Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Altered solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

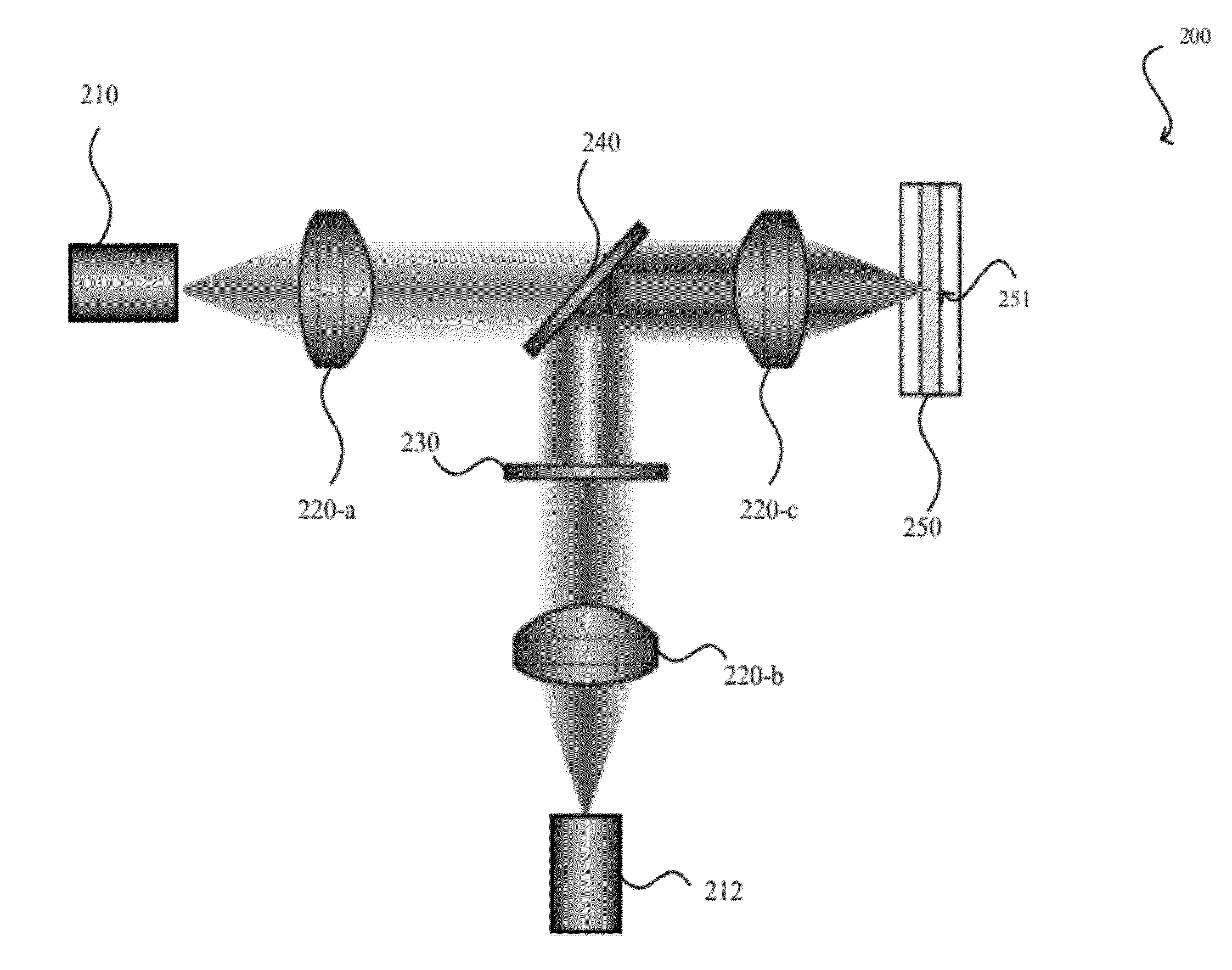

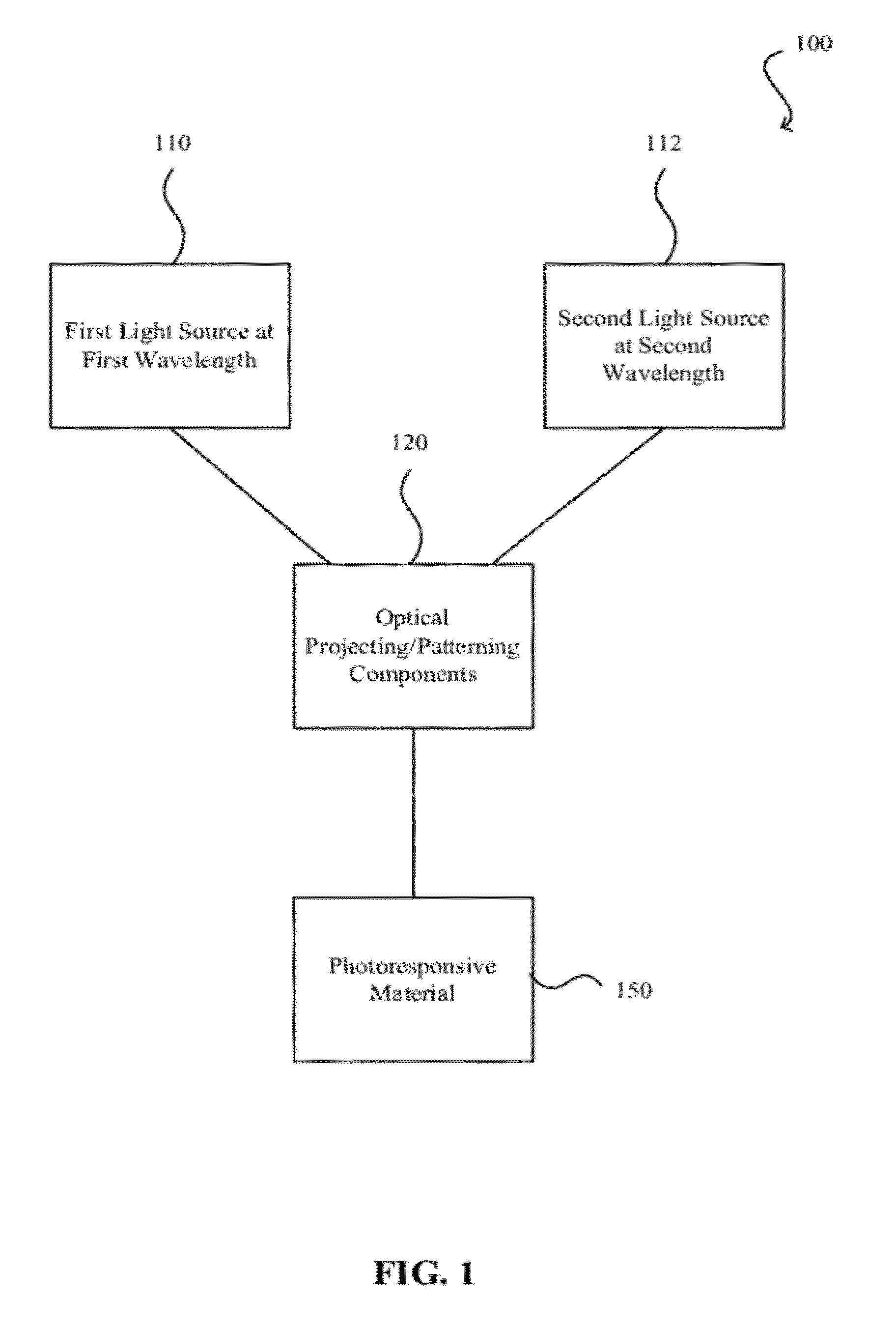

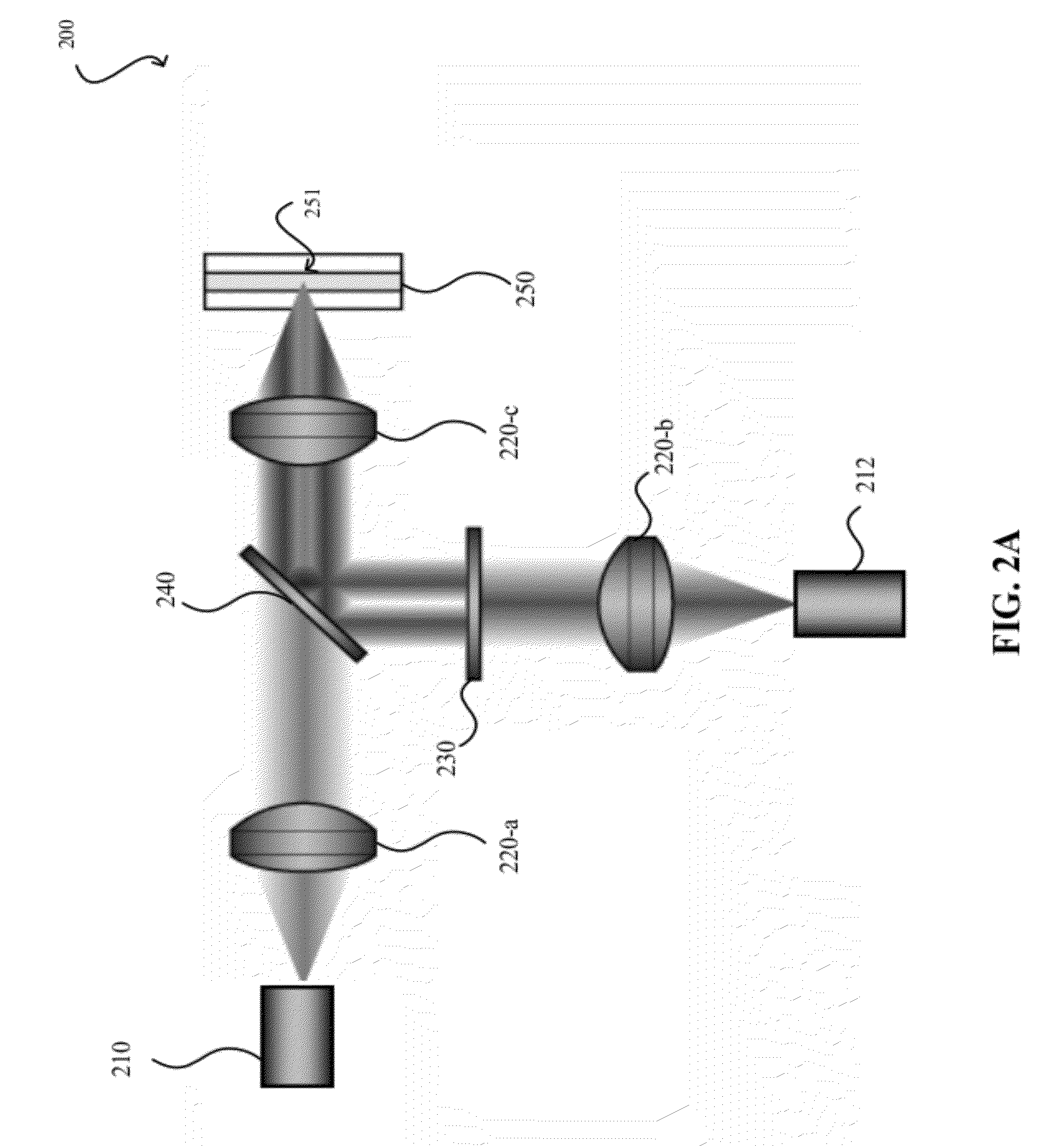

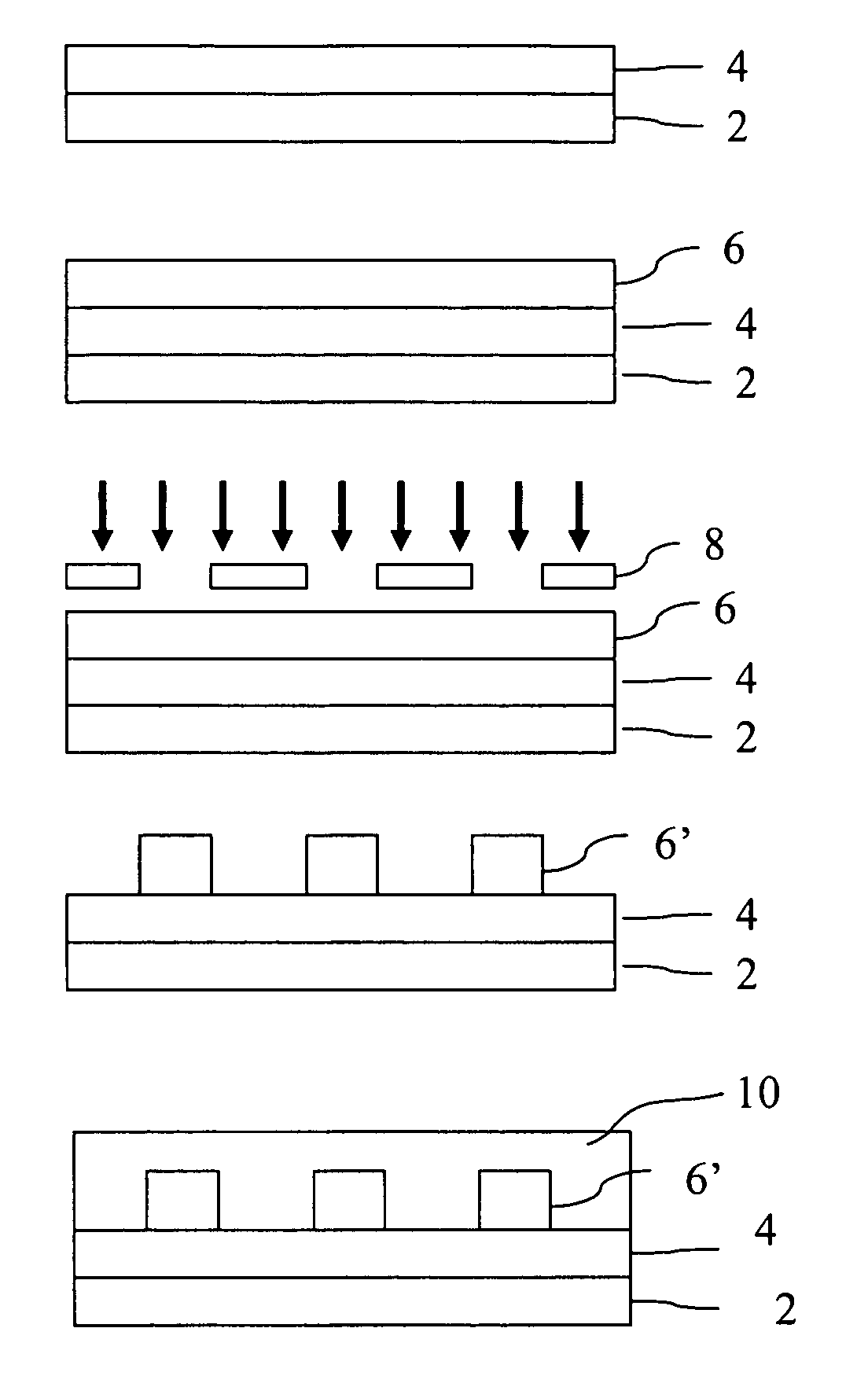

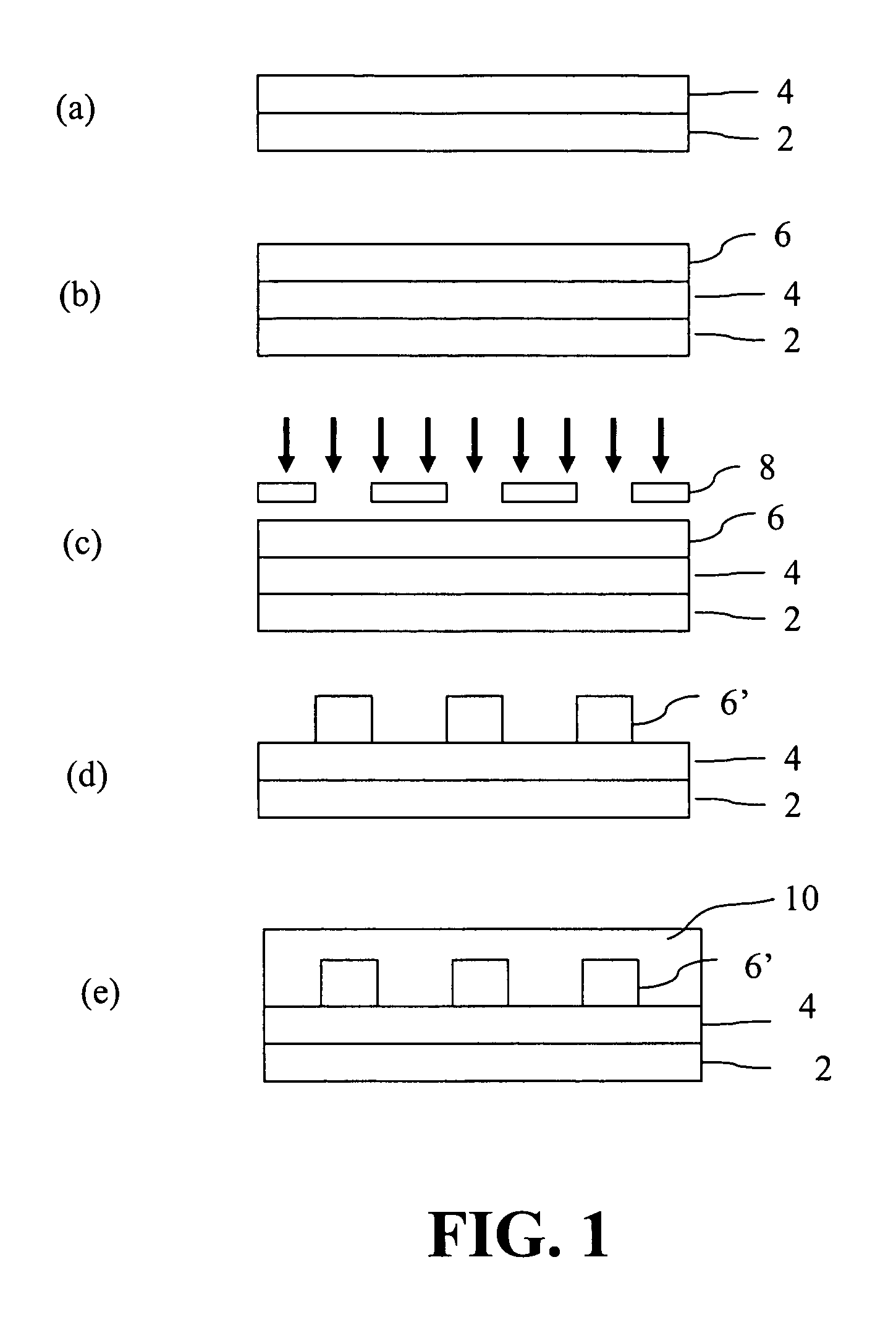

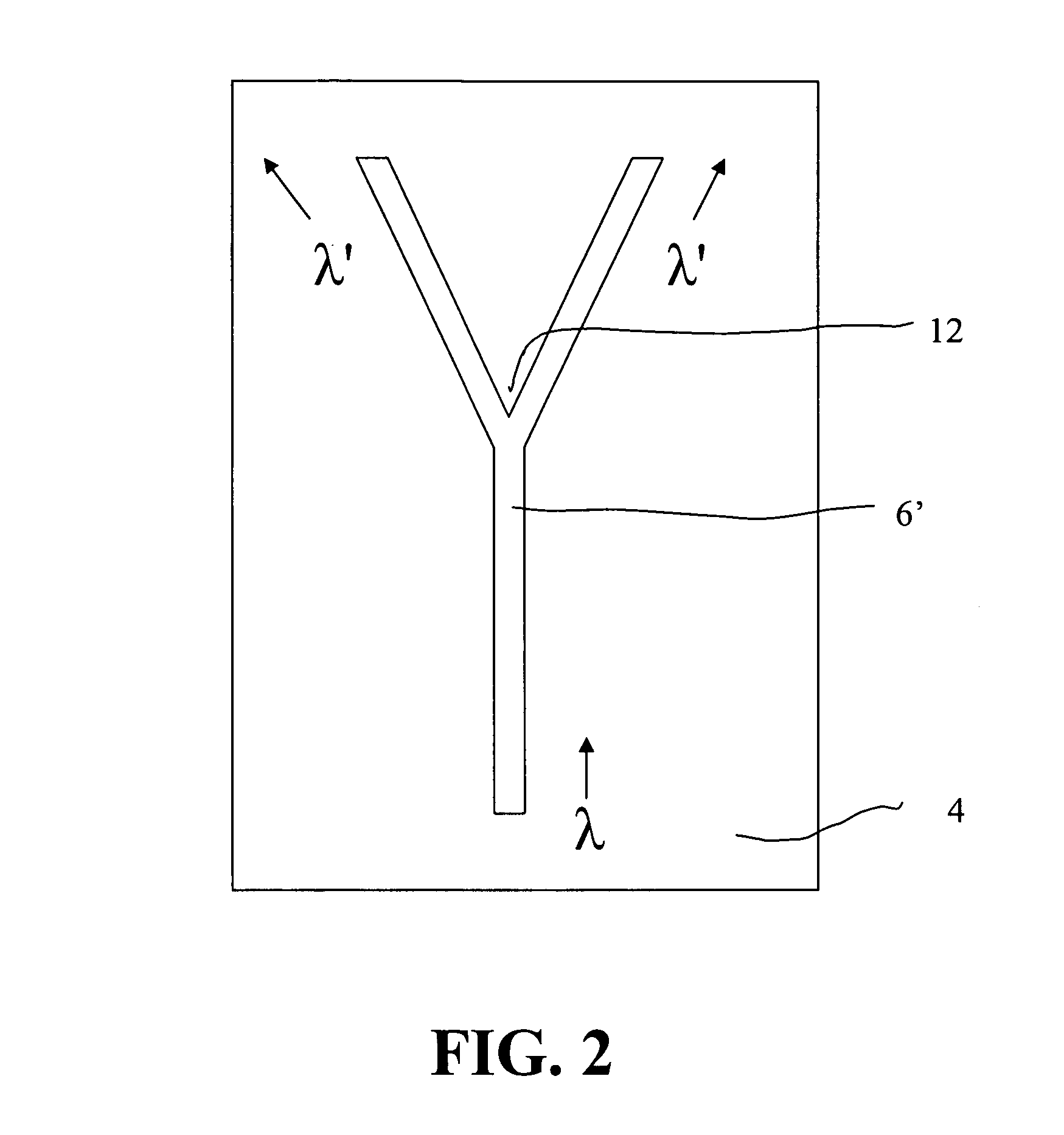

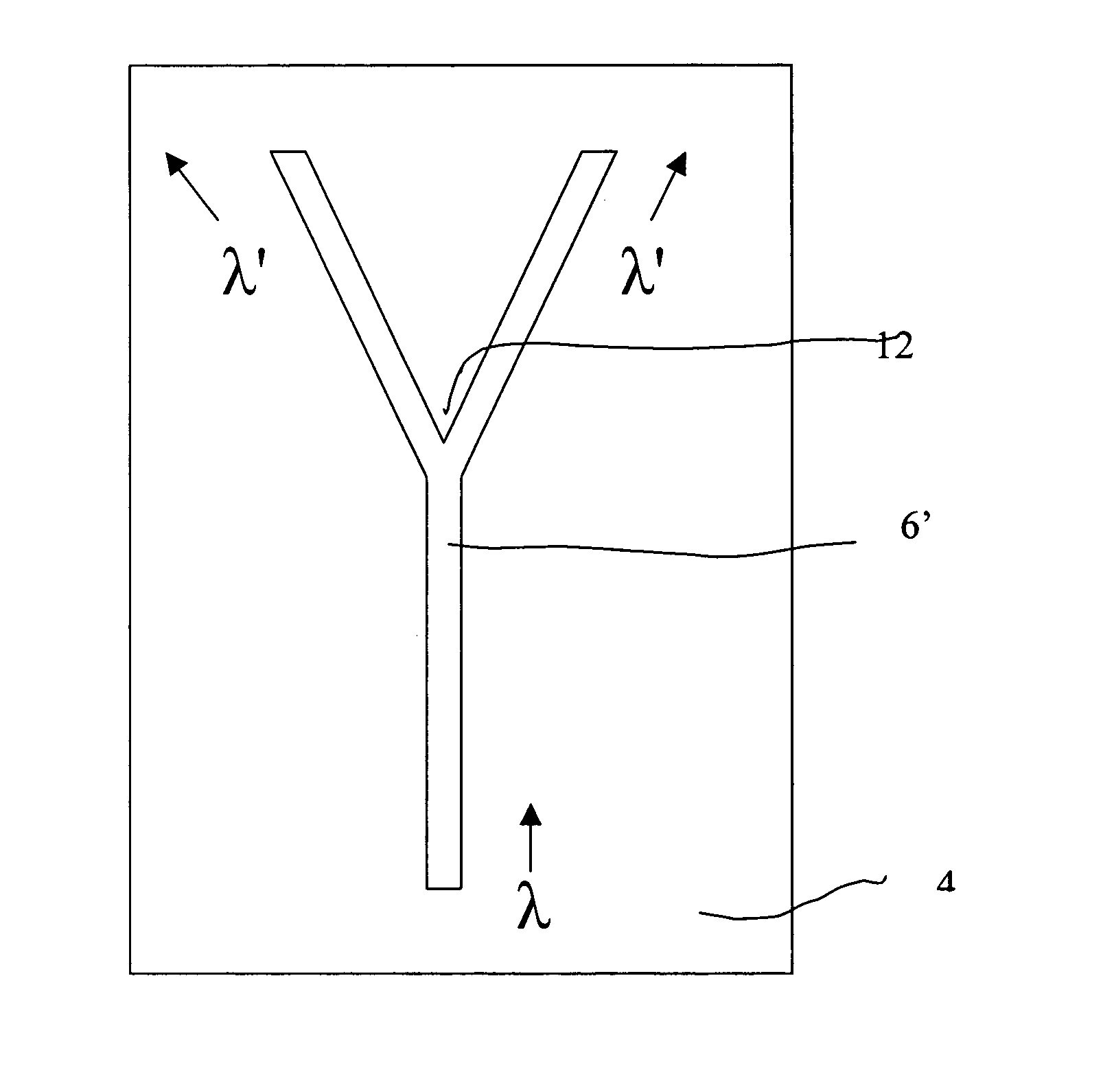

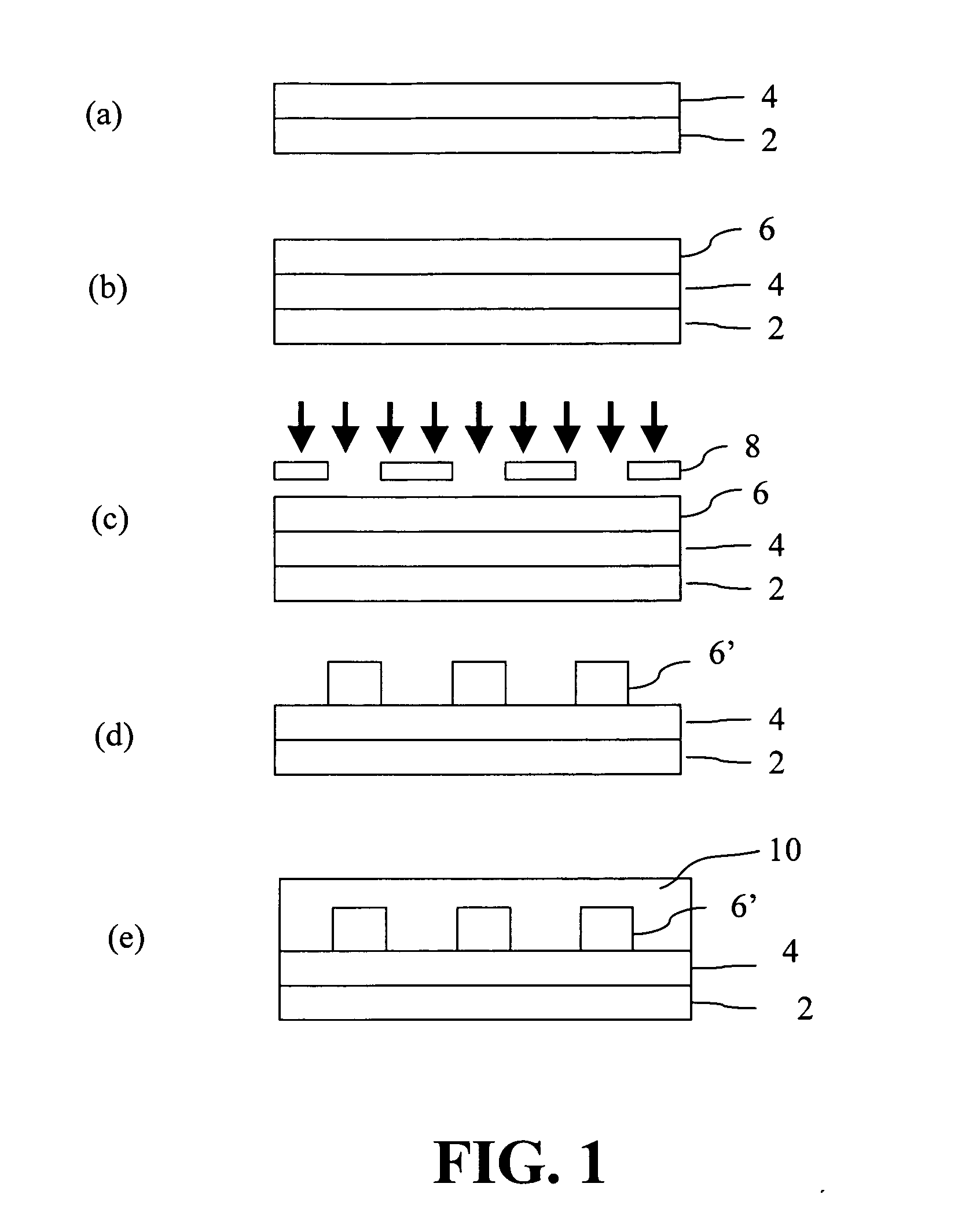

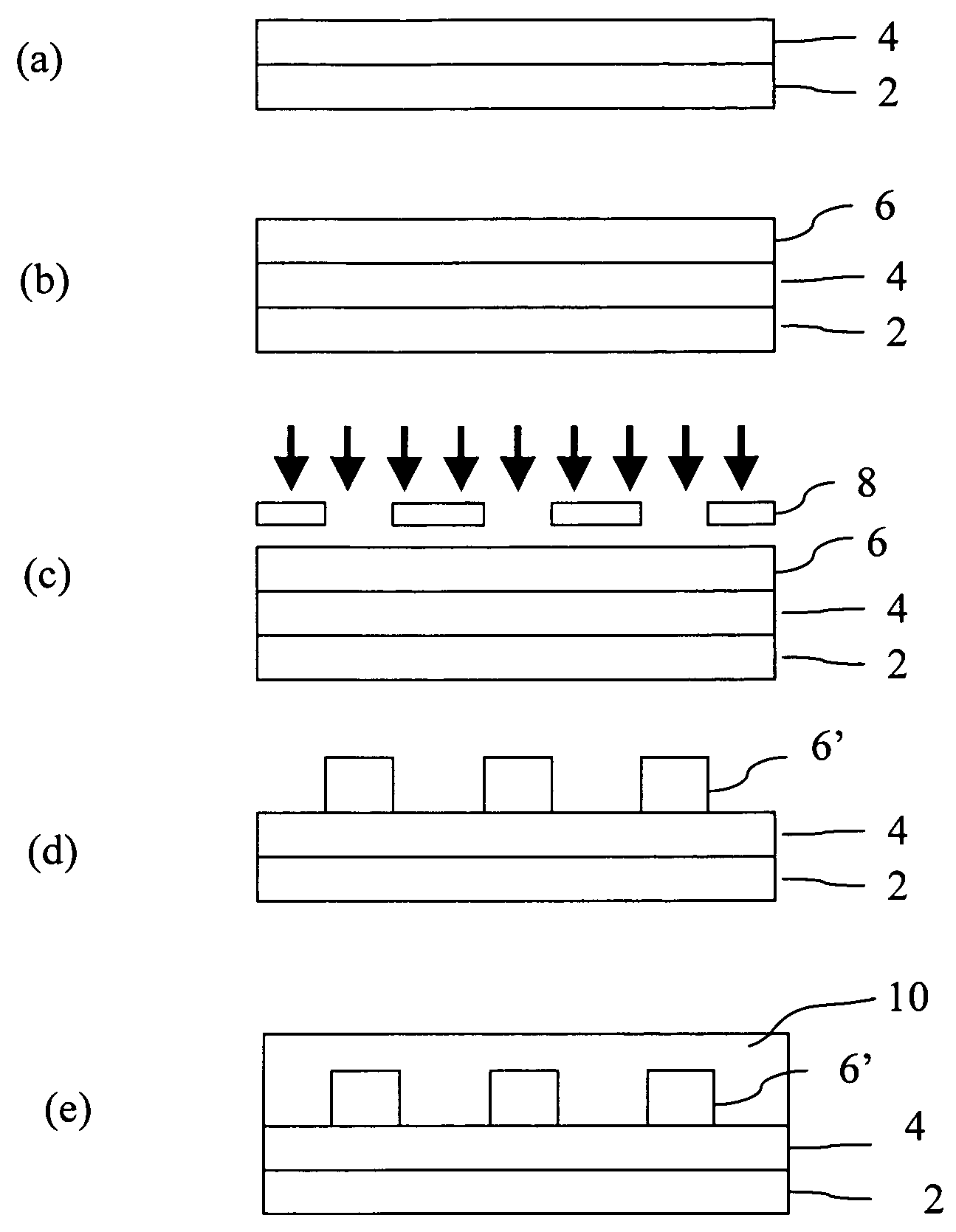

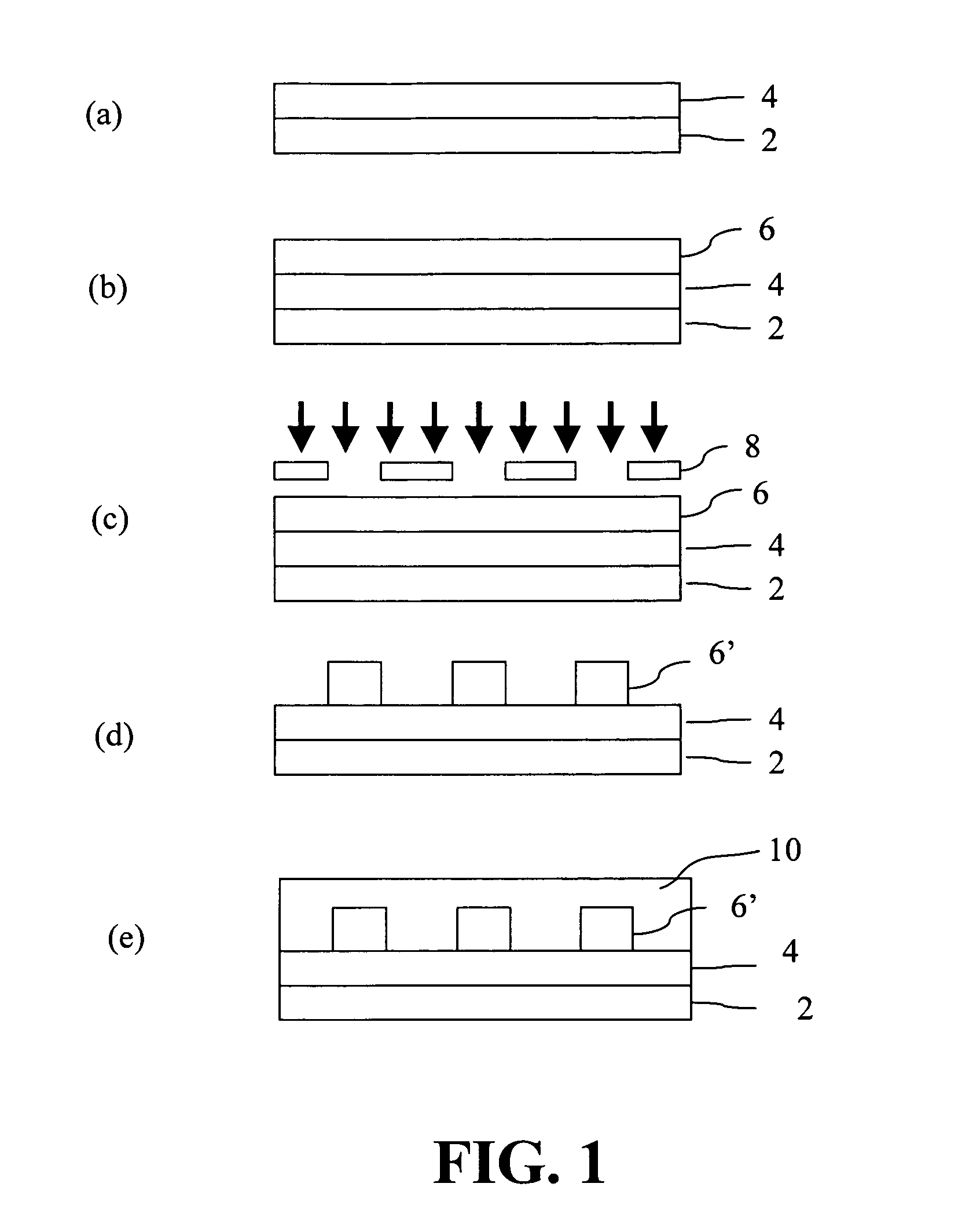

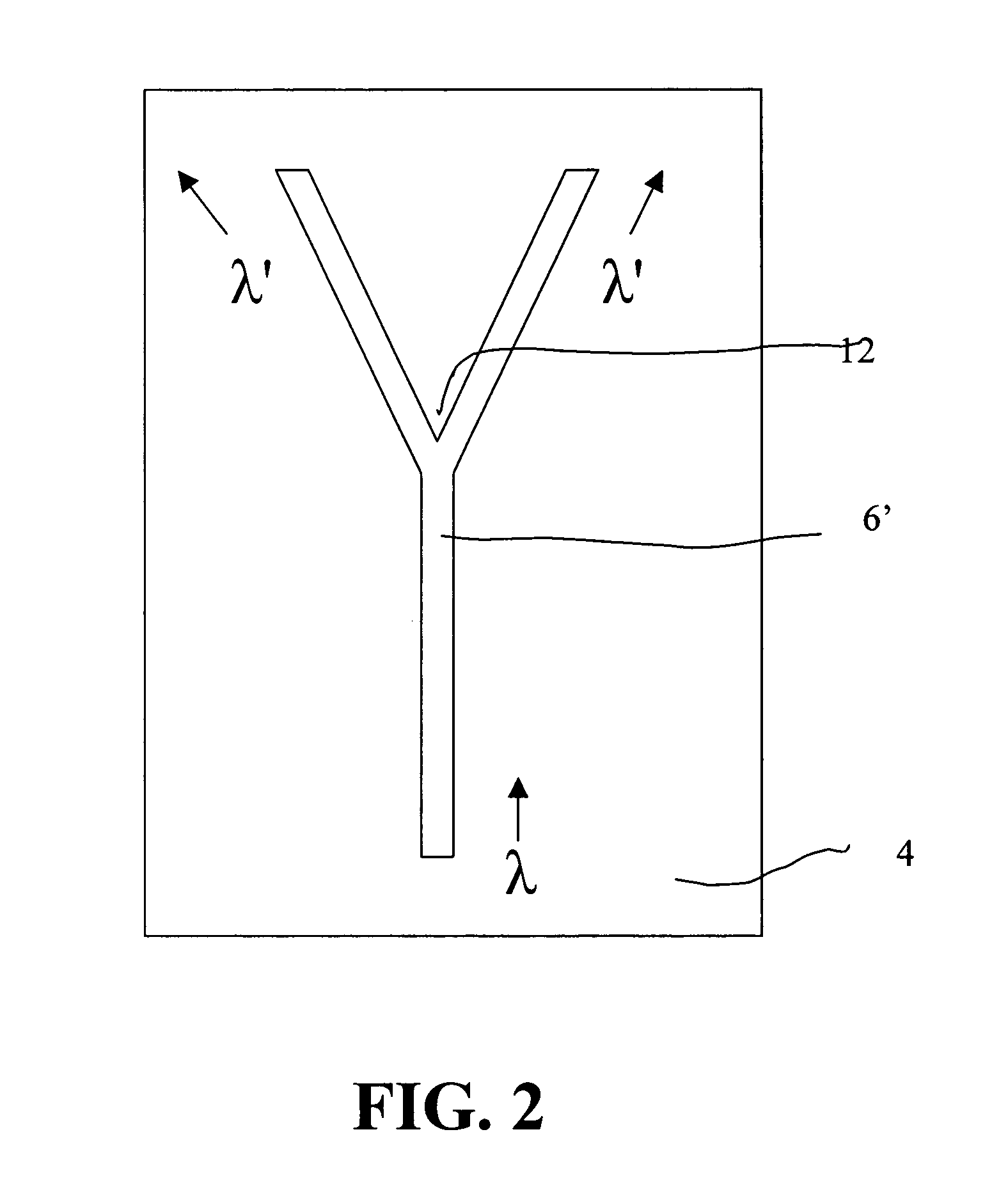

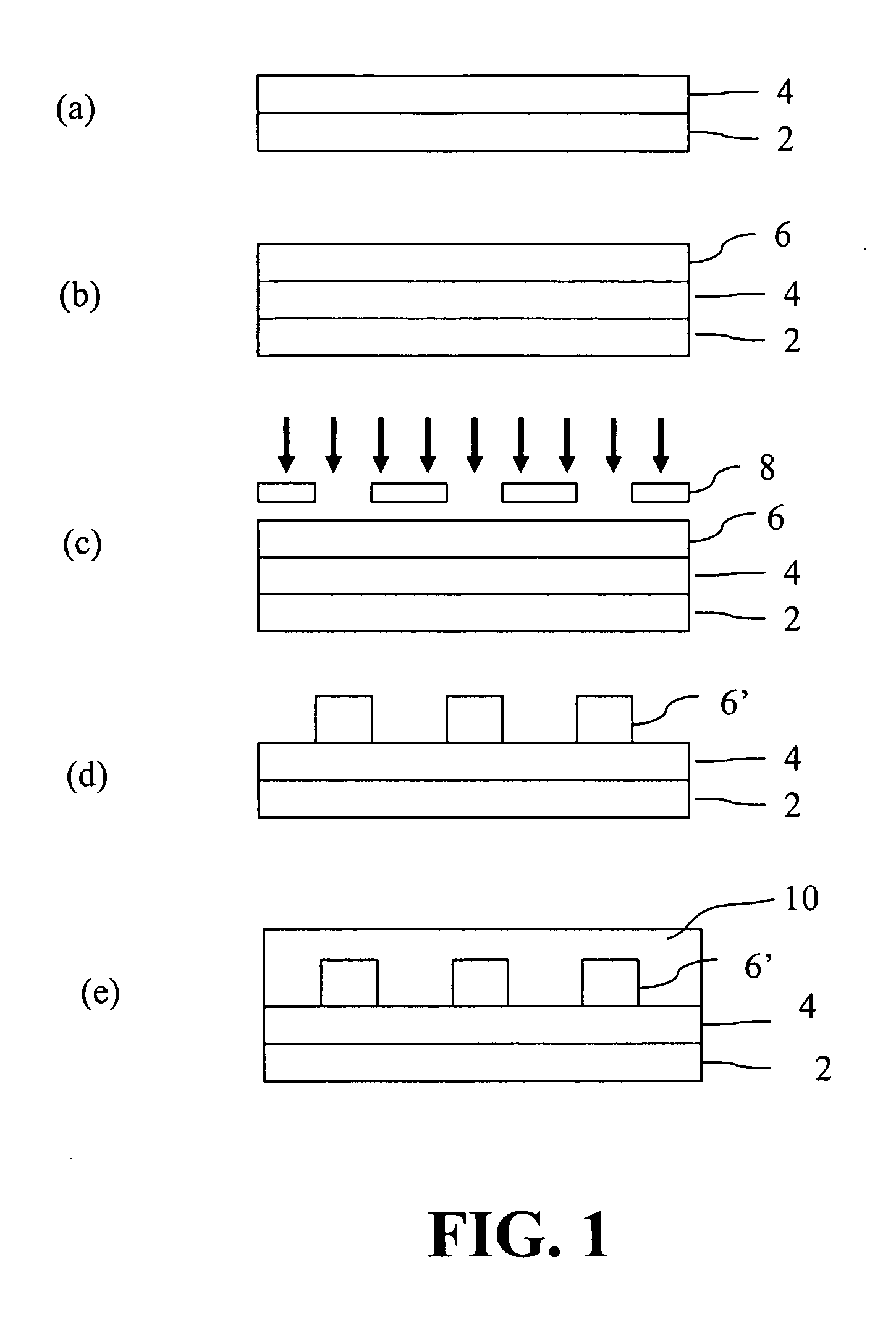

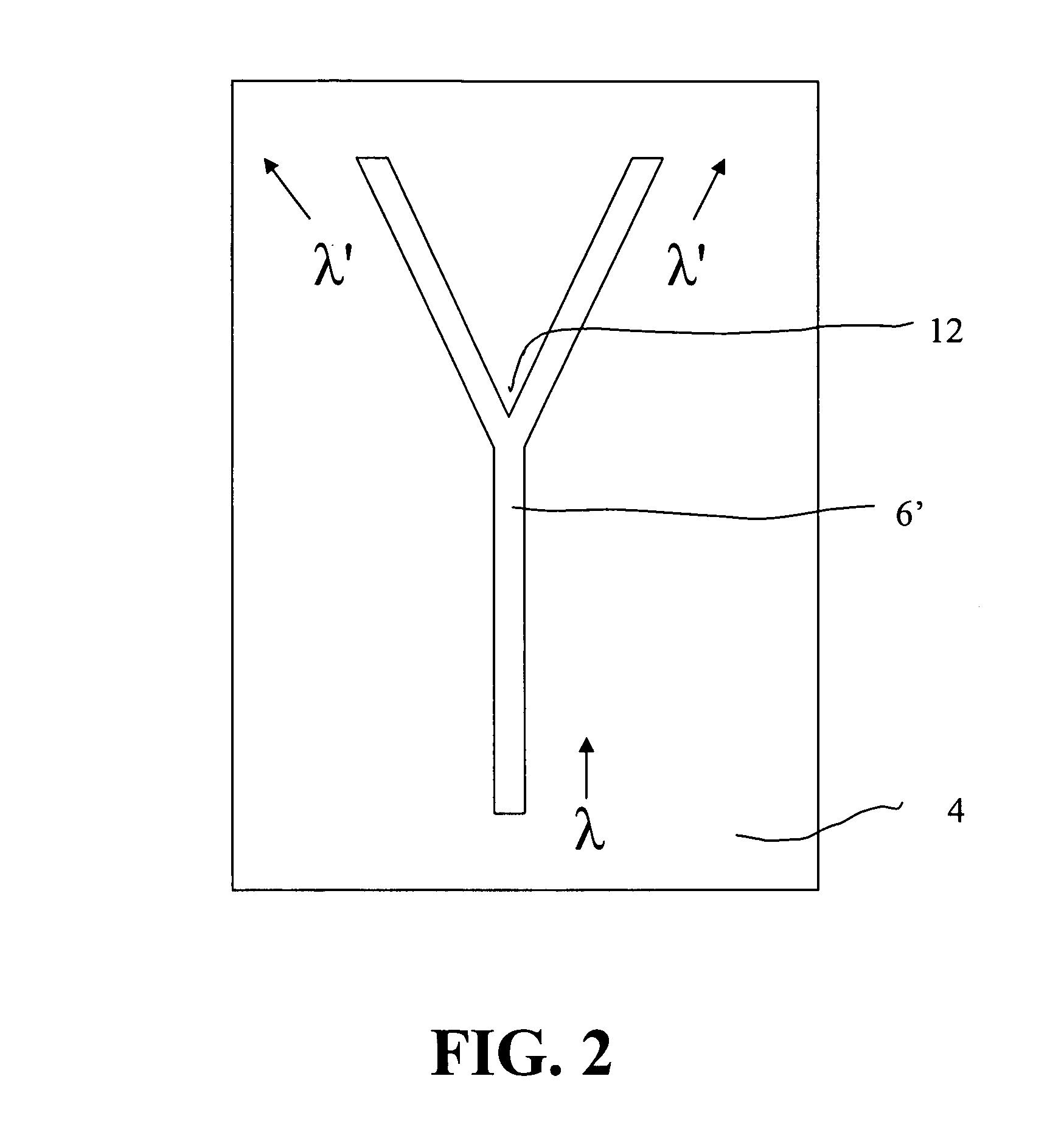

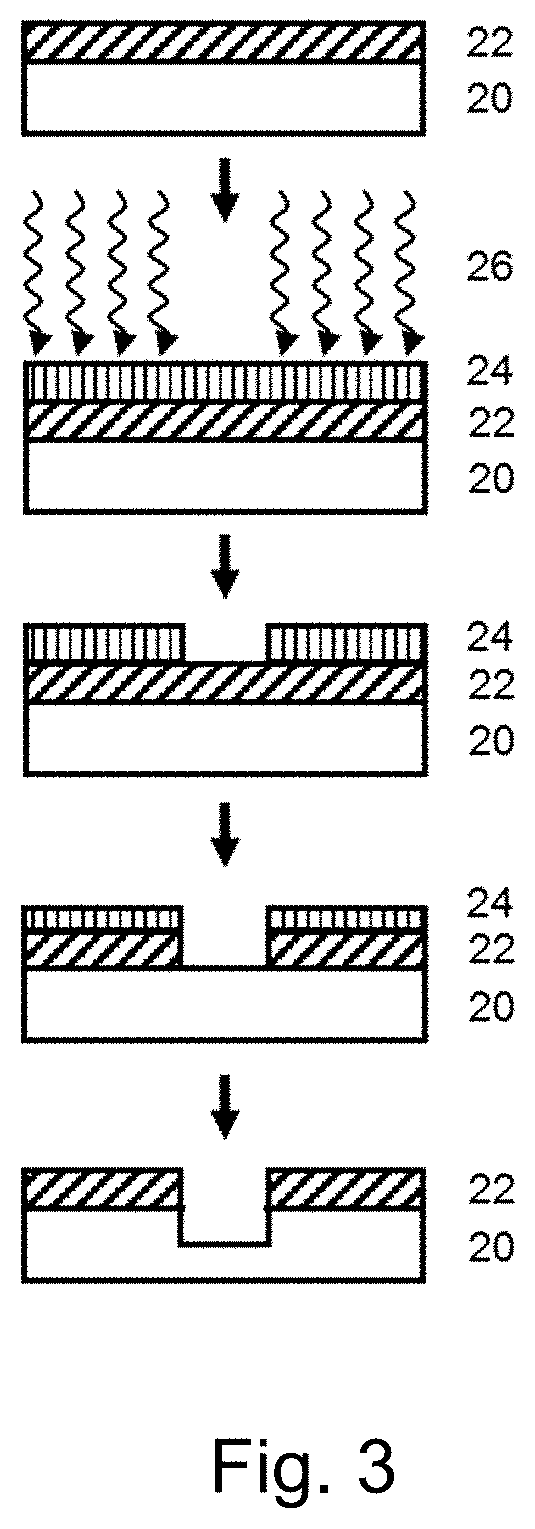

Diffraction unlimited photolithography

InactiveUS20120092632A1Altered solubilityInhibitionPhotosensitive materialsPhotomechanical exposure apparatusSolubilityWavelength

Methods, devices, systems, and materials are disclosed for diffraction unlimited photofabrication. A method is provided where a photoresponsive material is illuminated with a first optical pattern at a first wavelength of light. The first wavelength of light alters a solubility of the photoresponsive organic material. The photoresponsive material is also illuminated with a second optical pattern at a second wavelength of light. The second wavelength of light hinders the ability of the first wavelength of light to alter the solubility of the photoresponsive organic material where the second optical pattern overlaps the first optical pattern. The photoresponsive organic material is then developed.

