Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Surface heat flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The transfer of heat from the interior to the surface is measured as heat flow. On continents, heat flow is usually measured in deep drill cores. Temperatures are measured going down the drill hole and establish a temperature gradient.

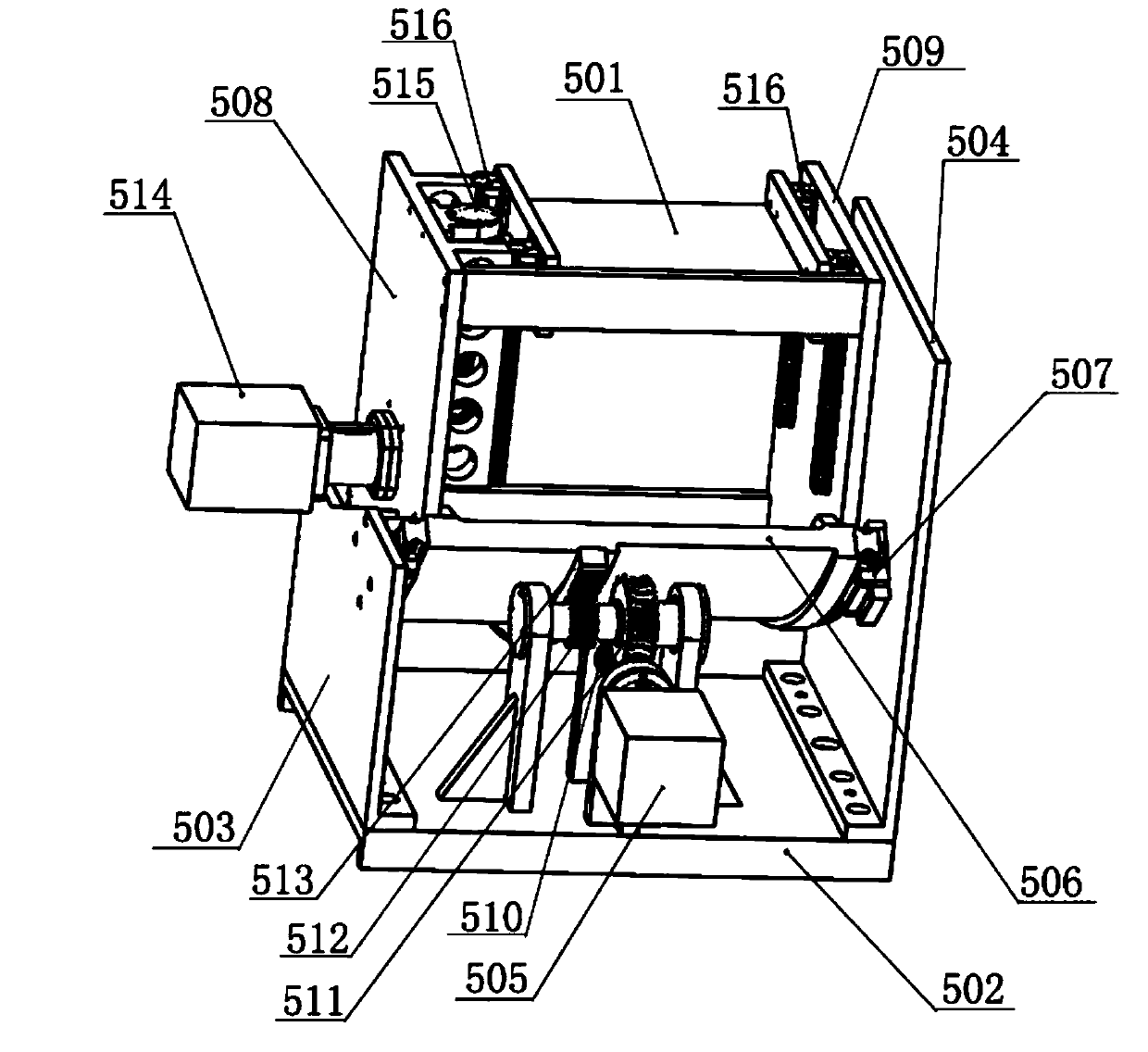

Self-adapting testing instrument for heat-moisture comfort performance of fabric and coupled testing method using same

InactiveCN102507641AActual measurement of dynamic heat and moisture transfer characteristicsThe experimental results are accurate and reliableMaterial heat developmentTextile testingHuman bodyPeristaltic pump

The invention relates to a self-adapting testing instrument and a testing method for heat-moisture comfort performance of fabric. The testing instrument comprises a testing main body and a testing accessory body, wherein the testing main body comprises a testing head; the testing head sequentially comprises a heating plate, a copper plate, a simulated skin, a simulated skin and a sample clamp clamped with a sample bottom to top; a temperature and humidity sensor is arranged between the sample and the simulated skin; a membrane couple is attached to the surface of the simulated skin device; multiple sweating micropores connected with a control valve of a peristaltic pump are disposed on the simulated skin device; the testing accessory body comprises a clothed human body heat physiological model module, a control module and a surface heat flow calculation module; the surface heat flow calculation module is used for calculating the surface heat flow according to the sweating amount of the sweating micropores and the temperature of the membrane couple; and the clothed human body heat physiological model module is used for real-time sending signals for controlling the peristaltic pump and the heating plate to the control module by taking the calculated surface heat flow as a boundary condition. The self-adapting testing instrument can simulate human body heat physiological characteristics changing along with the ambient change.

