Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about "Cathode heaters manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

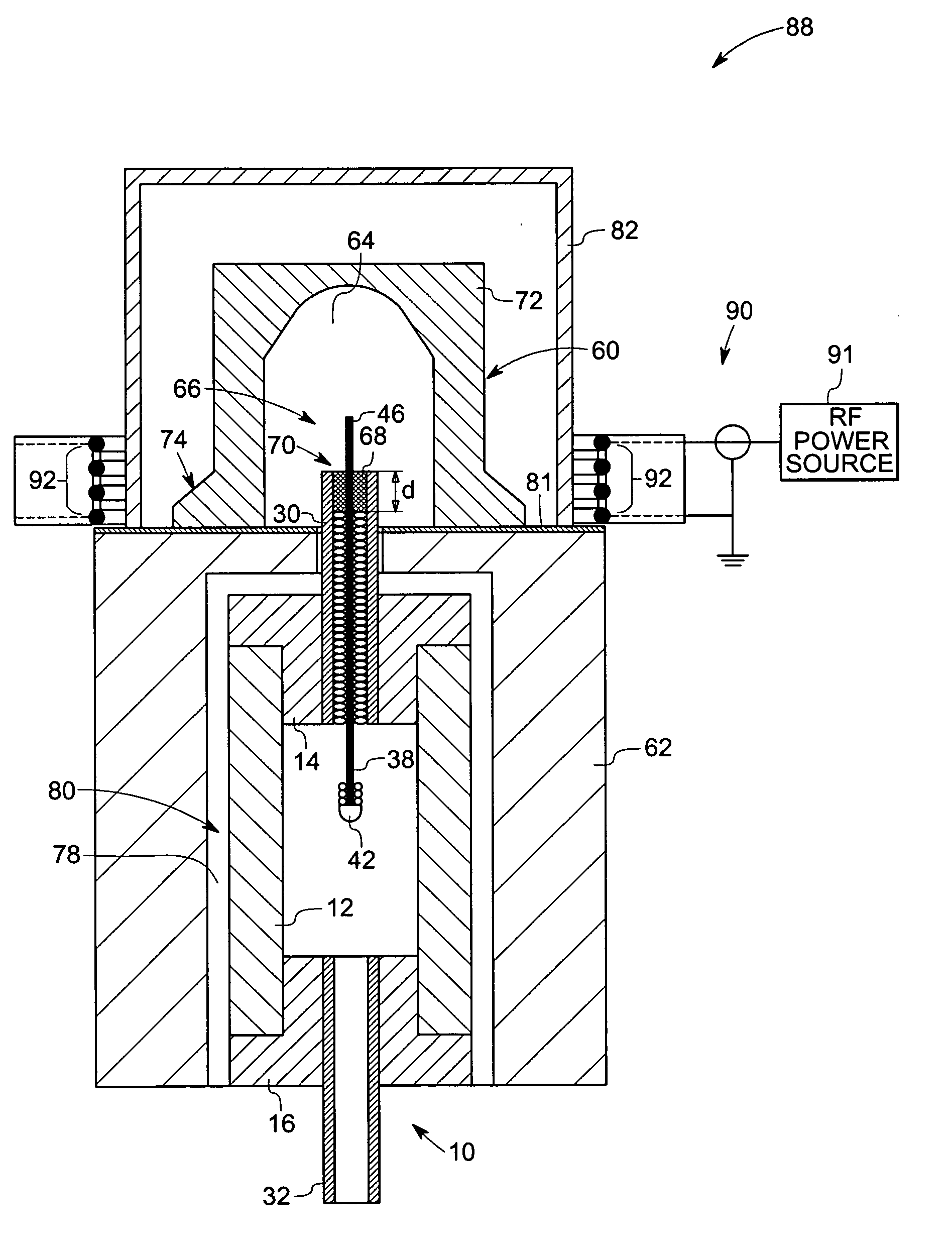

System and method for sealing high intensity discharge lamps

In accordance with certain embodiments, the present technique includes a system for sealing a lamp including a thermal shield and a thermally susceptible enclosure disposed adjacent the thermal shield. The thermal shield has a first receptacle adapted to receive a first portion of the lamp. The thermally susceptible enclosure comprises a wall about a second receptacle adapted to receive a second portion of the lamp. The wall has a varying thickness in a desired sealing region between the first and second portions of the lamp.

Owner:GENERAL ELECTRIC CO

Method for making thermionic electron source

ActiveUS20090170394A1Increase kinetic energyCathode ray tubes/electron beam tubesNon-emitting electrodes manufactureElectron sourceCarbon nanotube

A method for making a thermionic electron source includes the following steps: (a) supplying a substrate; (b) forming a first electrode and a second electrode thereon; and (c) spanning a carbon nanotube film structure on a surface of the first electrode and the second electrode with a space defined between the thermionic emitter and the substrate.

