Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

359results about "Sequential operation station machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

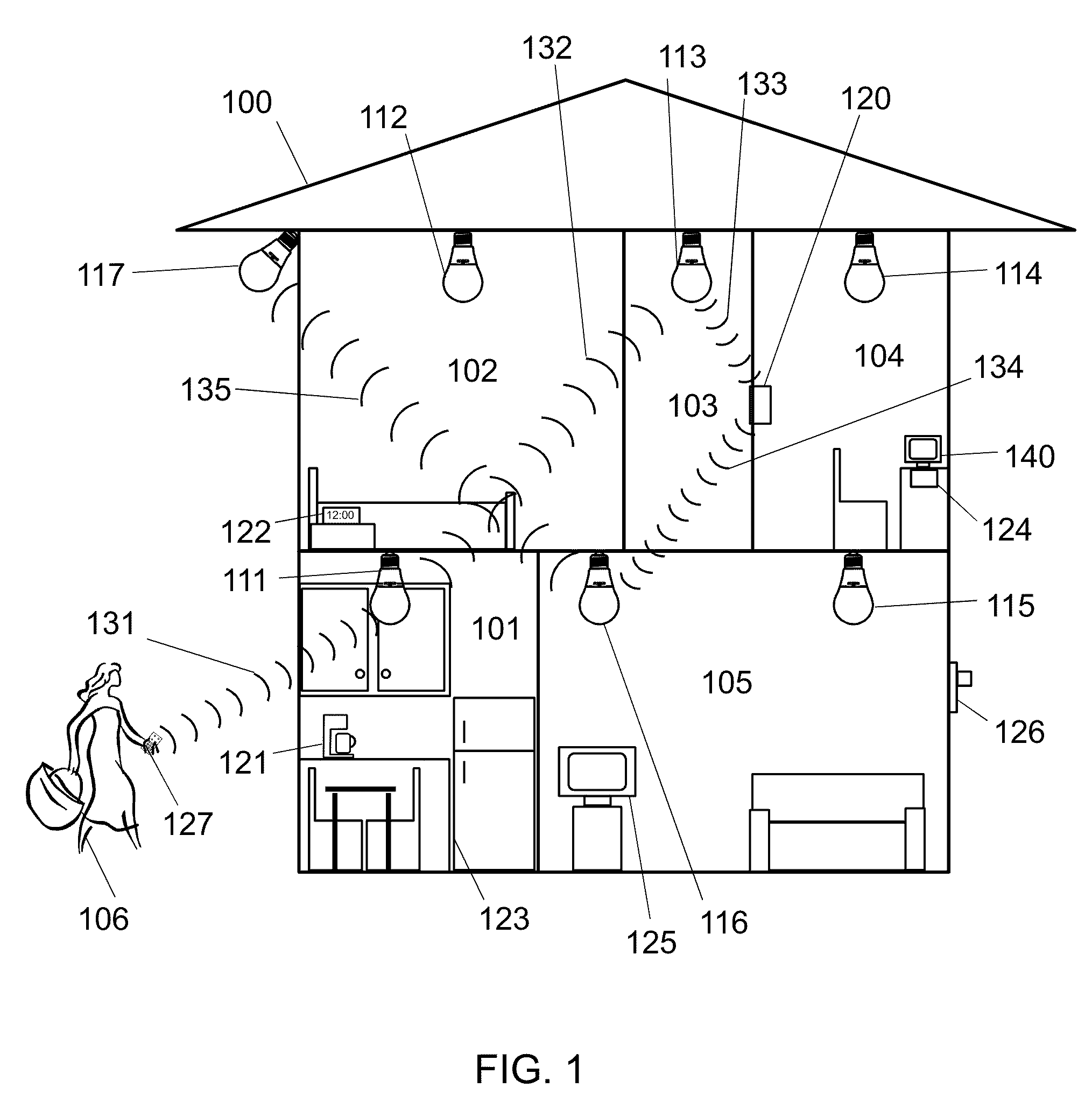

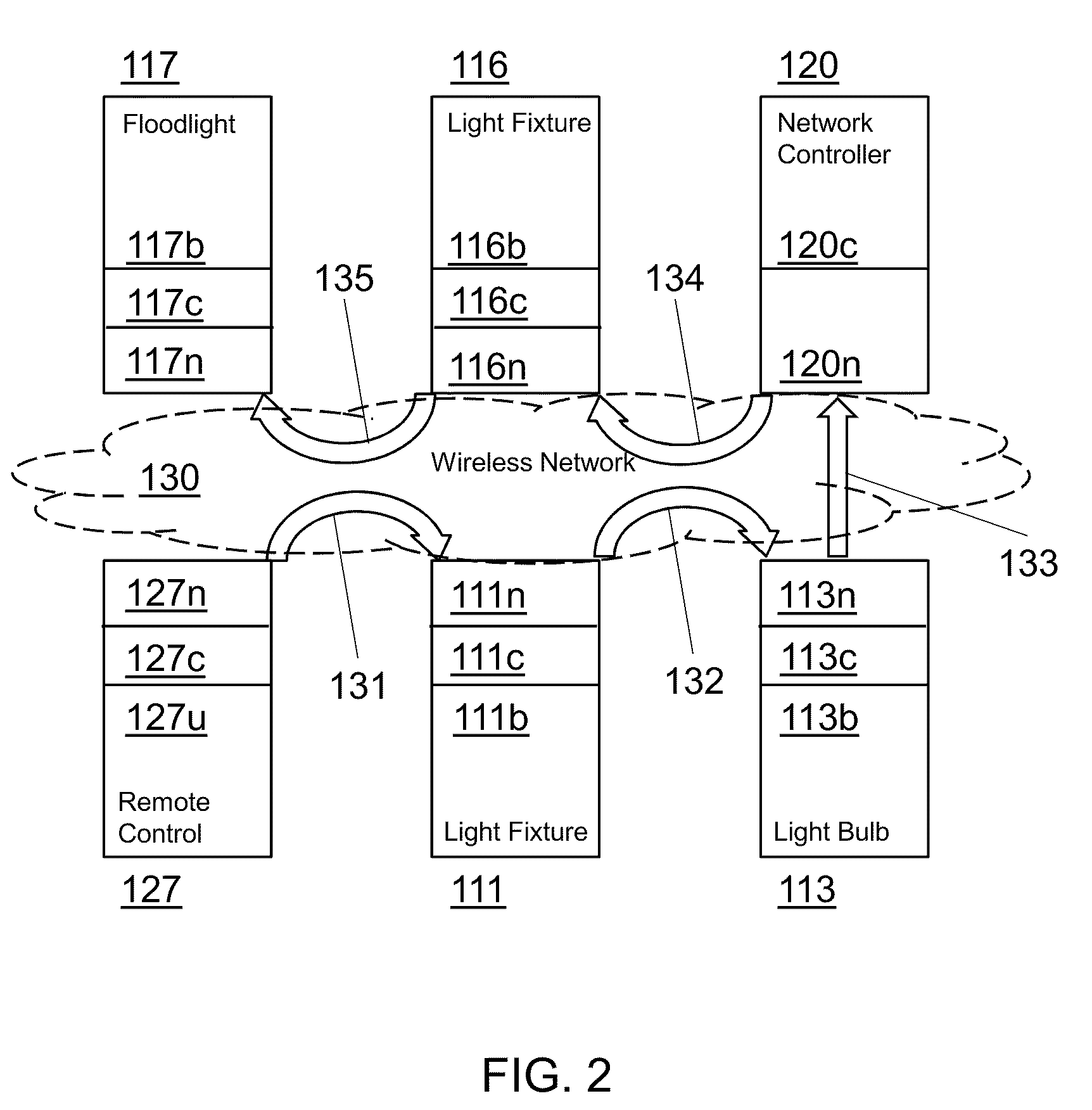

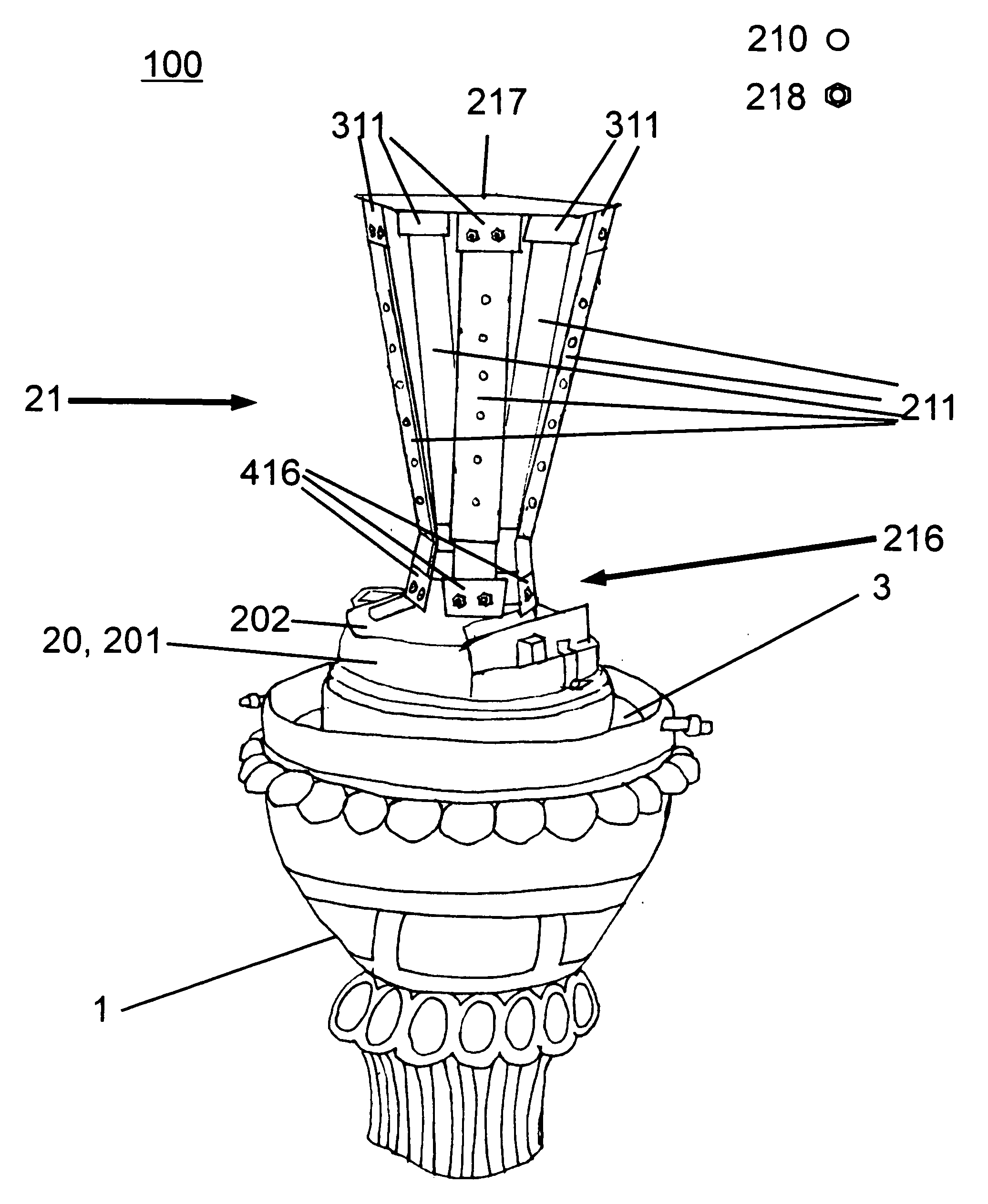

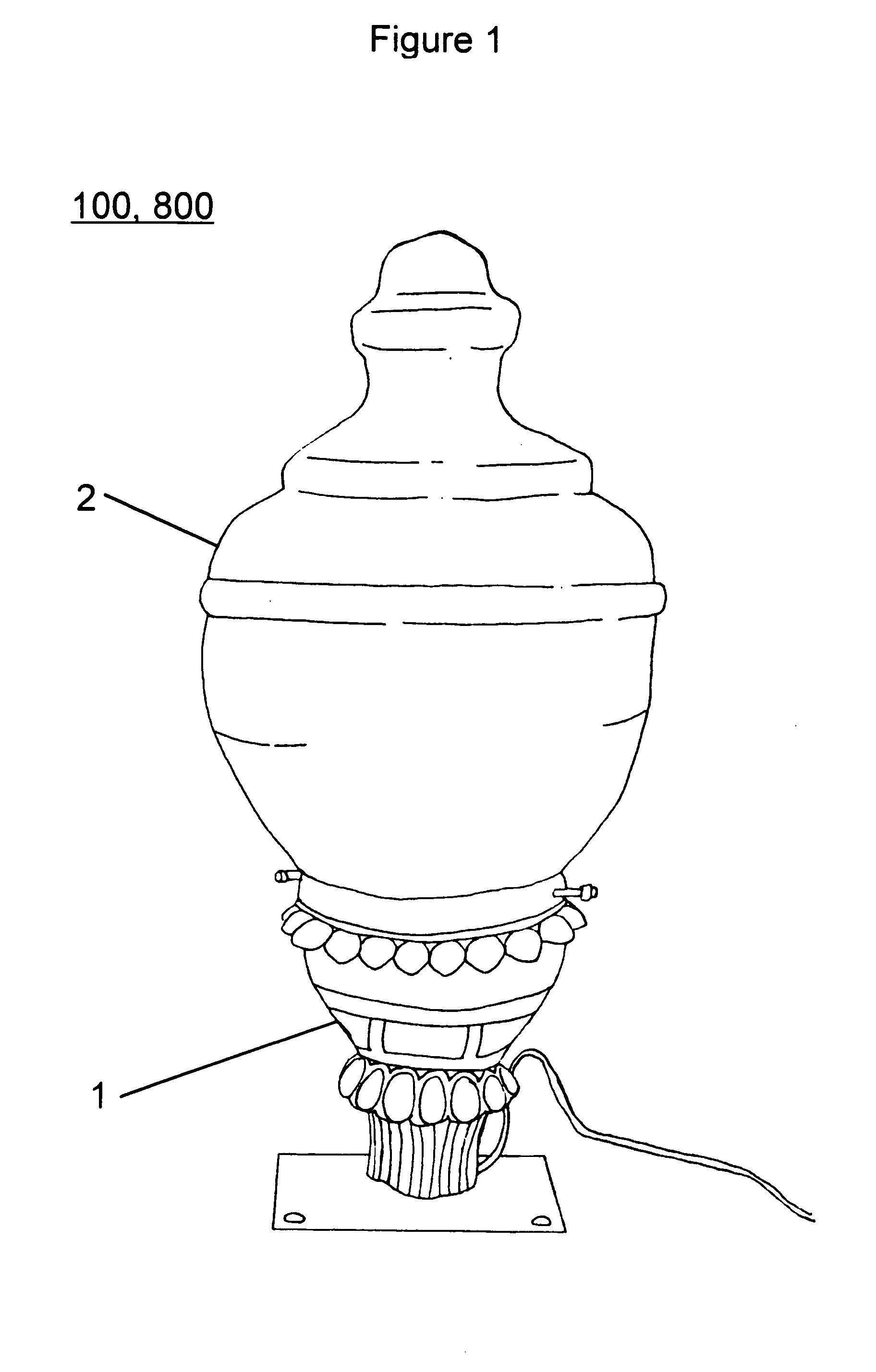

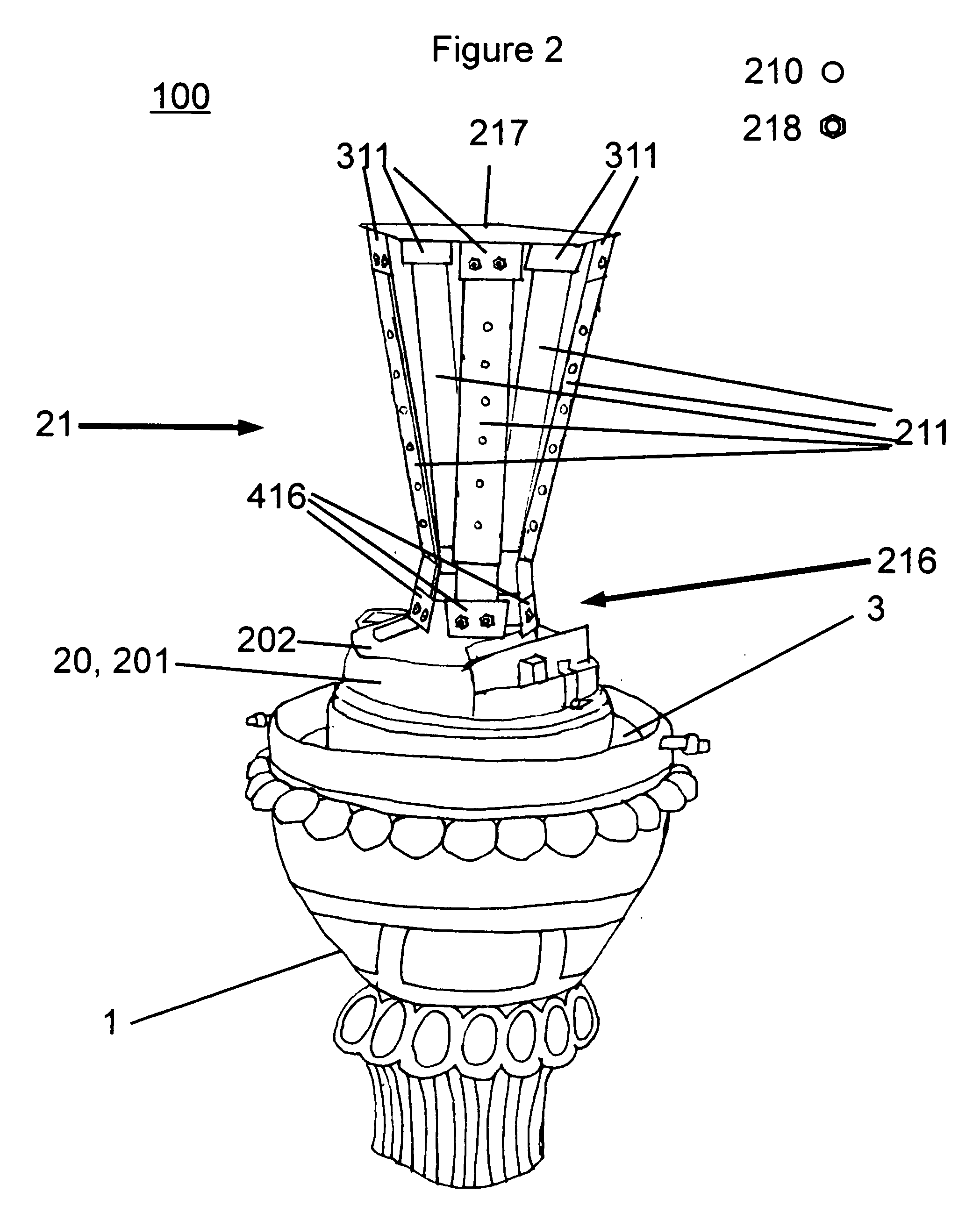

Modular Networked Light Bulb

ActiveUS20110095687A1Point-like light sourceElectric circuit arrangementsElectricityNetworking protocol

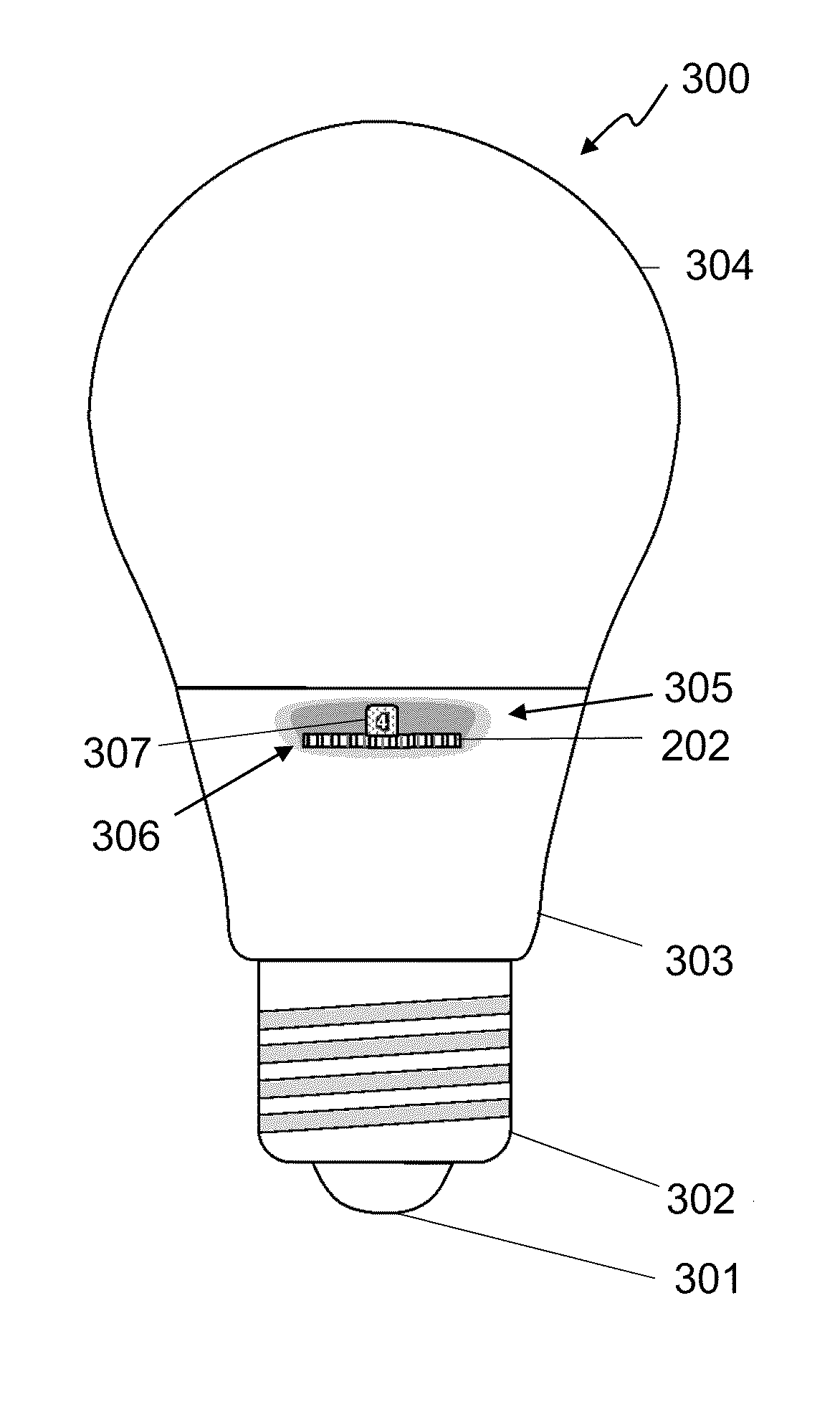

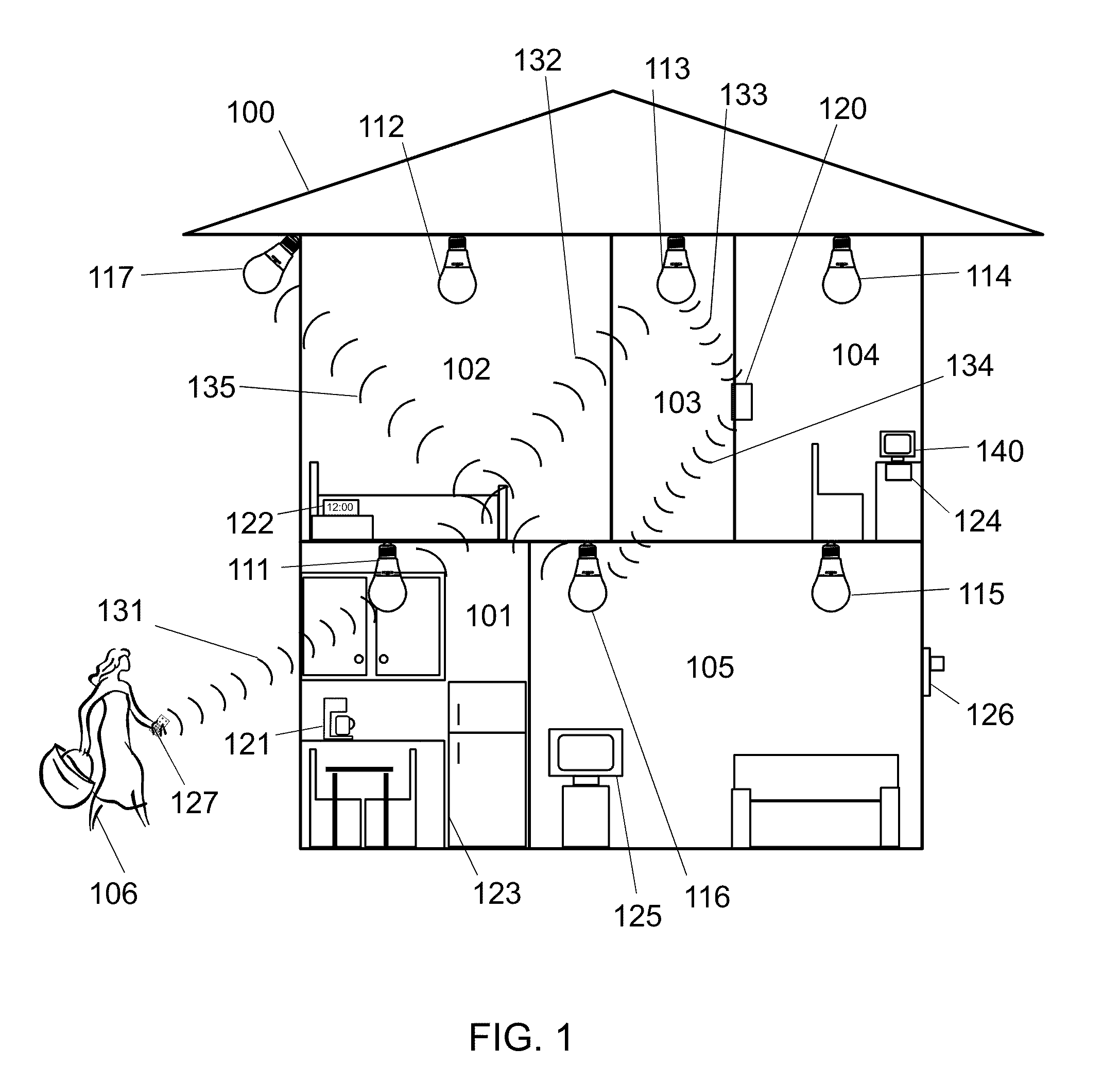

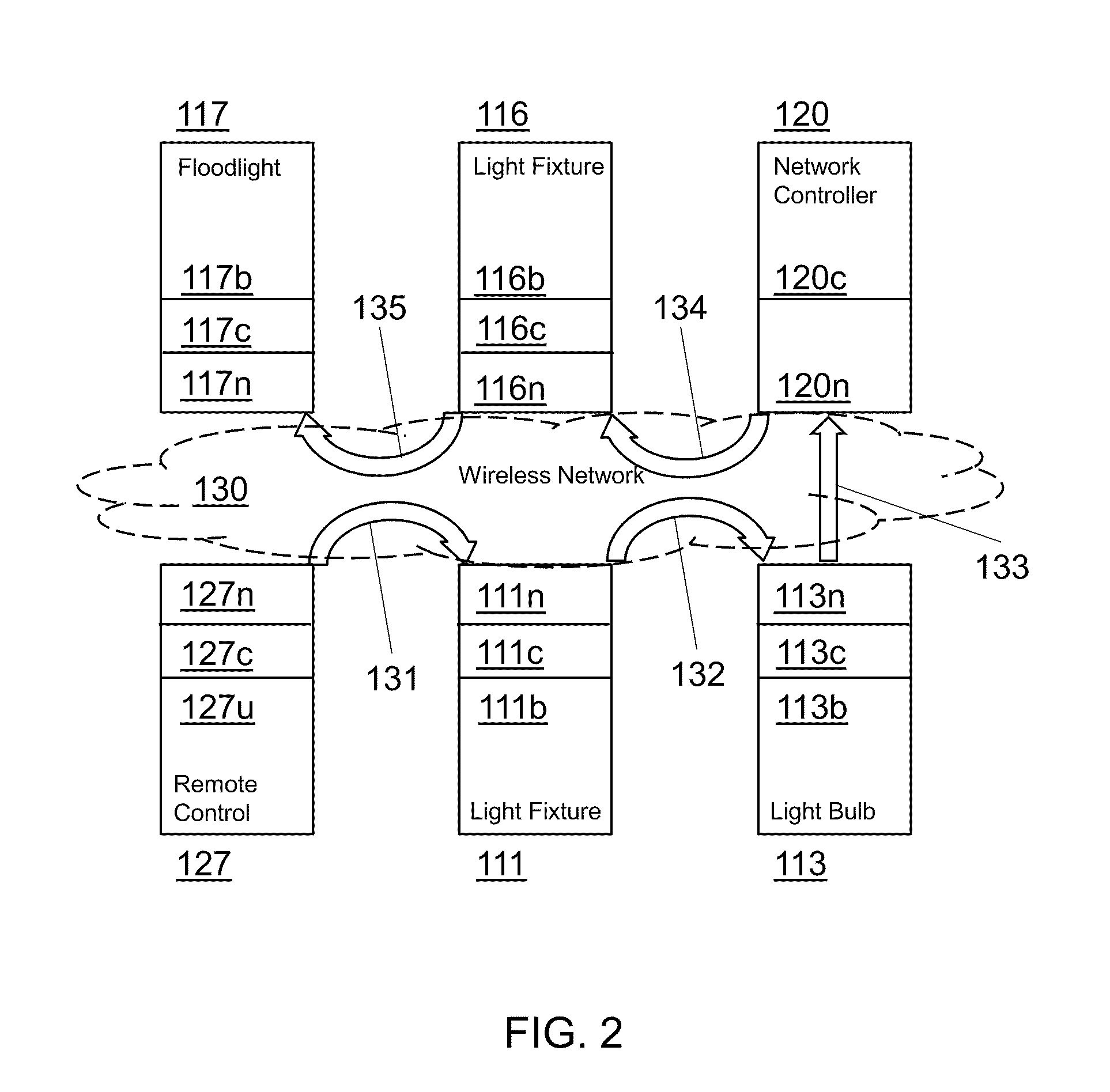

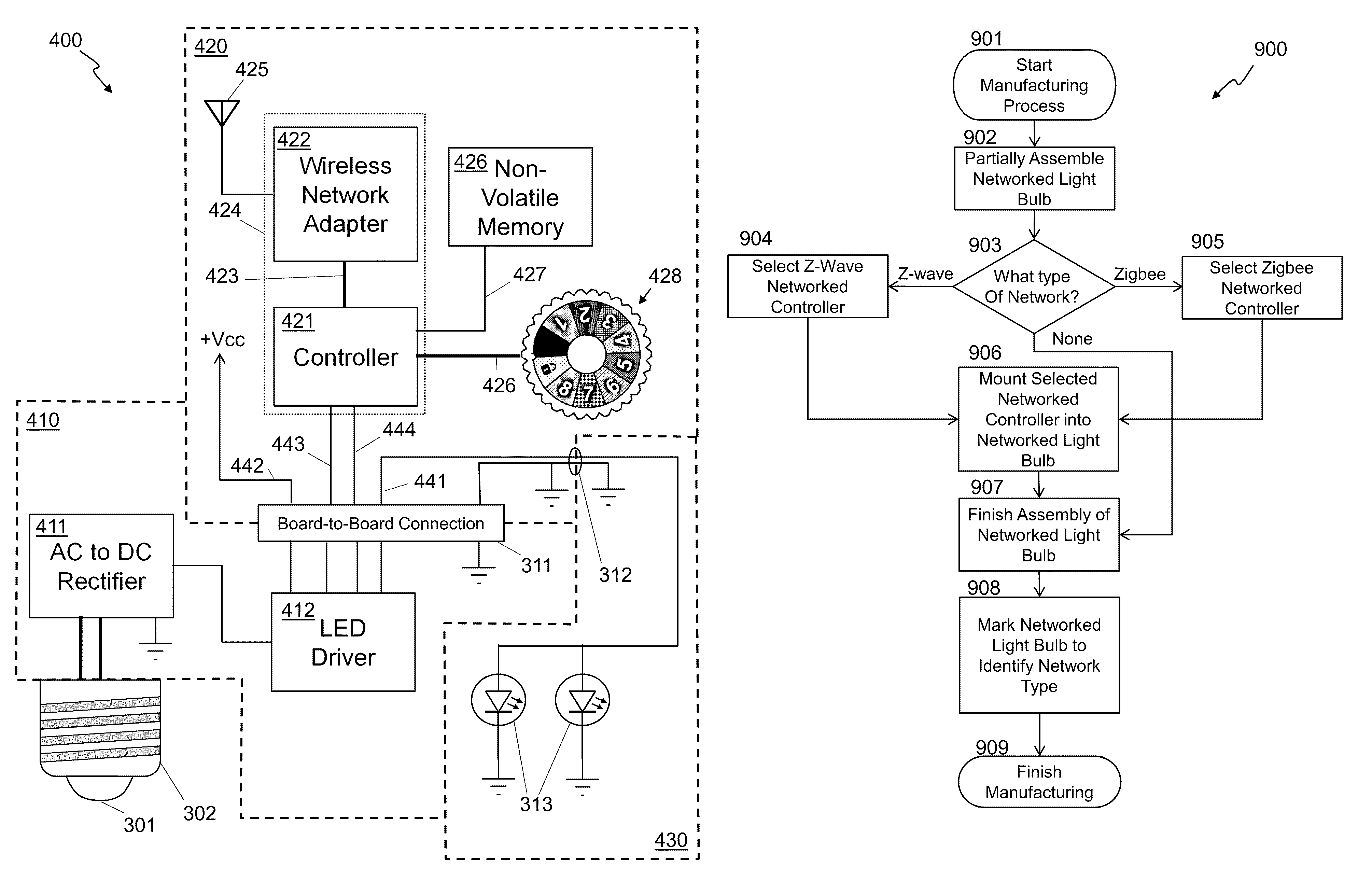

Various methods of manufacturing a lighting apparatus and embodiments of a modular networked lighting apparatus are disclosed. One method defines a mechanical form factor with a minimum set of electrical connections for a networking module, builds a subassembly of the networked lighting apparatus, the subassembly comprising attachment points compatible with the mechanical form factor for the networking module and contacts for the minimum set of electrical connections for the networking module, installs a networking module into the subassembly of the networked lighting apparatus, the networking module compatible with a selected networking protocol for the networked lighting apparatus, completes the final assembly of the networked lighting module, and marks the networked lighting apparatus to indicate the selected networking protocol for the networked lighting apparatus. In some embodiments, the lighting apparatus may function without the networking module installed. One embodiment of the modular, networked light bulb has means for supporting and holding an electronics module conforming with a predetermined form factor in place, and means for allowing the electronics module to control at least a brightness level of the at least one LED. The modular networked light bulb may have a networked controller conforming with the predetermined form factor used as the electronics module. The networked controller is able to connect to a network and may be positioned and held by the means for supporting and holding an electronics module.

