Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about "Hypochlorous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rigid porous carbon structures, methods of making, methods of using and products containing same

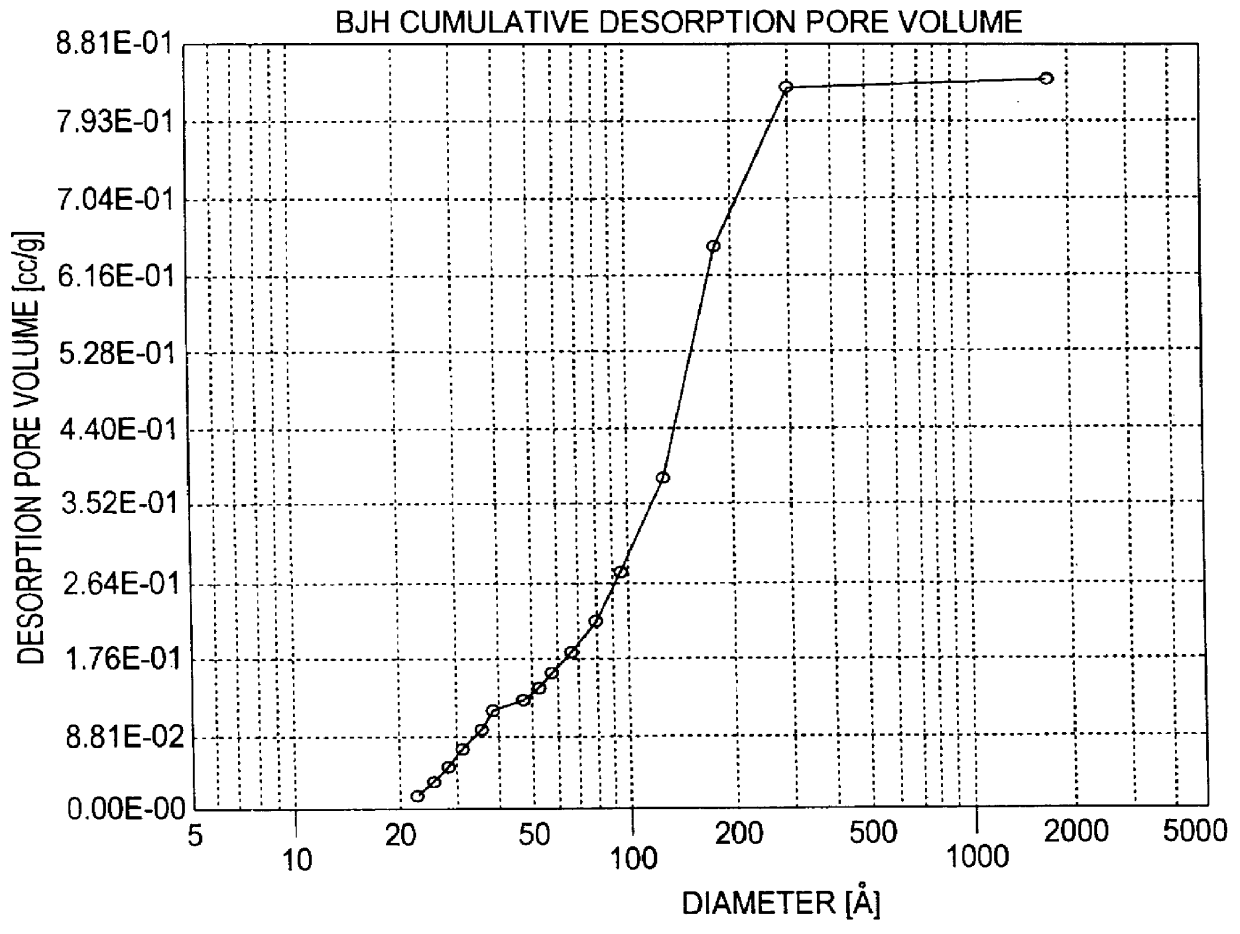

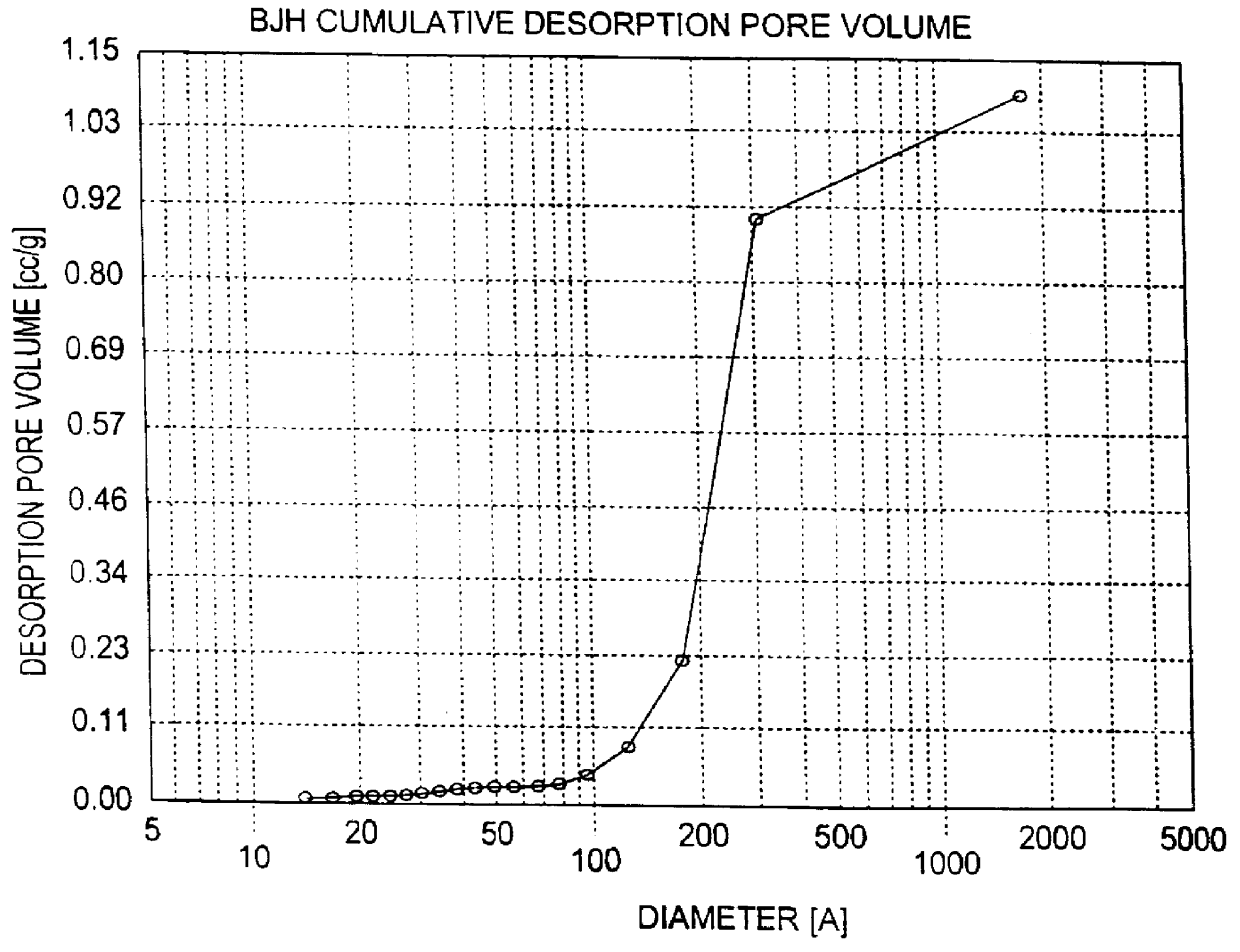

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

Oxidative reductive potential water solution and process for producing same

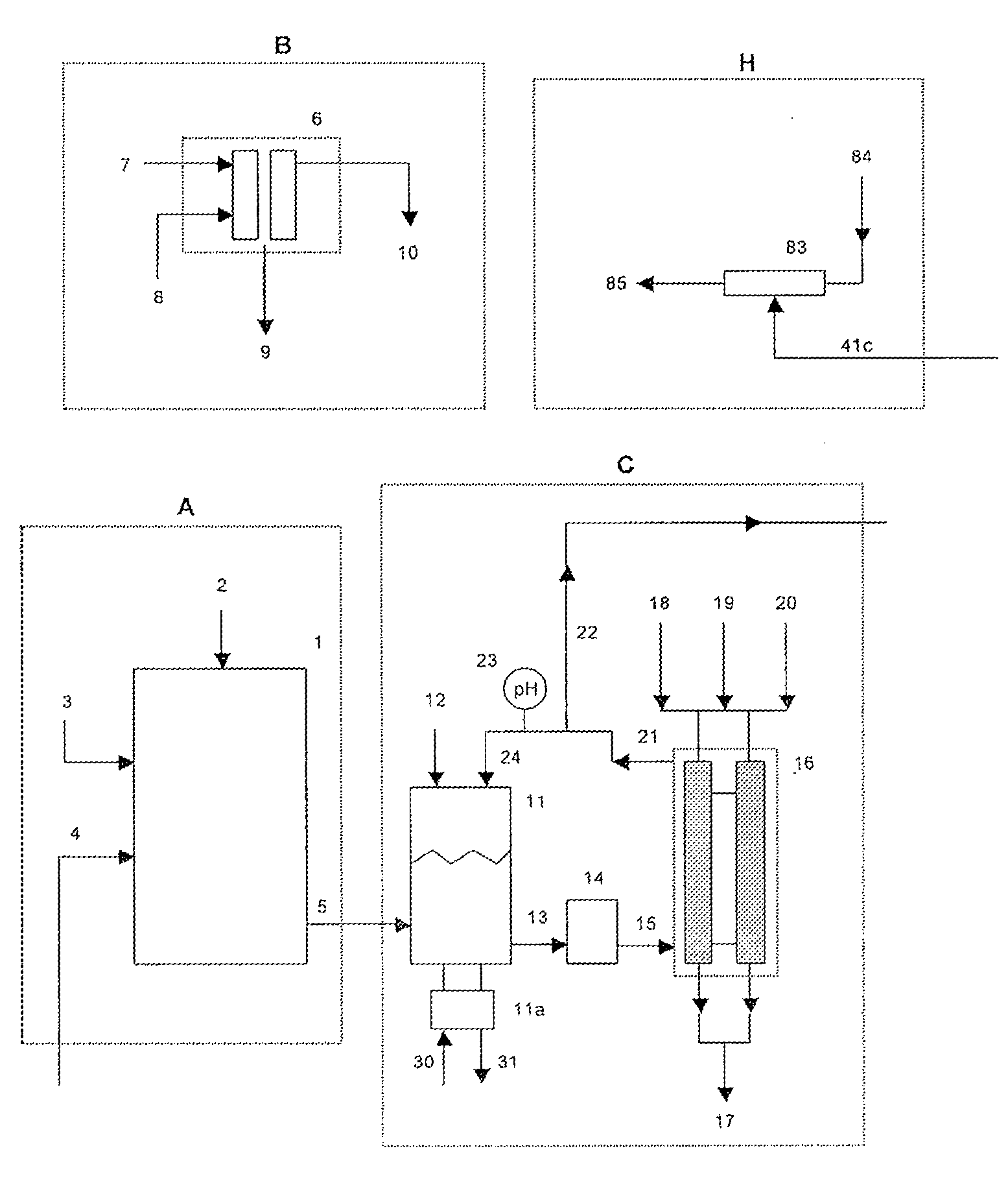

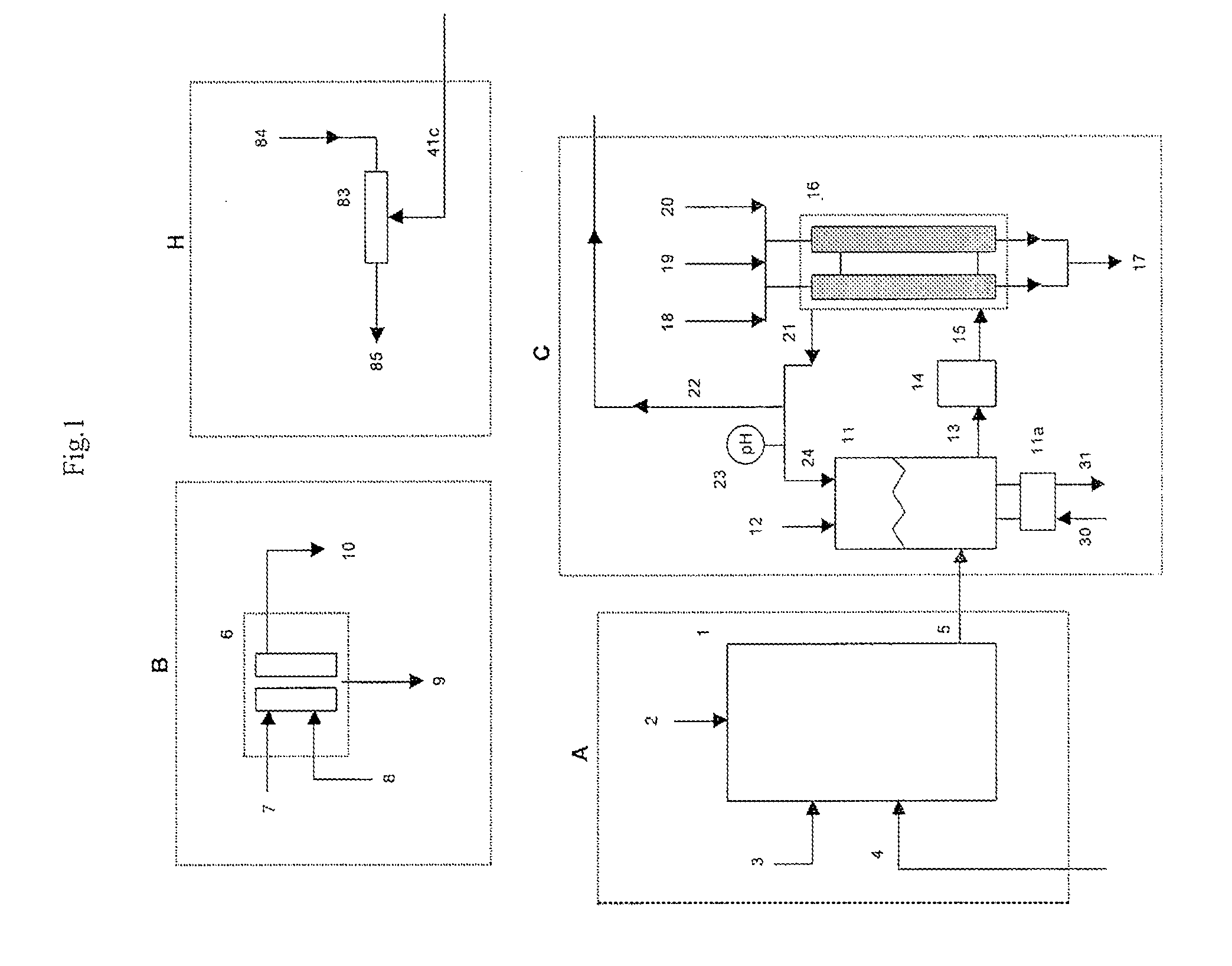

An oxidative reduction potential water solution that is stable for at least twenty-four hours. The invention also relates to an ORP water solution comprising anode water and cathode water. Another aspect of the invention is an apparatus for producing an ORP water solution comprising at least two electrolysis cells, wherein each cell comprises an anode chamber, cathode chamber and salt solution chamber located between the anode and cathode chambers, wherein the anode chamber is separated from the salt solution chamber by an anode electrode and a first membrane, and the cathode chamber is separated from the salt solution chamber by a cathode electrode and a second membrane.

Owner:SONOMA PHARMA INC

Physiologically balanced, ionized, acidic solution and methodology for use in wound healing

Described herein is a physiologically-balanced, acidic solution. Typically the solution is prepared by a chemical reactions or by the electrolysis of a solution comprising a mixture of an inorganic salt to form a physiologically balanced solution. This invention also relates to methods for use of the solutions, including a specialized bandage which may be used in combination with the solutions, or optionally with other topically applied materials. A mixture of inorganic salts and, optionally minerals, is used in order to mimic the electrolyte concentration and mixture of body fluid in an isotonic state. The solution typically comprises of one halide salt of lithium, sodium, potassium, calcium, and other cations. Typically the halide is fluoride, chloride, bromide, or iodide, and most typically chloride. A typical electrolyzed solution of the present invention has a pH within the range of about 2 to about 5, an oxidation reduction potential within the range of about +600 mV to about +1200 mV, and hypohalous acid concentration in the range of about 10 ppm to about 200 ppm. The solution has bactericidal, fungicidal, and sporicidal properties. The composition of the invention is nontoxic and has antibacterial properties, and is useful in any application in which antimicrobial properties are desirable.

Owner:NOVABAY PHARM INC

Method for Diluting Hypochlorite

InactiveUS20070231247A1Other chemical processesSurface-active detergent compositionsHypochloriteFood contact

