Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Visual reconstruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

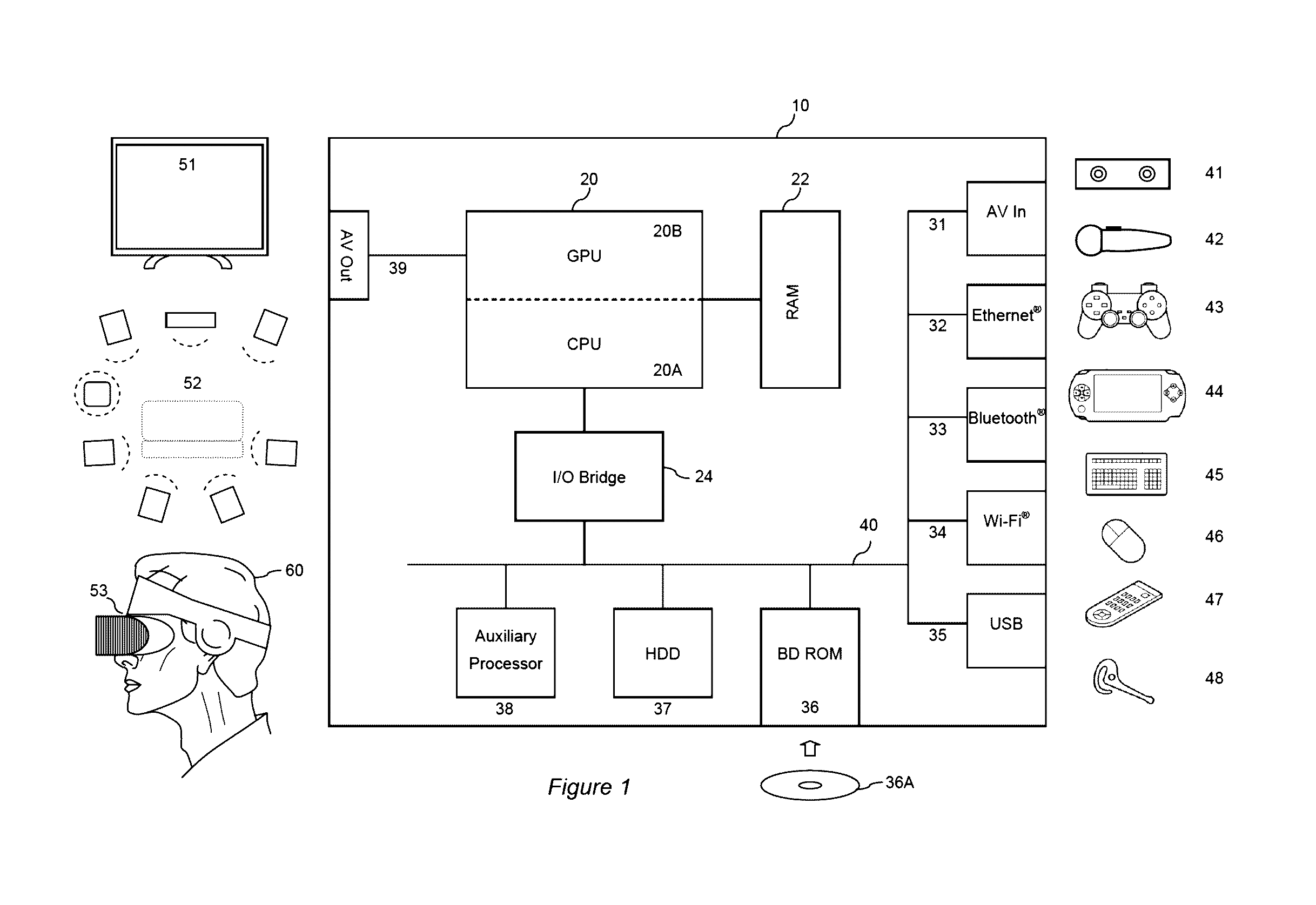

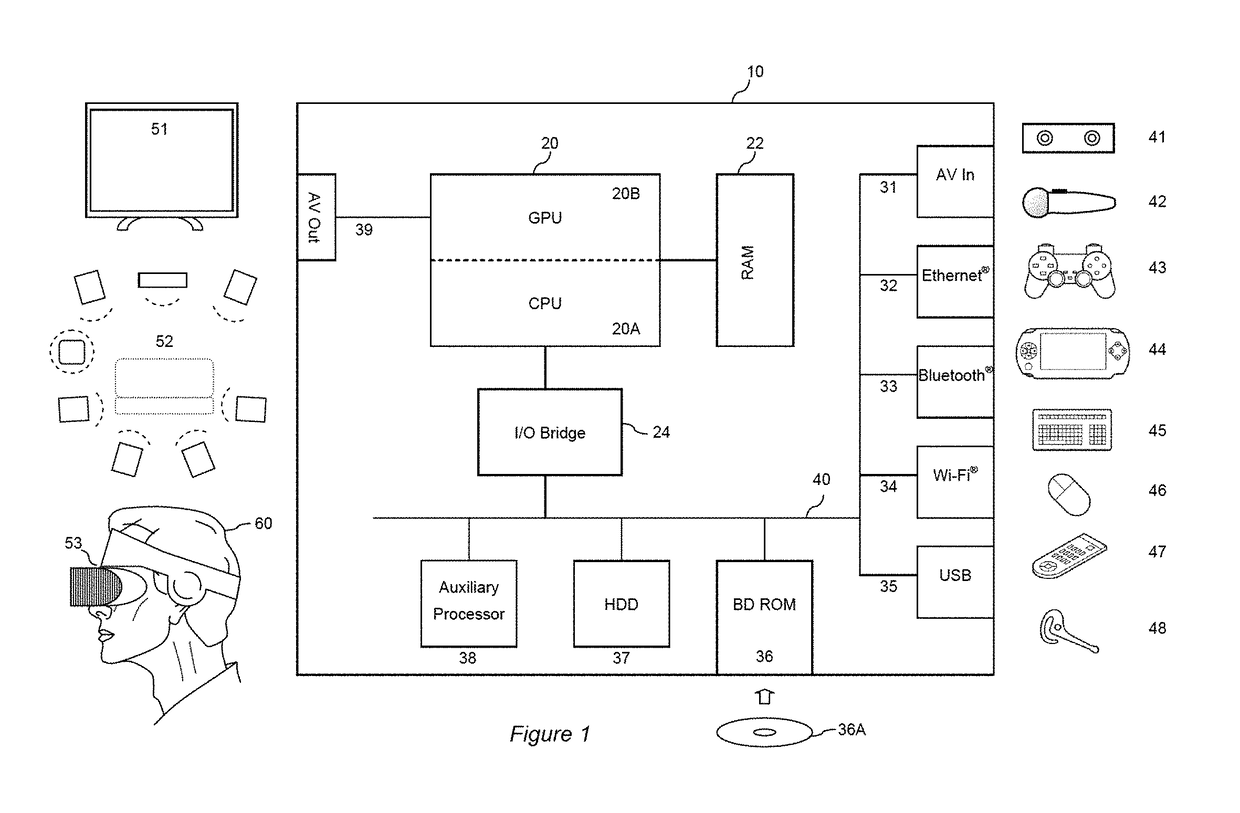

Device and method of selecting an object for 3D printing

ActiveUS20160314617A1Minimize impactEasy to recordProgramme controlAdditive manufacturing apparatusComputer graphics (images)Visual perception

Aspects of the technology include method of selecting an object from a videogame for 3D printing. The method involves periodically rendering a virtual environment of a videogame for display at a succession of points in time. Information is periodically recorded that enables visual reconstruction of at least part of the virtual environment at a succession of points in time. A predetermined set of values is periodically recorded responsive to the state of the rendered virtual environment at a succession of points in time. The predetermined set of values enables a model of a selected part of the rendered virtual environment to be generated that is configured for 3D printing.

Owner:SONY COMPUTER ENTERTAINMENT INC

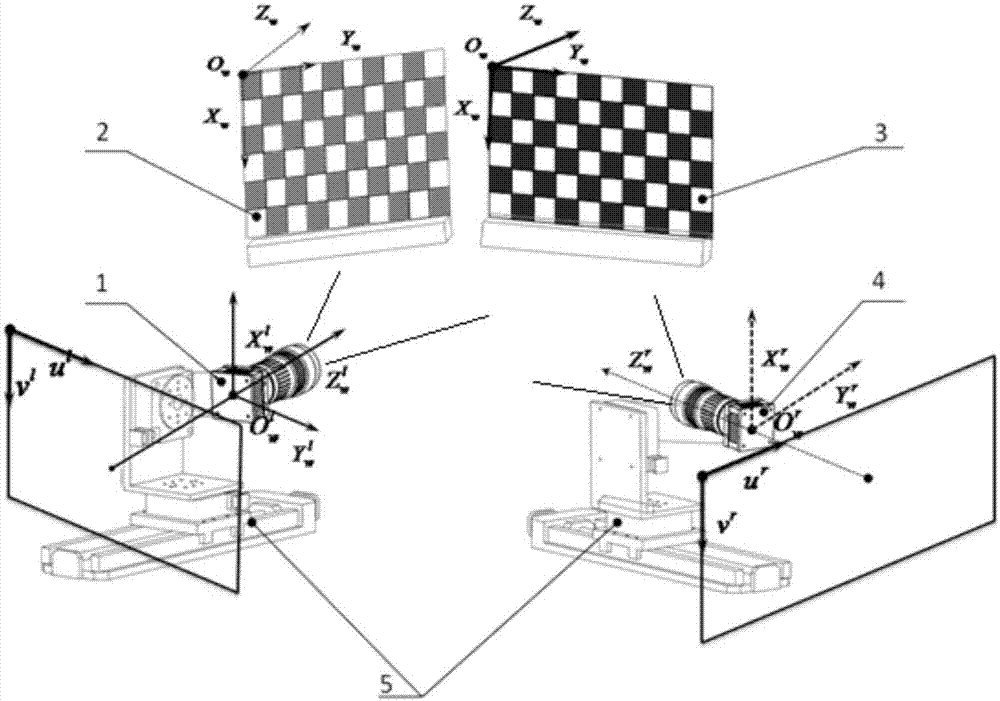

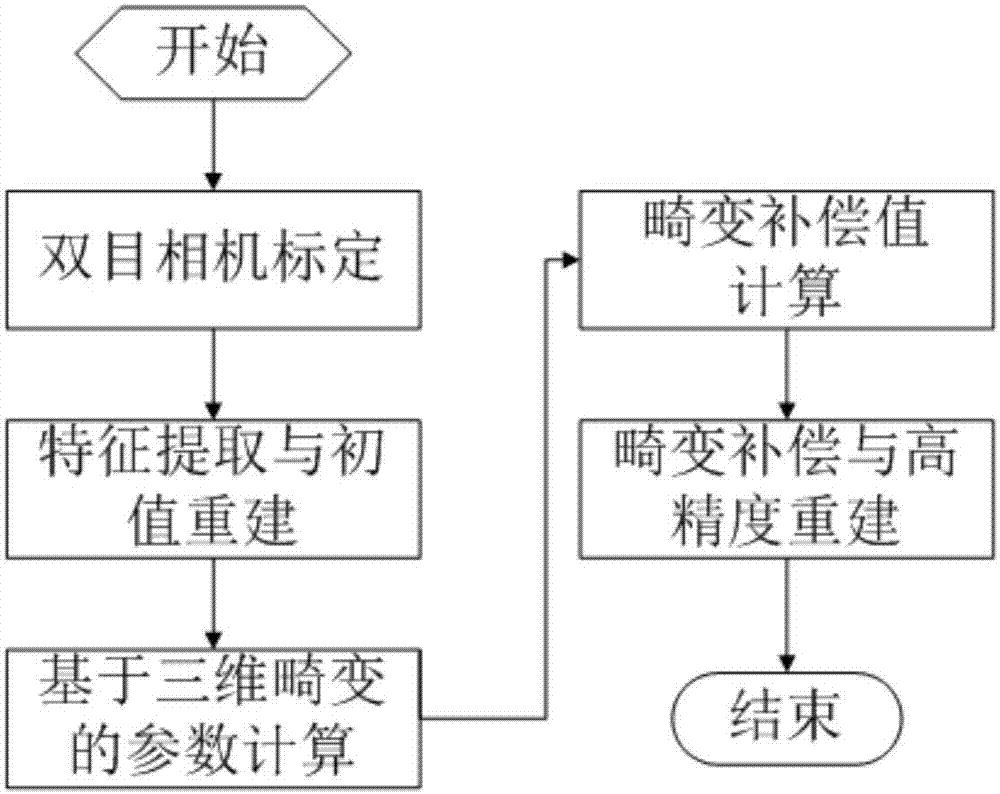

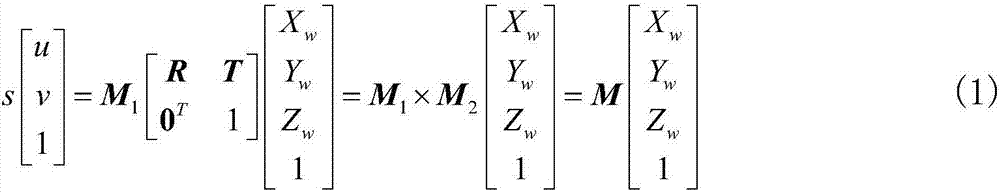

Binocular visual sense reconstruction method considering three-dimensional distortion

ActiveCN107358631AHigh measurement accuracyImprove 3D reconstruction accuracyImage enhancementImage analysisMeasurement pointReconstruction method

The invention discloses a binocular visual sense reconstruction method considering three-dimensional distortion, belonging to the computer visual sense measurement technology field. The binocular visual sense reconstruction method considering the three-dimensional distortion introduces a three-dimensional distortion correction function to perform compensation optimization on a visual sense reconstruction result and realizes three-dimensional high accuracy remodeling. The binocular visual sense reconstruction method considering the three-dimensional distortion adopts a traditional binocular visual sense reconstruction method to obtain a three-dimensional reconstruction initial values of measurement points, solves a three-dimensional distortion compensation value on the basis of a relative relation between a standard object and a binocular camera and the reconstruction initial values, thus performs distortion compensation on coordinates of the camera of a tested point which are respectively extracted from a left image and a right image, combines with binocular visual sense theory to reconstruct, and realizes the binocular three-dimensional high accuracy reconstruction. The binocular visual sense reconstruction method considering three-dimensional distortion is high in reconstruction accuracy, can compensate the three-dimensional distortion of the binocular visual sense, realizes form and surface reconstruction of a part having a big curvature and a big size and improves three-dimensional reconstruction accuracy of the binocular visual sense.

