Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

318 results about "Robot machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

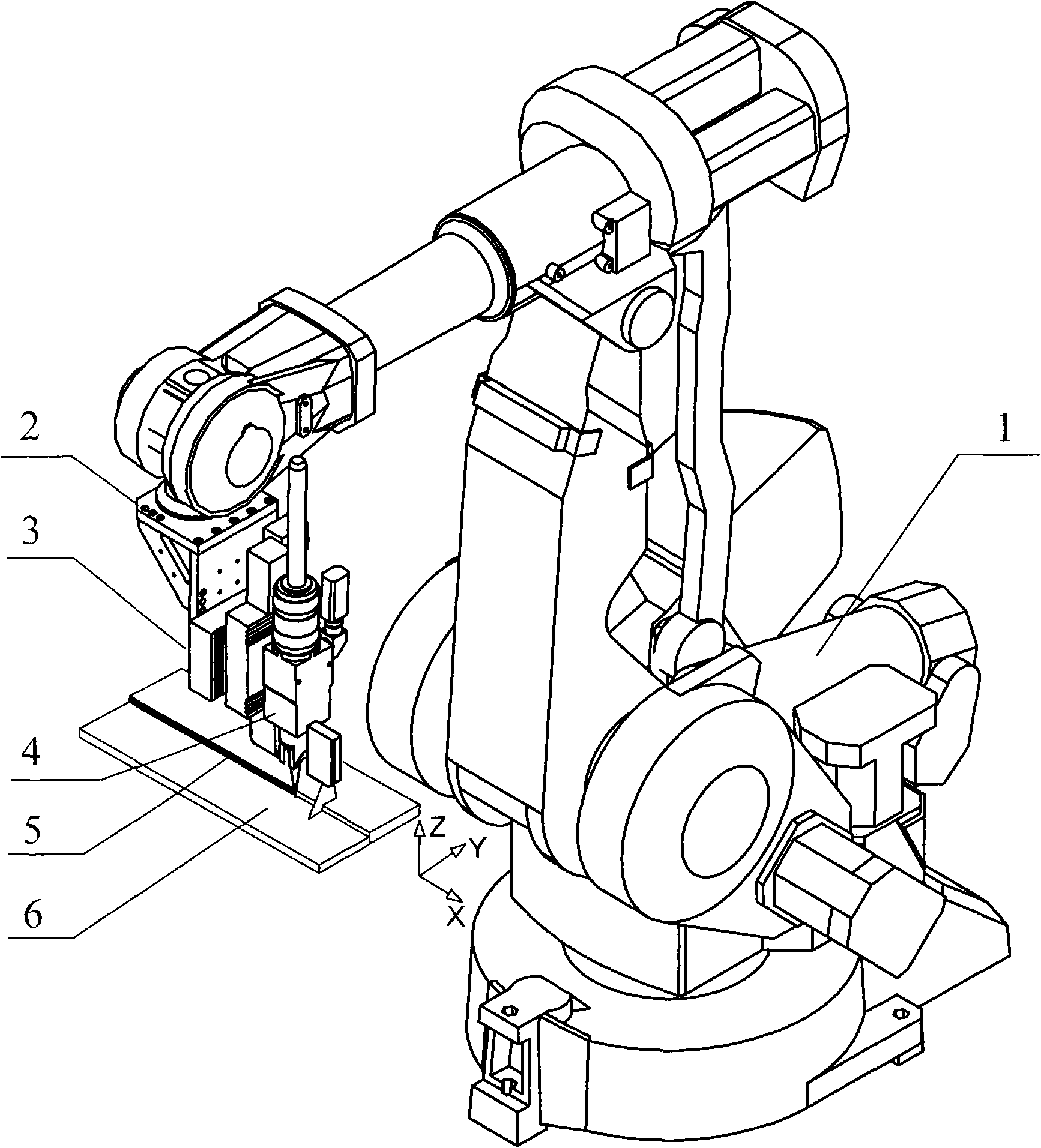

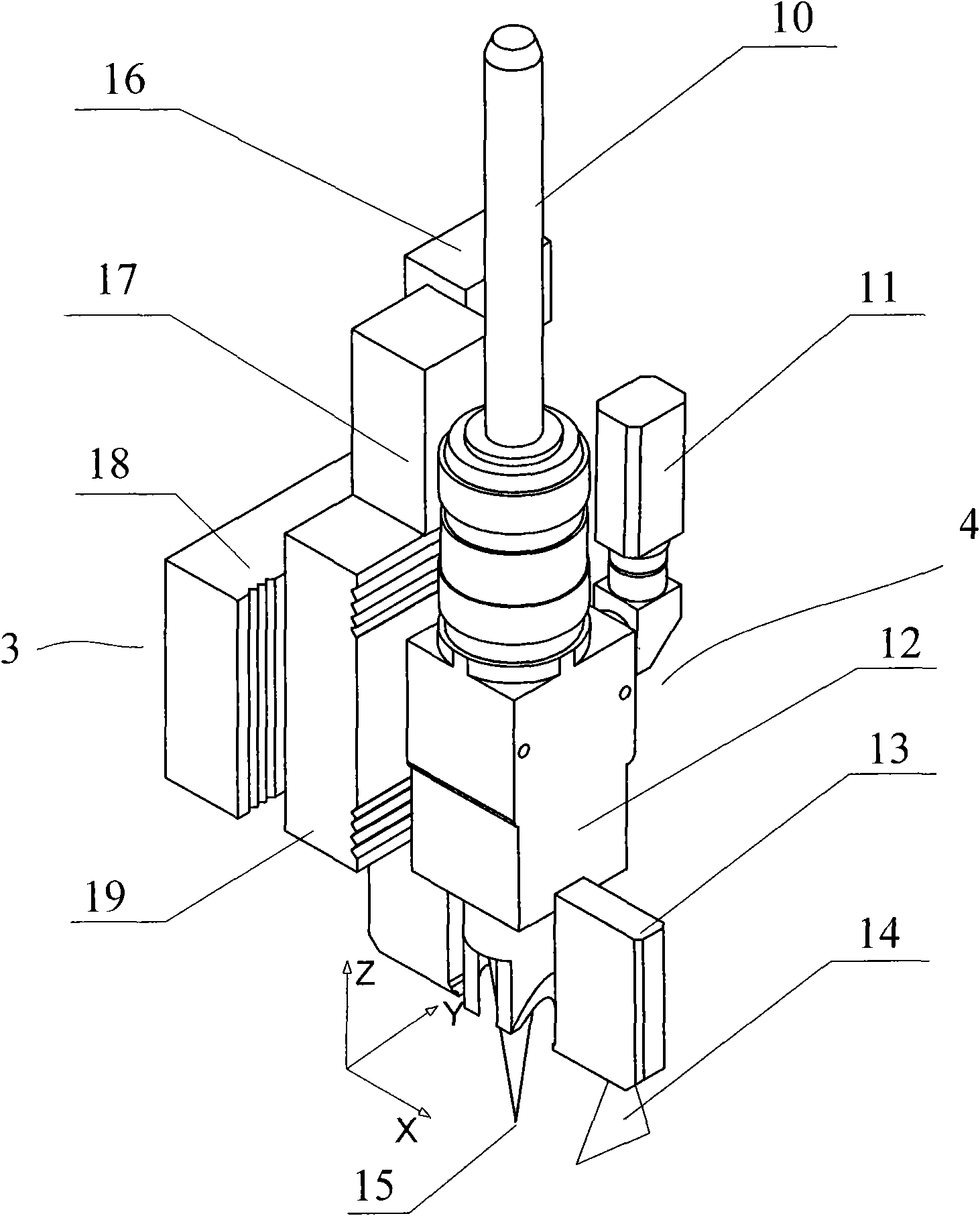

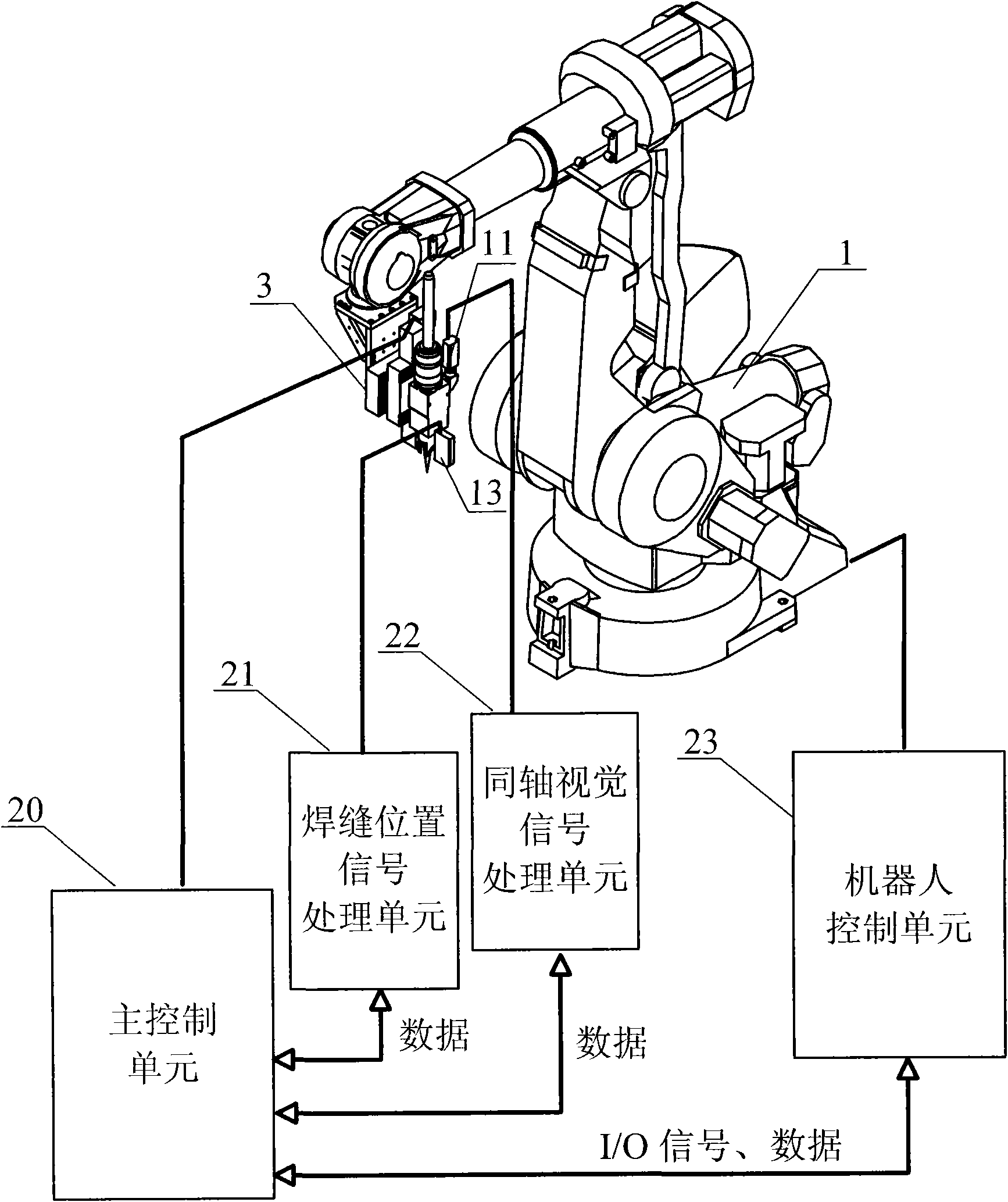

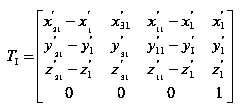

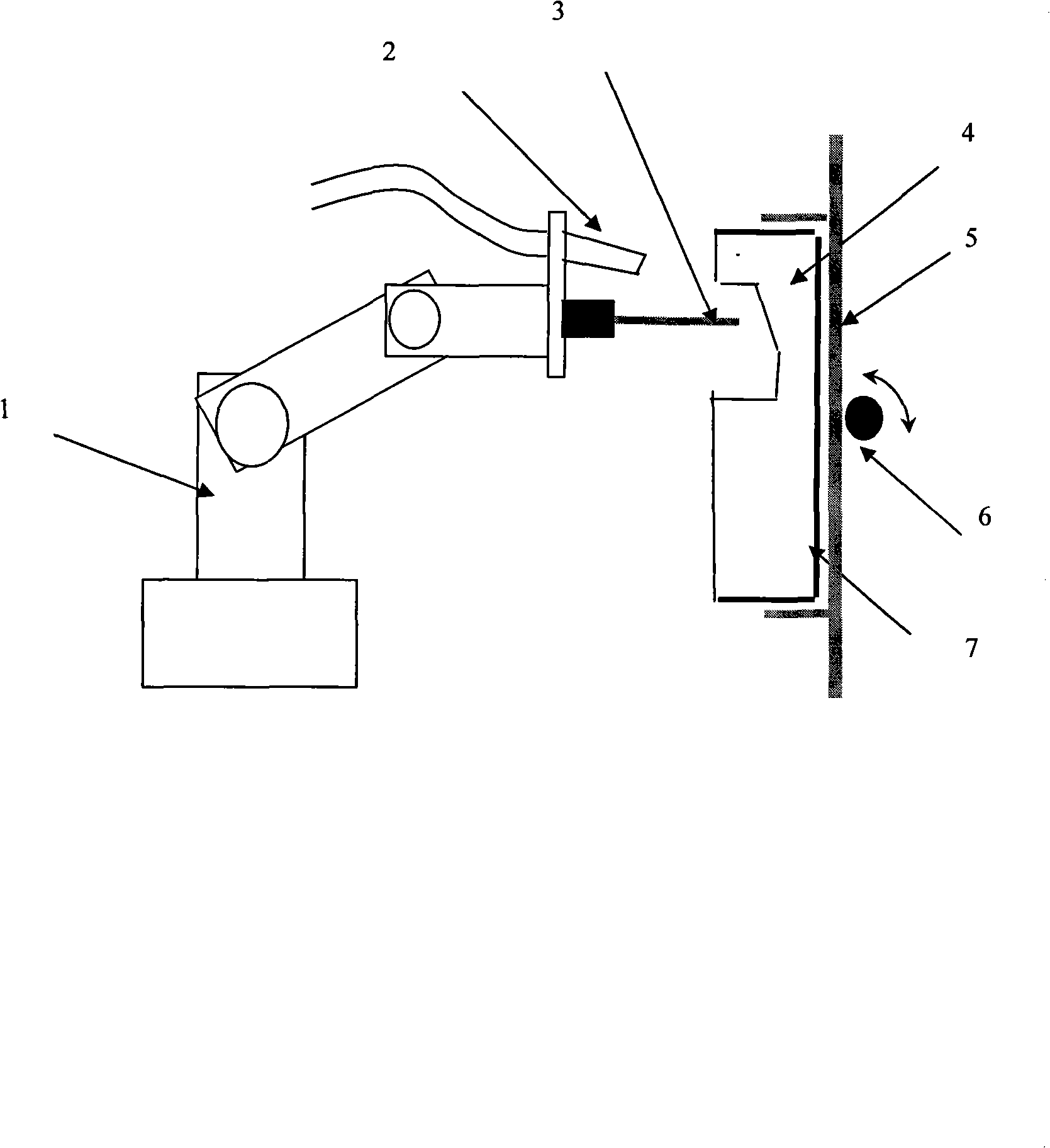

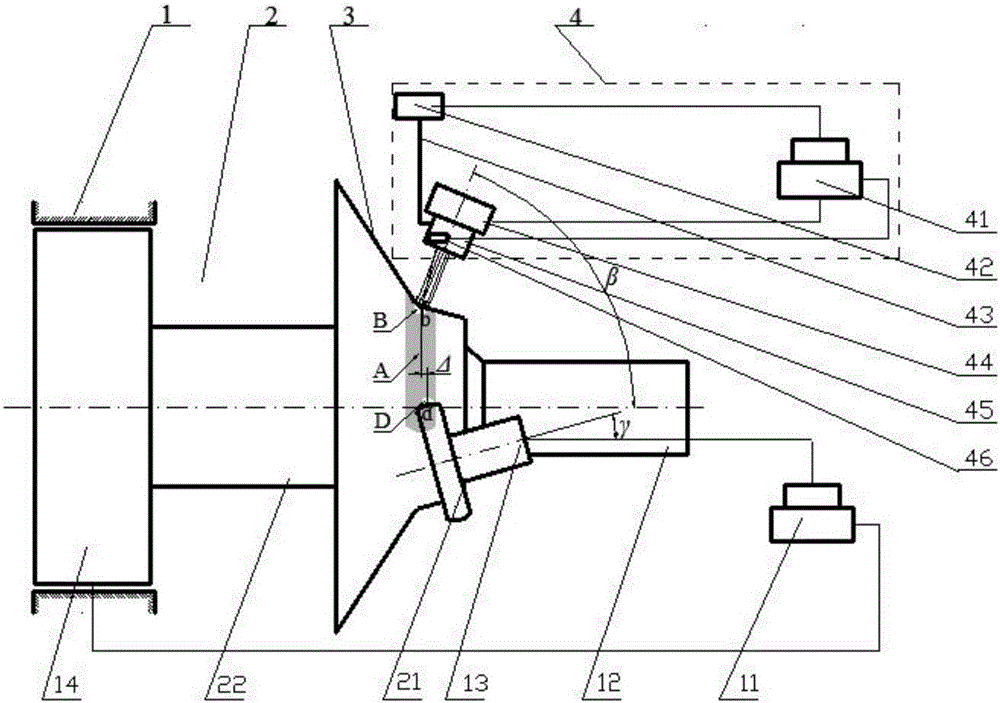

Device and method for making robot track given route at high accuracy

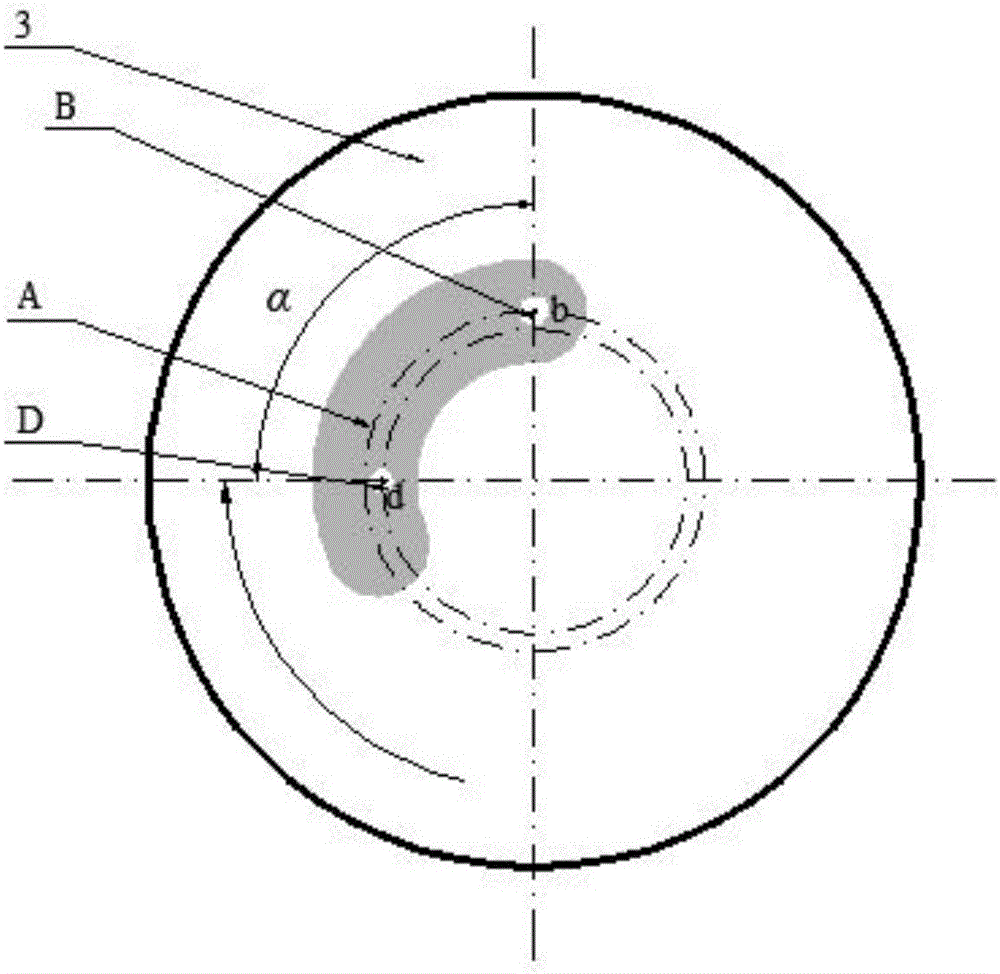

InactiveCN101623867ALow costGuaranteed to workProgramme controlProgramme-controlled manipulatorRobotic systemsThree stage

The invention relates to a device and a method for making a robot track a given route at high accuracy, in particular to a robot processing system for performing route tracking and deviation compensation by comprehensively utilizing a coaxial vision sensing system and a welding seam position measurement sensing system, and a route tracking method, which are used for high-accuracy processing of laser welding and the like. The implementation process is divided into three stages; the first two stages comprehensively utilize welding seam position measurement information and coaxial vision measurement information to calculate the deviation between the front welding seam position and the central point of a robot tool and a welding seam so as to obtain the compensation data of the track deviation of the central point of the robot tool and the welding seam position reference data; and the stage of actual welding utilizes the welding seam position measurement information and the welding seam position reference data to perform tracking and compensation control, a position correcting device corrects the motion of a robot system so that the central point of the robot tool moves forwards continuously along the given route, and the deviation of the given route is smaller than the route repeat accuracy of the robot. The device and the method can be widely applied to various occasions required to improve the motion path accuracy of the robot.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Offline programming and modifying method of six-axis grinding and polishing industrial robot

ActiveCN105269565ASimplified offline programming processPracticalProgramme-controlled manipulatorSpecial data processing applicationsComputer moduleWorking environment