This invention relates to methods of diluting hypochlorite and hypochlorous acid compositions with purified water to produce stable compositions. These compositions can be used to treat allergen containing surfaces, hard surfaces, food contact surfaces, hospital surfaces, food surfaces, kitchen surfaces, bathroom surfaces, human surfaces, animal surfaces, military equipment, transportation equipment, children's items, plant surfaces, seeds, outdoor surfaces, soft surfaces, air, wounds, and medical instruments.

Owner:THE CLOROX CO

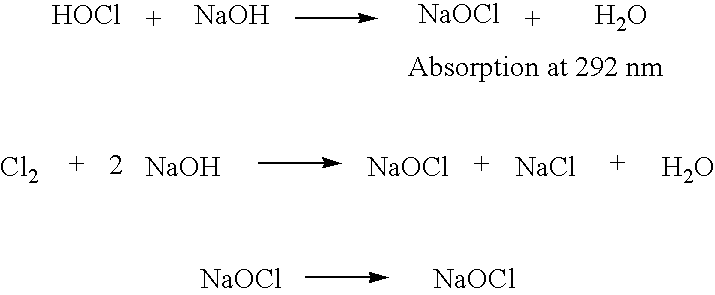

Process for the on-site production of chlorine and high strength sodium hypochlorite

ActiveUS20070251831A1Reduce hardnessGuaranteed uptimeCellsPhotography auxillary processesElectrolysisBleach

The present invention relates to a novel economical on-site electrochemical based membrane cell based process with the capability of producing high strength sodium hypochlorite and / or elemental chlorine gas in any ratio as required by the needs of a water or wastewater treatment plant. The system is compact and modular, using membrane cell based electrolyzers and utilizing novel process modifications and sensors to allow for the unattended control and safe operation of the process. The process allows the operator to produce elemental chlorine gas and sodium hypochlorite in any product ratio, such that 5% to 100% of the total chlorine produced by the process can be converted to high strength bleach. The process has the flexibility to produce stable high quality, low to high strength sodium hypochlorite solutions in concentrations ranging from about 2 to 15% trade as NaOCl.

Owner:ELECTROLYTIC TECH CORP

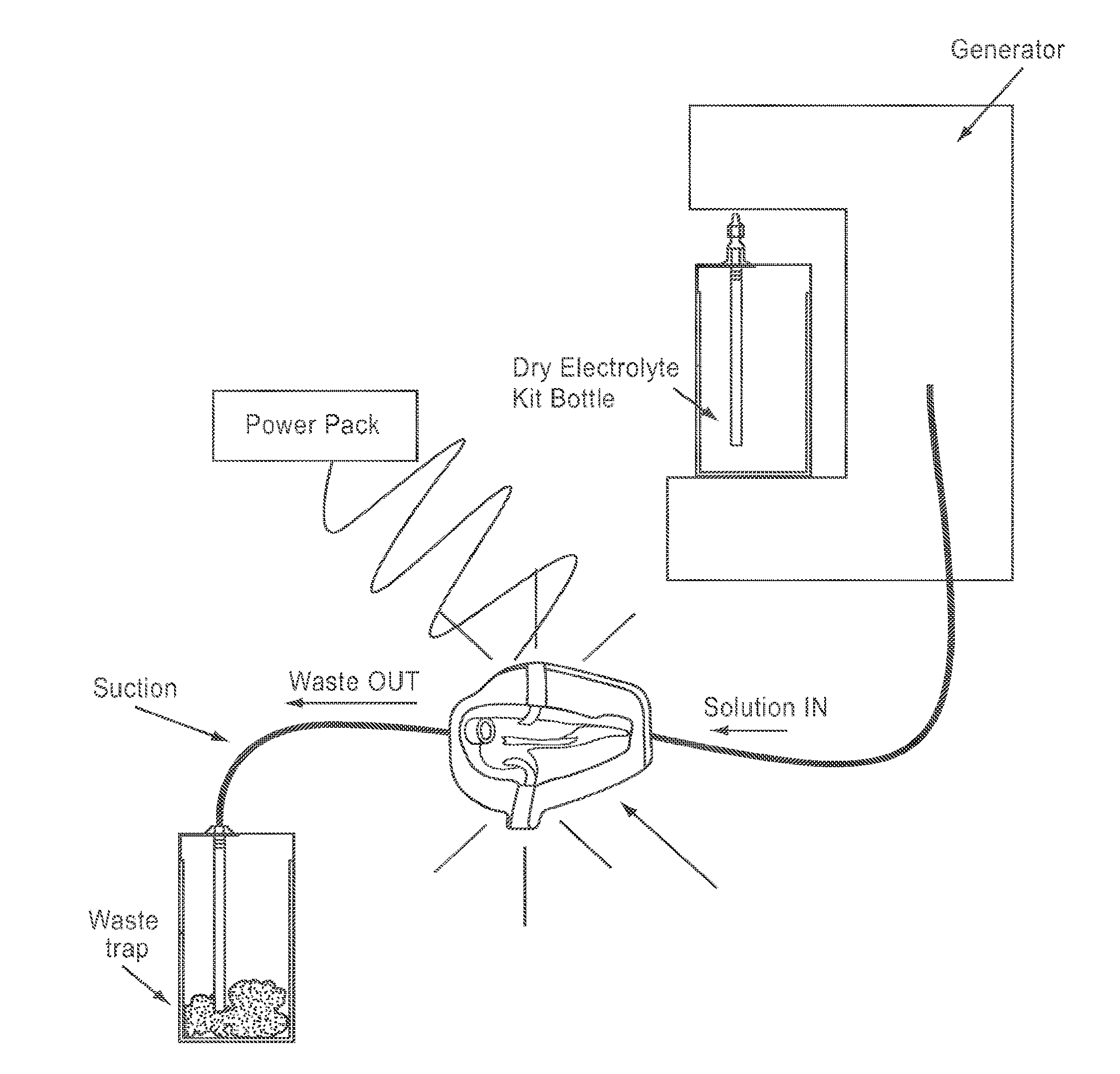

Apparatus and method for wound, cavity, and bone treatment

InactiveUS20130261534A1Environment safetyPromote formationElectrolysis componentsCannulasWound dressingWound care

Owner:PURICORE

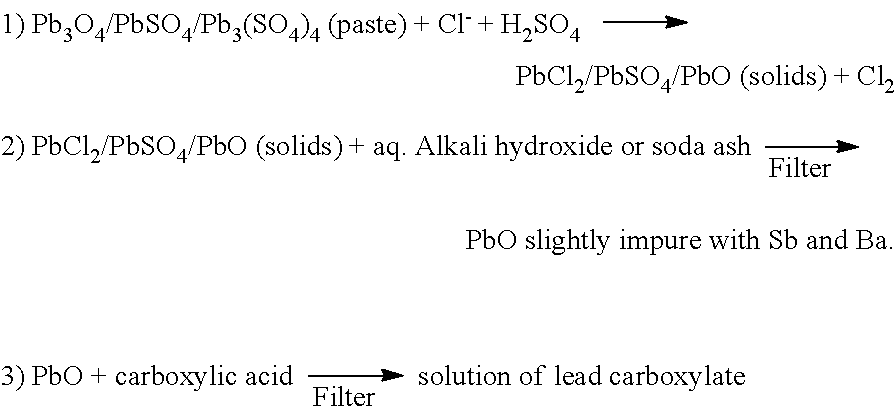

Recovery of high purity lead oxide from lead acid battery paste

There is provided a process for recovering high purity litharge PbO from spent lead acid battery paste at low temperatures and the further preparation of highly pure lead oxides and Pb(OH)2.

Owner:RETRIEV TECH

Method of preparing a biocide comprising stabilized hypochlorite and a bromide ion source and a method of controlling microbial fouling using the same

InactiveUS20050147528A1Long retentionIncreased durabilityBiocideSpecific water treatment objectivesAlkaline earth metalBromide ions

Disclosed is a method of preparing a biocide having improved durability of its biocidal activity as well as disinfection efficiency at an initial stage, comprising the steps of: (a) preparing stabilized alkali or alkaline earth metal hypochlorite having a pH at least 11 by mixing a chlorine oxidant including alkali or alkaline earth metal hypochlorite with a stabilizer in an alkali solution; (b) preparing a bromide ion source; and (c) adding the bromide ion source prepared in step (b) into the stabilized alkali or alkaline earth metal hypochlorite prepared in step (a). Also, a method of controlling the growth of microorganisms using a biocide prepared by the method of the present invention is disclosed.

