Off-line programming laser weld joint tracking system based on 3D vision

An off-line programming and tracking system technology, applied in welding equipment, arc welding equipment, comprehensive factory control, etc., can solve the problems of increasing production and manufacturing costs and time consumption costs of enterprises, large changes in weld position and size, etc., to solve personal problems damage, improve welding efficiency, and reduce the cumbersome effects of welding program teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

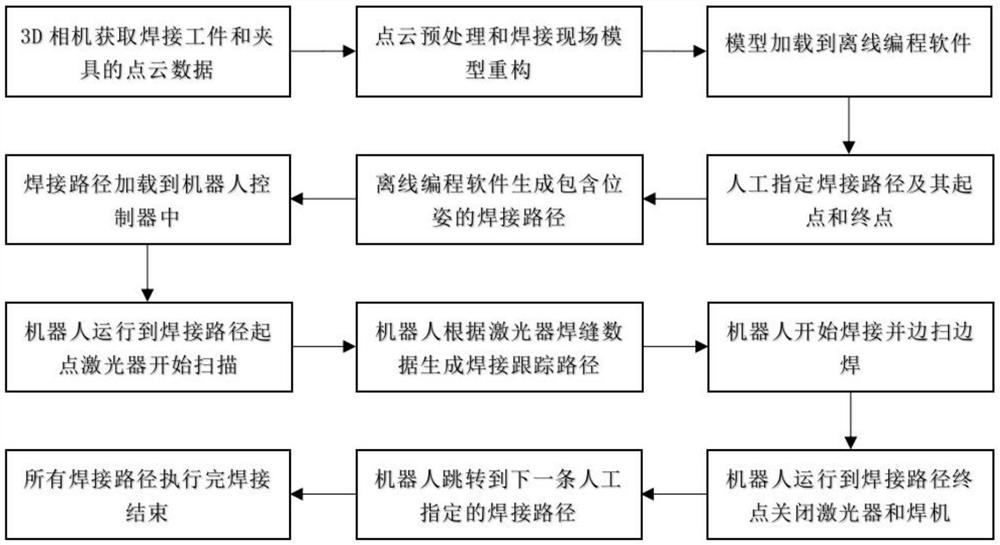

[0030] An off-line programming laser seam tracking system based on 3D vision, its specific operation process is as follows:

[0031] 1. The 3D camera is installed above the welding workpiece. After the workpiece is installed, the camera is remotely triggered to obtain the point cloud data of the welding site such as the workpiece and fixture;

[0032] 2. Point cloud data preprocessing, including point cloud coordinate transformation, point cloud segmentation and extraction, point cloud noise removal and point cloud data simplification;

[0033] 3. Generate a 3D model of the welding site after preprocessing the point cloud data, and reconstruct the 3D model of the welding site. The model information includes welding workpieces, fixtures and welding platforms, etc.;

[0034] 4. The 3D model is loaded into the offline programming software, and the offline programming software can perform basic operations such as rotating and translating the model and selecting points, lines and s...

Embodiment 2

[0043] The implementation principle of the present invention is: the present invention combines 3D visual reconstruction technology, offline programming technology and welding seam tracking technology to realize unmanned welding site.

[0044] 3D visual reconstruction technology obtains the original 3D point cloud data of the shape of the welding workpiece and fixture through the 3D camera, and preprocesses the original 3D point cloud data to reconstruct the 3D welding site;

[0045] Off-line programming technology automatically loads the 3D model into the off-line programming software, manually determines the starting point and end point of welding, and specifies the welding sequence of the weld seam to generate a welding path including posture and position;

[0046] The welding seam tracking technology runs the robot to the starting point of the welding path, and the laser installed on the welding torch scans the welding seam position in advance and sends it to the robot. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com