The invention discloses an offline programming and modifying method of a six-axis grinding and polishing industrial robot. The offline programming and modifying method particularly includes the steps of building a model, extracting workpiece machining path information, performing point data processing, generating a robot working motion joint angle, generating a robot working motion trail, performing robot grinding and polishing working motion simulation, generating a robot motion key parameter conversion module and a code, modifying the position of an abrasive belt, modifying the position, posture and singularity and modifying the grinding and polishing work environment. The offline programming and modifying method enables the offline programming process of the six-axis grinding and polishing industrial robot to be simplified, has practicability, can quickly generate programs applicable to the six-axis grinding and polishing industrial robot which grinds and polishes workpieces with complex surfaces, and improves the grinding and polishing uniformity.

Owner:FUJIAN CHANGJIANG IND

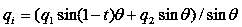

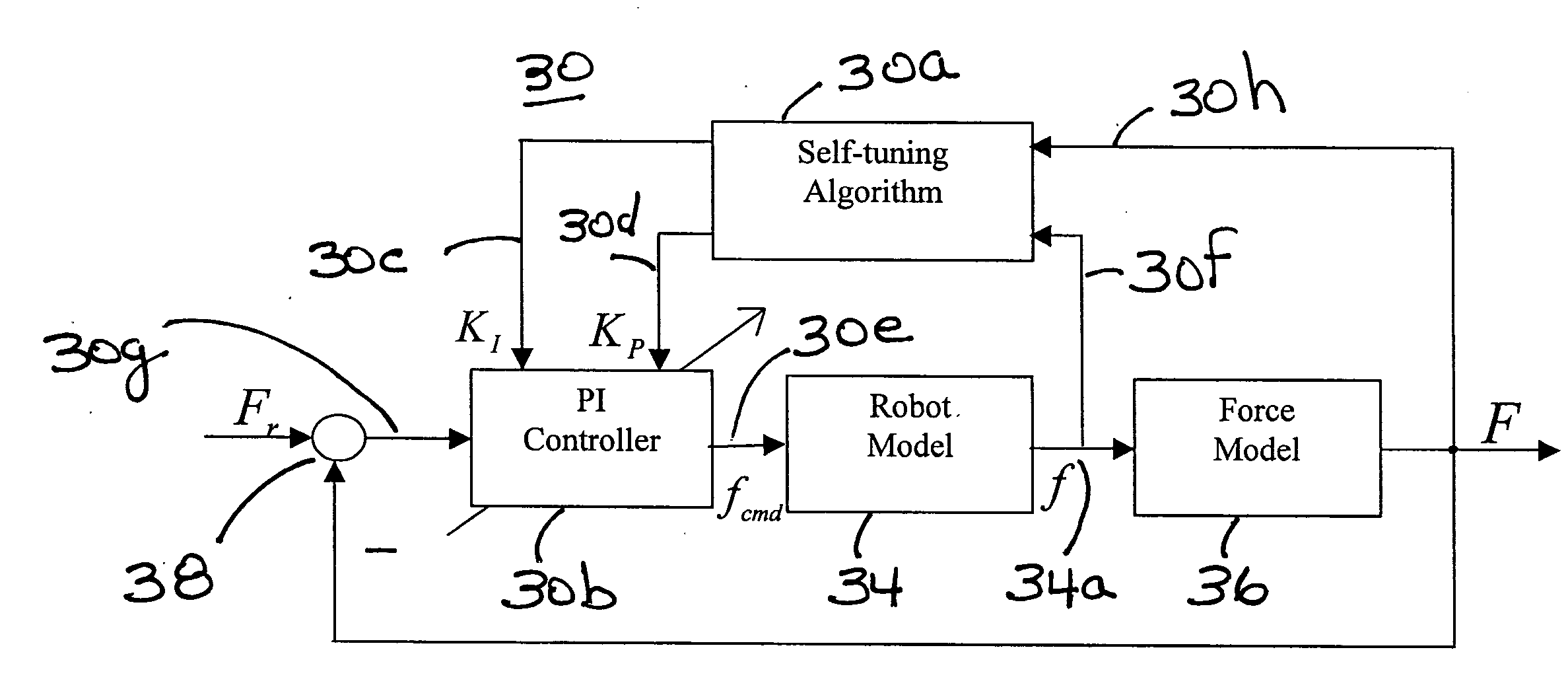

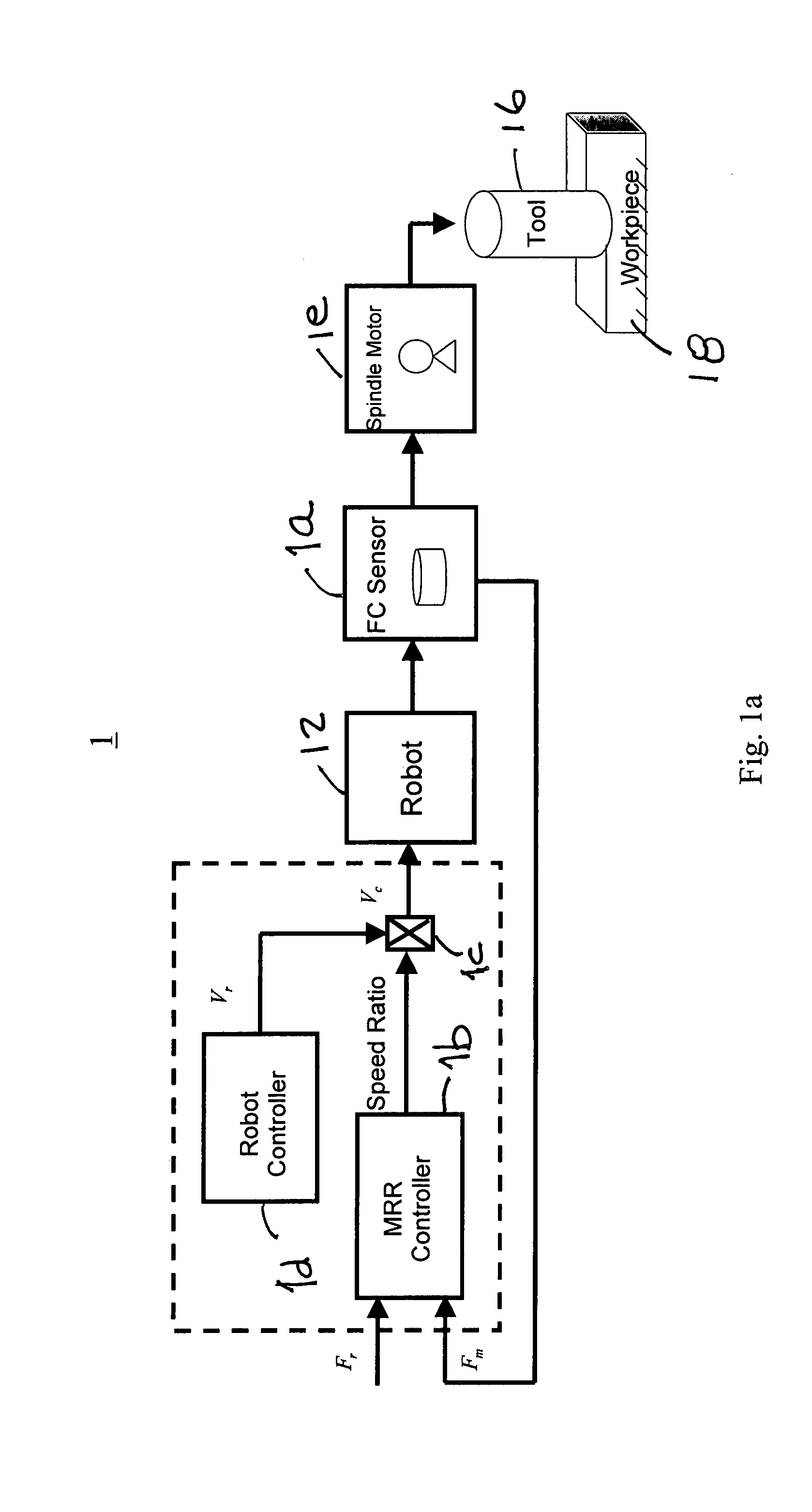

Controlled material removal rate (CMRR) and self-tuning force control in robotic machining process

InactiveUS20080065257A1Programme-controlled manipulatorMeasurement/indication equipmentsSelf-tuningMaterial removal

A method and apparatus for a robotic machining process that gives a controlled removal rate of material from a workpiece when an object, tool or workpiece, held by a robot is brought into contact with a stationary object, workpiece or tool. A signal indicative of the force applied by the held object t the stationary object is used to control the rate at which the robot moves the held object in relation to the stationary object. Associated with the robot is a controller that has tunable proportional and integral gains. The controller determines a command for the feed rate of the tool when the tool engages the workpiece. In response to that command, the proportional and integral gains are tuned to obtain a cutting force to be applied to the workpiece when the tool engages the workpiece that is substantially the same as a desired cutting force.

