Instant cubilose processed by ready-to-stew raw material and preparation method of instant cubilose

A technology for bird's nest and raw materials, applied in the fields of food science, food preservation, food ingredients containing natural extracts, etc., can solve the problems of high labor and time, general cleanliness of bird's nest, affecting product appearance, etc., and shorten the sterilization time. , The effect of retaining the sensory flavor and taste, reducing labor and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

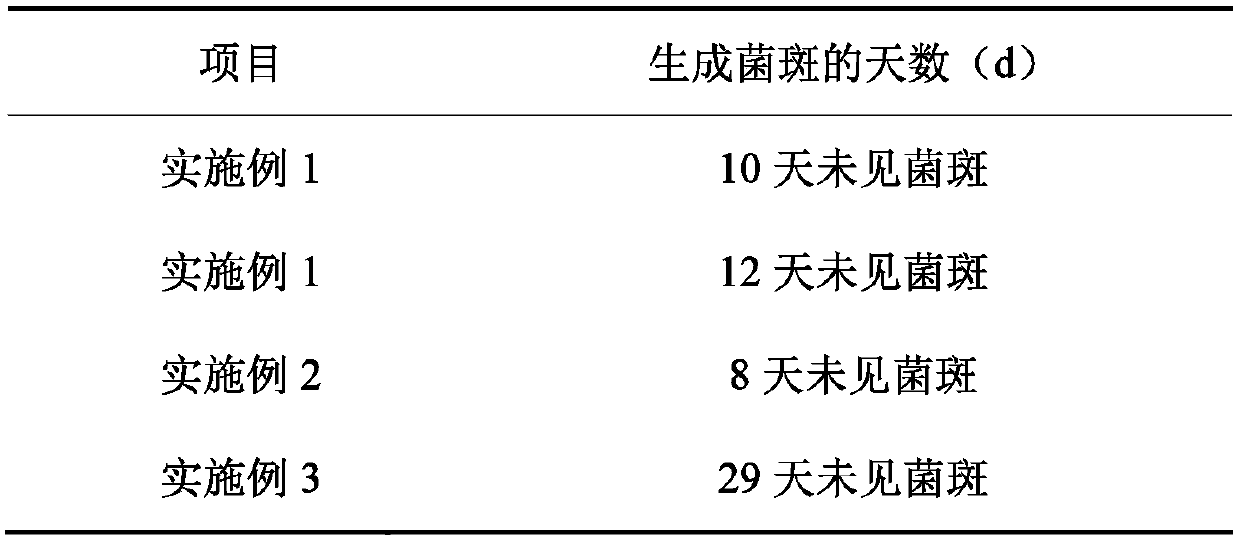

Embodiment 1

[0022] Instant stewed raw material processing instant bird's nest is made of the following raw materials in parts by weight: 80 parts of instant stewed bird's nest without washing, soaking and hair picking, 3 parts of collagen peptide, 40 parts of rock sugar syrup, and 5 parts of rose extract.

[0023] The preparation method of the rose extract: crush the rose, add water and decoct twice, each time for 2 hours, combine the decoction, filter, concentrate the filtrate to an appropriate amount, add ethanol to make the alcohol content reach 70%, let stand , take the supernatant, recover ethanol and concentrate to a relative density of 1.12-1.15 (50°C).

[0024] The preparation method of the instant bird’s nest processed by stewing raw materials is as follows: firstly weigh the instant bird’s nest, collagen peptide, rock sugar syrup, and rose extract according to the weight ratio; then bottle the instant stewed bird’s nest, fill it with sugar water, and add collagen Protein peptide...

Embodiment 2

[0026] Instant stewed raw material processing instant bird's nest is made of the following raw materials in parts by weight: 40 parts of instant stewed bird's nest without washing, soaking and hair picking, 5 parts of maca powder, 20 parts of white sugar syrup, and 1 part of astragalus extract.

[0027] The preparation method of the astragalus extract: crush the astragalus and add water to decoct twice, each time for 2 hours, combine the decoction, filter, concentrate the filtrate to an appropriate amount, add ethanol to make the alcohol content reach 80%, let stand, take The supernatant was recovered from ethanol and concentrated to a relative density of 1.15-1.21 (50°C).

[0028] The preparation method of the instant bird's nest processed by stewing raw materials is as follows: first, weigh the instant bird's nest, maca powder, white sugar syrup, and astragalus extract according to the weight ratio; After the coffee powder and astragalus extract are sealed, the lid is sealed...

Embodiment 3

[0030] Instant stewed raw material processing ready-to-eat bird's nest is made of the following raw materials in parts by weight: 60 parts of instant stewed bird's nest without washing, soaking and hair picking, 5 parts of Cordyceps militaris extract, 30 parts of glucose syrup, and 3 parts of Eucommia leaf extract .

[0031] The preparation method of the eucommia leaf extract: weigh a certain weight of eucommia leaves, add 8-10 times the weight of medicinal materials in pure water, soak for 2-5 hours, reflux and decoct for 2 hours, filter to remove residue, and concentrate the filtrate to 25 The concentrated solution with a relative density of 1.15-1.25 °C is obtained.

[0032] The preparation method of the instant bird's nest processed by stewing raw materials is as follows: first, weigh the instant bird's nest, Cordyceps militaris extract, glucose syrup, and Eucommia leaf extract according to the weight ratio; then bottle the instant bird's nest, fill it with sugar water, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com