Owner:ACCU LAB CO LTD

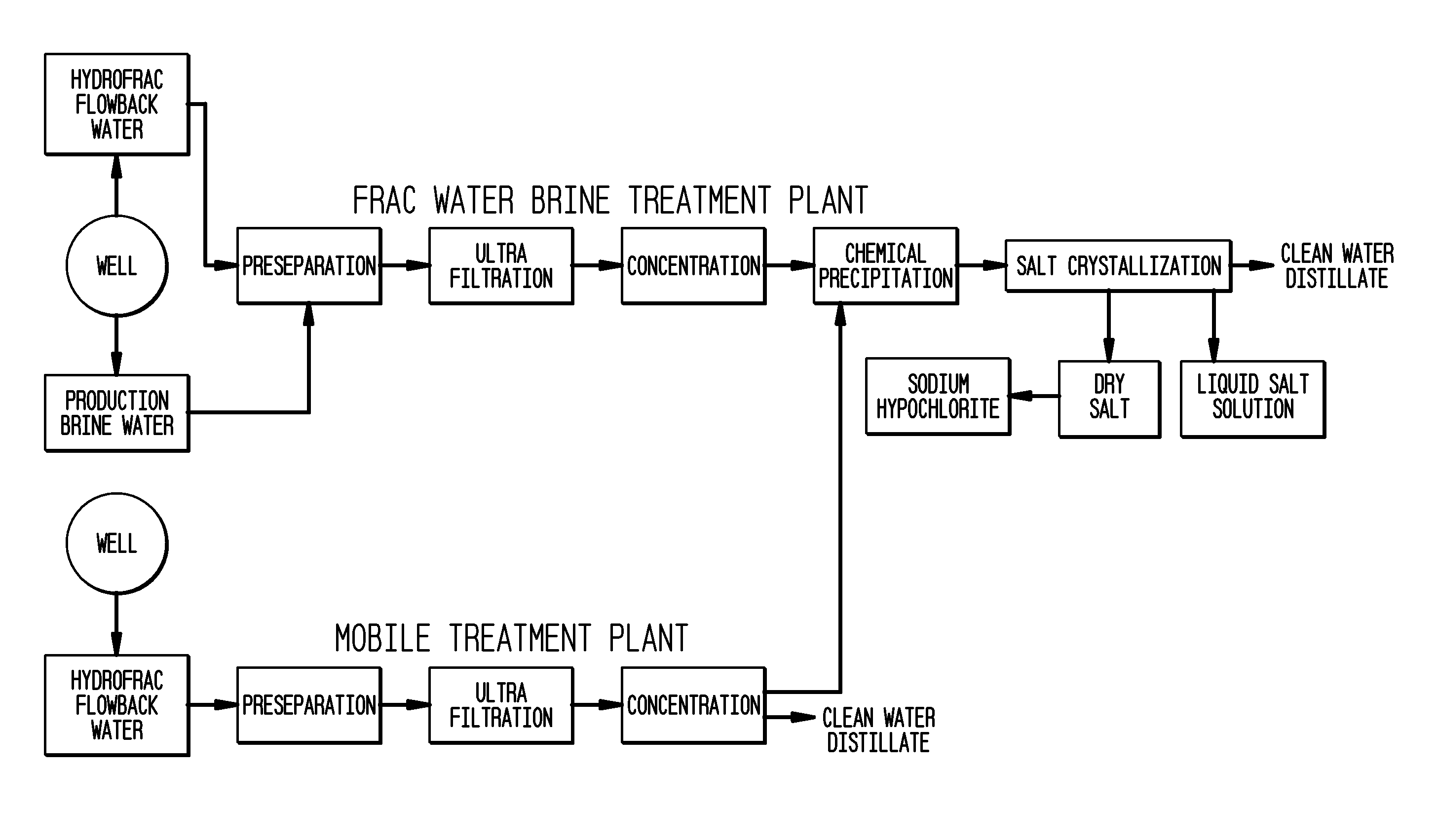

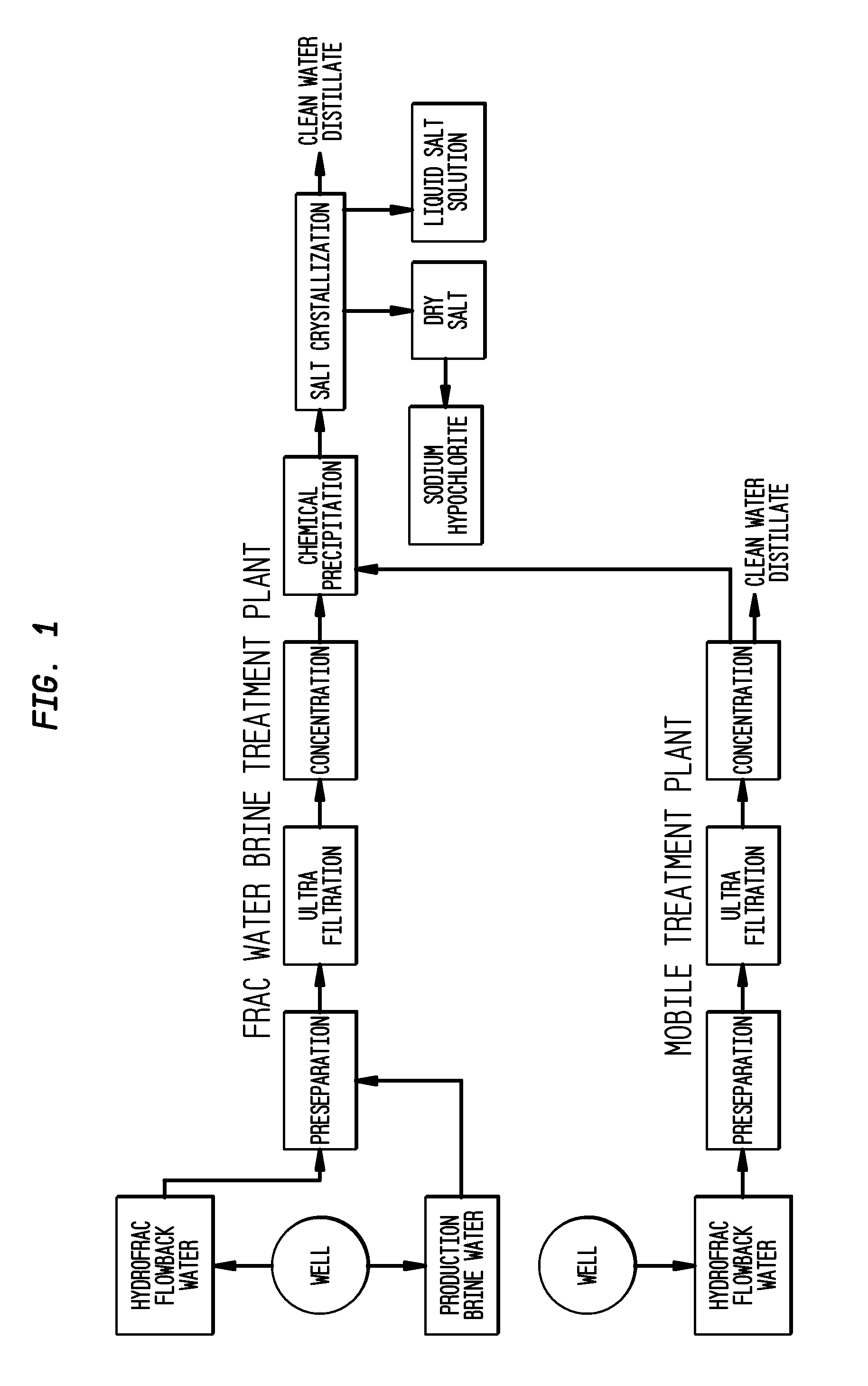

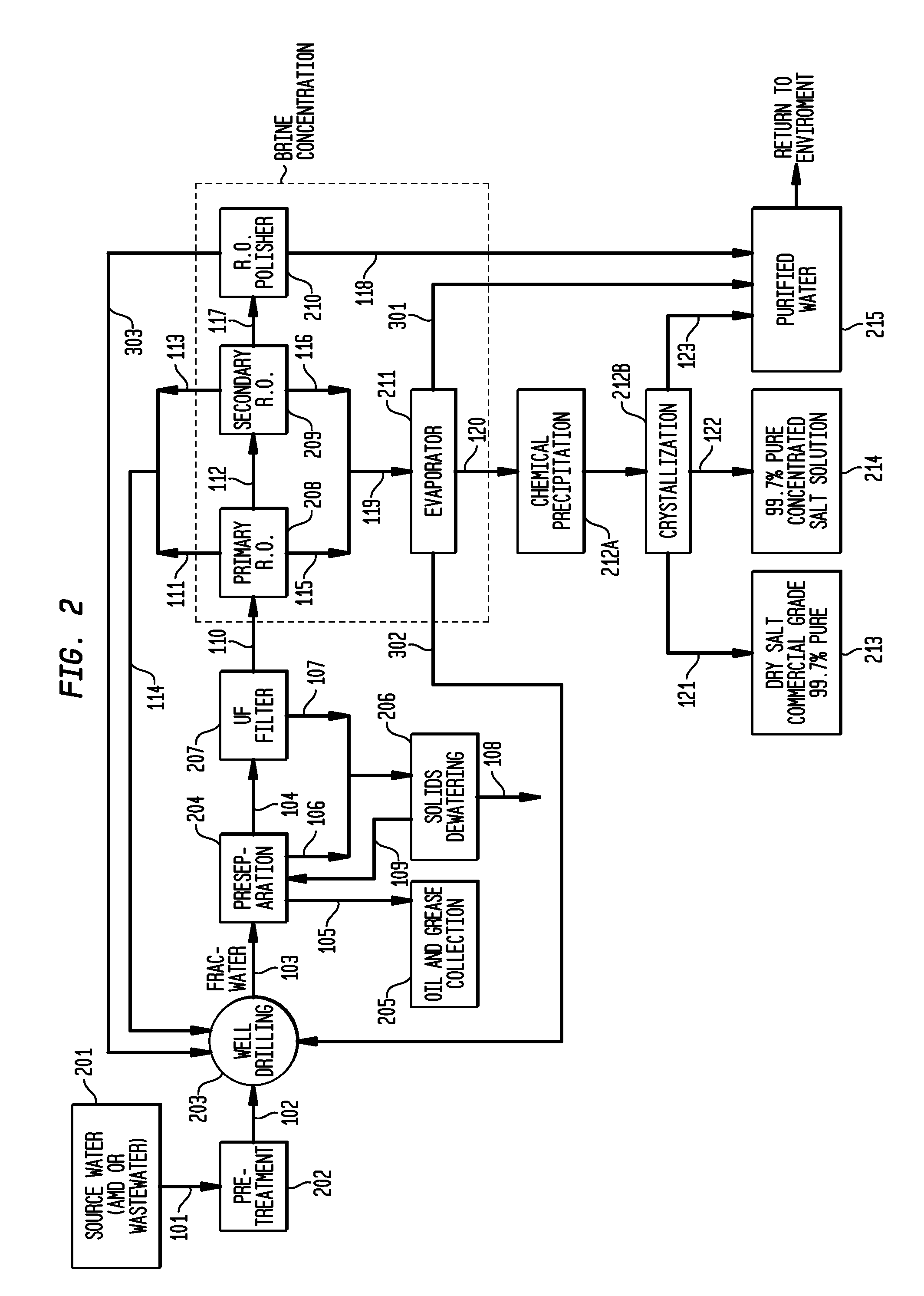

Method of making pure salt from FRAC-water/wastewater

ActiveUS8158097B2Yield maximizationQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesWater useParticulates

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

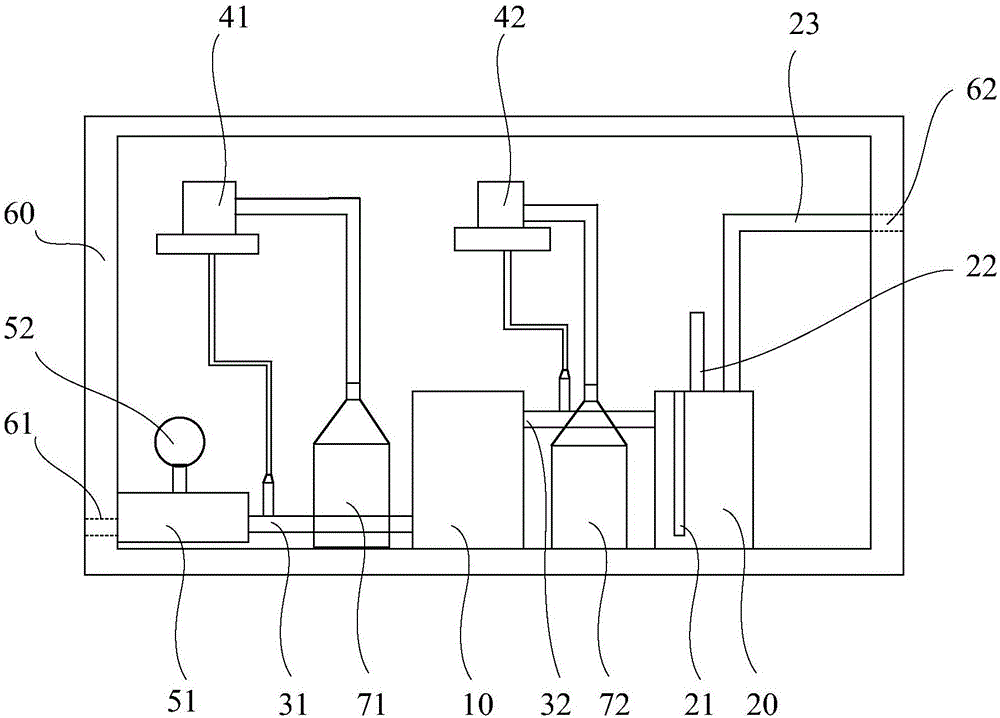

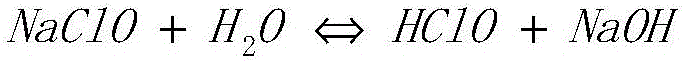

Preparation method and preparation apparatus of slightly-acidic hypochlorous acid water

InactiveCN106386850AImprove production efficiencyPrecise control of concentrationBiocideFungicidesElectrolysisHypochlorous acid

The invention provides a preparation method and a preparation apparatus of slightly-acidic hypochlorous acid water, and relates to the technical field of preparation of slightly-acidic hypochlorous acid water in order to solve the problem of low generation efficiency of the slightly-acidic hypochlorous acid water. The preparation method of slightly-acidic hypochlorous acid water comprises the following steps: mixing water with an alkaline solution containing hypochlorite ions to obtain a mixed solution; mixing the mixed solution with an acidic liquid when the effective chlorine concentration of the mixed solution reaches a preset effective chlorine concentration in order to obtain a hypochlorous acid solution; and detecting the pH value of the hypochlorous acid solution, and discharging the hypochlorous acid solution with a preset pH value when the pH value of the hypochlorous acid solution reaches the preset value, which is the required slightly-acidic hypochlorous acid water. The preparation method of the slightly-acidic hypochlorous acid water allows the slightly-acidic hypochlorous acid water to be produced continuously in a large-flow manner, and has a greatly higher slightly-acidic hypochlorous acid water generation efficiency than an electrolysis way.