Owner:ABB RES LTD

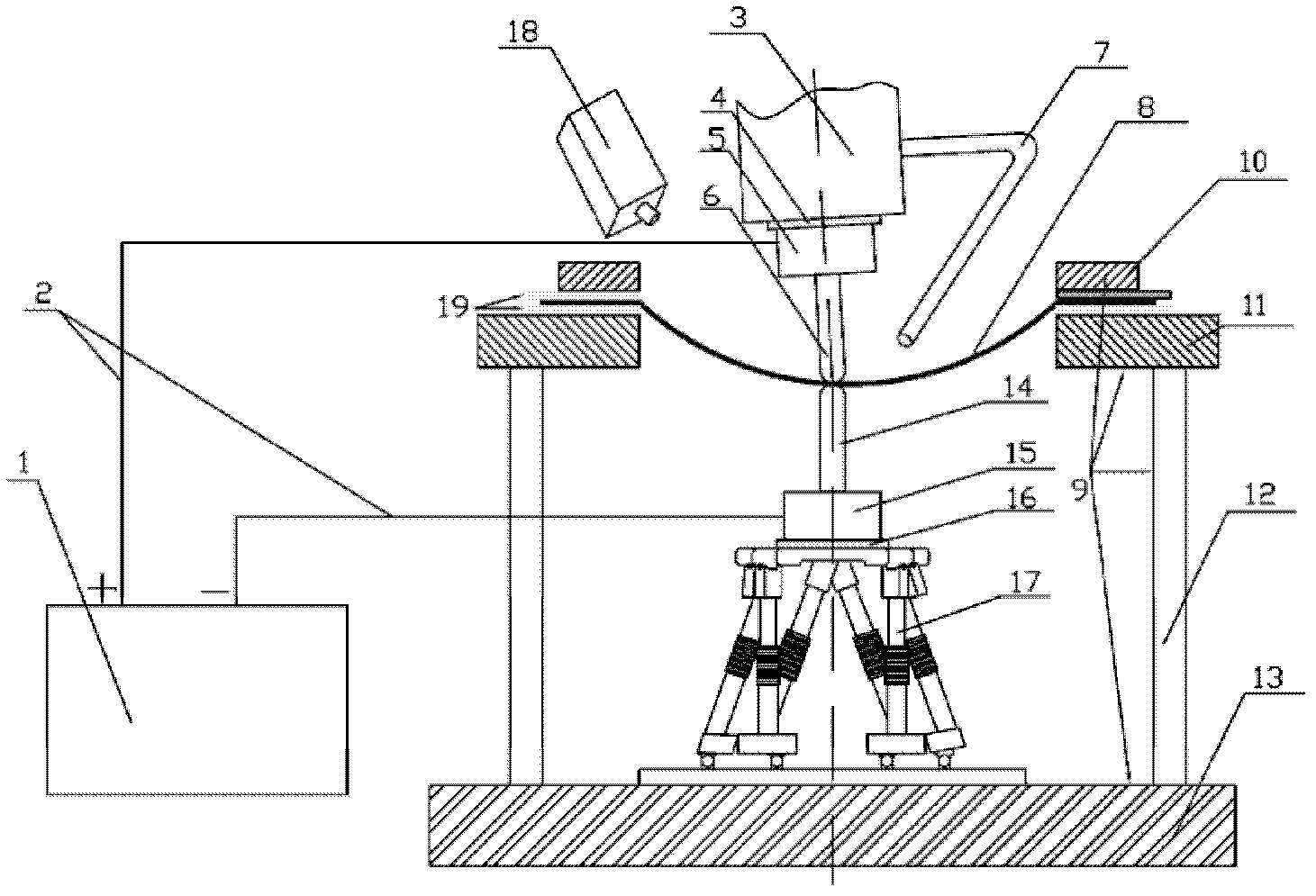

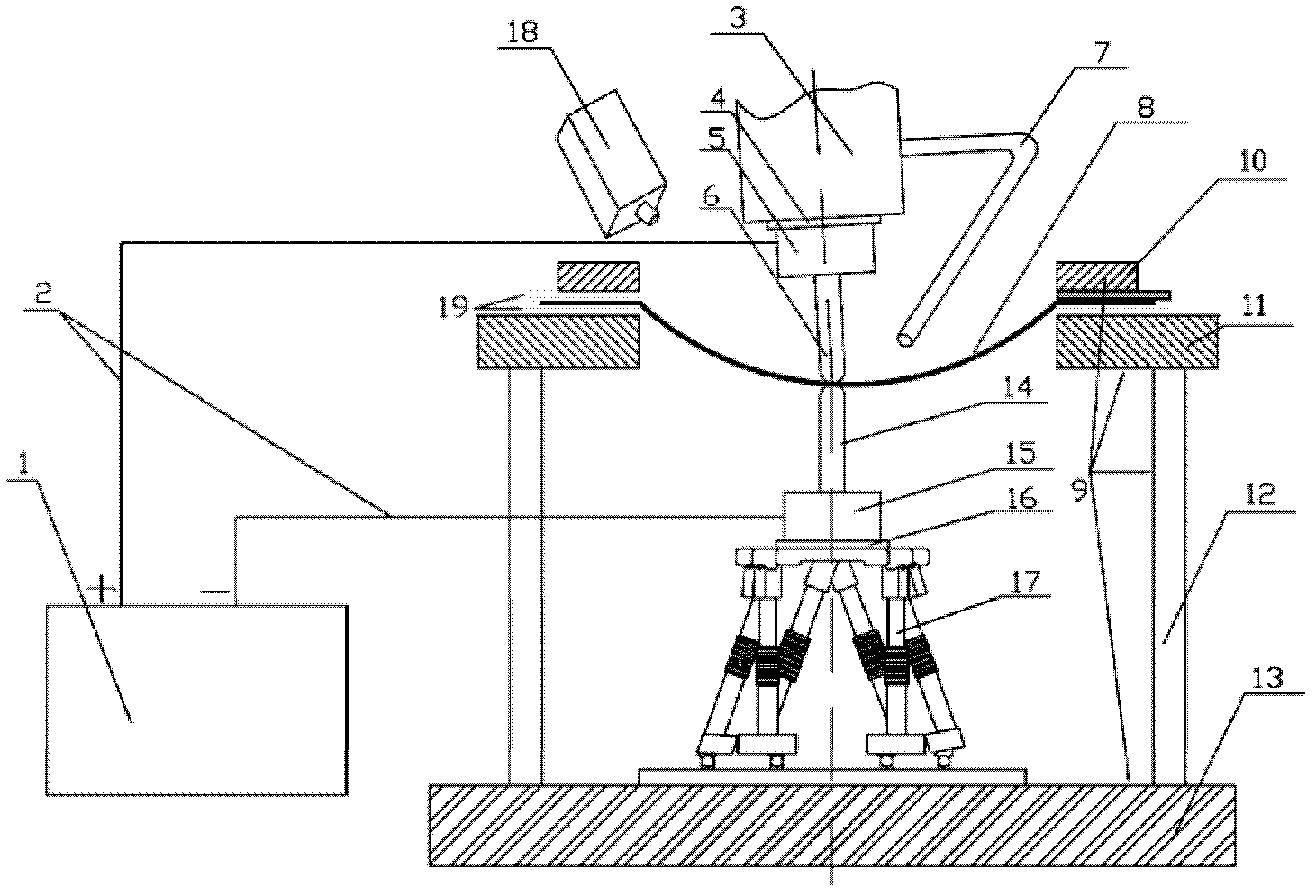

Electroplastic incremental forming device and method for plates

ActiveCN102527830ALower yield stressHigh geometric accuracyMetal-working feeding devicesPositioning devicesNumerical controlHigh energy

The invention relates to an electroplastic incremental forming device and an electroplastic incremental forming method for plates. The device comprises a five-axis numerical control forming machine tool, a six-axis parallel robot machining system, a plate forming clamp, a high energy pulse power supply, an infrared thermometer, and a compressed air cooling system embedded in the machine tool, wherein an upper forming pressing head is arranged at the tail end of a spindle of the five-axis numerical control forming machine tool; the six-axis parallel robot machining system is arranged on a working table of the machine tool; the top of the six-axis parallel robot machining system is provided with a lower forming pressing head; the plate forming clamp is fixed on the working table of the machine tool; positive and negative poles of the high energy pulse power supply are connected with the upper forming pressing head and the lower forming pressing head through high current-carrying conductors respectively so as to form a current loop among the high energy pulse power supply, the upper forming pressing head, the lower forming pressing head and the plates; a camera of the infrared thermometer is aligned with a central area of each plate; and the compressed air cooling system is aligned with a forming area of each plate. Compared with the prior art, the invention has the advantages of high efficiency, energy conservation, high machining precision, high surface quality and the like.

Owner:SHANGHAI JIAO TONG UNIV

Polishing method of portal lifting robot based on force control

InactiveCN105500147AImprove machining accuracyEasy to processAutomatic grinding controlGrinding machinesPersonal computerRobot machining

The invention relates to a polishing method of a portal lifting robot based on force control. The polishing method comprises the following steps: an industrial personal computer generates an offline path according to a workpiece model, and the robot processes a workpiece according to the offline path; a force sensor acquires force information at the tail end of the robot in real time to return to the industrial personal computer, and the industrial personal computer obtains returned force through gravity compensation according to the force information; the industrial personal computer obtains a difference between a set force target value and the returned force, and obtains a position corrected quantity through a force controller; and the sum of the position corrected quantity and a present position of the robot is obtained, and an impedance controller obtains a control quantity to control polishing acting force in robot processing. The polishing method eliminates the disturbance of tool gravity on the polishing acting force in the polishing process to guarantee the detecting and control precision of the polishing acting force, and is high in sensor measuring precision, high in robot control precision and excellent in processing effect.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

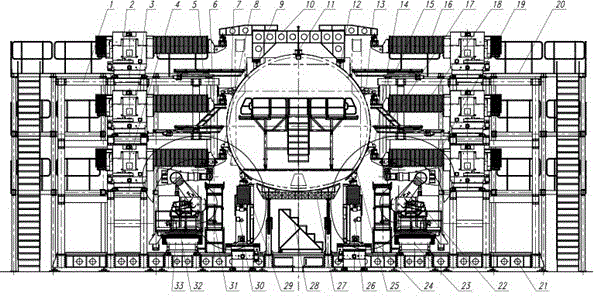

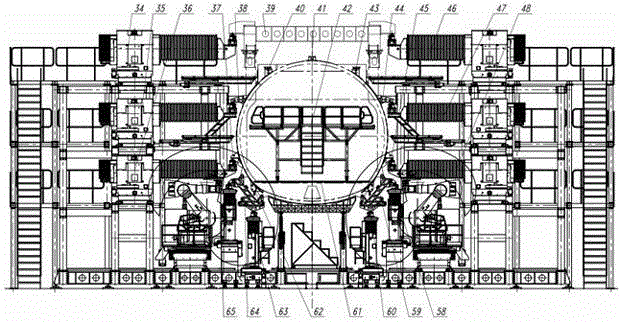

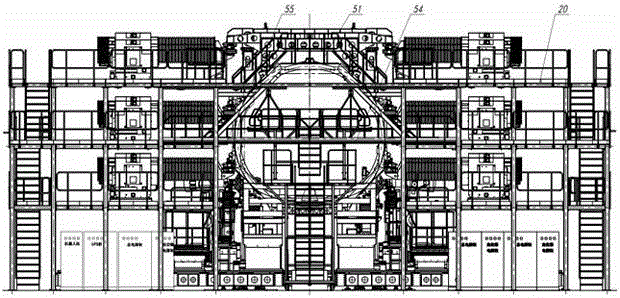

Digitalized assembly system for bodies of large planes

The invention discloses a digitalized assembly system for bodies of large planes. The digitalized assembly system comprises an attitude-adjusting positioning system base platform, an attitude-adjusting positioner unit, a shape-preserving frame, process connectors, end surface shape-preserving frame positioners, a process floor, a modularized external console and a robot machining plant. The digitalized assembly system integrates the numerically controlled positioners, the shape-preserving frame and the process connectors together to carry out flexible supporting, attitude adjustment and accurate positioning for each panel module and realize stress-free or low-stress assembly; the numerically controlled positioners can move in coordination to elastically restore deformed panel modules; the industrial robot holing technique and the industrial robot boring technique are adopted to increase the connection quality of opposite joint areas in body assembly, bore main intersection holes and increase the positional and surface precision of holes; the industrial robot-assisted assembly technique is adopted to accurately position and mount system parts; and by arranging the mounting positions of a plurality of numerically controlled positioners, the digitalized assembly system can be adapted to the change in the length of a body, and has certain scalability.

Owner:ZHEJIANG UNIV +1

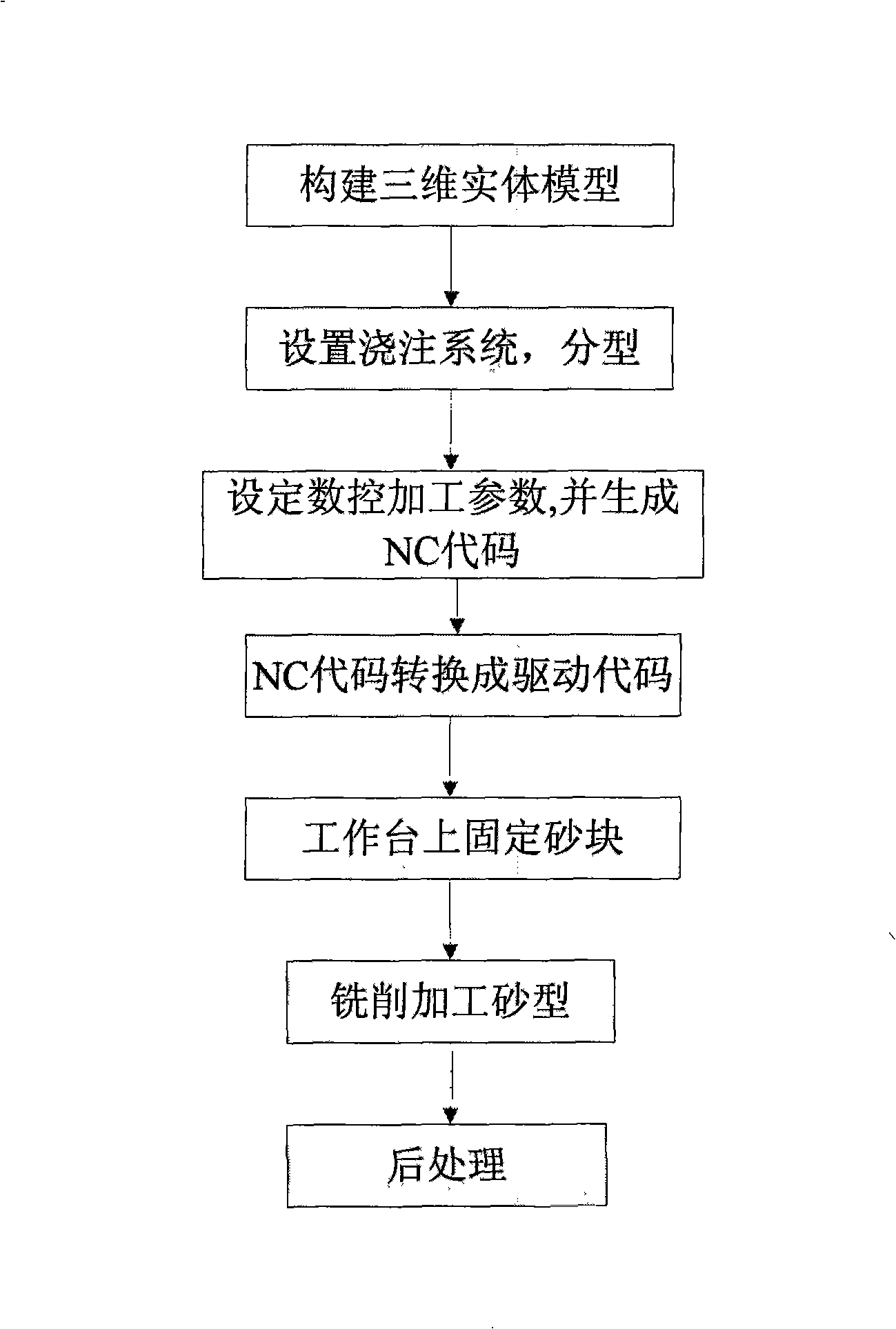

Sand mold milling method based on industrial robot

InactiveCN101279357AReduce preparationQuick cutFoundry mouldsFoundry coresBatch processingAttitude control