Owner:UNIV OF COLORADO THE REGENTS OF

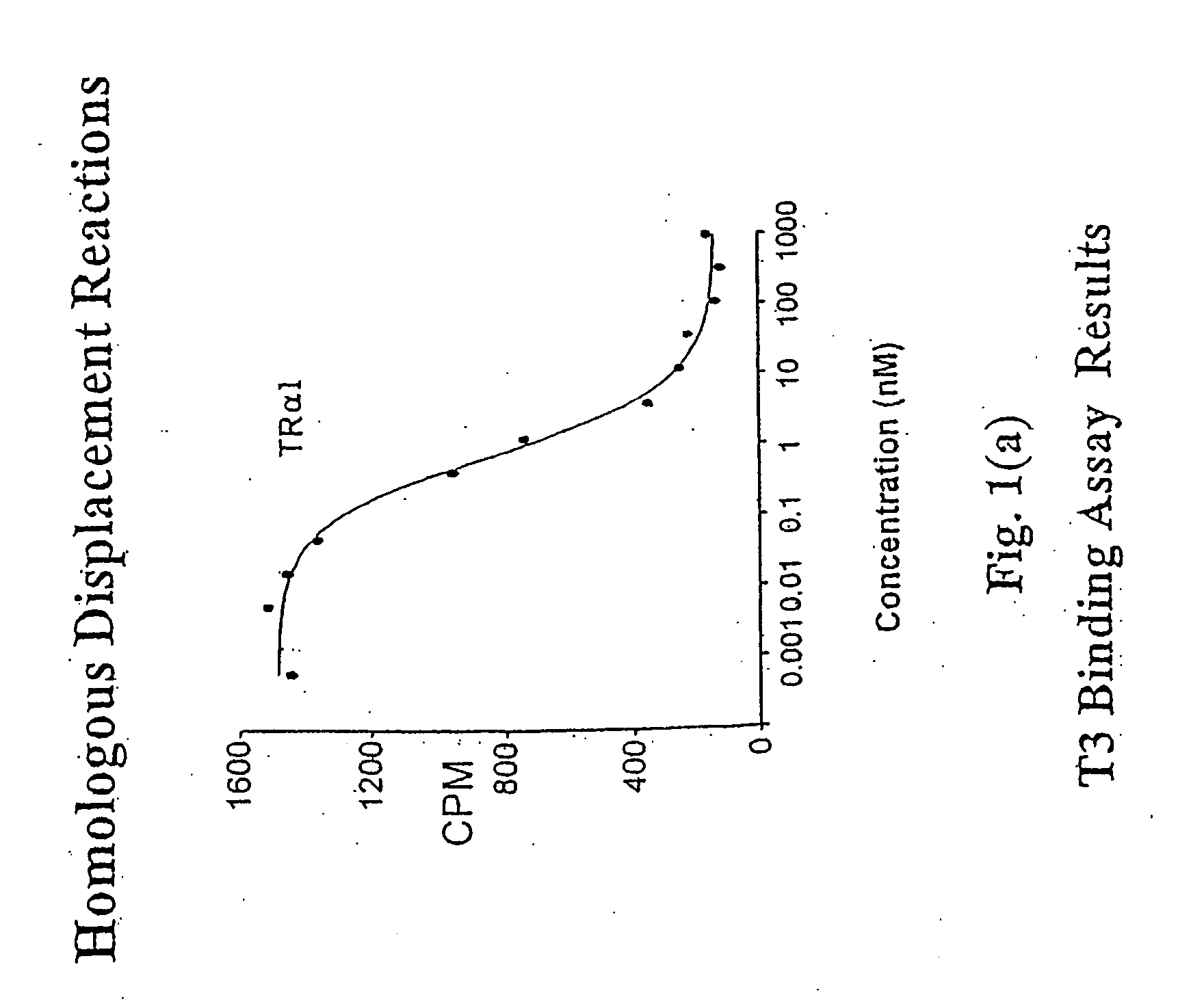

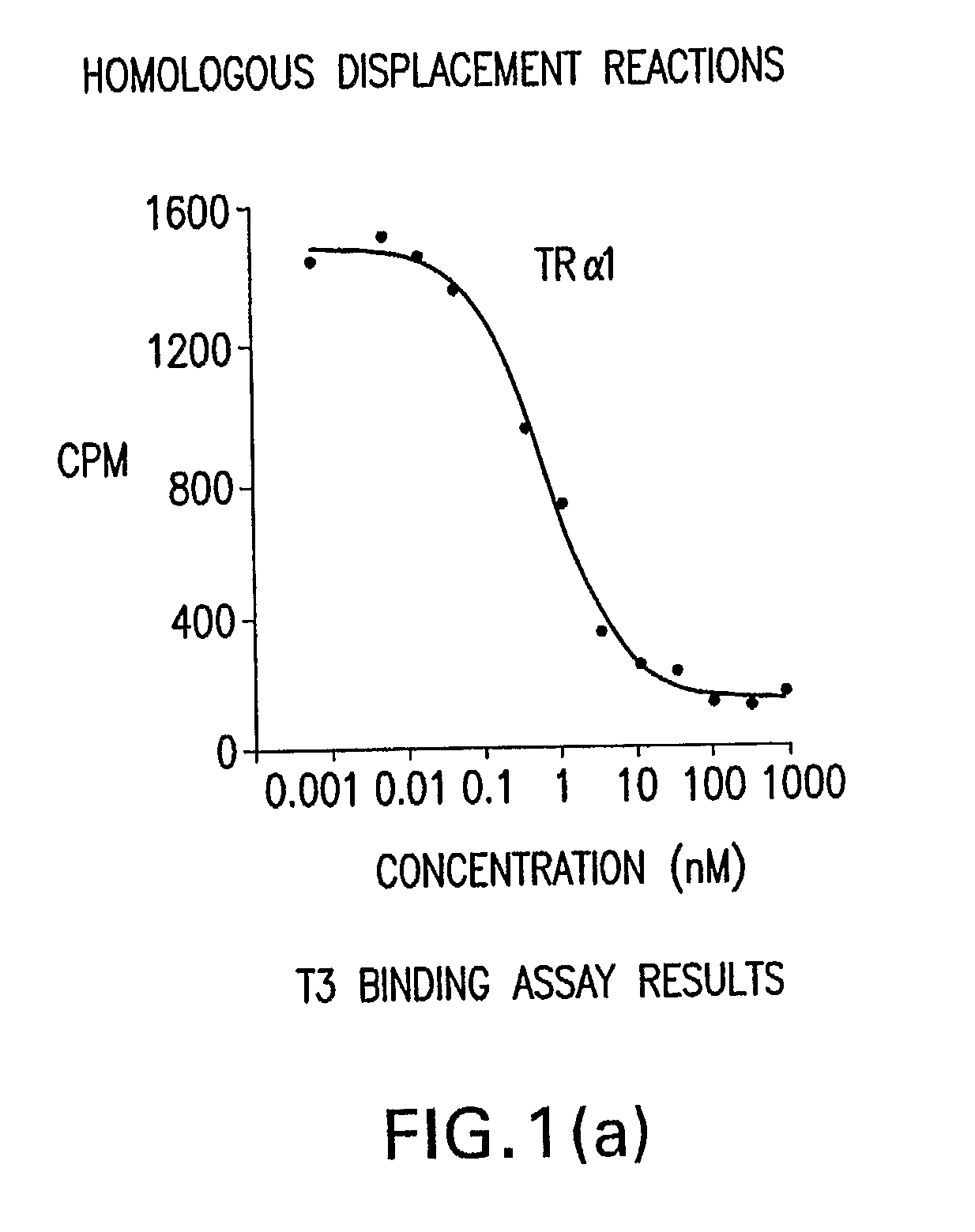

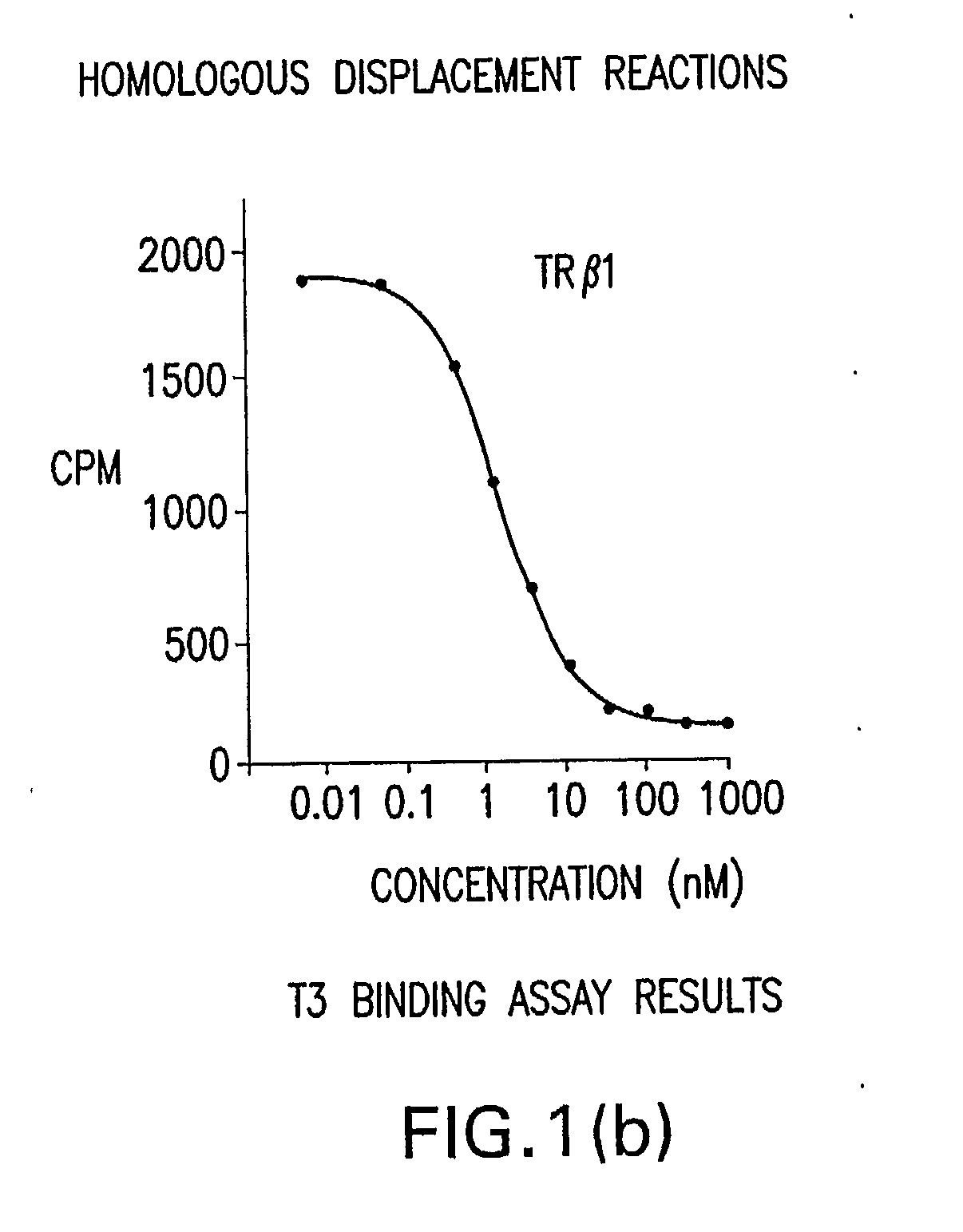

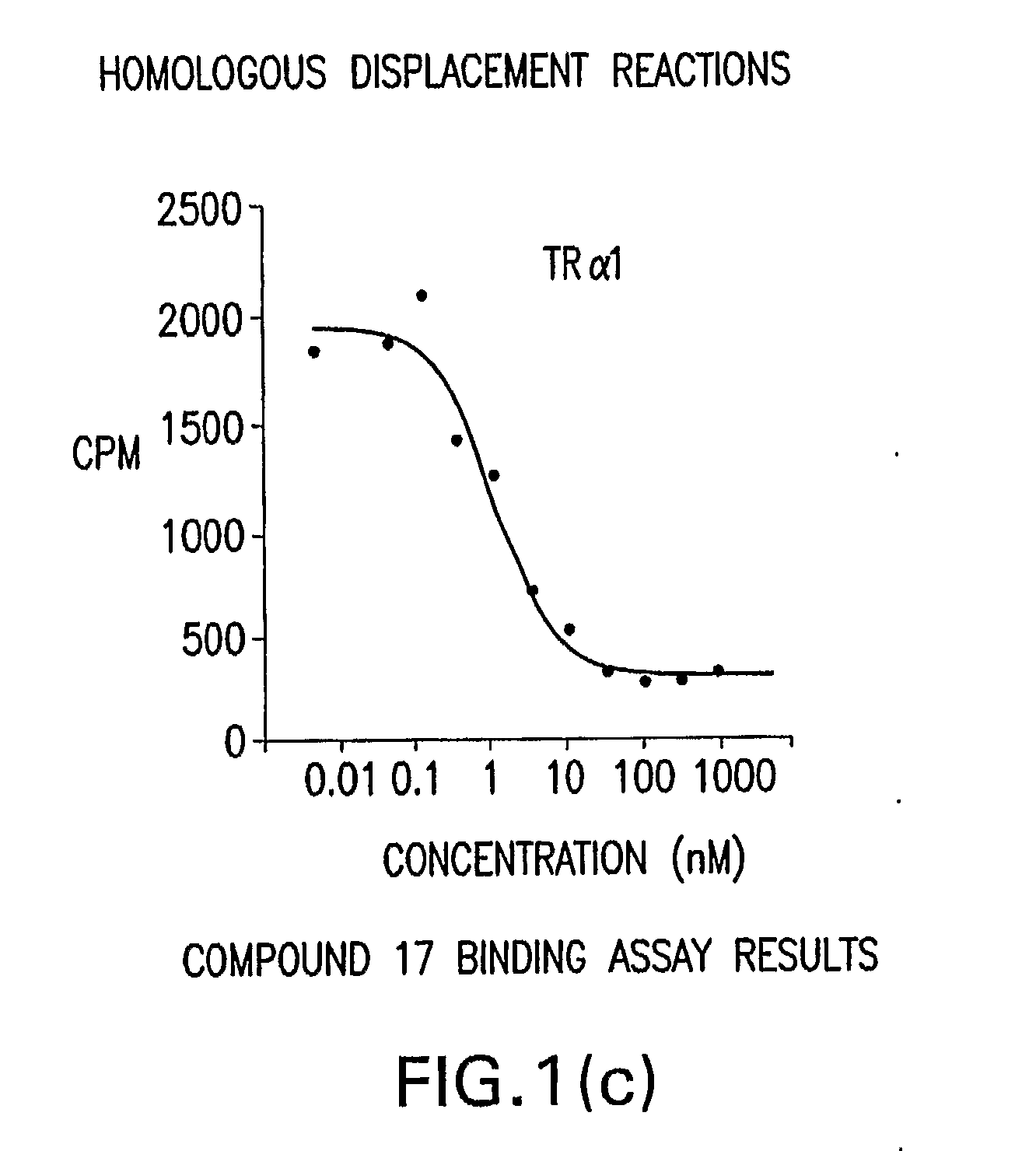

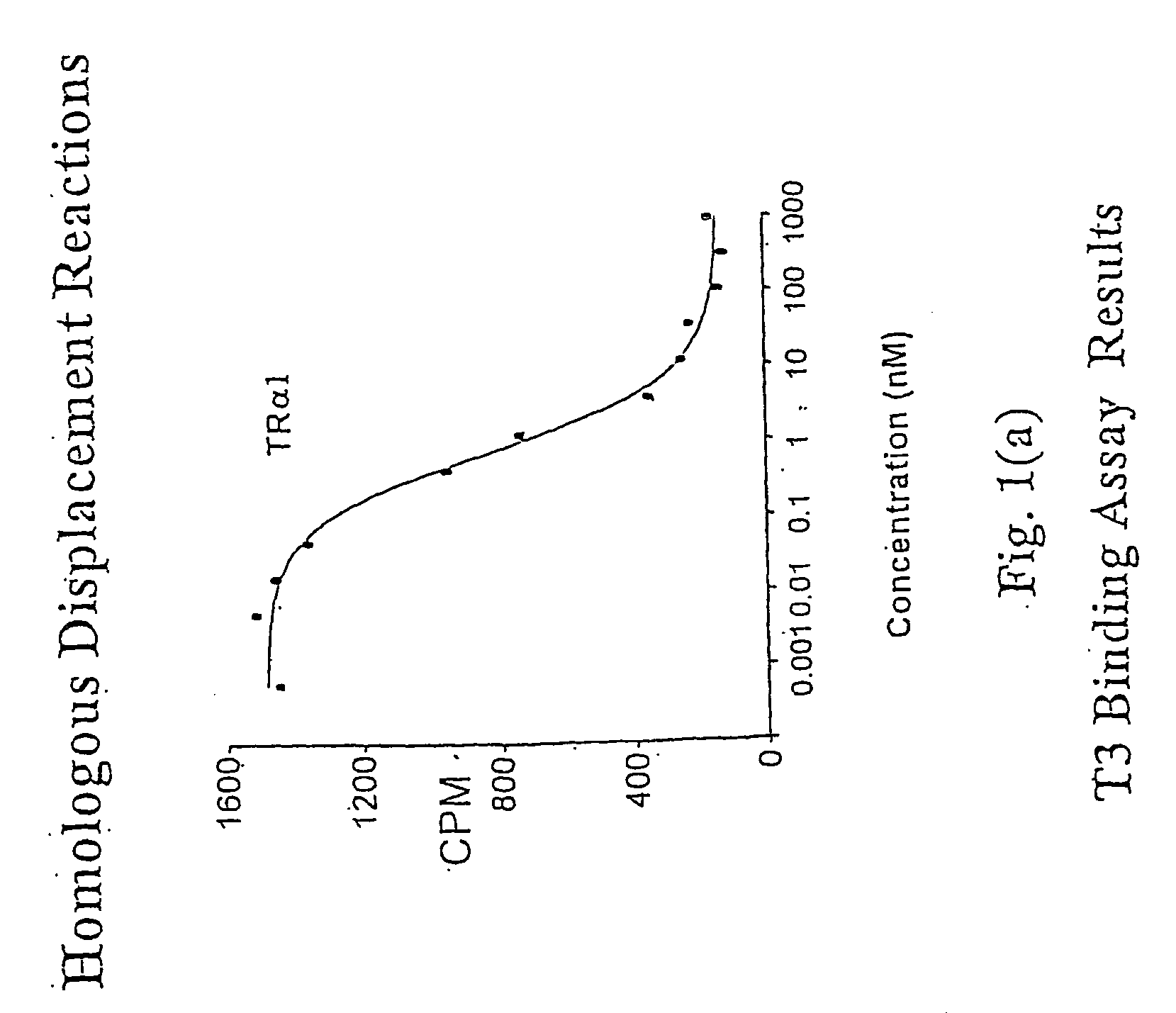

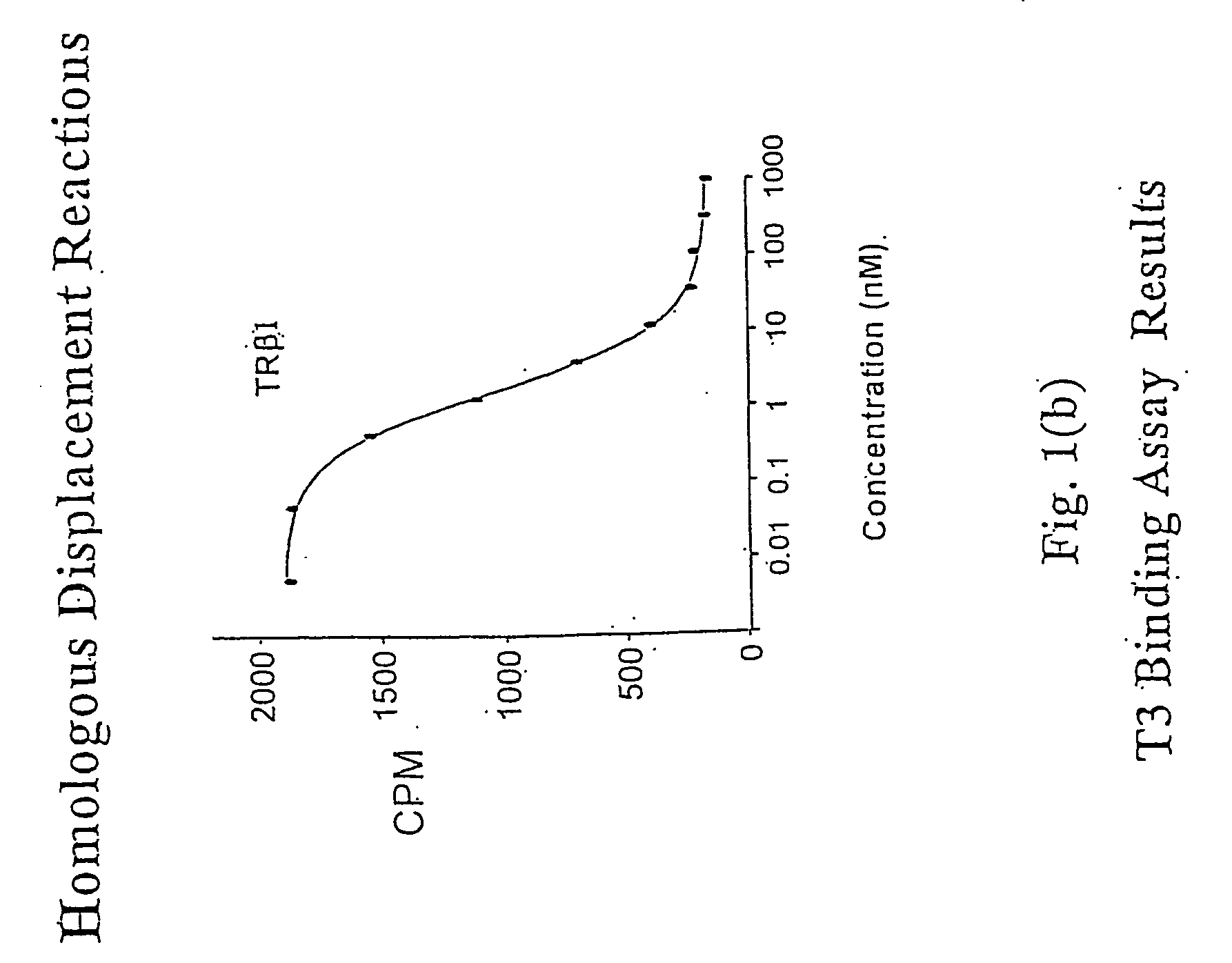

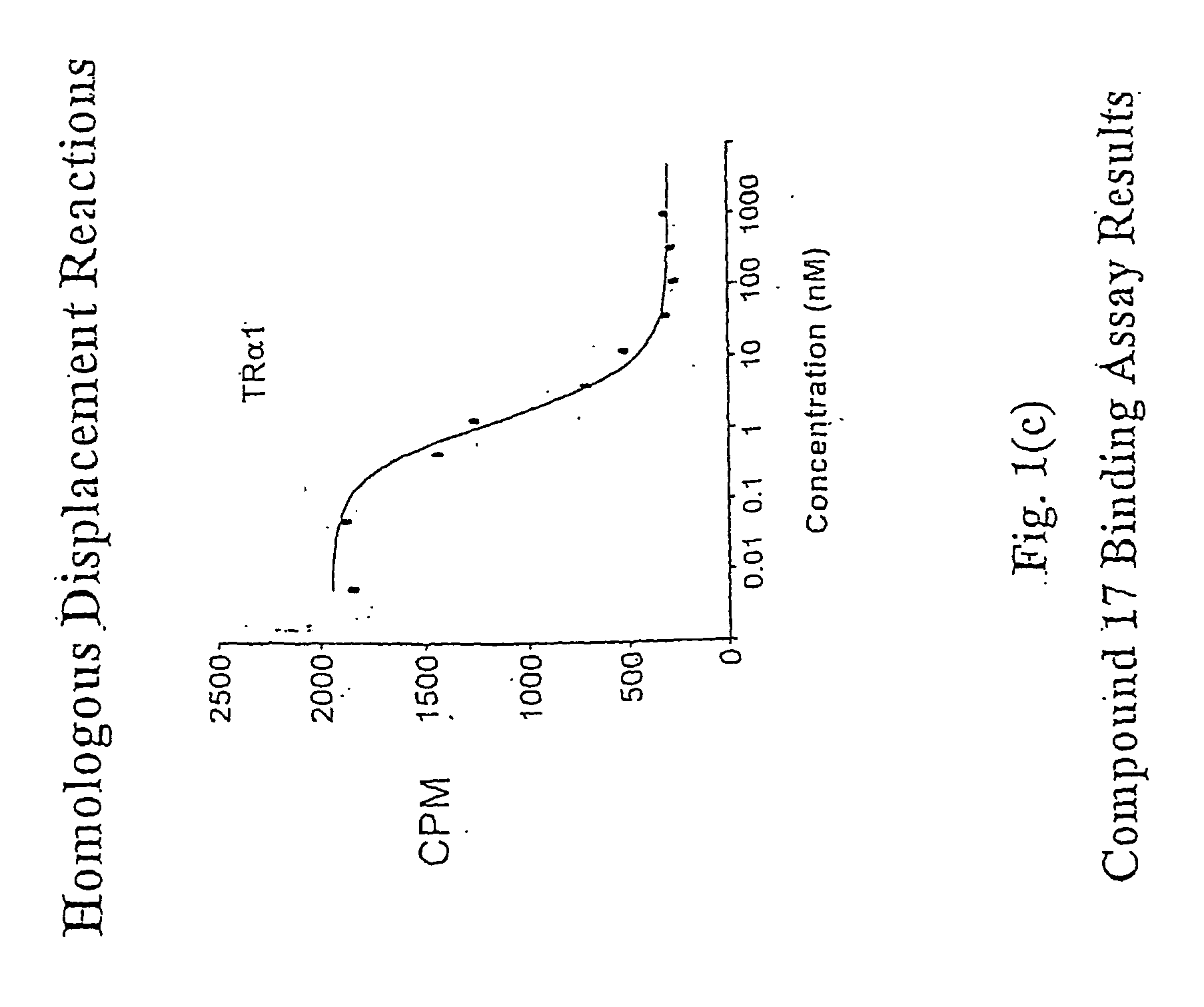

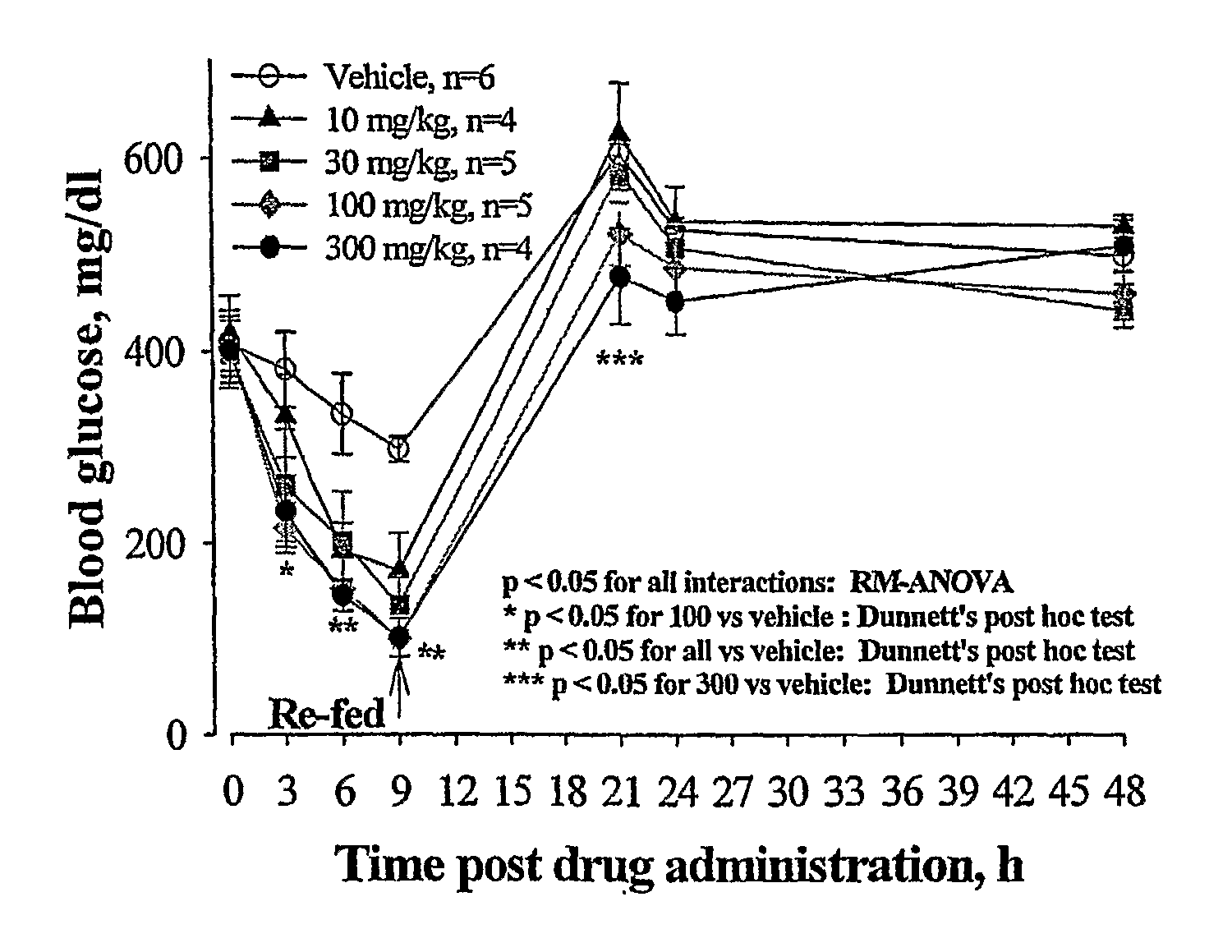

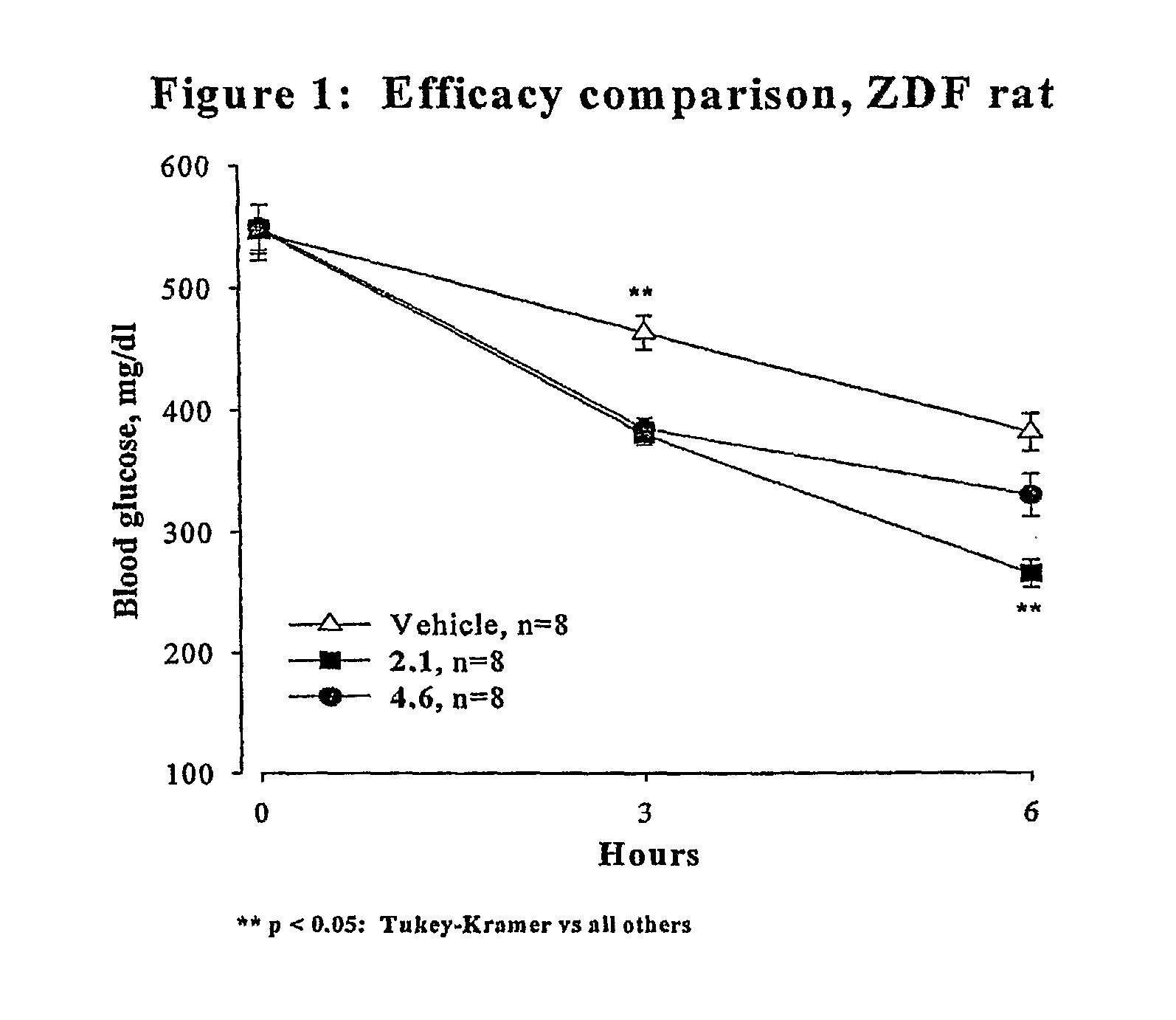

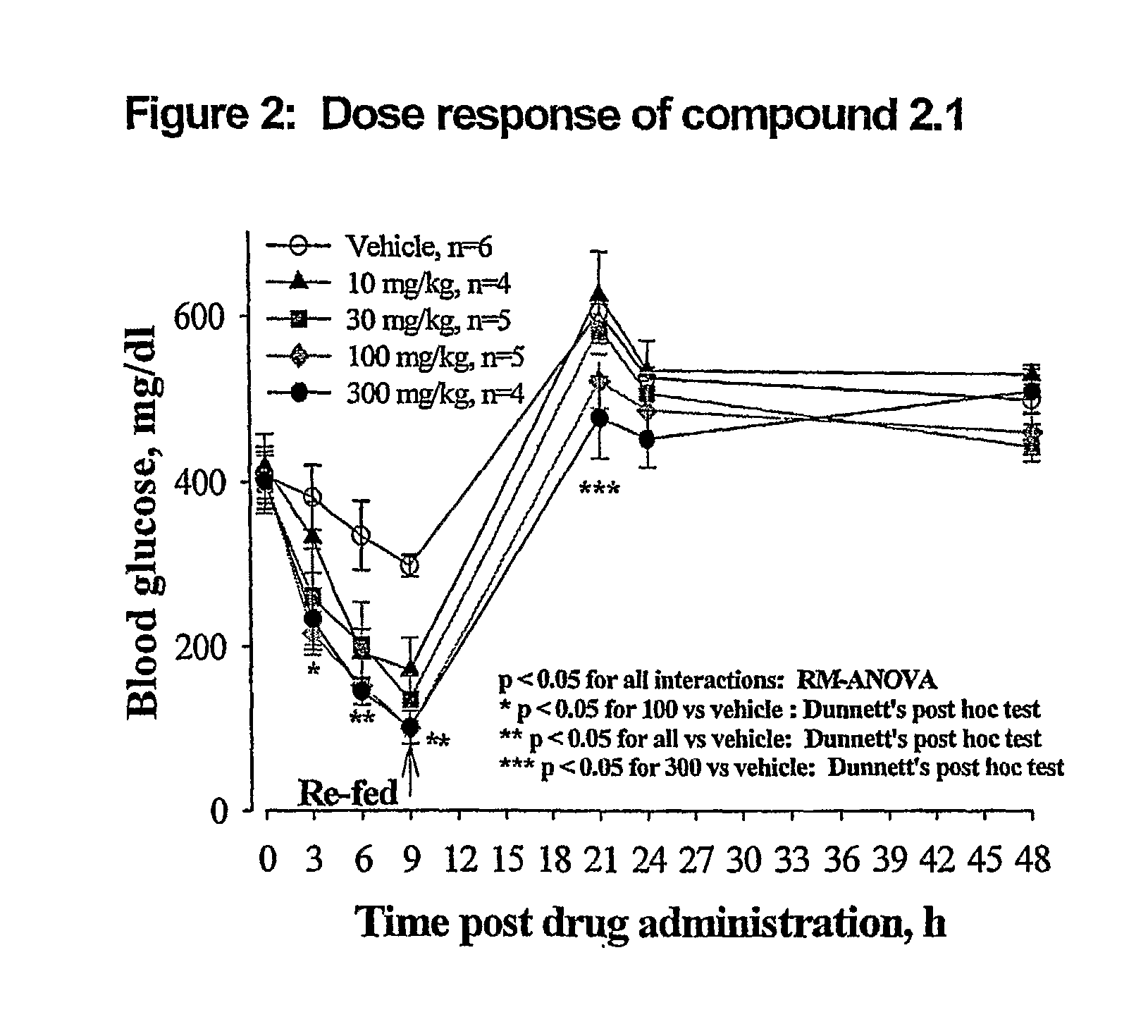

Novel phosphorus-containing thyromimetics

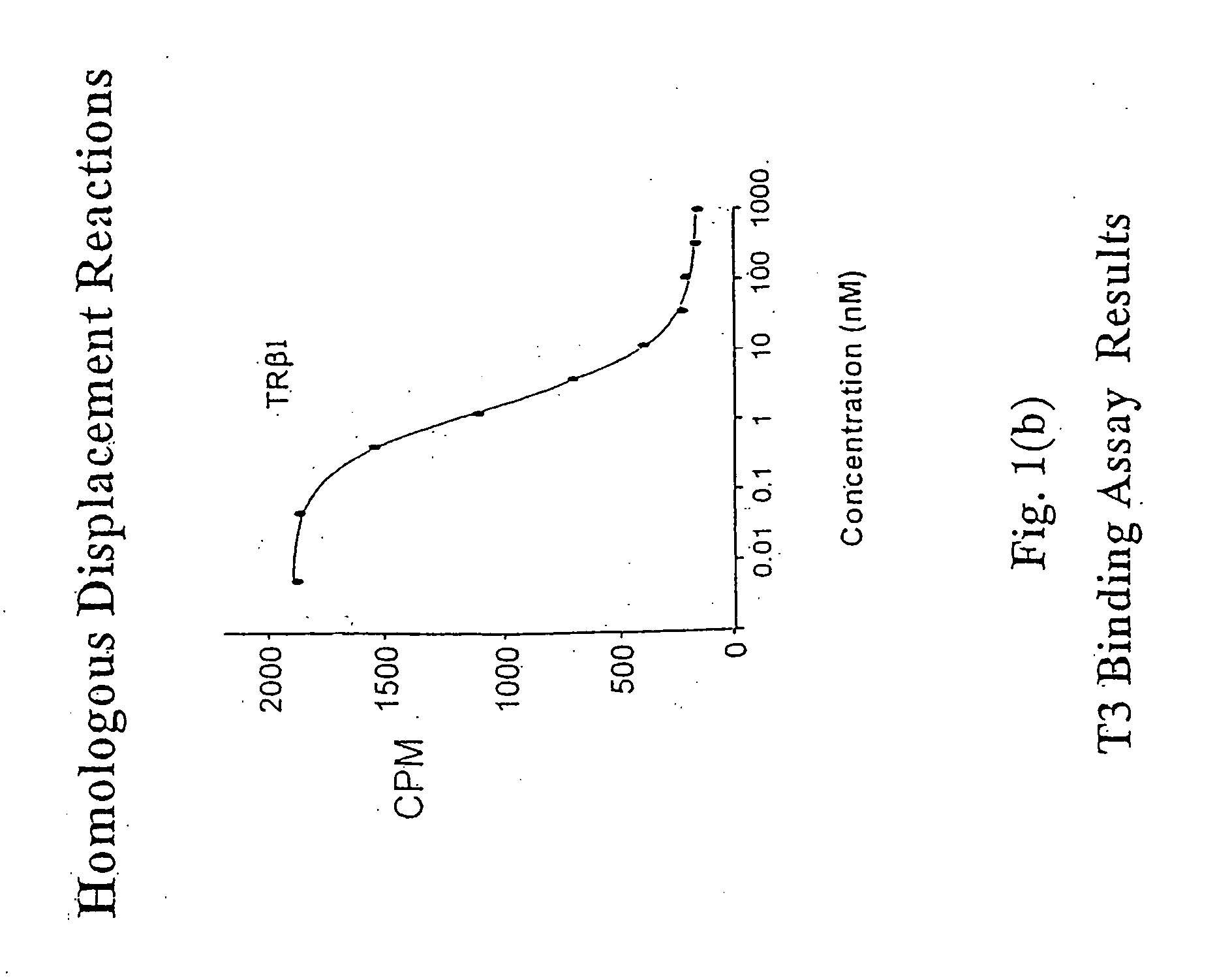

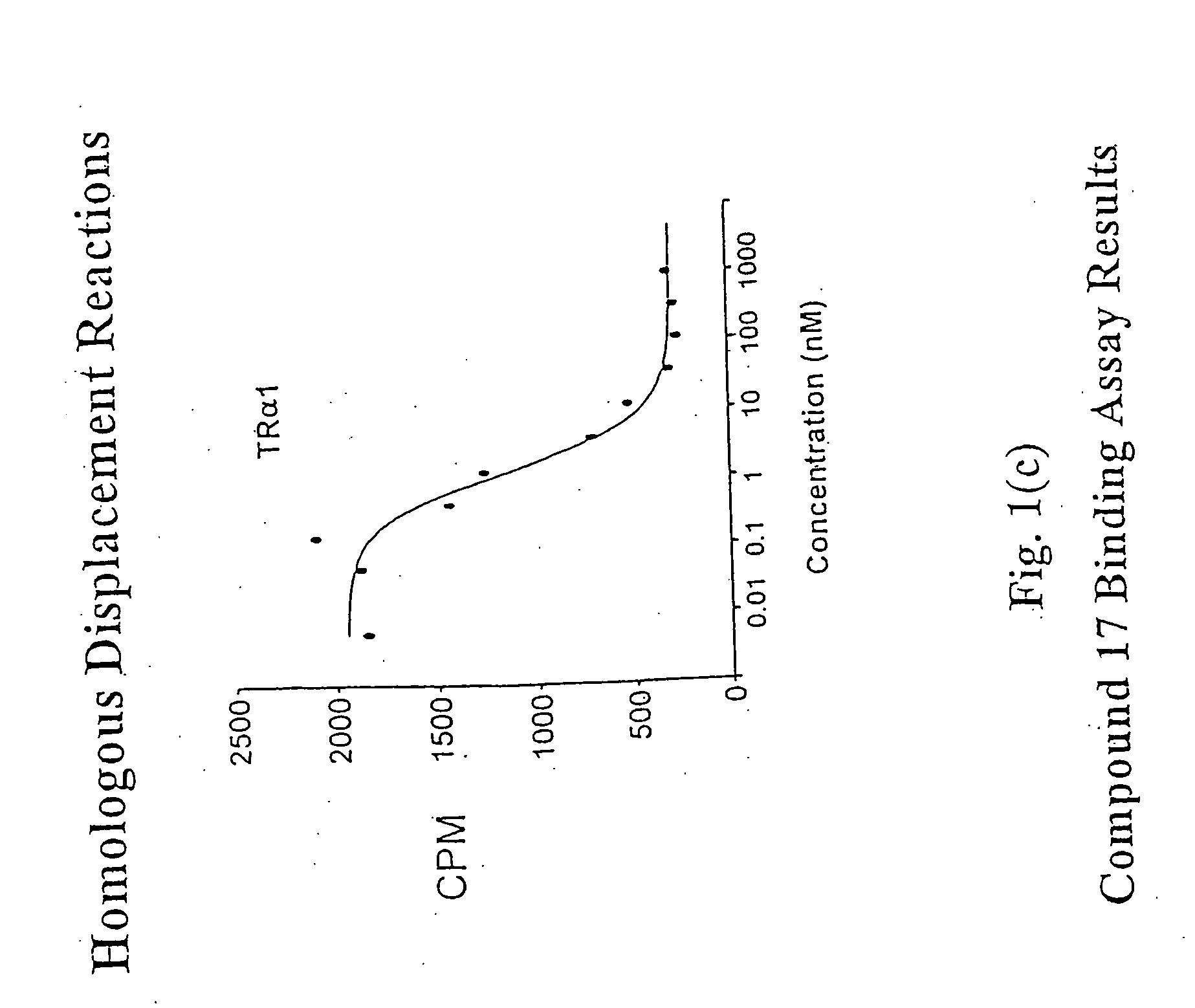

InactiveUS20060046980A1Good curative effectDecreasing non-liver toxicityBiocideSenses disorderCoronary heart diseaseProdrug

The present invention relates to compounds of phosphonic acid-containing T3 mimetics and monoesters thereof, stereoisomers, pharmaceutically acceptable salts, co-crystals, and prodrugs thereof and pharmaceutically acceptable salts and co-crystals of the prodrugs, as well as their preparation and uses for preventing and / or treating metabolic diseases such as obesity, NASH, hypercholesterolemia and hyperlipidemia, as well as associated conditions such as atherosclerosis, coronary heart disease, impaired glucose tolerance, metabolic syndrome x and diabetes.

Owner:METABASIS THERAPEUTICS INC

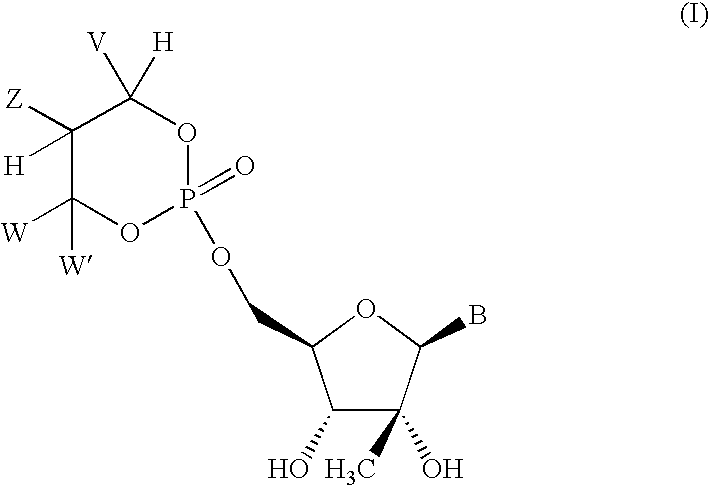

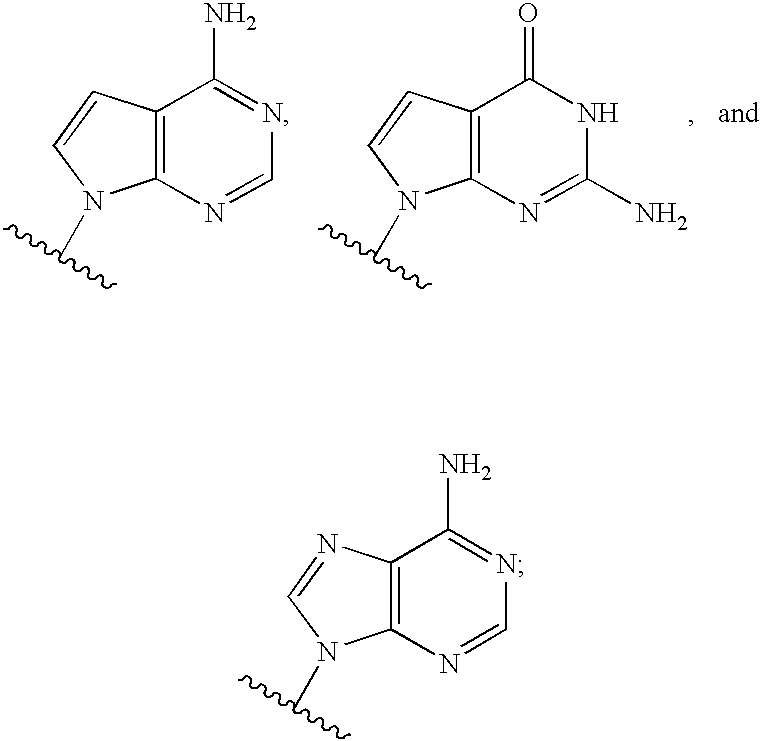

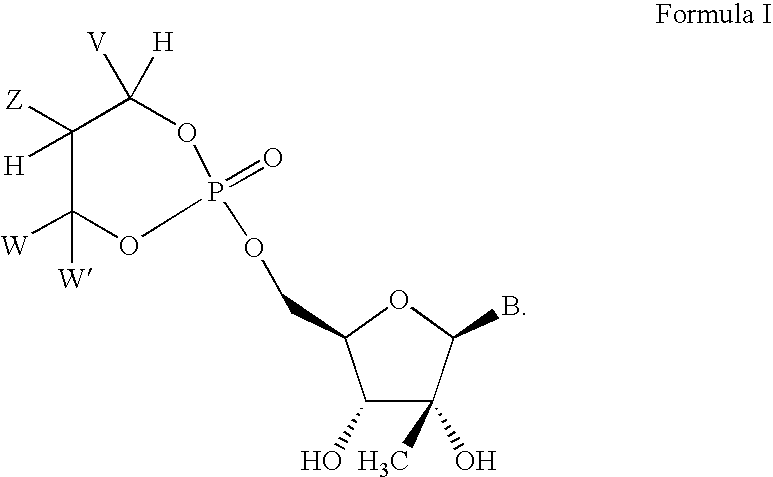

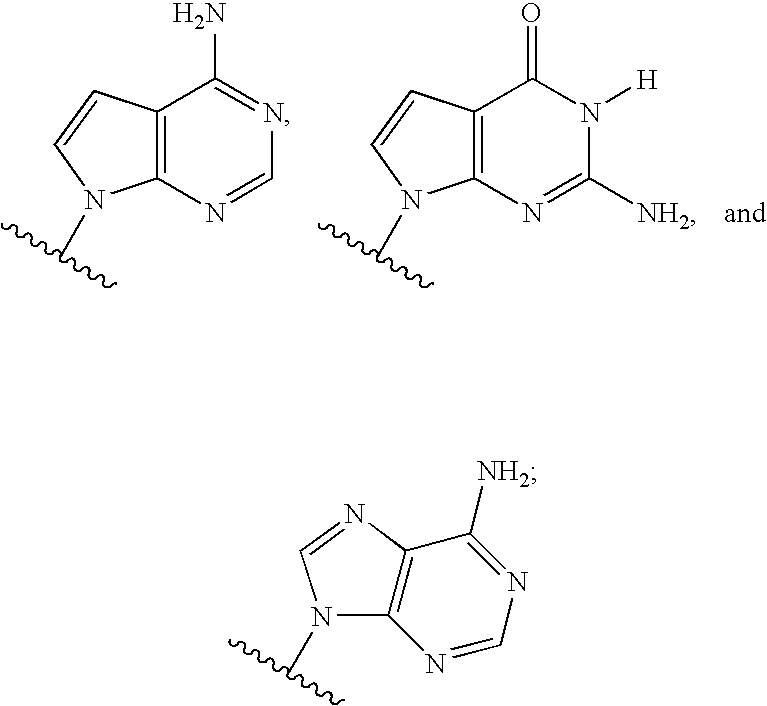

Novel 2'-c-methyl and 4'c-methyl nucleoside derivatives

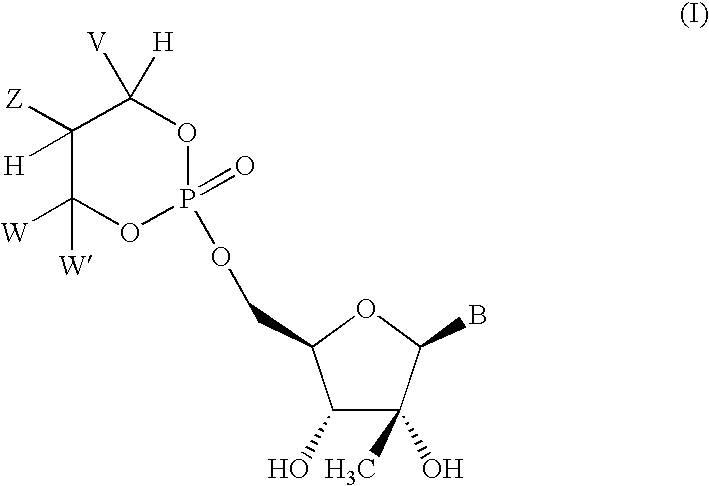

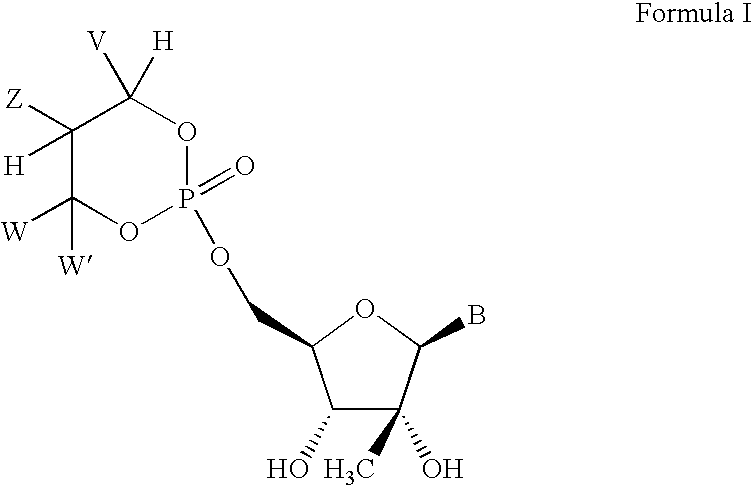

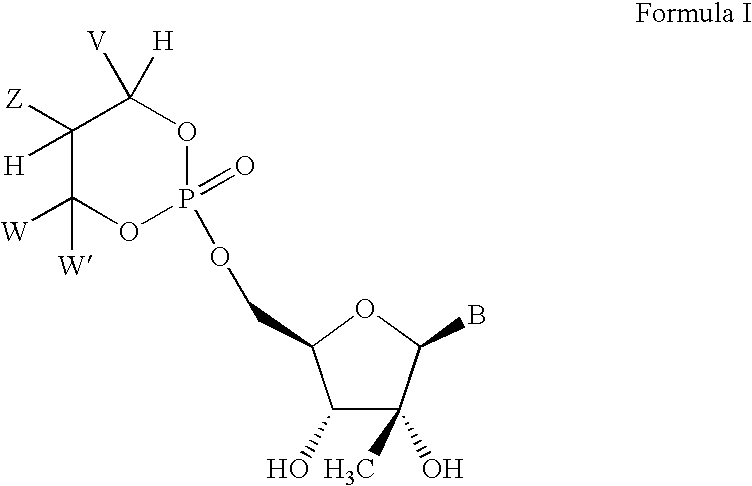

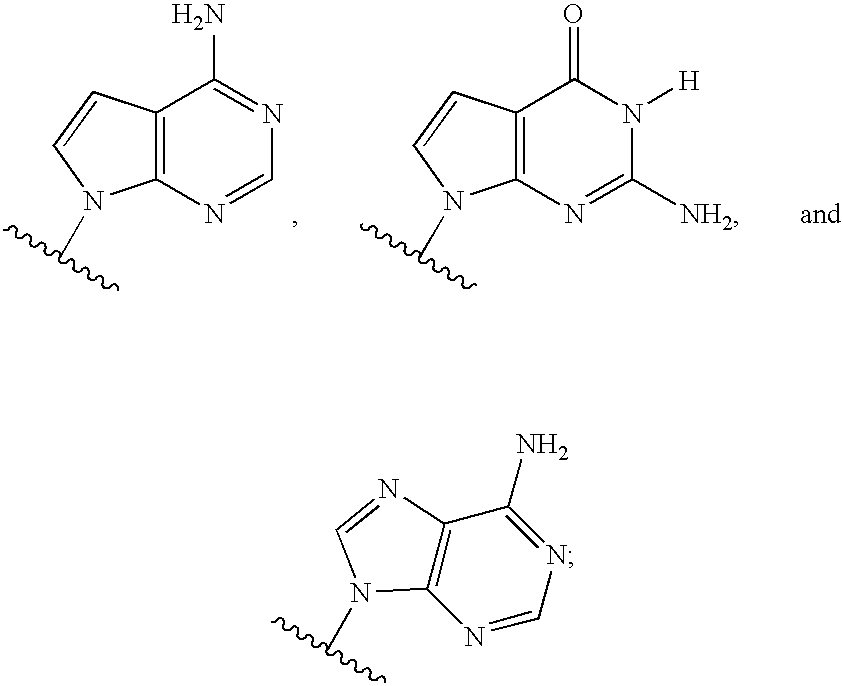

InactiveUS20090118223A1Improve efficacyImprove securityBiocideSugar derivativesHepatitis c viralPhosphoric acid

Novel 2′-C-methyl nucleoside 5′-monophosphate and 4′-C-methyl nucleoside 5′-monophosphate derivatives, stereoisomers, and pharmaceutically acceptable salts or prodrugs thereof, their preparation, and their uses for the treatment of hepatitis C viral infection are described.

Owner:METABASIS THERAPEUTICS INC +1

Novel 2'-C-methyl nucleoside derivatives

InactiveUS20050182252A1Improve drug efficacyImprove securitySugar derivativesAntiviralsHepatitis c viralStereoisomerism

Compounds of Formula I, stereoisomers, and pharmaceutically acceptable salts or prodrugs thereof, their preparation, and their uses for the treatment of hepatitis C viral infection are described:

Owner:METABASIS THERAPEUTICS INC

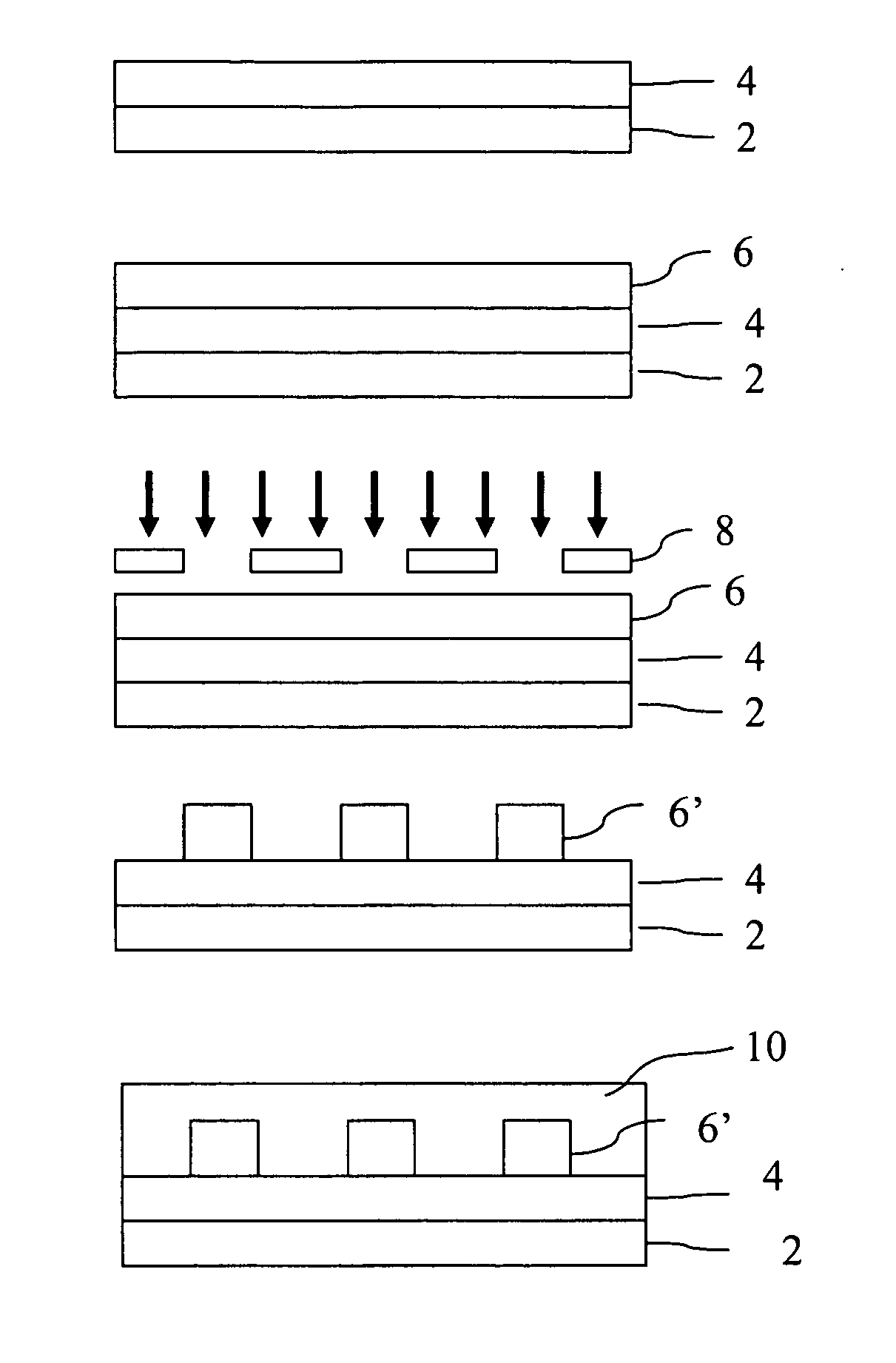

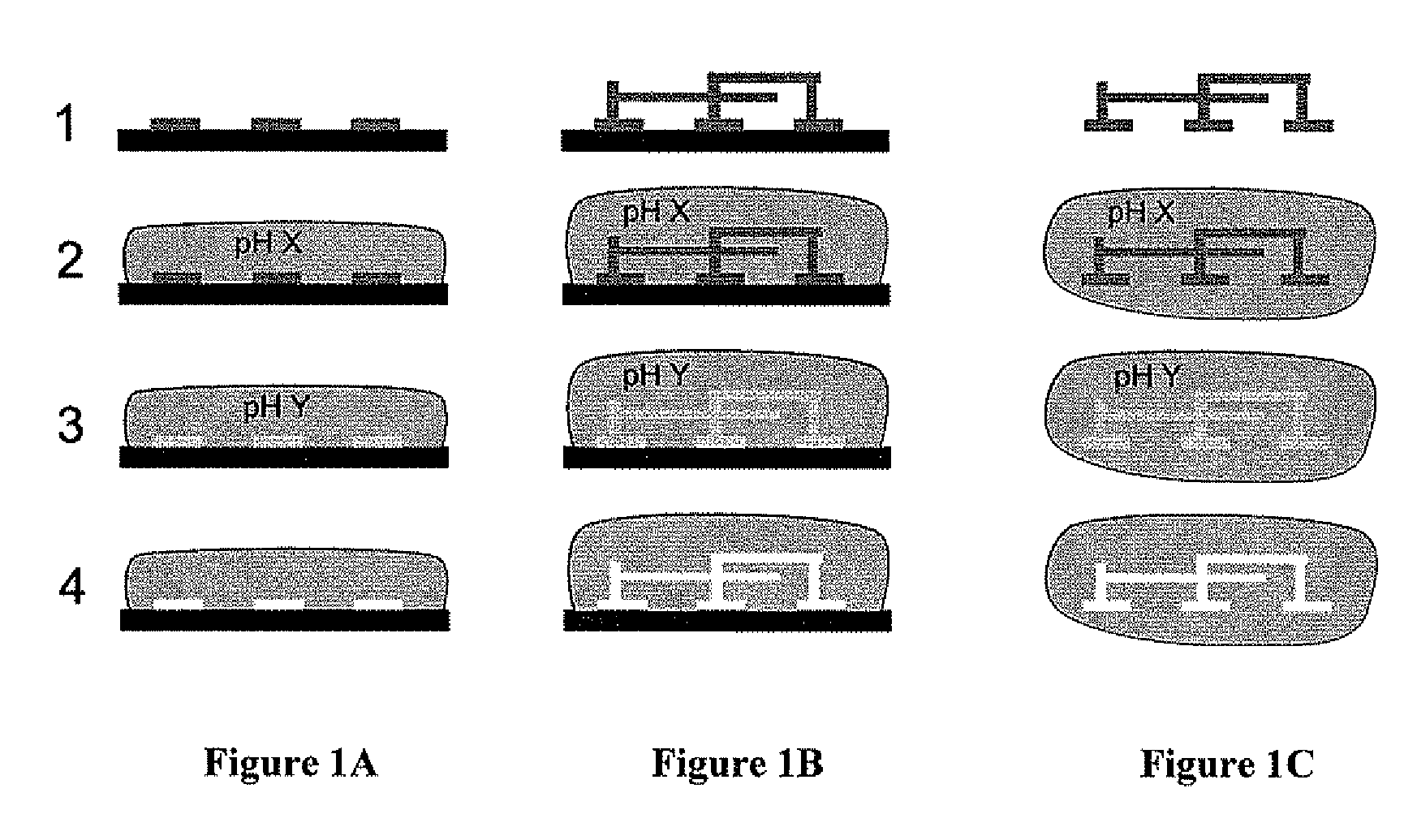

Ph-sensitive sacrificial materials for the microfabrication of structures

ActiveUS20130066045A1High removal rateAltered solubilityShellac coatingsPharmaceutical delivery mechanismSolubilityPorosity