Owner:沐康源科技(北京)有限公司

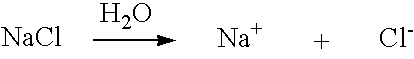

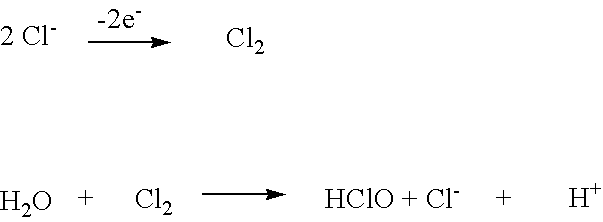

Two stage process for electrochemically generating hypochlorous acid through closed loop, continuous batch processing of brine

InactiveUS20110135562A1Eliminate externally introduced acid neutralization capabilityReduce the amount requiredCellsPhotography auxillary processesHigh concentrationBatch processing

High concentrations of hypochlorous acid can be produced from, most typically, brine using an system of simple design with minimum residual salt production, reduced power consumption, and at high operating efficiencies. This is accomplished by separating the system into two operations, each of which is preferably optimized. This process employs at least two electrochemical cells, the first of which has no separator between the anode and cathode and generates a high-strength hypochlorite solution. The hypochlorite is then diluted to a desired chlorine concentration and / or pH and fed into the anode compartment of a second electrochemical cell wherein the electrodes are separated by a barrier, such as, for example, a membrane or diaphragm. The separated cell produces a solution containing predominantly hypochlorous acid. Separation of the neutralization processes allows storage of hypochlorite which has a much greater stability in regards to temperature which can then be subsequently converted into hypochlorous acid at point of use or as needed or desired.

Owner:WATER STAR +1

Pressurized solution feed system for introducing hypochlorous acid to a fluid stream

InactiveUS6855307B2Reduced pHRaise the ratioWaste water treatment from animal processingMeat/fish preservation using liquidsHypochloriteTreated water

A system and method are disclosed for increasing the concentration of hypochlorous acid in a quantity of water. Acid is injected into chlorinated water to decrease the pH of the chlorinated water. By decreasing the pH, the hypochlorite / hypochlorous acid equilibrium of the chlorinated water is shifted to increase the concentration of hypochlorous acid on the treated water.

Owner:TOMCO2 EQUIP

Process for the production of aqueous chlorine dioxide solutions

InactiveUS6103950ASimple and dependable managementEliminate pollutionOther chemical processesChlorous acidChlorine dioxideRedox

The description relates to a process for the production of aqueous chlorine dioxide solutions through oxidation of chlorite with oxo acids and / or oxo acid anions having a suitable redox potential in a buffered aqueous medium, wherein an acidic aqueous solution A is produced which has a pH of about 5 or less and contains the oxo acids and / or oxo acid anions, and the acidic aqueous solution A is mixed with an aqueous chlorite solution B to form chlorine dioxide, wherein a pH of less than 6.95 is adjusted in the reaction mixture, this pH value being stabilized by a buffering system contained therein.

Owner:RIMPLER MANFRED +2

Microbicide compositions

InactiveUS20030155549A1High bactericidal effectImprove securityBiocideDead animal preservationParticulatesHypochlorite

A colored liquid hypochlorite bleach composition is provided, comprising a particulate pigment such as Ultramarine Blue, which is stably suspended in the composition by means of a flocculate, such as calcium soap flocs.

Owner:KAO CORP

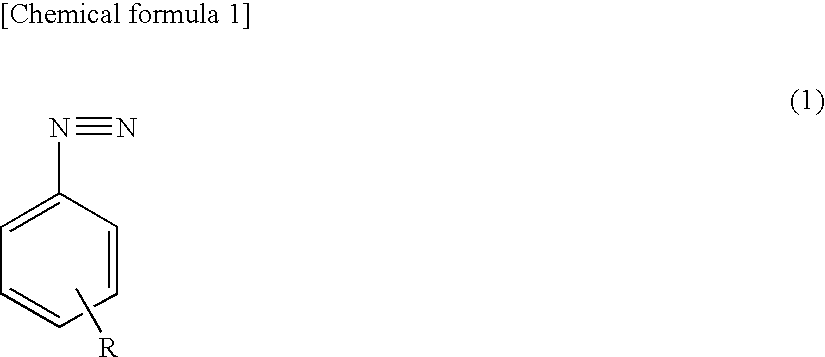

Method for producing stable hypochlorous acid solution

ActiveCN104555928ARealize continuous automatic productionImprove stabilityBiocideDisinfectantsHypochloriteAqueous solution

The invention discloses a method for producing stable a hypochlorous acid solution. According to the method, the hypochlorous acid solution is obtained by mixing and reacting raw water, an aqueous solution of hypochlorite ion provider, a weak acid aqueous solution with the pKa of 4.0-6.5 and a conjugate base aqueous solution of the weak acid aqueous solution according to the following quantitative ratio: Q1=C / C1.Q0; Q2>=C / C2.0.435(1+m) / m.Q0; Q3=m.C2 / C3.Q2; m=10(pH-pKa). The method for producing the stable hypochlorous acid solution disclosed by the invention achieves the continuous automatic production of hypochlorous acid solution, and moreover, the hypocholorous acid solution produced according to the method has the storage stability of at least one year; and in addition, the method has the advantages of easy availability of the raw materials, low requirements for needed equipment, simple operation, greenness, environment protection and the like, and has industrial application value.

Owner:上海日洁环境科技有限公司

Process for the preparation of concentrated solutions of stabilized hypobromites

The invention is a process for the preparation of stabilized aqueous solutions of alkali hypobromites, which comprises reacting a concentrated alkali hydroxide aqueous solution with bromine, allowing the mixture to react, adding to the reaction product, which is a non-stabilized solution, an aqueous solution of a sulfamic compound, such as sodium sulfamate, and thus forming stabilized alkali hypobromite solution. This solution can be further stabilized by the addition of a sulfamate solution. The temperatures of all the above stages are comprised between −5 and +10° C.

Owner:BROMINE COMPOUNDS

System and method for preparation of antimicrobial solutions

Owner:CLARTECH HLDG

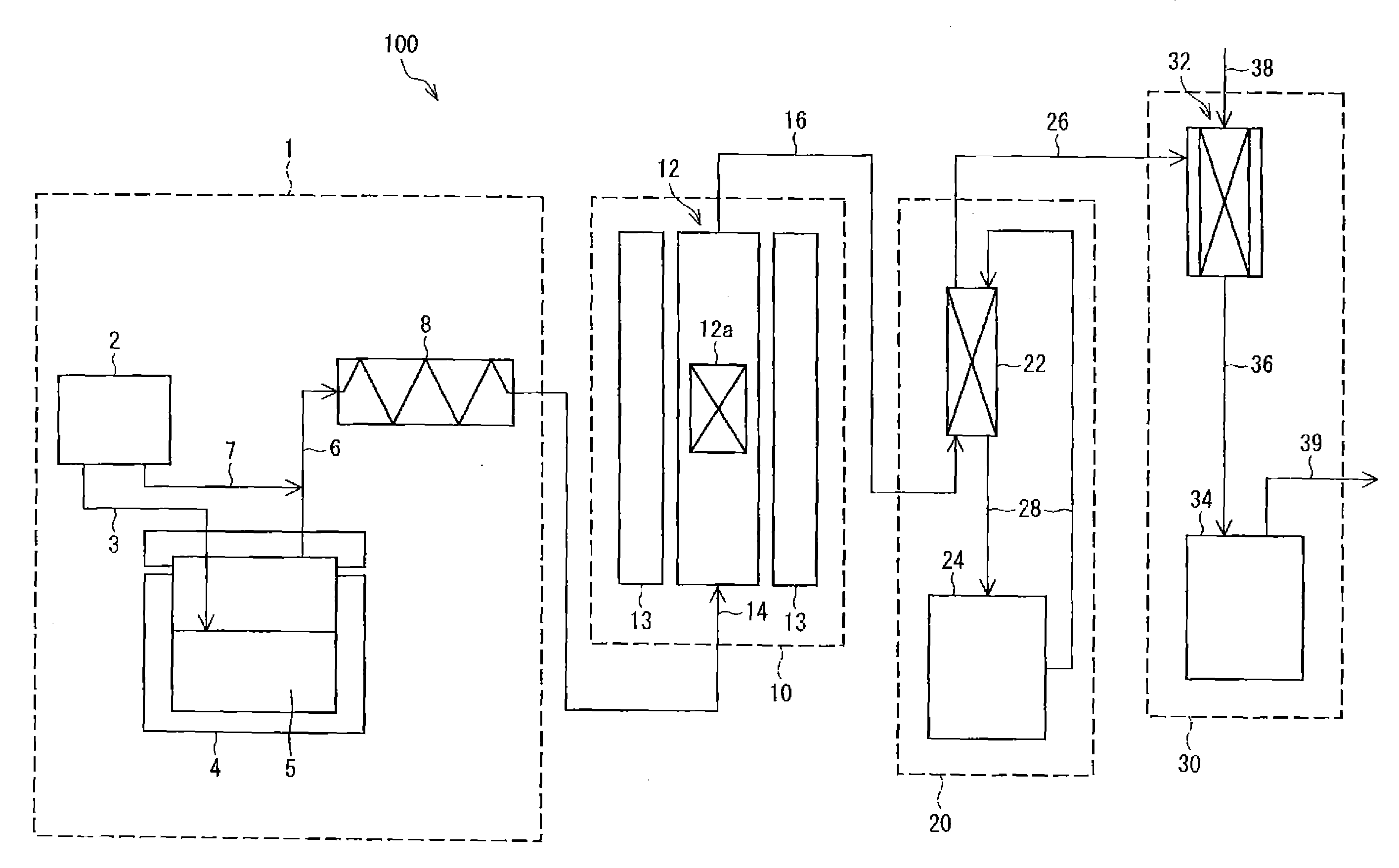

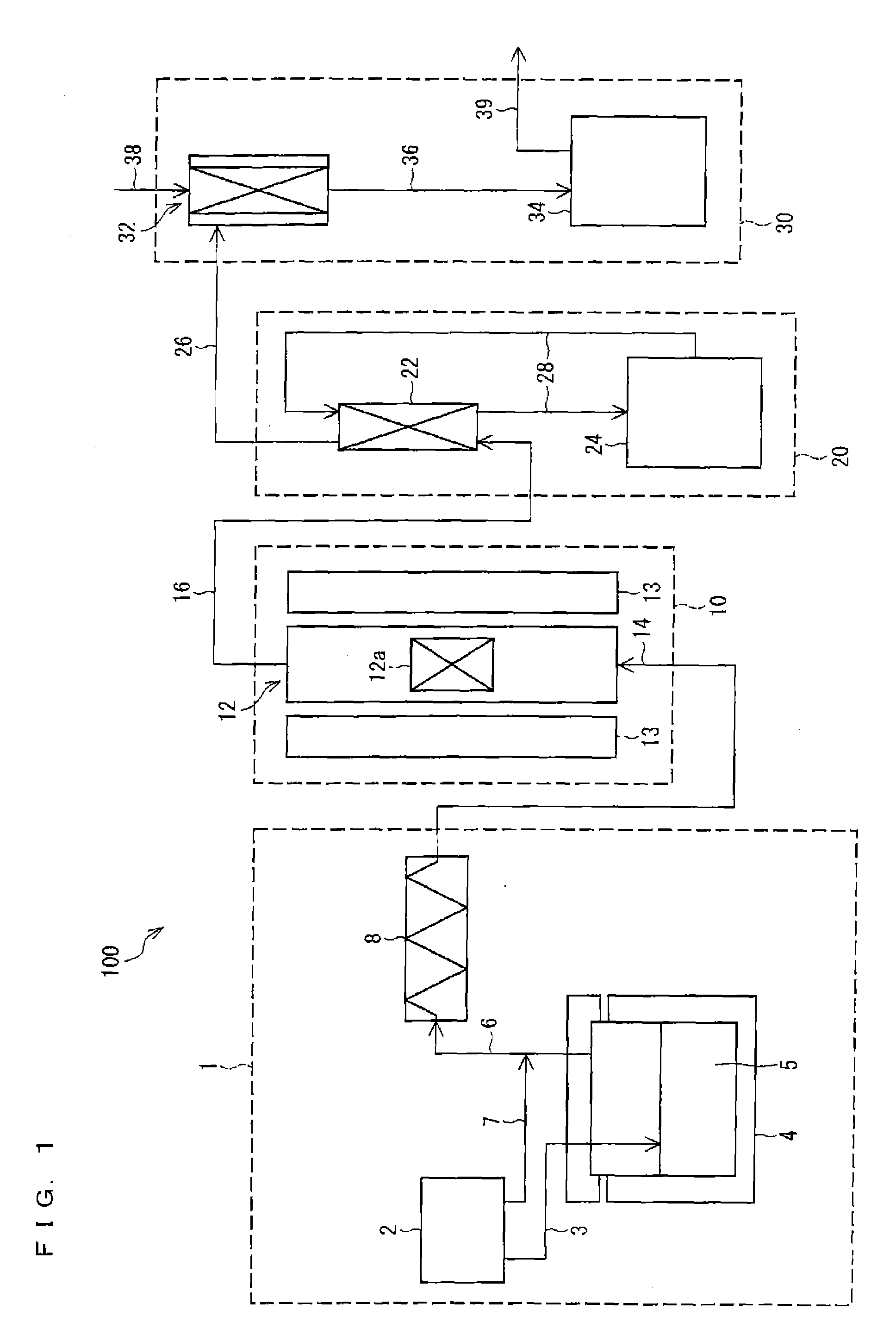

System and method for producing iodine compound

ActiveUS20100308261A1Avoid erosionSolution to short lifeHydrogen iodideIodide preparationTowerReagent

A system (100) of the present invention for producing an iodine compound includes: a raw material adjusting unit (1) for supplying hydrogen-containing gas to at least one of liquid iodine in an iodine melting pot (4) and gaseous iodine obtained by evaporating liquid iodine so as to obtain a mixture gas; a hydrogen iodide producing unit (10) including a hydrogen iodide producing tower (12) having a catalyst layer (12a) for converting the introduced mixture gas into crude hydrogen iodide gas; a hydrogen iodide refining unit for removing unreacted iodine from the introduced crude hydrogen iodide gas so as to obtain hydrogen iodide gas; and an iodine compound producing unit (30) for producing a target iodine compound from the obtained hydrogen iodide gas and a reaction material. This allows producing an iodine compound with high purity easily, efficiently, and with low cost.