Owner:DONGHUA UNIV

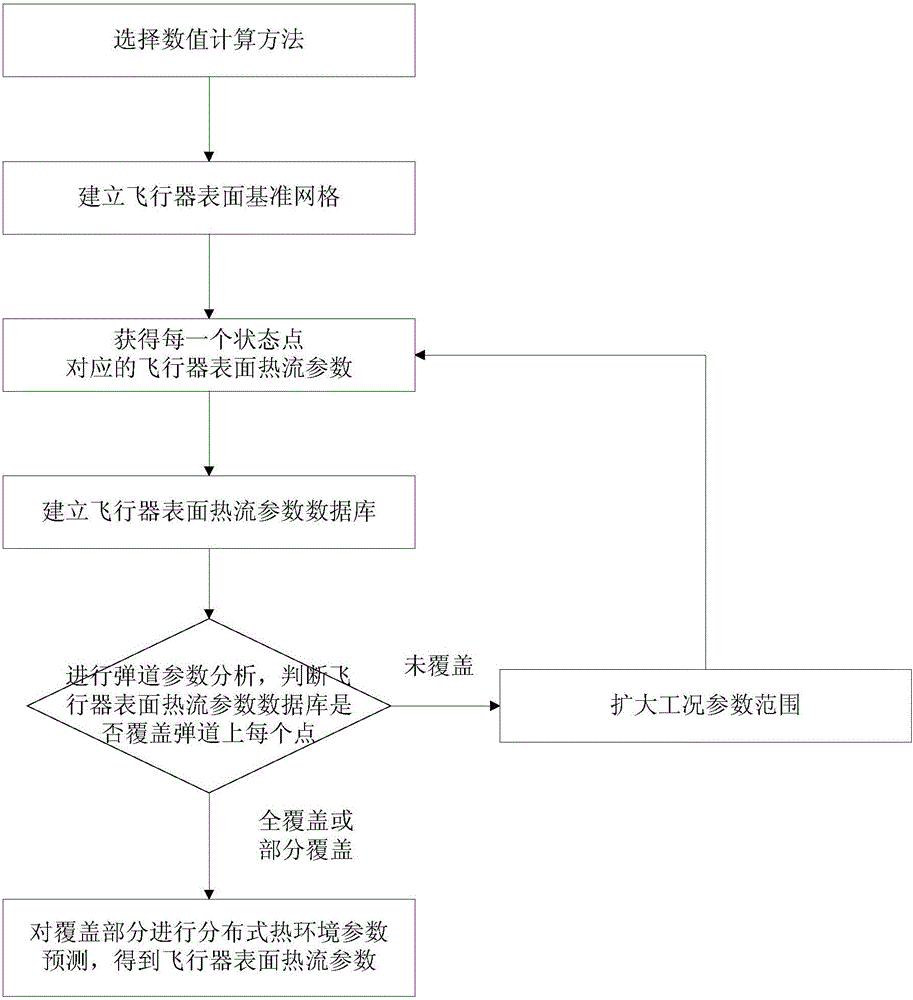

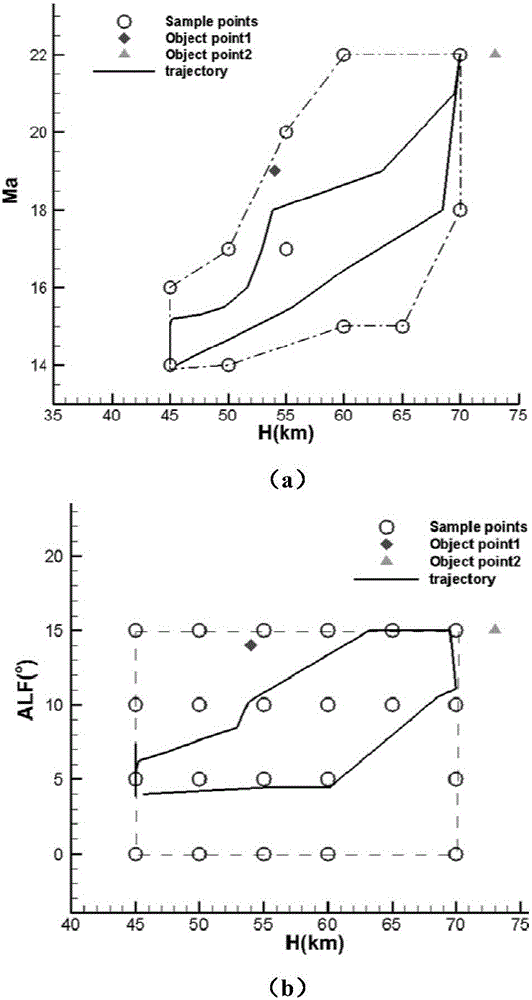

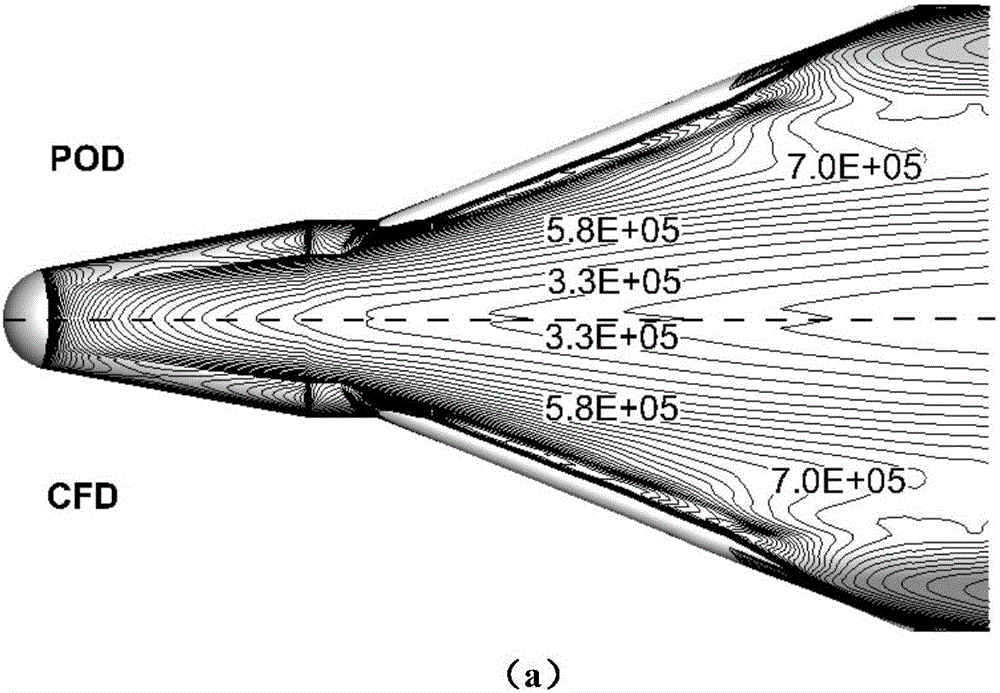

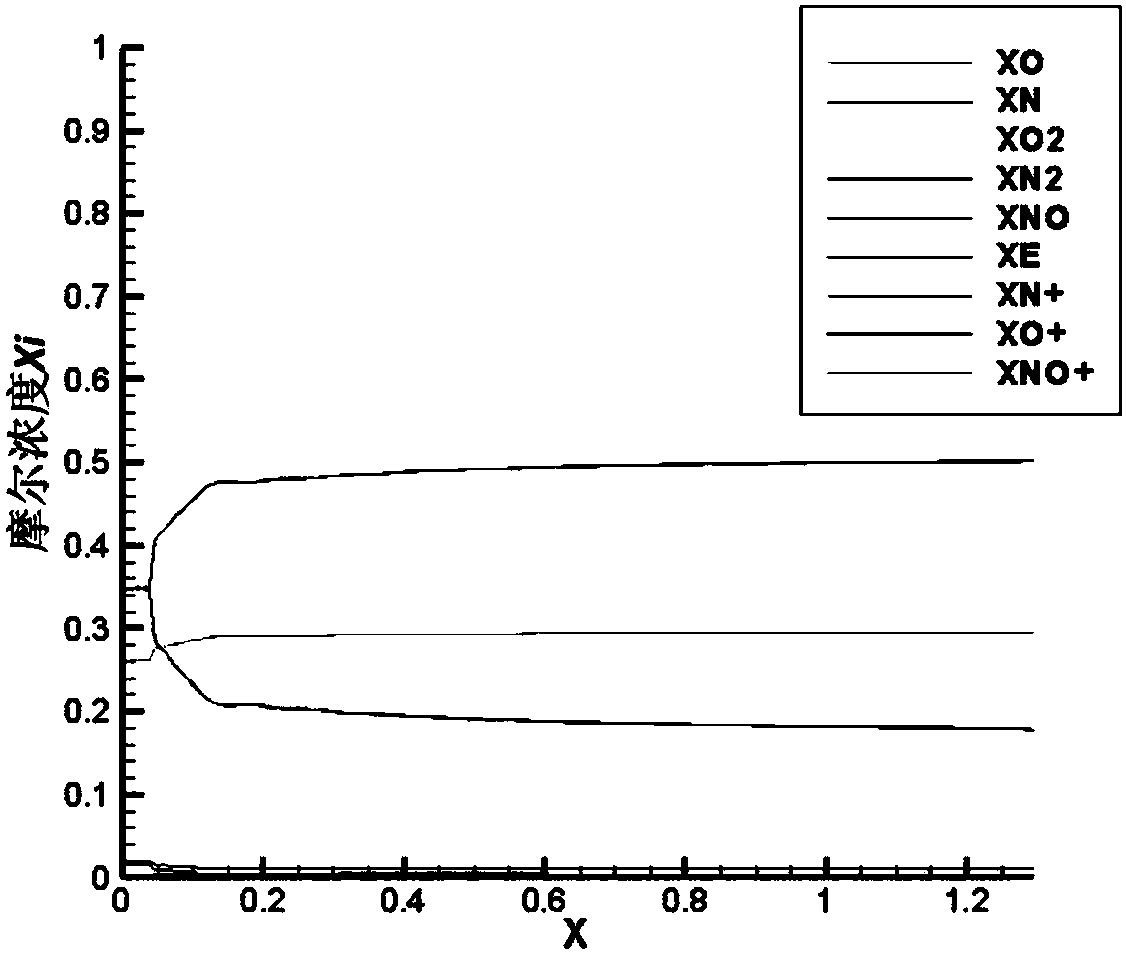

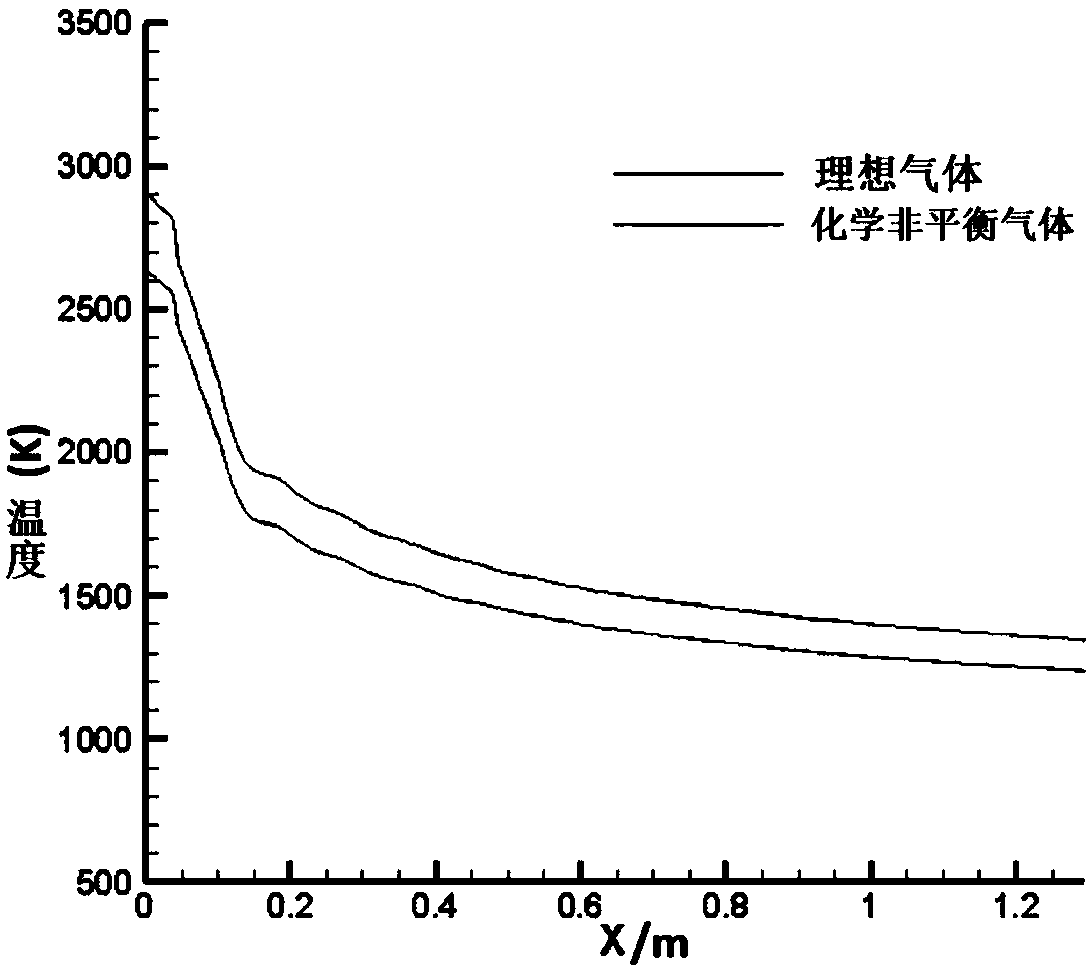

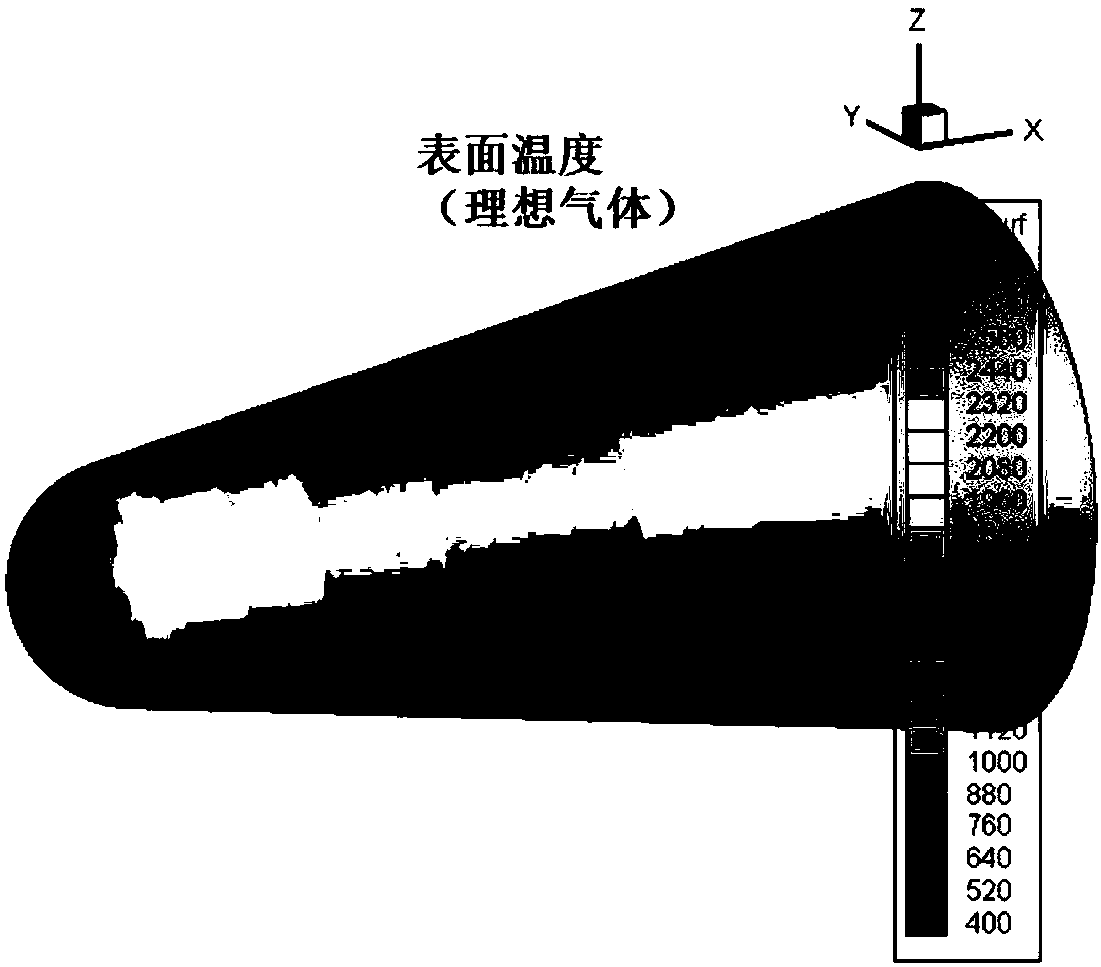

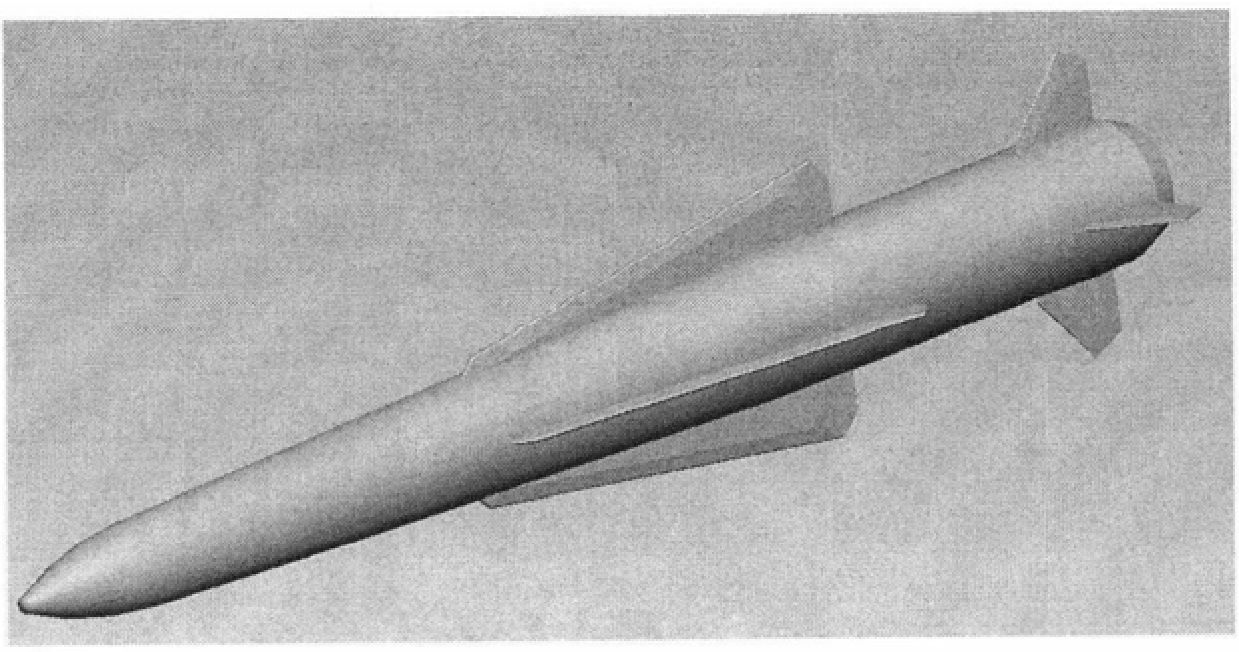

Database based complex-contour aircraft distributed heat environment parameter prediction method

ActiveCN106202804AAccurate predictionImprove design accuracyGeometric CADSustainable transportationEnvironmental designOrthogonal basis

The invention discloses a database based complex-contour aircraft distributed heat environment parameter prediction method and belongs to the field of aircraft heat environment design. The method comprises the steps that an aircraft surface heat flow database is established, order reducing processing is conducted on the database by utilizing a POD method to obtain orthogonal basis vectors of the database, and aircraft surface heat environment parameters can be predicted along a ballistic trajectory by combining with a corresponding basic coefficient interpolation method. The method can really reflect the space distribution characteristics and interference characteristics of the aerodynamic heat environment for all points on the surface of a complex-contour aircraft. Value result comparison shows that the method can remarkably improve the computational efficiency, and prediction precision is not lost. A surface distributed heat flow is provided for calculation of a heat proof temperature field through the points along the ballistic trajectory, more exquisite temperature distribution can be obtained, and accordingly the design level of a whole heat preventing and insulation system is improved.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

Fluid-solid-heat rapid calculation method for high-speed aircrafts with three-dimensional complicated appearances

The invention discloses a fluid-solid-heat rapid calculation method for high-speed aircrafts with three-dimensional complicated appearances, and belongs to the field of aircraft pneumatic calculation.According to the method, static aerodynamic heat calculation is simplified to inviscid outflow numerical solution and boundary layer inner heat flow solution by adoption of a CFD numerical calculation and engineering algorithm combined method according to a boundary layer theory, and anti-heat system structure heat transfer calculation model is coupled at the same time. According to the method, advantages of overall length numerical simulation and an engineering algorithm are combined, so that an aircraft whole surface heat flow density and anti-heat structure temperature field time-variant characteristics can be rapidly and efficiently given to a method for calculating pneumatic heating and structure coupling heat transfer characteristics of aircrafts with three-dimensional complicated appearances under multiple flight states, the gaps such as high calculation cost, low efficiency and long period of numerical simulation method are filled, and the application range of the engineeringalgorithm is broadened at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

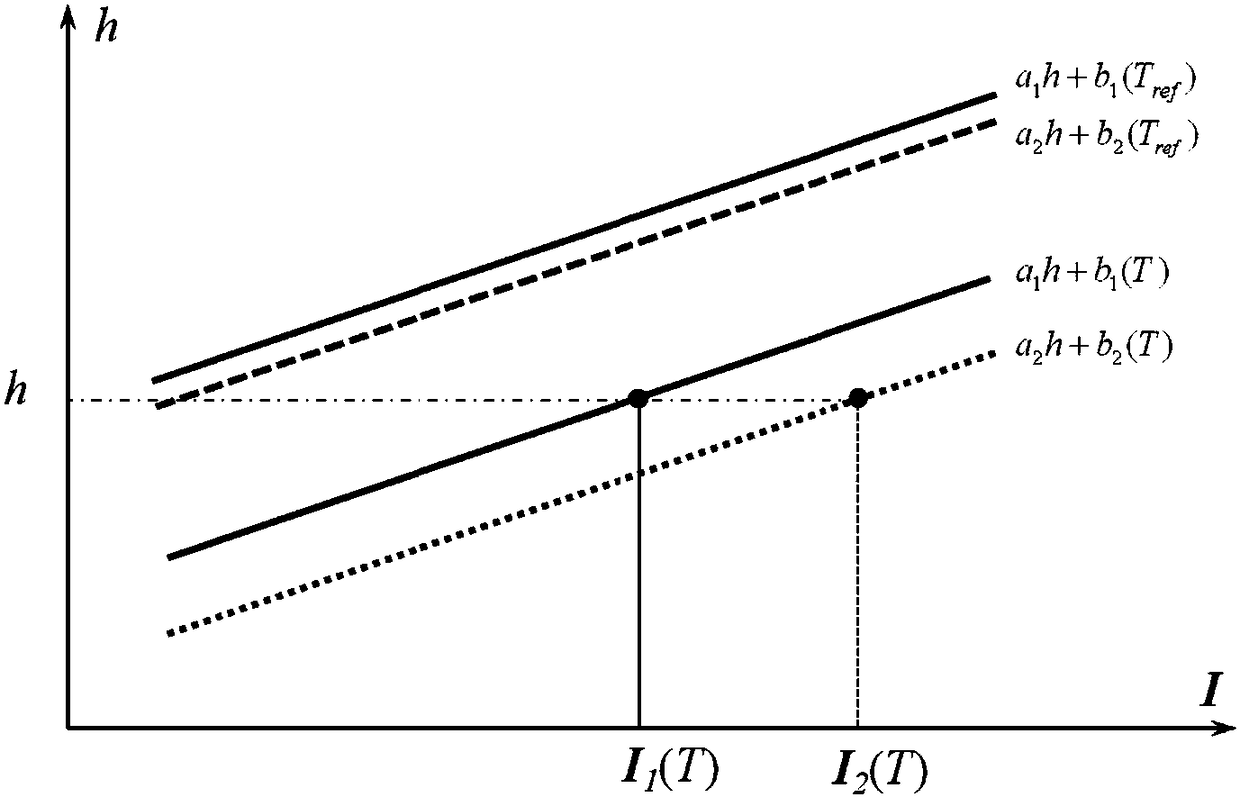

Temperature effect-based fluorescent oil film thickness calibration method

ActiveCN108225718AHigh precisionEasy to measureAerodynamic testingUsing optical meansHeat flowFluorescence

The invention provides a temperature effect-based fluorescent oil film thickness calibration method, which comprises the following steps: calibrating an oil film in the selected test environment temperature and acquiring oil film parameters, acquiring a linear function relation formula of a gray value and a height value of the oil film, further acquiring the linear function relation formula of a linear image intercept and an oil film temperature value, so as to finally achieve the purpose of calculating the oil film height value and oil film temperature value in a wind tunnel test according tothe currently acquired image gray value. According to the calibration method, the parameter calculation is simple, the measurement stability is good, the effect from surface heat flow does not exist,and the measurement precision is high.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

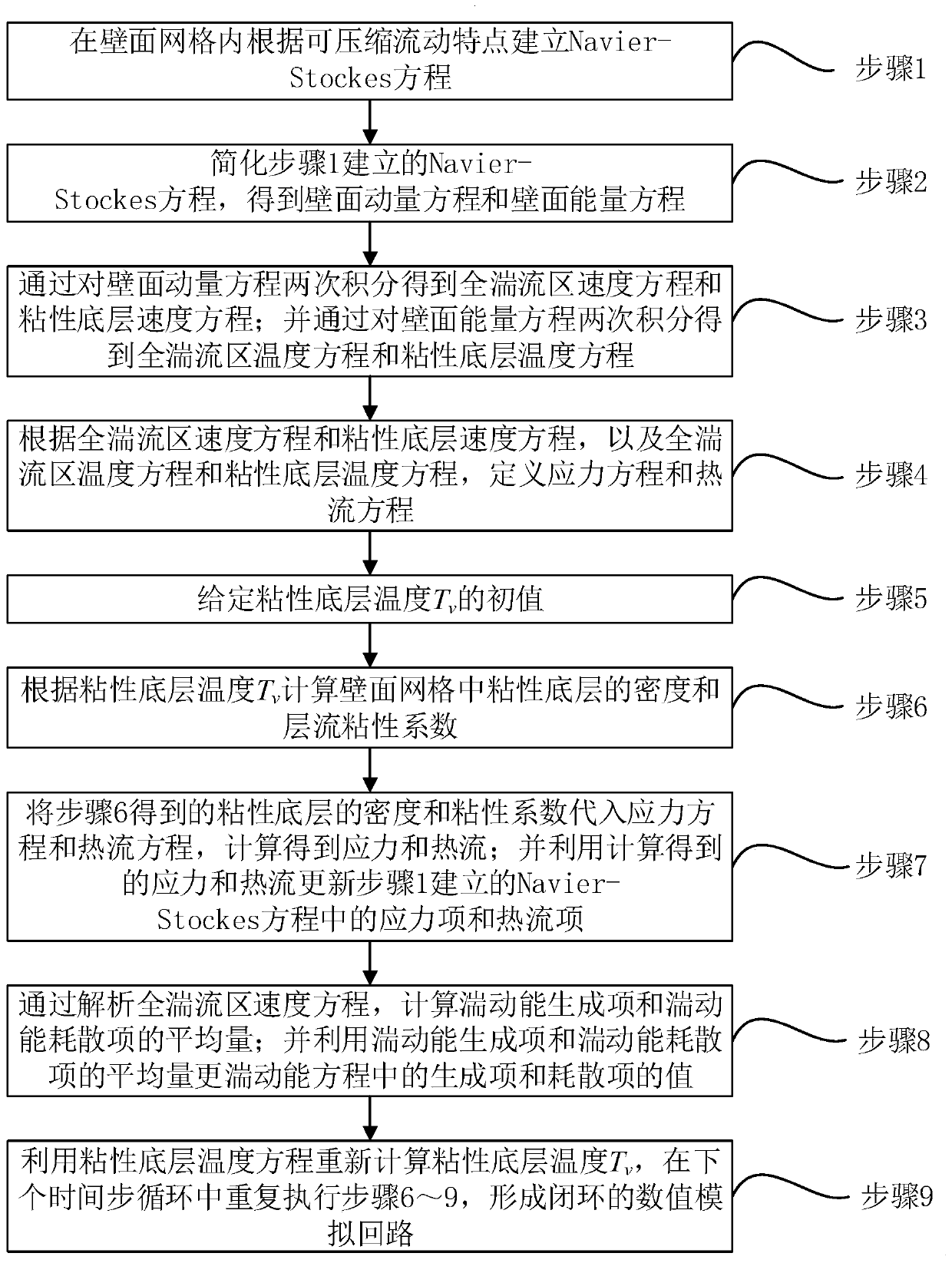

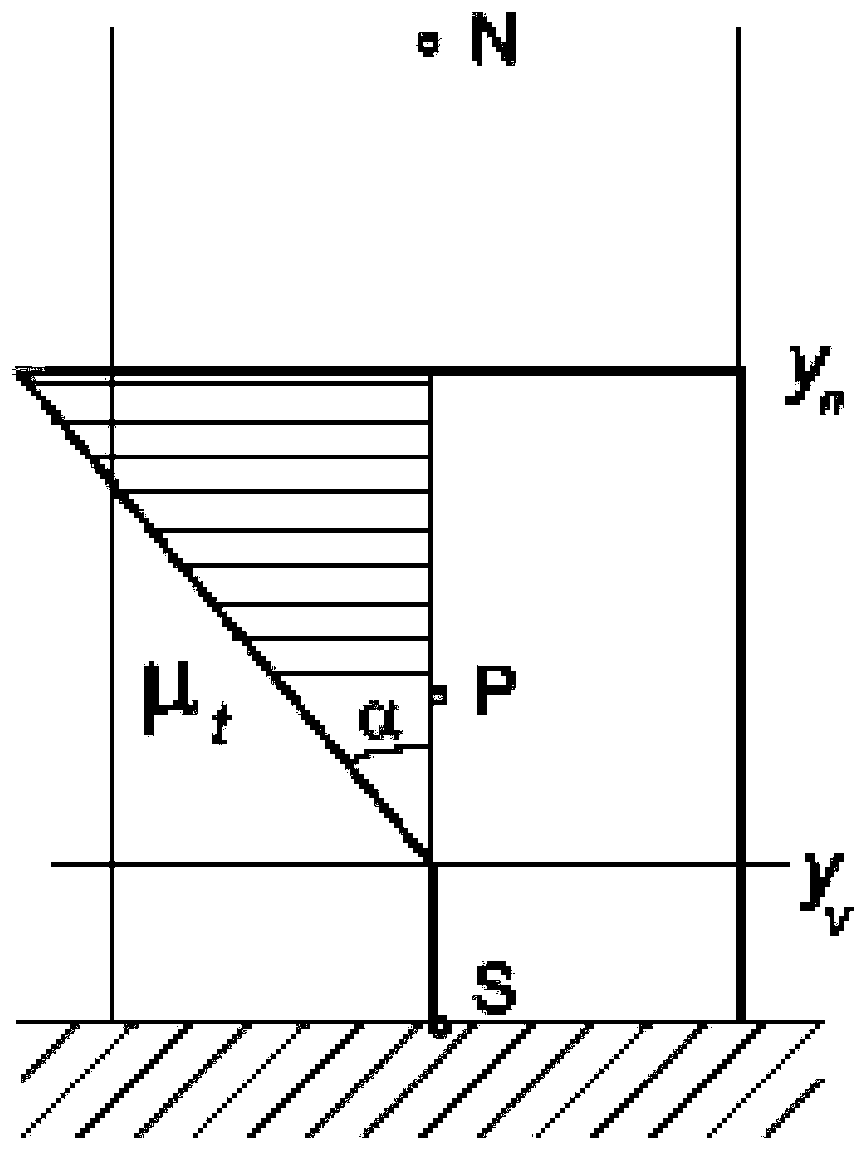

Compressible flow-based numerical simulation method for analyzing wall surface function

