Composite filter element containing kieselguhr and starch and manufacturing method of composite filter element

A composite filter element, diatomite technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve problems such as inability to be complicated, and achieve the effect of reducing defective products, saving filtration time, and having a smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

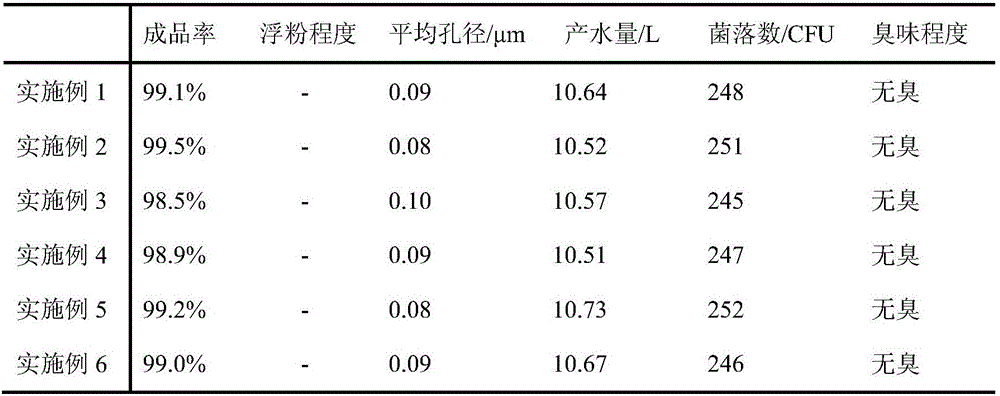

Examples

Embodiment 1

[0050] (1) Mix macroporous starch and microporous starch in a weight ratio of 50:1 to make mixed starch;

[0051] (2) Each component is added into the high-speed mixer according to the following weight ratio, 60 parts of modified diatomite, 15 parts of mixed starch obtained in step (1), 10 parts of cellulose acetate, 6 parts of molecular sieve powder, 1 part of aluminum oxide, Add 5 parts of montmorillonite, 5kg in total, into the high-speed mixer, and stir the dry powder for 1.5min to form a dry powder;

[0052] (3) Mix camphor oil and absolute ethanol at a mass fraction of 0.8:1 to form a binder, and add a total of 3 parts of binder, 2 parts of emulsified paraffin, aluminum sulfate ammonium sulfate to the dry powder obtained in step (2) three times. Add 1 part of non-toxic bentonite and 3.5kg of water into a high-speed mixer, and stir for 5 minutes to form a semi-dry powder;

[0053] (4) passing the semi-dry powder obtained in step (3) through a 10-mesh sieve to obtain semi...

Embodiment 2

[0058] (1) Mix macroporous starch and microporous starch in a weight ratio of 60:1 to make mixed starch;

[0059] (2) Each component is added into the high-speed mixer according to the following weight ratio, 60 parts of modified diatomite, 15 parts of mixed starch obtained in step (1), 10 parts of cellulose acetate, 6 parts of molecular sieve powder, 1 part of aluminum oxide, Add 5 parts of montmorillonite, 5kg in total, into the high-speed mixer, and stir the dry powder for 1.5min to form a dry powder;

[0060] (3) Mix camphor oil and absolute ethanol at a mass fraction of 1.1:1 to form a binder, and add a total of 5 parts of binder, 3 parts of emulsified paraffin, and aluminum sulfate ammonium to the dry powder obtained in step (2) three times. Add 3 parts of permanent bentonite and 4.0kg of water into a high-speed mixer, and stir for 5 minutes to form a semi-dry powder;

[0061] (4) passing the semi-dry powder obtained in step (3) through a 10-mesh sieve to obtain semi-dr...

Embodiment 3

[0066] (1) Mix macroporous starch and microporous starch in a weight ratio of 70:1 to make mixed starch;

[0067] (2) Each component is added in the high-speed mixer according to the following weight ratio, 80 parts of modified diatomite, 20 parts of mixed starch obtained in step (1), 15 parts of cellulose acetate, 8 parts of molecular sieve powder, 2 parts of aluminum oxide, Add 8 parts of montmorillonite, 5kg in total, into the high-speed mixer, and stir the dry powder for 1.5min to form a dry powder;

[0068] (3) Mix camphor oil and absolute ethanol at a mass fraction of 1:1 to form a binder, and add a total of 3 parts of binder, 2 parts of emulsified paraffin, and aluminum sulfate ammonium to the dry powder obtained in step (2) three times. Add 1 part of permanent bentonite and 4.5kg of water into a high-speed mixer, and stir for 5 minutes to form a semi-dry powder;

[0069] (4) passing the semi-dry powder obtained in step (3) through a 10-mesh sieve to obtain semi-dry po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com