Owner:NIPPON CHEMICALS CO LTD

Stabilized hypohalous acid solutions

ActiveUS20140134277A1Sanitizing, disinfecting or cleansing a hard surfaceMaintain activityAntibacterial agentsBiocideCut flowersMammalian tissue

The present invention provides a stabilized hypohalous acid solution (or formulation thereof), which may be conveniently packaged for sale, or stored for later use on demand. The invention further provides methods of making the stabilized hypohalous acid solution, as well as methods of use for disinfecting mammalian tissue, including wounds and burns, disinfecting or cleansing surfaces, or treating and / or preserving food products and cut flowers, among other uses.

Owner:URGO US INC

Method for removing sulfur compounds from sour gas streams and hydrogen rich streams

InactiveUS20140271451A1Reducing and eliminating capitalReducing and eliminating and operating costCell electrodesGold compoundsIndustrial gasSteam reforming

The present invention relates to a process for purifying a gas stream comprising hydrogen sulfide or mercaptans, or mixtures thereof. The gas stream can be a sour natural gas stream, a landfill gas or an industrial gas stream. The process comprises contacting the gas stream at effective absorption conditions including an absorption temperature less than about 300° C. with a solid absorbent effective to absorb the hydrogen sulfide, or mercaptans or mixtures thereof to provide a purified gas stream. Method is useful for treating gas streams having up to 90 vol-% hydrogen sulfide, or treating highly pure hydrogen streams. The invention is useful as a guard bed for fuel cells and sensitive laboratory instruments. The invention can also be employed to treat steam reformer product hydrogen streams without the need for further compression of the product hydrogen streams.

Owner:TERRAVIRE

Gas diffusion electrode and method of making the same

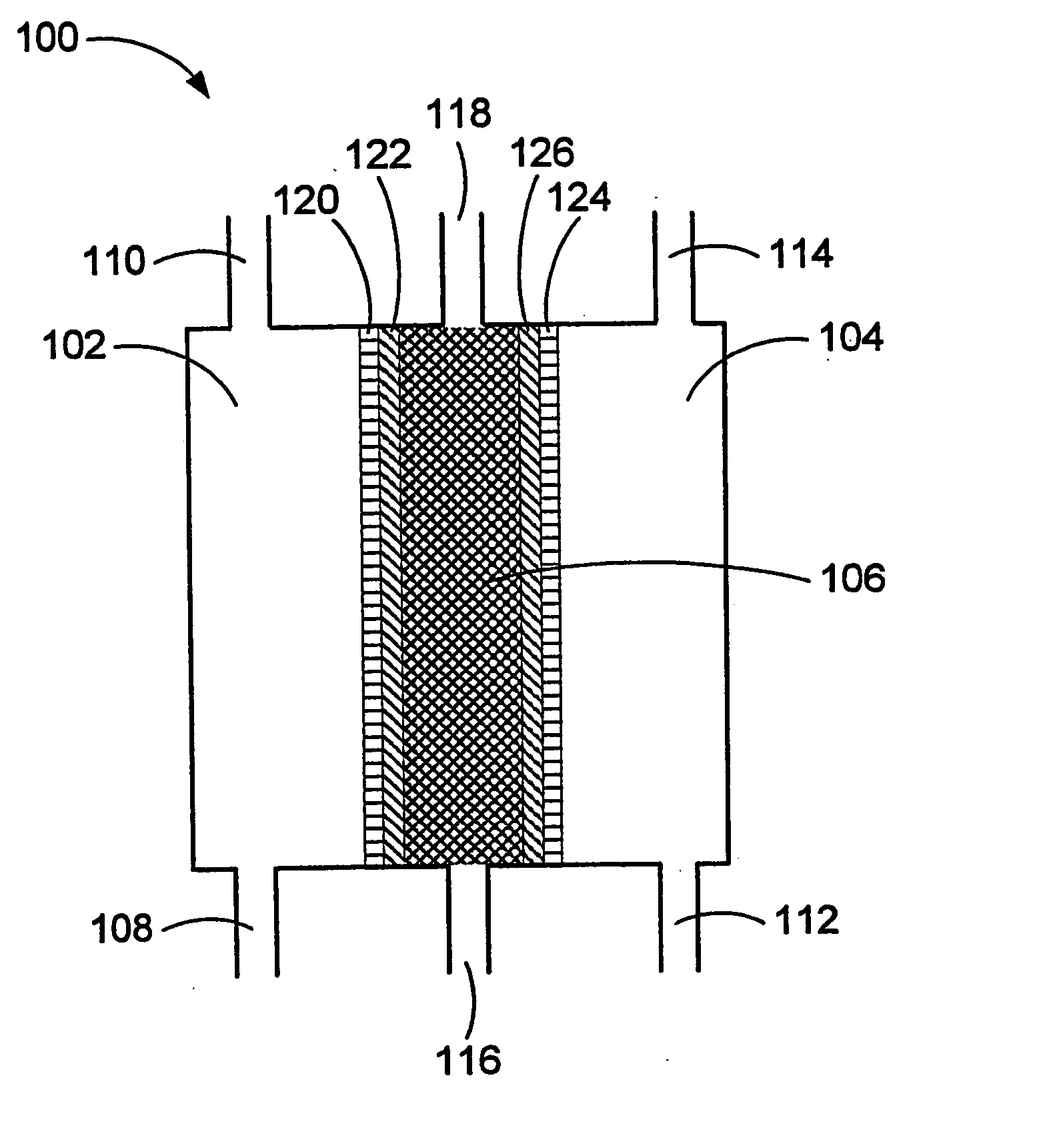

ActiveUS7629071B2Porosity adjustableNatural cellulose pulp/paperFinal product manufacturePorous substrateFiber

A gas diffusion electrode and method of making the same. According to one embodiment, the electrode comprises a support layer, a first cushioning layer positioned on top of the support layer, a second cushioning layer positioned on top of the first cushioning layer, and a catalyst layer positioned on top of the second cushioning layer. The support layer is a mechanically stable, electrically-conductive, gas porous substrate, such as carbon fiber paper. The first cushioning layer, which is also gas porous, comprises a non-woven mat of electrically-conductive, chemically-inert fibers, preferably carbon nanofibers, bound together with a polymeric binder, such as polytetrafluoroethylene. The second cushioning layer is similar to the first cushioning layer, except that carbon black or a similar electrically-conductive, chemically-inert particulate material is included in addition to or instead of the fibrous material for the purpose of fine-tuning pore size.

Owner:PLUG POWER

Multi-chamber hypochlorous acid dispenser

ActiveUS20180179059A1Simple preparation processMeet the blocking requirementsBiocideSingle-unit apparatusAcetic acidLow ionic strength

The invention provides a skin disinfectant for treating skin with eczema, preventing bacterial proliferation, and removing biofilm. Compositions of the invention include hypochlorous acid, acetic acid, water, and one or more additives or excipients. The formulation process removes metal ions, reduces ionic strength, controls pH, and reduces exposure to air, thus improving stability and lengthening shelf-life.