Owner:DALIAN UNIV OF TECH

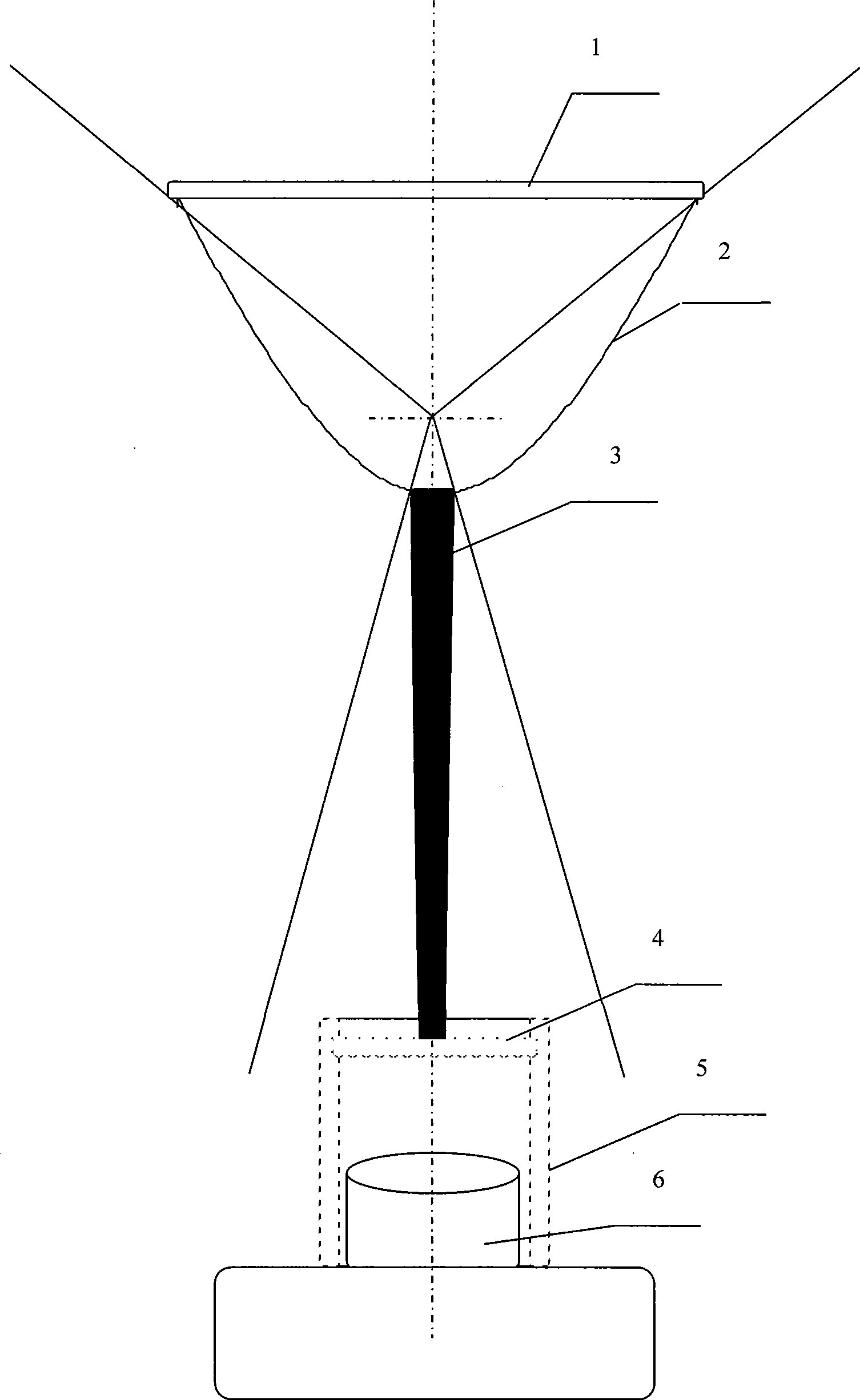

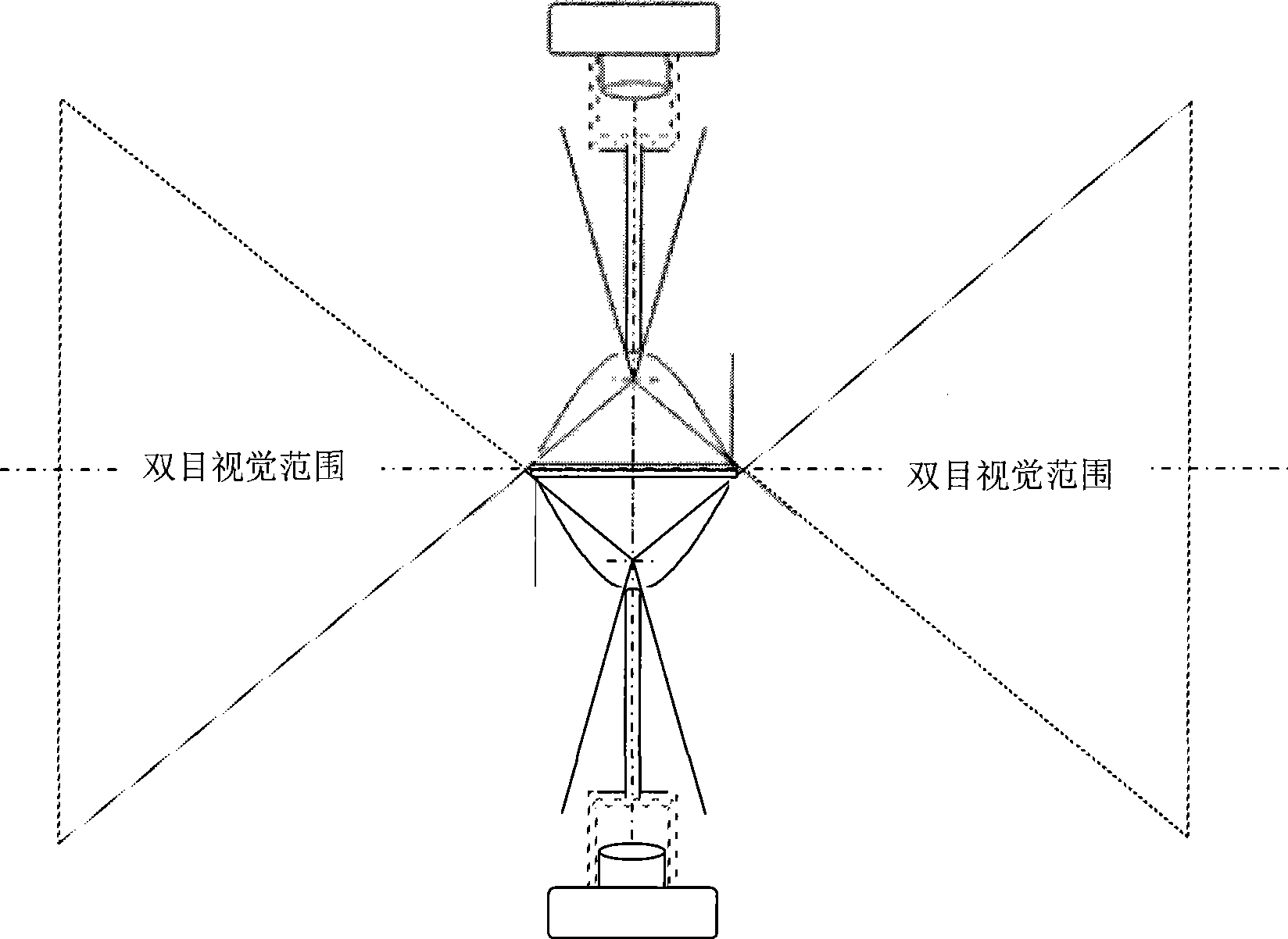

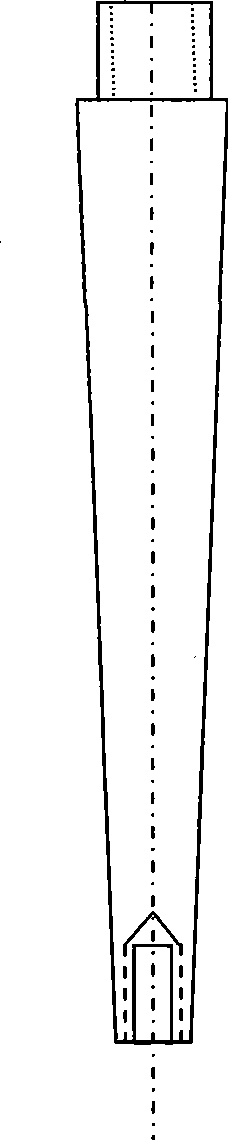

Novel binocular stereo vision measuring device

The invention relates to a novel binocular stereoscopic vision measuring device, which comprises two omnibearing vision sensors provided with the same imaging parameters, a connecting unit and a microprocessor which is used for performing three-dimensional stereoscopic vision reconstruction on images of the two omnibearing vision sensors, wherein the omnibearing vision sensors comprise hyperbolic mirror surfaces, upper covers, stand bars, transparent glass surfaces, supplementary lens frames and image units; the upper covers are arranged on the hyperbolic mirror surfaces; the stand bars are round platforms with thick upper parts and thin lower parts; upper ends of the stand bars are arranged inside small holes in bottom centers of the hyperbolic mirror surfaces, and lower ends of the stand bars are arranged inside mounting holes in the centers of the transparent glass surfaces which are embedded into the supplementary lens frames; the stand bars are perpendicular to the transparent glass surfaces; and the image units are positioned inside the supplementary lens frames. The novel binocular stereoscopic vision measuring device simplifies the complexity of calculation of stereo matching and so on, saves the operation of camera calibration, is convenient to perform feature extraction, is easy to realize stereo image matching, and finally achieves the aim of high-efficiency, real-time and accurate stereoscopic vision measurement.

Owner:汤一平

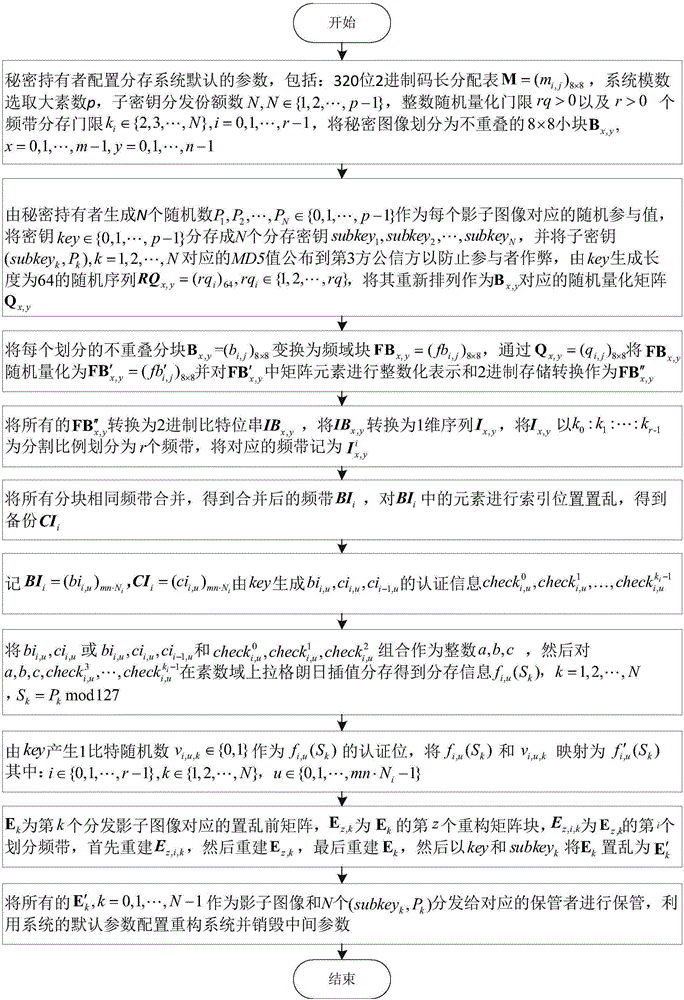

Prime-domain multi-threshold progressive secret image preservation and reconstruction method

ActiveCN106530368AImprove certification accuracyEnhanced Image Restoration CapabilitiesTexturing/coloringImage data processing detailsReconstruction methodGlyph

The invention provides a prime-domain multi-threshold progressive secret image sharing and reconstruction method. The method comprises the steps that a random participation value is combined to share a secret key, and the shared secret key and an MD5 value corresponding to the participation value are announced to prevent cheating; a secret image is subjected to 8*8 frequency domain transform; random quantization and binary representation with a specified code length allocation table are carried out on a block frequency domain coefficient; a number of divided bands are formed according to a zigzag scanning order and band recombination, and band backup is formed through scrambling; multi-threshold sharing is carried out on the bands, the band backup and authentication information in prime-domain; and a distribution shadow image is reconstructed with additional 1-bit authentication information. When recovery is carried out, the MD5 value is detected, and multiple thresholds are combined to determine a reconstructable band; double authentication are used to reconstruct first and secondary band backup tables and the corresponding band; and the reconstructed band is used to reconstruct the secret image. Compared with the existing methods, the provided method can make full use of the distribution shadow image to carry out progressive sharing on the secret image to enhance the quality of visual reconstruction.

Owner:SHAANXI NORMAL UNIV

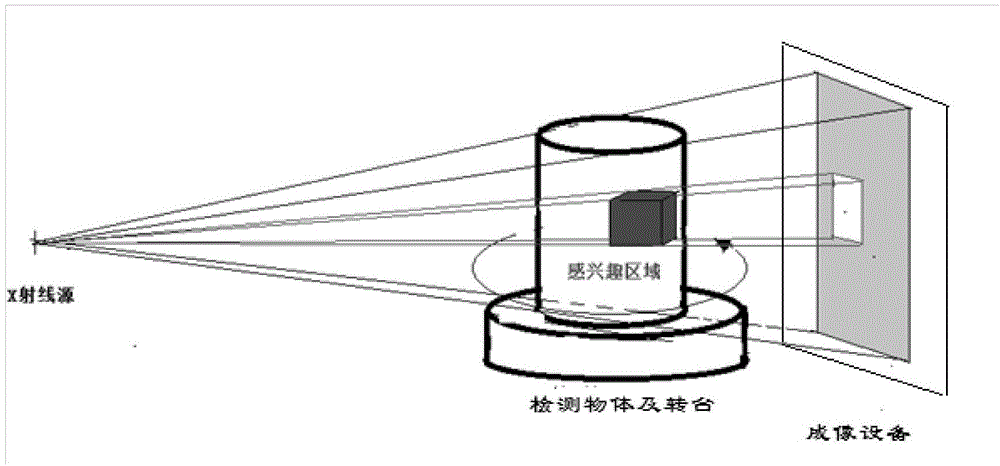

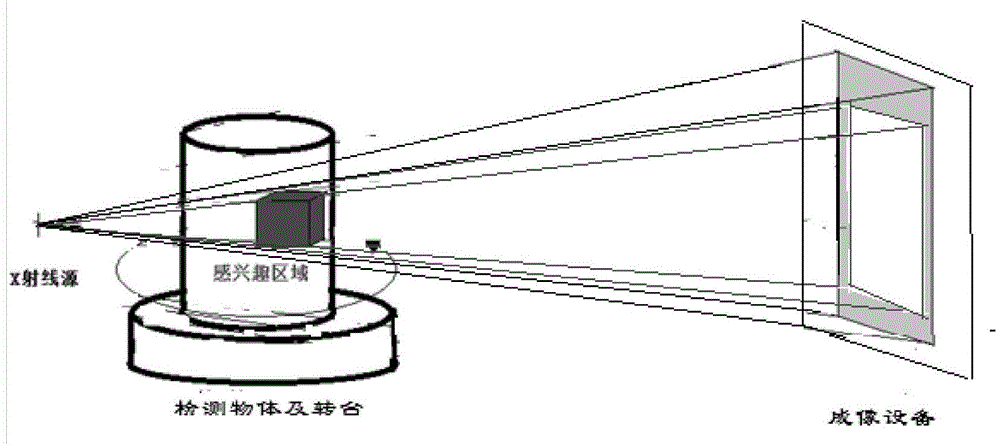

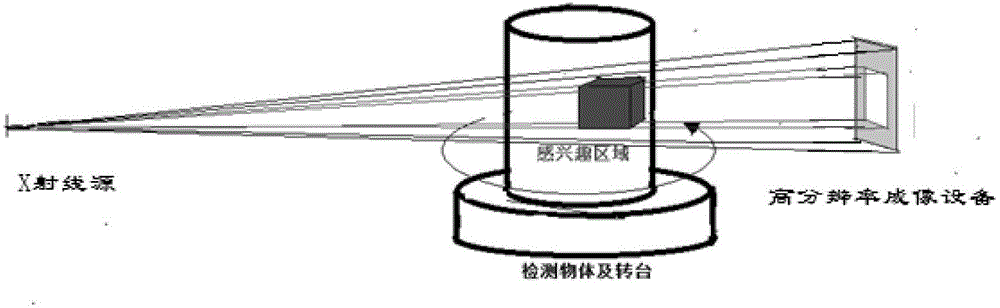

Cone beam CT (computed tomography) area-of-interest scanning method based on visualization

InactiveCN104352246AHigh resolutionSolve the problem that high-resolution images of characteristic areas cannot be obtainedComputerised tomographsTomographyHigh resolution imageImaging equipment

The invention discloses a method for obtaining a high-resolution area-of-interest image through secondary scanning on the basis of visualization. The method comprises the following steps that the positions of a turntable and a radiation source are regulated, the distance is zoomed out, the wider visual field is shown, and an object is subjected to whole primary scanning; the three-dimensional visual reconstruction and the MPR (multiple planar reconstruction) are carried out according to a scanning result; reconstruction results are combined to be displayed, and the area-of-interest position is determined through interaction in the three-dimensional space; meanwhile, the positions of the turntable and the radiation source, the height of the turntable, the position of the object on the turntable and the resolution of imaging equipment are regulated, so that the center of interest is positioned in the center of the turntable, meanwhile, the visual field can just accommodate the area of interest, and the area-of-interest fine scanning is carried out after the regulation. The reconstruction is carried out according to the fine scanning result, and a high- resolution image of the area of interest is obtained. The method has the advantages that the positioning scanning of the area of interest can be realized, meanwhile, the resolution of the region scanning can be obviously improved, simplicity is realized, and the realization is easy.

Owner:SOUTHEAST UNIV

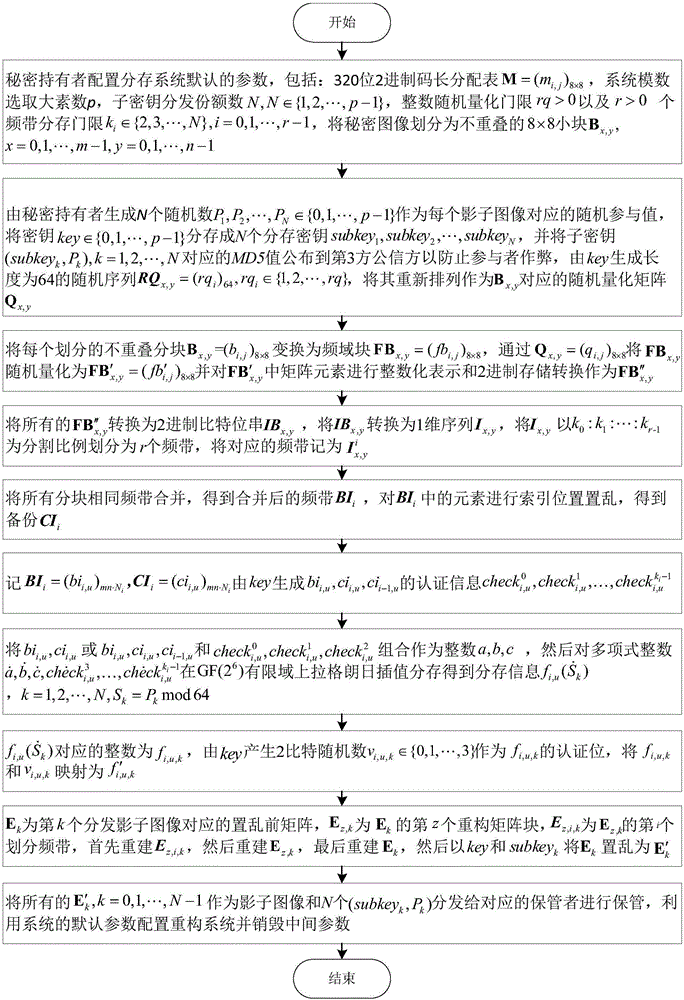

GF(2<6>) finite-field multi-threshold progressive secrete image sharing and reconstruction methods

ActiveCN106683053AImprove certification accuracyEnhanced Image Restoration CapabilitiesImage enhancementKey distribution for secure communicationReconstruction methodGlyph

The invention provides GF(2<6>) finite-field multi-threshold progressive secrete image sharing and reconstruction methods. A secret key is shared by combining a random participation value, and an MD5 value corresponding to the shared secrete key and participation value is published to prevent cheating; 8*8 frequency domain transformation is carried out on a secret image, sub-block frequency domain coefficients are quantified randomly, a specific code length distribution list is represented in a binary manner, multiple division frequency bands are formed according to a similar Z-shaped scanning sequence and frequency band recombination, and a frequency band backup is formed by scrambling; and frequency band, frequency band backup and authentication information is shared in multiple thresholds in the GF(2<6>) finite-field, and 2-bit authentication information is added to reconstruct a distribution shadow image. During recovery, the MD5 value is detected, a reconstructable frequency band is determined by combining the multiple thresholds, primary and secondary frequency band backup tables are reconstructed via dual authentication, a corresponding frequency band is reconstructed, and the reconstructed frequency band is used to reconstruct a secret image. Compared with existing methods, the distribution shadow image can be used fully to share the secret image progressively, and the visual reconstruction quality is improved.