The invention relates to a method for adopting an industrial robot to carry out the ordinary sand mold milling processing, which pertains to the filed of the cross technology of casting, numeric control processing and the industrial robot. The steps of the method of the invention are that: a tool and a planned milling path are selected according to the shape of a sand mold to be processed, the generated NC code is translated into a control code of the robot according to a motion model of the industrial robot, thus realizing the gesture control of the robot during the processing process, carrying out the milling of a sand lump and finally carrying out the post-processing of the sand lump after the processing. Compared with the existing traditional casting mold processing method, the processing method of the invention can save the manufacturing link of the mold, reduce the processing procedure, shorten the production period and reduce the production cost; compared with the machine tool-based sand mold milling processing method, the processing method of the invention has larger processing range and higher processing flexibility, in particular to a motion guide track without the need of carrying out the strict sand control protection. The method of the invention is especially applicable to the single and small-batch processing and manufacturing of the large-scale sand mold.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

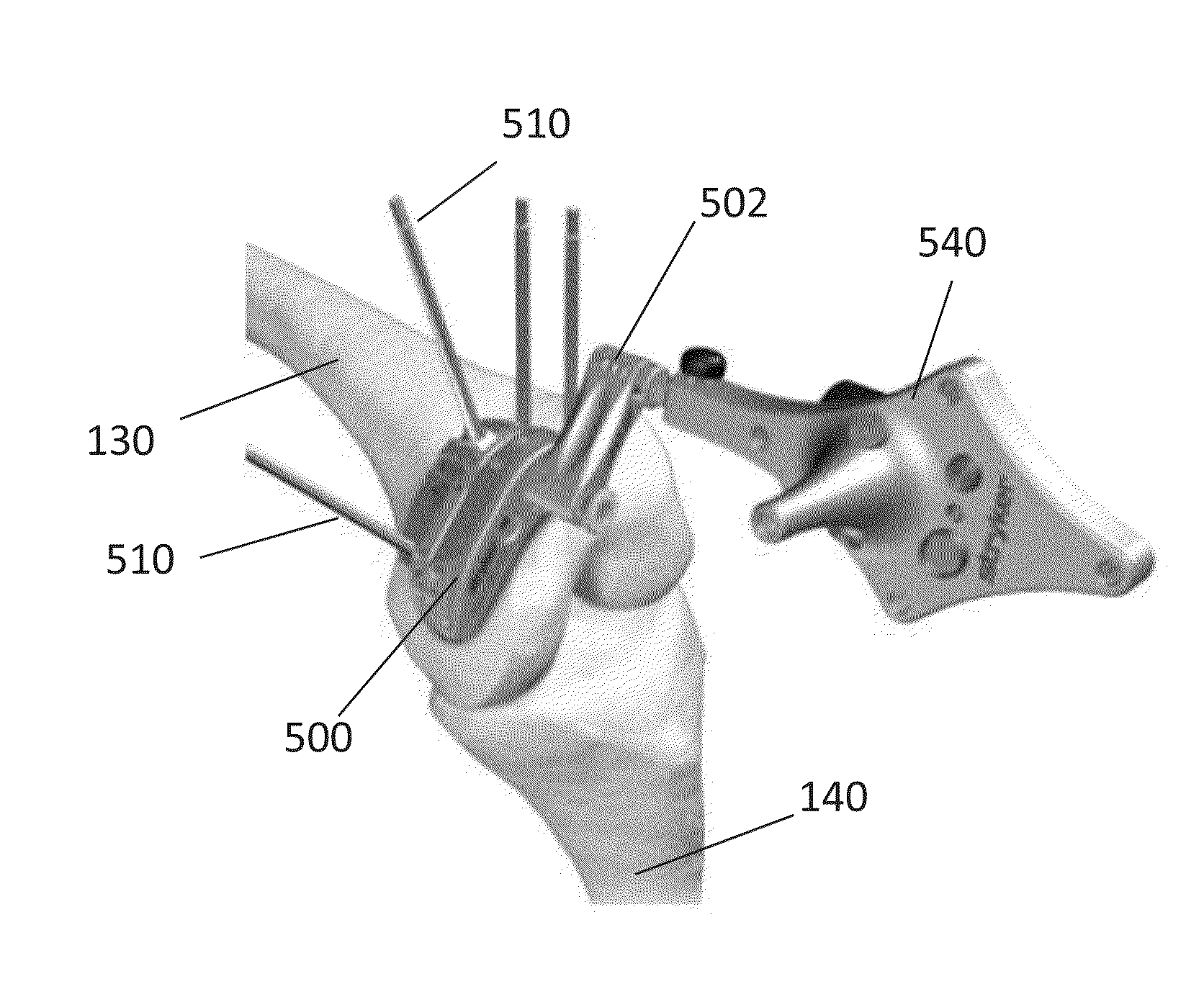

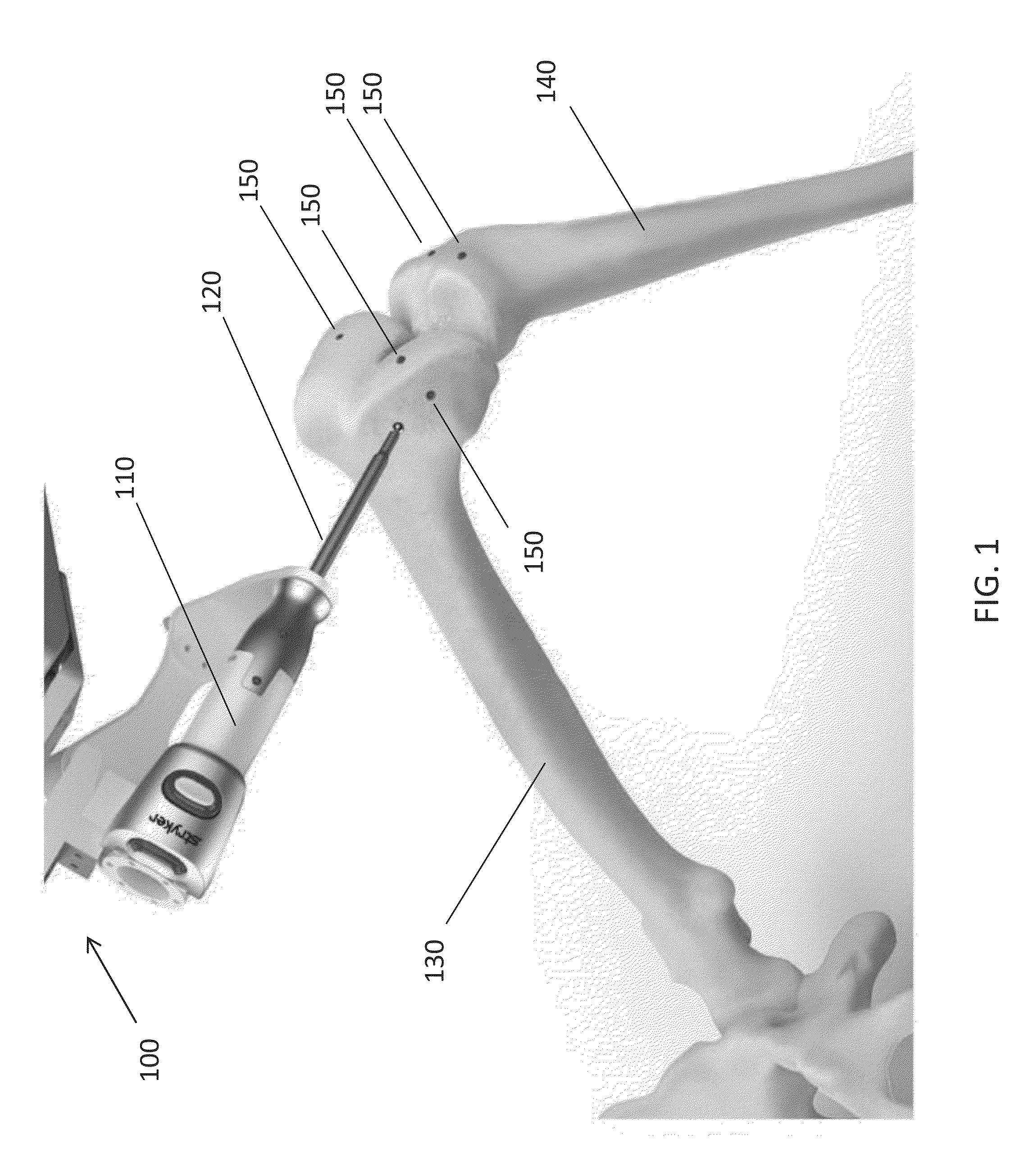

Surgical plan options for robotic machining

InactiveUS20160045268A1Improve accuracyGood reproducibilityDiagnosticsSurgical robotsRobot machiningRobot control

A method of performing surgery on a bone includes providing a robotically controlled bone preparation system and creating at least one hole in the bone with the robotically controlled bone preparation system prior to machining the bone. The bone hole aligns with a hole or a post in a guide for a manual cutting tool. If the robot fails during surgery, or if the surgeon does not wish to complete the procedure with the robot, the guide is attached to the bone after aligning the guide hole with the bone hole. The surgery is completed manually after the guide is attached to the bone, and the robot is not used after the guide is attached to the bone.

Owner:STRYKER CORP

Spinning forming method and device based on laser heating

InactiveCN106424286AImprove heating efficiencyGood process flexibilityShaping toolsProcess equipmentSpinning

The invention discloses a spinning forming method and device based on laser heating. The spinning forming device is characterized by comprising a numerically-controlled spinning machine, spinning process equipment, a laser device, a light guide system, a six-degree-of-freedom robot machining system, a laser machining head, a temperature measuring device and the like. The spinning forming device conducts high-accuracy flexible control over a heating area according to the characteristics of high laser heating speed, accurate and controllable heating parts and temperatures and high degree of freedom and accurate control of the six-degree-of-freedom robot machining system, and spun blanks can be dynamically and locally heated while the spinning process equipment is not heated. The purposes of improving the material spinnability and reducing damage to the spinning machine are achieved. Meanwhile, closed-loop control over the heating temperature and laser output is realized, and realization of production automation is realized. The spinning forming method and device based on laser heating have the advantages of being high in production efficiency, good in process stability, high in forming precision, convenient to operate and the like.

Owner:JIANGSU UNIV OF TECH

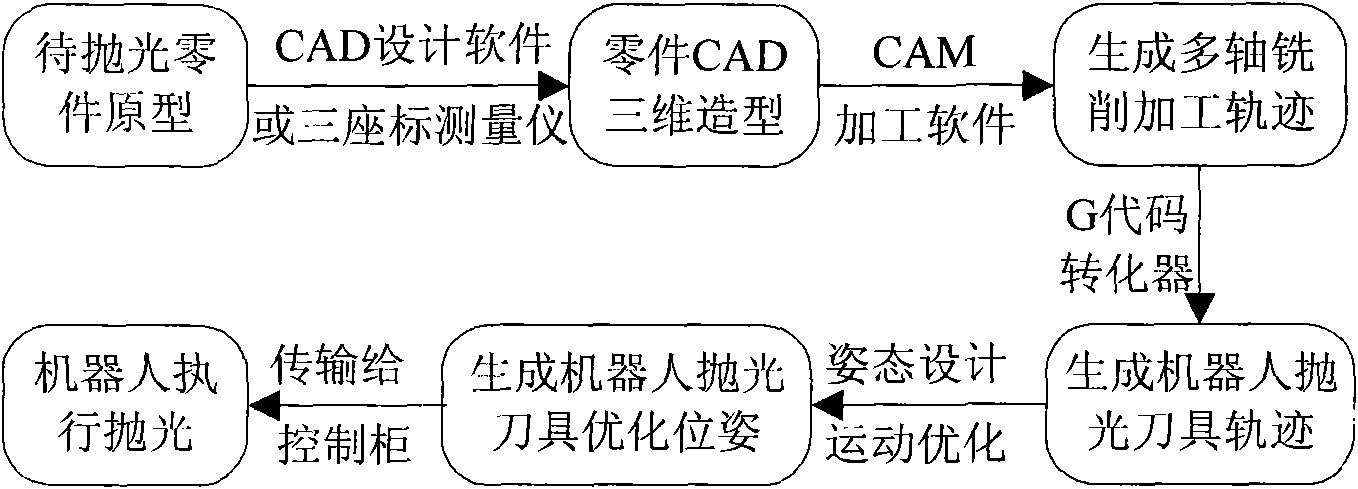

Offline programming method for six-axis grinding and polishing industrial robot

ActiveCN105302959ASimplified offline programming processPracticalSpecial data processing applicationsRobot machiningProgramming process

The invention discloses an offline programming method for a six-axis grinding and polishing industrial robot. The method specifically comprises: establishing a model; extracting workpiece processing path information; processing point data; generating processing motion joint angles of the robot; generating a processing motion track of the robot; simulating a grinding and polishing processing motion of the robot; and generating motion key parameter conversion module and code of the robot. The offline programming method simplifies the offline programming process for the six-axis grinding and polishing industrial robot, has practicality, and can quickly generate a six-axis grinding and polishing industrial robot program applied to grinding and polishing of workpieces with complicated surfaces.