Owner:WIAB WATER INNOVATION

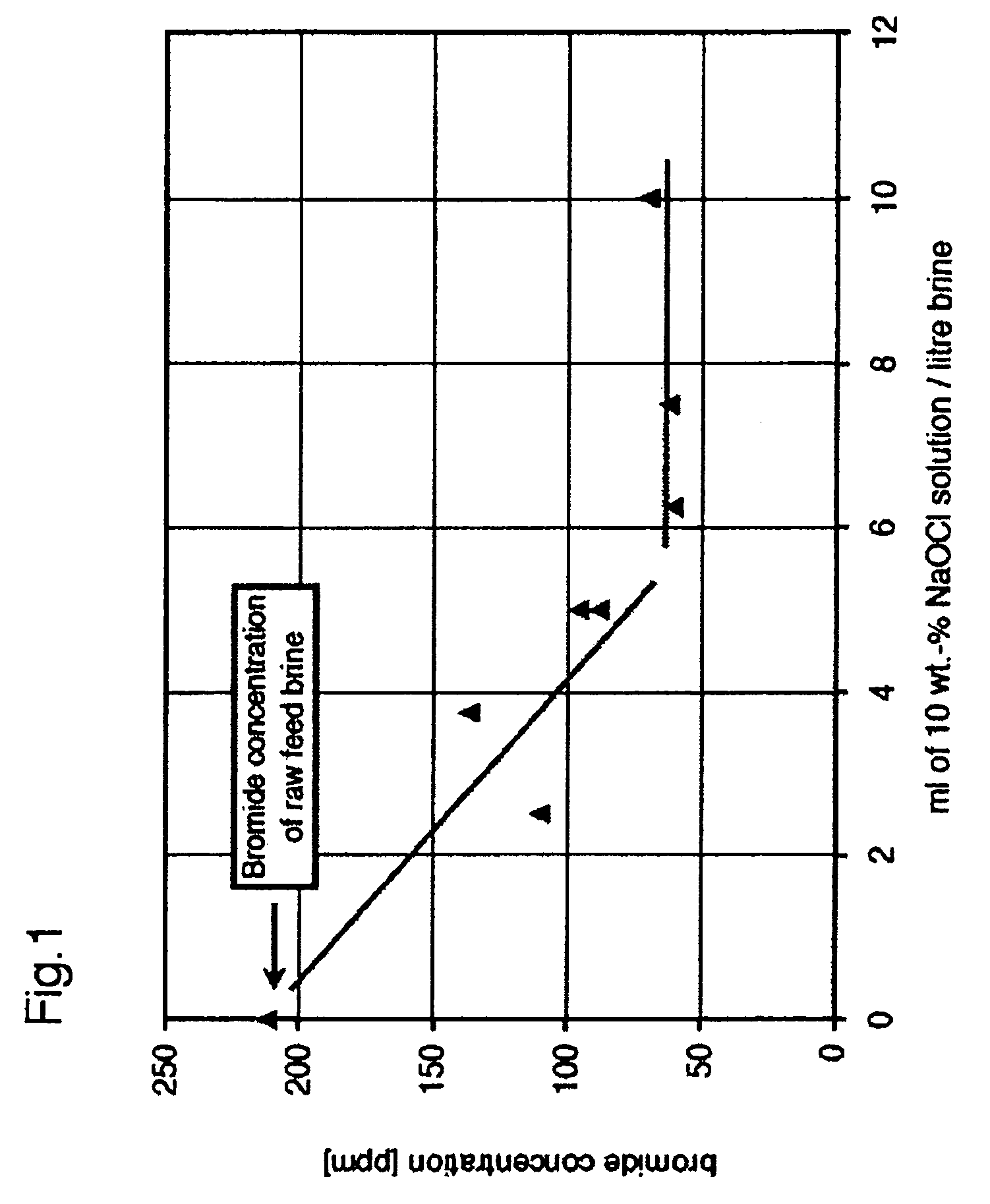

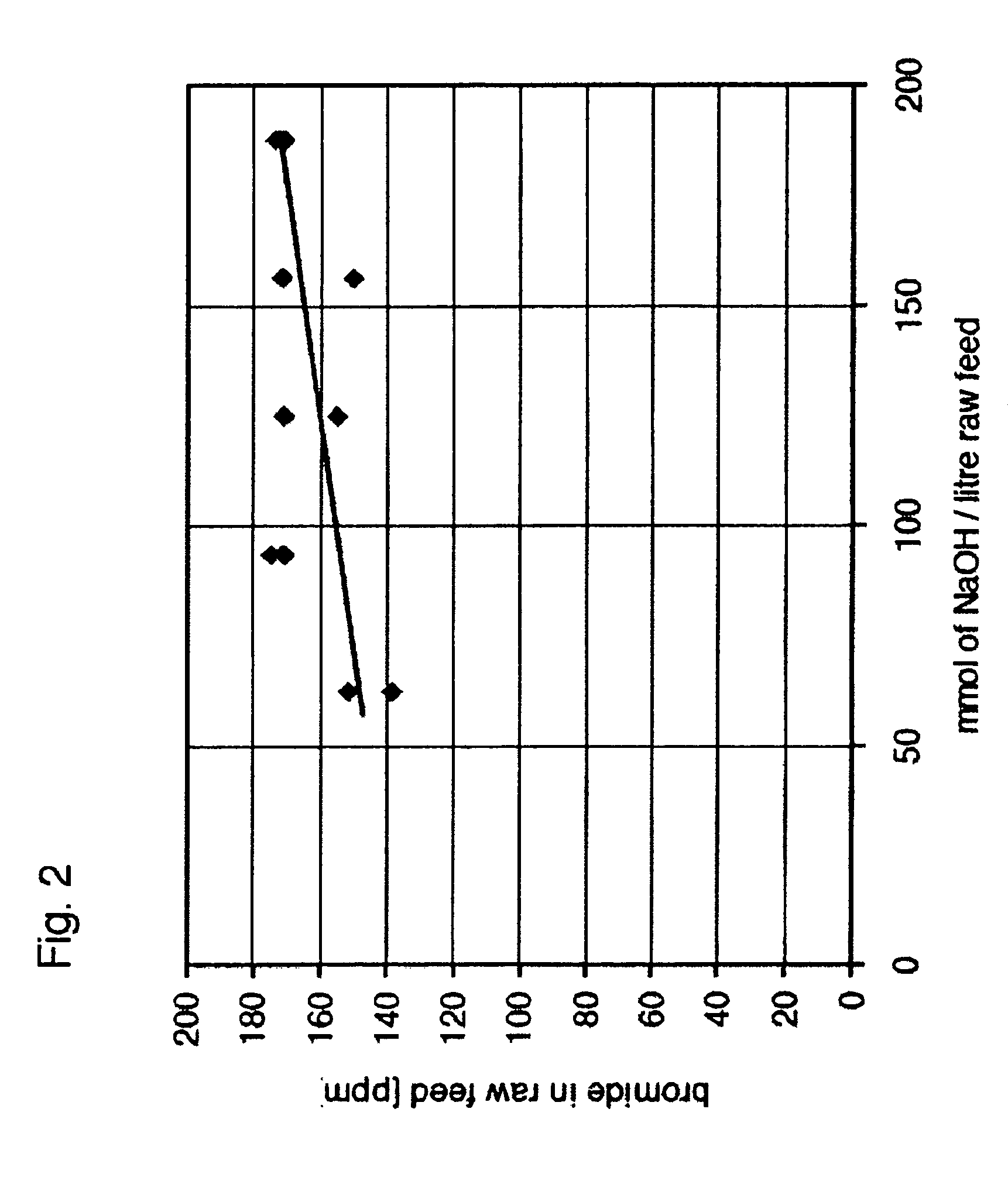

Bromide reduction process in liquid solutions

InactiveUS20060110312A1Increase supplyReduced effectivenessHypochlorous acidBromine oxygen compoundsPotassiumPh dependent

The invention provides a method for reducing bromine levels in brine solutions such as potassium chloride brine solutions. Bromide in solution is converted to hypobromite by the addition of an oxidant such as sodium hypochlorite. Hypobromite is precipitated by the addition of a metal cation such as magnesium under conditions of basic pH. The process is pH dependent such that the most efficient removal of bromine is achieved at a sodium hydroxide concentration of 90-200 mM. The pH optimum is also temperature dependent such that increased temperature lowers the optimal pH for bromide removal. The invention further provides a bromine-reduced potassium chloride product, suitable for uses in industrial applications. By the method of the invention bromine levels in a potassium chloride feed stock can be reduced by 97% or more.