Owner:SHAANXI NORMAL UNIV

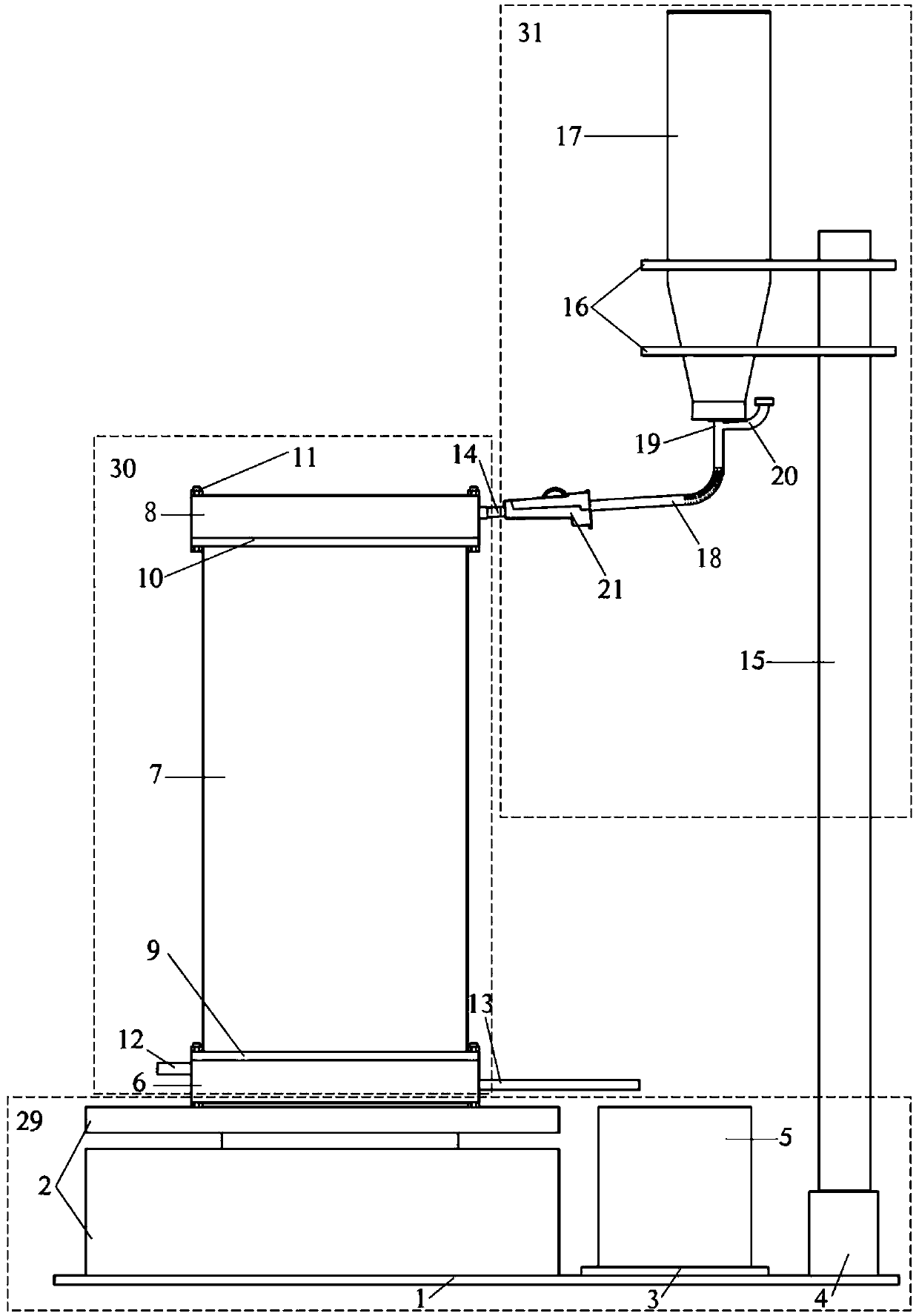

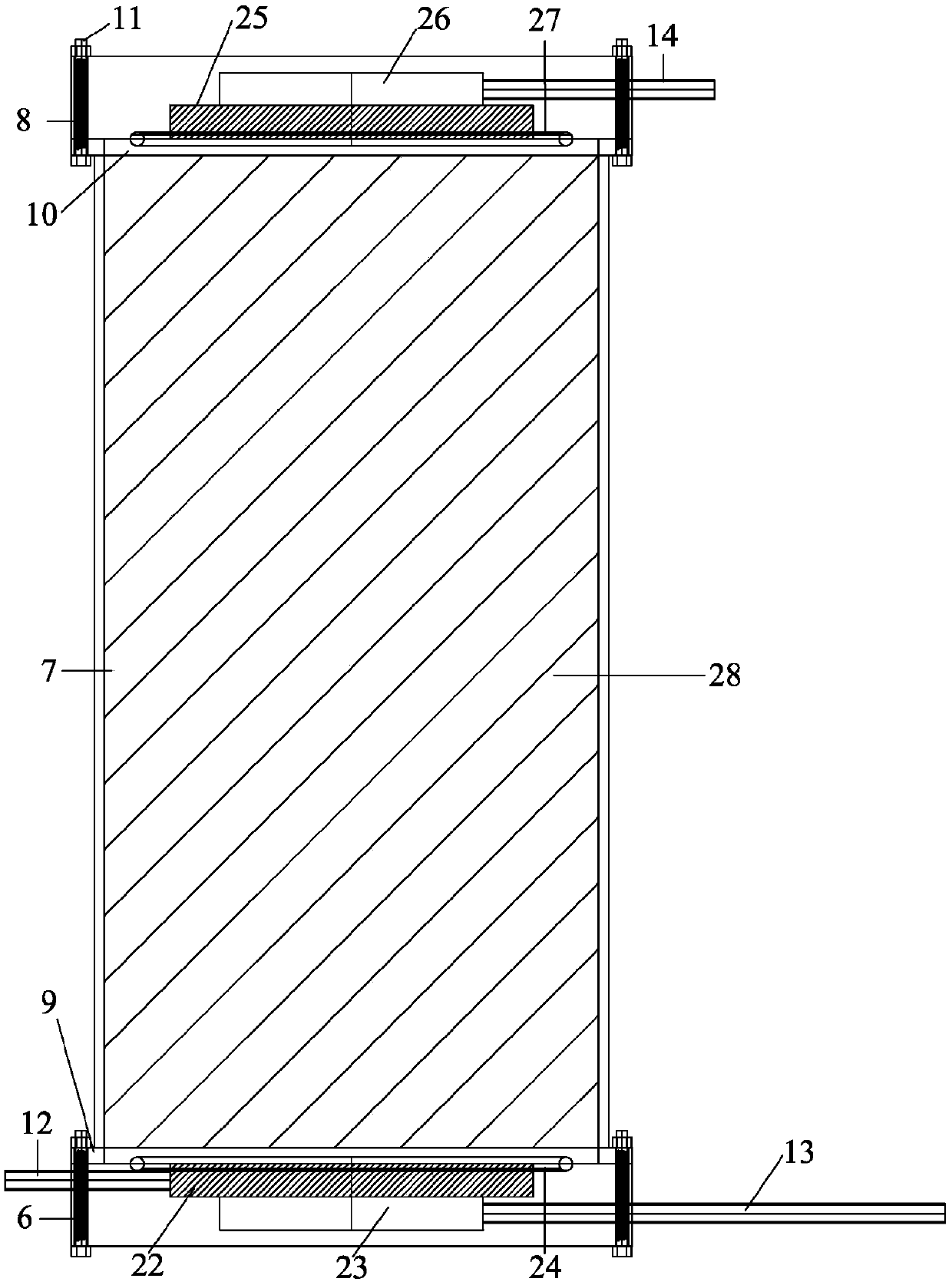

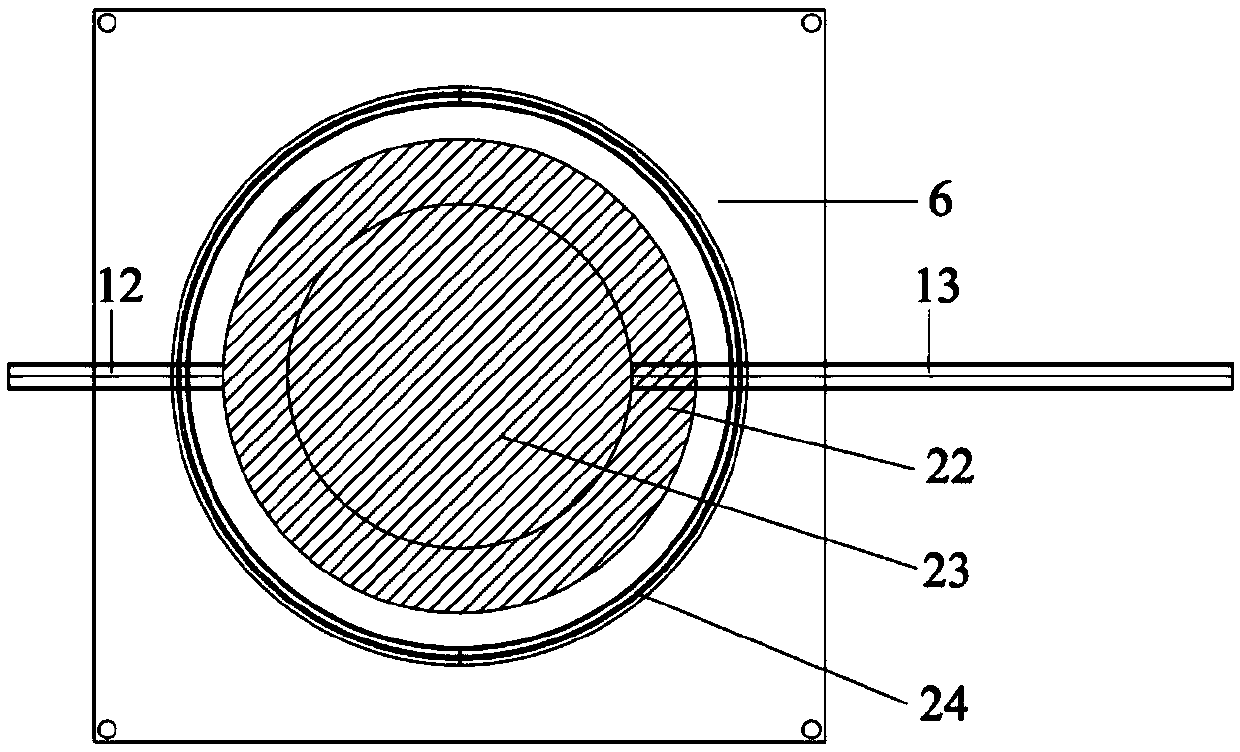

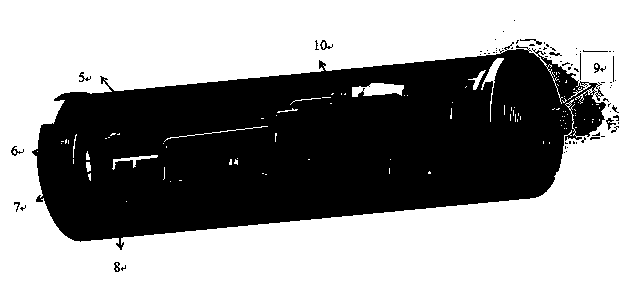

Undisturbed loess preferential flow dynamic observation device for CT scanning and method of use

ActiveCN109540935ASimple structureEasy to installMaterial analysis using wave/particle radiationWater resource assessmentNon destructivePreferential flow

The invention discloses an undisturbed loess preferential flow dynamic observation device for CT scanning and a method of use. The loess is stored in a visual container of the device. A continuous fluid adding device continuously supplies liquid to a percolation chamber. During the gradual seepage of the loess, CT can clearly scan related parameters such as pore changes in the loess and seepage paths of the liquid. The device is simple in structure, convenient to mount and dismount, and high in automation degree. The method of using the device adopts advanced X-ray CT non-destructive testing technology to perform dynamic CT scanning on undisturbed loess samples in an undisturbed soil visual seepage device under continuous humidification conditions, and uses an AVIZO three-dimensional visual reconstruction platform to perform image processing, three-dimensional visual reconstruction, pore fracture characteristic analysis and preferential flow seepage path extraction on CT scanning results under dry wet conditions to obtain preferential seepage channels of the pore fracture and dynamic development rules of the preferential flow.

Owner:CHANGAN UNIV

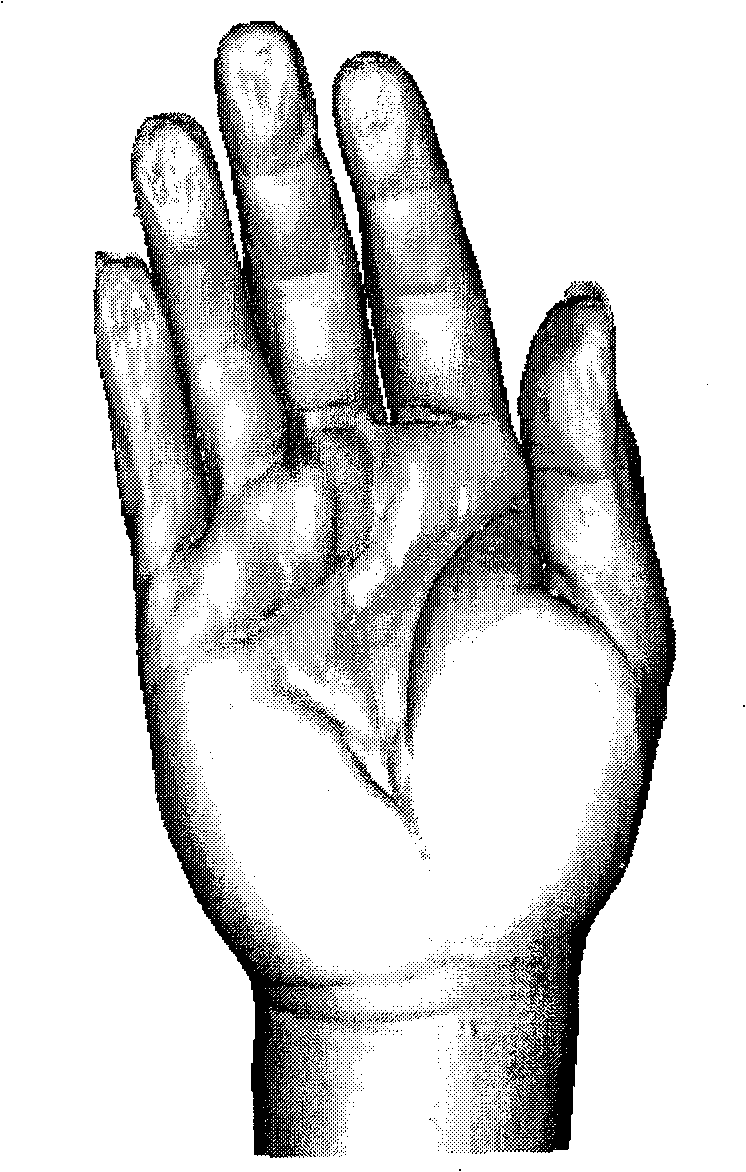

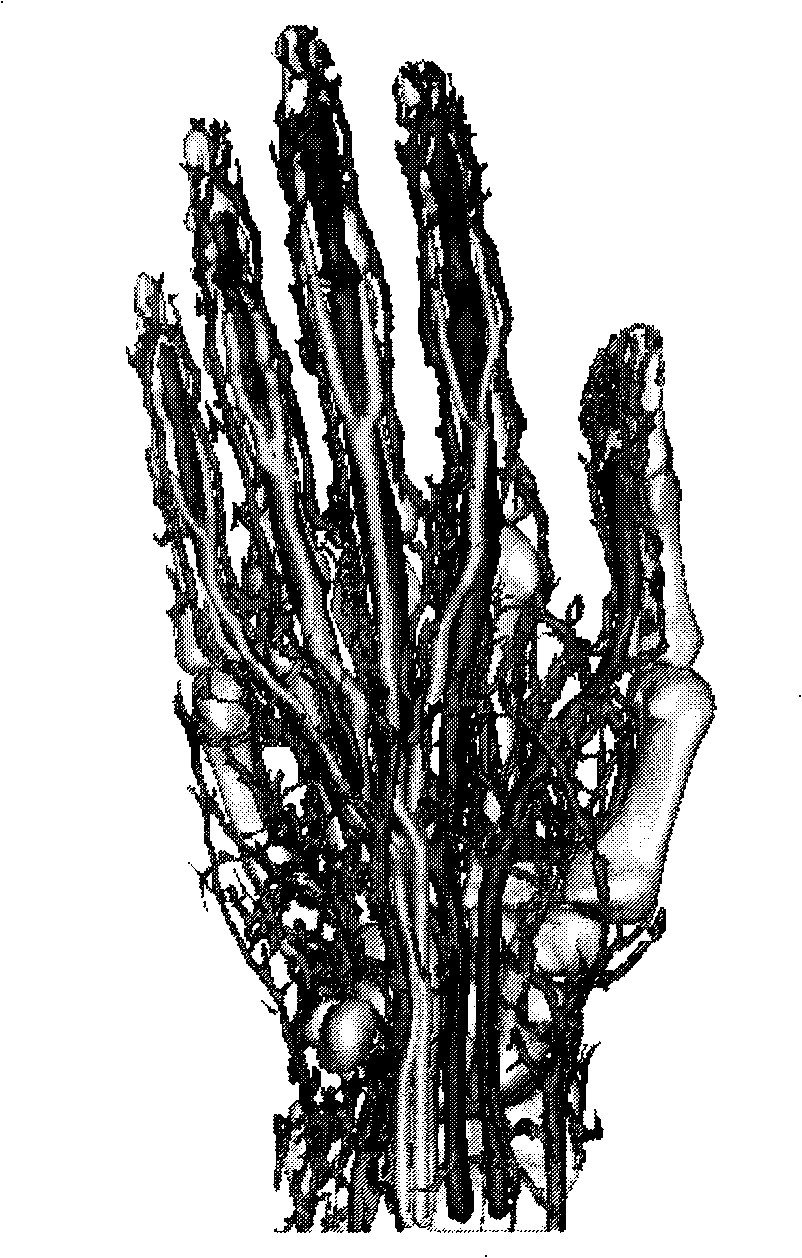

Construction method for digitized virtual hand and longitudinal shaped severed finger anatomic structure model

InactiveCN101401728AClear and accurate arterial appearanceAdjacent relationship is clear and accurateSurgeryX-ray constrast preparationsData set3d image

The invention discloses a method for constructing anatomical structural models for a virtual hand and a longitudinally amputated finger. The method comprises the following steps: A. specimen selection and pretreatment; B. specimen irrigation; C. CT scan and data set acquisition; D. 3D visual reconstruction of a hand with Mimics software of Materalise Company of Belgium on a platform of a common personal computer; and E. digital virtual construction of a longitudinally amputated finger. The invention applies a virtual hand constructed by a digital virtual technology to clinic anatomical research of longitudinally amputated fingers (palms) and provides the method for constructing the anatomical structural models for the virtual hand and the longitudinally amputated finger which converts 2D images commonly used in clinic into 3D images, thereby improving the understanding of the structure of a hand and providing scientific foundation for clinic diagnosis and treatment protocol decision, surgeries, prognosis, etc.