ActiveCN110489709ATightly coupledAccurate predictionComplex mathematical operationsSpeed of soundKinetic energy

The invention discloses a numerical simulation method for analyzing a wall surface function based on compressible flow. The method comprises the following steps: establishing a Navier-Stokes equationaccording to compressible flow characteristics, simplifying the Navier-Stokes equation, analyzing the Navier-Stokes equation to obtain a full turbulence zone speed equation, a viscous bottom layer speed equation, a full turbulence zone temperature equation and a viscous bottom layer temperature equation, and further defining a stress equation and a heat flow equation; giving an initial value of the temperature Tv of the viscous bottom layer, and calculating according to the Tv to obtain stress and heat flow; updating a stress item and a heat flow item by utilizing the calculated stress and heat flow; updating the values of a generation item and a dissipation item in the turbulence energy equation by calculating the average quantity of the turbulence energy generation item and the turbulence energy dissipation item; and finally, recalculating Tv by utilizing a viscous bottom layer temperature equation, and repeatedly updating in the next time step cycle. Based on the compressible flow characteristic, the method is particularly suitable for hypersonic flow, and the wall surface heat flow can be predicted more accurately.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

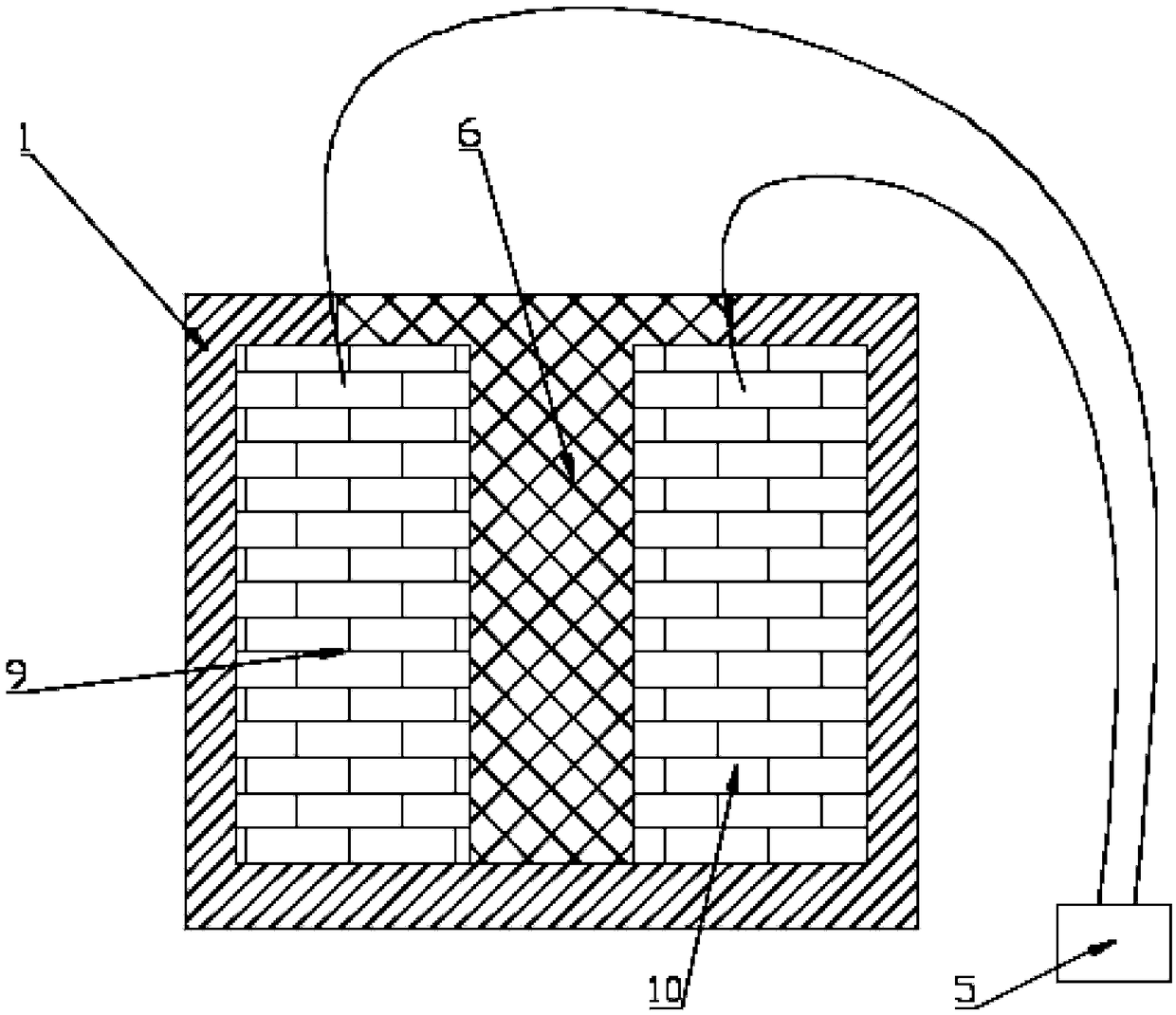

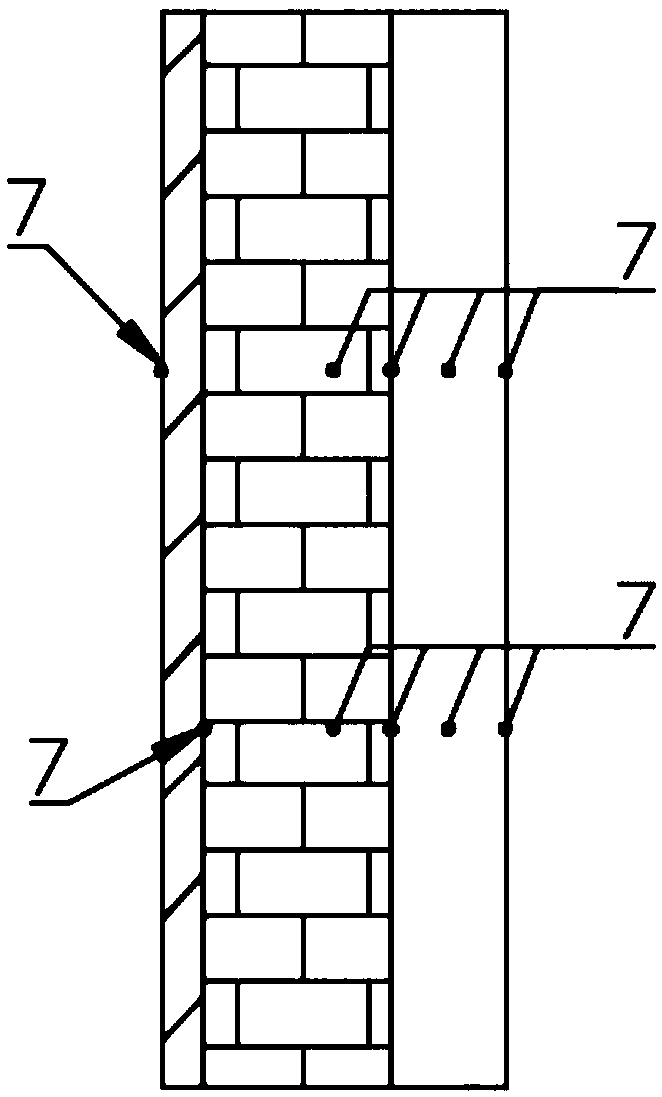

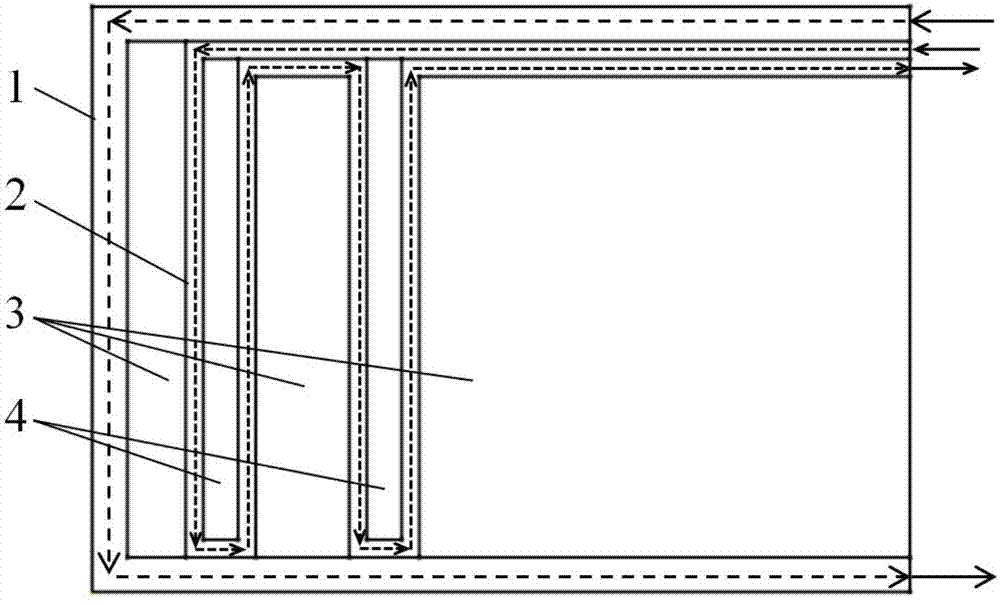

Method for comparison test of thermal performance of two walls and test device

InactiveCN109187626AReduce experimental errorImprove the accuracy of comparative analysisMaterial heat developmentData acquisitionEngineering

The invention discloses a method for comparison test of thermal performance of two walls and a test device. The test device comprises a test frame, two walls with different properties, temperature sensors, heat flow sensors and a data collecting and recording terminal. The method comprises the steps of collecting parameters of internal temperature distribution and surface heat flow transfer and the like under same heat transfer boundary conditions, of the two walls with different properties in the test frame, by utilizing the temperature sensors and the heat flow sensors; and carrying out comparative analysis on difference between the two walls on the aspects of the attenuation and the delay of temperature waves, heat transfer coefficient thermal performance parameters according to test data, wherein by applying the alternating temperature waves, specific values of the attenuation coefficients and the delay time of the two test walls can also be obtained respectively under periodic boundary conditions. The method disclosed by the invention has the advantages that not only can the advantages and the disadvantages of the thermal performance of the two walls be directly compared, butalso the test error can be reduced and the accuracy of the comparative analysis is improved. The device has the advantages of being simple in structure, low in manufacturing cost and convenient to install.

Owner:CHINA UNIV OF MINING & TECH +1

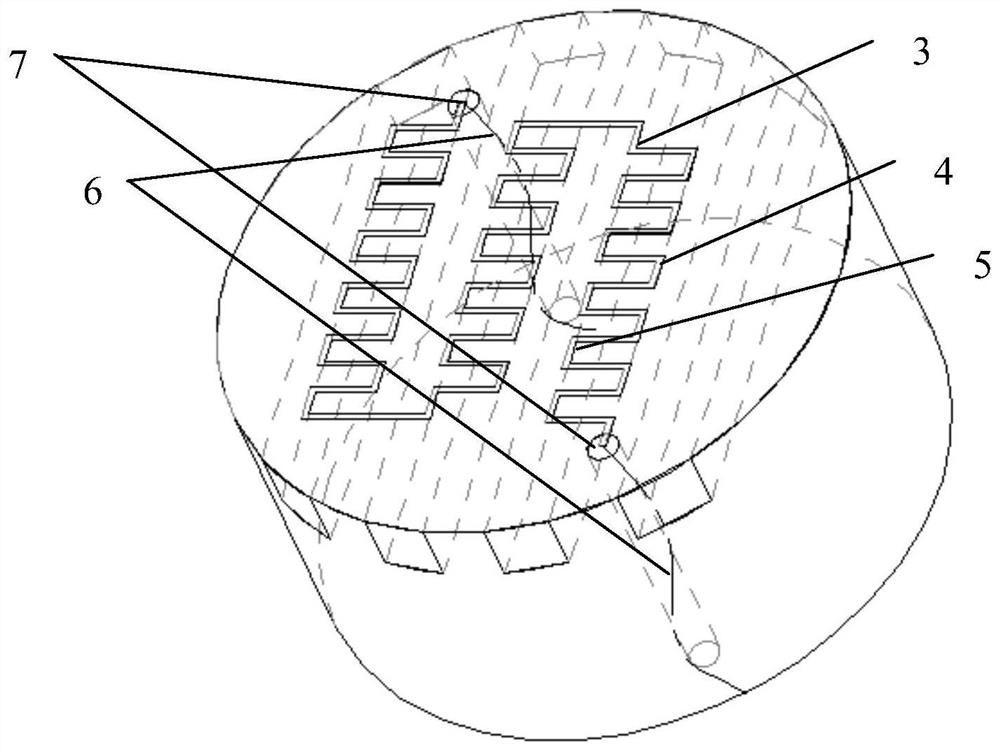

Aerodynamic heat measuring method suitable for blunt body reentry vehicle

InactiveCN108216685ATrue reentry heat flow loadGeometric CADSustainable transportationStagnation pointHeat flow

The invention provides an aerodynamic heat measuring method suitable for a blunt body reentry vehicle. The aerodynamic heat measuring method is used for measuring of surface heat flow distribution ofthe side walls, the large bottom, the stagnation point area and the boundary layer transition area of the blunt body reentry vehicle and measuring of total heating capacity of the windward side and the leeward side. The aerodynamic heat measuring method comprises the following steps that according to the appearance and a reentry trajectory of the blunt body reentry vehicle, simulation analysis onaerodynamic heat load on the surface of the blunt body reentry vehicle is conducted; according to the sizes and distribution of aerodynamic heating heat flows, sensor selecting and measuring range determining are conducted; according to the aerodynamic heat measuring task requirement of the blunt body reentry vehicle, configuration demand analysis of sensors is conducted; sensor layout design is conducted; and sensor calibration and mounting are conducted. According to the aerodynamic heat measuring method, the real reentry heat flow load can be obtained, particularly, real-time data of transition of the boundary layer on the surface of the vehicle can be provided, and guiding significance is achieved on a current calculating analysis model and the ground test technical scheme.

Owner:BEIJING SPACE TECH RES & TEST CENT

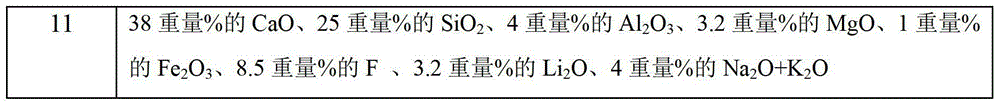

Continuous casting method for low-alloy steel wide and thick slabs

The invention discloses a continuous casting method for low-alloy steel wide and thick slabs. The continuous casting method comprises the following steps: pouring molten steel from a tundish into a crystallizer; in the crystallizer, adding casting powder on the liquid level of molten steel; enabling the molten steel to form casting blanks with liquid cores through the vibration of the crystallizer and the cooling action of the wide surface and the narrow surface of the crystallizer, and then continuously pulling out the casting blanks with the liquid cores from the outlet of the crystallizer at a pulling speed Vc to pass through a secondary cooling zone so as to obtain completely solidified casting blanks. The continuous casting method is characterized in that the crystallizer is composed of a copper plate, the flow speed of cooling water in cooling water seams of the copper plate is 8.8-9.3m / s, and the specific value of the narrow surface heat flow and the wide surface heat flow of the crystallizer is 0.85-0.95. As the cooling schedule of the crystallizer is reasonably controlled, the continuous casting method can reduce the surface cracks of the produced wide and thick slabs and optimize the product quality.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

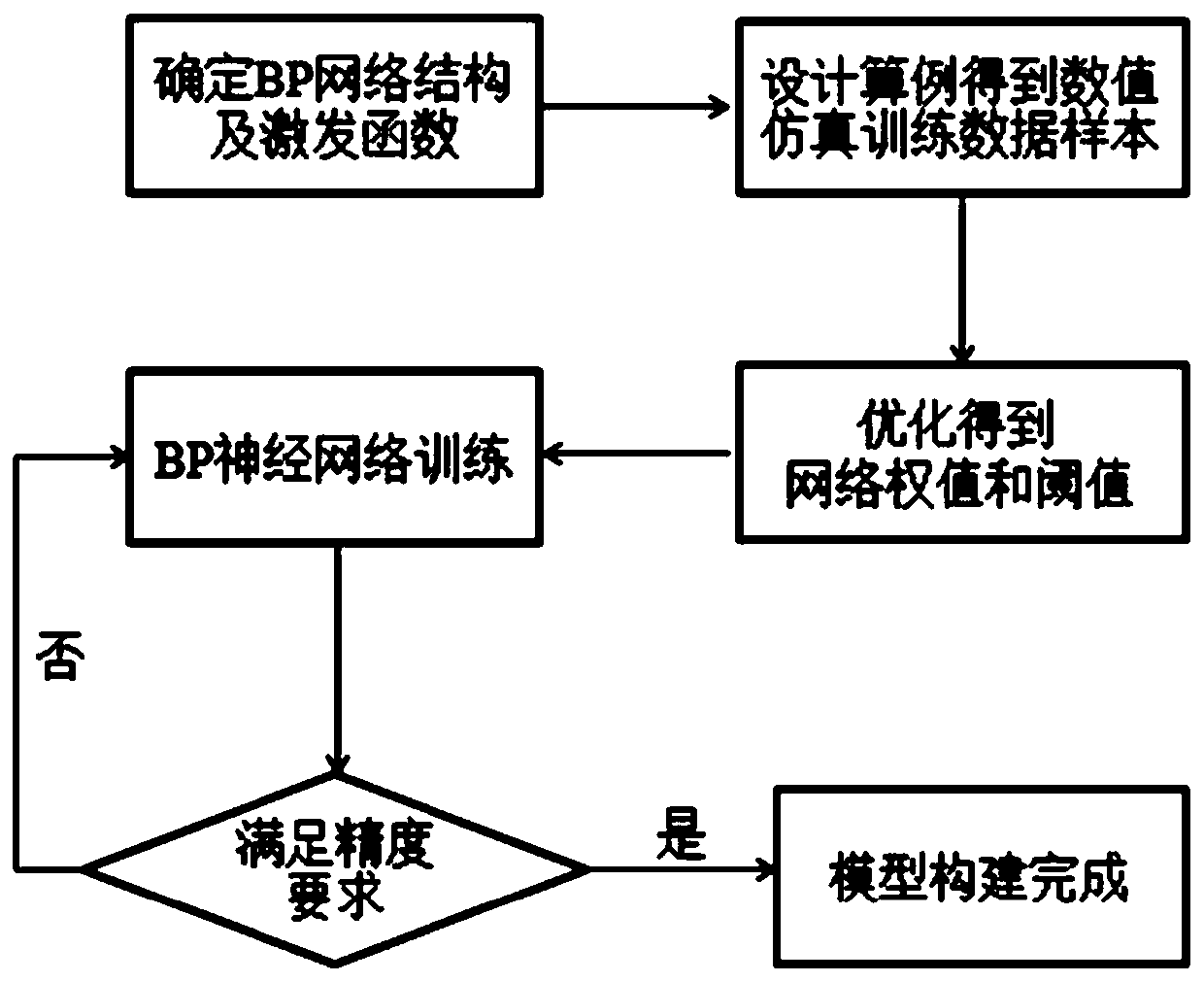

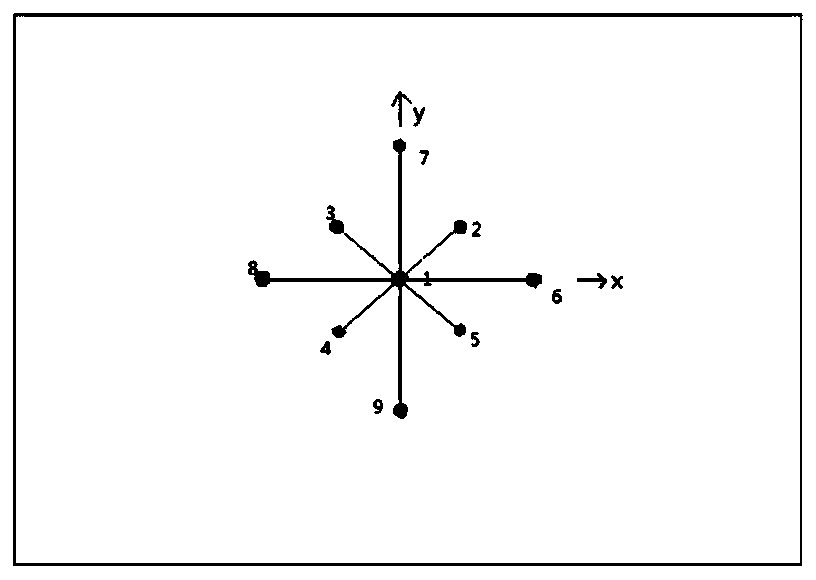

Surface heat flow identification three-dimensional effect correction method based on neural network