Owner:FUJIAN CHANGJIANG IND

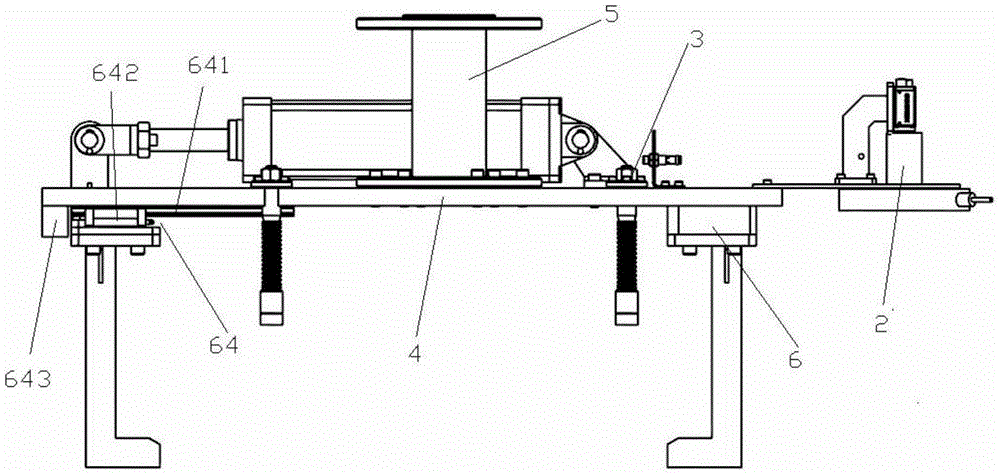

Blade grinding and polishing machining three-dimensional non-contact type measuring device and method

InactiveCN110640585AAccurate shapeSolve the accuracy problemGrinding carriagesGrinding feed controlControl systemEngineering

The invention belongs to the technical field of robot machining measuring, and discloses a blade grinding and polishing machining three-dimensional non-contact type measuring device and method. The device comprises a worktable (1), a linear guide rail (2) arranged on the worktable (1), a six-freedom-degree robot (6) arranged on one side of the worktable (1) and a control system, a blade clamp (3)is arranged on the linear guide rail (2), the six-freedom-degree robot (6) comprises a robot operation arm (7), and the tail end of the robot operation arm (7) is provided with a line structure lightvisual sensor (4). According to the three-dimensional non-contact type measuring device, the line structure light visual sensor is adopted for scanning the ground and polished surface and the geometric outline of a blade, through an image optimized technology of a detection system, analysis processing is carried out, the accurate shape of the ground and polished blade can be obtained, and the problem that in the prior art, the blade cannot be subjected to high-precision three-dimensional non-contact measuring and detecting can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

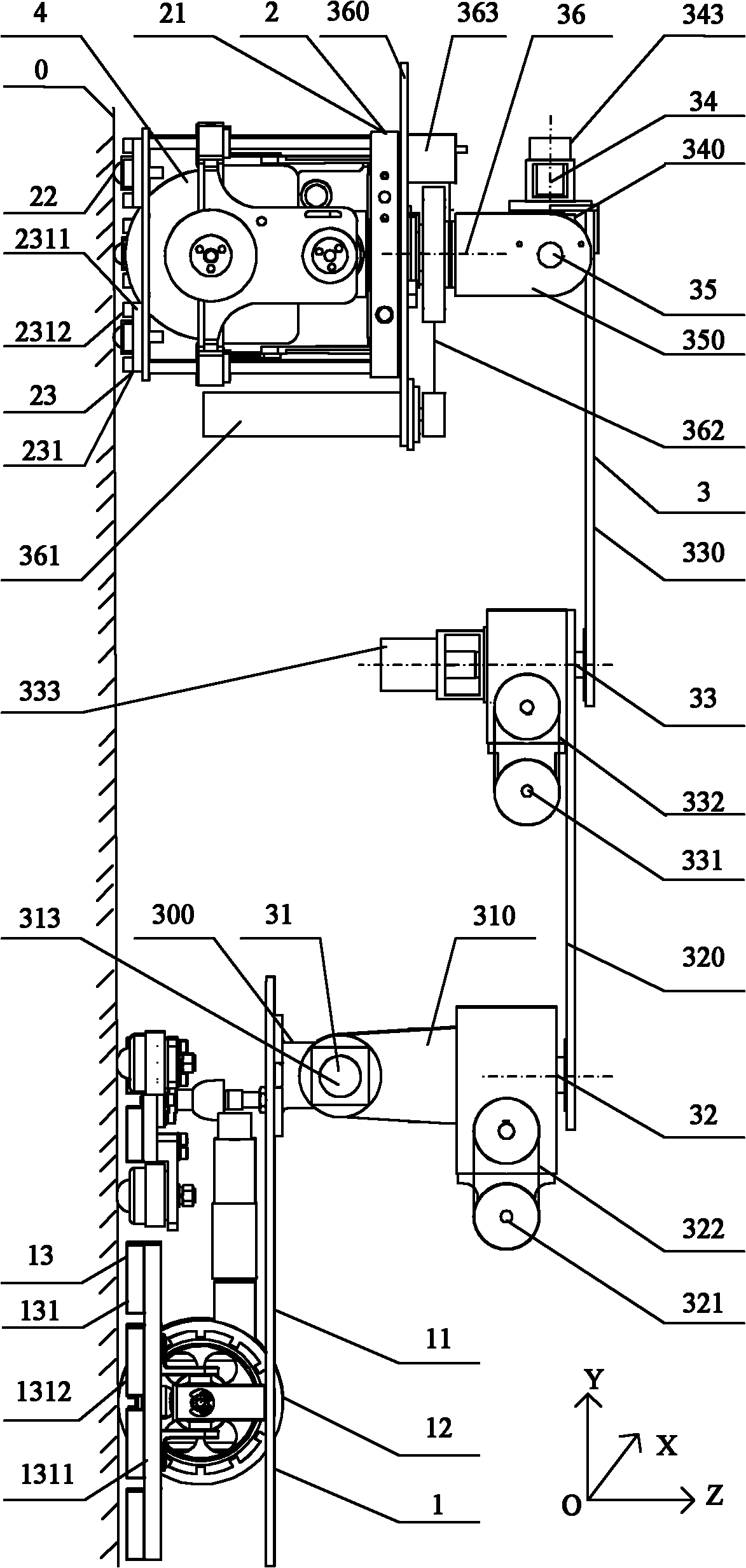

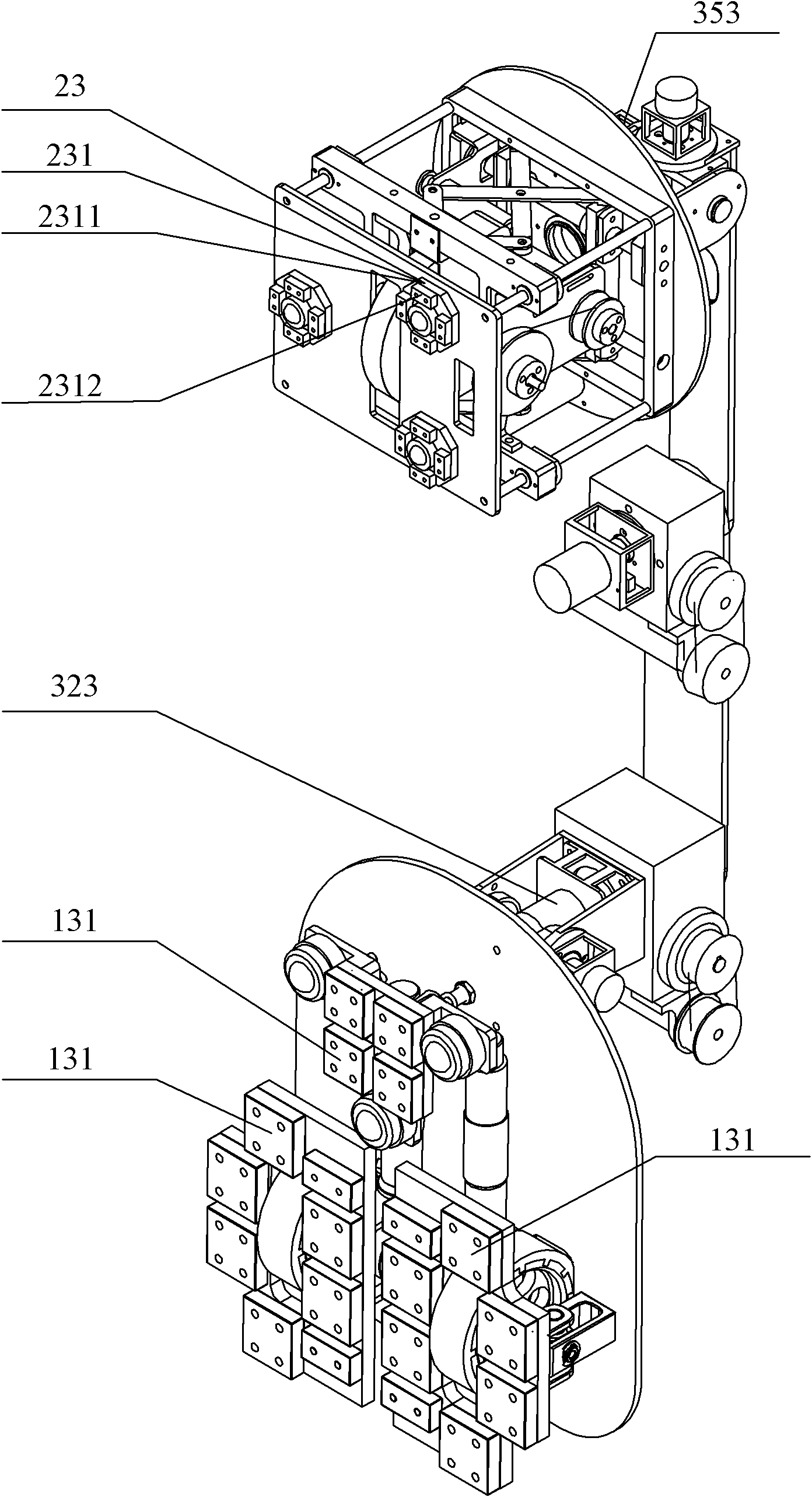

Moving type hybrid robot processing integrated system

ActiveCN109605371AIncrease stiffnessLarge working spaceProgramme-controlled manipulatorProcessing InstructionSimulation

The invention discloses a moving type hybrid robot processing integrated system. The moving type hybrid robot processing integrated system comprises a control cabinet, an omni-directional mobile platform, and a hybrid robot. The control cabinet is used to receive a processing instruction from operators, and according to the processing instruction, a moving track instruction and a processing routeinstruction are generated; the omni-directional mobile platform is used to move according to the moving track instruction until the omni-directional mobile platform moves to a processing station, andafter moving to the processing station, telescopic movement is conducted, stable supporting of the omni-directional moving platform to the hybrid robot is realized, and self-adaptive leveling is conducted to ensure a subsequent process; and the hybrid robot is used for processing to-be-process workpiece. According to the moving type hybrid robot processing integrated system, the high-performance hybrid robot is adopted, an omni-directional intelligent mobile platform and visual measurement technology are assisted, processing is controlled by numerical control system integration, a brand new solution is provided for processing of large complex components with high efficiency, high precision and high flexibility, andalignment, milling and drilling requirements of integral precision processing can be met to breakthrough processing technology bottleneck.

Owner:BEIJING SATELLITE MFG FACTORY

Multi-body magnetic adsorption type adaptive wall climbing robot

ActiveCN102039592AExpand the scope of processingIncrease load capacityArmsCarrying capacityEngineering

The invention discloses a multi-body magnetic adsorption type adaptive wall climbing robot and belongs to the technical field of special robots. The robot comprises a main body device, at least one slave body device, at least one mechanical arm and a working tool arranged on each slave body device, wherein the main body device comprises a main body frame, a movable mechanism and a main body magnetic adsorption device; the slave body device comprises a slave body frame, a slave body magnetic adsorption device and at least one auxiliary supporting wheel; and each mechanical arm comprises at least five connecting rods, at least two active joints and at least two passive joints. The invention provides a wall climbing robot which flexibly moves and steers on a magnetized wall surface at full positions spatially, is adaptive to a spatial curved surface and can perform welding, gouging, cutting, grinding, milling, detecting, cleaning or spraying work. The robot has wide processing range, high carrying capacity, high flexibility of movement and high working efficiency.