Owner:SIGNIFY HLDG BV

Modular networked light bulb

Various methods of manufacturing a lighting apparatus and embodiments of a modular networked lighting apparatus are disclosed. One method defines a mechanical form factor with a minimum set of electrical connections for a networking module, builds a subassembly of the networked lighting apparatus, the subassembly comprising attachment points compatible with the mechanical form factor for the networking module and contacts for the minimum set of electrical connections for the networking module, installs a networking module into the subassembly of the networked lighting apparatus, the networking module compatible with a selected networking protocol for the networked lighting apparatus, completes the final assembly of the networked lighting module, and marks the networked lighting apparatus to indicate the selected networking protocol for the networked lighting apparatus. In some embodiments, the lighting apparatus may function without the networking module installed. One embodiment of the modular, networked light bulb has means for supporting and holding an electronics module conforming with a predetermined form factor in place, and means for allowing the electronics module to control at least a brightness level of the at least one LED. The modular networked light bulb may have a networked controller conforming with the predetermined form factor used as the electronics module. The networked controller is able to connect to a network and may be positioned and held by the means for supporting and holding an electronics module.

Owner:SIGNIFY HLDG BV

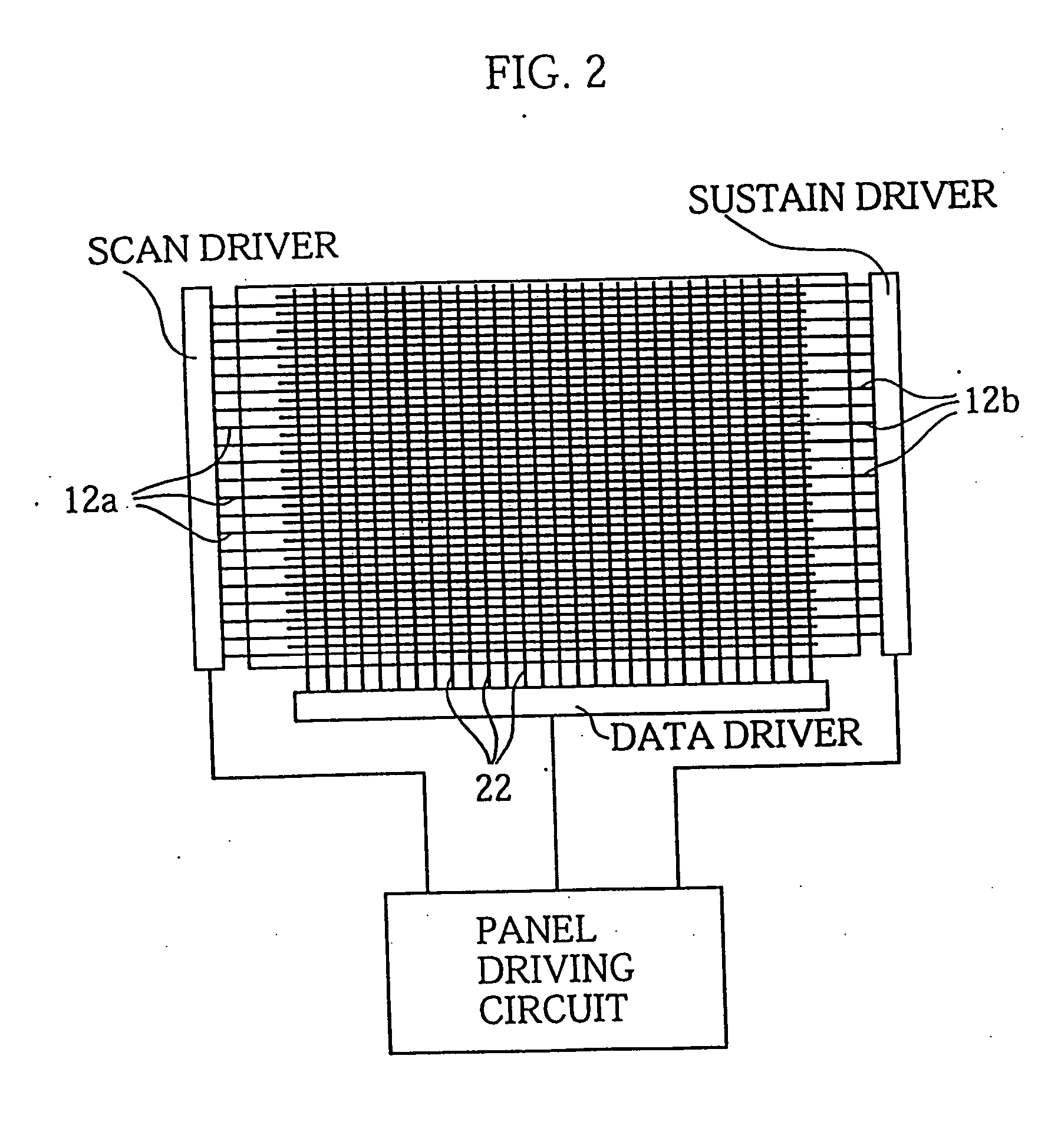

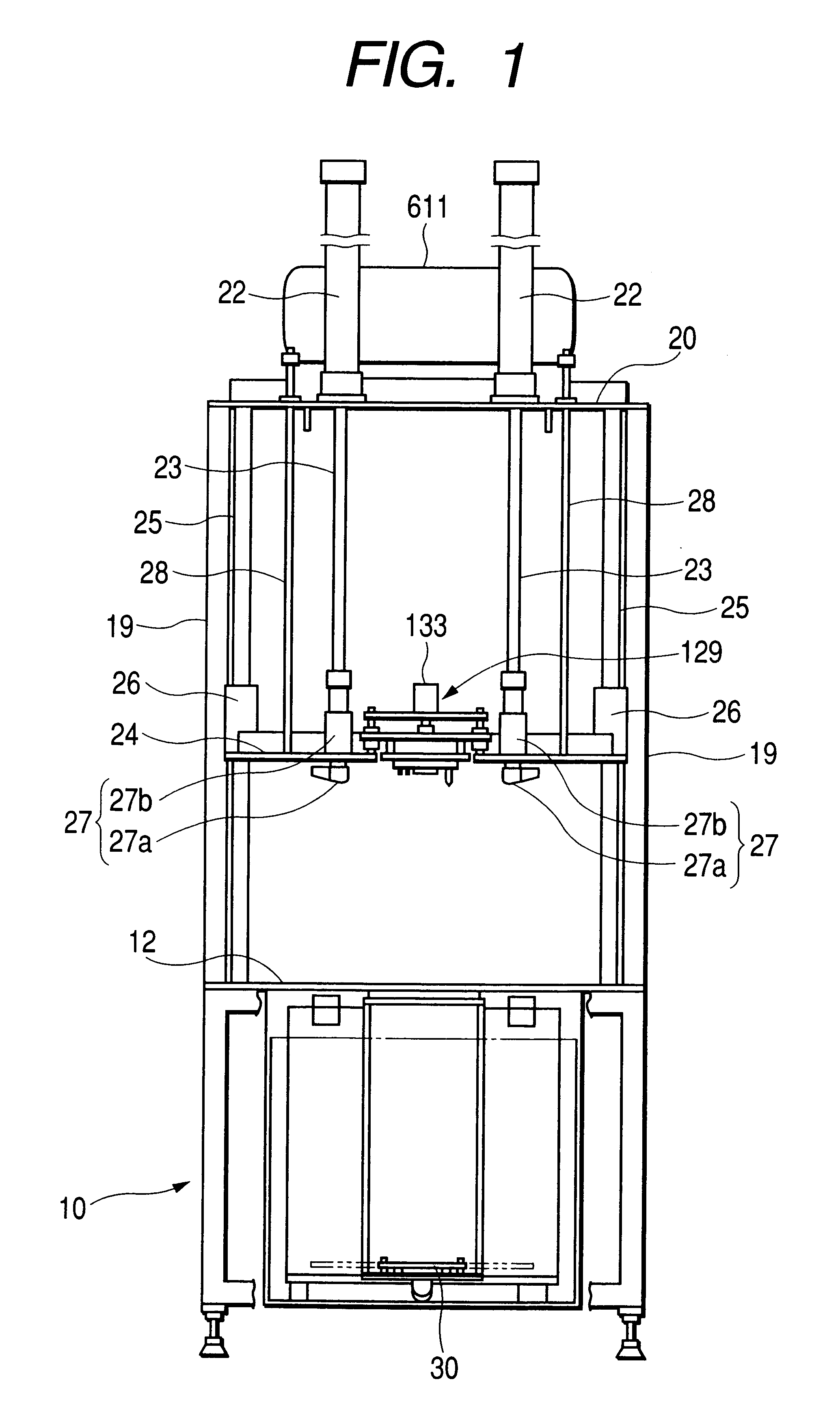

Display device, method for manufacturing the same and apparatus for manufacturing the same

InactiveUS20060055314A1Low costImprove featuresDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

The present inventions provides a method for manufacturing a film-type display device efficiently, and a method for manufacturing a large-size film-type display device, and an apparatus for manufacturing the film-type display device. An apparatus for manufacturing a film-type display device includes: transferring means for transferring a substrate over which an integrated circuit constituting the display device is provided; first separating means for separating the integrated circuit from the substrate by adhering a first sheet material to one surface of the integrated circuit; second separating means for separating the integrated circuit from the first sheet material by adhering a second sheet material to the other surface of the integrated circuit; processing means for forming one or both of a conductive film and an insulating film on the integrated circuit; and sealing means for sealing the processed integrated circuit with the second sheet material and a third sheet material.

Owner:SEMICON ENERGY LAB CO LTD

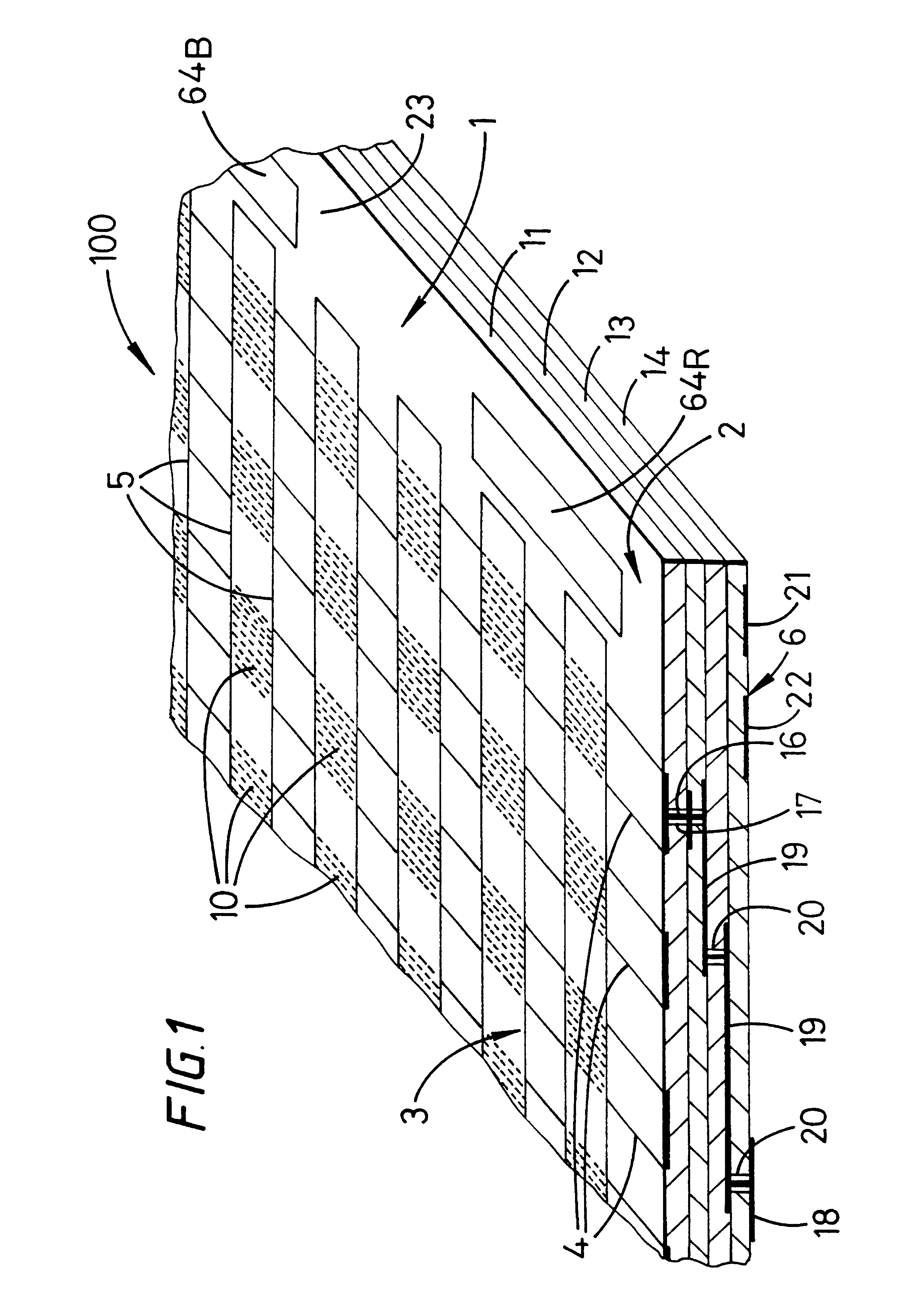

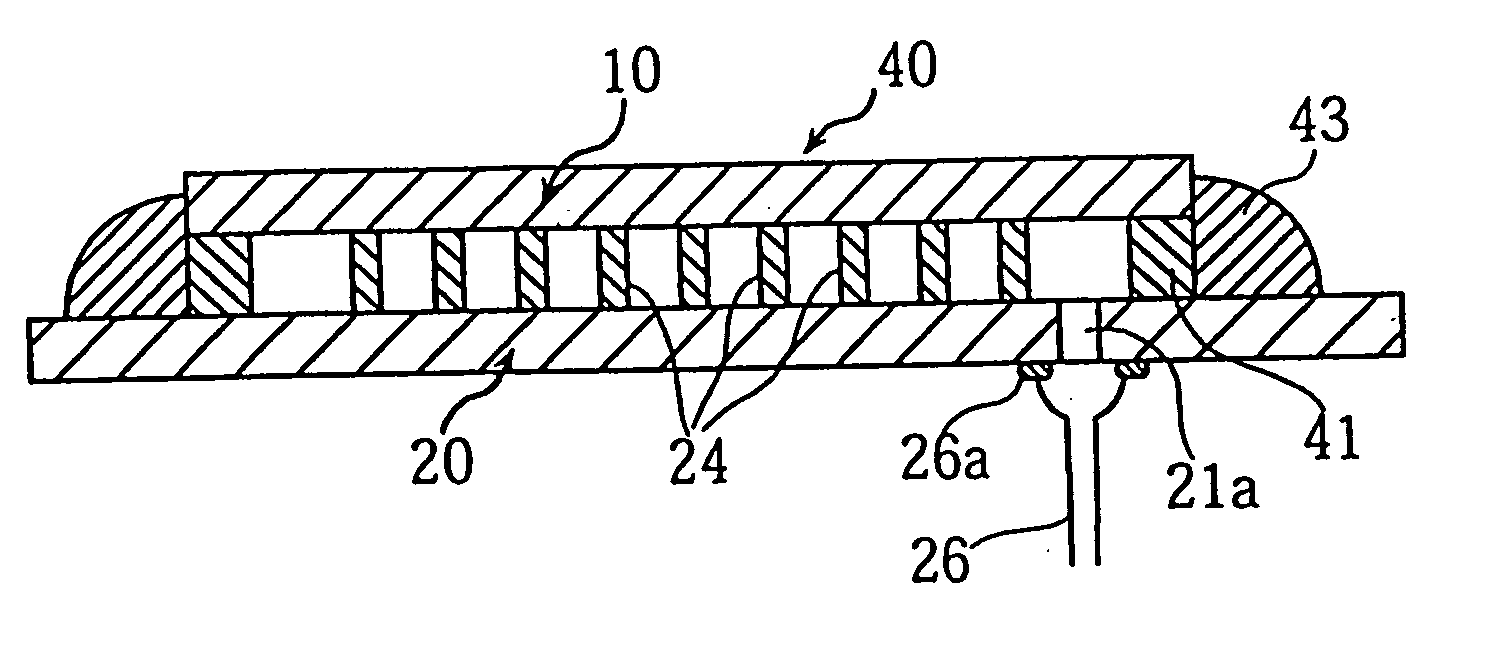

Use of printing and other technology for micro-component placement

InactiveUS6796867B2Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusEngineeringImproved method

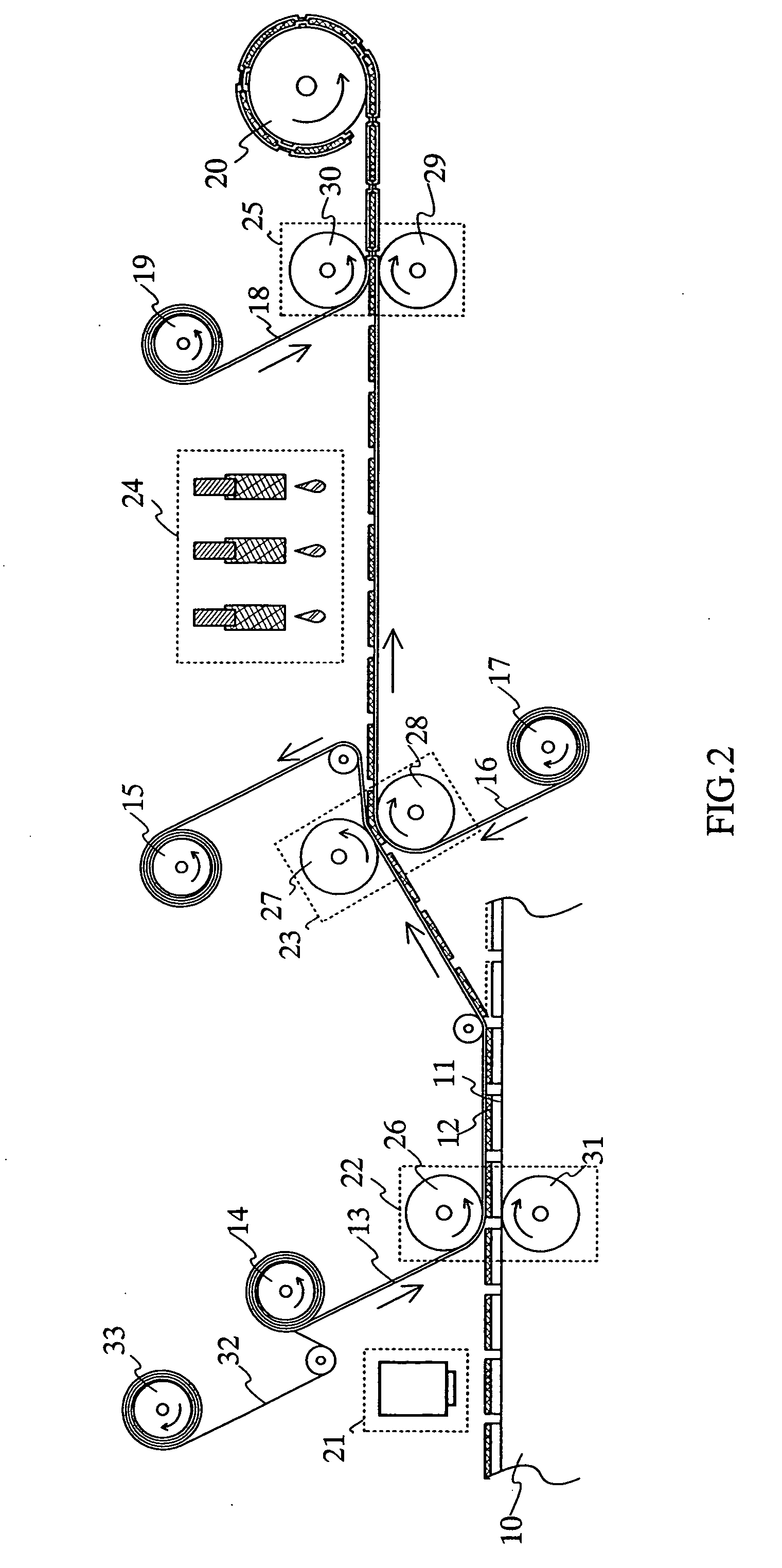

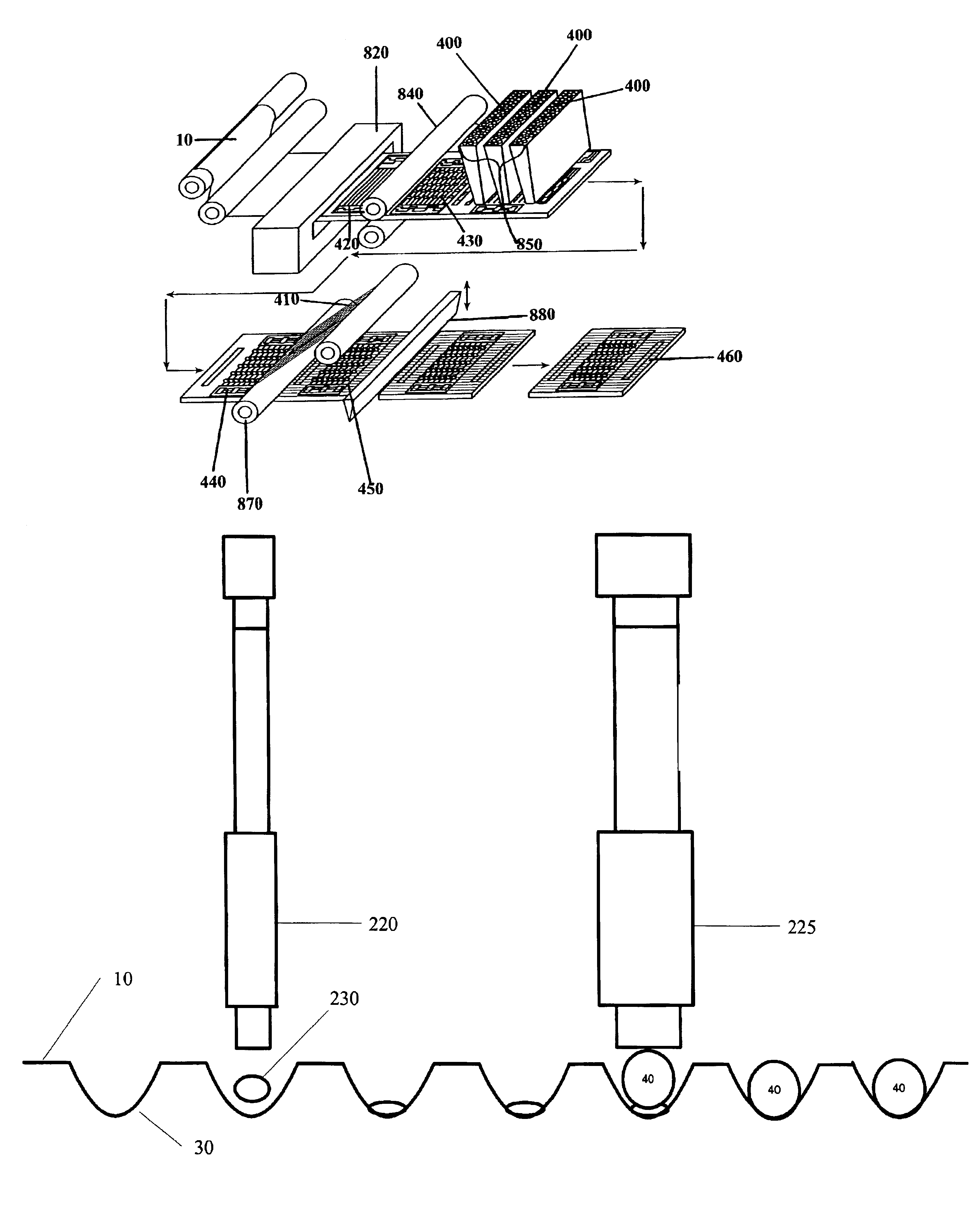

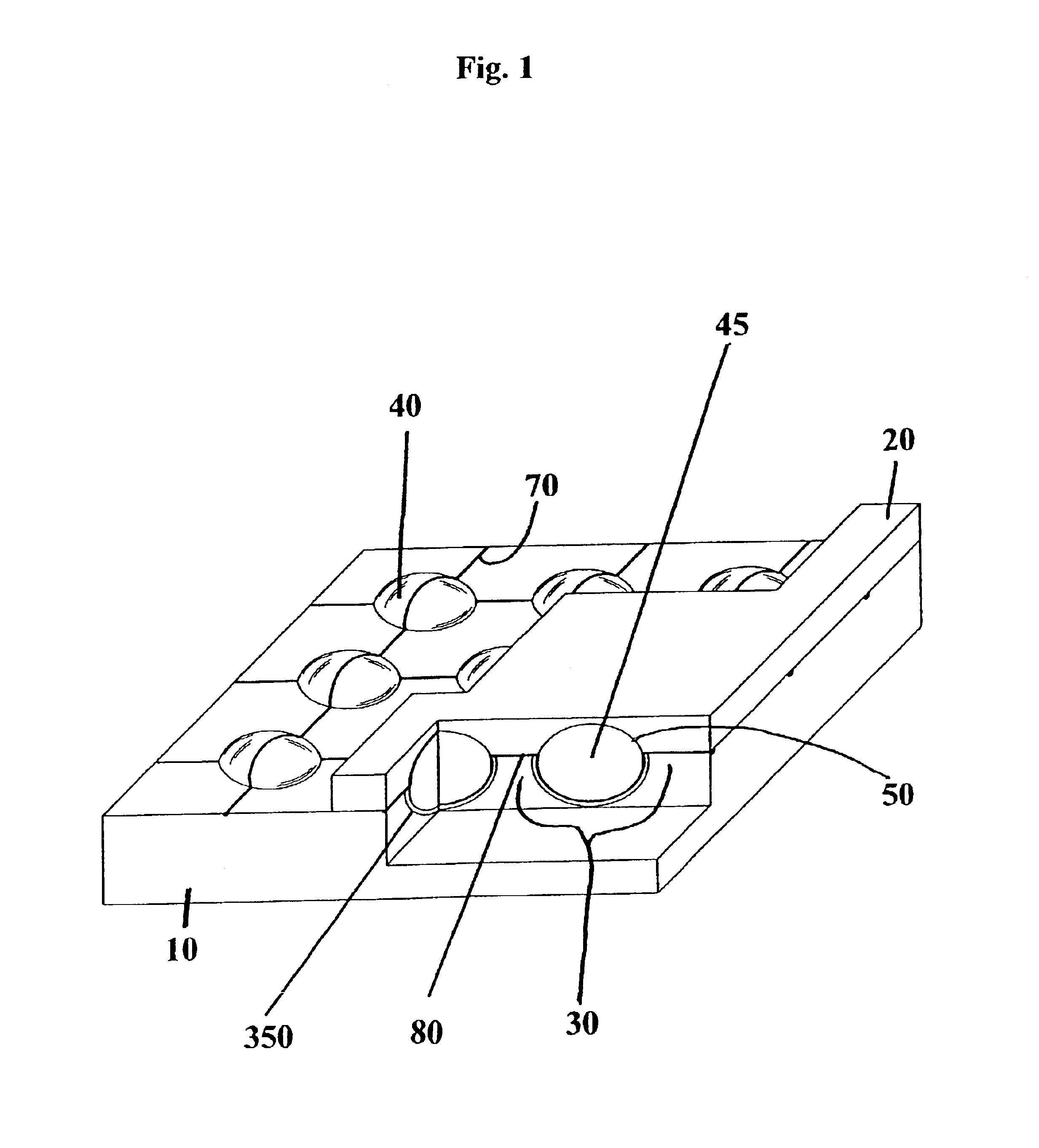

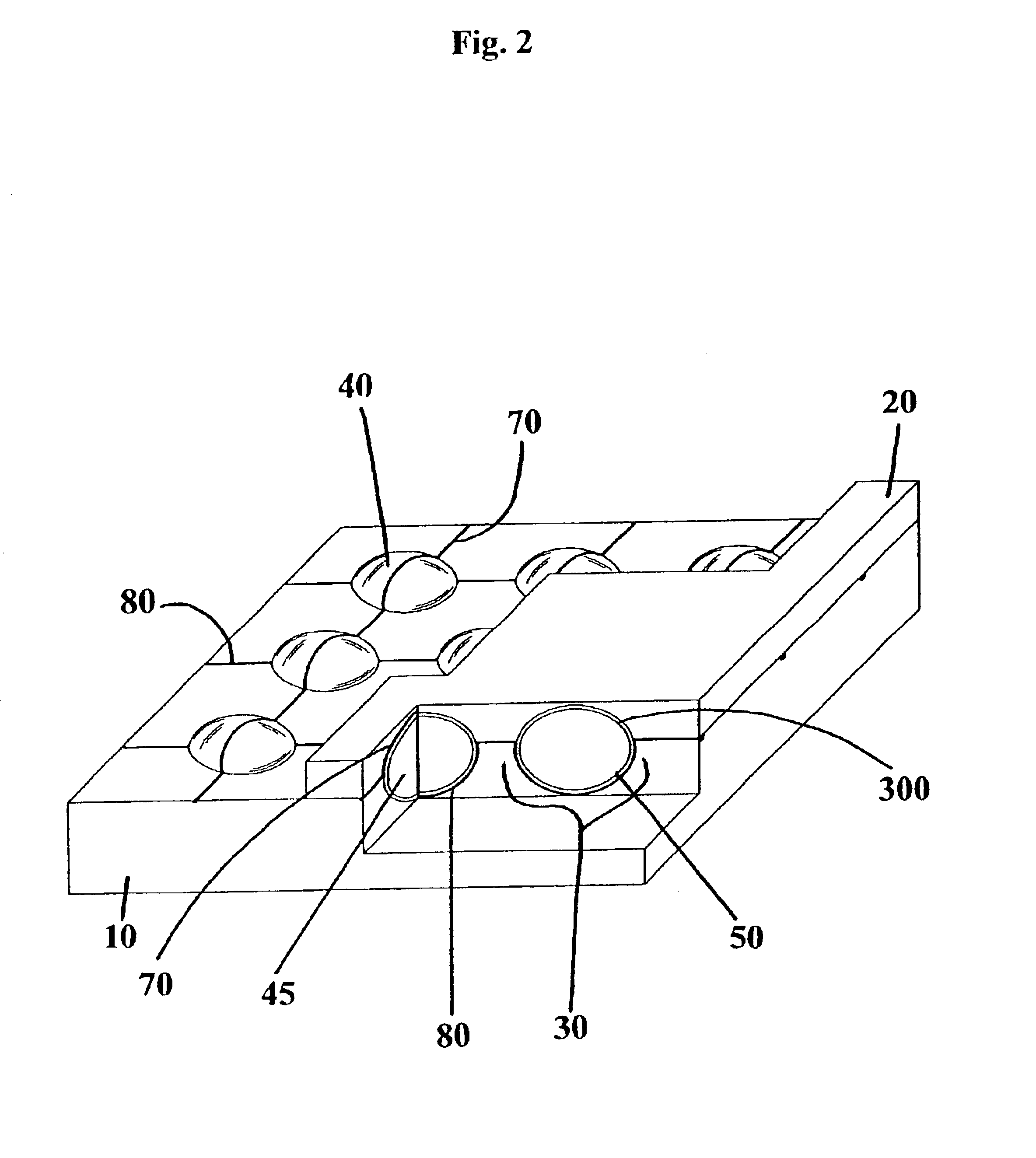

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

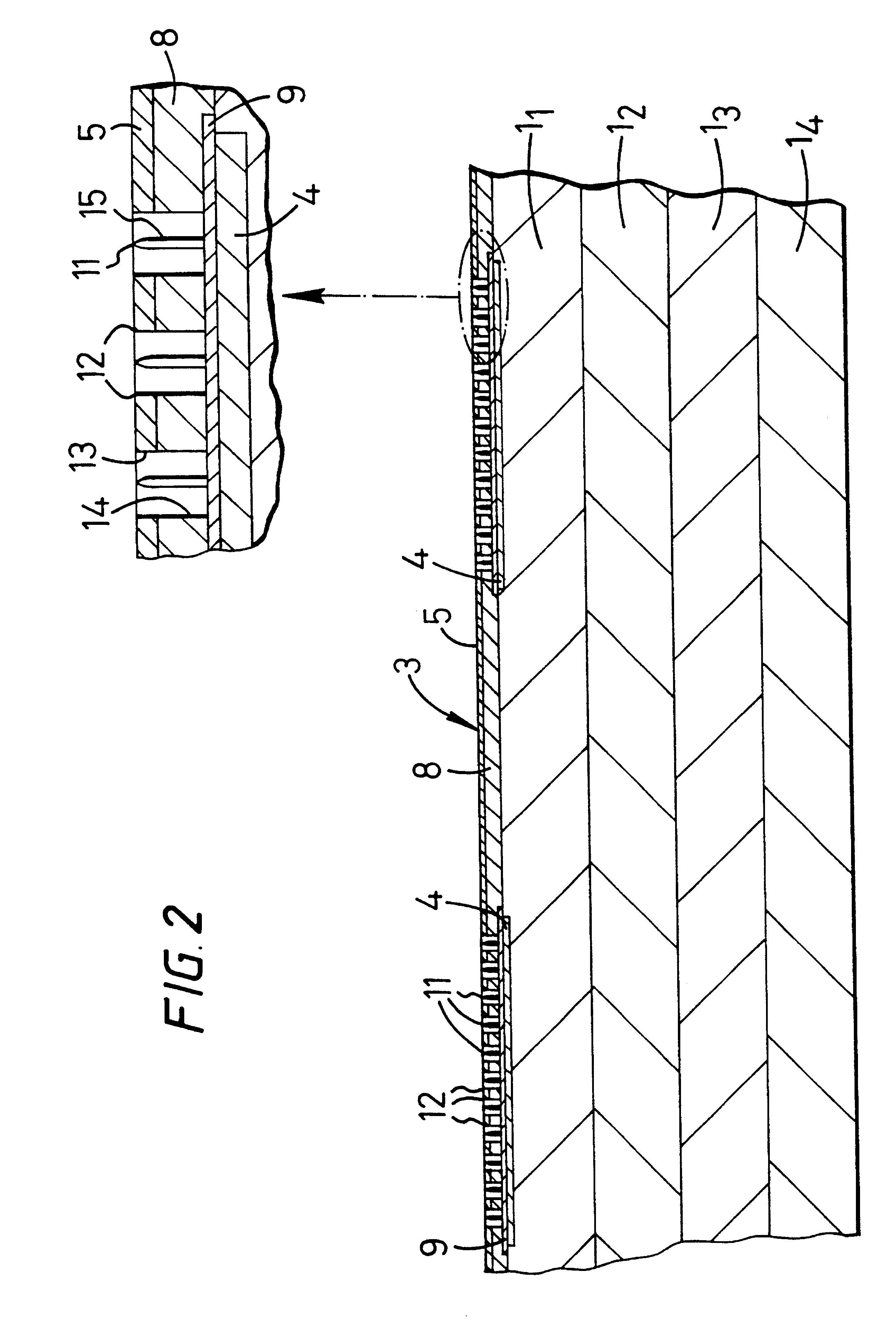

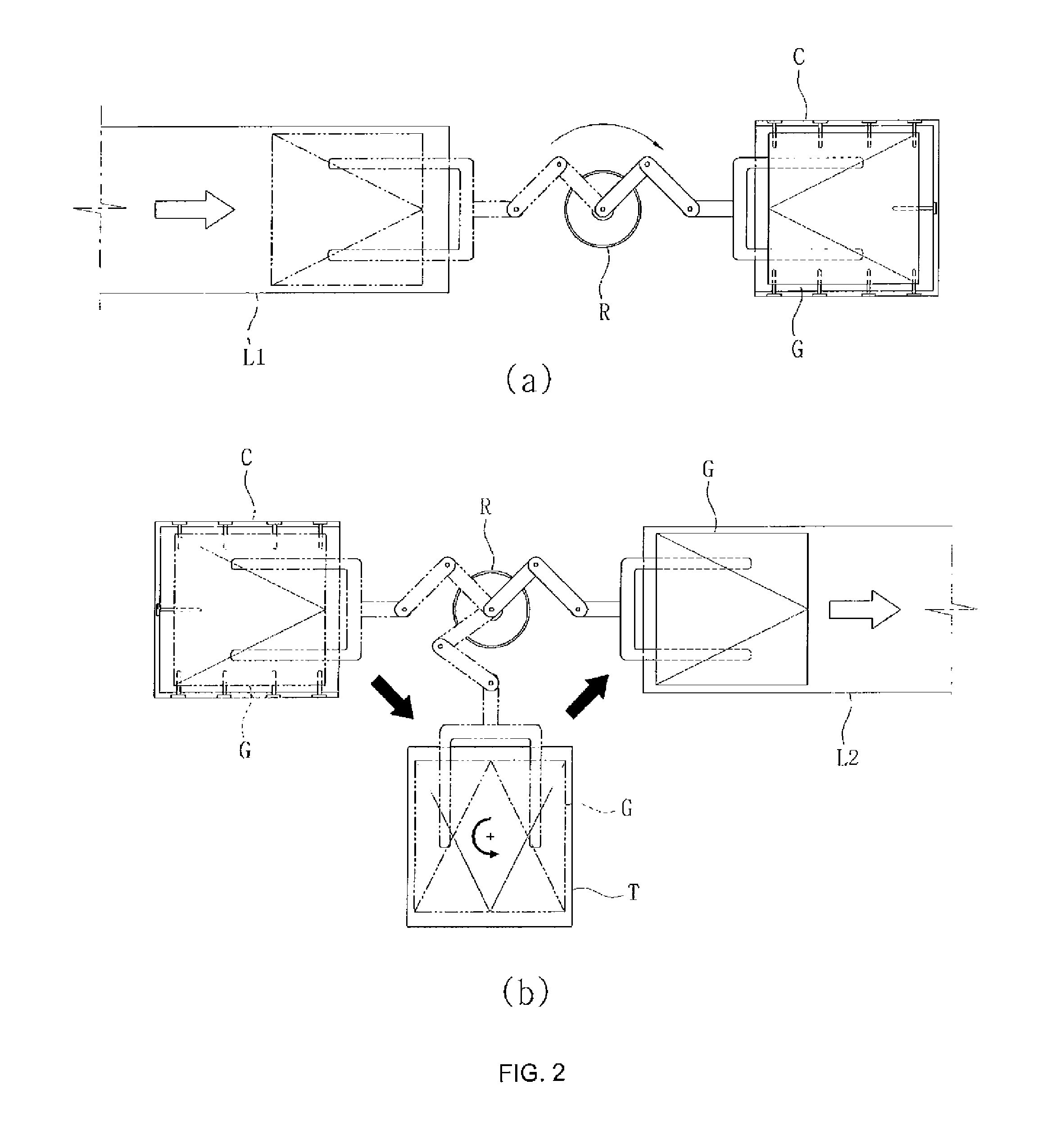

Apparatus and method for manufacturing display panel, and display panel manufactured by the method