Owner:TSINGHUA UNIV

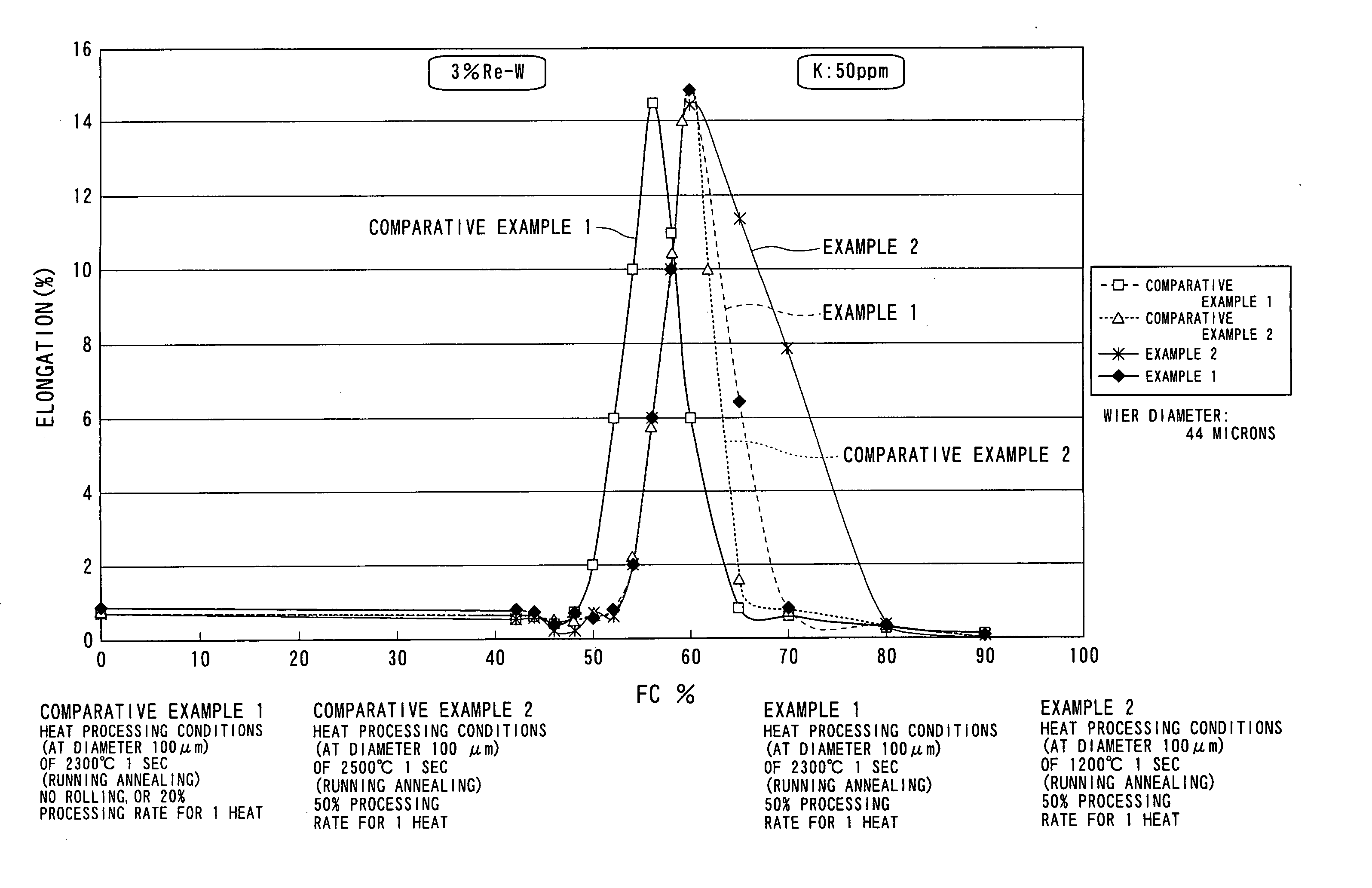

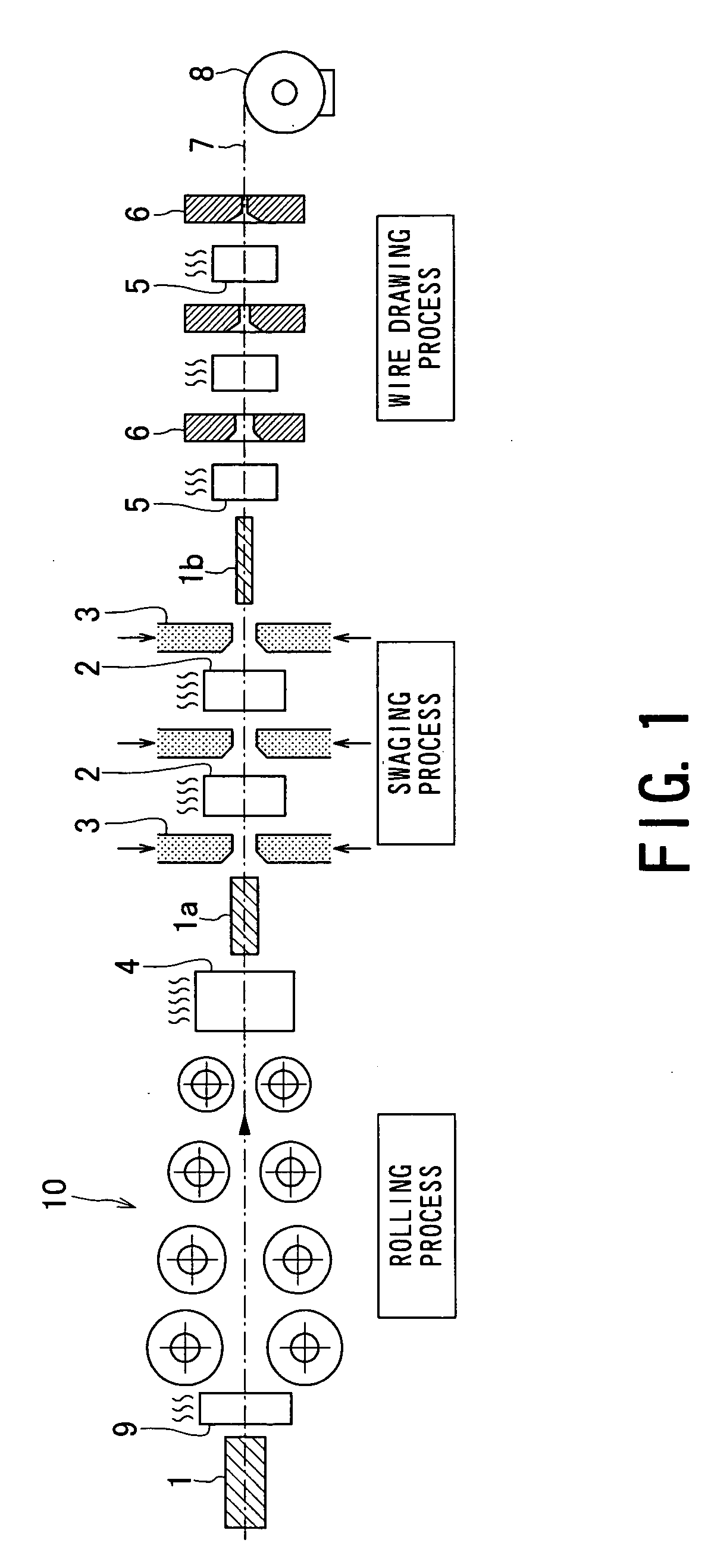

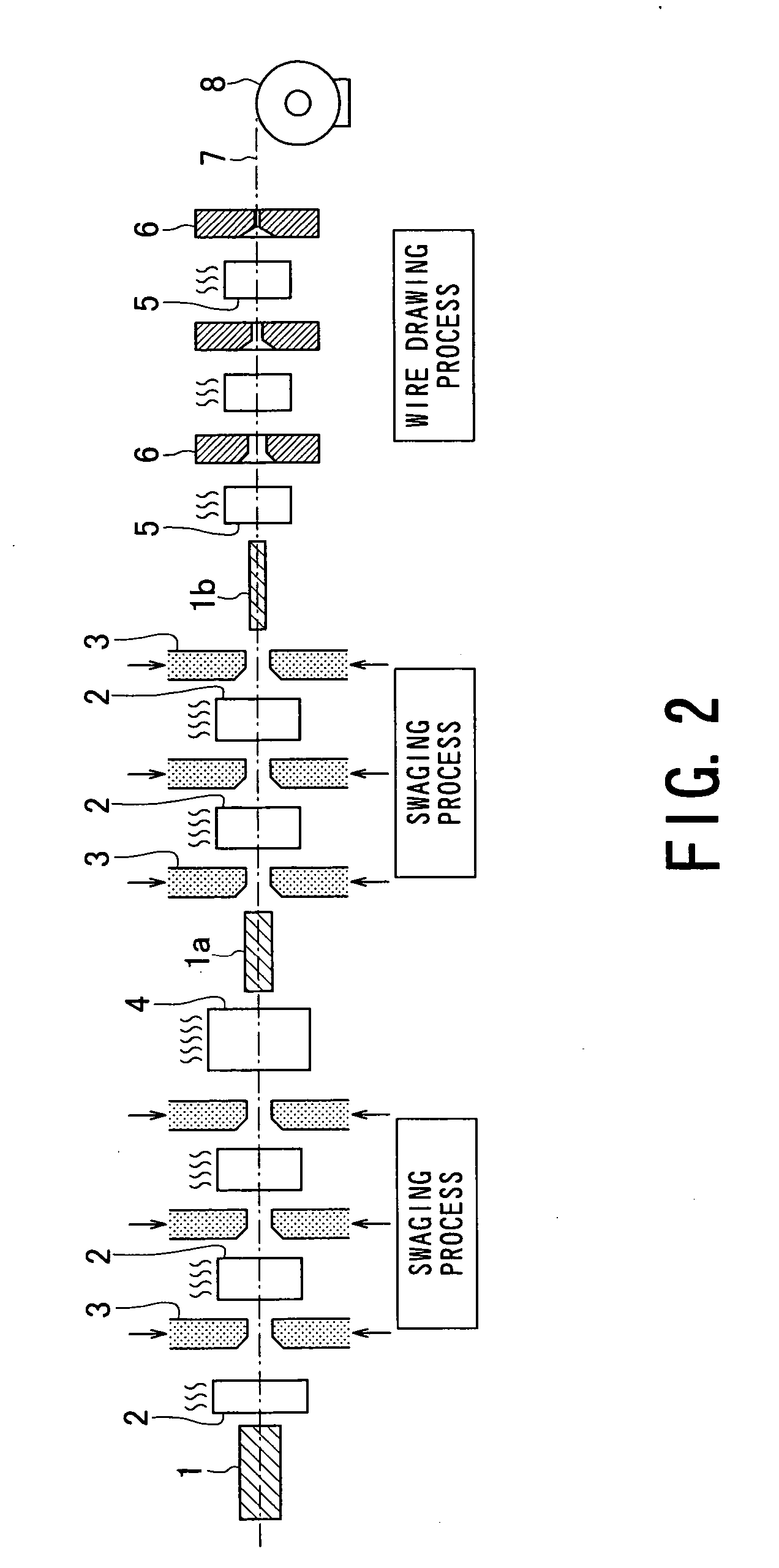

Tunsten wire, cathode heater, and filament for vibration service lamp

InactiveUS20040244879A1Efficient preparationHigh elongationForging/pressing devicesElectric discharge tubesRheniumHorizontal axis