InactiveCN110083895AGood strong nonlinearityImprove recognition accuracyGeometric CADDesign optimisation/simulationNerve networkHeat flow

The invention discloses a surface heat flow identification three-dimensional effect correction method based on a neural network. The correction method comprises the following steps: mounting a plurality of temperature sensors on the inner wall surface of an area around a stationary point heat flow; utilizing temperature data of each internal temperature measuring point; obtaining a heat flow on acorresponding heating surface point through a one-dimensional heat flow identification method; and then introducing an artificial neural network algorithm, carrying out normalization processing on theidentified heat flow corresponding to each measuring point in the previous step to serve as an input sequence of the neural network, and carrying out training in the neural network to obtain an output anti-normalization result to serve as a heat flow identification value of a region of interest. According to the correction method provided by the invention, the time complexity of three-dimensionalidentification is avoided, meanwhile, the good noise resistance of the sequential function method and the strong nonlinearity of the neural network are combined, a traditional model can be greatly simplified, the identification precision of the stationary point heat flow is improved, and the real-time performance of on-line identification is ensured.

Owner:ZHEJIANG UNIV

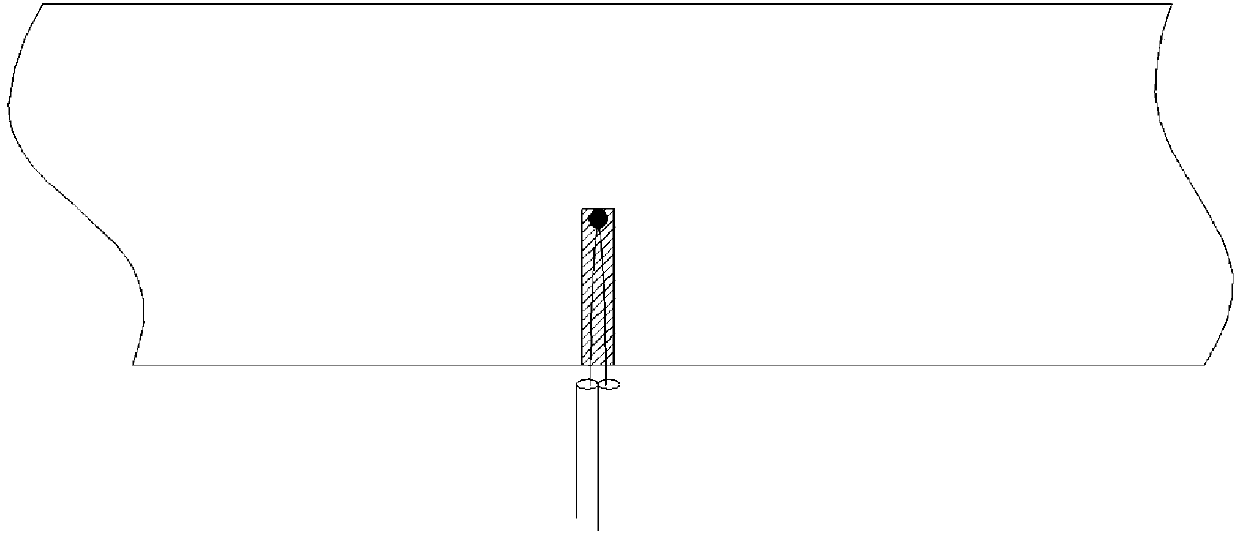

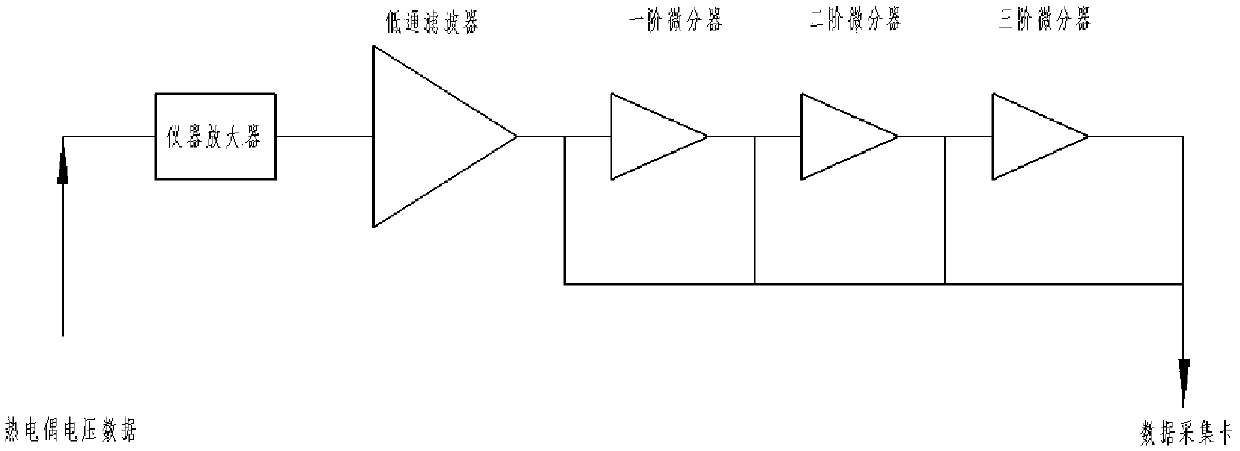

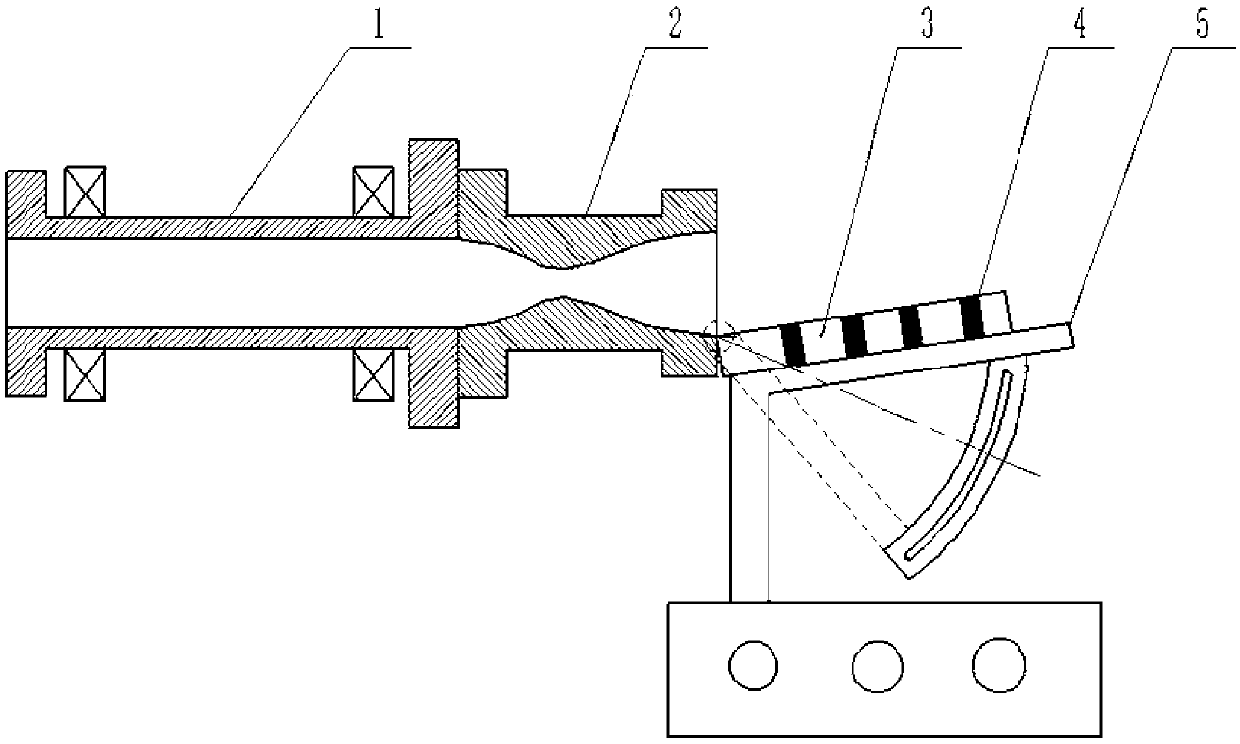

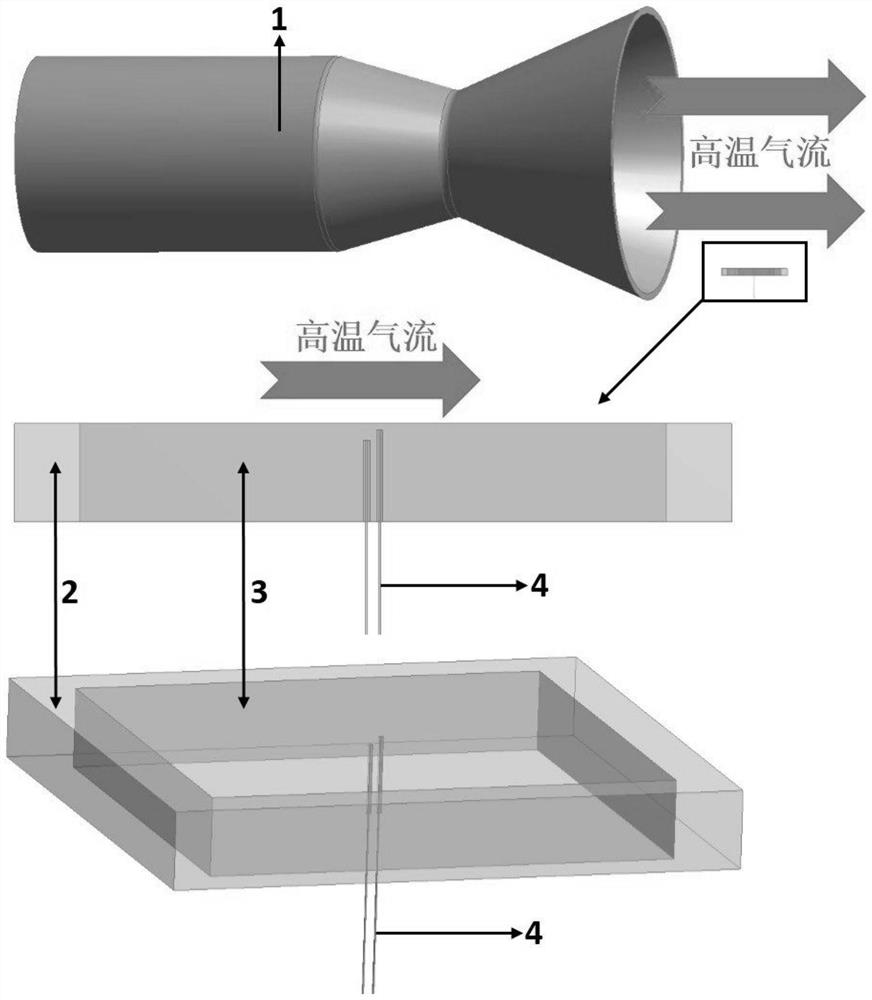

Method for measuring surface heat flow of embedded thermocouple

ActiveCN108287030AAvoid issues that compromise the material integrity of aircraft modelsRealize measurementThermometers using electric/magnetic elementsUsing electrical meansTemporal changeDifferentiator

A method for measuring the surface heat flow of an embedded thermocouple is provided. The thermocouple is installed on the inner surface of the model material of an aircraft by punching the inner surface, thereby ensuring the integrity of the surface of the model. A relationship between temperature and time is obtained according to a relationship between temperature and thermoelectric potential and a relationship between the thermoelectric potential and time without affecting the measurement accuracy. In a calculation process, the differentiator of an acquisition system is configured to visually reflect a derivative relationship to ensure the accuracy of the calculation. Further, according to the obtained derivative relationship, and the parameters of the thermocouple and the aircraft model material, the calculation of the surface heat flow value is completed. The method is high in measurement accuracy, good in stability, and easy to operate.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

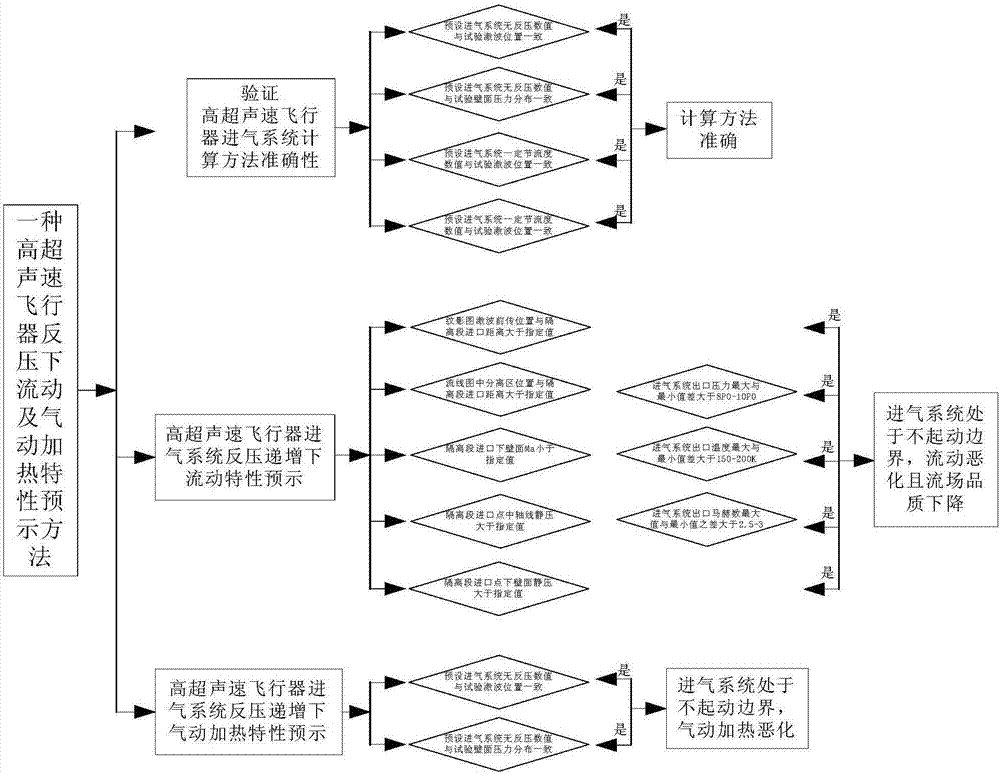

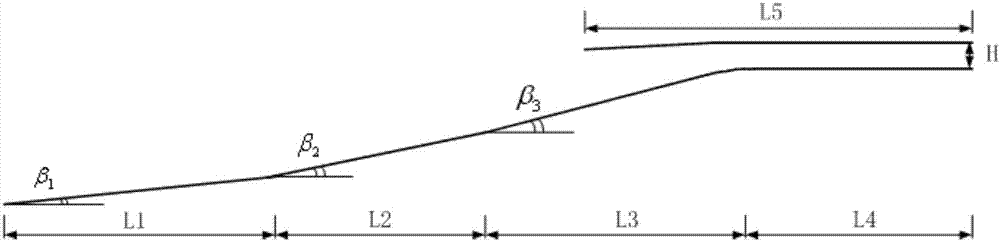

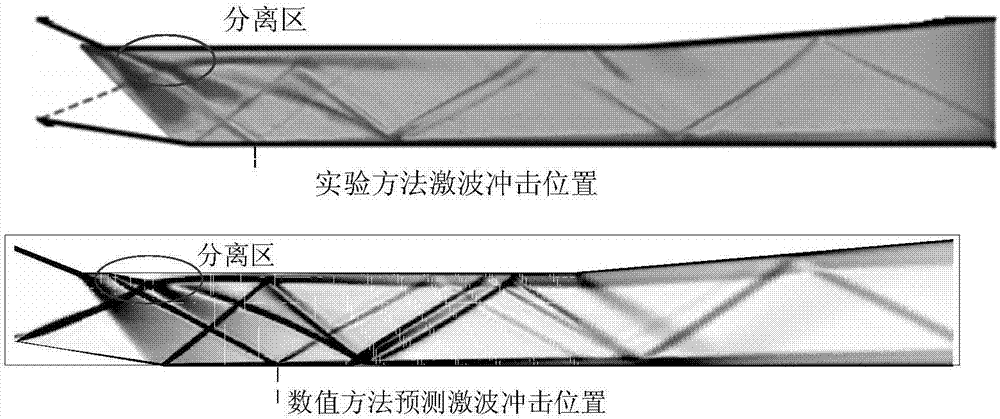

Method and system for indicating characteristics of air intake systems under back pressure of hypersonic aircrafts

InactiveCN107977494AForeshadowing the location of the shock waveForeshadowing Separation FlowGeometric CADSustainable transportationShock waveEngineering

The invention discloses a method and system for indicating characteristics of air intake systems under back pressure of hypersonic aircrafts. The method comprises the following steps of: verifying thecorrectness of a hypersonic aircraft air intake system calculation method; simulating a hypersonic aircraft air intake system flow field to obtain air intake system schlieren figure under progressiveincrease of back pressure, judging an appointed range of distance between a shock wave forward pass position corresponding to each air intake schlieren figure and an inlet of an isolated section of the aircraft, and considering that the air intake systems are located in a non-starting boundary; and simulating the hypersonic aircraft air intake system flow field to obtain air intake system upper wall surface heat flow distribution figures under progressive increase of back pressure, judging an upper wall surface heat flow value of the inlet point at the isolated section according to each air intake system upper wall surface heat flow distribution figure, and if the upper wall surface heat flow value is greater than an appointed value, considering that the air intake systems are located inthe non-starting boundary and aerodynamic heating degrades. According to the method and system, back pressure preventing performance of the air intake systems can be pre-judged accurately, and designof the air intake systems is improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