InactiveUS20100208190A1Apparatus cost be reducedReduce manufacturing costEngine sealsMechanical working/deformationLiquid-crystal displayManufactured apparatus

A liquid crystal display panel manufacturing apparatus for successively bonding a pair of film substrates, each having a plurality of display regions defined at least along a longitudinal direction, along the longitudinal direction through a sealant formed in every display region of one of the film substrates includes: a first processing unit arranged to form a bonded body by bonding the film substrates so that the respective display regions are superimposed on each other; and a second processing unit including a molding roll configured to hold the bonded body formed in the first processing unit onto a peripheral wall thereof, and arranged to mold the bonded body into a curved shape along the peripheral wall of the molding roll by curing the sealant while holding the bonded body on the peripheral wall of the molding roll.

Owner:SHARP KK

Substrate processing apparatus and substrate positioning device

Owner:TOKYO ELECTRON LTD

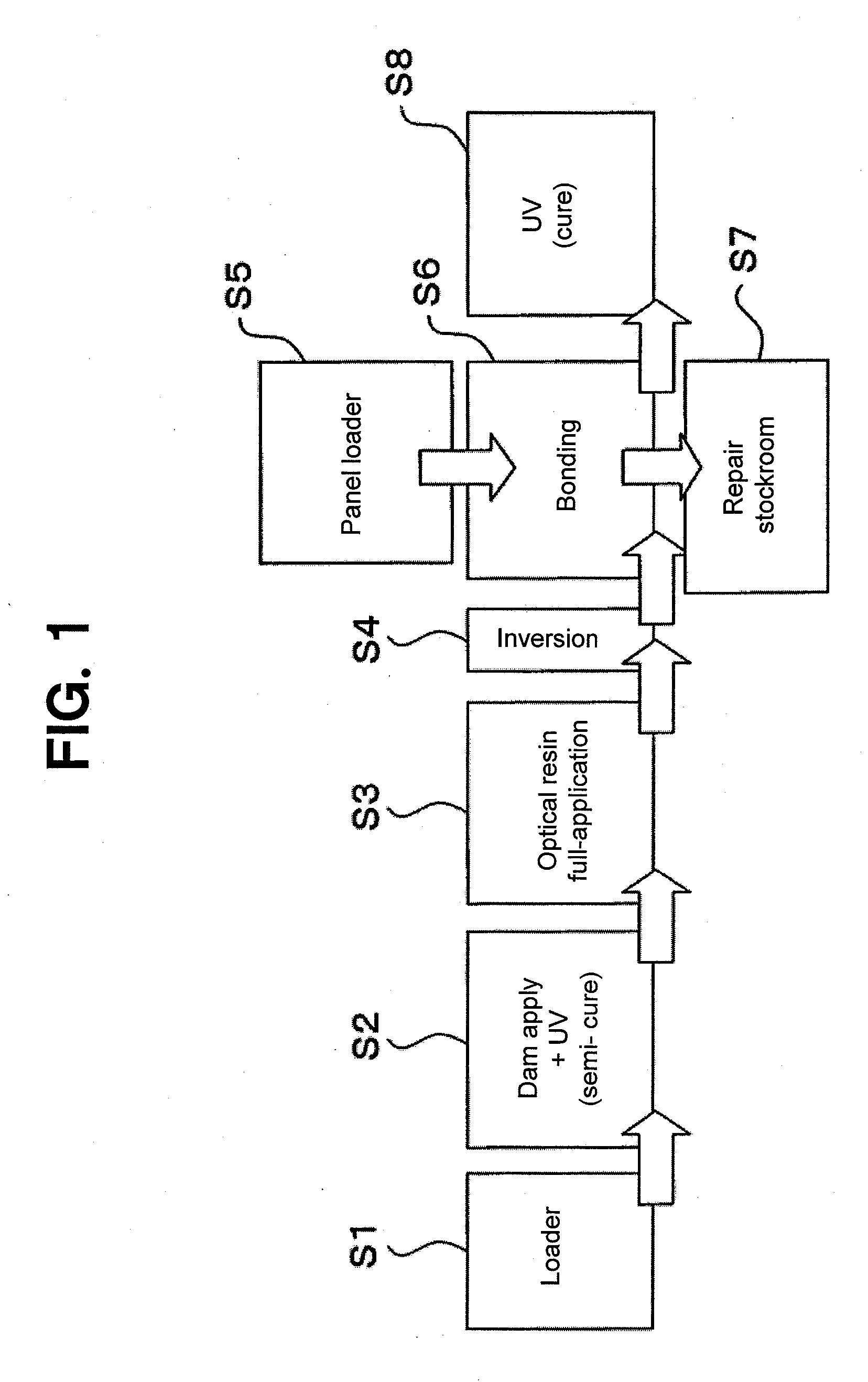

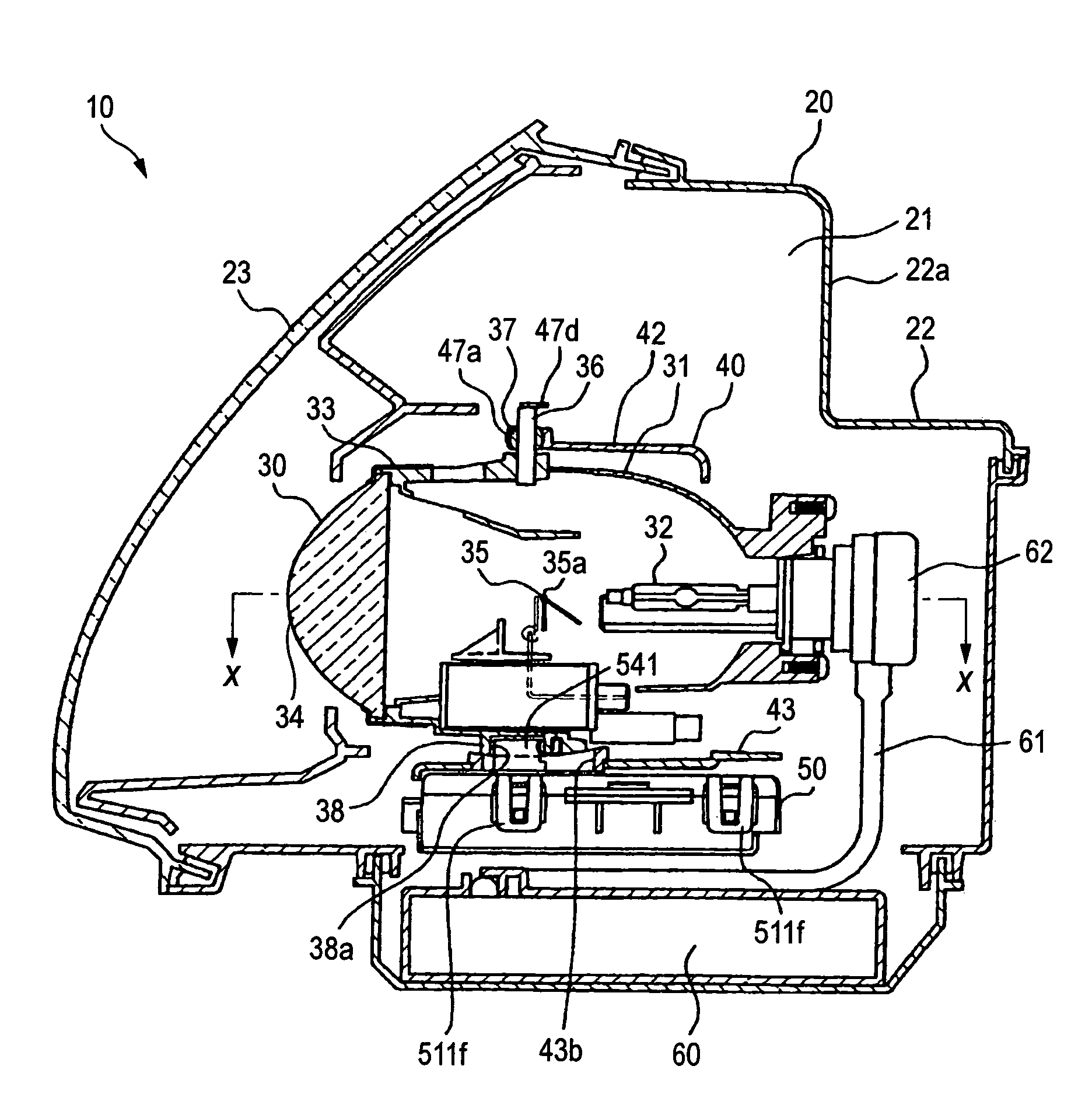

Method and apparatus for manufacturing a liquid crystal component

InactiveUS20100197187A1Desirable shapeElectroluminescent light sourcesSequential operation station machinesEngineeringLiquid crystal

Provided is a liquid crystal component manufacturing method wherein a gap between a panel surface of a liquid crystal module and a transparent cover is filled with a transparent resin, then, the liquid crystal module and the transparent cover are bonded by curing the resin. In the method, at the peripheral section of at least one surface of the panel surface and the facing surface of the transparent cover, the resin is applied, then, a dam is formed by semi-curing the resin. At the same time, the resin is applied to the center, the panel surface and the transparent cover are permitted to face, and the resin applied at the center is pushed to spread by reducing the gap between the facing panel surface and the transparent cover. The resin pushed to spread is dammed up by the dam, and the whole resin that exists in the gap is cured. An apparatus for manufacturing the liquid crystal component is also provided. An optical resin layer recently developed and made known to the public is formed between the liquid crystal module panel surface and the transparent cover in desirable mode.

Owner:TORAY ENG CO LTD

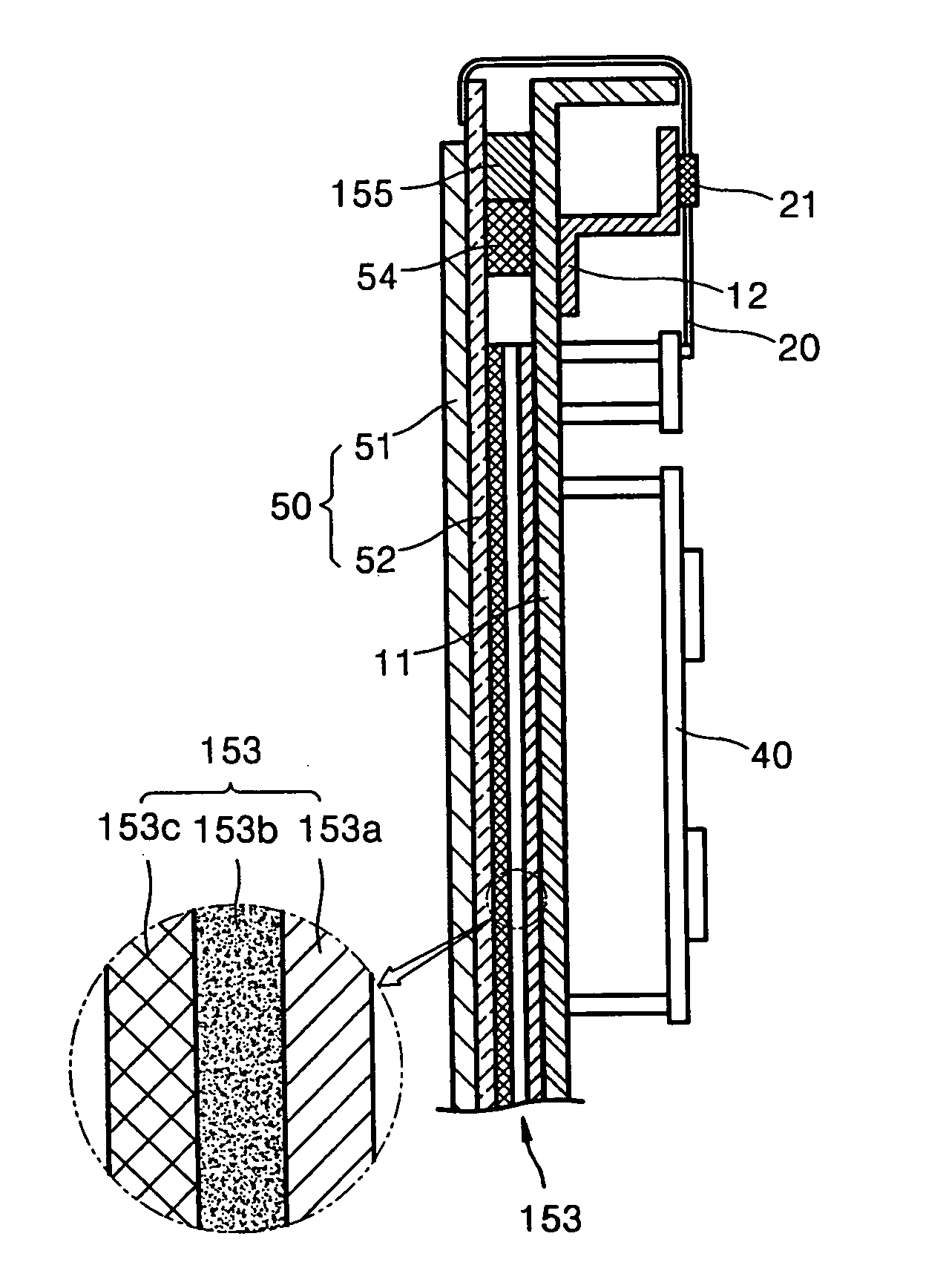

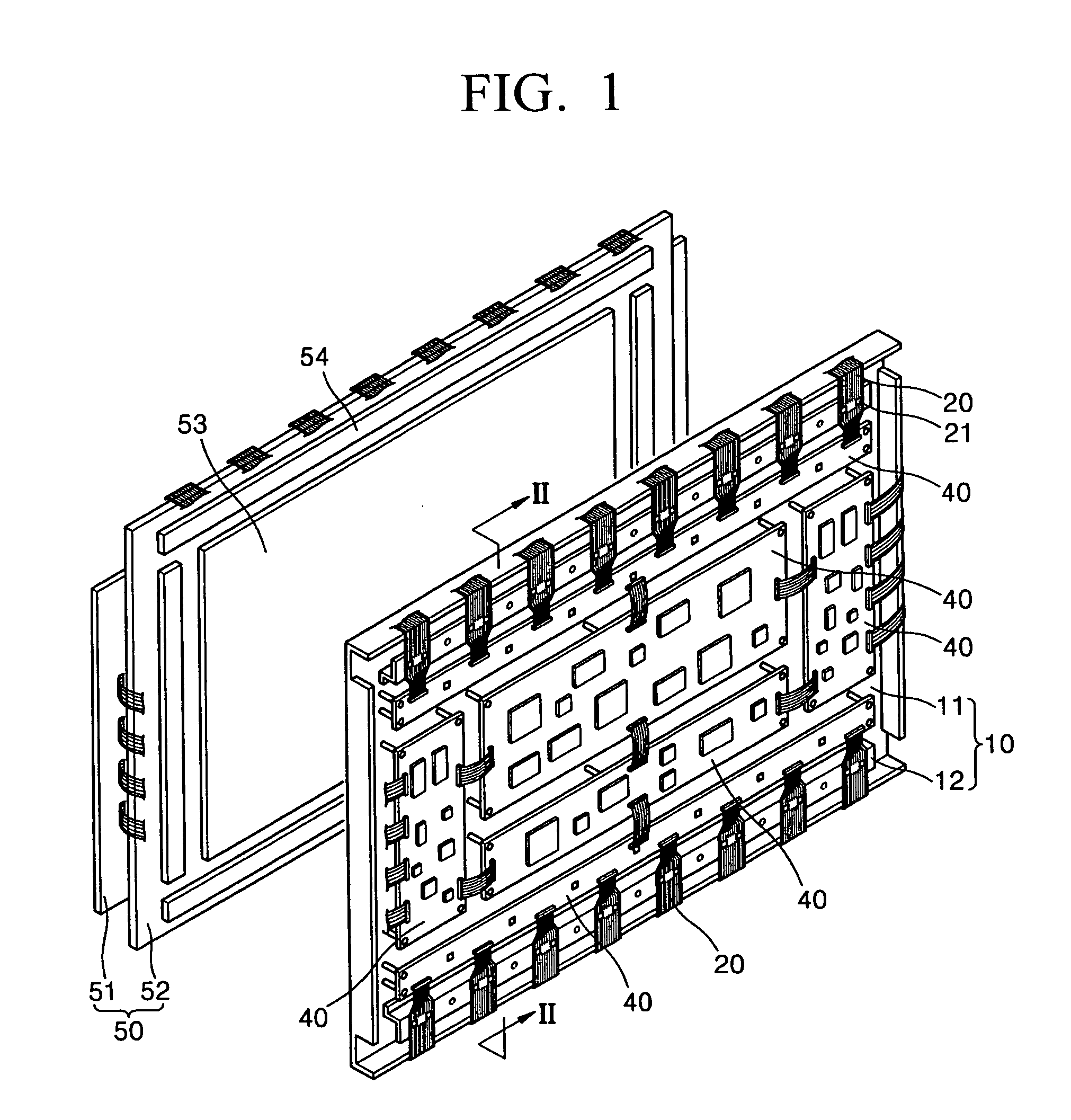

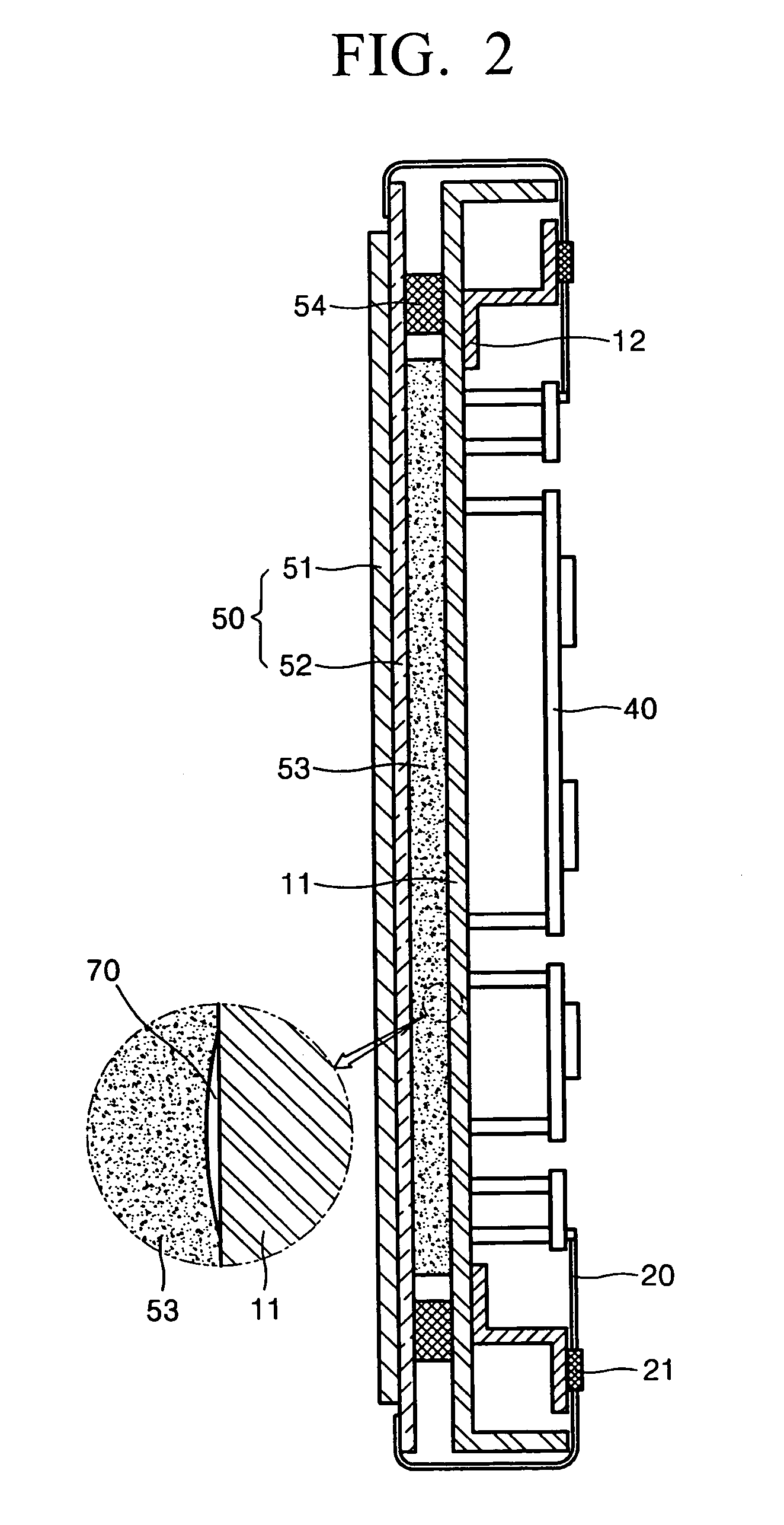

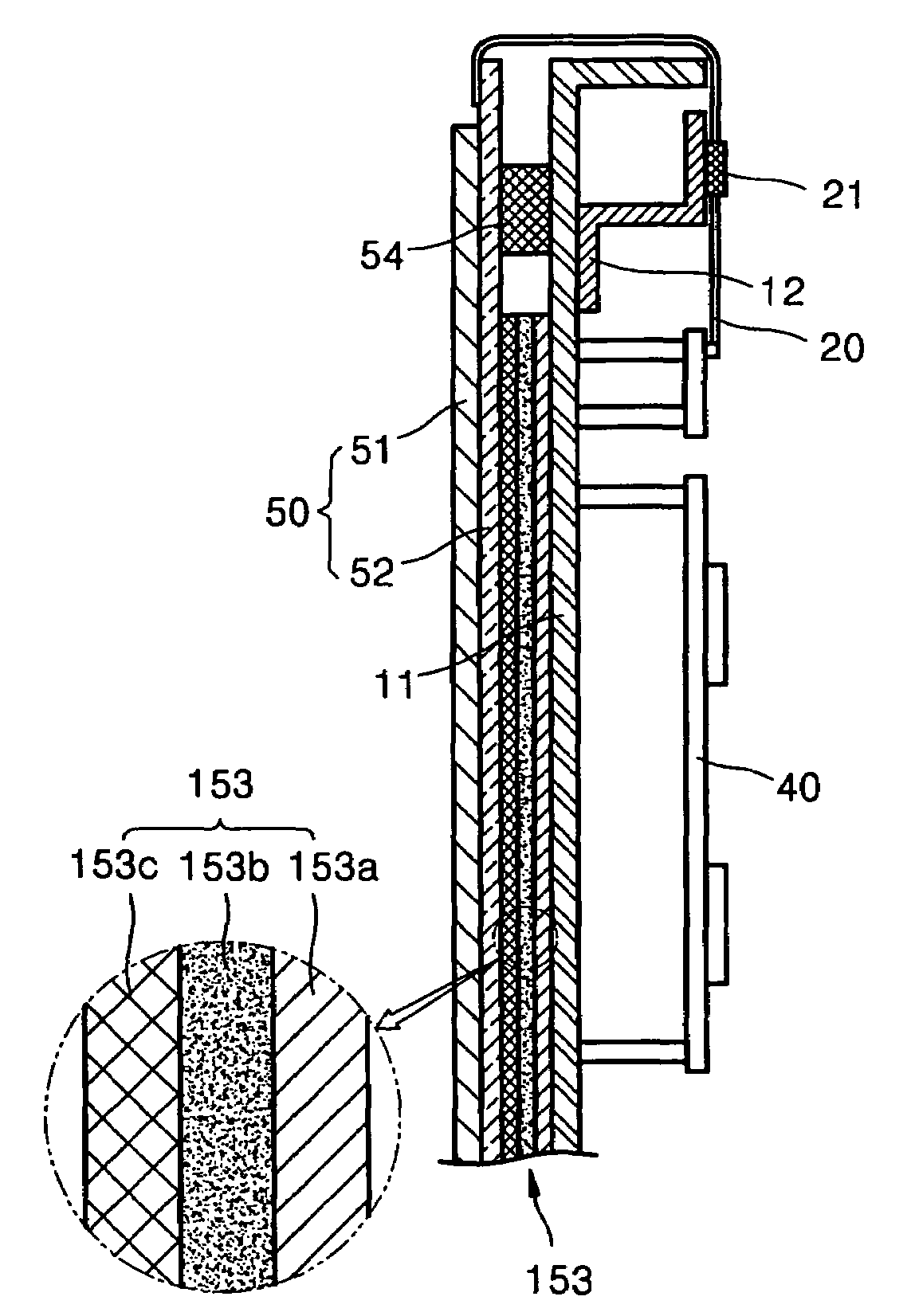

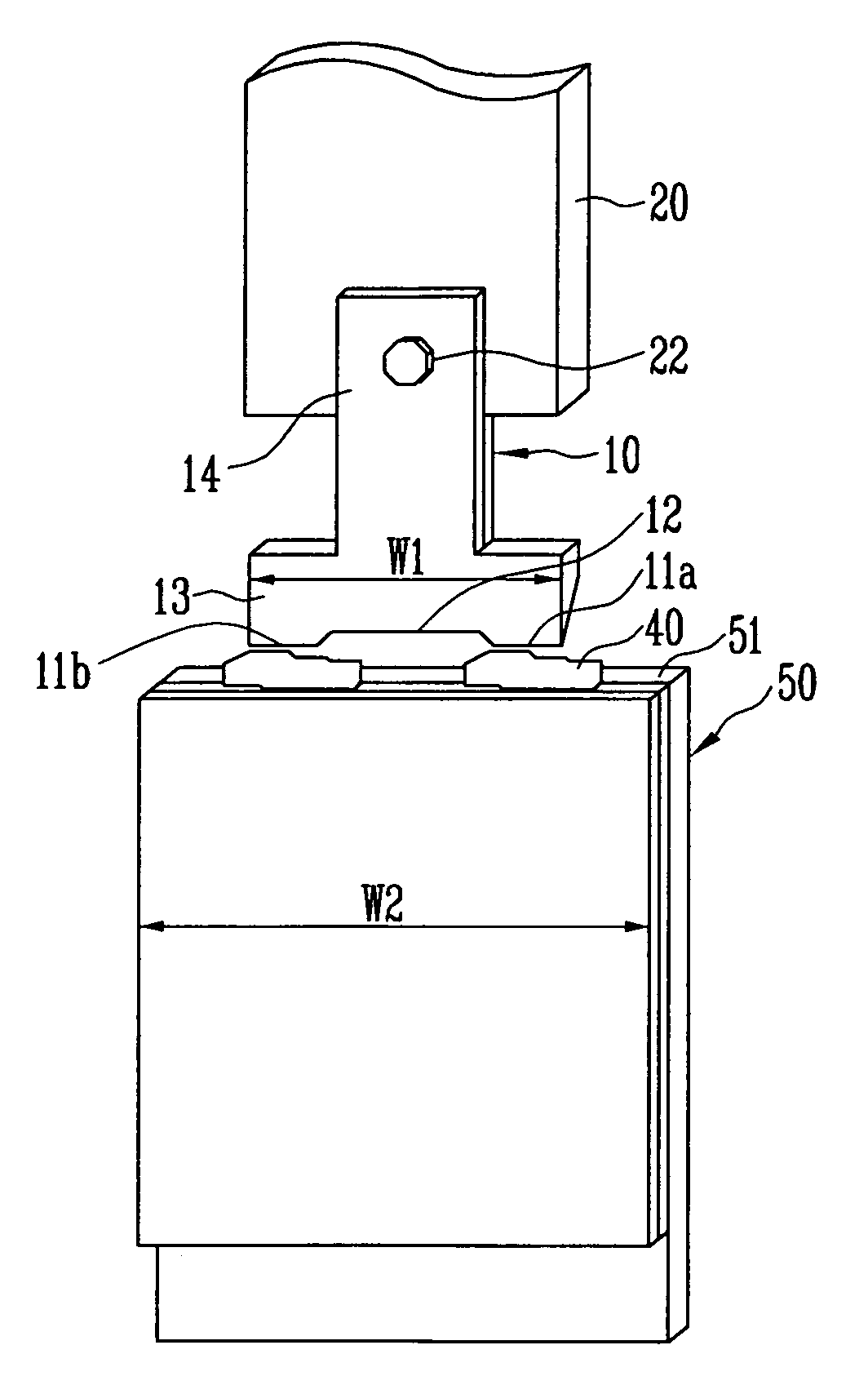

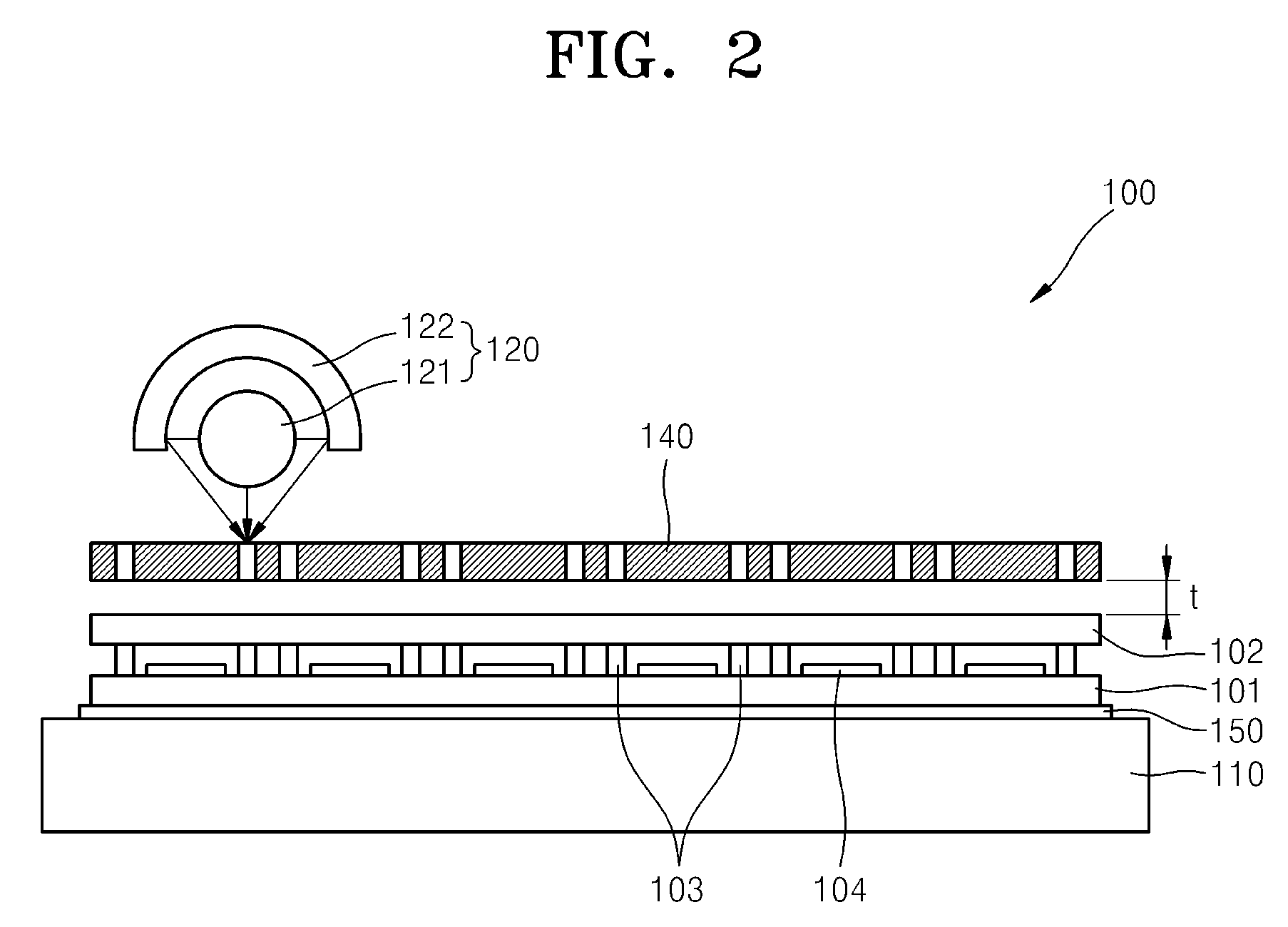

Heat dissipation structure for display panel and display module equipped with the structure

InactiveUS20060098412A1Efficiently dissipatedStatic indicating devicesLayered productsEngineeringMetal sheet

A heat dissipation structure for a display panel efficiently dissipates heat generated during operation of the display panel, and a display module including the heat dissipation structure is also so characterized. The heat dissipation structure is capable of preventing electromagnetic waves generated during the operation of the display panel operation from adversely influencing a driving circuit. The heat dissipation structure comprises: a display panel; a heat dissipating sheet contacting a rear surface of the display panel; and a chassis base disposed on a rear side of the heat dissipating sheet and connected to the display panel via a double-sided adhesive element. The heat dissipating sheet includes two heat dissipating layers and a metal sheet layer interposed between the two heat dissipating layers.