Owner:东莞市厚街医院

Underwater binocular stereo vision measuring system and method based on dynamic reference coordinate system

ActiveCN110260820AHigh measurement accuracyNo systematic biasPicture taking arrangementsCharacter and pattern recognitionSingular value decompositionObservational error

The invention provides an underwater binocular stereo vision measuring system and method based on a dynamic reference coordinate system. A dynamic reference coordinate system is built through using four active cursor targets to eliminate a measurement error caused by vibration. An underwater stereo vision reconstruction method based on a light field model is used to calculate a three-dimensional coordinate of a target angular point under a scanning system. A coded point coordinate system is established by carrying out singular value decomposition on a coordinate matrix of the target angular point. A spatial three-dimensional point of a laser stripe in a scanning system coordinate system is calculated by using an underwater laser stripe matching and stereo reconstruction method based on the light field model. The measurement error caused by the vibration is eliminated by calculating the three-dimensional coordinate of a laser stripe center point of each group of pictures under the scanning system and converting to the scanning system coordinate system of the first group of picture target points. An underwater target point is packaged in a high pressure resistant state and can withstand high pressure of deep sea 4000 meters. Therefore, the system can be used for a dynamic high precision measurement scene of the deep sea 4000 meters.

Owner:SHANGHAI UNIV

Ultrasonic or CT medical image three-dimensional reconstruction method based on transfer learning

ActiveCN112767532ARealize 3D reconstructionImprove the efficiency of auxiliary diagnosisNeural architecturesMachine learningNuclear medicineUnsupervised learning

The invention discloses an ultrasonic or CT medical image three-dimensional reconstruction method based on transfer learning, which is characterized in that an unsupervised learning mechanism is adopted, and a three-dimensional reconstruction function of an ultrasonic image is achieved through transfer learning by utilizing a visual method according to the characteristics of ultrasonic or CT image acquisition. By means of the method, three-dimensional reconstruction of ultrasonic or CT images can be effectively achieved, in auxiliary diagnosis of artificial intelligence, the effect of auxiliary diagnosis is fully played, and the efficiency of auxiliary diagnosis can be improved through the 3D visual reconstruction result.

Owner:EAST CHINA NORMAL UNIVERSITY

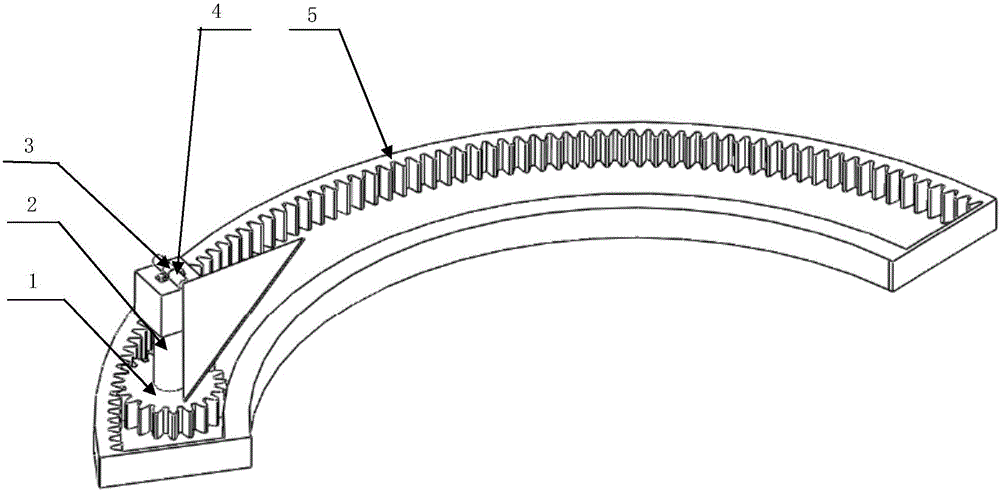

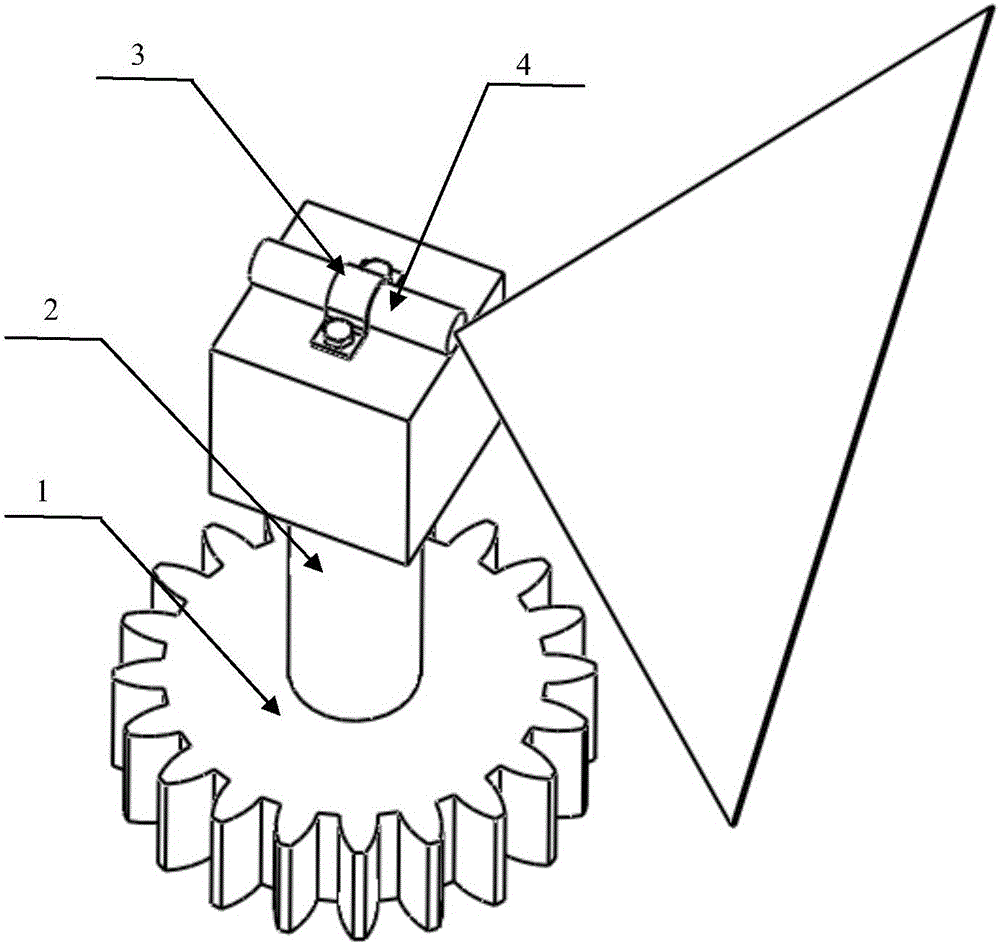

Automobile wheel rim appearance arcuate path visual reconstruction system

InactiveCN105928471ARealize arc trajectory scanning reconstructionImprove detection accuracyUsing optical meansSmall footprintEngineering

The invention discloses an automobile wheel rim appearance arcuate path visual reconstruction system. The system comprises a gear (1), a motor (2), a clamp (3), a laser demarcation device (4) and an arcuate rail (5). A round hole in the gear (1) passes through an output shaft of the motor (2) and is in key joint with a stepped shaft intermediate section of the motor (2). A nut is in fixed threaded connection with the end part of the output shaft of the motor (2). The gear (1) is placed in the arcuate rail (5) and is engaged with an arcuate rack of the arcuate rail (5). The laser demarcation device (4) is placed between two threaded holes in the top of the motor (2). Two bolts run into round holes on both sides of the clamp (3) and two threaded holes in the top of the motor (2) to be in fixed threaded connection with the motor (2). The system provided by the invention has the advantages of small footprint, simple structure, high detection precision, easy operation and easy installation.

Owner:JILIN UNIV

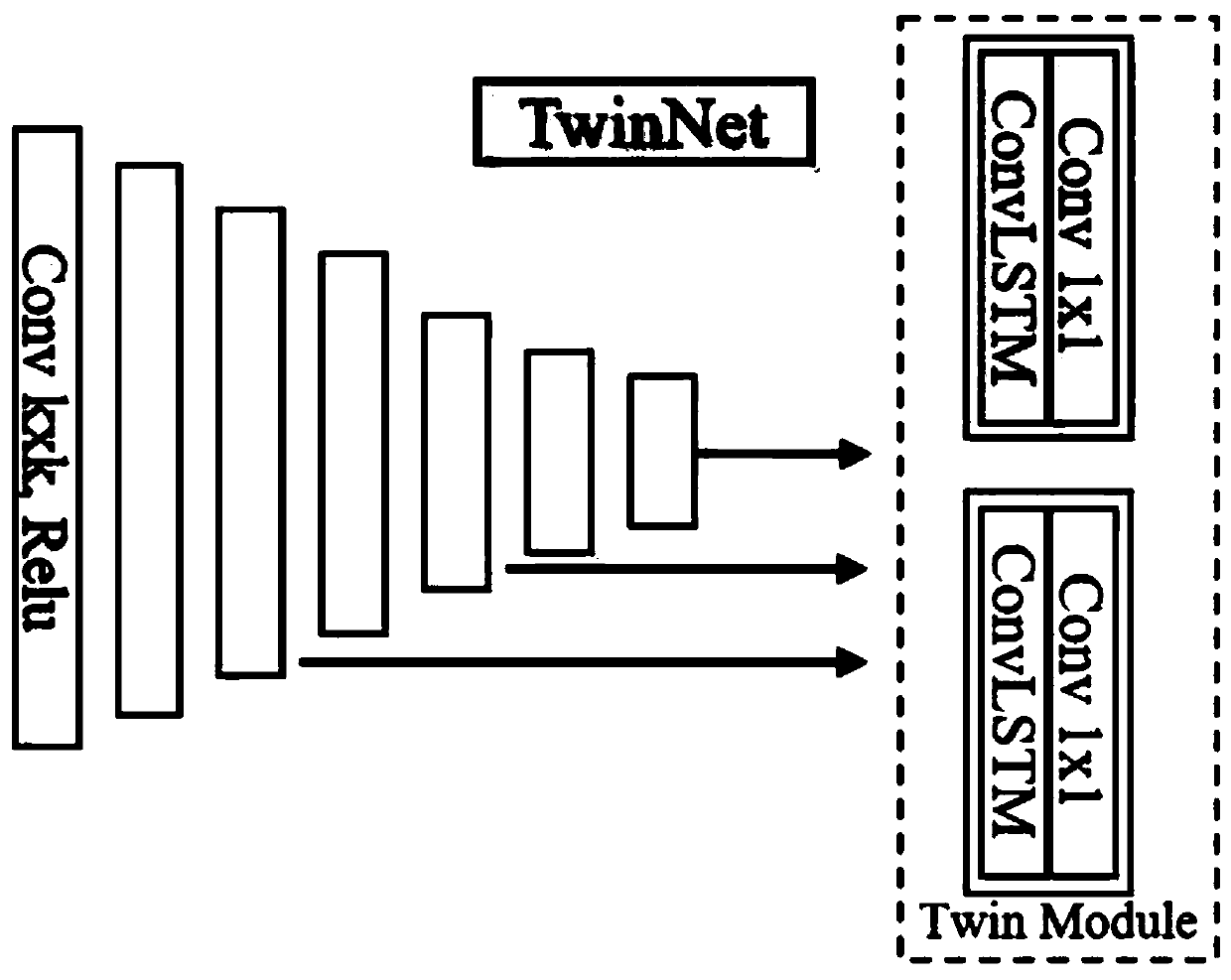

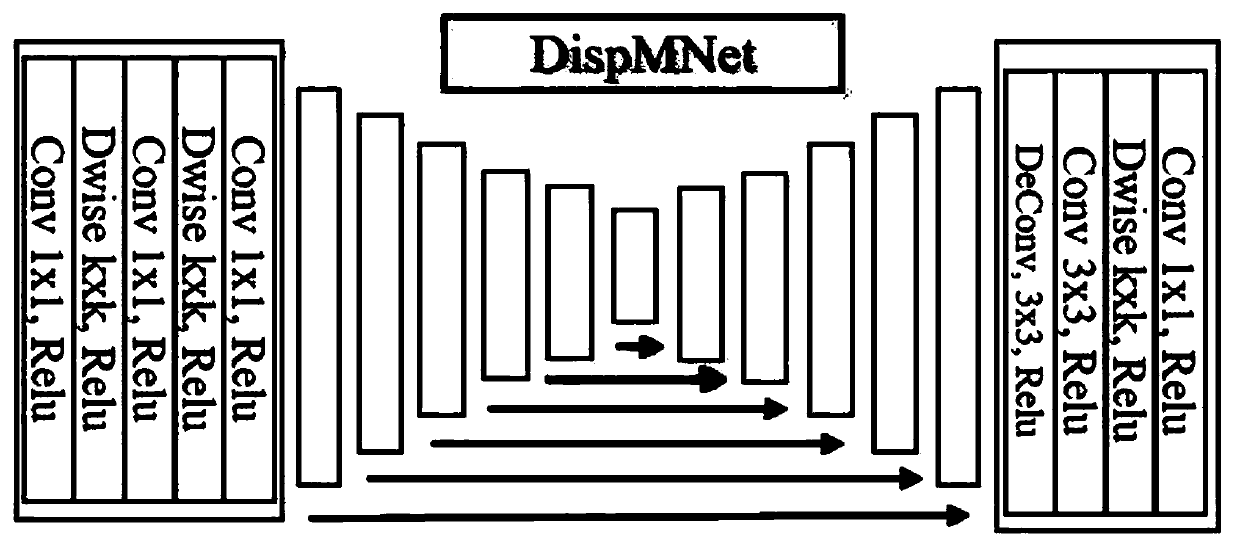

Unsupervised pose and depth calculation method and system

InactiveCN111028282AImproving pose estimation accuracy performanceImprove pose estimation accuracyImage enhancementImage analysisNetwork modelImage pair

The invention discloses an unsupervised pose and depth calculation method and a system. The unsupervised pose and depth calculation method mainly adopts the following modules: a pose prediction network model TNet, a depth estimation network model DMNet, a visual reconstruction model V and an error loss function module. The method comprises the steps of calculating a forward motion relative pose and a backward motion relative pose; calculating the depth estimation result of the image and the corresponding depth of the image, summing the reconstruction error, the smoothing error and the twin consistency error to obtain a loss function, performing iterative updating until the loss function converges, and finally calculating the relative pose and the predicted depth map of the camera accordingto the trained model Tnet and model DNet.

Owner:ADVANCED INST OF INFORMATION TECH AIIT PEKING UNIV +1

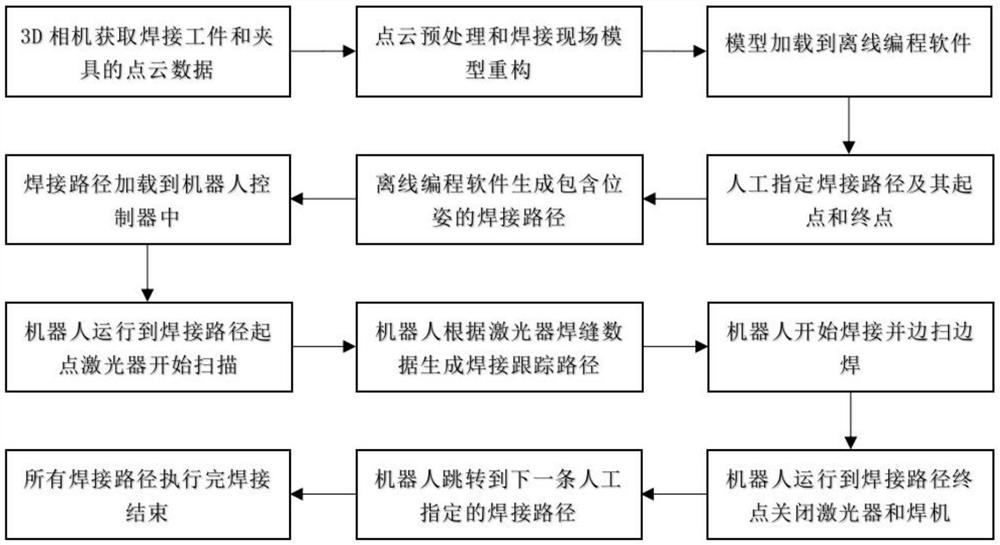

Off-line programming laser weld joint tracking system based on 3D vision

ActiveCN112453648ASolve the cumbersome teachingReduce the tediousness of teachingArc welding apparatusTotal factory controlPoint cloudModel reconstruction

The invention fuses a 3D vision reconstruction technology, an off-line programming technology and a weld joint tracking technology to realize unmanned welding sites, and provides an off-line programming laser weld joint tracking system based on 3D vision. The specific operation process is that a 3D camera is installed above a welding workpiece, remote triggering photographing is conducted after the workpiece is installed, and point cloud data of welding sites such as a workpiece and a clamp are obtained; and according to the off-line programming laser weld joint tracking system, three technologies of 3D visual model reconstruction, offline programming and laser welding joint tracking are fused and applied, so that unmanned welding site is realized. At present, the laser welding joint tracking technology can solve the problem of frequent demonstration due to large change of a part of welding paths, robot machining can be directly generated through off-line programming, however, based ona standard model, the increasingly mature 3D vision reconstruction technology is applied to welding application, and through the welding site reconstruction, the cumbersome demonstration of a weldingprocedure on the welding sites is reduced, and the welding efficiency is improved.