A tungsten wire containing 1 to 10% by mass of rhenium has a point which indicates a 2% elongation within a quadrangle formed by joining points with straight lines, where the values of x and y are point (20, 75), point (20, 87), point (90, 75), and point (90, 58), in this order, wherein the wire diameter of the aforementioned tungsten wire is represented by x mum, and the elongation of the tungsten wire is 2% after electrically heating with an electrical current which is a ratio of y % to the fusion current (FC) at the wire diameter x mum, and wherein a semi-logarithmic system of coordinates is expressed by a horizontal axis using a logarithmic scale of the aforementioned wire diameter x and a vertical axis using a normal scale of ratio y to the fusion current. According to the above-described configuration, a tungsten wire having a great elongation even under conditions of high temperature can be provided, and the tungsten wire can exhibit an excellent durability when used as component material for constituting cathode heaters and so forth, and the tungsten wire can be manufactured efficiently.

Owner:KK TOSHIBA

Apparatus and method for manufacturing liquid crystal display devices

InactiveUS20050020177A1Electroluminescent light sourcesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

An apparatus for manufacturing a liquid crystal display device includes a unitary vacuum processing chamber, upper and lower stages confronting each other at upper and lower spaces inside the vacuum processing chamber to bond a first and second substrates, and a first substrate lifting system formed in the lower stage for lifting the second substrate.

Owner:AVACO

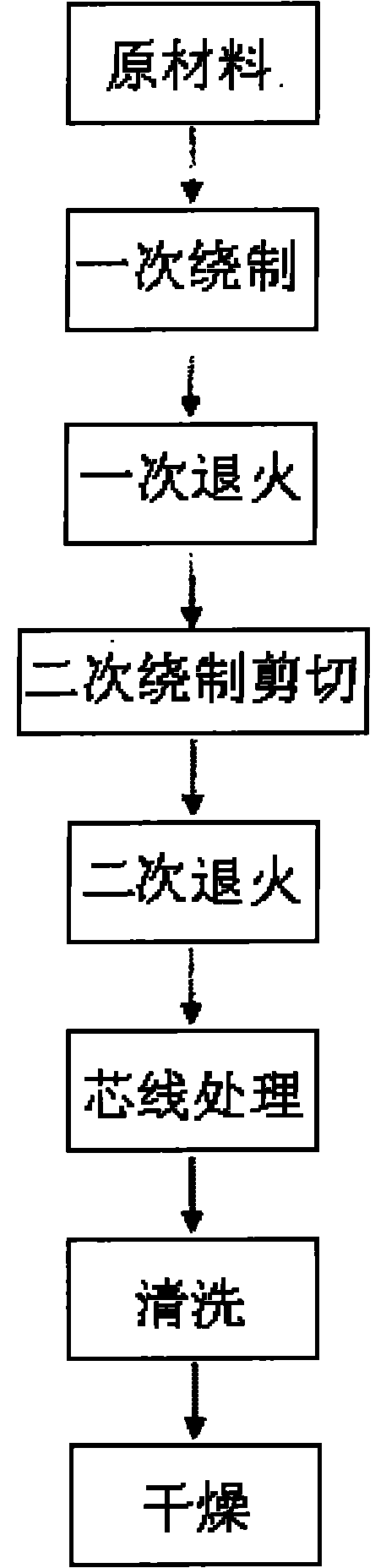

Coreless winding method of coiled-coil filament

InactiveCN102082067AReduce usageEmission reductionCathode heaters manufactureWinding machineWastewater

The invention discloses a coreless winding method of a coiled-coil filament. In the process of secondary winding of the filament, the coreless winding process is adopted, and two-pass molybdenum wires acting as core wires, a coiled-coil filament winding machine and a shearer are not used any more, but the automatic core pulling operation of a coreless filament winding machine is directly used for winding. The method has the following beneficial effects: the process is easy to operate, the usage amount of the rare metal molybdenum for filament production is greatly reduced, and complex equipment is simultaneously reduced, thus reducing the production procedures and saving the raw materials; and in addition, the wastewater discharge is reduced, the disposal costs for environmental protection in the process of production is reduced, and at the same time, the production speed and the product quality are improved.

Owner:ANHUI HUSN HUAGUANG ENERGY SAVING TECH

Coil winder

InactiveCN101694811AEasy to operateNeat wiringCoils manufactureCathode heaters manufactureEngineering

The invention discloses a coil winder which comprises a handle and a tubular rotating handle, wherein one end of the tubular rotating handle is arranged on the handle, a lead handle for fixing the end of a coil is also arranged on the rotating handle; the rotating handle of the coil winder is inserted on a coil column to be wound by the coil, the end of the coil is fixed on the lead handle, at last, the handle is rotated to drive the rotation of the rotating handle and the lead handle so as to enable the coil to be wound on the coil column. The coil wound by the coil winder is neat, safe and reliable; meanwhile, by using the coil winder, the operation is convenient, and the working efficiency can be improved.

Owner:常熟卓辉光电科技股份有限公司

Method for manufacturing lamp filament of self-rectifying mercury lamp

ActiveCN103295858AStrong silk feet at both endsExtended service lifeCathode heaters manufactureEngineeringMercury-vapor lamp

The invention relates to a method for manufacturing a lamp filament of a self-rectifying mercury lamp. The method includes the steps of winding, first sizing, cutting, second sizing and melting a core filament. The lamp filament of the self-rectifying mercury lamp is eventually manufactured and obtained through the steps. Compared with the prior art, filament feet at the two ends of the lamp filament manufactured by adopting the method are firmer, so that the filament is not prone to being broken, and the service life of the lamp filament is greatly prolonged.

Owner:上海亚尔精密零件制造有限公司

Method of fabricating electron source substrate and image forming apparatus

InactiveUS6837768B2Vessels or leading-in conductors manufactureSparking plugsElectron sourceElectrical and Electronics engineering

A method of fabricating an electron source includes the steps of fixing a first sealing member to a substrate disposed with an electroconductive member, the first sealing member surrounding the electroconductive member excepting a portion of the electroconductive member, abutting a chamber on the first sealing member to cover the electroconductive member excepting the portion of the electroconductive member and form a hermetically sealed atmosphere between the substrate and the chamber, supplying power to the portion of the electroconductive member to give part of the electroconductive member covered with the chamber an electron-emitting function, and removing the chamber from the substrate.

Owner:CANON KK

Heat emission cathode and manufacturing method thereof

InactiveCN103956310ALower working temperatureHigh mechanical strengthDischarge tube solid thermionic cathodesCathode heaters manufactureRheniumAlloy

The invention provides a heat emission cathode. The heat emission cathode comprises a U-shaped hot filament, one end of cathode base metal is connected with the center of a U-shaped bottom of the U-shaped hot filament, and the cathode base metal is coated with emission matter. The invention further provides a manufacturing method of the heat emission cathode. The method includes the steps that first, a tungsten-rhenium alloy wire is closely wound on a rectangular core bar, high temperature shaping is conducted, the tungsten-rhenium alloy wire is longitudinally cut off along the core bar after shaping, and accordingly the U-shaped hot filament is obtained; then, one end of tungsten-rhenium alloy foil serving as the cathode base metal is connected with the center of the bottom of the U-shaped hot filament, so that a cathode hot filament component is formed; finally, the cathode base metal is placed in triple carbonate turbid liquid for conducting electrophoresis. According to the heat emission cathode, an applicative hot cathode is provided for certain millimeter wave band ultrahigh frequency electron tubes with special structures or small structural sizes, the nonmagnetic performance of the cathode base metal can be guaranteed, high mechanical strength is achieved, the emitting matter can be evenly coated and can firmly adhere to the base metal, and qualified electron emission capacity is achieved as well.