Owner:TSINGHUA UNIV +1

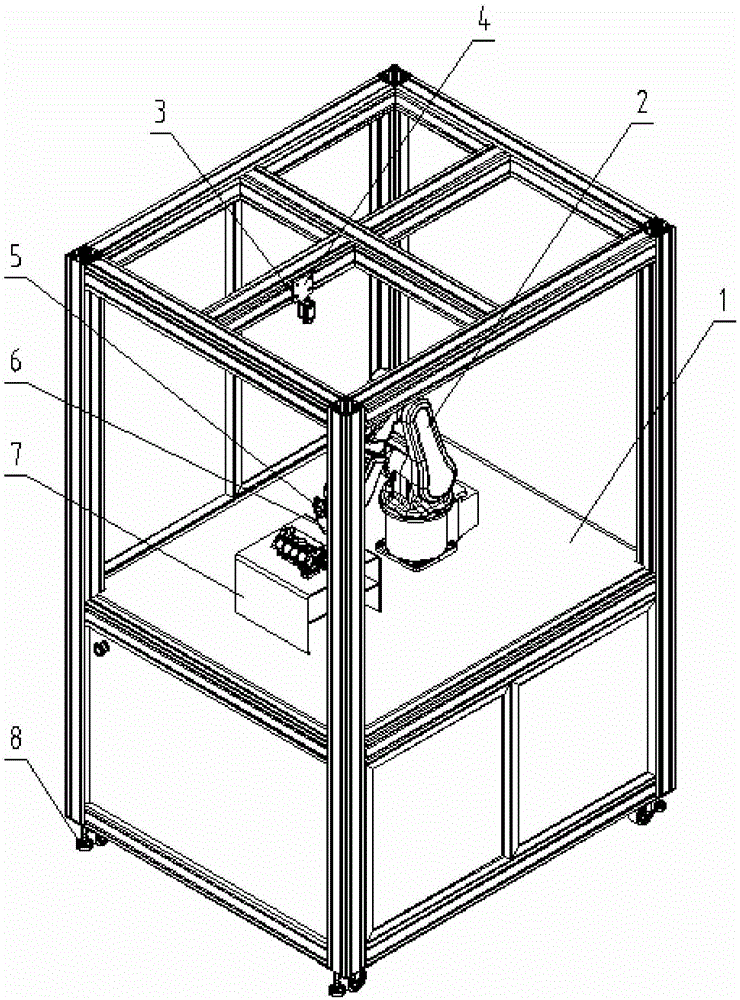

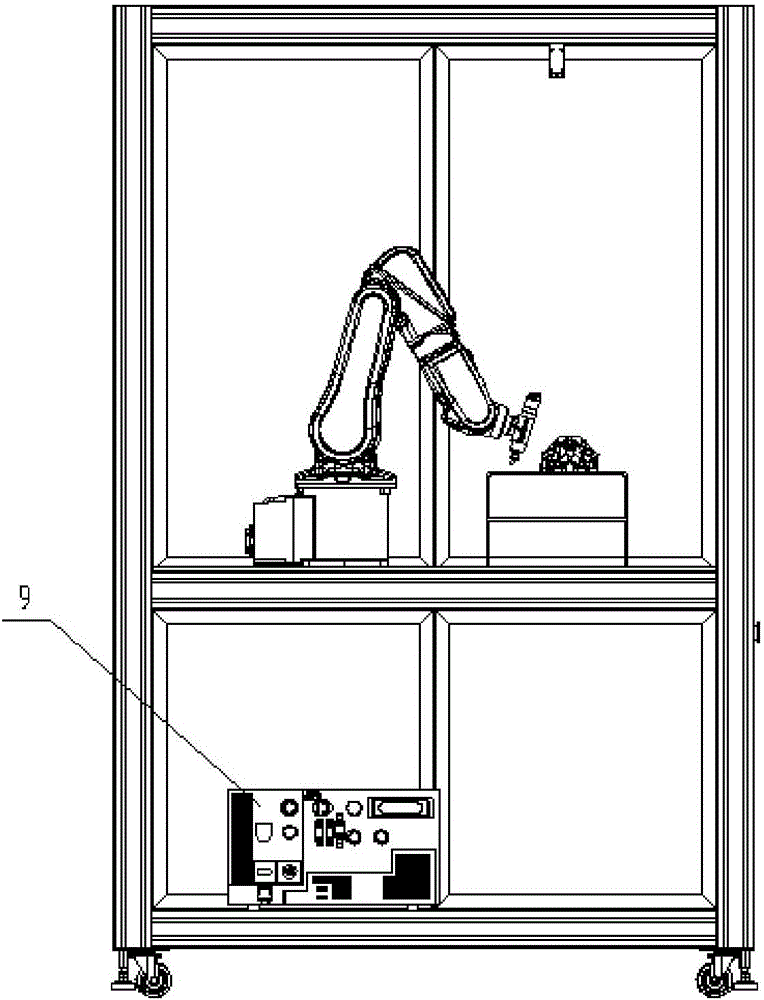

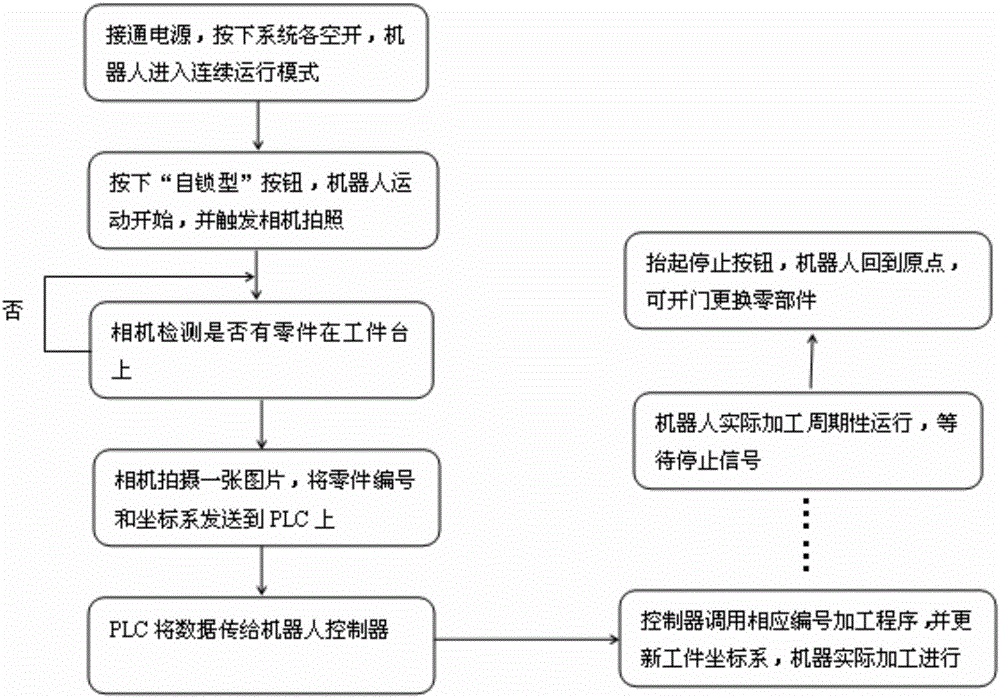

Robot deburring system and method through visual inspection

ActiveCN106041948AFree from harmImprove work efficiencyEdge grinding machinesGrinding feed controlRobotic systemsVisual inspection

The invention provides a robot deburring system through visual inspection. The robot deburring system comprises a robot installation rack, a robot system, a high-speed electric spindle system, a visual camera system, a PLC control module and a workpiece placing platform. At the same time, the invention further provides a robot deburring method through visual inspection, and the robot deburring system through visual inspection is applied. According to the robot deburring system through visual inspection, the advantages that the working efficiency is high, the precision is high, deburring is thorough, and a worker can be prevented from being hurt by removed burrs are achieved; and meanwhile, the visual camera system is adopted by the system, and when a to-be-machined component is replaced, a coordinate system of the workpiece does not need to be revised by the worker, so that robot machining becomes easy, and the requirements for high efficiency and high quality of machining at present are met.

Owner:黑龙江哈工华粹智能装备有限公司

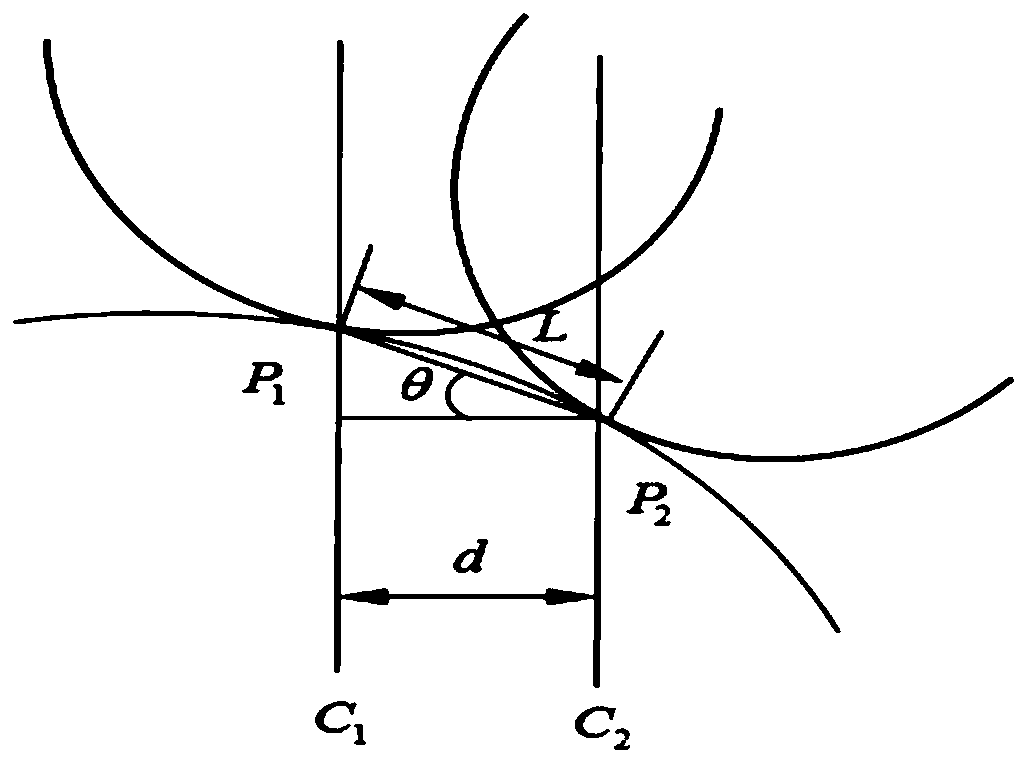

Robot track planning method based on large complex component point cloud information

ActiveCN110039538AMeet offline programming technologyMeet needsProgramme-controlled manipulatorPoint cloudSimulation

The invention belongs to the field of industrial robot machining and discloses a robot track planning method based on large complex component point cloud information. The method includes the steps that a, a point cloud model of a to-be-machined component is reversely reconstructed to obtain a CAD model, and the main normal vector direction of the CAD model, the projection direction and the forwardmoving direction of a robot are set; b, the CAD model is adopted for conducting slicing so that multiple track lines can be obtained, each track line is dispersed into multiple dispersed points, eachdispersed point is projected on the CAD model to obtain a corresponding track point of the dispersed point, the three-dimensional coordinates of the dispersed point and corresponding U and V values;and c, the tangent vector, the auxiliary tangent vector and the main normal vector of the track points are obtained, six-dimensional information of the track points is obtained, the six-dimensional information of each track point is stored according to the preset machining sequence, and a needed robot machining track is obtained. By means of the robot track planning method, the large component robot machining track planning requirement is met, the track planning precision is improved, and good machining quality is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

Pneumatic pole climbing robot based on bionic worming principles

ActiveCN107140050AIncrease speed of climbReduce air pressureManipulatorVehiclesEngineeringRobot machining

The invention provides a pneumatic pole climbing robot based on bionic worming principles. The robot comprises a base and a main body support, wherein a steel rail is disposed on one side of the main body support, and a climbing drive air cylinder support is disposed on the other side; a climbing drive air cylinder is installed in the climbing drive air cylinder support; a composite slide car and a lower slide car are installed on the steel rail; a claw supporting frame is installed on the lower slide car and the composite slide car respectively; two fingers are in hinged connection to each claw supporting frame; a claw drive air cylinder is disposed between the two fingers on each claw supporting frame; an output end of the drive air cylinder is connected to the composite slide car by a fisheye bearing; fixed pulley bases are disposed on the upper and lower ends of the main body support; two fixed pulleys are installed on each fixed pulley base; and a closed rope structure composed of a steel wire rope and a damping spring is disposed on the four pulleys. According to the invention, the robot is simple and compact; mass of the robot is greatly reduced; and workloads of processing and manufacture of the robot are reduced.

Owner:HARBIN ENG UNIV

Processing assembly line and processing method for valve special for extreme high voltage transformer by robots

ActiveCN106112559AReduce work intensityNo manual operationOther manufacturing equipments/toolsMetal working apparatusProduction lineAssembly line

The invention provides a processing assembly line and processing method for a valve special for an extreme high voltage transformer by robots. The processing assembly line is composed of two production lines; what the two production lines in common is that a robot and a clamp are mounted on a robot guide rail; a first-process numerically-controlled lathe, a workpiece rotating positioning table, a workpiece transfer table, a third-process processing center, a second-process numerically-controlled lathe, a workpiece turnover table, a fourth-process processing center and a fifth-process square workpiece processing center are respectively arranged at two sides of the robot guide rail; the two production lines differ in that a fifth-process round workpiece processing center is additionally arranged at one side of one production line; and the production line additionally provided with the fifth-process round workpiece processing center can process both square workpieces and round workpieces. By means of the processing assembly line, the problems that the production efficiency is low and the quality is not stable existing a processing mode that skilled workers operate and control the numerically-controlled lathes in one-to-one correspondence are solved, and the method and equipment provided by the invention are efficient, the quality is controllable, the automation degree is high and the labor intensity is low.

Owner:湖南省国创电力有限公司

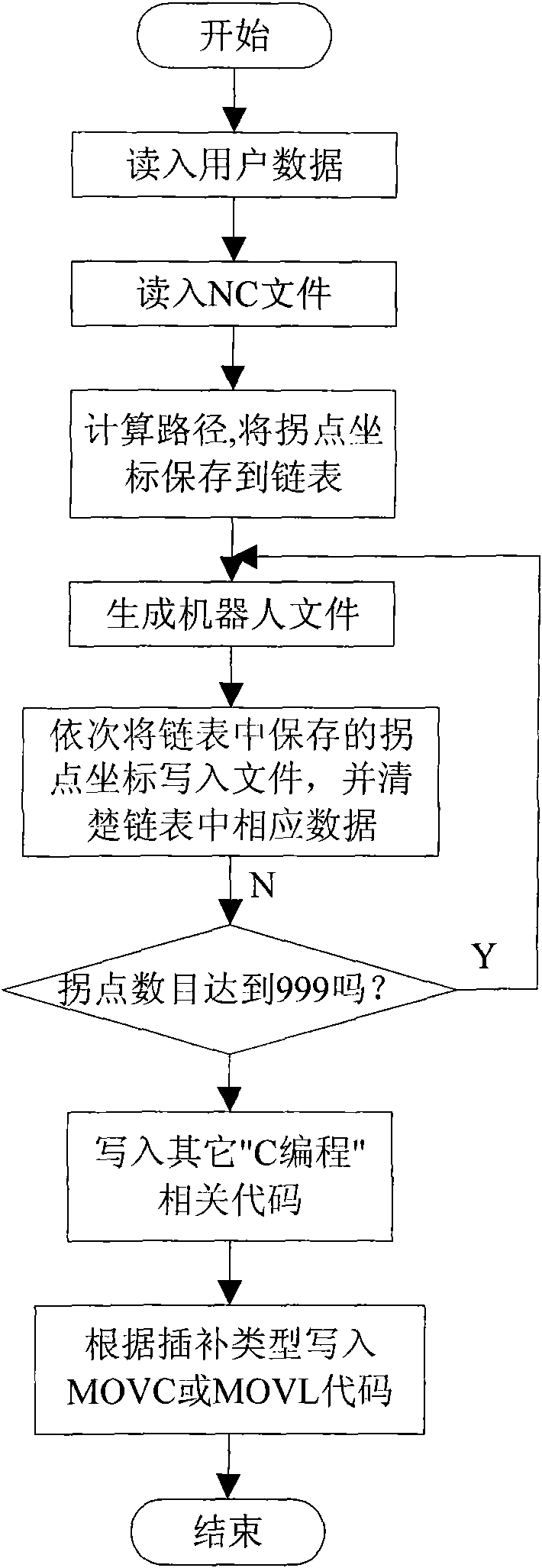

Processing control method of industrial robot based on G code conversion method

The invention relates to a processing control method of an industrial robot based on a G code conversion method. The method comprises the following steps: firstly, obtaining data customized by a userand inputting initial condition and robot information in a graphical user interface; secondly, importing NC files of G code format and calculating inflection point coordinates; thirdly, designating working files to be output and loading the inflection point coordinates saved in a chain table in the working files in sequence; fourthly, loading robot C programming codes or P programming codes in theworking files after loading the inflection point coordinates in the working files; fifthly, converting G codes into working files according to the following rules; and sixthly, outputting the converted working files into the controller of an industrial robot and controlling the processing of the industrial robot according to the instructions of the working files. The method has the advantage thatthe G codes can be directly used for the processing of robots and the practicability is good.

Owner:日照新睿招商发展有限公司

Complex curved surface machining track generation method in off-line programming

ActiveCN111230880AReduce planning timeHigh degree of intelligenceProgramme-controlled manipulatorAnimationSimulation

The invention discloses a complex curved surface machining track generation method in off-line programming. The complex curved surface machining track generation method in off-line programming comprises the steps of using a NURBS complex curved surface track generation algorithm based on STEP standard to generate a track and visualize the track; before animation simulation, detecting the generatedtrack points in advance by using a robot kinematics algorithm so as to detect abnormal points such as unreachable points, axis overrun points and jumping points; and correcting the abnormal points byusing a track posture correction module until all the track points are normal, and finally performing animation simulation by using computer graphics, and converting the post-code into a real machineto operate. The complex curved surface machining track generation method in off-line programming can be applied to generating and planning a complex curved surface machining track in off-line programming and provides systematic solutions for the problems of high workload, high difficulty, low efficiency and the like of manual demonstration for machining a complex curved surface by a robot; the method has the characteristics of high precision, speed and universality and good simulation visualization effect, and can be widely applied to the machining environment of the complex curved surface; and meanwhile, the provided complex curved surface track generation algorithm is high in precision and robustness.