Methods for microfabricating composite materials and composite materials prepared there from are described herein. The sacrificial material can be etched or patterned to create a two-dimensional and / or three-dimensional sacrificial material structure. The resulting sacrificial material structure can be embedded in one or more embedding materials. The sacrificial material(s) are materials whose solubility can be altered by application of a stimulus typically pH, and / or temperature, light, pH, pressure, presence of absence of ions, and combinations thereof. The embedding materials can contain one or more additives that modify one or more properties of the embedding materials, such as degradation properties, porosity, mechanical properties, viscosity, conductive properties, and combinations thereof. The composite materials can be used in tissue engineering, drug screening, toxin detection, drug delivery, filtrations, bioseparations, and as microfluidic devices for fluid mixing and structural repair.

Owner:MASSACHUSETTS INST OF TECH +1

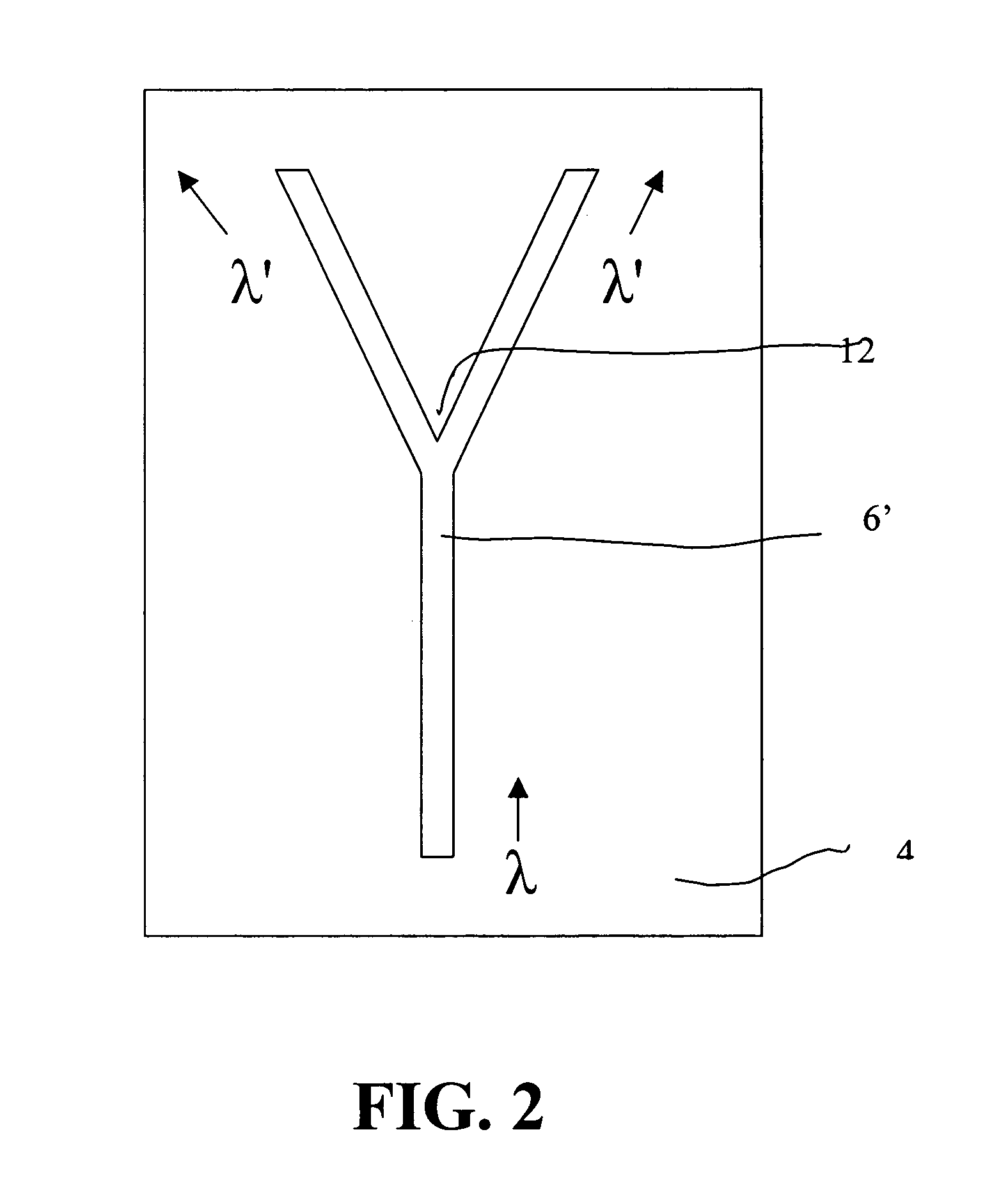

Waveguide compositions and waveguides formed therefrom

ActiveUS7072565B2Altered solubilityIncrease flexibilityMaterial nanotechnologyOptical fibre with graded refractive index core/claddingSolubilityVinyl ether

Provided are compositions which include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from epoxides, oxetanes, vinyl ethers and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Waveguide compositions and waveguides formed therefrom

ActiveUS20050141839A1Altered solubilityIncrease flexibilityOptical fibre with graded refractive index core/claddingPhotosensitive materialsSolubilityThiol

Provided are compositions suitable for use in forming a flexible optical waveguide. The compositions include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from hydroxy, amino, thiol, sulphonate ester, carboxylate ester, silyl ester, anhydride, aziridine, methylolmethyl, silyl ether, and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Novel Phosphorus-Containing Thyromimetics

InactiveUS20100081634A1Optimize allocationIncreasing oral bioavailability and sustained deliveryBiocideSenses disorderDiseaseCoronary heart disease

The present invention relates to compounds of phosphonic acid-containing T3 mimetics and monoesters thereof, stereoisomers, pharmaceutically acceptable salts, co-crystals, and prodrugs thereof and pharmaceutically acceptable salts and co-crystals of the prodrugs, as well as their preparation and uses for preventing and / or treating metabolic diseases such as obesity, NASH, hypercholesterolemia and hyperlipidemia, as well as associated conditions such as atherosclerosis, coronary heart disease, impaired glucose tolerance, metabolic syndrome x and diabetes.