Owner:SAMSUNG SDI CO LTD

Spherical bulb production line

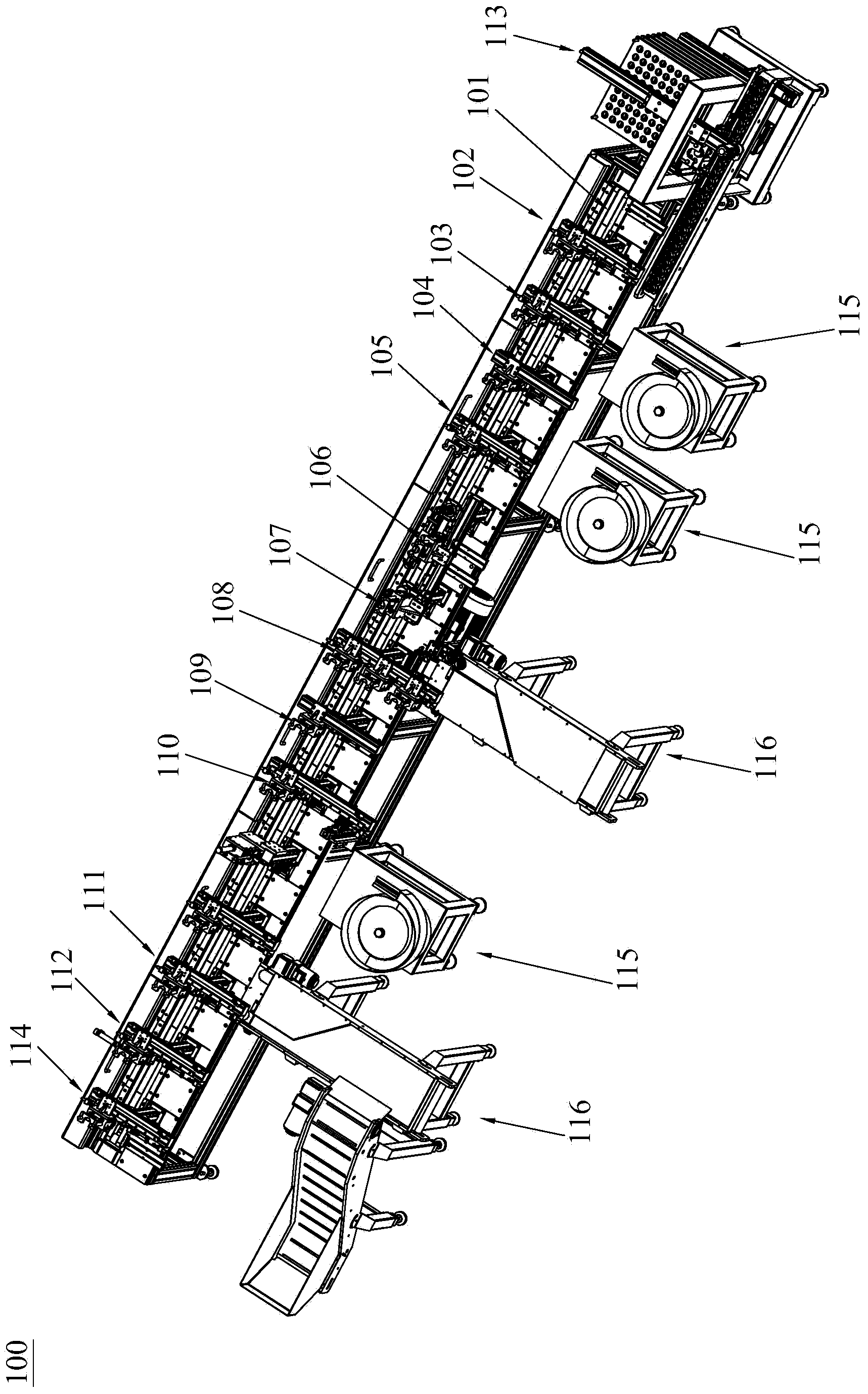

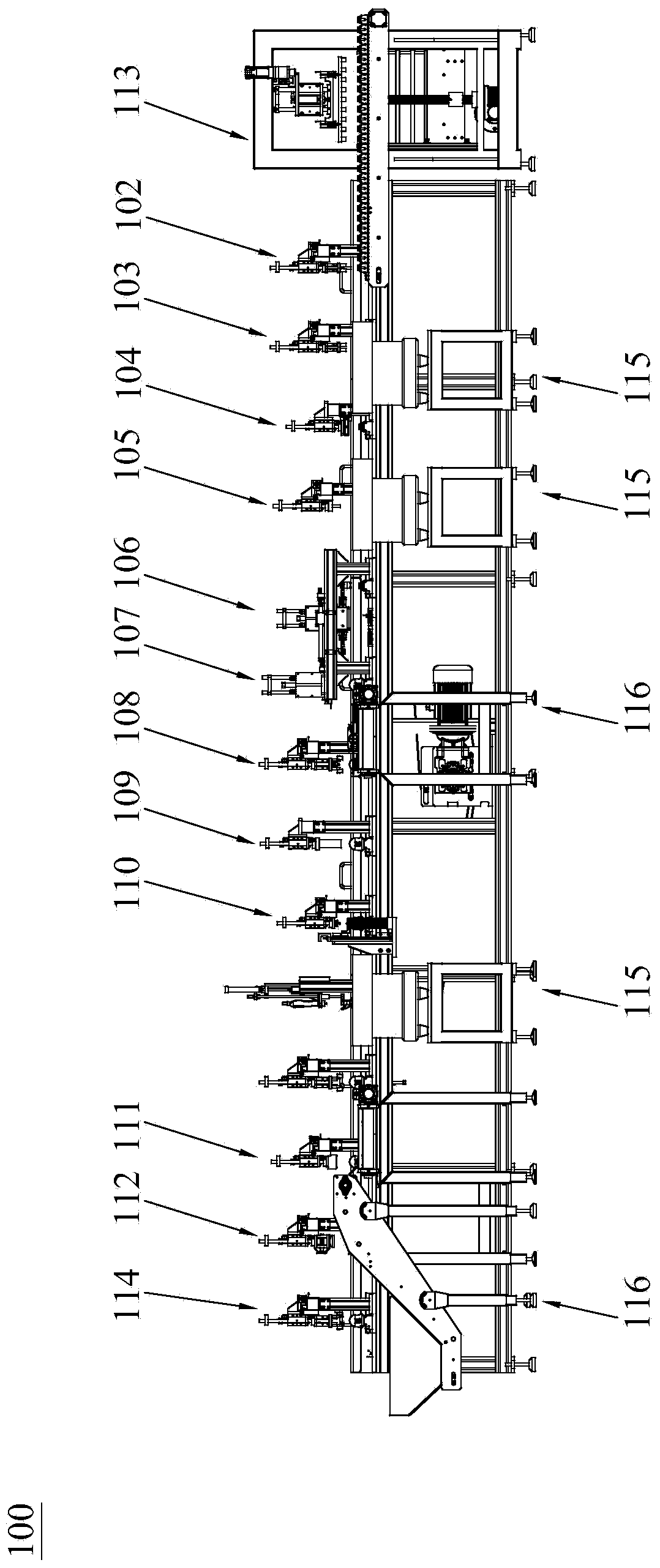

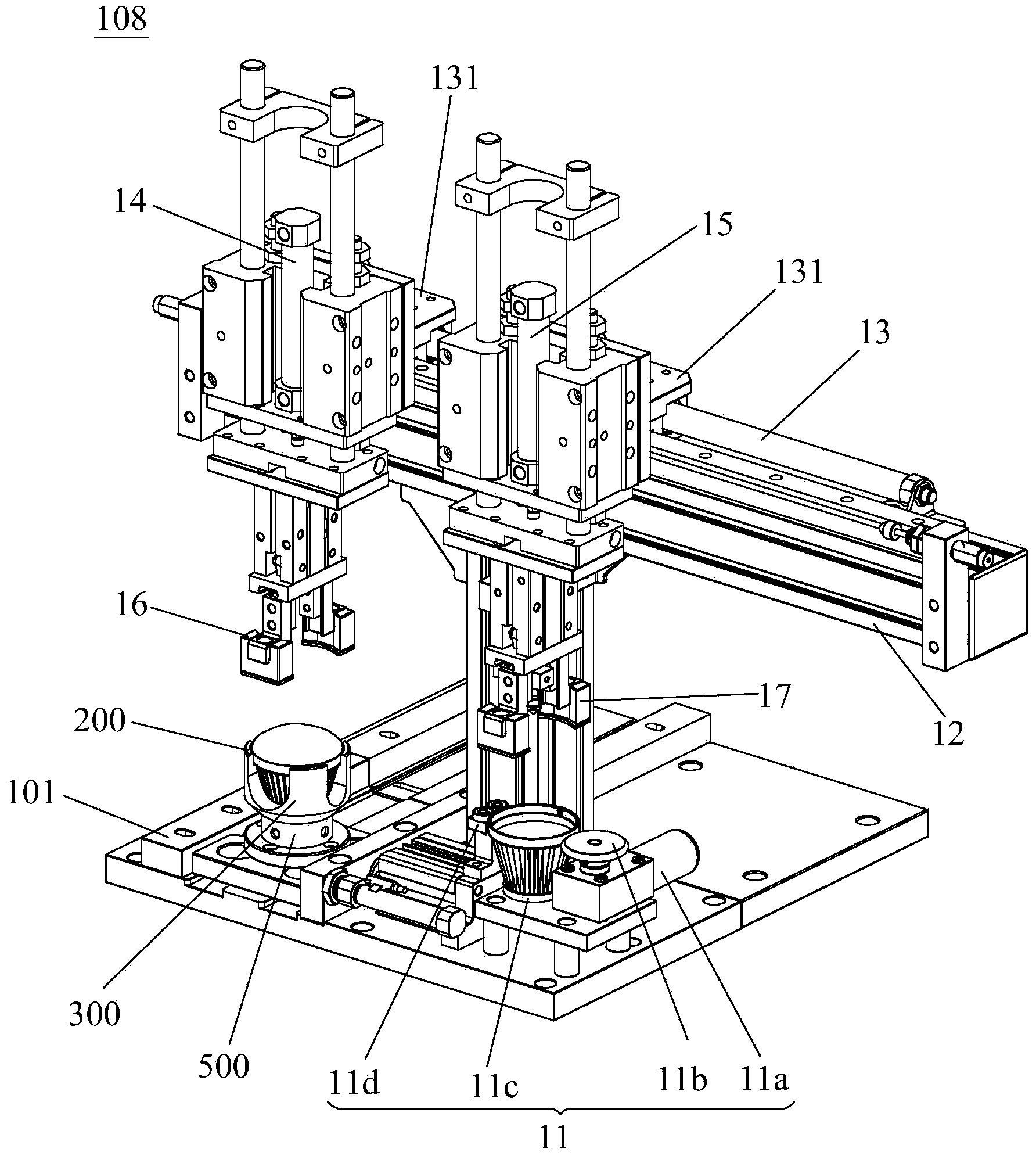

InactiveCN103681168ARealize automatic positioningQuality assuranceSequential operation station machinesDrive motorEngineering

The invention discloses a spherical bulb production line which comprises a conveyor belt. The conveyor belt is provided with a lamp holder one-side locating device, a gluing device and a press-fit screwing device. The lamp holder one-side locating device comprises a lamp holder locating mechanism, a supporting beam, a first air cylinder, a second air cylinder, a third air cylinder, a first pneumatic finger and a second pneumatic finger. The lamp holder locating mechanism comprises a drive motor, a rotary table and a locating groove used for containing a lamp holder. The inner bottom surface of the locating groove is provided with two ejector pins used for locating the lamp holder, wherein the two ejector pins are arranged in a protruding and extending mode. The lamp holder is provided with a locating hole. The rotary table is in rolling contact with the upper edge of the outer side of the lamp holder. The first air cylinder is fixed to the supporting beam, and the second air cylinder and the third air cylinder are fixed to the output end of the first air cylinder. The first pneumatic finger and the second pneumatic finger are fixed to the output end of the second air cylinder and the output end of the third air cylinder respectively. The spherical bulb production line can be used for automatic assembly of a spherical bulb, thereby lowering labor intensity and production cost and improving production efficiency and product quality.

Owner:OUTRACE TECH

LED luminaire

ActiveUS20090244896A1Lower energy requirementsLow calorific valueMechanical apparatusLighting support devicesEffect lightEngineering

Owner:MCGEHEE MICHAEL EUGENE +1

Heat dissipation structure for display panel and display module equipped with the structure

InactiveUS7315451B2Efficiently dissipatedStatic indicating devicesLayered productsMetal sheetEngineering

A heat dissipation structure for a display panel efficiently dissipates heat generated during operation of the display panel, and a display module including the heat dissipation structure is also so characterized. The heat dissipation structure is capable of preventing electromagnetic waves generated during the operation of the display panel operation from adversely influencing a driving circuit. The heat dissipation structure comprises: a display panel; a heat dissipating sheet contacting a rear surface of the display panel; and a chassis base disposed on a rear side of the heat dissipating sheet and connected to the display panel via a double-sided adhesive element. The heat dissipating sheet includes two heat dissipating layers and a metal sheet layer interposed between the two heat dissipating layers.

Owner:SAMSUNG SDI CO LTD

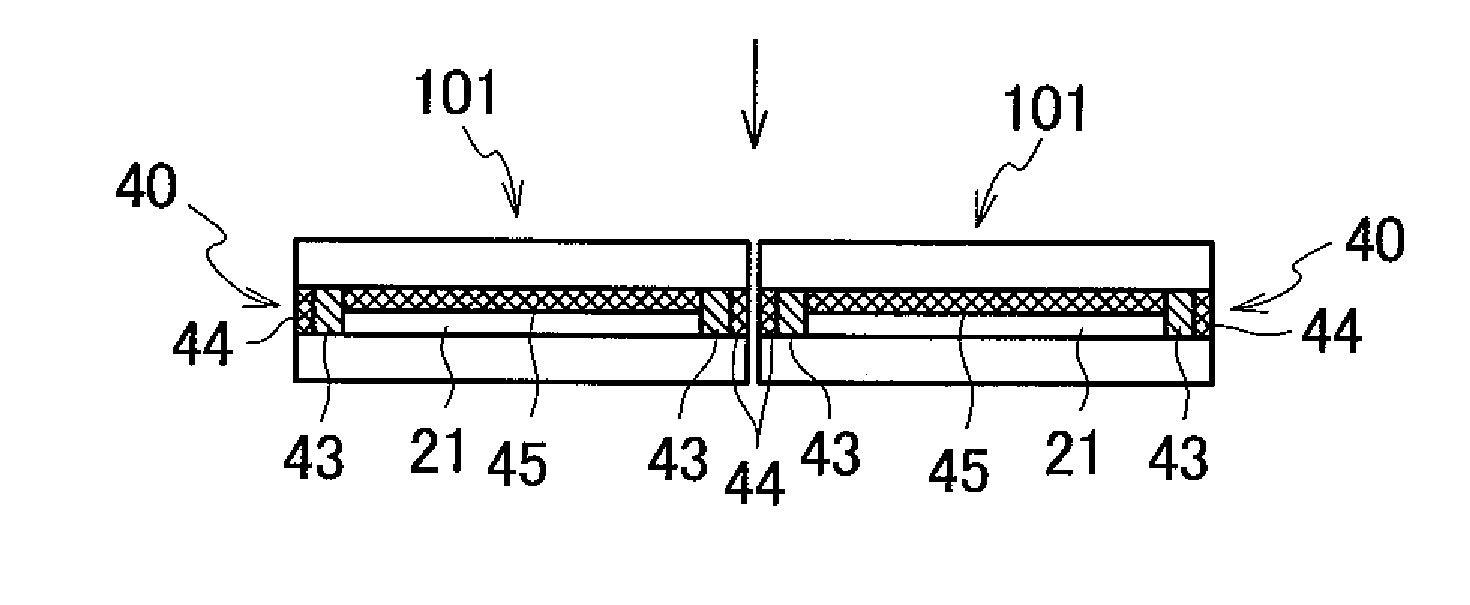

Apparatus of encapsulating display panel and method of manufacturing organic light emitting display device using the same

ActiveUS20090068917A1Effective installationSolve low luminous efficiencyTube/lamp screens manufactureElectroluminescent light sourcesInjection portDisplay device

An encapsulation apparatus capable of securely sealing a gap of a display panel and improving intensity of the display panel, and a method of manufacturing an organic light emitting display device using the encapsulation apparatus are taught. The encapsulation apparatus includes an injection port having tapered projecting edges formed in both sides of one end the injection port, and injecting a reinforcing material into a gap of a display panel in a dual surface contact manner, the first substrate and the second substrate being attached to each other using a sealant; and a supporter coupled to the injection port and supporting the injection port.