Owner:甘肃虹光电子有限责任公司

Plasma display panel with superior light-emitting characteristics, and method and apparatus for producing the plasma display panel

InactiveUS20050042968A1High light emitting efficiencyHigh color reproductionAlternating current plasma display panelsVessels or leading-in conductors manufactureCooking & bakingRoom temperature

A PDP with superior light-emitting characteristics and color reproduction is achieved by setting the chromaticity coordinate y (the CIE color specification) of light to 0.08 or less, more preferably to 0.07 or less, or 0.06 or less, enabling the color temperature of light to be set to 7,000K or more, and further to 8,000K or more, 9,000K or more, or 10,000K or more. The PDP is manufactured by a method in which the processes for heating the fluorescent substances such as the fluorescent substance baking, sealing material temporary baking, bonding, and exhausting processes are performed in the dry gas atmosphere, or in an atmosphere in which a dry gas is circulated at a pressure lower than the atmospheric pressure. This PDP is also manufactured by: a method in which after the front and back panels are bonded together, the exhausting process for exhausting gas from the inner space between panels is started while the panels are not cooled to room temperature; or a method in which after the front and back panels are temporarily baked, the process for bonding the panels is started while the panels are not cooled to room temperature. This reduces the time and energy required for heating, resulting in reduction of manufacturing cost.

Owner:PANASONIC CORP

Method and apparatus for manufacturing image displaying apparatus

InactiveUS20050181698A1Easy to fallImprove production efficiencyTube/lamp vessel degassingMechanical actuationPhosphorComputer science

A method and an apparatus for manufacturing an image displaying apparatus having a display panel. A first substrate of the display panel on which a phosphor exciter is disposed and a second substrate of the display panel on which phosphors emitting light by the phosphor exciter is provided, are prepared under a vacuum atmosphere. Then, the first and the second substrates are carried in a getter processing chamber or bake processing chamber, and getter processing or bake processing is applied thereto under the vacuum atmosphere. After the processing, the first and the second substrates are carried in a seal processing chamber, where the substrates are heat sealed under the vacuum atmosphere. Thus, reduction of vacuum exhaust time and a high vacuum degree in manufacturing an image displaying apparatus is attained and efficiency of manufacturing is improved.

Owner:CANON KK

Method for Manufacturing Hot Cathode Fluorescent Lamp

InactiveUS20080070467A1Increase production capacityHigh luminous intensityElectroluminescent light sourcesLow-pressure discharge lampsNoble gasLuminous intensity

A method for manufacturing a hot cathode fluorescent lamp can ensure or facilitate stable initial luminous intensity and provide improved product life characteristics even when the hot cathode fluorescent lamp employs a glass tube with an outer diameter of less than 7 mmφ. One end of a glass tube can be sealed with a glass bead of a mount structure. The other opening end of the glass tube can be welded with an opening end of an exhaust pipe with bent portions of lead wires being sandwiched between the opening ends of the glass tube and the exhaust pipe. After evacuating a vacuum system that is constituted by the inner spaces of the glass tube and the exhausted pipe communicating with each other, the bent portions of the lead wires which extrude outside the vacuum system can be clamp-connected to power source lines extending from an external power source. The emitter of the filaments can be activated by the generated heat of the filament. After supplying mercury and a rare gas into the glass tube, the glass bead can be sealed, and unnecessary portions of the glass tube, the exhaust pipe, and the lead wires can be removed to complete the hot cathode fluorescent lamp, in accordance with one aspect of the disclosed subject matter.

Owner:STANLEY ELECTRIC CO LTD

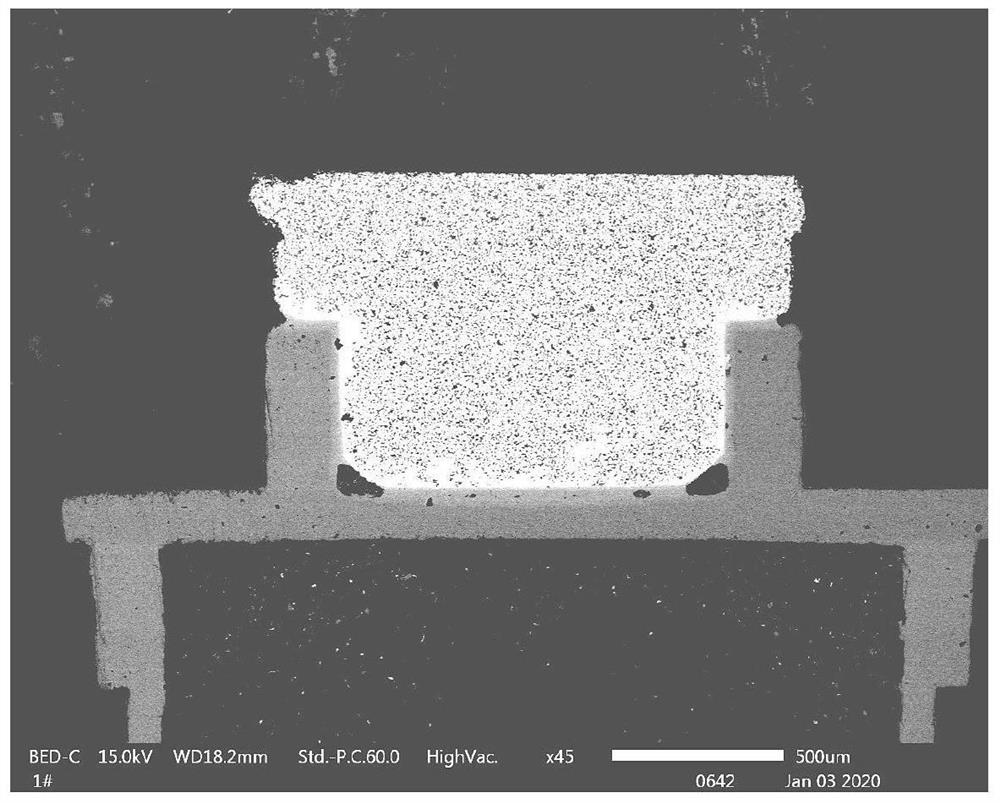

Cathode heater assembly and preparation method thereof

ActiveCN111243917ASimple structureImprove yieldDischarge tube solid thermionic cathodesThermionic cathode manufactureMetal stripsMetal sheet

The invention provides a cathode heater assembly and a preparation method thereof. The preparation method comprises the following steps of cutting a metal sheet with a preset thickness to obtain a rectangular metal strip, and taking the rectangular metal strip as a heater; and welding the heater on the surface of the cathode substrate, wherein the surface is opposite to the emitting surface of thecathode substrate. The cathode heater assembly is simple in structure, the prepared cathode heater assembly is high in yield, short in preheating time, small in size, high in heat efficiency, high inheating temperature, uniform in heating, good in vibration resistance, good in thermal shock resistance, high in reliability and simple in manufacturing method, and is free of short circuit.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Optical fiber code holding structure in which the number of the parts for the function of protecting the light from being directly viewed and the function of holding the optical fiber code is reduced and the connecting work of an optical connector is easily performed

InactiveUS7037162B2Increase added valueEasy connection workElectroluminescent light sourcesTube/lamp factory adjustmentEngineeringOptical fiber cable

An optical fiber code holding structure, includes: an optical adapter and an optical fiber code holding member. An optical connector of an optical fiber is connected to an optical adapter. The optical connector is attached to an end of an optical fiber code of the optical fiber. The optical fiber code holding member has a light shielding device shielding lights emitted from the optical adapter and a holding device holding the optical fiber code.