Owner:METABASIS THERAPEUTICS INC

Waveguide compositions and waveguides formed therefrom

ActiveUS7072563B2Altered solubilityIncrease flexibilityOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingSolubilitySilylene

Provided are compositions suitable for use in forming a flexible optical waveguide. The compositions include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from hydroxy, amino, thiol, sulphonate ester, carboxylate ester, silyl ester, anhydride, aziridine, methylolmethyl, silyl ether, and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Treatment of Metakaolin

InactiveUS20080264295A1High whitenessReduce the impactPigmenting treatmentPaper coatingMedicineMetakaolin

A method for increasing the brightness of metakaolins comprises calcining a metakaolin under reducing conditions. The calcined metakaolins are suitable for use in a variety of applications including in polymer products and paints.

Owner:IMERYS MINERALS

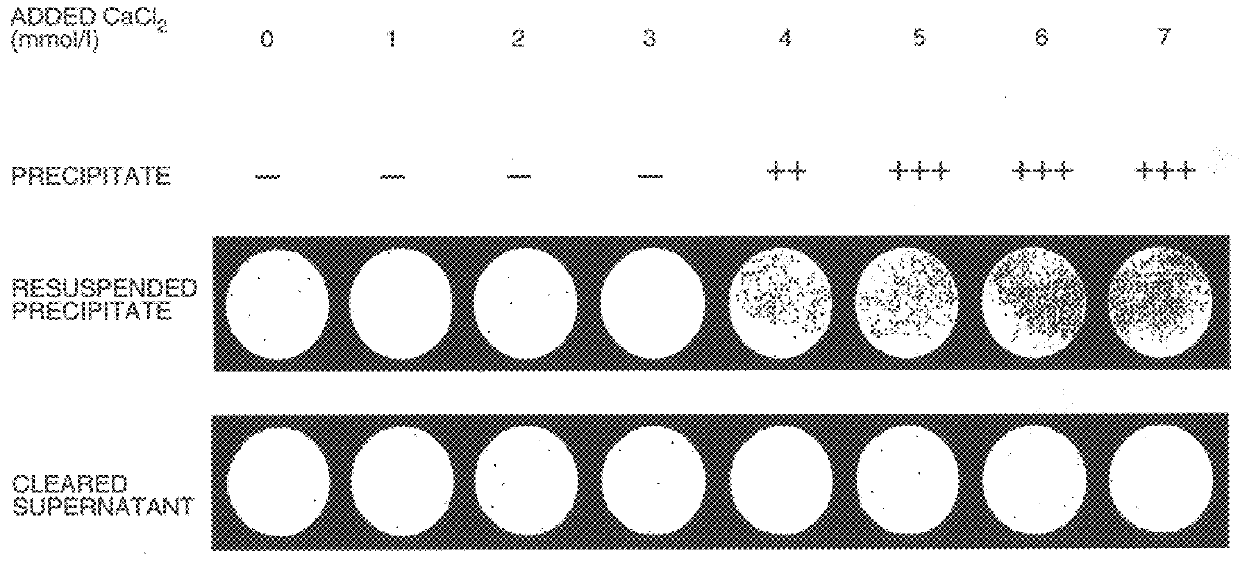

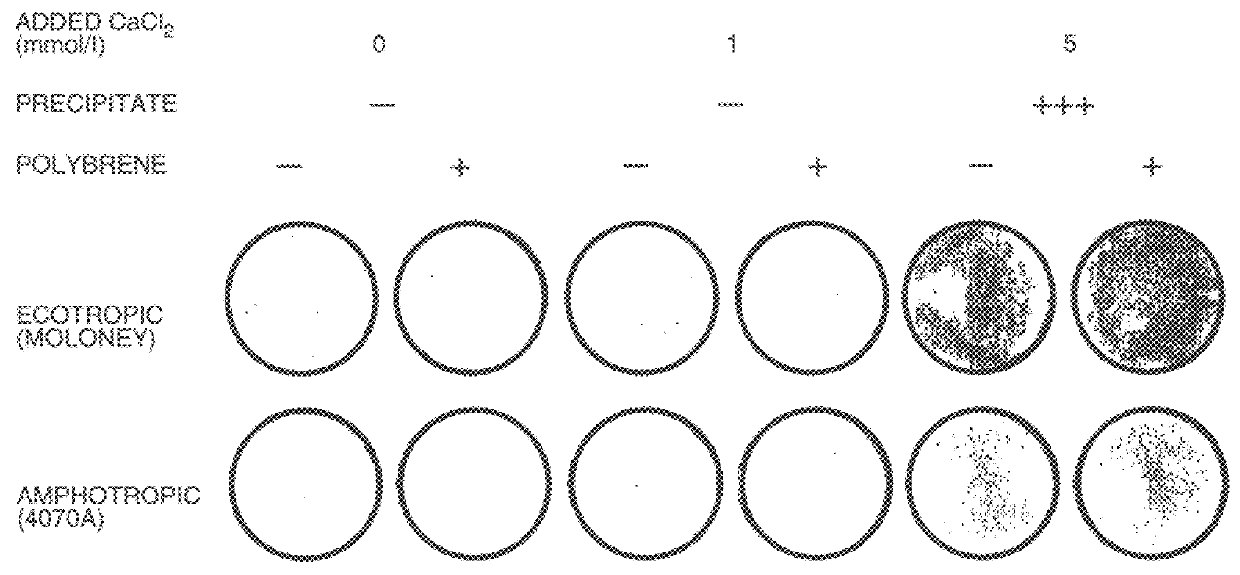

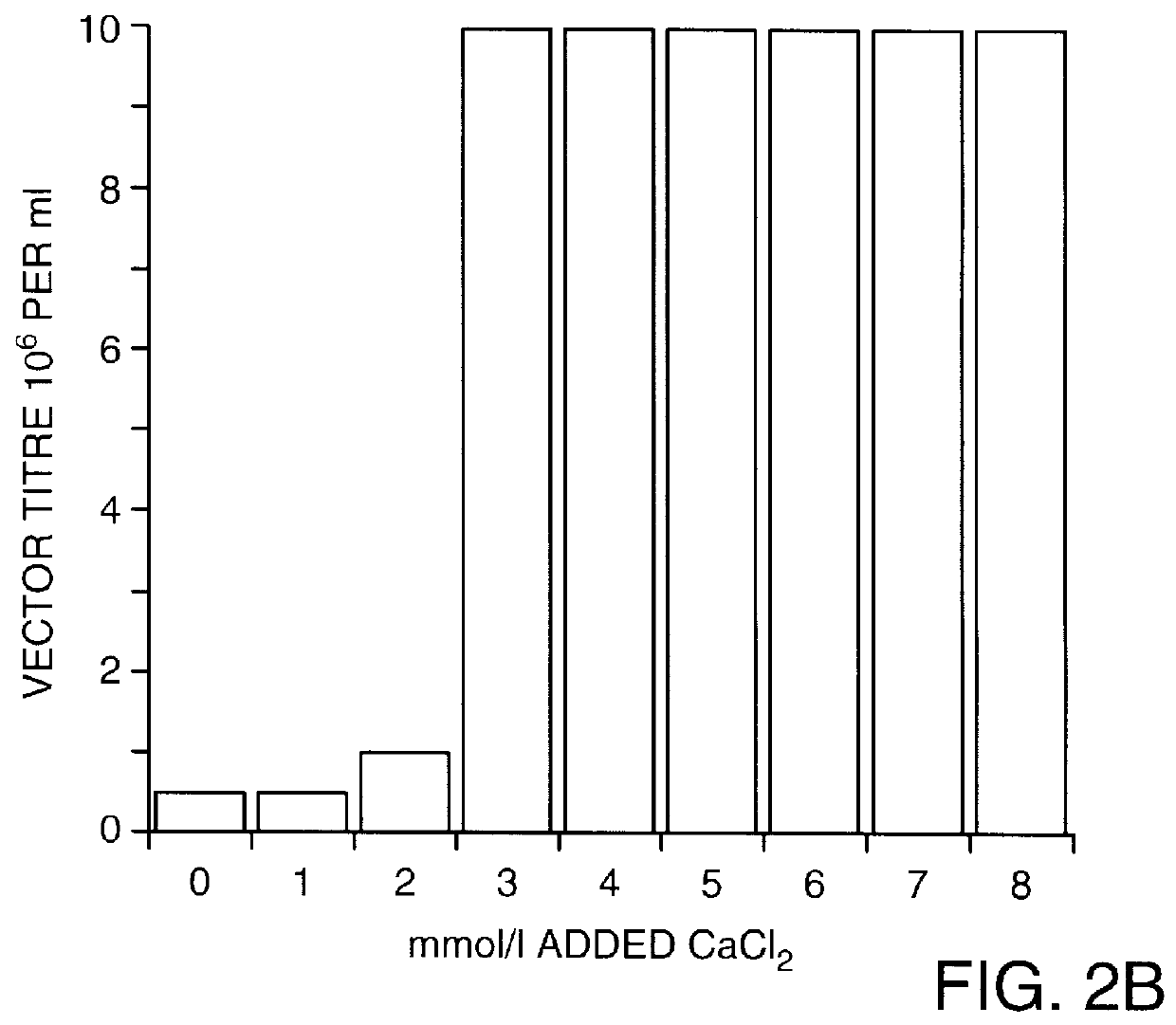

Delivery of nucleic acid

Disclosed are various compositions for use in the delivery of nucleic acid to a target cell including: a composition comprising a calcium salt in particulate form, the nucleic acid to be delivered, and one or more further components to enhance the efficiency of delivery of the nucleic acid to a target cell, the nucleic acid and the one or more further components being complexed with the particulate calcium salt; and methods of delivering a nucleic acid to a target cell.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Waveguide compositions and waveguides formed therefrom

ActiveUS20050244124A1Improve flexibilityAlter solubilityMaterial nanotechnologyOptical fibre with graded refractive index core/claddingChemistryEpoxide

Provided are compositions which include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from epoxides, oxetanes, vinyl ethers and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

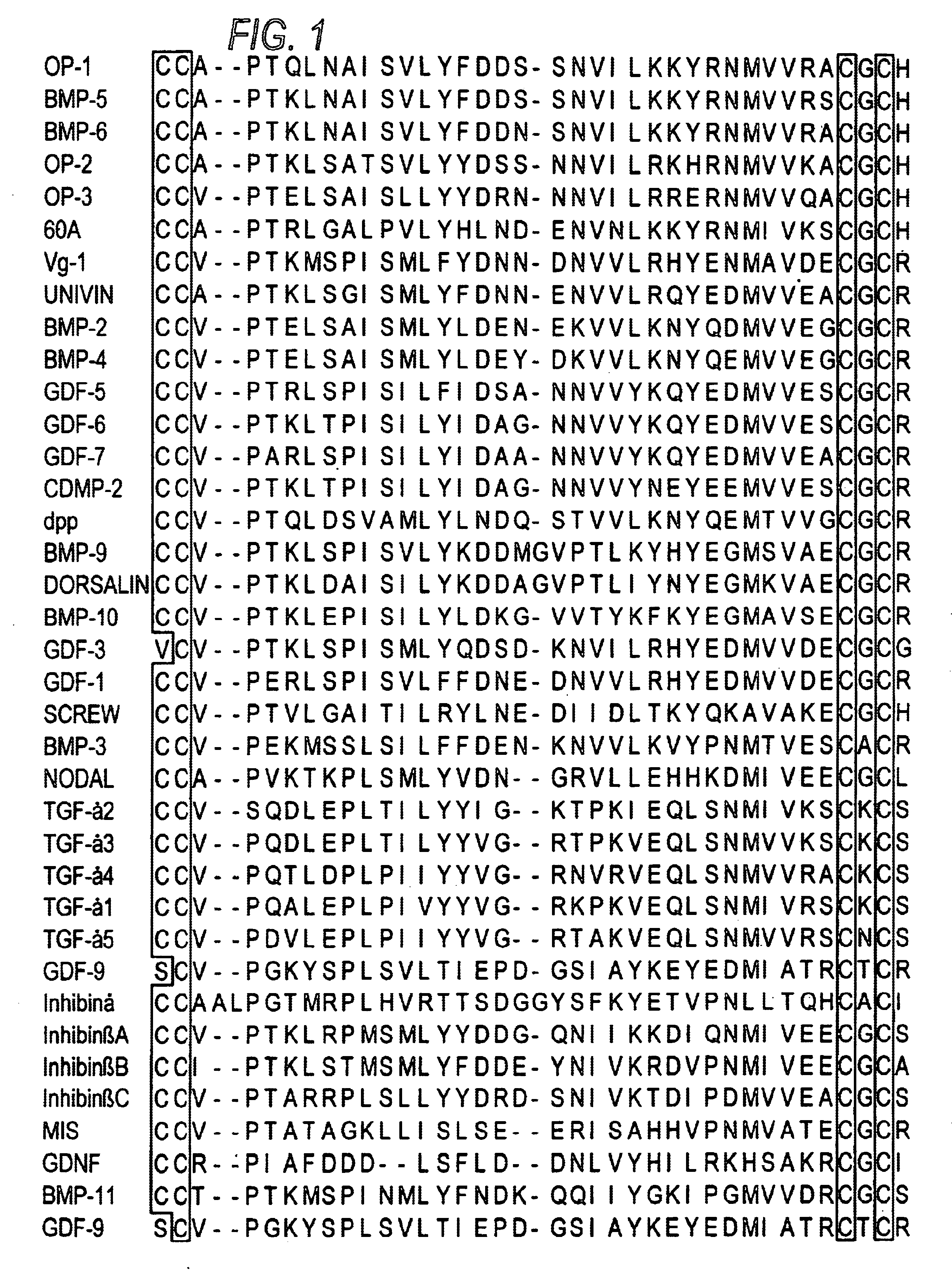

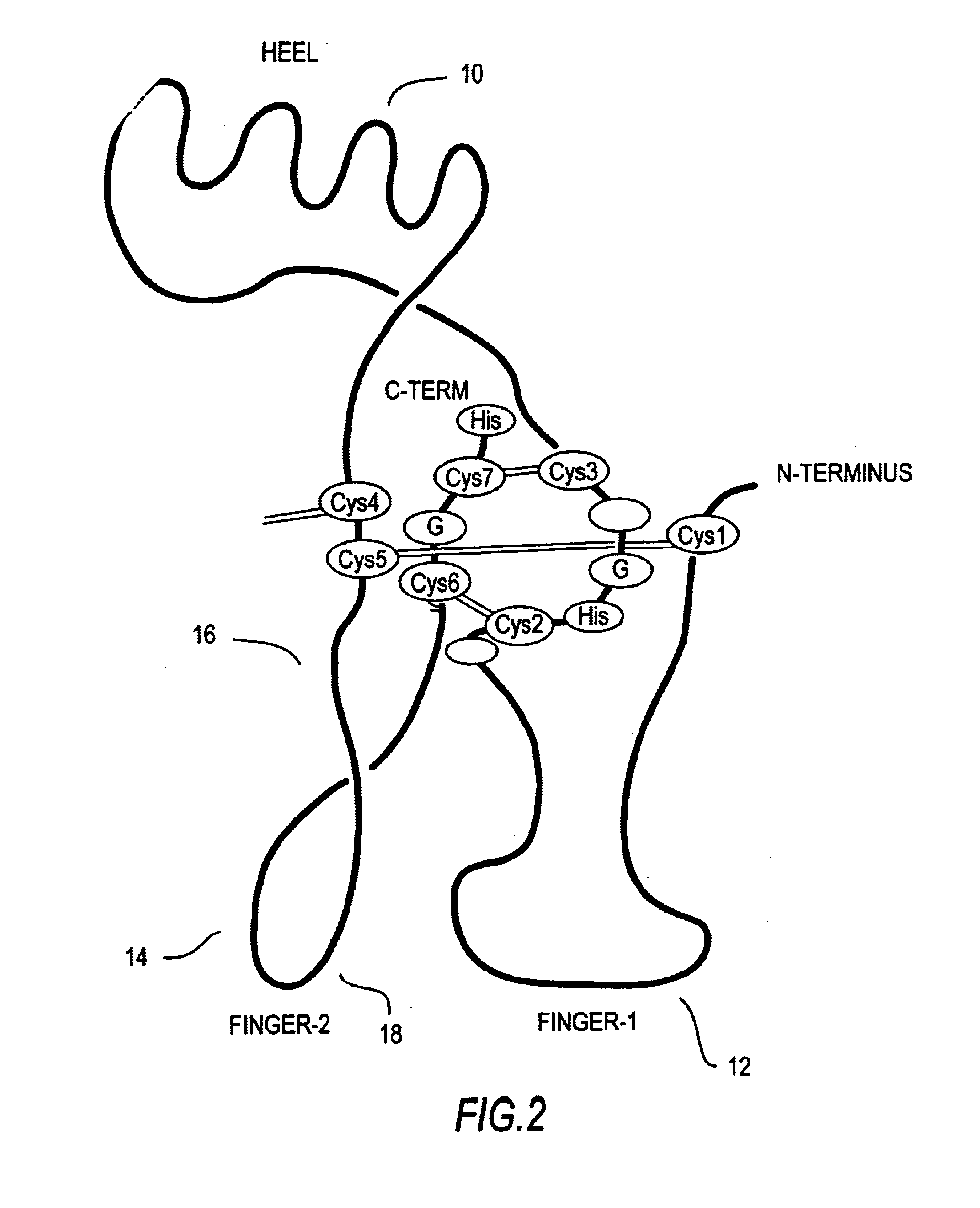

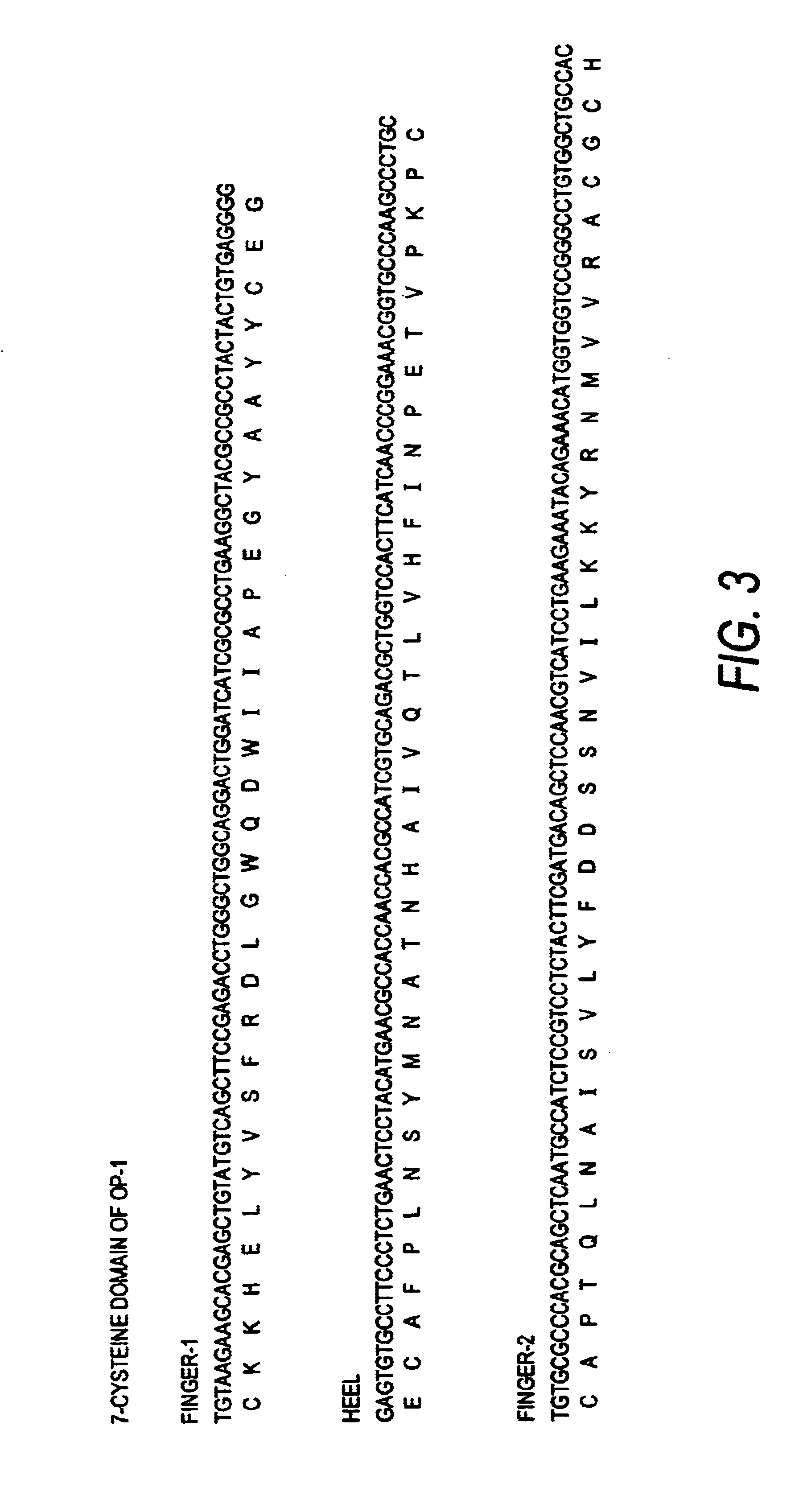

Modified proteins of the TGF-β superfamily, including morphogenic proteins

InactiveUS6846906B1Improve biological activityAltered biological activityPeptide/protein ingredientsAntibody mimetics/scaffoldsADAMTS ProteinsMorphogenesis

Owner:MARIEL THERAPEUTICS

Ph-sensitive sacrificial materials for the microfabrication of structures

ActiveUS9458357B2High removal rateAltered solubilityShellac coatingsPharmaceutical delivery mechanismSolubilityPorosity

Methods for microfabricating composite materials and composite materials prepared there from are described herein. The sacrificial material can be etched or patterned to create a two-dimensional and / or three-dimensional sacrificial material structure. The resulting sacrificial material structure can be embedded in one or more embedding materials. The sacrificial material(s) are materials whose solubility can be altered by application of a stimulus typically pH, and / or temperature, light, pH, pressure, presence of absence of ions, and combinations thereof. The embedding materials can contain one or more additives that modify one or more properties of the embedding materials, such as degradation properties, porosity, mechanical properties, viscosity, conductive properties, and combinations thereof. The composite materials can be used in tissue engineering, drug screening, toxin detection, drug delivery, filtrations, bioseparations, and as microfluidic devices for fluid mixing and structural repair.

Owner:MASSACHUSETTS INST OF TECH +1

Novel 2'-C-methyl nucleoside derivatives

ActiveUS20070042989A1Improve efficacyImprove securityBiocideSugar derivativesHepatitis c viralStereoisomerism

Compounds of Formula I, stereoisomers, and pharmaceutically acceptable salts or prodrugs thereof, their preparation, and their uses for the treatment of hepatitis C viral infection are described:

Owner:METABASIS THERAPEUTICS INC

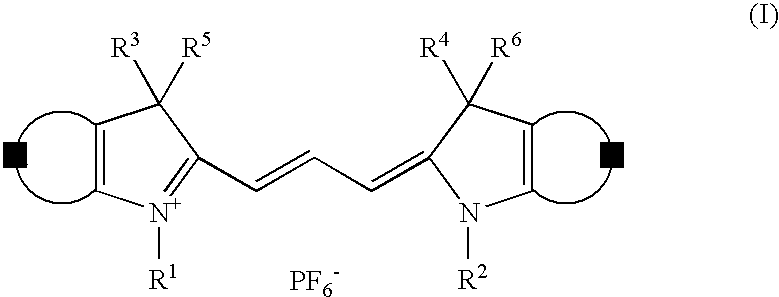

Optical disk

InactiveUS20060046009A1Excellent recording characteristicAltered solubilityLayered productsRecord information storageLow speedSolvent

An optical disk having excellent recording characteristics at both low speed and high speed is provided by modifying a cyanine dye serving as a material of a recording layer such that the cyanine dye does not excessively remain in a groove in an optically transparent substrate. The optical disc comprises the recording layer on a surface of the optically transparent substrate, a reflective layer on the recording layer, and a protective layer on the reflective layer, wherein the recording layer contains at least one cyanine dye expressed by the following chemical formula I: wherein, R1, R2 R3, R4, R5, and R6 are hydrocarbon groups, and A and B are independently a fused benzene ring or a fused naphthalene ring optionally having a substituent, and wherein the recording layer is formed by applying the at least one cyanine dye in a fluoroalcohol solvent to the optically transparent substrate.

Owner:TDK CORPARATION

Novel Phosphorus-Containing Thyromimetics

ActiveUS20090118236A1Optimize allocationImprove bioavailabilityBiocideSenses disorderDiseaseIGT - Impaired glucose tolerance

The present invention relates to compounds of phosphonic acid containing T3 mimetics, stereoisomers, pharmaceutically acceptable salts, co-crystals, and prodrugs thereof and pharmaceutically acceptable salts and co-crystals of the prodrugs, as well as their preparation and uses for preventing and / or treating metabolic diseases such as obesity, NASH, hypercholesterolemia and hyperlipidemia, as well as associated conditions such as atherosclerosis, coronary heart disease, impaired glucose tolerance, metabolic syndromex and diabetes.

Owner:METABASIS THERAPEUTICS INC

Novel Thiazole Inhibitors of Fructose 1,6-Bishosphatase

InactiveUS20070225259A1Disease reliefPrevent diseaseBiocideOrganic active ingredientsThiazoleEnzyme inhibitor