Owner:智昌科技集团股份有限公司

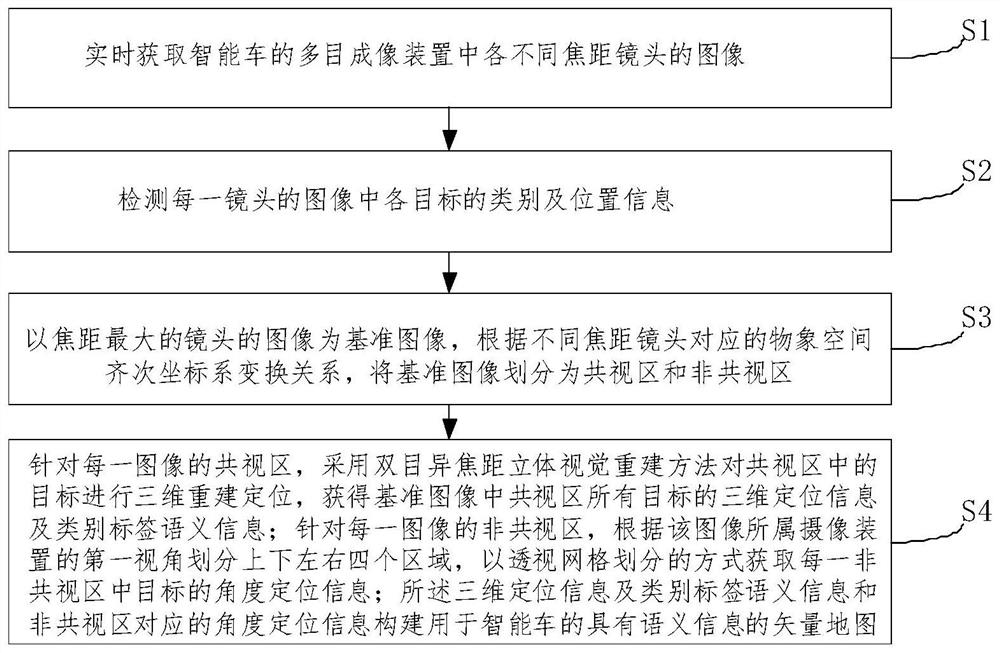

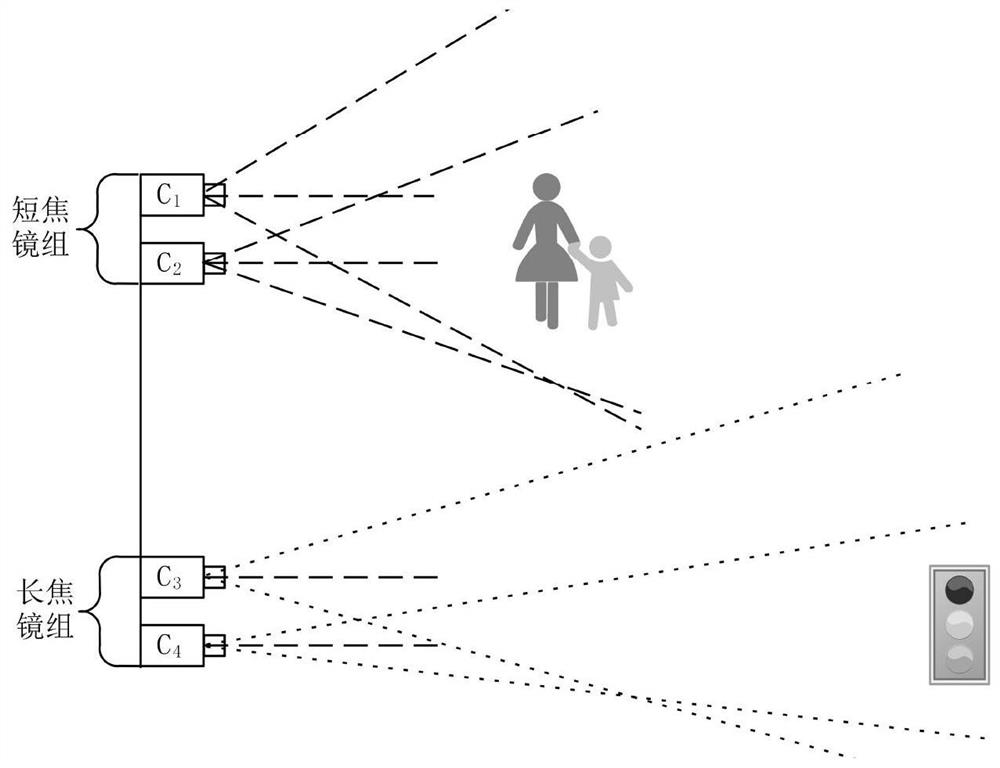

Intelligent vehicle target real-time detection and positioning method based on bionic vision

ActiveCN111914715AAchieve precise positioningSmall amount of calculationImage enhancementImage analysisPattern recognitionComputation complexity

The invention relates to an intelligent vehicle target real-time detection and positioning method based on bionic vision. The method comprises the steps of acquiring images of lenses with different focal lengths in a multi-view imaging device of an intelligent vehicle in real time; detecting the category and position information of each target in each image; dividing a reference image into a common-view area and a non-common-view area according to an object space homogeneous coordinate system transformation relationship of each lens; for the common-view area of each image, performing three-dimensional reconstruction positioning on a target in the common-view area by adopting a binocular different-focal-length stereoscopic vision reconstruction method to obtain three-dimensional positioninginformation and category label semantic information of the target; and for the non-common-view areas of the reference image, obtaining angle positioning information of a target in each non-common-view area so as to construct a vector map with semantic information for the intelligent vehicle. The method solves the technical problems that in the prior art, a three-dimensional semantic map cannot beconstructed on line in real time, and the calculation amount and the calculation complexity of visual point cloud data in unmanned driving cannot be reduced.

Owner:廊坊和易生活网络科技股份有限公司

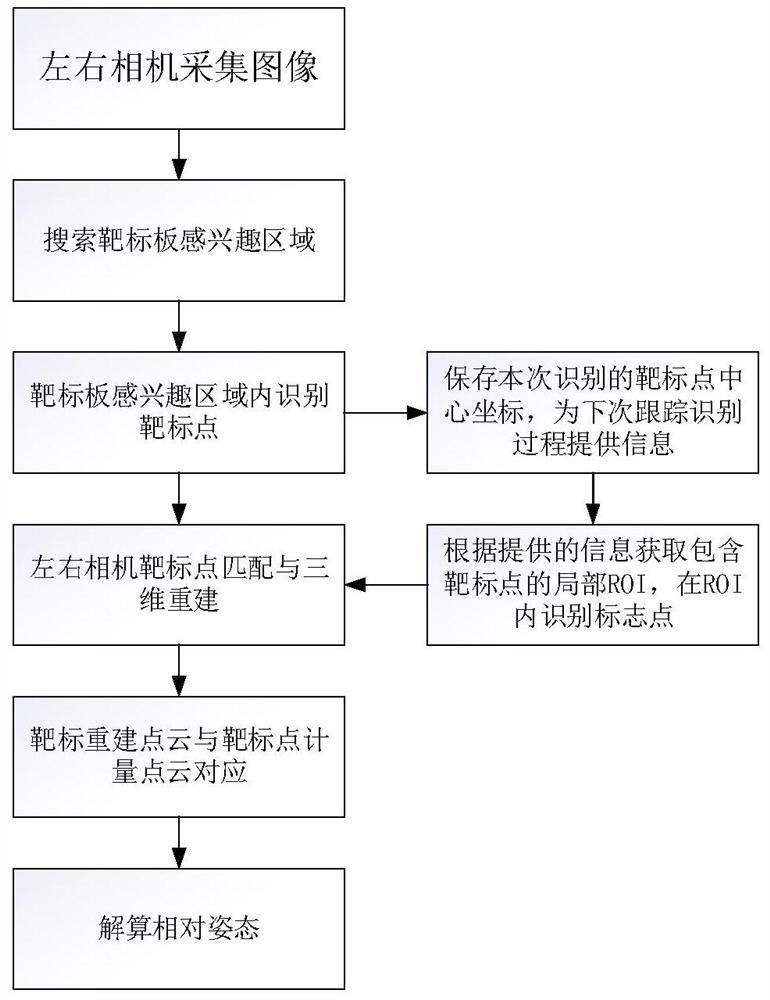

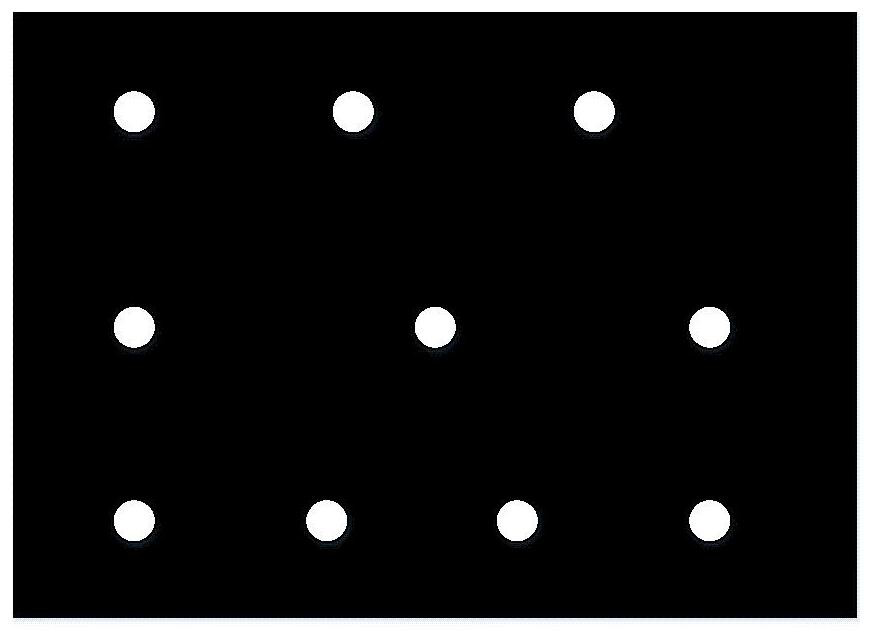

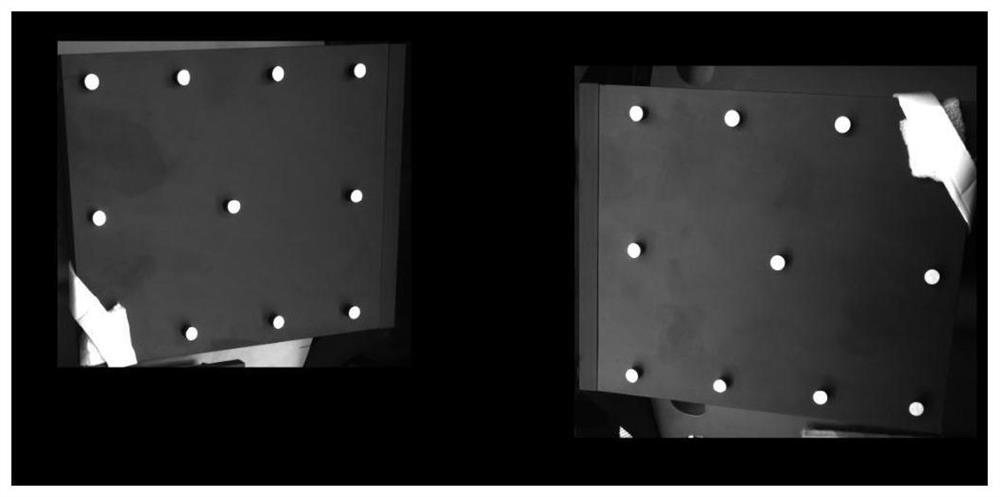

Multi-target identification tracking resolving method

ActiveCN111932565AReal-time acquisition of relative attitudeHigh measurement accuracyImage enhancementImage analysisPattern recognitionPoint cloud

The invention relates to a multi-target identification tracking resolving method. The method comprises the following steps of installing targets, acquiring images by left and right cameras, and positioning regions of interest of the targets; extracting mark points of a left target and a right target in the target interested area; matching left and right image target points according to epipolar constraint and homography transformation; recording the coordinates of the target mark point image obtained by the current tracking identification; three-coordinate measurement target point cloud Q, binocular vision reconstruction target three-dimensional point cloud P, traversal point cloud P and point cloud Q being carried out, three points being randomly taken out respectively to form a space triangle, and matching of corresponding points of the point cloud P and the point cloud Q being realized by comparing whether the three points are congruent triangles or not; and resolving a relative attitude matrix of the target according to a corresponding result of the reconstructed point cloud and the target point cloud. According to the method, real-time tracking, identification and calculationof a plurality of targets can be realized, positioning precision is high, and a new way suitable for target identification and calculation of a plurality of target working systems is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

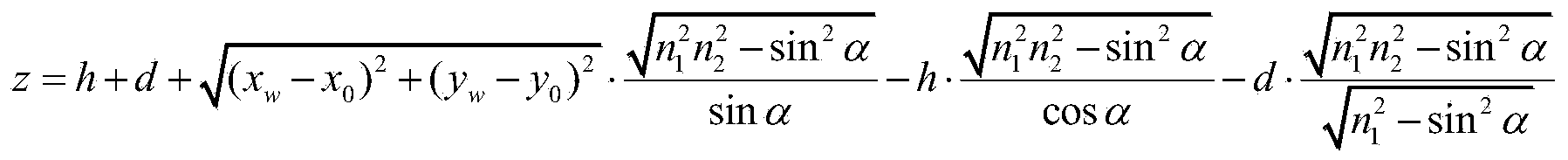

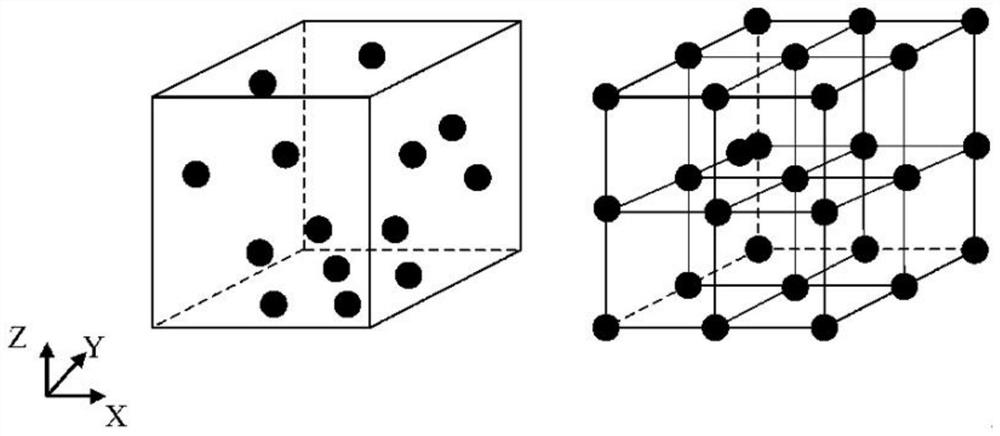

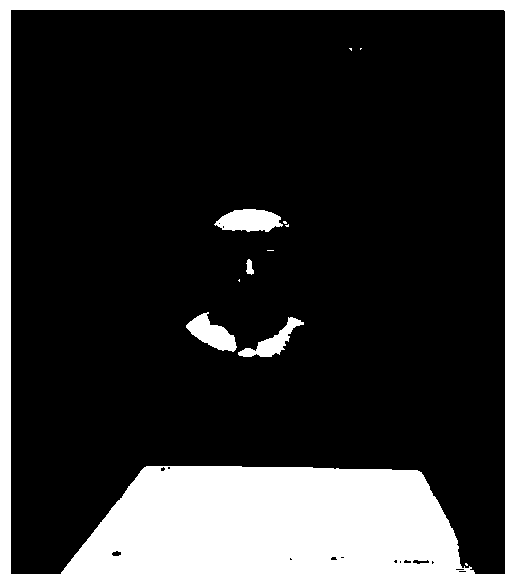

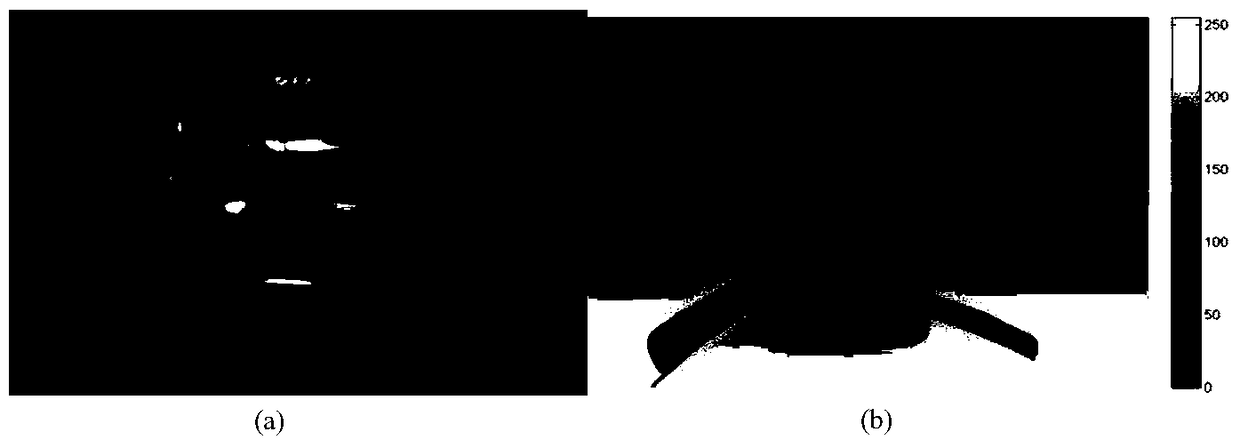

Method for achieving visual reconstruction of space coordinates of target point in water tank

The invention disclose a method for achieving visual reconstruction of the space coordinates of a target point in a water tank and belongs to the technical field of visual measurement. Two cameras (1), transmission wires (2), a computer (3) and the experimental water tank (4) are included, wherein the two cameras (1) are fixed outside the experimental water tank (4), used for observing the underwater target point (9) through the side wall (5) of the glass water tank and connected with the computer (3) through the transmission wires (2). The distorted coordinates are corrected through system calibration, coordinate system direction correction, target location and the like based on the geometrical relationship of light in stereoscopic vision imaging so as to obtain the real position of the underwater target point (9). According to the method, influence of refraction of media is fully taken into account, the coordinates of the underwater target point (9) are corrected without additionally arranging any testing device, and the real position of the underwater target point (9) is accurately obtained.

Owner:DALIAN UNIV OF TECH

Device and method of selecting an object for 3D printing

ActiveUS9922456B2Programme controlAdditive manufacturing apparatusComputer graphics (images)Visual reconstruction

Aspects of the technology include method of selecting an object from a videogame for 3D printing. The method involves periodically rendering a virtual environment of a videogame for display at a succession of points in time. Information is periodically recorded that enables visual reconstruction of at least part of the virtual environment at a succession of points in time. A predetermined set of values is periodically recorded responsive to the state of the rendered virtual environment at a succession of points in time. The predetermined set of values enables a model of a selected part of the rendered virtual environment to be generated that is configured for 3D printing.