Owner:XI AN JIAOTONG UNIV

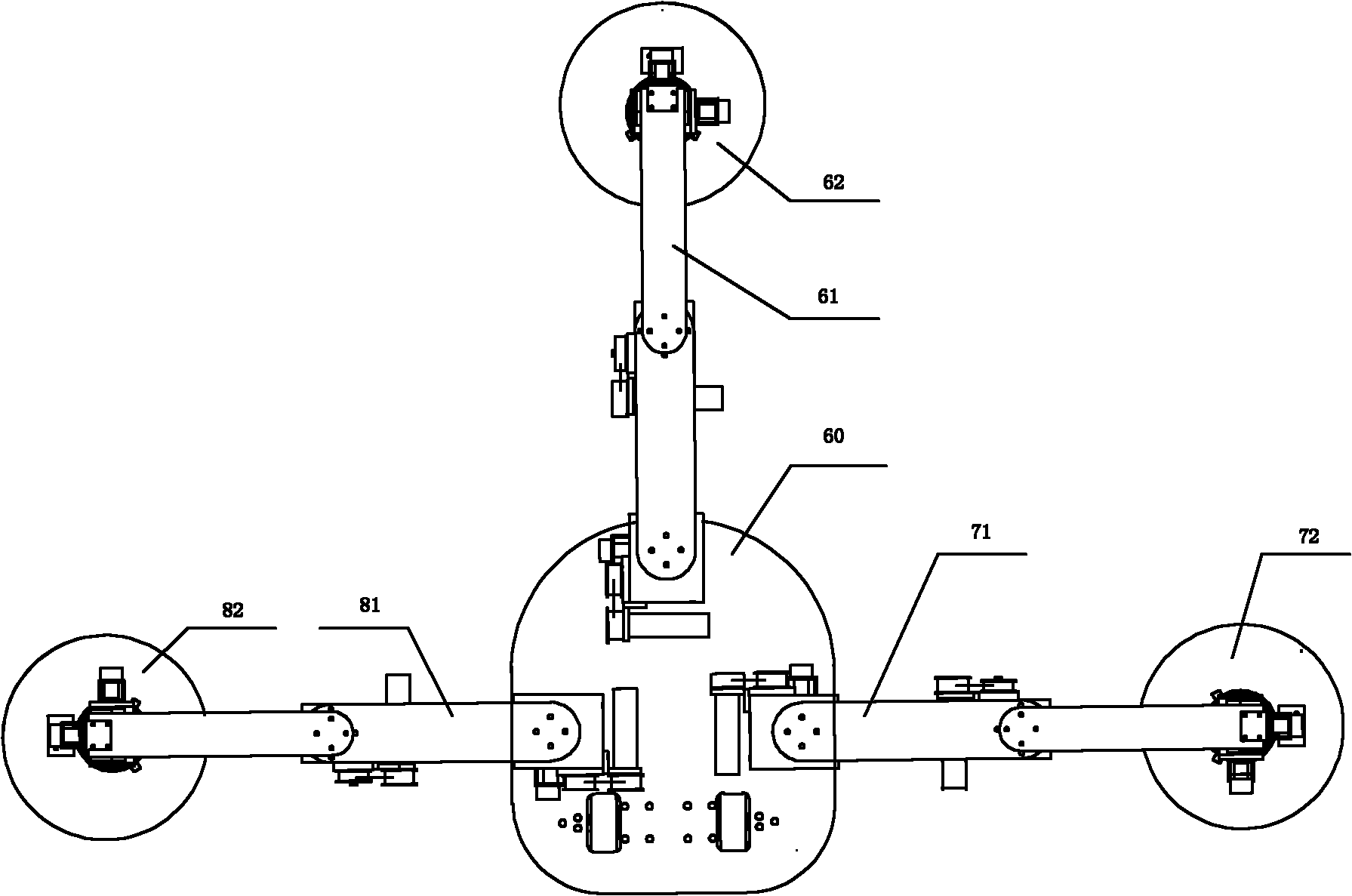

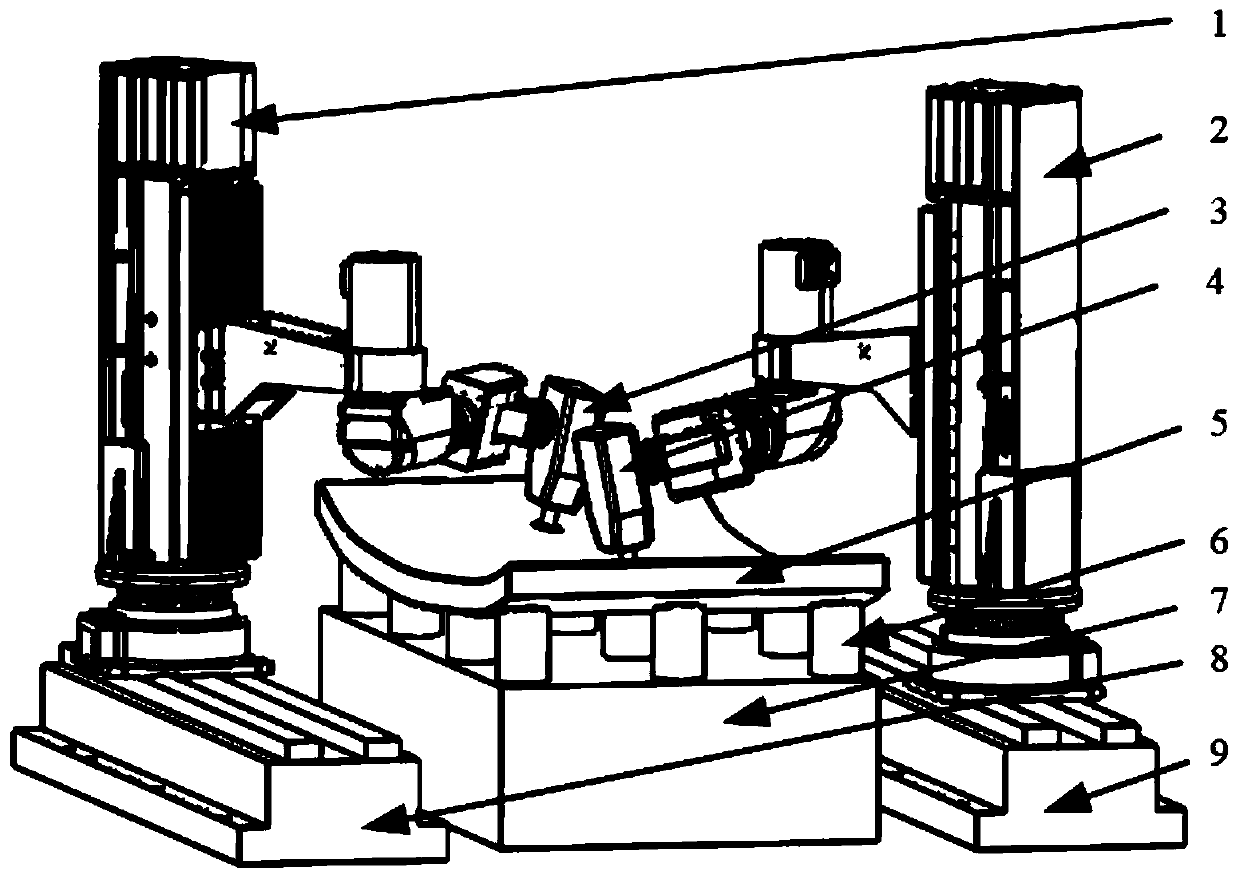

Multi-robot precision machining system and method for large-aperture integral optical element

ActiveCN110732932AShorten the production cycleSave handling timeOptical surface grinding machinesLapping machinesOptical processingRobot machining

The invention discloses a multi-robot precision machining system and a method for a large-aperture integral optical element. The multi-robot precision machining system comprises a robot machining system part and a modular machining tool, the modular machining tool comprises a grinding disk machining module, a polishing fluid supply recycling tool head module and a magnetorheological polishing toolhead module. The multi-robot precision machining system and method adopts a flexible intelligent robot with the low cost for machining, by means of multi-robot collaborative machining, machining of large-aperture integrated optical elements with various curvature is realized, meanwhile, the manufacturing efficiency of the optical elements is greatly improved, and a highly integrated modular chemical tool head enables the machining system to be able to conduct grinding modification, polishing modification and precision polishing modification on the large-aperture integral optical elements. Thesystem completes the whole optical machining process, the manufacturing cost of the large-aperture optical elements is greatly saved, and the cycle of the large-aperture optical elements is greatly shortened.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

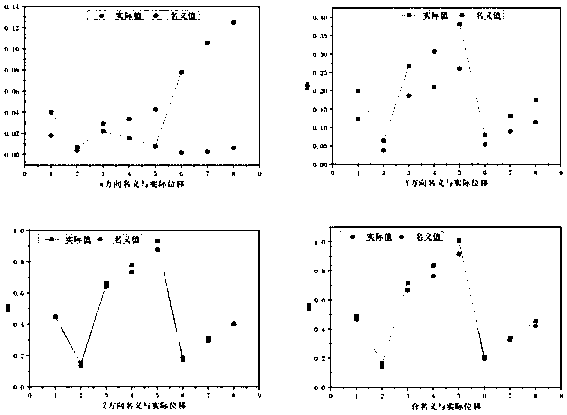

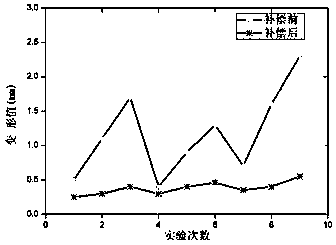

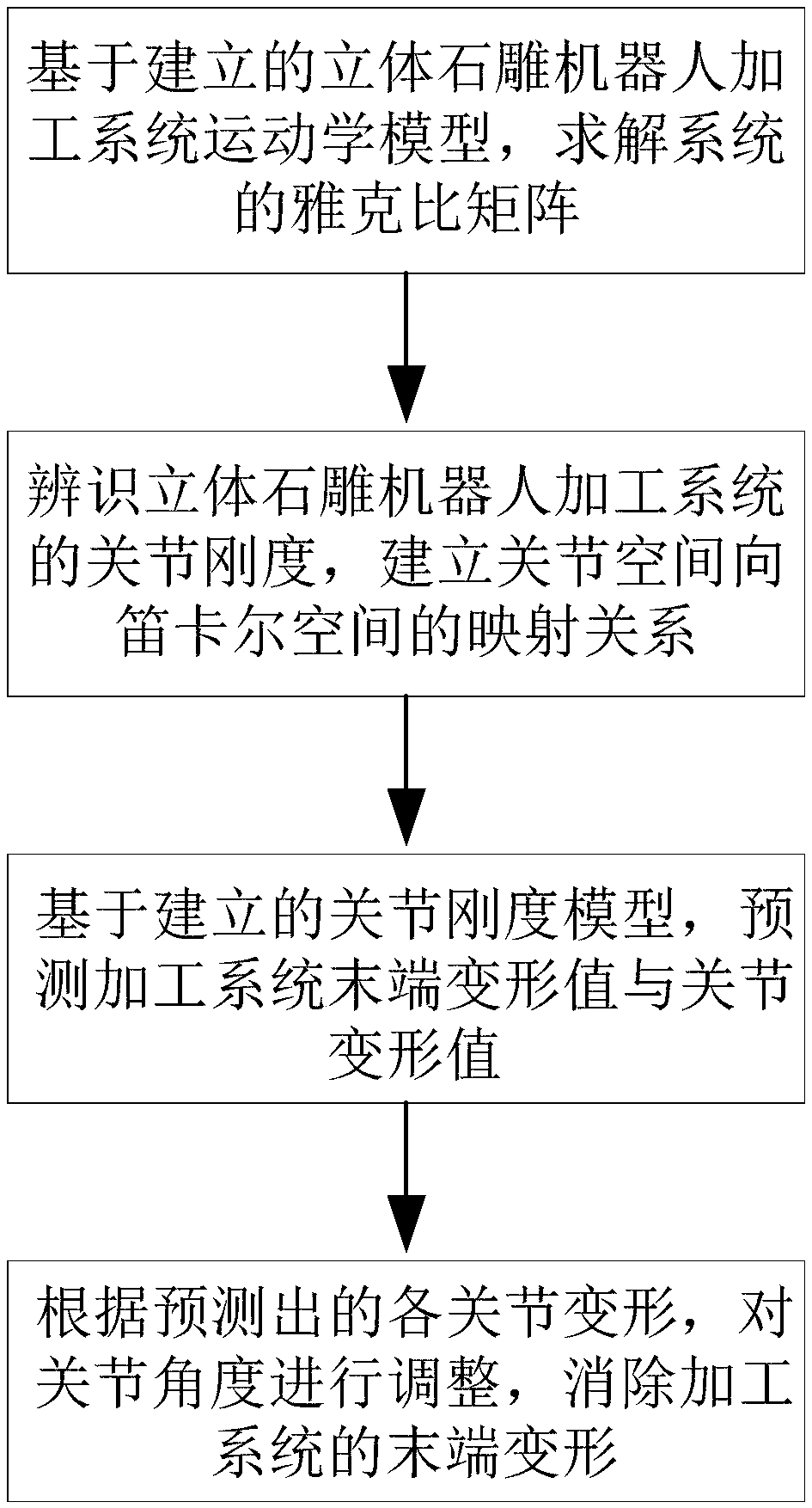

Deformation prediction and compensation method of three-dimensional stone carving robot processing system

ActiveCN109434829ADistortion Value EliminationImprove trajectory accuracyProgramme-controlled manipulatorModel makingStructural deformationStone carving

The invention relates to a deformation prediction and compensation method of a three-dimensional stone carving robot processing system. The deformation prediction and compensation method comprises thesteps that a kinematic model of the three-dimensional stone carving robot processing system is constructed, and a Jacobian matrix of the three-dimensional stone carving robot processing system is solved; a robot stiffness identification experiment is designed, the joint stiffness of the three-dimensional stone carving robot processing system is identified, and the mapping relationship of stiffness from a joint space to a Cartesian space at the end is established; according to the position and posture of the three-dimensional stone carving robot processing system and the external force received during processing, a joint stiffness model is used for predicting the tail end deformation value and each joint deformation value of the three-dimensional stone carving robot processing system; andaccording to the predicted deformation of each joint, the angle of each joint is adjusted to eliminate the deformation at the tail end of the robot processing system for processing three-dimensional stone carvings. The quantitative compensation of the structural deformation value of any three-dimensional stone carving robot processing system is realized, and the tool path precision of the three-dimensional stone carving robot processing system is improved when stone is processed.

Owner:HUAQIAO UNIVERSITY

Robot machining work normal constant force tracking method and device

ActiveCN110948504AAvoid the effects of frictionHigh precision of force controlProgramme-controlled manipulatorConstant forceControl system

The invention provides a robot machining work normal constant force tracking method and device. The method comprises the steps that the initial reference track is given; a robot is controlled to movealong the reference track; according to the error between the actual contact force and the expected contact force, iterative computation and updating of the position of the current reference track areconducted; and based on the updated reference track position and the actual contact force direction, the posture of the reference track is calculated. According to the method, the reference track isintroduced into an existing robot machining force control system, the high-precision reference track is obtained through iterative learning and posture estimation, the outline of a machined workpieceand the posture with which a robot machining tool needs to be kept are reflected, machining is conducted according to the reference track, and normal constant force tracking in the machining work process of various curved surfaces can be achieved. Meanwhile, the robot machining work normal constant force tracking method and device can be achieved only through a three-dimensional force sensor, andcost increasing caused by adopting a six-dimensional force sensor is avoided.