Owner:METABASIS THERAPEUTICS INC

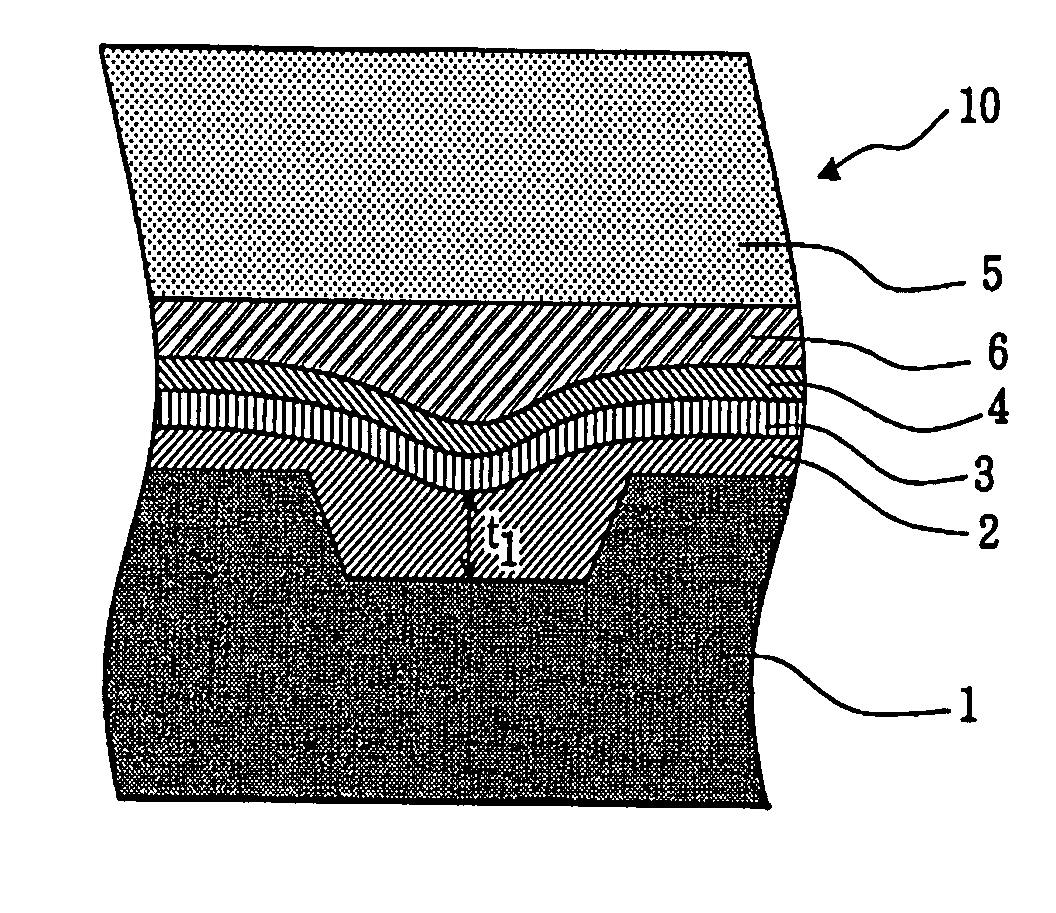

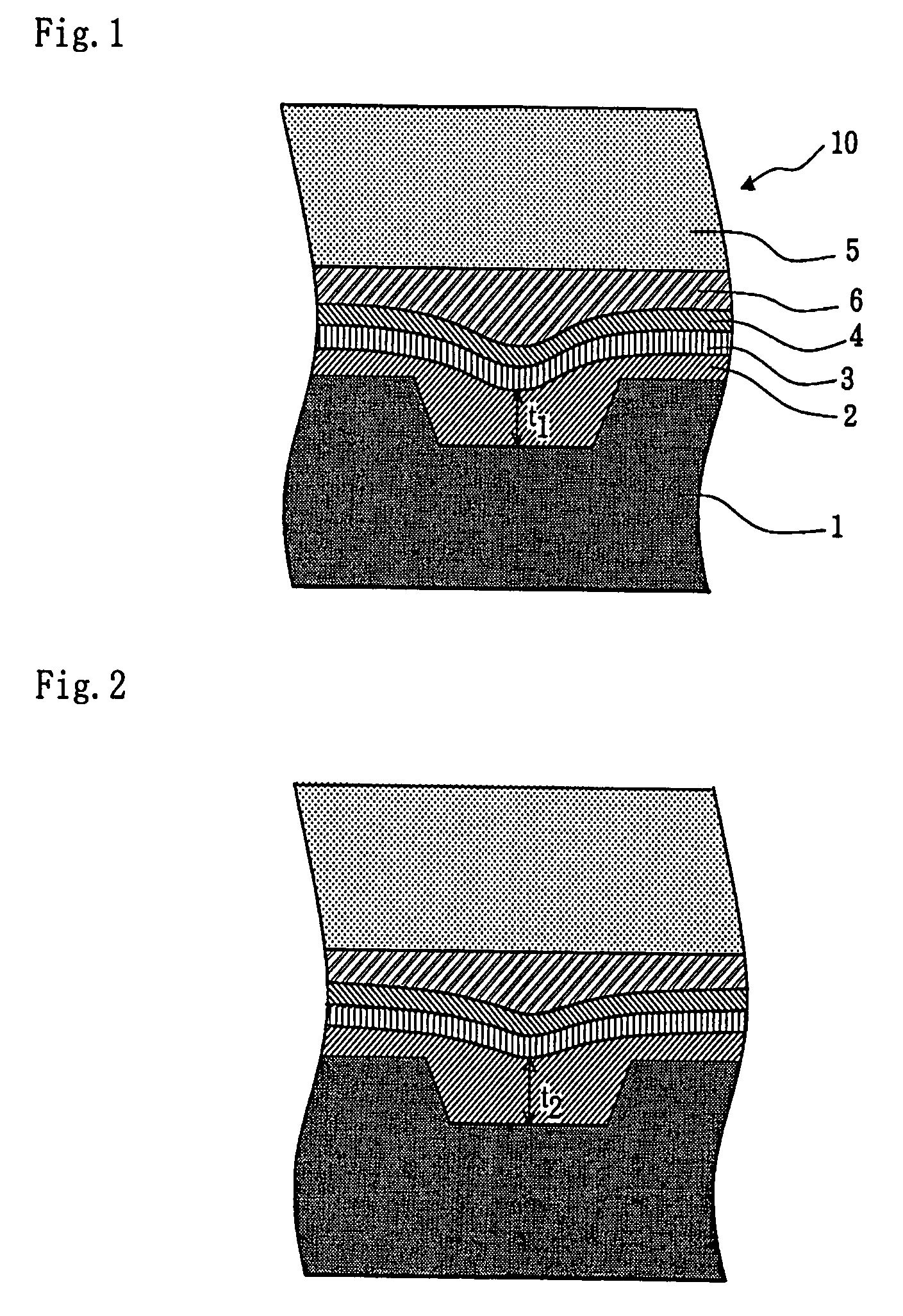

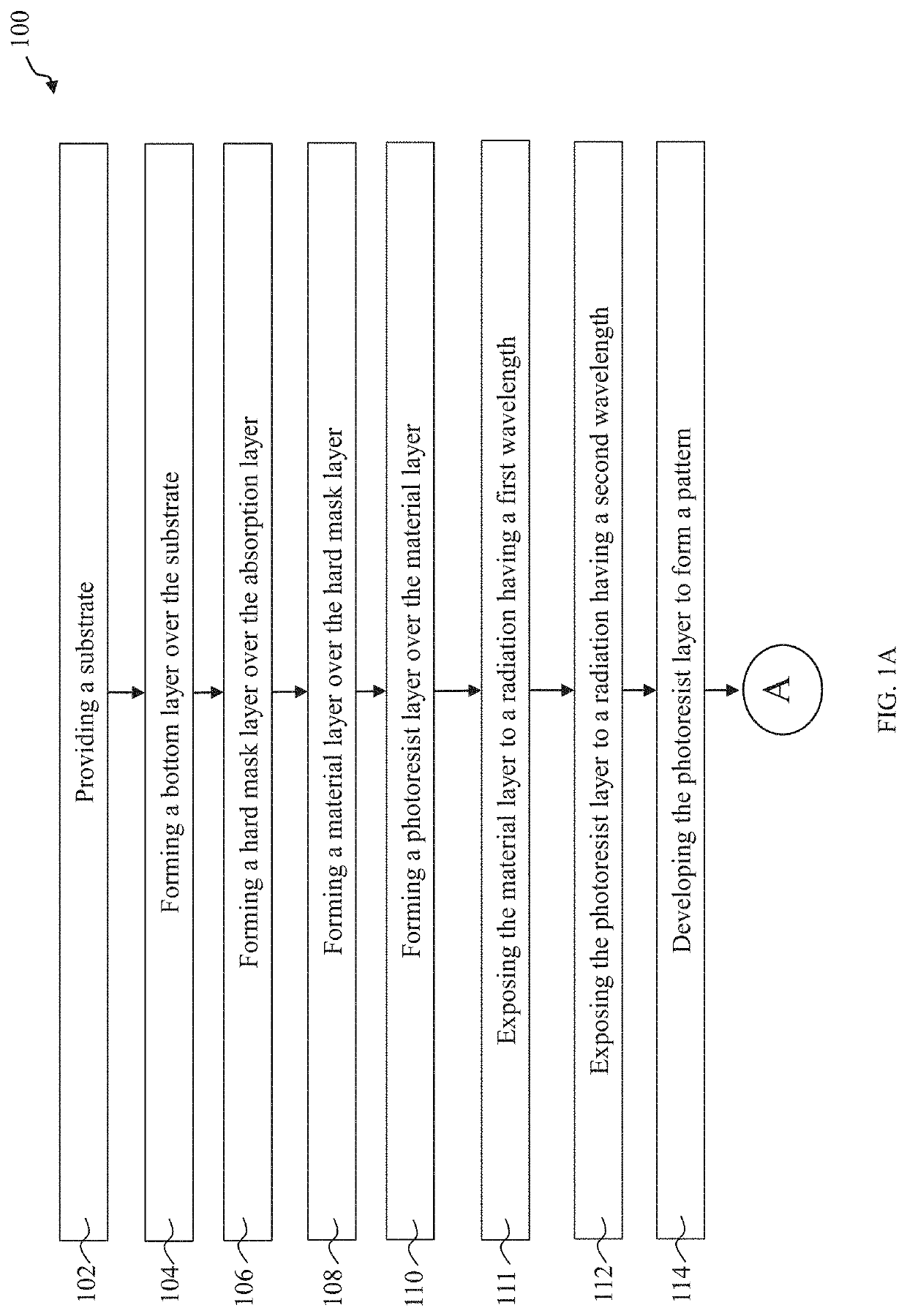

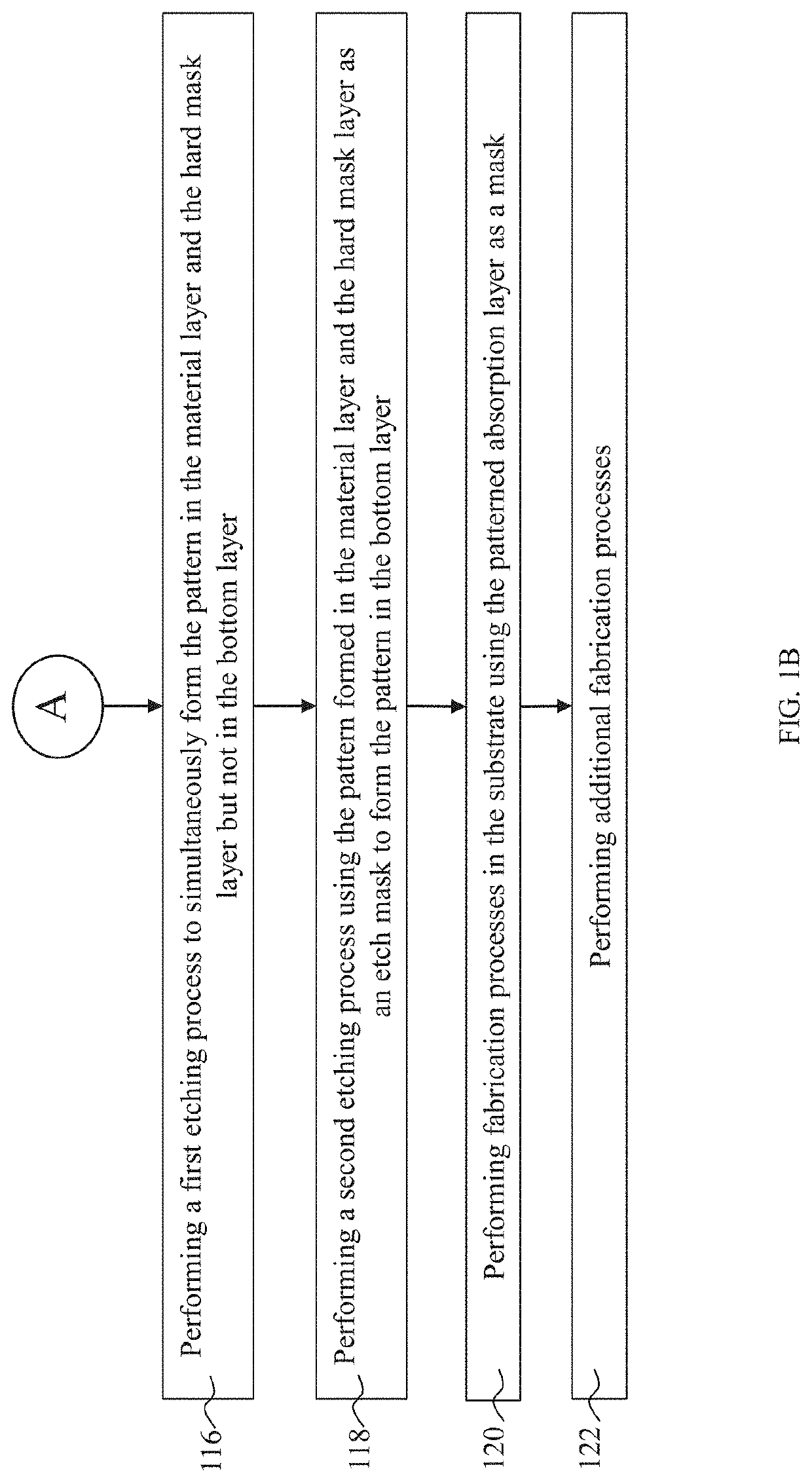

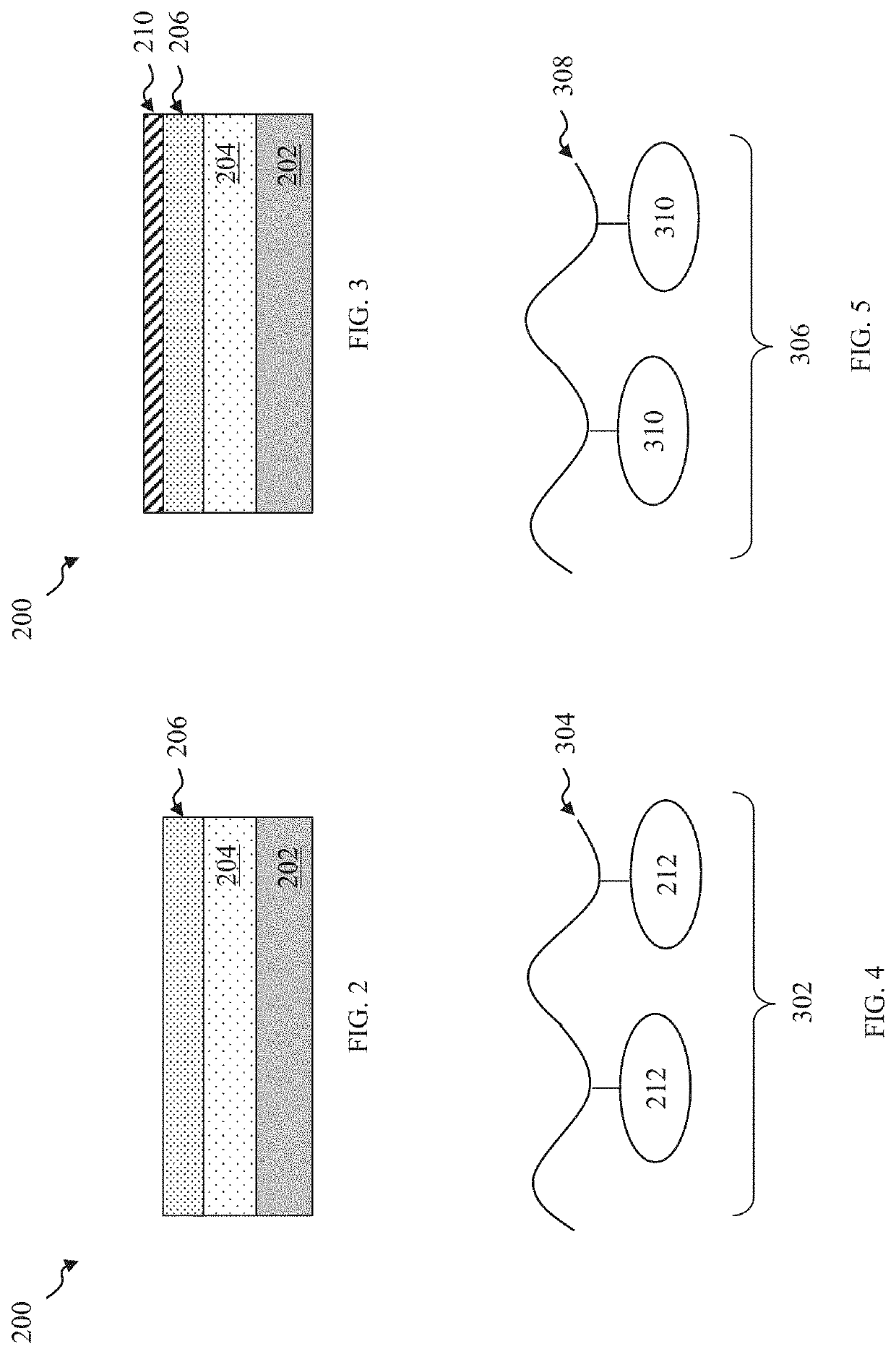

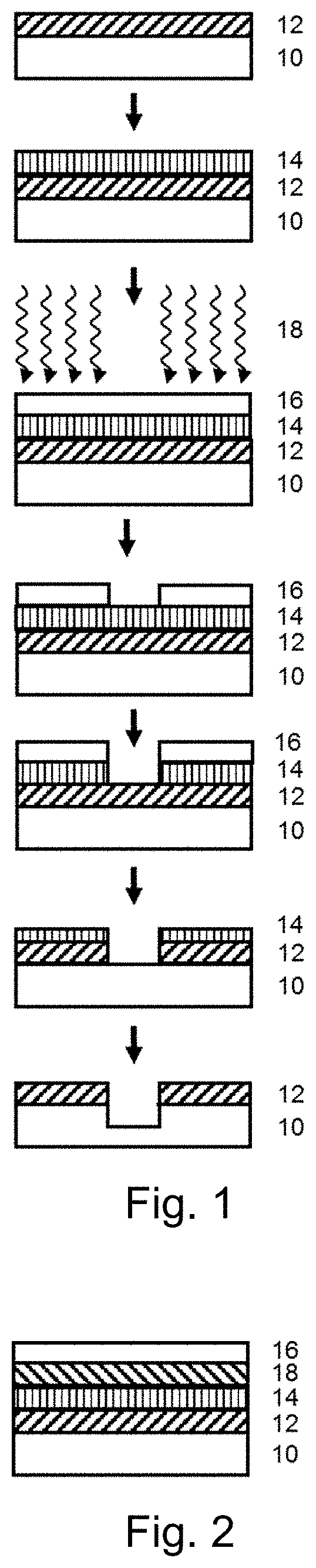

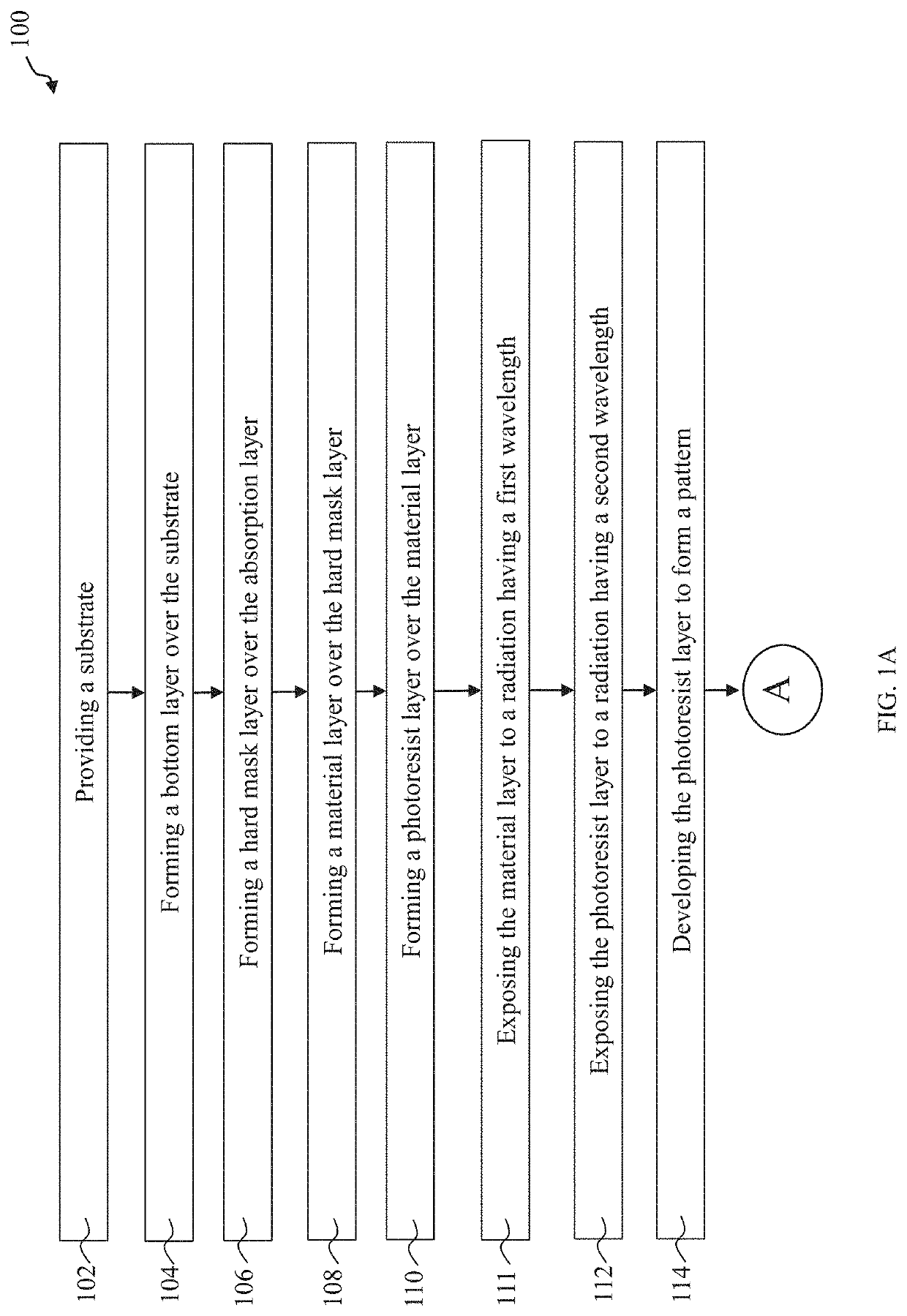

Underlayer Material for Photoresist

ActiveUS20200333710A1Light reflectivity is minimizedImprove etch selectivitySemiconductor/solid-state device manufacturingPhotomechanical coating apparatusPhotoresistHard mask

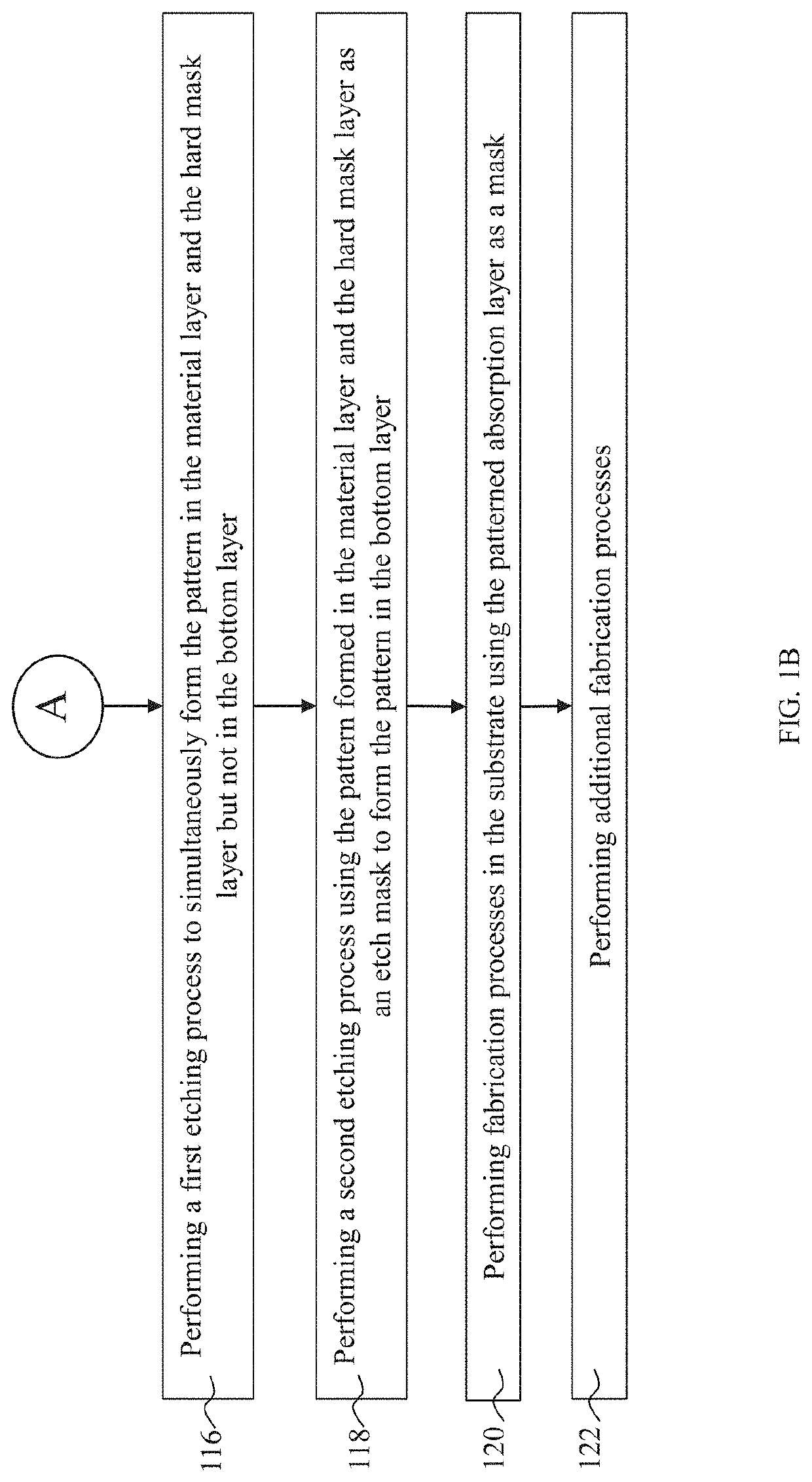

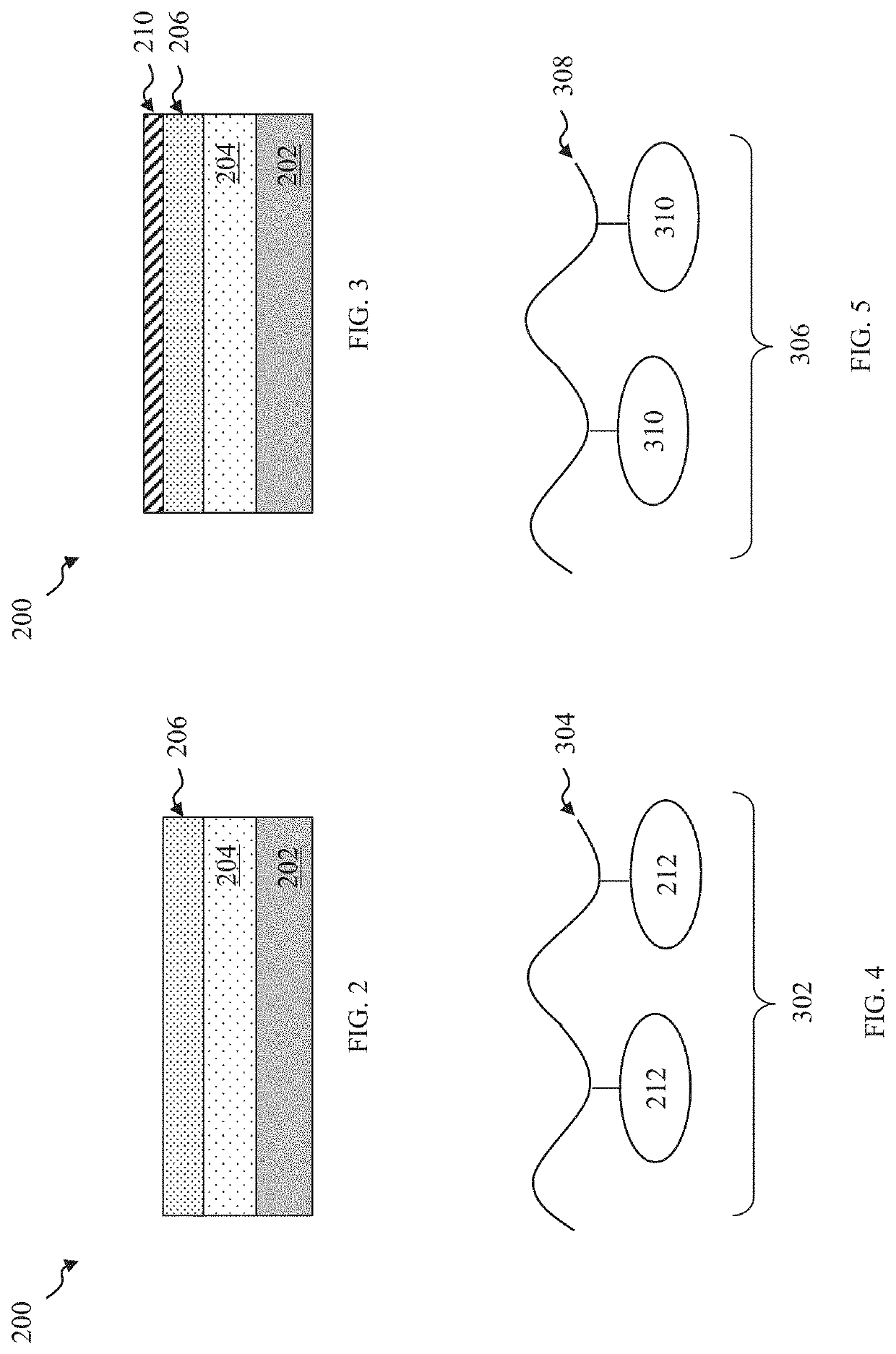

A method includes providing a layered structure on a substrate, the layered structure including a bottom layer formed over the substrate, a hard mask layer formed over the bottom layer, a material layer formed over the hard mask layer, and a photoresist layer formed over the material layer, exposing the photoresist layer to a radiation source, developing the photoresist layer, where the developing removes portions of the photoresist layer and the material layer in a single step without substantially removing portions of the hard mask layer, and etching the hard mask layer using the photoresist layer as an etch mask. The material layer may include acidic moieties and / or acid-generating molecules. The material layer may also include photo-sensitive moieties and crosslinking agents.

Owner:TAIWAN SEMICON MFG CO LTD

Functional hydrogen silsesquioxane resins and the use thereof

PendingUS20220162391A1Improve solubilityAltered solubilitySemiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialOptical radiationSilsesquioxane

Carbon-carbon unsaturated bond containing, halogen containing, and solubility-enhancer containing coatings on semiconductor substrates for forming patterns thereon. The present coatings can be produced by coating of semiconductor substrates with carbon-carbon unsaturated bond-containing, halogen-containing, and solubility-enhancer containing polyhydrogensilsesquioxane resin solutions. Provided herein is also a method for patterning substrate coating of a polyhydrogensilsesquioxane containing a carbon-carbon unsaturated bond, halogen, and solubility-enhancer with radiation of light, the method comprising the steps of irradiating a coated substrate along a selected pattern to form an irradiated structure with a region of irradiated coating and a region with un-irradiated coating and selectively developing the irradiated structure to remove a substantial portion of the un-irradiated coating to form a patterned substrate.

Owner:PIBOND OY

Underlayer material for photoresist

ActiveUS11269256B2Light reflectivity is minimizedImprove etch selectivitySemiconductor/solid-state device manufacturingPhotomechanical coating apparatusPhotoresistMaterials science

A method includes providing a layered structure on a substrate, the layered structure including a bottom layer formed over the substrate, a hard mask layer formed over the bottom layer, a material layer formed over the hard mask layer, and a photoresist layer formed over the material layer, exposing the photoresist layer to a radiation source, developing the photoresist layer, where the developing removes portions of the photoresist layer and the material layer in a single step without substantially removing portions of the hard mask layer, and etching the hard mask layer using the photoresist layer as an etch mask. The material layer may include acidic moieties and / or acid-generating molecules. The material layer may also include photo-sensitive moieties and crosslinking agents.

Owner:TAIWAN SEMICON MFG CO LTD

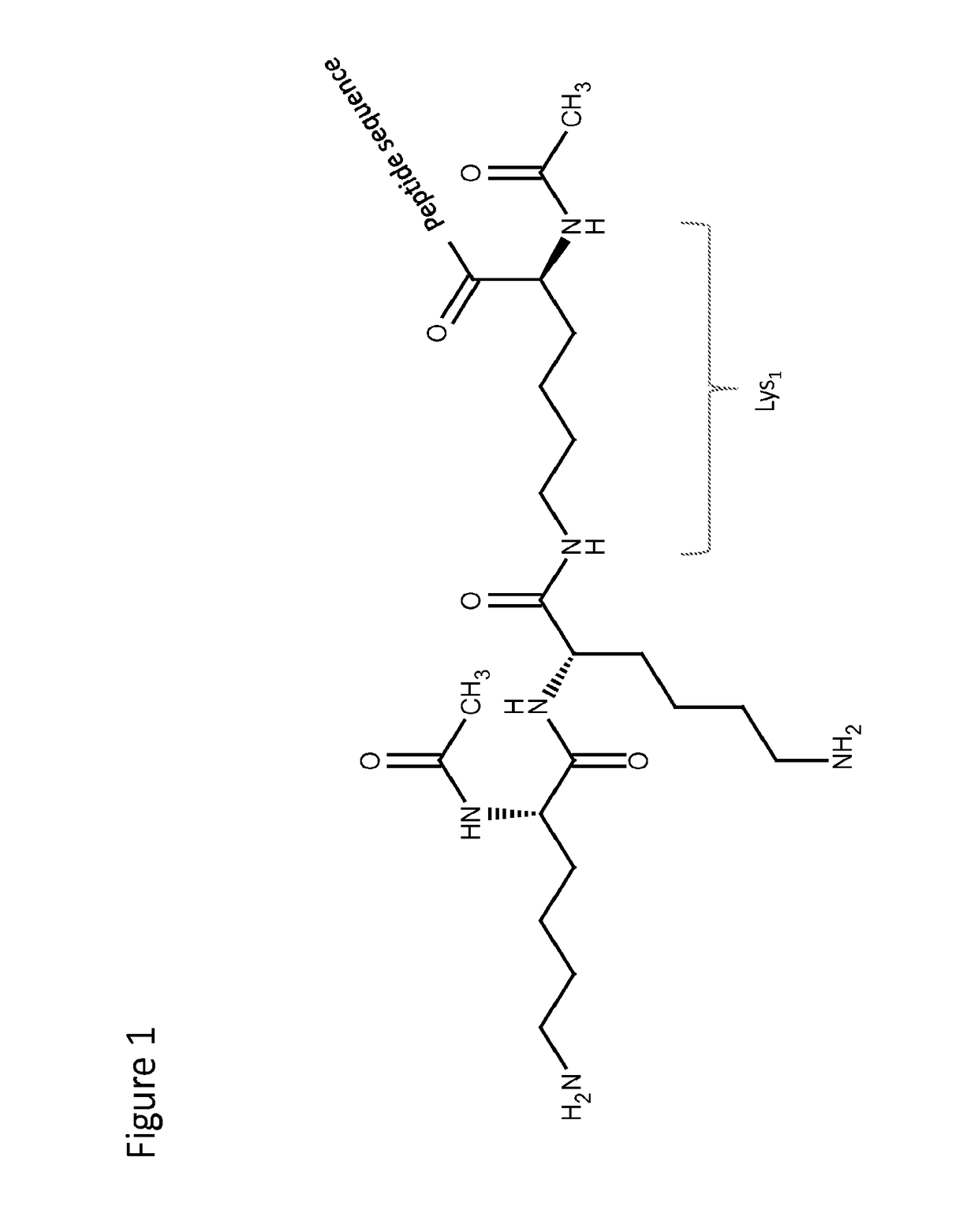

Peptide analogues with branched amino acid probe(s)

ActiveUS20190030115A1Add featureImprove propertiesAntibacterial agentsNervous disorderAmino acidPeptide

The present invention relates to peptide analogues comprising one or more branched amino acid probes and a peptide, native or variants thereof.

