A Heat Flow Sensor Based on Thermopile Principle

A heat flow sensor and thermopile technology, applied in the field of sensor measurement, can solve the problems of low sensor sensitivity and response speed, and achieve the effects of facilitating mass production, improving sensitivity and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

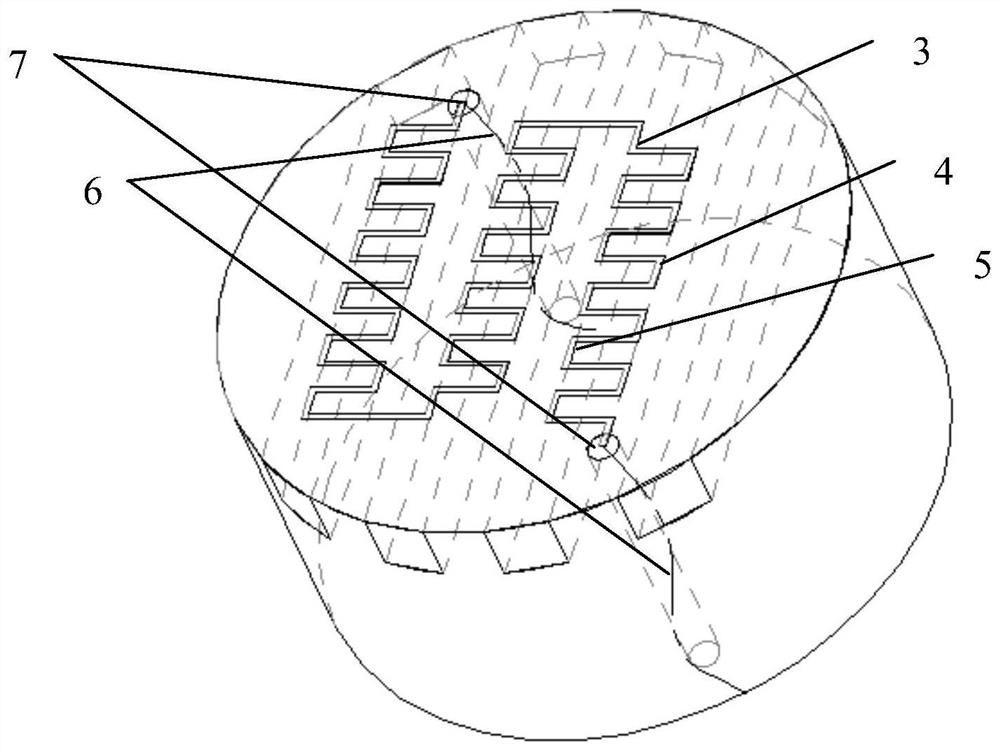

[0030] The present invention proposes a heat flow sensor based on the principle of thermopile, which selects the material of the measured part and conformal design, can greatly reduce the measurement error, and at the same time, the sensor has fast response speed and high sensitivity.

[0031] Such as figure 1 As shown, the heat flow sensor of the present invention has a cylindrical structure, and its cylindrical base 1 is processed by the material to be measured. There are several grooves 2, and the grooves are filled with special materials, and the shape of the measuring surface after filling is consistent with that before the grooves are opened. The depth of the groove 2 is directly proportional to the sensitivity of the heat flow sensor.

[0032] The difference in thermal conductivity between the special material and the material of the cylindrical base 1 is more than 10 times. If the thermal conductivity of the material of the cylindrical base 1 is low, the material wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com