Method and structure for helically coiling left, left and right three-segment type energy-saving filament

A three-stage, left-helical technology, applied to the left and right three-stage spiral winding method and structure, the winding structure of the filament, and the left field of the energy-saving filament. Problems such as falling off and affecting the qualified rate of stretching yarn, etc., achieve the effects of high qualified rate, easy operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

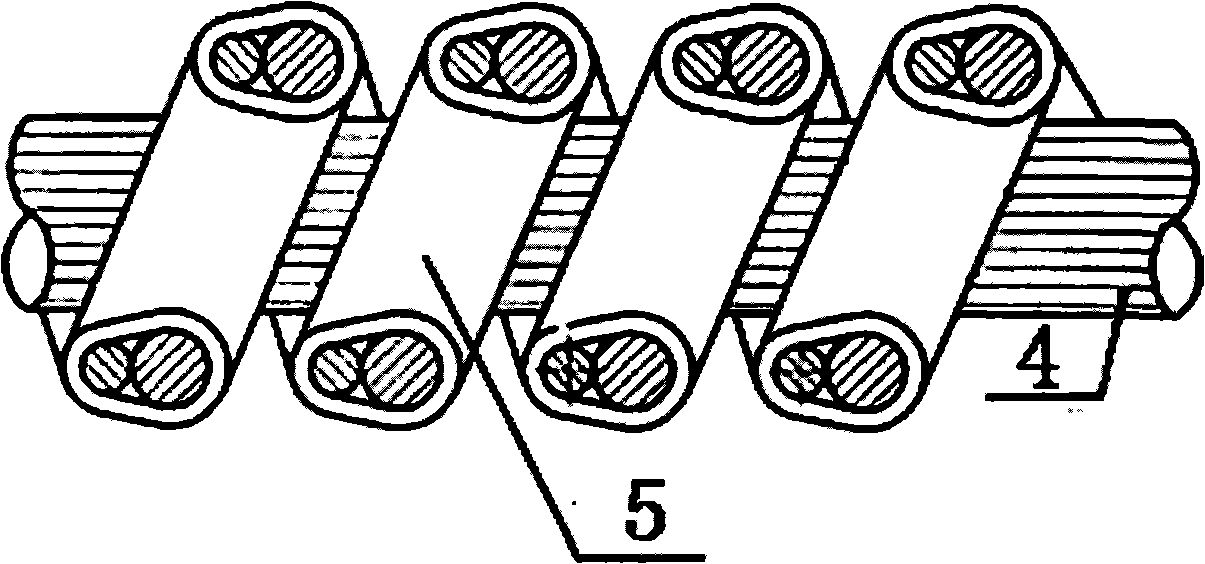

[0014] Embodiment of the present invention: it includes a spiral filament body 1, the filament body 1 is composed of a mandrel 2 and a filament secondary winding 3 wound around the mandrel 2, as attached figure 1 As shown; the filament secondary winding body 3 is composed of a molybdenum core wire 4 and a filament primary winding body 5 wound around the molybdenum core wire 4, as attached figure 2 As shown; the filament primary winding body 5 is composed of a molybdenum core wire 6 and a tungsten wire 7 wound around the molybdenum core wire 6, as attached image 3 shown. Among them, the filament primary winding 5 is wound on the molybdenum core wire 4 in a left-handed manner, the secondary winding body 3 of the filament is wound on the mandrel 2 in a right-handed manner, and the tungsten wire 7 is wound on the molybdenum core wire in a left-handed man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com