A Calculation Method for Aerodynamic Heating of Complex Aircraft Applicable to Engineering Design

ActiveCN106508020BOvercome the disadvantages that it is difficult to solve the parameters of the complex shape object surfaceGuaranteed adaptabilitySpecial data processing applicationsAerodynamic dragEngineering design process

This method proposes a complex aircraft aerodynamic heating calculation method that can be used in engineering design. This method uses the CFD method to solve the Euler equation for the external inviscid flow field to calculate the complex shape; determine the outer edge parameters of the aircraft boundary layer through CFD; and then in Inside the boundary layer where the viscosity plays a dominant role, the engineering reference enthalpy method is used to calculate the surface heat flow, and various forms of the reference enthalpy method are synthesized. This method not only overcomes the disadvantage that the pure engineering algorithm is difficult to solve the complex shape and surface parameters, but also the calculation amount is much smaller than the pure numerical algorithm, which effectively improves the accuracy and calculation efficiency of the outer edge parameters of the aircraft boundary layer. This method and software use the CFD method to establish a surface flow field database for the complex shape of the aircraft, and can calculate the aerodynamic heating of the aircraft for a long time along the flight trajectory. The calculation efficiency is much higher than the direct numerical solution of the N-S equation to calculate the aerodynamic heat. It can be applied to engineering design.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

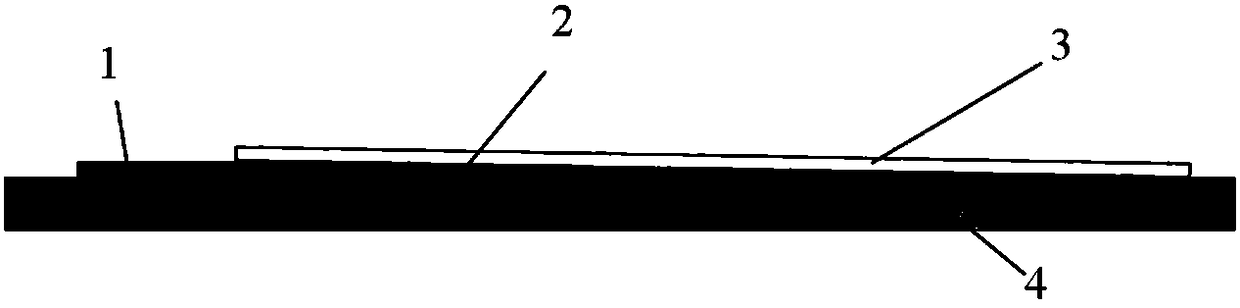

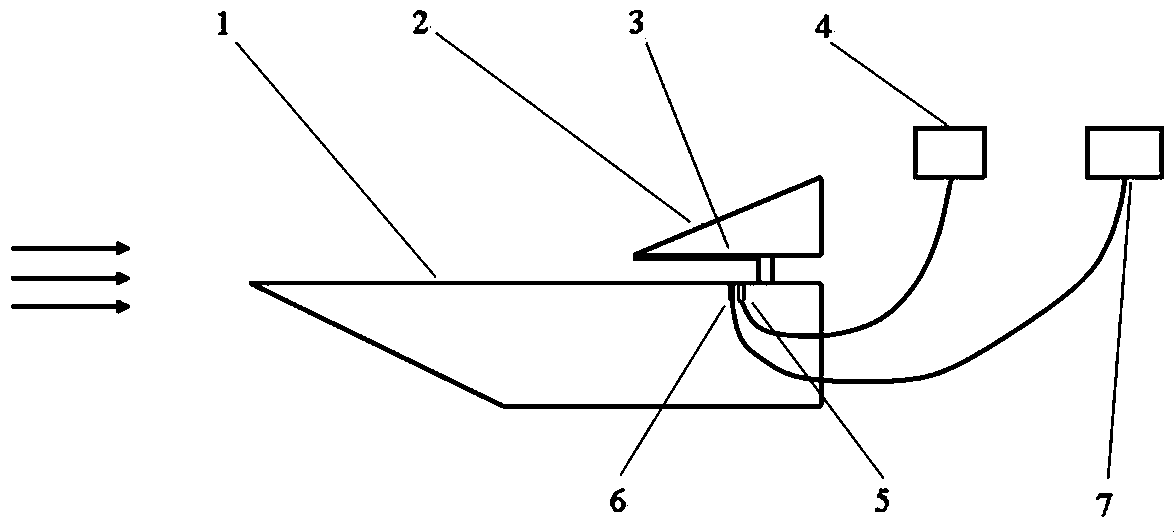

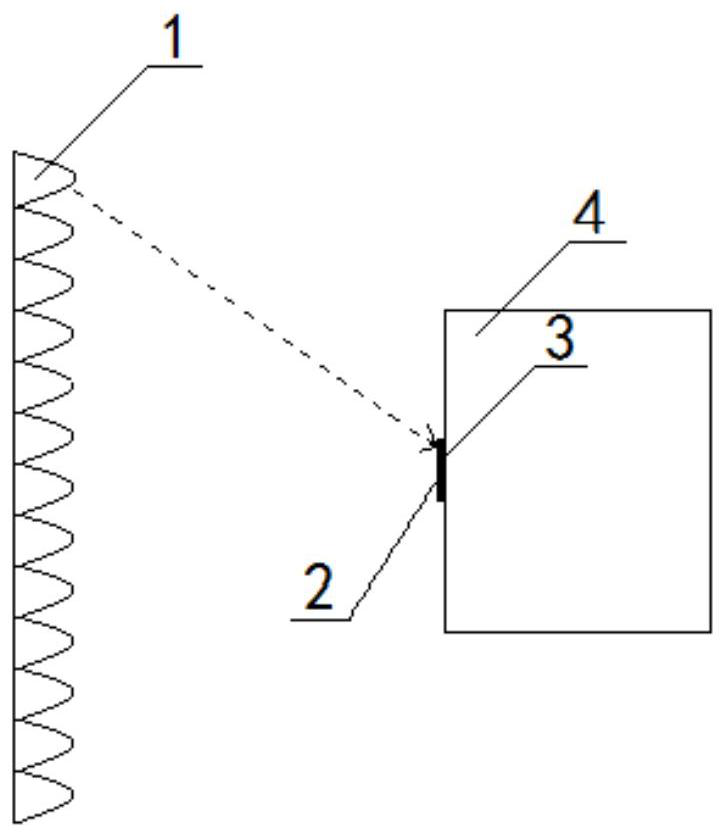

Temperature-sensitive heat map test device for occluded areas for aerodynamic thermal tests of shock tunnel

PendingCN110411699AConvenient ArrangementRealize surface heat flow distribution measurementAerodynamic testingThermometers using physical/chemical changesShock waveEngineering

The invention discloses a temperature-sensitive heat map test device for occluded areas for aerodynamic thermal tests of a shock tunnel. The test device includes a model installed in the shock tunnel,an air rudder is fixed to the model, a gap is reserved between the model and the air rudder, at the position where the model corresponds to the air rudder, the surface of the air rudder is coated with a temperature-sensitive illuminating coating, the surface of the model is provided with an excitation light signal output probe and a temperature-sensitive fluorescent signal acquisition probe, theexcitation light signal output probe is connected with an excitation light source through an optical fiber, and the temperature-sensitive fluorescent signal acquisition probe is connected with an optical signal acquisition camera through an optical fiber. The temperature-sensitive heat map test device for the occluded areas for the aerodynamic thermal tests of the shock tunnel can realize the surface heat flow distribution measurement of the occluded areas in the aerodynamic thermal tests of the shock tunnel, the device is simple, easy to arrange and not limited by the size of the model, and the temperature-sensitive heat map test device and a test method thereof can be widely applied to the occluded areas of various gaps.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Attack-angle-changing test method for electric arc heater

ActiveCN109253669AReal-time measurementBroaden your matchAmmunition testingSelf-propelled projectilesHeat flowEngineering

The invention relates to an attack-angle-changing test method for an electric arc heater. The attack-angle-changing test method includes mounting a test device; performing a state debugging test, operating the electric arc heater, changing the attack angle of a calibration model by an attack angle changing device, measuring cold-wall heat flows under different states by a water cooling heat flow sensor, and acquiring a discrete debugging state distribution map; putting an track curve into the discrete debugging state distribution map, selecting the discrete debugging states of the track curveto perform joint coordination, changing the attack angle by the attack angle changing device, connecting the discrete states in series, adjusting the change speed of the attack angle to smoothen the simulated track curve, and tracking the heat flow changes of the surface of the model in real time by the water cooling heat flow sensor; replacing the water cooling calibration model by a formal testpiece, keeping the test piece at the same position, and eroding the test piece according to a joint coordination program. The attack-angle-changing test method has the advantages that the efficiency of the state debugging test can be improved, the matching range of surface heat flows / enthalpy values of test pieces in the same batch can be widened, and the parameter change capability close to the real trajectory changes can be realized.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

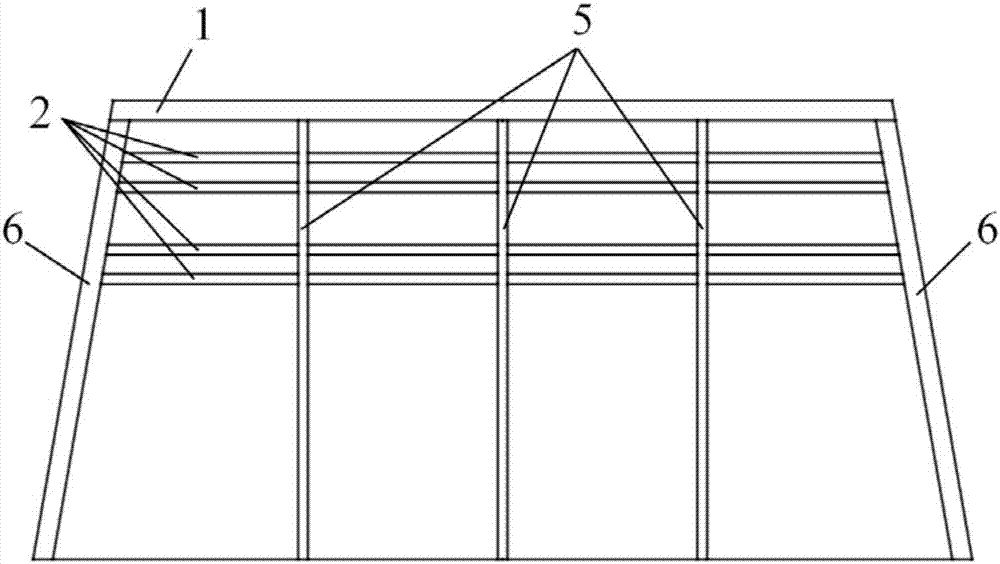

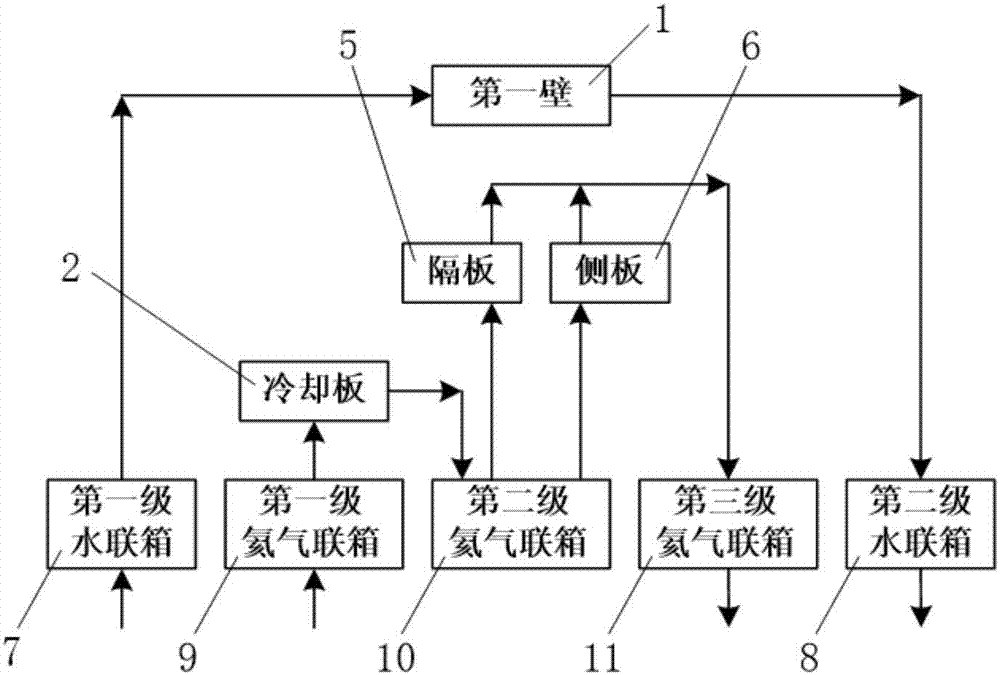

Fusion reactor water-helium cold ceramic breeder cladding

ActiveCN107516549AImprove affordabilityIncrease productionNuclear energy generationThermonuclear fusion reactorInterior spaceChinese characters

The invention discloses a fusion reactor water-helium cold ceramic breeder cladding, which comprises parts such as a first wall, a cooling plate, separators and side plates. The cladding simultaneously adopts water and helium as a coolant, the water is used for cooling the first wall, and the helium is used for cooling the parts except the first wall. The first wall is a U-shaped plate; the cooling plate is in a shape like a Chinese character ao; the cooling plate is located at the inner side of the first wall and is connected with the side wall of the first wall; the cooling plate is crossed with the separators and the side plates, the inner space of the cladding is divided to multiple independent cavities arranged along a radial direction, cavities contacted with the first wall are filled with Li2TiO3 / Be12Ti mixed ball beds as tritium breeding zones, and cavities not contacted with the first wall are filled with Be ball beds as neutron multiplication zones. The fusion reactor water-helium cold ceramic breeder cladding has the advantages that the surface heat flow endurance capability is strong, the tritium production performance is good, the coolant outlet temperature is high, the coolant is well compatible with the neutron multiplication zone material, the flow of the coolant is easy to control, and the development prospect is good.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

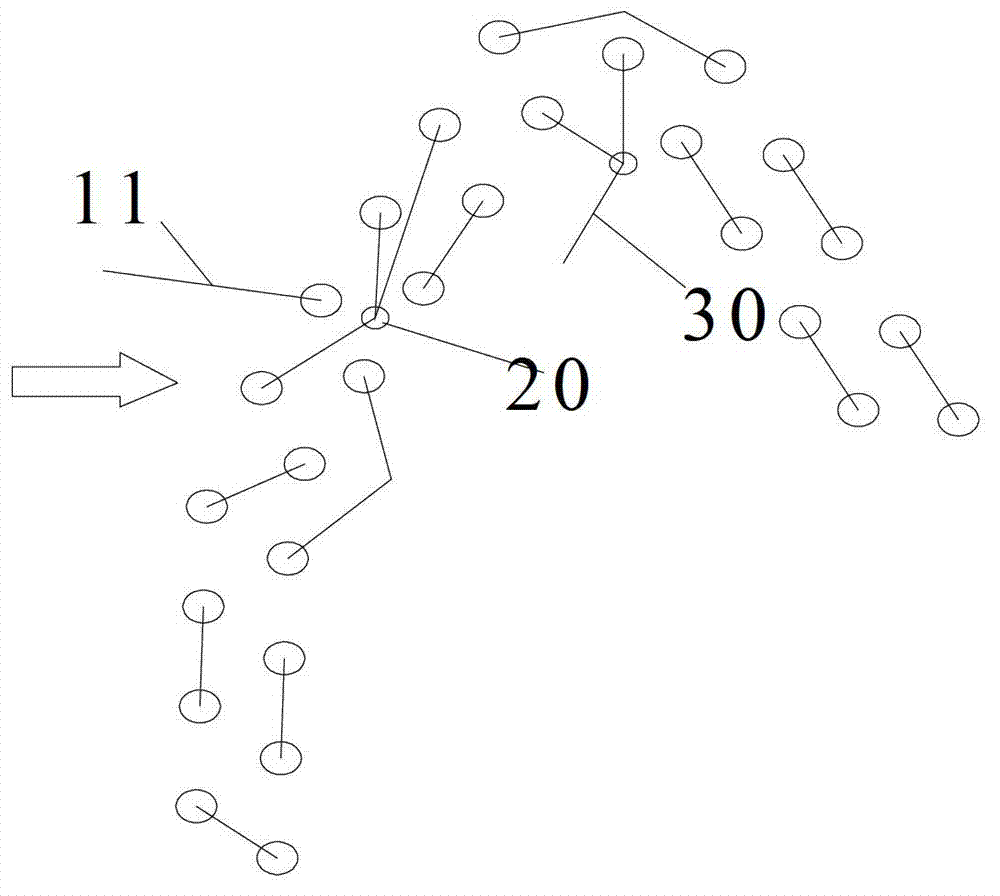

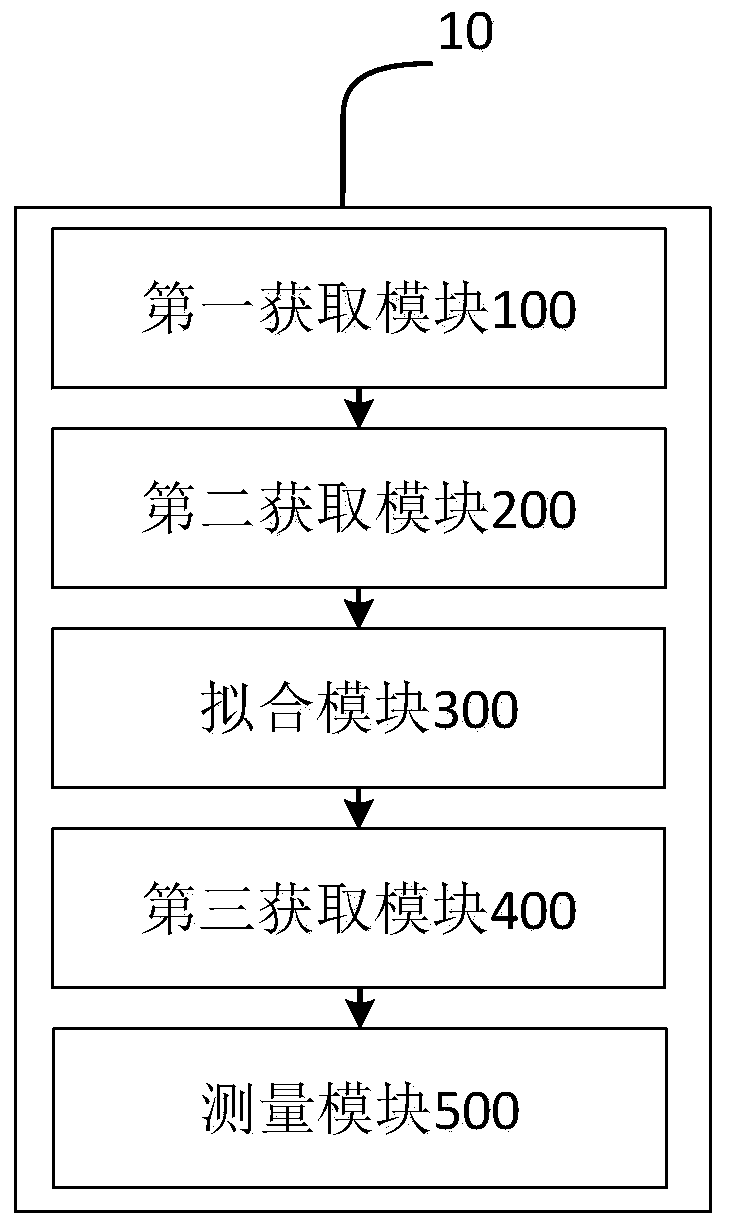

Paleo-thermal lithosphere thickness determination method and device

ActiveCN105242328ASolve Thickness ProblemsSolve the problem of evolutionMaterial thermal analysisGeological measurementsProduction rateHeat flow