Owner:NEC CORP

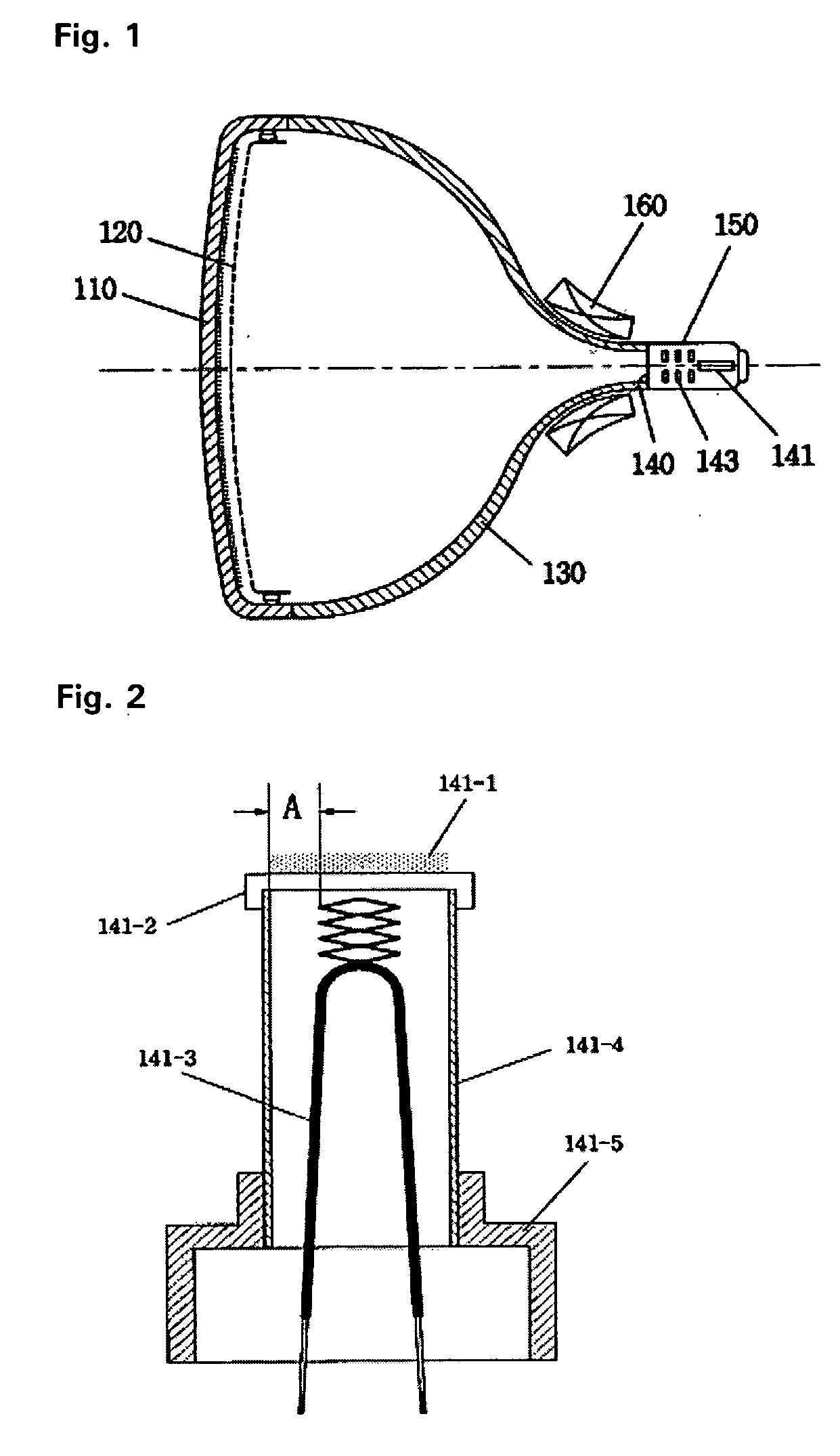

Cathode ray tube and method for manufacturing the same

InactiveUS20050012835A1Quality improvementImprove reliabilityTelevision system scanning detailsElectrode and associated part arrangementsThree levelElectron

The present invention discloses a cathode ray tube including an electron gun having a heater and a method for manufacturing the same. The heater is formed using a coil and includes a heat-emitting part having a heat-focusing part on which heat generated from the coil is focused and a buffering part for buffering shocks, and a triple coil part formed such that the coil is wound in three levels at predetermined pitches. The pitches of second and third levels of the triple coil part are substantially identical to each other and larger than the pitch of the first level. The present invention can improve the quality and welding reliability of the heater and reduce the quantity of coil required and time required for winding the coil while accomplishing high efficiency heating.

Owner:LG PHILIPS DISPLAY KOREA CO LTD

Cathode ray tube and method for manufacturing the same

InactiveCN1577708AGood quality and stabilityImprove welding stabilityElectrode and associated part arrangementsPicture signal generatorsThree levelEngineering

Owner:LG PHILIPS DISPLAY KOREA CO LTD

Mixed filling powder for hot filament assembly and preparation method of mixed filling powder

ActiveCN112490098AHigh thermal radiation coefficientFast heat conductionHeating element materialsDischarge tube solid thermionic cathodesAluminium oxidesYttrium(III) oxide

The invention discloses mixed filling powder for a hot filament assembly and a preparation method of the mixed filling powder, and the filling powder can realize rapid heat transfer of the hot filament assembly so as to realize rapid starting of a cathode. The filling powder comprises the following components in parts by weight: 95-105 parts of aluminum oxide powder, 19-21 parts of yttrium oxide powder and 28.5-31.5 parts of tungsten oxide powder.

Owner:CHENGDU GUOGUANG ELECTRIC

Preparation for vacuum fluorescent displaying device without discharge pipe

InactiveCN1614733AImprove production conditionsK decomposition is uninterrupted and smoothCathode heaters manufactureCold cathode manufactureFluorescenceDecomposition

The feature that the filament completes decomposition of constant current k in vacuum furnace is: for 0.8-1.0 v / cm filament, the range of added constant current I is between 38.28-43.72 mA; the temperature of tungsten filament Tw is 981-1099deg.C; The temperature of carbonate Tk is 905-1015.