Owner:SIASUN CO LTD

Carcass cutting methods and apparatus

Methods of automated meat processing including an end to end processing method in which carcasses are cut into major portions at a first robotic processing station and into minor portions at robotic processing sub-stations. In one processing method carcass portions are acquired by a robotic arm, imaged and then cuts performed without transfer. In another a first series of processing steps are performed by rotating carcass portions through a plurality of processing stations and a second series of processing steps are performed as carcass portions are advanced along a linear conveyor. In another processing method a plurality of clamps are employed to stabilize a saddle section during a flap cut. In another processing method split pins are used to position a saddle section for a vertebrae cut. In another method a spinal cord is removed by applying a pressurized fluid stream against one end of the spinal cord and applying suction at the other end of the spinal cord.

Owner:ROBOTIC TECH

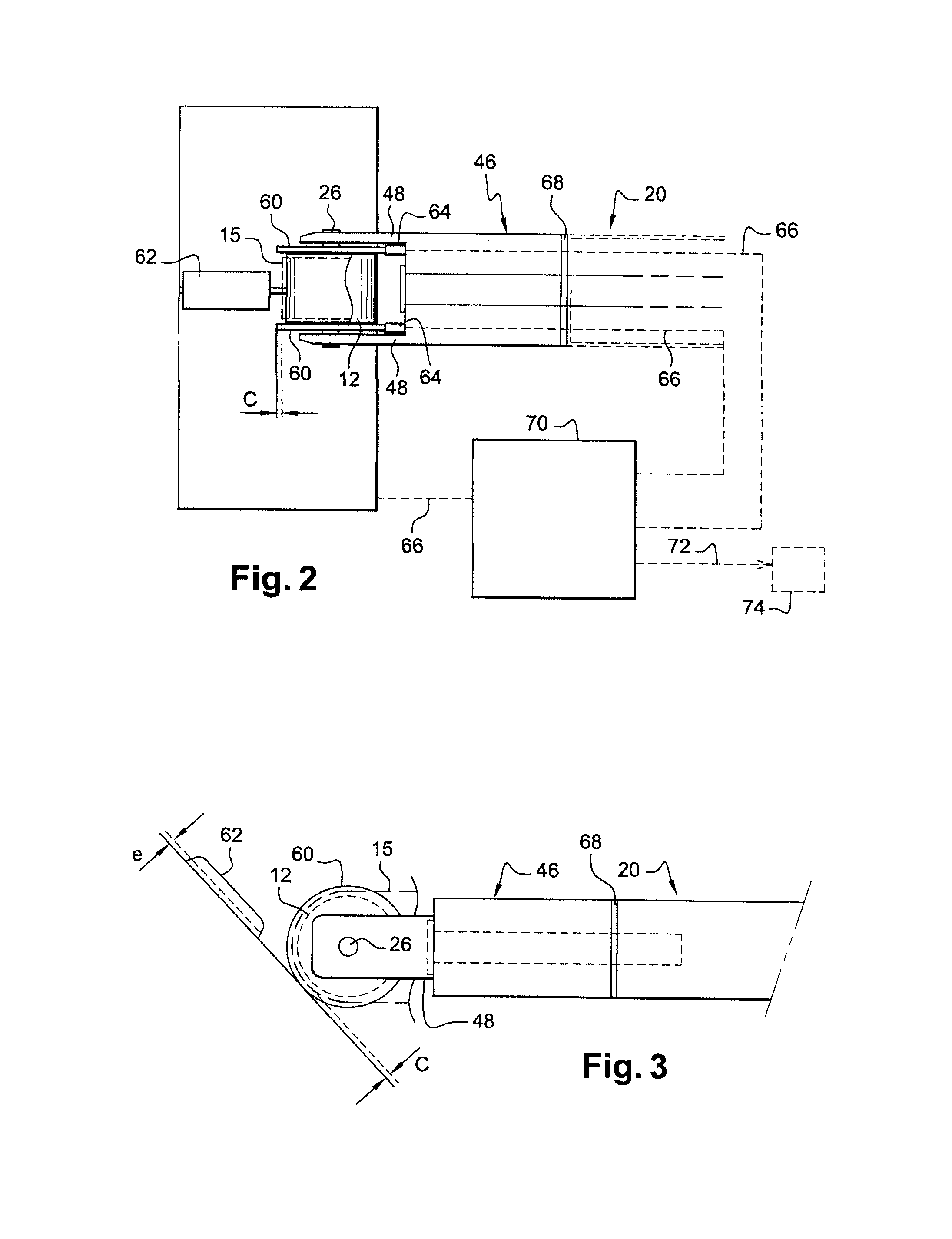

Robotic machining tool employing an endless machining belt

ActiveUS20090011691A1Prevent escapeEdge grinding machinesBelt grinding machinesFree rotationEngineering

A robotic machining tool, employing an endless machining belt (10), comprising a front pulley (12) and a rear pulley (14) for guiding a machining belt, the rear pulley being turned by drive means (22), and the front pulley being free to rotate about a spindle (26) and being flanked by two wheels (60) mounted idly on the spindle of the front pulley, these two wheels having an outside diameter greater than that of the front pulley in order to roll over a surface to be machined and in order to define a machining distance between the machining belt guided around the front pulley and the surface to be machined.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Robot closed-loop machining system used for pin welding of membrane water wall

ActiveCN106891111ASimplify programmingOvercome tedious and time-consuming difficultiesProgramme controlComputer controlSocial benefitsUser input

The invention discloses a robot closed-loop machining system used for pin welding of a membrane water wall. A sensor detection route and a welding robot theoretical machining route are automatically planned according to membrane water wall size parameters and sensor detection parameters which are input by a user. A sensor is connected to a welding robot to move along with a welding gun head and detects the outline of the membrane water wall in real time, and detection data are sent back to a correction module. Compensation and correction are conducted on the theoretical machining route, and a movement instruction of the welding robot is generated. A controller is used for controlling the welding robot to weld pins to the membrane water wall according to the technology parameters, and closed-loop machining is achieved. By means of the robot closed-loop machining system, a sensor detection algorithm is merged, the welding robot machining route is automatically planned according to the machining technology parameters input by the user, the sensor is used for detecting field data in real time and conducting compensation and correction on the theoretical machining route, the welding robot machining instruction is automatically generated, the machining precision is improved, and good social benefits and economic benefits are achieved.

Owner:BEIJING GXK CNC EQUIP

Vision-based robot transfer clamp and system for engine cylinder blocks

ActiveCN105345585AHigh positioning accuracyImprove applicabilityMetal working apparatusControl systemTransfer system

The invention discloses a vision-based robot transfer clamp for engine cylinder blocks. The vision-based robot transfer clamp for the engine cylinder blocks comprises a clamp body which is connected with a transfer robot body. The clamp body is provided with a vision system, a detection system and a pneumatic control system. The vision system, the detection system and the pneumatic control system are all connected with a control system of a transfer robot. The invention further discloses a vision-based robot transfer system for the engine cylinder blocks. The vision-based robot transfer system for the engine cylinder blocks comprises the transfer robot, the robot control system, the vision system, the detection system and the pneumatic control system. The robot control system controls the transfer robot, the vision system, the detection system and the pneumatic control system. Through the robot transfer clamp and the robot control system, automation and intellectualization of cylinder block transfer can be achieved, the transfer efficiency is high, the production cost is low, the transfer safety is high, and the requirement for the takt of robot machining can be met.

Owner:CHANGSHA CTR ROBOTICS

Robotic machining apparatus method and system for turbine buckets

InactiveUS20130173043A1Opportunities decreaseSolve insufficient capacityProgramme controlProgramme-controlled manipulatorControl systemRobotic arm

A robotic apparatus for machining tenons on turbine buckets of a steam turbine machine is disclosed. The robotic apparatus includes a machining device having a spindle head. A robotic arm is coupled to the machining device and a base member is coupled to the robotic arm. The base member is mounted independently of the machine element. A vision system is provided for locating the tenon on the turbine bucket. A control system is coupled to the vision system, the machining device and the robotic apparatus. The control system is configured to control movement of the robotic apparatus and the machining device based upon vision system data and spatial information about the tenon and the turbine bucket.

Owner:GENERAL ELECTRIC CO

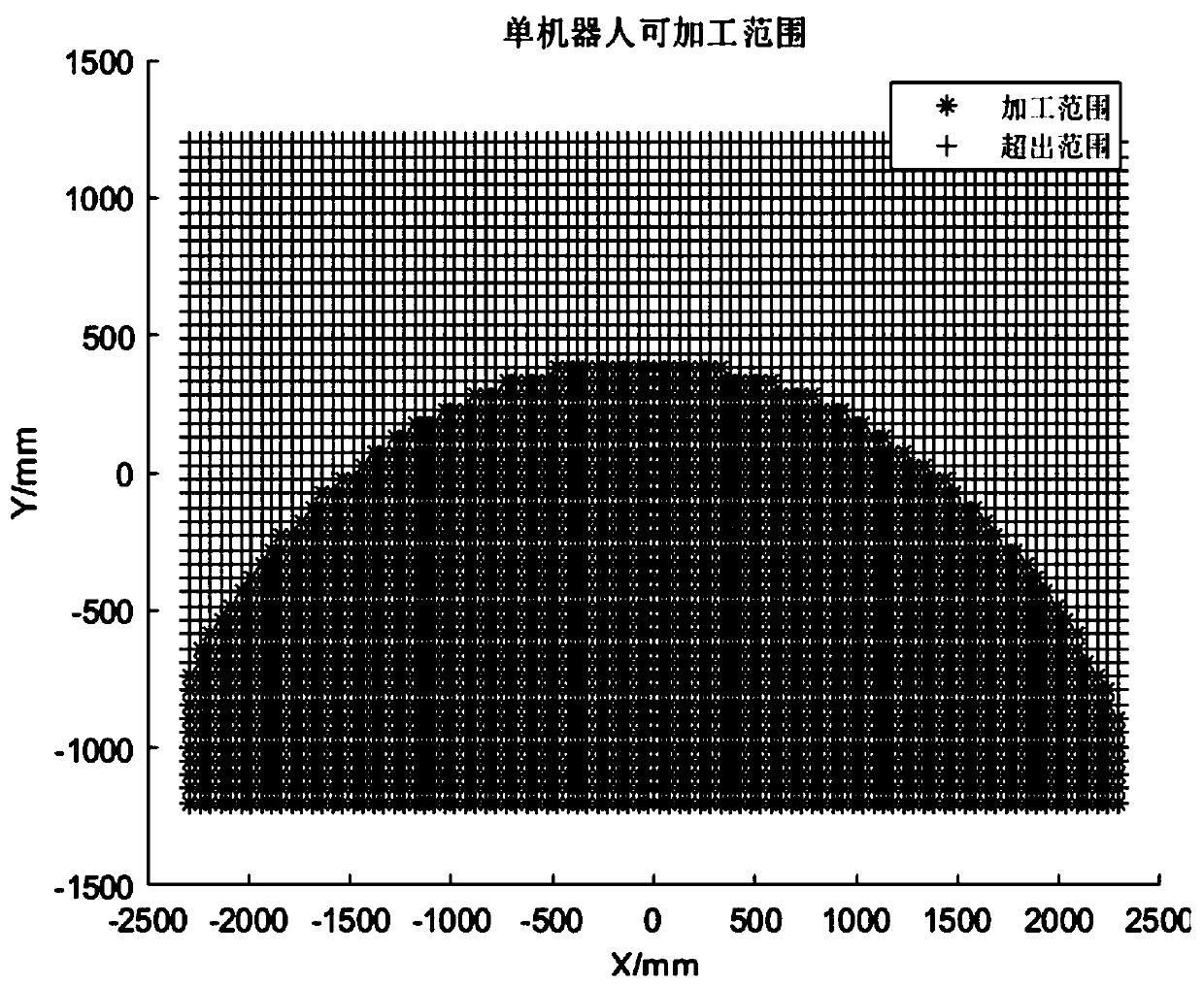

Multi-robot cooperative path planning method

ActiveCN106997201ASolve the handshake avoidance problemUnrestricted structurePosition/course control in two dimensionsVehiclesWork taskSimulation

The invention relates to the field of robot path planning and particularly relates to a multi-robot cooperative path planning method. A workpiece is provided, a main robot and a slave robot are defined, and the main information of the main robot and the slave information of the slave robot are acquired; the main robot adopts an active vision mode to acquire the information of the workpiece; according to the main information and the slave information, a robot model is built, and an environment model is built according to the workpiece information; according to the robot model and the environment model, the main robot determines the working tasks and the working paths of the main robot and the slave robot; and the main robot and the slave robot execute the working tasks according to the working paths. A three-dimensional object is intelligently identified through a binocular active vision system, which is not limited to features of the color and the shape and the like of the object. A sectional path planning technology is adopted, the path optimization efficiency is improved, a handshake collision avoidance problem in multi-robot superimposed motion can be solved, and dynamic adjustment of each joint and online optimization of the path during the multi-robot processing process can be realized.

Owner:SHANGHAI ELECTRICGROUP CORP

Ultrasonic rolling strengthening robot machining system and control method for aero-engine blades

ActiveCN111876570ARealization of ultrasonic rolling strengtheningExtended service lifeControl systemRobot machining

The invention relates to an ultrasonic rolling strengthening robot machining system and control method for aero-engine blades. The ultrasonic rolling strengthening robot machining system comprises a robot, a base and a control system, wherein an ultrasonic rolling strengthening device is fixed to the robot and driven by the robot to move; a spindle rotating table and a three-dimensional moving lifting device are mounted on the base, a rotatable blade clamp is arranged on the spindle rotating table, and a flexible follow-up supporting head is fixed to the three-dimensional moving lifting device; and the control system is in electrical connection or communication connection with the robot, the spindle rotating table and the three-dimensional moving lifting device. According to the ultrasonicrolling strengthening robot machining system and control method for the aero-engine blades, the robot is adopted to assist clamping the ultrasonic rolling device, so that the ultrasonic rolling device is matched with the three-dimensional moving lifting device and the flexible follow-up supporting head, and accurate ultrasonic rolling strengthening of the aero-engine blades is realized by collaboratively controlling the ultrasonic rolling device, the three-dimensional moving lifting device and the flexible follow-up supporting head.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Multi-robot machining method for rotary structural part

ActiveCN109849019AIncrease the level of automationImprove processing efficiencyProgramme-controlled manipulatorGripping headsRobot machiningEngineering

The invention discloses a multi-robot machining method for a rotary structural part. The multi-robot machining method for the rotary structural part comprises the following steps: initializing a real-time scene location system, at least two robots, and a rotary workpiece position-posture keeping and adjustment system; generating multi-robot collaborative operation instruction; fixing the rotary structural part to be machined to the rotary workpiece position-posture keeping and adjustment system; controlling the robots to move to corresponding machining positions through the real-time scene location system; carrying out position-posture adjustment by the robots according to the multi-robot collaborative operation instruction to determine a high-accuracy position-posture relationship betweena machining tool and profiles to be machined; and machining the corresponding profiles to be machined on the rotary structural part to be machined by the robots according to the multi-robot collaborative operation instruction. Through the multi-robot machining method for the rotary structural part, parallel milling, drilling and grinding for a plurality of machining surfaces on a large rotary structure are realized; and due to a parallel operation method, the automation level and the machining efficiency of the large rotary structure can be effectively increased.

Owner:BEIJING SATELLITE MFG FACTORY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com