Owner:SAMSUNG DISPLAY CO LTD

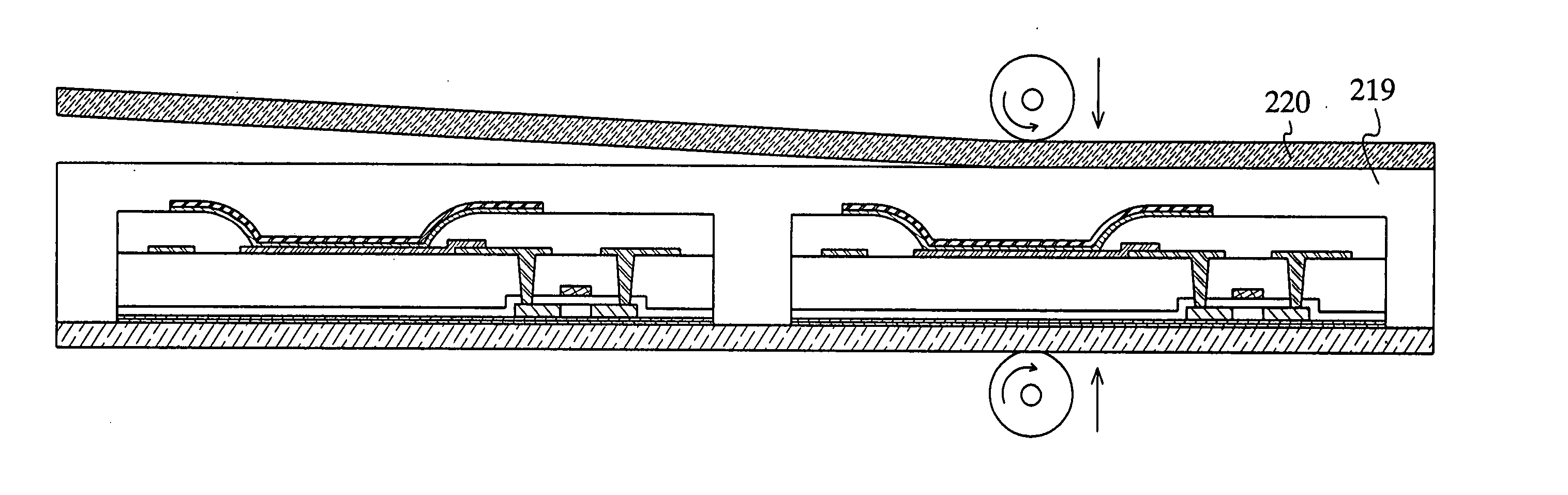

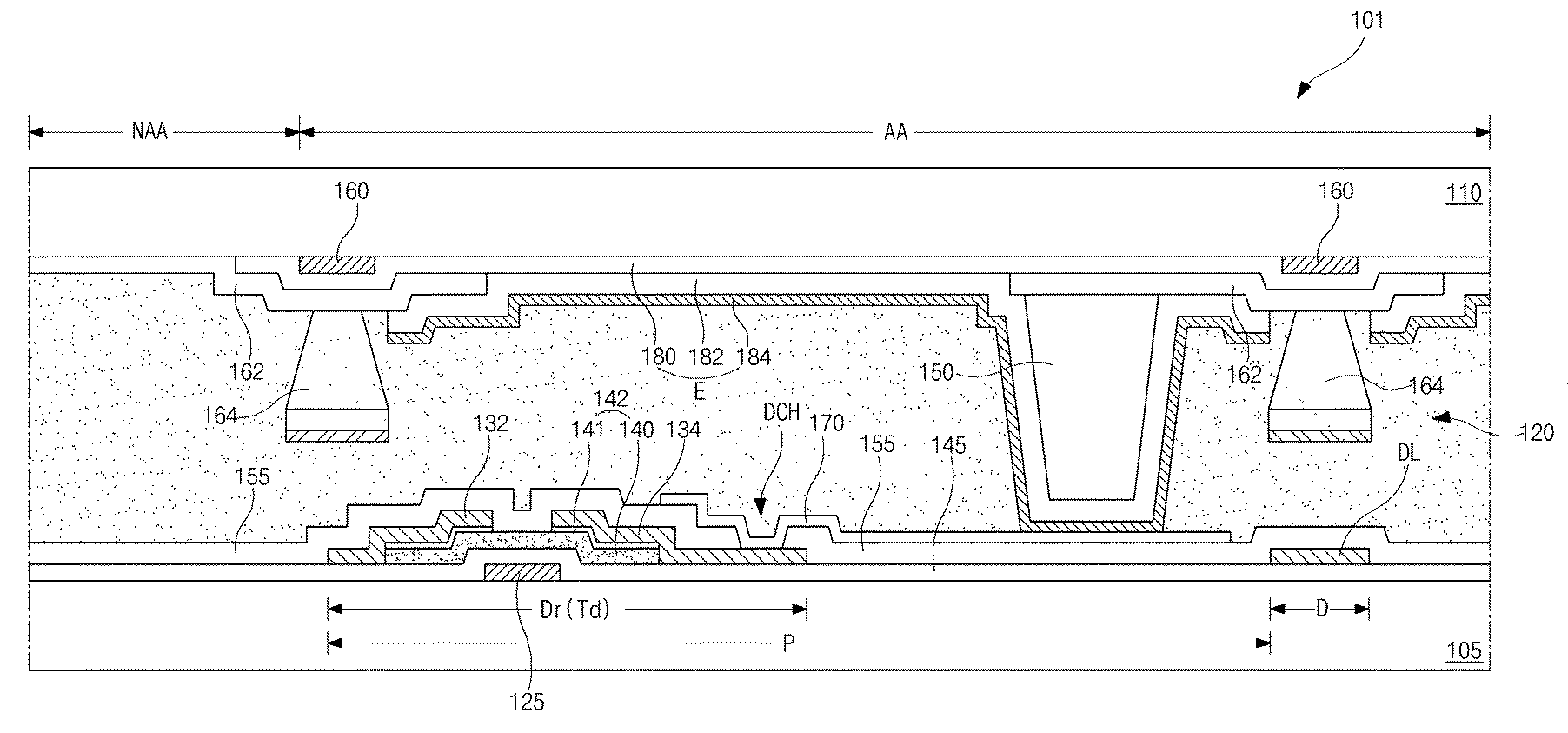

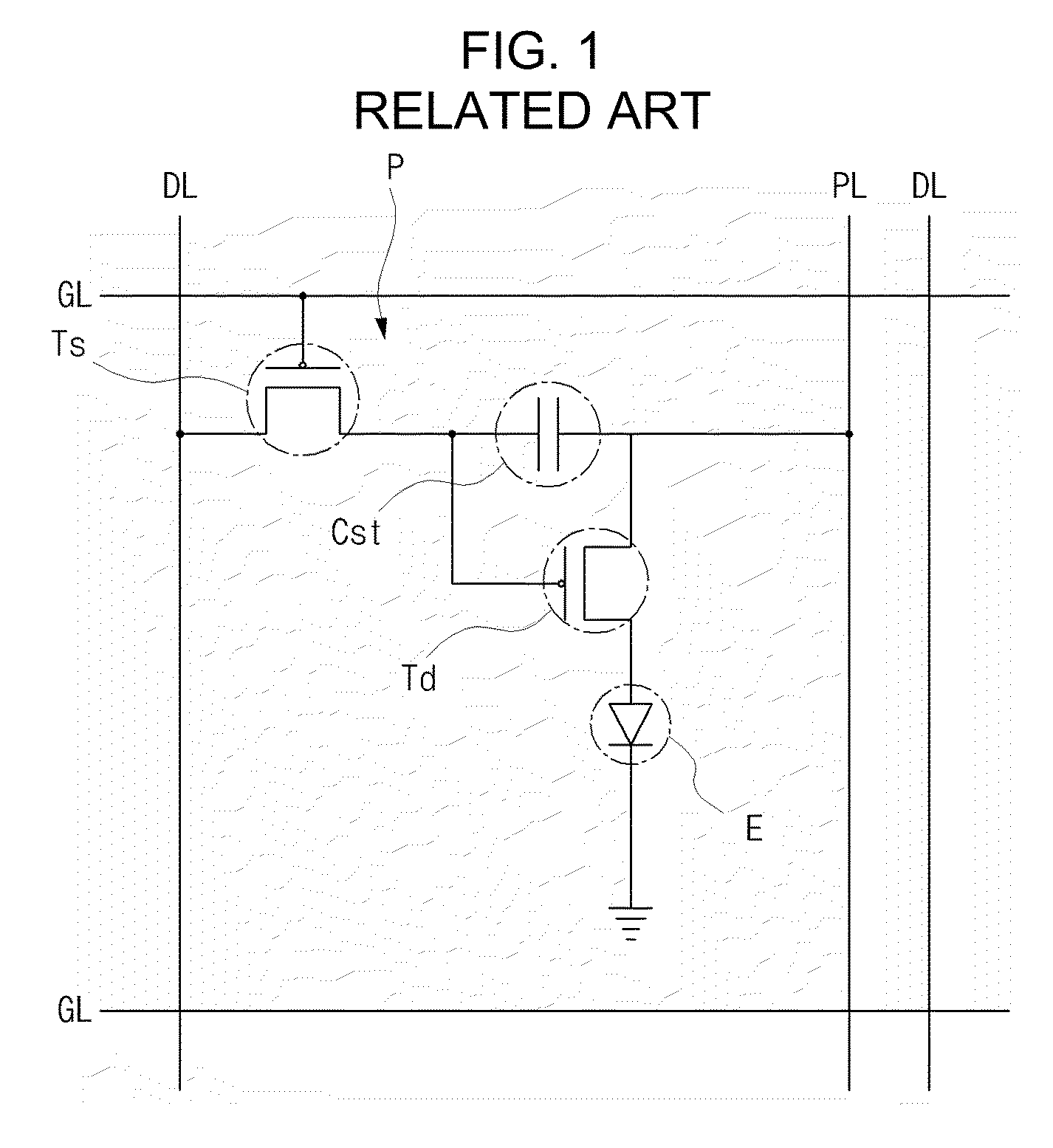

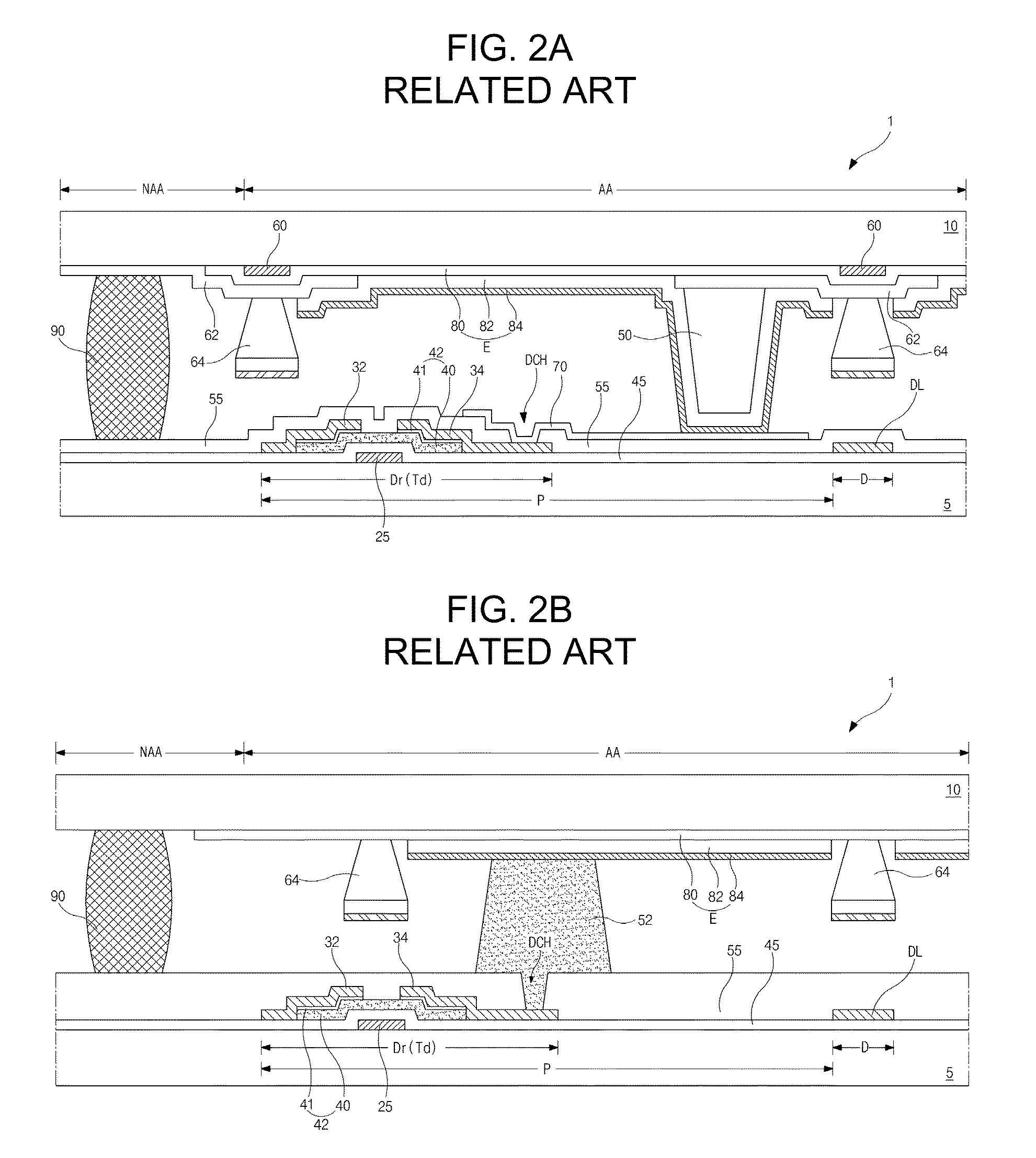

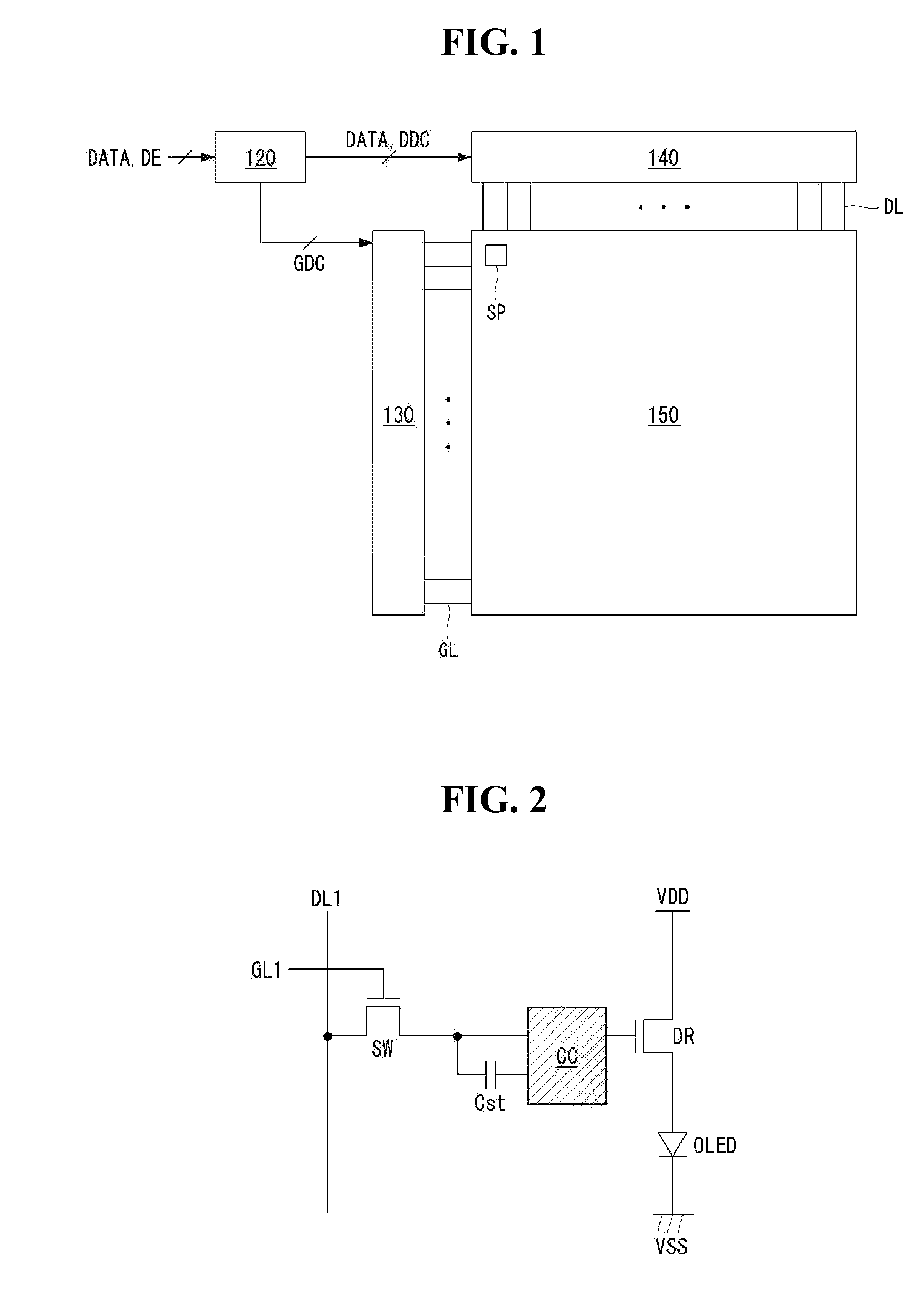

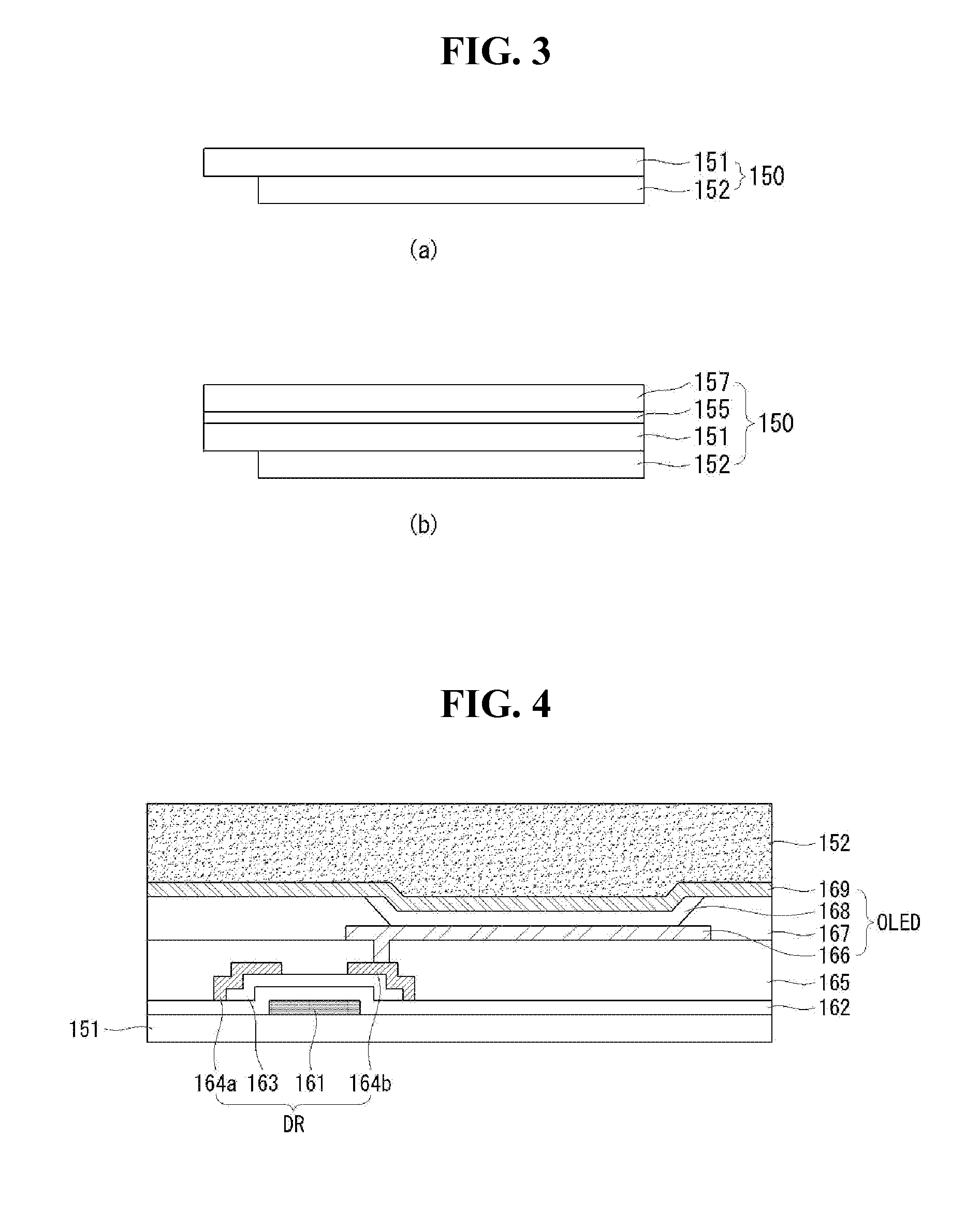

Organic electroluminescent display device and method and apparatus of manufacturing the same

ActiveUS20100127615A1Improve display qualityImprove production efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceLight-emitting diode

A an organic electroluminescent display device includes an array substrate including a driving thin film transistor in a pixel region on a first substrate; an opposing substrate including an organic electroluminescent diode in the pixel region on a second substrate; an adhesive layer filling a space between the array substrate and the opposing substrate; and a connection spacer to electrically connect the organic electroluminescent diode with the driving thin film transistor.

Owner:LG DISPLAY CO LTD

Visual display

InactiveUS6517403B1Cathode-ray/electron-beam tube electrical connectionGas filling substance selectionRadiant heaterIrradiation

The apparatus for sealing face plates (753) and cathodes (754) has three stations (701, 702, 703). The first (701) is a preheater, the second (702) is an alignment and irradiation station and the third (703) is a controlled cooling station. Beneath each station, a vacuum pump (710) capable of drawing ultralow pressures is provided. The preheater is equipped with upper and lower banks of radiant heaters and reflectors (712). The upper heaters are Provided above a quartz: window (713) of a chamber (714) constituting the station. The pressure in the preheater is pumped down to that in the alignment and irradiation station prior to opening of the gate valve between them and transfer of the face plate and cathode. At the alignment and irradiation station, further heaters (716) are provided. Those above the face plate and cathode, the face plate being uppermost, are mounted on frames (717) about hinges (718), whereby they can be swung up to clear this station's top quartz window, exposing the face plate to the view of an optical system (719) and a laser (720). Manipulation controls (722) are provided for manipulating the position of the face plate to be pixel alignment, as measured by the optical system (719), with the cathode. The laser is traversed around further. The cooling station (703) has meanwhile been pumped down and the sealed device is transferred to it. The temperature of the device is allowed to rise very slowly, in order to reduce the risk of thermal cracking to as great an extent as possible. As the temperature slowly falls, air is slowly introduced, so that the finished device can be removed to the ambient surroundings.

Owner:COMPLETE MULTILAYER SOLUTIONS +1

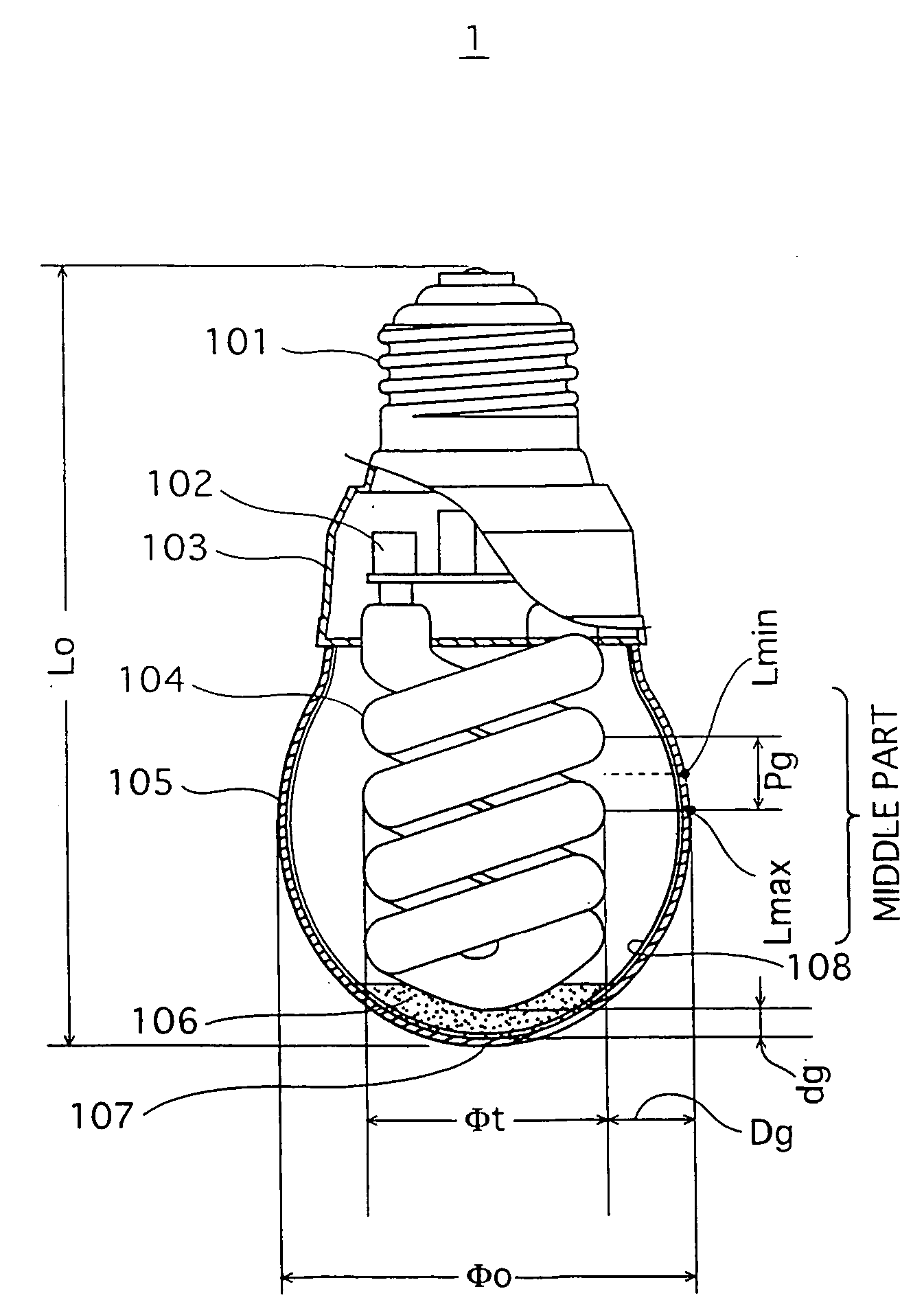

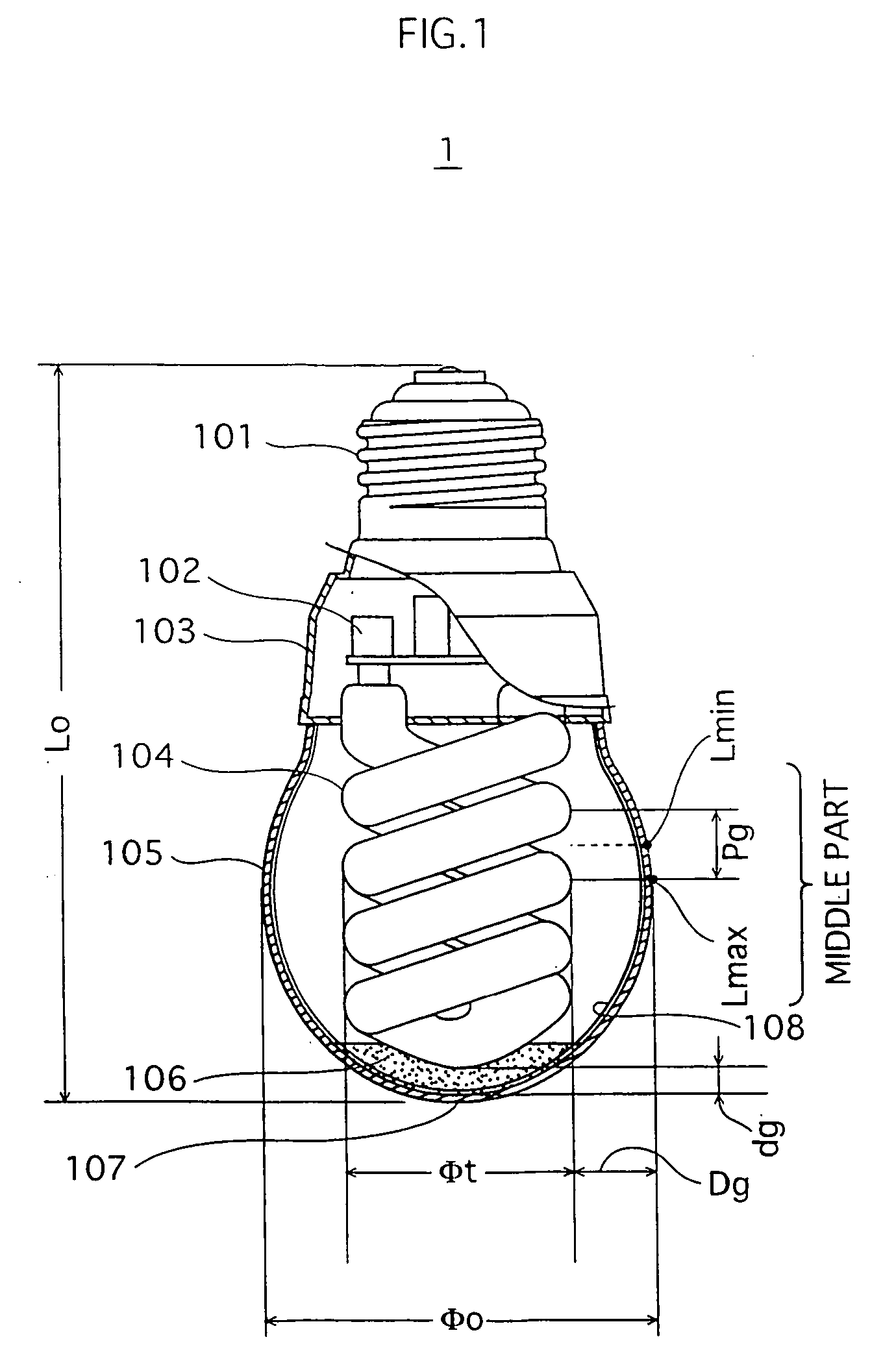

Compact self-ballasted fluorescent lamp, fluorescent lamp and helical glass tube

InactiveUS20050104522A1Excellent finished dimension accuracyEasily woundTube/lamp screens manufactureDischarge tube luminescnet screensEngineeringFluorescent lamp

A diffuser is formed on an inner surface of a globe included in a compact self-ballasted fluorescent lamp, and a diffuse transmittance of the diffuser τ is set at 95%. When designing dimensions of the compact self-ballasted fluorescent lamp, at the same time, a ratio Dg / Pg is set at 0.8 or greater. Here, Pg is a helical pitch of an arc tube having a helical configuration, and Dg is a half of a difference between a helix diameter of the arc tube and a maximum outside diameter of the globe.

Owner:PANASONIC CORP

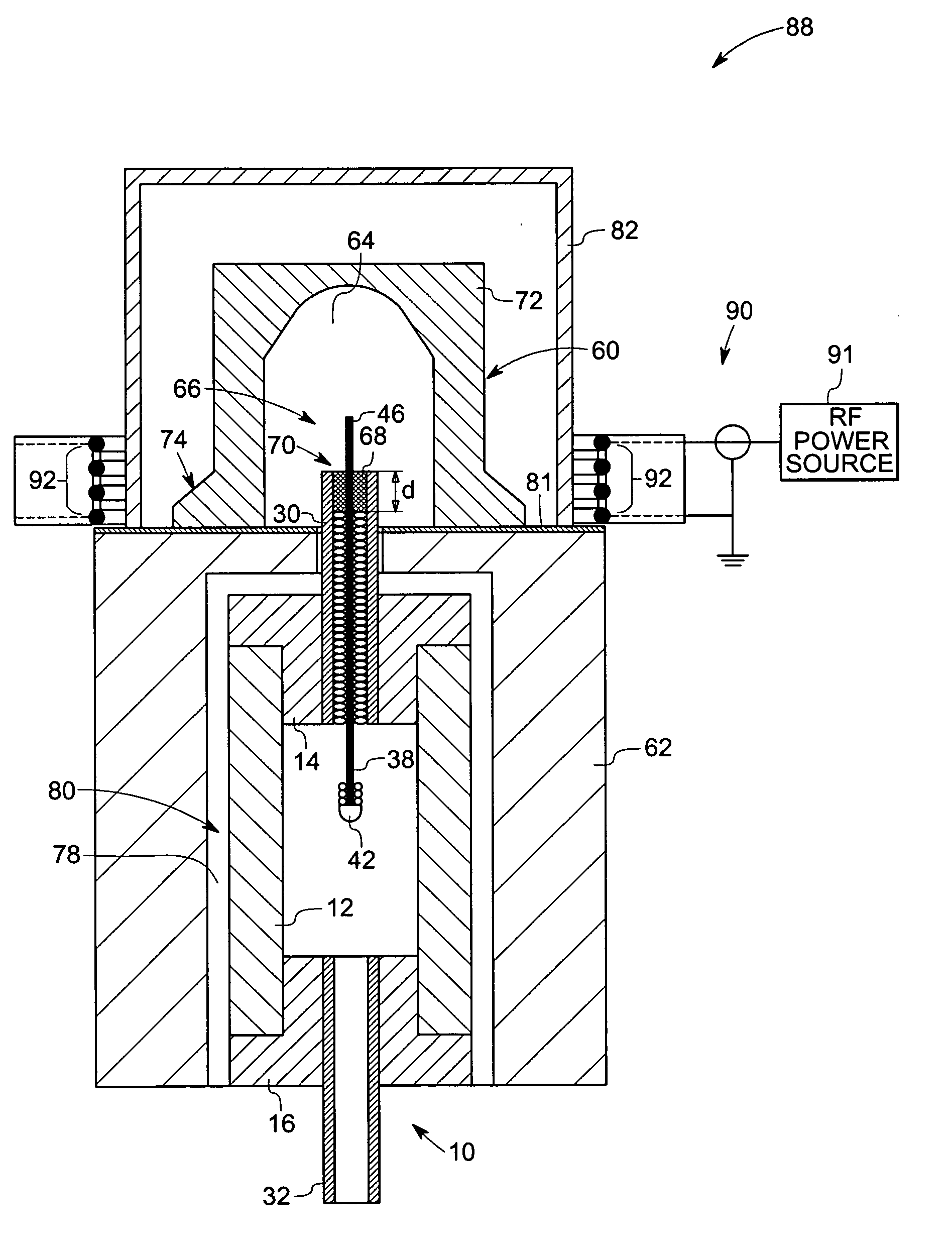

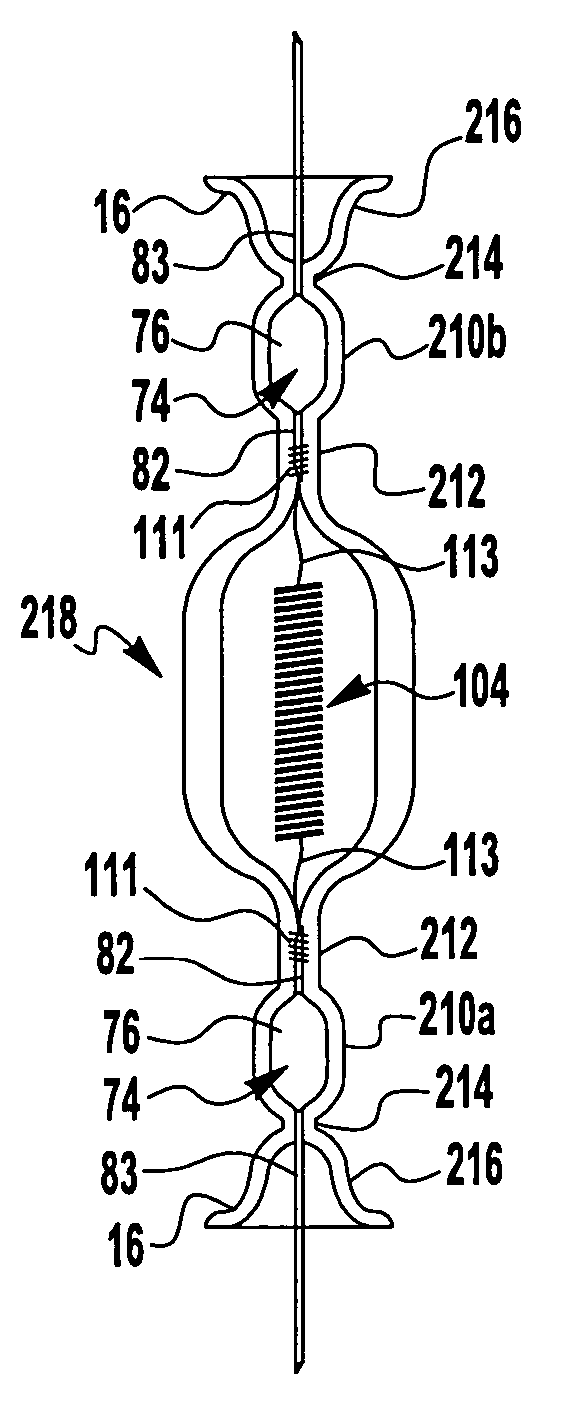

System and method for sealing high intensity discharge lamps

In accordance with certain embodiments, the present technique includes a system for sealing a lamp including a thermal shield and a thermally susceptible enclosure disposed adjacent the thermal shield. The thermal shield has a first receptacle adapted to receive a first portion of the lamp. The thermally susceptible enclosure comprises a wall about a second receptacle adapted to receive a second portion of the lamp. The wall has a varying thickness in a desired sealing region between the first and second portions of the lamp.

Owner:GENERAL ELECTRIC CO

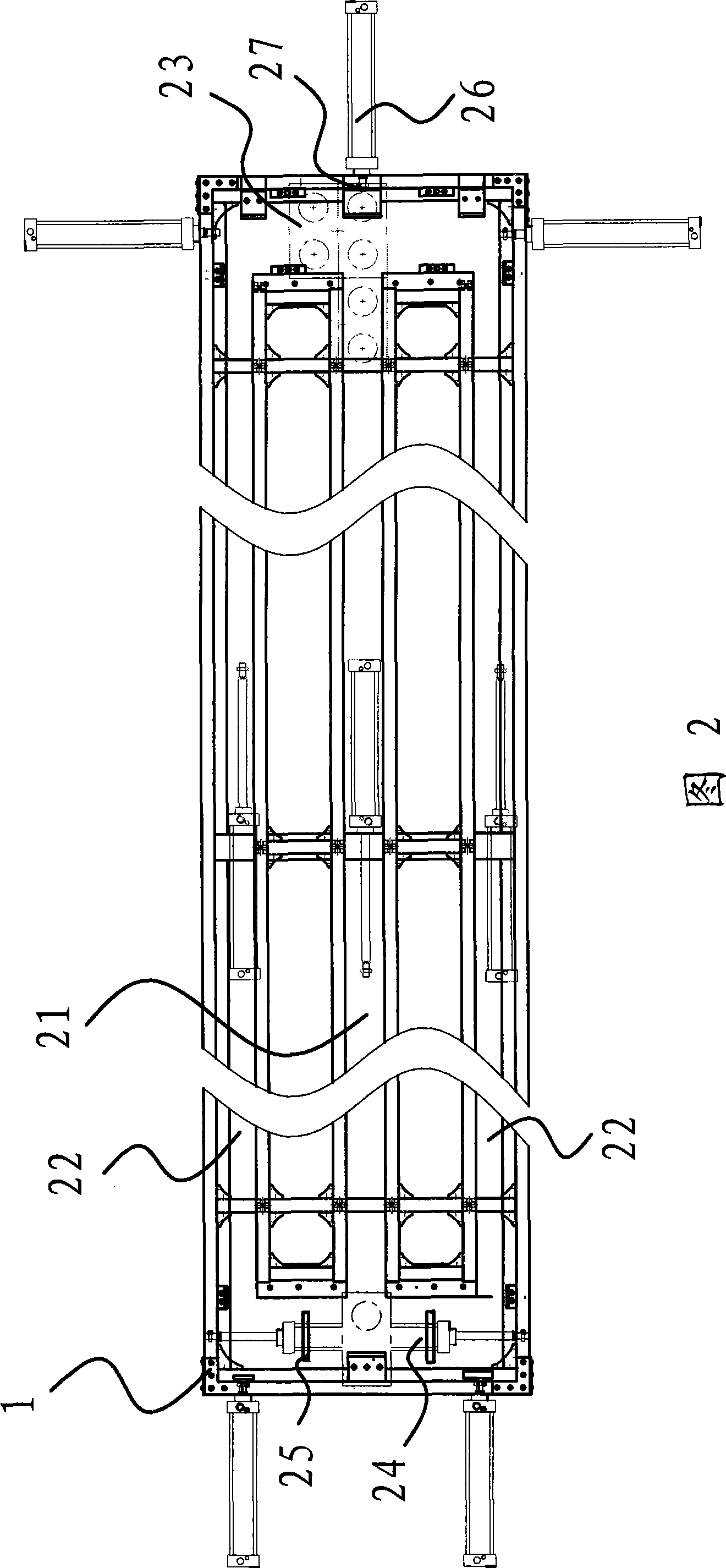

Energy-saving lamp automatic assembly line

InactiveCN101447382AReduce labor costsReduce manufacturing costSequential operation station machinesAutomatic transmissionControl system

The invention provides an energy-saving lamp automatic assembly line which belongs to the technical field of machine. The energy-saving lamp automatic assembly line solves the problem that the existing energy-saving lamp automatic assembly line adopts manual assembly and has low production efficiency. The energy-saving lamp automatic assembly line is provided with an energy-saving lamp assembly transmission system on a frame. The energy-saving lamp assembly transmission system comprises a middle transmission track and branch transmission tracks. Joint parts of one end of the middle transmission track with two branch transmission tracks are provided with distributing mechanisms which can distribute energy-saving lamps at the middle transmission track to two branch transmission tracks. Each branch transmission track is respectively provided with an automatic rotating energy-saving lamp cap device, an energy-saving lamp automatic filament-cutting device, an energy-saving lamp automatic tin soldering device, an energy-saving lamp automatic detecting and controlling system and an energy-saving lamp automatic nailing device. The energy-saving lamp automatic assembly line is equipped with two sets of assembly devices and realizes the advantages of automatic transmission and assembly, etc.

Owner:ZHEJIANG SHENDU OPTOELECTRONICS TECH

Vehicle lamp

ActiveUS7315127B2Simple supportLow costPoint-like light sourceLighting support devicesLight beamActuator

Owner:KOITO MFG CO LTD

Sealing apparatus and method of manufacturing flat display device using the same

ActiveUS20100267307A1Minimize stressMinimizing stress occurringElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A sealing apparatus and a method of manufacturing a flat display device using the sealing apparatus. The sealing apparatus to attach a first substrate and a second substrate to each other using an attachment member disposed between the first and second substrates, the sealing apparatus comprises a stage on which the first substrate is seated, a halogen lamp irradiating light, and a reflector reflecting light irradiated from the halogen lamp to the attachment member.

Owner:SAMSUNG DISPLAY CO LTD

Cassette for loading substrate

ActiveUS8528750B2Avoid damageSemiconductor/solid-state device manufacturingOther accessoriesMagnetic tapeEngineering

Owner:HYDIS TECH CO LTD

Full-automatic assembly production chain of energy-saving lamp

InactiveCN101083190ANovel ideaReasonable process structure designSequential operation station machinesCold cathode manufactureProduction chainEngineering

The invention relates to the energy-saving lamp full automatic-assembly assembly line. It belongs to the energy-saving lamp manufacture equipment technology area. Its characteristic lies in that the rack intermediate deck coordinate installs the work piece conveying appliance by the transmission chain drive, the one output end of the decelerator which installs on the sublayer of the rack and connects the motor driver connects the dynamic major axis which coordinates the cam major axis driver, another output through the cam dismember coordinates to the work piece conveying appliance, above the work piece conveying appliance fit establishes automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment, compression moulding cam, soldering lamp base cam, dial nail cam which installs on the cam major axis separately connects the automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment. The line flow has rational design, the automation pattern substitutes manual work, reduces the suggestion factor of the quality flaw, enormously raises the production efficiency and the product quality, creates the scale effect, take a foundation for promoting the enterprise brand image.

Owner:王佩诚

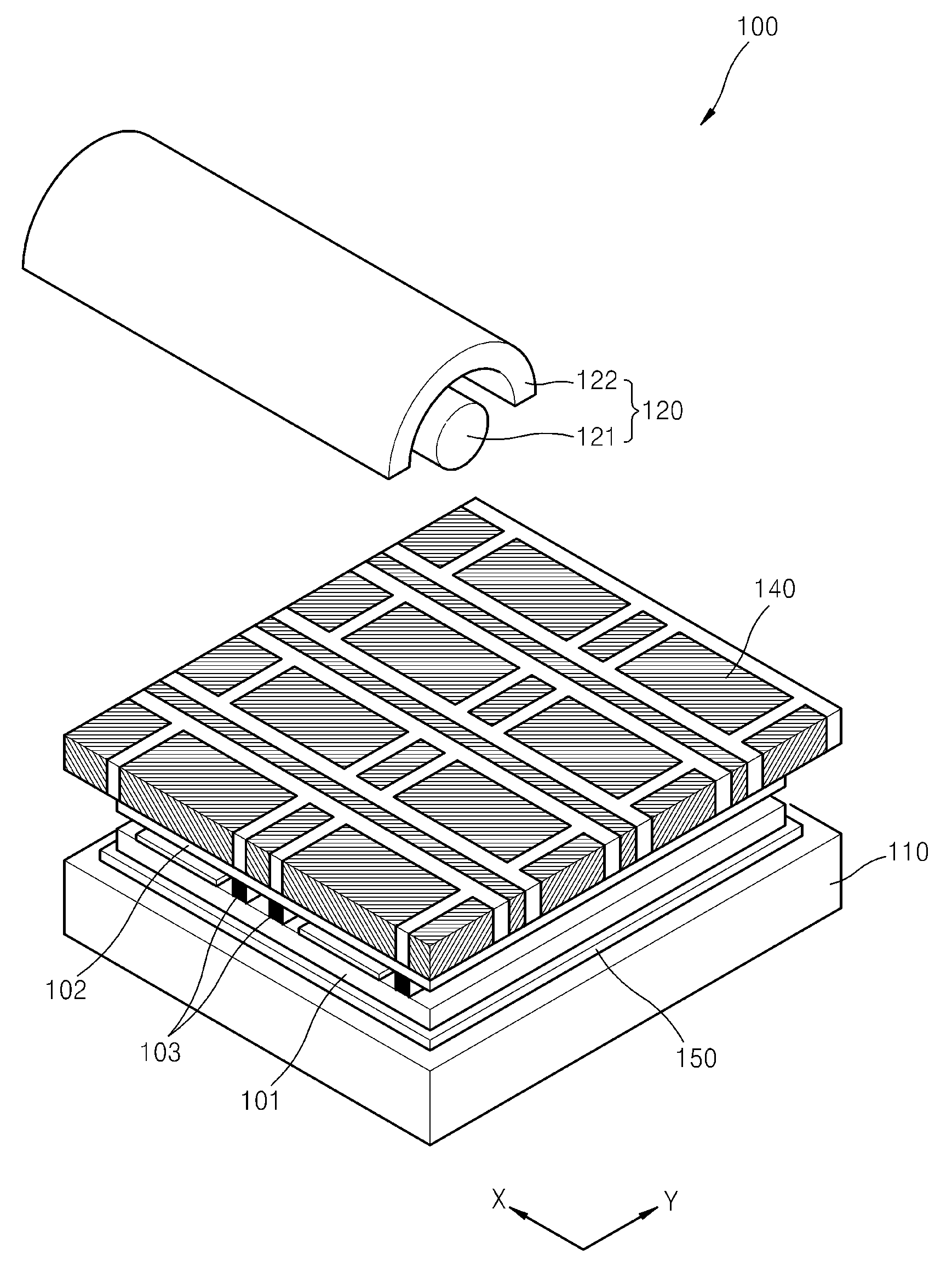

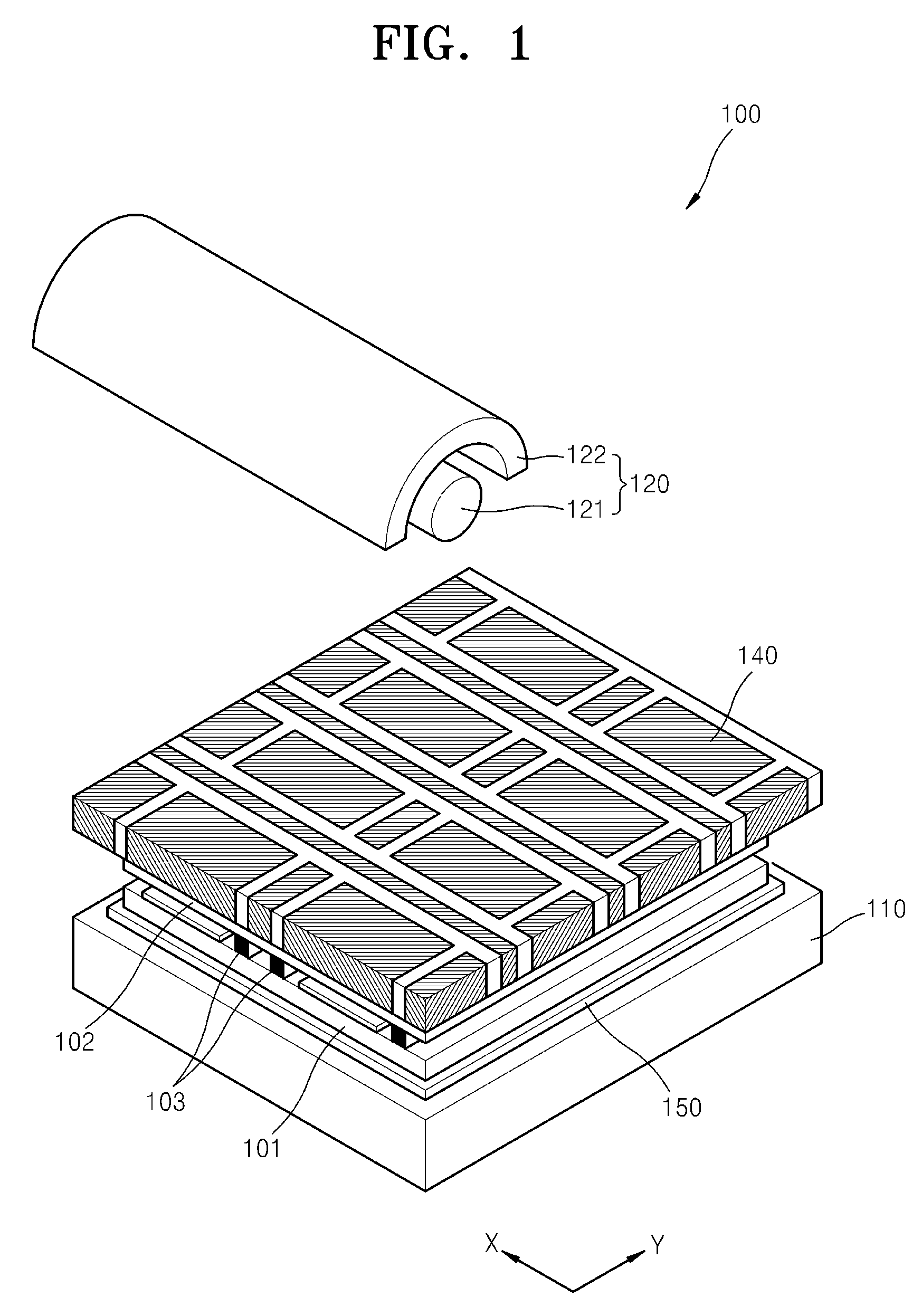

Sealing method and apparatus for manufacturing high-performance gas discharge panel

InactiveUS20050151475A1Reduce pressureAvoid deformationElectroluminescent light sourcesAlternating current plasma display panelsEngineeringLaser beams

A method is provided to steadily produce a gas discharge panel, such as a PDP, in which a panel and the top of the barrier ribs are in intimate contact in entirety. First a surrounding unit for the gas discharge panel is formed, then a process for sealing the surrounding unit with a sealing material inserted between two panels at the rim is performed while pressure is adjusted so that pressure inside the surrounding unit is lower than pressure outside. With this construction, the panels constituting the surrounding unit are bonded together while they are pressurized from outside. As a result, a panel and the top of the barrier ribs on the other panel are bonded together while they are in intimate contact in entirety. To fully acquire these effects, it is preferable that the adjustment of pressure starts before the sealing material hardens. During, before, or after the sealing step, an energy such as laser beams or ultrasonic waves may be radiated onto the top of the barrier ribs to bond a panel and the top of the barrier ribs in entirety almost without a gap between them.