Owner:IMC GLOBAL

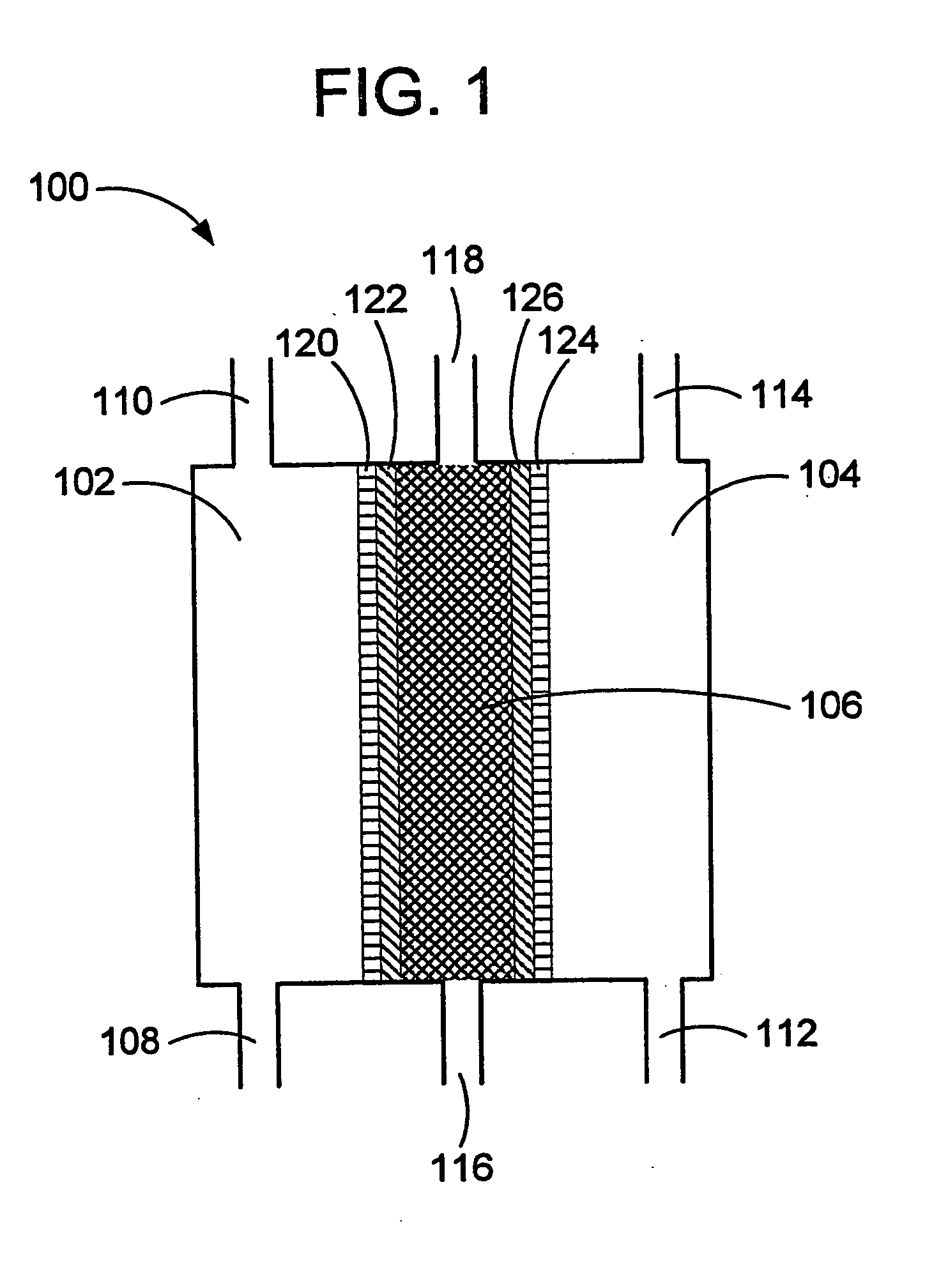

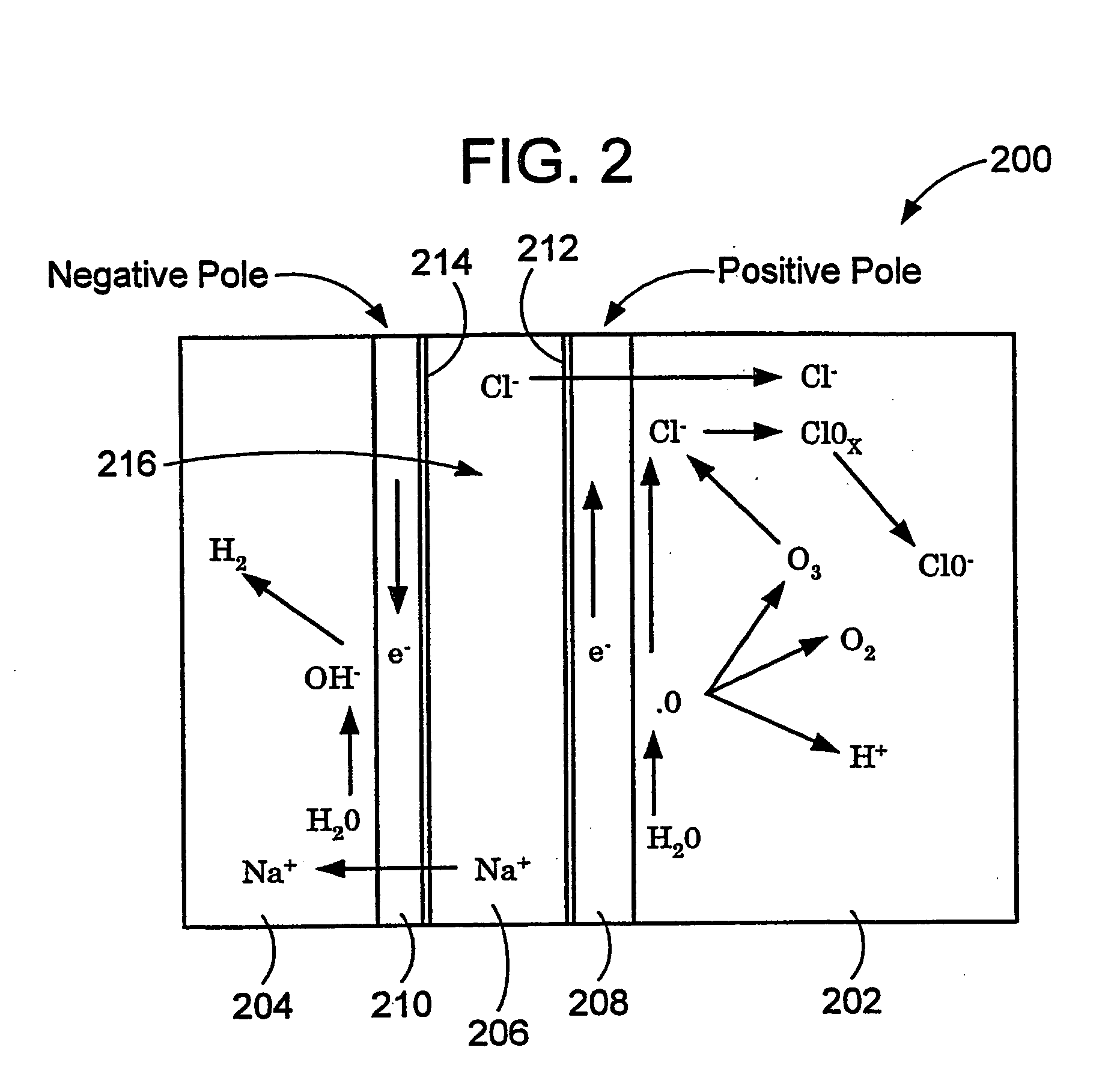

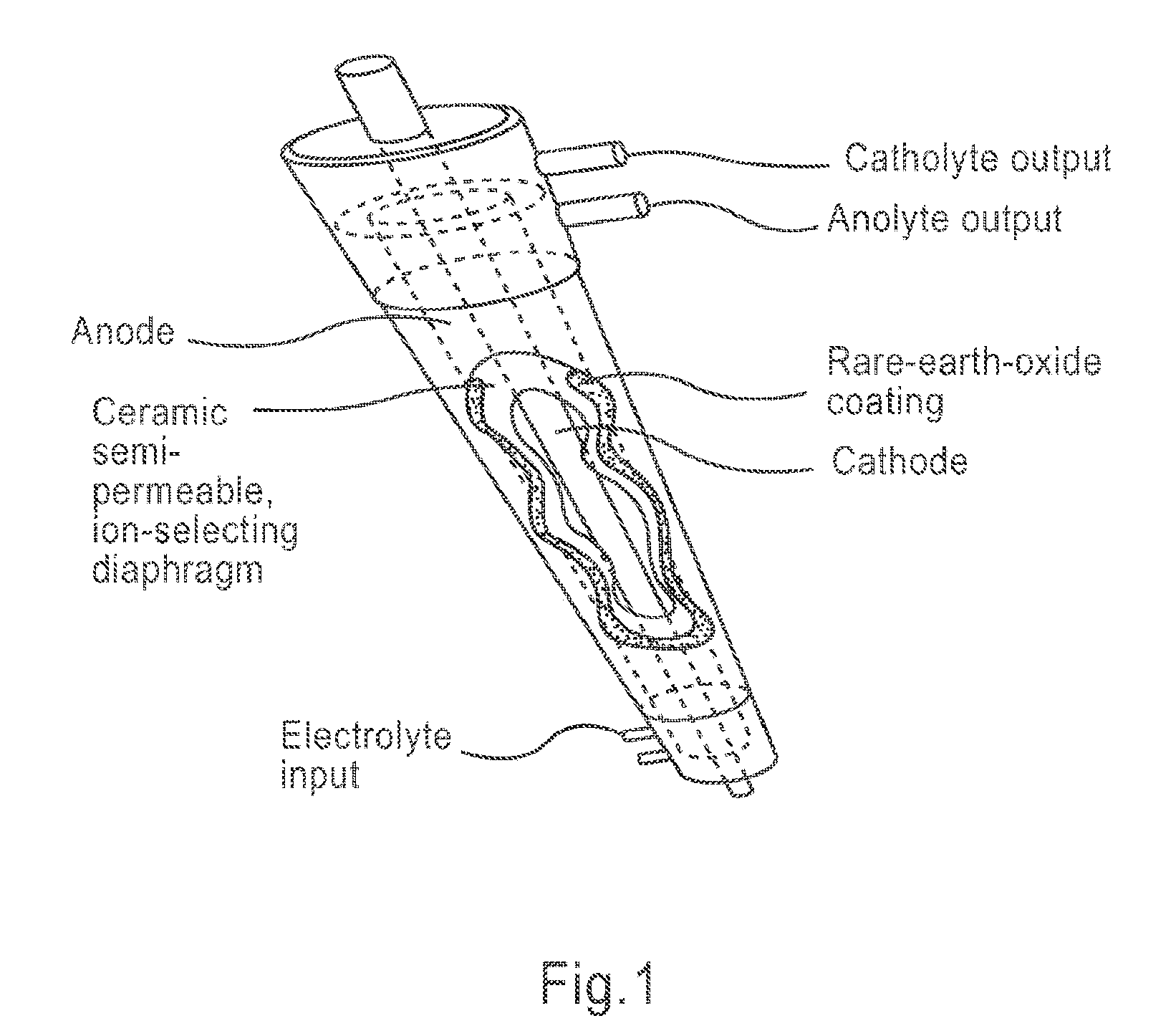

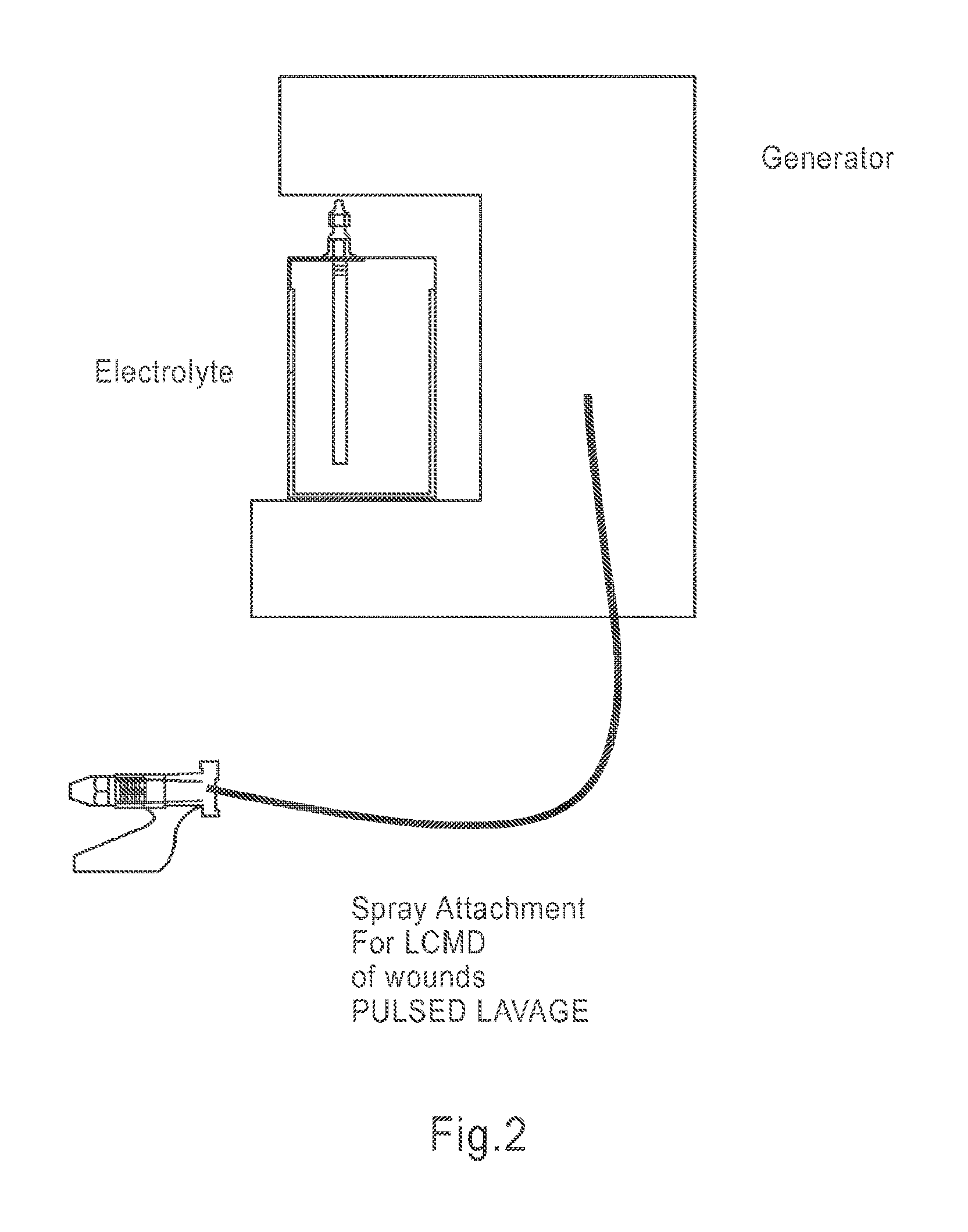

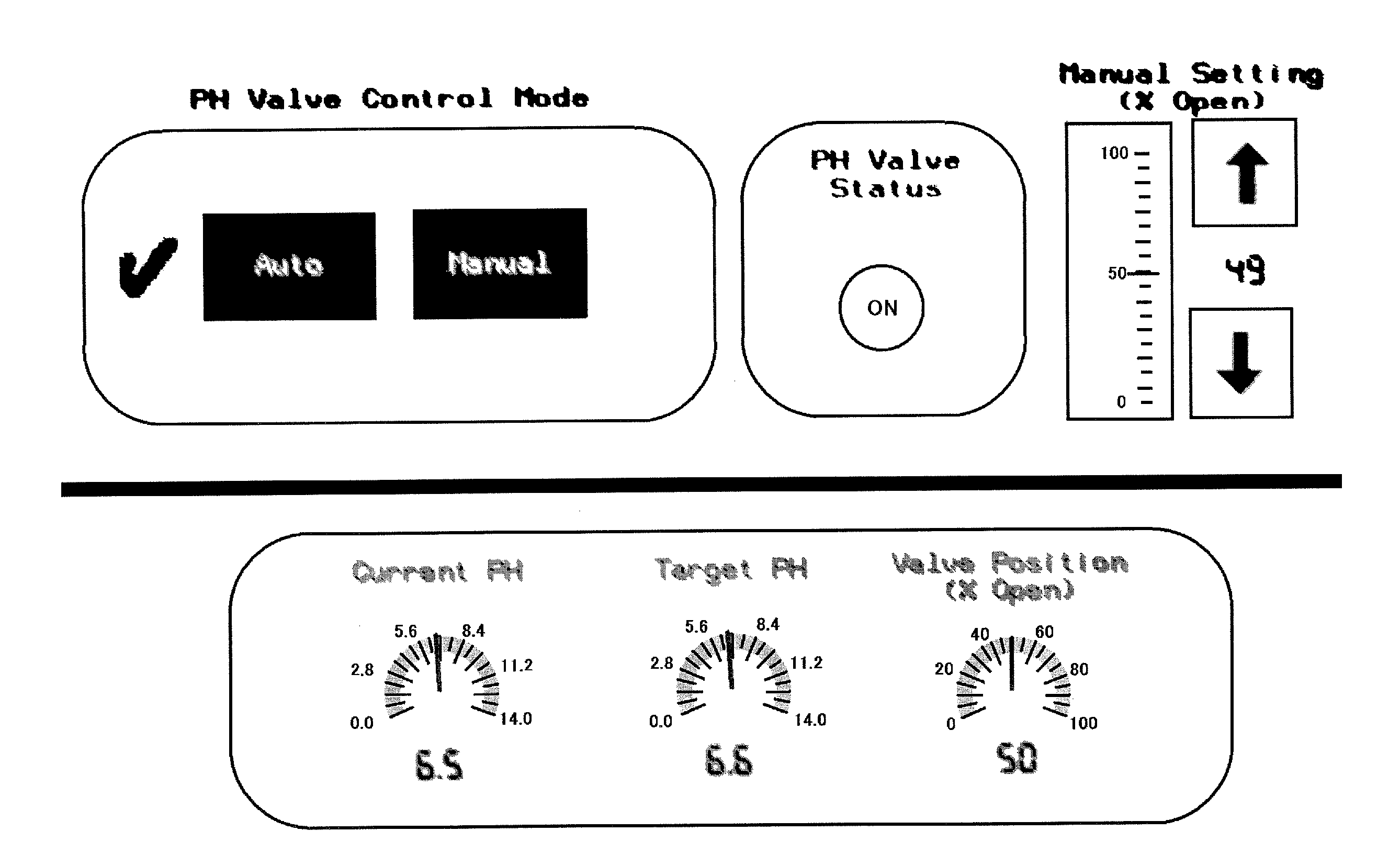

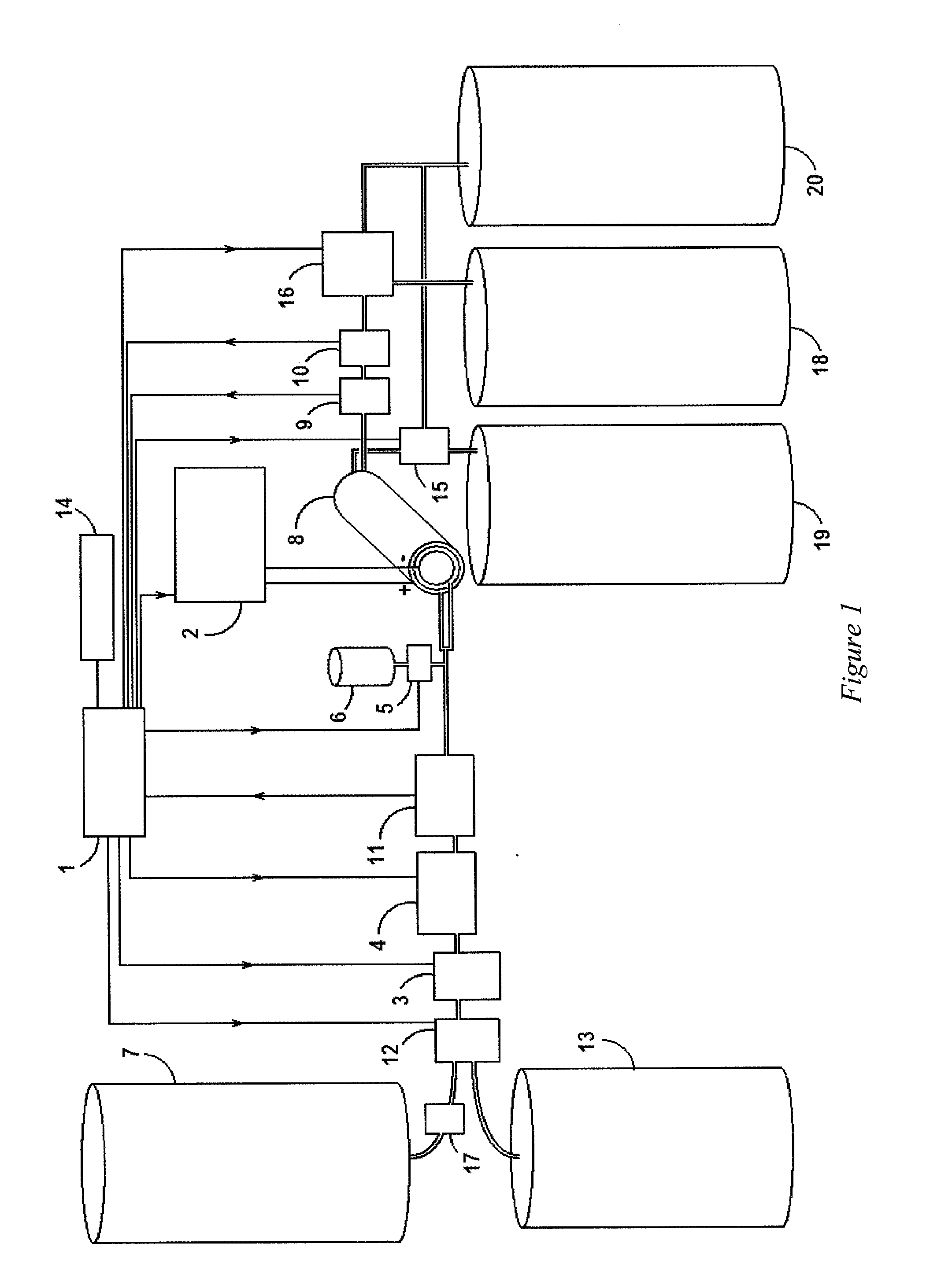

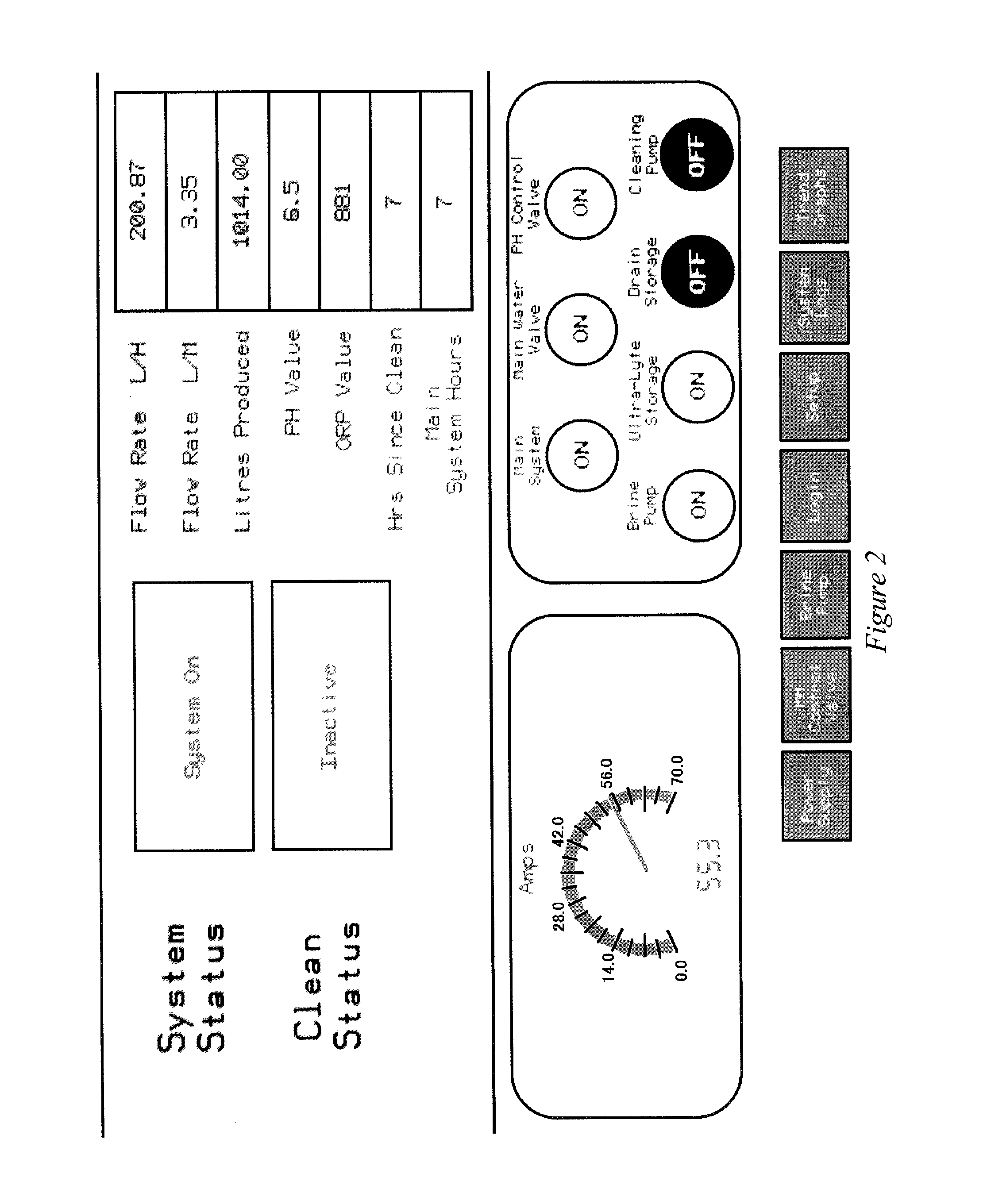

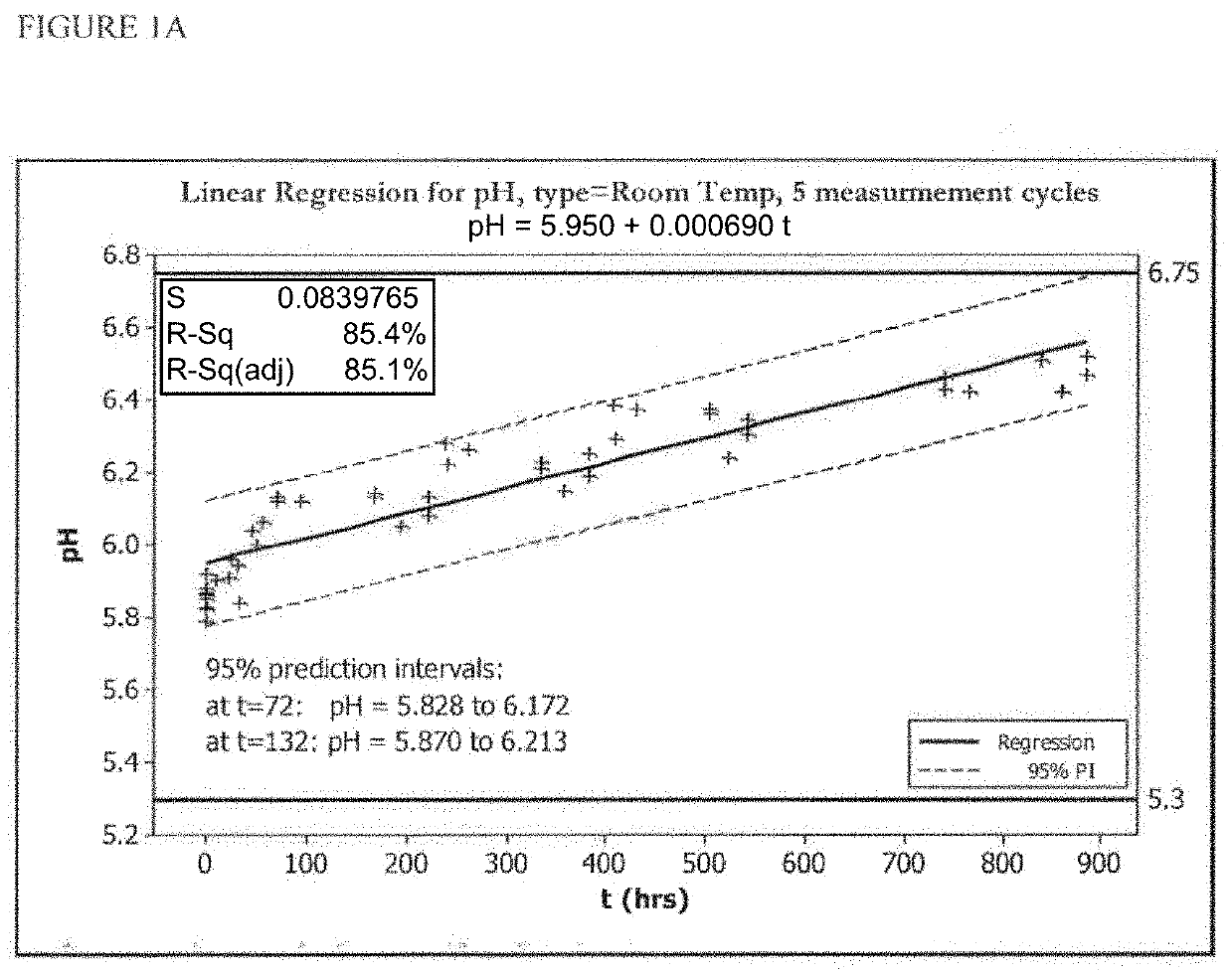

Cell and system for preparation of antimicrobial solutions

ActiveUS20160265123A1Convenient power distributionHigh in HOClCellsBiocideCeramic membraneHypochlorous acid

A system to prepare an antimicrobial solution by the electrolysis of brine is presented where the antimicrobial solution is a solution comprising HOCl that contains a HOCl concentration in excess of 500 ppm or more at a pH of 6 to 6.8 with a low residual salt concentration and displays a stability in excess of 60 days and can have a HOCl concentration in excess of 450 for 180 days. The system includes an electrolysis cell that is improved by a superior anode and ceramic membrane such that when employed with a DC power supply controlled by a microprocessor and a controlled brine concentration provided to the cell at ambient temperature at a controlled rate, delivers a fluid that is continuously monitored by a pH probe and an ORP probe for input to the microprocessor.

Owner:CLARTECH HLDG

Stabilized hypohalous acid solutions

ActiveUS20200138953A1Sanitizing, disinfecting or cleansing a hard surfaceMaintain activityBiocideFruit and vegetables preservationCut flowersPreserved Foods

The present invention provides a stabilized hypohalous acid solution (or formulation thereof), which may be conveniently packaged for sale, or stored for later use on demand. The invention further provides methods of making the stabilized hypohalous acid solution, as well as methods of use for disinfecting mammalian tissue, including wounds and burns, disinfecting or cleansing surfaces, or treating and / or preserving food products and cut flowers, among other uses.

Owner:URGO US INC

System and method for producing iodine compound

A system (100) of the present invention for producing an iodine compound includes: a raw material adjusting unit (1) for supplying hydrogen-containing gas to at least one of liquid iodine in an iodine melting pot (4) and gaseous iodine obtained by evaporating liquid iodine so as to obtain a mixture gas; a hydrogen iodide producing unit (10) including a hydrogen iodide producing tower (12) having a catalyst layer (12a) for converting the introduced mixture gas into crude hydrogen iodide gas; a hydrogen iodide refining unit for removing unreacted iodine from the introduced crude hydrogen iodide gas so as to obtain hydrogen iodide gas; and an iodine compound producing unit (30) for producing a target iodine compound from the obtained hydrogen iodide gas and a reaction material. This allows producing an iodine compound with high purity easily, efficiently, and with low cost.

Owner:NIPPON CHEMICALS CO LTD

Hypochlorous acid and preparation technology for generating epoxypropane by using same

ActiveCN103058142AIncrease concentrationNo wasteOrganic chemistryHypochlorous acidWastewaterHypochlorous acid

The invention discloses hypochlorous acid and a preparation technology for generating epoxypropane by using the hypochlorous acid. The preparation technology is characterized in that chlorine gas and saturated sodium chloride aqueous alkali are introduced into the bottom of a tubular reactor through a pump, and chlorination reaction takes places at the bottom of the tubular reactor to generate a hypochlorous acid solution. The preparation technology has the beneficial effects that as the chlorine gas and the saturated sodium chloride aqueous alkali are introduced