Right, right, left three-section type spiral winding method and structure of energy-saving filament

A three-stage, right-spiral technology, applied in the right and left three-stage spiral winding method and structure, in the field of the right and left winding structure of energy-saving filaments, can solve the problem of electronic powder bumping and falling off, and the coil is easily twisted. Problems such as stitching and affecting the pass rate of thread tensioning, to achieve the effects of easy operation, high pass rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

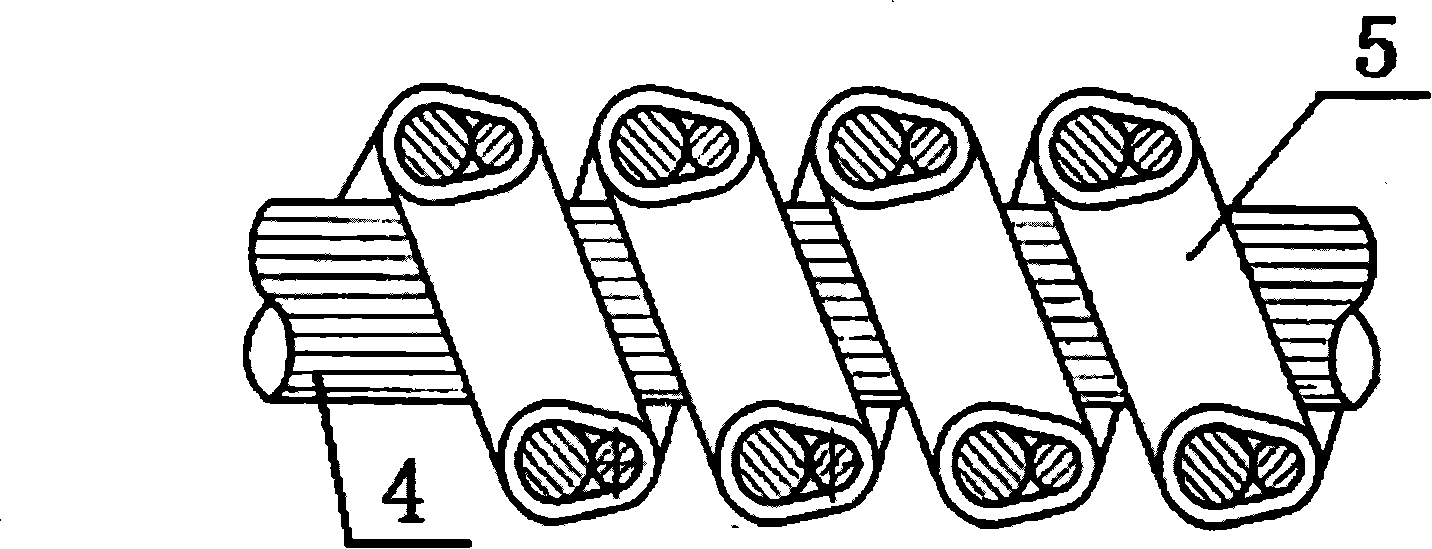

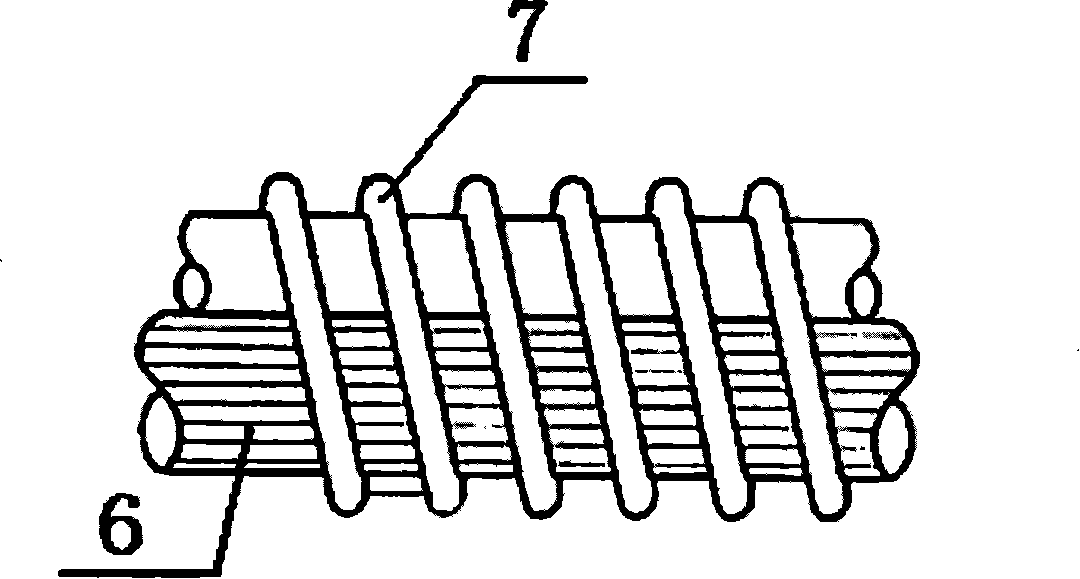

[0014] Embodiment of the present invention: it includes a spiral filament body 1, the filament body 1 is composed of a mandrel 2 and a filament secondary winding 3 wound around the mandrel 2, as attached figure 1 As shown; the filament secondary winding body 3 is composed of a molybdenum core wire 4 and a filament primary winding body 5 wound around the molybdenum core wire 4, as attached figure 2 As shown; the filament primary winding body 5 is composed of a molybdenum core wire 6 and a tungsten wire 7 wound around the molybdenum core wire 6, as attached image 3 shown. Among them, the filament primary winding 5 is wound on the molybdenum core wire 4 in a right-handed manner, the secondary winding body 3 of the filament is wound on the mandrel 2 in a left-handed manner, and the tungsten wire 7 is wound on the molybdenum core wire in a right-handed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com