Owner:PANASONIC CORP

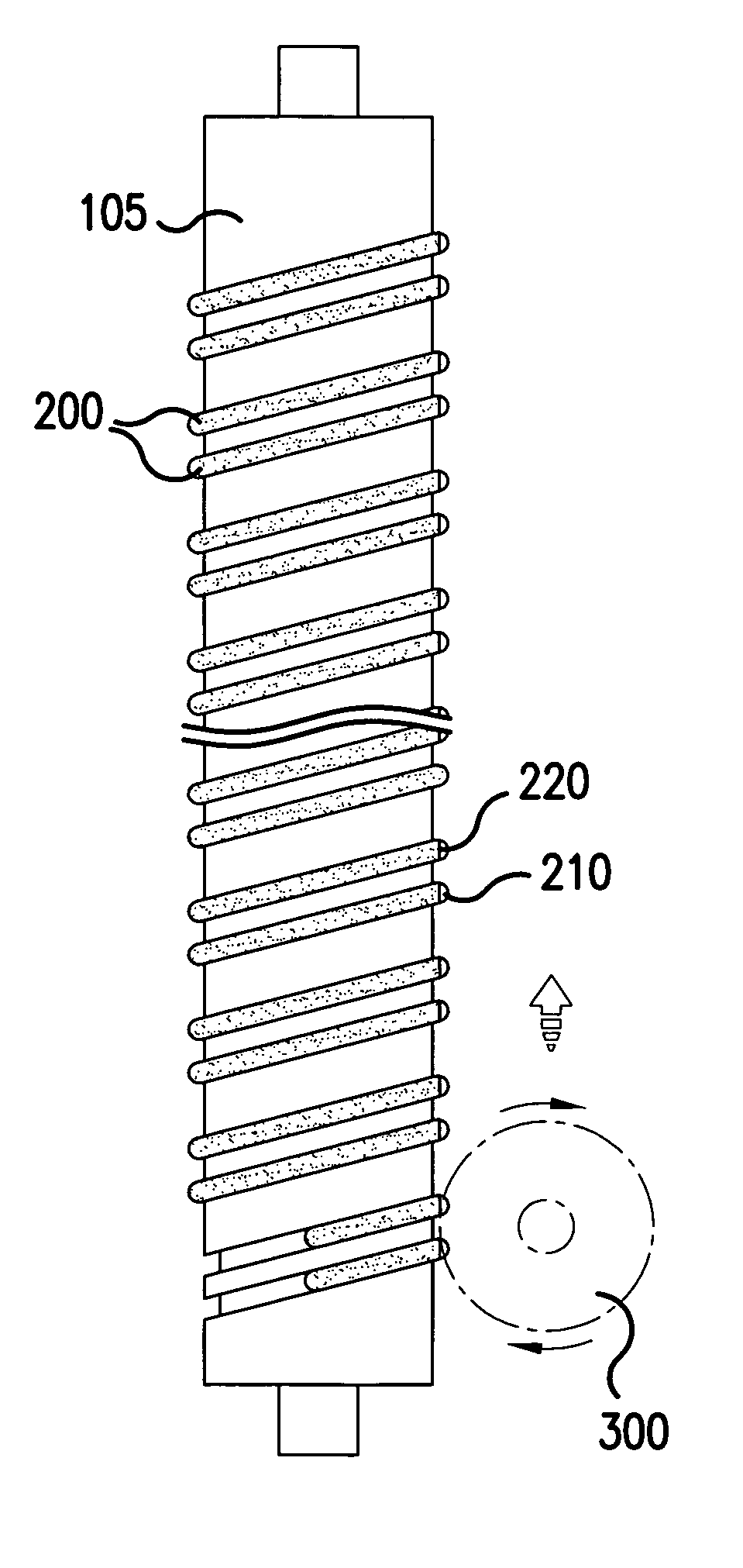

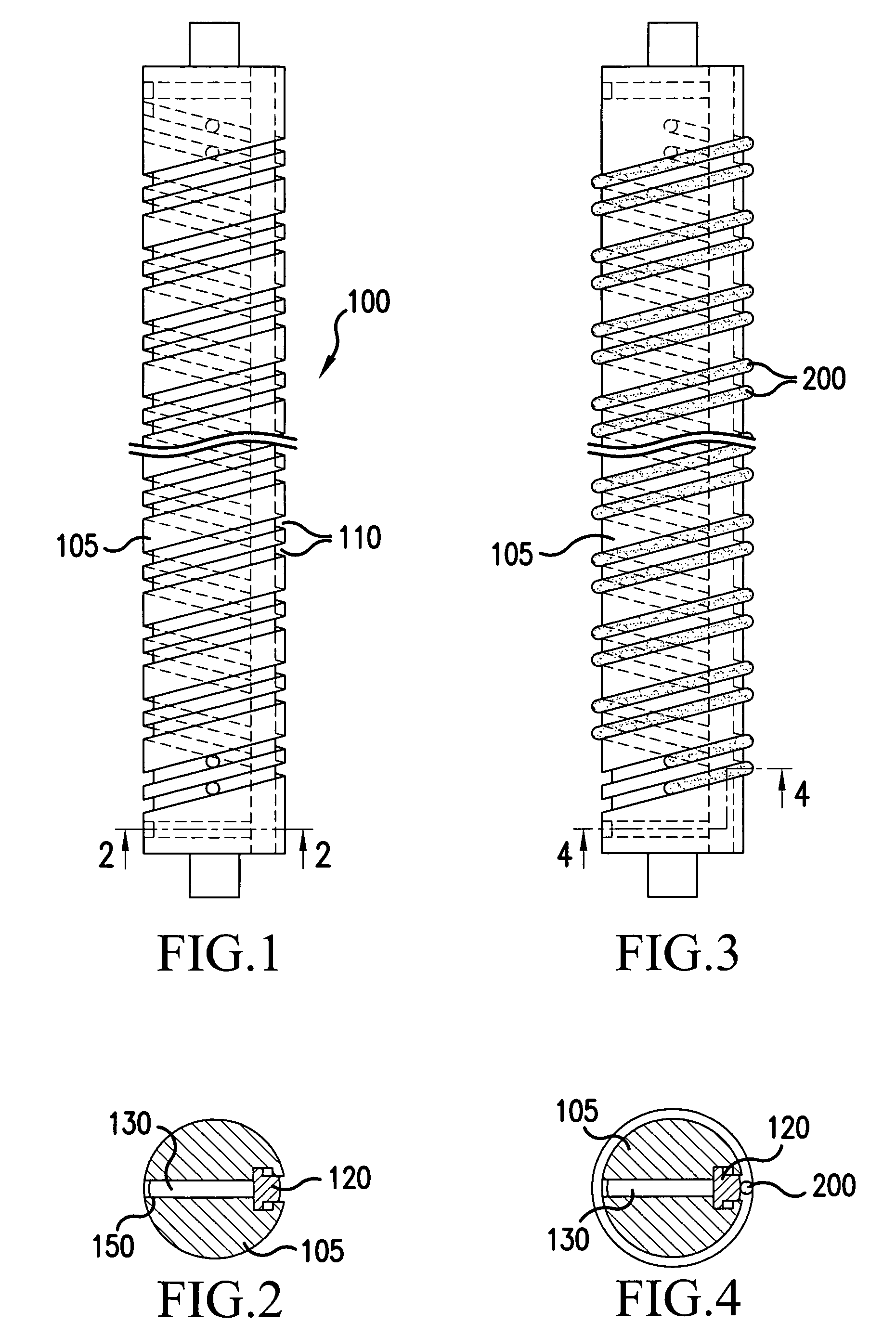

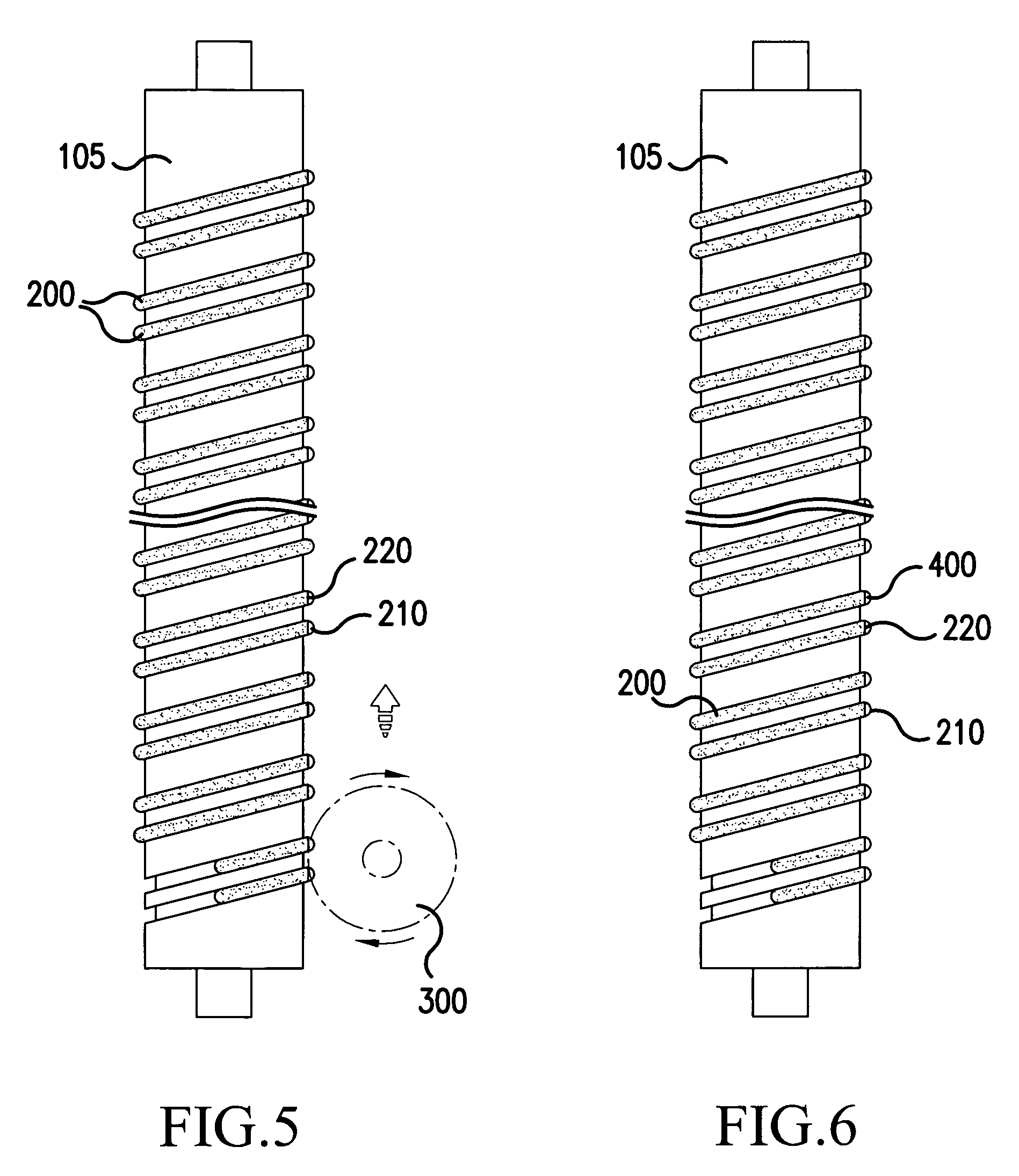

Manufacturing method for an LED light string and a jig for making the LED light string

InactiveUS20080200089A1Complete efficientlyPoint-like light sourceElectroluminescent light sourcesLED lampElectric wire

A method of manufacturing an LED light string using a jig having a main body and a plurality of spiral grooves formed thereon adjacent to each other is provided. The method includes winding an electrical wire in each of the grooves, removing portions of the electrical wires to provide a plurality of spaced exposed segments at successive locations on each of the electrical wires, placing LED chips on at least some of the plurality of exposed segments formed in one of the electrical wires, connecting each LED chip to a corresponding exposed segment on a different electrical wire by a connector, and sealing each LED chip and connector. A jig for attaching one or more LED chips to a plurality of electrical wires is also provided.

Owner:REAL BONUS

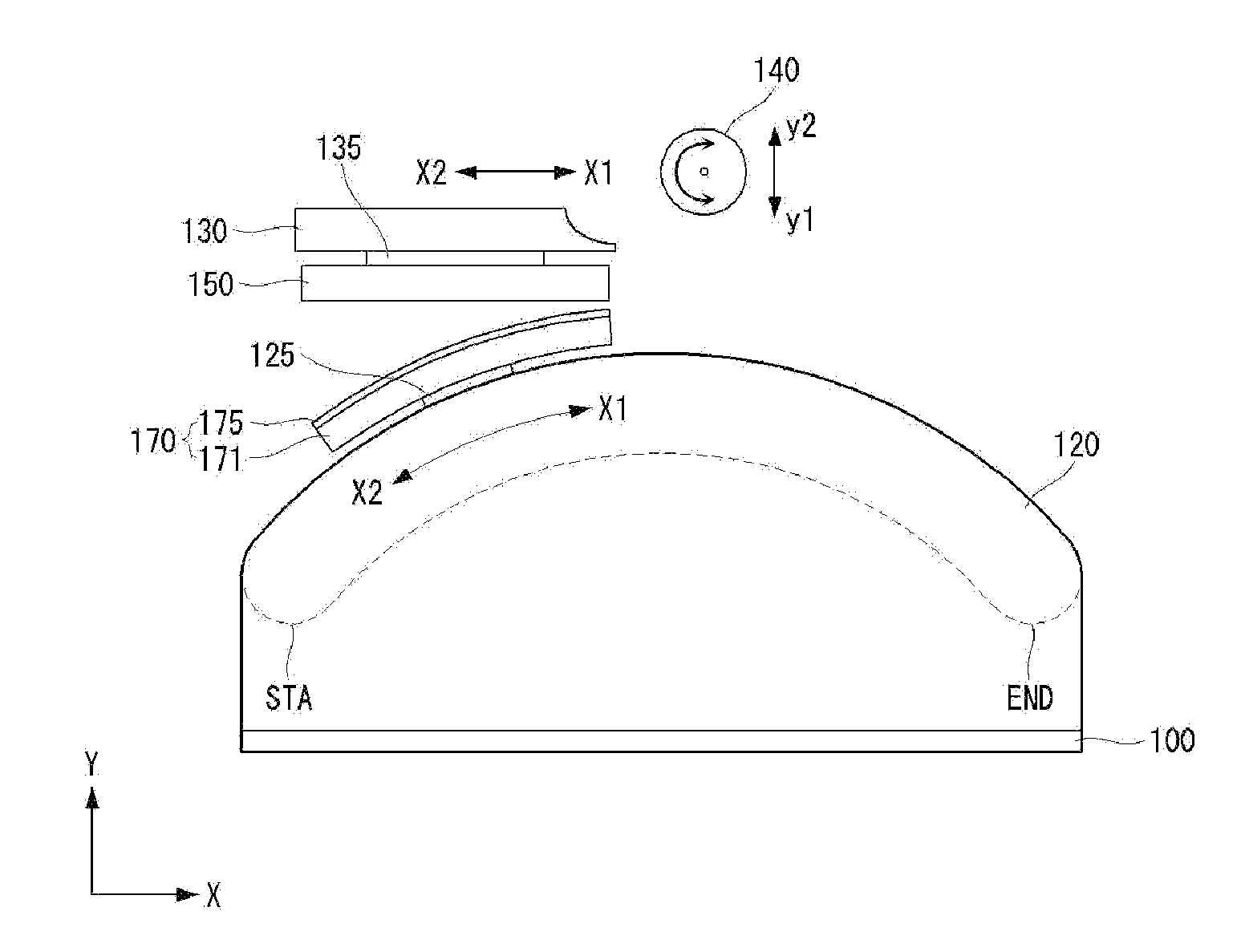

Substrate attachment device of display device and method for manufacturing display device using the same

ActiveUS20140179191A1Electroluminescent light sourcesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A substrate attachment device of a display device and a method for manufacturing the display device using the same are disclosed. The substrate attachment device of the display device includes a guide unit which is curvedly disposed, a first support unit which moves forward and backwards along the guide unit and transfers a cover substrate having a curved surface, a second support unit which is disposed on the guide unit, moves forward and backwards, and transfers a display panel, and a roller unit which rotates so that the cover substrate having the curved surface is attached to the display panel.

Owner:LG DISPLAY CO LTD

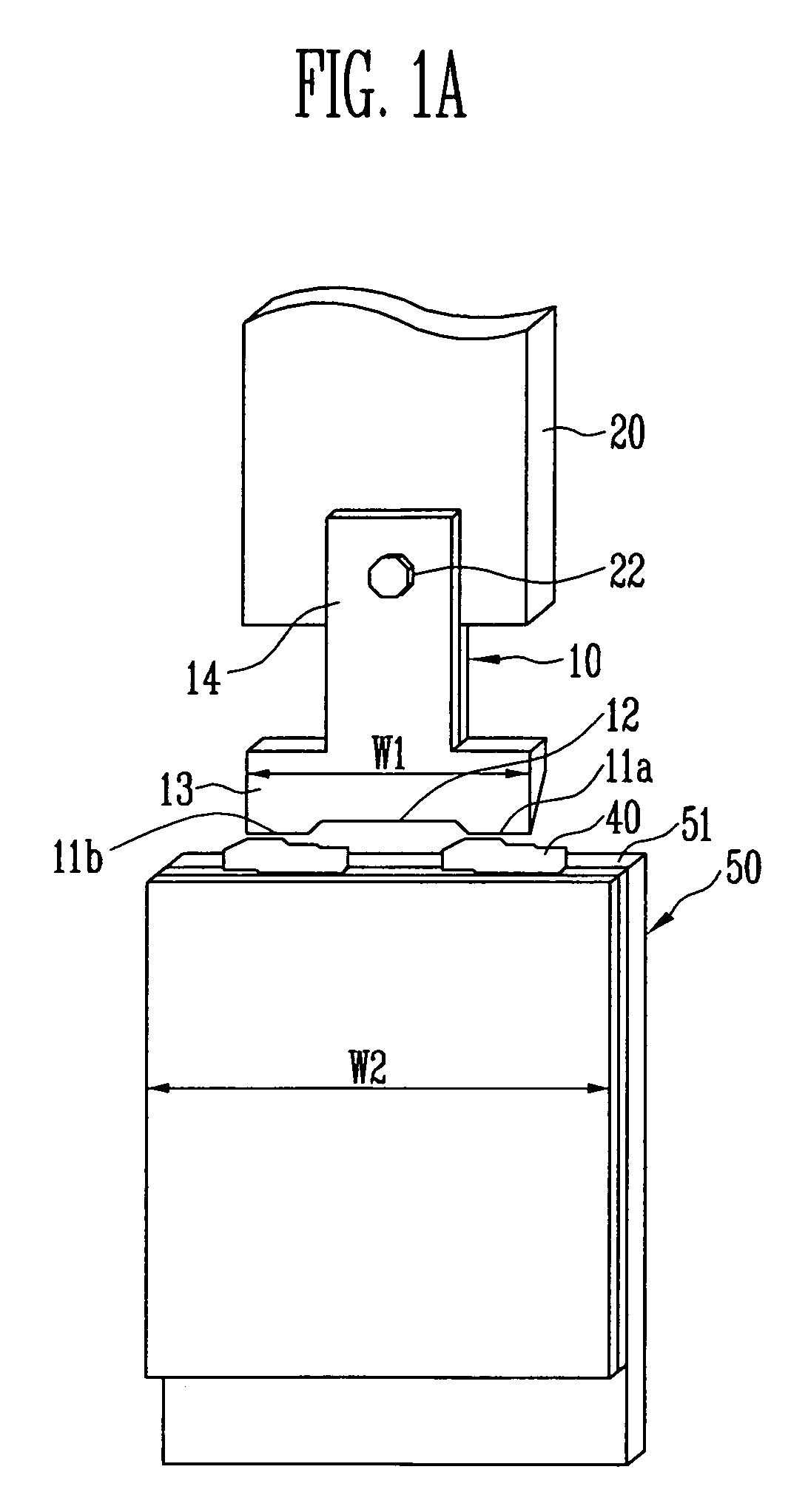

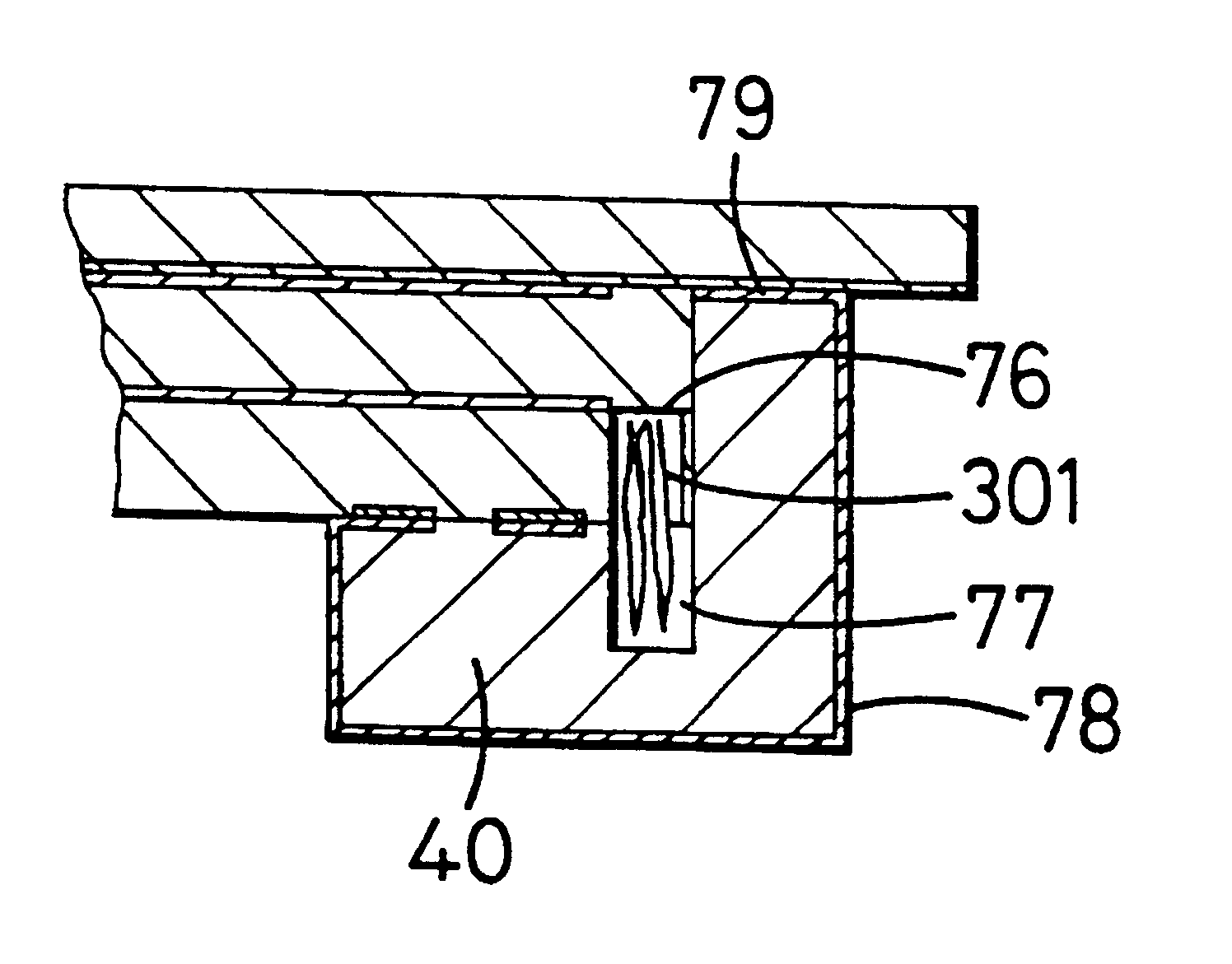

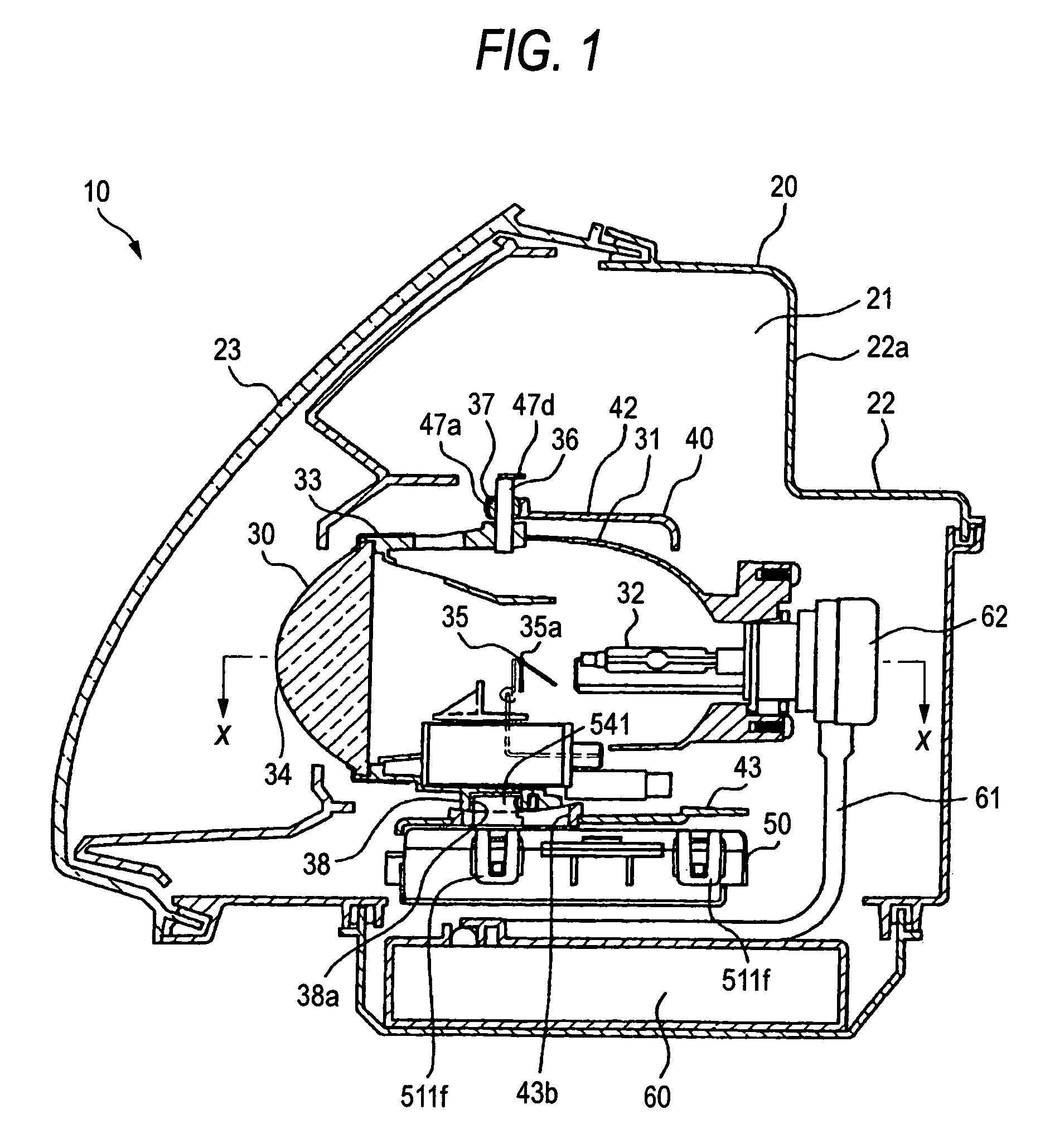

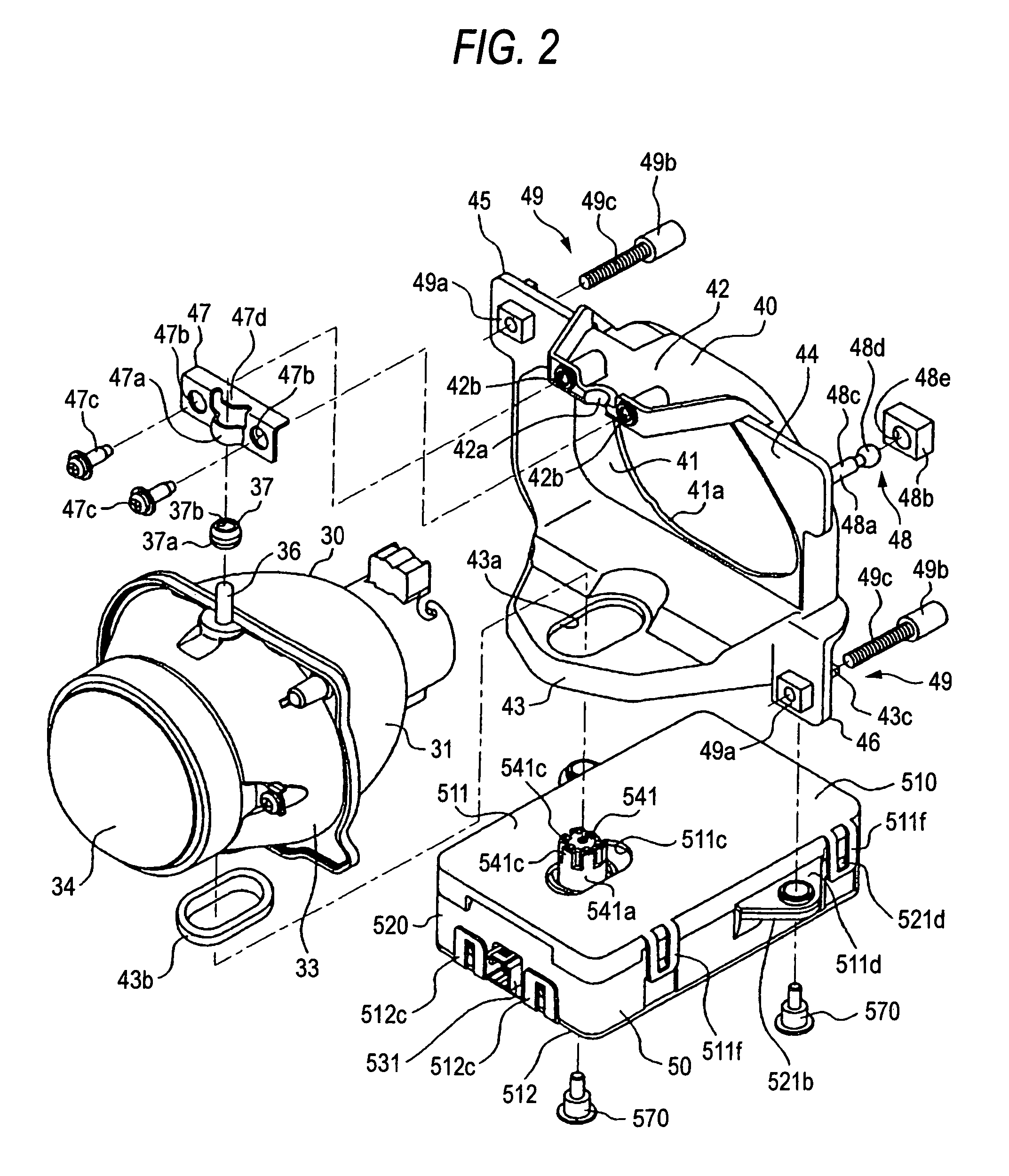

Vehicle lamp assembling apparatus

InactiveUS6609941B1Reduce loadPhotometry using reference valueAssembly machinesControl dataEngineering

An vehicle lamp assembling apparatus including a jig which supports a lamp component, an apparatus main body having disposed thereon positioning and fastening mechanisms (plungers and engagement holes) for positioning and fastening the jig to the apparatus main body. Some equipment (contact units) is disposed on the apparatus main body, and / or on the jig, for carrying out a predetermined processing, such as working or inspection, on the lamp component supported by the jig. Further, a control part is disposed on the apparatus main body, for drive control of the equipment. An ID plate that stores processing information, such as driving procedures and driving amount of the equipment, is disposed on the jig, whereas a non-contact memory reader is disposed on the apparatus main body so as to oppose the ID plate when the jig is fastened to the apparatus main body. The control part drives the equipment based on the processing information read from the ID plate via the memory reader. Thus, the amount of equipment-drive-control data stored in the control part of the apparatus main body is reduced, and the control part need not be a high-performance CPU.