Owner:TXP PHARMA

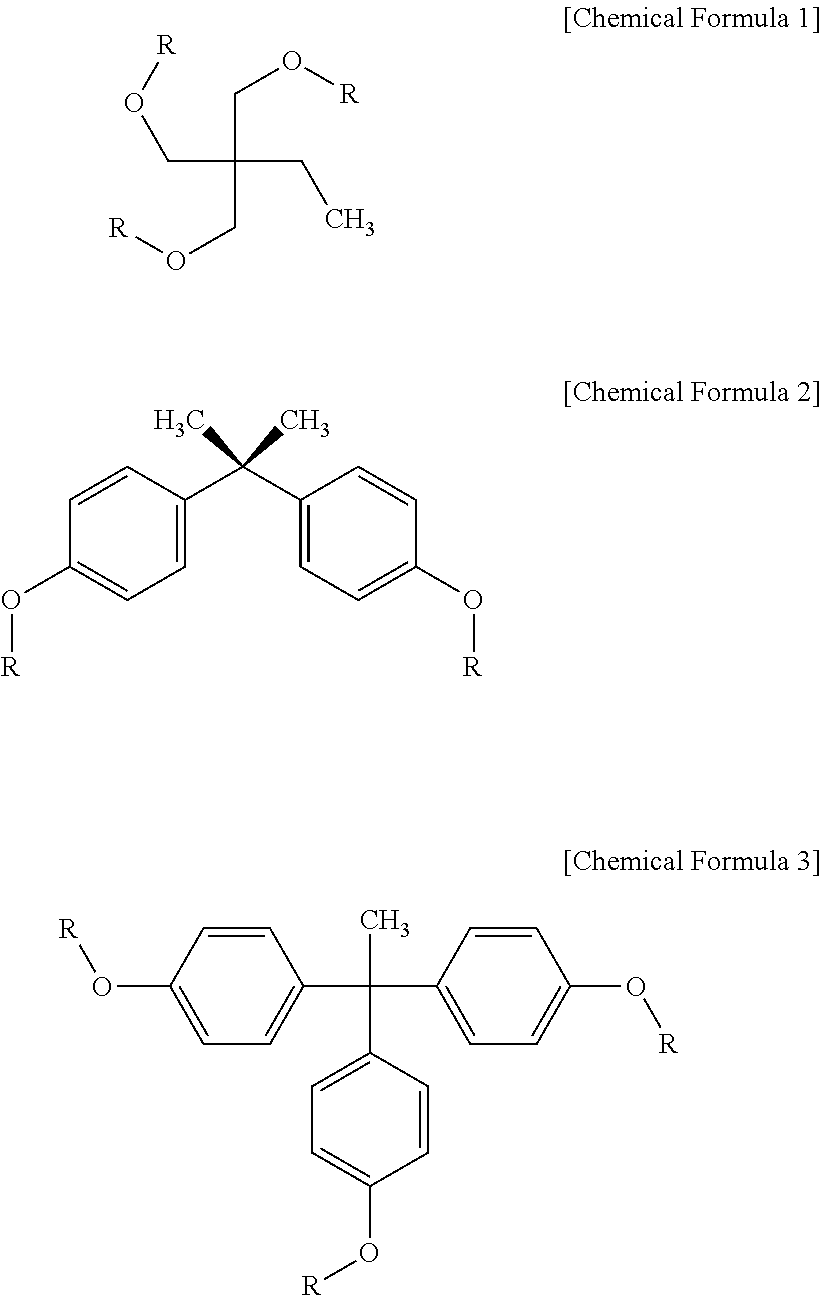

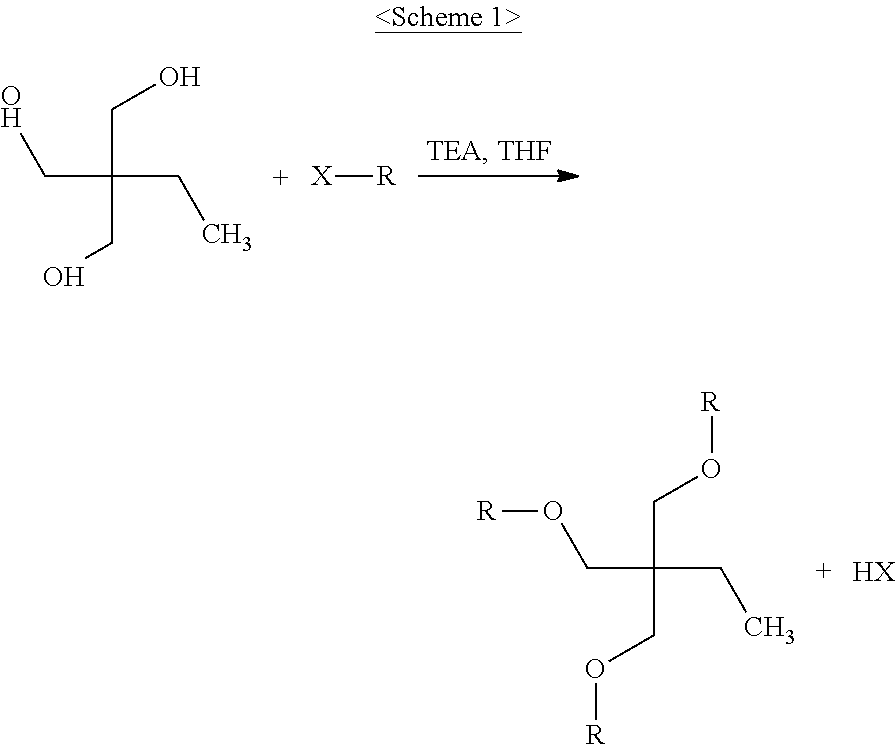

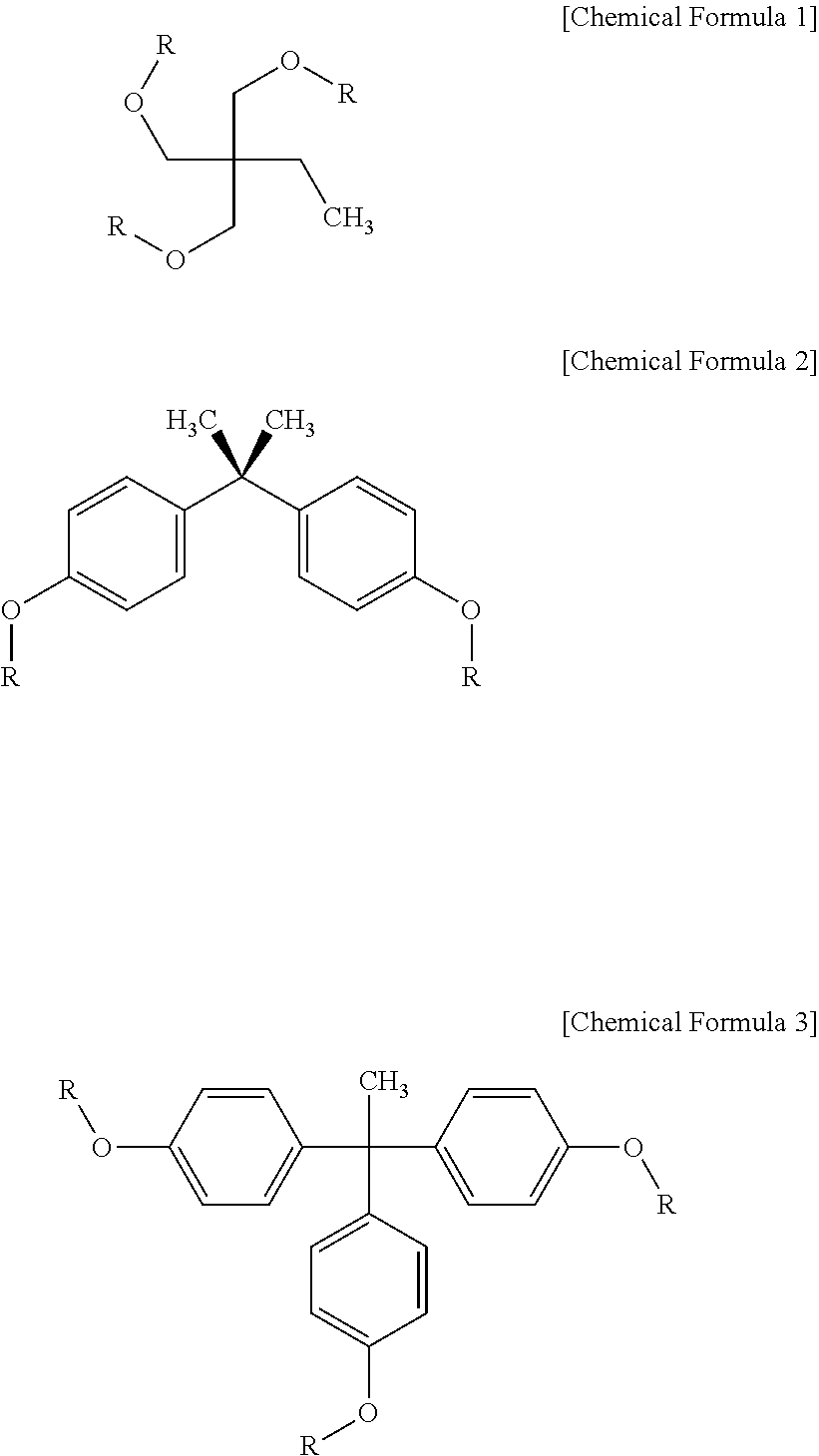

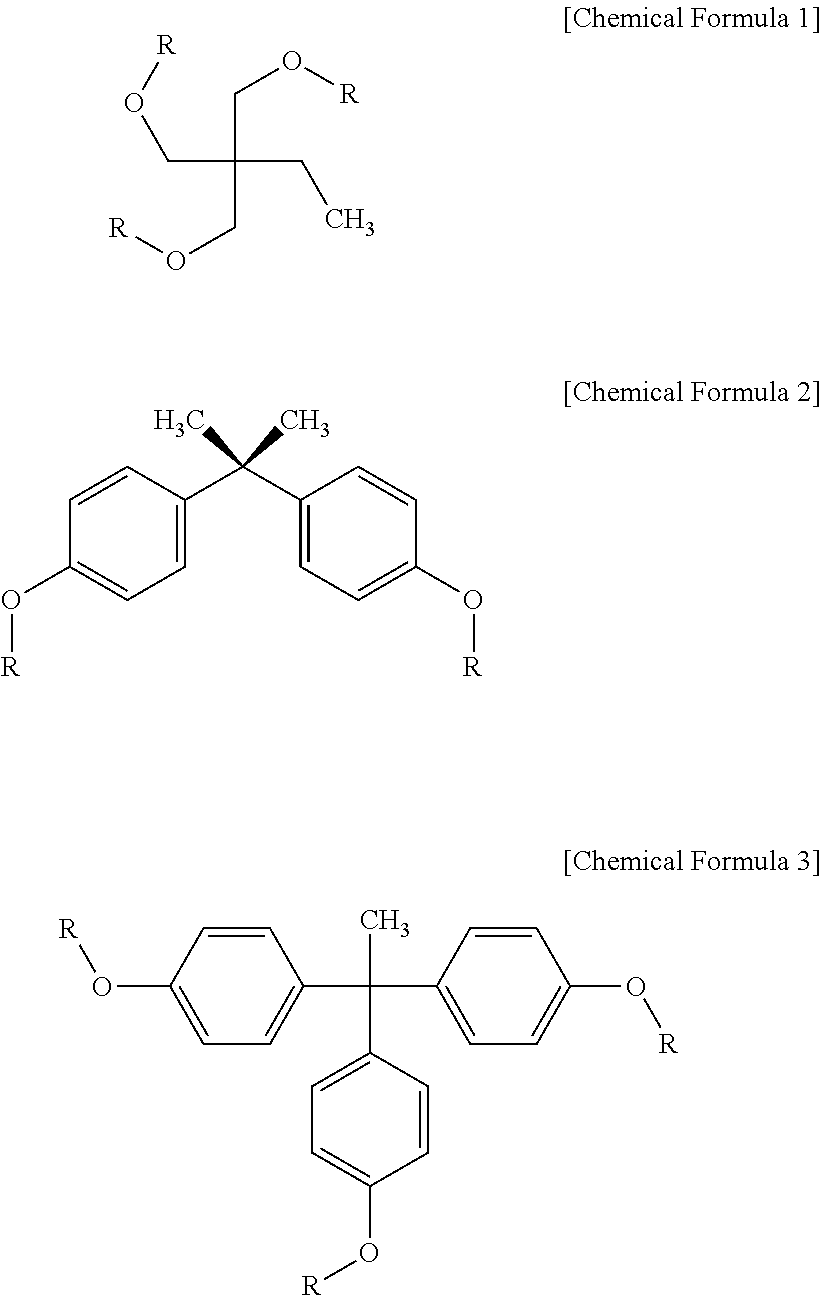

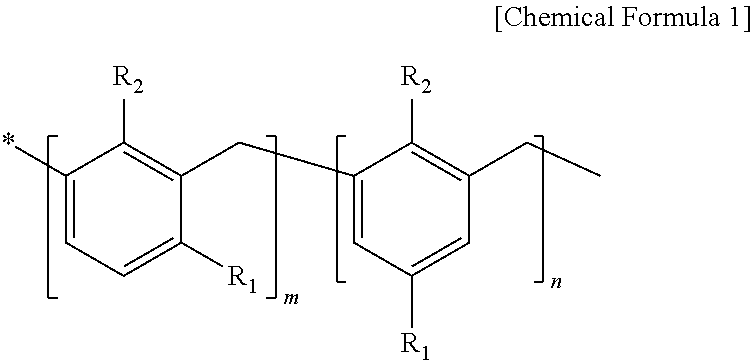

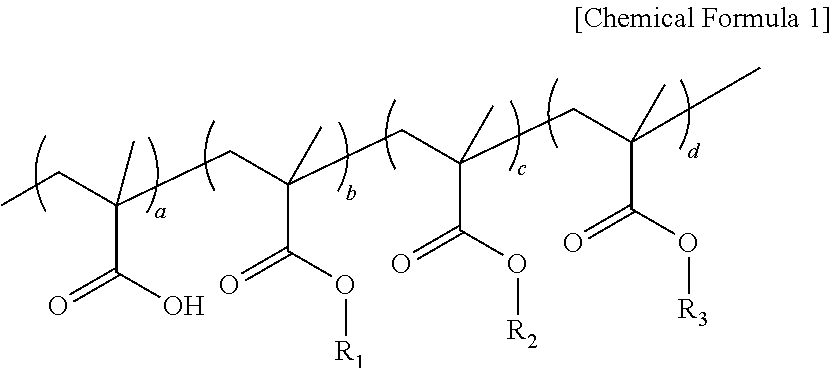

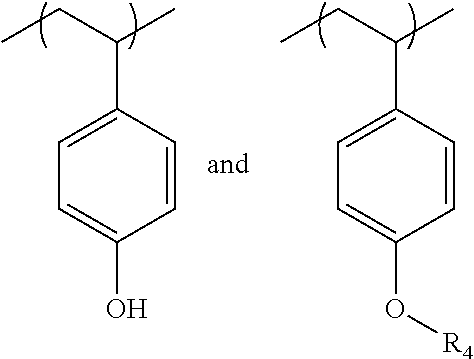

Negative photoresist composition for KrF laser for forming semiconductor patterns

ActiveUS10162261B2High transparencyEnhance the imagePhotosensitive materials for photomechanical apparatusResistImage resolution

Owner:YCCHEM CO LTD

Negative photoresist composition for krf laser for forming semiconductor patterns

ActiveUS20180203351A1High transparencyEnhance the imagePhotosensitive materials for photomechanical apparatusResistImage resolution

Provided is a negative photoresist composition for a KrF laser for semiconductor pattern formation, which includes a predetermined compound in order to improve the properties of a conventional negative photoresist, thereby realizing high transparency, high resolution and an excellent profile, even in the presence of an exposure source having a short wavelength compared to the conventional negative photoresist, and is thus suitable for use in semiconductor processing.

Owner:YCCHEM CO LTD

Novel Thiazole Inhibitors of Fructose 1,6-bisphosphatase

InactiveUS20080070868A1Increasing gluconeogenesisHigh outputBiocideOrganic active ingredientsThiazoleProdrug

Owner:METABASIS THERAPEUTICS INC

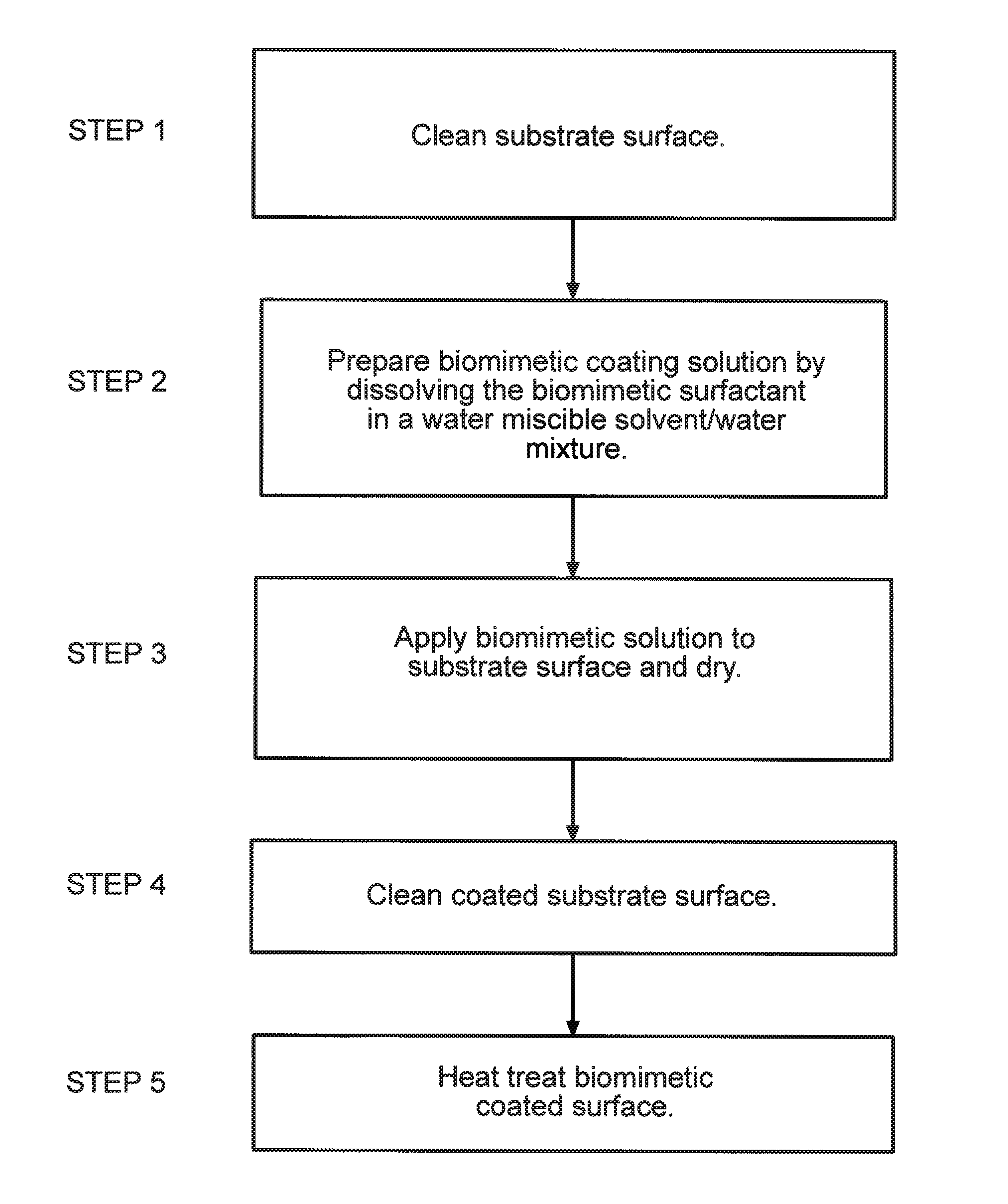

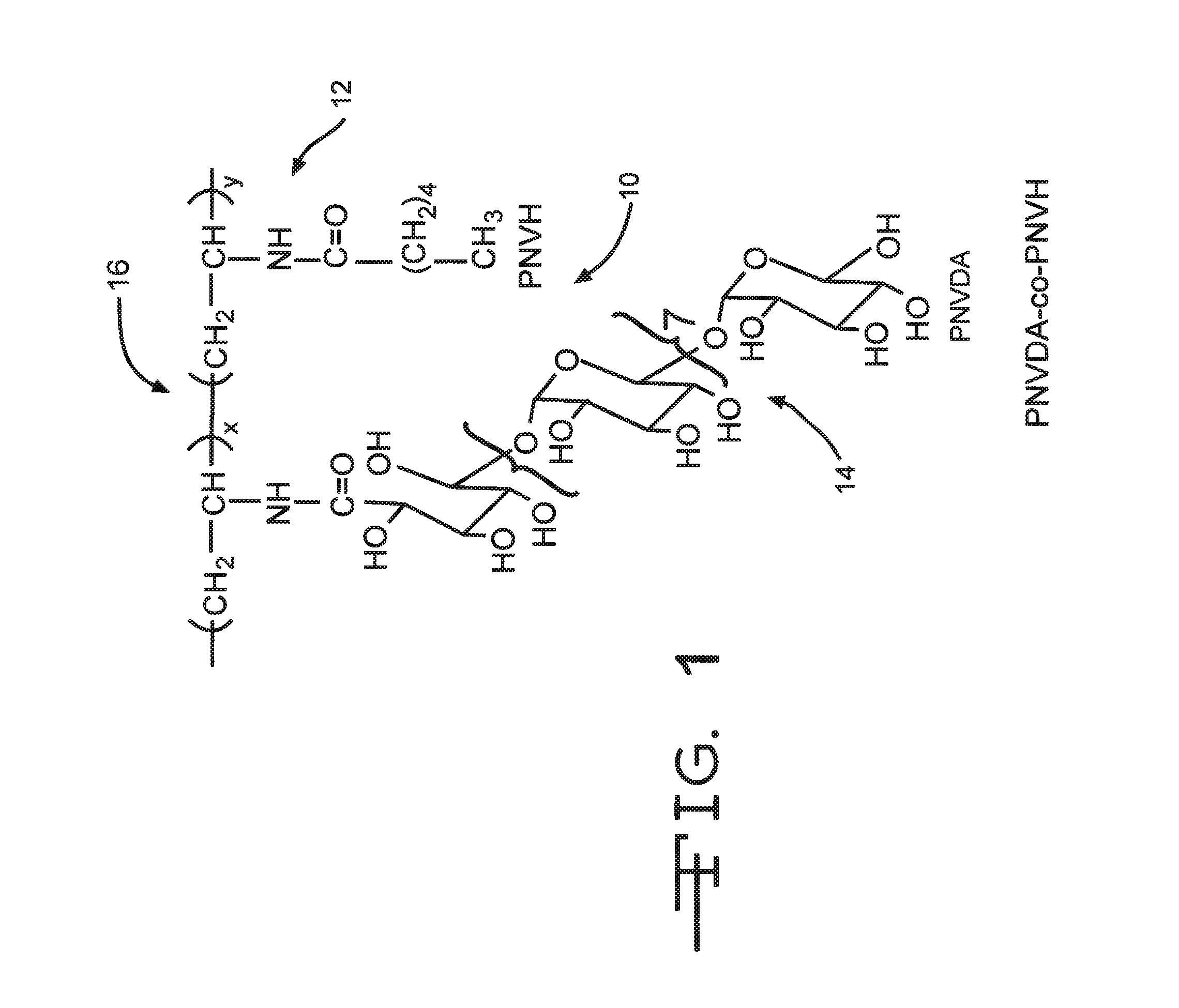

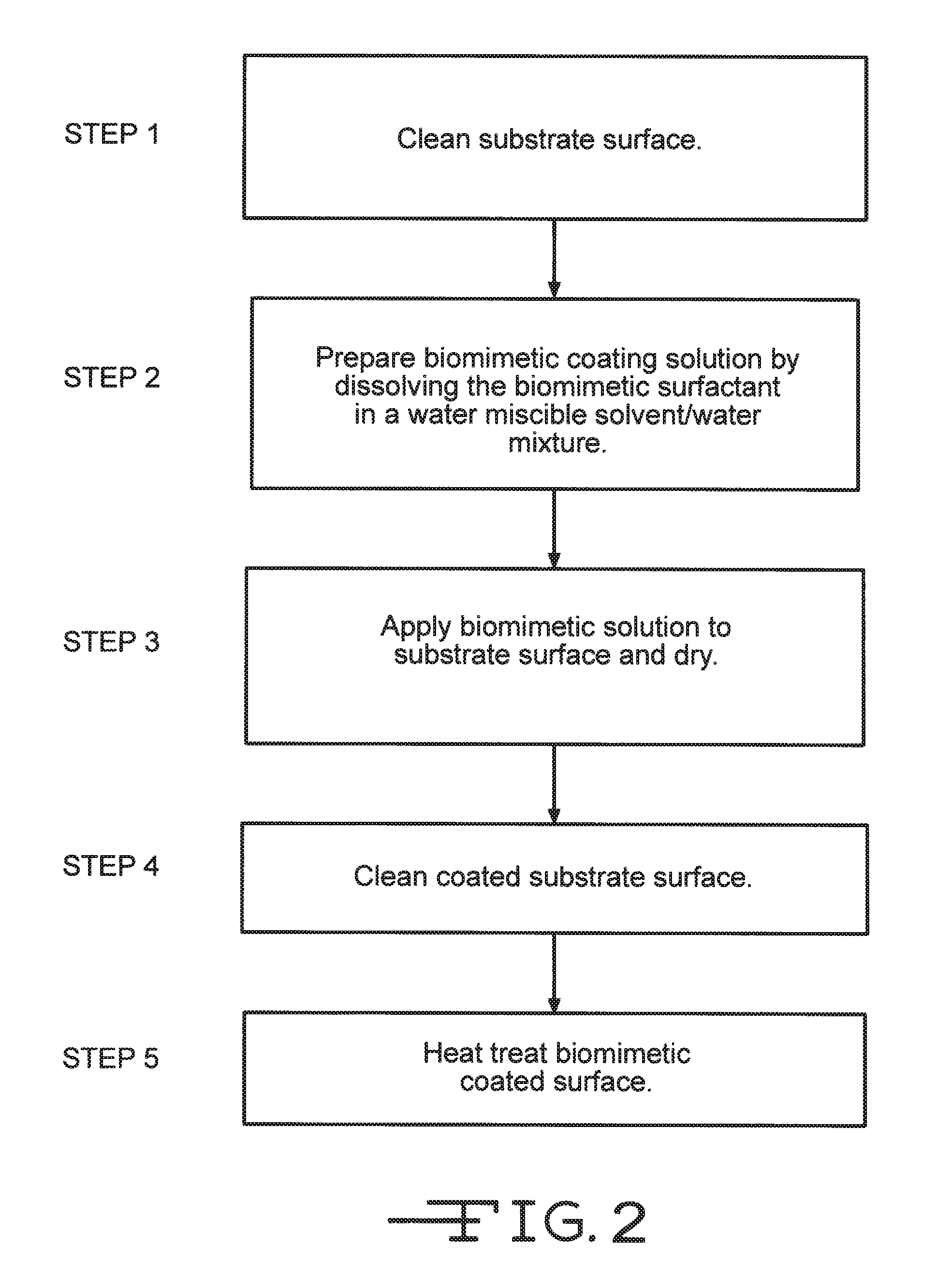

Biomimetic Coating Method

InactiveUS20100316787A1Altered solubilitySufficient timeStentsPharmaceutical containersModified methodSolvent

A modified method of preparing and applying a biomimetic coating to a medical device substrate surface is described. The modified biomimetic coating method utilizes a solvent mixture of water and an organic water miscible solvent that results in a more efficient coating process, reducing the time required to apply a sufficiently adherent biomimetic coating.

