Method for producing cathode component for flashlight

A manufacturing method and flash lamp technology, which are applied in the manufacture of cathode heaters, etc., can solve problems such as inability to form complex shapes, weak electron emission capabilities, and unstable electron emission, and achieve improved material utilization, controllable aperture size, and energy saving. The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

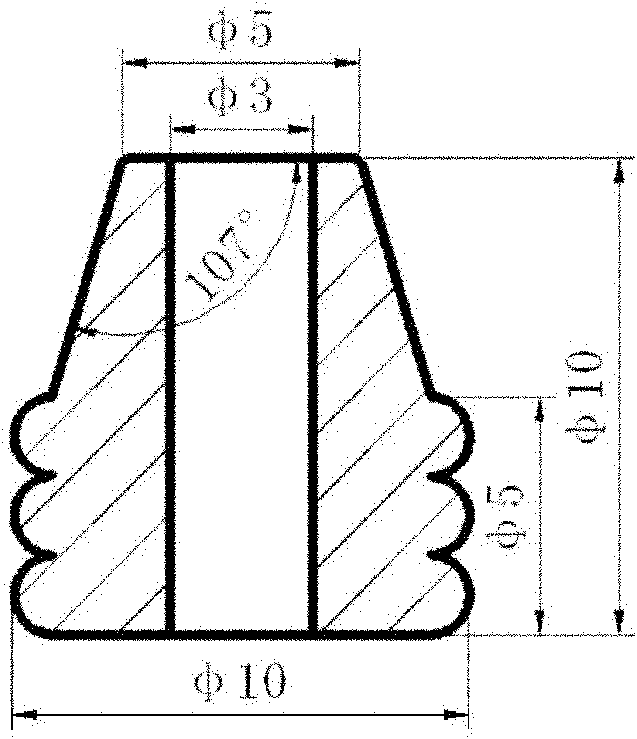

[0030] Calcinate 2,500g of tungsten powder with a Fischer particle size of 7 μm in a hydrogen furnace at 1,500°C for 3 hours, mill with a ball mill for 1 hour, and pass through a 200-mesh sieve for use. At a temperature of 150°C, mix the above-mentioned treated tungsten powder with 48g of paraffin wax, 20g of polypropylene, 8g of polyethylene and 4g of stearic acid with a double Z-type mixer, and prepare the mixture with an injection molding machine and a mold. figure 2 The shape shown is green and the forming temperature is 160°C. Soak the green body in trichlorethylene at 40°C for 4 hours to remove most of the paraffin and stearic acid in the green body, then slowly raise the temperature to 500°C in a hydrogen furnace and keep it warm for 2 hours to remove the remaining organic matter in the green body , and then heated up to 2000° C. for 3 hours to obtain a cathode substrate, the cathode substrate has a porosity of about 20% and an average pore diameter of 2.6 μm. The alu...

example 2

[0032] Mix 2250g of tungsten powder with a Fischer particle size of 3μm and 250g of rhenium powder with a Fischer particle size of 10μm evenly, calcinate in a hydrogen furnace at 1000°C for 5 hours, use a ball mill for 2 hours, and pass through a 150-mesh sieve for use. At a temperature of 190°C, mix the raw material powder treated above with 68g of polyoxymethylene, 4.8g of polyethylene, 4g of ethylene-vinyl acetate copolymer, 1.6g of paraffin wax and 1.6g of zinc stearate with a double Z-type mixer, The mixture is prepared with an injection molding machine and a mold figure 2 The shape shown is green and the forming temperature is 180°C. Put the green body in the mixed atmosphere of nitrogen and nitric acid for 4 hours, use nitric acid to decompose the polyoxymethylene in the green body, then slowly raise the temperature of the green body to 700 degrees Celsius and keep it warm for 2.5 hours to remove the remaining organic matter in the green body, and then heat up to The ...

example 3

[0034] Mix 2250g tungsten powder with a Fischer particle size of 5μm, 125g rhenium powder with a Fischer particle size of 6μm, and 125g iridium powder with a Fischer particle size of 6μm, calcinate in a hydrogen furnace at 1200°C for 1h, use a ball mill for 4h, and pass through 250 Mesh sieve for spare. At a temperature of 160°C, mix 2500g of the above-treated tungsten powder with 52g of paraffin wax, 16g of polypropylene, 5.6g of polyethylene, 4g of ethylene-vinyl acetate copolymer and 2.4g of zinc stearate with a double Z-type mixer. The mixture is prepared with an injection molding machine and a mold image 3 The shape shown is green and the forming temperature is 165°C. Put the green body in a hydrogen furnace and slowly raise the temperature to 800 degrees Celsius and keep it warm for 3 hours to remove the organic matter in the green body, then raise the temperature to 1900 degrees Celsius and keep it warm for 5 hours to obtain a cathode substrate. The porosity of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com