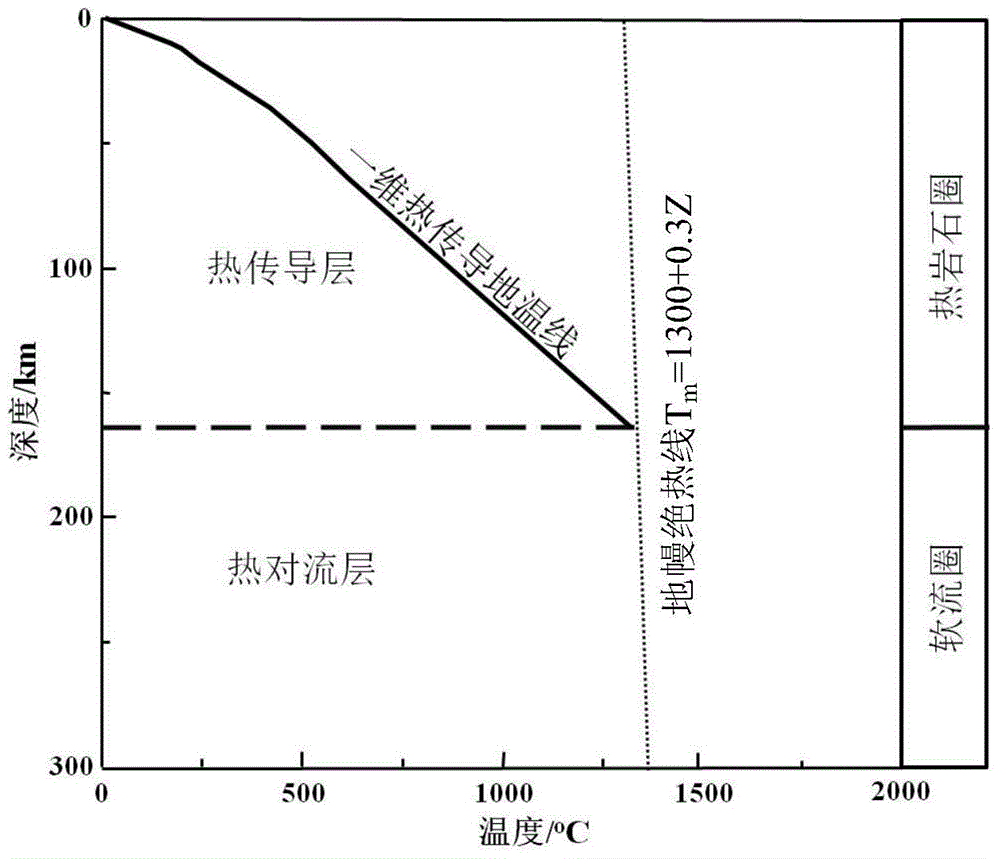

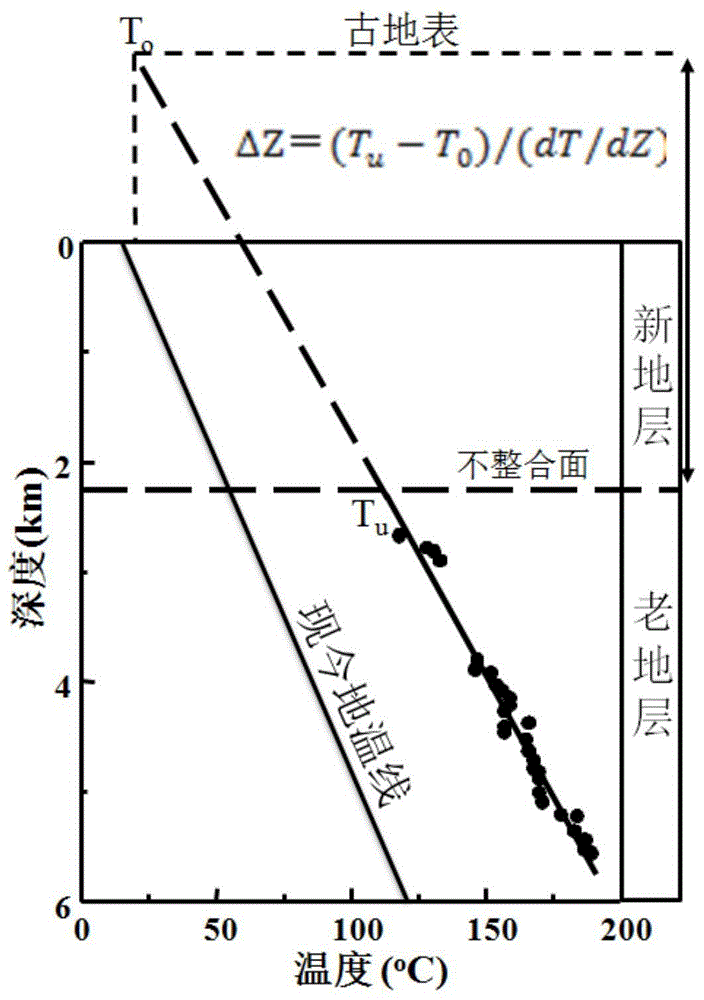

The invention discloses a paleo-thermal lithosphere thickness determination method and device. The method comprises the following steps: obtaining rock heat conductivity and rock heat production rate of each structure layer in a research area; establishing a paleostructure layer model of the research area in a preset geological time by utilizing a stratum backstripping technology, and determining the thickness of each structure layer according to the paleostructure layer model; obtaining paleo-surface heat flow value of each structure layer in a simulated manner according to vitrinite reflectance actually-measured value; calculating top boundary heat flow values of each structure layer according to the paleo-surface heat flow values, rock heat production rate and the thickness of each structure layer; determining shallow earth one-dimensional heat conduction geotherm according to the top boundary heat flow values, the thickness of each structure layer, the rock heat conductivity and rock heat production rate; and determining the depth of the shallow earth one-dimensional heat conduction geotherm intersecting with a mantle adiabatic line as the thickness of the paleo-thermal lithosphere. According to the method and device, the paleo-surface heat flow and paleo-surface thickness can be obtained, and furthermore, the thickness of the paleo-thermal lithosphere is calculated; and the problem that the paleo-thermal lithosphere thickness and evolution cannot be determined in the prior art is solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

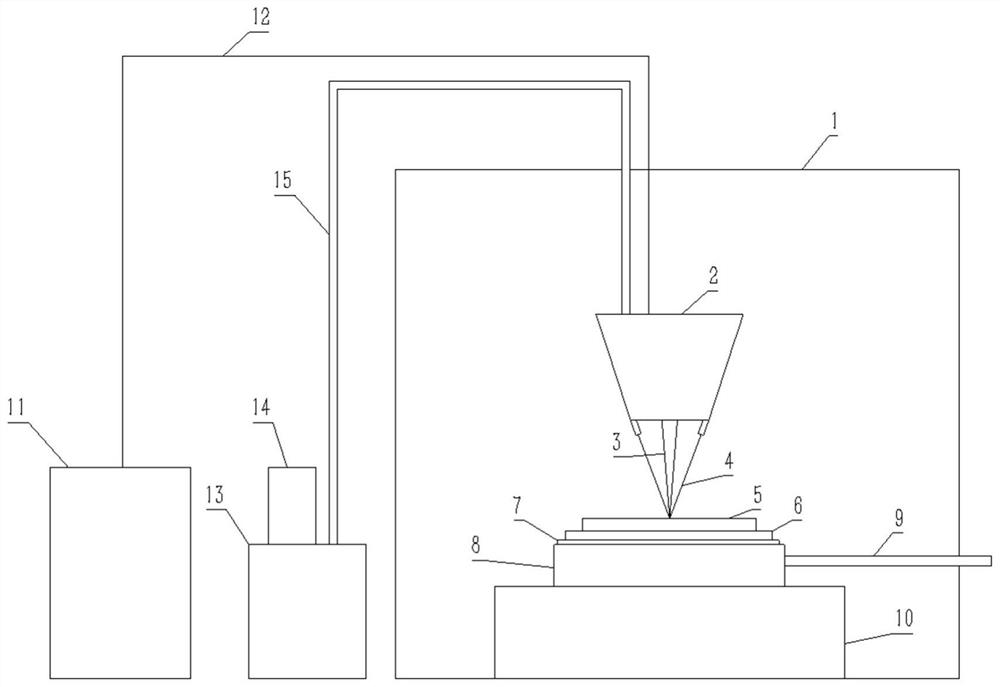

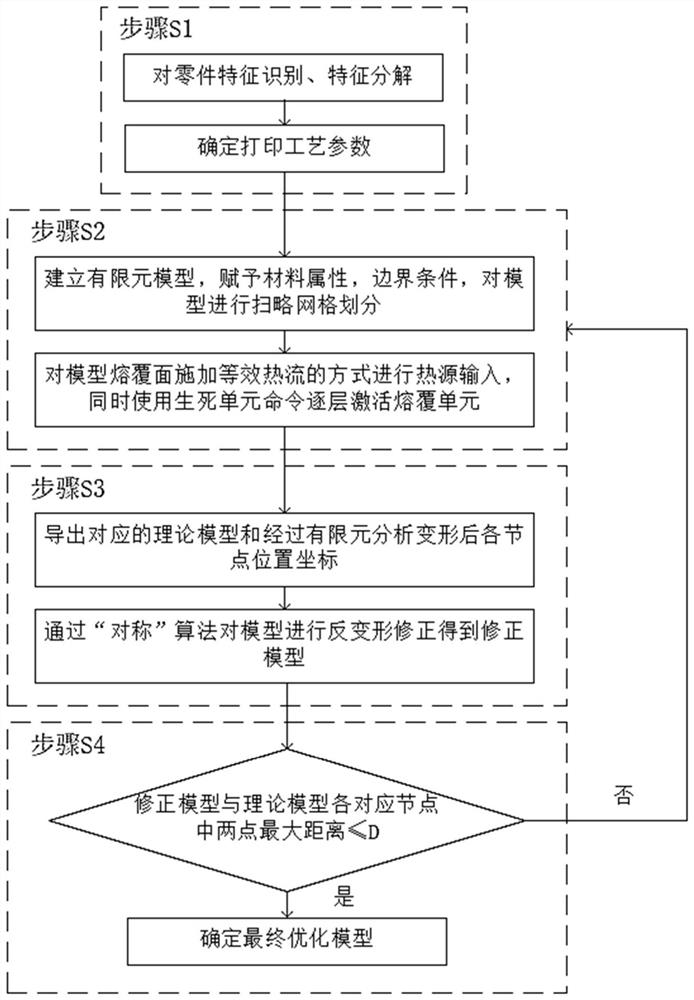

Additive and subtractive composite manufacturing part deformation prediction and control method and equipment

ActiveCN113158368ASimple calculationCalculation speedGeometric CADIncreasing energy efficiencyHeat flowProcess engineering

The invention discloses an additive and subtractive composite manufacturing part deformation prediction and control method and equipment. The method comprises conducting feature recognition and feature decomposition on a target part model, and determining printing parameters; performing finite element thermal coupling analysis of equivalent loading on the model; performing model reversible deformation optimization design according to a simulation result; and determining an optimized final part structure model in an iteration mode. According to the method, a method of combining unit-by-unit activation and Gaussian moving heat source commonly adopted at present is converted into surface heat flow loading of layer-by-layer life and death unit activation in an energy equivalent mode. In the simulation process, birth and death units are used for simulation, all the units are killed firstly, namely, the rigidity is changed into 0, and then the rigidity is activated to be changed into a'birth 'state. Compared with other current life-death unit analog simulation additive manufacturing methods, the method has the advantages that the calculation process can be simplified, the calculation speed can be increased, overall simulation of large parts can be achieved, and an overall temperature field-stress field-displacement field can be obtained quickly.

Owner:XI AN JIAOTONG UNIV +1

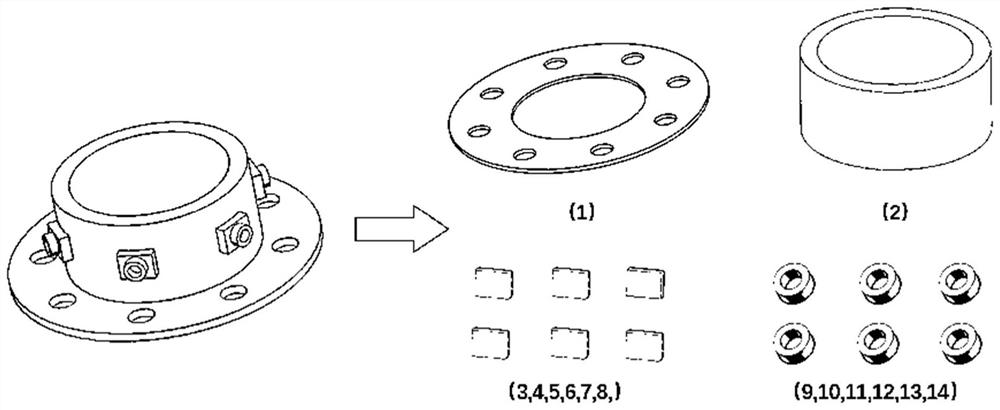

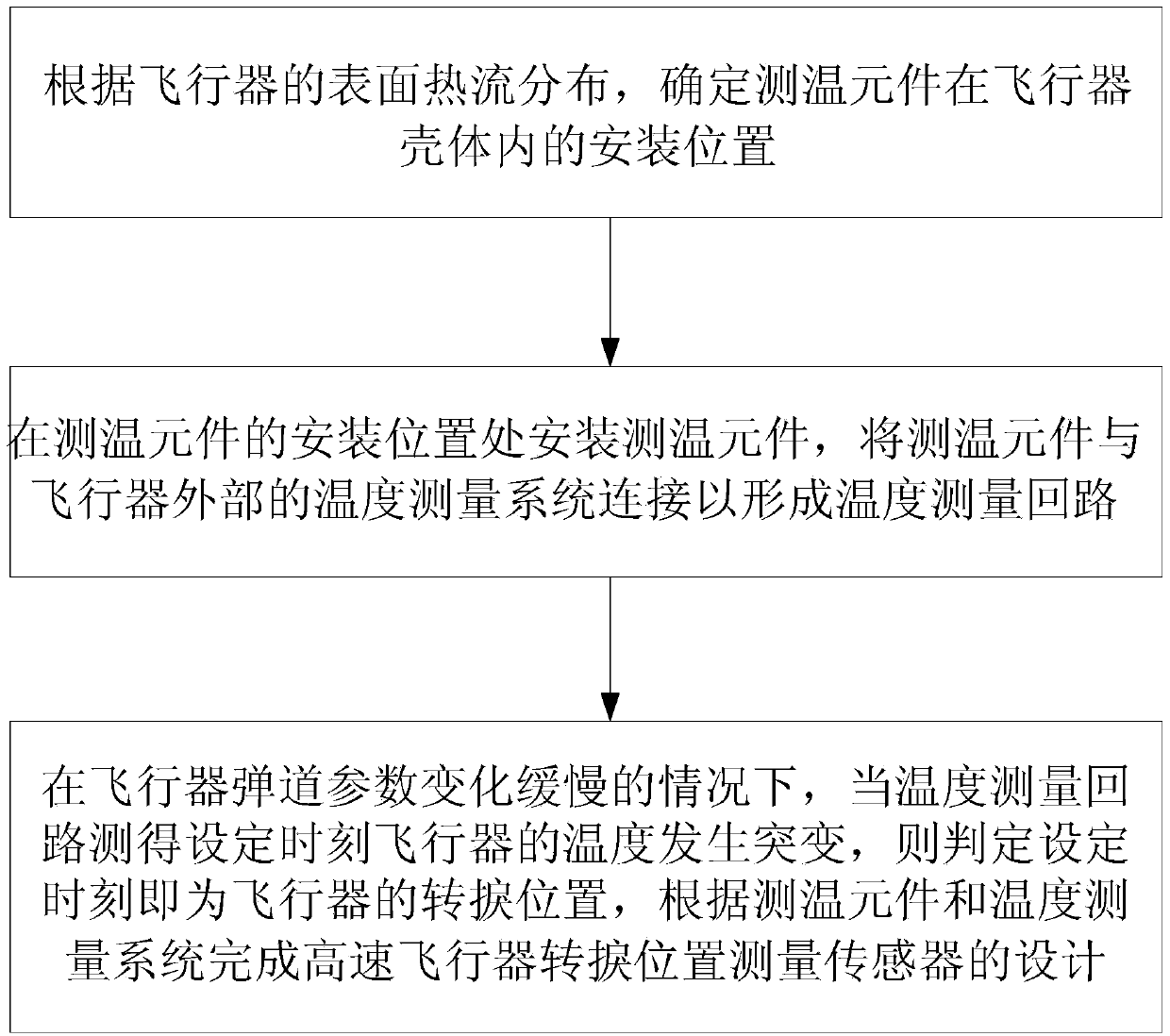

High-speed aircraft transition position measurement sensor design method based on temperature balance

ActiveCN109583067AEasy to useReduce measurement errorDesign optimisation/simulationSpecial data processing applicationsEngineeringMoment measure

The invention provides a high-speed aircraft transition position measurement sensor design method based on temperature balance, and the method comprises the steps: 1, determining the installation position of a temperature measurement element in an aircraft housing according to the surface heat flow distribution of an aircraft; 2, mounting a temperature measuring element at the mounting position ofthe temperature measuring element determined in the step 1, and connecting the temperature measuring element with a temperature measuring system outside the aircraft to form a temperature measuring loop; Step 3, measuring the temperature of the loop according to the temperature formed in the step 2; and in combination with the change of the trajectory parameters of the aircraft, when the temperature of the aircraft suddenly changes at the set moment measured by the temperature measurement loop, that the set moment is the transition position of the aircraft is judged and the design of the measurement sensor is finished according to the temperature measurement element and the temperature measurement system. By applying the technical scheme provided by the invention, the technical problems of complex measurement and poor accuracy of the transition position of the aircraft in the prior art are solved.