Owner:WILSON GREATBATCH LTD

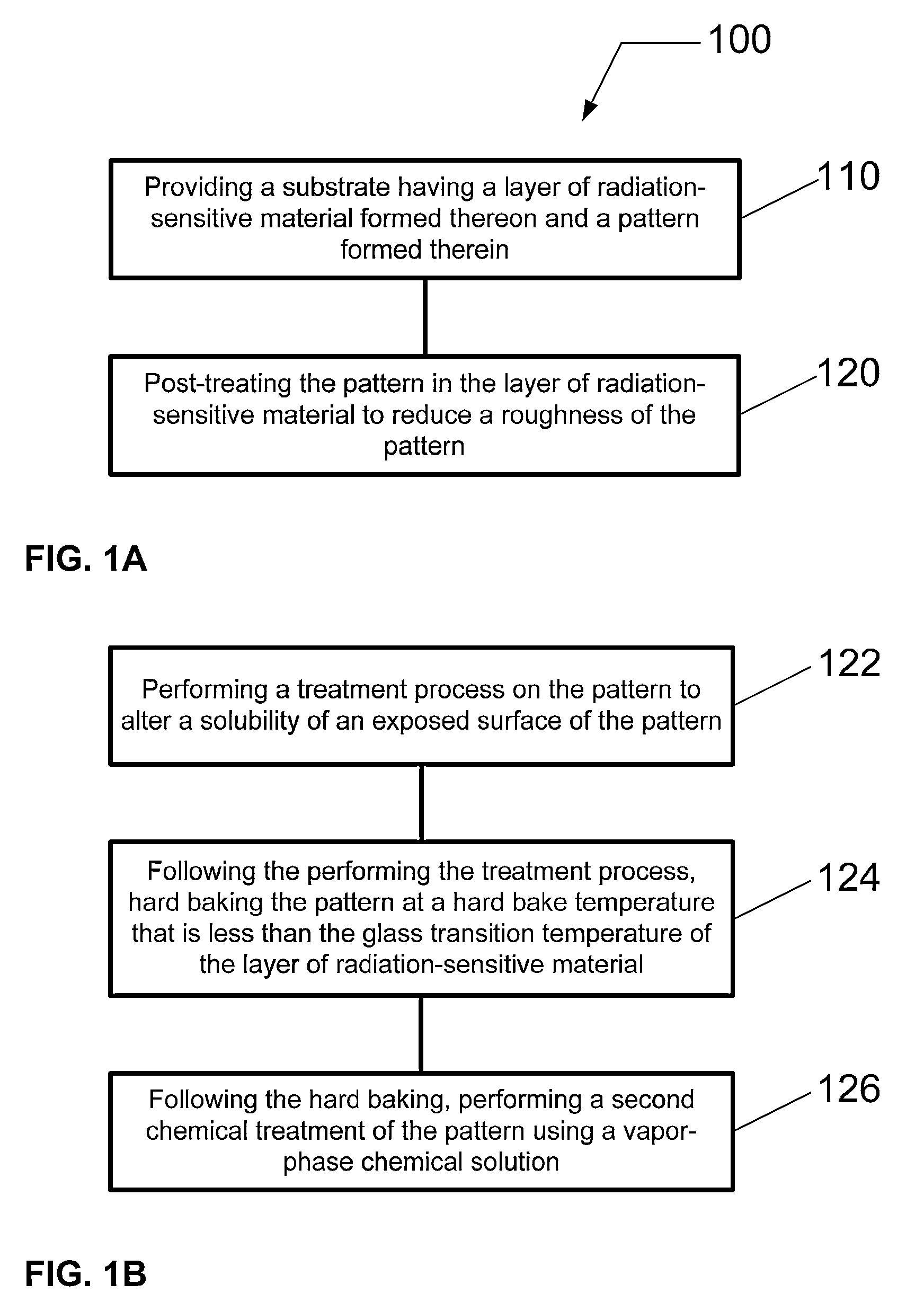

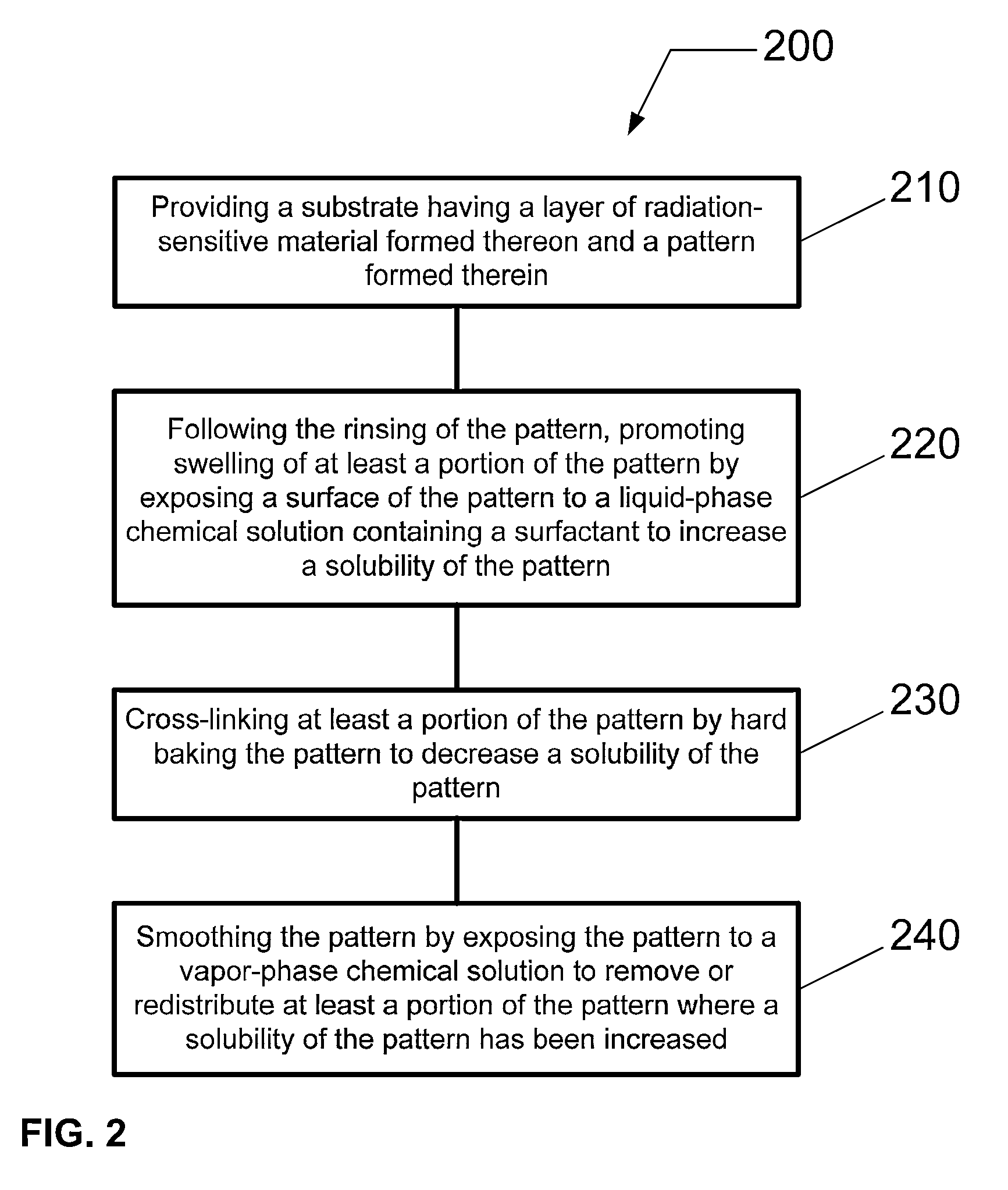

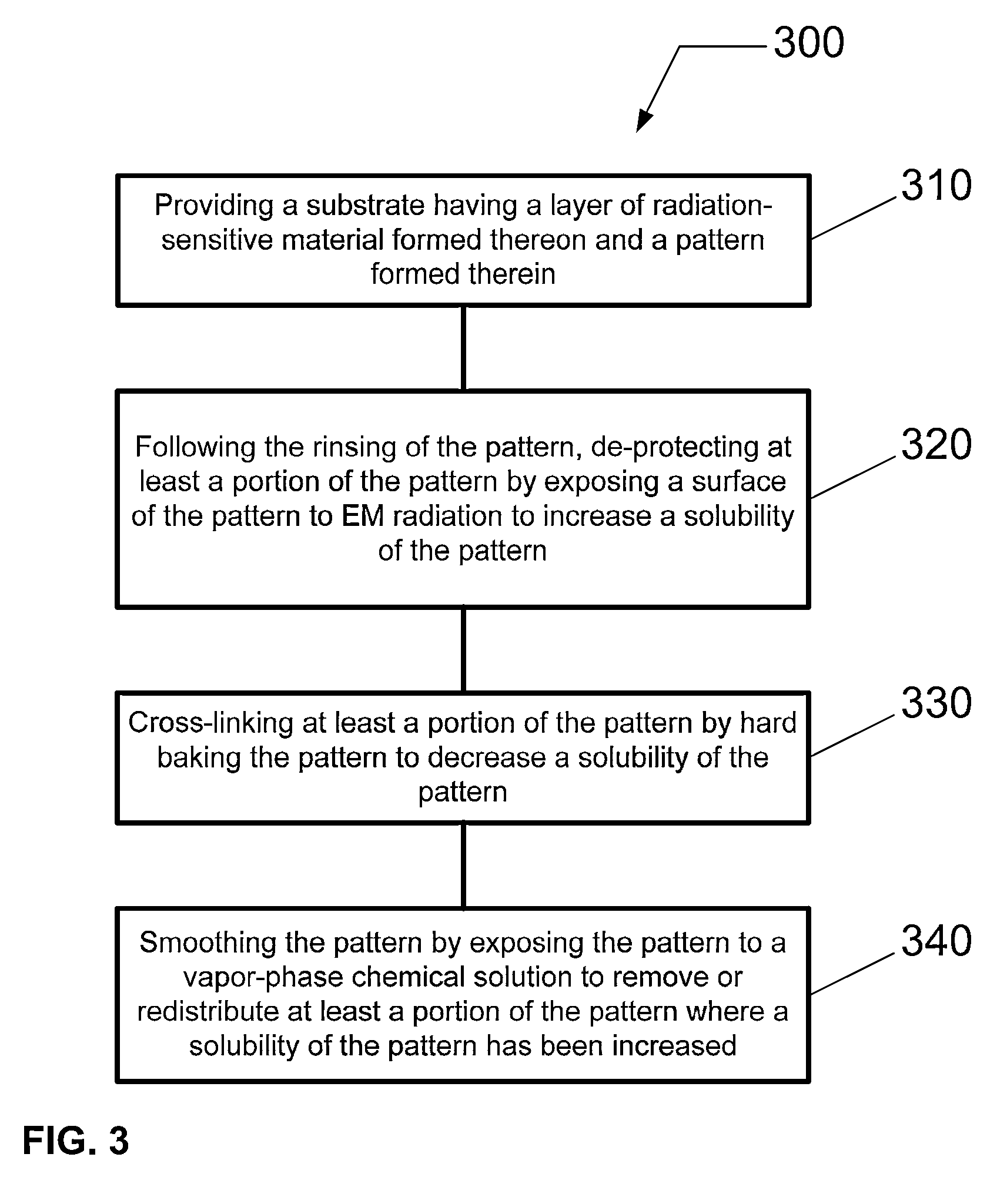

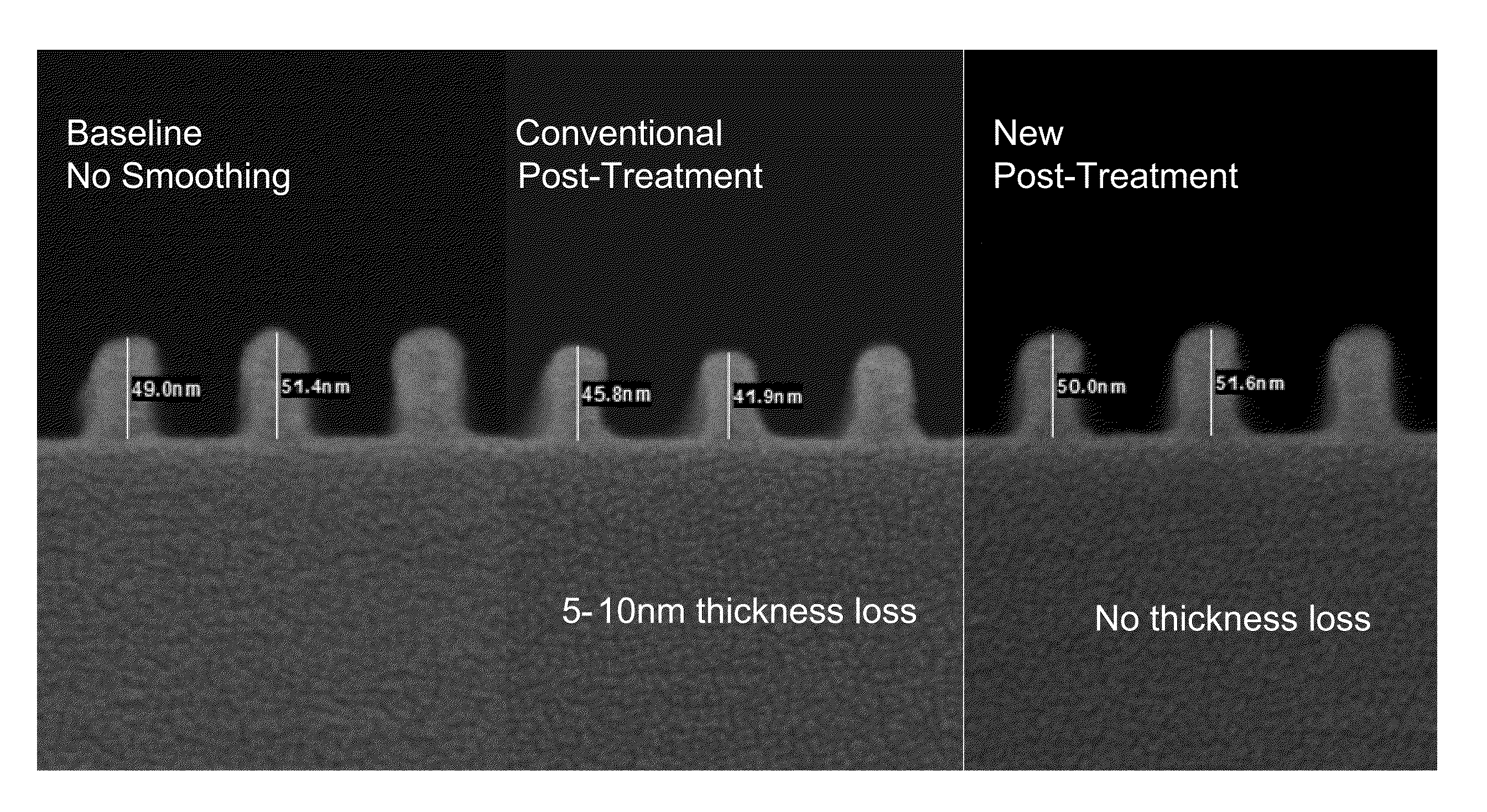

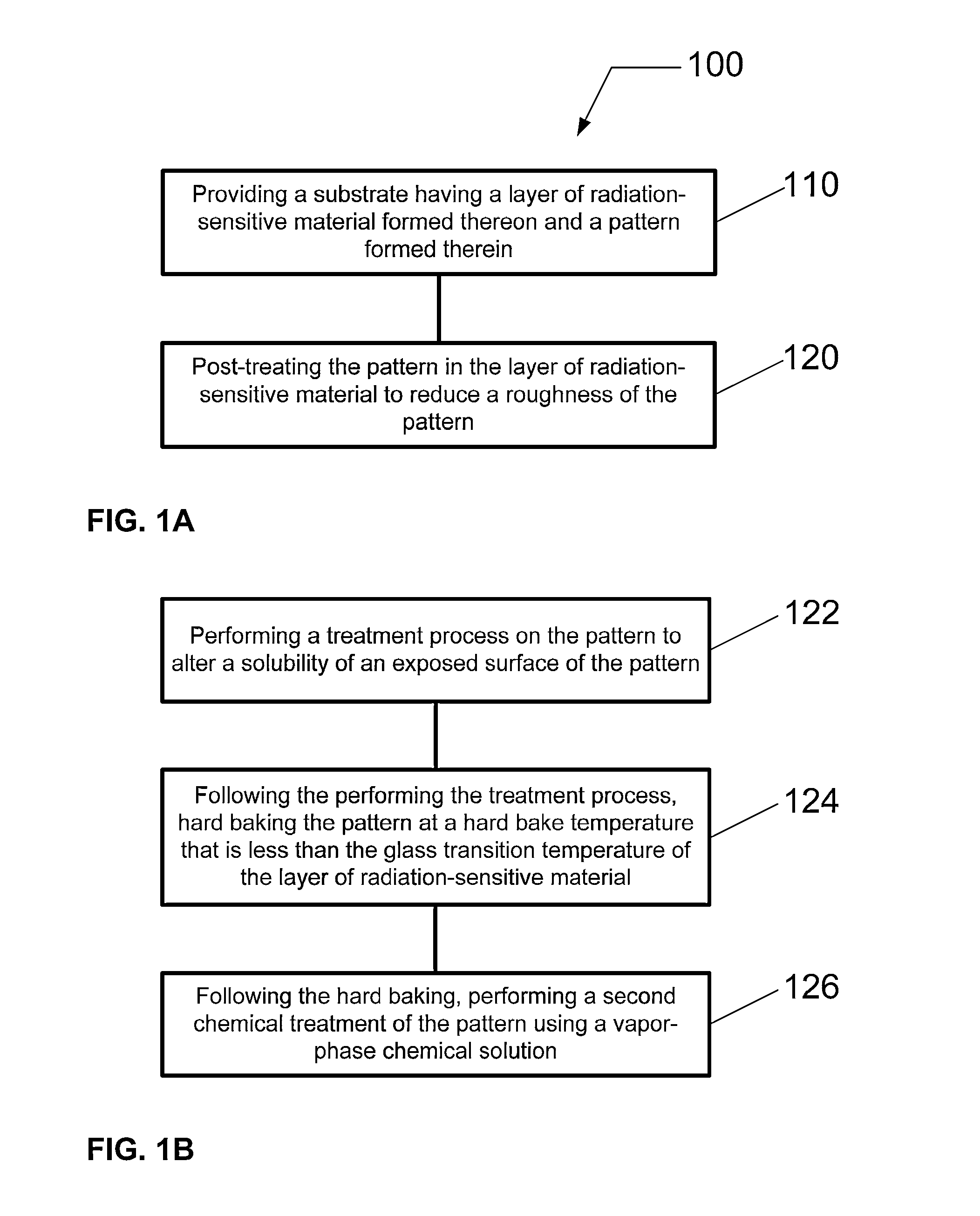

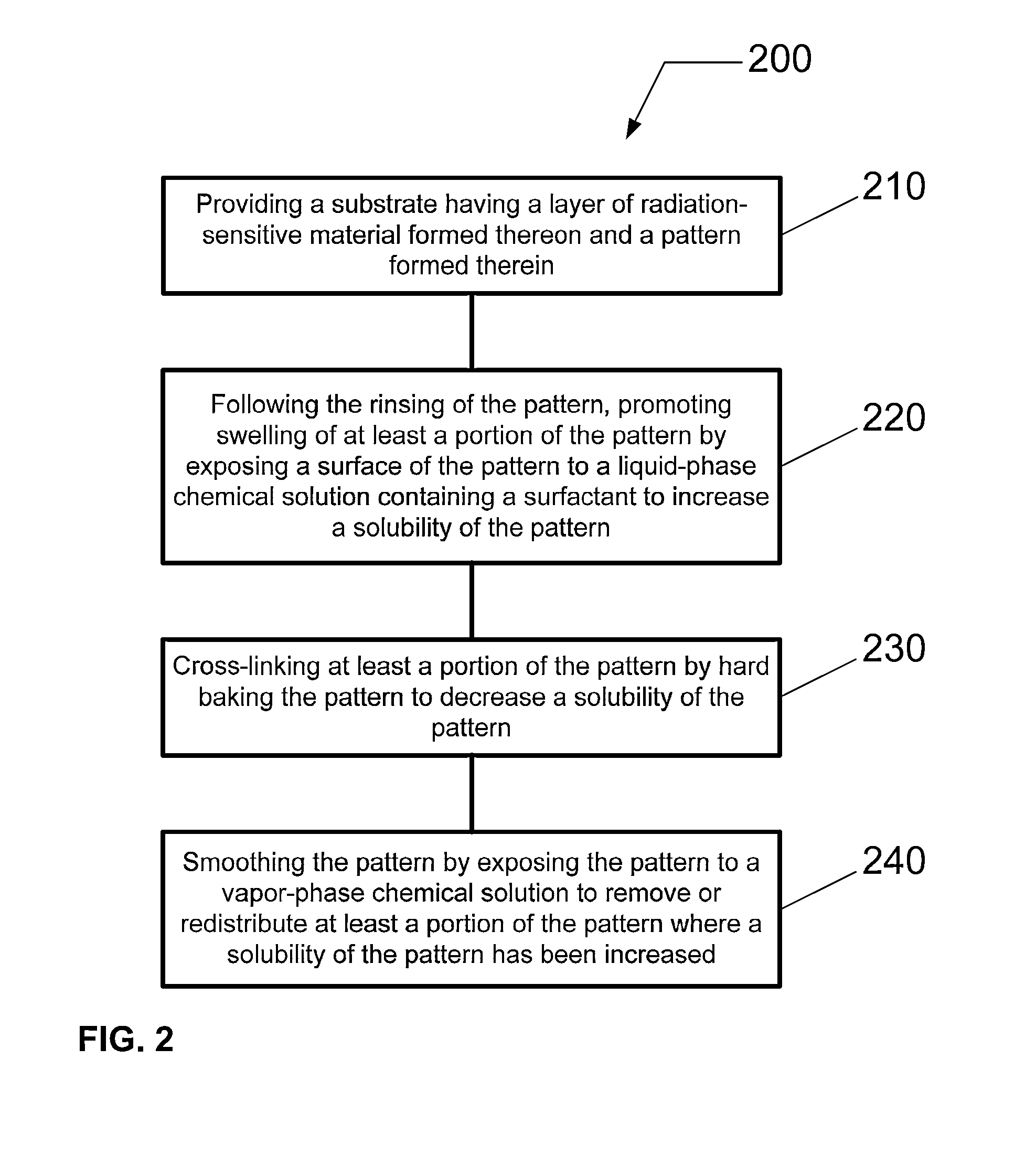

Process sequence for reducing pattern roughness and deformity

ActiveUS9097977B2Reduce defectsReduce deformityPhotoprinting processesSemiconductor/solid-state device manufacturingChemical treatmentSolubility

A method for patterning a substrate with reduced defectivity is described. Once a pattern is formed in a layer of radiation-sensitive material using lithographic techniques, the pattern formed on the substrate is post-treated. The post-treating of the pattern in the layer of radiation-sensitive material is performed to reduce a roughness of the pattern. The post-treating includes performing a treatment process on the pattern to alter a solubility of an exposed surface of the pattern, wherein the treatment process involves performing a first chemical treatment of the pattern using a liquid-phase chemical solution containing a first surfactant, or exposing said pattern to second EM radiation different than said first EM radiation. Following the treatment process, the post-treating includes hard baking the pattern, and performing a second chemical treatment of the pattern using a vapor-phase chemical solution to reduce the roughness.

Owner:TOKYO ELECTRON LTD

Process sequence for reducing pattern roughness and deformity

ActiveUS20130309615A1Reduce defectivityReduce pattern collapse and pattern deformityPhotoprinting processesSemiconductor/solid-state device manufacturingSolubilityVapor phase

A method for patterning a substrate with reduced defectivity is described. Once a pattern is formed in a layer of radiation-sensitive material using lithographic techniques, the pattern formed on the substrate is post-treated. The post-treating of the pattern in the layer of radiation-sensitive material is performed to reduce a roughness of the pattern. The post-treating includes performing a treatment process on the pattern to alter a solubility of an exposed surface of the pattern, wherein the treatment process involves performing a first chemical treatment of the pattern using a liquid-phase chemical solution containing a first surfactant, or exposing said pattern to second EM radiation different than said first EM radiation. Following the treatment process, the post-treating includes hard baking the pattern, and performing a second chemical treatment of the pattern using a vapor-phase chemical solution to reduce the roughness.

Owner:TOKYO ELECTRON LTD

Negative photoresist composition for KRF laser, having high resolution and high aspect ratio

ActiveUS10775699B2High strengthHigh resolutionPhotosensitive material processingPhotosensitive materials for photomechanical apparatusImage resolutionPhysical chemistry

Owner:YCCHEM CO LTD

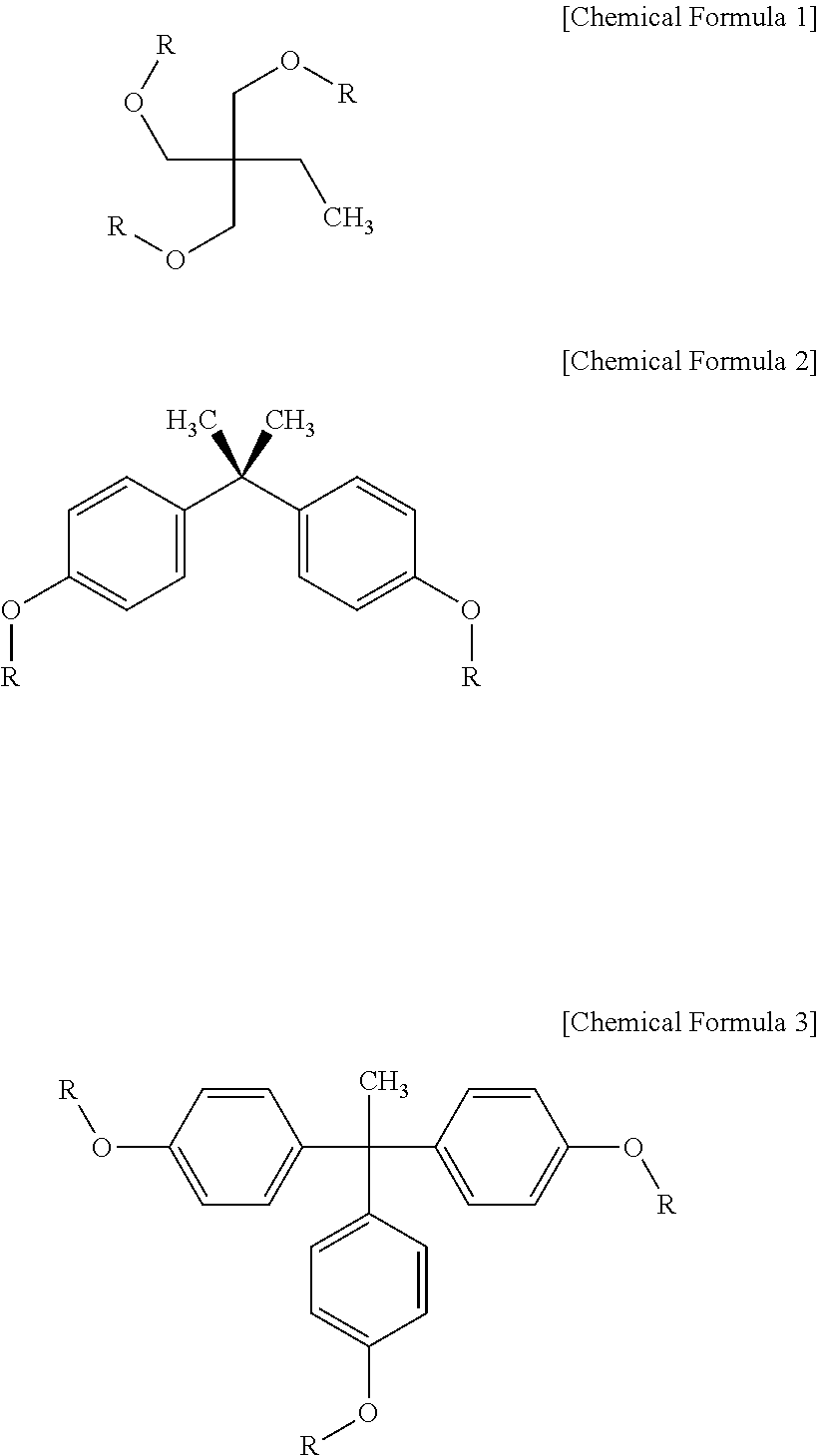

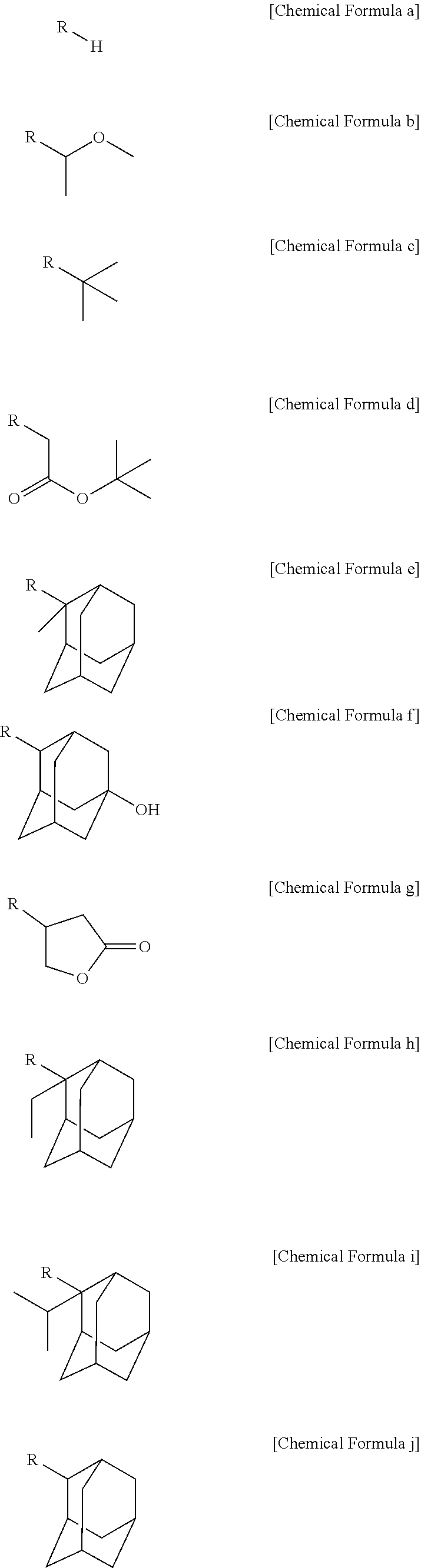

Chemically amplified positive photoresist composition for improving pattern profile

PendingUS20210216013A1Increase process marginHigh sensitivityPhotosensitive materials for photomechanical apparatusPolymer sciencePolymer resin

Proposed is a photoresist composition for a KrF light source, which exhibits a vertical profile compared to conventional KrF positive photoresists by adding a resin capable of increasing transmittance in order to form a semiconductor pattern, particularly a chemically amplified positive photoresist composition for improving a pattern profile, which includes, based on the total weight of the composition, 5 to 60 wt % of a polymer resin, 0.1 to 10 wt % of a transmittance-increasing resin additive represented by Chemical Formula 1, 0.05 to 10 wt % of a photoacid generator, 0.01 to 5 wt % of an acid diffusion inhibitor, and the remainder of a solvent, thus making it possible to provide a composition exhibiting a vertical profile, enhanced sensitivity and a superior processing margin compared to conventional positive photoresists.

Owner:YOUNG CHANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com