Owner:上海三星广电电子器件有限公司

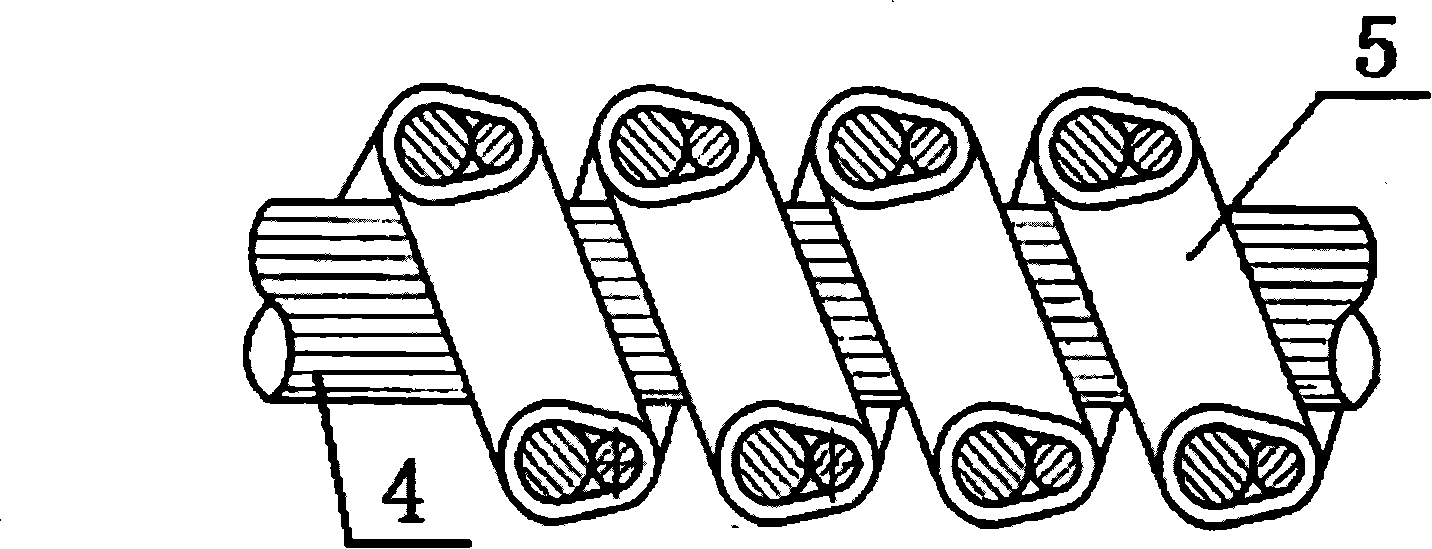

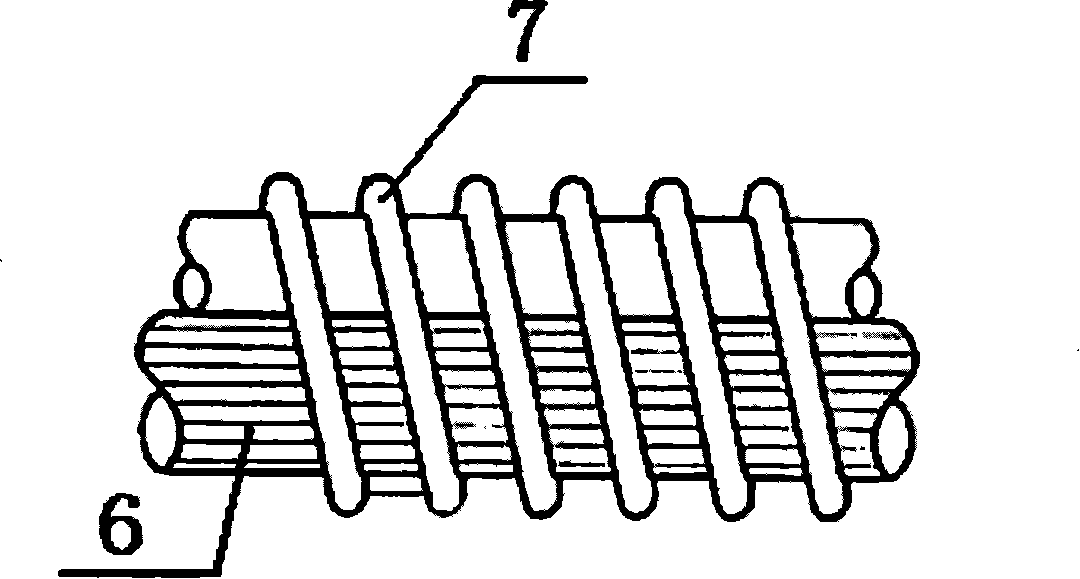

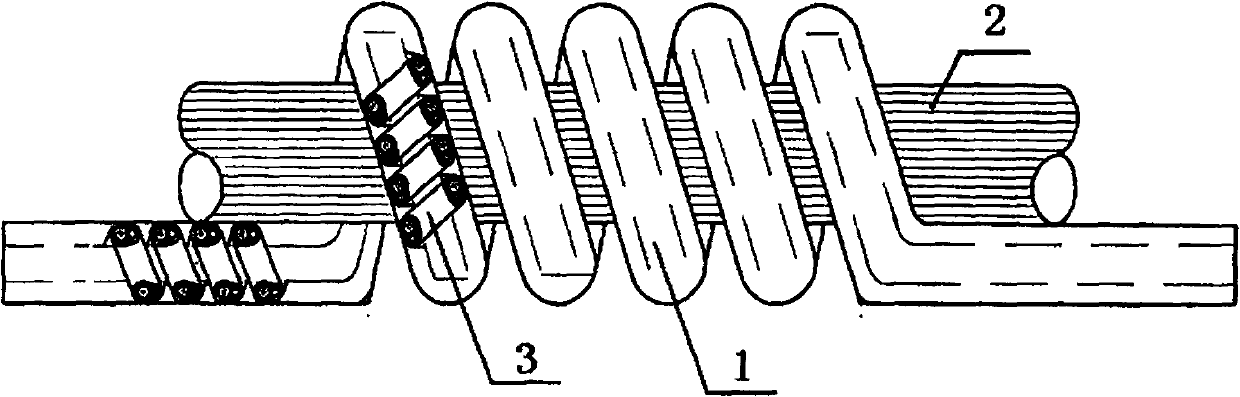

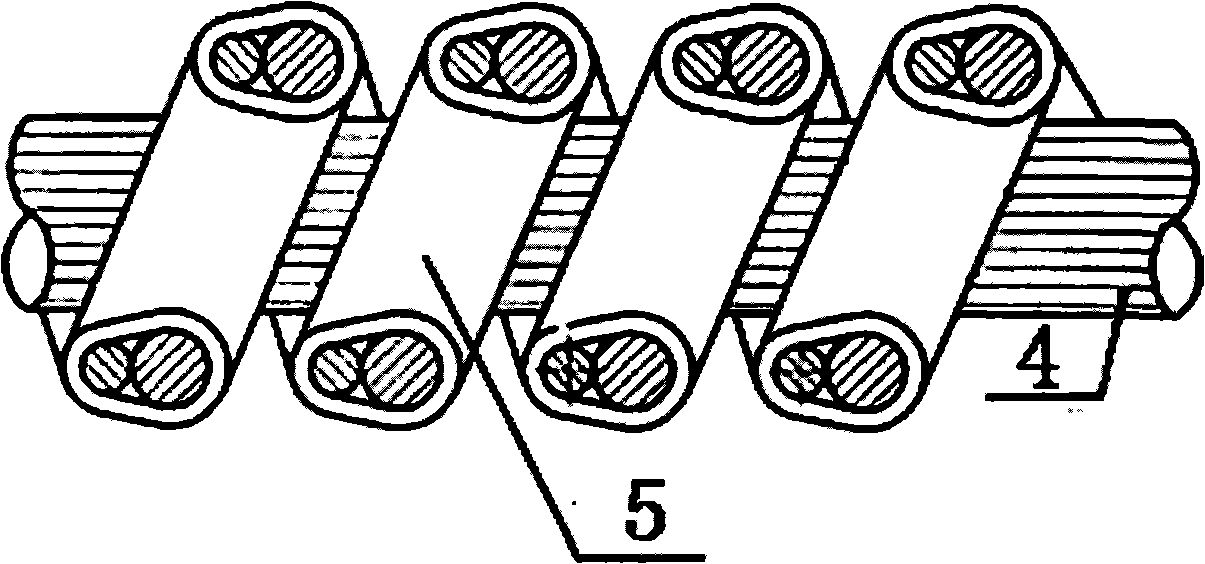

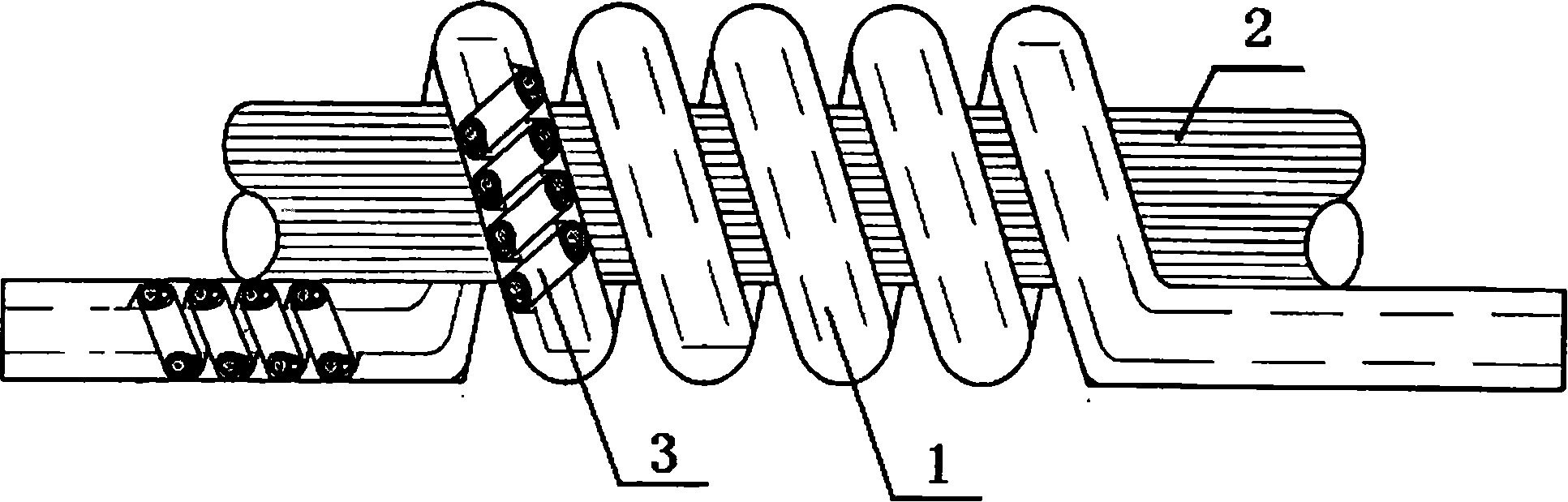

Left, right, right three-section type spiral winding method and structure of energy-saving filament

InactiveCN101252065AReduce defective productsReduce manufacturing costLamp incadescent bodiesGas discharge lamp detailsThree stageEngineering

The invention discloses a left-right-right three-stage helical winding method and a left-right-right three-stage helical winding structure for an energy saving filament. The structure comprises a helical filament body (1), wherein, the filament body (1) consists of a mandrel (2) and a filament secondary winding body (3) which is wound on the periphery of the mandrel (2); the filament secondary winding body (3) consists of a molybdenum core wire (4) and a filament primary winding body (5) which is wound on the periphery of the molybdenum core wire (4); the filament primary winding body (5) consists of a molybdenum core wire (6) and a tungsten filament (7) which is wound on the periphery of the molybdenum core wire (6); the tungsten filament (7) is wound on the molybdenum core wire (6) by means of left screw; the filament primary winding body (5) is wound on the molybdenum core wire (4) by means of right screw; the filament secondary winding body (3) is wound on the mandrel (2) by means of right screw. The filament adopts the left-right-right three-stage helical winding method and is characterized in difficult distortion, deformation, formation of a ring and so on after filament stretching, thereby the product qualification ratio of lighting tubes is improved; a large number of labors used for repair are reduced; the production cost is greatly reduced.

Owner:湖州太箭照明有限公司

Process for the manufacture of filaments for self-rectifying mercury lamps

ActiveCN103295858BStrong silk feet at both endsExtended service lifeCathode heaters manufactureEngineeringSizing

The invention relates to a method for manufacturing a lamp filament of a self-rectifying mercury lamp. The method includes the steps of winding, first sizing, cutting, second sizing and melting a core filament. The lamp filament of the self-rectifying mercury lamp is eventually manufactured and obtained through the steps. Compared with the prior art, filament feet at the two ends of the lamp filament manufactured by adopting the method are firmer, so that the filament is not prone to being broken, and the service life of the lamp filament is greatly prolonged.

Owner:上海亚尔精密零件制造有限公司

Right, right, left three-section type spiral winding method and structure of energy-saving filament

InactiveCN101252067AReduce defective productsReduce manufacturing costLamp incadescent bodiesGas discharge lamp detailsThree stageEngineering

The invention discloses a right-right-left three-stage helical winding method and a right-right-left three-stage helical winding structure for an energy saving filament. The structure comprises a helical filament body (1), wherein, the filament body (1) consists of a mandrel (2) and a filament secondary winding body (3) which is wound on the periphery of the mandrel (2); the filament secondary winding body (3) consists of a molybdenum core wire (4) and a filament primary winding body (5) which is wound on the periphery of the molybdenum core wire (4); the filament primary winding body (5) consists of a molybdenum core wire (6) and a tungsten filament (7) which is wound on the periphery of the molybdenum core wire (6); the tungsten filament (7) is