Owner:BEIJING AEROSPACE TECH INST

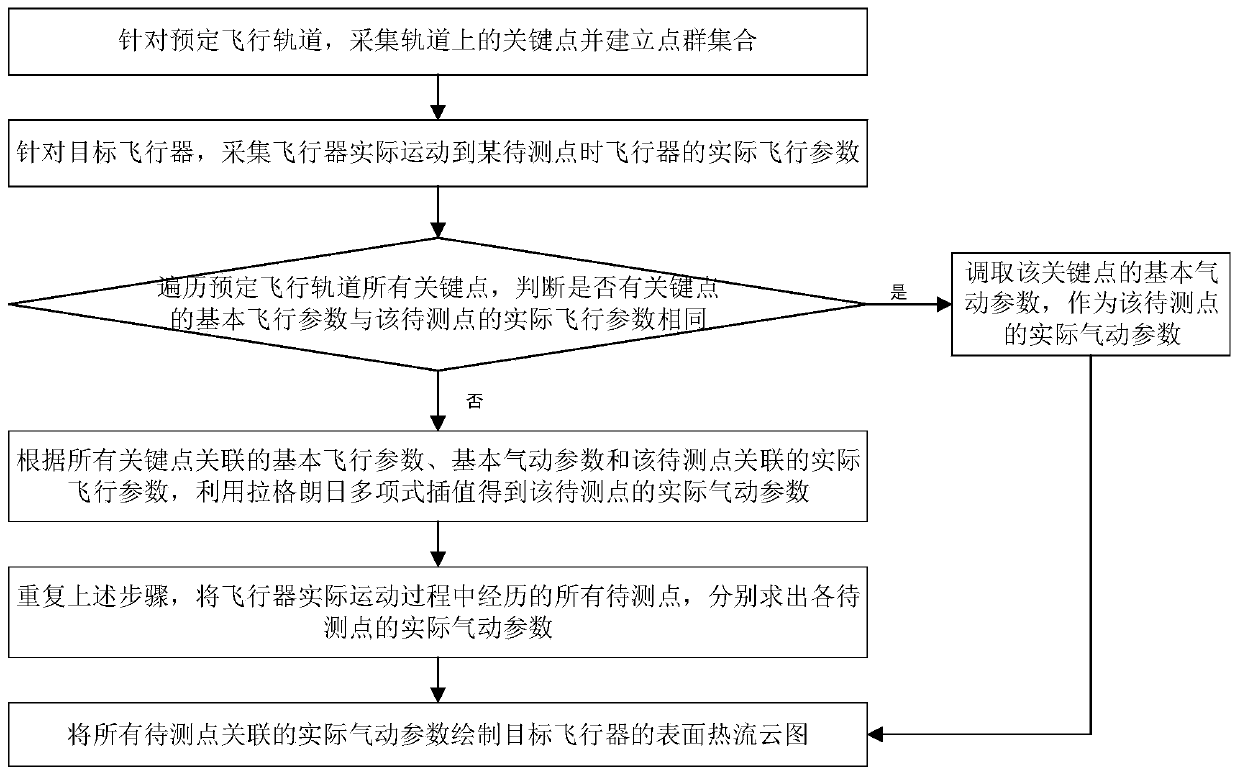

Method for calculating aerodynamic parameters of actual flight orbit based on predetermined flight orbit

ActiveCN110955859AAccurate calculationImprove the ability of fast calculationComplex mathematical operationsHeat flowFlight vehicle

The invention discloses a method for calculating aerodynamic parameters of an actual flight orbit based on a predetermined flight orbit, and belongs to the field of parameter design and prediction ofaircrafts. The method comprises the steps: for a predetermined flight orbit, collecting key points on the orbit and establishing a point group set; acquiring actual flight parameters of the aircraft when the target aircraft actually moves to a certain point to be measured; traversing all key points of the predetermined flight orbit; if the basic flight parameters of the key points are different from the actual flight parameters of a to-be-measured point, obtaining the actual aerodynamic parameters of the to-be-measured point through Lagrange polynomial interpolation according to the basic flight parameters and the basic aerodynamic parameters associated with all the key points and the actual flight parameters associated with the to-be-measured point; solving actual aerodynamic parameters of all to-be-measured points experienced by the aircraft in the actual motion process, and drawing a surface heat flow cloud chart of the target aircraft. According to the method, the aerodynamic parameter calculation is faster and more accurate, and the rapid calculation capacity of the aerodynamic thermal environment is greatly improved.

Owner:BEIHANG UNIV

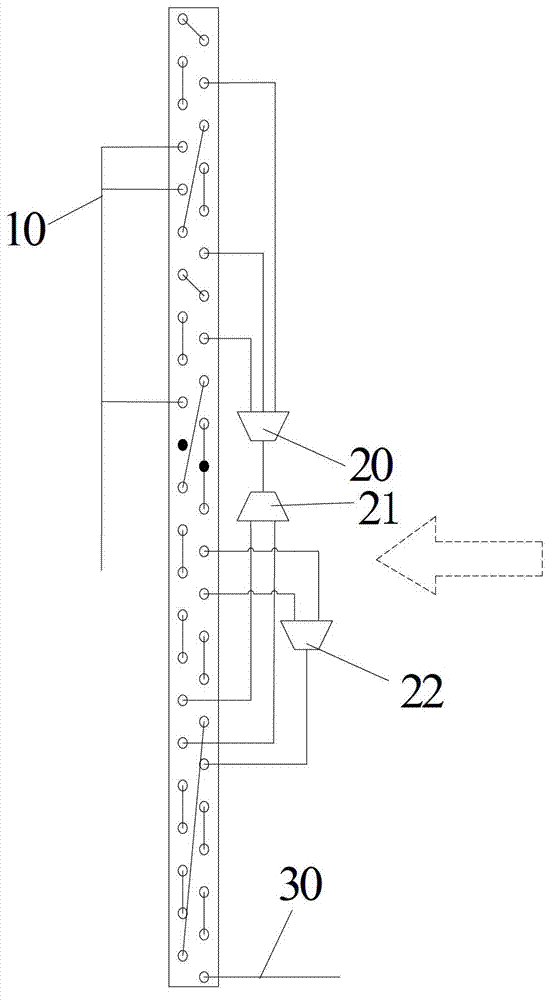

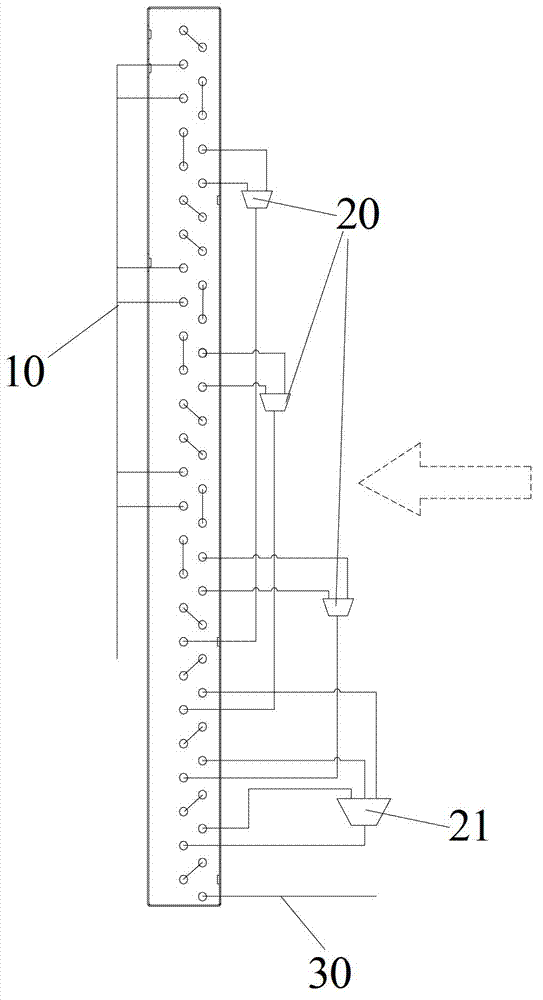

Heat exchanger for R32 twin-step compressed heat pump air conditioner

ActiveCN103712327AImprove performanceUniform heat fluxLighting and heating apparatusSpace heating and ventilation detailsHeat flowEngineering

The invention provides a heat exchanger for an R32 twin-step compressed heat pump air conditioner. The heat exchanger for R32 twin-step compressed heat pump air conditioner is provided with a refrigerating fluid flow channel, and branching numbers of the refrigerating fluid flow channel increase according to the increase of refrigerating fluid flow dryness. The heat exchanger for R32 twin-step compressed heat pump air conditioner comprises an outdoor heat exchanger and an indoor heat exchanger, the flow path design method takes inner heat transfer and flow characteristics of the heat exchanger into full consideration, and the branching numbers of the refrigerating fluid flow channel increase according to the increase of refrigerating fluid flow dryness, so that surface heat flow intensity of the heat exchanger is even, and pressure gradient change is even.

Owner:GREE ELECTRIC APPLIANCES INC

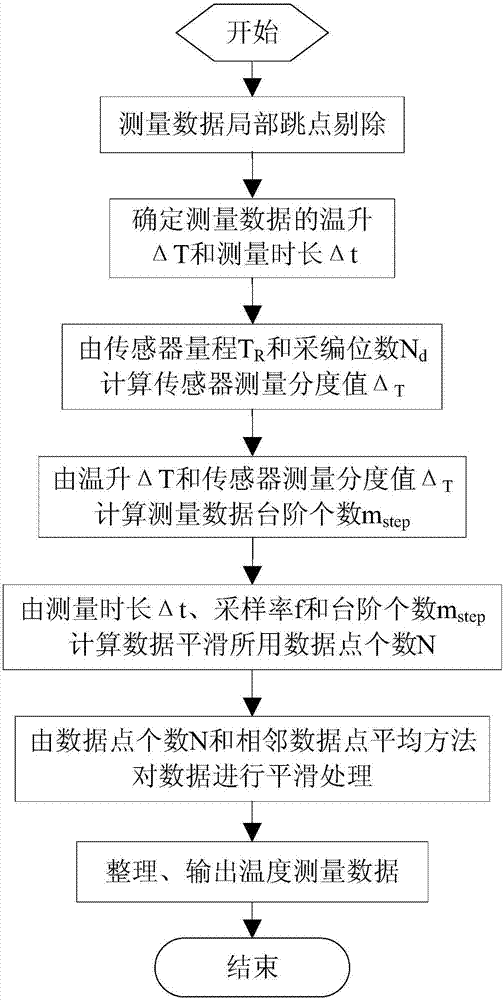

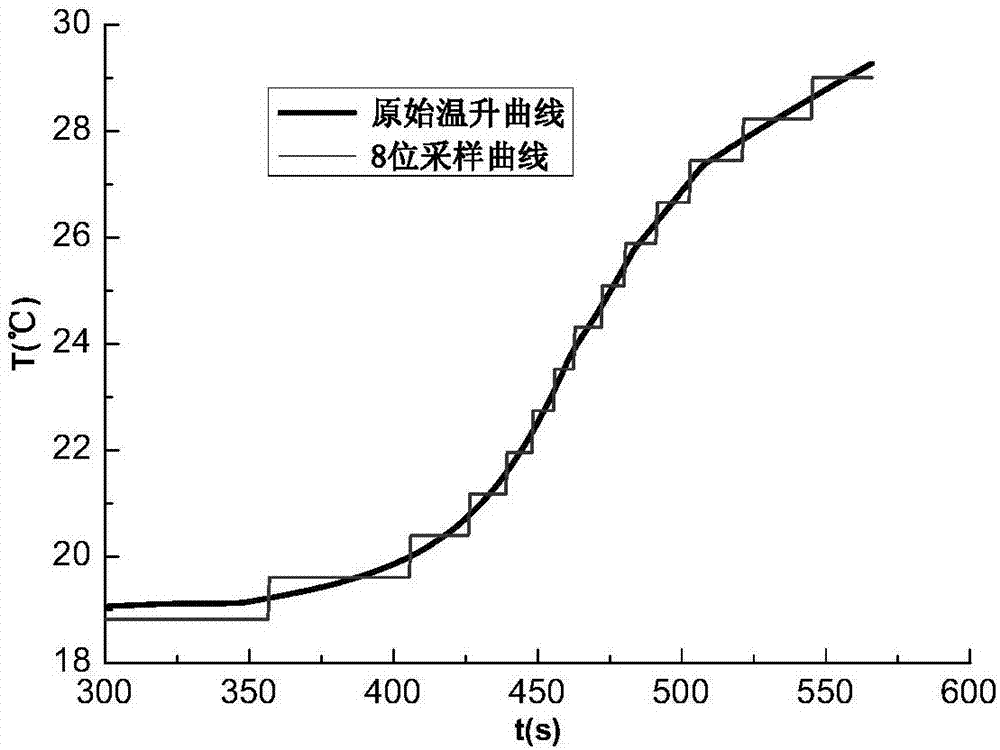

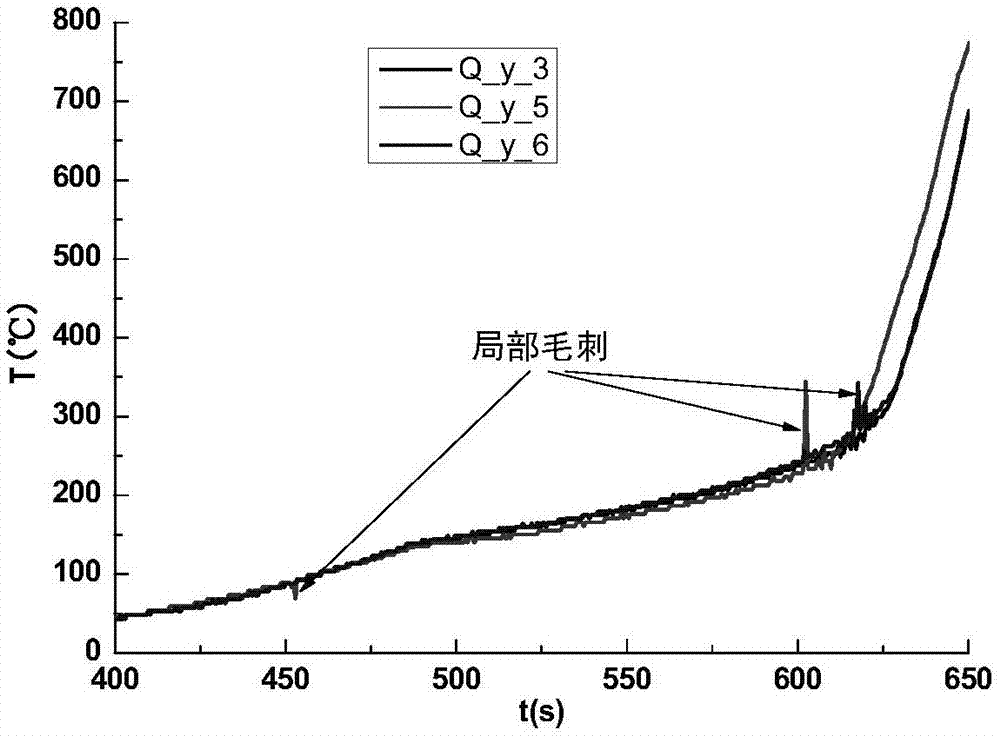

Method for preprocessing temperature measurement data of aircraft surface heat flow identification device

ActiveCN107958206AImprove data qualityImprove impactThermometers using electric/magnetic elementsUsing electrical meansFlight testAviation

The present invention provides a method for preprocessing temperature measurement data of an aircraft surface heat flow identification device, and belongs to the technical field of aerospace flight test thermal parameter measurement and processing. The method comprises: carrying out local distortion point (local hop point) removal processing on the temperature rise measurement data of the heat flow identification device, using the average smooth processing method of N adjacent data points to carry out smooth processing on the measurement data, and finally obtaining temperature measurement datasatisfying the requirement of heat flow identification, wherein the N value is determined according to temperature sensor related parameters and temperature profile characteristics. By virtue of themethod provided by the present invention, heat flow identification can be carried out on the preprocessed temperature measurement data, the influence of the temperature hop and the local hop point onthe heat flow identification result can be effectively improved, and the accuracy and reliability of the identification result of the heat flow can be improved.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

