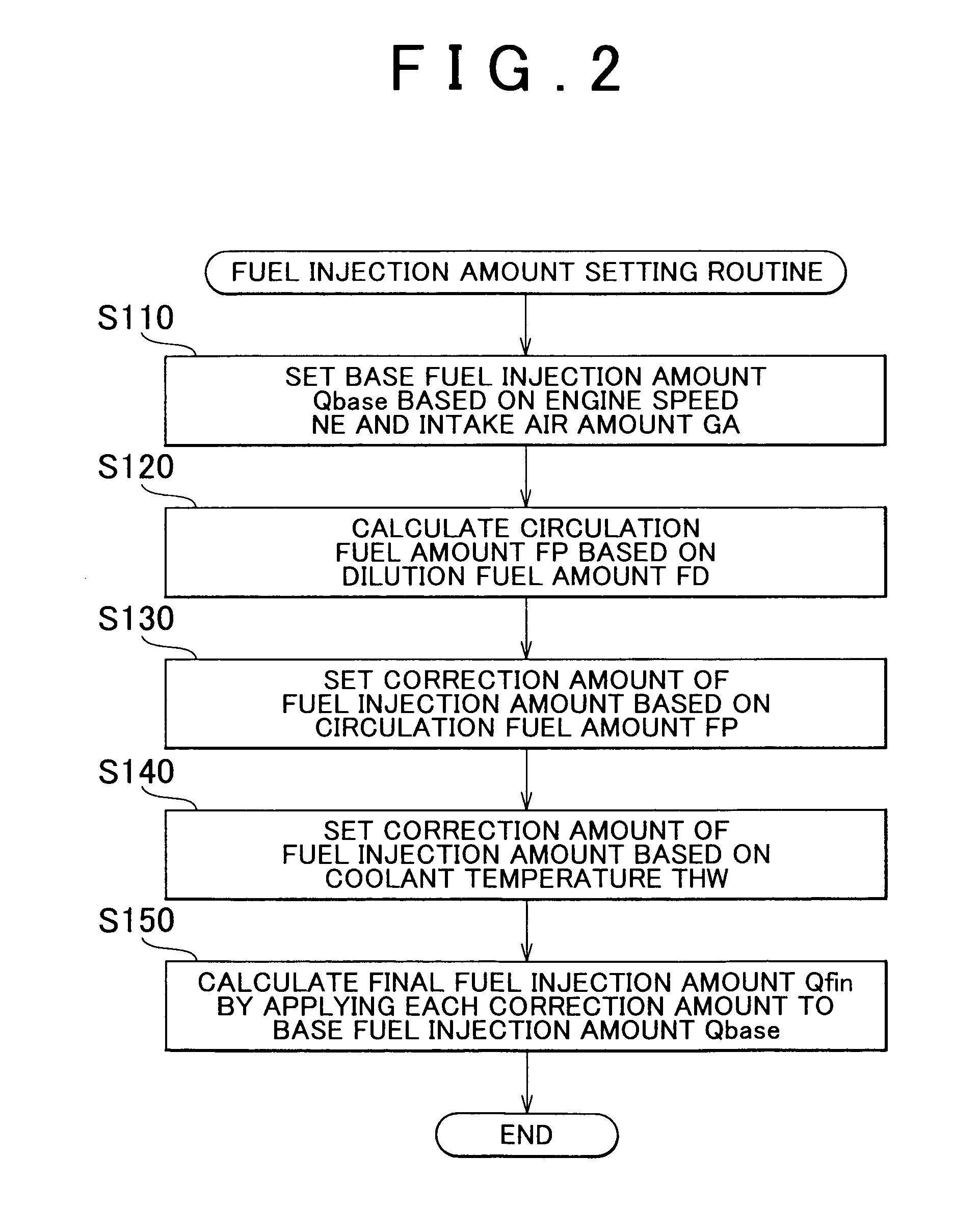

Fuel injection control apparatus for direct injection type internal combustion engine

A fuel injection control apparatus for a direct injection type internal combustion engine according to the invention includes a control unit. The control unit estimates the degree to which lubricating oil, which is used in the internal combustion engine, has been diluted with fuel based on the length of time the internal combustion engine has been running, and an accumulated value that indicates an amount of air that has been taken in by the internal combustion engine while the internal combustion engine has been running or an accumulated value that indicates an amount of fuel that has been injected while the internal combustion engine has been running. The control unit determines the amount of fuel to be injected based on the degree of dilution.

Owner:TOYOTA JIDOSHA KK

Popular searches

Crankcase ventillation Lubrication for crankcase compression engines Electric propulsion mounting Plural diverse prime-mover propulsion mounting Lubrication check valves Lubrication indication devices Thin material handling Safety devices for pressure lubrication Engine revolutions Pressure lubrication with lubrication pump

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com