wound on the molybdenum core wire (6) by means of right screw; the filament primary winding body (5) is wound on the molybdenum core wire (4) by means of right screw; the filament secondary winding body (3) is wound on the mandrel (2) by means of left screw. The filament adopts the right-right-left three-stage helical winding method and is characterized in difficult distortion, deformation, formation of a ring and so on after filament stretching, thereby the product qualification ratio of lighting tubes is improved; a large number of labors used for repair are reduced; the production cost is greatly reduced.

Owner:湖州太箭照明有限公司

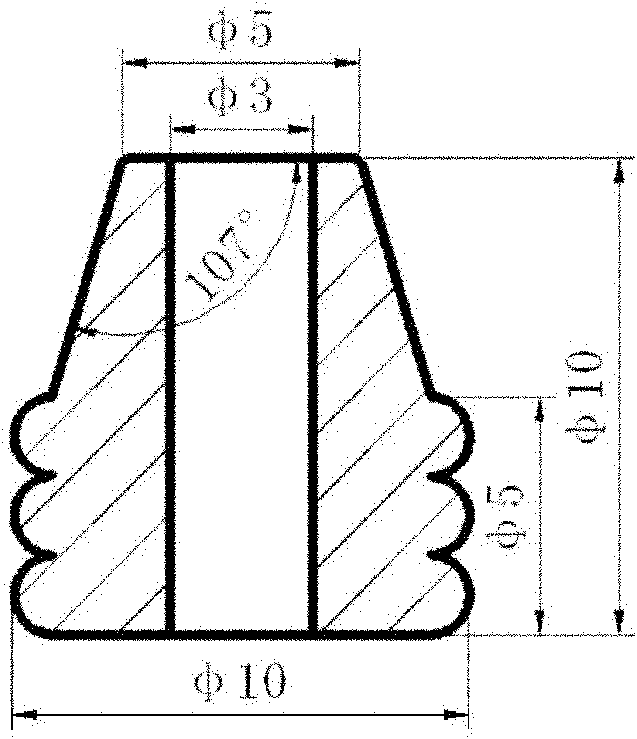

Method for producing cathode component for flashlight

InactiveCN102157319BUniform densityUniform pore sizeCathode heaters manufactureThermoplasticSurface cleaning

The invention provides a new method for producing a cathode component for a flashlight. The method comprises the following steps of: carrying out calcining, ball milling and sieving on powdered raw materials, uniformly mixing the powdered raw materials with a thermoplastic or thermoset organic matter under the heating state, preparing the mixture into a green body having a certain shape by adopting the metal injection molding process, removing the organic matter in the green body through a chemical or heating method, obtaining a cathode basal body with certain porosity through high-temperature sintering, immersing an electron emission substance in a gap on the cathode basal body, and finally obtaining the cathode component for the flashlight through surface cleaning, washing and high-temperature treatment. The method has the advantage of preparing the cathode basal body material with considerably uniform density, controllable porosity and pore diameters, uniform pore diameters and narrow pore diameter distribution, simplifying the process for preparing the cathode component for the flashlight, reducing the production cost, and achieving volume production, low cost and considerablycomplex production shapes.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Coreless winding method of coiled-coil filament

InactiveCN102082067BReduce usageEmission reductionCathode heaters manufactureWinding machineWastewater

Owner:ANHUI HUSN HUAGUANG ENERGY SAVING TECH

High-efficiency and high-consistency cathode assembly welding method for Ku-band communication traveling wave tube

ActiveCN113828879AReduce heating powerFully contactedCathode heaters manufactureSolder feeding devicesPhysicsWave band

The invention relates to the technical field of stack type welding mold design and welding, and discloses a high-efficiency and high-consistency cathode assembly welding method for a Ku-band communication traveling wave tube. The high-efficiency and high-consistency cathode assembly welding method comprises the following steps of S1, mold assembly; S2, solder coating; S3, assembling a cathode and a mold; S4, assembling the cathode and the mold; and S5, welding quality inspection. According to the high-efficiency and high-consistency cathode assembly welding method for the Ku-band communication traveling wave tube, a stack type self-adjusting welding mold is adopted, a cathode cylinder is fixed to the mold, and the parallelism and concentricity of an assembly formed by combining an emitter and the cathode cylinder are strictly controlled before welding, and it is guaranteed that after the welding, the emitter vertically moves downwards, the emitter moves downwards in parallel, the cathode which is firmly welded is obtained, and the welding quality of a heater assembly is improved.