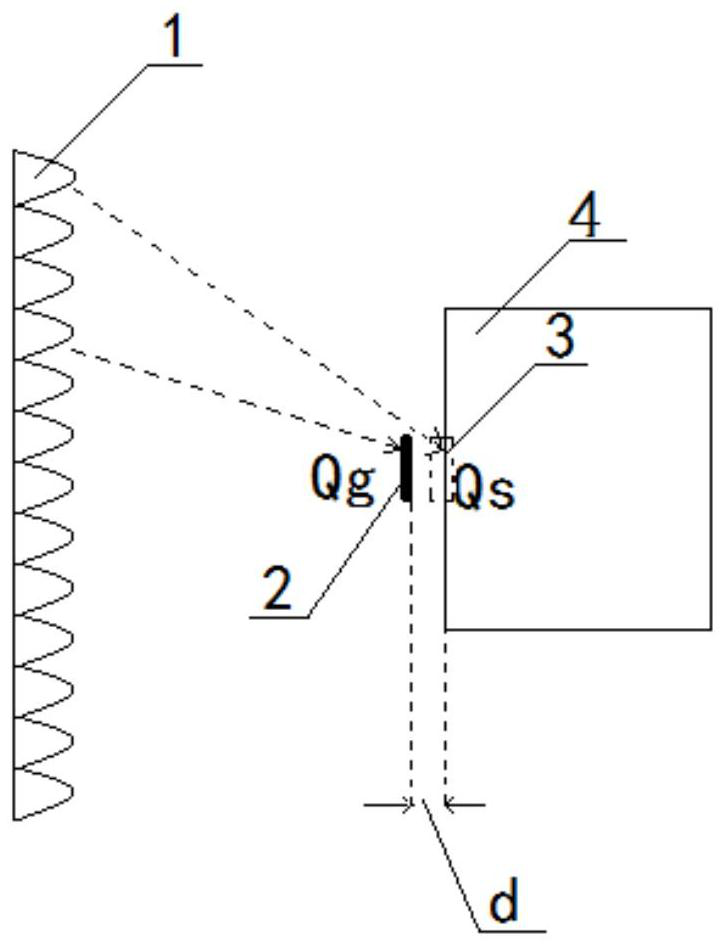

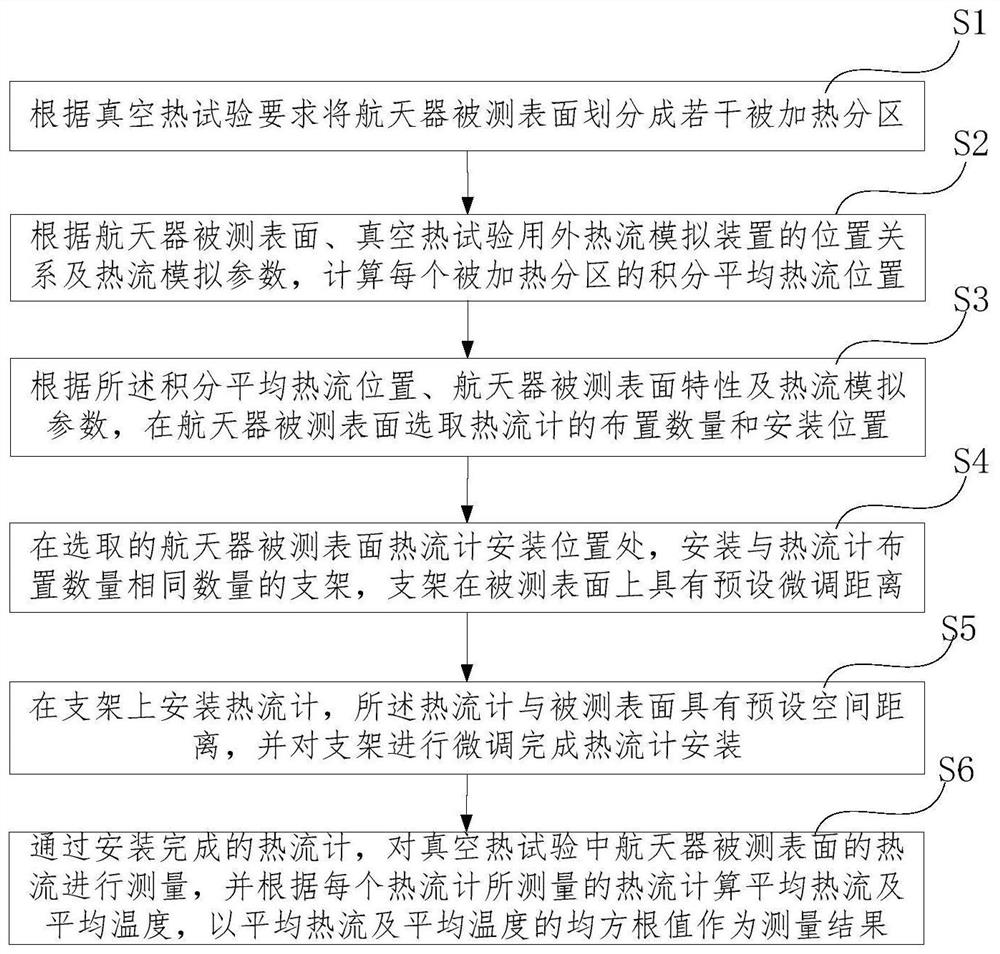

Spacecraft surface heat flow non-contact measurement method based on vacuum thermal test

ActiveCN112213137AImprove effectivenessAccurate measurementStructural/machines measurementThermodynamicsHeat flow

The invention provides a spacecraft surface heat flow non-contact measurement method based on a vacuum thermal test, which is used for solving the problem of inaccurate non-contact heat flow measurement in the prior art. The non-contact measurement method comprises the following steps: on the basis that a measured surface is divided into a plurality of heated subareas, calculating the integral average heat flow position of each heated subarea, selecting the arrangement number and installation positions of heat flow meters and the spatial distance between the heat flow meters and the measured surface according to the integral average heat flow positions, installing the heat flow meters through a bracket, measuring the heat flow of the measured surface of the spacecraft in the vacuum thermaltest, calculating the average heat flow and the average temperature according to the heat flow measured by each heat flow meter, and taking the root-mean-square values of the average heat flow and the average temperature as measurement results. The heat flow meters do not need to make contact with the surface of the spacecraft, heat flow reaching the surface of the spacecraft is accurately measured, the heat flow meter is suitable for the spacecraft surface where a fixed heat flow meter cannot be installed in a vacuum thermal test, and effectiveness of the spacecraft vacuum thermal test is improved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Method and device for determining thickness of paleothermal lithosphere

The invention discloses a paleo-thermal lithosphere thickness determination method and device. The method comprises the following steps: obtaining rock heat conductivity and rock heat production rate of each structure layer in a research area; establishing a paleostructure layer model of the research area in a preset geological time by utilizing a stratum backstripping technology, and determining the thickness of each structure layer according to the paleostructure layer model; obtaining paleo-surface heat flow value of each structure layer in a simulated manner according to vitrinite reflectance actually-measured value; calculating top boundary heat flow values of each structure layer according to the paleo-surface heat flow values, rock heat production rate and the thickness of each structure layer; determining shallow earth one-dimensional heat conduction geotherm according to the top boundary heat flow values, the thickness of each structure layer, the rock heat conductivity and rock heat production rate; and determining the depth of the shallow earth one-dimensional heat conduction geotherm intersecting with a mantle adiabatic line as the thickness of the paleo-thermal lithosphere. According to the method and device, the paleo-surface heat flow and paleo-surface thickness can be obtained, and furthermore, the thickness of the paleo-thermal lithosphere is calculated; and the problem that the paleo-thermal lithosphere thickness and evolution cannot be determined in the prior art is solved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

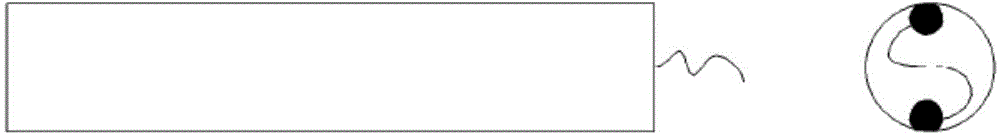

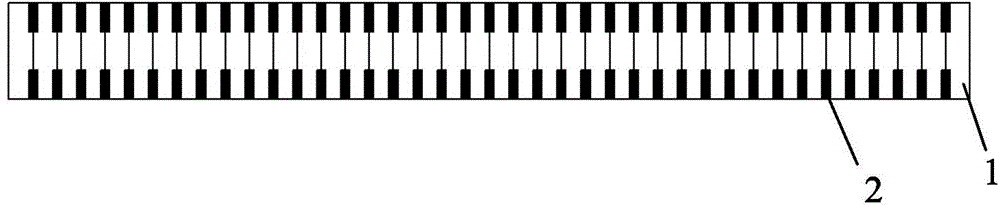

Integrated thin film sensor for measuring surface heat flow rate in hypersonic flow

The invention discloses an integrated thin film sensor for measuring surface heat flow rate in hypersonic flow. The integrated thin film sensor includes a glass substrate which is of an integrated structure and is a flat plate, and a temperature measuring element group; each temperature measuring element comprises a metal thin film which is prepared in a certain area of the glass substrate through adopting a film plating process; adjacent metal thin films are spaced from each other by a certain distance; all the metal thin films are arranged regularly and have the same resistance-temperature characteristics; and the metal thin films are made of platinum. The sensor has highest integration, so that the accuracy of measurement data can be improved; the sensor can be in seamless cementation with a model to be tested, and therefore, deviation caused by installation can be decreased; and the sensor has been subjected to repetitive tests for many times, so that the accuracy of the sensor can be ensured. As test results indicated, the integrated thin film sensor of the invention has been subjected to 23 times of high-and-low pressure air flow scour, and the damage rate of the sensor is only 6%, and the data repeatability error of the sensor is within 5%.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Channel structure capable of inhibiting supercritical fluid flow distribution deviation

ActiveCN112228905AReduce flow rateRelieve pressureContinuous combustion chamberRam jet enginesHeat flowLiquid state

The invention provides a channel structure capable of inhibiting supercritical fluid flow distribution deviation. The channel structure comprises a refrigerant inlet, an inlet liquid collecting chamber, a liquid chamber, a mixing chamber, a supercritical state chamber, an outlet liquid collecting chamber and a refrigerant outlet, wherein the liquid chamber comprises multiple uniform-section runners which are arranged in parallel. The mixing chamber comprises a plurality of regularly-arranged wedge-shaped turbulent flow structures. The supercritical state chamber comprises a plurality of variable-cross-section runners arranged at equal intervals. By means of the channel structure, fluid near the critical state between the runners can be mixed mutually, so that the pressure difference and the temperature difference between the runners are reduced, in addition, the sensitivity of supercritical state fluid flow resistance to wall surface heat flow changes can be reduced, the flow distribution deviation between the runners in the multi-mode thermal environment is inhibited, and the flow distribution uniformity is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

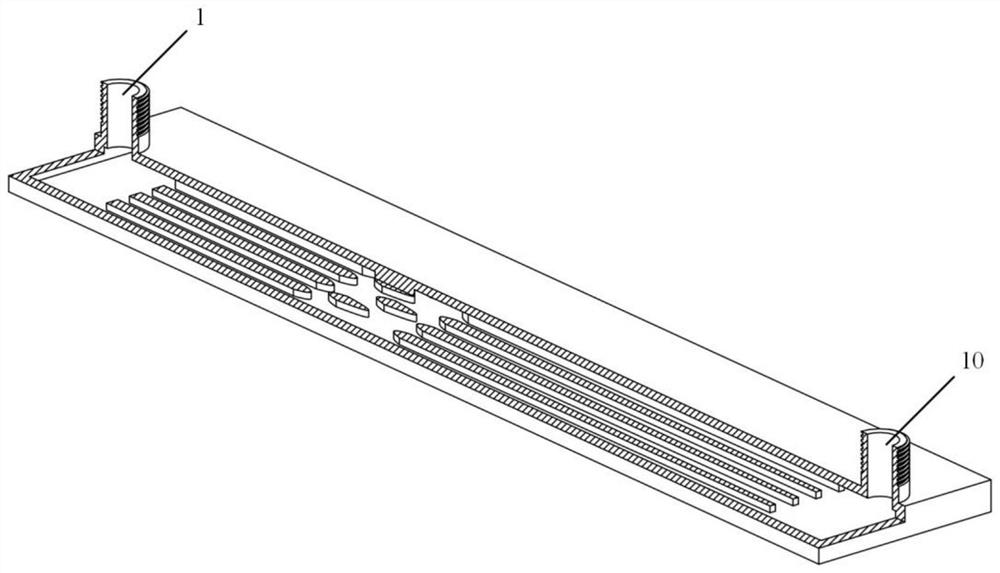

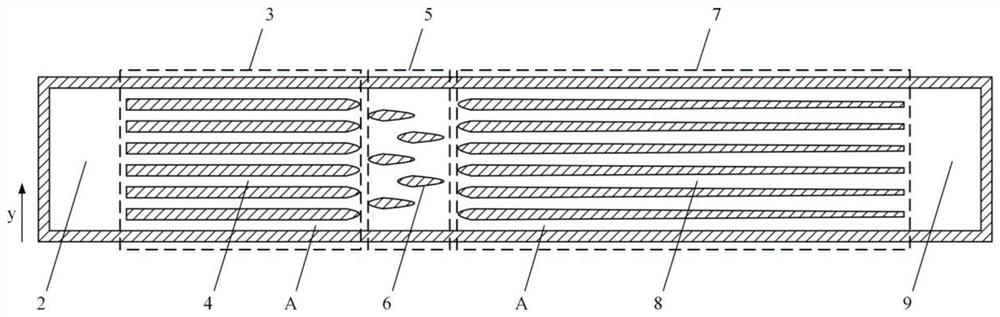

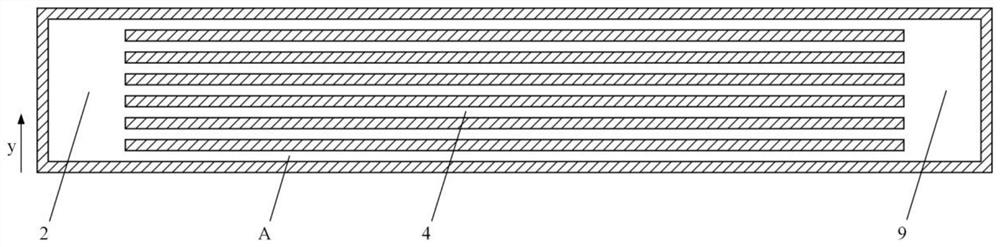

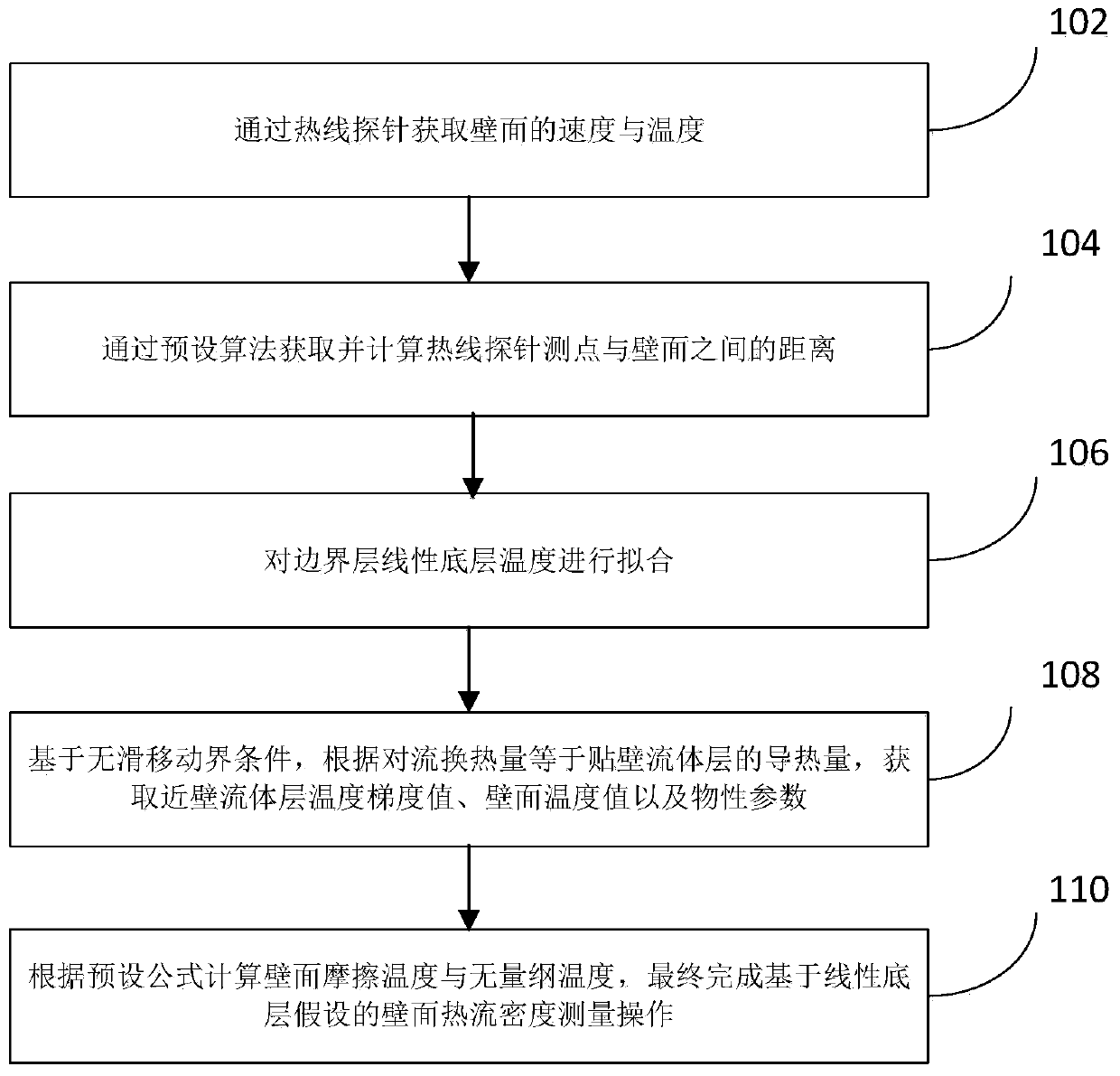

Linear underlying hypothesis based wall surface heat flow density measuring method and device

The invention provides a linear underlying hypothesis based wall surface heat flow density measuring method. Two paths of hot line probes with parallel boundary layers, a stepping motor displacement mechanism, a mini CTA module, a mini digital to analog conversion module, a slip ring power initiator and a computer are used in the method, the speed and temperature of the lower boundary layer under the rotation condition are measured, and the wall surface heat flow density is calculated via linear underlying hypothesis and verification of the turbulent flow standard temperature wall surface rate. Measurement is accurate and easy. The invention also discloses a linear underlying hypothesis based wall surface heat flow density measuring device.

Owner:BEIHANG UNIV

Two-dimensional surface heat flux density real-time online measuring device and method

ActiveCN111735847AQuick responseGuaranteed repeatabilityMaterial heat developmentCalorimeterHeat flowData acquisition

The invention relates to a real-time online measuring device and method, in particular to a two-dimensional surface heat flux density real-time online measuring device and method. According to the technical scheme provided by the invention, the two-dimensional surface heat flux density real-time online measuring device comprises a base body and a base body temperature sensor capable of monitoringthe temperatures of multiple points of the base body, the base body temperature sensor is electrically connected with a measurement control calculation device through a data acquisition board card, and the measurement control calculation device can synchronously acquire the temperatures of multiple points of the base body monitored by the base body temperature sensor through the data acquisition board card; and the measurement control calculation device calculates and determines the surface multi-point heat flux density of the base body by adopting a two-dimensional filtering method after obtaining the multi-point temperature values of the base body. The online monitoring and measuring problems of the surface heat flux density of thermal conversion equipment such as boilers and internal combustion engines can be solved, and therefore optimization and development of related industrial processes are promoted.

Owner:常州江苏大学工程技术研究院

Solid-liquid phase change material surface heat flow measurement method and system based on dispersive fuzzy reasoning mechanism

PendingCN114018972AImprove utilizationImprove utilization efficiencyMaterial heat developmentInference methodsEngineeringInternal radiation

Owner:ZHUZHOU NAT INNOVATION RAILWAY TECH CO LTD

A Heat Flow Sensor Based on Thermopile Principle

Owner:BEIJING RES INST OF TELEMETRY +1

Temperature acquisition assembly and electric arc wind tunnel flat plate test piece surface heat flux density measurement method

PendingCN114593835AResistance to scourImprove reliabilityAerodynamic testingThermometers using electric/magnetic elementsThermodynamicsHeat flow

The invention provides a temperature acquisition device and an arc wind tunnel flat plate test piece surface heat flux density measurement method, the device comprises a metal flat plate, a heat insulation frame and thermocouples, the heat insulation frame surrounds the metal flat plate, the two thermocouples are installed at the center of the lower surface of the metal flat plate, and the distances between probes of the two thermocouples and the upper surface of the metal flat plate are different. The temperature acquisition assembly is arranged at a to-be-measured position of an arc wind tunnel nozzle outlet. The temperature acquisition assembly can measure temperature repeatedly for a long time and calculate the heat flux density through temperature data, and in combination with the heat flux density measurement method, the change process of the transient heat flux density can be measured in a short time, and the steady-state heat flux density and the radiation equilibrium temperature can be measured for a long time.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com