Owner:KOITO MFG CO LTD

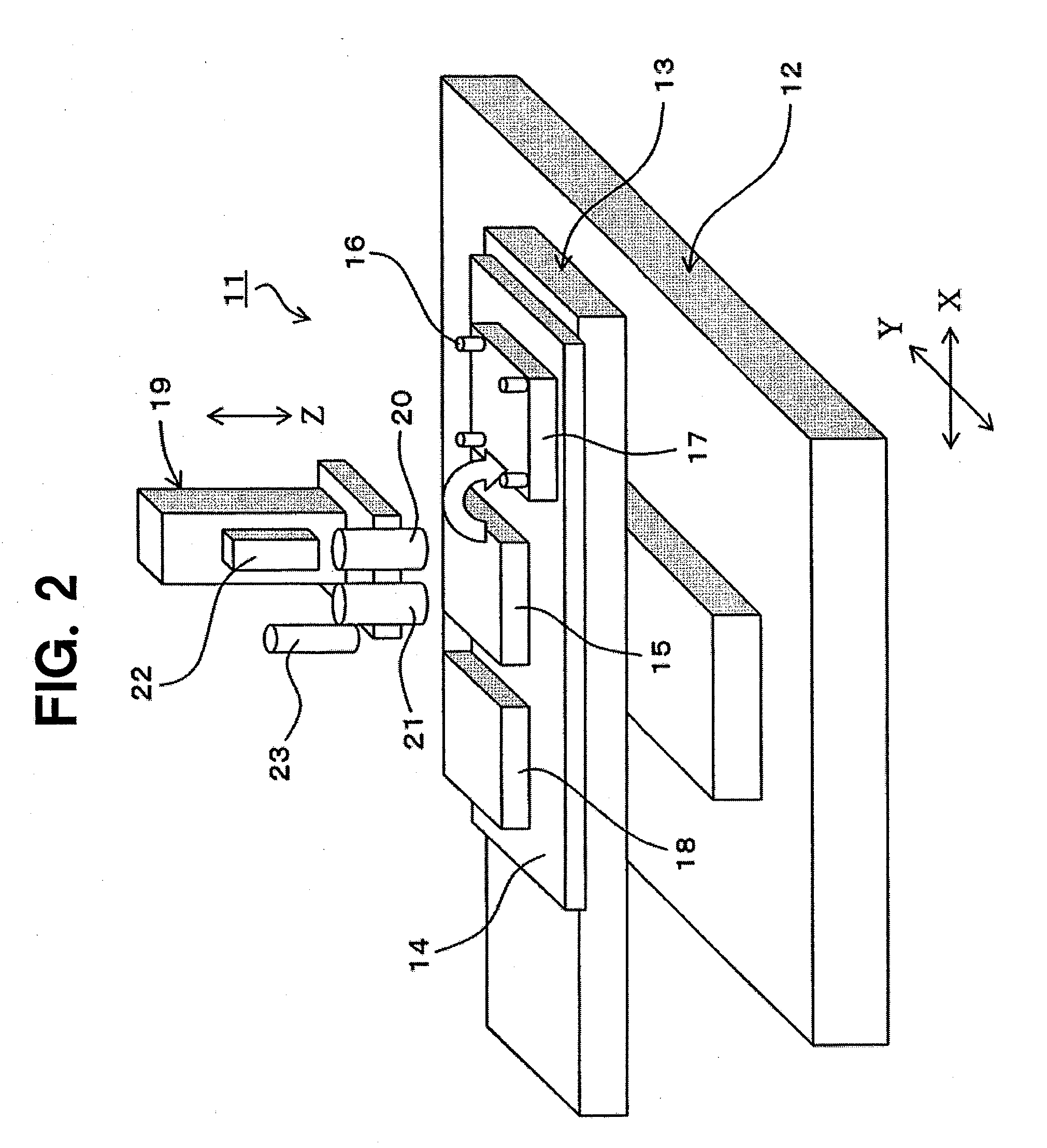

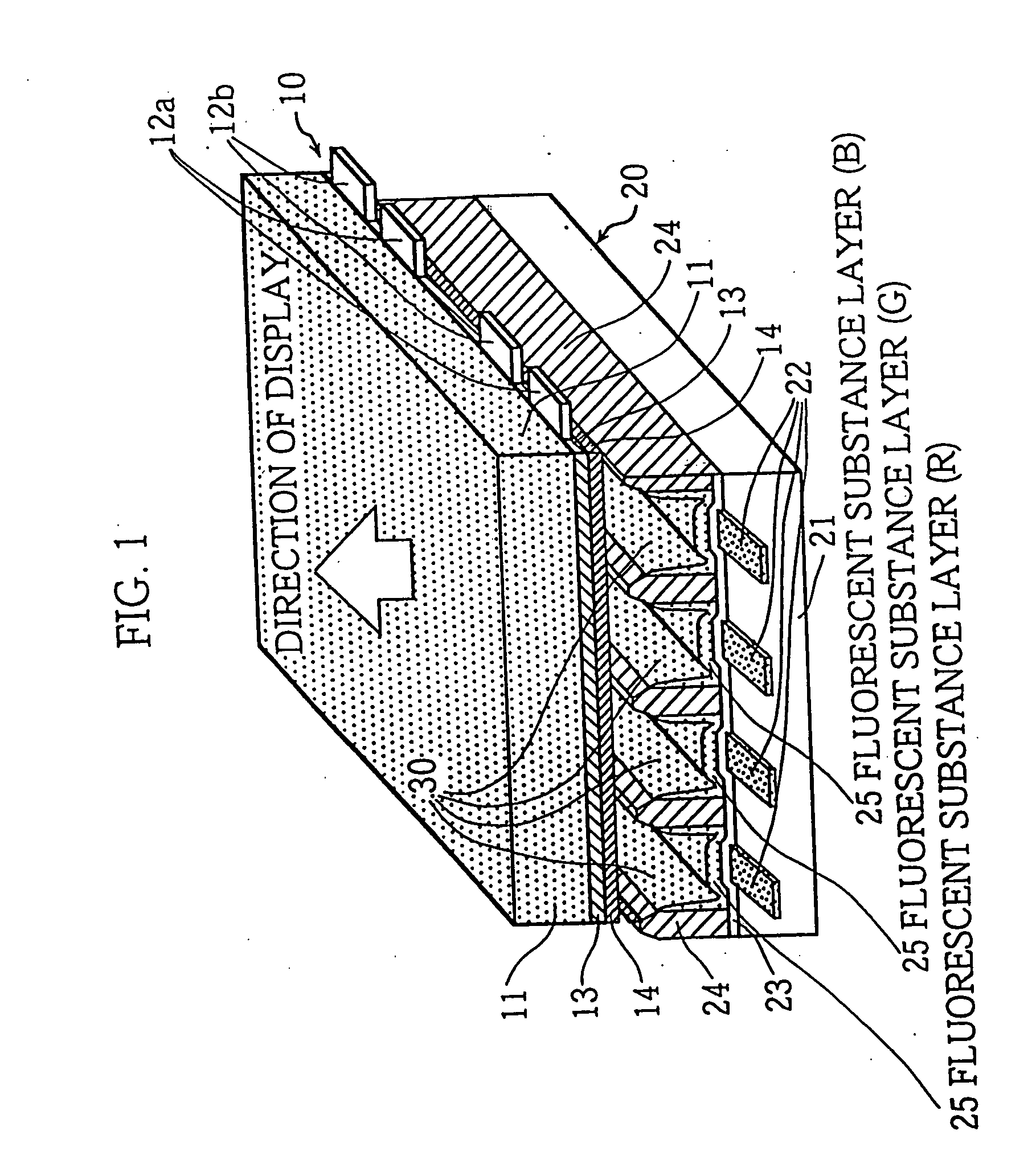

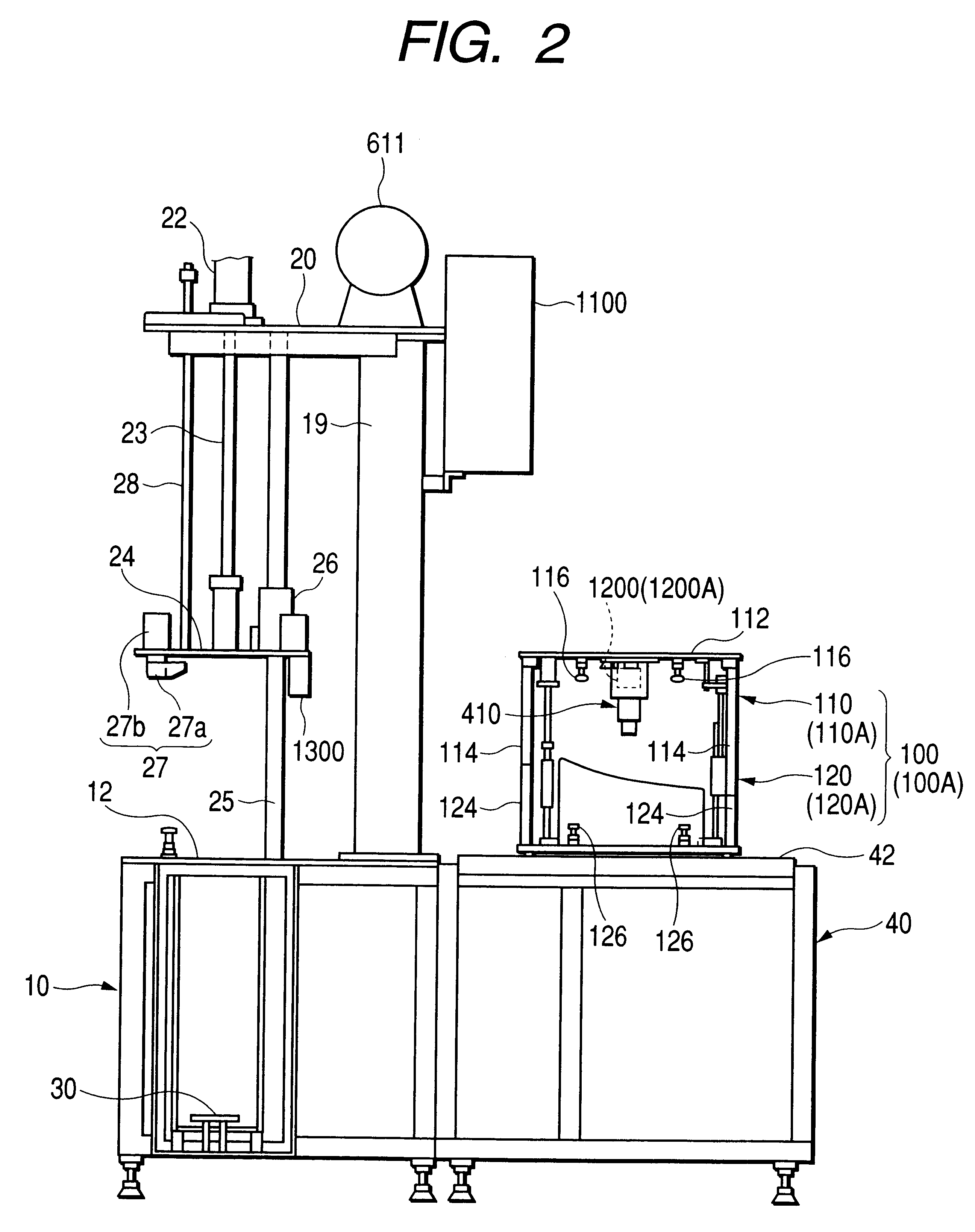

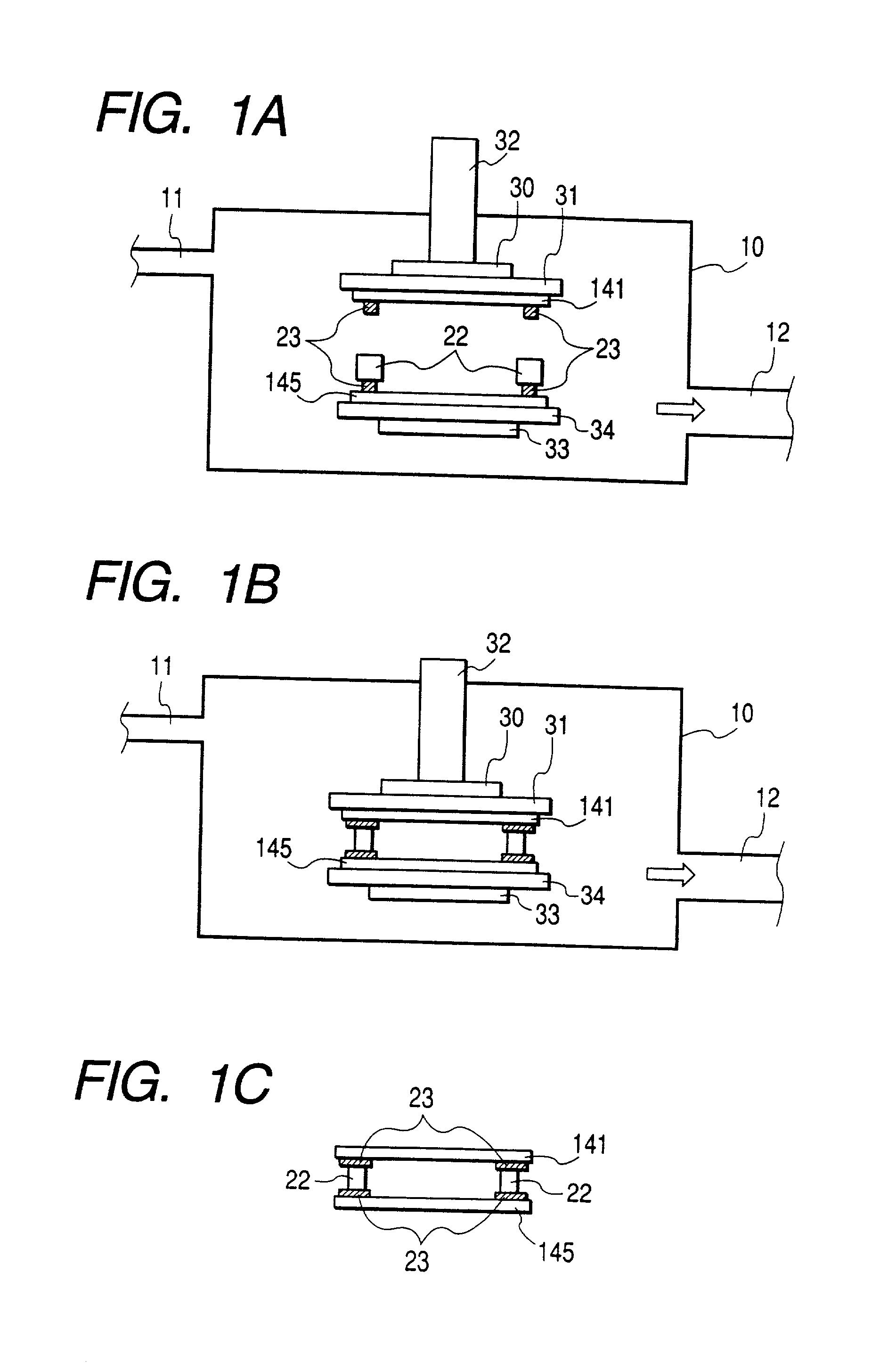

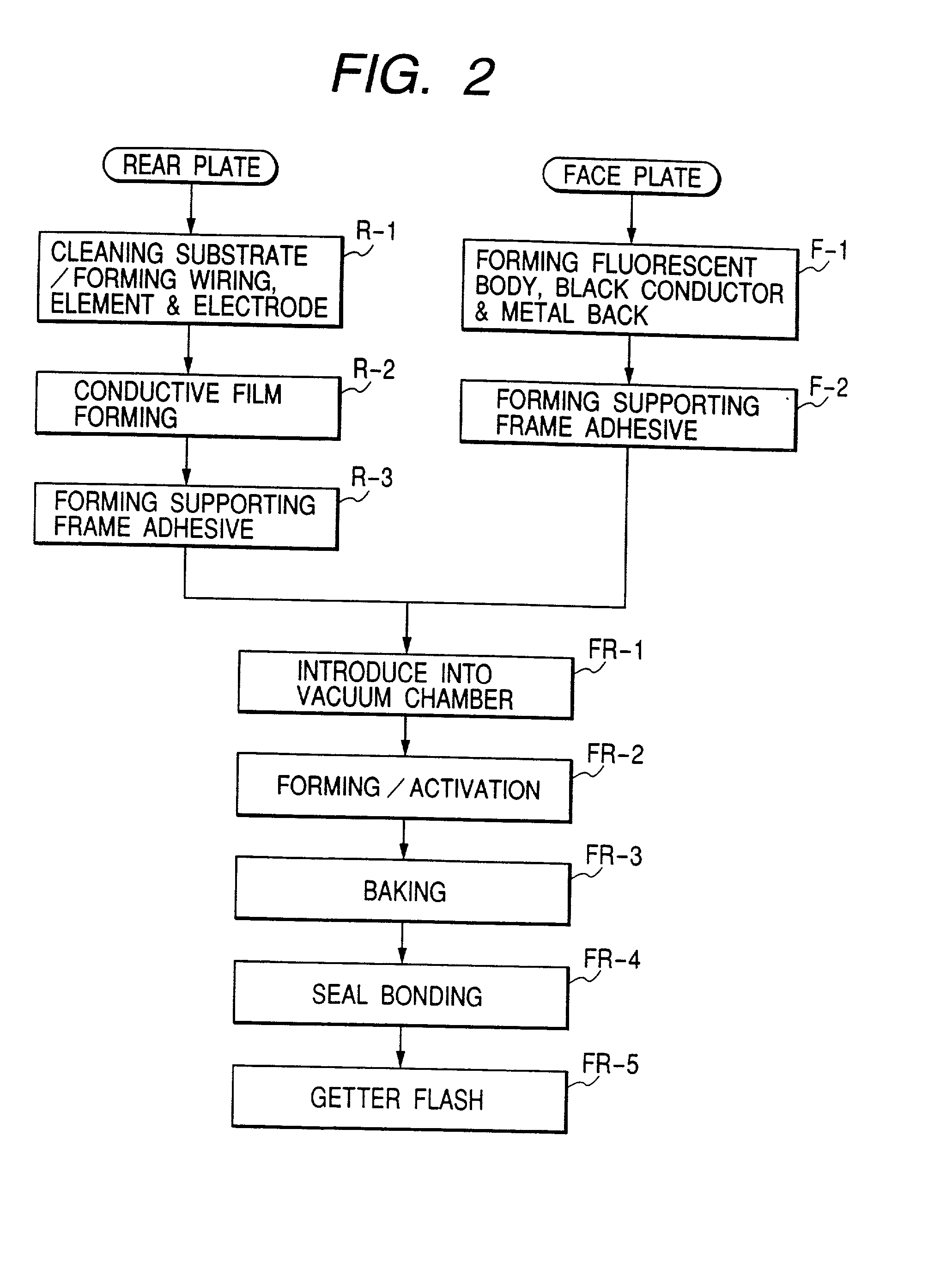

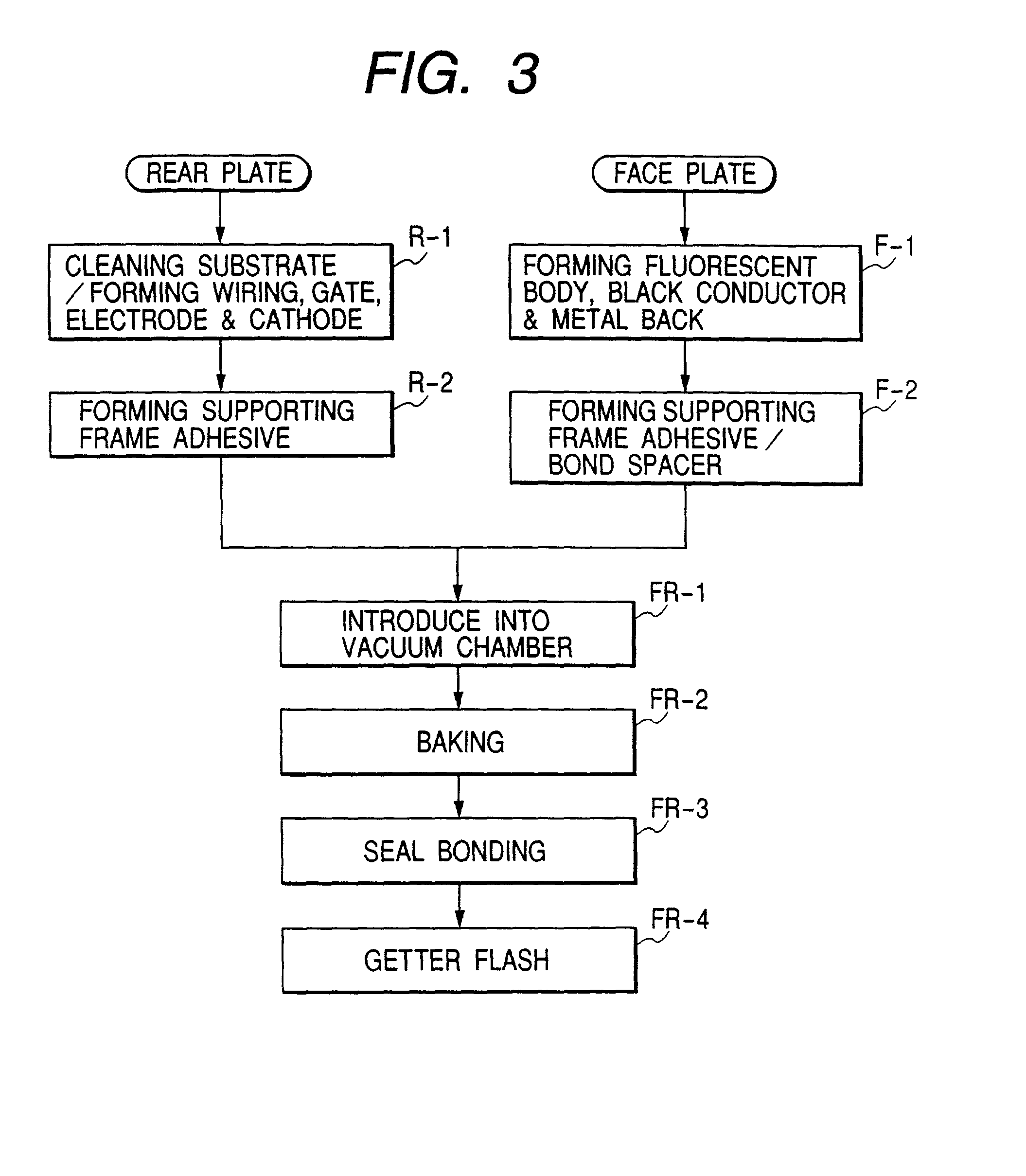

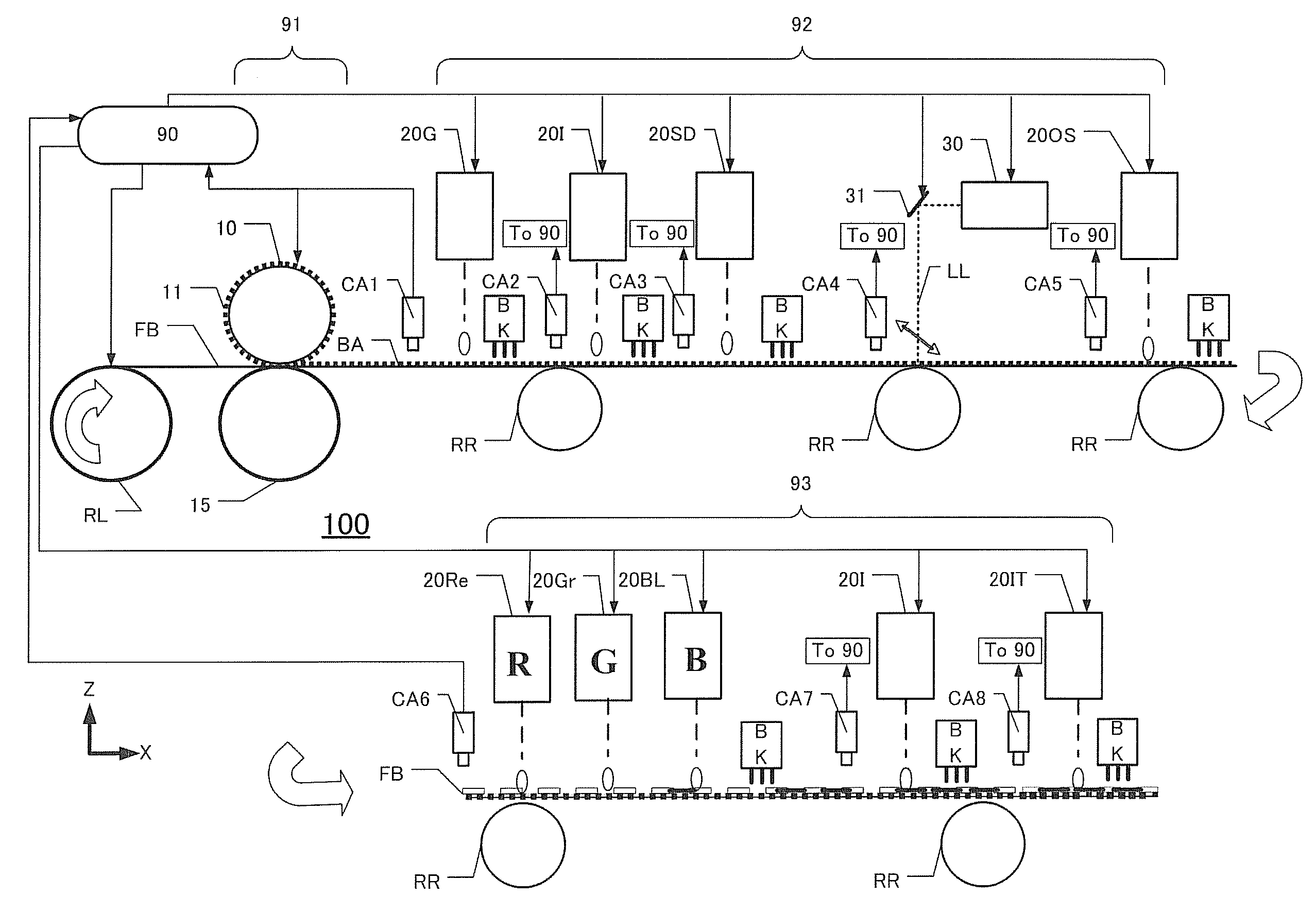

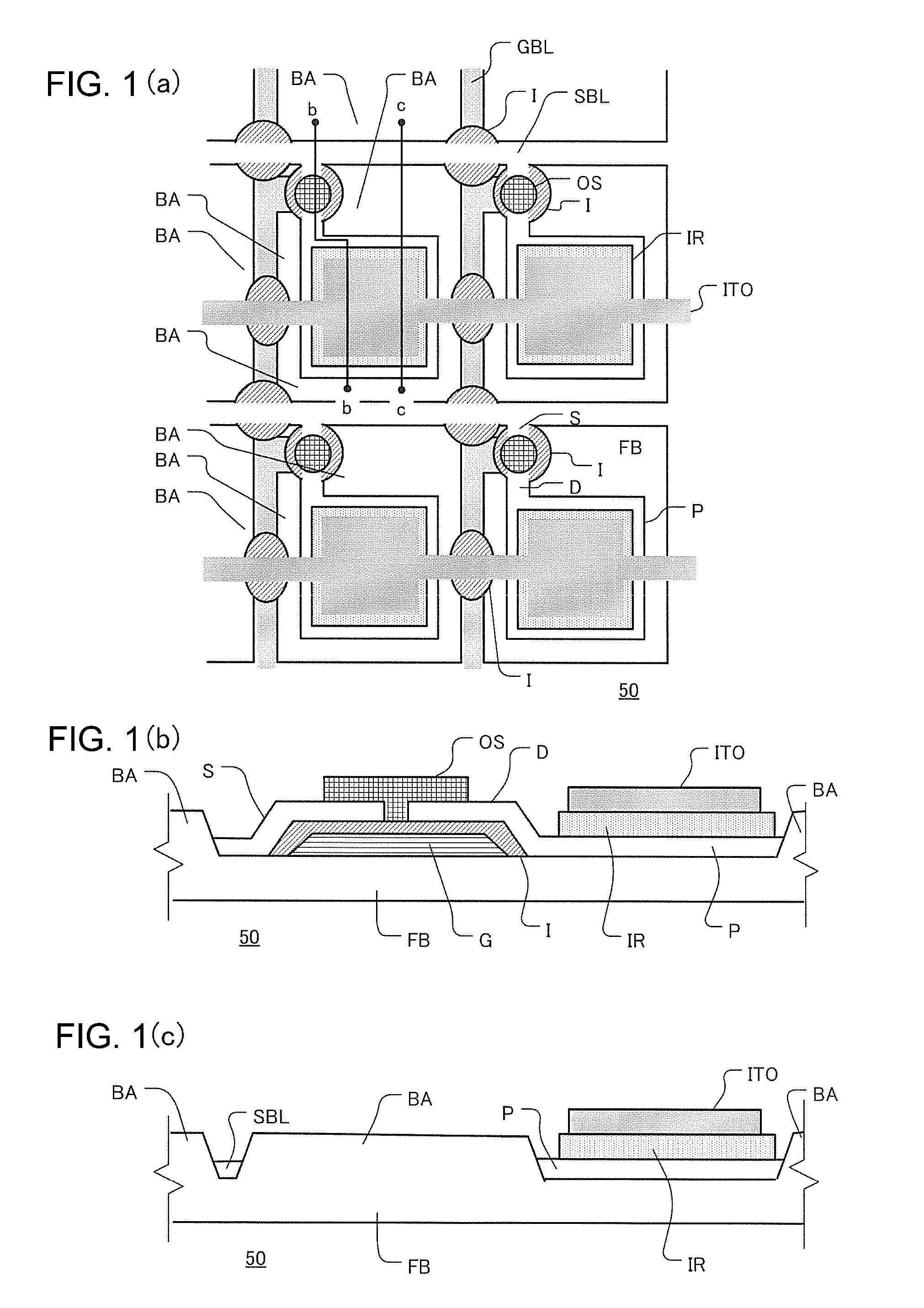

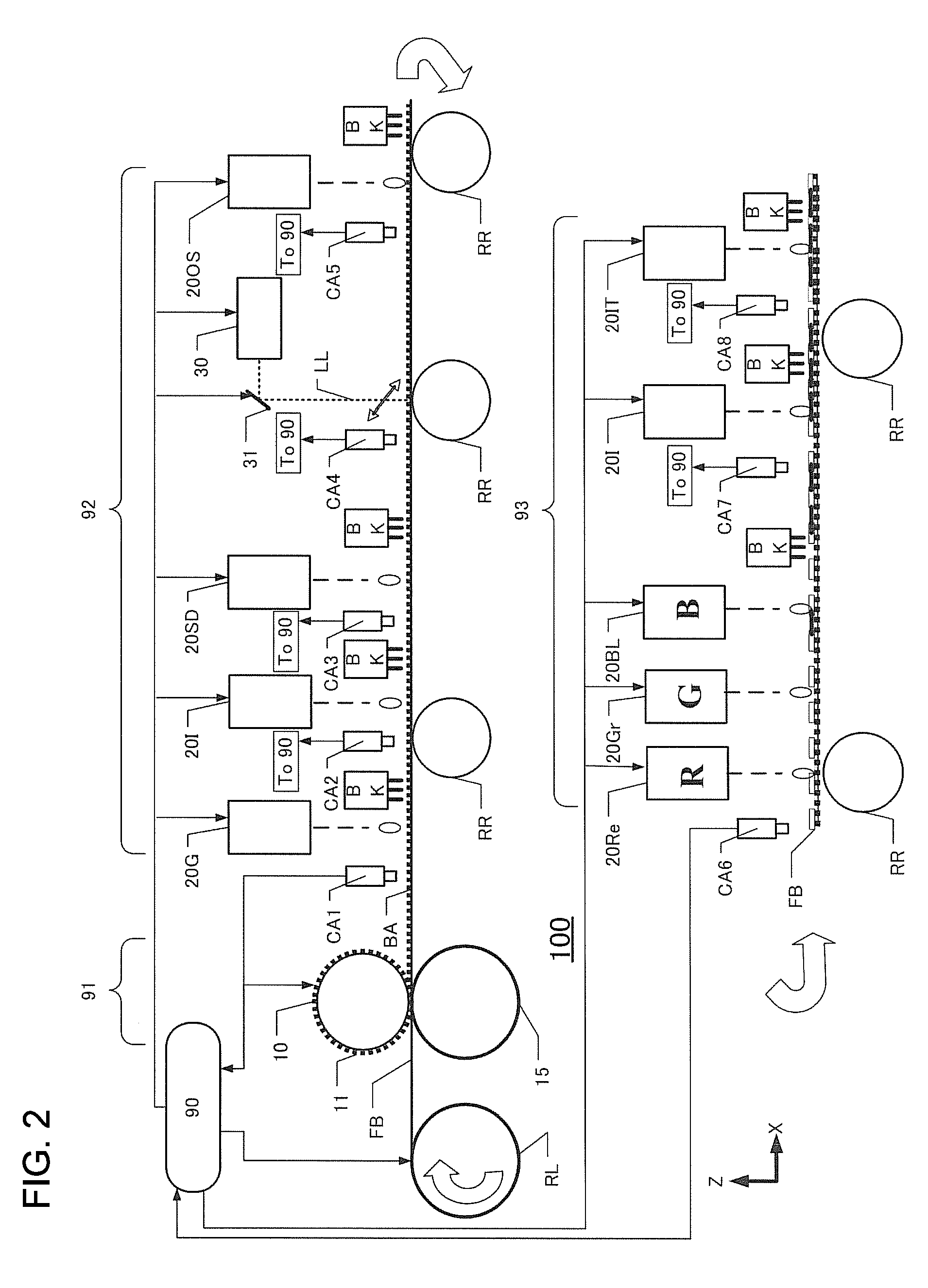

Manufacturing method of image forming apparatus, manufacturing apparatus of image forming apparatus, image forming apparatus, manufacturing method of panel apparatus, and manufacturing apparatus of panel apparatus

InactiveUS20010009836A1Electroluminescent light sourcesTube/lamp vessels exhaustionManufactured apparatusImage formation

To obtain a stable image forming apparatus of a high quality without a luminance fluctuation and a color mixture due to a positional deviation, the following construction is disclosed. A method of manufacturing an image display apparatus in which a first substrate on which fluorescent body exciting means is arranged and a second substrate on which a fluorescent body that emits light by the fluorescent body exciting means is arranged are arranged so as to face each other and are adhered through joining members at their peripheries, wherein a seal bonding step of adhering the first and second substrates through a joining members and a step of performing a position matching of the first and second substrates are executed in a vacuum.