Owner:SONY COMPUTER ENTERTAINMENT INC

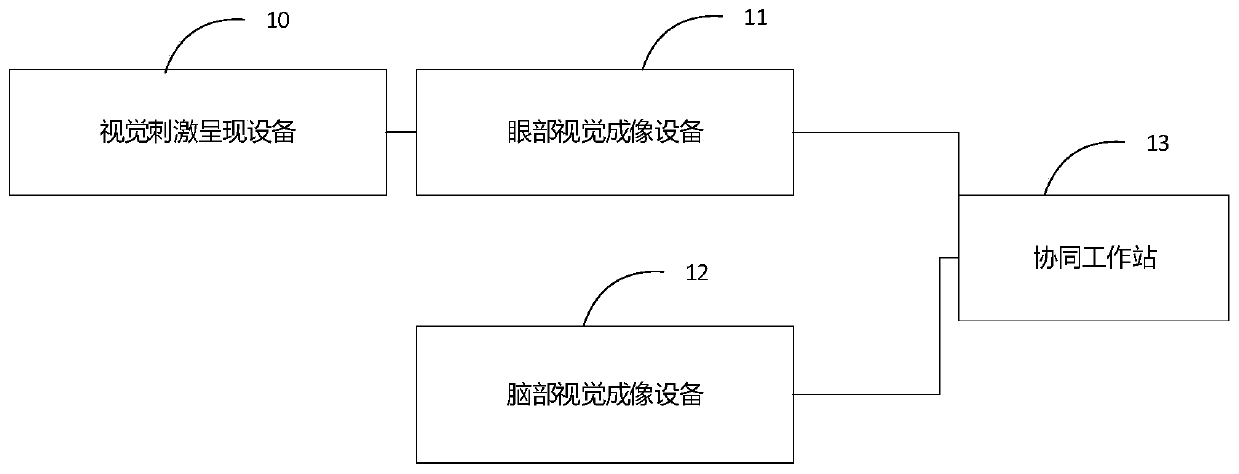

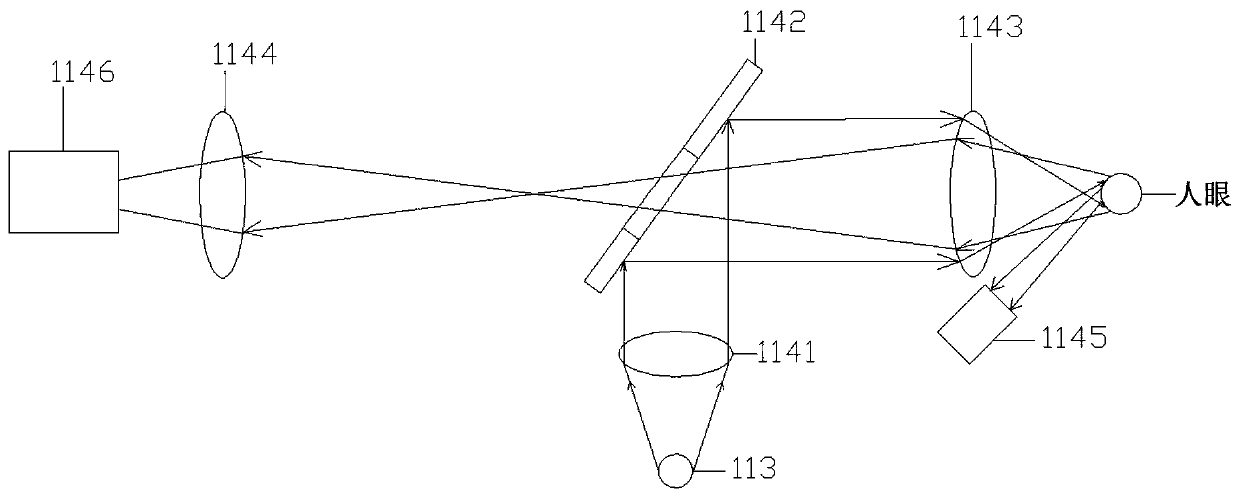

Integrated eye and brain visual function imaging system

PendingCN110236482AAccurate analysisComprehensively enrich the visual nerve function detection informationMedical imagingDiagnostics using spectroscopyVisual cortexDiagnostic Radiology Modality

The invention discloses an integrated eye and brain visual function imaging system. The system includes: a visual stimulus presentation device which presents pictures and videos comprising a plurality of stimulus-inducing patterns; an eye vision imaging device which is a retina and pupil imaging device based on multi-spectrum; a brain vision imaging device which is a visual cortex blood flow signal imaging device based on a spectrum technology related to near infrared diffusion; and a cooperative working station which comprises an imaging acquisition control module and an image analysis module and is used for cooperatively controlling the eye vision imaging device and the brain vision imaging device and processing and analyzing the acquired multispectral retina and pupil images and visual cortex blood flow images. The system can realize synchronous recording of nerve function response of eye retina, pupil and brain visual cortex, carry out joint analysis on multi-mode multi-parameter visual physiological signals, and provide a method for visual information coding and decoding, visual reconstruction mechanism research, visual nerve regulation and quantitative evaluation damage positioning and the like.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

FMRI visual reconstruction method based on discrete representation and conditional autoregression

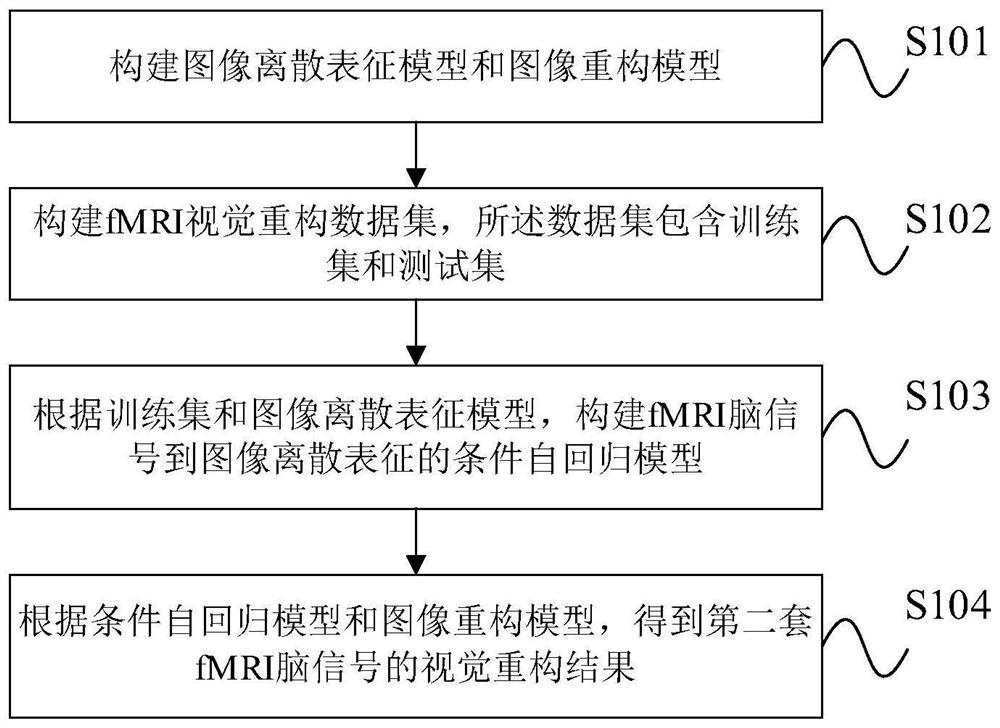

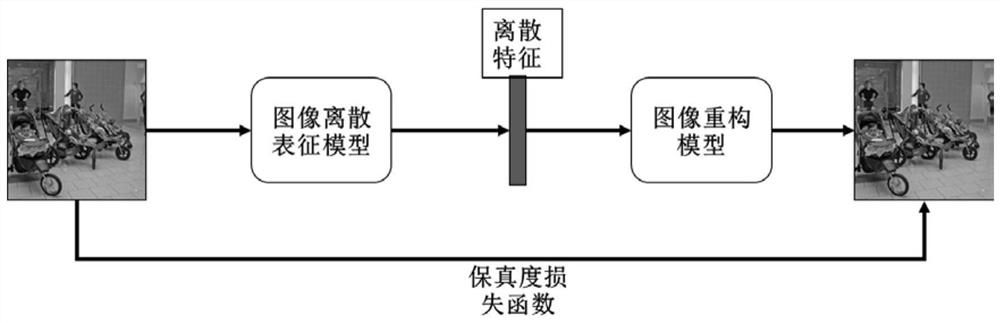

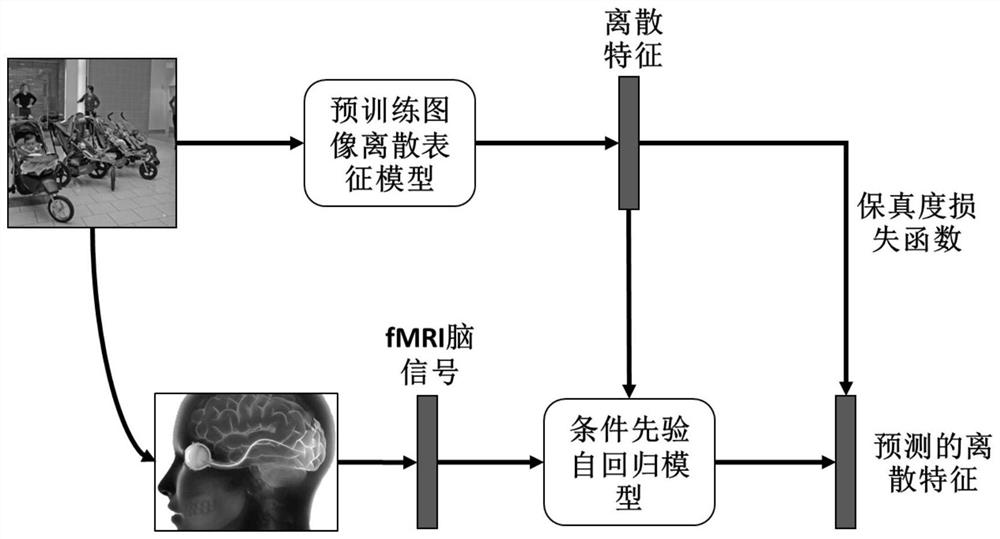

PendingCN112233199AImprove refactoring qualityGood match mapReconstruction from projectionNeural architecturesPattern recognitionData set

The invention provides an fMRI visual reconstruction method based on discrete representation and conditional autoregression. The method comprises the following steps: step 1, constructing an image discrete representation model and an image reconstruction model; step 2, creating an fMRI visual reconstruction data set, wherein the data set comprises a training set and a test set, and the training set comprises a first set of images and a first set of fMRI brain signals after a subject sees stimulation of the first set of images; wherein the test set comprises a second set of images and a secondset of fMRI brain signals after a subject sees stimulation of the second set of images; 3, constructing a conditional autoregression model from the fMRI brain signal to image discrete representation according to the training set and the image discrete representation model; and 4, obtaining a visual reconstruction result of the second set of fMRI brain signals according to the conditional autoregression model and the image reconstruction model. The method is mainly used for reconstruction of complex natural images.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

Zero sample image recognition method and recognition device thereof, medium and computer terminal

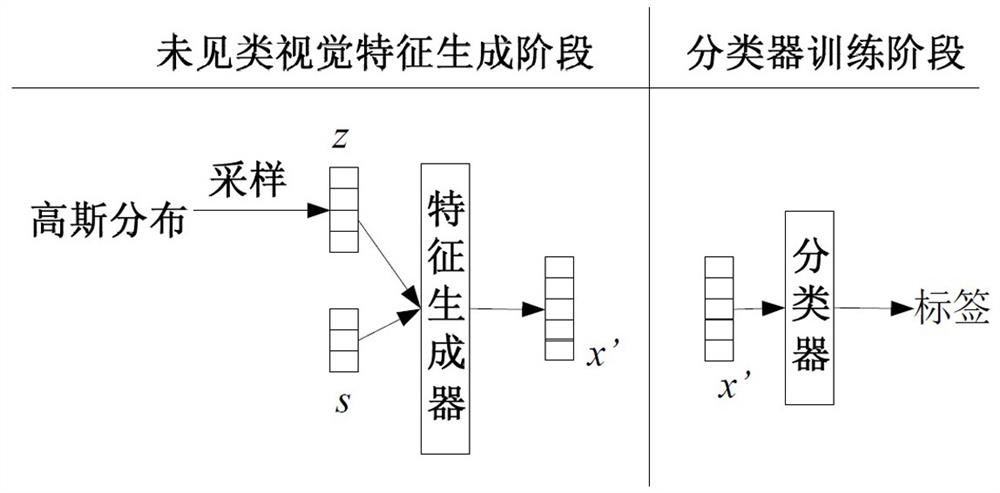

PendingCN114821196AClose to the true distributionIncrease class distinctionNeural architecturesSample imageComputer terminal

The invention relates to a zero sample image recognition method based on prototype domain alignment and cross-modal reconstruction. The method comprises the following main steps: extracting visual features of visible samples; obtaining visual distribution information of the visible images through a feature distribution encoder; obtaining generated visual features through a feature generator; training and optimizing parameters of the model of the feature generator by designing distribution regularization loss, domain consistency loss, visual reconstruction loss, adversarial loss and semantic reconstruction loss to obtain a trained feature generator; inputting the unseen class semantic features into a trained feature generator to obtain generated unseen class visual features; training an unseen class classifier by using the generated unseen class visual features; and utilizing the trained unseen class classifier to predict the unseen class image. According to the method, through prototype domain consistency alignment and cross-modal reconstruction, the generated visual features are closer to real visual features, and more category discrimination features are included.

Owner:ANHUI UNIVERSITY

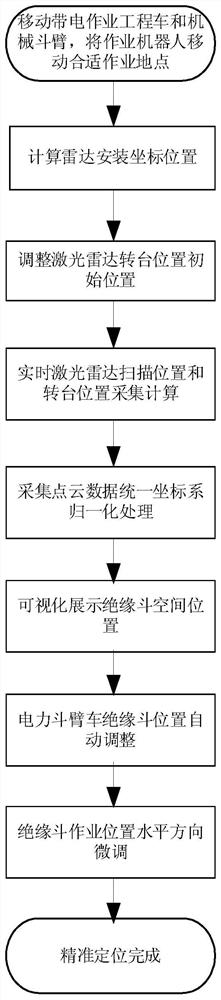

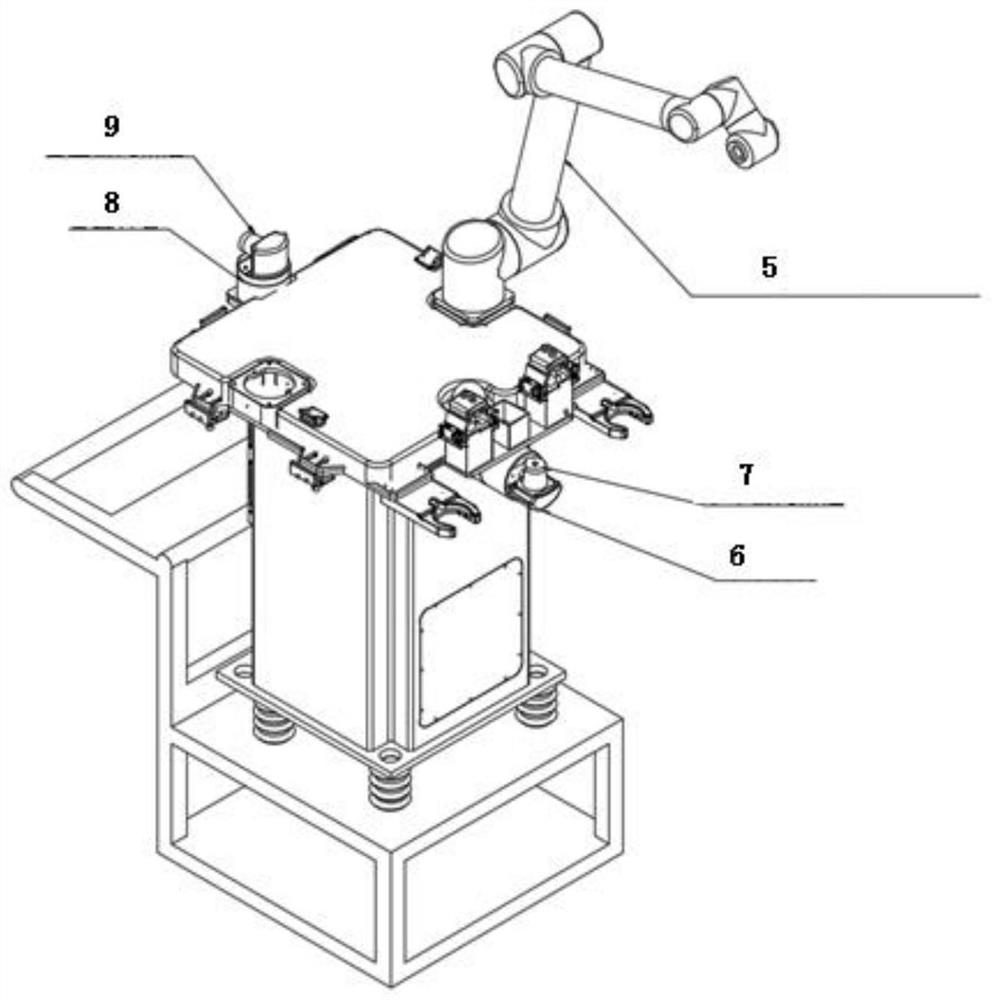

Method and system for accurately moving insulating bucket of distribution network hot-line work electric bucket arm vehicle

PendingCN112596517AVisual movementImplement security controlsPosition/course control in two dimensionsVehiclesPoint cloudRadar

The invention discloses a method and a system for accurately moving the insulating bucket of a distribution network hot-line work electric bucket arm vehicle. The method comprises the following steps:collecting the distance measurement data of vertical and horizontal laser radars and the rotation angle data of a vertical rotary table and a horizontal rotary table, and obtaining the spatial coordinate positions of the vertical and horizontal laser radars through calculation; visually displaying the real-time position of the space in a side view mode, and calculating to obtain a point cloud position corresponding to the row line; visually displaying the real-time position of the space in a top view mode, and calculating to obtain the optimal operation position; and adjusting the insulatingbucket of the electric bucket arm vehicle to operate to the optimal target position. According to the invention, through the methods of scene perception, visual reconstruction and spatial position solving, the manual qualitative movement of the insulating bucket arm is eliminated, the visual automatic movement of the insulating bucket arm is realized, and the field operation efficiency is improved.