into the bottom of the tubular reactor through the pump, chlorination reaction takes places at the bottom of the tubular reactor to generate the hypochlorous acid solution, the concentration of the hypochlorous acid in the generated hypochlorous acid solution is high, so that chlorohydrination reaction completely takes places between the hypochlorous acid solution and propylene, further the yield of generated chloropropanol is high, the waste of the hypochlorous acid is avoided, the generation of lots of wastewater is avoided, and the quantity of wastewater generated due to production of the epoxypropane is reduced by 30%, and environments are protected.

Owner:山东昌邑海能化学有限责任公司

Production method of high-stability hypochlorous acid

InactiveCN111517280AReaction raw materials are readily availableWith transshipmentHypochlorous acidHypochloriteAcid substances

The invention relates to the technical field of hypochlorous acid production methods, in particular to a production method of high-stability hypochlorous acid. The production method of high-stabilityhypochlorous acid comprises the following steps: (1) mixing water with a hypochlorite solution to obtain a hypochlorite solution; (2) mixing the pypocholoride solution with an acidic substance, adjusting the pH value of the solution to 3-5, and filtering to remove insoluble substances; then adding an alkaline substance, adjusting the pH value of the solution to 5-6.5, and filtering to remove insoluble substances to obtain a hypochlorous acid solution; and (3) adding a stabilizer into the hypochlorous acid solution, and uniformly mixing to obtain the product. The method is high in efficiency and low in cost, the prepared hypochlorous acid solution has the advantages of being stable in concentration and convenient to use, the storage validity period reaches two years or longer, packaging, storage and transfer of the disinfection solution are achieved, commercialization of the disinfection solution becomes possible, the limitation that the disinfection solution is prepared and used on site in the prior art is overcome, and the method has industrial application value.

Owner:中天朗洁(厦门)环保科技有限公司

Improvements relating to hypochlorous acid solutions

ActiveUS20180282160A1Solution stableEase of productionInorganic active ingredientsHypochlorous acidHypochloriteAqueous solution

A process for preparing an aqueous solution comprising hypochlorous acid, the process comprising: (i) treating an aqueous starting solution comprising hypochlorite and a precipitable counter-ion with a precipitation agent to form a counter-ion precipitate and a supernatant liquid having a pH greater than 6; (ii) removing at least part of said precipitate; and subsequently (iii) acidifying at least part of the supernatant liquid with a strong inorganic acid other than hydrochloric acid, to a pH in the range of from 3.0 to 6.0, to form an aqueous product solution comprising hypochlorous acid. Solutions obtainable by the process are also described, as are related uses.

Owner:XANADOX TECH

Systems and methods for reducing carbonates in a chlorination system

Systems and methods are disclosed for increasing the concentration of hypochlorous acid in a quantity of water. Acid is added into chlorinated water to decrease the pH of the chlorinated water. By decreasing the pH, the hypochlorite / hypochlorous acid equilibrium of the chlorinated water is shifted to increase the concentration of hypochlorous acid on the treated water and the tendency for precipitation of solids such as carbonates is reduced. A portion of the chlorinated solution can be continuously returned to a mixing tank under pressure.

Owner:TOMCO2 EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com