Owner:CANON KK

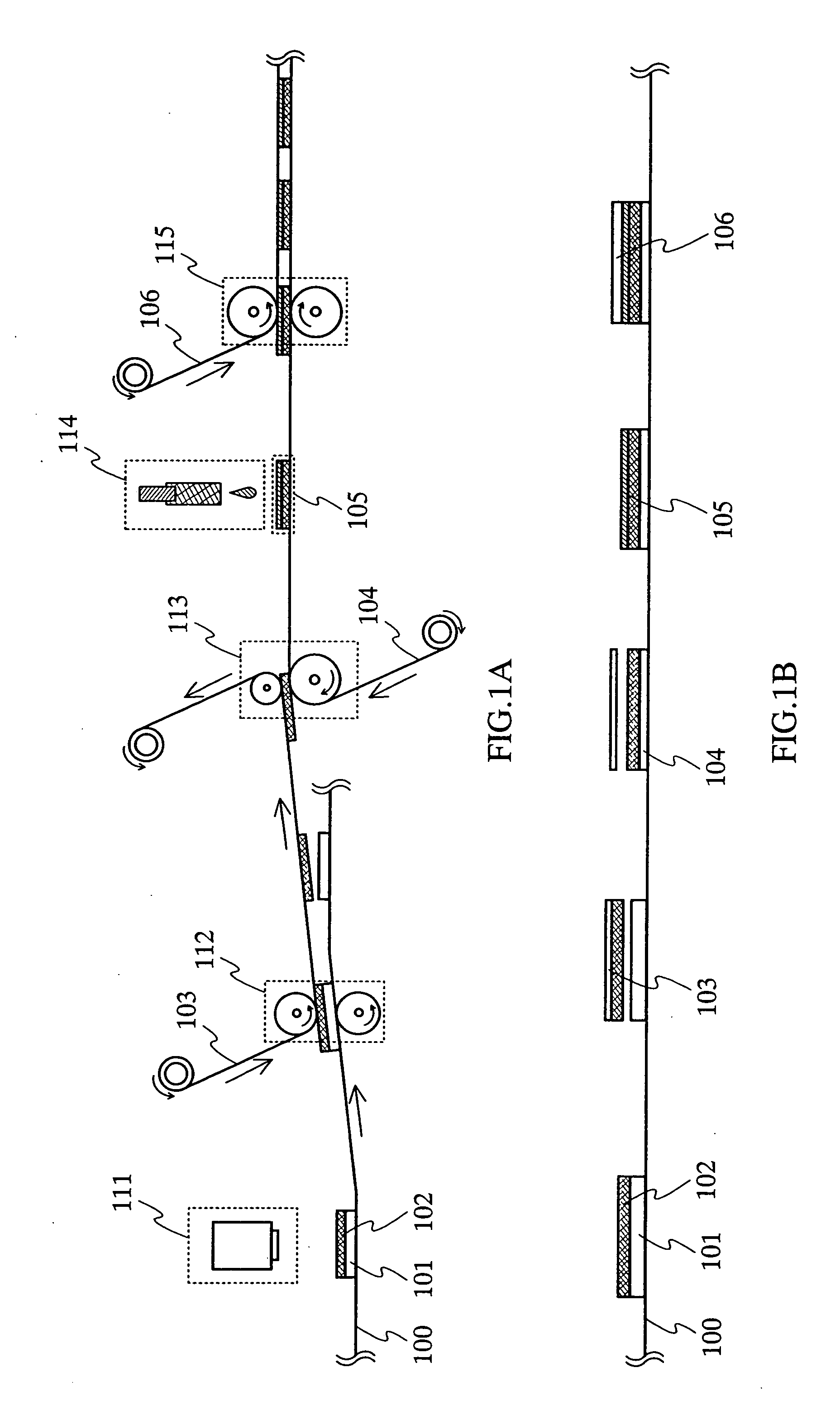

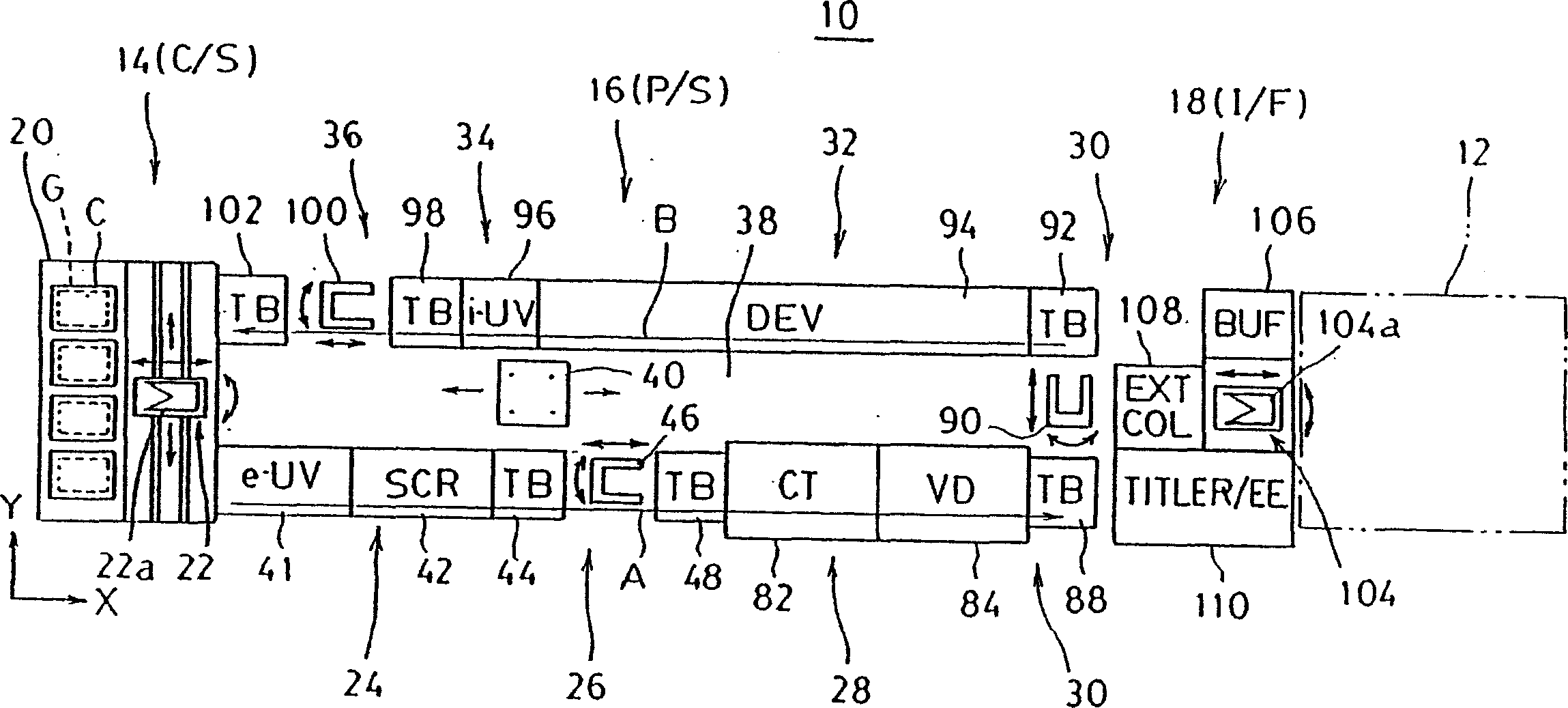

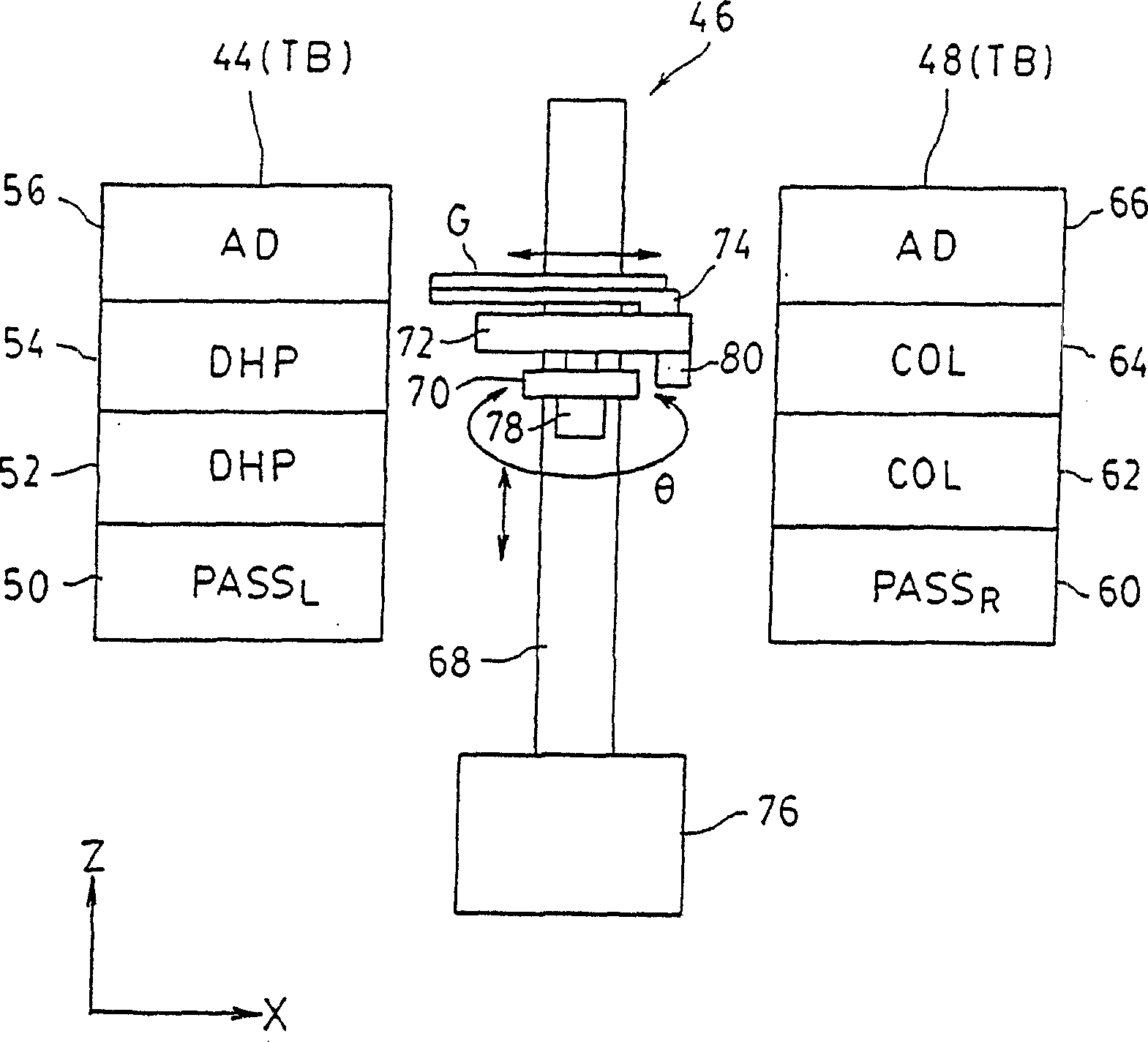

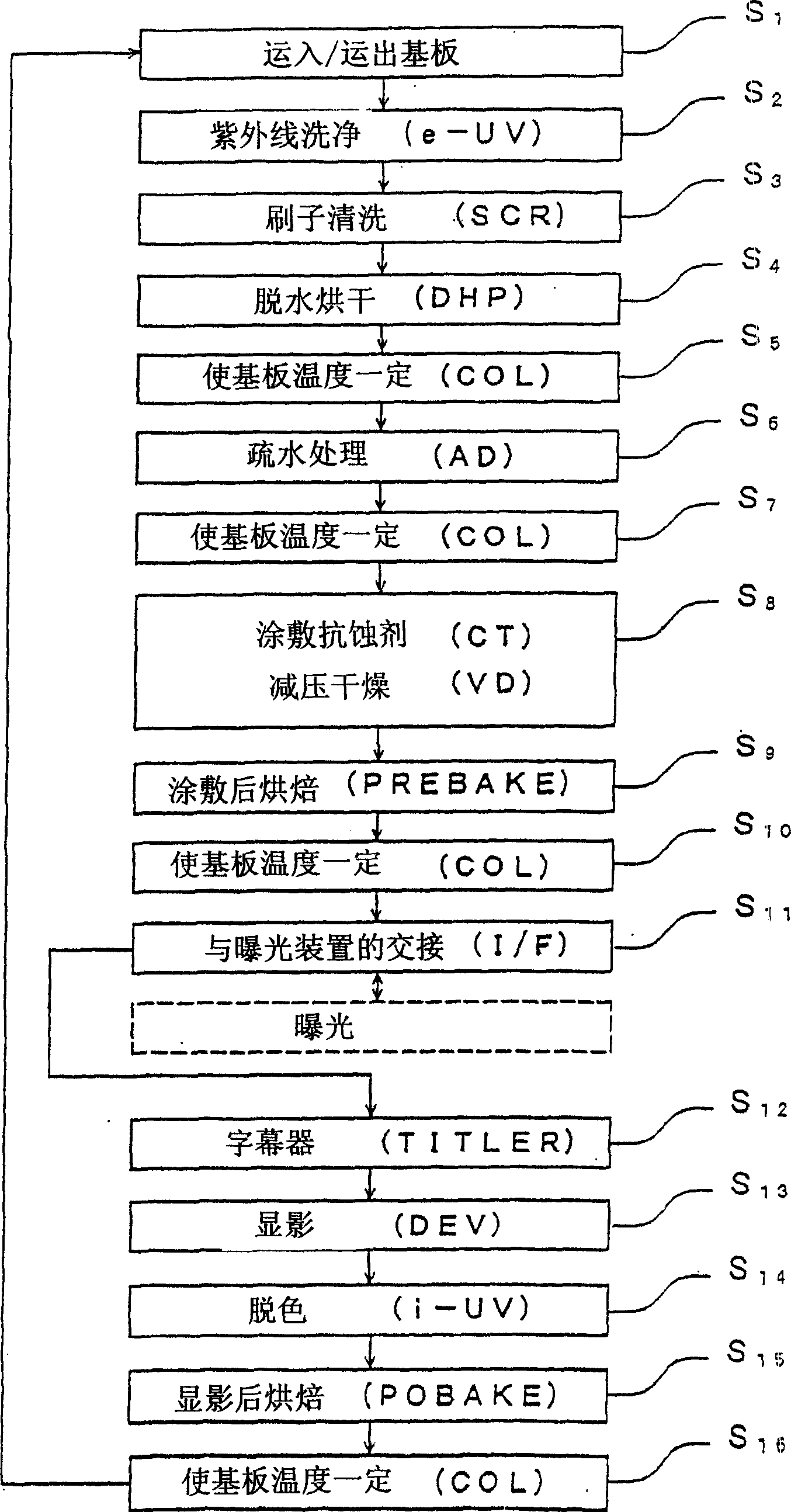

Method and apparatus for manufacturing display devices

ActiveUS20080254704A1Low costReduce runningDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

A method for fabricating a display device including forming a standard mark in a flexible substrate fed in a first direction, forming a partition wall in the flexible substrate, and forming an electrode by applying a conductive member at a predetermined position between the partition walls by an applicator based on the standard mark. An apparatus is provided that includes a transportation unit to transport a flexible substrate in a first direction, a mark formation unit to form a standard mark in the flexible substrate, a partition wall formation unit to form a partition wall in the flexible substrate, and an application unit to apply a conductive member to a predetermined position between the partition walls based on the standard mark. A display device is provided that includes a flexible substrate, a partition wall formed by pressing the flexible substrate, and an electrode formed by application between the partition walls.

Owner:NIKON CORP

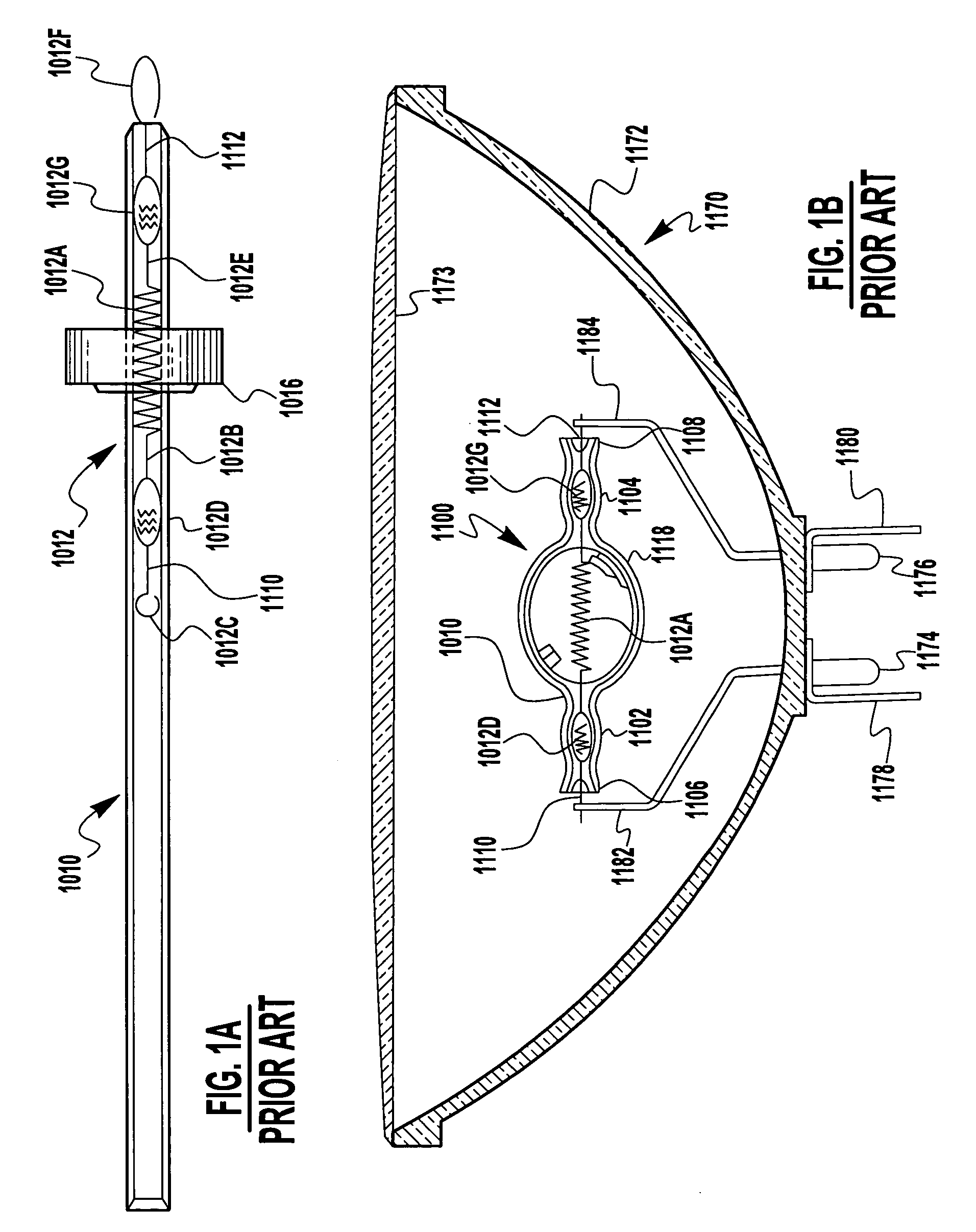

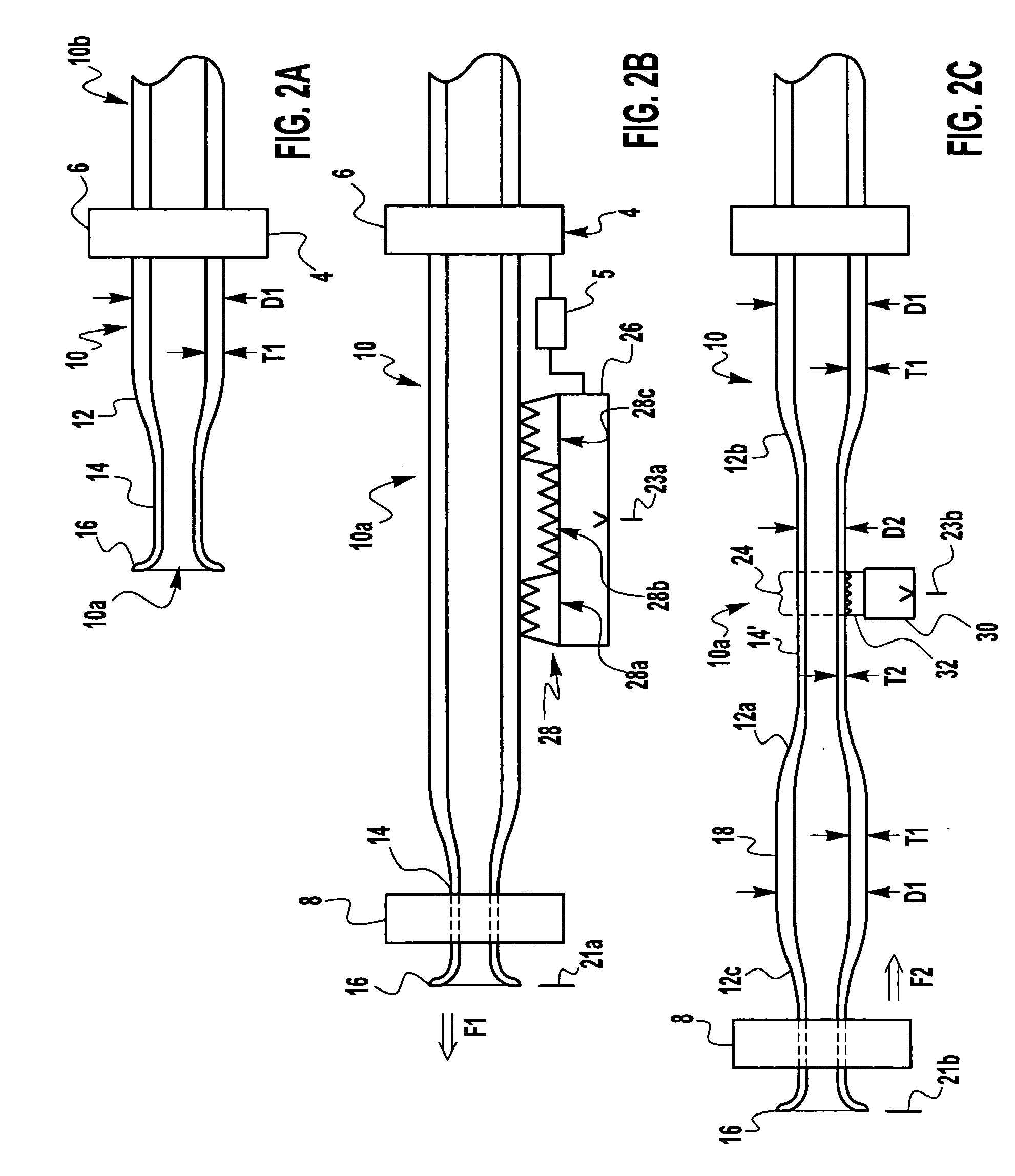

Apparatus and process for finishing light source filament tubes and arc tubes

InactiveUS20050092025A1Minor misalignmentAvoid pollutionTube/lamp screens manufactureElectroluminescent light sourcesManufacturing technologyEngineering

Manufacturing equipment and manufacturing process steps that improve upon prior art processes for the manufacturing of filament tube and arc tube light sources, their components and subassemblies, and lamps employing said light sources. A double ended, tipless filament tube or arc tube light source incorporates a drawn-down tubular body, and one piece foliated leads with spurs for process handling and for spudding into a filament with stretched-out legs. Bugled ends on the body provide a novel cutoff means, facilitate a flush-fill finishing process, and enhance mounting and support of the light sources in lamps. The foliated leads are made from a continuous length of wire in a process including foil hammering and two-bath AC electrochemical etching. Cost-reduced light source and lamp production enables affordable household consumer lamps, even when containing two series-connected halogen filament tubes. Safety benefits ensue from series connection, especially in combination with disclosed body and filament constructions.

Owner:THE FRIDRICH FAMILY TRUST

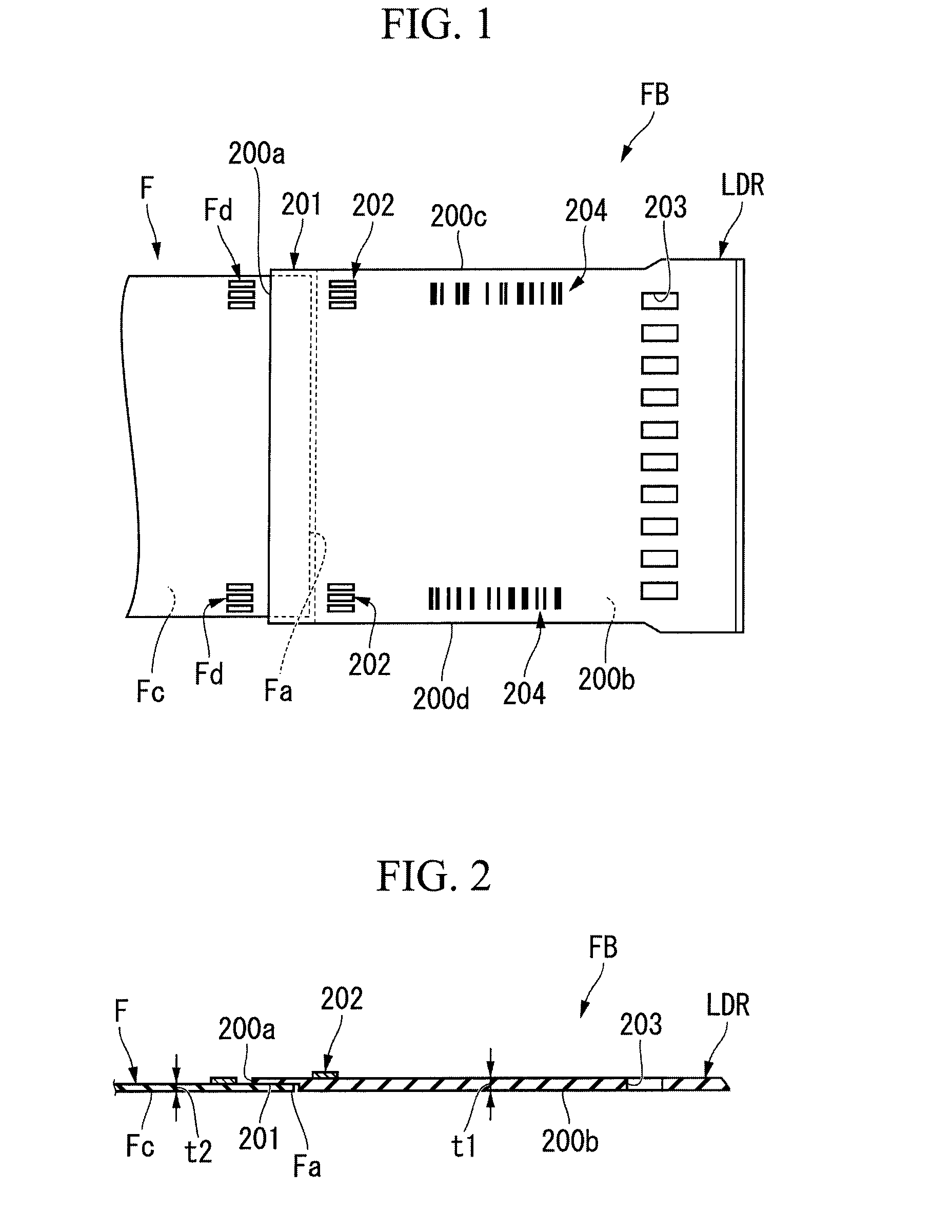

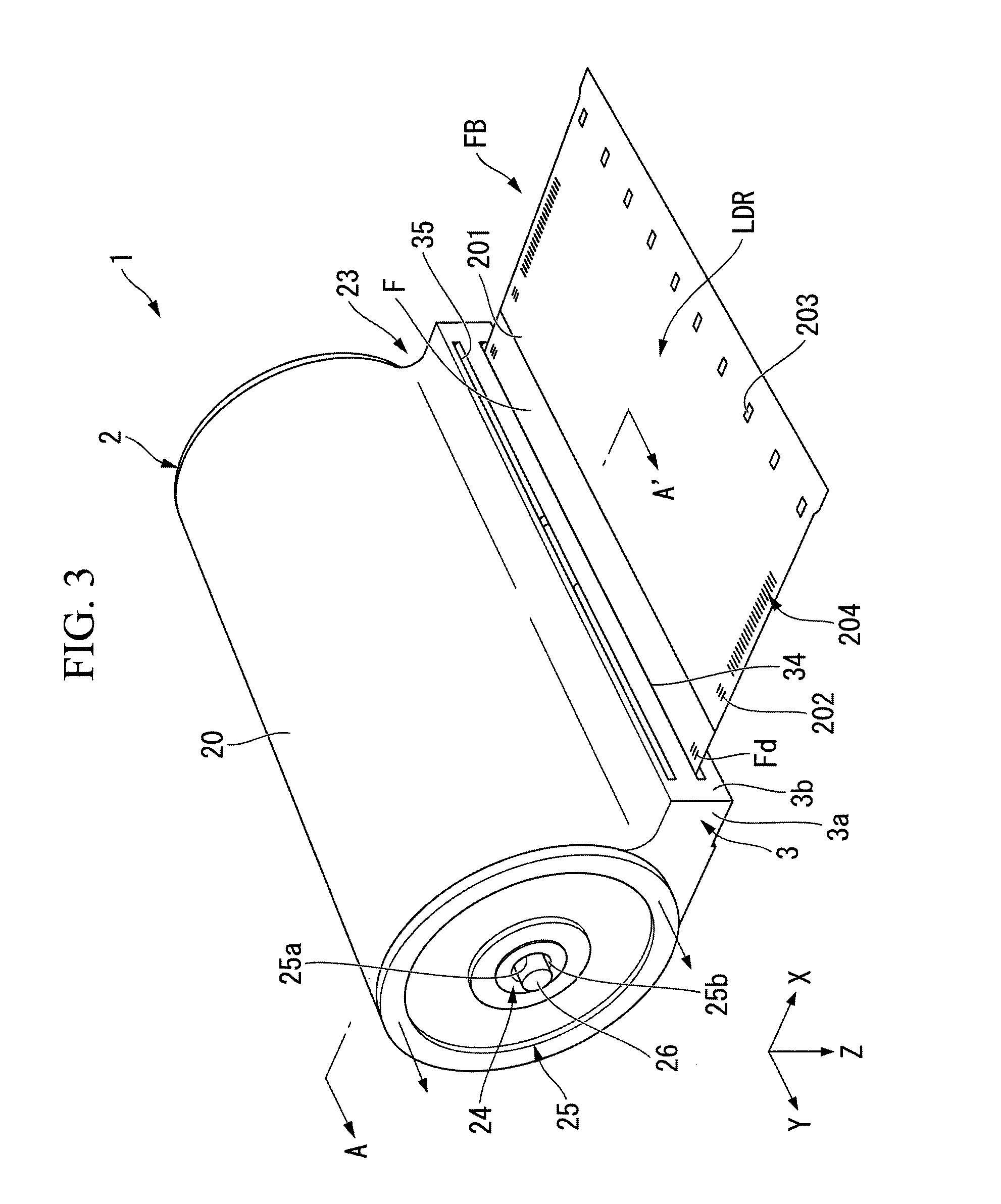

Leader member, substrate, substrate cartridge, substrate-processing apparatus, leader-connecting method, method of manufacturing display element, and apparatus for manufacturing display element

ActiveUS20120231694A1High precisionElectroluminescent light sourcesVessels or leading-in conductors manufactureEngineeringMechanical engineering

Owner:NIKON CORP

Display device manufacturing method and apparatus thereof

InactiveUS20100141135A1Easy to cutDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

The present invention provides a manufacturing method of a display device which can favorably cut a display panel having the structure where a resin layer is sandwiched between an element substrate and a sealing substrate. The manufacturing method of a display device includes the steps of: forming a display panel by sandwiching a resin which is hardened by any one of electromagnetic waves, radioactive rays and electron beams and heat between an element substrate having a display region in which a plurality of light emitting elements are formed and a sealing substrate in such a manner that the resin covers the display region; radiating at least one of electromagnetic waves, radioactive rays and electron beams to the display panel thus hardening first portions of the resin and leaving second portions of the resin in a state softer than the first portions; separating the display panel at positions corresponding to the second portions; and heating the separated display panel thus further hardening the resin.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com