Owner:NARI TECH CO LTD +3

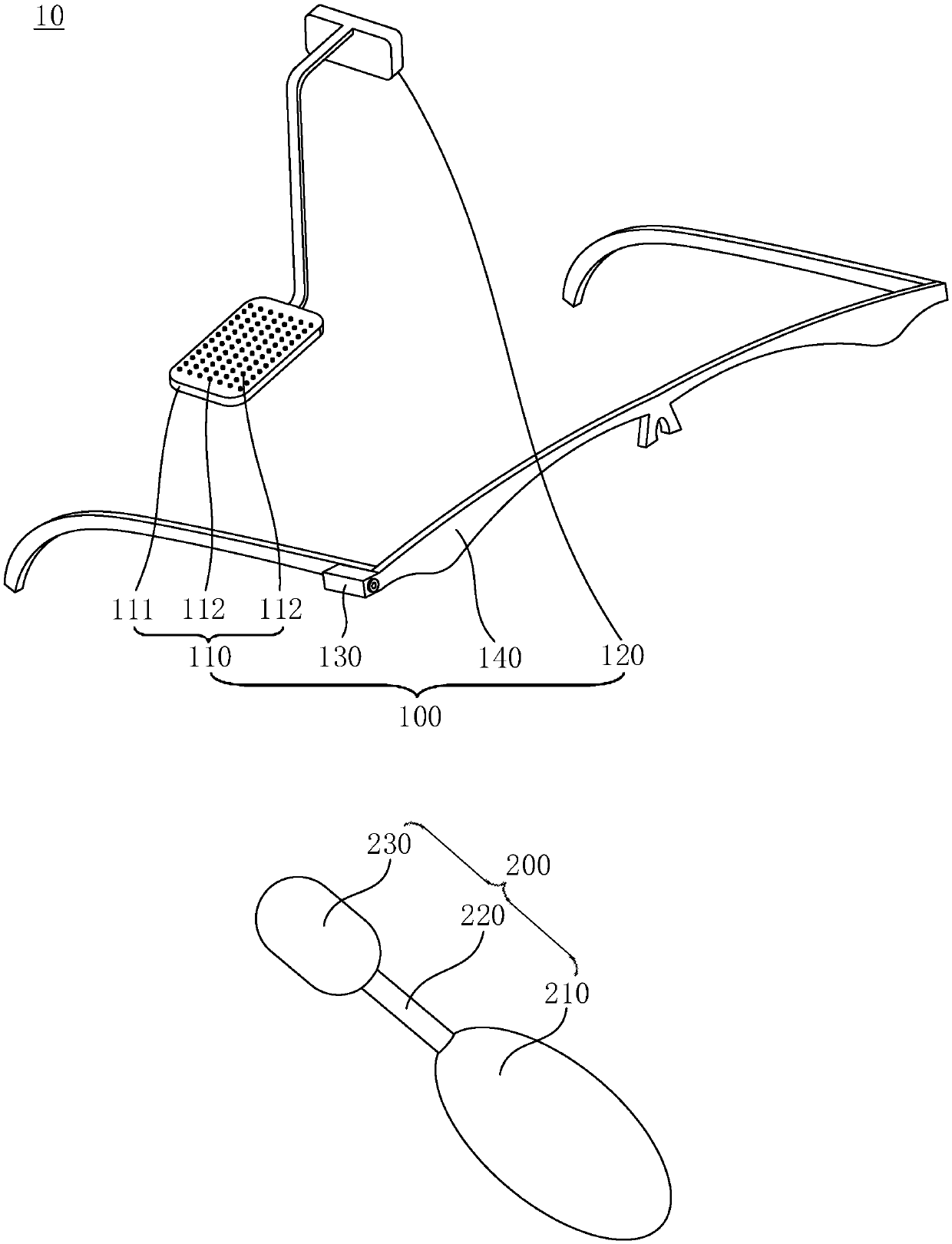

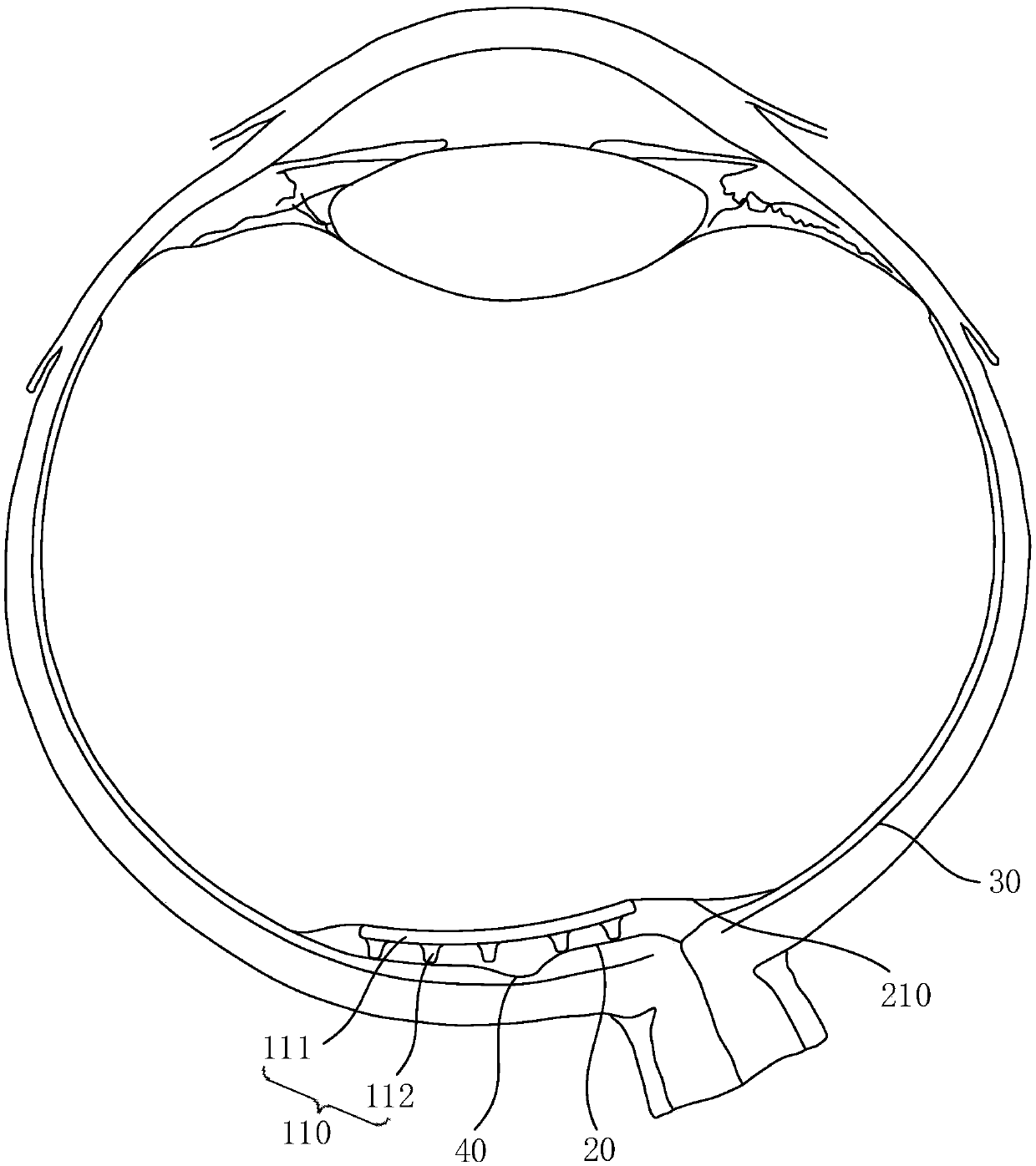

Visual reconstruction device

PendingCN109568790AReduce or avoid the risk of disengagementMinimize or avoid punctureHead electrodesExternal electrodesElectricityMedicine

The invention relates to a visual reconstruction device. The visual reconstruction device comprises a retina surface prosthesis and a pushing-pressing part, wherein the retina surface prosthesis comprises a signal receiver and a chip which are connected electrically; the signal receiver is used for receiving an external signal and transmitting a first electrical signal to the chip; the chip is used for transmitting a second electric signal for stimulating retinal ganglion cells after receiving the first electric signal; the pushing-pressing part comprise a balloon; both the balloon and the chip can be implanted into a vitreous body cavity; the balloon is used for pushing and pressing the chip against retina in order to realize the fixing of the chip. In a surgical process, an eyeball wallcan be prevented from being punctured, so that the visual reconstruction device has the characteristics of avoiding the generation of direct iatrogenic wound and achieving stable fixing.

Owner:ZHONGSHAN OPHTHALMIC CENT SUN YAT SEN UNIV

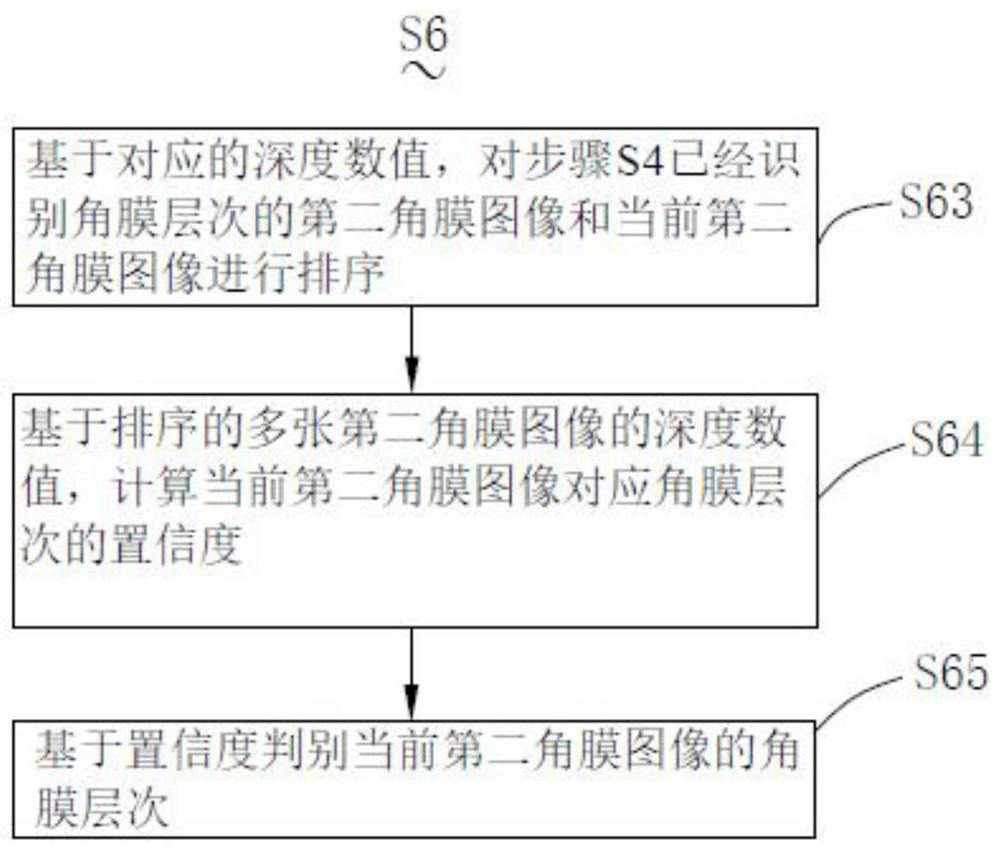

Image and depth-based cornea level identification and lesion positioning method and system

PendingCN112634221ARealize fully automatic hierarchical labelingRealize manual interventionImage enhancementImage analysisPattern recognitionRadiology

The invention relates to the field of medical artificial intelligence image identification, and particularly discloses an image and depth-based corneal hierarchy identification and lesion positioning method and system. After a corneal hierarchy image is obtained, image identification is carried out through a deep learning algorithm, the depth numerical analysis is carried out by combining with a machine learning algorithm, an anatomical level is automatically detected in cornea living body scanning, a level of a lesion or abnormal area can be accurately identified, visual reconstruction is performed on a lesion depth range, full-automatic level labeling and lesion positioning are realized, manual intervention is not needed, the labor cost is reduced, and meanwhile, corneal hierarchies are identified by using an analysis method integrated by multiple machine learning algorithms, the accuracy is high, and the effect is stable.

Owner:THE PEOPLES HOSPITAL OF GUANGXI ZHUANG AUTONOMOUS REGION

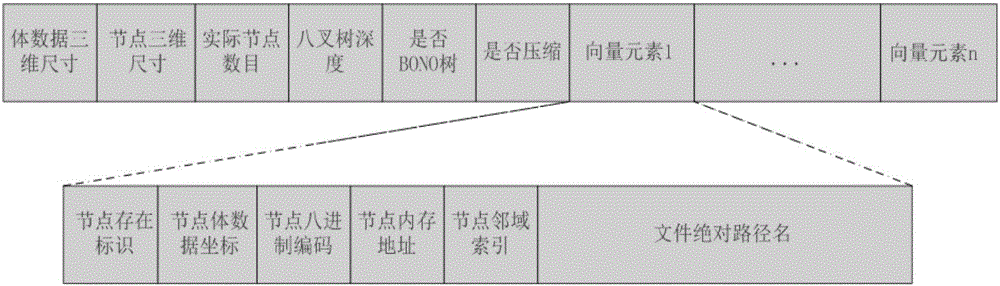

Octree parallel construction method for visual reconstruction of CT slice data

ActiveCN106846457AReduce duplicate data I/O overheadImprove data reuse effectImage memory managementProcessor architectures/configurationNODALParallel programming model

The invention relates to the field of parallel computation application technology and the field of high-performance scientific computation, in particular to an octree parallel construction method for visual reconstruction of CT slice data with a TB-level data processing ability. According to the method, octree parallel construction is performed based on an MPI+OpenMP parallel programming model by use of the characteristics of mesh generation of original volume data, non-dependency of octree node data, etc. based on the scheme of "construction on demand-Branch on need Octrees, BONOs" according to actual three-dimensional size of the volume data; on the one hand, waste of computation resources and storage resources and I / O expenditure in the construction process are reduced; and on the other hand, rapid octree data structure construction of the TB-level CT slice data is realized by means of parallel computation, and the MPI+OpenMP parallel programming technology meets the requirement for rapid construction of an octree data structural body of the TB-level CT slice data under different resolution requirements. The method has a good parallel speedup ratio and good parallel efficiency.

Owner:国家超级计算天津中心

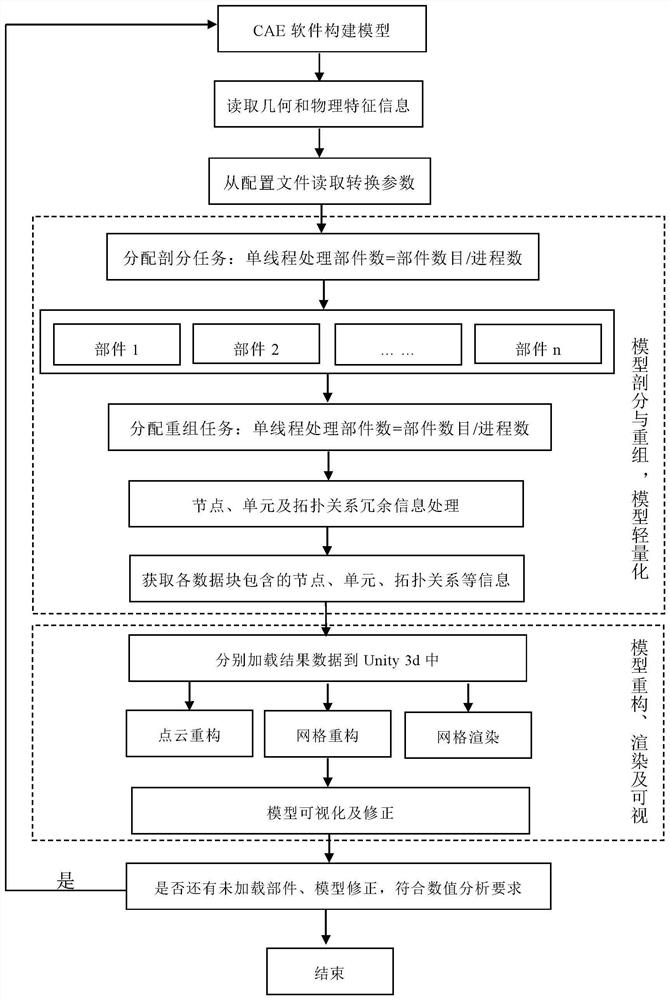

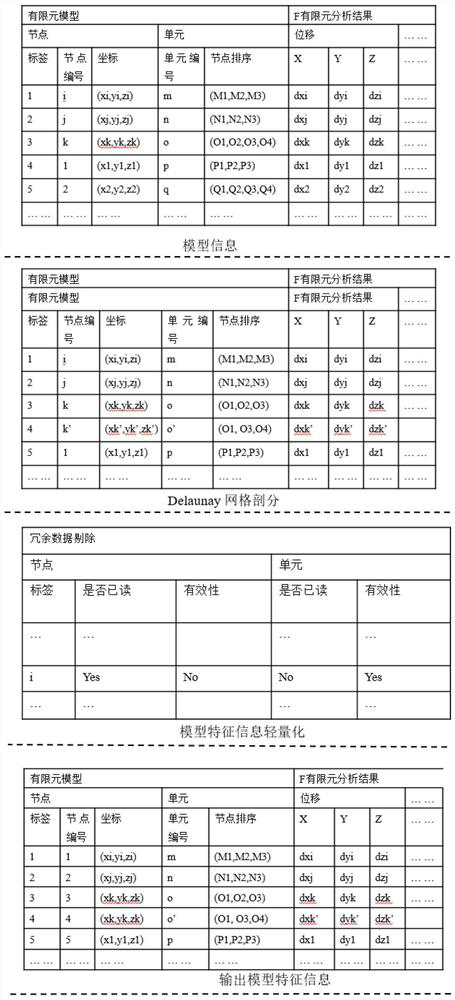

Virtual visual reconstruction method for ship structure finite element model

ActiveCN114633850ARapid refactoringReduce modeling errorsVessel designing3D-image renderingComputational scienceData transformation

The invention relates to a ship structure finite element model virtual visualization reconstruction method comprising the following steps: extracting finite element model characteristic information, pre-defining a general visualization data storage format function library and a configuration file, and generating a characteristic information file; establishing a data conversion interface through the predefined function library, reconstructing the finite element model, correcting three-dimensional point cloud data of the reconstructed model into a triangular network topological structure in a unified form, and processing and correcting the topological structure; the reconstructed finite element model is published through a system, and the virtual visualization reconstruction method of the ship structure finite element model is achieved. According to the method, the finite element analysis technology and the virtual reality technology are combined, efficient inspection and correction of the quality of the finite element grid can be achieved, and an effective way is provided for visualization of postprocessing of the finite element analysis result.