Owner:NANJING SANLE GROUP

Left, right, right three-section type spiral winding method and structure of energy-saving filament

InactiveCN101252065BReduce defective productsReduce manufacturing costLamp incadescent bodiesGas discharge lamp detailsThree stageEngineering

The invention discloses a left-right-right three-stage helical winding method and a left-right-right three-stage helical winding structure for an energy saving filament. The structure comprises a helical filament body (1), wherein, the filament body (1) consists of a mandrel (2) and a filament secondary winding body (3) which is wound on the periphery of the mandrel (2); the filament secondary winding body (3) consists of a molybdenum core wire (4) and a filament primary winding body (5) which is wound on the periphery of the molybdenum core wire (4); the filament primary winding body (5) consists of a molybdenum core wire (6) and a tungsten filament (7) which is wound on the periphery of the molybdenum core wire (6); the tungsten filament (7) is wound on the molybdenum core wire (6) by means of left screw; the filament primary winding body (5) is wound on the molybdenum core wire (4) by means of right screw; the filament secondary winding body (3) is wound on the mandrel (2) by meansof right screw. The filament adopts the left-right-right three-stage helical winding method and is characterized in difficult distortion, deformation, formation of a ring and so on after filament stretching, thereby the product qualification ratio of lighting tubes is improved; a large number of labors used for repair are reduced; the production cost is greatly reduced.

Owner:湖州太箭照明有限公司

Tungsten wire, cathode heater and vibration service lamp filament

InactiveUS20100084055A1Efficient preparationHigh elongationForging/pressing devicesElectric discharge tubesRheniumPower flow

Owner:KK TOSHIBA

Left, right, left three-section type spiral winding method and structure of energy-saving filament

InactiveCN101252066BReduce defective productsReduce manufacturing costLamp incadescent bodiesGas discharge lamp detailsThree stageEngineering

The invention discloses a right-left-left three-stage helical winding method and a right-left-left three-stage helical winding structure for an energy saving filament. The structure comprises a helical filament body (1), wherein, the filament body (1) consists of a mandrel (2) and a filament secondary winding body (3) which is wound on the periphery of the mandrel (2); the filament secondary winding body (3) consists of a molybdenum core wire (4) and a filament primary winding body (5) which is wound on the periphery of the molybdenum core wire (4); the filament primary winding body (5) consists of a molybdenum core wire (6) and a tungsten filament (7) which is wound on the periphery of the molybdenum core wire (6); the tungsten filament (7) is wound on the molybdenum core wire (6) by means of right screw; the filament primary winding body (5) is wound on the molybdenum core wire (4) by means of left screw; the filament secondary winding body (3) is wound on the mandrel (2) by means ofleft screw. The filament adopts the right-left-left three-stage helical winding method and is characterized in difficult distortion, deformation, formation of a ring and so on after filament stretching, thereby the product qualification ratio of lighting tubes is improved; a large number of labors used for repair are reduced; the production cost is greatly reduced.

Owner:湖州太箭照明有限公司

Composite heater assembly and preparation method thereof

PendingCN113808892AHigh resistivityGuaranteed to workTransit-tube cathodesElectrode assembly manufactureMetal powderMagnetic field

The invention provides a composite heater assembly and a preparation method thereof. The method comprises the following steps: mixing insulating powder and metal powder to obtain mixed powder, and enabling the insulating powder and the metal powder to expand and contract synchronously; compacting the mixed powder to obtain a bar; sintering the bar to obtain a green body; turning the green body to obtain a composite heater (5); and bonding a cathode cylinder (2) and an electrode (7) to the two ends of the composite heater (5) through welding flux (6), so as to obtain the composite heater assembly. The preparation method disclosed by the invention is simple in process, and the cathode composite heater assembly which is high in reliability, small in size, high in efficiency, uniform in heating and free of a magnetic field can be prepared.

Owner:AEROSPACE INFORMATION RES INST CAS

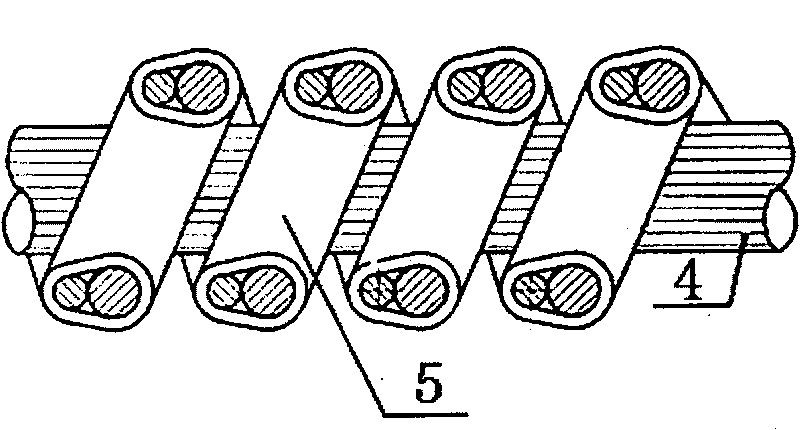

Method and structure for helically coiling left, left and right three-segment type energy-saving filament

InactiveCN101281842AReduce defective productsReduce manufacturing costLamp incadescent bodiesGas discharge lamp detailsHelical coilEngineering

The present invention discloses a three-segment (left, left, right) helical coiling method and a structure of power saving filament, which comprises: a helical filament main body (1) composed of a core rod (2) and secondary wound filament body (3) around the core rod (2); the secondary wound filament body (3) comprises a molybdenum wire (4) and a primary wound filament body (5) around the molybdenum wire (4); the primary wound filament body (5) comprises a molybdenum wire (6) and a tungsten filament (7) wound around the molybdenum wire (6); the tungsten filament (7) is wound around the molybdenum wire (6) in left-handed direction; the primary wound filament body (5) is wound around the molybdenum wire (4) in left-handed direction; the secondary wound filament body (3) is wound on the core rod (2) in right-handed direction. The filament in the present invention is wound with a three-segment helical winding wound (left-handed, left-handed, right-handed); therefore, the filament will have little deformation, distortion, or misalignment, etc.; the percent of pass of the lamp product can be increased, rework can be reduced greatly, and therefore the production cost can be reduced significantly.

Owner:湖州太箭照明有限公司

Right, right, right three-section type spiral winding method and structure of energy-saving filament

InactiveCN101252068AReduce defective productsReduce manufacturing costLamp incadescent bodiesGas discharge lamp detailsThree stageEngineering

The invention discloses a right-right-right three-stage helical winding method and a right-right-right three-stage helical winding structure for an energy saving filament. The structure comprises a helical filament body (1), wherein, the filament body (1) consists of a mandrel (2) and a filament secondary winding body (3) which is wound on the periphery of the mandrel (2); the filament secondary winding body (3) consists of a molybdenum core wire (4) and a filament primary winding body (5) which is wound on the periphery of the molybdenum core wire (4); the filament primary winding body (5) consists of a molybdenum core wire (6) and a tungsten filament (7) which is wound on the periphery of the molybdenum core wire (6); the tungsten filament (7) is wound on the molybdenum core wire (6) by means of right screw; the filament primary winding body (5) is wound on the molybdenum core wire (4) by means of right screw; the filament secondary winding body (3) is wound on the mandrel (2) by means of right screw. The filament adopts the right-right-right three-stage helical winding method and is characterized in difficult distortion, deformation, formation of a ring and so on after filament stretching, thereby the product qualification ratio of lighting tubes is improved; a large number of labors used for repair are reduced; the production cost is greatly reduced.

Owner:湖州太箭照明有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com