Owner:SHANGHAI JIAO TONG UNIV

Ultrasonic or CT medical image three-dimensional reconstruction method based on feature migration

ActiveCN112700534AImprove accuracyImprove the efficiency of auxiliary diagnosisNeural architecturesNeural learning methodsNuclear medicineUnsupervised learning

The invention discloses an ultrasonic or CT medical image three-dimensional reconstruction method based on feature migration. Feature migration from an ultrasonic image to a CT image is realized by adopting unsupervised learning, utilizing a visual method and by feature migration principle and sharing a network parameter mechanism according to the characteristics of medical image acquisition. The three-dimensional reconstruction of the ultrasonic image and the CT image can be realized, the three-dimensional reconstruction of the ultrasonic image or the CT image can be effectively realized, and a rapid 3D visual reconstruction result can be provided in artificial intelligence auxiliary diagnosis, so that the efficiency of the auxiliary diagnosis is improved.

Owner:EAST CHINA NORMAL UNIV

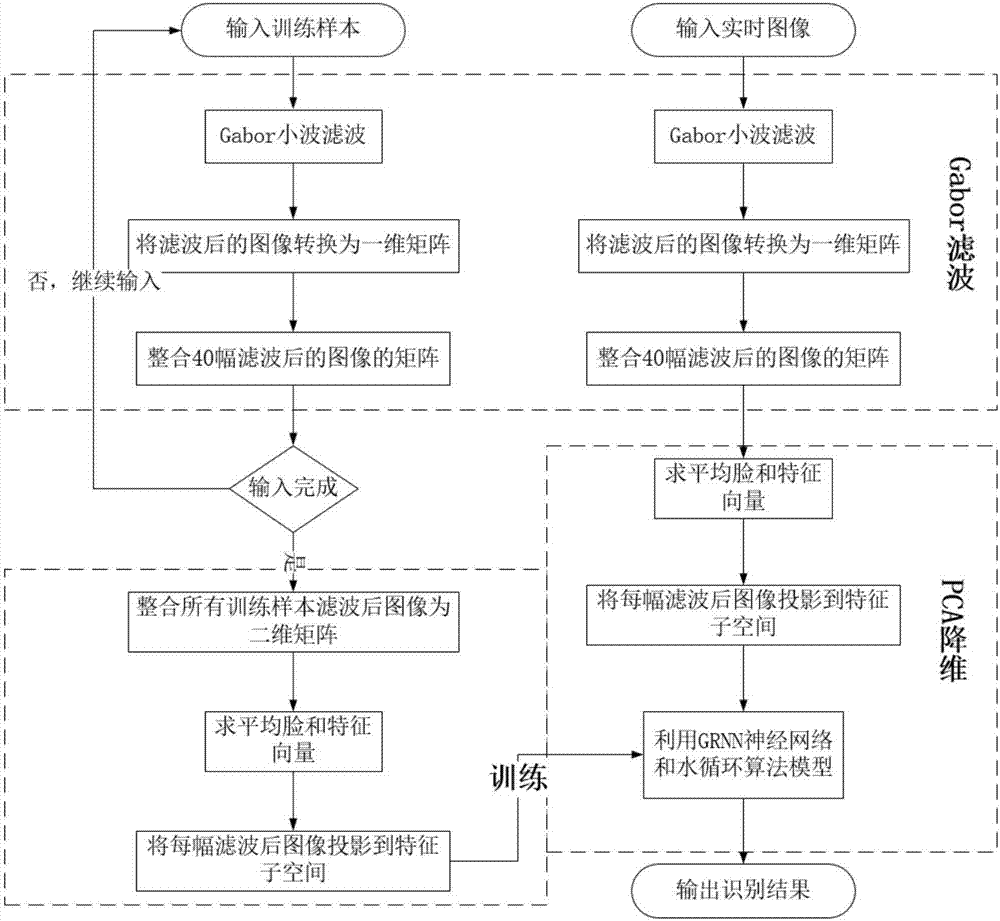

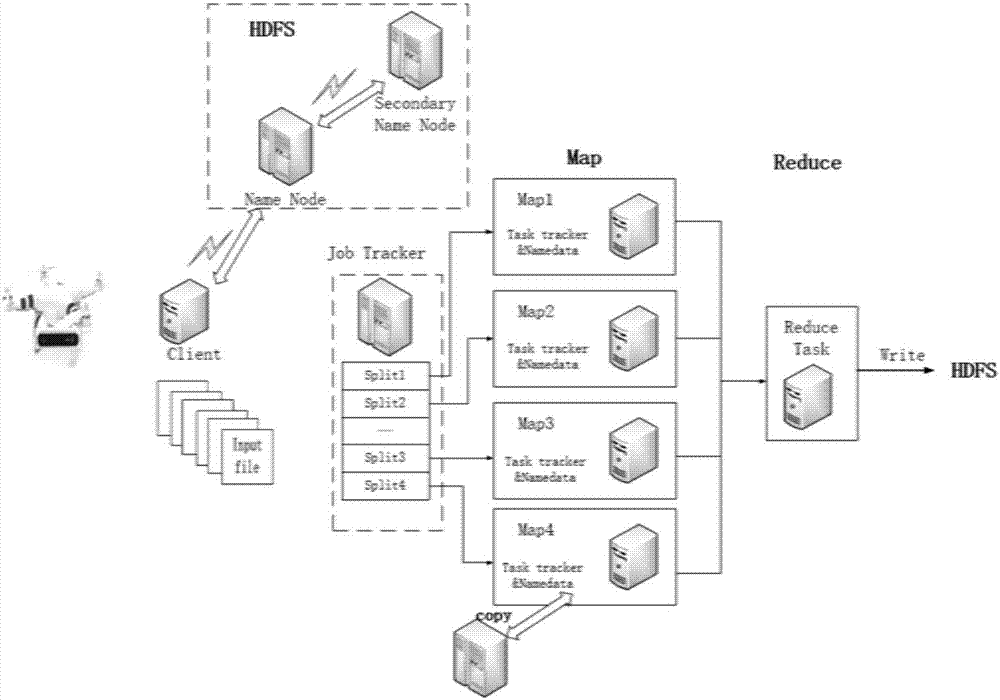

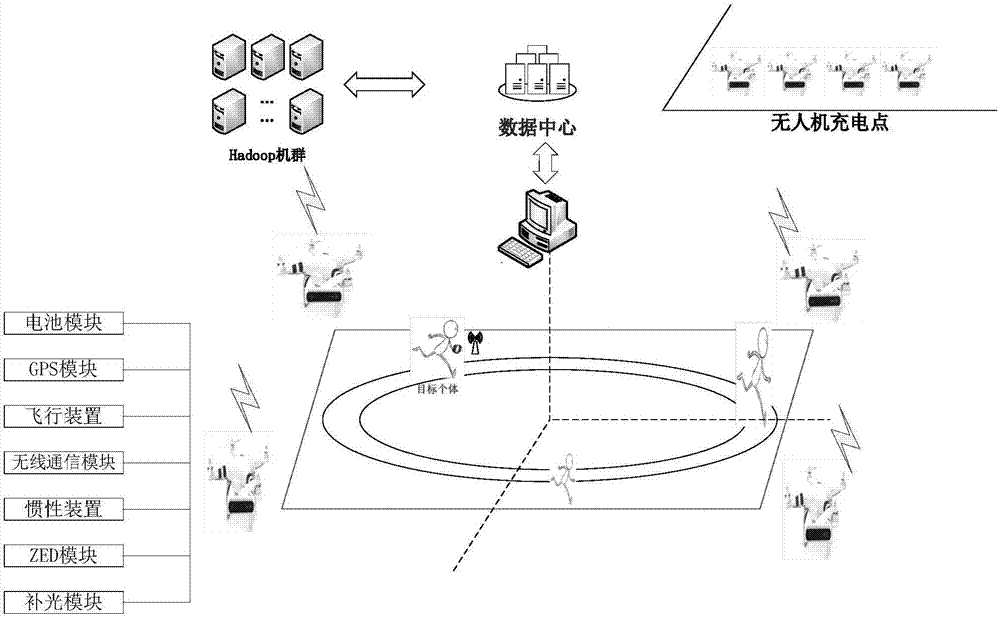

UAV human body health monitoring method and system based on intelligent visual reconstruction

InactiveCN107967941AImprove recognition efficiencyShorten the training periodHealth-index calculationCharacter and pattern recognitionHuman bodyNerve network

The invention discloses a UAV human body health monitoring method and a UAV human body health monitoring system based on intelligent visual reconstruction. The UAV human body health monitoring methodcomprises the steps of: step 1, constructing a human body natural physical sign database and a human body extreme sports database; step 2, utilizing human body heights obtained by means of a ZED camera carried on a UAV to screen a human body group to be identified; step 3, step 3, performing rapid identification on human body face images to be identified by utilizing a generalized regression neural network based on a Hadoop platform; step 4, tracking identified human bodies by means of the UAV, acquiring health data of human bodies to be identified and transmitting the health data to a remoteserver by means of wearable equipment; step 5, and inputting the acquired health data into a human body health assessment model based on a PID neural network, so as to obtain health detection degreesof the human bodies to be identified. The UAV human body health monitoring method and the UAV human body health monitoring system are based on a big data platform, employ the wearable equipment, the UAV and the binocular camera to acquire outdoor sports human body health information, and perform real-time health monitoring, so as to make a reasonable decision.

Owner:CENT SOUTH UNIV

Ultrasonic image three-dimensional reconstruction method for intelligent medical auxiliary diagnosis

ActiveCN112700535ARealize 3D reconstructionImprove the efficiency of auxiliary diagnosisNeural architecturesNeural learning methodsMedicineReconstruction method

The invention discloses an ultrasonic image three-dimensional reconstruction method for intelligent medical auxiliary diagnosis, and the method is characterized in that the method achieves the unsupervised learning and training, can obtain a three-dimensional structure according to an inputted ultrasonic image sequence, designs three convolutional neural networks A, B and C, obtains network parameters through training. A three-dimensional structure of an ultrasonic image is acquired. Three-dimensional reconstruction of the ultrasonic image can be effectively achieved, in artificial intelligence auxiliary diagnosis, the effect of auxiliary diagnosis and the 3D visual reconstruction result are brought into full play, and the efficiency of auxiliary diagnosis can be improved.

Owner:EAST CHINA NORMAL UNIV

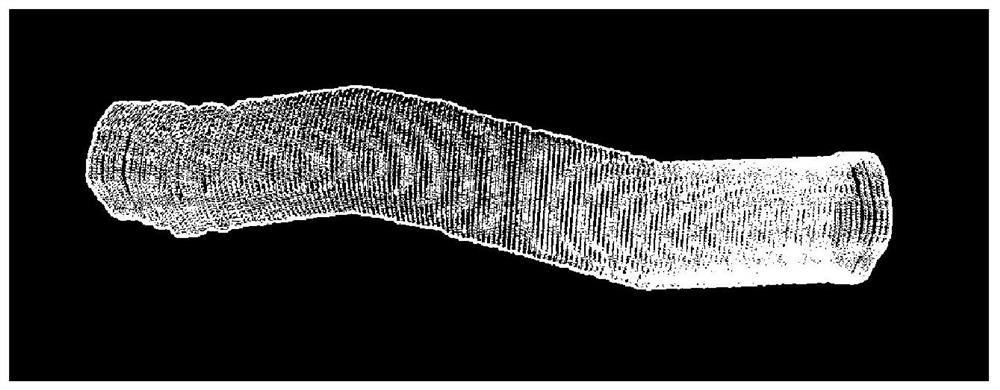

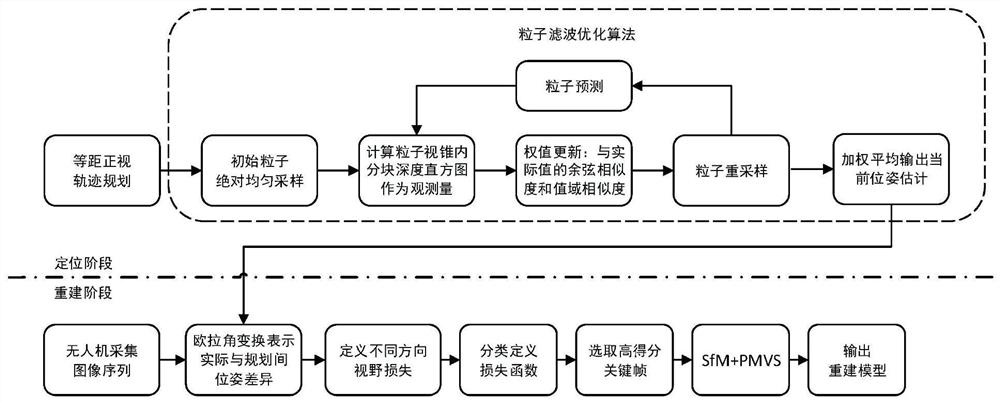

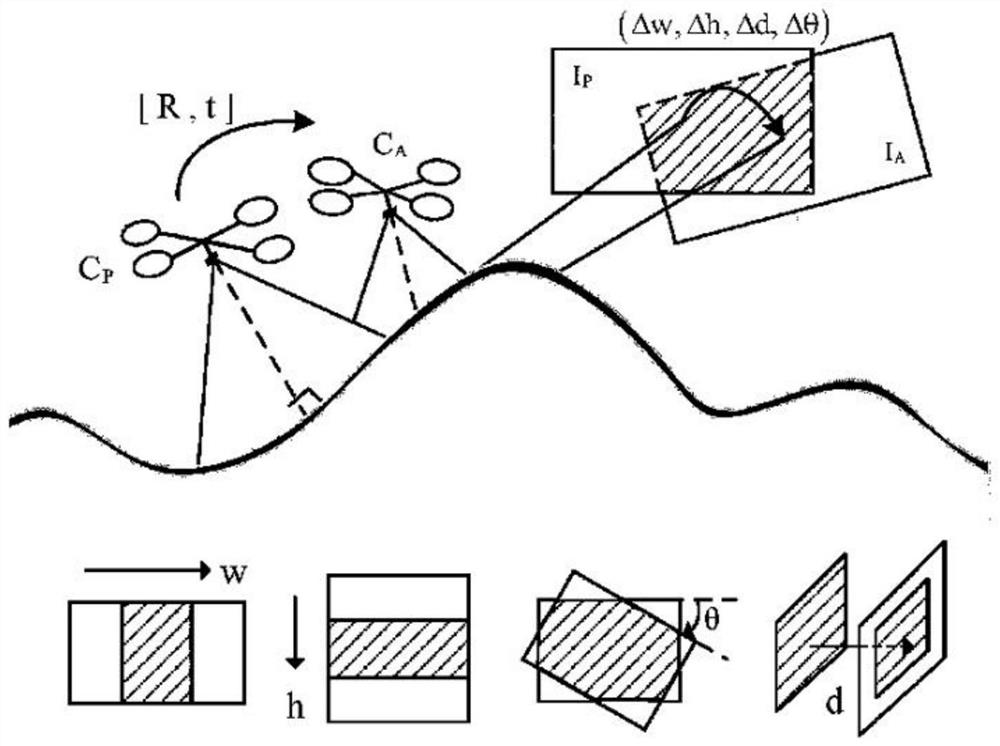

Three-dimensional reconstruction error active correction method based on unmanned aerial vehicle

ActiveCN113436313AAccurate estimateQuantitative definitionImage enhancementImage analysisComputer graphics (images)Uncrewed vehicle

The invention provides a three-dimensional reconstruction error active correction method based on an unmanned aerial vehicle, and the method comprises the following steps: planning a shooting track of the unmanned aerial vehicle through employing an equidistant front view constraint, so as to achieve an expected three-dimensional reconstruction optimization effect; positioning the airborne camera of the unmanned aerial vehicle through an improved particle filter positioning algorithm based on a block depth histogram; designing a group of quantitative indexes to evaluate the image view loss caused by the error between the actual flight and the expected planning pose; and selecting a key frame from the image acquired by the unmanned aerial vehicle to participate in reconstruction according to the view overlapping rate and the loss function score. According to the method, the reconstruction track of the unmanned aerial vehicle is planned by adopting the equidistant front view constraint, a particle filtering optimization method based on depth block histogram analysis is provided to accurately position the unmanned aerial vehicle, and a group of quantitative indexes is further designed to evaluate the expected view loss of the image caused by the pose error, and the key frames participating in the three-dimensional reconstruction are reselected, so that the visual reconstruction effect is enhanced.

Owner:NANKAI UNIV

A 3D Vision Reconstruction Method

ActiveCN105698708BMake up for defects that cannot be rebuiltRealize 3D reconstructionDetails involving processing stepsUsing optical meansThree dimensional measurementReconstruction method

The invention relates to the technology of structured light measurement and specifically relates to a three-dimensional visual sense reconstruction method, comprising following steps: establishing a three-dimensional measurement system; projecting a sine projection pattern with phase shift by a projector and capturing modulated sine pattern on a measured object surface with a camera in real time by use of a multi-frequency phase measuring profilometry structured light scan method, and calculating measured object surface phase information according to the multi-frequency phase measuring profilometry phase developing method; calculating the relative depth of the measured object by use of torsion resistance which changes with the surface depth of the measured object for the phase pattern in space, and realizing three-dimensional reconstruction according to the relative depth. The method can be applied in situations where complicated calibration cannot be realized due to condition limiting, calibration is difficult to carried out, or only low precision three-dimensional coordinate image reconstruction is required to quickly realize three-dimensional reconstruction; the method gives a solution to the problem that the present three-dimensional reconstruction method can not be carried out with insufficient calibrating data; the method has wide applications in the field of archaeology and three-dimensional data visualization.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com